STIHL FC 56 C Owner's Manual

{

STIHL FC 56 C

Instruction Manual Manual de instrucciones

Warning!

Read and follow all safety precautions in Instruction Manual – improper use can cause serious or fatal injury.

Advertencia!

Lea y siga todas las precauciones de seguridad dadas en el manual de instrucciones – el uso incorrecto puede causar lesiones graves o mortales.

Instruction Manual 1 - 37

Manual de instrucciones 39 - 81

Contents

|

|

Guide to Using this Manual |

2 |

|

|

|

Safety Precautions and Working |

|

|

|

|

Techniques |

3 |

|

Manual |

|

Using the Unit |

12 |

|

|

Mounting the Loop Handle |

14 |

||

Instruction |

|

Fuel |

15 |

|

|

|

Mounting the Cutting Blade |

15 |

|

Original |

|

Fueling |

16 |

|

|

Starting / Stopping the Engine |

19 |

||

|

recycled. |

Operating Instructions |

21 |

|

|

Engine Management |

22 |

||

|

|

Cleaning the Air Filter |

21 |

|

|

be |

Adjusting the Carburetor |

22 |

|

|

can |

|||

|

Spark Plug |

23 |

||

|

paper |

|||

|

Engine Running Behavior |

24 |

||

|

oils, |

|||

|

Lubricating the Gearbox |

25 |

||

paperfree-chlorineon vegetablecontaininks |

||||

Rewind Starter |

25 |

|||

|

|

|||

|

|

Storing the Machine |

25 |

|

|

|

Replacing the Depth Wheel |

26 |

|

|

|

Replacing the Skirt |

26 |

|

Printed |

Printing |

Replacing the Cutting Blade |

27 |

|

Inspections and Maintenance by |

27 |

|||

|

|

Dealer |

||

|

|

Maintenance and Care |

28 |

|

|

|

Main Parts |

30 |

|

2011 |

|

Specifications |

31 |

|

|

Special Accessories |

32 |

||

ANDREAS©STIHL AG & Co. KG, |

|

|||

8621-545-0458-B. M1.G11.PM. 0000001053006 GB |

Maintenance and Repairs |

32 |

||

{ |

|

|||

|

|

STIHL Incorporated Federal |

|

|

|

|

Emission Control Warranty |

|

|

|

|

Statement |

33 |

|

STIHL Incorporated California

Exhaust and Evaporative

Emissions Control Warranty

Statement

Trademarks

English

|

Allow only persons who fully understand |

|

this manual to operate your edger. |

35 |

To receive maximum performance and |

satisfaction from your STIHL edger, it is |

37important that you read, understand and follow the safety precautions and the operating and maintenance instructions in chapter "Safety Precautions and Working Techniques" before using your edger. For further information you can go to www.stihlusa.com.

Contact your STIHL dealer or the STIHL distributor for your area if you do not understand any of the instructions in this manual.

Warning!

Warning!

Because an edger is a high-speed cutting tool some special safety precautions must be observed to reduce the risk of personal injury. Careless or improper use may cause serious or even fatal injury.

Make sure your unit is equipped with the proper deflector and handle for the type of cutting attachment being used.

Always wear proper eye protection.

FC 56 C |

1 |

English

Guide to Using this Manual

Symbols in Text

Many operating and safety instructions are supported by illustrations.

The individual steps or procedures described in the manual may be marked in different ways:

N A bullet marks a step or procedure.

A description of a step or procedure that refers directly to an illustration may contain item numbers that appear in the illustration. Example:

N Loosen the screw (1). N Lever (2) ...

In addition to the operating instructions, this manual may contain paragraphs that require your special attention. Such paragraphs are marked with the symbols and signal words described below:

Danger!

Indicates an imminent risk of severe or fatal injury.

Warning!

Indicates a hazardous situation which, if not avoided, could result in severe or fatal injury.

Caution!

Indicates a risk of property damage, including damage to the machine or its individual components.

Engineering Improvements

STIHL’s philosophy is to continually improve all of its products. As a result, engineering changes and improvements are made from time to time. Therefore, some changes, modifications and improvements may not be covered in this manual. If the operating characteristics or the appearance of your machine differs from those described in this manual, please contact your STIHL dealer for assistance.

Pictograms

The meanings of the pictograms attached to or embossed on the machine are explained in this manual.

Depending on the model concerned, the following pictograms may be on your machine.

Fuel tank for gasoline and engine oil mixture

Press to operate decompression valve

Manual fuel pump

Press to operate manual fuel pump

Filler hole for gear lubricant

Air intake summer mode

Air intake winter mode

Handle heating

2 |

FC 56 C |

Safety Precautions and

Working Techniques

Because an edger is a high-speed, fast-cutting power tool, special safety precautions must be observed to reduce the risk of personal injury.

It is important that you read, fully understand and observe the following safety precautions and warnings. Read the instruction manual and the safety precautions periodically. Careless or improper use may cause serious or fatal injury.

Warning!

As more fully explained later in these Safety Precautions, to reduce the risk of personal injury, make sure your unit is equipped with the proper handle, harness and deflector. Use only cutting attachments that are specifically authorized by STIHL for use on your FC model.

Have your STIHL dealer show you how to operate your power tool. Observe all applicable local safety regulations, standards and ordinances.

Warning!

Do not lend or rent your power tool without the instruction manual. Be sure that anyone using it understands the information contained in this manual.

Warning!

The use of this machine may be hazardous. If the rotating blade comes in contact with your body, it will cut you. When it comes in contact with solid foreign objects such as rocks or bits of metal, it may fling them directly or by ricochet in the direction of bystanders or the operator. Striking such objects could damage the cutting attachment and may cause blades to crack, chip or break. Thrown objects, including broken blades, may result in serious or fatal injury to the operator or bystanders.

Use your edger only for edging in grass, weeds and soft green plants.

Warning!

Do not use it for other purposes, since misuse may result in personal injury or property damage, including damage to the machine.

Warning!

Minors should never be allowed to use this power tool. Bystanders, especially children, and animals should not be allowed in the area where it is in use.

Warning!

To reduce the risk of injury to bystanders and damage to property, never let your power tool run unattended. When it is not in use (e.g. during a work break), shut it off and make sure that unauthorized persons do not use it.

English

Most of these safety precautions and warnings apply to the use of all STIHL edgers. Different models may have different parts and controls. See the appropriate section of your instruction manual for a description of the controls and function of the parts of your model.

Safe use of an edger involves

1.the operator

2.the power tool

3.the use of the power tool.

THE OPERATOR

Physical Condition

You must be in good physical condition and mental health and not under the influence of any substance (drugs, alcohol, etc.) which might impair vision, dexterity or judgment. Do not operate this machine when you are fatigued.

Warning!

Be alert – if you get tired, take a break. Tiredness may result in loss of control. Working with any power tool can be strenuous. If you have any condition that might be aggravated by strenuous work, check with your doctor before operating this machine.

Warning!

Prolonged use of a power tool (or other machines) exposing the operator to vibrations may produce whitefinger disease (Raynaud's phenomenon) or carpal tunnel syndrome.

FC 56 C |

3 |

English

These conditions reduce the hand's ability to feel and regulate temperature, produce numbness and burning sensations and may cause nerve and circulation damage and tissue necrosis.

All factors which contribute to whitefinger disease are not known, but cold weather, smoking and diseases or physical conditions that affect blood vessels and blood transport, as well as high vibration levels and long periods of exposure to vibration are mentioned as factors in the development of whitefinger disease. In order to reduce the risk of whitefinger disease and carpal tunnel syndrome, please note the following:

–Most STIHL power tools are available with an anti-vibration ("AV") system designed to reduce the transmission of vibrations created by the machine to the operator's hands. An AV system is recommended for those persons using power tools on a regular or sustained basis.

–Wear gloves and keep your hands warm.

–Keep the AV system well maintained. A power tool with loose components or with damaged or worn AV elements will tend to have higher vibration levels.

–Maintain a firm grip at all times, but do not squeeze the handles with constant, excessive pressure. Take frequent breaks.

All the above-mentioned precautions do not guarantee that you will not sustain whitefinger disease or carpal tunnel syndrome. Therefore, continual and regular users should closely monitor the

4

condition of their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

Warning!

The ignition system of the STIHL unit produces an electromagnetic field of a very low intensity. This field may interfere with some pacemakers. To reduce the risk of serious or fatal injury, persons with a pacemaker should consult their physician and the pacemaker manufacturer before operating this tool.

Proper Clothing

Warning!

To reduce the risk of injury, the operator should wear proper protective apparel.

The deflector provided with your power tool will not protect the operator from all foreign objects (gravel, glass, wire, etc.) thrown back by the rotating cutting attachment. Thrown objects may also ricochet and strike the operator.

Warning!

To reduce the risk of injury to your eyes never

operate your power tool unless wearing goggles or properly fitted protective glasses with

adequate top and side protection complying with ANSI Z 87.1 (or your applicable national standard). To reduce the risk of injury to your face STIHL recommends that you also wear a face shield or face screen over your goggles or protective glasses.

Warning!

Power tool noise may damage your hearing.

Wear sound barriers (ear plugs or ear mufflers) to protect your hearing.

Continual and regular users should have their hearing checked regularly.

Be particularly alert and cautious when wearing hearing protection because your ability to hear warnings (shouts, alarms, etc.) is restricted.

Always wear gloves when handling the machine and metal blades. Heavy-duty, nonslip gloves improve your grip and help to protect your hands.

Clothing must be sturdy and snug-fitting, but allow

complete freedom of movement. Wear long

pants made of heavy material to help protect your legs. Do not wear shorts, sandals or go barefoot.

Avoid loose-fitting jackets, scarfs, neckties, jewelry, flared or cuffed pants, unconfined long hair or anything that could become caught on branches, brush or the moving parts of the unit. Secure hair so it is above shoulder level.

Good footing is very important. Wear sturdy boots with nonslip soles. Steel-toed safety boots are recommended.

FC 56 C

Wear an approved safety hard hat to reduce the risk of injury to your head when there is a danger of head injuries.

THE POWER TOOL

For illustrations and definitions of the power tool parts see the chapter on "Main Parts."

Warning!

Never modify this power tool in any way. Only attachments supplied by STIHL and expressly approved by STIHL for use with the specific STIHL model are authorized. Although certain unauthorized attachments are useable with STIHL power tools, their use may, in fact, be extremely dangerous.

If this tool is subjected to unusually high loads for which it was not designed (e.g. heavy impact or a fall), always check that it is in good condition before continuing work. Check in particular that the fuel system is tight (no leaks) and that the controls and safety devices are working properly. Do not continue operating this machine if it is damaged. In case of doubt, have it checked by your STIHL servicing dealer.

THE USE OF THE POWER TOOL

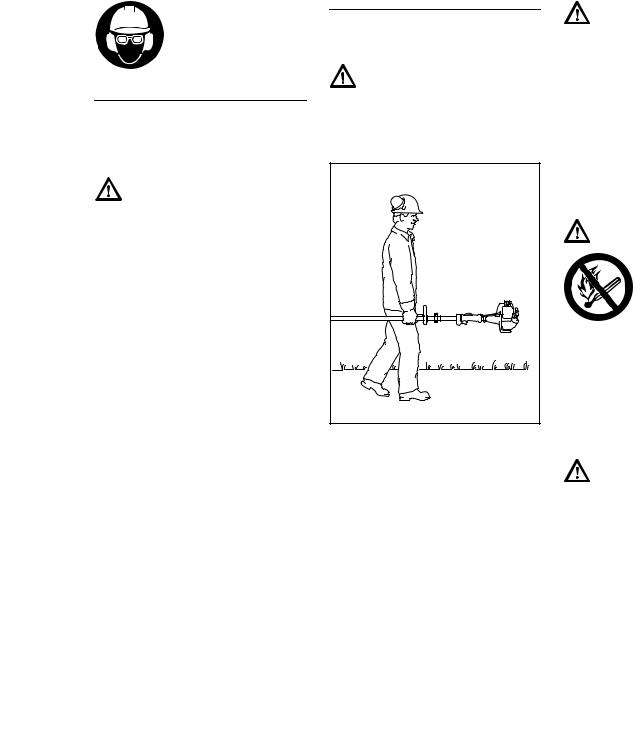

Transporting the Power Tool

Warning!

To reduce the risk of injury from loss of control and blade contact, never carry or transport your power tool with the cutting attachment moving.

389BA019 KN |

It may be carried only in a horizontal position. Grip the shaft in a manner that the machine is balanced horizontally. Keep the hot muffler away from your body and the cutting attachment behind you.

English

Warning!

Always shut off the engine and make sure that the cutting attachment has stopped before putting an edger down. When transporting it in a vehicle, properly secure it to prevent turnover, fuel spillage and damage to the unit.

Fuel

Your STIHL power tool uses an oilgasoline mixture for fuel (see the chapter on "Fuel" of your instruction manual.)

Warning!

Gasoline is an extremely flammable fuel. If spilled and ignited by a spark or

other ignition source, it can cause fire and serious burn injury or

property damage. Use extreme caution when handling gasoline or fuel mix. Do not smoke or bring any fire or flame near the fuel or the power tool. Note that combustible fuel vapor may escape from the fuel system.

Fueling Instructions

Warning!

To reduce the risk of serious injury from burns, never attempt to refuel the unit until it has been completely removed from the operator.

FC 56 C |

5 |

English

Warning!

Fuel your power tool in well-ventilated areas, outdoors. Always shut off the engine and allow it to cool before refueling. Gasoline vapor pressure may build up inside the fuel tank depending on the fuel used, the weather conditions and the tank venting system.

In order to reduce the risk of burns and other personal injury from escaping gas vapor and fumes, remove the fuel filler cap on your power tool carefully so as to allow any pressure build-up in the tank to release slowly. Never remove the fuel filler cap while the engine is running.

Select bare ground for fueling and move at least 10 feet (3 m) from the fueling spot before starting the engine. Wipe off any spilled fuel before starting your machine.

Warning!

Check for fuel leakage while refueling and dur-

ing operation. If fuel leakage is found, do not start or run the engine until the leak is fixed and

any spilled fuel has been wiped away. Take care not to get fuel on your clothing. If this happens, change your clothing immediately.

Different models may be equipped with different fuel caps.

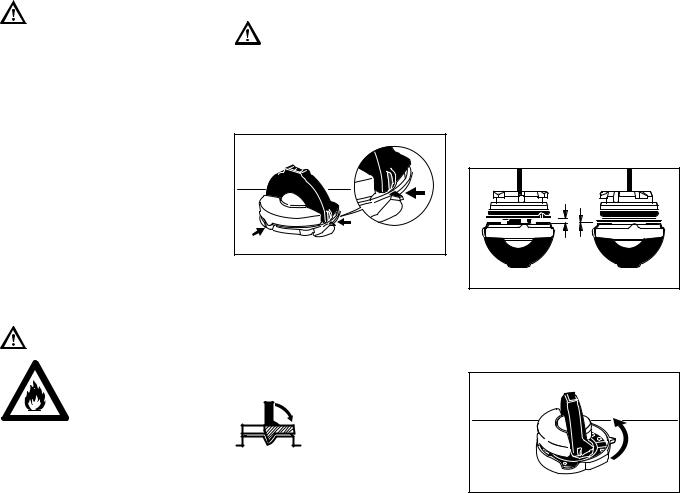

Toolless cap with grip

Warning!

In order to reduce the risk of fuel spillage and fire from an improperly tightened fuel cap, correctly position and tighten the fuel cap in the fuel tank opening.

001BA220 KN

To do this with this STIHL cap, raise the grip on the top of the cap until it is upright at a 90° angle. Insert the cap in the fuel tank opening with the raised positioning marks on the grip of the cap and on the fuel tank opening lining up. Using the grip, press the cap down firmly while turning it clockwise as far as it will go (approx. 1/4 turn).

Fold the grip flush with the top of the cap. Grip

the cap and check for tightness. If the grip does not lie completely flush with the cap and the detent on the grip does not fit in the corresponding recess in the filler opening, or if the cap is loose in the filler opening, the cap is not properly seated and tightened and you must repeat the above steps.

Misaligned, damaged or broken cap

NIf the cap does not drop fully into the opening when the positioning marks line up and/or if the cap does not tighten properly when twisted, the base of the cap may be prematurely rotated (vis-à-vis the top) to the closed position. Such misalignment can result from handling, cleaning or an improper attempt at tightening.

001BA227 KN |

Left: |

Base of cap in closed posi- |

|

tion (with open space) |

Right: |

Base of cap correctly posi- |

|

tioned for installation |

001BA226 KN |

NTo return the cap to the open position for installation, turn the cap (with the grip up) until it drops fully into the tank opening. Next, twist the cap counterclockwise as far as it will go (approx. 1/4 turn) – this will twist

6 |

FC 56 C |

the base of the cap into the correct position. Then, twist the cap clockwise, closing it normally.

NIf your cap still does not tighten properly, it may be damaged or broken; immediately stop use of the unit and take it to your authorized STIHL dealer for repair.

Screw Cap

Warning!

Unit vibrations can cause an improperly tightened

fuel filler cap to loosen or

come off and spill quanti-

ties of fuel. In order to reduce the risk of fuel spillage and fire, tighten the fuel filler

ties of fuel. In order to reduce the risk of fuel spillage and fire, tighten the fuel filler

cap by hand as securely as possible.

See also the "Fueling" chapter in your Instruction Manual for additional information.

Before Starting

Warning!

Always check your power tool for proper condition and operation before starting, particularly the throttle trigger, throttle trigger lockout, momentary stop switch, cutting blade, deflector and harness. The throttle trigger must move freely and always spring back to the idle position. Never attempt to modify the controls or safety devices. Never use a power tool that is damaged or not properly maintained.

FC 56 C

Warning!

Do not attach any cutting attachment to a unit without proper installation of all required parts. Failure to use the proper parts may cause the blade to fly off and seriously injure the operator or bystanders.

Warning!

The cutting attachment must be properly tightened and in safe operating condition. Inspect for loose parts (nuts, screws, etc.) and for cracked, bent, warped or damaged blades. Replace damaged blades before using the power tool.

Keep the handles clean and dry at all times; it is particularly important to keep them free of moisture, pitch, oil, fuel mix, grease or resin in order for you to maintain a firm grip and properly control your power tool.

Warning!

Check that the spark plug boot is securely mounted on the spark plug – a loose boot may cause arcing that could ignite combustible fumes and cause a fire.

Warning!

To reduce the risk of personal injury

to the operator

from blade contact and thrown objects, make

sure your unit is equipped with the proper deflector, handle and harness.

English |

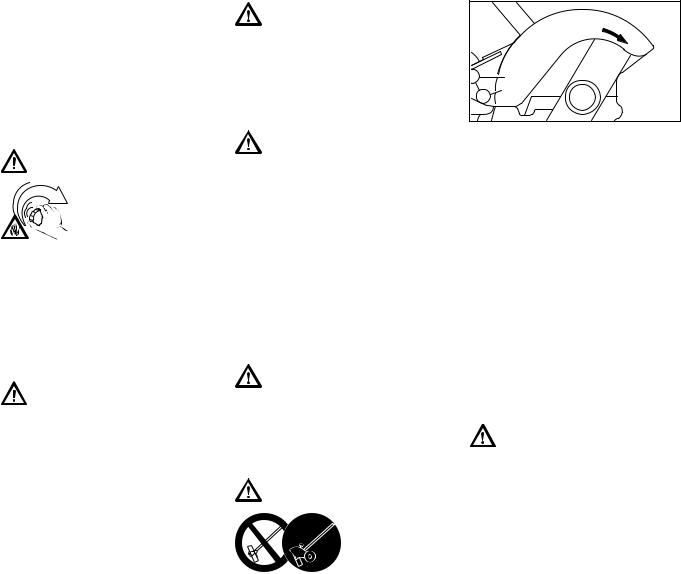

002BA118 KN |

An arrow on the deflector shows the correct direction of rotation of the cutting blade.

The arrow on the deflector must always face away from you, so that cuttings and other debris will be diverted away from the machine and your position (see chapter "Working Techniques".)

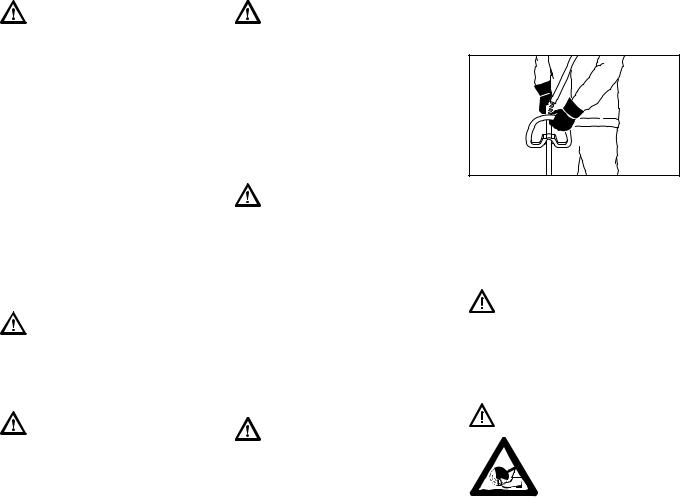

Adjust carrying harness and hand grip to suit your size before starting work. The machine should be properly balanced as specified in your instruction manual for proper control and less fatigue in operation. To be better prepared in case of an emergency, practise releasing the unit from the harness as quickly as possible.

Starting

Warning!

Start the engine at least 10 feet (3 m) from the fueling spot, outdoors only.

For specific starting instructions, see the appropriate section of your manual. Place the power tool on firm ground or other solid surface in an open area. Maintain good balance and secure footing.

7

English

Warning!

To reduce the risk of injury from blade contact, be absolutely sure that the cutting attachment is clear of you and all other obstructions and objects, including the ground, because when the engine starts at starting-throttle, engine speed will be fast enough for the clutch to engage and move the cutting attachment.

Once the engine has started, immediately blip the throttle trigger, which should release the starting throttle and allow the engine to slow down to idle.

With the engine running only at idle, attach the power tool to the spring hook of your harness (see appropriate chapter of this manual.)

Warning!

Your power tool is a one-person machine. Do not allow other persons in the general work area, even when starting.

Warning!

To reduce the risk of injury from loss of control, do not attempt to "drop start" your power tool.

Warning!

When you pull the starter grip, do not wrap the starter rope around your hand. Do not let the grip snap back, but guide the starter rope to rewind it properly. Failure to follow this procedure may result in injury to your hand or fingers and may damage the starter mechanism.

Important Adjustments

Warning!

To reduce the risk of personal injury from loss of control or contact with the running cutting attachment, do not use your unit with incorrect idle adjustment. At correct idle speed, the cutting attachment should not move. For directions on how to adjust idle speed, see the appropriate section of your instruction manual.

If you cannot set the correct idle speed, have your STIHL dealer check your power tool and make proper adjustments and repairs.

Warning!

This unit is equipped with an ignition system that is normally in operational readiness. After the setting lever is used to stop the engine, it automatically springs back to the "on" position. If the engine is warm, it may be possible to start it by simply pulling the starter rope, with no further adjustments. To reduce the risk of injury, be particularly alert to keep children away from the unit.

During Operation

Holding and Controlling the Power

Tool

002BA054 KN

Always hold the unit firmly with both hands on the handles while you are working. Wrap your fingers and thumbs around the handles.

Your right hand should grip the rear handle. This also applies to left-handers.

Warning!

To reduce the risk of injury from loss of control, never work on a ladder or on any other insecure support. Never hold the cutting attachment above waist height.

Warning!

Never attempt to operate your power tool with one hand. Loss of control of

the power tool resulting in serious or fatal injury may result. To reduce

the risk of cut injuries, keep hands and feet away from the cutting attachment. Never touch a moving cutting attachment with your hand or any other part of your body.

8 |

FC 56 C |

Warning!

Do not overreach. Keep proper footing and balance at all times. Special care must be taken in slippery conditions (wet ground, snow) and in difficult, overgrown terrain. Watch for hidden obstacles such as tree stumps, roots and ditches to avoid stumbling. For better footing, clear away scrub and cuttings. Be extremely cautious when working on slopes or uneven ground.

Working Conditions

Operate and start your power tool only outdoors in a well ventilated area. Operate it under good visibility and daylight conditions only. Work carefully.

Warning!

As soon as the engine is running, this product generates toxic exhaust

fumes containing chemicals, such as unburned hydrocarbons (including

benzene) and carbon monoxide, that are known to cause respiratory problems, cancer, birth defects, or other reproductive harm. Some of the gases (e.g. carbon monoxide) may be colorless and odorless. To reduce the risk of serious or fatal injury / illness from inhaling toxic fumes, never run the machine indoors or in poorly ventilated locations.

Warning!

If the vegetation being cut or the surrounding ground is coated with a chemical substance (such as an active pesticide or herbicide), read and follow the instructions and warnings that accompanied the substance at issue.

Warning!

Inhalation of certain dusts, especially organic dusts such as mold or pollen, can cause susceptible persons to have an allergic or asthmatic reaction. Substantial or repeated inhalation of dust and other airborne contaminants, in particular those with a smaller particle size, may cause respiratory or other illnesses. Control dust at the source where possible. Use good work practices, such as operating the unit so that the wind or operating process directs any dust raised by the power tool away from the operator. Follow the recommendations of EPA / OSHA / NIOSH and occupational and trade associations with respect to dust ("particulate matter".) When the inhalation of dust cannot be substantially controlled, i.e., kept at or near the ambient (background) level, the operator and any bystanders should wear a respirator approved by NIOSH / MSHA for the type of dust encountered.

Operating Instructions

Warning!

Do not operate your power tool using the starting throttle lock, as you do not have control of the engine speed.

English

In the event of an emergency, switch off the engine immediately – move the slide control / momentary stop switch to 0 or

STOP.

Warning!

The cutting attachment continues to rotate for a short period after the throttle trigger is released (flywheel effect.)

Warning!

The rotating cutting attachment may fling foreign objects directly or by ricochet a great distance.

15m (50ft)

15m (50ft)

To reduce the risk of eye and other injury always wear proper eye protection (see the chapter on "Proper Clothing") and ensure that bystanders are at least

50 feet (15 m) away. To reduce the risk of damage to property, also maintain this distance from such objects as vehicles or windows. Any coworkers who must be in the restricted area should also wear goggles or protective glasses. Stop the engine immediately if you are approached.

FC 56 C |

9 |

English

Warning!

Before you start work, examine the area for

stones, glass, fence wire,

metal, trash or other solid objects. The cutting attachment could throw

objects of this kind.

Warning!

During cutting, check the tightness and the condition of the cutting attachment at regular short intervals with the engine and attachment stopped. If the behavior of the attachment changes during use, stop the engine immediately, wait until the cutting attachment stops, and check the nut securing the attachment for tightness and the blade for cracks, wear and damage.

Warning!

A loose blade may vibrate, crack, break or come off the edger, which may result in serious or fatal injury. Make sure that the cutting attachment is properly tightened. Use the wrench supplied or one of sufficient length to obtain the proper torque. If the blade loosens after being properly tightened, stop work immediately. The retaining nut may be worn or damaged and should be replaced. If the blade continues to loosen, see your STIHL dealer. Never use an edger with a loose cutting attachment.

10

Warning!

Replace a cracked, bent, warped, damaged, dull or worn out blade immediately, even if damage is limited to superficial cracks. Such attachments may shatter at high speed and cause serious or fatal injury.

Warning!

When using your edger, avoid cutting close to fences, sides of buildings, tree trunks, stones or other such objects that could cause the power tool to kick out or could cause damage to the blade.

Warning!

If the blade or deflector becomes clogged or stuck, always shut off the engine and make sure the cutting attachment has stopped before cleaning. Grass, weeds, etc. should be cleaned off the blade at regular intervals.

Warning!

To reduce the risk of unintentional rotation of the cutting attachment and injury, always shut off the engine before replacing the cutting attachment.

Warning!

The gearbox becomes hot during operation. To reduce the risk of burn injury, do not touch the gear housing when it is hot.

Warning!

Never modify your muffler. Any modification could cause an increase in heat radiation, sparks or sound level, thereby increasing the risk of fire, burn injury or hearing loss. You may also permanently damage the engine. Have your muffler serviced and repaired by your STIHL servicing dealer only.

Warning!

The muffler and other parts of the engine (e.g. fins of the cylinder, spark plug) become hot during operation and remain hot for a while after stopping the engine. To reduce risk of burns, do not touch the muffler and other parts while they are hot. Keep the area around the muffler clean. Remove excess lubricant and all debris such as pine needles, branches or leaves. Let the engine cool down sitting on concrete, metal, bare ground or solid wood away from any combustible substances.

Warning!

An improperly mounted or damaged cylinder housing or a damaged/deformed muffler shell may interfere with the cooling process of the muffler. To reduce the risk of fire or burn injury, do not continue work with a damaged or improperly mounted cylinder housing or a damaged/deformed muffler shell.

Your muffler is furnished with a spark arresting screen designed to reduce the risk of fire from the emission of hot particles. Never operate your unit with a missing or damaged spark arresting screen. If your gas/oil mix ratio is correct

FC 56 C

(i.e., not too rich), this screen will normally stay clean as a result of the heat from the muffler and need no service or maintenance. If you experience loss of performance and you suspect a clogged screen, have your muffler maintained by a STIHL servicing dealer. Some state or federal laws or regulations may require a properly maintained spark arrestor for certain uses. See the "Maintenance, Repair and Storing" section of these Safety Precautions. Remember that the risk of a brush or forest fire is greater in hot or dry conditions.

Warning!

Some STIHL power tools are equipped with a catalytic converter, which is

designed to reduce the exhaust emissions of the engine by a chemical

process in the muffler. Due to this process, the muffler does not cool down as rapidly as conventional mufflers when the engine returns to idle or is shut off. To reduce the risk of fire and burn injuries when using a catalytic converter, always set your power tool down in the upright position and never locate it where the muffler is near dry brush, grass, wood chips or other combustible materials while it is still hot.

USING THE CUTTING ATTACHMENT

For an illustration of the cutting attachment and instructions on proper mounting see the chapter on "Replacing the Cutting Blade" in your instruction manual.

FC 56 C

Warning!

To reduce the risk of severe or fatal injury from blade contact and / or loss of control, never attempt to use a metal blade on an FC model for which it is not authorized.

MAINTENANCE, REPAIR AND STORING

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. However, if you make a warranty claim for a component which has not been serviced or maintained properly or if nonapproved replacement parts were used, STIHL may deny coverage.

Warning!

Use only identical STIHL replacement parts for maintenance and repair. Use of non-STIHL parts may cause serious or fatal injury.

Strictly follow the maintenance and repair instructions in the appropriate sections of your instruction manual.

Warning!

Always stop the engine and make sure that the cutting attachment is stopped before doing any maintenance or repair work or cleaning the power tool. Do not attempt any maintenance or repair work not described in your instruction manual. Have such work performed by your STIHL servicing dealer only.

English

Wear gloves when handling or performing maintenance on blades.

Warning!

Use the specified spark plug, and make sure it and the ignition lead are always clean and in good condition. Always press the spark plug boot snugly onto the spark plug terminal of the proper size. (Note: If the terminal has a detachable SAE adapter nut, it must be securely attached.) A loose connection between the spark plug and the ignition wire connector in the boot may create arcing that could ignite combustible fumes and cause a fire.

Warning!

Never test the ignition system with the spark plug boot removed from the spark plug or with a removed spark plug, since uncontained sparking may cause a fire.

Warning!

Do not operate your power tool if the muffler is damaged, missing or modified. An improperly maintained muffler will increase the risk of fire and hearing loss. Your muffler is equipped with a spark-arresting screen to reduce the risk of fire; never operate your power tool if the screen is missing, damaged or clogged. Remember that the risk of a brush or forest fire is greater in hot or dry weather.

In California, it is a violation of § 4442 or § 4443 or the Public Resources Code to use or operate gasoline-powered tools on forest-covered, brush-covered or grass-covered land unless the engine’s

11

English

exhaust system is equipped with a complying spark arrester that is maintained in effective working order. The owner/operator of this product is responsible for properly maintaining the spark arrester. Other states or governmental entities/agencies, such as the U.S. Forest Service, may have similar requirements. Contact your local fire agency or forest service for the laws or regulations relating to fire protection requirements.

Warning!

Never repair damaged cutting attachments by welding, straightening or modifying the shape. This may cause parts of the cutting attachment to come off and result in serious or fatal injuries.

Tighten all nuts, bolts and screws, except the carburetor adjustment screws, after each use.

Do not clean your machine with a pressure washer. The solid jet of water may damage parts of the machine.

Store the power tool in a dry and high or locked location out of reach of children.

Before storing for longer than a few days, always empty the fuel tank. See chapter "Storing the Machine" in the instruction manual.

Using the Unit

0815BA003 KN

0815BA003 KN

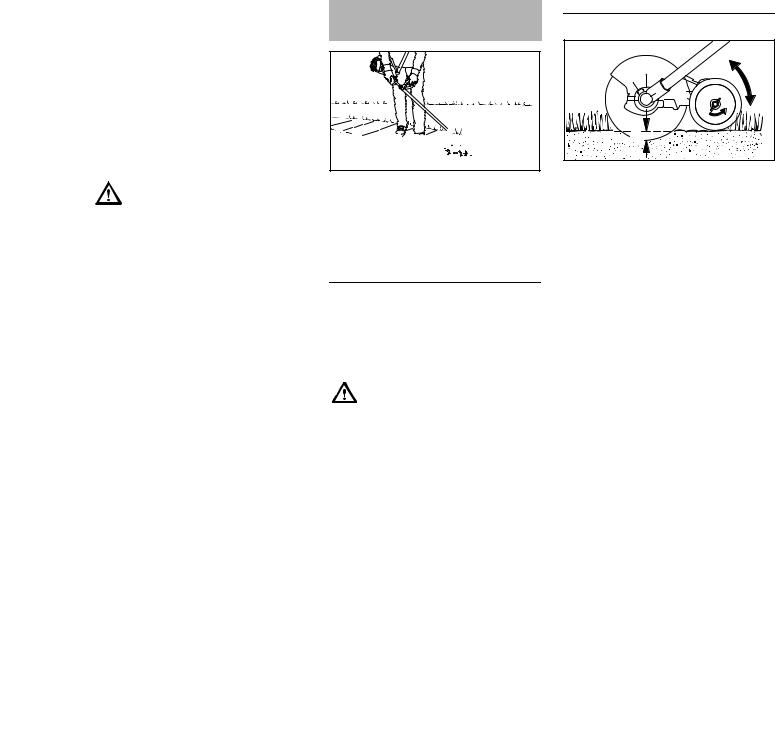

Your power edger is designed to produce sharp contoured borders around lawns and flower beds. It will cut almost all types of grass, weeds and soft green plants.

Preparations

If the soil is very dry, spray it with water before you start work: this softens the soil a little and also reduces the amount of dust created. Slightly damp green plants are easier to cut.

Clear away all obstacles and solid objects from the work area.

NPlan the best route for edging. Always hold and operate your edger on the right-hand side of your body.

Adjusting Depth of Cut

|

|

2 |

|

1 |

KN |

|

|

|

A |

|

241BA001 |

|

|

NTo reduce the risk of injury, shut off the engine.

NLoosen the wingnut (1) counterclockwise.

NAdjust the wheel (2): Upwards to increase the depth of cut (A) or downwards to reduce the depth of cut (A).

12 |

FC 56 C |

Adjust correctly

B

B

2 |

3

241BA002 KN

241BA002 KN

The depth of cut depends on the uneveness of the ground, your height and the way you hold the edger. Use the following procedure:

NAdjust the depth wheel (2) so that the blade (3) just touches the ground or breaks the surface of the soil by no more than 0.2 in

(5 mm) (B) in the normal working position.

241BA003 KN

NTighten down the wingnut clockwise.

NStanding in the normal working position, check the depth of cut again and correct it if necessary,

0815BA004 KN |

Do not adjust the deflector.

Do not adjust the deflector.

The deflector has been set at the factory so that the arrow on the deflector and the open side point away from the operator. This ensures that cuttings and other debris are directed away from the machine and operator.

English

Lawn edging

90° |

241BA004 KN |

N Starting the engine

NStart the cut at no less than half throttle and continue cutting at full throttle.

NHold and guide your edger so that the blade is vertical.

NCut steadily so that the engine is not lugged down – do not apply force.

NCut at no more than a normal walking pace.

NDo not push the blade into the ground.

NAlways walk forwards when cutting, do not pull the unit towards you.

NEdge at a steady pace to avoid having to make several passes.

FC 56 C |

13 |

English |

1 |

241BA005 KN |

NUse the gunning sight (1) to line up the blade on the edge.

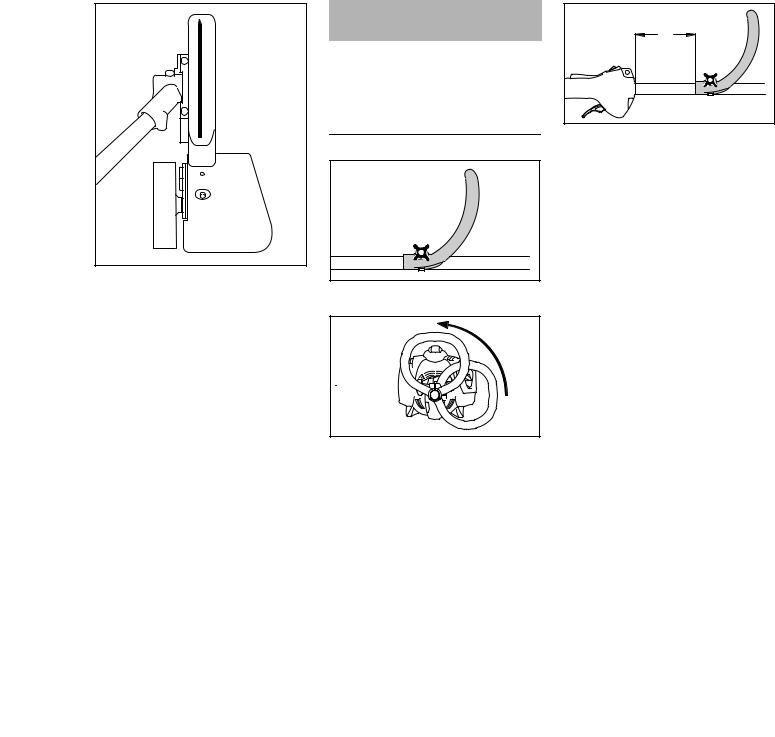

Mounting the Loop Handle

Your new power tool comes with the loop handle mounted on the drive tube, but it must be turned and lined up to suit your requirements.

Adjusting the Loop Handle

1 |

KN |

|

546BA010 |

N Loosen the star knob (1).

A

546BA011 KN

The loop handle can be adjusted to suit the height and reach of the operator and the application by changing

distance (A).

Recommended distance (A): about 6 in (15 cm)

NSlide the handle to the required position.

NTighten down the star knob so that the handle cannot be rotated on the drive tube.

545BA004 KN

NTurn the handle to the vertical position.

14 |

FC 56 C |

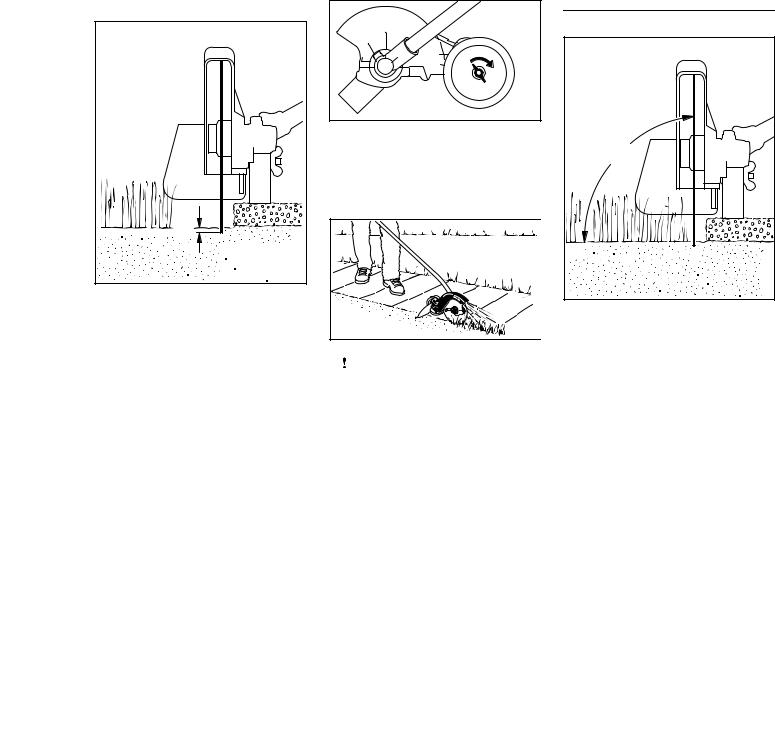

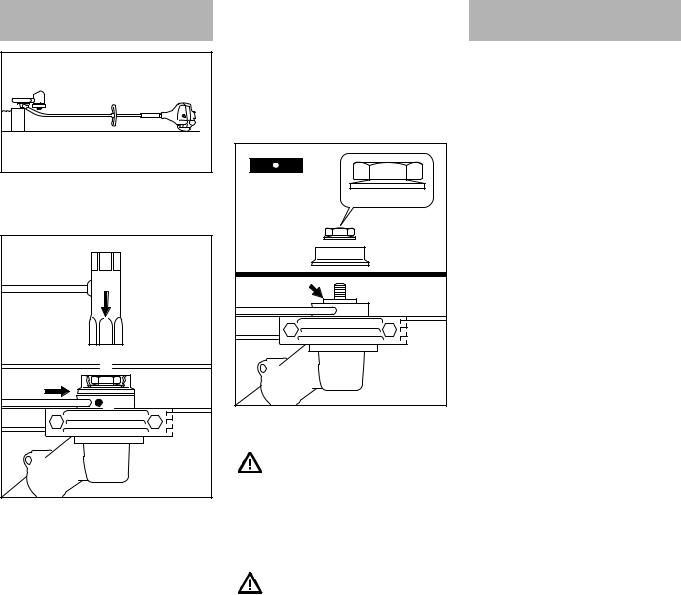

Mounting the Cutting Blade

1 |

241BA006 KN |

NLay the power edger on its back so that the blade mounting (1) faces up.

|

5 |

|

|

6 |

|

2 |

4 |

|

3 |

||

|

||

|

241BA011 KN |

NInsert the stop pin (2) or screwdriver

– see "Special Accessories" – into the hole (3) as far as stop – apply slight pressure and turn back and

forth together with the thrust washer (4) until the pin slips into position and blocks the shaft.

NFit the combination wrench (5) on the nut (6).

NLoosen and unscrew the nut clockwise (left-hand thread).

N Remove the thrust washer.

7 |

|

10 |

|

6 |

|

4 |

7 |

|

|

9 |

|

8 |

|

|

241BA012 KN |

NPlace the blade (7) on the thrust plate (8).

Collar (see arrow) must engage the blade's mounting hole.

NFit the thrust washer (4) on the shaft (9) and block the shaft.

NScrew the mounting nut (6) on to the shaft counterclockwise and tighten it down firmly.

If the cup spring (10) on the nut (6) has lost its tension, fit a new nut.

English

Fuel

This engine is certified to operate on unleaded gasoline and the STIHL twostroke engine oil at a mix ratio of 50:1.

Your engine requires a mixture of highquality gasoline and two-stroke air cooled engine oil.

Use mid-grade unleaded gasoline with a minimum octane rating of 89 (R+M/2) and no more than 10% ethanol content.

Fuel with a lower octane rating may increase engine temperatures. This, in turn, increases the risk of piston seizure and damage to the engine.

The chemical composition of the fuel is also important. Some fuel additives not only detrimentally affect elastomers (carburetor diaphragms, oil seals, fuel lines, etc.), but magnesium castings and catalytic converters as well. This could cause running problems or even damage the engine. For this reason STIHL recommends that you use only high-quality unleaded gasoline!

Gasoline with an ethanol content of more than 10% can cause running problems and major damage in engines with a manually adjustable carburetor and should not be used in such engines.

The ethanol content in gasoline affects engine running speed – it may be necessary to readjust the carburetor if you use fuels with various ethanol contents.

FC 56 C |

15 |

English

Warning!

To reduce the risk of personal injury from loss of control and / or contact with the running cutting tool, do not use your unit with incorrect idle adjustment. At correct idle speed, the cutting tool should not move.

If your power tool shows an incorrect idle adjustment, have your STIHL dealer check your power tool and make proper adjustments and repairs.

The idle speed and maximum speed of the engine change if you switch from a fuel with a certain ethanol content to another fuel with a much higher or lower ethanol content.

This problem can be avoided by always using fuel with the same ethanol content.

Use only STIHL two-stroke engine oil or equivalent high-quality two-stroke engine oils that are designed for use only in air cooled two-cycle engines.

We recommend STIHL HP Ultra 2-Cycle Engine Oil since it is specially formulated for use in STIHL engines.

Do not use BIA or TCW rated (twostroke water cooled) mix oils or other mix oils that state they are for use in both water cooled and air cooled engines (e.g., outboard motors, snowmobiles, chain saws, mopeds, etc.).

Take care when handling gasoline. Avoid direct contact with the skin and avoid inhaling fuel vapor. When filling at the pump, first remove the container from your vehicle and place the container on the ground before filling. To reduce the risk of sparks from static

discharge and resulting fire and/or explosion, do not fill fuel containers that are sitting in or on a vehicle or trailer.

The container should be kept tightly closed in order to limit the amount of moisture that gets into the mixture.

The machine‘s fuel tank should be cleaned as necessary.

Fuel mix ages

Only mix sufficient fuel for a few days work, not to exceed 3 months of storage. Store in approved fuel-containers only. When mixing, pour oil into the container first, and then add gasoline. Close the container and shake it vigorously by hand to ensure proper mixing of the oil with the fuel.

Gaso- |

Oil (STIHL 50:1 or equiva- |

line |

lent high-quality oils) |

US gal. |

US fl.oz. |

1 |

2.6 |

2 1/2 |

6.4 |

5 |

12.8 |

Dispose of empty mixing-oil containers only at authorized disposal locations.

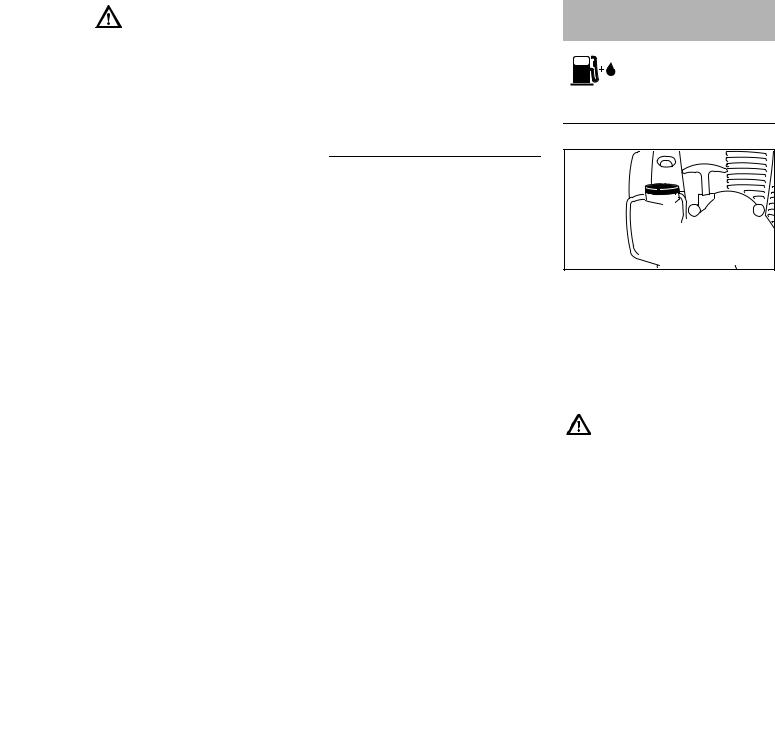

Fueling

Preparations

002BA456 KN

002BA456 KN

NBefore fueling, clean the filler cap and the area around it to ensure that no dirt falls into the tank.

Always thoroughly shake the mixture in the canister before fueling your machine.

NPosition the machine so that the filler cap is facing up.

In order to reduce the risk of fire and personal injury from escaping

gas vapor and fumes, remove the fuel filler cap carefully so as to allow any pressure build-up in the tank to release slowly.

One of two different filler caps is installed as standard at the factory.

16 |

FC 56 C |

002BA418 KN

Toolless filler cap (with folding grip)

002BA419 KN

Threaded filler cap

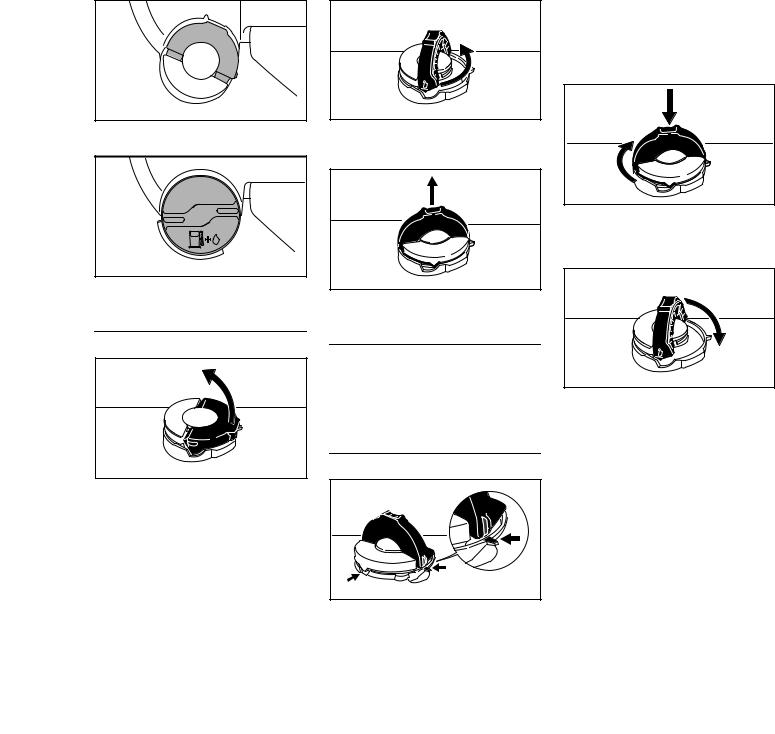

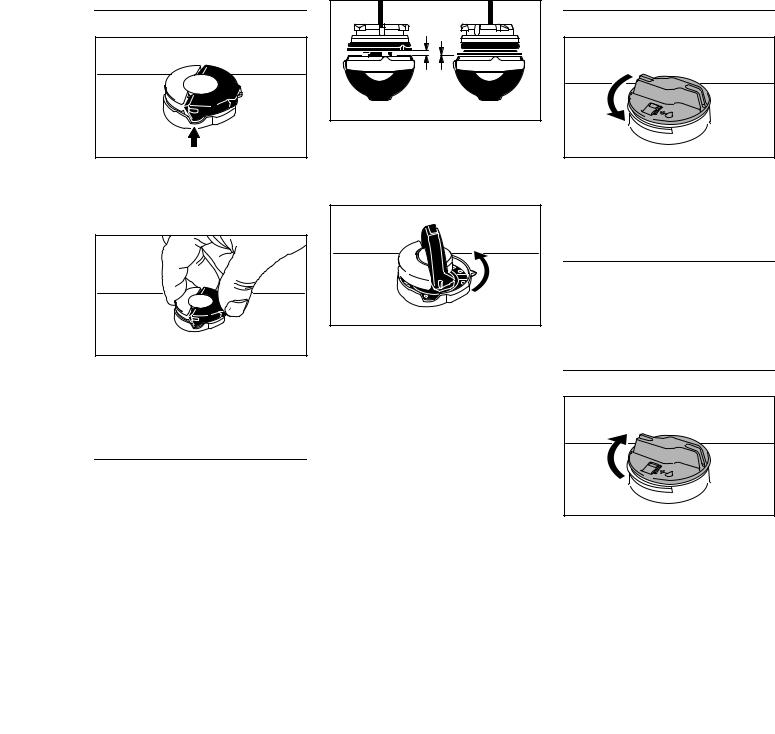

Opening the toolless filler cap

001BA218 KN |

NRaise the grip into an upright position.

FC 56 C

001BA219 KN |

NTurn the cap counterclockwise (approx. 1/4 turn).

001BA224 KN |

N Remove fuel filler cap.

Refueling

Take care not to spill fuel while fueling and do not overfill the tank. STIHL recommends use of the STIHL filling system (special accessory).

Closing the toolless filler cap

English

NInsert the cap – positioning marks on the cap and the fuel tank opening must line up.

NThe cap should drop fully into the opening in this position.

001BA221 KN |

NWhile pressing the cap down, twist it firmly clockwise as far as it will go (approx. 1/4 turn).

001BA222 KN |

N Fold down the grip.

001BA220 KN

With grip in an upright position:

17

English

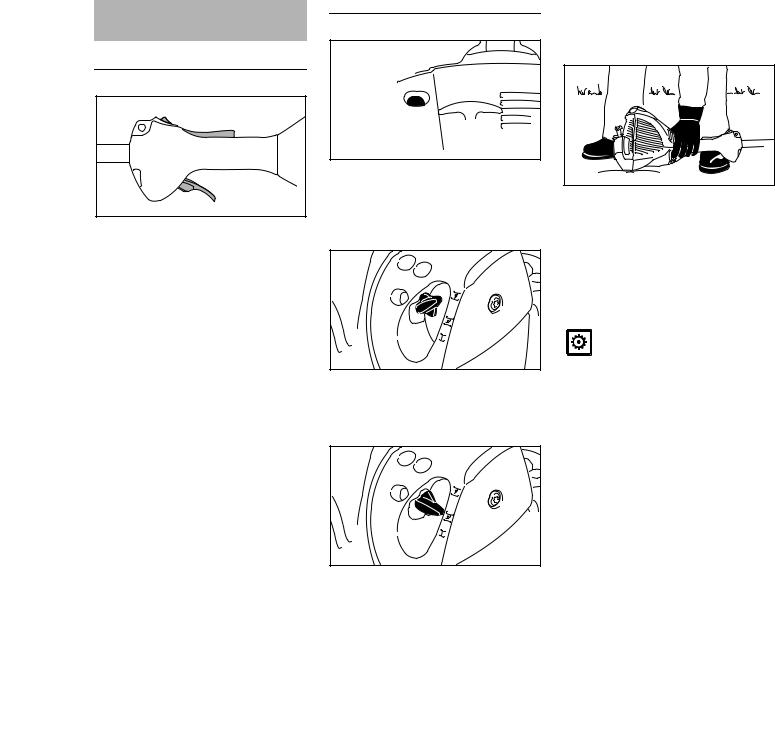

Checking for proper closure

001BA223 KN |

NThe lug on the grip must engage entirely in the recess (arrow), and the grip must lie completely flush with the top of the cap.

001BA225 KN

NGrip the cap and check for tightness.

NIf the cap can be moved, it is not properly installed.

Misalignment of the cap parts

NIf the cap does not drop fully into the opening when the positioning marks line up and/or if the cap does not tighten properly when twisted, the base of the cap may be rotated out of position vis-à-vis the top.

NSuch misalignment can result from handling, cleaning or an improper attempt at tightening.

001BA227 KN |

Left: |

Base of improperly aligned |

|

cap (with open space) |

Right: |

Base of cap correctly posi- |

|

tioned for installation |

001BA226 KN |

NTo correct a misalignment, turn the cap (with the grip up) until it drops fully into the tank opening.

NTwist the cap counterclockwise as far as it will go (approx. 1/4 turn) – this will twist the base of the cap into the correct position.

NTwist the cap clockwise, closing it normally – see the sections "Closing" and "Checking for proper closure."

NIf your cap still does not tighten properly, it may be damaged or broken; immediately stop use of the unit and take it to your authorized STIHL dealer for repair.

Opening the threaded filler cap

002BA447 KN |

NTurn the cap counterclockwise until it can be removed from the tank opening.

N Remove the filler cap.

Refueling

Take care not to spill fuel while fueling and do not overfill the tank. STIHL recommends use of the STIHL filling system (special accessory).

Closing the threaded filler cap

002BA448 KN |

N Position cap.

NTurn the cap clockwise as far as it will go and tighten it as securely as possible by hand.

18 |

FC 56 C |

Starting / Stopping the

Engine

Controls

3 1

545BA002 KN

1Throttle trigger lockout

2Throttle trigger

3Momentary stop switch with Run and 0 = Stop positions.

Function of stop switch and ignition system

The momentary stop switch is normally in the Run position: Ignition is on in this position – the engine is ready to start and may be started. If the momentary stop switch is moved to the 0 position, the ignition is off. It is automatically switched on again after the engine comes to a standstill.

Starting the Engine

4

4

KN547BA015

KN547BA015

NPress the fuel pump bulb (4) at least five times – even if the bulb is already filled with fuel.

Cold engine (cold start)

5 |

KN |

|

547BA016 |

NPress in the choke lever (5) and turn it to g at the same time.

Warm engine (warm start)

English

Also use this setting if the engine has been running but is still cold.

Starting |

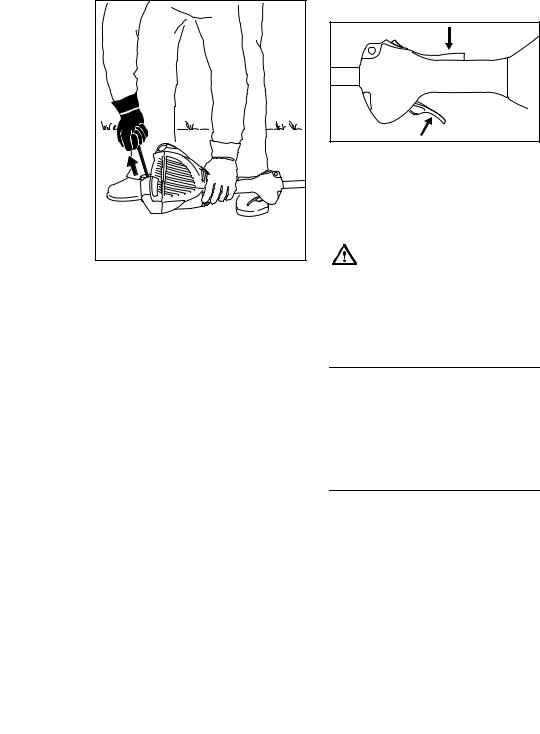

547BA018 KN |

NPlace the unit on the ground: Check that the cutting blade is not touching the ground of any other obstacles.

N Make sure you have a firm footing.

NHold the unit firmly on the ground with your left hand and press down

– do not touch the throttle trigger or throttle trigger lockout.

Do not stand or kneel on the drive tube.

547BA017 KN

547BA017 KN

NPress in the choke lever (5) and turn it to <at the same time.

FC 56 C |

19 |

English

547BA020 KN

NPull the starter grip slowly with your right hand until you feel it engage and then continue pulling it slowly and steadily. Do not pull out the starter rope to full length – it might otherwise break.

NDo not let the starter grip snap back. Guide it slowly back into the housing so that the starter rope can rewind properly.

NContinue cranking until the engine runs.

As soon as the engine runs

547BA021 KN

NPress down the throttle trigger lockout and open the throttle – the choke lever moves to the run position F . After a cold start, warm up the engine by opening the throttle several times.

Make sure the carburetor is

correctly adjusted. The cutting blade must not rotate when the engine is idling.

Your machine is now ready for operation.

Shut off the engine.

NMove the momentary stop switch in the direction of 0 – the engine stops – release the momentary stop switch – it springs back to the run position.

Other hints on starting

Engine stalls in cold start position g or under acceleration

NMove the choke lever to <and continue cranking until the engine runs.

Engine does not start in warm start position <

NMove the choke lever to gand continue cranking until the engine runs.

If the engine does not start

NCheck that choke lever is in correct position.

NCheck that there is fuel in the tank and refuel if necessary.

NCheck that the spark plug boot is properly connected.

N Repeat the starting procedure.

Fuel tank run until dry

NAfter refueling, press the fuel pump bulb at least five times – even if the bulb is filled with fuel.

NSet the choke lever to suit the engine temperature.

N Now start the engine.

20 |

FC 56 C |

|

|

|

Operating Instructions |

Cleaning the Air Filter |

|

|

|

|

During break-in period

A factory-new machine should not be run at high revs (full throttle off load) for the first three tank fillings. This avoids unnecessary high loads during the break-in period. As all moving parts have to bed in during the break-in period, the frictional resistances in the engine are greater during this period. The engine develops its maximum power after about 5 to 15 tank fillings.

During Operation

After a long period of full throttle operation, allow the engine to run for a short while at idle speed so that engine heat can be dissipated by the flow of cooling air. This protects enginemounted components (ignition, carburetor) from thermal overload.

After Finishing Work

Storing for a short period: Wait for the engine to cool down. Empty the fuel tank and keep the machine in a dry place, well away from sources of ignition, until you need it again. For longer out-of- service periods – see "Storing the Machine".

If there is a noticeable loss of engine power

|

3 |

1 |

2 |

KN |

|

|

547BA022 |

N Move the choke lever (1) to <.

NTurn the screw (2) in the filter cover (3) counterclockwise until the cover is loose.

NEase the filter cover (3) over the choke lever and lift it away.

NClean away loose dirt from around the filter.

English

4

4

547BA023 KN

NReach into the recess (4) in the filter housing and take out the felt

filter (5).

NFit a new felt filter element (5). As a temporary measure you can knock it out on the palm of your hand or blow it out with compressed air. Do not wash.

Replace damaged parts.

Replace damaged parts.

NFit the felt filter (5) in the filter housing, make sure it is properly seated – the arrow points to the recess.

N Move the choke lever (1) to <.

NFit the filter cover in position, making sure the screw is square. Tighten down the screw.

FC 56 C |

21 |

English

Engine Management

Exhaust emissions are controlled by the design of the fundamental engine parameters and components (e.g. carburation, ignition, timing and valve or port timing) without the addition of any major hardware.

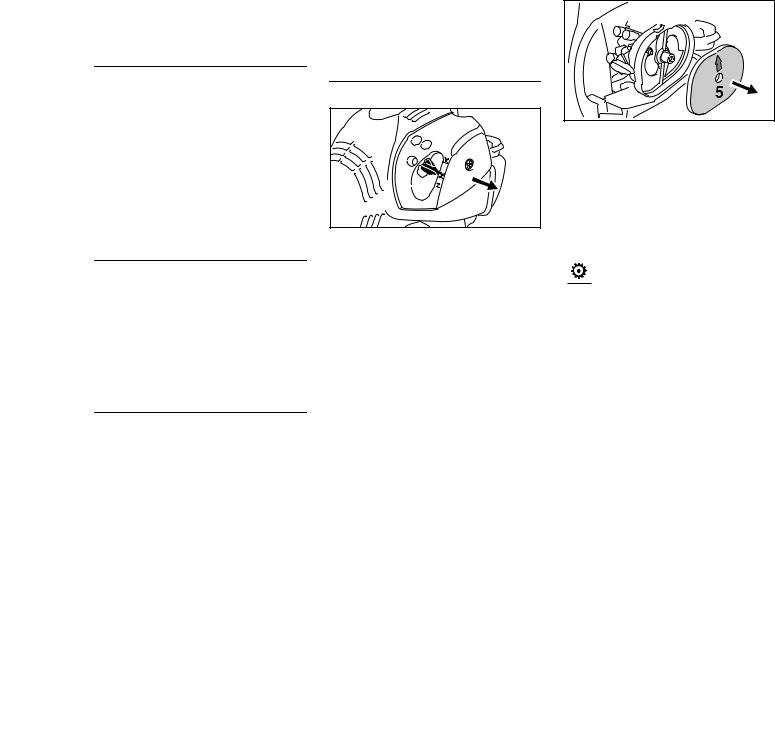

Adjusting the Carburetor

The carburetor comes from the factory with a standard setting.

This setting provides an optimum fuel-air mixture under most operating conditions.

With this carburetor it is only possible to make corrections with the adjusting screws within fine limits.

Standard Setting

N Shut off the engine.

NMount the cutting blade, check it and clean it if necessary (it must be clean and not warped).

NCheck the air filter and replace the element if necessary.

NHave the spark arresting screen (not all markets) checked – see “Inspection and Maintenance by Dealer"

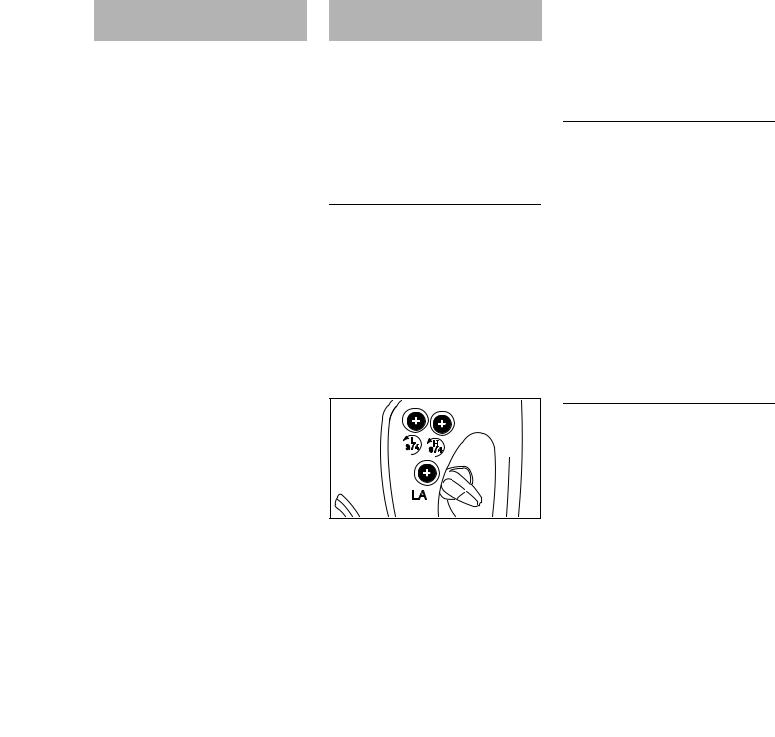

547BA024 KN

547BA024 KN

NTurn the high speed screw (H) counterclockwise as far as stop (max. 3/4 turn possible).

NTurn the low speed screw (L) counterclockwise as far as stop (max. 3/4 turn possible).

NStart and warm up the engine if necessary.

NAdjust idle speed with the idle speed screw (LA) so that the cutting blade does not turn.

Fine Tuning for Operation in Mountains or at Sea Level

A slight correction of the setting may be necessary if engine power is not satisfactory when operating at high altitude or at sea level.

N Warm up the engine.

At high altitude

NTurn high speed screw (H) clockwise (leaner) – no further than stop.

At sea level

NTurn high speed screw (H) slightly counterclockwise (richer) – no further than stop.

Adjusting Idle Speed

N Warm up the engine.

Engine stops while idling

NTurn the idle speed screw (LA) slowly clockwise until the engine runs smoothly – the cutting blade must not turn.

22 |

FC 56 C |

Cutting blade rotates when engine is idling

NTurn the idle speed screw (LA) counterclockwise until the blade stops moving and then turn the screw another full turn in the same direction.

If the cutting blade continues to rotate when the engine is idling, have your machine checked and repaired by your servicing dealer.

Erratic idling behavior, engine stops even though setting of LA screw has been corrected, poor acceleration

Idle setting is too lean

NTurn the low speed screw (L) counterclockwise, no further than stop, until the engine runs and accelerates smoothly.

Erratic idling behavior, engine speed drops when swinging the machine

Idle setting is too rich

NTurn the low speed screw (L) clockwise (1/8 of a turn or 45° at a time) until the engine runs smoothly and accelerates well.

It is usually necessary to change the setting of the idle speed screw (LA) after corrections to the low speed screw (L).

Spark Plug

If engine is down on power, difficult to start or runs poorly at idling speed, first check the spark plug.

Fit a new spark plug after approx. 100 operating hours or earlier if the electrodes are badly eroded.

Wrong fuel mix (too much engine oil in the gasoline), a dirty air filter and unfavorable running conditions (mostly at part throttle etc.) affect the condition of the spark plug. These factors cause deposits to form on the insulator nose which may result in trouble in operation.

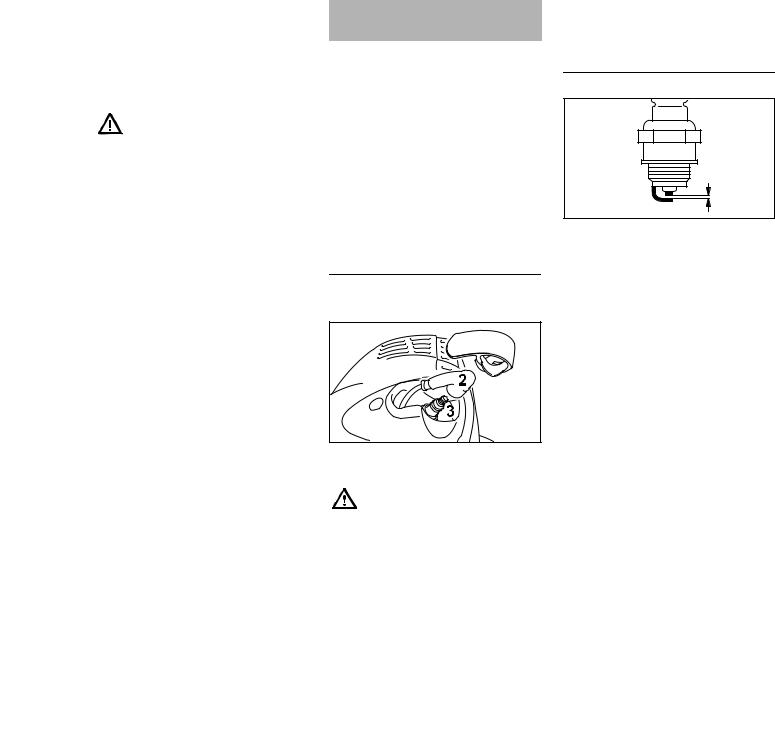

Removing the Spark Plug

N Shut off the engine

1

547BA028 KN

The spark plug boot (2) sits inside the cap (1).

The cap (1) protects the spark plug boot from damage. Do not operate the machine without a cap – replace a damaged cap.

NPull off the spark plug boot (2) together with the cap (1).

N Unscrew the spark plug (3).

English

If the cap becomes detached while pulling off the spark plug boot, see "Installing the Spark Plug".

Checking the Spark Plug

|

KN |

A |

000BA039 |

|

N Clean dirty spark plug.

NCheck electrode gap (A) and readjust if necessary – see "Specifications".

NUse only resistor type spark plugs of the approved range.

Rectify problems which have caused fouling of spark plug:

–Too much oil in fuel mix.

–Dirty air filter.

–Unfavorable running conditions, e.g. operating at part load.

FC 56 C |

23 |

English

N Push the cap on to the spark plug boot as far as stop.

1

2

2

000BA071 KN

Engine Running Behavior

If engine running behavior is unsatisfactory even though the air filter is clean and the carburetor is properly adjusted, the cause may be the muffler.

Have the muffler checked for contamination (carbonization) by your servicing dealer.

STIHL recommends that you have servicing and repair work carried out exclusively by an authorized STIHL servicing dealer.

Warning!

To reduce the risk of fire and burn injury, use only spark plugs authorized by STIHL. Always press spark plug boot (1) snugly onto spark plug terminal (2) of the proper size. (Note: If terminal has detachable SAE adapter nut, it must be attached.) A loose connection between spark plug boot and ignition wire connector in the boot may create arcing that could ignite combustible fumes and cause a fire.

Installing the Spark Plug

NScrew the spark plug into the cylinder.

NPress the spark plug boot with cap firmly on to the spark plug.

If the cap has become detached from the spark plug boot:

24 |

FC 56 C |

English

|

|

|

|

|

Lubricating the Gearbox |

Rewind Starter |

Storing the Machine |

||

|

|

|

|

|

2 |

1 |

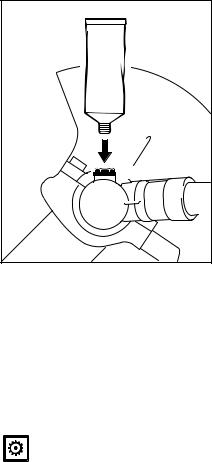

241BA018 KN |

Check grease level regularly, about every 25 hours of operation.

NUnscrew the filler plug (1). If no grease can be seen on the inside of the filler plug, screw the tube (2) of STIHL gear lubricant for brushcutters – see "Special Accessories" – into the filler hole.

NSqueeze up to 0.2 oz (5 g) grease into the gearbox.

Do not completely fill the gearbox with grease.

NRefit the filler plug and tighten it down firmly.

To help prolong the wear life of the starter rope, observe the following points:

NPull the starter rope only in the direction specified.

NDo not pull the rope over the edge of the guide bushing.

NDo not pull out the rope more than specified.

NDo not allow the starter grip to snap back, guide it back into the housing slowly – see chapter on "Starting / Stopping the Engine."

Have a damaged starter rope replaced by your dealer before it breaks completely. STIHL recommends that you have servicing and repair work carried out exclusively by an authorized STIHL servicing dealer.

For periods of 3 months or longer

NDrain and clean the fuel tank in a well ventilated area.

NDispose of fuel properly in accordance with local environmental requirements.

NRun the engine until the carburetor is dry – this helps prevent the carburetor diaphragms sticking together.

NThoroughly clean the machine – pay special attention to the cylinder fins and air filter.

NRemove, clean and inspect the cutting blade.

NStore the machine in a dry, high or locked location, out of the reach of children and other unauthorized persons.

FC 56 C |

25 |

Loading...

Loading...