Page 1

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

SFI SYSTEM

PRECAUTION

NOTICE:

• Perform the RESET MEMORY (AT) initialization

operation after replacing the automatic transmission

assembly, engine assembly or ECM (See page AX-25).

• Perform REGISTRATION (VIN registration) when

replacing the ECM (See page ES-20).

ES–1

ES

Page 2

ES

ES–2

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

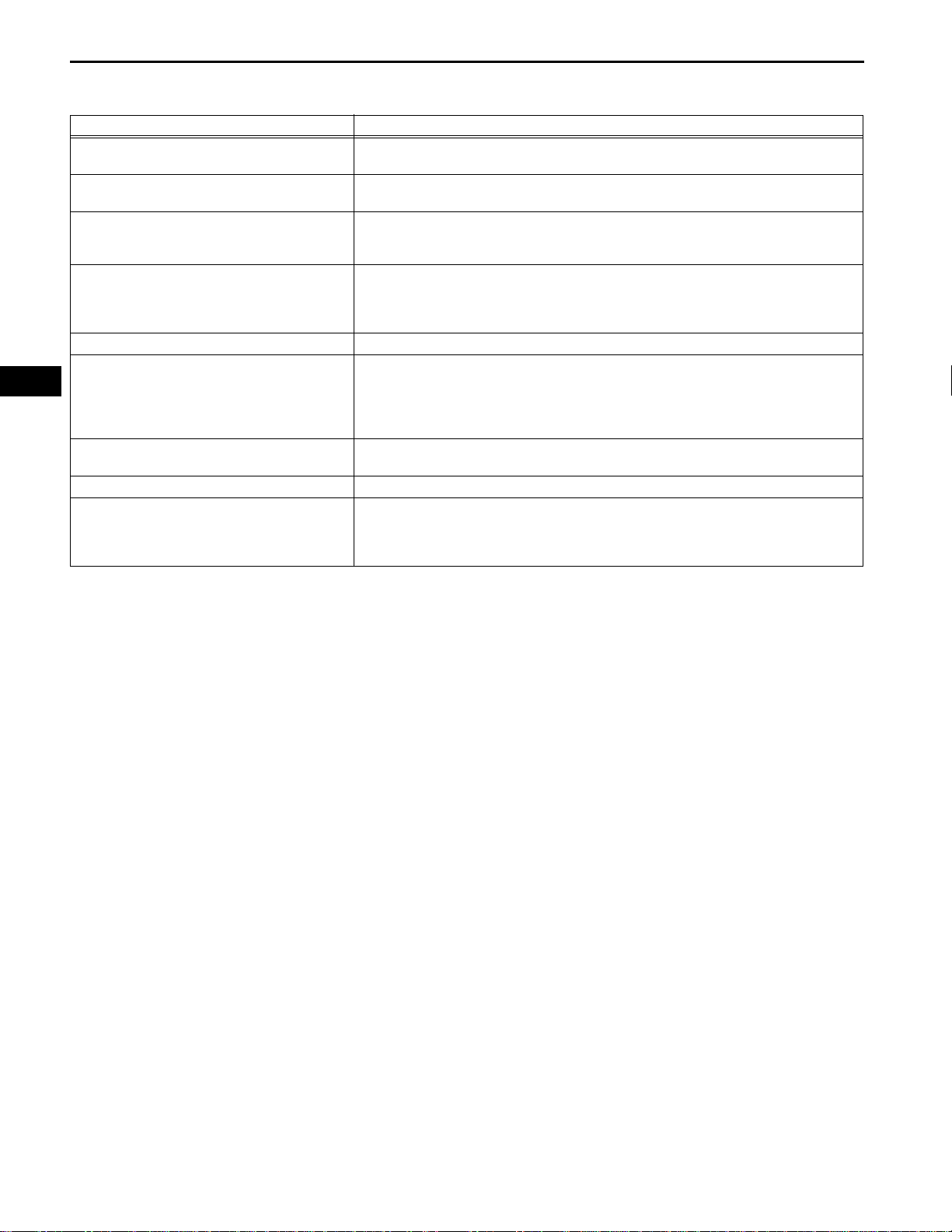

DEFINITION OF TERMS

Terms Definition

Monitor Description Description of what ECM monitors and how to detect malfunctions (monitoring purpose and

its details).

Related DTCs A group of diagnostic trouble codes that are output by ECM based on the same

malfunction detection logic.

Typical Enabling Condition Preconditions that allow ECM to detect malfunctions.

With all preconditions satisfied, ECM sets DTC when monitored value(s) exceeds

malfunction threshold(s).

Sequence of Operation Order of monitor priority, applied if multiple sensors and components are involved in single

malfunction detection process.

Each sensor and component monitored in turn and not monitored until previous detection

operation is completed.

Required Sensor/Components Sensors and components used by ECM to detect each malfunction.

Frequency of Operation Number of times ECM checks for each malfunction during each driving cycle.

"Once per driving cycle" means that ECM checks for malfunctions only once in single

driving cycle.

"Continuous" means that ECM checks for malfunctions whenever enabling conditions are

met.

Duration Minimum time for which ECM must detect continuous deviation in monitored value(s) in

order to set DTC. Timing begins when Typical Enabling Conditions are met.

Malfunction Thresholds Value, beyond which, ECM determines malfunctions exist and sets DTCs.

MIL Operation Timing of MIL illumination after a malfunction is detected.

"Immediate" means that ECM illuminates MIL as soon as a malfunction is detected.

"2 driving cycle" means that ECM illuminates MIL if the same malfunction is detected twice

during next sequential driving cycle.

Page 3

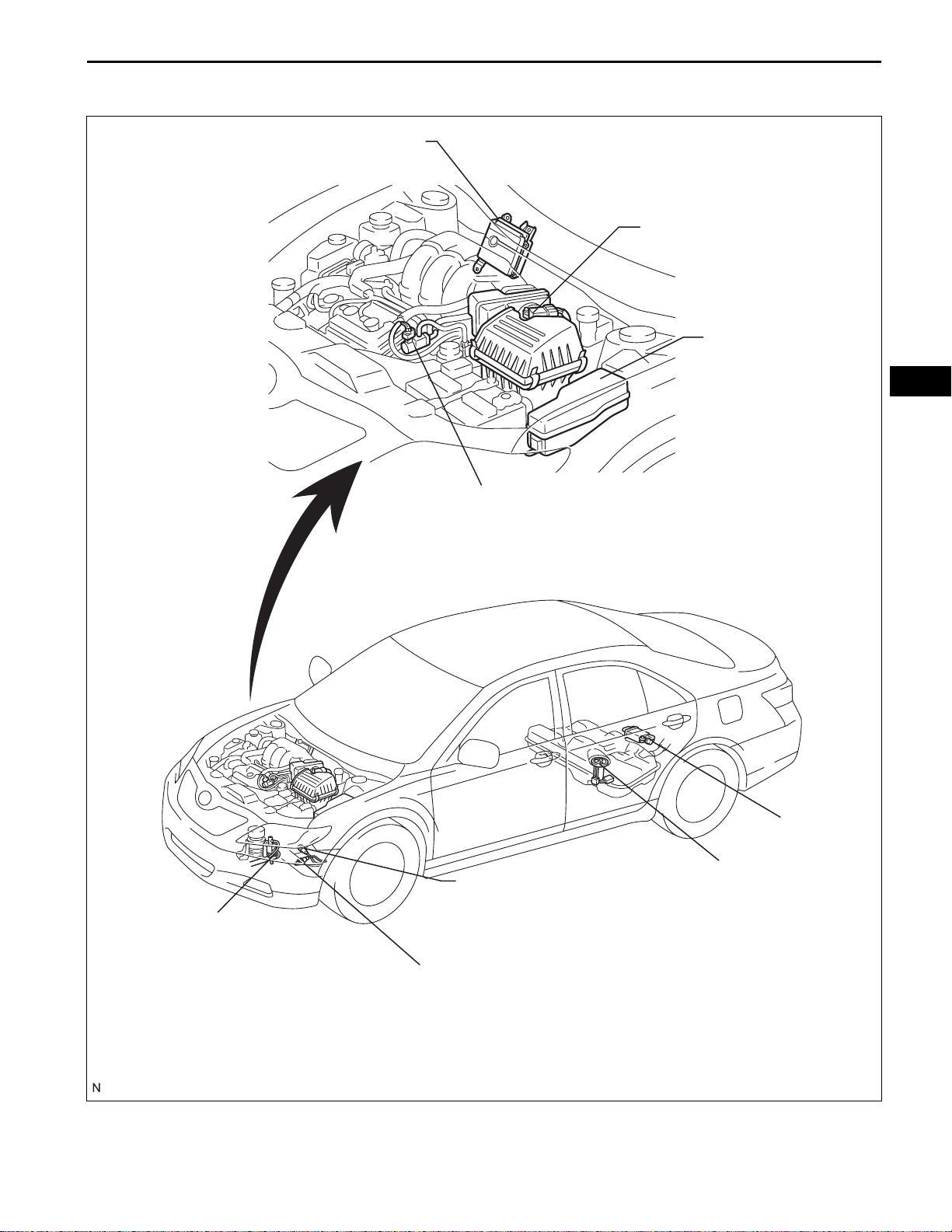

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

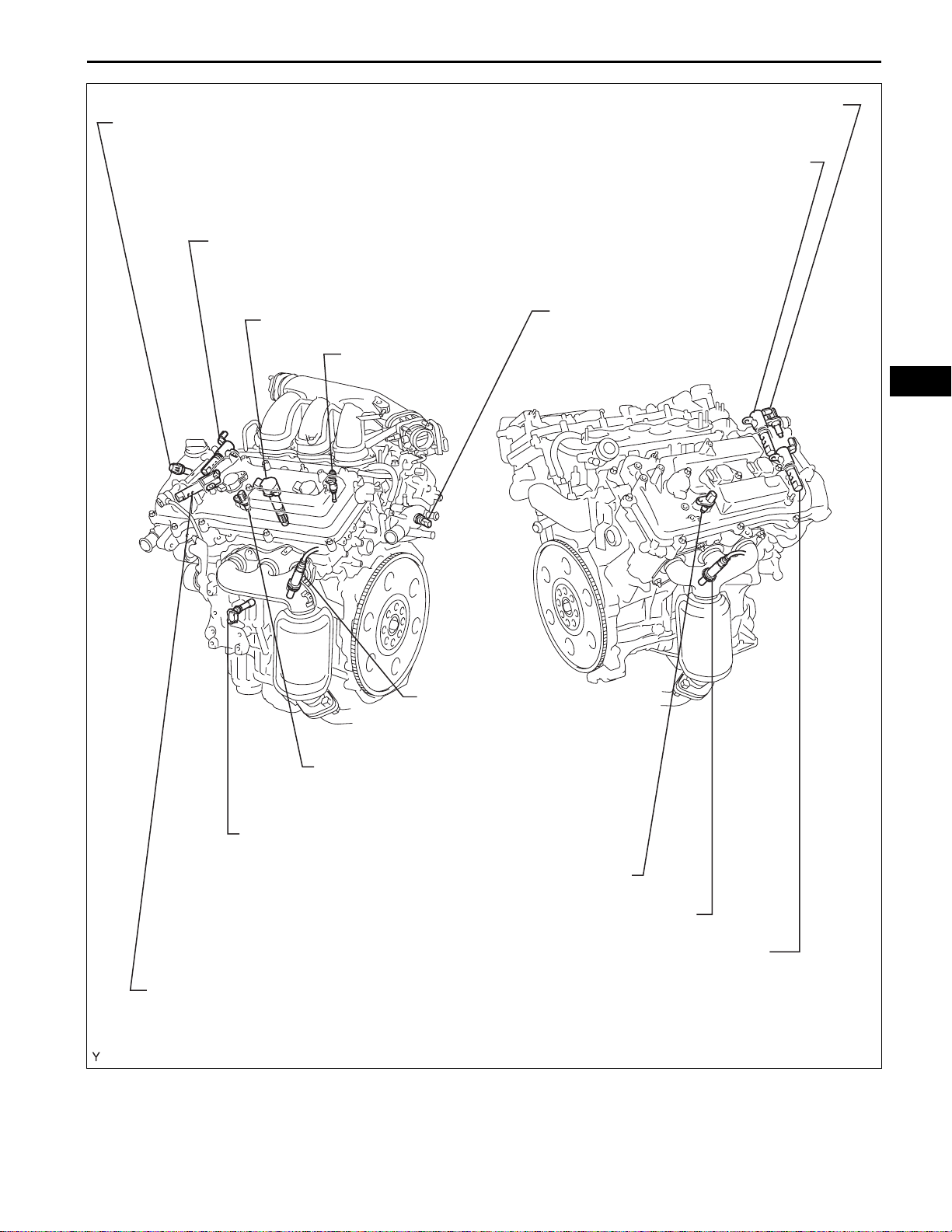

PARTS LOCATION

ES–3

ECM

MASS AIR FLOW METER

ENGINE ROOM R/B

- EFI RELAY

ES

- A/F RELAY

- C/OPN RELAY

- ST RELAY

ACTIVE MOUNT CONTROL VSV

PURGE VSV

HEATED OXYGEN SENSOR

(BANK 1 SENSOR 2)

- ST CUT RELAY

- IG2 RELAY

CANISTER

FUEL PUMP

HEATED OXYGEN SENSOR

(BANK 2 SENSOR 2)

A134870E01

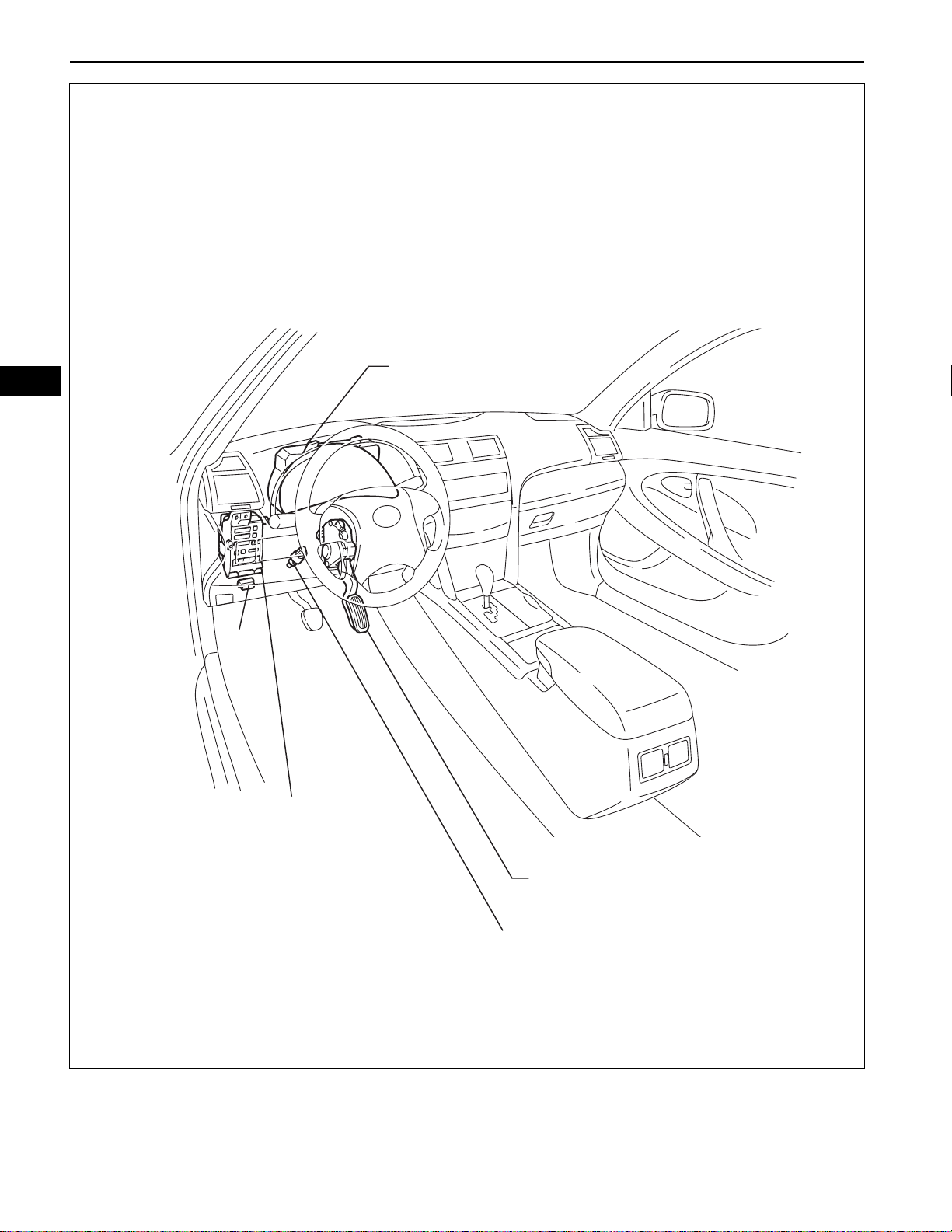

Page 4

ES

ES–4

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

COMBINATION METER

DLC3

INSTRUMENT PANEL J/B

- IGN FUSE

- STOP FUSE

ACCELERATOR PEDAL

STOP LIGHT SWITCH

A139510E01

Page 5

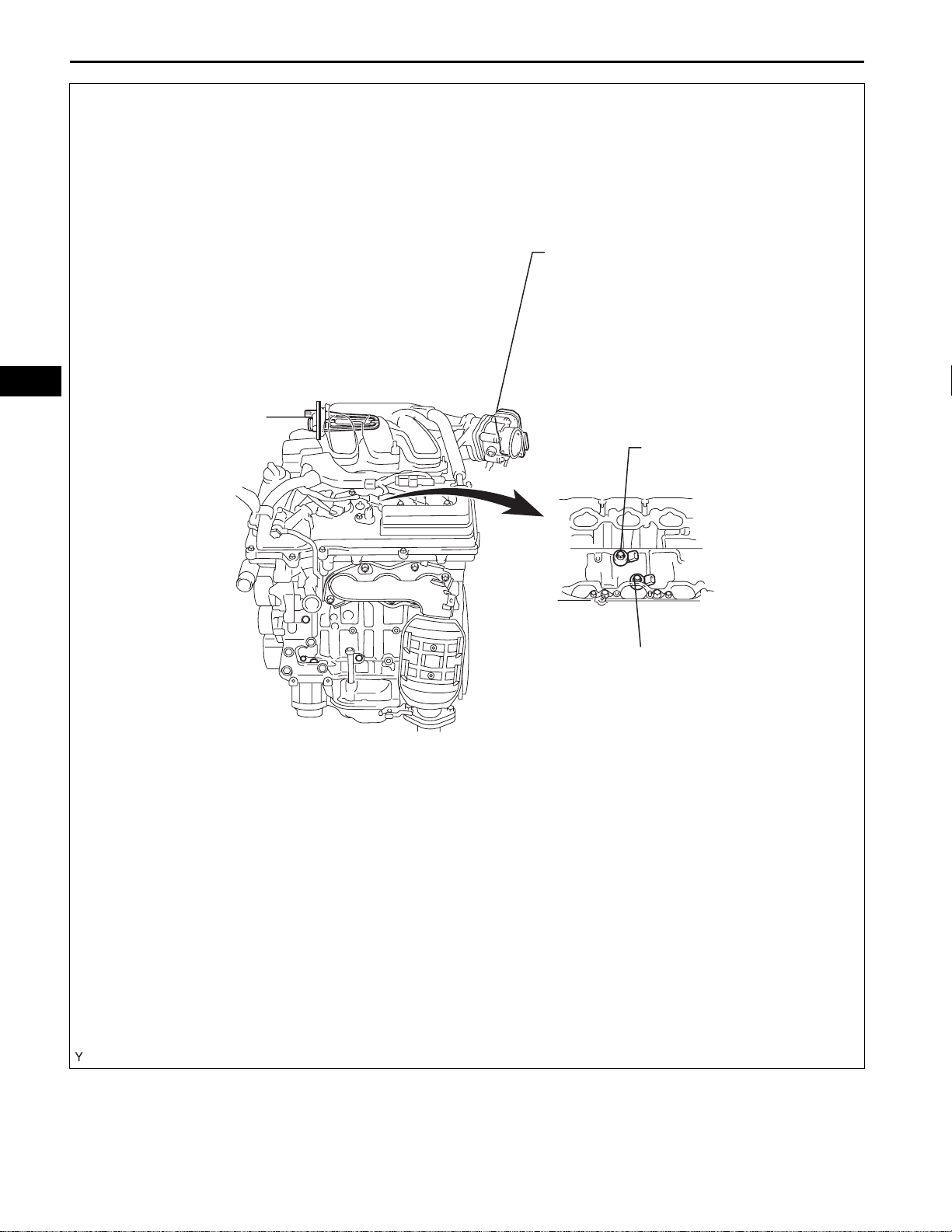

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

VVT SENSOR FOR INTAKE CAMSHAFT

(BANK 2)

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

(BANK 2 INTAKE SIDE)

ES–5

VVT SENSOR (BANK 1 INTAKE SIDE)

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

(BANK 1 INTAKE SIDE)

IGNITION COIL WITH IGNITER

FUEL INJECTOR

AIR FUEL RATIO SENSOR

(BANK 2 SENSOR 1)

ENGINE COOLANT

TEMPERATURE SENSOR

ES

VVT SENSOR FOR EXHAUST CAMSHAFT

(BANK 2)

CRANKSHAFT POSITION SENSOR

VVT SENSOR FOR EXHAUST CAMSHAFT (BANK 1)

AIR FUEL RATIO SENSOR (BANK 1 SENSOR 1)

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

(BANK 2 EXHAUST SIDE)

A114586E05

Page 6

ES

ES–6

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

THROTTLE BODY

(THROTTLE POSITION

SENSOR)

ACIS ACTUATOR

KNOCK SENSOR

KNOCK SENSOR

(BANK 1)

(BANK 2)

A114543E04

Page 7

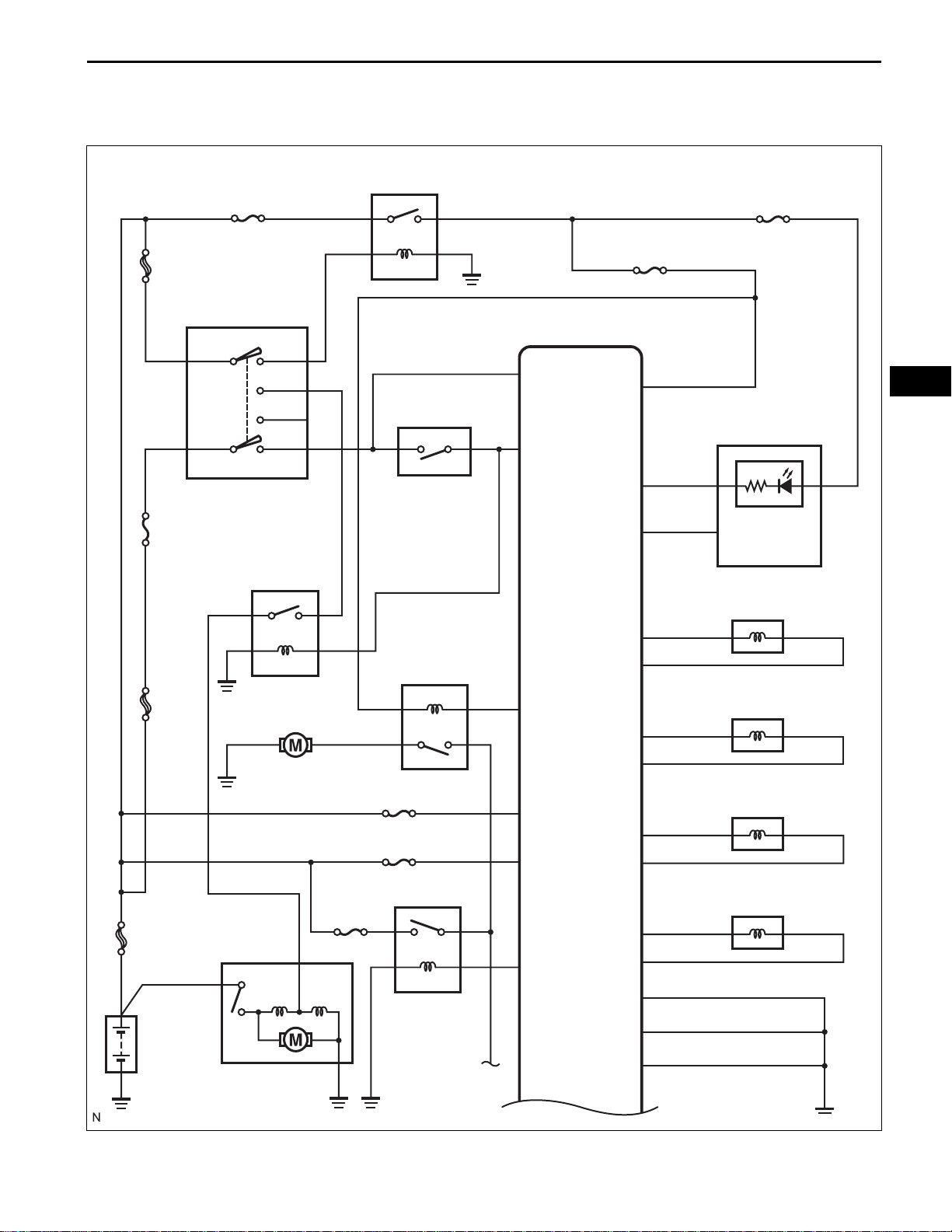

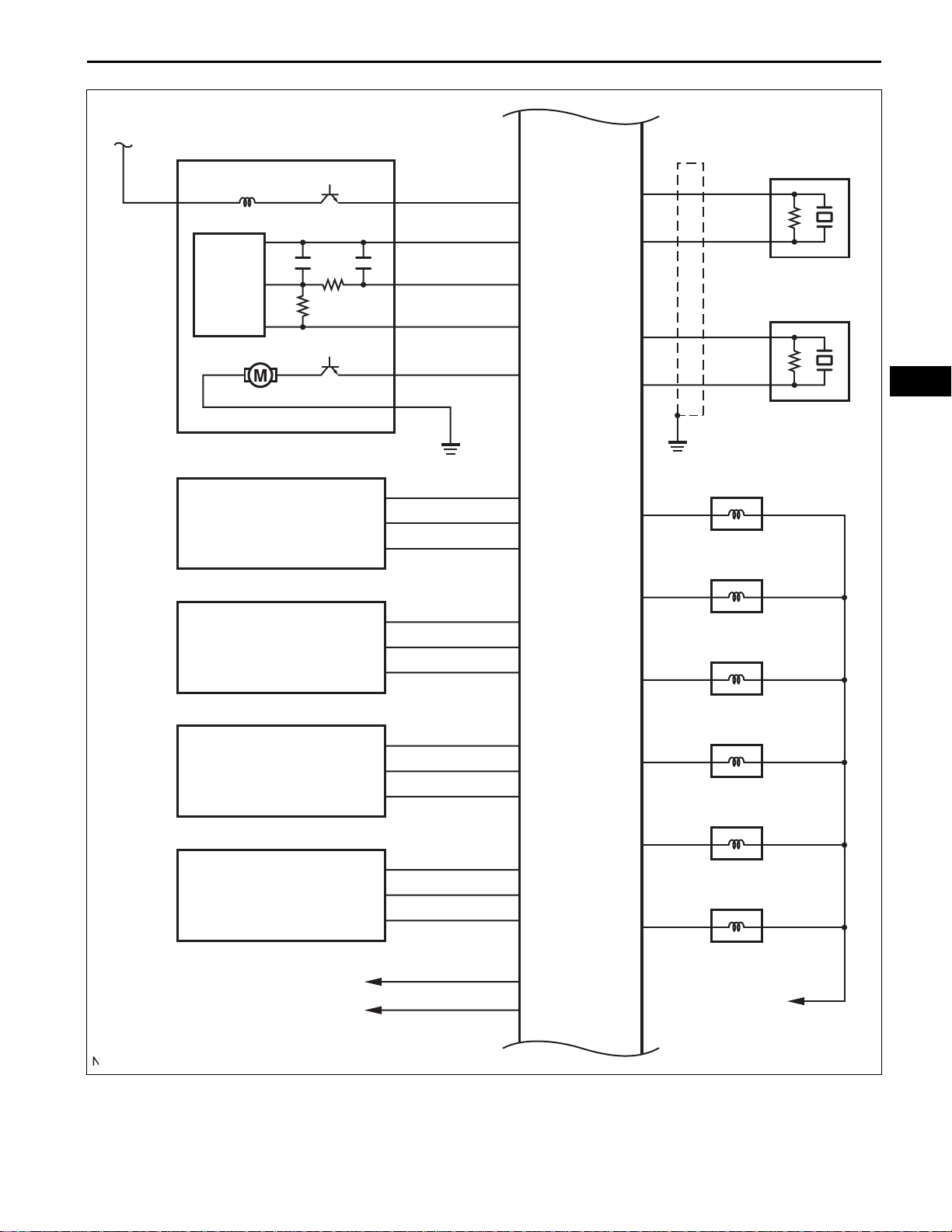

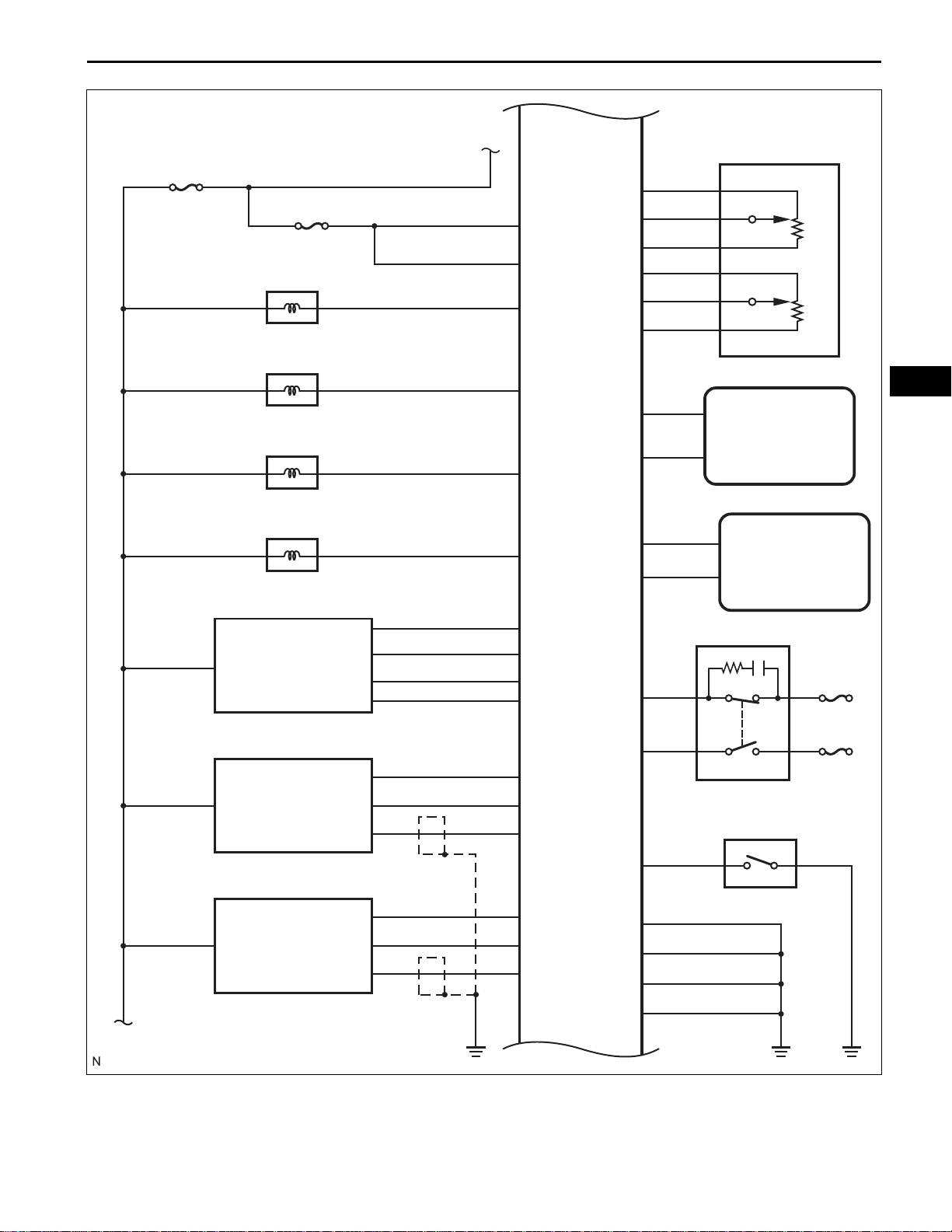

ST/AM2

AM2

AM1

IG2

IG SW

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

SYSTEM DIAGRAM

1. Without Smart Key System:

IG2

ECM

IG2

ST2

IG1

ST1

PNP SW

NSW

IGSW

STA

W

ES–7

GAUGE No. 2

IGN

ES

Combination Meter

AM1

ALT

FL MAIN

ST

Fuel Pump

EFI MAIN

C/OPN

ETCS

EFI No. 1

EFI

FC

+BM

BATT

MREL

SPD

OC1+

OC1-

OC2+

OC2-

OE1+

OE1-

OE2+

OE2-

MIL

VVT OCV (Intake Side RH)

VVT OCV (Intake Side LH)

VVT OCV (Exhaust Side RH)

VVT OCV (Exhaust Side LH)

Battery

Starter

E02

E05

A

E1

A137635E02

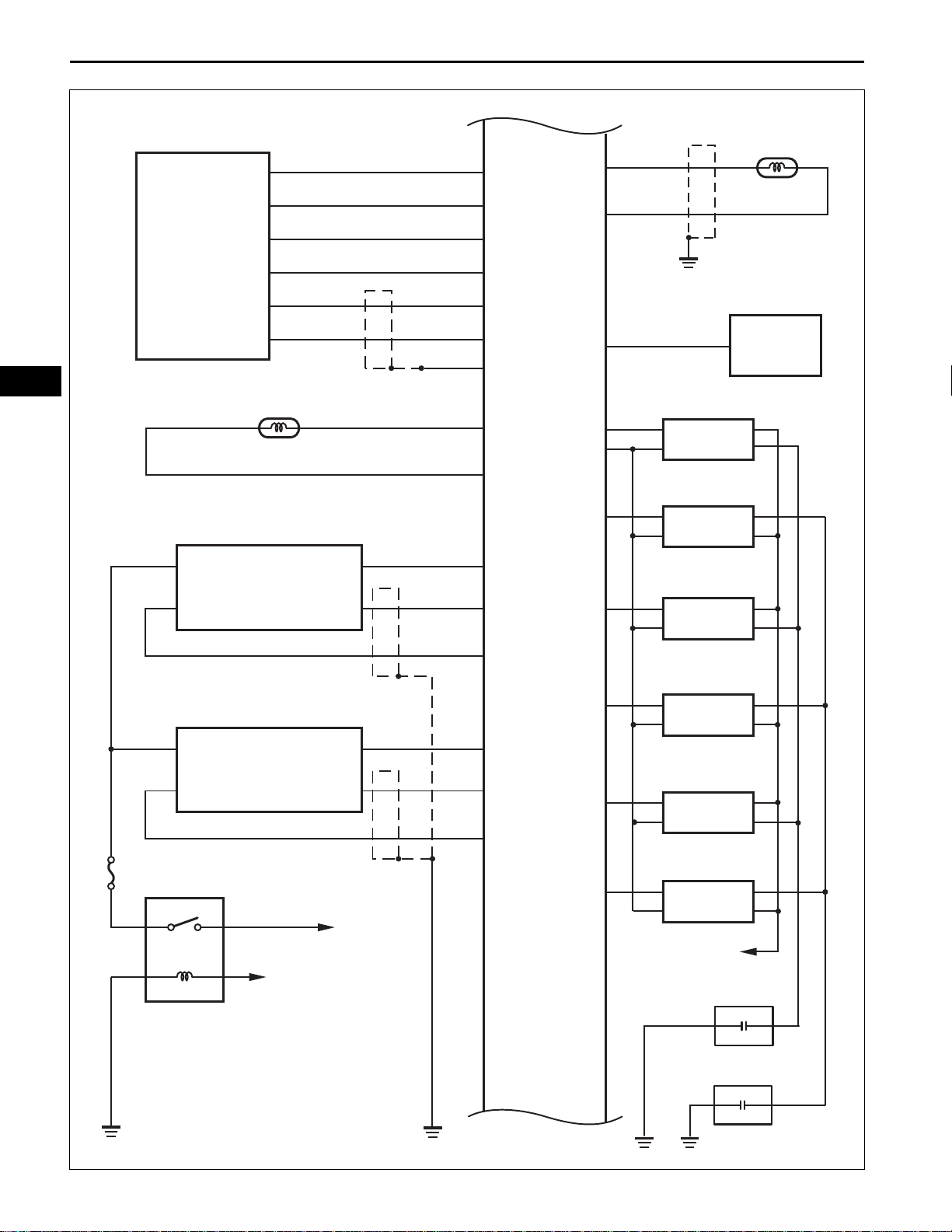

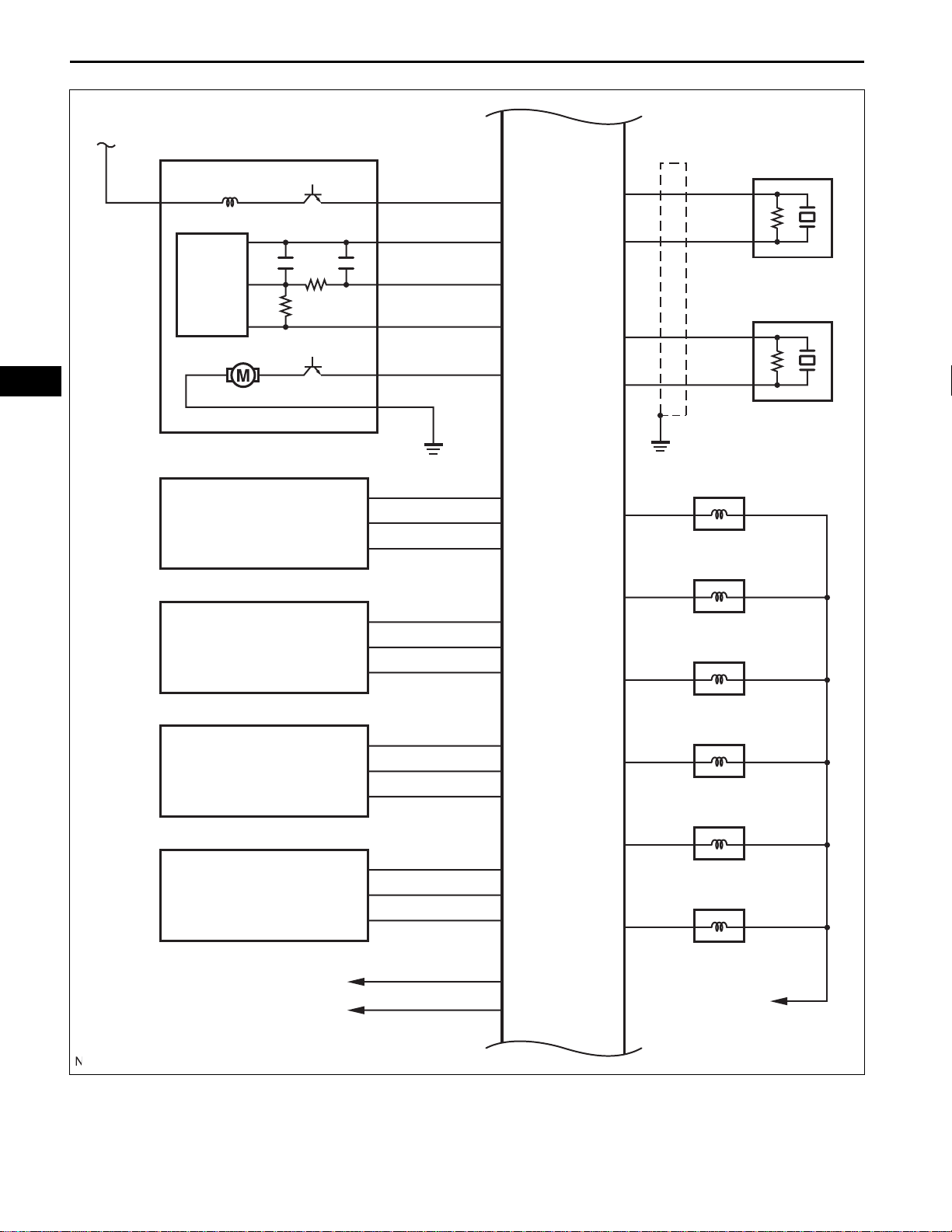

Page 8

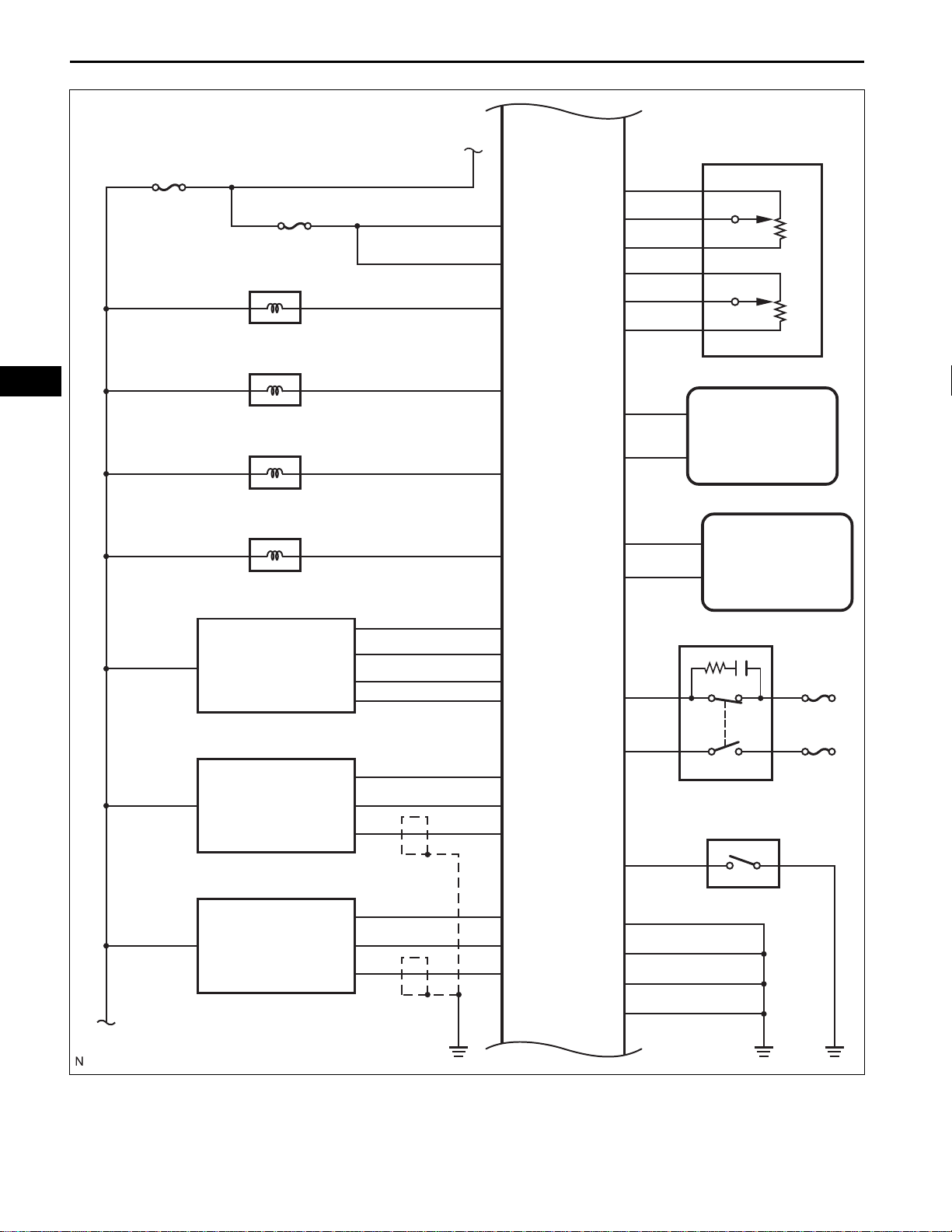

ES–8

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

EFI No. 3

EFI No. 2

VSV for ACIS

VSV for EVAP System

VSV for ACIS

VSV for Active Control Mount System

+B

+B2

AICV

PRG

ACIS

ACM

ECM

VCP2

VPA2

EPA2

VCPA

VPA

EPA

CAN+

CAN-

IMO

IMI

A

APP Sensor

Transmission

Control ECU

Transponder Key

ECU

THA

MAF Meter

HO2 Sensor

(Bank 1 Sensor 2)

HO2 Sensor

(Bank 2 Sensor 2)

B

E2G

VG

ETHA

HT1B

EX1B

OX1B

HT2B

EX2B

OX2B

STP

ST1-

Power Steering Oil Pressure SW

PSW

E04

E01

E03

ME01

Stop Light SW

STOP

IGN

A137631E02

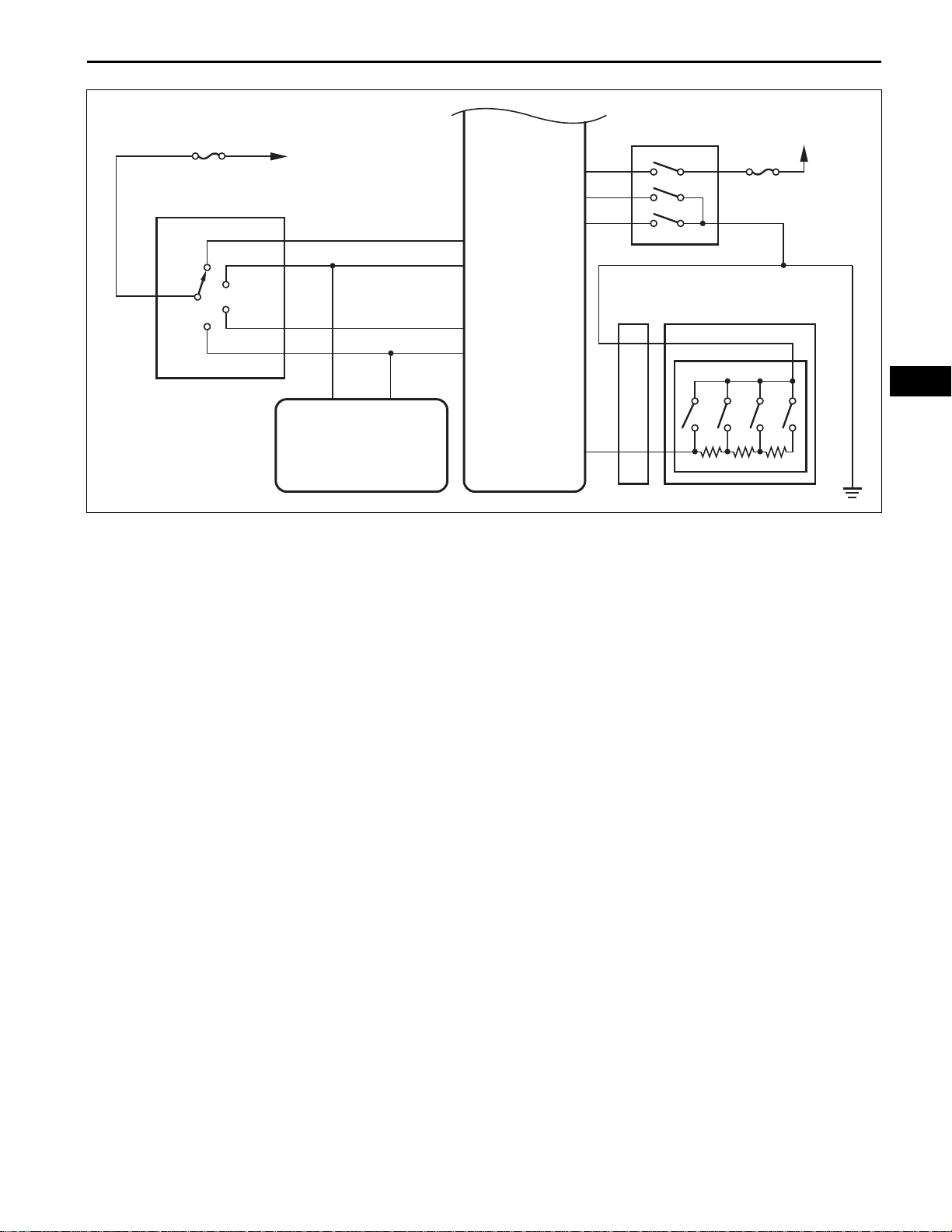

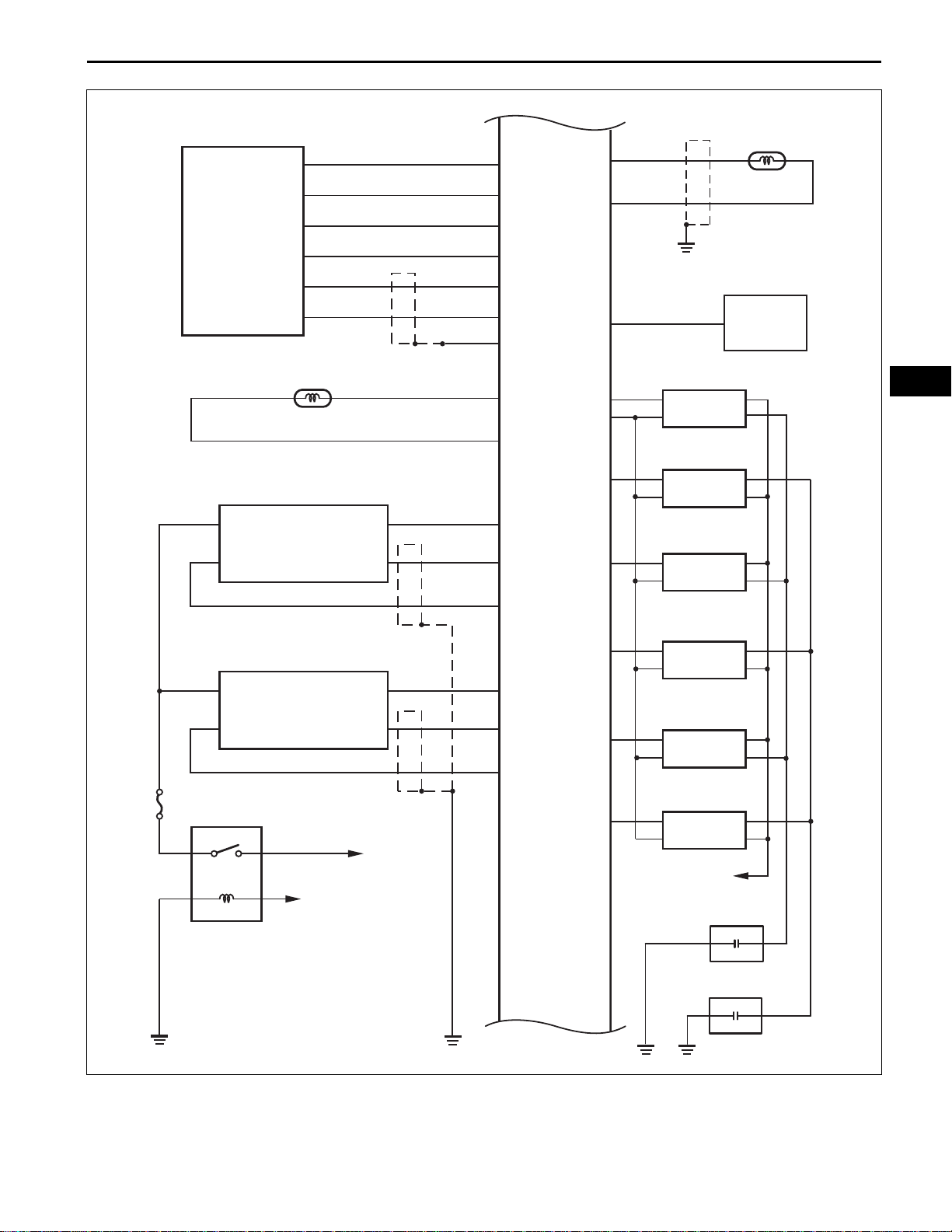

Page 9

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–9

B

Canister Pump Module

VVT Sensor

(Bank 1 Intake Side)

ECM

VPMP

EPPM

PPMP

VCPP

MPMP

VV1+

VV1-

VCV1

KNK1

EKNK

KNK2

EKN2

#10

Knock Sensor (Bank 1)

ES

Knock Sensor (Bank 2)

No. 1 Fuel Injector

VVT Sensor

(Bank 2 Intake Side)

VVT Sensor

(Bank 1 Exhaust Side)

VVT Sensor

(Bank 2 Exhaust Side)

To Main Body ECU

VV2+

VV2-

VCV2

EV1+

EV1-

VCE1

EV2+

EV2-

VCE2

CANH

CANL

#20

No. 2 Fuel Injector

#30

No. 3 Fuel Injector

#40

No. 4 Fuel Injector

#50

No. 5 Fuel Injector

#60

No. 6 Fuel Injector

To IG2 Relay

A137632E02

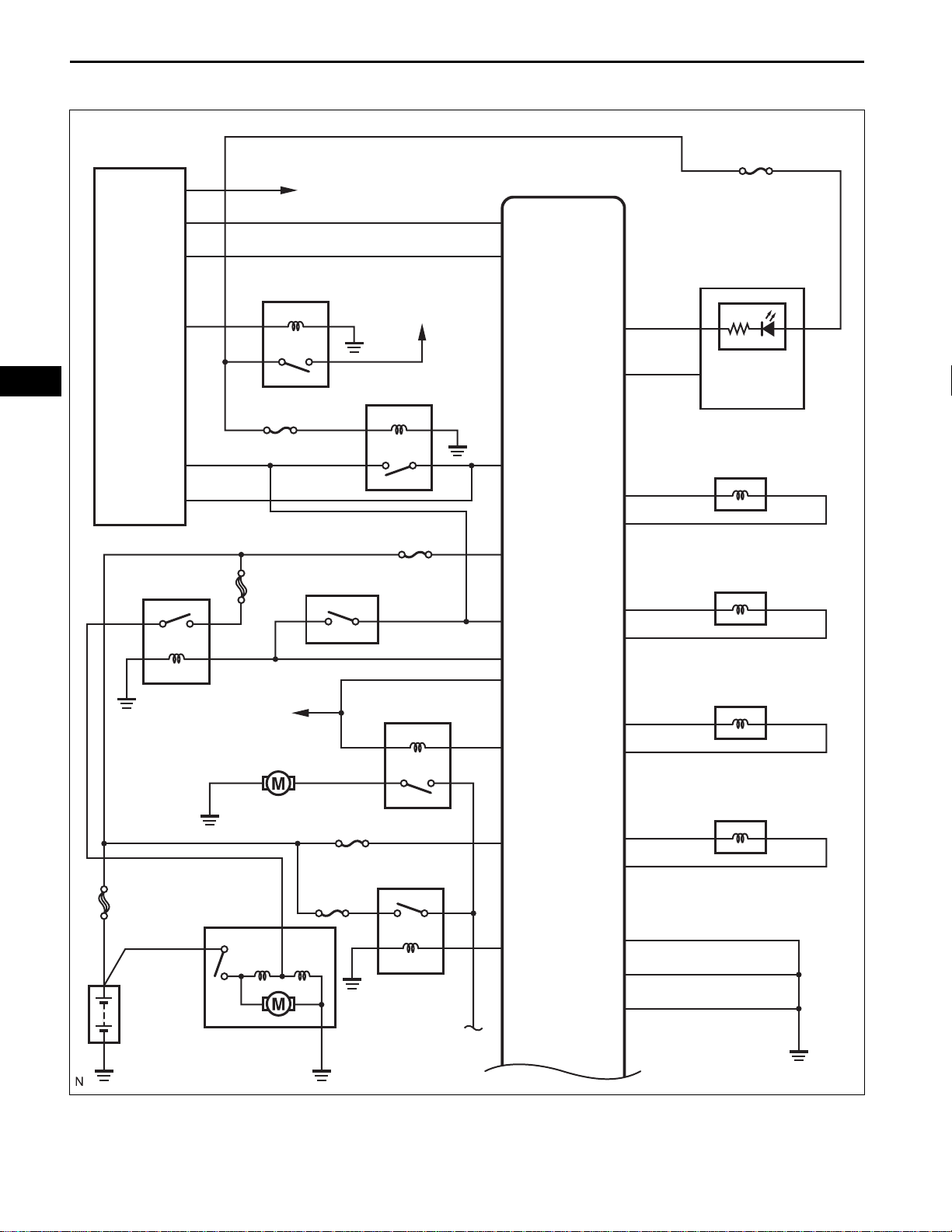

Page 10

ES–10

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ECM

VTA1

NE+

Crankshaft Position Sensor

ES

Throttle Body

Assembly

A/F Sensor

(Bank 1 Sensor 1)

ECT Sensor

VCTA

VTA2

ETA

M+

M-

GE01

THW

ETHW

HA1A

A1A+

A1A-

NE-

TC

IGT1

IGF1

IGT2

IGT3

DLC3

Ignition Coil (No. 1)

Ignition Coil (No. 2)

Ignition Coil (No. 3)

Ignition Coil (No. 4)

A/F

A/F Sensor

(Bank 2 Sensor 1)

A/F

To EFI Relay

To Battery

HA2A

A2A+

A2A-

IGT4

Ignition Coil (No. 5)

IGT5

Ignition Coil (No. 6)

IGT6

To IG2 Relay

Noise Filter (RH Side)

Noise Filter (LH Side)

A137633E02

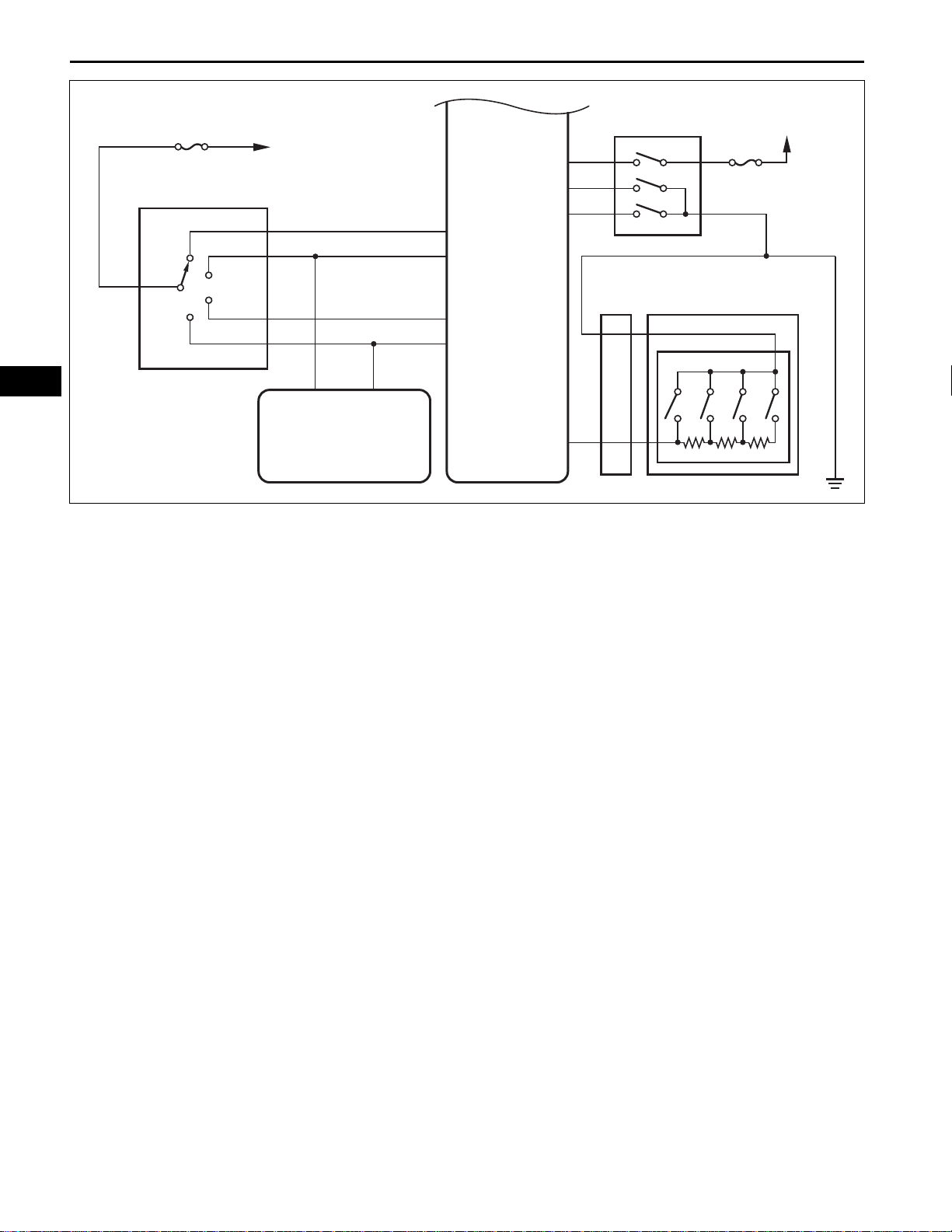

Page 11

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–11

GAUGE No. 1

To IG1 Relay

Park / Neutral Position SW

Transmission Control

ECU

ECM

SFTD

SFTU

P

R

N

D

Transmission Control SW

S

ECU IG No. 2

Spiral Cable

Cruise Control SW

To IG1 Relay

ES

CCS

A137634E02

Page 12

ES–12

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

2. With Smart Key System:

ES

Main Body ECU

ACC

STSW

ACCR

IG2D

STR

STR2

ST

IG2

IGN

ST/AM2

To ECU-ACC Fuse

To IG2 Fuse

ST CUT

ETCS

PNP SW

STSW

ACCR

STAR

+BM

NSW

STA

IGSW

ECM

W

SPD

OC1+

OC1-

OC2+

OC2-

GAUGE No. 2

Combinatiion Meter

MIL

VVT OCV (Intake Side RH)

VVT OCV (Intake Side LH)

VVT OCV (Exhaust Side RH)

FL MAIN

Battery

To IGN Fuse

Fuel Pump

Starter

EFI No. 1

EFI MAIN

C/OPN

EFI

OE1+

FC

BATT

MREL

A

OE1-

VVT OCV (Exhaust Side LH)

OE2+

OE2-

E02

E05

E1

A137630E02

Page 13

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–13

EFI No. 3

EFI No. 2

VSV for ACIS

VSV for EVAP System

VSV for ACIS

VSV for Active Control Mount System

+B

+B2

AICV

PRG

ACIS

ACM

ECM

VCP2

VPA2

EPA2

VCPA

VPA

EPA

CAN+

CAN-

IMO

IMI

A

APP Sensor

ES

Transmission

Control ECU

Transponder Key

ECU

THA

MAF Meter

HO2 Sensor

(Bank 1 Sensor 2)

HO2 Sensor

(Bank 2 Sensor 2)

B

E2G

VG

ETHA

HT1B

EX1B

OX1B

HT2B

EX2B

OX2B

STP

ST1-

Power Steering Oil Pressure SW

PSW

E04

E01

E03

ME01

Stop Light SW

STOP

IGN

A137631E02

Page 14

ES–14

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

B

Canister Pump Module

VVT Sensor

(Bank 1 Intake Side)

ECM

VPMP

EPPM

PPMP

VCPP

MPMP

VV1+

VV1-

VCV1

KNK1

EKNK

Knock Sensor (Bank 1)

KNK2

EKN2

Knock Sensor (Bank 2)

#10

No. 1 Fuel Injector

VVT Sensor

(Bank 2 Intake Side)

VVT Sensor

(Bank 1 Exhaust Side)

VVT Sensor

(Bank 2 Exhaust Side)

To Main Body ECU

VV2+

VV2-

VCV2

EV1+

EV1-

VCE1

EV2+

EV2-

VCE2

CANH

CANL

#20

No. 2 Fuel Injector

#30

No. 3 Fuel Injector

#40

No. 4 Fuel Injector

#50

No. 5 Fuel Injector

#60

No. 6 Fuel Injector

To IG2 Relay

A137632E02

Page 15

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Crankshaft Position Sensor

ECM

VTA1

NE+

ES–15

Throttle Body

Assembly

A/F Sensor

(Bank 1 Sensor 1)

ECT Sensor

VCTA

VTA2

ETA

M+

M-

GE01

THW

ETHW

HA1A

A1A+

A1A-

NE-

TC

IGT1

IGF1

IGT2

IGT3

DLC3

Ignition Coil (No. 1)

ES

Ignition Coil (No. 2)

Ignition Coil (No. 3)

Ignition Coil (No. 4)

A/F

A/F Sensor

(Bank 2 Sensor 1)

A/F

To EFI Relay

To Battery

HA2A

A2A+

A2A-

IGT4

Ignition Coil (No. 5)

IGT5

Ignition Coil (No. 6)

IGT6

To IG2 Relay

Noise Filter (RH Side)

Noise Filter (LH Side)

A137633E02

Page 16

ES–16

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

GAUGE No. 1

To IG1 Relay

Park / Neutral Position SW

Transmission Control

ECU

ECM

SFTD

SFTU

P

R

N

D

CCS

Transmission Control SW

S

ECU IG No. 2

Spiral Cable

Cruise Control SW

To IG1 Relay

A137634E02

Page 17

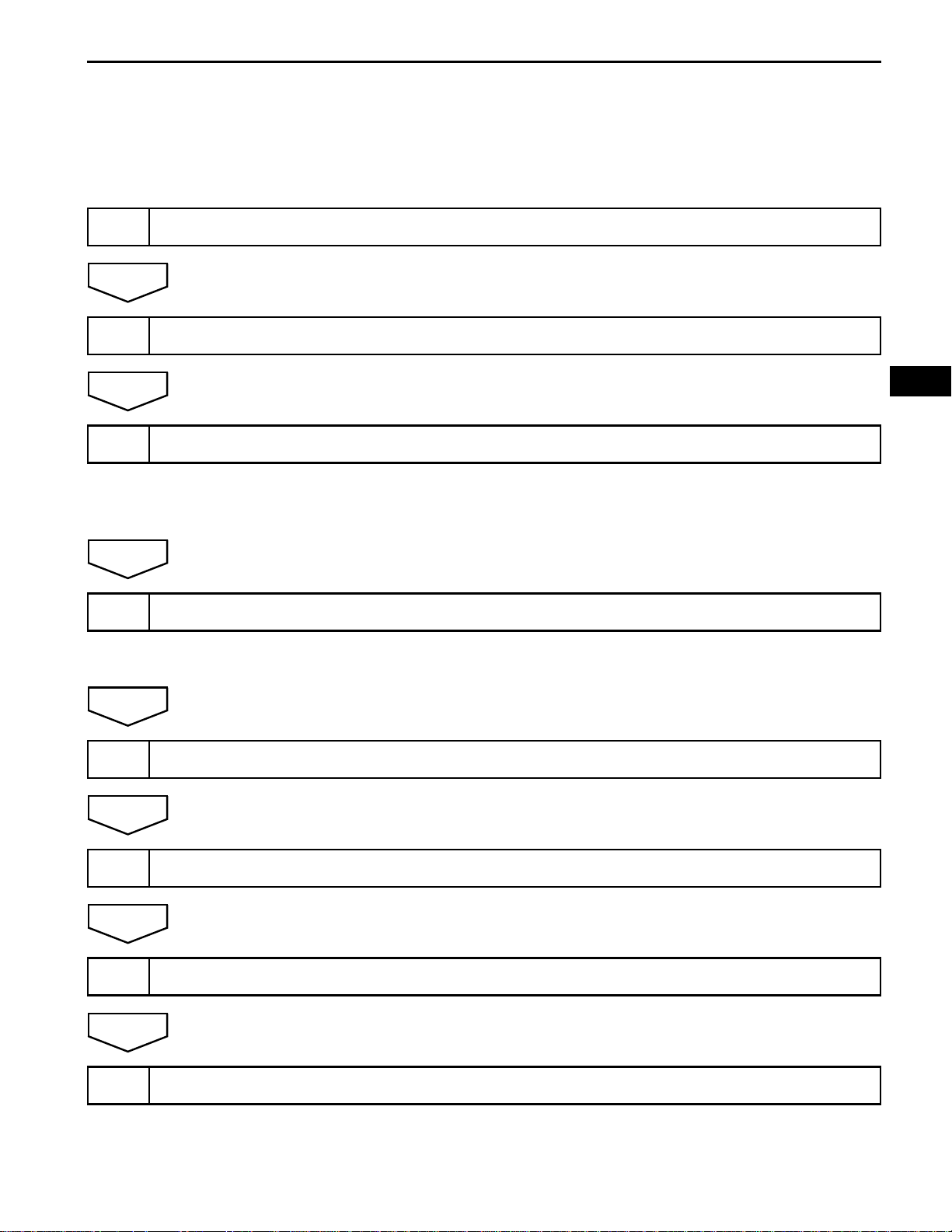

1

NEXT

2

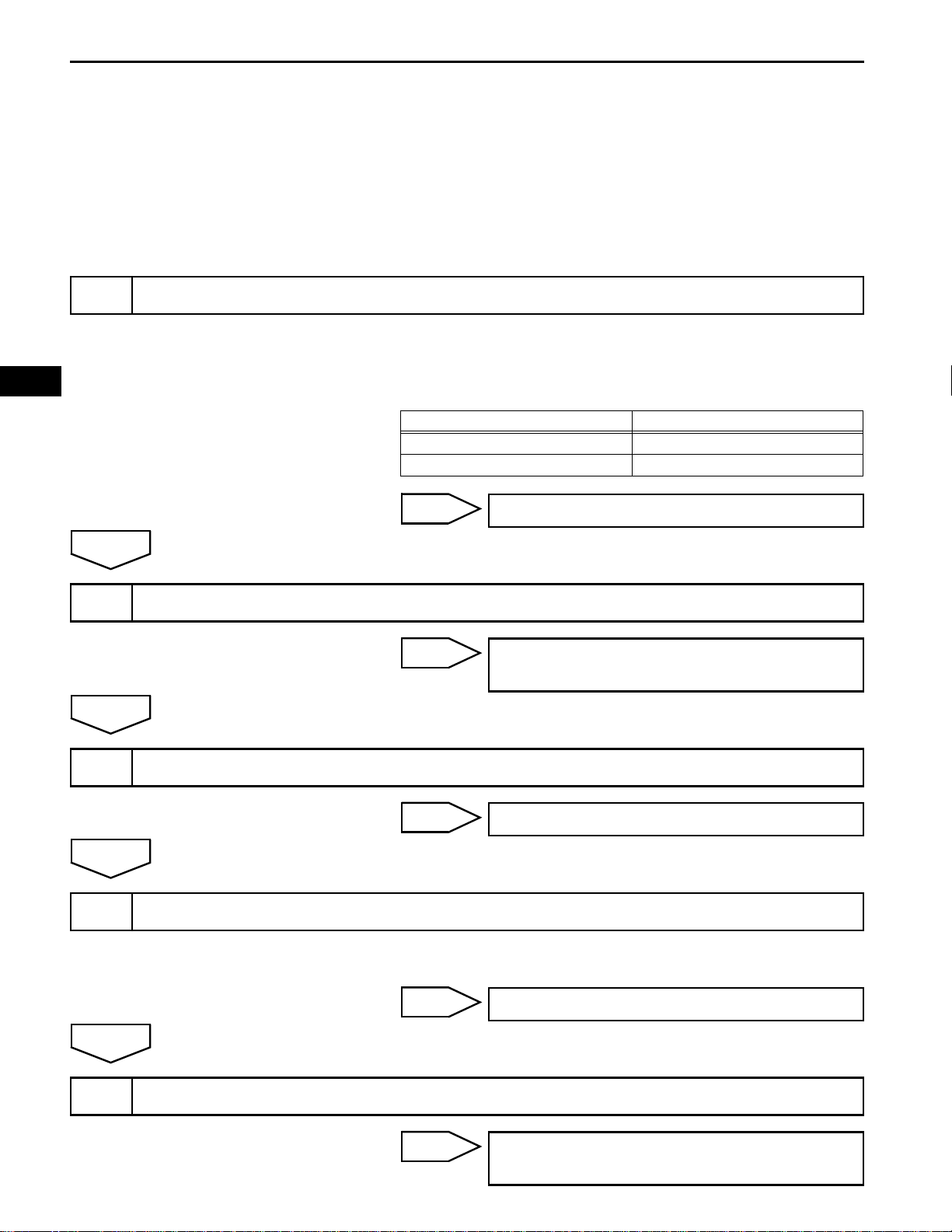

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

*: Use the intelligent tester.

VEHICLE BROUGHT TO WORKSHOP

CUSTOMER PROBLEM ANALYSIS

ES–17

NEXT

3

NEXT

4

NEXT

5

NEXT

ES

CONNECT INTELLIGENT TESTER TO DLC3*

HINT:

If the display indicates a communication fault in the tester,

inspect the DLC3.

CHECK DTC AND FREEZE FRAME DATA*

HINT:

Record or print DTCs and freeze frame data, if necessary.

CLEAR DTC AND FREEZE FRAME DATA*

6

NEXT

7

NEXT

8

CONDUCT VISUAL INSPECTION

SET CHECK MODE DIAGNOSIS*

CONFIRM PROBLEM SYMPTOMS

HINT:

If the engine does not start, perform steps 10 and 12 first.

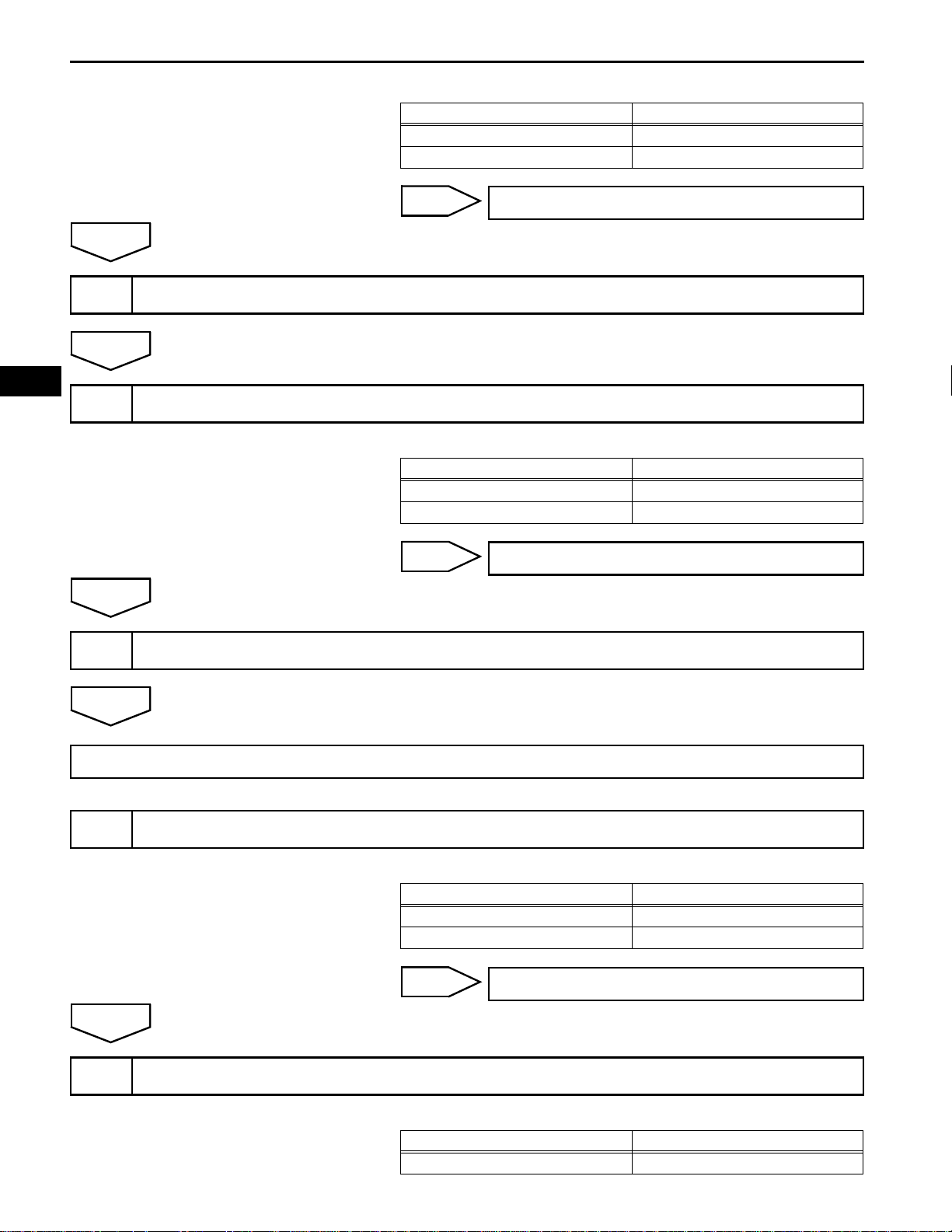

Page 18

ES–18

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Result

Result Proceed to

Malfunction does not occur A

Malfunction occurs B

ES

A

9

NEXT

10

A

11

SIMULATE SYMPTOMS

CHECK FOR DTCS*

REFER TO DTC CHART

B

Result

B

GO TO STEP 10

Result Proceed to

Trouble code A

No code B

GO TO STEP 12

NEXT

GO TO STEP 14

12

CONDUCT BASIC INSPECTION

A

13

REFER TO PROBLEM SYMPTOMS TABLE

Result

Result Proceed to

Malfunctioning parts not confirmed A

Malfunctioning parts confirmed B

B

GO TO STEP 17

Result

Result Proceed to

Malfunctioning circuit confirmed A

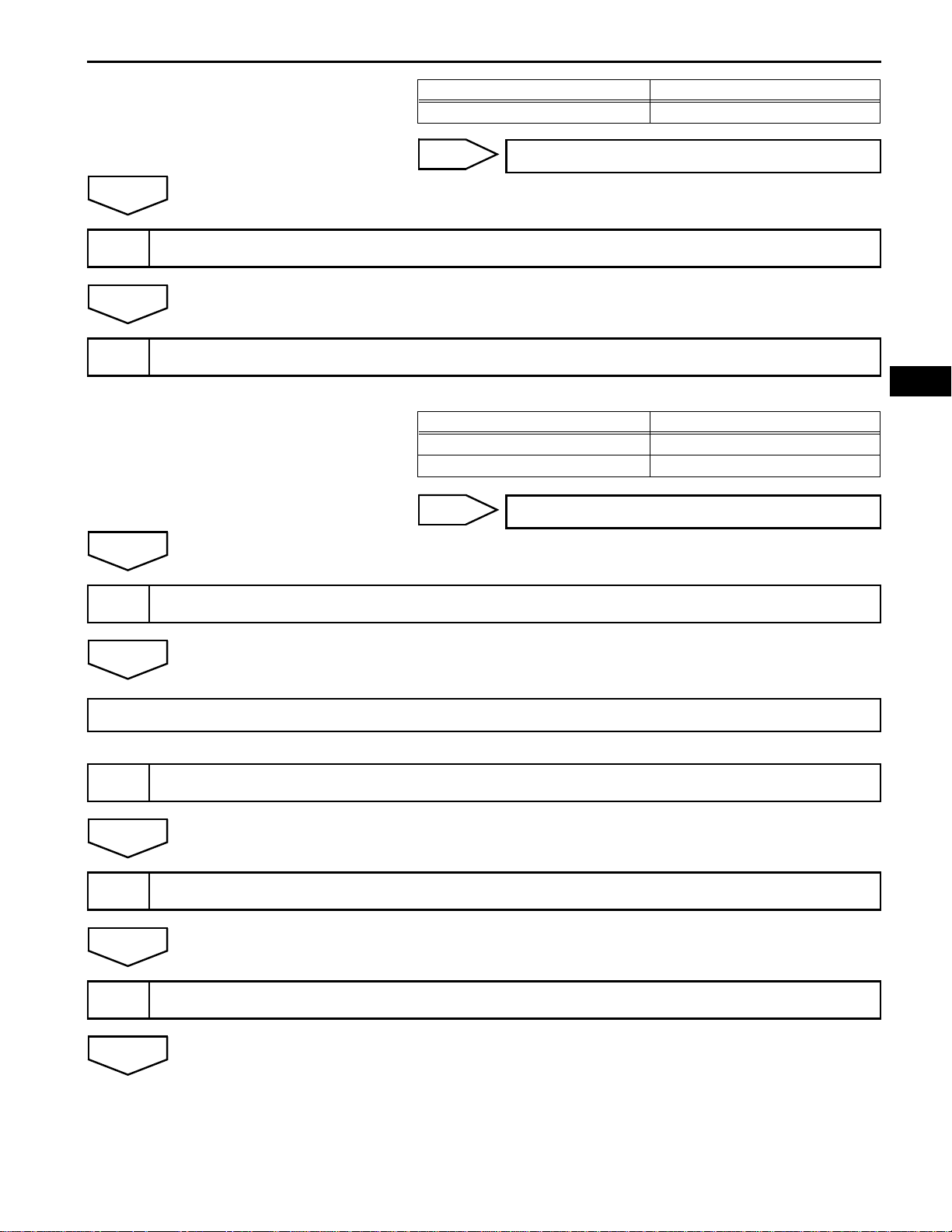

Page 19

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Result Proceed to

Malfunctioning parts confirmed B

ES–19

A

14

NEXT

15

A

16

B

CHECK ECM POWER SOURCE CIRCUIT

CONDUCT CIRCUIT INSPECTION

Result

Malfunction not confirmed A

Malfunction confirmed B

B

CHECK FOR INTERMITTENT PROBLEMS

GO TO STEP 17

ES

Result Proceed to

GO TO STEP 18

NEXT

GO TO STEP 18

17

NEXT

18

NEXT

19

NEXT

CONDUCT PARTS INSPECTION

IDENTIFY PROBLEM

ADJUST AND/OR REPAIR

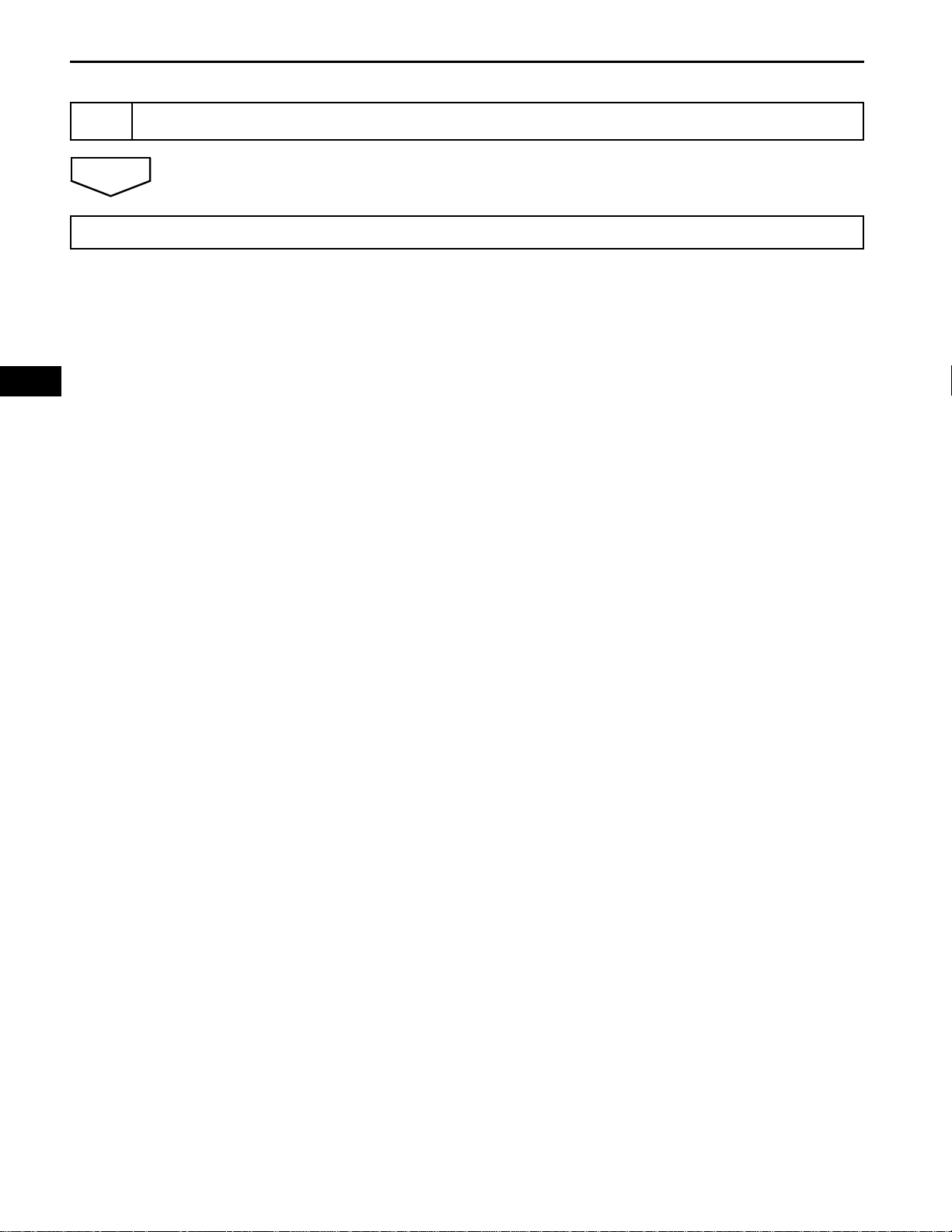

Page 20

ES–20

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

20

NEXT

END

CONDUCT CONFIRMATION TEST

Page 21

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CHECK FOR INTERMITTENT

PROBLEMS

HINT:

Inspect the vehicle's ECM using check mode. Intermittent

problems are easier to detect with an intelligent tester when

the ECM is in check mode. In check mode, the ECM uses 1

trip detection logic, which is more sensitive to malfunctions

than normal mode (default), which uses 2 trip detection logic.

1. Clear the DTCs.

2. Switch the ECM from normal mode to check mode using

an intelligent tester (See page ES-49).

3. Perform a simulation test (See page IN-40).

4. Check and wiggle the harness(es), connector(s) and

terminal(s) (See page IN-45).

ES–21

ES

Page 22

ES

ES–22

1

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

BASIC INSPECTION

When the malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when troubleshooting the engine.

CHECK BATTERY VOLTAGE

NOTICE:

Carry out this check with the engine stopped and the

engine switch off.

Result

Result Proceed to

11 V or more OK

Below 11 V NG

OK

CHECK WHETHER ENGINE CRANKS

2

OK

CHECK WHETHER ENGINE STARTS

3

OK

CHECK AIR FILTER

4

NG

NG

NG

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

CHARGE OR REPLACE BATTERY

PROCEED TO PROBLEM SYMPTOMS

TABLE

GO TO STEP 6

OK

CHECK IDLING SPEED

5

NG

NG

REPLACE AIR FILTER

TROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

Page 23

OK

CHECK FUEL PRESSURE

6

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–23

NG

OK

CHECK FOR SPARKS

7

NG

OK

PROCEED TO PROBLEM SYMPTOMS TABLE

TROUBLESHOOT FUEL PRESSURE AND

PROCEED TO NEXT STEP

TROUBLESHOOT SPARK AND PROCEED

TO NEXT STEP

ES

Page 24

ES

ES–24

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

REGISTRATION

NOTICE:

The Vehicle Identification Number (VIN) must be input

into the replacement ECM.

HINT:

The VIN is in the form of a 17-digit alphanumeric vehicle

identification number. An intelligent tester is required to

register the VIN.

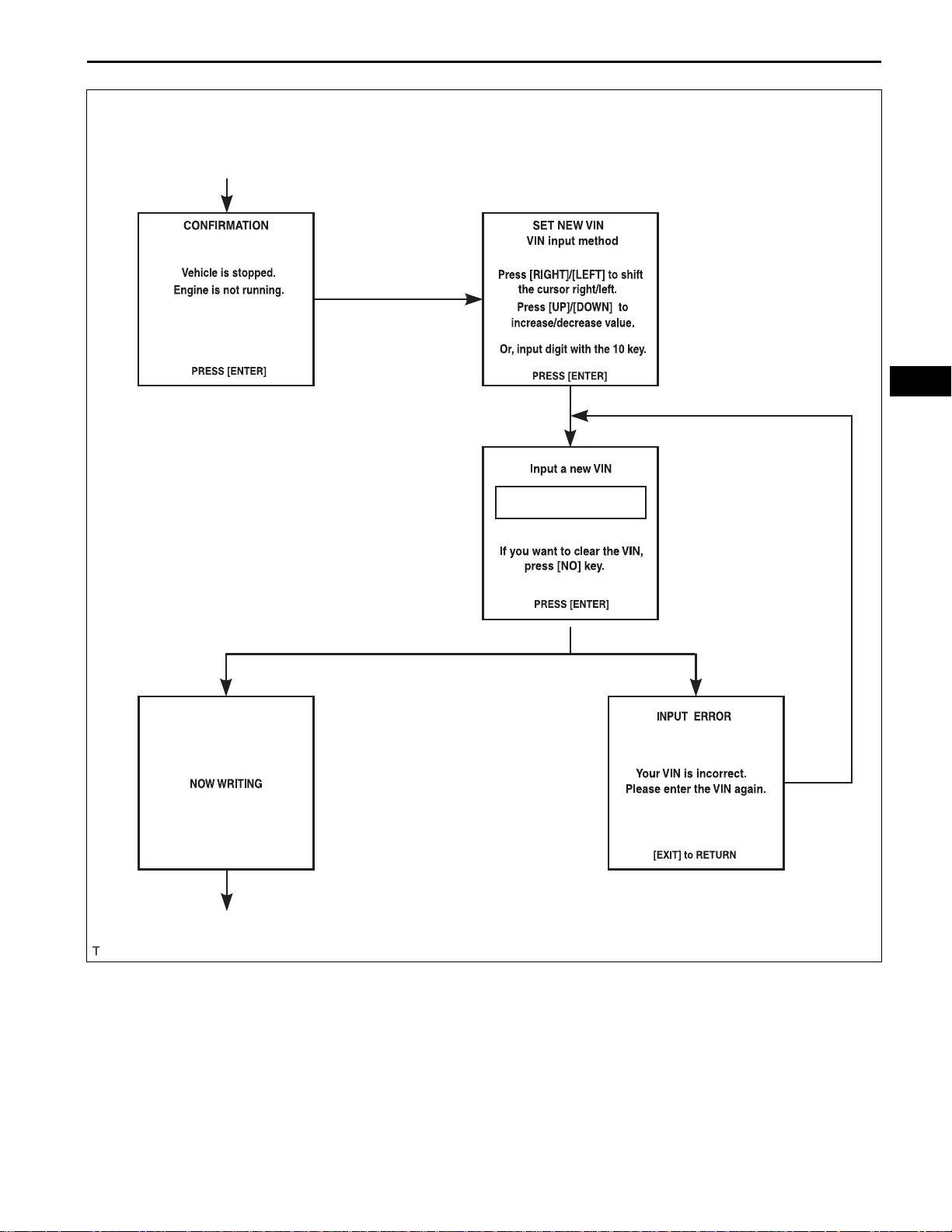

1. INPUT INSTRUCTIONS

(a) The general VIN input instructions using an

intelligent tester are explained below:

(b) The arrow buttons (UP, DOWN, RIGHT and LEFT)

and numerical buttons (0 to 9) are used, in order to

input the VIN.

(c) Cursor Operation

To move the cursor around the tester screen, press

the RIGHT and LEFT buttons.

(d) Alphabetical Character Input

(1) Press the UP and DOWN buttons to select the

desired alphabetical character.

(e) Numeric Character Input

(1) Press the numerical button corresponding to

the number that you want to input.

HINT:

Numerical characters can be selected by using

the UP and DOWN buttons.

(f) Correction

(1) When correcting the input character(s), put the

cursor onto the character using the RIGHT or

LEFT button.

(2) Select or input the correct character using the

UP and DOWN buttons, or the numerical

buttons.

(g) Finishing Input Operation

(1) Make sure that the input VIN matches the

vehicle VIN after input.

(2) Press the ENTER button on the tester.

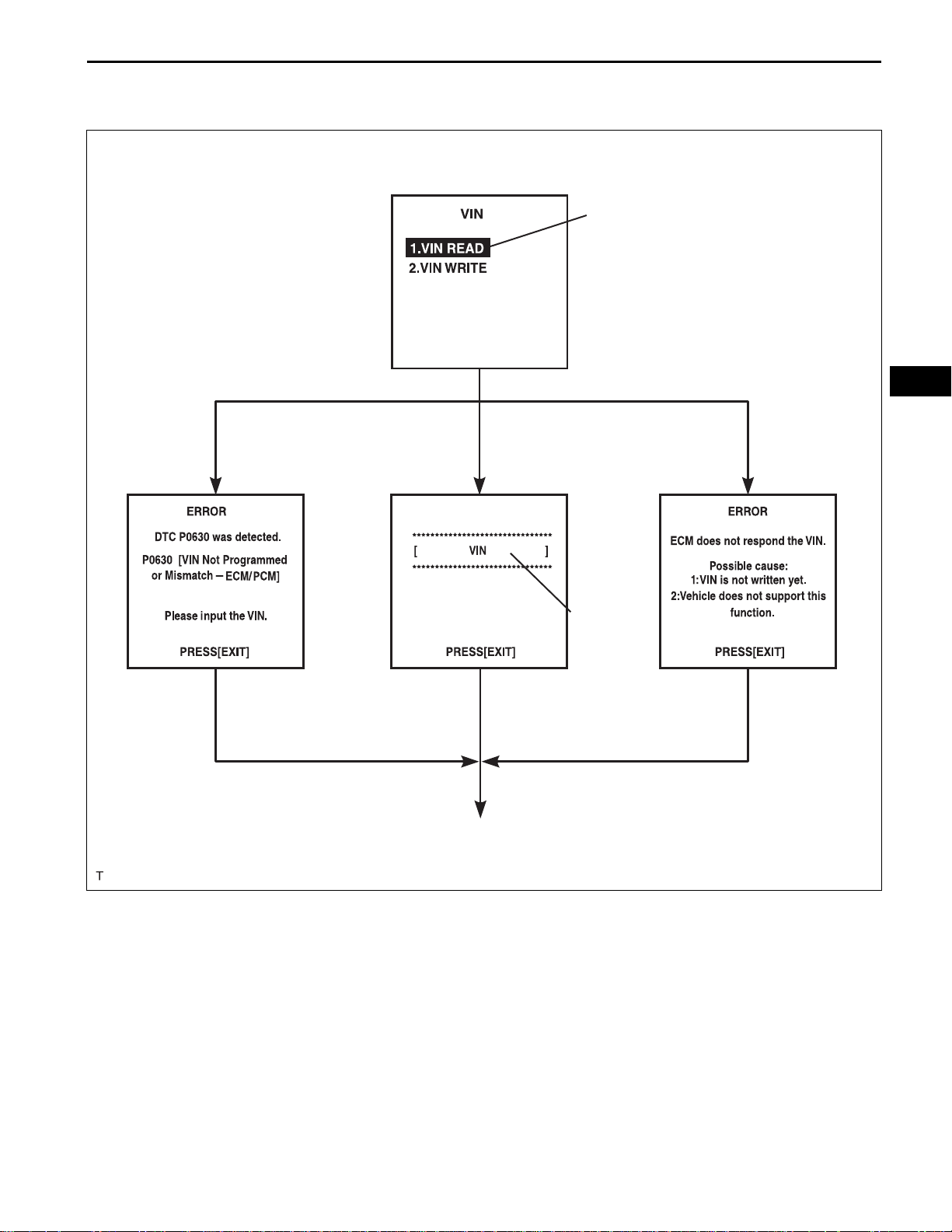

2. READ VIN (Vehicle Identification Number)

(a) The flowchart of the VIN reading process is shown.

This process allows the VIN stored in the ECM to be

read, in order to confirm that the two VINs, provided

with the vehicle and stored in the vehicle's ECM, are

the same.

(b) Read VIN using an intelligent tester.

(c) Check the vehicle's VIN.

(d) Connect the intelligent tester to the DLC3.

(e) Turn the ignition switch on (IG).

(f) Turn the tester on.

Page 25

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(g) Enter the following menus: DIAGNOSIS /

ENHANCED OBD ll / VIN.

Menu Screen:

Select VIN READ

ES–25

ES

DTC P0630 Set

[EXIT]

VIN Previously Stored

[EXIT]

To Menu Screen

VIN Not Stored

17-digit VIN

displayed

[EXIT]

A103812E03

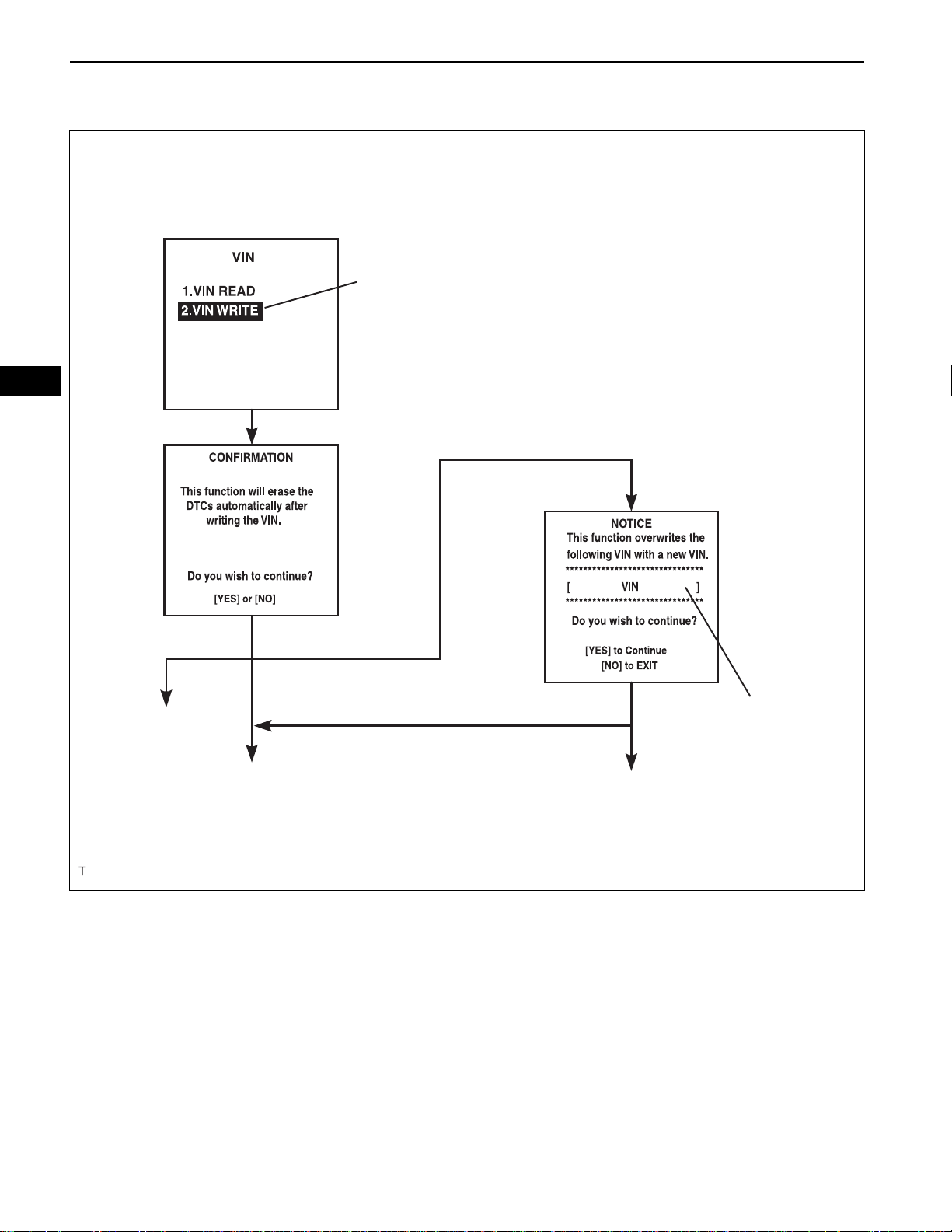

3. WRITE VIN

(a) The flowchart of the VIN writing process is shown.

This process allows the VIN to be input into the

ECM. If the ECM is changed, or the VINs do not

match, the VIN can be registered, or overwritten in

the ECM by following this procedure.

(b) Write VIN using the intelligent tester.

(c) Check the vehicle's VIN.

(d) Connect the intelligent tester to the DLC3.

(e) Turn the ignition switch on (IG).

(f) Turn the tester on.

Page 26

ES

ES–26

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(g) Enter the following menus: DIAGNOSIS /

ENHANCED OBD ll / VIN.

Menu Screen:

Select VIN WRITE

VIN Previously Stored

To Menu

Screen

[YES][NO]

[YES]

Continue to next illustration

[YES]

17-digit VIN displayed

[NO]

To Menu Screen

A103813E01

Page 27

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

New Registration

ES–27

Input Instructions

[ENTER]

ES

[ENTER]

Continue to next illustration

[ENTER]

[ENTER]

Input Error

[EXIT]

A103814E03

Page 28

ES

ES–28

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

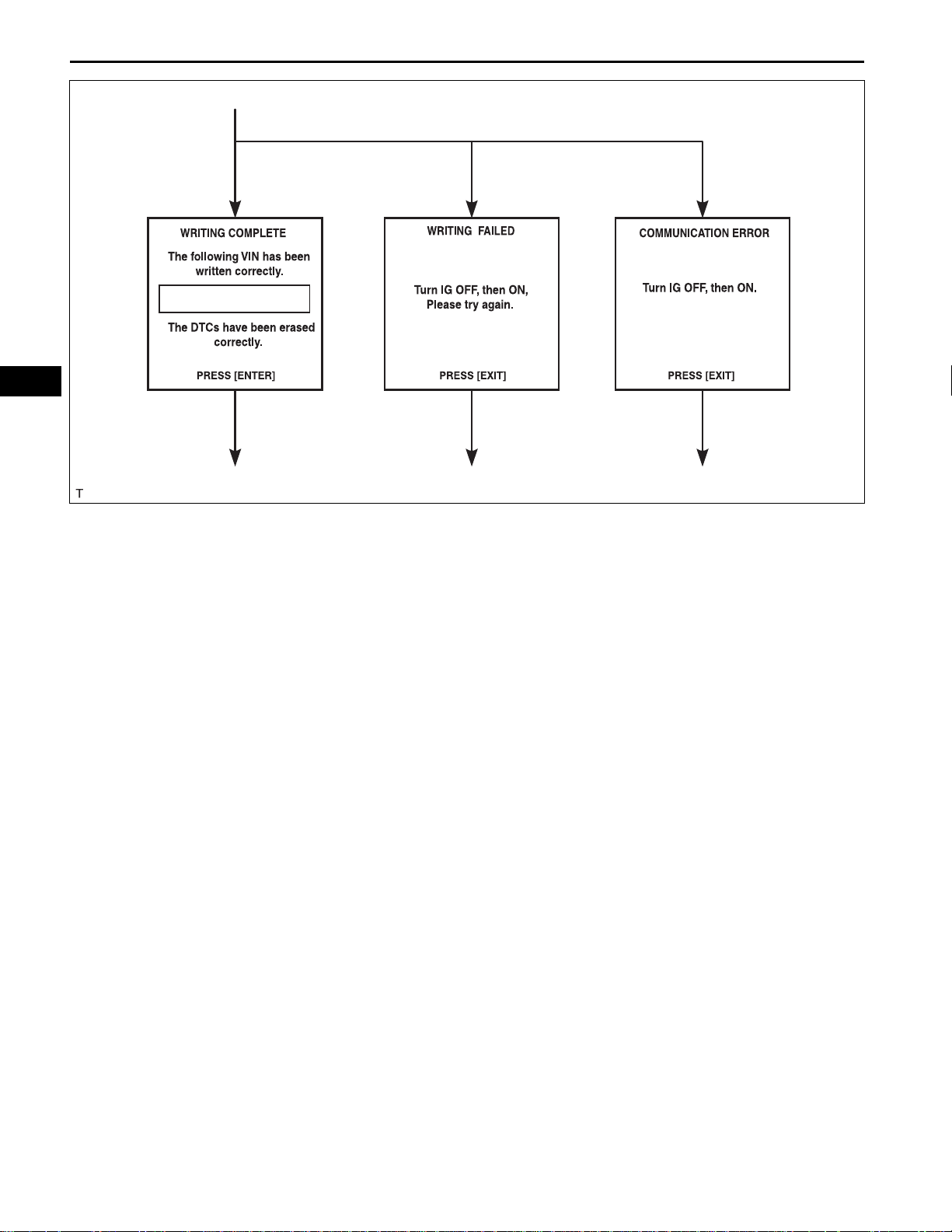

Writing Successful Writing Error Communication Error

[ENTER] [EXIT] [EXIT]

To Menu Screen To Menu Screen To Menu Screen

A103815E03

Page 29

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow

access to the results for on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalyst, evaporative emission

(EVAP) and thermostat.

The monitor result allows the OBD II scan tool to display the

monitor status, test value, minimum test limit and maximum

test limit. These data are displayed after the vehicle has been

driven to run the monitor.

When the test value is not between the minimum test limit

and maximum test limit, the ECM (PCM) interprets this as a

malfunction. When the component is not malfunctioning, if the

difference of the test value and test limit is very small, the

component will malfunction in the near future.

Perform the following instructions to view the monitor status.

Although the Toyota diagnostic tester is used in the following

instructions, it can be checked using a generic OBD II scan

tool. Refer to your scan tool operator's manual for specific

procedures.

1. PERFORM MONITOR DRIVE PATTERN

The monitor results and test values can be checked with

the OBD II scan tool or the intelligent tester. The engine

control module (ECM) monitors the emissions-related

components such as the thermostat, catalyst converter

and evaporative emissions (EVAP), and determines

whether they are functioning normally or not. When

monitoring is finished, the ECM stores the monitor

results and the test values. The monitor result indicates

whether the component is functioning normally or not.

The test value is the value that was used to determine

the monitor result. If the test value is outside of the test

limit (malfunction criterion), the ECM determines the

component is malfunctioning. Some emissions-related

components have multiple test values to determine

monitor result. If one of these test values is outside of the

test limit, the ECM determines the component is

malfunctioning.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Clear the DTCs.

(d) Run the vehicle in accordance with the applicable

drive pattern described in READINESS MONITOR

DRIVE PATTERN (See page ES-28). DO NOT turn

the engine switch off.

NOTICE:

The test results will be lost if the engine switch

is turned off.

ES–29

ES

Page 30

ES

ES–30

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

2. ACCESS MONITOR RESULT

(a) Select the following menus on the intelligent tester:

DIAGNOSIS, ENHANCED OBDII, MONITOR INFO

and MONITOR RESULT. The monitor status

appears after the component name.

• INCMP: The component has not been monitored

yet.

• PASS: The component is functioning normally.

• FAIL: The component is malfunctioning.

(b) Confirm that the component is either PASS or FAIL.

(c) Select the component and press ENTER. The

accuracy test value appears if the monitor status is

either PASS or FAIL.

HINT:

The monitor result might be PASS on rare

occasions even if the Malfunction Indicator Lamp

(MIL) is illuminated. This indicates that the system

was malfunctioning in the previous driving cycle.

This might be caused by an intermittent problem.

3. CHECK COMPONENT STATUS

(a) Compare the test value with the minimum test limit

(MIN LIMIT) and maximum test limit (MAX LIMIT).

(b) If the test value is between the minimum test limit

and maximum test limit, the component is

functioning normally. If not, the component is

malfunctioning. The test value is usually significantly

higher or lower than the test limit. If the test value is

on the borderline of the test limit, the component will

malfunction in the near future.

HINT:

The monitor result might be PASS on rare occasions even if

the Malfunction Indicator Lamp (MIL) is illuminated. This

indicates that the system was malfunctioning in the previous

driving cycle. This might be caused by an intermittent

problem.

4. MONITOR RESULT INFORMATION

If you use a generic scan tool, multiply the test value by

the scaling value listed below.

A/F Sensor Bank 1:

Monitor ID Test ID Scaling Unit Description

$01 $8E Multiply by 0.0003 No dimension A/F sensor deterioration level

$01 $91 Multiply by 0.004 mA A/F sensor current

HO2S Bank 1 Sensor 2:

Monitor ID Test ID Scaling Unit Description

$02 $07 Multiply by 0.001 V Minimum sensor voltage

$02 $08 Multiply by 0.001 V Maximum sensor voltage

$02 $8F Multiply by 0.003 g Maximum oxygen storage capacity

A/F Sensor Bank 2:

Monitor ID Test ID Scaling Unit Description

$05 $8E Multiply by 0.0003 No dimension A/F sensor deterioration level

$05 $91 Multiply by 0.004 mA A/F sensor current

Page 31

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

HO2S Bank 2 Sensor 2:

Monitor ID Test ID Scaling Unit Description

$06 $07 Multiply by 0.001 V Minimum sensor voltage

$06 $08 Multiply by 0.001 V Maximum sensor voltage

$06 $8F Multiply by 0.003 g Maximum oxygen storage capacity

Catalyst-Bank 1:

Monitor ID Test ID Scaling Unit Description

$21 $A9 Multiply by 0.003 No dimension Oxygen storage capacity of catalyst-bank 1

Catalyst-Bank 2:

Monitor ID Test ID Scaling Unit Description

$22 $A9 Multiply by 0.003 No dimension Oxygen storage capacity of catalyst-bank 2

EVAP:

Monitor ID Test ID Scaling Unit Description

$3D $C9 Multiply by 0.001 kPa Test value for small leak (P0456)

$3D $CA Multiply by 0.001 kPa Test value for gross leak (P0455)

$3D $CB Multiply by 0.001 kPa Test value for leak detection pump OFF stuck (P2401)

$3D $CD Multiply by 0.001 kPa Test value for leak detection pump ON stuck (P2402)

$3D $CE Multiply by 0.001 kPa Test value for vent valve OFF stuck (P2420)

$3D $CF Multiply by 0.001 kPa Test value for vent valve ON stuck (P2419)

$3D $D0 Multiply by 0.001 kPa Test value for reference orifice low flow (P043E)

$3D $D1 Multiply by 0.001 kPa Test value for reference orifice high flow (P043F )

$3D $D4 Multiply by 0.001 kPa Test value for purge VSV close stuck (P0441)

$3D $D5 Multiply by 0.001 kPa Test value for purge VSV open stuck (P0441)

$3D $D7 Multiply by 0.001 kPa Test value for purge flow insufficient (P0441)

ES–31

ES

Misfire:

Monitor ID Test ID Scaling Unit Description

$A1 $0B Multiply by 1 Time

$A1 $0C Multiply by 1 Time

$A2 $0B Multiply by 1 Time

$A2 $0C Multiply by 1 Time

$A3 $0B Multiply by 1 Time

$A3 $0C Multiply by 1 Time

$A4 $0B Multiply by 1 Time

$A4 $0C Multiply by 1 Time

$A5 $0B Multiply by 1 Time

$A5 $0C Multiply by 1 Time

$A6 $0B Multiply by 1 Time

$A6 $0C Multiply by 1 Time

$A7 $0B Multiply by 1 Time

Exponential Weighted Moving Average (EWMA) misfire for all

cylinders: Misfire counts for last ten driving cycles-Total

Misfire rate for all cylinders: Misfire counts for last/current driving

cycles-Total

EWMA misfire for cylinder 1: Misfire counts for last ten driving cyclesTotal

Misfire rate for cylinder 1: Misfire counts for last/current driving cycleTotal

EWMA misfire for cylinder 2: Misfire counts for last ten driving cyclesTotal

Misfire rate for cylinder 2: Misfire counts for last/current driving cycleTotal

EWMA misfire for cylinder 3: Misfire counts for last ten driving cyclesTotal

Misfire rate for cylinder 3: Misfire counts for last/current driving cycleTotal

EWMA misfire for cylinder 4: Misfire counts for last ten driving cyclesTotal

Misfire rate for cylinder 4: Misfire counts for last/current driving cycleTotal

EWMA misfire for cylinder 5: Misfire counts for last ten driving cyclesTotal

Misfire rate for cylinder 5: Misfire counts for last/current driving cycleTotal

EWMA misfire for cylinder 6: Misfire counts for last ten driving cyclesTotal

Page 32

ES

ES–32

Monitor ID Test ID Scaling Unit Description

$A7 $0C Multiply by 1 Time

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Misfire rate for cylinder 6: Misfire counts for last/current driving cycleTotal

Rear Oxygen Sensor Heater:

Monitor ID Test ID Scaling Unit Description

$42 $91 Multiply by 0.001 Ohm Oxygen sensor heater resistance bank 1 sensor 2

$46 $91 Multiply by 0.004 Ohm Oxygen sensor heater resistance bank 2 sensor 2

Page 33

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

READINESS MONITOR DRIVE

PATTERN

1. PURPOSE OF READINESS TESTS

• The On-Board Diagnostic (OBD II) system is

designed to monitor the performance of emissionrelated components, and indicate any detected

abnormalities with DTCs (Diagnostic Trouble Codes).

Since various components need to be monitored in

different driving conditions, the OBD II system is

designed to run separate monitoring programs called

Readiness Monitors.

• The intelligent tester's software must be version 9.0 or

newer to view the Readiness Monitor status. To view

the status, select the following menu items:

DIAGNOSIS / ENHANCED OBD II / MONITOR INFO

/ MONITOR STATUS.

• When the Readiness Monitor status reads COMPL

(complete), the necessary conditions have been met

for running the performance tests for that Readiness

Monitor.

• A generic OBD II scan tool can also be used to view

the Readiness Monitor status.

HINT:

Many Inspection and Maintenance (I/M) programs

require a vehicle's Readiness Monitor status to show

COMPL before beginning emission tests.

The Readiness Monitor will be reset to INCMPL

(incomplete) if:

• The ECM has lost battery power or broken a fuse.

• DTCs have been cleared.

• The conditions for running the Readiness Monitor

have not been met.

If the Readiness Monitor status shows INCMPL, follow

the appropriate Readiness Monitor Drive Pattern to

change the status to COMPL.

CAUTION:

Strictly observe posted speed limit s, traffic laws, and

road conditions when performing these drive

patterns.

NOTICE:

These drive patterns represent the fastest me thod of

satisfying all conditions necessary to achieve

complete status for each specific Readiness

Monitor.

In the event of a drive pattern being interrupted

(possibly due to factors such as traffic conditions),

the drive pattern can be resumed. In most cases, the

Readiness Monitor will still achieve complete status

upon completion of the drive pattern.

To ensure completion of the Readiness Monitors,

avoid sudden changes in vehicle load and speed

(driving up and down hills and/or sudden

acceleration).

ES–33

ES

Page 34

ES–34

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

Vehicle Speed

NOTICE:

ES

Between 40 mph and

70 mph (64 km/h and

113 km/h)

Idling

Ignition Switch off

This test will not be completed if

the vehicle is driven under absolute

constant speed condition such as

with cruise control activated.

Warm up

Note: Even when vehicle stops during driving pattern, the test can be resumed

10 minutes

Time

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch on (IG).

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8,000 ft (2,450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4°C and 35°C (40°F to 95°F).

• The intake air temperature is between 4.4°C and

35°C (40°F to 95°F).

• Vehicle was driven in the city area (or on freeway) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

A079199E85

Page 35

Monitor Drive Pattern:

ECT: 75°C (167°F) or more

Vehicle Speed

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch on (IG).

(3) Turn the tester or scan tool on.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

Accelerator Pedal Depressed

At least 3 times

ES–35

Accelerator

Pedal Released

(Fuel-cut)

ES

Idling

38 to 75 mph

(60 to 120 km/h)

Warming up

10 minutes or more

(a) Preconditions

(b) Drive Pattern for front A/F sensor and HO2 sensor

40 mph (64 km/h)

or more

6 mph (10

km/h)

Time

10 seconds or more

4 seconds or more

G039003E12

The monitor will not run unless:

• 2 minutes or more have elapsed sin ce the engine

was started.

• The Engine Coolant Temperature (ECT) is 75°C

(167°F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch on (IG).

(3) Turn the tester on.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75°C (167°F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

Page 36

ES

ES–36

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10)Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11)Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met and then perform the Drive

Pattern again.

5. AIR-FUEL RA TIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONI TORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

Vehicle Speed

25 mph

(40 km/h)

Idling

Ignition Switch off

10 minutes or more

2 minutes or more

A078886E24

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch on (IG).

(3) Clear the DTCs.

(4) Start the engine.

(5) Allow the engine to idle for 10 minutes or more.

(6) Drive the vehicle at 25 mph (40 km/h) or more

for at least 2 minutes.

Page 37

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met, and repeat the Drive Pattern.

ES–37

ES

Page 38

ES

ES–38

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

SFI SYSTEM

Symptom Suspected area See page

Without Smart Key System: Engine does not crank

(Does not start)

With Smart Key System: Engine does not crank (Does

not start)

No initial combustion (Does not start)

Engine cranks normally but difficult to start

Difficult to start with cold engine

Difficult to start with warm engine

PROBLEM SYMPTOMS TABLE

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority order indicated in the table below.

1. Immobilizer system (with smart key system) EI-7

2. Immobilizer system (without smart key system) EI-55

3. Starter signal circuit ES-304

4. Starter ST-143

5. STARTER relay ST-149

1. Immobilizer system (with smart key system) EI-7

2. Immobilizer system (without smart key system) EI-55

3. Cranking holding function circuit ES-455

4. Starter signal circuit ES-304

5. Starter ST-143

6. STARTER relay ST-149

7. ECM power source circuit ES-432

8. ECM ES-518

1. ECM power source circuit ES-432

2. Ignition system IG-3

3. Fuel pump control circuit ES-449

4. Injector FU-15

5. Crank angle sensor ES-497

6. ECM ES-518

1. Electronic Throttle Control System (ETCS) ES-320

2. Fuel pump control circuit ES-449

3. Ignition system IG-3

4. Spark plug IG-5

5. Compression EM-3

6. Injector FU-15

7. Crank angle sensor ES-497

1. Starter signal circuit ES-304

2. Electronic Throttle Control System (ETCS) ES-320

3. Fuel pump control circuit ES-449

4. Spark plug IG-5

5. Ignition system IG-3

6. Injector FU-15

7. Engine coolant temperature sensor ES-500

1. Starter signal circuit ES-304

2. Electronic Throttle Control System (ETCS) ES-320

3. Fuel pump control circuit ES-449

4. Spark plug IG-5

5. Ignition system IG-3

6. Injector FU-15

7. Engine coolant temperature sensor ES-500

Page 39

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Symptom Suspected area See page

1. Electronic Throttle Control System (ETCS) ES-320

2. ECM power source circuit ES-432

High engine idling speed (Poor idling)

Low engine idling speed (Poor idling)

Rough idling (Poor idling)

Hunting (Poor idling)

Hesitation/Poor acceleration (Poor driveability)

Surging (Poor driveability)

Engine stalls soon after starting

Engine stalls during A/C operation

Unable/difficult to refuel Refueling valve (canister) Engine vibrates frequently when idling (Active Control

engine Mount (ACM) system does not operate)

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS) ES-462

5. PCV hose EC-5

6. ECM ES-518

1. Electronic Throttle Control System (ETCS) ES-320

2. ECM power source circuit ES-432

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS) ES-462

5. PCV hose EC-5

6. Injector FU-15

7. ECM ES-518

1. Electronic Throttle Control System (ETCS) ES-320

2. Injector FU-15

3. Ignition system IG-3

4. Compression EM-3

5. Fuel pump control circuit ES-449

6. Spark plug IG-5

7. Acoustic Control Induction System (ACIS) ES-462

8. PCV hose EC-5

1. Electronic Throttle Control System (ETCS) ES-320

2. ECM power source circuit ES-432

3. Fuel pump control circuit ES-449

4. Spark plug IG-5

5. Ignition system IG-3

6. Injector FU-15

7. Acoustic Control Induction System (ACIS) ES-462

8. PCV hose EC-5

1. Injector FU-15

2. Fuel pump control circuit ES-449

3. Ignition system IG-3

4. Spark plug IG-5

5. Air Intake Control System (AICS) ES-462

6. A/T faulty AX-9

1. Fuel pump control circuit ES-449

2. Spark plug IG-5

3. Ignition system IG-3

4. Injector FU-15

1. Fuel pump control circuit ES-449

2. Electronic Throttle Control System (ETCS) ES-320

3. Crank angle sensor ES-497

4. Spark plug IG-5

5. Ignition system IG-3

6. Injector FU-15

1. A/C signal circuit -

2. ECM ES-518

Active control engine mount circuit ES-393

ES–39

ES

Page 40

ES–40

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

TERMINALS OF ECM

1. SFI SYSTEM

A55C55

ES

A107881E29

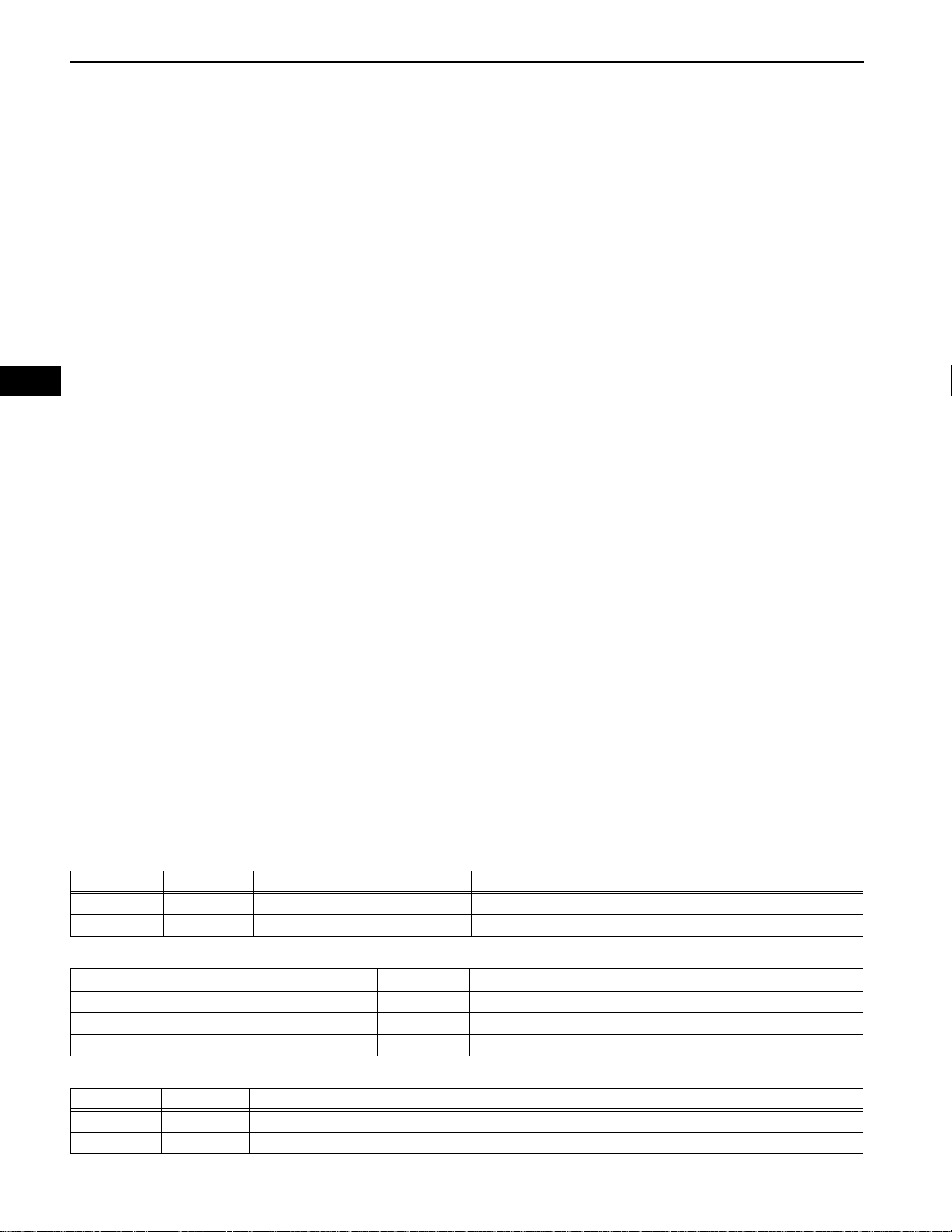

HINT:

The standard normal voltage between each pair of the

ECM terminals is shown in the table below. The

appropriate conditions for checking each pair of the

terminals are also indicated.

The check results should be compared with the standard

normal voltage for that pair of terminals, listed in the

"STD Voltages" column.

The illustration above can be used as a reference to

identify the ECM terminal locations.

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

+B (A55-2) - E1 (C55-81) R - W-B Power source of ECM Ignition switch on (IG) 9 to 14 V

+B2 (A55-1) - E1 (C55-81) R - W-B Power source of ECM Ignition switch on (IG) 9 to 14 V

BATT (A55-20) - E1 (C55-81) Y - W-B

VPMP (A55-42) - E1 (C55-81) W - W-B

MPMP (A55-34) - E1 (C55-81) G - W-B

MPMP (A55-34) - E1 (C55-81) G - W-B

+BM (A55-3) - E1 (C55-81) LG - W-B

MREL (A55-44) - E1 (C55-81) O - W-B EFI relay operation signal Ignition switch on (IG) 9 to 14 V

IGSW (A55-28) - E1 (C55-81) Y - W-B Ignition switch signal Ignition switch on (IG) 9 to 14 V

FC (A55-7) - E1 (C55-81)

FC (A55-7) - E1 (C55-81)

STP ( A55-36 ) - E1 (C55-81) - W-B Stop light switch signal W-Brake pedal depressed 7.5 to 14 V

STP (A55-36) - E1 (C55-81) - W-B Stop light switch signal W-Brake pedal released Below 1.5 V

ST1- (A55-35) - E1 (C55-81) GR - W-B

FC (A55-7) - E1

(C55-81)

FC (A55-7) - E1

(C55-81)

Battery (for measuring the

battery voltage and for the

ECM memory)

Vent valve operation

signal (built into pump

module)

Vacuum pump operation

signal (built into pump

module)

Vacuum pump operation

signal (built into pump

module)

Power source of ETCS

throttle motor

C/OPEN relay operation

signal (fuel pump control)

C/OPEN relay operation

signal (fuel pump control)

Stop light switch signal

(opposite to STP terminal)

Always 9 to 14 V

Ignition switch on (IG) 9 to 14 V

Vacuum pump OFF 0 to 3 V

Vacuum pump ON 9 to 14 V

Always 9 to 14 V

Ignition switch on (IG), Engine

stopped

Ignition switch on (IG), Engine

idling

Ignition switch on (IG), W-Brake

pedal depressed

9 to 14 V

0 to 1.5 V

Below 1.5 V

Page 41

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

ST1- (A55-35) - E1 (C55-81) GR - W-B

*2

ACCR

(A24-17) - E1 (C55-81)

VPA (A55-55) - E1 (C55-81) G - W-B

VPA (A55-55) - E1 (C55-81) G - W-B

VPA2 (A55-58) - EPA2 (A55-60) R - O

VPA2 (A55-58) - EPA2 (A55-60) R - O

EPA (A5-59) - VPA (A55-55) Y - G

EPA (A5-59) - VPA (A55-55) Y - G

EPA2 (A55-60) - VPA2 (A55-58) O - R

EPA2 (A55-60) - VPA2 (A55-58) O - R

PPMP (C55-77) - E1 (C55-81) L - W-B

TC (A55-27) - E1 (C55-81) P - W-B Terminal TC of DLC3 Ignition switch on (IG) 9 to 14 V

VCPA (A55-57) - EPA (A55-59) R - Y

VCP2 (A55-56) - EPA2 (A55-60) L - O

TACH (A55-15) - E1 (C55-81) B - W-B

CCS (A55-40) - E1 (C55-81) W - W-B

SPD (A55-24) - E1 (C55-81) BR - W-B

W (A55-24) - E1 (C55-81) BR - W-B

W (A55-24) - E1 (C55-81) BR - W-B

CANH (A55-41) - CANL (A55-49) B - W

E1 (C55-81) - Body ground W-B - -

B - W-B ACC relay control signal Cranking Below 1.5 V

Stop light switch signal

(opposite to STP terminal)

Accelerator pedal position

sensor signal (for engine

control)

Accelerator pedal position

sensor signal (for engine

control)

Accelerator pedal position

sensor signal (for sensor

malfunction detection)

Accelerator pedal position

sensor signal (for sensor

malfunction detection)

Accelerator pedal position

sensor signal (for engine

control)

Accelerator pedal position

sensor signal (for engine

control)

Accelerator pedal position

sensor signal (for sensor

malfunction detection)

Accelerator pedal position

sensor signal (for sensor

malfunction detection)

Pressure sensor signal

(built into pump module)

Power source of

accelerator pedal position

sensor (for VPA)

Power source of

accelerator pedal position

sensor (for VPA2)

Engine speed signal (for

combination meter)

Cruise control main switch

signal

Vehicle speed signal from

combination meter

Malfunction Indicator

Lamp (MIL) operation

signal

Malfunction Indicator

Lamp (MIL) operation

signal

CAN communication

circuit

Earth (ground) circuit of

ECM

Ignition switch on (IG), W-Brake

pedal released

Ignition switch on (IG),

Accelerator pedal fully released

Ignition switch on (IG),

Accelerator pedal fully depressed

Ignition switch on (IG),

Accelerator pedal fully released

Ignition switch on (IG),

Accelerator pedal fully depressed

Ignition switch on (IG),

Accelerator pedal fully released

Ignition switch on (IG),

Accelerator pedal fully depressed

Ignition switch on (IG),

Accelerator pedal fully released

Ignition switch on (IG),

Accelerator pedal fully depressed

Ignition switch on (IG) 3 to 3.6 V

Ignition switch on (IG) 4.5 to 5.0 V

Ignition switch on (IG) 4.5 to 5.0 V

Idling

Ignition switch on (IG)

CANCEL switch ON

SET/COAST switch ON

RES/ACC switch ON

Main switch ON

Ignition switch on (IG), driving

wheel rotated slowly

Ignition switch on (IG) Below 3.0 V

Idling 9 to 14 V

Ignition switch off 54 to 69 Ω

Always Below 1 V

Pulse generation

(see waveform 11)

Pulse generation

(see waveform 8)

ES–41

7.5 to 14 V

0.5 to 1.1 V

2.6 to 4.5 V

1.2 to 2.0 V

3.4 to 5.0 V

0.5 to 1.1 V

2.6 to 4.5 V

1.2 to 2.0 V

3.4 to 5.0 V

10 to 16 V

6.6 to 10.1 V

4.5 to 7.1 V

2.3 to 4.0 V

Below 1 V

ES

Page 42

ES

ES–42

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

#10 (C55-45) - E01 (C55-22)

#20 (C55-85) - E01 (C55-22)

#30 (C55-44) - E01 (C55-22)

#40 (C55-84) - E01 (C55-22)

#50 (C55-43) - E01 (C55-22)

#60 (C55-83) - E01 (C55-20)

#10 (C55-45) - E01 (C55-22)

#20 (C55-85) - E01 (C55-22)

#30 (C55-44) - E01 (C55-22)

#40 (C55-84) - E01 (C55-22)

#50 (C55-43) - E01 (C55-22)

#60 (C55-83) - E01 (C55-20)

PSW (C55-810) - E1 (C55-81) B - W-B P/S pressure switch signal Ignition switch on (IG) 9 to 14 V

STA (A55-48) - E1 (C55-81) V - W-B

*2

STSW

(A55-14) - E1 (C55-81)

OC2- (C55-51) - OC2+ (C55-52) R - BR

OC2+ (C55-52) - OC2- (C55-51) BR - R

OC1- (C55-57) - OC1+ (C55-58) B - W

OC1+ (C55-58) - OC1- (C55-57) W - B

VV2+ (C55-67) - VV2- (C55-90) W - B

VV1+ (C55-69) - VV1- (C55-92) L - LG

NE- (C55-111) - NE+ (C55-110) R - G

NE+ (C55-110) - NE- (C55-111) G - R

EV2- (C55-89) - EV2+ (C55-66) L - G-R

EV2+ (C55-66) - EV2- (C55-89) G-R - L

EV1- (C55-91) - EV1+ (C55-68) B - Y

EV1+ (C55-68) - EV1- (C55-91) Y - B

OE1+ (C55-16) - OE1- (C55-17) L - LG

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

B - W-B

R - W-B

Y - W-B

L - W-B

W-L - W-B

BR - W-B

B - W-B

R - W-B

Y - W-B

L - W-B

W-L - W-B

BR - W-B

R - W-B

Fuel injector operation

signal

Fuel injector operation

signal

Starter relay operation

signal

Starter relay operation

signal

Camshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Intake

side)

Variable Valve Timing

(VVT) sensor signal

(Intake side)

Variable Valve Timing

(VVT) sensor signal

(Intake side)

Crankshaft position sensor

signal

Crankshaft position sensor

signal

Variable Valve Timing

(VVT) sensor signal

(Exhaust side)

Variable Valve Timing

(VVT) sensor signal

(Exhaust side)

Variable Valve Timing

(VVT) sensor signal

(Exhaust side)

Variable Valve Timing

(VVT) sensor signal

(Exhaust side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Exhaust

side)

Ignition switch on (IG) 9 to 14 V

Idling

Cranking 9 to 14 V

Cranking 9 to 14 V

Ignition switch on (IG)

Ignition switch on (IG)

Ignition switch on (IG)

Ignition switch on (IG)

Idling

Idling

Idling

Idling

Idling

Idling

Idling

Idling

Ignition switch on (IG)

Pulse generation

(see waveform 3)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 1)

Page 43

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

Camshaft timing Oil

OE2+ (C55-14) - OE2- (C55-15) W-L - Y

VV2- (C55-90) - VV2+ (C55-67) B - W

VV1- (C55-92) - VV1+ (C55-69) LG - L

OE1- (B47-31) - OE1+ (B47-26) LG - L

OE2- (C55-15) - OE2+ (C55-14) Y - W-L

HT1B (C55-48) - E1 (C55-81)

HT2B (C55-47) - E1 (C55-81)

HT1B (C55-48) - E1 (C55-81)

HT2B (C55-47) - E1 (C55-81)

ACM (C55-42) - E1 (C55-81) L-B - W-B

M- (C55-18) - ME01 (C55-20) R - B

M+ (C55-19) - ME01 (C55-20) G - B

E02 (C55-21) - Body ground B-W - -

E01 (C55-22) - Body ground W-B - IGT1 (C55-40) - E1 (C55-81)

IGT2 (C55-39) - E1 (C55-81)

IGT3 (C55-38) - E1 (C55-81)

IGT4 (C55-37) - E1 (C55-81)

IGT5 (C55-36) - E1 (C55-81)

IGT6 (C55-35) - E1 (C55-81)

GE01(C55-41) - E1 (C55-81) G-R - W-B

OX1B (C55-88) - EX1B (C55-65)

OX2B (C55-87) - EX2B (C55-64)

VTA2 (C55-99) - ETA (C55-97) W-L - P

VTA2 (C55-99) - ETA (C55-97) W-L - P

VTA1 (C55-98) - ETA (C55-97) Y - P

VTA1 (C55-98) - ETA (C55-97) Y - P

THW (C55-79) - ETHW (C55-78) B - P

THA (C55-71) - ETHA (C55-74) P - G-R

LG - W-B

Y - W-B

LG - W-B

Y - W-B

W - W-B

GR - W-B

G - W-B

LG - W-B

P - W-B

G-R - W-B

W - BR

B - W-B

Control Valve (OCV)

operation signal (Exhaust

side)

Variable Valve Timing

(VVT) sensor signal

(Intake side)

Variable Valve Timing

(VVT) sensor signal

(Intake side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Exhaust

side)

Camshaft timing Oil

Control Valve (OCV)

operation signal (Exhaust

side)

Heated oxygen sensor

heater operation signal

Heated oxygen sensor

heater operation signal

VSV for active control

mount system operation

signal

Throttle drive motor

operation signal (negative

terminal)

Throttle drive motor

operation signal (positive

terminal)

Earth (ground) circuit of

ECM

Earth (ground) circuit of

ECM

Ignition coil with igniter

(ignition signal)

Shielded earth (ground)

circuit of throttle drive

motor

Heated oxygen sensor

signal

Throttle position sensor

signal (for sensor

malfunction detection)

Throttle position sensor

signal (for sensor

malfunction detection)

Throttle position sensor

signal (for engine control)

Throttle position sensor

signal (for engine control)

Engine coolant

temperature sensor signal

Intake air temperature

sensor signal

Ignition switch on (IG)

Idling

Idling

Ignition switch on (IG)

Ignition switch on (IG)

Idling Below 3.0 V

Ignition switch on (IG) 9 to 14 V

Ignition switch on (IG) 9 to 14 V

Idling with warm engine

Idling with warm engine

Always Below 1 V

Always Below 1 V

Idling

Always Below 1 V

With engine speed at 2,500 rpm

for 2 minutes after warming up

Ignition switch on (IG),

Accelerator pedal fully released

Ignition switch on (IG),

Accelerator pedal fully depressed

Ignition switch on (IG), Throttle

valve fully closed

Ignition switch on (IG), Throttle

valve fully open

Idling, Engine coolant

temperature 80°C (176°F)

Idling, Intake air temperature

20°C (68°F)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 5)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 1)

Pulse generation

(see waveform 10)

Pluse generation

(see waveform 9)

Pulse generation

(see waveform 6)

Pulse generation

(see waveform 2)

2.1 to 3.1 V

4.5 to 5.0 V

0.5 to 1.2 V

3.2 to 4.8 V

0.2 to 1.0 V

0.5 to 3.4 V

ES–43

ES

Page 44

ES

ES–44

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

IGF1 (C55-106) - E1 (C55-81) BR - W-B

IGF1 (C55-106) - E1 (C55-81) BR - W-B

AICV (A55-4) - E1 (C55-81) V - W-B

E2G (C55-73) - E1 (C55-81) LG - W-B

VG (C55-72) - E2G (C55-73) L-B - LG

ACIS (C55-107) - E1 (C55-81) R - W-B

PRG (C55-108) - E1 (C55-81) G-R - W-B

PRG (C55-108) - E1 (C55-81) G-R - W-B

HA2A (C55-109) - E05 (C55-46) B-W - W

HA2A (C55-109) - E05 (C55-46) B-W - W

HA1A (C55-86) - E04 (C55-23) G - W

HA1A (C55-86) - E04 (C55-23) G - W

ME01 (C55-20) - E1 (C55-81) B - W-R

E03 (C55-104) - E1 (C55-81) B - W-B

HT2B (C55-47) - E1 (C55-81)

HT1B (C55-48) - E1 (C55-81)

HT2B (C55-47) - E1 (C55-81)

HT1B (C55-48) - E1 (C55-81)

E05 (C55-46) - E1 (C55-81) W - W-B

E04 (C55-23) - E1 (C55-81) W - W-B

NSW (C55-62) - E1 (C55-81) R - W-B

NSW (C55-62) - E1 (C55-81) R - W-B

EKN2 (C55-117) - KNK2 (C55-

118)

KNK2 (C55-118) - EKN2 (C55-

117)

A1A+ (C55-93) - E1 (C55-81) P - W-B A/F sensor signal Ignition switch on (IG)

A1A+ (C55-93) - E1 (C55-81) P - W-B A/F sensor signal Ignition switch on (IG)

A2A+ (C55-120) - E1 (C55-81) L - W-B A/F sensor signal Ignition switch on (IG)

A2A+ (C55-120) - E1 (C55-81) L - W-B A/F sensor signal Ignition switch on (IG)

EKNK (C55-94) - KNK1 (C55-95) G - R

KNK1 (C55-95) - EKNK (C55-94) R - G Knock sensor signal

A1A- (C55-116) - E1 (C55-81) P - W-B A/F sensor Ignition switch on (IG)

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Ignition coil with igniter

(ignition confirmation

signal)

Ignition coil with igniter

(ignition confirmation

signal)

VSV for Air intake control

system operation signal

Earth (ground) circuit of

sensor for mass air flow

meter

Mass Air Flow (MAF)

meter signal

VSV for ACIS (Acoustic

Control Induction System)

operation signal

Purge VSV for EVAP

system operation signal

Purge VSV for EVAP

system operation signal

A/F sensor heater

operation signal

A/F sensor heater

operation signal

A/F sensor heater

operation signal

A/F sensor heater

operation signal

Earth (ground) circuit of

ECM

Earth (ground) circuit of

ECM

Y - W-B

LG - W-B

Y - W-B

LG - W-B

W - B

B - W Knock sensor signal

Heated oxygen sensor

heater operation signal

Heated oxygen sensor

heater operation signal

Earth (ground) circuit of

ECM

Earth (ground) circuit of

ECM

Park/Neutral position

switch signal

Park/Neutral position

switch signal

Earth (ground) circuit of

knock sensor

Earth (ground) circuit of

knock sensor

Ignition switch on (IG) 4.5 to 5.0 V

Idling

Ignition switch on (IG) 9 to 14 V

Always Below 1 V

Idling, Shift lever position P or N,

A/C switch OFF

Ignition switch on (IG) 9 to 14 V

Ignition switch on (IG) 9 to 14 V

Idling

Idling Below 3.0 V

Ignition switch on (IG) 9 to 14 V

Idling Below 3.0 V

Ignition switch on (IG) 9 to 14 V

Always Below 1 V

Always Below 1 V

Idling Below 3.0 V

Ignition switch on (IG) 9 to 14 V

Always Below 1 V

Always Below 1 V

Ignition switch on (IG), Shift lever

position P or N

Ignition switch on (IG), Shift lever

position other than P or N

With engine speed at 4,000 rpm

after warming up

With engine speed at 4,000 rpm

after warming up

With engine speed at 4,000 rpm

after warming up

With engine speed at 4,000 rpm

after warming up

Pulse generation

(see waveform 6)

Pulse generation

(see waveform 7)

Pulse generation

(see waveform 4)

Pulse generation

(see waveform 4)

Pulse generation

(see waveform 4)

Pulse generation

(see waveform 4)

0.5 to 3.0 V

Below 3.0 V

9 to 14 V

*1

3.3 V

*1

3.0 V

*1

3.3 V

*1

3.0 V

*1

3.3 V

Page 45

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Symbols (Terminal No.) Wiring Colors Terminal Descriptions Conditions STD Voltages

A1A- (B46-30) - E1 (C55-81) P - W-B A/F sensor Ignition switch on (IG)

A2A- (C55-119) - E1 (C55-81) Y - W-B A/F sensor Ignition switch on (IG)

A2A- (C55-119) - E1 (C55-81) Y - W-B A/F sensor Ignition switch on (IG)

OX2B (C55-87) - EX2B (C55-64)

OX1B (C55-88) - EX1B (C55-65)

B - W-R

W - BR

Heated oxygen sensor

signal

*1

: The ECM terminal voltage is constant regardless of

With engine speed at 2,500 rpm

for 2 minutes after warming up

Pulse generation

(see waveform 2)

the output voltage from the sensor.

*2

: With Smart Key system

(a) WAVEFORM 1

5 V/DIV

(1) Camshaft timing Oil Control Valve (OCV)

operation signal

Between OC1+ and OC1- , OC2+ and OC2- , OE1+

and OE1- , or OE2+ and OE2-

Ground

ECM Terminal Names

Tester Ranges 5 V/DIV, 1 ms./DIV

Conditions Idling

3.0 V

3.3 V

3.0 V

ES–45

*1

*1

*1

ES

0.2 V/DIV

Ground

30 V/DIV

Ground

1 ms./DIV

200 ms./DIV

20 ms./DIV

A093229E19

A088863E21

G035622E06

HINT:

The wavelength becomes shorter as the engine

rpm increases.

(b) WAVEFORM 2

(1) Heated oxygen sensor signal

ECM Terminal Names Between OX1B and EX1B, or OX2B and EX2B

Tester Ranges 0.2 V/DIV, 200 ms./DIV

Conditions

Engine speed is maintained at 2,500 rpm for 2

minutes after sensor is warmed up

HINT:

In the DATA LIST, item O2S B1S2 shows the

ECM input values from the heated oxygen

sensor.

(c) WAVEFORM 3

(1) Fuel injector operation signal

ECM Terminal Names Between #10 (to 60) and E01

Tester Ranges 30 V/DIV, 20 ms./DIV

Conditions Idling

HINT:

The wavelength becomes shorter as the engine

rpm increases.

Page 46

ES

ES–46

(2) NE

(1) VV1

or EV1

VV2 or

EV2

1 ms./DIV

20 ms./DIV (Idling)

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(d) WAVEFORM 4

(1) Knock sensor signal

1 V/DIV

Ground

ECM Terminal Names Between KNK1 and EKNK, or KNK2 and EKN2

Tester Ranges 0.01 to 10 V/DIV, 0.01 to 10 ms./DIV

Conditions

Engine speed is maintained at 4,000 rpm after engine

is warmed up

HINT:

• The wavelength becomes shorter as the

A085286E41

engine rpm increases.

• The waveforms and amplitudes displayed

differ slightly depending on the vehicle.

(e) WAVEFORM 5

5 V/DIV

(1) Variable Valve Timing (VVT) sensor signal (1)

(2) Crankshaft position sensor signal (2)

GND

GND

GND

G035795E23

ECM Terminal Names

Tester Ranges 5 V/DIV, 20 ms./DIV

Conditions Idling

HINT:

(1) Between VV1+ and VV1- , VV2+ and VV2-, EV1+

and EV1-, or EV2+ and EV2(2) Between NE+ and NE-

The wavelength becomes shorter as the engine

rpm increases.

(1)

(2)

10 V/DIV

Ground

20 ms./DIV

50 ms./DIV

2 V/DIV

Ground

Ground

G035664E08

G042964E02

(f) WAVEFORM 6

(1) Igniter IGT signal (from ECM to igniter) (1)

(2) Igniter IGF signal (from igniter to ECM) (2)

ECM Terminal Names

Tester Ranges 2 V/DIV, 20 ms./DIV

Conditions Idling

(1) Between IGT (1 to 6) and E1

(2) Between IGF1 and E1

HINT:

The wavelength becomes shorter as the engine

rpm increases.

(g) WAVEFORM 7

(1) Purge VSV for EVAP system operation signal

ECM Terminal Names Between PRG and E1

Tester Ranges 10 V/DIV, 50 ms./DIV

Conditions Idling

HINT:

If the waveform is not similar to that shown in the

illustration, check the waveform again after idling

for 10 minutes or more.

Page 47

2 V/DIV

Ground

5 V/DIV

Ground

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(h) WAVEFORM 8

(1) Vehicle speed signal

ECM Terminal Names Between SPD and E1

Tester Ranges 2 V/DIV, 20 ms./DIV

Conditions Driving at 12 mph (20 km/h)

HINT:

• The wavelength becomes shorter as the

20 ms./DIV

A093224E20

vehicle speed increases.

• Depending on the vehicle, the output

waveform voltage may rise to 12 V if

influenced by optionally installed systems.

(i) WAVEFORM 9

(1) Throttle drive motor operation signal (positive

terminal)

ECM Terminal Names Between M+ and ME01

Tester Ranges 5 V/DIV, 1 ms./DIV

Conditions Idling with warm engine

HINT:

1 ms./DIV

A093274E21

The duty ratio varies depending on the throttle

actuator operation.

ES–47

ES

5 V/DIV

Ground

5 V/DIV

Ground

1 ms./DIV

10 ms./DIV

A093275E21

A093225E18

(j) WAVEFORM 10

(1) Throttle drive motor operation signal (negative

terminal)

ECM Terminal Names Between M- and ME01

Tester Ranges 5 V/DIV, 1 ms./DIV

Conditions Idling with warm engine

HINT:

The duty ratio varies depending on the throttle

actuator operation.

(k) WAVEFORM 11

(1) Engine speed signal

ECM Terminal Names Between TACH and E1

Tester Ranges 5 V/DIV, 10 ms./DIV

Conditions Idling

HINT:

The wavelength becomes shorter as the engine

rpm increases.

Page 48

ES

ES–48

DLC3

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

Intelligent Tester

FI00534

C110200E01

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting OBD II (On-Board Diagnostics)

vehicles, the intelligent tester (complying with SAE

J1987) must be connected to the DLC3 (Data Link

Connector 3) of the vehicle. Various data in the vehicle's

ECM (Engine Control Module) can be then read.

OBD ll regulations require that the vehicle's on-board

computer illuminates the MIL (Malfunction Indicator

Lamp) on the instrument panel when the computer

detects a malfunction in:

(a)The emission control systems and components.

(b)The power train control components (which affect

vehicle emissions).

(c)The computer itself.

In addition, the applicable DTCs (Diagnostic Trouble

Codes) prescribed by SAE J2012 are recorded on 3

consecutive trips, the MIL turns off automatically but the

DTCs remain recorded in the ECM memory.

To check for DTCs, connect the intelligent tester to the

DLC3. The tester displays DTCs, freeze frame data, and

a variety of the engine data. The DTCs and freeze frame

data can be erased with the tester. In order to enhance

OBD function on vehicles and develop the Off-Board

diagnosis system, CAN communication is introduced in

this system (CAN: Controller Area Network). It minimizes

a gap between technician skills and vehicle technology.

CAN is a network, which uses a pair of dat a transmission

lines, spanning multiple computers and sensors. It allows

a high speed communication between the systems and

simplification of the wire harness connection. Since this

system is equipped with the CAN communication,

connecting the CAN VIM (VIM: V ehicle Interface Module)

with the intelligent tester is necessary to display any

information from the ECM. (Also the communication

between the intelligent tester and the ECM uses CAN

communication signal). When confirming the DTCs and

any data of the ECM, connect the CAN VIM between the

DLC3 and the intelligent tester.

2. NORMAL MODE AND CHECK MODE

The diagnosis system operates in normal mode during

normal vehicle use. In normal mode, 2 trip detection

logic is used to ensure accurate detection of

malfunctions. Check mode is also available as an option

for technicians. In check mode, 1 trip detection logic is

used for simulating malfunction symptoms and

increasing the system's ability to detect malfunctions,

including intermittent problems (intelligent tester only).

3. 2 TRIP DETECTION LOGIC

When a malfunction is first detected, the malfunction is

temporarily stored in the ECM memory (1st trip). If the

same malfunction is detected during the next

subsequent drive cycle, the MIL is illuminated (2nd trip).

Page 49

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

DLC3

12345678

ES–49

4. FREEZE FRAME DATA

The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is

stored. When troubleshooting, freeze frame data can be

helpful in determining whether the vehicle was running or

stopped, whether the engine was warmed up or not,

whether the air-fuel ratio was lean or rich, as well as

other data recorded at the time of a malfunction.

5. DLC3 (Data link Connector 3)

The vehicle's ECM uses ISO 15765-4 for communication

protocol. The terminal arrangement of the DLC3

complies with SAE J1962 and matches the ISO 15765-4

format.

161514131211109

A122830E11

Symbols Terminal No. Names Reference terminal Results Condition

SIL 7 Bus "+" line 5 - Signal ground Pulse generation During transmission

CG 4 Chassis ground Body ground 1 Ω or less Always

SG 5 Signal ground Body ground 1 Ω or less Always

BAT 16 Battery ground Body ground 9 to 14 V Always

CANH 6 CAN "High" line CANL 54 to 69 Ω Engine switch off

CANH 6 CAN "High" line Battery positive 1 MΩ or higher Engine switch off

CANH 6 CAN "High" line CG 1 kΩ or higher Engine switch off

CANL 14 CAN "Low" line Battery positive 1 MΩ or higher Engine switch off

CANL 14 CAN "Low" line CG 1 kΩ or higher Engine switch off

HINT:

The DLC3 is the interface prepared for reading various

data from the vehicle's ECM. After connecting the cable

of an intelligent tester , turn the ignition switch on (IG) and

turn the tester on. If a communication failure message is

displayed on the tester screen (on the tester: UNABLE

TO CONNECT TO VEHICLE), a problem exists in either

the vehicle or tester. In order to identify the location of

the problem, connect the tester to another vehicle.

If communication is normal: Inspect the DLC3 on the

original vehicle.

If communication is still not possible: The problem is

probably in the tester itself. Consult the Service

Department listed in the instruction manual.

6. BATTERY VOLTAGE

Standard Voltage:

11 to 14 V

If voltage is below 11 V, replace or recharge the battery

before proceeding to the next step.

7. MIL (Malfunction Indicator Lamp)

(a) The MIL is illuminated when the engine switch is

first turned on (the engine is not running).

ES

Page 50

ES

ES–50

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

(b) The MIL should turn OFF when the engine is

started. If the MIL remains illuminated, the diagnosis

system has detected a malfunction or abnormality in

the system.

HINT:

If the MIL is not illuminated when the engine switch is first

turned on, check the MIL circuit (See page ES-471).

Page 51

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from the normal

mode to check mode or vice versa, all DTCs and freeze

frame data recorded in normal mode are erased. Before

changing modes, always check and make a note of DTCs

and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on an

intelligent tester. An intelligent tester can display the

current and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during a second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

1. CHECK DTC (Using an intelligent tester)

(a) Connect an intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Turn the tester on.

(d) Enter the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES.

(e) Check the DTC(s) and freeze frame data, and then

write them down.

(f) Check the details of the DTC(s) (See page ES-63).

2. CLEAR DTC (Using an intelligent tester)

(a) Connect an intelligent tester to the DLC3.

(b) Turn the ignition switch on (IG).

(c) Turn the tester on.

(d) Enter the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using an intelligent tester)

(a) Perform either one of the following operations:

(1) Disconnect the negative battery cable for more

than 1 minute.

(2) Remove the EFI MAIN and ETCS fuses from the

Engine Room relay block located inside the

engine compartment for more than 1 minute.

ES–51

ES

Page 52

ES

ES–52

0.5 seconds0.5 seconds

Freeze frame data which can be read

0.5 seconds

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

FREEZE FRAME DATA

1. DESCRIPTION

The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is

stored. When troubleshooting, freeze frame data can be

helpful in determining whether the vehicle was running or

stopped, whether the engine was warmed up or not,

whether the air/fuel ratio was lean or rich, as well as

other data recorded at the time of a malfunction.

HINT:

If it is impossible to duplicate the problem even though a

DTC is detected, confirm the freeze frame data.

The ECM records engine conditions as freeze frame

DTC was set.

data every 0.5 seconds. Using the intelligent tester, five

separate sets of freeze frame data, including the data

values at the time when the DTC was set, can be

checked.

– 3 data set before the DTC was set.

– 1 data set when the DTC was set.

– 1 data set after the DTC was set.

These data sets can be used to simulate the condition

of the vehicle around the time of the occurrence of the

malfunction. The data may assist in identifying of the

cause of the malfunction, and in judging whether it

was temporary or not.

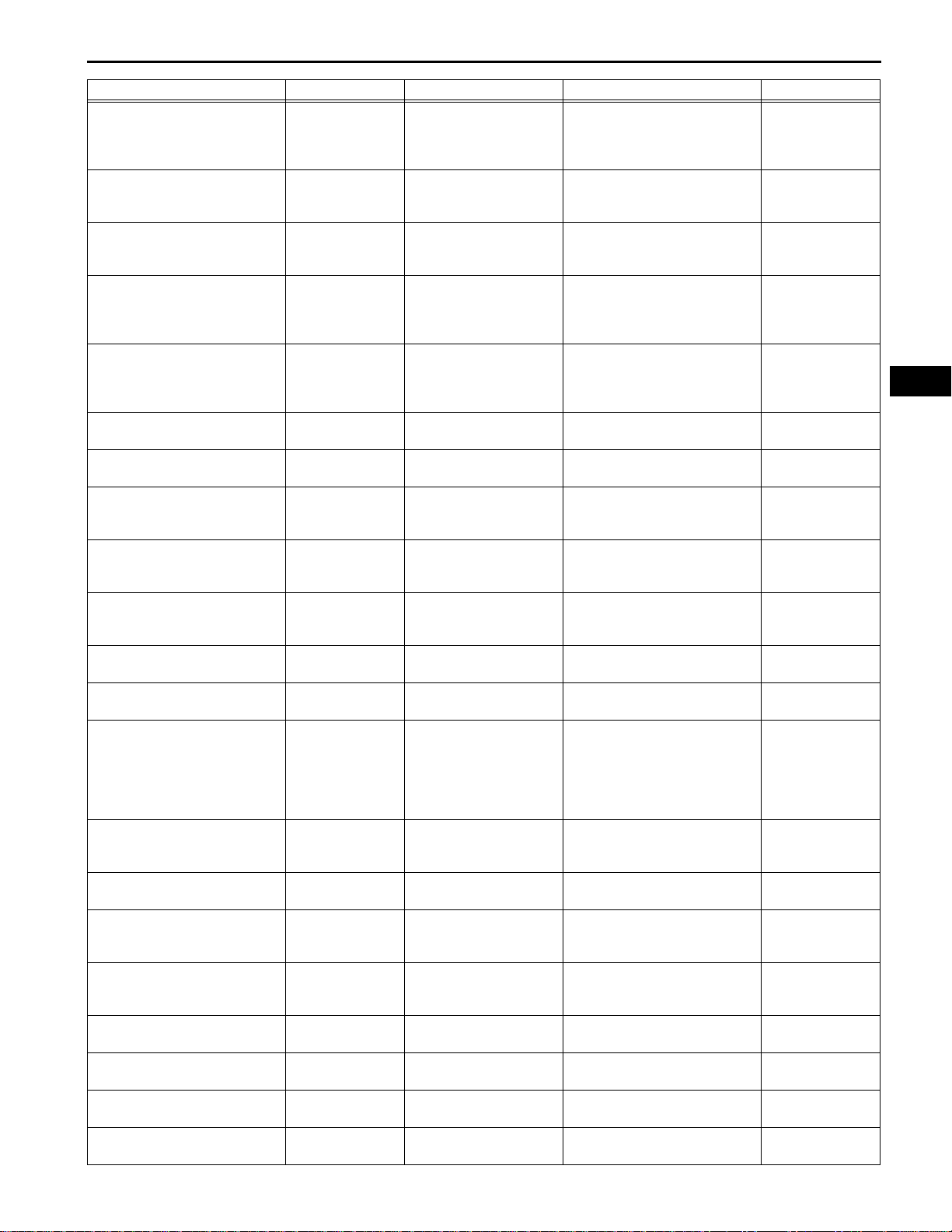

2. LIST OF FREEZE FRAME DATA

A103809E02

LABEL

(Intelligent Tester Display)

IGN ADVANCE Ignition advance CALC LOAD Calculate load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volume

ENGINE SPD Engine speed VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperature

INTAKE AIR Intake air temperature

FUEL PRESS Fuel pressure AIR-FUEL PATIO Air-fuel ratio AMBIENT TEMP Ambient temperature PURGE DENSITY Learning value of purge density PURGE FLOW Purge flow EVAP PURGE VSV EVAP purge VSV duty ratio KNOCK CRRT VAL Correction learning value of knocking -

Measurement Item/Range Diagnostic Note

If value is approximately 0.0 g/s:

• Mass air flow meter power source circuit

open or shorted

• VG circuit open or shorted

If value is 160.0 g/s or more:

• E2G circuit open

If value is -40°C (-40°F), sensor circuit open

If value is 140°C (284°F), sensor circuit

shorted

If value is -40°C (-40°F), sensor circuit open

If value is 140°C (284°F), sensor circuit

shorted

Page 53

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–53

(Intelligent Tester Display)

KNOCK FB VAL Feedback value of knocking ACCEL POS #1

ACCEL POS #2 Absolute APP No. 2 THROTTLE POS Throttle position

THROTTLE POS Throttle sensor positioning

THROTTLE POS #2 Throttle sensor positioning #2 -

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor output

O2S B2 S2 Heated oxygen sensor output

AFS B1 S1 A/F sensor output

AFS B2 S1 A/F sensor output

TOTAL FT #1 Total fuel trim TOTAL FT #2 Total fuel trim -

SHORT FT #1 Short-term fuel trim

LONG FT #1 Long-term fuel trim

SHORT FT #2 Short-term fuel trim

LONG FT #2 Long-term fuel trim

FUEL SYS #1 Fuel system status (Bank 1)

FUEL SYS #2 Fuel system status (Bank 2)

O2FT B1 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #1

O2FT B2 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #1

LABEL

Absolute Accelerator Pedal Position (APP)

No. 1

Measurement Item/Range Diagnostic Note

-