FOREWORD

This wiring diagram manual has been prepared to provide

information on the electrical system of the 2007 CAMRY.

Applicable models: GSV40 Series

ACV40 Series

Refer to the following manuals for additional service

specifications and repair procedures for these models:

Manual Name

D 2007 CAMRY Repair Manual

D 2007 CAMRY New Car Features

All information in this manual is based on the latest product

information at the time of publication. However, specifications

and procedures are subject to change without notice.

Pub. No.

RM0250U

NM0250U

NOTICE

Always follow the directions given in the above repair manuals when handling

supplemental restraint system components (such as removal, installation,

inspection, etc.) in order to prevent accidents and supplemental restraint

system malfunction.

E2006

All rights reserved. This book may not be

reproduced or copied, in whole or in part, without

the written permission of Toyota Motor

Corporation.

First Printing : Jan. 13, 2006 01–060113–00

2007 CAMRY

ELECTRICAL WIRING DIAGRAM

Section Code

INTRODUCTION A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

HOW TO USE THIS MANUAL B. . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING C. . . . . . . . . . . . . . . . . . . . . . . . . .

ABBREVIATIONS D. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLOSSARY OF TERMS AND SYMBOLS E. . . . . . . . . 18

RELAY LOCATIONS F. . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL WIRING ROUTING G. . . . . . . . . . . . . . .

SYSTEM CIRCUITS H. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

3

12

17

20

48

70

GROUND POINT I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER SOURCE (Current Flow Chart) J. . . . . . . . .

CONNECTOR LIST K. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PART NUMBER OF CONNECTORS L. . . . . . . . . . . . .

OVERALL ELECTRICAL WIRING DIAGRAM M. . . . .

396

404

414

436

440

CAMRY (EM0250U)

1

A INTRODUCTION

A

H

This manual consists of the following 13 sections:

No. Section Description

INDEX Index of the contents of this manual.

INTRODUCTION Brief explanation of each section.

HOW TO USE THIS

B

MANUAL

TROUBLE–

C

SHOOTING

D ABBREVIATIONS Defines the abbreviations used in this manual.

GLOSSARY OF

TERMS AND

E

SYMBOLS

Instructions on how to use this manual.

Describes the basic inspection procedures for electrical circuits.

Defines the symbols and functions of major parts.

F RELAY LOCATIONS

ELECTRICAL

G

WIRING ROUTING

INDEX Index of the system circuits.

SYSTEM CIRCUITS

I GROUND POINT Shows ground positions of all parts described in this manual.

POWER SOURCE

J

(Current Flow Chart)

K CONNECTOR LIST

PART NUMBER OF

L

CONNECTORS

Shows position of the Electronic Control Unit, Relays, Relay Block, etc.

This section is closely related to the system circuit.

Describes position of Parts Connectors, Splice points, Ground points, etc.

This section is closely related to the system circuit.

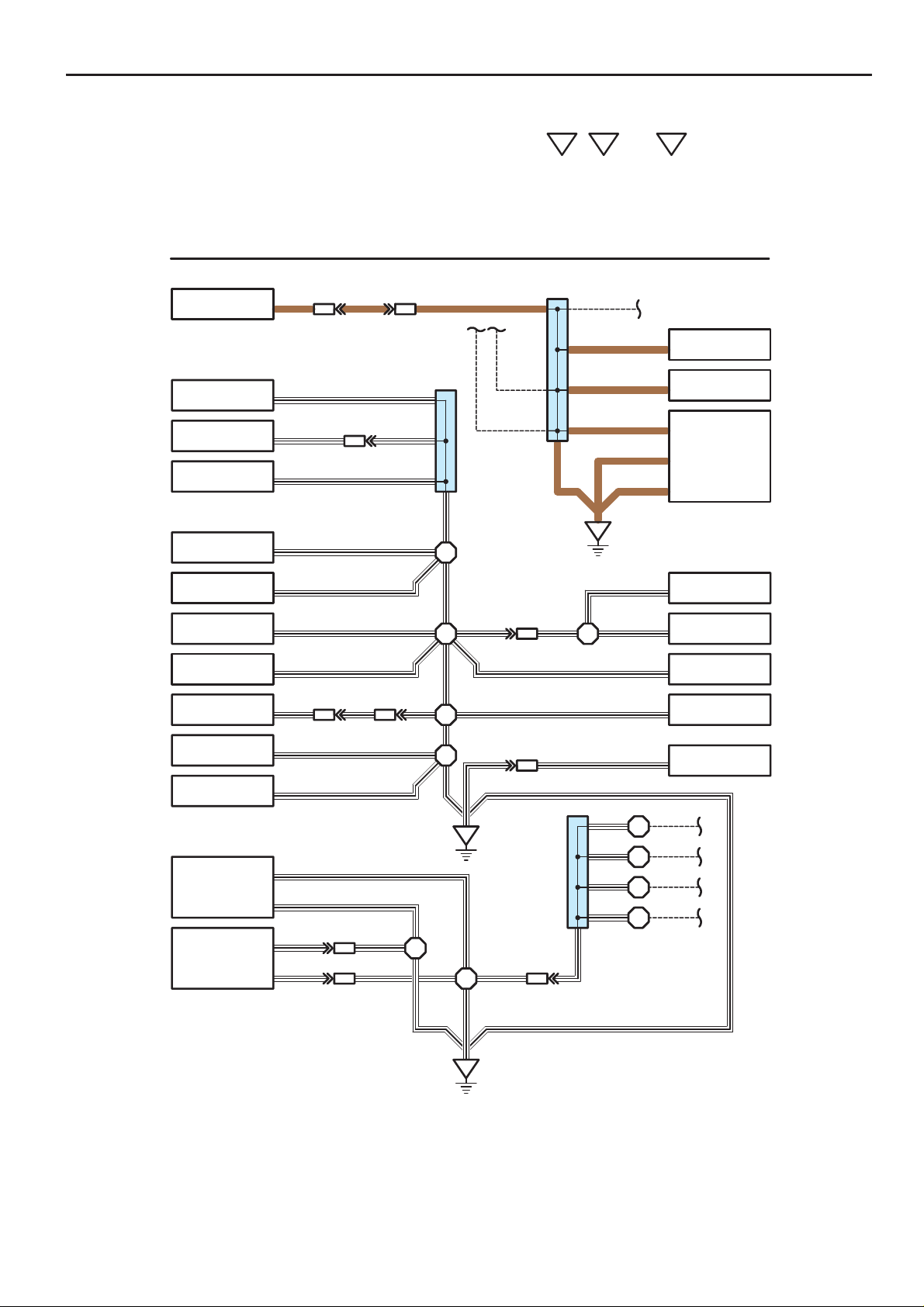

Electrical circuits of each system are shown from the power supply through ground

points. Wiring connections and their positions are shown and classified by code

according to the connection method. (Refer to the section, ”How to use this manual”).

The ”System Outline” and ”Service Hints” useful for troubleshooting are also contained

in this section.

Describes power distribution from the power supply to various electrical loads.

Describes the form of the connectors for the parts appeared in this book.

This section is closely related to the system circuit.

Indicates the part number of the connectors used in this manual.

OVERALL

ELECTRICAL

M

WIRING DIAGRAM

Provides circuit diagrams showing the circuit connections.

2

CAMRY (EM0250U)

HOW TO USE THIS MANUAL B

This manual provides information on the electrical circuits installed on vehicles by

dividing them into a circuit for each system.

The actual wiring of each system circuit is shown from the point where the power

source is received from the battery as far as each ground point. (All circuit

diagrams are shown with the switches in the OFF position.)

When troubleshooting any problem, first understand the operation of the circuit

where the problem was detected (see System Circuit section), the power source

supplying power to that circuit (see Power Source section), and the ground points

(see Ground Point section). See the System Outline to understand the circuit

operation.

When the circuit operation is understood, begin troubleshooting of the problem

circuit to isolate the cause. Use Relay Location and Electrical Wiring Routing

sections to find each part, junction block and wiring harness connectors, wiring

harness and wiring harness connectors and ground points of each system circuit.

Internal wiring for each junction block is also provided for better understanding of

connection within a junction block.

Wiring related to each system is indicated in each system circuit by arrows

(from__, to__). When overall connections are required, see the Overall Electrical

Wiring Diagram at the end of this manual.

CAMRY (EM0250U)

3

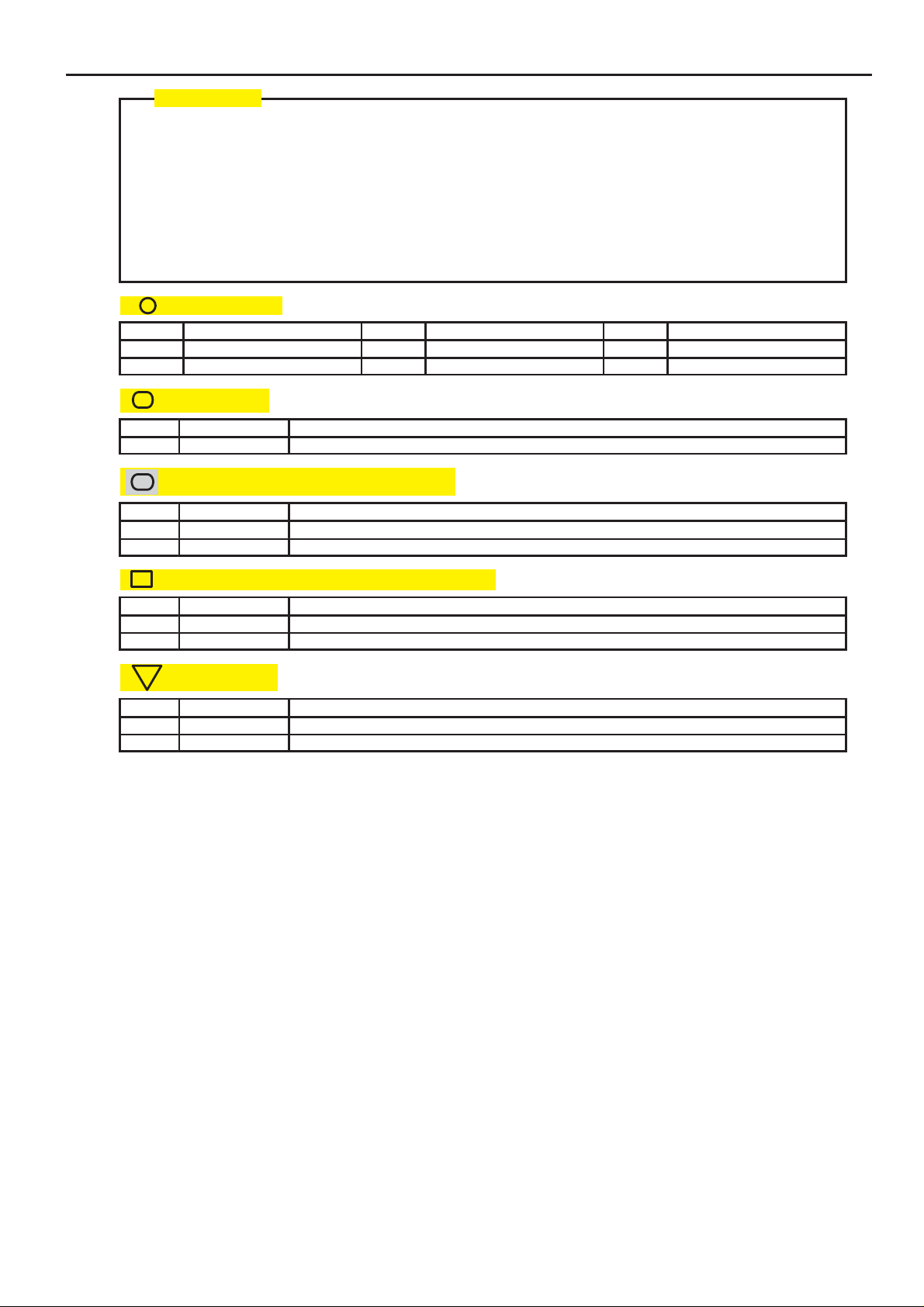

B HOW TO USE THIS MANUAL

* The system shown here is an EXAMPLE ONL Y . It is different to the actual

circuit shown in the SYSTEM CIRCUITS SECTION.

[A]

Stop Light

[D]

[B]

G – W

Skid Control ECU

with Actuator

(BAT)

2

1

W – RG – W

2

1

G – W

15A

STOP

H6

Stop Lamp SW

(IG)

7.5A

GAUGE

34

IB

R

[M]

(S/D)

[C]

CH114

LL

(W/G)

CH1

15

L

[E]

(S/D) (S/D)

[F]

IB

R – L

3C

7

[G]

3C

15

R – L

4

Rear

Lights

H7

13

Y – G

Combination Meter

H4

7

Light Failure Sensor

12

48

11

[H]

1

G – R

HJ1

G – R G – R

4

Stop

Rear Combination Lamp (RH)

3

W – B G – R

J7

1

HJ1

3

6

W – BW – B

W – B

H1 H2

[N]

Stop

Rear Combination Lamp (LH)

H9

[K]

[I]

(Shielded)

[J]

G – B

2

1

W – B

H17

Center Stop

Lamp

W – B

4

50

[L]

CAMRY (EM0250U)

B

[A] : System Title

[B] : Indicates a Relay Block. No shading is used and

only the Relay Block No. is shown to distinguish it

from the J/B

Example: Indicates Relay Block No.1

[C] : ( ) is used to indicate different wiring and

connector, etc. when the vehicle model, engine

type, or specification is different.

[D] : Indicates related system.

[E] : Indicates the code for the (male and female)

connectors which are used to join two wire

harnesses. The connector code consists of two

alphabetical and one numerical characters.

Female Male ( )

The first character of the connector code indicates

the alphabetical code allocated to the wire harness

which has the female connector, and the second

shows that of the wire harness which has the male

connector.

The third character indicates a serial number used

to distinguish between the wire harness

combinations in cases when more than one of the

same combination of wire harnesses exist

(e.g. CH1 and CH2).

[H] : Indicates the wiring color.

Wire colors are indicated by an alphabetical code.

B = Black W = White BR = Brown

L = Blue V = V iolet SB = Sky Blue

R = Red G = Green LG = Light Green

P = Pink Y = Yellow GR= Gray

O = Orange

The first letter indicates the basic wire color and the

second letter indicates the color of the stripe.

Example: L – Y

L

(Blue)Y(Yellow)

[I] : Indicates a shielded cable.

[J] : Indicates the pin number of the connector.

The numbering system is different for female and

male connectors.

Example:

Numbered in other

from upper left to

lower right

Numbered in other

from upper right to

lower left

Symbol (

) indicates the male terminal connector.

Numbers outside connector codes indicate the pin

numbers of both male and female connectors.

[F] : Represents a part (all parts are shown in sky blue).

The code is the same as the code used in parts

position.

[G] : Junction Block (The number in the circle is the J/B

No. and the connector code is shown beside it).

Junction Blocks are shaded to clearly separate

them from other parts.

Example:

3C indicates that

it is inside

Junction Block

No.3

Female

Male

[K] : Indicates the ground point. The code consists of the

two characters: A letter and number.

The first character of the code indicates the

alphabetical code allocated to the wire harness.

The second character indicates a serial number

used to distinguish between the ground points in

cases when more than one ground point exist on the

same wire harness.

[L] : Page No.

[M] : Indicates the ignition key position(s) when the

power is supplied to the fuse(s).

[N] : Indicates a wiring Splice Point.

Example:

CAMRY (EM0250U)

5

B HOW TO USE THIS MANUAL

[O]

[P]

[Q]

[R]

System Outline

Current is applied at all times through the STOP fuse to TERMINAL 2 of the stop lamp SW .

When the ignition SW is turned on, current flows from the GAUGE fuse to TERMINAL 8 of the light failure sensor, and also flows

through the rear lights warning light to TERMINAL 4 of the light failure sensor.

Stop Light Disconnection Warning

When the ignition SW is turned on and the brake pedal is pressed (Stop lamp SW on), if the stop light circuit is open, the current

flowing from TERMINAL 7 of the light failure sensor to TERMINALS 1, 2 changes, so the light failure sensor detects the

disconnection and the warning circuit of the light failure sensor is activated.

As a result, the current flows from TERMINAL 4 of the light failure sensor to TERMINAL 11 to GROUND and turns the rear lights

warning light on. By pressing the brake pedal, the current flowing to TERMINAL 8 of the light failure sensor keeps the warning

circuit on and holds the warning light on until the ignition SW is turned off.

: Parts Location

Code See Page Code See Page Code See Page

H4 36 H7 36 H17 38

H6 36 H9 38 J7 38

: Relay Blocks

Code See Page Relay Blocks (Relay Block Location)

1 18 R/B No.1 (Instrument Panel Brace LH)

: Junction Block and Wire Harness Connector

Code See Page Junction Block and Wire Harness (Connector Location)

3C 22 Instrument Panel Wire and J/B No.3 (Instrument Panel Brace LH)

IB 20 Instrument Panel Wire and Instrument Panel J/B (Lower Finish Panel)

[S]

[T]

: Connector Joining Wire Harness and Wire Harness

Code See Page Joining Wire Harness and Wire Harness (Connector Location)

CH1 42 Engine Room Main Wire and Instrument Panel Wire (Left Kick Panel)

HJ1 50 Instrument Panel Wire and Floor Wire (Right Kick Panel)

: Ground Points

Code See Page Ground Points Location

H1 50 Under the Left Center Pillar

H2 50 Back Panel Center

6

CAMRY (EM0250U)

[O] : Explains the system outline.

[P] : Indicates reference pages showing the parts locations in the system circuit on the vehicle.

Example : Code ”H4” (Light Failure Sensor) is on page 36 of the manual.

* The first character of the code indicates the alphabetical code allocated to the wire harness, and the

second character indicates the serial number of the parts connected to the wire harness.

B

Example : H 4

[Q] : Indicates the reference page showing the position on the vehicle of Relay Block Connectors in the system circuit.

Example : Connector ”1” is described on page 18 of this manual and is installed on the left side of the instrument

panel.

[R] : Indicates the reference page showing the position on the vehicle of J/B and Wire Harness in the system circuit.

Example : Connector ”3C” connects the Instrument Panel Wire and J/B No.3. It is described on page 22 of this

manual, and is installed on the instrument panel left side.

[S] : Indicates the reference page describing the wiring harness and wiring harness connector (the female wiring

harness is shown first, followed by the male wiring harness).

Example : Connector ”CH1” connects the Engine Room Main Wire (female) and Instrument Panel Wire (male).

It is described on page 42 of this manual, and is installed on the left side kick panel.

[T] : Indicates the reference page showing the position of the ground points on the vehicle.

Example : Ground point ”H2” is described on page 50 of this manual and is installed on the back panel center.

Serial number for the connected parts

Code for the wire harness

CAMRY (EM0250U)

7

B HOW TO USE THIS MANUAL

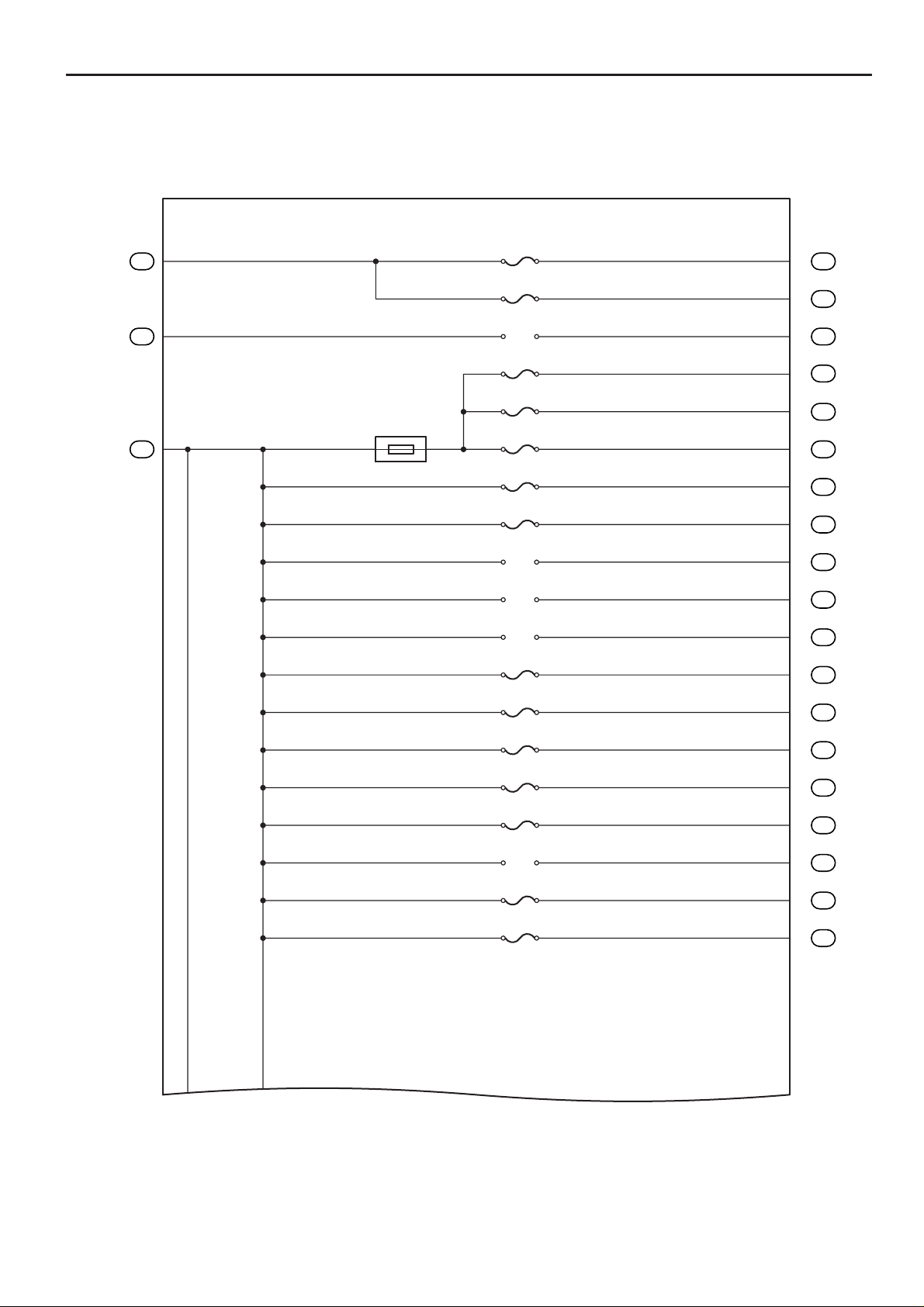

The ground points circuit diagram shows the connections from all major parts to the respective ground points. When

troubleshooting a faulty ground point, checking the system circuits which use a common ground may help you identify

A1

the problem ground quickly. The relationship between ground points (

checked this way.

I GROUND POINT

H23

DLC3

(SG)

HB4

DB1

912

10

D43

Junction

Connector

A2

,

6

(Shielded)BRBRBR

and

D4

shown below) can also be

A20

Headlamp Leveling

Motor (LH)

L5

Power Window

Master SW

A22

Cooling Fan

Motor No.3

A8

Headlamp Leveling

Motor (RH)

A5

Pressure SW

A23

Turn Signal Lamp

(Front LH)

A11

Windshield

Wiper Motor

I9

Headlamp

Leveling SW

A6

Clearance Lamp

(Front RH)

A21

Clearance Lamp

(Front LH)

A24

Option Connector

(Vacuum)

B19

Skid Control ECU

with Actuator

(LH E)

(RH E)

(–S)

(GND2)

(GND1)

(GND)

(GND)

5

(Shielded)

(Shielded)

W – B

W – B

(E)

W – B

(E)

W – B

W – B

W – B

(E)

W – B

(E)

(E)

W – B

(E)

W – B

(E)

W – B

W – B

W – B

3

LA1

12 7

IH2

21

W – BW – B

AB1

12

W – B

AB1

HA1

W – B

8

7

4

A25

Junction

Connector

3

W – B W – BW – B

W – B

CA1

W – BW – BW – B

W – B W – B

W – B W – B

A1

W – BW – B

KA1

W – B

W – B

34

2

11

1

BR

5

W – B

3

Junction

Connector

B36

16

W – B

6

AB1

BR

BR

BR

BR

BR

(5L–E)

D4

W – B

W – B

W – B

W – B

W – B

20

W – B

19

W – B

18

W – B

17

(L)

(E1)

(E1)

(E01)

(E02)

(E)

(E)

(E)

(E)

(E)

(Shielded)

(Shielded)

(Shielded)

(Shielded)

D63

Throttle

Position SW

D60

Injection

Pump Assembly

D2

Engine ECU

C2

Fog Lamp

(Front LH)

C4

Fog Lamp

(Front RH)

A10

Brake Fluid Level

Warning SW

A1

Turn Signal Lamp

(Front RH)

K5

Power Window

Master SW

W – B

A2

W – B

* The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

8

CAMRY (EM0250U)

B

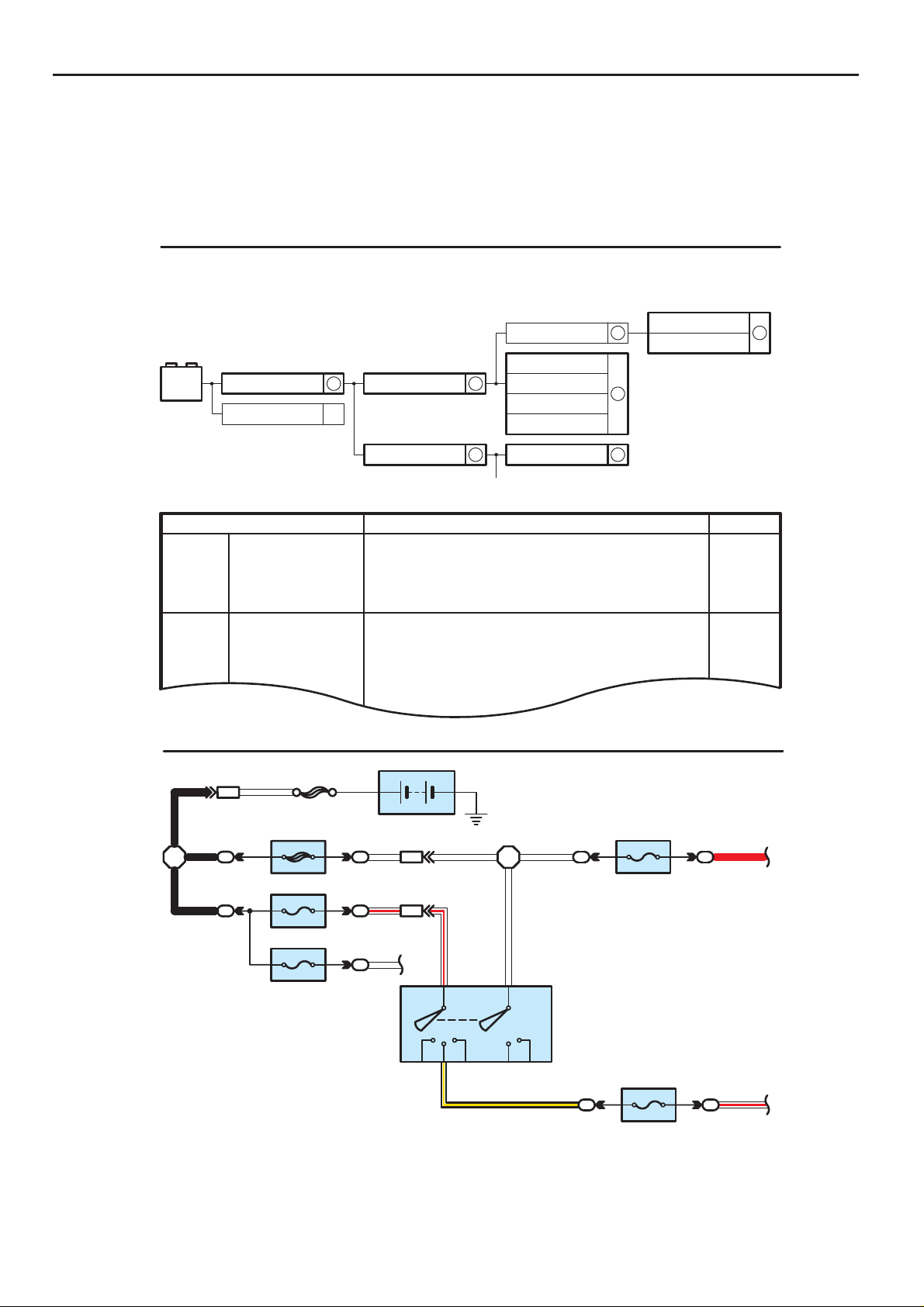

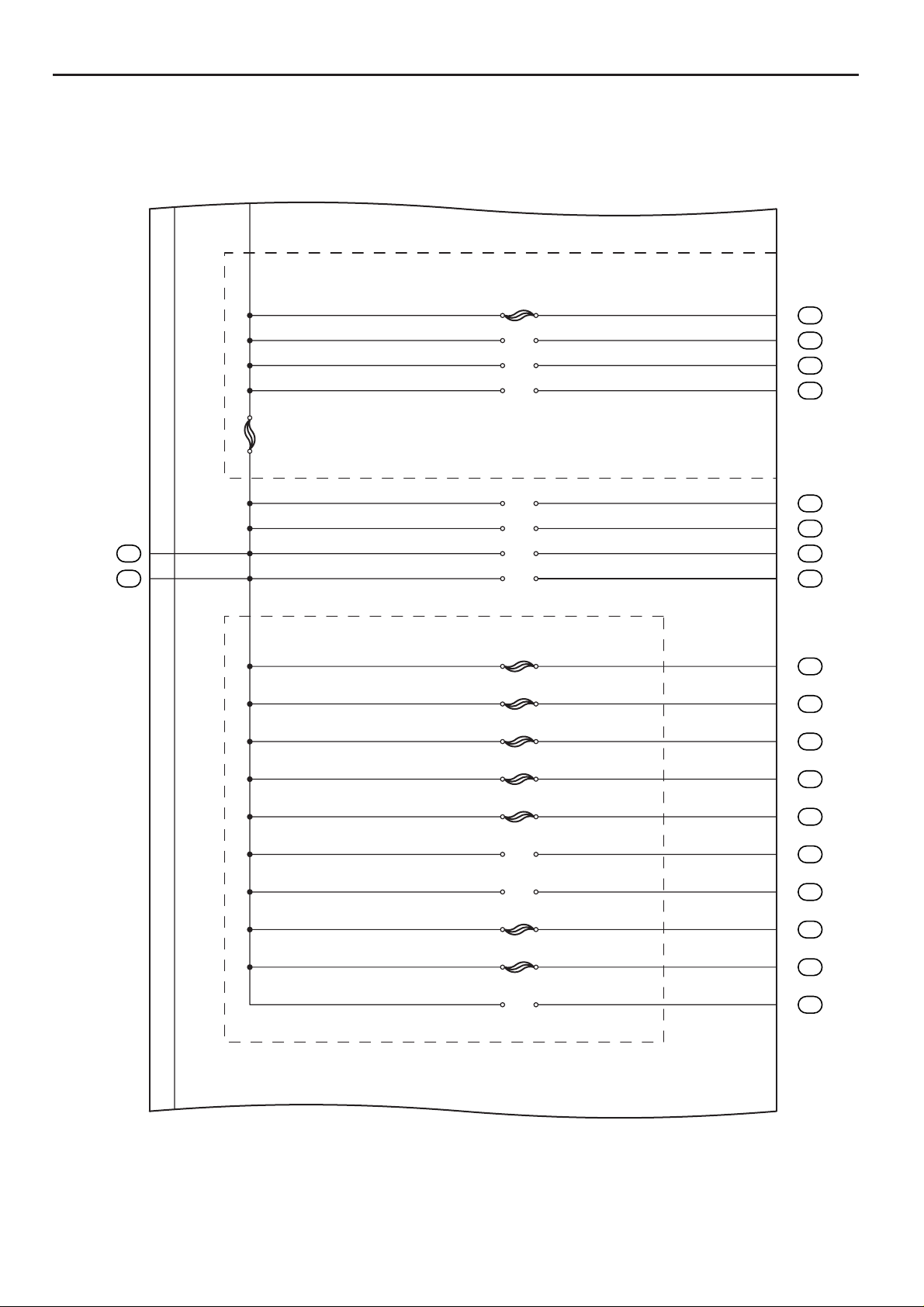

The ”Current Flow Chart” section, describes which parts each power source (fuses, fusible links, and circuit breakers)

transmits current to. In the Power Source circuit diagram, the conditions when battery power is supplied to each system

are explained. Since all System Circuit diagrams start from the power source, the power source system must be fully

understood.

J POWER SOURCE (Current Flow Chart)

The chart below shows the route by which current flows from the battery to each electrical source

(Fusible Link, Circuit Breaker, Fues, etc.) and other parts

Battery

30A AM2

Starter

2

S 2

Fusible Link Block

100A AL T

Engine Room R/B (See Page 20)

System

ABS

ABS and Traction Control

Cruise Control

Electronically Controlled Transmission

Multiplex Communication System

Cigarette Lighter

Combination Meter

Headlight

Interior Light

Key Reminder and Seat Belt Warning

Light Auto Turn Off System

Theft Deterrent and Door Lock Control

20A

10A

Fuse

STOP

DOME

Power Source

6

6

Short Pin

15A EFI

10A HAZARD

20A RADIO NO.1

10A HORN

60A ABS

10A ECU–B

2

7.5A DOME

2

5

2

Page

194

187

180

166

210

214

230

112

122

1

B

BA1

B

2

B

2

1.25B

FL MAIN

W

50A MAIN

7.5A AM1

15A HAZ–RADIO

1

Battery

W – R

W

AH1

AH1

7

6

21

2

21

2

2

2

ACC

W – R

8

AM1

IG1

2

WW

ST1

W

W

4

AM2

H8

Ignition SW

IG2

ST2

B – Y

7.5A DOME

1

1

20A DEFOG

121W – R

1

2

R

1

∗ The system shown here is an EXAMPLE ONLY. It is different to the actual circuit shown in the SYSTEM CIRCUITS SECTION.

9

CAMRY (EM0250U)

B HOW TO USE THIS MANUAL

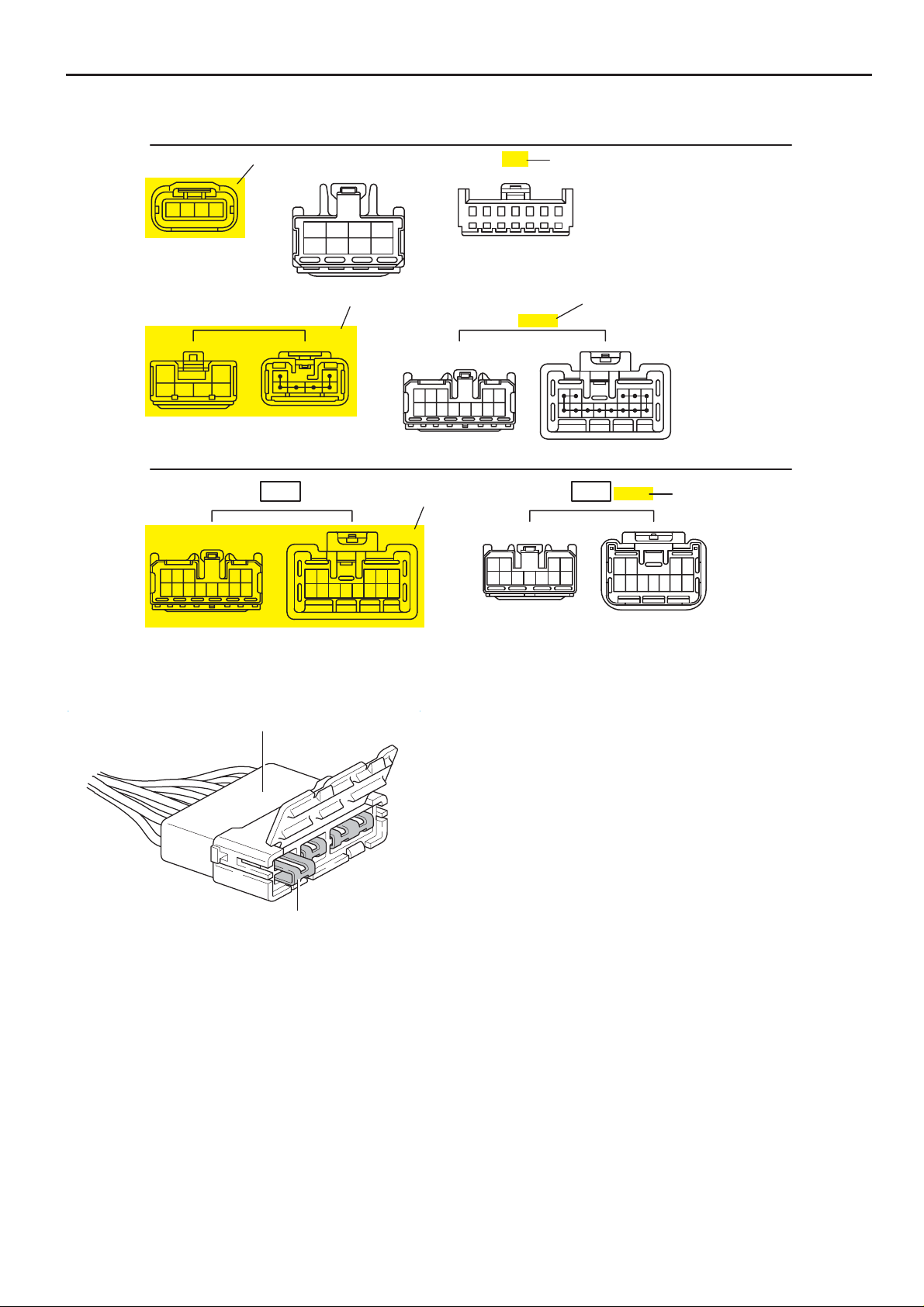

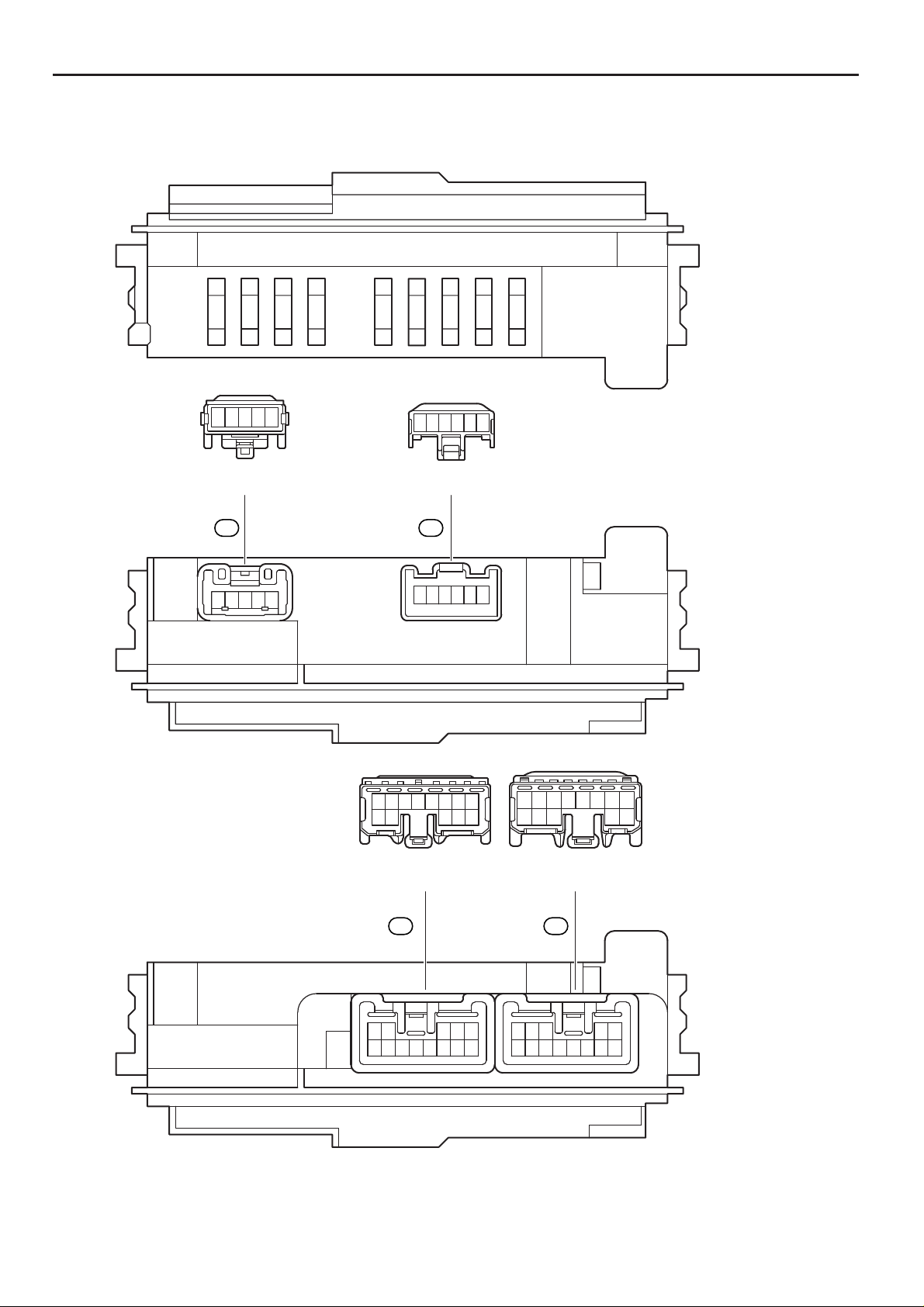

K CONNECTOR LIST

A1

Black

[A]

A2

A3

Gray

[C]

1234

B1

Black

12

3456

1234

5678

[B]

123 45

678910111213

12345 76

B2

Gray

[D]

K CONNECTOR LIST

Black

123 45

6 7 8 9 10 11 12 13

BA1

13 6789101112

[E]

12345

12 34

567891011

[A] : Indicates connector to be connected to a part. (The numeral indicates the pin No.)

BD2

Gray

43 21

11

[F]

5678910

[B] : Junction Connector

Indicates a connector which is connected to a short terminal.

Junction Connector

Junction connector in this manual include a short terminal which is

connected to a number of wire harnesses. Always perform

inspection with the short terminal installed.

Short Terminal

[C] : Parts Code

The first letter of the code is taken from the first letter of part, and the numbers indicates its order in parts which

start with the same letter.

[D] : Connector Color

Connectors not indicated are milky white in color.

[E] : Indicates the connector shapes which are used to join wire harnesses.

On Left : Female connector shapes

On Right : Male connector shapes

Numbers indicate pin numbers.

[F] : Indicates connector colors. (Connectors with not indicated colors are white)

10

CAMRY (EM0250U)

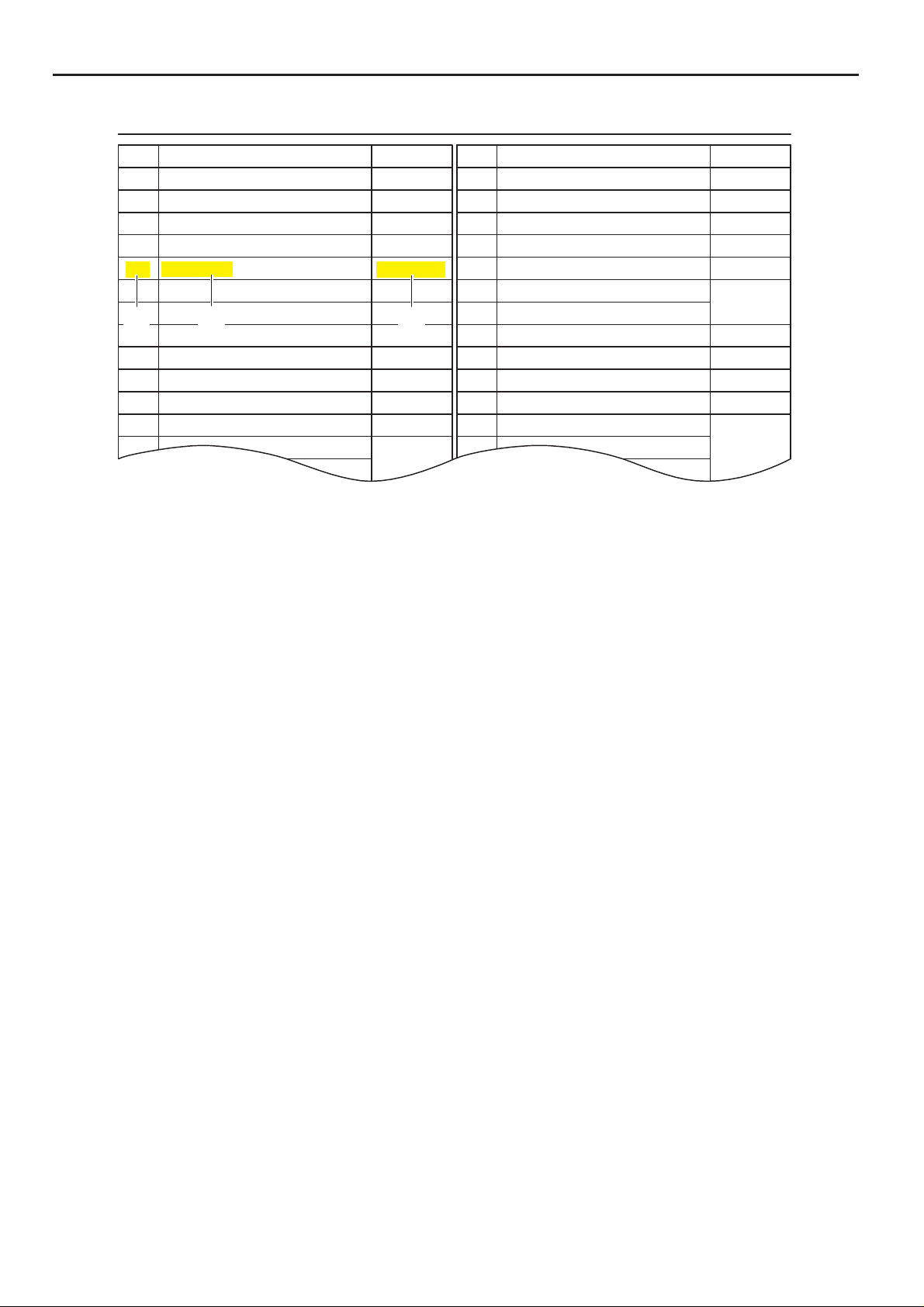

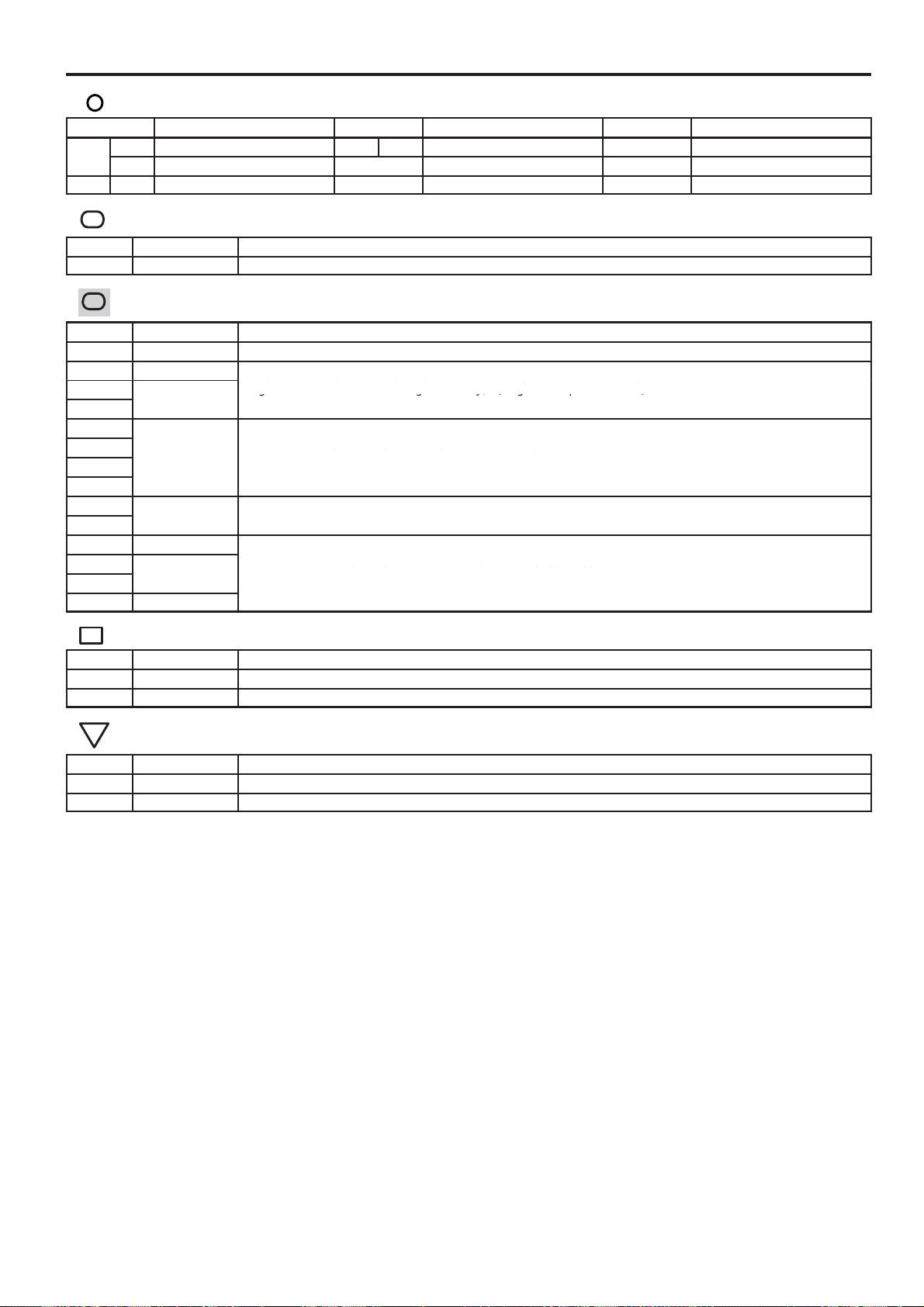

L PART NUMBER OF CONNECTORS

B

Code

A1

Turn Signal Lamp (Front RH)

A2 Inlet Air Temp. Sensor 90980–1 1163 B23 Front Seat Outer Belt (LH) 90980–12253

A3 Air Flow Meter 90980–12292 B24 Blower SW (Rear Heater) 90980–10463

A4 A/C Pressure Sensor 90980–10845

A5 Pressure SW

A6 Clearance Lamp (Front RH)

A7 Headlamp (RH)

[A]

A9 Brake Vacuum Warning SW

A10

A11

A12

A13 Airbag Squib

[B]

Brake Fluid Level Warning SW

Airbag Sensor (Front RH) Junction Connector

[A] : Part Code

[B] : Part Name

[C] : Part Number

Toyota Part Number are indicated.

Part Number

90980–11019

90980–10943

90980–11156

90980–11314

[C]

90980–11016

90980–11252

90980–11207

90980–11599

90980–11856

90980–12490

Code

B22 Door Courtesy SW (Front LH)

B25 Front Seat Outer Belt (RH) 90980–12253

B26 Door Courtesy SW (Front RH) 90980–12470

B27

Cooling Fan ECU No.1

B28

Cooling Fan ECU No.2

B29

Water Temp. Sensor (Radiator)

B30

Fuel Filter Warning SW

B32

Door Control Relay (LH)

B33

B34

B35

Junction Connector 90980–1 1398

Part NumberPart NamePart Name

90980–12470

90980–10841

90980–10735A8 Headlamp Leveling Motor (RH)

90980–11003

90980–10789

90980–10121Windshield Washer Motor Step Lamp (LH)

Not all of the above part numbers of the connector are established for the supply.

CAMRY (EM0250U)

11

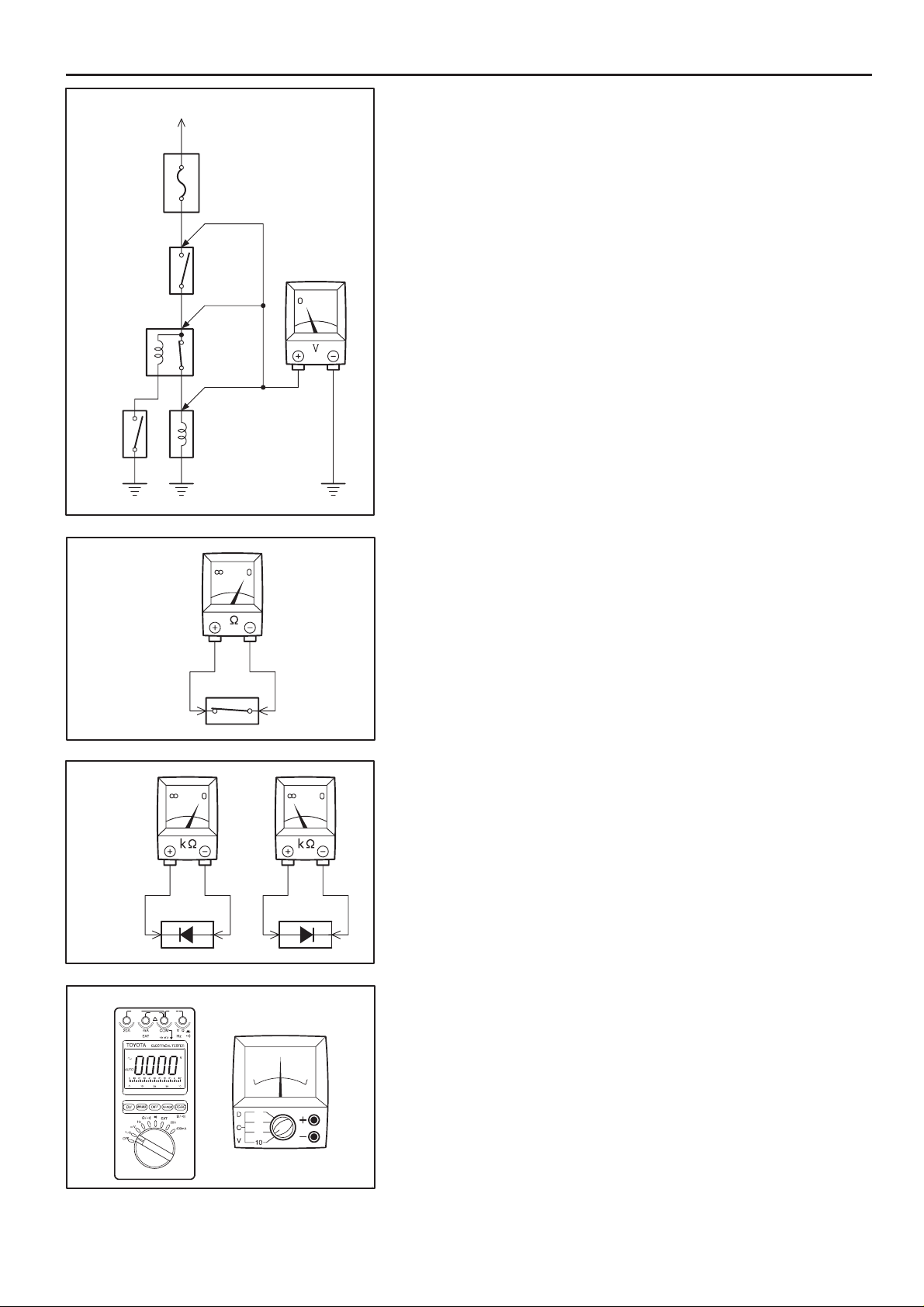

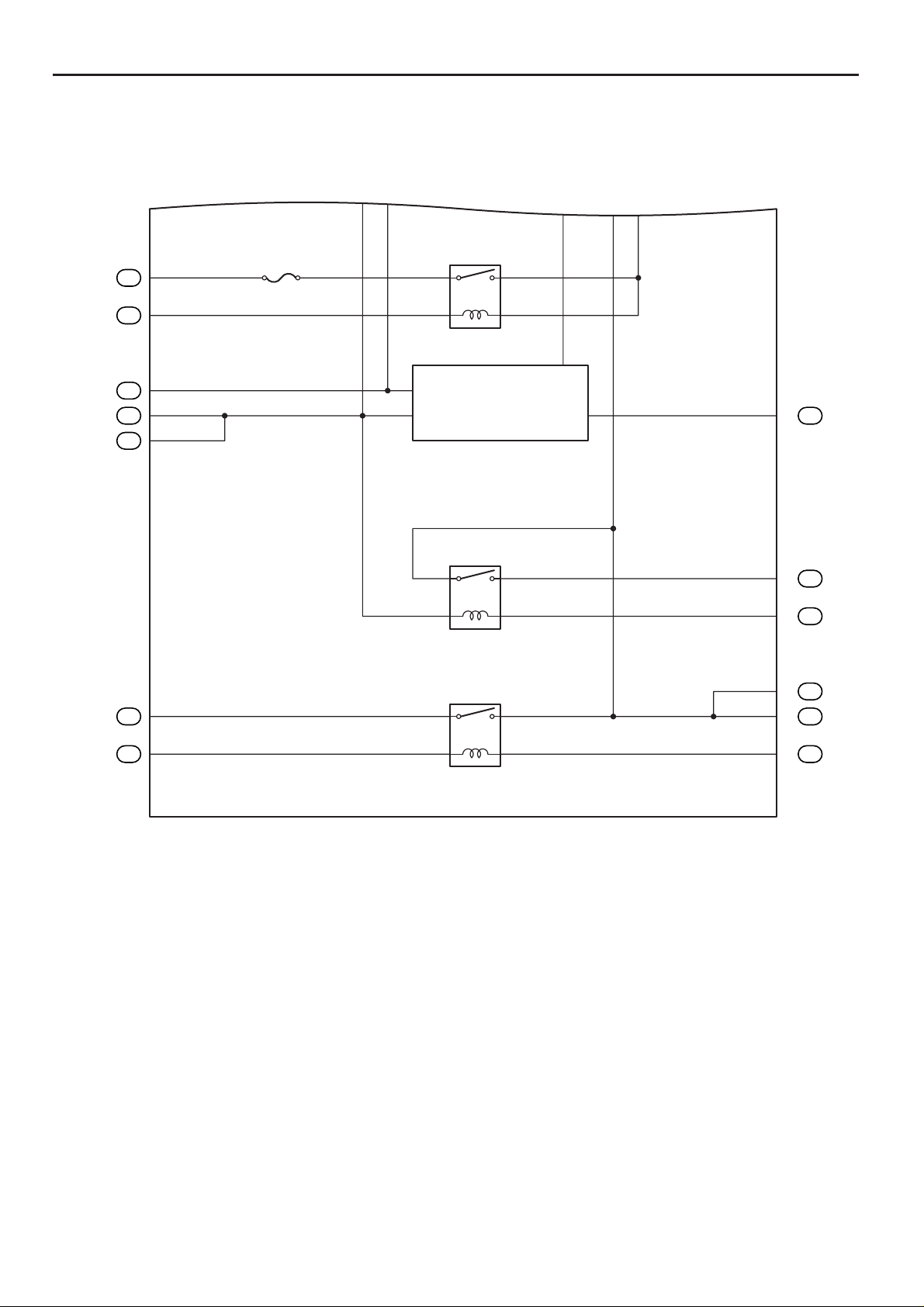

C TROUBLESHOOTING

SW 2

To Ignition SW

IG Terminal

Fuse

[A]

[B]

Relay

[C]

Solenoid

VOLTAGE CHECK

(a) Establish conditions in which voltage is present at the check

point.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (SW 2 off)

(b) Using a voltmeter, connect the negative lead to a good ground

VoltmeterSW 1

point or negative battery terminal, and the positive lead to the

connector or component terminal.

This check can be done with a test light instead of a voltmeter.

CONTINUITY AND RESISTANCE CHECK

Ohmmeter

SW

Ohmmeter

Diode

Digital Type Analog Type

(a) Disconnect the battery terminal or wire so there is no voltage

between the check points.

(b) Contact the two leads of an ohmmeter to each of the check

points.

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative lead to the diode positive side

and the positive lead to the negative side, there should be

continuity.

When contacting the two leads in reverse, there should be no

continuity.

(c) Use a volt/ohmmeter with high impedance (10 kΩ/V

minimum) for troubleshooting of the electrical circuit.

12

CAMRY (EM0250U)

C

Test Light

Disconnect

To Ignition SW

IG Terminal

Fuse Case

Short [A]

SW 1

Short [B]

Disconnect

RelayLight

Short [C]

Disconnect

SW 2 Solenoid

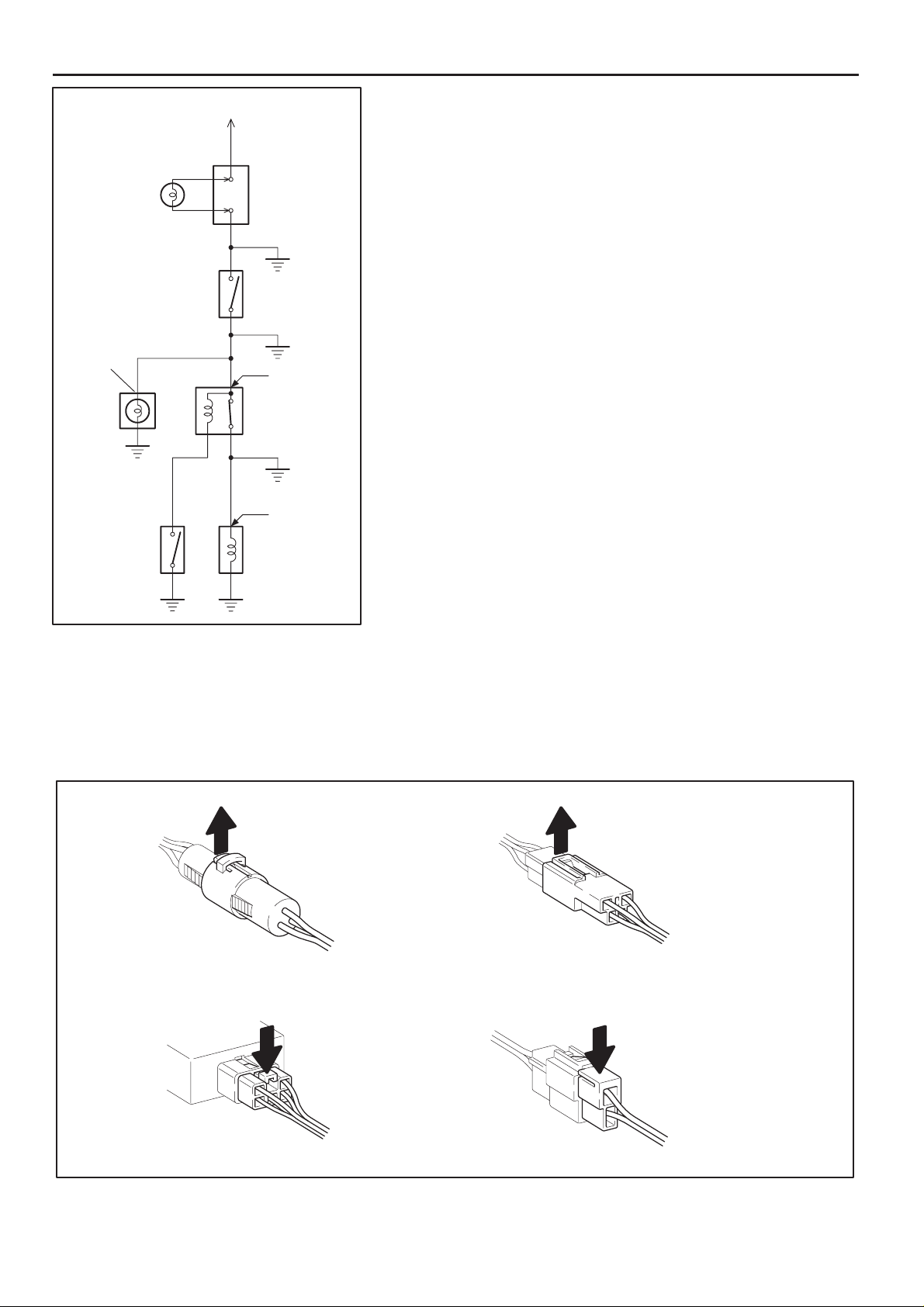

FINDING A SHORT CIRCUIT

(a) Remove the blown fuse and disconnect all loads of the fuse.

(b) Connect a test light in place of the fuse.

(c) Establish conditions in which the test light comes on.

Example:

[A] – Ignition SW on

[B] – Ignition SW and SW 1 on

[C] – Ignition SW, SW 1 and Relay on (Connect the

Relay) and SW 2 off (or Disconnect SW 2)

(d) Disconnect and reconnect the connectors while watching the

test light.

The short lies between the connector where the test light

stays lit and the connector where the light goes out.

(e) Find the exact location of the short by lightly shaking the

problem wire along the body.

CAUTION:

(a) Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) When replacing the internal mechanism (ECU part) of

the digital meter, be careful that no part of your body or

clothing comes in contact with the terminals of leads

from the IC, etc. of the replacement part (spare part).

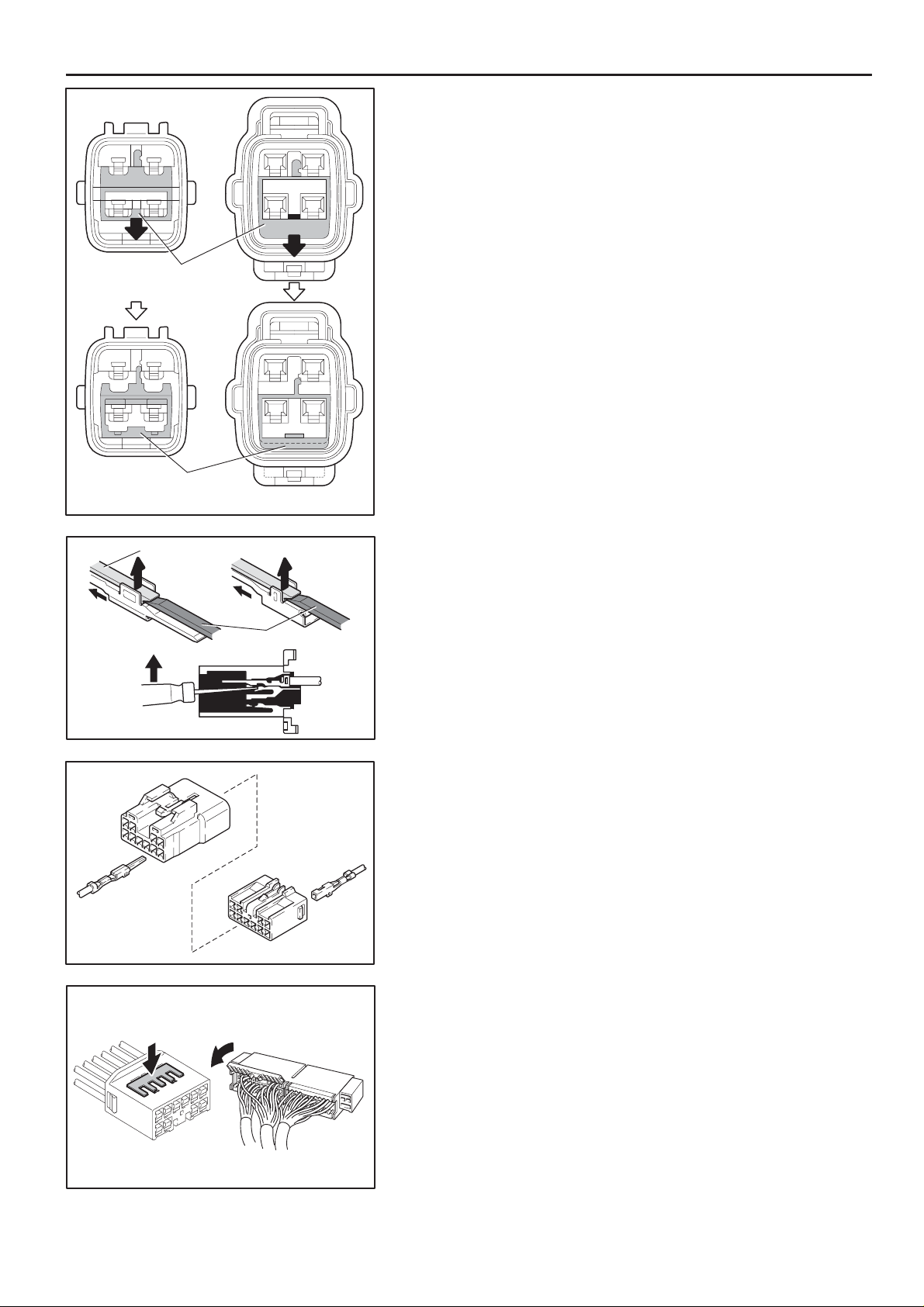

DISCONNECTION OF MALE AND FEMALE

CONNECTORS

To pull apart the connectors, pull on the connector itself, not

the wire harness.

HINT : Check to see what kind of connector you are

disconnecting before pulling apart.

Pull Up

Press Down Press Down

Pull Up

CAMRY (EM0250U)

13

C TROUBLESHOOTING

Reference:

10

1

Example:

(Case 1)

Terminal Retainer

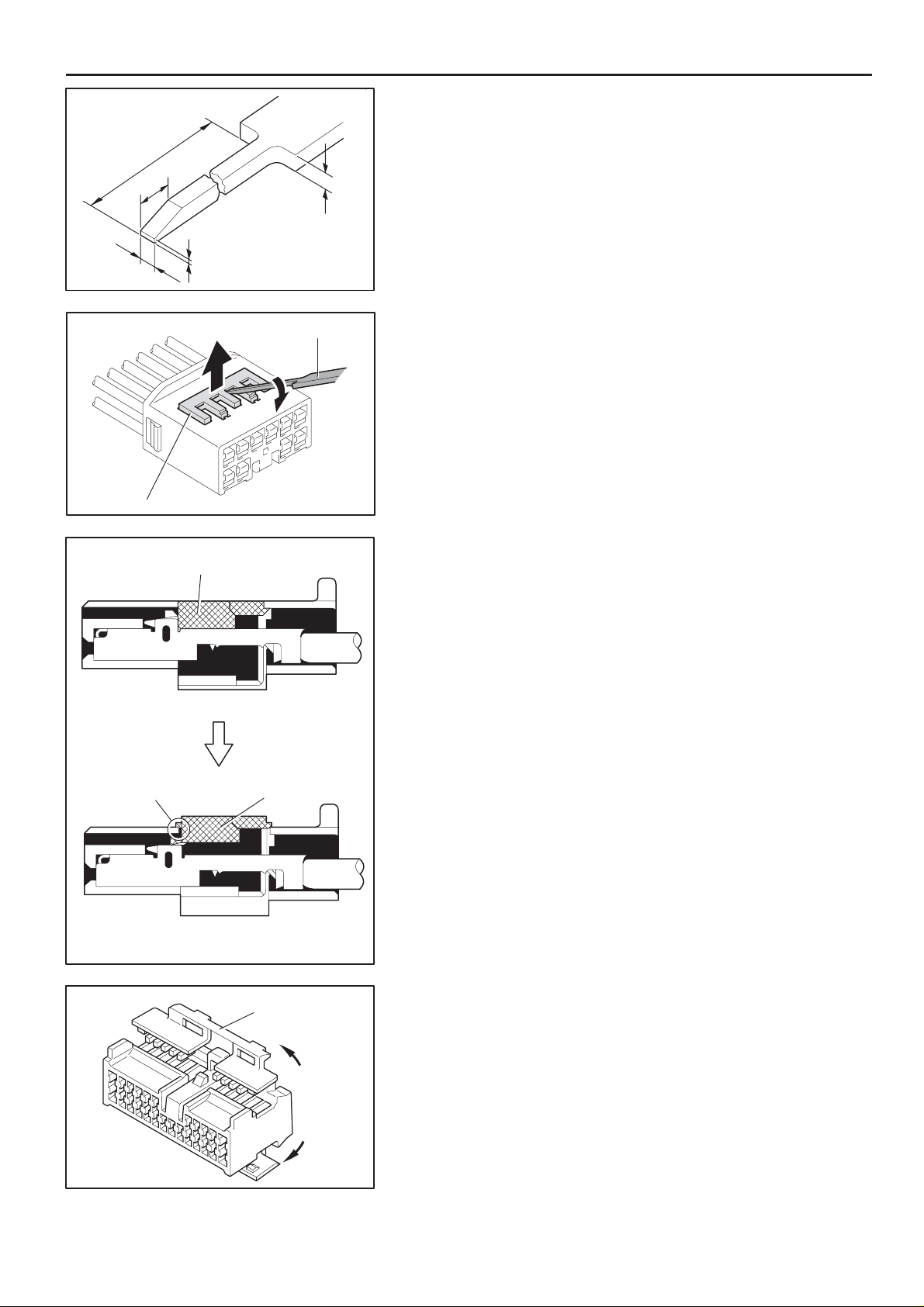

HOW TO REPLACE TERMINAL

(with terminal retainer or secondary locking device)

1. PREPARE THE SPECIAL TOOL

3

0.2

Up

Tool

1

(mm)

HINT : To remov e the te rmin al from th e connector, please

construct and use the special tool or like object shown on

the left.

2. DISCONNECT CONNECT OR

3. DISENGAGE THE SECONDARY LOCKING DEVICE OR

TERMINAL RETAINER.

(a) Locking device must be disengaged before the terminal

locking clip can be released and the terminal removed from

the connector.

(b) Use a special tool or the terminal pick to unlock the secondary

locking device or terminal retainer.

NOTICE:

Do not remove the terminal retainer from connector body.

Terminal Retainer

[Retainer at Full Lock Position]

Stopper

[Retainer at Temporary Lock Position]

Example:

(Case 2)

Terminal

Retainer

Secondary

Locking Device

[A] For Non–Waterproof Type Connector

HINT : The needle insertion position varies according to the

connector’s shape (number of terminals etc.), so

check the position before inserting it.

”Case 1”

Raise the terminal retainer up to the temporary lock

position.

”Case 2”

Open the secondary locking device.

14

CAMRY (EM0250U)

Tab

Tab

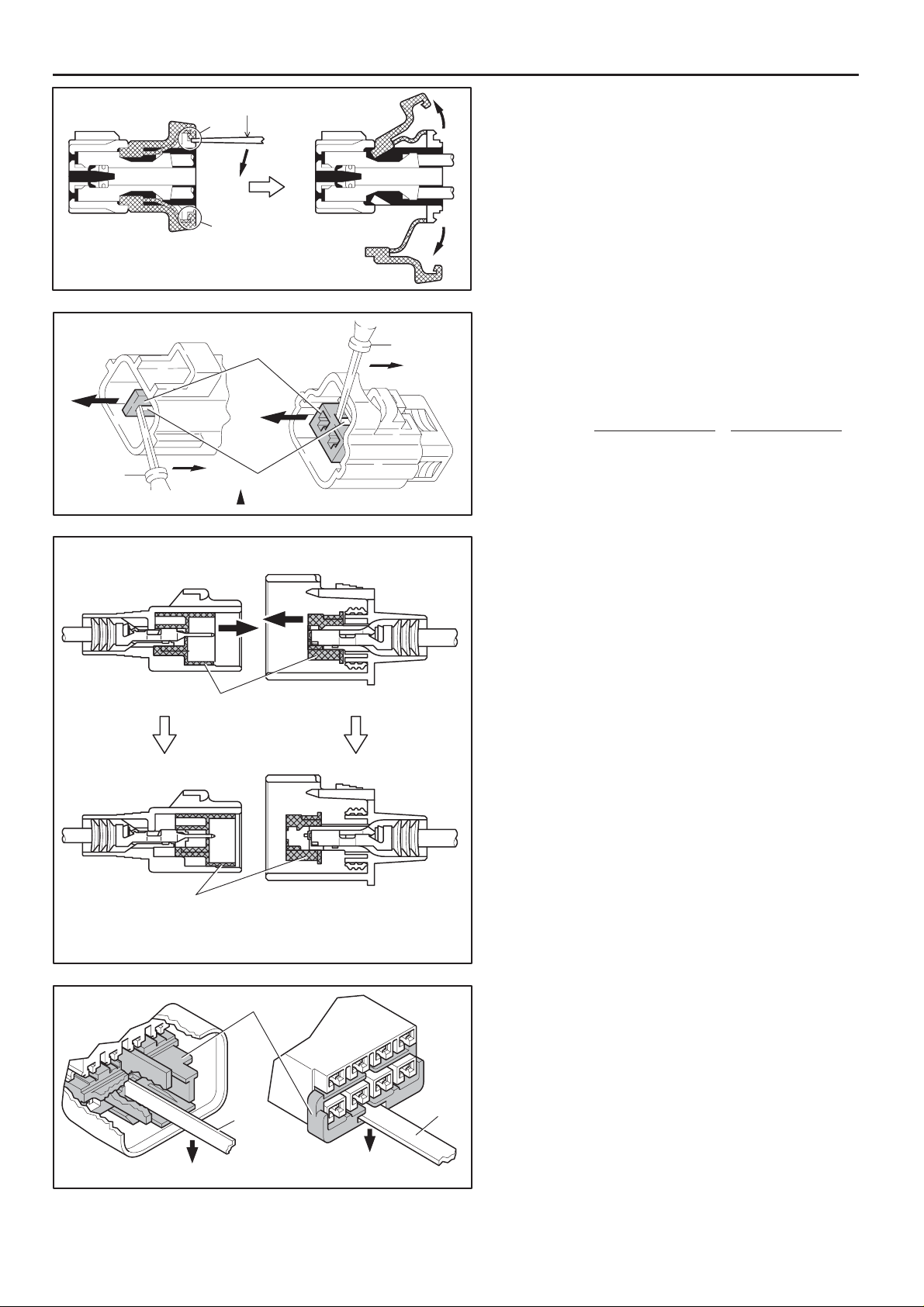

C

Tool

Example:

(Case 1)

Tool

[Male]

Terminal

Retainer

Access Hole

( Mark)

Retainer

at Full Lock Position

[Female]

Tool

[B] For Waterproof Type Connector

HINT : Terminal r etainer co lor is different

according to connector body.

Example:

Terminal Retainer

: Connector Body

Black or White : Gray

Black or White : Dark Gray

Gray or White : Black

”Case 1”

Type where terminal retainer is pulled

up to the temporary lock position (Pull

Type).

Insert the special tool into the terminal

retainer access hole (YMark) and pull

the terminal retainer up to the

temporary lock position.

HINT : The needle insertion position varies

according to the connector’s shape

(Number of terminals etc.), so check

the position before inserting it.

Example:

(Case 2)

[Male]

Retainer

at Temporary Lock Position

[Male] [Female]

Terminal Retainer

Tool

Press Down

Press Down

[Female]

CAMRY (EM0250U)

”Case 2”

Type which cannot be pulled as far as

Power Lock insert the tool straight into

the access hole of terminal retainer as

shown.

Tool

15

C TROUBLESHOOTING

Retainer at

Full Lock Position

Retainer at

Temporary Lock Position

[Male] [Female]

Push the terminal retainer down to the temporary lock position.

Locking Lug

(c) Release the locking lug from terminal and pull the terminal out

from rear.

Tool

4. INSTALL TERMINAL TO CONNECTOR

(a) Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with terminal retainer in the temporary lock

position.

16

(b) Push the secondary locking device or terminal retainer in to

the full lock position.

5. CONNECT CONNECT OR

CAMRY (EM0250U)

ABBREVIATIONS D

ABBREVIATIONS

The following abbreviations are used in this manual.

A/C = Air Conditioning

A/T = Automatic Transaxle

ABS = Anti–Lock Brake System

ACIS = Acoustic Control Induction System

ACM = Active Control Engine Mount

CAN = Controller Area Network

EC = Electrochromic

ECU = Electronic Control Unit

ESA = Electronic Spark Advance

ETCS–i = Electronic Throttle Control System–intelligent

FL = Fusible Link

IC = Integrated Circuit

J/B = Junction Block

LCD = Liquid Crystal Display

LH = Left–Hand

M/T = Manual Transaxle

R/B = Relay Block

RH = Right–Hand

SFI = Sequential Multiport Fuel Injection

SRS = Supplemental Restraint System

SW = Switch

TEMP. = Temperature

TRAC = Traction Control

VSC = Vehicle Stability Control

VSV = Vacuum Switching Valve

VVT = Variable Valve Timing

VVT–i = Variable Valve Timing–intelligent

w/ = With

w/o = Without

∗ The titles given inside the components are the names of the terminals (terminal codes) and are not treated as being

abbreviations.

CAMRY (EM0250U)

17

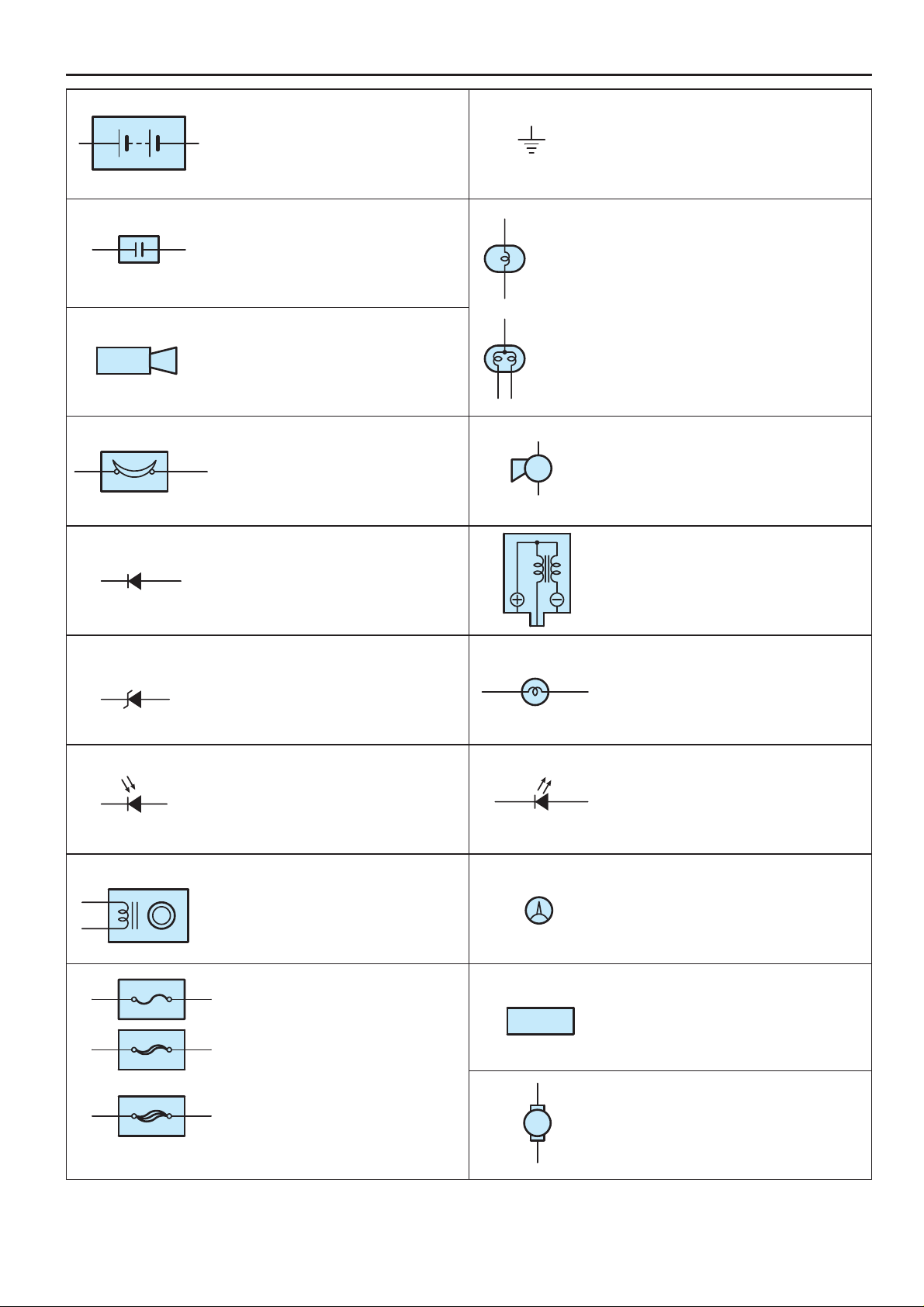

E GLOSSARY OF TERMS AND SYMBOLS

FUSIBLE LINK

FUSIBLE LINK

BATTERY

Stores chemical energy and

converts it into electrical energy .

Provides DC current for the auto’s

various electrical circuits.

CAPACITOR (Condenser)

A small holding unit for temporary

storage of electrical voltage.

CIGARETTE LIGHTER

An electric resistance heating

element.

CIRCUIT BREAKER

Basically a reusable fuse, a circuit

breaker will heat and open if too

much current flows through it.

Some units automatically reset when

cool, others must be manually reset.

DIODE

A semiconductor which allows

current flow in only one direction.

1. SINGLE

FILAMENT

2. DOUBLE

FILAMENT

GROUND

The point at which wiring attaches to

the Body , thereby providing a return

path for an electrical circuit; without a

ground, current cannot flow.

HEADLIGHTS

Current flow causes a headlight

filament to heat up and emit light. A

headlight may have either a single

(1) filament or a double (2) filament

HORN

An electric device which sounds a

loud audible signal.

IGNITION COIL

Converts low–voltage DC current

into high–voltage ignition current for

firing the spark plugs.

(for Medium Current Fuse)

(for High Current Fuse or

Fusible Link)

DIODE, ZENER

A diode which allows current flow in one

direction but blocks reverse flow only up

to a specific voltage. Above that potential,

it passes the excess voltage. This acts as

a simple voltage regulator.

PHOTODIODE

The photodiode is a semiconductor

which controls the current flow

according to the amount of light.

DISTRIBUTOR, IIA

Channels high–voltage current from

the ignition coil to the individual

spark plugs.

FUSE

A thin metal strip which burns through

when too much current flows through it,

thereby stopping current flow and

protecting a circuit from damage.

A heavy–gauge wire placed in high

amperage circuits which burns through on

overloads, thereby protecting the circuit.

The numbers indicate the crosssection

surface area of the wires.

FUEL

M

LIGHT

Current flow through a filament

causes the filament to heat up and

emit light.

LED (LIGHT EMITTING DIODE)

Upon current flow, these diodes emit

light without producing the heat of a

comparable light.

METER, ANALOG

Current flow activates a magnetic

coil which causes a needle to move,

thereby providing a relative display

against a background calibration.

METER, DIGITAL

Current flow activates one or many

LED’s, LCD’s, or fluorescent

displays, which provide a relative or

digital display .

MOTOR

A power unit which converts

electrical energy into mechanical

energy , especially rotary motion.

18

CAMRY (EM0250U)

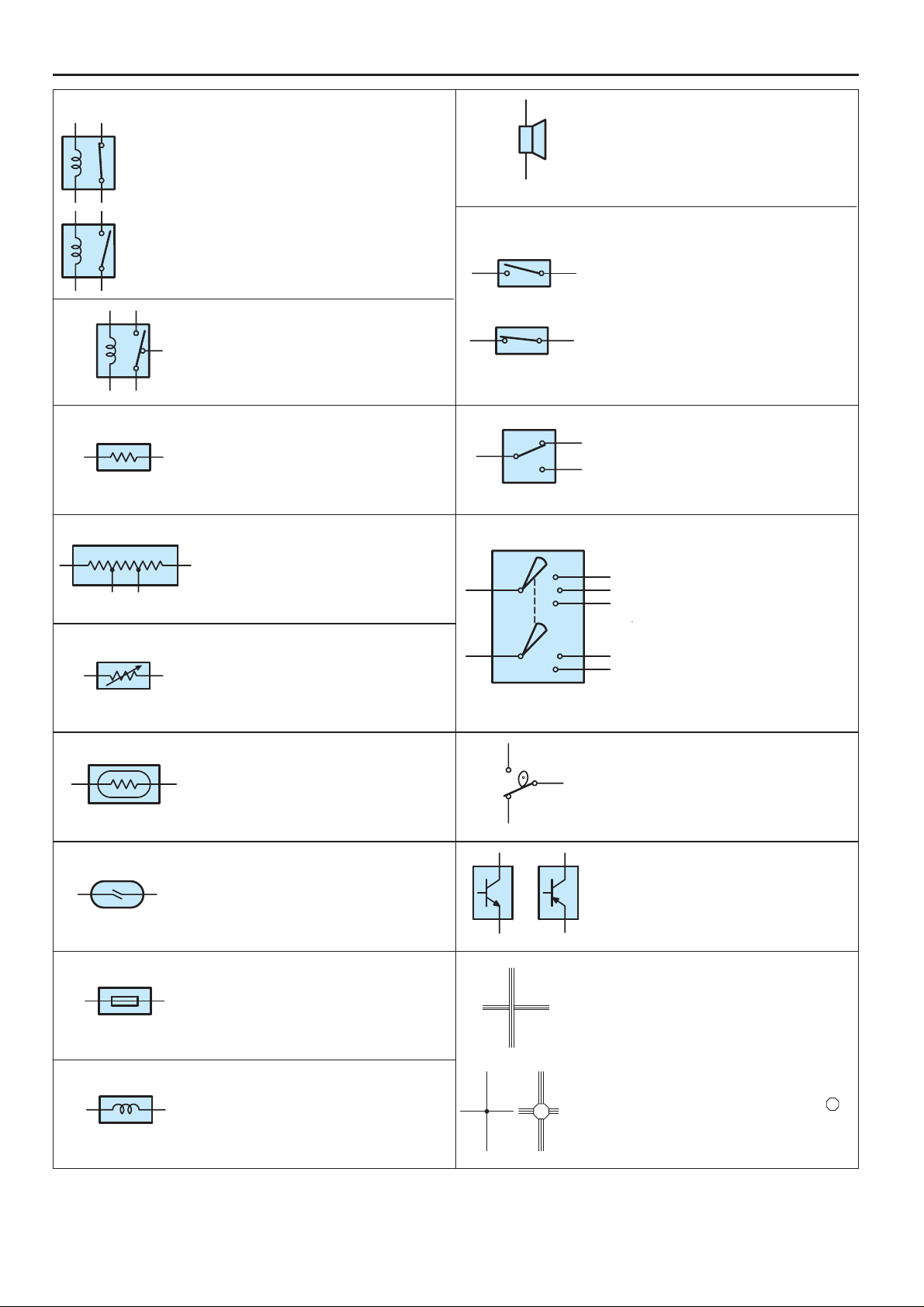

E

Opens and closes

operational.

black dot at the junction are

black dot at the junction are

RELAY

1. NORMALLY

CLOSED

2. NORMALLY

OPEN

RELAY, DOUBLE THROW

RESISTOR

RESISTOR, TAPPED

RESISTOR, VARIABLE or RHEOSTAT

Basically, an electrically operated

switch which may be normally

closed (1) or open (2).

Current flow through a small coil

creates a magnetic field which either

opens or closes an attached switch.

A relay which passes current

through one set of contacts or the

other.

An electrical component with a fixed

resistance, placed in a circuit to

reduce voltage to a specific value.

A resistor which supplies two or

more different non adjustable

resistance values.

A controllable resistor with a variable

rate of resistance.

Also called a potentiometer or

rheostat.

SPEAKER

An electromechanical device which

creates sound waves from current

flow.

SWITCH, MANUAL

Opens and closes

1. NORMALLY

OPEN

2. NORMALLY

CLOSED

SWITCH, DOUBLE THROW

A switch which continuously passes

current through one set of contacts

or the other.

SWITCH, IGNITION

A key operated switch with several

positions which allows various

circuits, particularly the primary

ignition circuit, to become

operational.

circuits, thereby

stopping (1) or

allowing (2) current

flow.

(Reed Switch Type)

SENSOR (Thermistor)

A resistor which varies its resistance

with temperature.

SENSOR, SPEED

Uses magnetic impulses to open

and close a switch to create a signal

for activation of other components.

SHORT PIN

Used to provide an unbroken

connection within a junction block.

SOLENOID

An electromagnetic coil which forms

a magnetic field when current flows,

to move a plunger, etc.

SWITCH, WIPER PARK

Automatically returns wipers to the

stop position when the wiper switch

is turned off.

TRANSISTOR

A solidstate device typically used as

an electronic relay; stops or passes

current depending on the voltage

applied at ”base”.

WIRES

(1) NOT

CONNECTED

(2) SPLICED

Wires are always drawn as

straight lines on wiring

diagrams.

Crossed wires (1) without a

not joined;

crossed wires (2) with a

black dot or octagonal ( )

mark at the junction are

spliced (joined)

connections.

19

CAMRY (EM0250U)

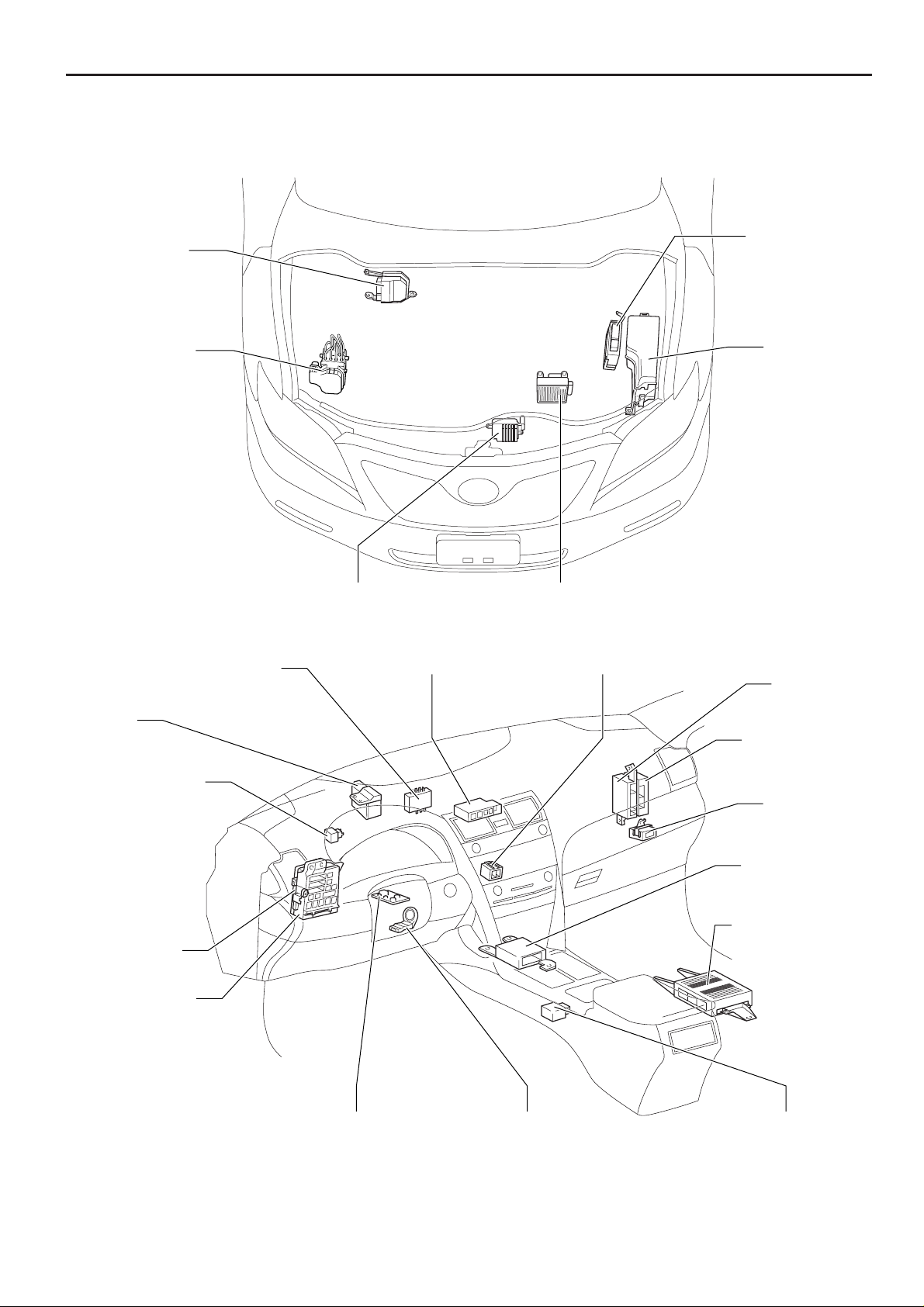

F RELAY LOCATIONS

)

r

t

r

M

T

I

J

[Engine Compartment]

Engine Control

Module(2GR-FE)

Skid Control ECU

with Actuator

[Instrument Panel]

ID Code Box (*1)

Transponder Key ECU (*2)

Cooling Fan ECU

Junction Connector (CAN) J/B No.4

Transmission Control ECU

Engine Control

Module(2AZ-FE

Engine Room

R/B

Engine Room

J/B

A/C Amplifie

J/B No.3

urn Signal Flasher

ain Body ECU

nstrument Panel

/B

* 1:w/ Smart System

* 2:w/o Smart System

Steering Lock ECU Transponder Key Amplifier

Certification ECU

Tire Pressure

Warning ECU

Airbag Sensor

Assembly Cente

Stereo Componen

Amplifier

Shift Lock Control ECU

20

CAMRY (EM0250U)

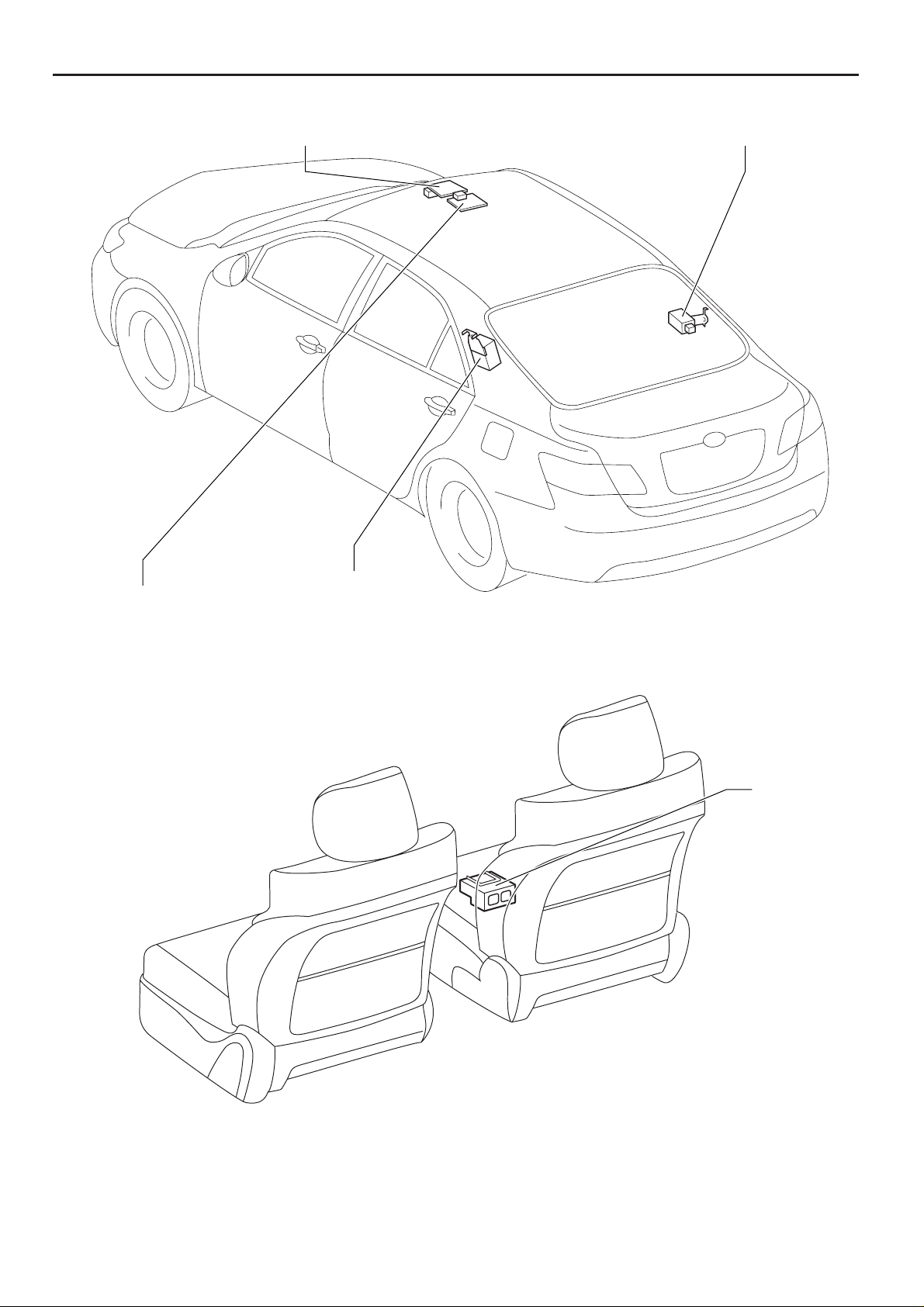

[Body]

F

Sliding Roof Control ECU and Motor Door Control Receiver

Overhead J/B

[Seat]

Tire Pressure Warning

Antenna and Receiver

Occupant

Classification

ECU

CAMRY (EM0250U)

21

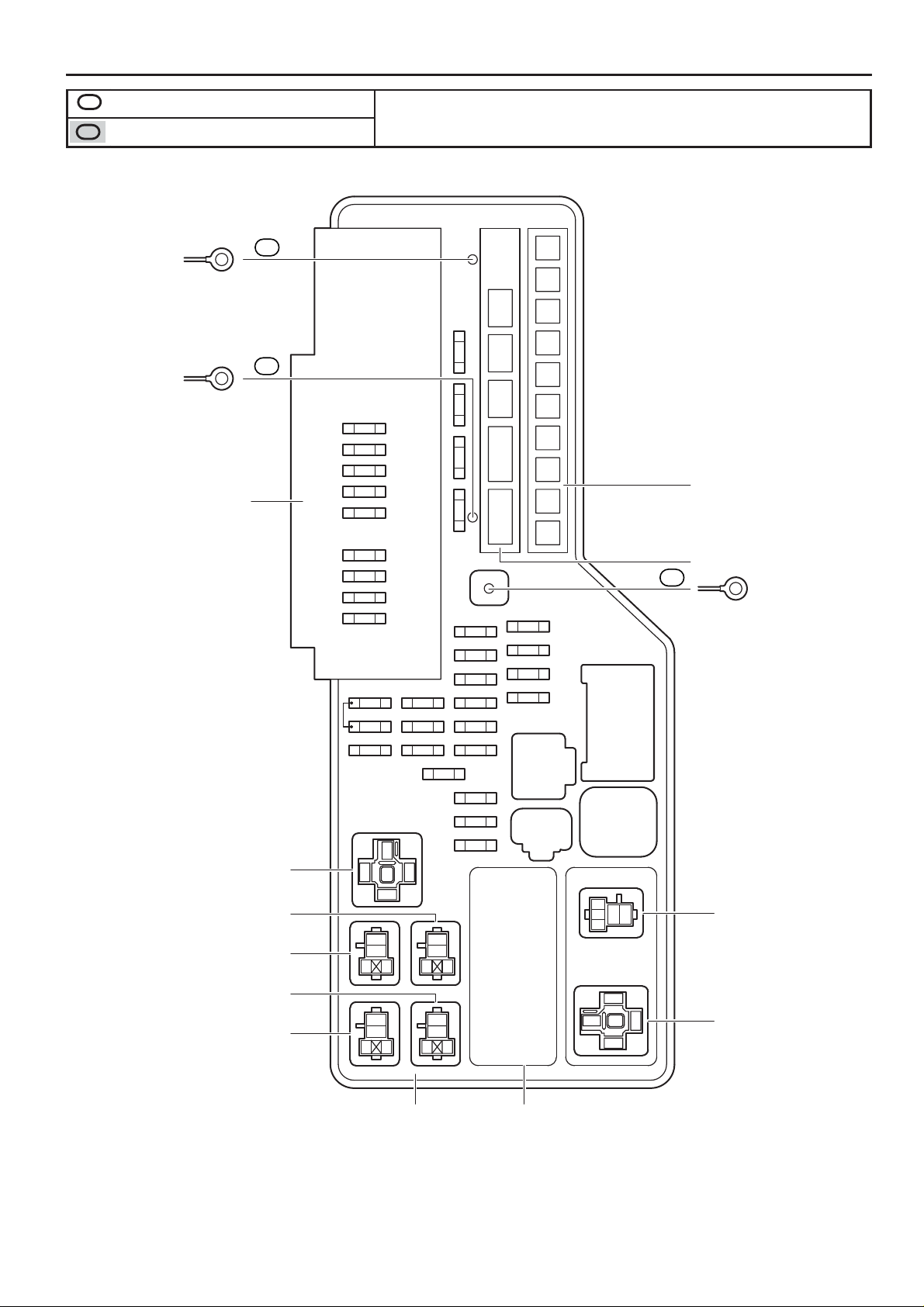

F RELAY LOCATIONS

Engine Compartment Left (See Page 20)

1

: Engine Room R/B

: Engine Room J/B

1G

1

(from Engine Room Main Wire)

Wire Color : W

1F

1

(from Engine Room Main Wire)

Wire Color : B

Unit D

H-LP (LH)

15A

H-LP (RH)

15A

H-LP (LL)

15A

H-LP (RL)

15A

HORN

10A

EFI NO.1

10A

MPX-B

10A

A/F

20A

S-HORN

7.5A

EFI NO.2

15A

EFI NO.3

10A

RADIO NO.1

21

ECU-B NO.1

21

DOME

15A

10A

10A

12

12

SHORT

2

30A

1

EFI MAIN

2

25A

AMP

1

2

25A

1

DOOR NO.1

STR LOCK

20A

21

IG2

20A

21

HAZ

15A

1

2

ETCS

1

212

10A

12

* 1:120A ALT (for High Current)

* 2:30A ST/AM2 (for High Current)

* 3:50A HTR (for High Current)

* 4:50A ABS No.1 (for High Current)

* 5:50A FAN MAIN (for High Current)

* 6:30A ABS No.2 (for High Current)

* 7:50A RR DEF (for High Current)

* 8:40A CDS FAN (for High Current)

*9

*2

*8

*7

*6

*5

* 9:40A RDI FAN (for High Current)

Unit B

*4

*1

*3

Unit A

1C

(from Engine Wire)

Wire Color : B

1

22

RR DEF Relay

IG2 Relay

ST CUT Relay

ST Relay

MGC Relay

3

12

4

5

3

5

12

3

5

12

3

5

12

3

5

12

Unit C Unit E

ALT-S

12

7.5A

AM2

12

7.5A

1

35

2

2

35

1

VSC No.1 Relay

VSC NO.2 Relay

CAMRY (EM0250U)

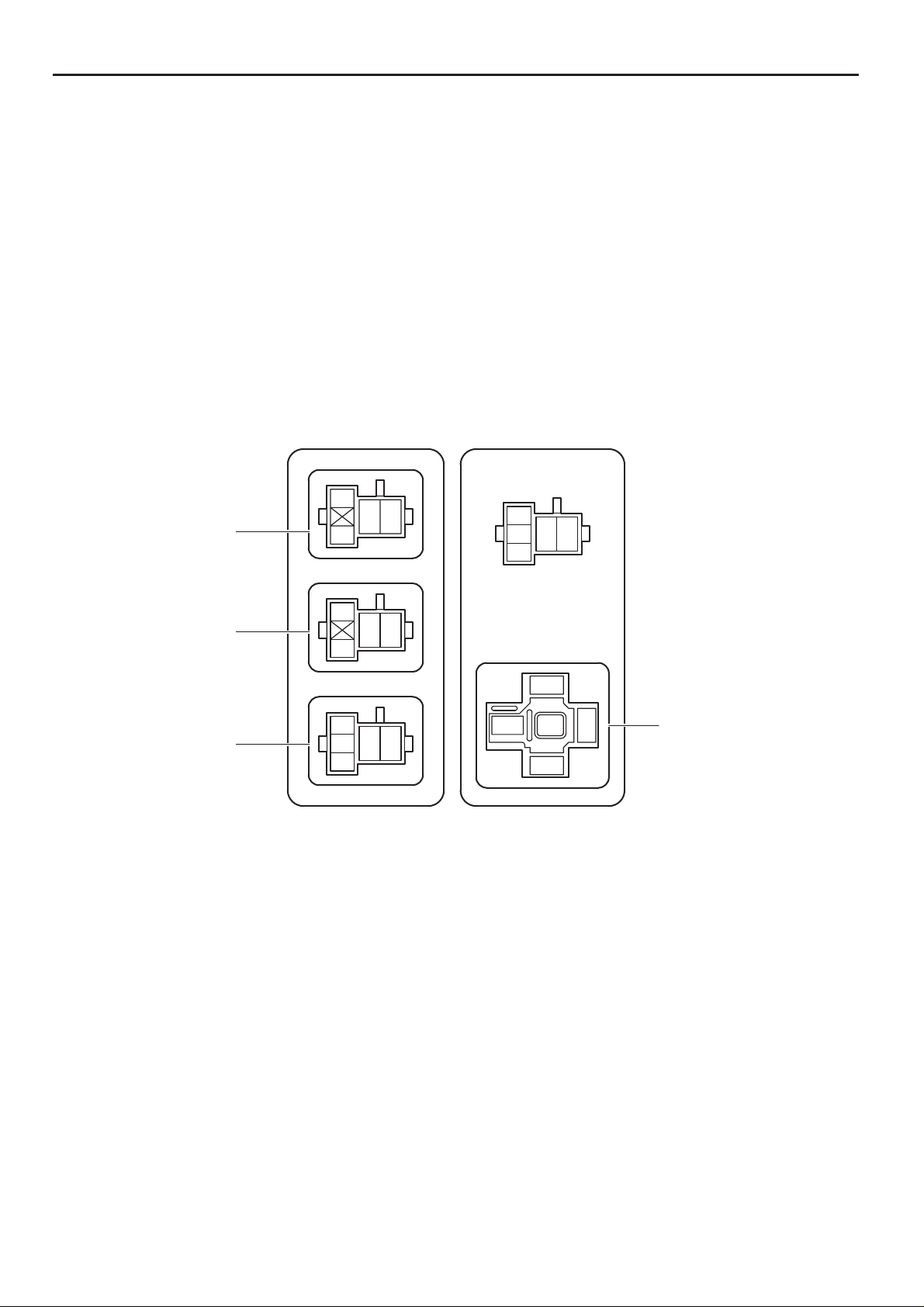

Unit E

F

FAN NO.1 Relay

FAN NO.3 Relay

FAN NO.2 Relay

2AZ-FE

1

2

1

2

1

4

2

2GR-FE

35

35

2

35

35

1

FAN MAIN Relay

CAMRY (EM0250U)

23

F RELAY LOCATIONS

Engine Compartment Left (See Page 20)

1

: Engine Room R/B

: Engine Room J/B

Unit D

View A

View B

View C

24

CAMRY (EM0250U)

F

View A

Black

12345

123456

(from Engine Room

Main Wire)

1A

12345

(from Engine Room

Main Wire)

1B

123456

10111213

(from Engine Room

Main Wire)

6789

12345

View B

Black

678910111213

12345

(from Engine Room

Main Wire)

1D 1E

543 21

12345

6789

CAMRY (EM0250U)

1011121310111213

6987

View C

25

F RELAY LOCATIONS

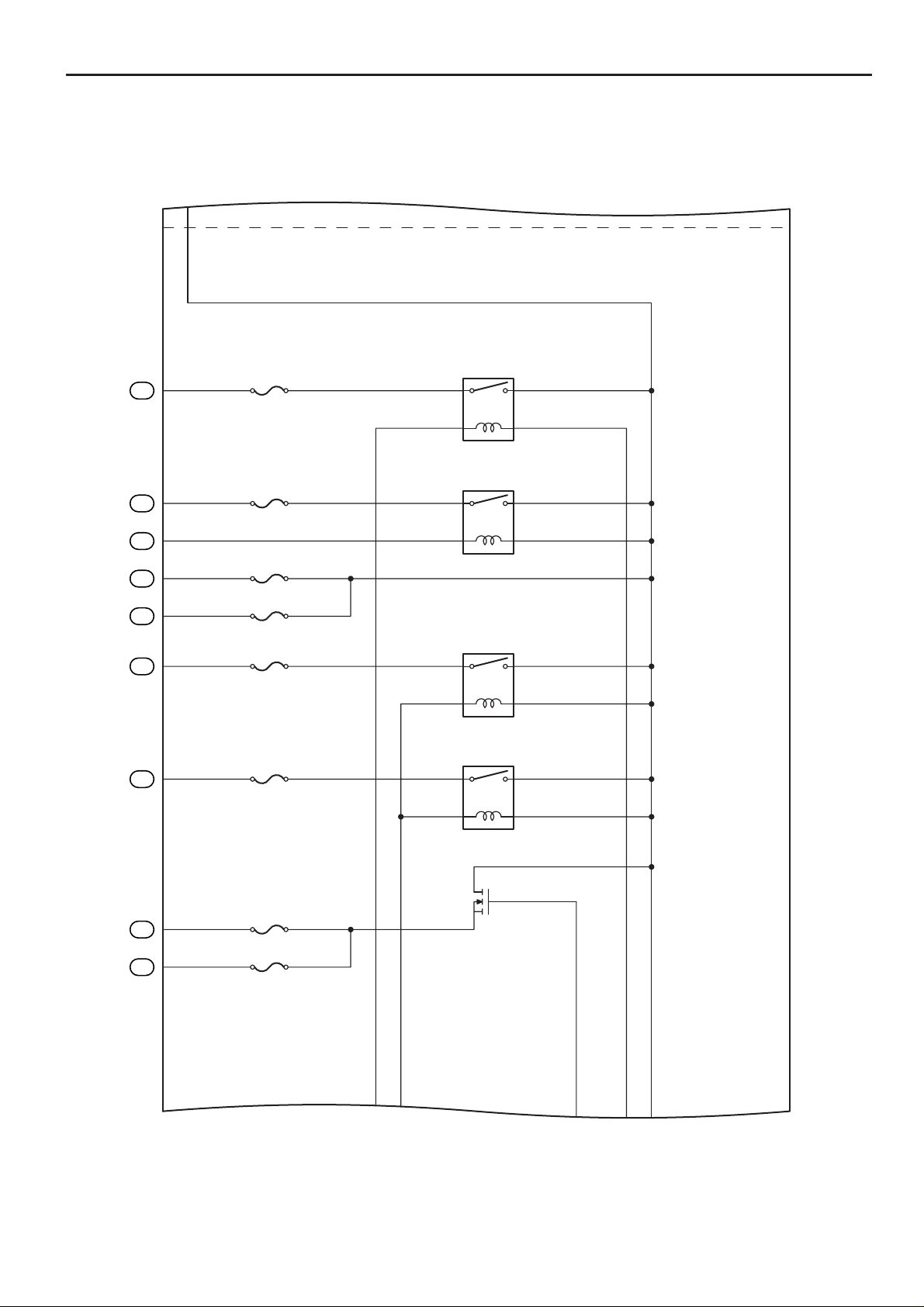

[Engine Room R/B and Engine Room J/B Inner Circuit]

Unit C

1 1

1

1

15A EFI NO.2

1

10A EFI NO.3

2

2

1

1

1

15A RADIO NO.1

1

SHORT

1

1G

21

10A ECU-B NO.1

1

10A DOME

12

7.5A AM2

1

7.5A ALT-S

1

10A ETCS

1

15A HAZ

1

20A IG2

1

20A STR LOCK

1

30A EFI MAIN

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

26

12

25A AMP

21

25A DOOR NO.1

(Cont. Next Page)

CAMRY (EM0250U)

1

1

F

(Cont'd)

Unit A

30A ST/AM2

120A

ALT

1

1C

1

1F

1

1

1

1

1

1

1

1

Unit B

50A HTR

1

1

50A ABS No.1

1

50A FAN MAIN

1

30A ABS No.2

1

50A RR DEF

1

1

1

40A CDS FAN

1

40A RDI FAN

1

(Cont. Next Page)

CAMRY (EM0250U)

27

F RELAY LOCATIONS

[Engine Room R/B and Engine Room J/B Inner Circuit]

(Cont'd)

Unit D

11

4

1A

5

1A

1D

3

1A

2

1A

5

1B

4

1B

20A A/F

7.5A S-HORN

10A MPX-B

10A EFI NO.1

15A H-LP (RL)

15A H-LP (LL)

A/F Relay

S-HORN Relay

H-LP (RL) Relay

H-LP (LL) Relay

28

3

1B

2

1B

15A H-LP (RH)

15A H-LP (LH)

DRL Relay

(Cont. Next Page)

CAMRY (EM0250U)

(Cont'd)

F

10

10

11

13

6

1B

1D

9

1D

1E

1E

1E

10A HORN

HORN Relay

Light Control Circuit

EFI Relay

C/OPN Relay

12

8

1D

1E

9

1E

6

1E

7

1E

8

1E

12

1D

CAMRY (EM0250U)

29

F RELAY LOCATIONS

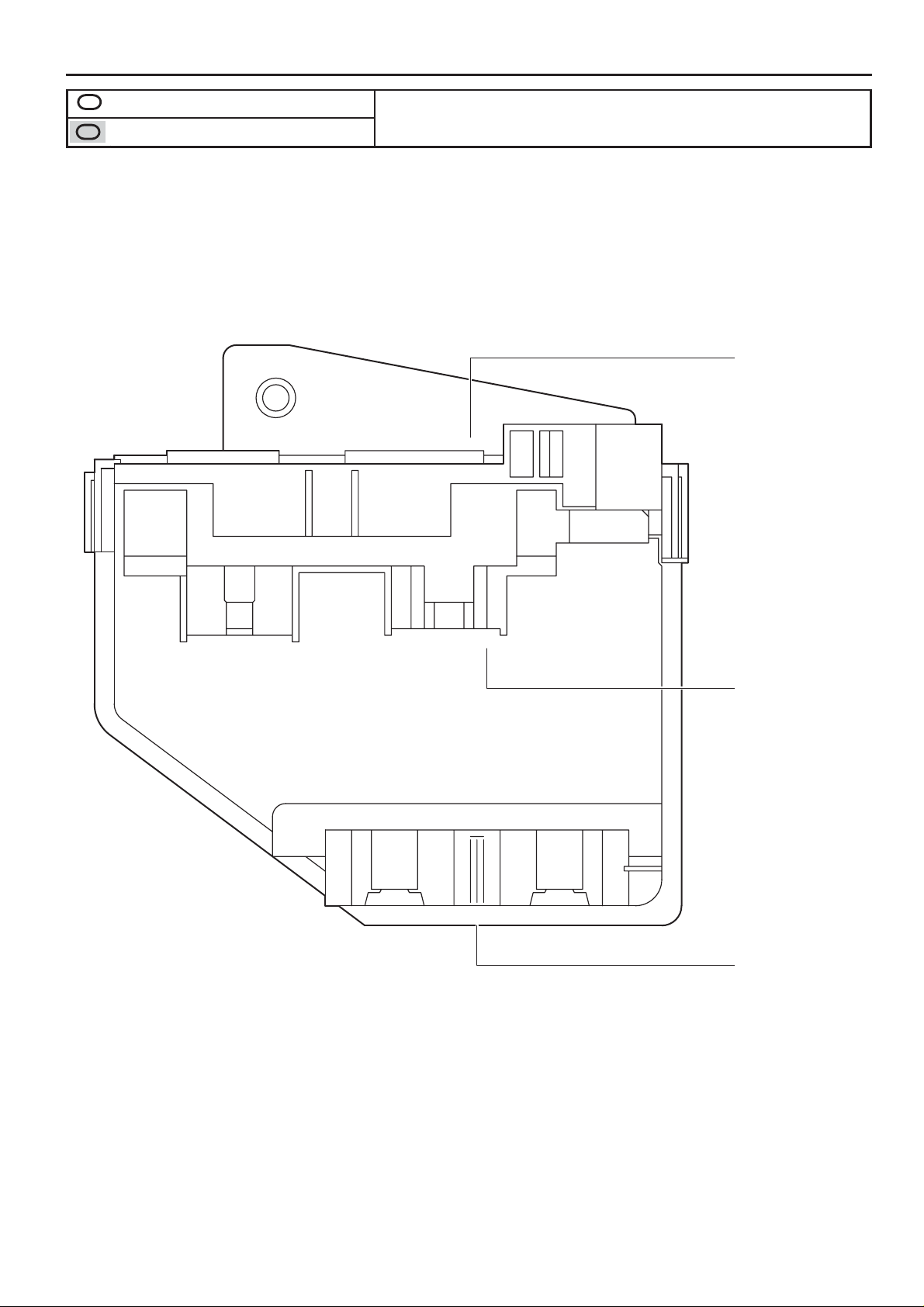

: Instrument Panel J/B Cowl Side Left (See Page 20)

20

10

111213

14

1234

56789

(from Instrument Panel Wire)

9

10

11

13

12

14

16

45678

123

(from Instrument Panel Wire)

11

12

789

123456

(from Instrument Panel Wire)

11

12

10

14

67

89

123

45

(from Engine Room Main Wire)

14

13

15

16

12

9

123

45678

(from Engine Room Main Wire)

IB

12

(from Engine Room Main Wire)

IA

1

(from Engine Room Main Wire)

FOG Relay

TAIL Relay

IM

IK

IL

IC

ID

9

10

11

321

97

3218456

8

9

11

10

321

1

2

21

5

3

13

12

14

151516

4 678

5

101011

12

12

131314

67

45

21

IJ

12

6

345

78

12

10

11

9

(from Instrument Panel Wire)

Yellow

123456

78 9

10

20

10

1

2345

7

11

89

12

11

13

15

16

13

14

12

1234

56789

6

12

10

789

123

456

1

9

1

11

111112

10

1213

2

2

1515161617171818191920

14

431

15

13

14

431

13

14

12

11

32

16

17171818191920

15

645

78

12

6

34

12

7

132

5

78

12

9

10

11

123456

789

10

IE

(from Instrument Panel Wire)

IF

1

6

2345

7

89

101011

12

10

11

8

9

13

645

(from Instrument Panel Wire)

IR

(from Instrument Panel Wire)

IO

98756

10

98756

10

16

1010111112

97

8

321

456

(from Floor Wire)

4

5

3

3

12

2

5

12

5

3

3

1

5

IP

12

(from Floor Wire)

789

10

11

123456

IG1 Relay

PWR Relay

ACC Relay

30

CAMRY (EM0250U)

F

Main Body ECU

IG

78

910101112

3456

12

(from Instrument Panel Wire)

67

89

345

12

II

(from Instrument Panel Wire)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

6

8

7

9

10 101112 10101111121213

356

21

7

9

4

5384

21

IH

16

13

9

1234

5

678

(from Instrument Panel Wire)

2

1414151516

9

1

542

8376

2

1

1

30A POWER

(for High Current)

30A P/SEAT

(for High Current)

CAMRY (EM0250U)

31

F RELAY LOCATIONS

: Instrument Panel J/B Cowl Side Left (See Page 20)

25A

25A

RR DOOR LH

RR DOOR RH

10A

7.5A

A/C NO.2

ECU IG NO.1

ECU IG NO.2

10A

FR FOG

10A

WASH

15A

7.5A

OBD

20A

S-HTR

GAUGE NO.1

10A

WIP

10A

STOP

25A

INJ

15A

IGN

A/C

AM1

7.5A

7.5A

10A

7.5A

ECU-ACC

GAUGE NO.2

PWR

7.5A

25A

25A

30A

S/ROOF

DOOR NO.2

20A

RADIO NO.2

PWR OUTLET

15A

TAIL

7.5A

MIR HTR

7.5A

PANEL

10A

32

CAMRY (EM0250U)

[Instrument Panel J/B Inner Circuit]

1

IE

2

IE

10

IF

1

IR

4

5

1

TAIL Relay

5

1

FOG Relay

11

1

IA

4

IK

5

IK

6

IK

IM

4

ID

4

IL

15A FR FOG

F

4

IC

5

IC

6

ID

14

ID

11

IH

3

15A TAIL

3

7. 5A PANEL

2

3

2

IL

8

IP

6

IF

2

IO

3

IR

4

IH

1

IC

5

ID

6

IG

8

II

10

10

13

10

12

14

10

IM

11

6

IE

IH

5

IE

IG

3

IM

3

II

2

IB

IO

3

IE

3

IG

IE

3

IF

1

IH

IM

9

IJ

IK

4

IR

12

30A P/SEAT

5

2

ACC Relay

3

1

7.5A RADIO NO.2

20A PWR OUTLET

7.5A ECU-ACC

10A MIR HTR

12

10

16

12

12

11

12

IO

IF

IO

IM

IO

2

IF

8

IK

5

IH

IJ

1

IK

IL

4

IO

7

ID

8

ID

8

IG

6

II

IP

(Cont. Next Page)

CAMRY (EM0250U)

33

F RELAY LOCATIONS

[Instrument Panel J/B Inner Circuit]

(Cont'd)

14

16

12

11

11

13

13

10

10

12

12

17

2

IP

IF

IH

9

IO

4

IE

4

IF

IH

6

IM

8

IF

9

IF

1

IG

IR

IJ

IK

2

IR

9

II

ID

7

IF

IL

IP

6

IR

7

IR

3

IC

9

IC

2

IG

1

II

9

IL

IR

30A S/ROOF

IL

IM

10A GAUGE NO.1

25A PWR

5

2

IG1 Relay

5

1

PWR Relay

3

1

3

2

10A ECU IG NO.1

25A WIP

10A WASH

10A A/C NO.2

20A S-HTR

7.5A ECU IG NO.2

12

30A POWER

25A RR DOOR LH

25A RR DOOR RH

7.5A A/C

7.5A AM1

25A DOOR NO.2

7.5A OBD

10A STOP

11

10

11

12

12

16

19

20

19

10

11

18

17

6

IC

IF

3

IO

IR

2

IC

2

II

IC

IC

ID

IF

IM

IM

IF

6

IO

7

IJ

IK

1

IP

7

IP

1

IL

8

IM

IK

IM

4

II

9

IK

IF

6

IJ

4

IM

4

IP

8

IC

5

IM

34

(Cont. Next Page)

CAMRY (EM0250U)

(Cont'd)

F

13

13

15

10

15

10

18

12

14

12

13

14

11

11

7

IC

IC

4

IG

3

IH

2

IM

IG

1

ID

9

IE

9

IG

2

IH

IM

IM

8

IO

IG

7

IH

8

IH

5

IF

1

IJ

2

IK

IP

IF

7

IK

9

IP

IC

IF

7

IL

7

IM

3

IP

7

II

IC

ID

5

IG

II

1

IM

5

IR

IF

2

IJ

6

IP

4

IJ

IK

7.5A GAUGE NO.2

10A IGN

15A INJ

11

10

7

IE

9

IR

8

IE

6

IL

7

IO

5

IL

5

IP

ID

5

II

ID

1

IF

12 18 21 13 23 24 22 15

UL1 PWS HU UL2STP TRLY ACT+

14

16

17

20

25

26

ACT- ILE GND1

LIN1

LCTY

LSR (*2)

LSWL (*1)

HORN

BECU (*2)

57

19

Main Body ECU

13 2

IGPKB

ACC

*1:w/ Smart Key System

*2:w/o Smart Key System

BATB

(*1)

ALTB

GND2

HRLY

L1

L2

DRL

6

4

8

9

10

11

16

15

13

15

16

ID

IH

9

IM

3

ID

IH

3

IJ

IK

5

IJ

IK

9

ID

35

CAMRY (EM0250U)

F RELAY LOCATIONS

: J/B No.3 Behind the Combination Meter (See Page 20)

Gray

23456789

1

10 11 12

(from Instrument Panel No.2 Wire)

987654321

12 11 10

(from Instrument Panel No.2 Wire)

987654321

12 11 10

(from Instrument Panel No.2 Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

Gray

987654321

12 11 10

(from Instrument Panel Wire)

3Q

3S

3U

3B

3D

3F

3H

3J

3N

3L

101112

101112

101112

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

123

749586

749586

749586

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

694857

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

10 11 12

3P

123

123

123

3R

123456789

(from Instrument Panel No.2 Wire)

123456789

10 11 12

10 11 12

(from Instrument Panel No.2 Wire)

3T

12 11 10

Gray

987654321

(from Instrument Panel No.2 Wire)

3A

3C

3E

3G

(from Instrument Panel Wire)

(from Instrument Panel Wire)

(from Instrument Panel Wire)

987654321

12 11 10

987654321

12 11 10

987654321

12 11 10

987654321

12 11 10

(from Instrument Panel Wire)

3I

3K

3M

3O

(from Instrument Panel Wire)

(from Instrument Panel Wire)

(from Instrument Panel Wire)

987654321

12 11 10

987654321

12 11 10

987654321

12 11 10

987654321

12 11 10

(from Instrument Panel Wire)

36

CAMRY (EM0250U)

Memo

CAMRY (EM0250U)

37

F RELAY LOCATIONS

[J/B No.3 Inner Circuit]

10

10

10

10

10

10

11

11

2

3P

3N

3

3P

3T

9

3T

3U

9

3U

3B

9

3J

3M

3O

4

3P

3C

5

3P

8

3G

8

3H

6

3P

7

3O

7

3P

7

3F

7

3G

8

3P

6

3E

9

3P

3

3B

3P

3

3D

5

3C

5

3K

4

3K

5

3L

5

3I

5

3O

10

12

11

12

12

12

10

10

12

11

11

11

12

11

11

10

11

10

3P

3

3J

2

3J

1

3Q

1

3R

3B

3G

3H

3I

3L

2

3Q

3K

3L

3N

3

3Q

3J

4

3Q

4

3R

3S

3T

3U

3U

9

3B

9

3C

5

3Q

3A

3D

3H

3H

6

3Q

6

3A

7

3J

7

3M

38

(Cont. Next Page)

CAMRY (EM0250U)

(Cont'd)

F

10

10

11

12

12

11

11

11

7

3Q

8

3Q

8

3R

2

3S

2

3T

5

3U

4

3U

3

3U

2

3U

1

3U

9

3Q

9

3R

2

3G

1

3H

3Q

3R

3Q

3

3O

3Q

1

3D

2

3R

3C

3I

3K

3L

3

3R

9

3F

9

3M

5

3R

9

3D

9

3K

8

3M

11

12

12

10

10

11

6

3R

8

3E

7

3R

5

3S

5

3T

4

3T

3

3T

4

3A

4

3B

4

3C

4

3L

3

3L

3R

5

3D

6

3K

6

3B

3R

2

3O

3S

9

3A

3S

3C

9

3E

9

3H

9

3L

3N

9

3S

8

3S

7

3S

6

3S

8

3K

8

3L

(Cont. Next Page)

CAMRY (EM0250U)

39

F RELAY LOCATIONS

[J/B No.3 Inner Circuit]

(Cont'd)

12

10

4

3S

3

3M

3

3S

3

3A

1

3S

2

3C

1

3L

1

3M

3T

3A

8

3T

8

3A

7

3T

6

3T

7

3U

6

3U

6

3L

1

3T

1

3A

8

3U

7

3D

7

3A

7

3B

5

3J

5

3B

5

3H

6

3O

1

3B

1

3C

1

3J

12

11

10

12

11

11

12

3A

3F

3F

3O

3O

5

3A

6

3C

5

3G

5

3N

4

3I

2

3A

2

3B

3

3F

3

3G

6

3H

3

3H

3

3I

2

3K

1

3K

2

3M

1

3N

1

3O

3

3C

3B

3E

8

3B

8

3C

7

3K

7

3L

8

3N

40

(Cont. Next Page)

CAMRY (EM0250U)

(Cont'd)

F

12

11

11

11

10

10

12

7

3C

7

3I

6

3N

3D

6

3M

3D

3M

8

3D

6

3D

7

3E

6

3F

6

3J

4

3D

4

3O

2

3D

2

3N

3E

3J

3E

3M

5

3E

5

3F

4

3E

4

3H

3

3E

3

3K

2

3E

4

3M

1

3E

4

3N

12

12

12

12

10

10

3F

3J

3K

8

3F

9

3O

8

3O

4

3F

4

3J

2

3F

3

3N

1

3F

2

3L

3G

9

3N

3G

3I

9

3G

4

3G

9

3I

6

3G

6

3I

1

3G

2

3I

1

3I

7

3H

8

3J

2

3H

5

3M

8

3I

7

3N

CAMRY (EM0250U)

41

)

)

)

)

)

)

F RELAY LOCATIONS

: J/B No.4 Instrument Panel Brace Center (See Page 20)

Gray

123456789

101112

(from Instrument Panel Wire)

Gray

123456789

101112

(from Instrument Panel Wire)

Gray

123456789

101112

(from Instrument Panel Wire)

Gray

123456789

101112

(from Instrument Panel Wire)

Gray

Gray

123456789

101112

(from Instrument Panel Wire)

4B

4D

4F

4H

4J

4L

4A

741923586

101112

741923586

101112

741923586

101112

741923586

101112

741923586

101112

741923586

101112

741923586

101112

4C

4E

4G

123456789

(from Instrument Panel Wire

123456789

(from Instrument Panel Wire

123456789

(from Instrument Panel Wire

123456789

101112

101112

101112

101112

(from Instrument Panel Wire

741923586

101112

741923586

101112

741923586

101112

741923586

101112

741923586

101112

741923586

101112

4I

4K

4M

123456789

(from Instrument Panel Wire

123456789

101112

101112

(from Instrument Panel Wire

42

CAMRY (EM0250U)

[J/B No.4 Inner Circuit]

F

12

11

12

12

12

11

11

12

11

12

10

11

10

10

11

11

12

10

10

11

12

12

12

12

8

4B

9

4B

4B

8

4C

8

4D

4H

4J

4J

4

4I

5

4I

6

4K

3

4B

4

4B

5

4B

4

4D

4

4H

3

4J

4

4J

5

4J

3

4A

3

4I

7

4A

7

4L

4E

4G

4M

4

4E

5

4E

5

4H

4

4L

5

4L

4D

4H

4H

4K

4L

1

4A

1

4D

1

4E

2

4E

1

4G

1

4I

4

4A

5

4D

6

4F

6

4I

4B

4I

4I

4M

4B

9

4D

4D

4D

4J

4K

4K

2

4D

1

4F

2

4F

4A

4C

(Cont. Next Page)

CAMRY (EM0250U)

43

F RELAY LOCATIONS

[J/B No.4 Inner Circuit]

(Cont'd)

10

10

10

11

3

4G

5

4K

2

4A

1

4B

2

4B

3

4D

3

4F

4

4F

1

4H

2

4H

3

4H

2

4I

1

4J

2

4J

1

4K

1

4L

5

4C

4

4M

9

4F

9

4G

9

4E

8

4K

9

4C

7

4K

4A

4G

5

4A

5

4G

4L

4L

10

10

10

10

9

4A

4C

9

4L

8

4H

7

4I

8

4I

9

4H

9

4I

4I

2

4G

2

4K

3

4K

4

4K

8

4A

7

4F

8

4F

1

4M

4E

4M

6

4H

5

4M

7

4H

6

4M

6

4C

8

4L

3

4L

3

4M

1

4C

2

4C

3

4C

44

(Cont. Next Page)

CAMRY (EM0250U)

(Cont'd)

F

11

11

11

10

9

4J

9

4M

6

4J

6

4L

8

4J

8

4M

7

4J

7

4M

8

4E

8

4G

7

4E

7

4G

4E

4G

3

4E

4

4G

4C

4F

11

12

12

4

4C

5

4F

6

4E

6

4G

4F

9

4K

4A

4F

2

4L

2

4M

6

4A

6

4B

7

4B

7

4C

6

4D

7

4D

CAMRY (EM0250U)

45

F RELAY LOCATIONS

Junction Connector (CAN) Instrument Panel Brace Center (See Page 20)

E42

2

1

E45

Black

2

1

1

1

22

46

E46

Blue

1

2

E62

Gray

1

2

2

1

E63

Brown

1

2

2

2

2

2

1

1

1

1

E43

E44

Black

1

2

1

2

CAMRY (EM0250U)

[Junction Connector (CAN) Inner Circuit]

E42(A), E43(B), E44(C), E45(D),

E46(E), E62(G), E63(H)

1

A

1

B

1

C

1

D

1

E

1

G

1

H

F

2

A

2

B

2

C

2

D

2

E

2

G

2

H

CAMRY (EM0250U)

47

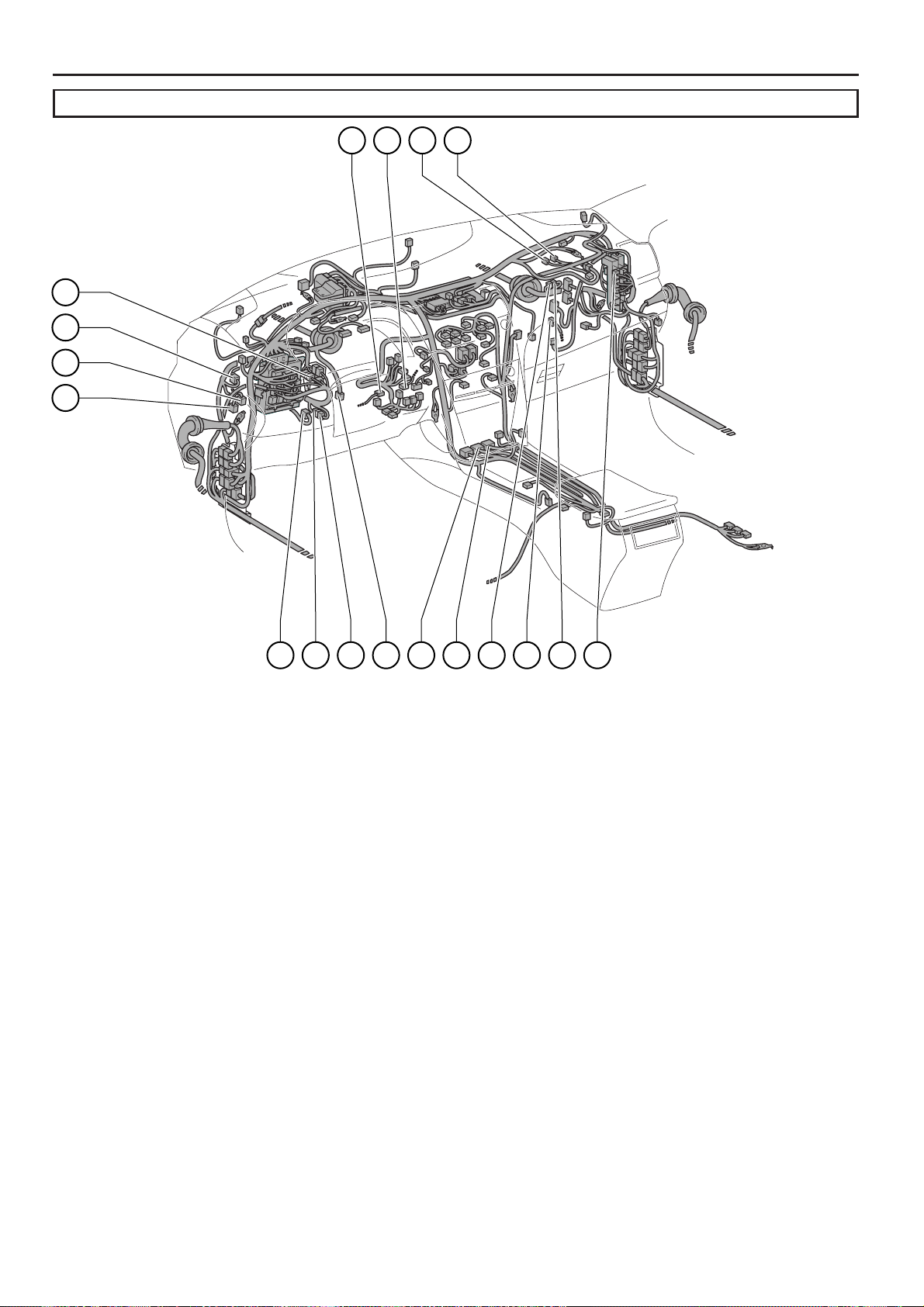

G ELECTRICAL WIRING ROUTING

4

6

(*1)

Position of Parts in Engine Compartment

[2GR–FE]

A35

(*2)

A26

A29

A1

A1

A8

A37

* 1:w/o VSC

* 2:w/ VSC TMC Made

A 1 Fog Lamp (Front LH)

A 2 Ambient Temp. Sensor

A 3 Horn (High)

A 4 Horn (Low)

A 5 Engine Hood Courtesy SW

A 8 Headlamp (LH High)

A13 Airbag Sensor (Front LH)

A14 Speed Sensor (Front LH)

A16 Brake Fluid Level Warning SW

A27A25A28A34

A23

A2A4

A3A5 A13 A1

A23 Security Horn

A25 Skid Control ECU with Actuator

A26 Skid Control ECU with Actuator

A27 A/C Pressure Sensor

A28 Airbag Sensor (Front RH)

A29 Headlamp (RH High)

A34 Fog Lamp (Front RH)

A35 Speed Sensor (Front RH)

A37 Windshield Washer Motor

48

CAMRY (EM0250U)

[2GR–FE]

7

9

6

5

8

3

A55

(*3)

A60

Position of Parts in Engine Compartment

(*5)

(*4)

G

A5

B1

A4

A51

A50

A49

* 3:w/ VSC TMMK Made

* 4:TMC Made

* 5:TMMK Made

A43 Junction Connector

A45 Headlamp (LH Low)

A46 Turn Signal and Parking Lamp (Front LH)

A47 Side Marker Lamp (Front LH)

A48 Wireless Door Lock Buzzer

A49 Headlamp (RH Low)

A50 Turn Signal and Parking Lamp (Front RH)

A51 Side Marker Lamp (Front RH)

A52 Washer Level Warning SW

A53 VSV (Air Intake Control)

A54 Cooling Fan ECU

A55 Engine Control Module

A59 Windshield Wiper Motor

A60 Skid Control ECU with Actuator

A4

A4

A4

A4

A52 A54 A53

B 1 Windshield Wiper Motor

CAMRY (EM0250U)

49

G ELECTRICAL WIRING ROUTING

0

4

Position of Parts in Engine Compartment

[2GR–FE]

C17 C11 C12 C16 C15 C5

C2

C1

C4

C7

C8

C9

C13

C 1 Park/Neutral Position SW

C 2 Mass Air Flow Meter

C 3 Starter

C 4 Engine Coolant Temp. Sensor

C 5 Throttle Body Assembly

C 6 VSV (Purge)

C 7 Fuel Injector (No.1)

C 8 Fuel Injector (No.3)

C 9 Fuel Injector (No.2)

C10 Fuel Injector (No.4)

C11 Ignition Coil (No.1)

C1

C6

C3

C1

C23 C21 C18 C19

C12 Ignition Coil (No.3)

C13 Ignition Coil (No.2)

C14 Ignition Coil (No.4)

C15 Air Fuel Ratio Sensor (Bank 1 Sensor 1)

C16 Noise Filter (Ignition RH)

C17 Power Steering Oil Pressure SW

C18 Generator

C19 Generator

C21 A/C Compressor

C23 Engine Oil Pressure SW

50

CAMRY (EM0250U)

[2GR–FE]

5

9

7

9

6

G

Position of Parts in Engine Compartment

C42

C43

C41

C48

C47

C46

C45

C55 C40

C36

C38 C57

V2

V1

C3

C4

C3

C3

C5

C34 VSV (ACM)

C35 Air Fuel Ratio Sensor (Bank 2 Sensor 1)

C36 Fuel Injector (No.5)

C37 Fuel Injector (No.6)

C38 Ignition Coil (No.5)

C39 Ignition Coil (No.6)

C40 VVT Sensor (Bank 1 Exhaust Side)

C41 VVT Sensor (Bank 1 Intake Side)

C42 Camshaft Timing Oil Control Valve (RH Exhaust Side)

C43 Camshaft Timing Oil Control Valve (RH Intake Side)

C44 VVT Sensor (Bank 2 Exhaust Side)

C45 VVT Sensor (Bank 2 Intake Side)

C46 Camshaft Timing Oil Control Valve (LH Exhaust Side)

C47 Camshaft Timing Oil Control Valve (LH Intake Side)

C48 VSV (ACIS)

C49 Noise Filter (Ignition LH)

C50 Crankshaft Position Sensor

C51 Heated Oxygen Sensor (Bank 2 Sensor 2)

C52 Heated Oxygen Sensor (Bank 1 Sensor 2)

C53 A/C Compressor

C55 Engine Control Module

C56 Transmission Control ECU

C57 Junction Connector

C52 C51C50C53 C44 C34 D1

D 1 Starter

V 1 Knock Control Sensor (Bank 2)

V 2 Knock Control Sensor (Bank 1)

CAMRY (EM0250U)

51

G ELECTRICAL WIRING ROUTING

4

4

6

(*1)

Position of Parts in Engine Compartment

[2AZ–FE]

A35

(*2)

A26

A29

A1

A2

A1

A8

A37

* 1:w/o VSC

* 2:w/ VSC TMC Made

A 1 Fog Lamp (Front LH)

A 2 Ambient Temp. Sensor

A 3 Horn (High)

A 4 Horn (Low)

A 5 Engine Hood Courtesy SW

A 6 A/C Condenser Fan Motor

A 7 Radiator Fan Motor

A 8 Headlamp (LH High)

A13 Airbag Sensor (Front LH)

A14 Speed Sensor (Front LH)

A16 Brake Fluid Level Warning SW

A27A25A28A34

A4A23

A6

A2

A23 Security Horn

A24 Engine Control Module

A25 Skid Control ECU with Actuator

A26 Skid Control ECU with Actuator

A27 A/C Pressure Sensor

A28 Airbag Sensor (Front RH)

A29 Headlamp (RH High)

A34 Fog Lamp (Front RH)

A35 Speed Sensor (Front RH)

A37 Windshield Washer Motor

A3A5 A13A7A1

52

CAMRY (EM0250U)

[2AZ–FE]

7

9

6

5

8

G

Position of Parts in Engine Compartment

(*4)

B1

(*3)

A60

A51

A50

A49

A52

* 3:w/ VSC TMMK Made

* 4:TMC Made

* 5:TMMK Made

A45 Headlamp (LH Low)

A46 Turn Signal and Parking Lamp (Front LH)

A47 Side Marker Lamp (Front LH)

A48 Wireless Door Lock Buzzer

A49 Headlamp (RH Low)

A50 Turn Signal and Parking Lamp (Front RH)

A51 Side Marker Lamp (Front RH)

A52 Washer Level Warning SW

A59 Windshield Wiper Motor

A60 Skid Control ECU with Actuator

B 1 Windshield Wiper Motor

(*5)

A5

A4

A4

A4

A4

CAMRY (EM0250U)

53

G ELECTRICAL WIRING ROUTING

6

5

Position of Parts in Engine Compartment

[2AZ–FE]

C7

C11

C17

C19

C18

C9 C13 C8

C12 C10 C14

C5

C6 C2

C1

C1

C4

C3

C1

C 1 Park/Neutral Position SW

C 2 Mass Air Flow Meter

C 3 Starter

C 4 Engine Coolant Temp. Sensor

C 5 Throttle Body Assembly

C 6 VSV (Purge)

C 7 Fuel Injector (No.1)

C 8 Fuel Injector (No.3)

C 9 Fuel Injector (No.2)

C10 Fuel Injector (No.4)

C11 Ignition Coil (No.1)

C12 Ignition Coil (No.3)

C13 Ignition Coil (No.2)

C14 Ignition Coil (No.4)

C15 Air Fuel Ratio Sensor (Bank 1 Sensor 1)

C16 Noise Filter (Ignition RH)

C17 Power Steering Oil Pressure SW

C18 Generator

C19 Generator

54

CAMRY (EM0250U)

[2AZ–FE]

6

5

7

9

8

4

G

Position of Parts in Engine Compartment

C32C20 C21 C22 C33

C23 D1C31C30

C2

C2

C2

C2

C2

C2

C20 Crankshaft Position Sensor

C21 A/C Compressor

C22 Heated Oxygen Sensor (Bank 1 Sensor 2)

C23 Engine Oil Pressure SW

C24 Engine Control Module

C25 Electronically Controlled Transmission Solenoid

C26 Transmission Revolution Sensor (Turbine)

C27 Transmission Revolution Sensor (Counter Gear)

C28 Back–Up Lamp SW

C29 Starter

C30 Knock Control Sensor (Bank 1)

C31 Camshaft Position Sensor

C32 Camshaft Timing Oil Control Valve

C33 Intake Air Control Valve

D 1 Starter

CAMRY (EM0250U)

55

G ELECTRICAL WIRING ROUTING

(*1)

(*1)

Position of Parts in Instrument Panel

E5

E8

E9

E13

E3

E1E6E7 E15

E12E14 E11 E24 E23 E25 E10

E27

E 1 Diode (Door Courtesy Rear LH)

E 2 Diode (Door Courtesy Rear RH)

E 3 Outer Mirror SW

E 5 Diode (Door Courtesy Front LH)

E 6 Main Body ECU

E 7 Main Body ECU

E 8 Main Body ECU

E 9 Main Body ECU

E10 Data Link Connector 3

E11 Automatic Light Control Sensor

E12 Ion Generator

E13 VSC Warning Buzzer

E14 Turn Signal Flasher

E15 Transponder Key ECU

E16 Airbag Squib (Steering Wheel Pad)

E20E18E16E17E21E2 E22E19

* 1:w/o Smart Key System

E30 E32E29 E33 E31

E17 Steering Sensor

E18 Spiral Cable

E19 Windshield Wiper SW Assembly

E20 Windshield Wiper SW Assembly

E21 Headlamp Dimmer SW Assembly

E22 Unlock Warning SW

E23 Ignition SW

E24 Key Interlock Solenoid

E25 Transponder Key Amplifier

E27 A/C Room Temp. Sensor

E29 Power Outlet Socket (Front)

E30 Airbag Sensor Assembly Center

E31 Transmission Control SW

E32 Shift Lock Control ECU

E33 Parking Brake SW

56

CAMRY (EM0250U)

Position of Parts in Instrument Panel

(*2)

1

9

9

0

(*3)(*4)(*2)

G

E40 E50

* 2:w/ Smart Key System

* 3:TMC Made

* 4:TMMK Made

E43

E62E46 E63 E58

E44 E45 E38 E37 E41

E6

E5

E6

E3

E42

E52

E34 Yaw Rate Sensor

E35 Power Outlet Socket (Rear)

E37 Diode (Door Courtesy Front RH)

E38 A/C Amplifier

E39 Blower Motor

E40 Junction Connector

E41 Junction Connector

E42 Junction Connector

E43 Junction Connector

E44 Junction Connector

E45 Junction Connector

E46 Junction Connector

E48 Junction Connector

E49 Junction Connector

E50 ID Code Box

E49E48

E55

E56

E54E51

E57

E35E53

E65 E34

E51 Steering Lock ECU

E52 Power SW

E53 Tire Pressure Warning SW (Reset)

E54 Airbag Squib (Knee Airbag)

E55 Seat Heater SW

E56 Electrical Key Oscillator (Console)

E57 Shift Lock Control ECU

E58 Certification ECU

E59 Certification ECU

E60 Tire Pressure Warning ECU

E61 Option Connector (Bus Buffer)

E62 Junction Connector

E63 Junction Connector

E65 Yaw Rate Sensor

CAMRY (EM0250U)

57

G ELECTRICAL WIRING ROUTING

5

6

2

Position of Parts in Instrument Panel

(*5) (*6) (*5) (*6)

F21 F22

* 5:8 Speaker

* 6:6 Speaker

* 7:8 Speaker w/ Navigation System

* 8:8 Speaker w/o Navigation System

F2

F1

(*7)

(*8)

F6 F9

F8 F4F3 F11

F26

F14 F13 F5

F24

F23

F25

F1

F1

F1

F 1 Combination Meter

F 2 Combination Meter

F 3 Clock

F 4 Hazard Warning Signal SW

F 5 Glove Box Lamp

F 6 Radio Receiver Assembly

F 7 Radio Receiver Assembly

F 8 Radio Receiver Assembly

F 9 Navigation Receiver Assembly

F10 Navigation Receiver Assembly

F 11 Radio Receiver Assembly

F12 Navigation Receiver Assembly

F13 Navigation Receiver Assembly

F7 F17F10

F20 F18 F19

F14 Navigation Receiver Assembly

F15 Antenna Amplifier

F16 A/C Control Assembly

F17 Stereo Jack Adapter

F18 Stereo Component Amplifier

F19 Stereo Component Amplifier

F20 Stereo Component Amplifier

F21 Tweeter (Front LH)

F22 Tweeter (Front LH)

F23 Tweeter (Front RH)

F24 Tweeter (Front RH)

F25 Junction Connector

F26 Radio Receiver Assembly

58

CAMRY (EM0250U)

A58

A22

A21

A18

G

Position of Parts in Instrument Panel

c2c1b1a1

A17 Accelerator Position Sensor

A18 Parking Brake SW

A19 Stop Lamp SW

A21 Cruise Control Clutch SW

A22 Clutch Start SW

A40 Junction Connector

A41 Junction Connector

A42 Junction Connector

A56 Short Connector

A57 Short Connector

A58 Junction Connector

N 1 Airbag Sensor Assembly Center

N1A17A42A41A19 A56A57O1 e1 A40

O 1 Airbag Sensor Assembly Center

a 1 Spiral Cable

Steering Pad SW

b 1 Cruise Control SW

Spiral Cable

c 1 Airbag Squib (Front Passenger’s Airbag Assembly)

c 2 Airbag Squib (Front Passenger’s Airbag Assembly)

e 1 A/C Amplifier

A/C Blower Assembly

CAMRY (EM0250U)

59

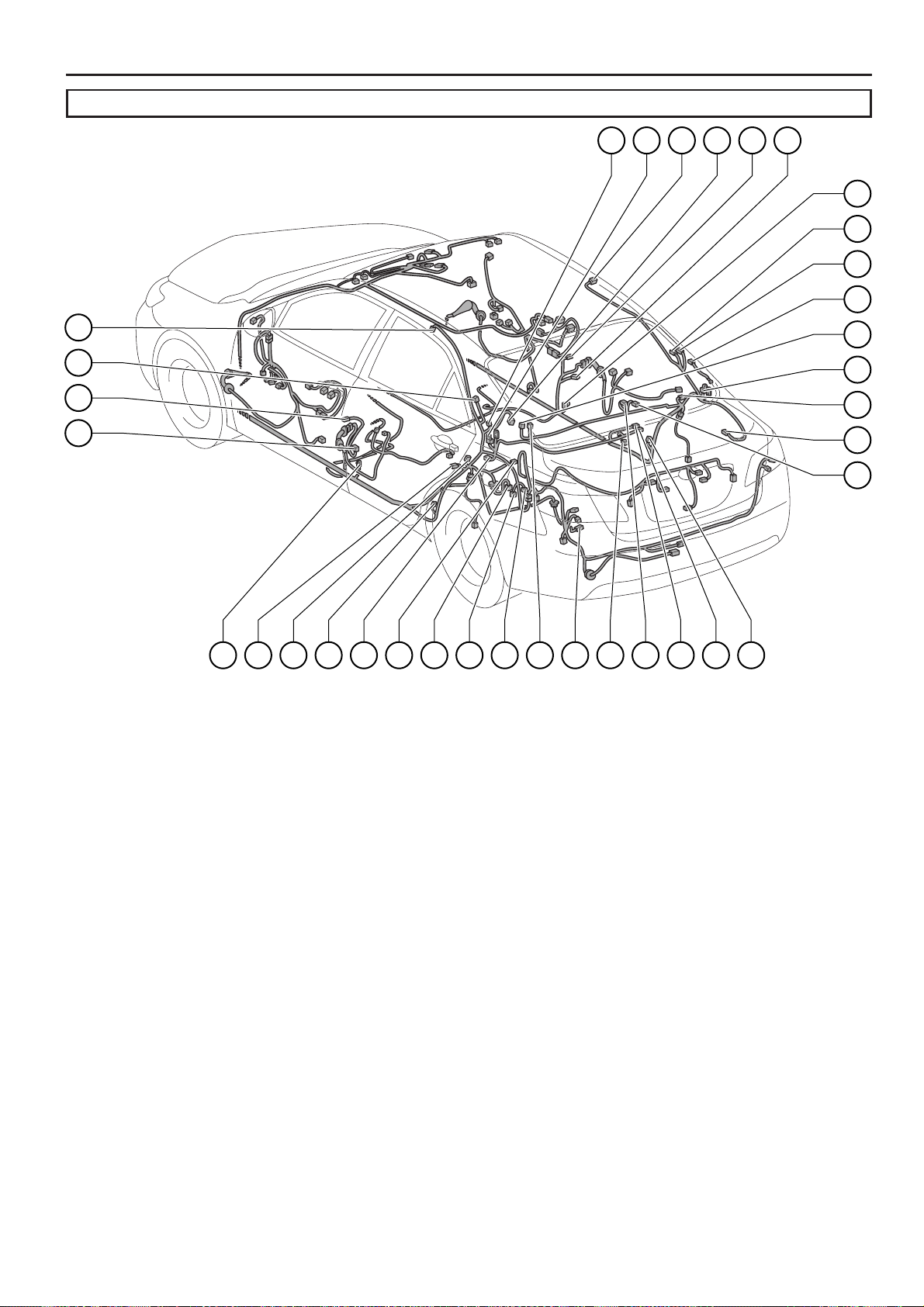

G ELECTRICAL WIRING ROUTING

2

7

8

1

0

9

3

Position of Parts in Body

N18 N29 O16 N19 O6 O7

O8

O1

O1

P1

N21

N34

N6

N7

N 6 Door Courtesy SW (Driver’s Side)

N 7 Side Airbag Sensor (Front LH)

N 8 Pretensioner (LH)

N10 Fuel Suction Pump and Gage Assembly

N11 Electrical Key Oscillator (Rear Seat)

N12 Side Airbag Sensor (Rear LH)

N13 Door Courtesy SW (Rear LH)

N15 Noise Filter (Dome and Stop)

N16 Center Stop Lamp

N17 Canister Pump Module

N18 Noise Filter (Rear Window Defogger)

N19 Rear Window Defogger

N21 Curtain Shield Airbag Squib (LH)

N23 Diode (Luggage Compartment Lamp)

N24 Luggage Compartment Lamp