3/97

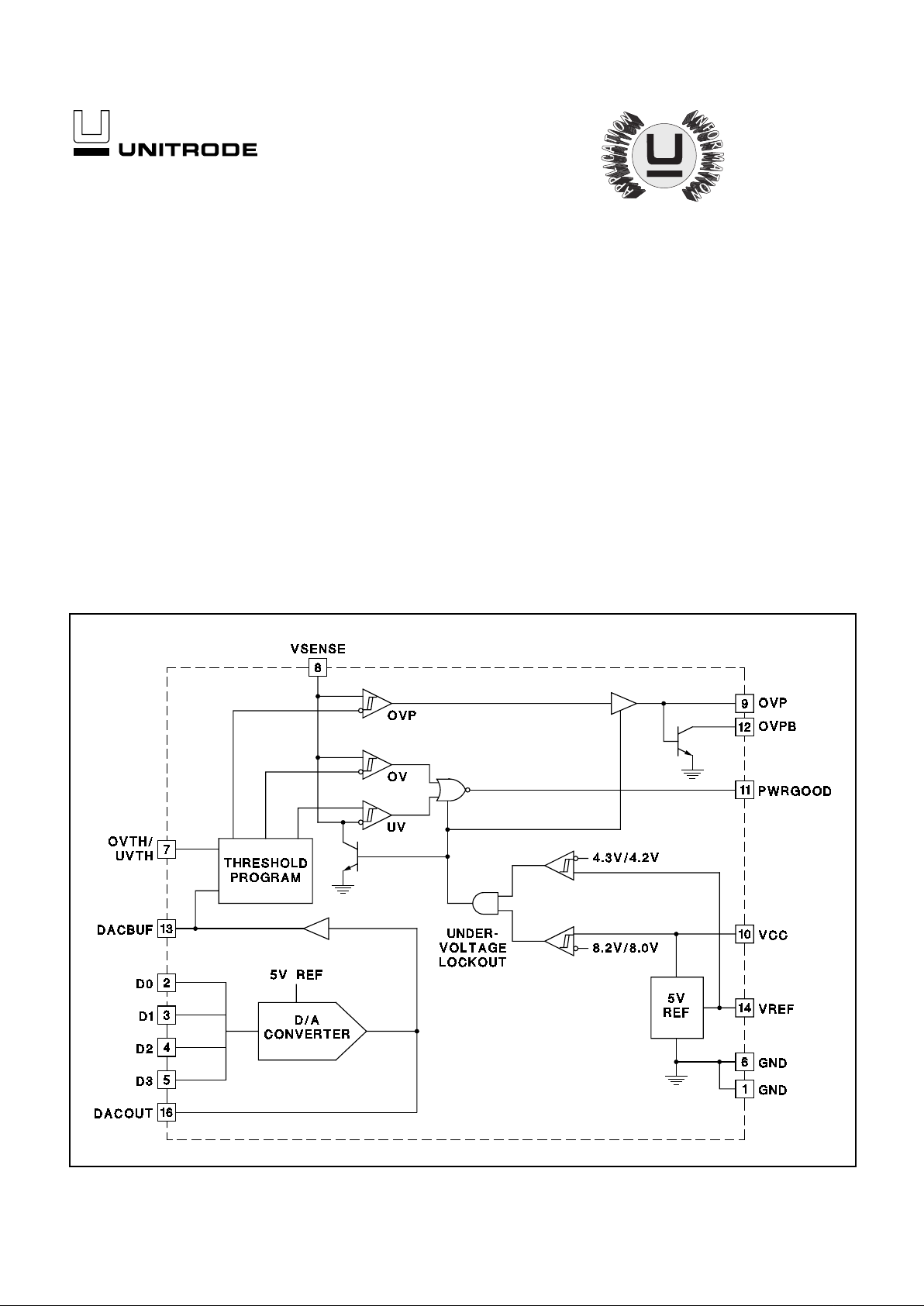

BLOCK DIAGRAM

• Precision 5V Reference

• 4-Bit Digital-to-Analog (DAC)

Converter

• 0.5% DAC/Reference Combined

Error

• Programmable Undervoltage and

Overvoltage Fault Windows

• Overvoltage Comparator with

Complementary SCR Driver and

Open Collector Outputs

• Undervoltage Lockout

The UC3910 is a com plete precision reference and voltage monitor circuit for Intel Pentium® Pro and other high-end microprocessor power

supplies. It is designed for use in conjunction with the UC3886 PWM. The

UC3910 together with the UC3886 converts 5VDC to an adjustable output ranging fr o m 2. 0V D C to 3 .5 V DC i n 10 0mV steps with 1% DC sy stem

accuracy.

The UC3910 utilizes thin film resistors to ensure high accuracy and stability of its precision circuits. The chip includes a precision 5V voltage reference which is capable of sourcing 10mA to external circuitry. The

output voltage of th e DAC is derived from this reference, and the accuracy of the DAC/reference combination is 0.5%. Programmable window

comparators monitor the supply voltage to indicate that it is within acceptable limits. The window is programmed as a percentage centered

around the DAC output. An overvoltage protection comparator is set at a

percentage 2 times large r than the programmed lower overvoltage level

and drives an external SCR as well as provides an open collector output.

Undervoltage lockout protection assures the correct logic states at the

outputs during power-up and power-down.

4-Bit DAC and Voltage Monitor

FEATURES DESCRIPTION

UC1910

UC2910

UC3910

UDG-95097-3

UC1910

UC2910

UC3910

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Undervoltage Lockout

VIN UVLO Turn-on Threshold 7 8 9 V

UVLO Threshold Hysteresis 50 200 500 mV

Supply Current

I

IN

Startup VCC = 5V 2 3.5 mA

I

IN

VCC = 12V 10 12 mA

DAC/Reference

DACOUT Voltage Accuracy Line, Load, 0°C < T

A

< 70°C (Note 1)

−

0.9 0.9 %

Line, Load, –55°C < TA < 125°C –1.5 1.5 %

D0-D3 Voltage High D

X

Pin Floating 4.6 4.85 V

D0-D3 Input Bias Current D

X

Pin Tied to GND –140−105

µ

A

VREF Output Voltage I

VREF

= 0mA, 0°C < TA < 70°C 4.97 5 5.03 V

VREF Total Variation Line, Load, 0°C < TA < 70°C (Note 1) 4.96 5 5.04 V

Line, Load, –55°C < T

A

< 125°C 4.925 5 5.075 V

VREF Sourcing Current VREF = 0V 10 mA

DAC Buffer

Input Offset Voltage I

DACBUF

= –1mA, 0°C < TA < 70°C

−

25 25 mV

Output Sourcing Current –12 –1 mA

Monitor Circuitry (Note 2)

VSENSE UV Threshold Voltage Code 0, Ratio = 0.45 (Note 3) 3.174 3.237 3.3 V

Code 0, Ratio = 0.9 2.87 2.975 3.08 V

Code 15, Ratio = 0. 45 1.816 1.85 1.884 V

Code 15, Ratio = 0.9 1.635 1.7 1.765 V

VSENSE OV Threshold Voltage Code 0, Ratio = 0.45 3.7 3.763 3.826 V

Code 0, Ratio = 0.9 3.92 4.025 4.13 V

Code 15, Ratio = 0. 45 2.116 2.15 2.184 V

Code 15, Ratio = 0.9 1.635 2.3 2.365 V

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, VCC = 12V, VSENSE = 3.5V, V

OVTH/UVTH

= 1.26V,

VD0 = VD1 = VD2 = VD3 = 0V, 0°C < TA < 70°C for the UC3910, –25°C < TA < 80°C for the UC2910, –55°C < TA < 125°C for the

UC1910 TA = TJ.

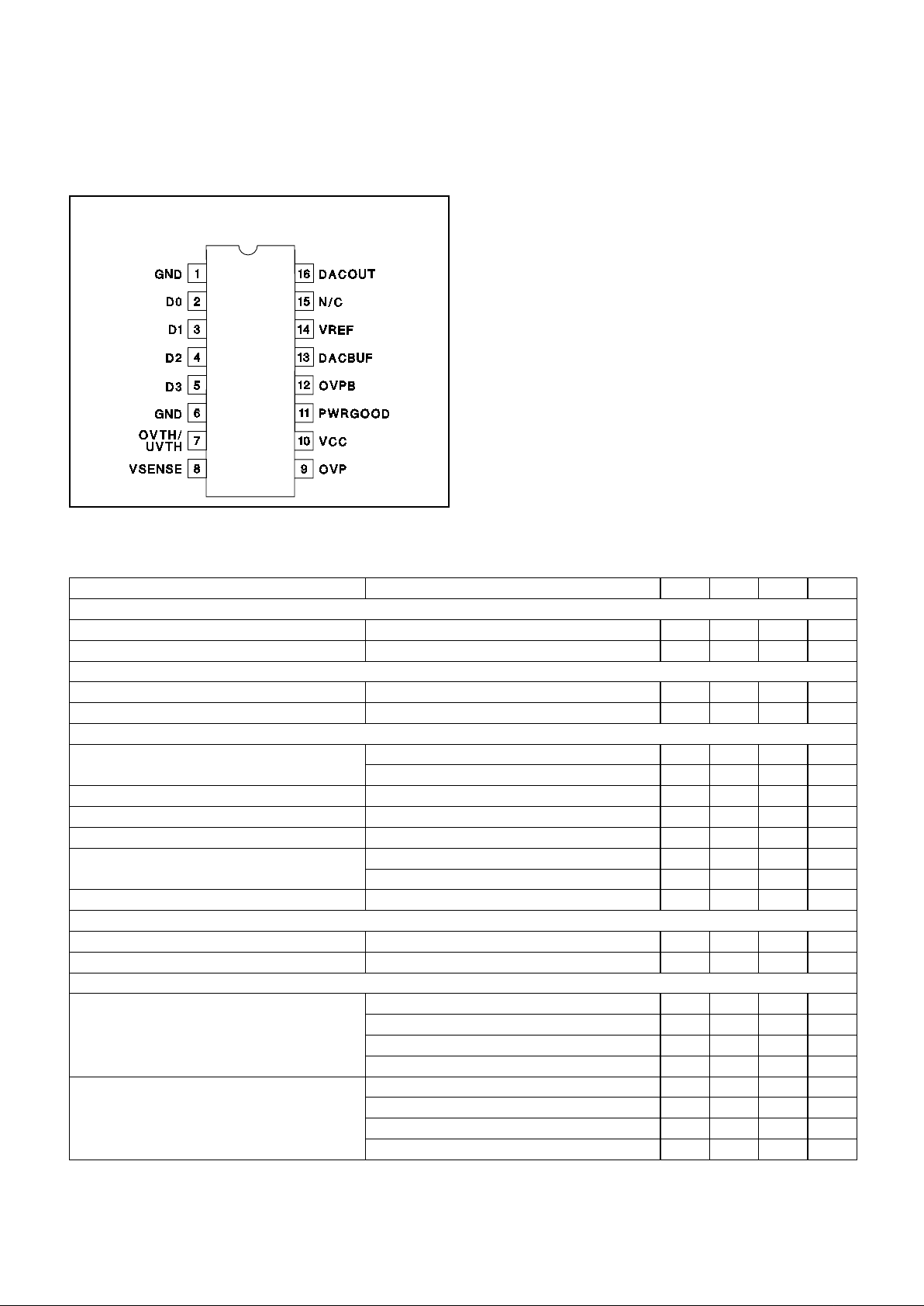

CONNECTION DIAGRAM

DIL-16, SOIC-16 (Top Vie w )

J, N, or D Packages

2

UC1910

UC2910

UC3910

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Monitor Circuitry (Note 2) (cont.)

VSENSE OVP Threshold Voltage Code 0, Ratio = 0.45 3.937 4.025 4.113 V

Code 0, Ratio = 0.9 4.41 4.55 4.69 V

Code 15, Ratio = 0.45 2.235 2.3 2.365 V

Code 15, Ratio = 0.9 2.505 2.6 2.695 V

OV, UV Comparator Hysteresis Code 0, Ratio = 0.9 70 88 120 mV

Code 15, Ratio = 0.45 15 25 40 mV

OVP Comparator Hysteresis Code 0, Ratio = 0.9 160 218 300 mV

Code 15, Ratio = 0.45 40 62 85 mV

Input Common Mode Range OV, UV, OVP Comparators 0 5 V

Propagation Delay OV, UV Comparators 5

µ

s

OVP Comparator 5

µ

s

PWRGOOD, OVP, OVPB Outputs

PWRGOOD Voltage Low I

PWRGOOD

= 10mA 0.4 V

OVP Sourcing Current V

OVP

= 1.4V 65 mA

OVPB Voltage Low I

OVPB

= 1mA 0.4 V

ELECTRICAL CHARACTERISTICS (cont.)

Unless otherwise specifie d, VCC = 12V, VSENSE = 3.5 V, V

OVTH/UVTH

=

1.26V, VD0 = VD1 = VD2 = VD3 = 0V, 0°C < TA < 70°C for the UC3910, –25°C < TA < 80°C for the UC2910, –55°C < TA < 125°C for

the UC1910 TA = TJ.

D0-D3 (DAC Digital Input Control Codes):

These are

the DAC digital input control codes, with D0 representing th e least sig nificant bit (LSB) and D3, the most

significan t bit (MSB) (See Table 1). A bit is set low by

being connec ted to GND; a bit is set high by floating it,

or connecting it to a 3V to 5V voltage source. Each control pin is pulled up to ap pr oximate ly 4. 8V by an internal

40µA current source.

DACBUF (Buffered DACOUT Voltage):

This pin provides a buffered version of the DACOUT voltage to allow external programming of the OV/UV thresholds (see

OVTH/UVTH below).

DACOUT (Digital-to-Analog Converter Output Voltage):

This pin is the out put of the 4-bit digital to analog

(DAC) converter. Setting all input control codes low produces 3.5V at DACOUT; setting all codes high produces 2.0V at DACOUT. The LSB step size (i.e.

resolution) is 100mV (See Table 1). The DACOUT

source impe dance is typically 3kΩ and must therefore

drive a high impedance input. Bypass DACOUT at the

driven input with a 0.01µF, low ESR, low ESL capacitor

for best circuit noise immunity.

GND (Sig nal Ground):

All voltages are measured with

respect to GND. The two GND pins are connected together internally but should also be connected externally using a short PC bo ard trace. Bypass capacitors

on the VCC and VREF pins should be connected directly to the gr ound plane near one of the signal ground

PIN DESCRIPTIONS

Note 1: "Line, Load" implies that the parameter is tested at all combinations of the conditions:

10.8V < VCC < 13.2V, –2mA < I

VREF

< 0mA.

Note 2: These are the actual voltages on VSENSE which will cause the OVPB and PWRGOOD outputs to swi tch, assuming the

DACOUT voltage is perfect. These limits apply for 0°C < TA < 70°C.

Note 3: "Code 0" means pins D0 - D4 are all low; "Cod e 15 " me ans they are all fl oa ti ng or high (See Table 1). "Ratio" is the divider

ratio of the resistor string between DACBUF and OVTH/UVTH (See Figure 1).

Decimal

Code

D3 D2 D1 D0 DACOUT

Voltage

1511112.0

1411102.1

1311012.2

1211002.3

1110112.4

1010102.5

910012.6

810002.7

701112.8

601102.9

501013.0

401003.1

300113.2

200103.3

100013.4

000003.5

T ab le 1. Programming the DACOUT Voltage

3

pins.

OVP (Overvoltage Comparator Output):

This output

pin drives an external SCR circuit with up to 65mA

when the voltage on VSENSE rises above its nominal

value by a percentage set by the voltage on the

OVTH/UVTH pin (see below). The OVP comparator hysteresis is a function of both the DACBUF voltage and

the OV/UV percentage programmed.

OVPB (Overvoltage Comparator Complementary

Output):

This output is a complement to th e OVP output (see above) and provides an open collector capable

of sinking 1mA when the voltage on VSENSE rises

above its nominal value by a percentage set by the voltage on the OVTH/UVTH pin (see below).

OVTH/UVTH (Undervoltage and Lower Overvoltage

Threshold Input):

This pin is us ed to program the window thresholds for the OV and UV comparators. The

OV- U V wi nd ow is c e nt ered ar ound the DACBUF voltage

and can be programmed from ±5% to ±15% about

DACBUF. Connect a resistor divider between DACBUF

and GND to set the percentage. The threshold for the

OVP comparator is internally set to a percentage 2

times larger than the programmed OV percentage;

therefore, its range extends from 10% to 30% above

DACBUF.

PWRGOOD (Undervoltage/Lower Overvoltage Out-

put):

This pin is an open collector output which is

driven low to rese t the microprocessor when VSENSE

rises above or falls below its nominal value by a percentage pro grammed by OVTH/UVTH. The OV and UV

comparators’ hysteresis is a function of the DACBUF

voltage and the OV/UV programmed percentage.

VCC (Positive Supply Voltage):

This pin supplies

power to the chip. Connect VCC to a stable voltage

source of at least 9V and ca pable of sourcing at least

15mA. The OVP and PWRGOOD outputs are held low,

the OVPB output is in a high impedance state, and the

VSENSE pin is pulled low until VCC exceeds the upper

undervolta ge lockout threshold. This pin should be bypassed direc tly to the GND pin with a 0.1µF low ESR,

low ESL capacitor.

VREF (Voltage Reference Output):

This pin provides

an accurate 5V reference, capable of delivering up to

10mA to exter nal cir cuitr y, and is internally shor t circuit

current limited. For best reference stability, bypass

VREF directly to the GND pin with a 0.1µF, low ESR,

low ESL capacitor.

VSENSE (Output Voltage Sensing Input):

This pin is

the input to the OVP and PWRGOOD comparators and

is connected to the system output voltage through a

lowpass filter. When choosing the resistor value for this

filter, make sure that no more than 500µA will flow

PIN DESCRIPTIONS (cont.)

UC1910

UC2910

UC3910

APPLICATION INFORMATION

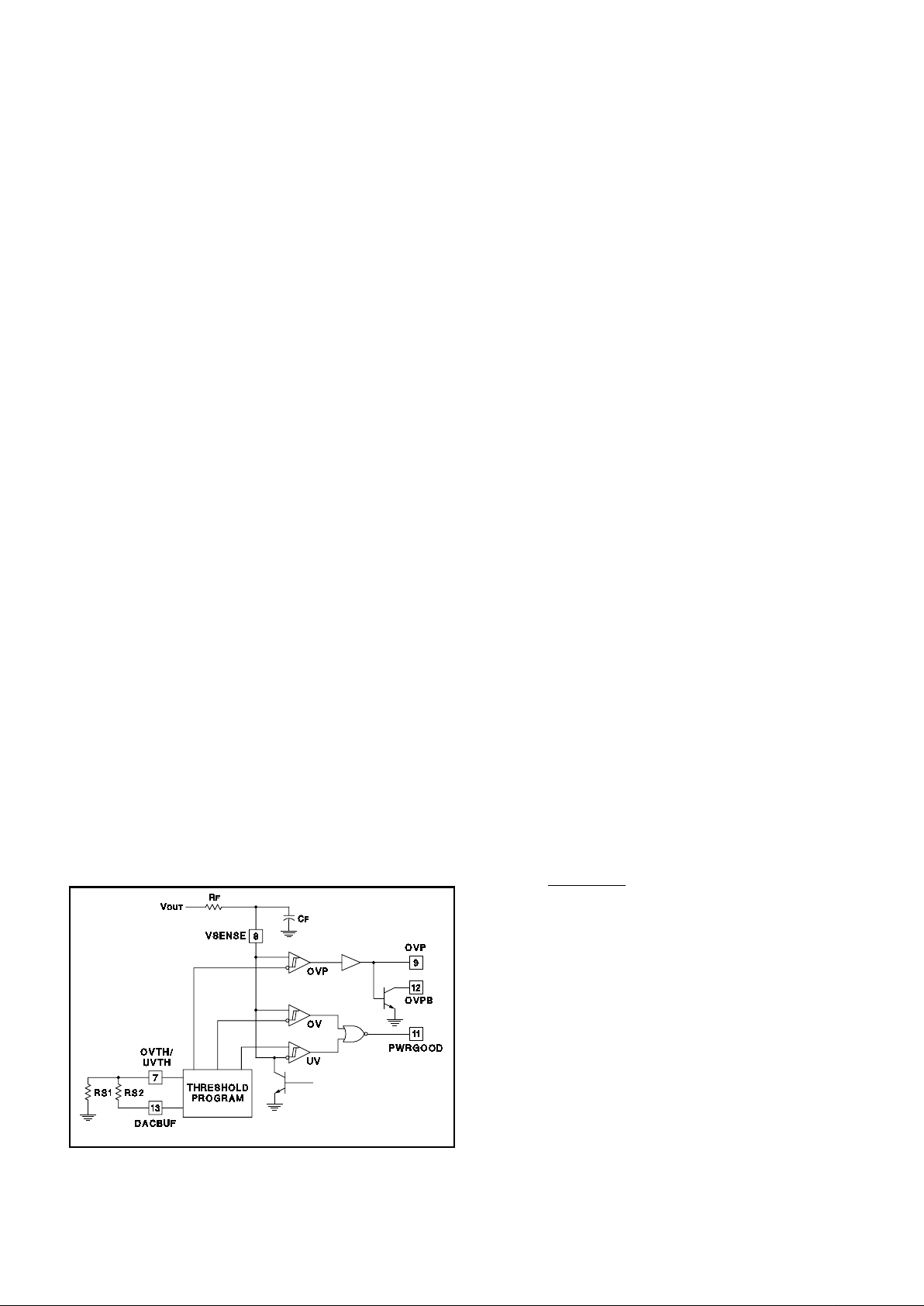

The Overvoltage ( OV), Undervoltage (UV) and Overvoltage Protection Voltage (OVP) threshold detection voltages are programmed as a percentage about the

nominal DAC output voltage, DACOUT. Figure 1 illus-

trates how to program the UC3910 by setting a voltage

divider, R

DIV

, at the OVTH/UVTH pin. The voltage di-

vider ratio is defined as

R

DIV

=

RS1

RS1 + RS2

The UC3910 a llows a ratio R

DIV

at the OVTH/UVTH pin

from 0.3 to 0.9, which cor responds to overvoltage and

undervoltage percentage thresholds from 5% to 15%

and an OVP percentage threshold from 10% to 30%.

These thresholds are shown in Figure 2.

The OV, UV and OVP percentage thresholds are given

by

%V

OV

= R

DIV

• 16.7

%V

UV

= –(R

DIV

• 16.7)

%V

OVP

= %VOV • 2.0 = R

DIV

• 33.4

An R-C filter is added to the VSENSE pin to filter noise

and ripple at the comparator inputs. An R-C filter frequency of F

SWITCH

/10 is recommended. Choose the

Figure 1. Setting the OV/UV/O VP Threshold

Percentages

UDG-96020

4

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

value of RF such that it limits the current into VSENSE

to ≤ 0.5mA.

R

F

• CF =

1

2

• π •

F

SWITCH

10

R

F

≥

V

OUT

0.5mA

The Overvoltage Protection output, OVP, can be used

to directly dr i ve a crowba rr ing S CR, as s hown i n Figure

3.

A typical application is shown in Figure 4 using the

UC3910 together with the UC3886 Average Current

Mode PWM Co nt roller IC for a power supply to drive Intel’s Pentium®Pro processor.

-15

-10

-5

0

5

10

15

20

25

30

0.3 0.4 0.5 0.6 0.7 0.8 0.9

Ratio R

DIV

Thresholds (%)

UV

OV

OVP

Figure 2. OV, UV and O VP Percentage Thresholds as a

Function of the Divider Ratio R

DIV

UC1910

UC2910

UC3910

Figure 3. Driving and SCR Using the UC3910 OVP

Signal

Figure 4. UC3910 Configured with the UC3886 for a Pentium® Pro DC/DC Co nverter

APPLICATION INFORMATION (cont.)

UDG-96021

UDG-96019

5

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...