BODY ELECTRICALHORN

HORN SYSTEM

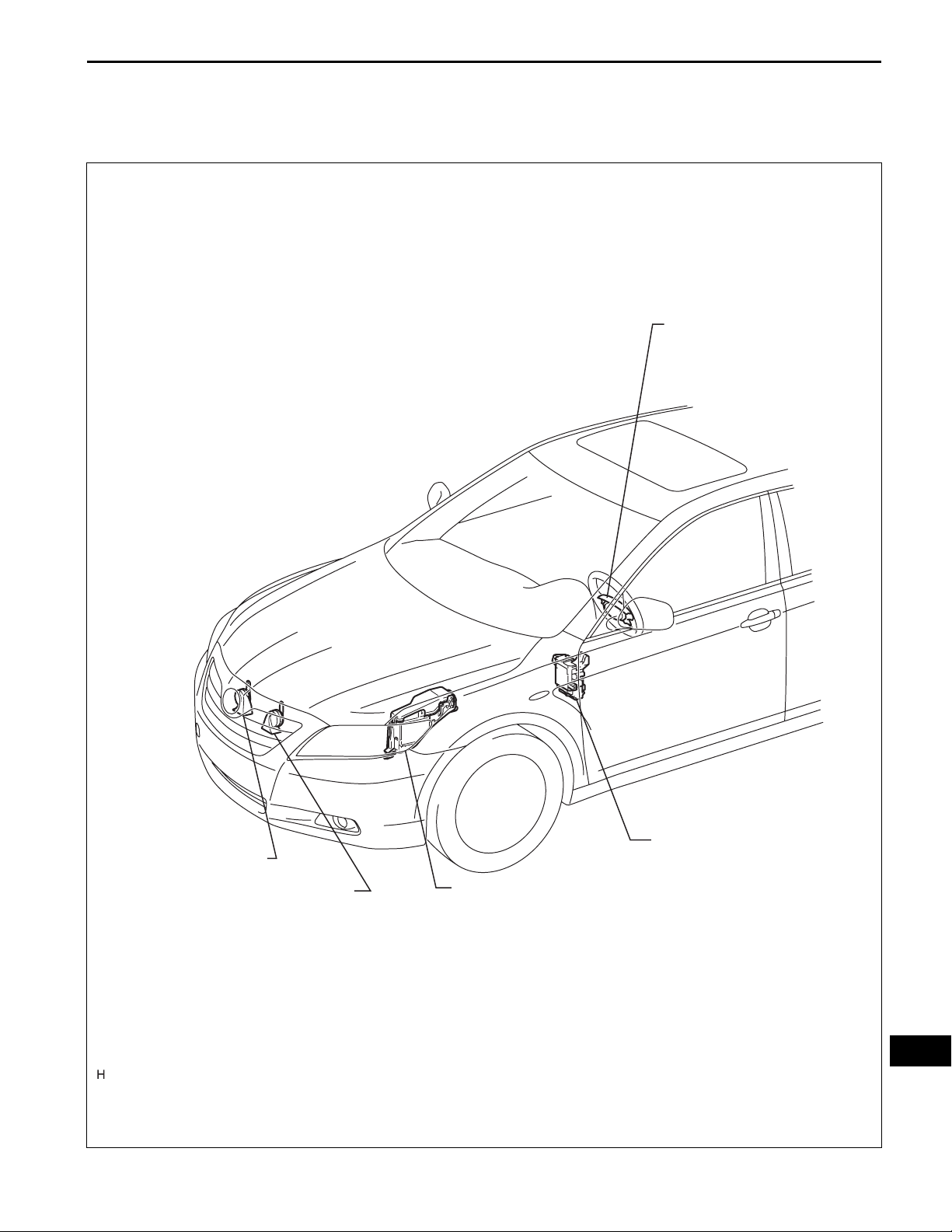

PARTS LOCATION

HORN – HORN SYSTEM

HO–1

STEERING PAD

(STEERING PAD SWITCH)

LOW PITCHED HORN

HIGH PITCHED HORN

MAIN BODY ECU

INSTRUMENT PANEL J/B

ENGINE ROOM R/B

ENGINE ROOM J/B

- HORN FUSE

- HORN RELAY

HO

B131106E01

HO–2

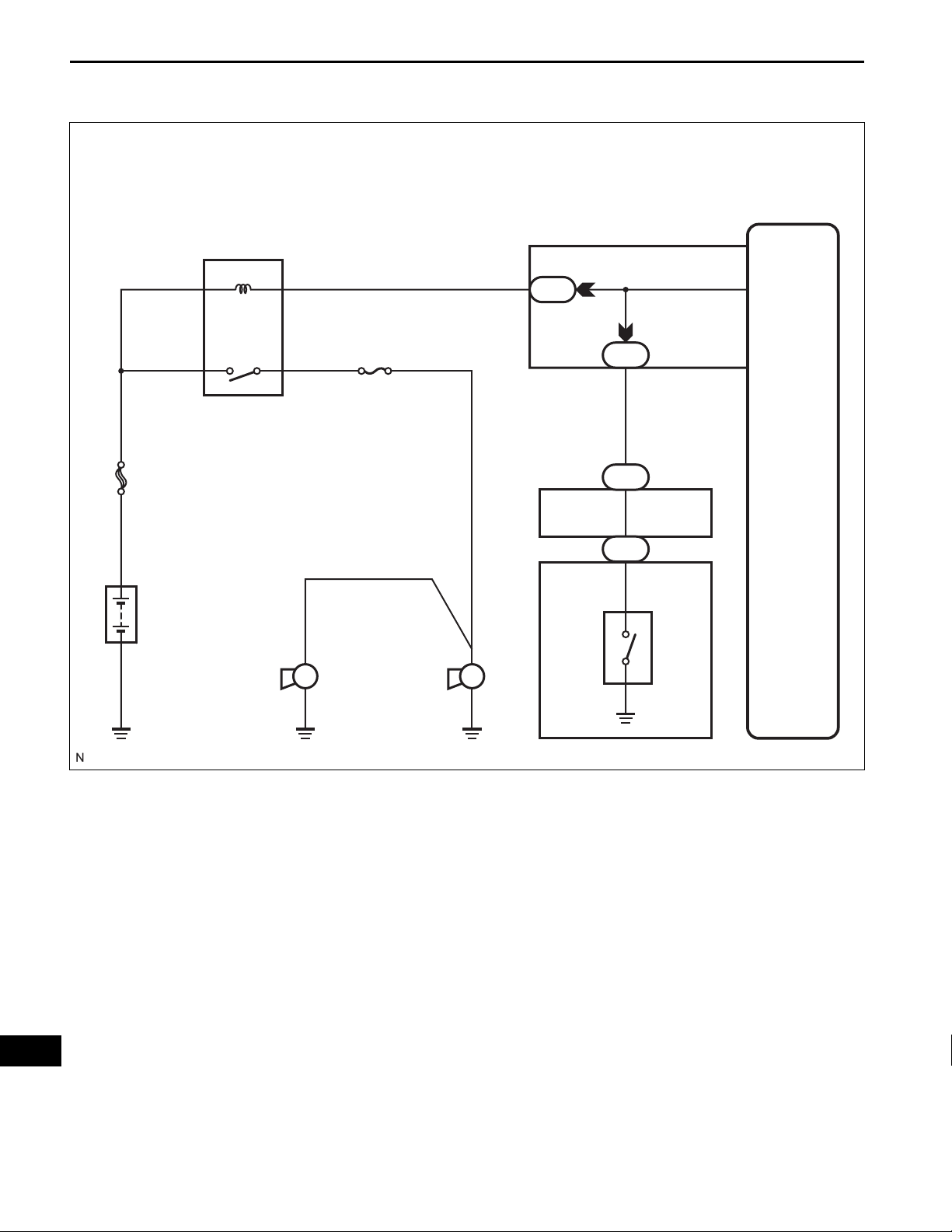

HORN

HORN – HORN SYSTEM

SYSTEM DIAGRAM

Instrument Panel J/B

11

ID

Main Body ECU

HORN

25

FL MAIN

HORN

8

Spiral

Cable

1

Steering

Pad

Switch

11

A4

Horn

(Low)

A3

Horn

(High)

II5

E18

HO

a1

L

Horn

Switch

B131104E01

HO

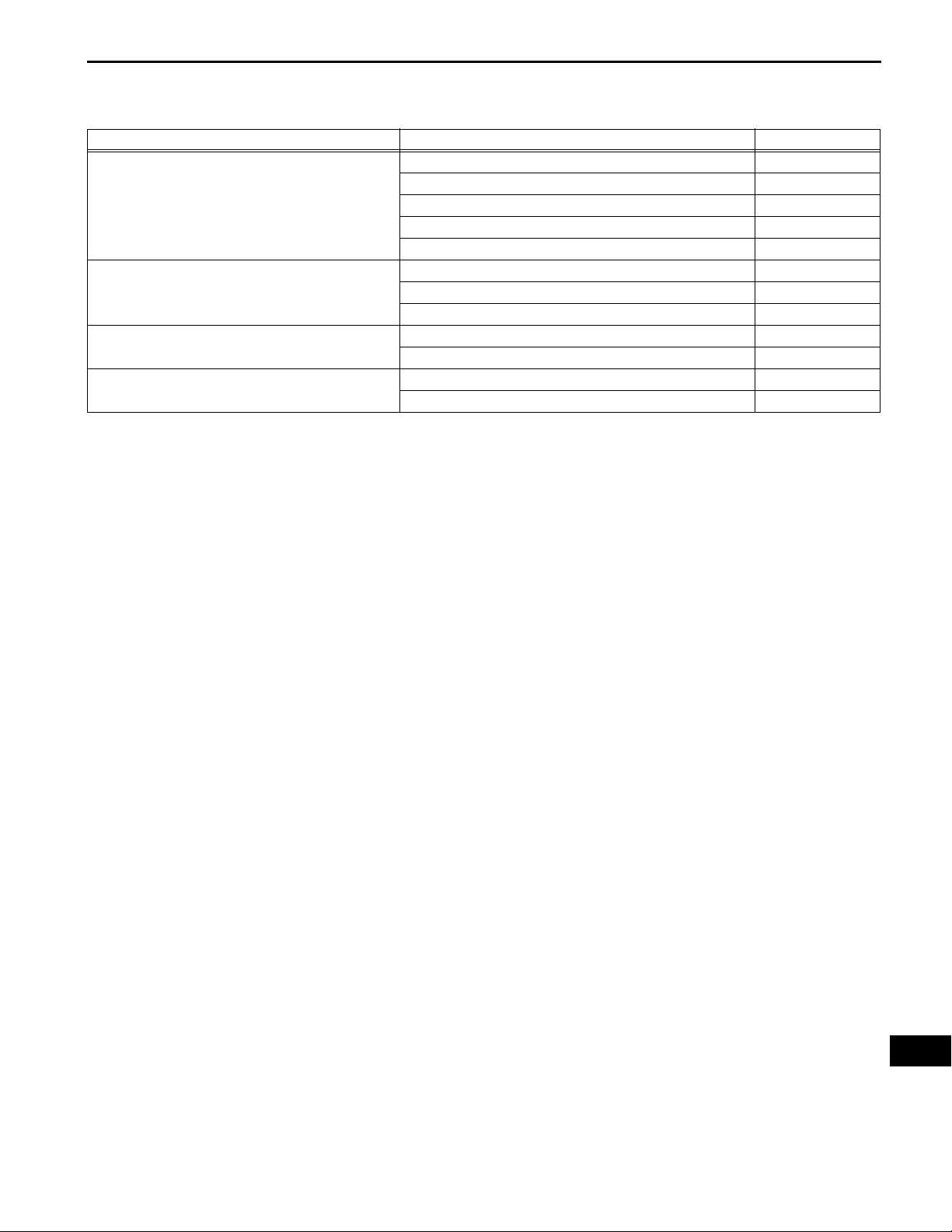

HORN SYSTEM

Symptom Suspected area See page

Horn does not sound

Horn blows all the time

Low pitched horn operates but high pitched horn does

not operate

High pitched horn operates but low pitched horn does

not operate

HORN – HORN SYSTEM

PROBLEM SYMPTOMS TABLE

1. HORN fuse HO-3

2. Horn relay HO-3

3. Steering pad switch RS-347

4. Spiral cable RS-364

5. Wire harness -

1. Horn relay HO-3

2. Steering pad switch RS-347

3. Wire harness -

1. High pitched horn HO-7

2. Wire harness -

1. Low pitched horn HO-5

2. Wire harness -

HO–3

HO

HORN – HORN RELAY

HORN RELAY

INSPECTION

1. INSPECT FUSE (HORN)

(a) Check the resistance of the HORN fuse.

Standard:

Below 1 Ω

2. INSPECT HORN RELAY

(a) Remove the engine room R/B and J/B (horn relay).

(b) Measure the resistance according to the value(s) in

the table below.

HO–3

1G

1B

654321

1D

16273

891011412513

B131164E01

Standard resistance

Tester Connection Condition Specified Condition

1G-1 - 1B-6 Always 10 kΩ or higher

When battery voltage is

1G-1 - 1B-6

applied to terminals 1G-

1 and 1D-10

Below 1 Ω

HO

HO–4

BODY ELECTRICALHORN

LOW PITCHED HORN

COMPONENTS

for 2GR-FE:

COOL AIR INTAKE DUCT SEAL

HORN – LOW PITCHED HORN

HO

20 (204, 15)

LOW PITCHED HORN ASSEMBLY

FRONT BUMPER ASSEMBLY

N*m (kgf*cm, ft.*lbf) : Specified torque

E127991E01

HORN – LOW PITCHED HORN

REMOVAL

1. REMOVE COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-4)

2. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-5)

3. REMOVE LOW PITCHED HORN ASSEMBLY

(a) Disconnect the connector.

(b) Remove the bolt and the low pitched horn assembly.

HO–5

E127994

B068846E01

INSPECTION

1. INSPECT LOW PITCHED HORN

(a) Apply battery voltage and check operation of the

horn, as shown in the table below.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Body ground

Horn sounds

INSTALLATION

1. INSTALL LOW PITCHED HORN ASSEMBLY

(a) Install the low pitched horn assembly with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the connector.

2. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

13)

3. INSTALL COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-14)

E127994

HO

HO–6

BODY ELECTRICALHORN

HIGH PITCHED HORN

COMPONENTS

for 2GR-FE:

COOL AIR INTAKE DUCT SEAL

HORN – HIGH PITCHED HORN

HO

20 (204, 15)

HIGH PITCHED HORN ASSEMBLY

FRONT BUMPER ASSEMBLY

N*m (kgf*cm, ft.*lbf)

: Specified torque

E127990E01

HORN – HIGH PITCHED HORN

REMOVAL

1. REMOVE COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-4)

2. REMOVE FRONT BUMPER ASSEMBLY (See page

ET-5)

3. REMOVE HIGH PITCHED HORN ASSEMBLY

(a) Disconnect the connector.

(b) Remove the bolt and the high pitched horn

assembly.

HO–7

E127995

B068846E01

INSPECTION

1. INSPECT HIGH PITCHED HORN

(a) Apply battery voltage and check operation of the

horn, as shown in the table below.

Standard

Measurement Condition Specified Condition

Battery positive (+) → Terminal 1

Battery negative (-) → Body ground

Horn sounds

INSTALLATION

1. INSTALL HIGH PITCHED HORN ASSEMBLY

(a) Install the high pitched horn assembly with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Connect the connector.

2. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

13)

3. INSTALL COOL AIR INTAKE DUCT SEAL (for 2GRFE) (See page ET-14)

E127995

HO

Loading...

Loading...