Page 1

Slush Freezer

Model C903

Operating Instructions

057072--M

6/10/04

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

EApril, 2004 Taylor

All rights reserved.

057072--M

Tayl o r

The word T aylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Air Cooled Units 1.......................................................

Water Connections 1....................................................

Electrical Connections 1.................................................

Section 2 To the Operator 2...........................................

Compressor Warranty Disclaimer 2.......................................

Section 3 Safety 3....................................................

Section 4 Operator Parts Identification 4...............................

Beater Bowl Assembly 5.................................................

Mix Cabinet Assembly - Standard 6.......................................

Mix Cabinet Assembly - KanPak 7........................................

Mix Cabinet Assembly - Optional 8........................................

Peristaltic Pump Tube Replacement 9.....................................

Accessories 10..........................................................

Section 5 Important: To the Operator 11.................................

Power Switch 11.........................................................

Viscosity Adjustment 11...................................................

Display 12..............................................................

Keypad 12..............................................................

Flavor Lights 12.........................................................

Audio Alarm 12..........................................................

Passcodes 12...........................................................

Power Up Initialization Screens 12.........................................

Operator Menus 13......................................................

Bowl Modes 29..........................................................

Cleaning Lockout 31.....................................................

Section 6 Operating Procedures 34.....................................

Assembly 34............................................................

Sanitizing 36............................................................

Installing the Mix Tanks ( Non Bag-In-Box Product Only) 39....................

Installing the Syrup Bag-in-Box (B.I.B. Product Only) 40......................

Ratio Products (Products Requiring Water Added) 42.........................

Priming 43..............................................................

Table of Contents Model C903

Page 4

Table of Contents - Page 2

Cleaning Procedure 43...................................................

Rinsing 43..............................................................

Disassembly 46..........................................................

Brush Cleaning 47.......................................................

Daily Opening and Closing Procedures 49..................................

Section 7 Important: Operator Checklist 50..............................

During Cleaning and Sanitizing 50.........................................

Troubleshooting Bacterial Count: 50........................................

Regular M a intenance Checks: 50..........................................

Shipping / Winter Storage 50..............................................

Section 8 Troubleshooting Guide 51....................................

Section 9 Parts Replacement Schedule 52...............................

Section 10 Parts List 53.................................................

Wiring Diagrams 64......................................................

Note: Contin u ing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Model C903 Table of Contents

Page 5

Section 1 To the Installer

This machine is designed for indoor use only.

DO NOT installthemachineinanarea

where a water jet could be used. Failure to follow

this instruction may result in serious electrical shock.

Air Cooled Units

Air cooled units require a minimum air clearance of

3” (76 mm) in the back and 12” (305 mm) on the top.

This is required to allow for adequate air flow across

the condensers. Failure to allow adequate clearance

can reduce the refrigeration capacity of the freezer

and possibly cause permanent damage to the

compressor.

Water Connections

An adequate cold water supply must be provided

with a hand shut-off valve. On the back of the unit, a

1/4” male flare water connection has been provided

for easy hook-up. A flexible line is recommended, if

local codes permit. A minimum of 25 psi water

pressure is required to avoid a low water pressure

alarm. A booster pump must be provided if this

pressure is not available. It is always a good practice

to have a filter system to improve the quality of the

water and to avoid clogging the operating

components.

Note: Water lines beyond 200 ft. (61 m) require 1/2”

(13 mm) water lines.

INSTALL POTABLE WATER CONNECTION

WITH ADEQUATE BACK-FLOW

PROTECTION TO COMPLY WITH

APPLICABLE NATIONAL, STATE AND

LOCAL CODES.

Electrical Connections

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED. FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK.

This unit must be plugged into a properly grounded

receptacle. A dedicated circuit is recommended,

sized for 15A usage. The standard voltage specification is 115V-60-1, however other electrical specifications may be available. Follow the specifications

listed on your data label.

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Stationary appliances which are not equipped with a

power cord and a plug or other device to disconnect

the appliance from the power source must have an

all-pole disconnecting device with a contact gap of at

least 3 mm installed in the external installation.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

050902

Model C903 To the Installer

1

Page 6

Section 2 To the Operator

The freezer you have purchased has been carefully

engineered and manufactured to give you

dependable operation. The Taylor Model C903,

when properly operated and cared for, will produce a

consistent quality product. Like all mechanical

products, they will require cleaning and

maintenance. A minimum amount of care and

attention is necessary if the operating procedures

outlined in this manual are followed closely.

This Operator’s Manual should be read before

operating or performing any maintenance on your

equipment.

Your Taylor freezer will NOT eventually compensate

for and correct any errors during the set-up or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that personnel responsible for the

equipment’s operation, both assembly and

disassembly, sit down together and go through

these procedures in order to be properly trained and

to make sure that no misunderstandings exist.

In the event you should require technical assistance,

please contact your local authorized Taylor

Distributor.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste.

The user is responsible for returning the product to

the appropriate collection facility, as specified by

your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty

card accompanying this machine. However, due to

the Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed, thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should

be noted that, in the event of ordinary service to this

machine’s refrigeration system, only the refrigerant

specified on the affixed data label should be

used. The unauthorized use of alternate refrigerants

will void your compressor warranty. It will be the

owner’s responsibility to make this fact known to any

technician he employs.

It should also be noted that Taylor does not warrant

the refrigerant used in its equipment. For example, if

the refrigerant is lost during the course of ordinary

service to this machine, Taylor has no obligation to

either supply or provide its replacement either at

billable or unbillable terms. Taylor does have the

obligation to recommend a suitable replacement if

the original refrigerant is banned, obsoleted, or no

longer available during the five year warranty of the

compressor.

Taylor will continue to monitor the industry and test

new alternates as they are being developed. Should

a new alternate prove, through our testing, that it

would be accepted as a drop-in replacement, then

the above disclaimer would become null and void.

To find out the current status of an alternate

refrigerant as it relates to your compressor warranty,

call the local Taylor Distributor or the Taylor Factory.

Be prepared to provide the Model/Serial Number of

the unit in question.

070124

2

Model C903To the Operator

Page 7

Section 3 Safety

We at Taylor are concerned about the safety of the

operator when he or she comes in contact with the

freezer and its parts. Taylor has gone to extreme

efforts to design and manufacture built-in safety

features to protect both you and the service

technician. As an example, warning labels have

been attached to the freezer to further point out

safety precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury. Failure to comply with

these warnings may damage the machine and

its components. Component damage will result

in part replacement expense and service repair

expense.

To Operate Safely:

DO NOT operate the freezer without reading

this operator’s manual. Failure to follow this

instruction may result in equipment damage, poor

freezer performance, health hazards, or personal

injury.

S DO NOT operate the freezer unless it is

properly grounded.

S DO NOT operate the freezer with larger

fuses than specified on the freezer data

label.

S DO NOT attempt any repairs unless the

main power supply to the freezer has been

disconnected.

Failure to follow these instructions may result in

electrocution or damage to the machine. Consult

your electrician.

DO NOT use a water jet to clean or rinse the

freezer. Failure to follow this instruction may result in

serious electrical shock.

This freezer must be placed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

S DO NOT allow untrained personnel to

operate this machine.

S DO NOT operate the freezer unless all

service panels and access doors are

restrained with screws.

Failure to follow these instructions may result in

contaminated product or personal injury from

hazardous moving parts.

S DO NOT put objects or fingers in the bowl

spout.

S USE EXTREME CAUTION when installing

the magnetic drive beater assembly.

Failure to follow these instructions may result in

contaminated product or personal injury from blade

contact.

IMPORTANT: Do not obstruct the air intake and

discharge openings. A minimum air clearance of 3”

(76 mm) in the back and 12” (305 mm) on the top is

required. Failure to follow this instruction may cause

poor freezer performance and damage to the

machine.

This freezer is designed to operate indoors, under

normal ambient temperatures of 70°-75°F

(21°-24°C). The freezer has successfully performed

in high ambient temperatures of 104°F (40°C) at

reduced capacities.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

The following statement applies to RFID units

only:

FCC ID: RPPTAYLORRFIDSYS

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received including interference that may cause

undesired operation.

070124

Model C903 Safety

3

Page 8

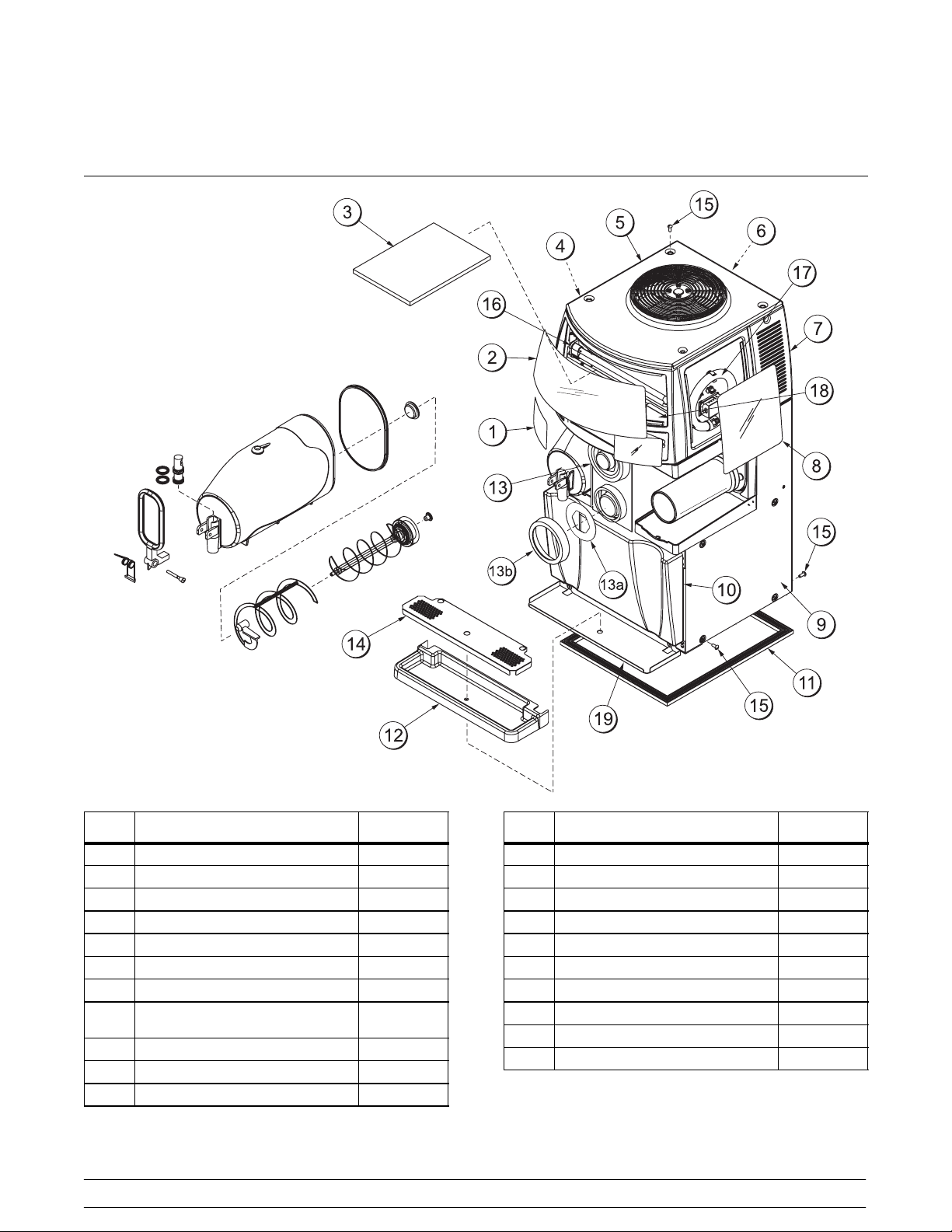

Section 4 Operator Parts Identification

ITEM DESCRIPTION PART NO.

*1 LENS-FLAVOR CARD (L & R) 057161

*2 LENS-DISPLAY-FRONT 057330

3 FILTER-AIR-17.00LX12.00HX.70 052779-8

4 PANEL-SIDE-LOWERLEFT 057052

5 HOOD 057050

6 PANEL-REAR 057054

7 PANEL-SIDE-UPPER 057049

*8 LENS-DISPLAY-LIGHTED-SIDE

(L & R)

9 PANEL-SIDE-LOWERRIGHT 057053

10 DOOR A.-CABINET X57081

11 GASKET-BASE PAN 057154

040802

057160

ITEM DESCRIPTION PART NO.

12 TRAY-DRIP 057051

13 DISPENSER-CUP-ADJUSTABLE 057144

13a KIT-GASKET-4 DISP CUP 057144-4

13b RING-TRIM-DISPENSERCUP 057144-3

14 SHIELD-SPLASH 057044

15 SCREW-10-24X 1/2 TRUSS HD 049189

16 BULB-FLUORESCENT U SHAPE 057157-12

17 BULB-FLUORSCENT CIRCL 054683-2

18 FILTER-AIR 057135

19 SHELF-DRIP TRAY 057307

*CONTACT YOUR PRODUCT SUPPLIER OR LOCAL

TAYLOR DISTRIBUTOR FOR MERCHANDISING

GRAPHICS.

4

Model C903Operator Parts Identification

Page 9

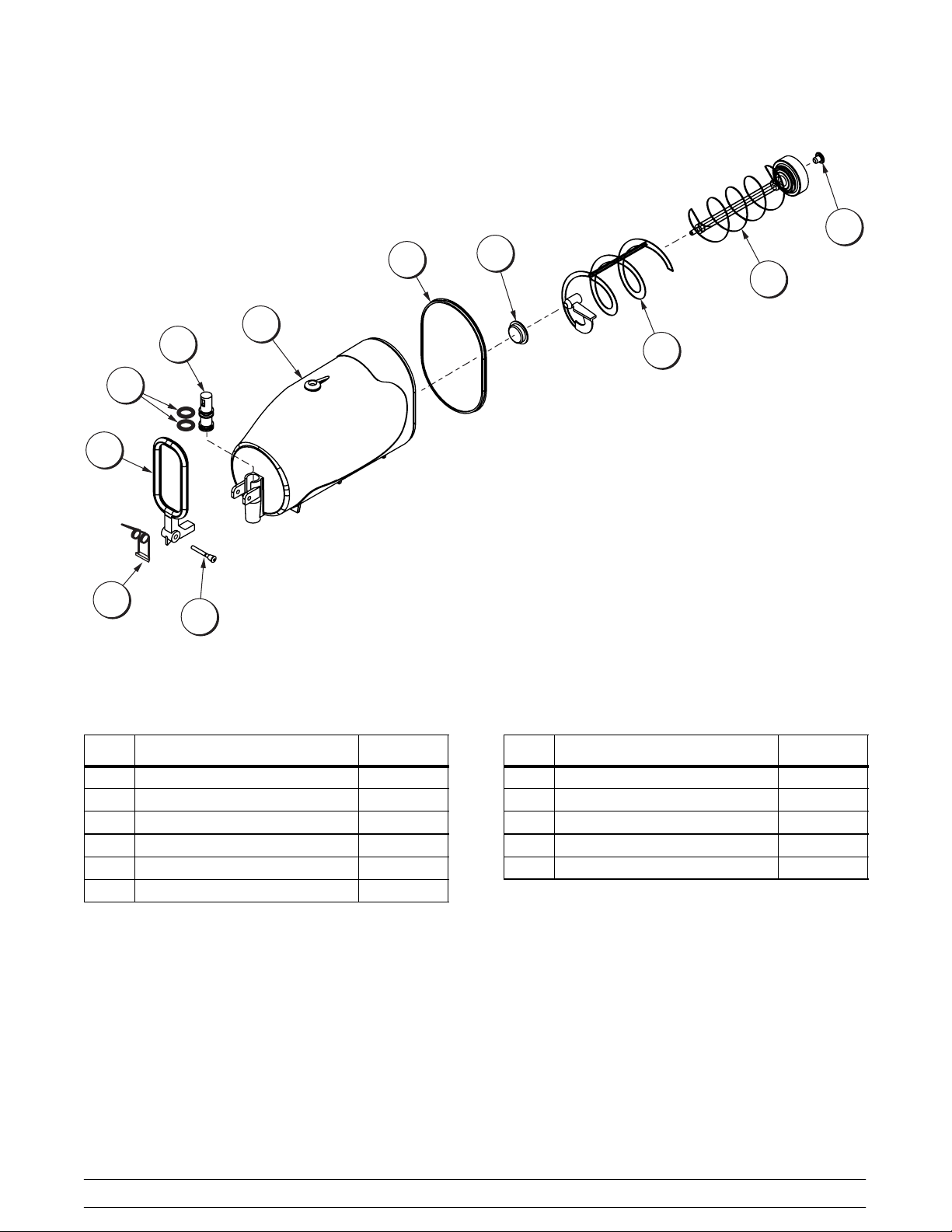

Beater Bowl Assembly

11

3

2

4

5

1

6

7

8

10

9

Figure 1

ITEM DESCRIPTION PART NO.

1 PIN-PIVOT 046461-1

2 SPRING-DRAW 046460

3 HANDLE-DRAW *BLACK 046459-1

4 O-RING *DRAW VALVE 046458

5 VALVE-DRAW 046457

6 BOWL-MIX 10 QT 057036

Model C903 Operator Parts Identification

ITEM DESCRIPTION PART NO.

7 GASKET-BOWL 057042

8 BEARING-FRONT 046462

9 BLADE-SCRAPER-OUTER 056754

10 BEATER-MAGNETIC 052204

11 BEARING-REARWALL-OUTER 052202

5

Page 10

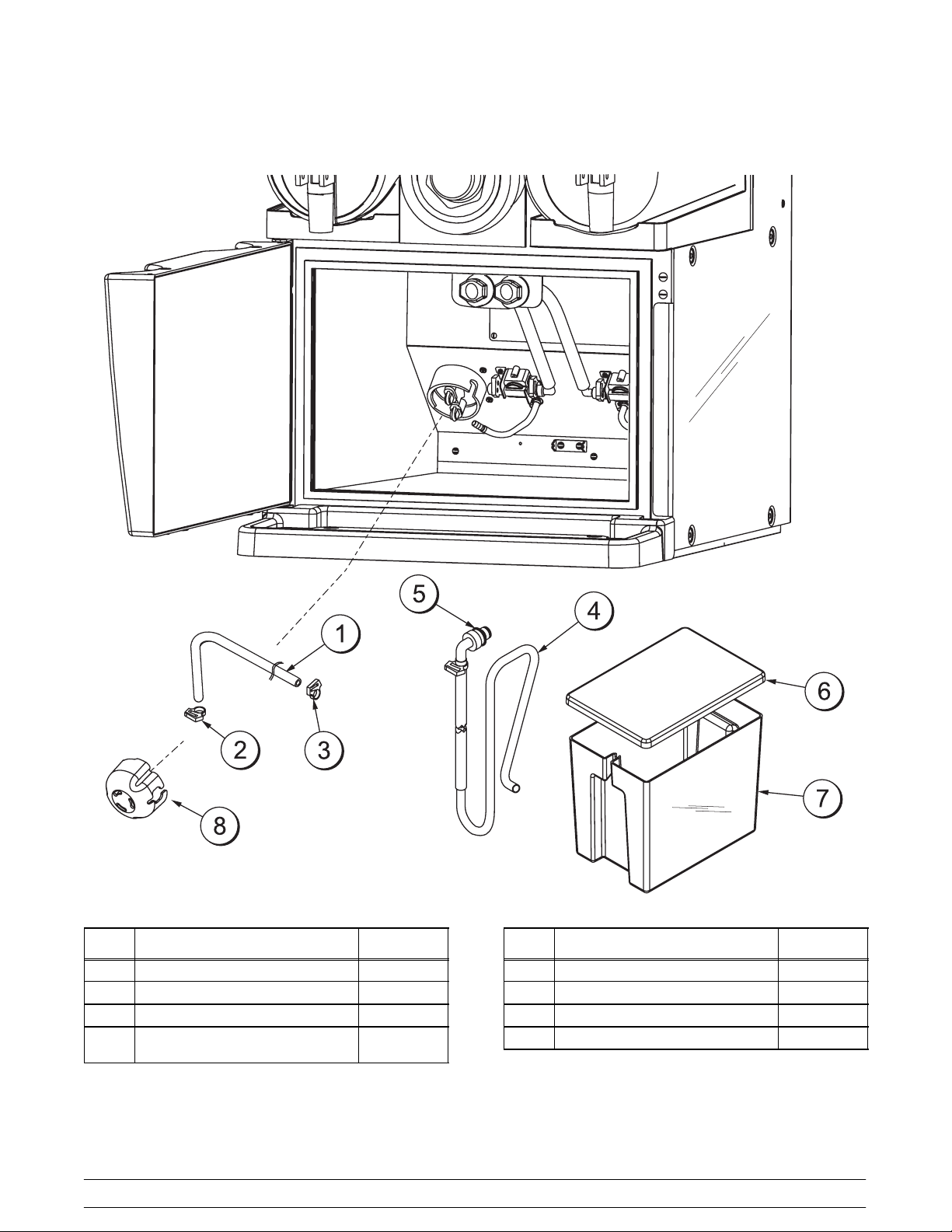

Mix Cabinet Assembly - Standard

ITEM DESCRIPTION PART NO.

1 TUBE-PERISTALTIC PUMP 057125

2 CLAMP-HOSE-SNAP IT 11/32 053630

3 CLAMP-HOSE-SNAP IT 17/32 052021

4 TUBE A. -PRODUCT-TANK

(MIX TANK)

X58433

Figure 2

6

ITEM DESCRIPTION PART NO.

5 O-RING - 3/8 021265

6 COVER-MIX TANK 057924

7 TANK-MIX 057923

8 COVER-PUMP 058832

Model C903Operator Parts Identification

Page 11

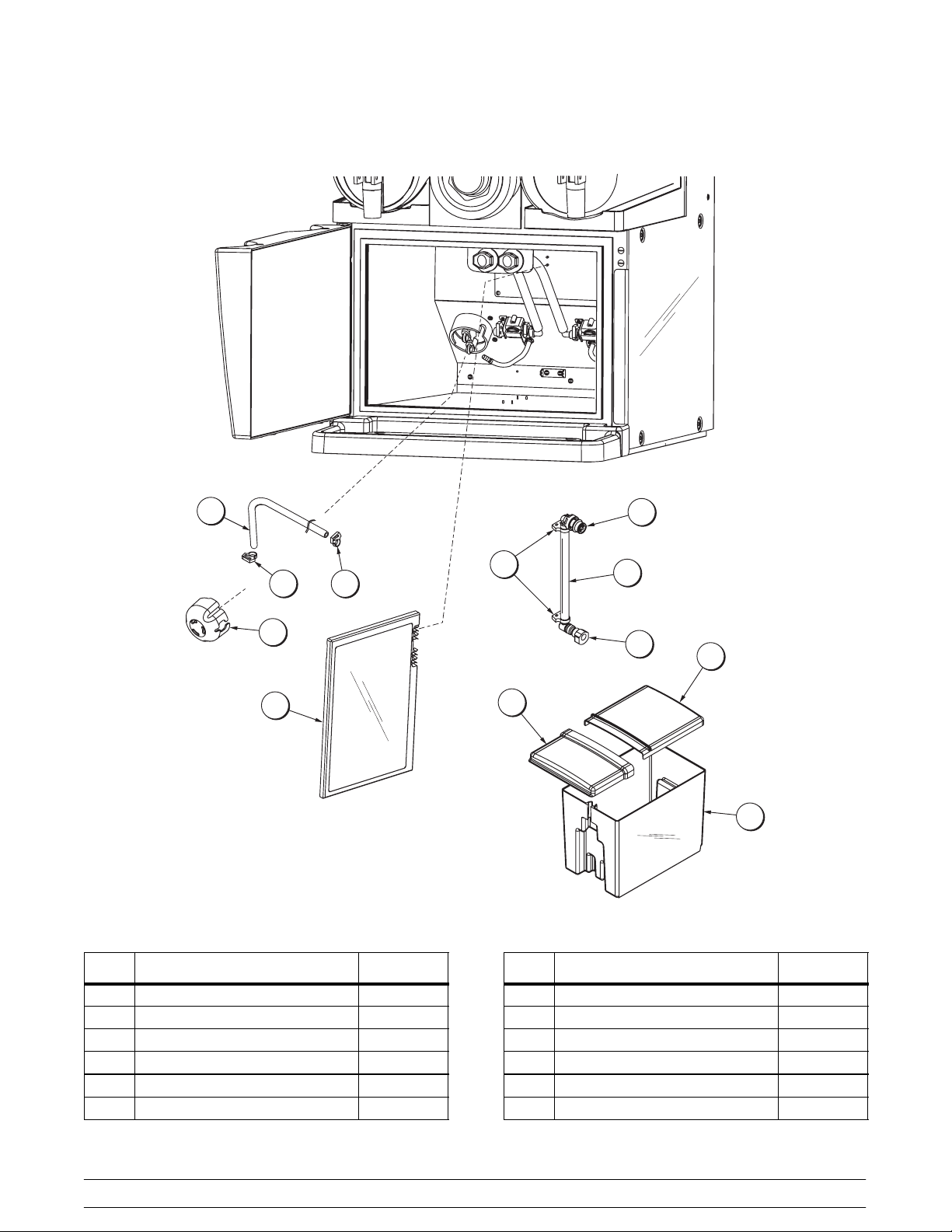

Mix Cabinet Assembly - KanPak

1

4c

2

3

9

8

6

4

4b

4a

5

7

Figure 3

ITEM DESCRIPTION PART NO.

1 TUBE-PERISTALTIC PUMP 057125

2 CLAMP-HOSE-SNAP IT 11/32 053630

3 CLAMP-HOSE-SNAP IT 17/32 052021

4 TUBE A. -PRODUCT (B.I.B.) X58141

4a FITTING-BIB-QD ELBOW 3/8 063103

4b FITTING-BIB-QD MALE 3/8 058143

Model C903 Operator Parts Identification

ITEM DESCRIPTION PART NO.

4c CLAMP-HOSE-SNAP IT 052021

5 COVER-REAR-MIX TANK 062021-R

6 COVER-FRONT-MIX TANK 062021-F

7 TANK-MIX 057923

8 ANTENNA ASSEMBLY 058291

9 COVER-PUMP 058832

060712

7

Page 12

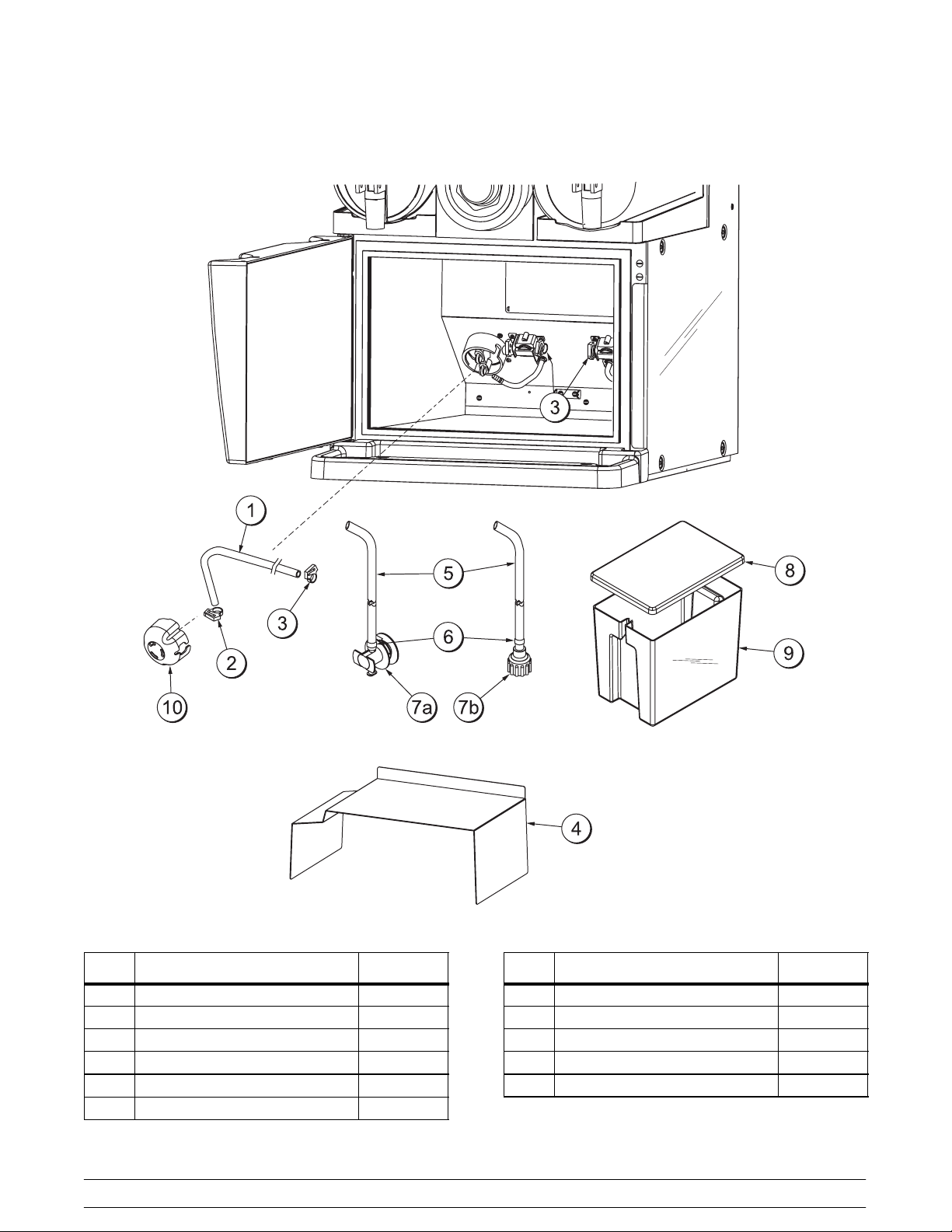

Mix Cabinet Assembly - Optional

ITEM DESCRIPTION PART NO.

1 TUBE-PERISTALTIC PUMP 057125

2 CLAMP-HOSE-SNAP IT 11/32 053630

3 CLAMP-HOSE-SNAP IT 17/32 052021

4 SHELF-CABINET 059188

5 TUBE-VINYL 3/8 ID X 9/16 OD 020943-28

6 CLAMP-HOSE 9/16 STEPLESS 053959

Figure 4

8

ITEM DESCRIPTION PART NO.

7a FITTING-BAG*BIB PEPSI 042945

7b FITTING-BAG *BIB COKE 048176

8 COVER-MIX TANK 057924

9 TANK-MIX 057923

10 COVER-PUMP 058832

Model C903Operator Parts Identification

Page 13

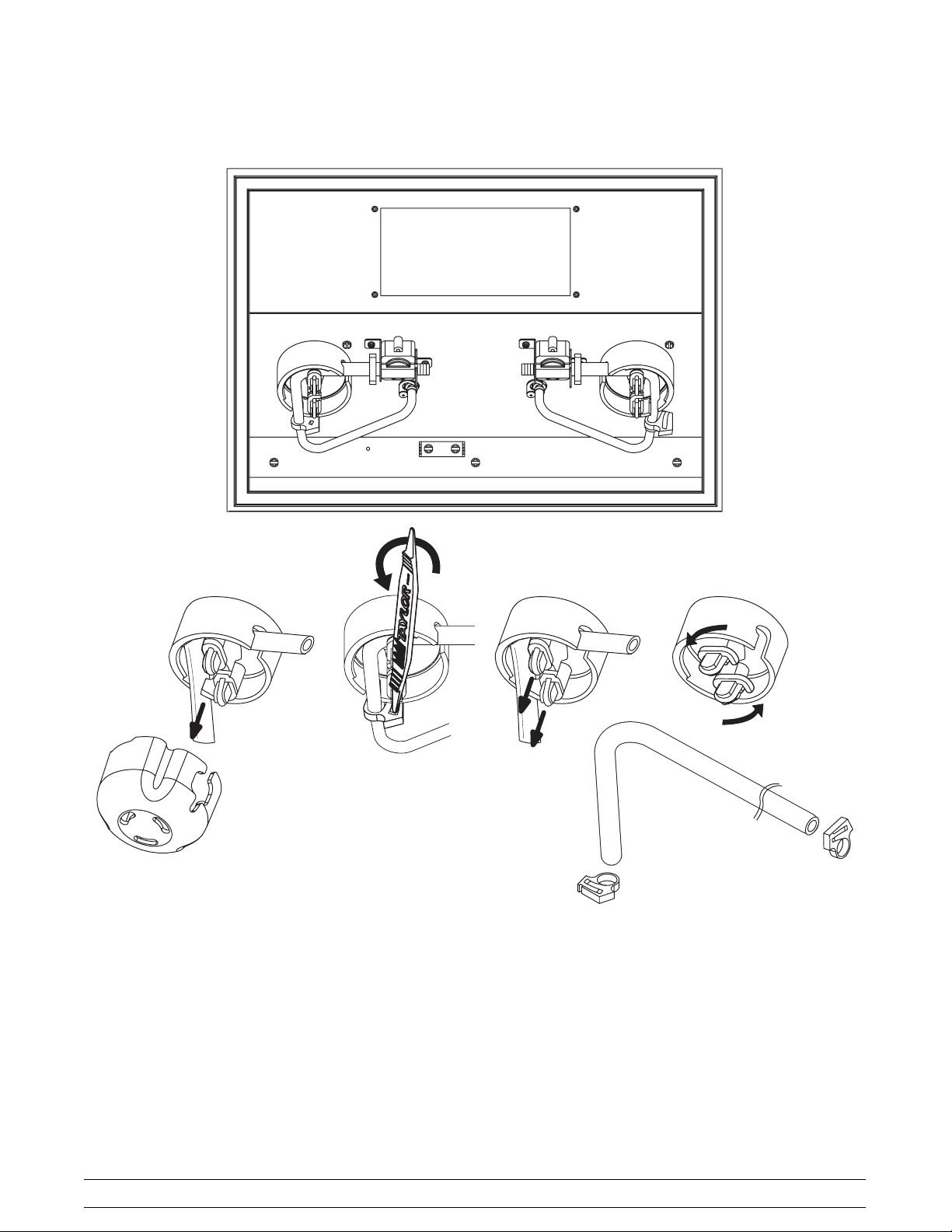

Peristaltic Pump Tube Replacement

Figure 5

Tube Replacement Procedure

1. Remove the black pump cover.

2. Twist open the hose clamps to disengage them

from the hose. (Note: The o-ring tool can be

used as an aid to remove the clamps.)

3. Pull the rounded tabs out all the way to

disengage them from the disk and then rotate

the tabs.

Model C903 Operator Parts Identification

4. Remove the tube.

5. Replace the tube and rotate the tabs back into

the locking position. Make sure the pins are

securely locked in the disk.

9

Page 14

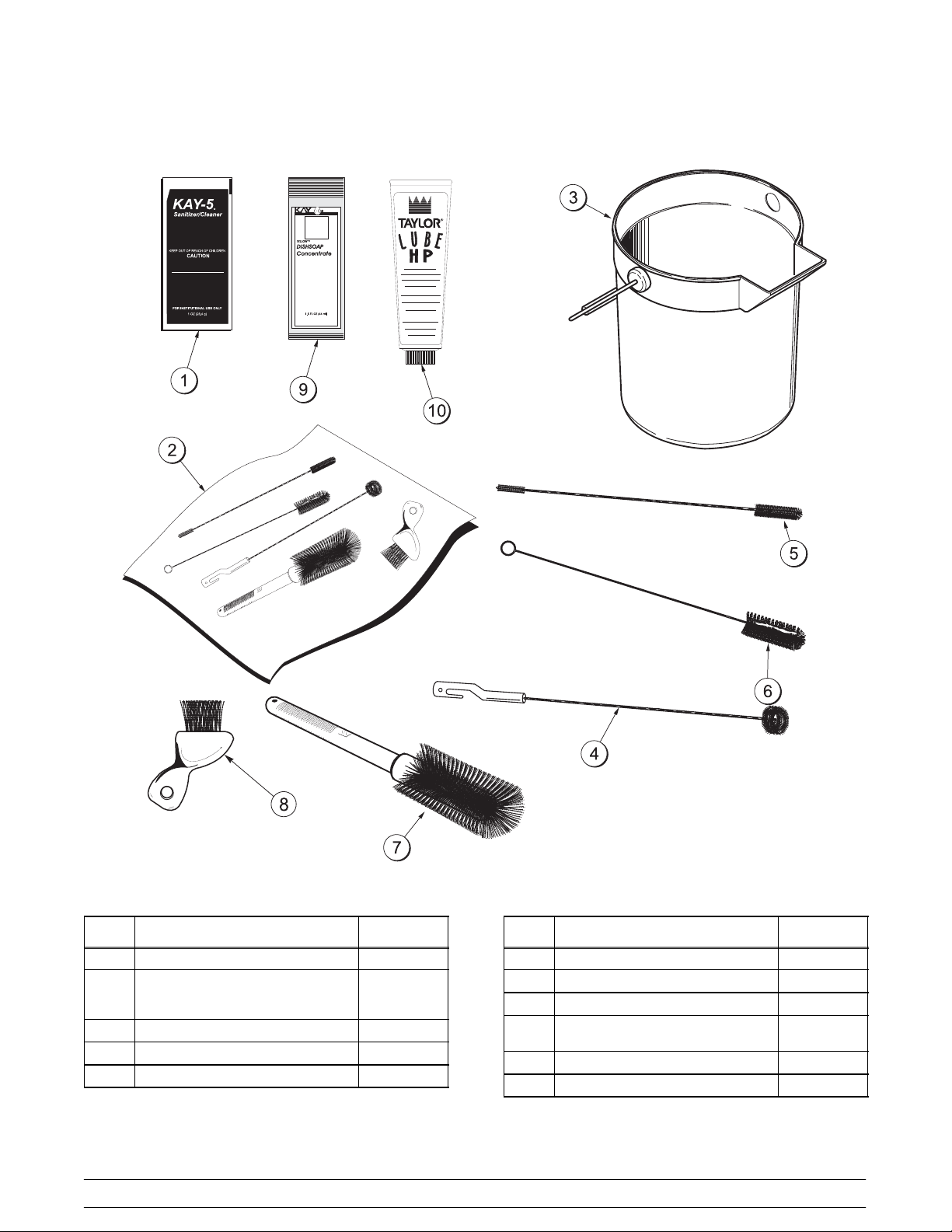

Accessories

ITEM DESCRIPTION PART NO.

1 SANITIZER KAY-5 125 PKTS 041082

2 BRUSH A.-PACKAGE

(CONSISTS OF BRUSH ITEMS

4-8)

3 PAIL-MIX 10 QT. 013163

4 BRUSH-BEATER & SHAFT 500313

5 BRUSH-DOUBLE ENDED 013072

040813

X58793

Figure 6

10

ITEM DESCRIPTION PART NO.

6 BRUSH-DRAW VALVE 1”ODX2” 013073

7 BRUSH-MIX PUMP BODY-3”X7” 023316

8 BRUSH-END-DOOR-SPOUT 039719

9 DETERGENT-YELLOW

DISHSOAP

10 LUBRICANT -TAYLOR HI PERF 048232

*11 TUNE-UP KIT X49463-69

*NOT SHOWN

059070

Model C903Operator Parts Identification

Page 15

Section 5 Important: To the Operator

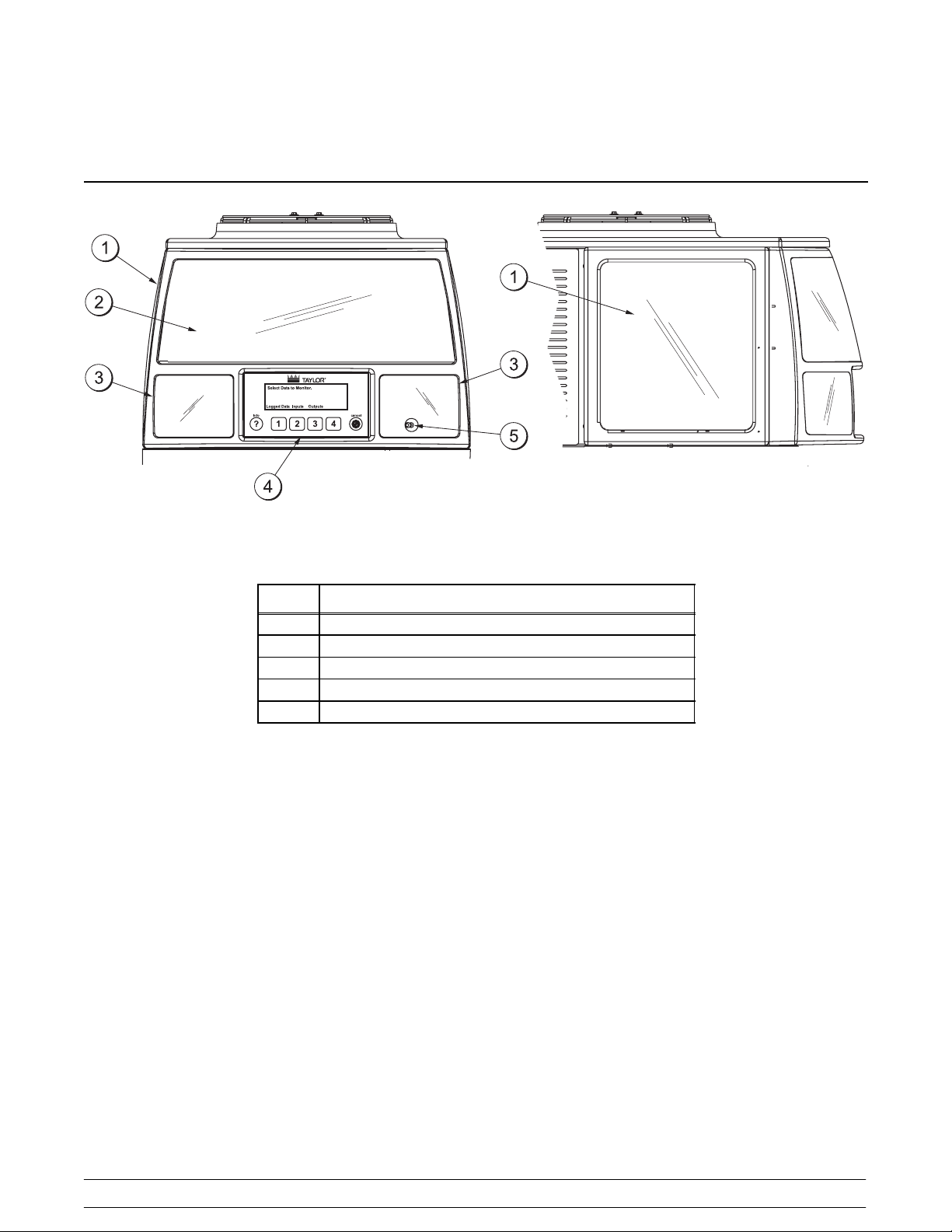

Figure 7

ITEM

1 LENS-SIDE

2 LENS-FRONT

3 CARD-FLAVOR

4 CONTROL PANEL

5 POWER SWITCH

Note: Contact your product supplier or local Taylor Distributor for merchandising graphics.

Power Switch

Remove the right side flavor card lens to place the

power switch in the ON position. (See item 5 above.)

When the power switch is placed in the ON position,

the large upper display and the side displays will

illuminate. The flavor card displays will illuminate

when the product is ready to serve. The flavor card

lights will flash if an alarm occurs (syrup out, low

water pressure, etc.).

DESCRIPTION

Viscosity Adjustment

Each bowl has a viscosity adjustment screw. The

left bowl adjustment screw is located on the left side

toward the back of the panel. The right bowl

adjustment screw is located on the right side toward

the back of the panel.

Turn the adjustment screw clockwise to obtain a

thicker product, and counterclockwise to obtain a

thinner product. Make the adjustments in 1/2 turn

increments to achieve proper viscosity.

Model C903 Important: To the Operator

11

Page 16

Display

Passcodes

The C903 display is an eight line by forty character

per line LCD (Liquid Crystal Display) with yellow

backlighting.

Keypad

The C903 keypad has six keys on a touch sensitive

glass panel. These keys are labeled, left to right:

info, 1, 2, 3, 4, and cancel.Theinfo key is used to

display menu related help text. Keys 1, 2, 3, and 4

are soft keys and their function is defined by the key

legends displayed above the keys on line 8 of the

LCD. The cancel key is used to exit or back out of

menus. The sensitivity or response of the keys can

be set in the Set Keypad Sensitivity menu. This

sensitivity can be set to quicken or slow the

response to touching the keys and to allow wipe

down of the display panel without false key

triggering.

If a key is pressed continuously, the key will

auto-repeat. If a key is held down for more than five

seconds, the auto-repeat rate will double.

The system will accept two levels of passcodes:

Operator (default 2133) and Manager (default 3312).

The different levels of passcodes provide different

levels of access to menus and menu items. The

Operator and Manager passcodes can be changed

in the Set Passcode menu.

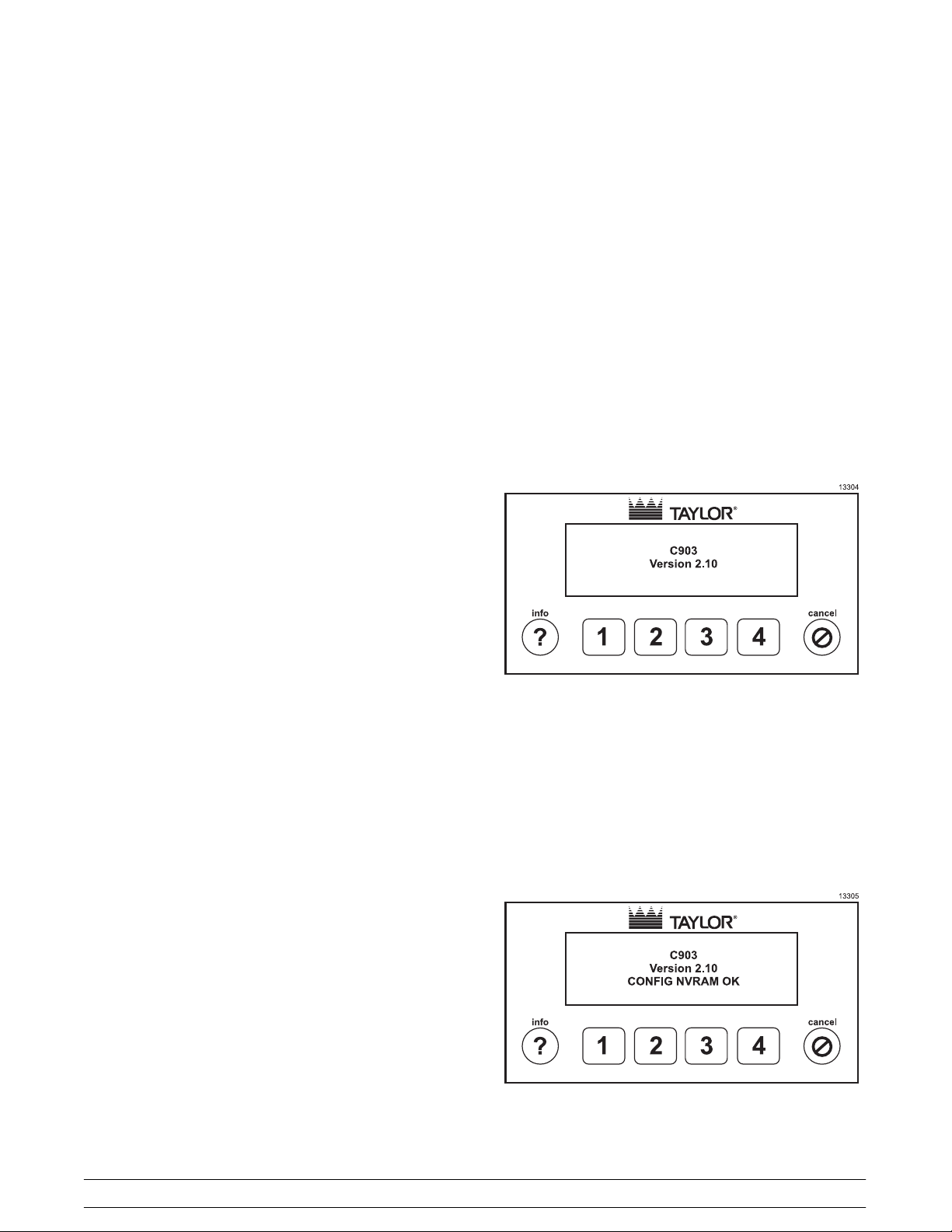

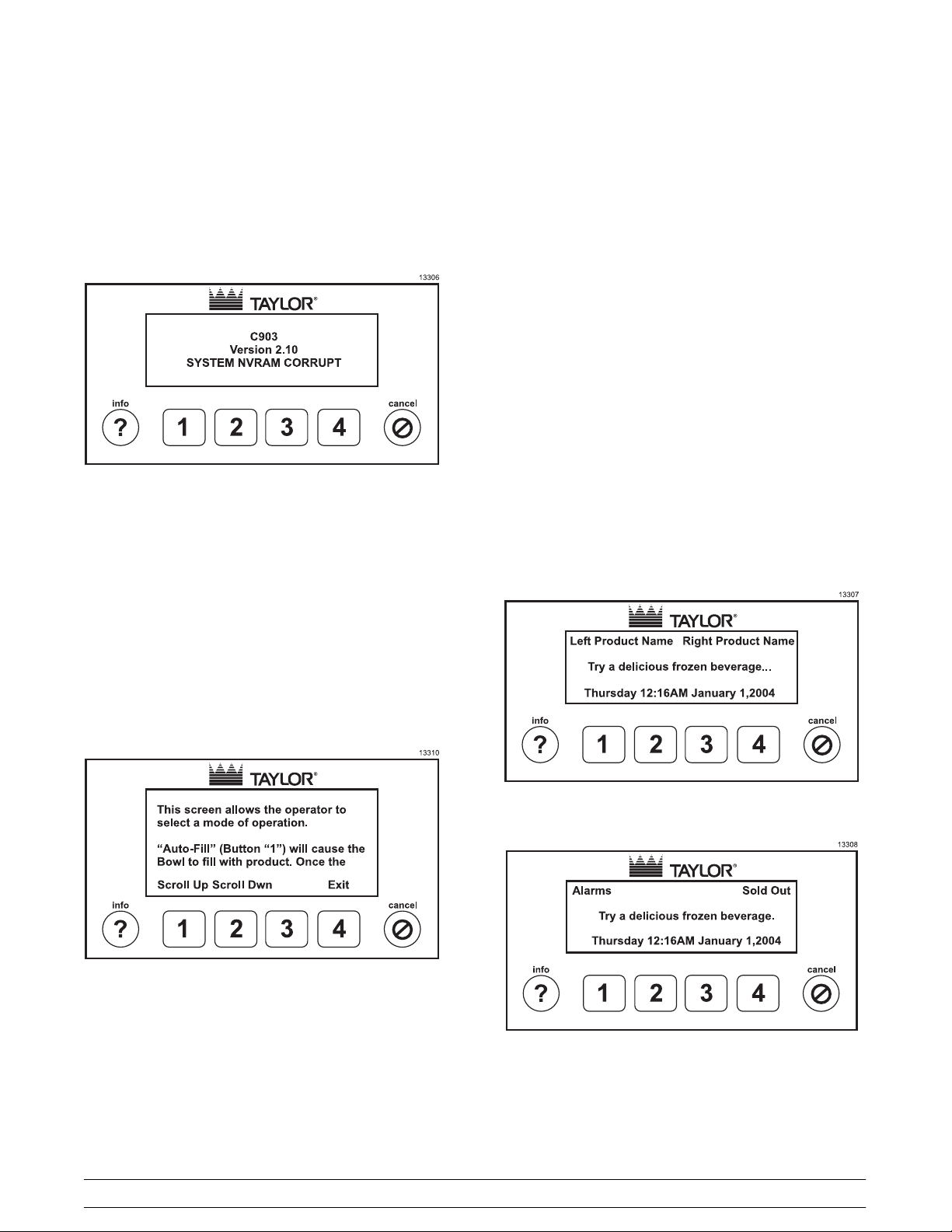

Power Up Initialization Screens

On power up, the model number and firmware

version are displayed on the screen for two seconds

and the audio alarm is turned on for 50ms (chirp).

Flavor Lights

A flavor light is provided for each bowl and is located

above the respective bowl. The flavor light is turned

on when the product in the bowl is ready to serve.

The flavor light is off if the bowl is not in a serving

mode or if the product is not ready to serve. If there

is a fault condition that affects a particular side, the

flavor light for that side is flashed for four seconds

on and four seconds off.

Audio Alarm

An audio alarm provides an audible tone to alert the

operator of alarm conditions and to indicate a

keypress. The audio alarm, when active as an

alarm, is on for ½ second and off for ½ second.

When active as an alarm, the audio alarm can be

silenced for 15 minutes by pressing the cancel key

when the Marketing screen is being displayed.

Figure 8

The memory for configuration data is then tested for

corruption. Configuration memory holds data that is

changed infrequently such as settings entered by

the operator. If the configuration memory is found to

be corrupted, the screen will display the message

“CONFIG NVRAM CORRUPT”. If configuration

memory is not corrupted the message “CONFIG

NVRAM OK” is displayed.

Figure 9

12

Model C903Important: To the Operator

Page 17

The memory for system data is then tested for

corruption. System memory holds data that is

changed frequently. If the system memory is found

to be corrupted, the screen will display the message

“SYSTEM NVRAM CORRUPT”. If system memory

is not corrupted the message “SYSTEM NVRAM

OK” is displayed.

Marketing Screen

The marketing screen is displayed after the power

up screens. The left product name is displayed on

line 1 in the first 20 columns and the right product

name is displayed in last 20 columns. On line 4, a

marketing message is displayed. On line 8, the day

of the week, the time of day, and the date are

displayed.

If the unit is a non-RFID unit, the product names will

be blank unless product names have been entered

by an operator.

If the unit is an RFID unit, the product names are

read from the RFID tag on the product boxes. If no

box is present, the product name is replaced by the

message “NO BOX”.

Figure 10

Operator Menus

Help

Help text is available in all operator and manager

accessible menus except the marketing and

passcode screens. The help text is brought up by

pressing the info key.

If there is an alarm condition, the product names are

replaced by the message, “Alarms”. If a syrup out or

sold out condition occurs, the display will show the

message “Syrup Out” or “Sold Out”, respectively,

alternating with the message “Alarms”.

Figure 12

Figure 11

Pressing key 1 (Scroll Up) will scroll the text down

to display the preceding text (up). Pressing key 2

(Scroll Dwn) will scroll text up to display the

following text (down). Pressing key 4 (Exit)orthe

cancel key will exit the help menu and return to the

menu from which the help was called.

Model C903 Important: To the Operator

If the audio alarm is on, pressing the cancel key will

silence the audio alarm for 15 minutes.

13

Figure 13

Page 18

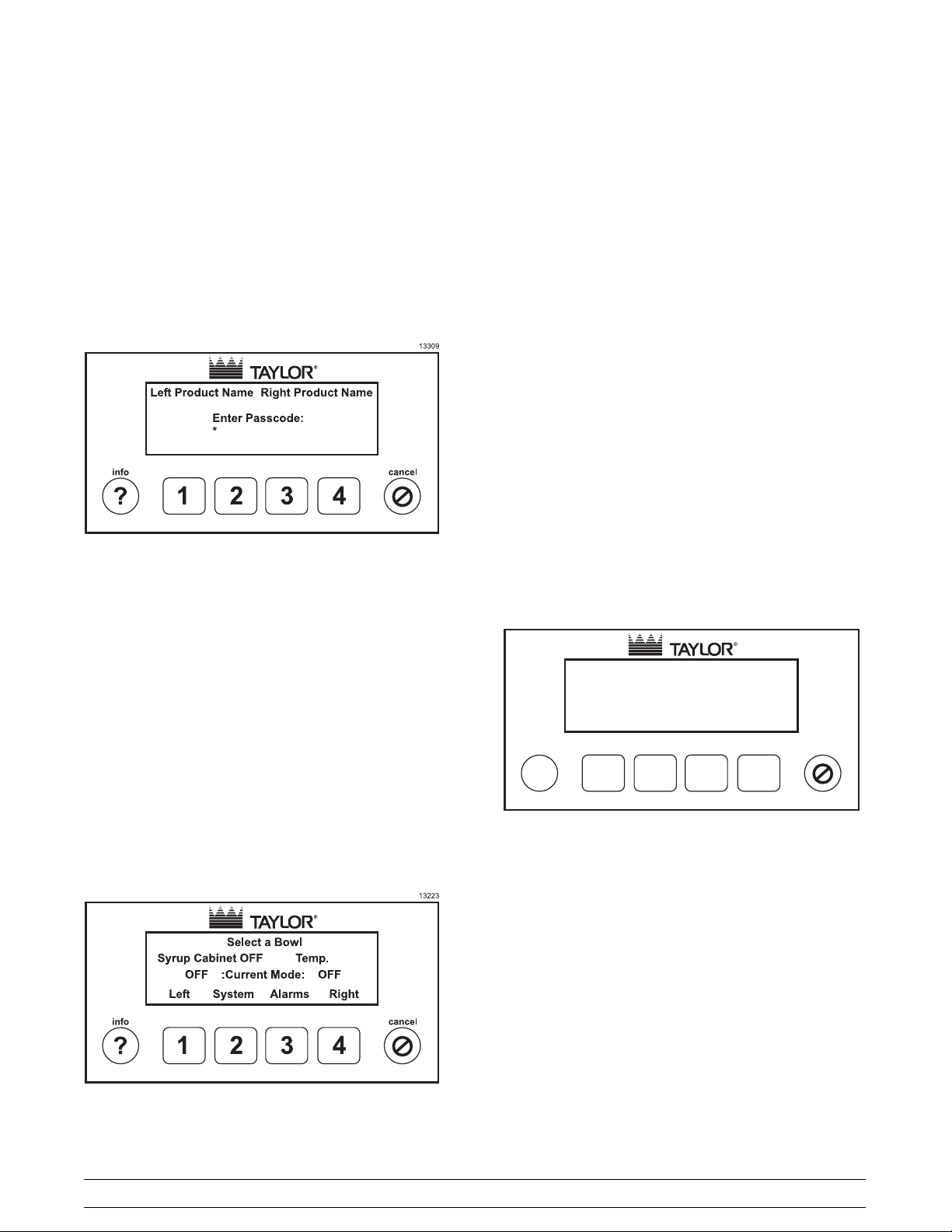

The menus are accessed by entering a four digit

passcode. Valid passcode keys are keys 1, 2, 3, and

4. If a key, other than the cancel key, is pressed

when the Marketing Screen is being displayed, the

passcode screen is displayed.

Passcode Menu

Figure 14

In the Bowl Select Menu, the product names are

displayed on line 1. The syrup cabinet temperature

is displayed on line 4. On line 6, the current mode of

the left and right bowls is displayed. On line 8, the

keypad legends are displayed for keys 1-4. Pressing

key 1 will change to the left Select Mode Menu,

pressing key 2 will change to the System Menu, and

pressing the 4 key will change to the right Select

Mode Menu. If there is an alarm active, the legend

above key 3 will be Alarm otherwise it will be blank.

When the alarm legend is present, pressing key 3

will change to the Alarm Menu. Pressing the cancel

key will return to the Marketing Screen.

If the bowl is already in Rinse or Sanitize mode,

pressing key 1 (Left) or pressing key 2 (Right) will

jump directly to the Rinsing or Sanitizing Menu

instead of going to the Bowl Mode Menu.

Bowl Mode Menu

An asterisk is displayed for each keypress, including

the first keypress from the Marketing Screen. Valid

passcode keys are the 1, 2, 3, and 4 keys. If no key

is entered for 30 seconds and the passcode entered

is not valid, the screen will return to the marketing

screen. Pressing the cancel key will return to the

Marketing Screen.

If a valid passcode is entered, the Bowl Select Menu

will be displayed.

Bowl Select Menu

Figure 15

13121

Select a Mode for the Left Bowl.

Current Mode: OFF

1

No-Fill

Chill

More

234

cancel

Auto-Fill

info

?

Figure 16

On line 1, the left and right product names are

displayed. On RFID units, this product name is read

from the product box. On non-RFID units, the

product name must be entered using the Product

Name menu. On line 4, the current bowl mode is

displayed. On line 8, are the key legends for

selecting the mode. Pressing key 1 (Auto-Fill) will

place the bowl into Auto-Fill mode. Pressing key 2

(No Fill) will place the bowl into No Fill mode.

Pressing key 3 (Chill) will place the bowl into Chill

mode. Pressing key 4 (More) will change to the

Rinse/Sanitize menu. Pressing the cancel key will

return to the Bowl Select Menu.

14

Model C903Important: To the Operator

Page 19

When the bowl is in Auto-Fill, No-Fill, or Chill mode,

the respective key legend will show OFF. Pressing a

key, when the key legend says OFF, will place the

bowl into Off mode.

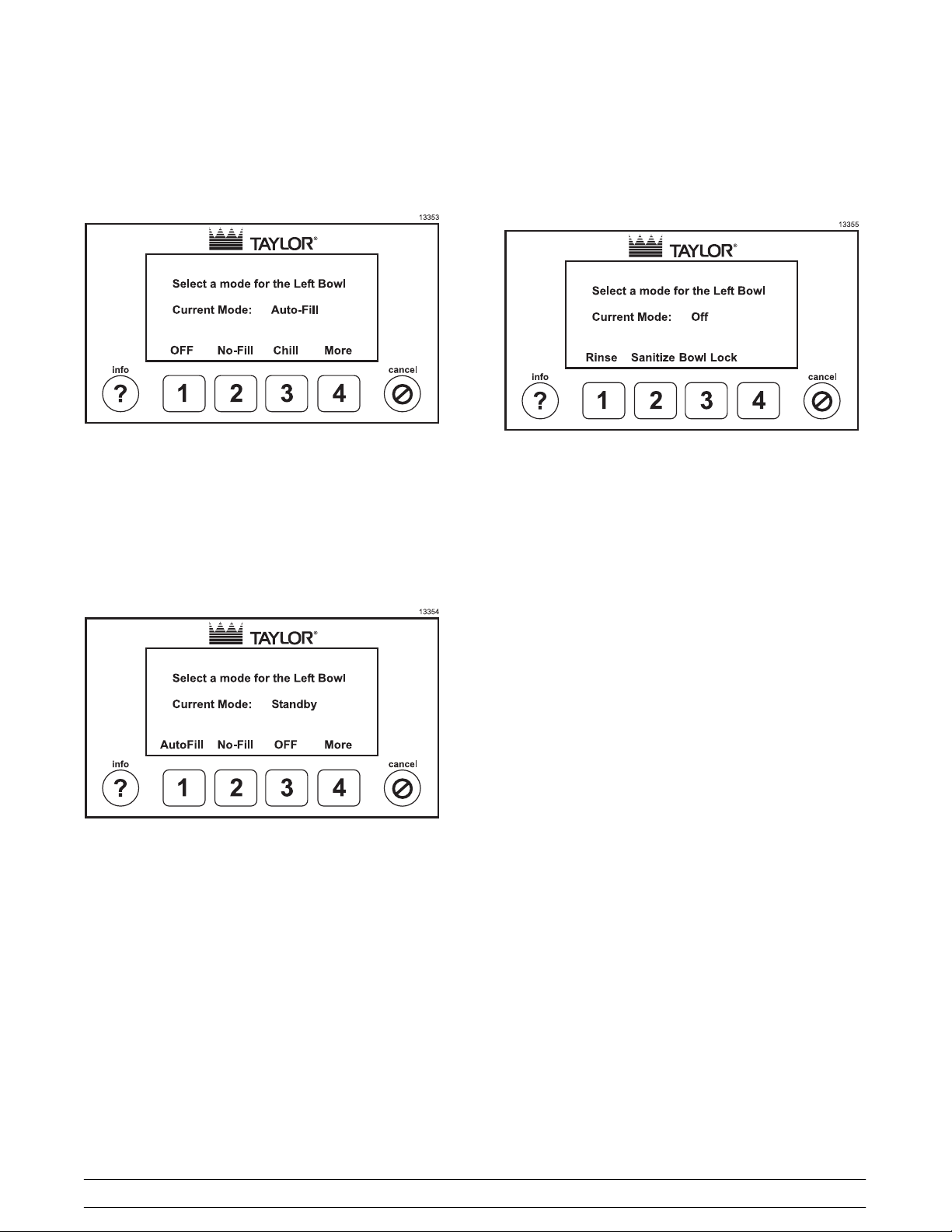

Rinse/Sanitize Menu

Press the MORE (4) key when in the Bowl Mode

Screen to go to the Rinse/Sanitize Menu.

Figure 17

If a bowl is in Standby mode, the Chill key legend

will show OFF. In this case, to place the bowl into

Chill mode, the bowl would first have to be placed

into Off mode and then can be placed into Chill

mode. Only the system can place a bowl into

Standby mode. The system will place a bowl into

Standby mode during Defrost or because of a fault.

Figure 18

This menu is the same for the right bowl,

respectively.

Figure 19

From the Rinse/Sanitize Menu, the operator can

place the bowl into Rinse Mode, Sanitize Mode, or

energize the bowl lock to remove the bowl. A bowl

can only be placed into Rinse or Sanitized mode if

the bowl mode is Off, Rinsed, or Sanitizedand all of

the level sensors are exposed.

Pressing key 1 will place the bowl into Rinse Mode

and change to the Rinsing Menu.

Pressing key 2 will place the bowl into Sanitize

mode and change to the Sanitizing Menu.

Pressing key 3 will raise the bowl lock pin. Pressing

key 3 while the bowl lock pin is raised will release

the bowl lock pin. When key 3 is pressed and the

bowl lock pin is raised, the bowl lock pin will

automatically de-energize after 15 seconds if key 3

is not pressed to de-energize the bowl lock pin. The

bowl lock key will only respond if the liquid level in

the bowl is below the Mix Low sensor.

Pressing the cancel key will return to the Bowl

Mode Menu. This menu is the same for the right

bowl, respectively.

Model C903 Important: To the Operator

15

Page 20

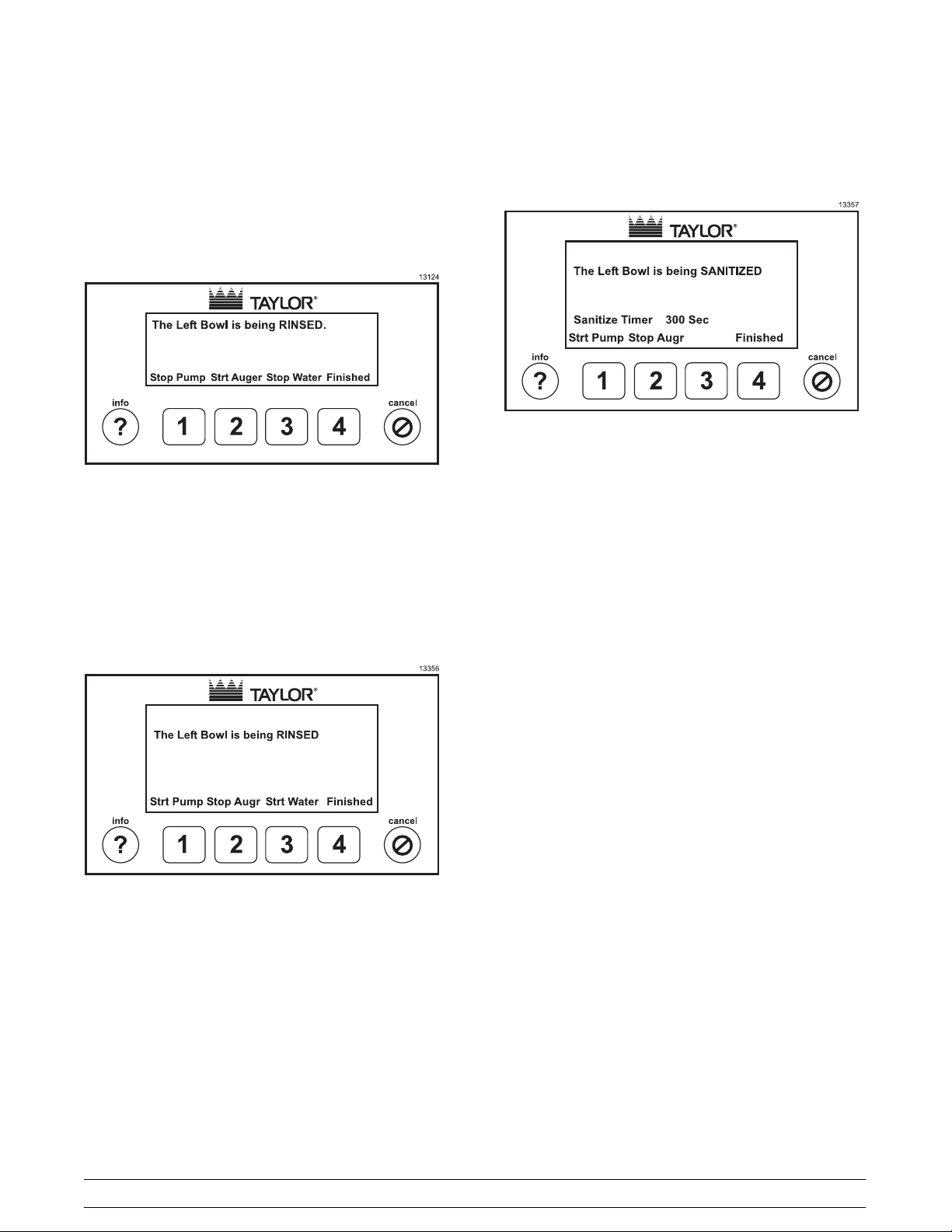

Rinsing Menu

Upon entering this menu, the bowl will have been

placed into the Rinse mode, with the syrup pump on,

the auger off, and the water on, unless there is a

fault that prevents the syrup pump or water from

being turned on.

Sanitizing Menu

Figure 22

Figure 20

The auger will turn on when the level in the bowl

reaches the mix full probe. Pressing key 1 will start

and stop the syrup pump. Pressing key 2 will start

and stop the auger. Pressing key 3 will start and

stop the water. Pressing key 4 will end the Rinse

mode and return to the Bowl Mode Menu. Pressing

the cancel key will return to the Bowl Select Menu

while leaving the bowl in the Rinse mode.

Figure 21

This menu is the same for the right bowl,

respectively.

Upon entering this menu from the Rinse/Sanitize

Menu, the bowl will have been placed into the

Sanitize mode with the syrup pump on and the

auger off, unless there is a fault that prevents the

syrup pump from being turned on.

The auger will turn on when the level in the bowl

reaches the mix full probe. Pressing key 1 will start

and stop the syrup pump. Pressing key 2 will start

and stop the auger. Pressing key 4 will end the

Sanitize mode and return to the Bowl Mode Menu.

Pressing the cancel key will return to the Bowl

Select Menu while leaving the bowl in the Sanitize

mode.

A Sanitize Timer will count down from 300 seconds

to zero. The timer will count down only if the auger is

running and the bowl is filled to the Mix Over probe.

If a lockout cleaning has been performed, the bowl

mode will show “Bowl Cleaned”, otherwise the bowl

mode will show “Sanitized”. The system will

automatically finish the Sanitizing mode when the

300 seconds (5 minutes) has counted down to 0.

This menu is the same for the right bowl,

respectively.

16

Model C903Important: To the Operator

Page 21

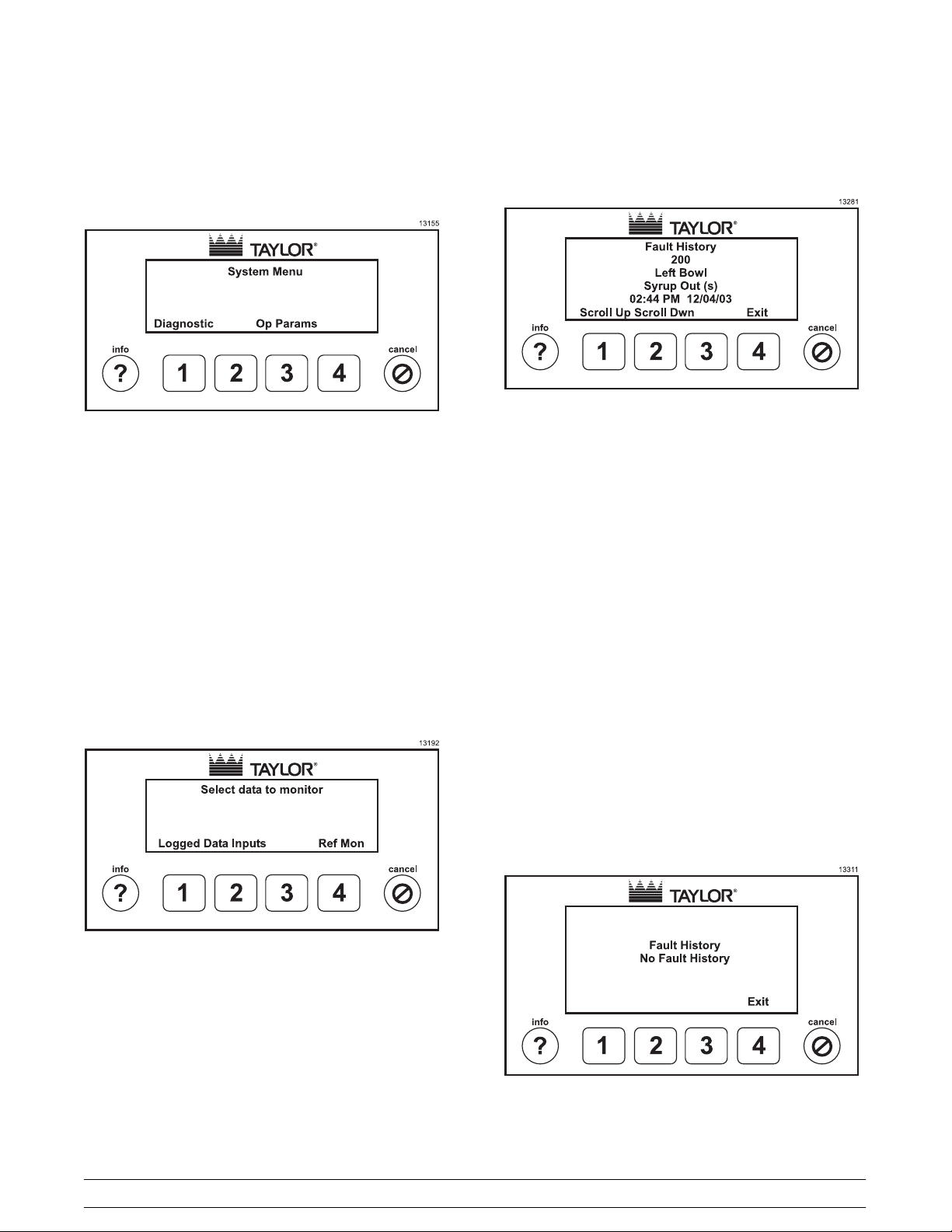

System Menu

Logged Data Menu

Figure 25

Figure 23

Pressing key 1 (Diagnostic) will change to the

Diagnostic Menu. Pressing key 3 (Op Params) will

change to the Operator Parameters Menu. Pressing

the cancel key will return to the Bowl Select Menu.

Diagnostic Menu

In the Logged Data Menu, the operator can view the

history of faults that the system has logged. Line 2 is

the menu title. Line 3 displays the record number

with the highest number being the most recent fault.

Line 4 displays the side on which the fault occurred.

The sides can be Left, Right, or System. System

indicates that the fault occurred on a device that is

common to both sides such as Low Water Pressure

fault. Line 5 displays the timestamp for the fault.

Pressing key 1 (Scroll Up) will increment the record

number, i.e. display the more recent fault. If the

current fault is the last, then key 1 will display the

first fault. Pressing key 2 (Scroll Dwn) will

decrement the record number, i.e. display the

previous fault. If the current fault is the oldest fault,

then key 2 will display the last fault. Pressing key 4

(Exit)orthecancel key will exit the menu and

return to the Diagnostics Menu.

If there are no faults, the following screen will be

displayed.

Figure 24

Pressing key 1 (Logged Data) will change to the

Diagnostic Menu. Pressing key 2 (Inputs) will

change to the Inputs Menu. Pressing key 4 (Refr

Mon) will change to the Refrigeration Monitor menu.

Pressing the cancel key will return to the Bowl

Select Menu.

Model C903 Important: To the Operator

17

Figure 26

Page 22

Inputs Menu (Diagnostic Menu)

Figure 27

Pressing key 1 (Scroll Up) will scroll up through the

list of inputs. Pressing key 2 (Scroll Dwn) will scroll

down through the list of inputs. Pressing key 4 (Exit)

or the cancel key will exit the menu and return to

the Diagnostics Menu.

Refrigeration Monitor Menu

This menu displays the current values for inputs.

The description of the input is in the first column

(left) of the display. The second column of

information is the input value. The third column

displays internal values which may be useful for

diagnosis of problems when contacting tech support.

The inputs and their values are:

Left Bowl Temperature °F

Right Bowl Temperature °F

Cabinet Temp °F

Left Mix Low Yes/No

Left Mix Full Yes/No

Left Mix Over Yes/No

Right Mix Low Yes/No

Right Mix Full Yes/No

Right Mix Over Yes/No

Left Syrup Out Sense Yes/No

Right Syrup Out Sense Yes/No

Left SyrupOut Switch OK/OUT

Right Syrup Out Switch OK/OUT

HPCO Yes/No

Water Pressure Switch OK/Low

Left Viscosity Switch OK/Low

Right Viscosity Switch OK/Low

Filter Switch Yes/No

Left Bowl In Place Switch Yes/No

Right Bowl In Place Switch Yes/No

Figure 28

This menu allows the operator to view various

parameters related to refrigeration of the product.

Line 1 displays the mode of the left and right bowls.

Line 2 displays the viscosity status. Line 3 displays

the setpoint, i.e. the temperature above which

refrigeration is turned off. Line 4 displays the current

bowl temperatures. Line 5 displays the current state

of the liquid line solenoids. Line 6 displays the syrup

cabinet temperature and the compressor state.

Pressing key 4 (Exit)orthecancel key will exit this

menu and return to the Diagnostics Menu.

Operator Parameters Menu

The following screen is displayed if the Operator

passcode is entered.

Figure 29

18

Model C903Important: To the Operator

Page 23

The following screen is displayed if the Manager

passcode is entered.

Figure 30

Version Menu

In this menu, the firmware and language versions

are displayed. Pressing key 4 (Exit)orthecancel

key will return to the System Menu.

This menu displays a list of operating parameters.

Pressing key 1 (Scroll Up) will move the cursor, >,

up through the list. Pressing key 2 (Scroll Dwn) will

move the cursor, >, down through the list. Pressing

key 4 (Enter) will select the list item pointed to by

the cursor. Pressing the cancel key will exit back to

the System Menu.

Only the first two items are available under the

Operator passcode. All of the following parameters

are available under the Manager passcode.

Version

View/Clear Component Run Data

Set Water to Syrup Ratio

Set Auto Defrost and Auto Start Times

Set Clock

Set Initial Freezedown Temperature

Download Data to Card(s)

Change Keypad Sensitivity

Set Lockout Interval

Set Lockout Notice Time

Set Lockout NoFill Time

Figure 31

View/Clear Component Run Data

Figure 32

This menu displays a list of run time parameters.

Pressing key 1 (Scroll Up) will move the cursor, >,

up through the list. Pressing key 2 (Scroll Dwn) will

move the cursor, >, down through the list. Pressing

key 4 (Enter) will select the list item pointed to by

the cursor. Pressing the cancel key will exit back to

the System Menu.

Model C903 Important: To the Operator

19

Page 24

The complete list of operator parameters is listed

below:

Syrup Pump Tube Run Volume Menu

Figure 33

This menu allows the operator to view and clear the

counter for the syrup pump tube run volume.

Pressing key 1 (LEFT) will select the left counter.

Pressing key 2 (RIGHT) will select the right counter.

Pressing the cancel key will return to the View/Clear

Component Run Data Menu.

Figure 35

Set Water to Syrup Ratio Menu

In this menu, the operator can set the water to syrup

ratio to achieve a desired brix (percent sugar).

Figure 34

The side selected is displayed on line 2. The value

of the counter is displayed on line 6. The volume

displayed is in units of 0.01 oz. In this display, the

volume would be 20.23 oz. Pressing key 1 (Clear)

will set the counter to zero. Pressing key 4 (Exit)or

the cancel key will return to the View/Clear

Component Run Data Menu without any change to

the value displayed for the counter.

Figure 36

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 37

20

Model C903Important: To the Operator

Page 25

Pressing key 2 (+++) will increase the water ratio in

0.1 increments. Pressing key 3 (---) will decrease

the water ratio in 0.1 increments. Pressing key 4

(Enter) will save the setting and return to the Set

Water to Syrup Ratio bowl select menu. Pressing

the cancel key will return to the Set Water to Syrup

Ratio bowl select menu without saving any changes.

Set Auto Defrost and Auto Start Times Menu

In this menu, the operator can set the time at which

the system will automatically enter the defrost mode

and set the time at which the system will

automatically exit defrost mode and return to a

freezing mode.

Note: During the defrost mode, refrigeration is shut

off and the product is allowed to liquify. The product

is then maintained at approximately 38°F (3.3°C).

Typically allow 4 - 6 hours for this to take place.

Auto Defrost Time Menu

In this menu, the operator can set the time at which

the system will automatically enter defrost mode.

Figure 39

Pressing key 1 (-->) will move the cursor between

hours and minutes. Pressing key 2 (+++) will

increment and pressing key 3 (---) will decrement the

value, hours or minutes, above the cursor. Pressing

key 4(Enter)will save the value and return to the

Set Auto Defrost and Auto Start Times Menu.

Pressing the cancel key will return to the Set Auto

Defrost and Auto Start Times Menu without saving

any changes.

Figure 38

Pressing key 1 (Defrost) will enter the menu for

setting the Defrost time. Pressing key 2 (Freeze) will

enter the menu for setting the Auto Freeze time.

Pressing key 3 (Disabled/Enabled) will toggle

between Enabled and Disabled and save the value,

enabled or disabled. Pressing the cancel key will

return to the Operator Parameters Menu.

Auto Freeze Time Menu

In this menu, the operator can set the time at which

the system will automatically exit defrost mode and

enter the freezing mode that was present before

entering Defrost mode.

Figure 40

Model C903 Important: To the Operator

21

Page 26

Pressing key 1 (-->) will move the cursor between

hours and minutes. Pressing key 2 (+++) will

increment and pressing key 3 (---) will decrement the

value, hours or minutes, above the cursor. Pressing

key 4(Enter)will save the value and return to the

Set Auto Defrost and Auto Start Times Menu.

Pressing the cancel key will return to the Set Auto

Defrost and Auto Start Times Menu without saving

any changes.

Set Clock Menu

In this menu, the operator can set the current time

and date. If the Lockout Interval has been set to a

non-zero value, the time and date can only be

changed when both bowls are in a Bowl Cleaned

state.

Set Initial Freezedown Temperature

In this menu, the operator can set the initial

temperature at which freezing control will begin.

Note: This value is not used at this time.

Figure 42

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 41

Pressing key 1 (-->) will move the cursor to the right.

If the cursor is on the century, the cursor will wrap to

hours. Pressing key 2 (+++) will increment and

pressing key 3 (---) will decrement the value above

the cursor. Pressing key 4(Enter)will save the

value and return to the Operator Parameters Menu.

Pressing the cancel key will return to the Operator

Parameters Menu without saving any changes.

If an invalid date is entered, such as February 30,

“INVALID DATE” will be displayed on line 6.

Pressing key 4(Exit)or the cancel key will return to

the Set Clock edit screen.

Figure 43

Pressing key 2 (+++) will increase the temperature

in 0.1°F increments. Pressing key 3 (---) will

decrease the temperature in 0.1°F increments.

Pressing key 4 (Enter) will save the setting and

return to the Operator Parameters Menu. Pressing

the cancel key will return to the Operator

Parameters Menu without saving any changes.

22

Model C903Important: To the Operator

Page 27

Download Data to Card(s) (RFID Units Only)

In this menu, the operator can download logged data

to a customer card. This procedure can only be

performed if the unit is equipped for RFID.

If a valid card cannot be found, the following screen

is displayed.

Figure 47

Figure 44

To download the logged data, a customer card

should be held up against the white panel above the

left bowl.

Figure 45

Pressing key 1 (Continue) will begin the download

process. The following screen will be displayed while

the system attempts to write to the customer card.

Pressing key 4(Exit)or the cancel key will return to

the previous screen.

If a valid card is found, the following screen is

displayed when the download is complete.

Figure 48

Pressing key 4(Exit)or the cancel key will return to

the Operator Parameters Menu.

Figure 46

040526

Model C903 Important: To the Operator

23

Page 28

Change Keypad Sensitivity

In this menu, the operator can change the sensitivity

or response of the keypad. Higher values increase

the sensitivity and lower values decrease the

sensitivity. Lower keypad sensitivity will help prevent

unintentional detection of key presses.

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 51

Figure 49

Pressing key 2 (+++) will increase the sensitivity in

increments of 10. Pressing key 3 (---) will decrease

the sensitivity in increments of 10. Pressing key 4

(Enter) will save the setting and return to the

Operator Parameters Menu. Pressing the cancel

key will return to the Operator Parameters Menu

without saving any changes.

Set Cleaning Lockout Interval

In this menu, the operator can set the Lockout

Interval, in days. The Lockout Interval is the number

of days at which the system will no allow the unit to

be placed in a freezing mode until the unit is

cleaned.

Pressing key 2 (+++) will increase the Lockout

Interval. Pressing key 3 (---) will decrease the

Lockout Interval. Pressing key 4 (Enter) will save

the setting and return to the Operator Parameters

Menu. Pressing the cancel key will return to the

Operator Parameters Menu without saving any

changes.

Set Cleaning Lockout Notice Time

In this menu, the operator can set the Lockout

Notice Time. The Lockout Notice Time is the

number of hours prior to a cleaning lockout that the

system will generate an alarm to forewarn the

operator.

Figure 50

24

Figure 52

Model C903Important: To the Operator

Page 29

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 53

Pressing key 2 (+++) will increase the Lockout

Notice Time. Pressing key 3 (---) will decrease the

Lockout Notice Time. Pressing key 4 (Enter) will

save the setting and return to the Operator

Parameters Menu. Pressing the cancel key will

return to the Operator Parameters Menu without

saving any changes.

Set Cleaning Lockout NoFill Time

In this menu, the operator can set the Lockout NoFill

Time. The Lockout NoFill Time is the number of

hours prior to a cleaning lockout that the system will

automatically switch to AutoNoFill mode. This is to

minimize product loss when cleaning.

Figure 55

Pressing key 2 (+++) will increase the Lockout NoFill

Time. Pressing key 3 (---) will decrease the Lockout

NoFill Time. Pressing key 4 (Enter) will save the

setting and return to the Operator Parameters Menu.

Pressing the cancel key will return to the Operator

Parameters Menu without saving any changes.

Set Cleaning Lockout Mix Low Time

In this menu, the operator can set the Lockout Mix

Low Time. The Lockout Mix Low Time is the number

of hours prior to a cleaning lockout that the system

will not generate an alarm if the bowl goes below

mix low. This is to minimize product loss when

cleaning.

Figure 54

Model C903 Important: To the Operator

25

Figure 56

Page 30

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 57

Pressing key 2 (+++) will increase the Lockout Mix

Low Time. Pressing key 3 (---) will decrease the

Lockout Mix Low Time. Pressing key 4 (Enter) will

save the setting and return to the Operator

Parameters Menu. Pressing the cancel key will

return to the Operator Parameters Menu without

saving any changes.

Figure 59

Pressing key 1 (-->) will move the cursor to the right.

If the cursor is on the fourth digit, the cursor will

wrap to the first digit. Pressing key 2 (+++) will

increment and pressing key 3 (---) will decrement the

digit above the cursor. Pressing key 4(Enter)will

save the value and return to the Operator

Parameters Menu. Pressing the cancel key will

return to the Operator Parameters Menu without

saving any changes. This menu screen is used for

both the operator and manager passcodes.

Change Passcode

In this menu, the operator can change the operator

and manager passcodes.

Figure 58

Pressing key 1 (Operator) will select the menu for

changing the operator passcode. Pressing key 2

(Manager) will select the menu for changing the

manager passcode. Pressing key 4(Exit)or the

cancel key will return to the Operator Parameters

Menu.

Product Name Menu

In this menu, the operator can set the product

names for the left and right sides. If the system is an

RFID unit, the product names are automatically read

from the product tags.

Figure 60

26

Model C903Important: To the Operator

Page 31

Pressing key 1 (LEFT) will select the left side.

Pressing key 2 (RIGHT) will select the right side.

Pressing the cancel key will return to the Operator

Parameters Menu.

Figure 61

Alarm Menu

The Alarm menu is entered by pressing key 3

(Alarm) in the Bowl Select menu. Key 3 (Alarm) will

only appear in the Bowl Select menu if there is an

active alarm.

Pressing key 1 (-->) will move the cursor to the right.

If the cursor is on the last character, the cursor will

wrap to the first character. Pressing key 2 (+++) will

increment and pressing key 3 (---) will decrement the

character above the cursor. Pressing key 4(Enter)

will save the value and return to the Operator

Parameters Menu. Pressing the cancel key will

return to the Operator Parameters Menu without

saving any changes.

Figure 62

Figure 63

Pressing key 1 (Select) will select the displayed fault

and allowing clearing of only that fault. Pressing key

2 (Clear All) will clear all active faults. Pressing key

3(ScrollUp)will scroll up through the active faults.

Pressing key 4 (Scroll Dwn) will scroll down through

the active faults. Pressing the cancel key will return

to the Bowl Select menu.

Figure 64

Pressing key 2 (+++) will increase the water ratio in

0.1 increments. Pressing key 3 (---) will decrease

the water ratio in 0.1 increments. Pressing key 4

(Enter) will save the setting and return to the Set

Water to Syrup Ratio bowl select menu. Pressing

the cancel key will return to the Set Water to Syrup

Ratio menu.

Model C903 Important: To the Operator

Pressing key 1 (Select) will select the displayed fault

and allowing clearing of only that fault. Pressing key

2 (Clear All) will clear all active faults. Pressing key

3(ScrollUp)will scroll up through the active faults.

Pressing key 4 (Scroll Dwn) will scroll down through

the active faults. Pressing the cancel key will return

to the Bowl Select menu.

27

Page 32

The possible alarms are described below:

HPCO

The HPCO fault indicates that a High Pressure Cut

Out occurred on the compressor.

Syrup Out (S)

A syrup out was detected from the vacuum switch.

This will occur when a bag-in-box of syrup runs out

of syrup or if nothing is connected to the quick

disconnect.

Syrup Out (C)

A syrup out was detected from the conductivity

sensor in the syrup pump tubing. The system

detects whether there is fluid in the syrup pump

tubing by measuring the conductivity of the fluid in

the tubing. If there is air in the tubing, as would be

the case if a mix tank or pail of fluid ran out of fluid,

then the conductivity measured would be low.

Low Water Pressure

Thermistor Fault

A thermistor fault is generated if the control

determines that a thermistor is shorted, open, or

outside of the valid measurement range. If there is a

thermistor fault, temperature displays for that

thermistor will display SHRT, OPEN,orOVER

instead of a temperature. If the bowl mode is

AutoFill, AutoNoFill, Chill mode, or Standby mode,

the bowl mode is changed to Off mode.

Pump On Too Long

The Pump On Too Long fault is generated if the

syrup pump runs for more than a period of time

dependent upon the water to syrup ratio.

Cleaning Lockout

The Cleaning Lockout fault is generated to inform

the operator that the system requires cleaning.

Bowl Overfill

The Bowl Overfill fault is generated if the system

detects that the level of product in a bowl has

reached the Mix Over sensor in AutoFill, AutoNoFill,

Chill, and Standby modes. This may be due to too

high of a viscosity setting or too high of a water to

syrup ratio.

Mix Low

The system monitors a sensor to determine if the

water pressure is too low. When the system detects

that the water pressure is low, there is a delay of 60

seconds before the Low Water Pressure alarm is

generated. If after 60 seconds, the water pressure is

still low, a Low Water Pressure alarm is generated.

If the bowl is in Rinsing mode, the mode is changed

to Off mode. If the bowl mode is AutoFill, the bowl

mode will be changed by the control to AutoNoFill

mode and if the water pressure returns and the

alarm is still active, the alarm will be automatically

cleared and the bowl mode will automatically be

changed back to AutoFill mode.

Lockout Notice

The Lockout Notice alarm is generated when the

time before a cleaning lockout is less than or equal

to the Lockout Notice Time. The Lockout Notice

alarm is generated to remind the operator that a

cleaning lockout is will be occurring soon. The

Lockout Notice alarm is regenerated every 60

minutes until the cleaning lockout occurs.

A Mix Low fault is generated if the product in the

bowl drops below the Mix Low sensor in AutoFill,

AutoNoFill, Chill, or Standby mode. (At this time,

Beta version x243, this alarm is not active since

product level is now allowed to go below Mix Low in

the serving modes.)

Locked Auger

A Locked Auger fault is generated if the system

detects that an auger is not turning. When a locked

auger is detected, the bowl is placed into Off mode.

If the temperature of the product is greater than

30.0°F at the time of the Locked Auger fault, the

system will then, after a delay of two minutes,

automatically place the bowl back into the mode the

bowl was in at the time of the Locked Auger fault.

Expired Product

An Expired Product fault is generated if the system

detects that the current date is greater than the

expiration date read from the box . This fault will

only occur on systems with RFID. This fault is only

informative and syrup will continue to be pumped

from the box.

28

Model C903Important: To the Operator

Page 33

Product Lifespan Expired

AutoFill and AutoNoFill Mode

A Product Lifespan Expired fault is generated if the

system detects that 30 days has passed since a box

of syrup was first detected by the system. If the bowl

is in AutoFill mode, the system will change the bowl

mode to AutoNoFill mode. If the bowl is in Chill

mode, the system will change the bowl mode to

Standby mode. This fault will only occur on systems

with RFID.

Maximum Volume Pumped

A Maximum Volume Pumped fault will be generated

if the volume of syrup pumped from a syrup box

exceeds the maximum allowable volume for the

syrup box. This fault will only occur on systems with

RFID.

Product Antenna Fault

A Product Antenna fault is generated if the system

detects the same syrup box on both sides of the

cabinet. If the bowl mode is AutoFill mode, the

system will change the bowl mode to AutoNoFill. If

the bowl mode is Chill mode, the system will change

the mode the Standby mode. This fault will only

occur on systems with RFID.

AutoFill mode produces and maintains frozen

product with automatic maintenance of the level of

product in the bowl. When the product level drops

below the Mix Full sensor, more product is pumped

into the bowl until the product is above the Mix Full

sensor. If the syrup being pumped is a syrup

concentrate and needs to be diluted with water, the

system runs the syrup pump at a speed such that

the syrup is mixed with an appropriate ratio of water

to provide the proper blend. The ratio of water to

syrup is set by either entering the ratio of water in

the Set Water to Syrup Ratio menu or, if the system

has RFID, the ratio is read from the product box.

AutoNoFill mode operates the same as AutoFill

mode except that product is not pumped into the

bowl as the product level drops.

When the AutoFill or AutoNofill button is pressed,

the system first tests to determine whether a bowl is

in place. If no bowl is present, No Bowl will be

displayed for the mode for that side. If a bowl is in

place, then AutoFill or AutoNoFill mode is begun.

If the bowl is empty when AutoFill is selected, the

syrup pump will turn on to pump syrup up into the

bowl. If the water:syrup ratio is not 0.0:1.0, water will

begin flowing after a delay (dependent upon the

water:syrup ratio) to allow syrup to fill to the syrup

line. When the mix level reaches the Mix Low

sensor, the refrigeration and auger are turned on.

The mix will continue to fill the bowl until the mix

reaches the Mix Full Sensor. When the control has

determined that the product is servable, the flavor

light will turn on.

If a locked auger is detected while the mix in the

Bowl Modes

There are ten bowl modes:

Off mode

AutoFill mode

AutoNoFill mode

Chill mode

Standby mode

Rinsing mode

Rinsed mode

Sanitizing mode

Sanitized mode

No Bowl mode

Model C903 Important: To the Operator

bowl is above 30°F (-1.1°C), a Locked Auger alarm

is generated and the side is placed into OFF mode.

After two minutes, the system will automatically

enter AutoFill mode if the mode has not been

manually changed.

If a locked auger is detected and the mix in the bowl

is at or below 30°F (-1.1°C), a Locked Auger alarm

is generated and the side is placed into OFF mode.

The side will remain in OFF mode until an operator

places the side into another mode.

If a syrup out condition, due to the syrup out switch,

syrup out conductivity, or syrup pump on too long, is

detected while the side is in AutoFill mode, the bowl

on that side will be placed into AutoNoFill mode.

29

Page 34

Chill Mode and Standby Mode

Rinsing and Rinsed Mode

Chill mode is used to produce and maintain

refrigerated, but not frozen product, with automatic

maintenance of the level of product in the bowl.

When the product level drops below the Mix Full

sensor, more product is pumped into the bowl until

the product is above the Mix Full sensor. If the syrup

being pumped is a syrup concentrate and needs to

be diluted with water, the system runs the syrup

pump at a speed such that the syrup is mixed with

an appropriate ratio of water to provide the proper

blend. The ratio of water to syrup is set by either

entering the ratio of water in the Set Water to Syrup

Ratio menu or, if the system has RFID, the ratio is

read from the product box. Standby mode operates

the same as Chill mode except that product is not

pumped into the bowl as the product level drops.

Standby mode is not operator selectable and can

only be entered through a fault condition or Defrost

mode.

When the Chill button is pressed, the system first

tests to determine whether a bowl is in place. If no

bowl is present, No Bowl will be displayed for the

mode for that side. If a bowl is in place, then Chill

mode is begun.

If the bowl is empty when Chill is selected, the syrup

pump will turn on to pump syrup up into the bowl. If

the water:syrup ratio is not 0.0:1.0, water will begin

flowing after a delay (dependent upon the

water:syrup ratio) to allow syrup to fill the syrup line.

When the mix level reaches the Mix Low sensor, the

refrigeration and auger are turned on. The mix will

continue to fill the bowl until the mix reaches the Mix

Full Sensor. When the temperature of the product is

less than 41.0°F, the flavor light is turned on.

Chill and Standby modes maintain the temperature

of the product between 36.0°F and 40.0°F.

If a syrup out condition, due to the syrup out switch,

syrup out conductivity, or syrup pump on too long, is

detected while the side is in Chill mode, the bowl on

that side will be placed into Standby mode.

Rinsing mode is used to rinse product from the bowl

and pump tubing. Rinsed mode is entered when the

Finished button is pressed to exit Rinsing mode.

Rinsing mode can only be entered if the bowl is on,

the bowl is in Off, Rinsed, or Sanitized mode, and

the level of liquid in the bowl is below the Mix Low

sensor.

When the Rinse button is pressed, the system first

tests to determine whether a bowl is in place. If no

bowl is present, No Bowl will be displayed for the

mode for that side. If a bowl is in place, then Rinsing

mode is begun.

When the side is placed into Rinsing mode, the

auger is off, the water is turned on (if water is

enabled), and the syrup pump is turned on. When

the water reaches the Mix Full sensor, the auger is

turned on. When the water reaches the mix over

sensor the syrup pump and the water are turned off.

Pressing key 1 will start and stop the syrup pump.

Pressing key 2 will start and stop the auger.

Pressing key 2 will not start the auger if the water

level in the bowl is below the Mix Full sensor.

Pressing key 3 will start and stop the water.

Pressing key 4 will end the Rinsing mode and return

to the Bowl Mode Menu.

Pressing the cancel key will return to the Bowl

Select Menu while leaving the bowl in the Rinsing

mode.

If the system detects that the tank with the rinse

water is empty, the syrup pump and water will be

turned off and a Syrup Out (C) fault will be

generated. If this occurs, refill the tank with rinse

water and press key 1 to start the syrup pump and

press key 3 to start the water. The system will

automatically clear the Syrup Out (C) fault.

30

Model C903Important: To the Operator

Page 35

Sanitizing and Sanitized Mode

Sanitizing mode is used to disinfect the bowl and

pump tubing. Sanitized mode is entered when the

Finished button is pressed to exit Sanitizing mode

or when the system automatically ends Sanitizing

mode. Sanitizing mode can only be entered if the

bowl is on, the bowl is in Off, Rinsed, or Sanitized

mode, and the level of liquid in the bowl is below the

Mix Low sensor.

A countdown timer is displayed to aid in sanitizing

for a minimum amount of time, i.e. 300 seconds

(5 minutes). The counter will count down when the

bowl is filled above the Mix Over sensor and the

auger is running. If the bowl level is below the Mix

Over sensor or the auger is not on, the timer will not

count down. The system will automatically exit the

Sanitizing mode and enter Sanitized mode when the

timer reaches zero. The Sanitizing mode can be

ended before the timer reaches zero, in which case

the system will change to Off mode rather than

Sanitized mode.

When the Sanitize button is pressed, the system

first tests to determine whether a bowl is in place. If

no bowl is present, No Bowl will be displayed for the

mode for that side. If a bowl is in place, then

Sanitizing mode is begun.

When the side is placed into Sanitizing mode, the

auger is off, the water is turned off, and the syrup

pump is turned on. When the sanitizing solution

reaches the Mix Full sensor, the auger is turned on.

When the sanitizing solution reaches the mix over

sensor the syrup pump will run for an additional ten

seconds.

Pressing key 1 will start and stop the syrup pump.

Pressing key 2 will start and stop the auger.

Pressing key 2 will not start the auger if the

sanitizing solution level in the bowl is below the Mix

Full sensor.

Pressing key 4 will end the Sanitizing mode and

return to the Bowl Mode Menu.

Pressing the cancel key will return to the Bowl

Select Menu while leaving the bowl in the Sanitizing

mode.

If the system detects that the tank with the sanitizing

solution is empty, the syrup pump will be turned off

and a Syrup Out (C) fault will be generated. If this

occurs refill the tank with sanitizing solution and

press key 1 to start the syrup pump. The system will

automatically clear the Syrup Out (C) fault.

No Bowl Mode

No Bowl mode is entered if an operator attempts to

enter AutoFill, AutoNoFill, or Chill mode and the

system detects that no bowl is present. The system

will end No Bowl mode when the bowl is present and

the system is placed into any mode. In No Bowl

mode, the syrup pump, water, auger, refrigeration,

and flavor light are all off.

Off Mode

In Off mode, the syrup pump, water, auger,

refrigeration, and flavor light are all off.

Cleaning Lockout

The system can be set to prevent the bowl mode

from being in a mode that is intended to allow

product to be served. These modes are AutoFill,

AutoNoFill, and Chill modes. Four parameters can

be set to enable cleaning lockout, alert the operator

of lockout conditions, and minimize product loss at

cleaning. These parameters are Lockout Interval,

Lockout Notice Time, Lockout NoFill Time, and

Lockout Mix Low Time. These parameters are set

for each individual bowl.

If the bowl mode, at the expiration of the Lockout

Interval, is AutoFill, AutoNoFill, or Chill mode, the

system will place the bowl into Standby mode. If the

bowl is in Off mode, the bowl cannot be placed into

AutoFill, AutoNoFill, or Chill mode.

Model C903 Important: To the Operator

31

Page 36

Cleaning Lockout Settings

Lockout Interval

Lockout Screen Information

The time interval from when a bowl, that is in a Bowl

Cleaned state, is first put into AutoFill, AutoNoFill, or

Chill mode to when the system will lock the bowl out

from syrup pumping modes is the Lockout Interval

time and is set in the System/Op Params/Set

Lockout Interval menu. The Lockout Interval time is

in days and can be between 0 and 30 days. If the

Lockout Interval time is set to 0 days, then lockout is

disabled. The Lockout Interval can only be changed

when both bowls are in a Bowl Cleaned state. When

the Lockout Interval is reached, if the bowl mode is

AutoFill, AutoNoFill, or Chill mode, then the system

will change the bowl mode to Standby mode.

Lockout Notice Time

The Lockout Notice Time can be set to generate an

alarm (fault) to alert the operator that a cleaning

lockout is will be occurring soon. The Lockout Notice

alarm is regenerated every 60 minutes until the

cleaning lockout occurs. The Lockout Notice Time is

set in the System/Op Params/Set Lockout Notice

Time menu and can be set from 0 to 48 hours. The

Lockout Notice Time can only be changed when

both bowls are in a Bowl Cleaned state.

Lockout NoFill Time

If cleaning lockout is enabled, that is the Lockout

Interval is set to one or more days, then lockout

information is shown in the Bowl Mode screen.

The beginning a cleaning lockout cycle begins with a

clean bowl as indicated in the Bowl Mode screen

below.

Figure 65

The Lockout NoFill Time is the number of hours

prior to a cleaning lockout that the system will

automatically switch to AutoNoFill mode. This is to

minimize product loss when cleaning. The Lockout

NoFill Time is set in the System/Op Params/Set

Lockout NoFill Time menu and can be set from 0 to

12 hours. The Lockout NoFill Time can only be

changed when both bowls are in a Bowl Cleaned

state.

Lockout Mix Low Time

The Lockout Mix Low Time is the number of hours

prior to a cleaning lockout that the system will not

generate an alarm if the bowl goes below mix low.

This is to minimize product loss when cleaning. The

Lockout Mix Low Time is set in the System/Op

Params/Set Lockout Mix Low Time menu and can

be set from 0 to 12 hours. The Lockout Mix Low

Time can only be changed when both bowls are in a

Bowl Cleaned state.

When the bowl is first put into AutoFill, AutoNoFill, or

Chill mode, the month and the day of the month are

displayed in the Bowl Mode screen.

Figure 66

32

Model C903Important: To the Operator

Page 37

When the Lockout Notice Time is reached, the

number of hours until lockout is displayed in the

Bowl Mode screen.

Figure 67

When the Lockout NoFill Time is reached, if the

bowl is in the AutoFill mode, the system will change

the mode to AutoNoFill mode. If the bowl is in Chill

mode, the system will change the mode to Standby

mode.

Lockout Cleaning Procedure

To clear the cleaning lockout, the bowl must be

cleaned according to the following sequence of

modes and times.

Step 1

The bowl must be placed into the Rinsing mode and

the level of liquid must be at a Mix Over level. There

is no minimum time required for this step.

Step 2

Once the bowl is in the Rinsed state, the bowl must

be removed for a minimum of five minutes (300

seconds). The timer for bowl off will begin 15

seconds after the Bowl Lock has been pressed to

remove the bowl and if the bowl is off. If the bowl is

detected to be present when the timer reaches zero

the bowl will have to be removed for another five

minutes to satisfy the bowl off time requirement for

lockout cleaning.

Step 3

After the bowl has been off for the minimum of five

minutes, then Sanitizing mode can be entered after

the bowl has been placed back on. Sanitizing mode

must be run with the fluid level above the Mix Over

sensor and the auger running for a minimum of five

minutes. The Sanitizing mode can be finished before

five minutes, but this will not satisfy the cleaning

lockout. When five minutes has elapsed, the system

will automatically terminate the Sanitizing mode.

Figure 68

When the Lockout Interval Time has been reached,

the hours to cleaning message is changed to

‘Cleaning Required’.

Figure 69

Model C903 Important: To the Operator

33

Page 38

Section 6 Operating Procedures

We begin our instructions at the point where the

parts are disassembled and laid out.

The following procedures will explain how to

assemble the parts into the freezer, sanitize them,

and prime the freezer with fresh product.

This unit is not pre-sanitized at the factory. Before

serving product, the machine must be disassembled,

cleaned and sanitized.

If you are disassembling the machine for the first

time or need information to get to this starting point

in our instructions, turn to “Disassembly” on

page 46, and start there.

Assembly

Step 2

Holding the front tip of the beater ONLY, insert it

into the evaporator. The magnet will automatically

pull the beater to the back of the evaporator.

CAUTION: DO NOT HOLD THE BEATER

AROUND THE SIDES! Failure to follow this

instruction may result in pinched fingers.

Note: To prevent damage to the beater, do not

release the beater until it is pulled to the back of the

evaporator.

Note: When lubricating parts, use an approved food

grade lubricant (example: Taylor Lube or Taylor

Lube HP).

Step 1

Install the rear bearing on the drive housing.

11260

Figure 70

Figure 71

Step 3

Install the outer spiral scraper blade. Slide the blade

over the evaporator until the front notch engages

with the exposed end of the magnetic beater shaft.

Figure 72

Note: If this alignment is incorrect, the bowl will not

seal properly.

34

Model C903Operating Procedures

Page 39

Step 4

Lubricate and insert the front bearing into the front of

the bowl.

Figure 73

Step 5

Install the bowl gasket on the back of the bowl.

Lightly lubricate the grooves on the gasket.

12180

Figure 75

Note: Failure to lubricate the o-rings may cause the

o-rings to tear.

Step 9

Slide the spring over the draw handle.

Figure 76

Step 10

Figure 74

Install the draw handle in the valve and slide the pin

through the holes.

Step 6

Lift the bowl lock plunger up and slide the bowl back

until the gasket goes into the groove in the back

wall.

Step 7

Make sure the bowl locking pin snaps into the notch

on the top of the bowl. Check to make sure the bowl

is secure, with the front feet inserted in the grooves.

Step 8

Install the o-rings on the draw valve and the quick

disconnect fitting. Lubricate the o-rings. Slide the

valve into the top of the bowl spout with the opening

facing the operator. Ensure that the opening in the

draw valve is fully exposed.

Model C903 Operating Procedures

35

Figure 77

Page 40

Step 11

Open the cabinet door. Install the drip tray bracket

by aligning the slots in the rear of the bracket over

the holding collars below the mix cabinet. Close the

cabinet door. Install the drip tray and the splash

shield.

10409

Figure 79

Step 3

Follow procedure A or B depending on whether or

not your unit is equipped with quick disconnect

fittings:

A. Units Equipped With Quick Disconnects

Figure 78

Sanitizing

Note: These are general guidelines. Sanitizing

procedures must conform to local health

authority guidelines.

Step 1

Prepare a clean mix tank or pail with 10 quarts (9.5

liters) of an approved 100 PPM sanitizing solution

(example: Kay-5r). USE WARM WATER AND

FOLLOW THE MANUFACTURER’S

SPECIFICATIONS.

Make sure your hands are CLEAN and

SANITIZED before proceeding.

Step 2

Insert the product tube into the mix tank. Place the

mix tank into the cabinet. Fill the mix tank with

sanitizing solution.

Brush clean the quick disconnect (QD) socket.

Connect the QD fitting/product tube to the

connector located at the top center of the

cabinet.

B. Units NOT Equipped With Quick

Disconnects

Using an empty bag of syrup, cut the syrup line

connector from the end of the bag.

Note: Choose the appropriate illustration below

showing the connector style used in your store.

Figure 80

36

Model C903Operating Procedures

Page 41

Figure 81