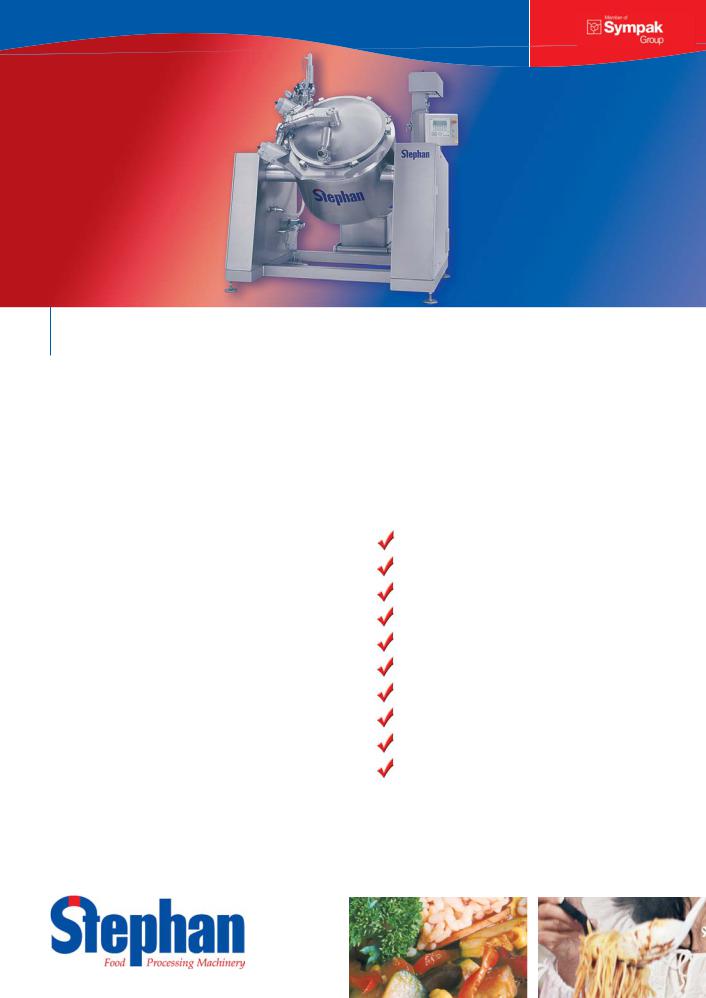

Stephan KM 450, KM 800, KM 1200 Specifications

STEPHAN Cooking Mixer

Constant product quality and efficient production

High Speed Heating -

Best Product Quality

I Precise process technology gives products of constant and reproducible quality. High quality ready meals, soups, sauces and meat products can be prepared economically. Heating and mixing steps protect quality and efficiency.

The STEPHAN Cooking Mixer has been designed in close cooperation with the food processing industry. I

|

|

|

|

|

|

|

|

|

|

|

|

s |

! |

|

|

|

|

|

|

|

|

|

|

|

g |

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

v |

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

e |

s |

|

|

|

|

|

|

|

|

|

|

|

m |

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

% |

t |

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

o |

7 |

|

|

|

|

|

|

|

|

|

|

|

p |

t |

|

|

|

|

|

|

|

|

|

|

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages for your production

Easy filling and emptying

Gentle as well as effective heating Both gentle and effective mixing Short batch times

Prevention of oxidation

Flavour saving process

Colour saving process

Constant product quality

Environmentaly friendly

No steam extractor hood needed

Applications and Processings Steps

Applications: |

Processes: |

Ready Meals |

Mixing |

Soups |

Direct + indirect heating |

Rice, Pasta, Potatoes |

Cooking |

Vegetables |

Blanching |

Meat |

Deaerating (Vacuum) |

Fish |

Cooling |

Poultry |

|

Stews |

|

Sauces |

|

|

|

Design of the Cooking Mixer

flavour and colour protecting processes

I The compact system consists of a tiltable vessel, equipped with a double jacket. The vessel can be closed hermetically by a pneumatically operated lid. The mixing arm is driven by a shaft through the bottom of the vessel. It is equipped with scrapers following the shape of the wall. Deposits on the inner vessel surface are avoided. Direct steam can be injected by means of nozzles in the bottom of the vessel.

The special geometry of the steam nozzles ensures an even distribution of hot steam in the product. The double jacket can be used for indirect heating or cooling.

For optimized charging with raw material the system is equipped with a special charging device. The tiltable vessel can be moved into three positions. The charging position (tilt angle into charging device direction) allows easy filling out of standard containers.The working position (STEPHAN specific inclination) allows gentle but effective mixing.

The discharge position (tilt angle opposite to charging position) supports easy emptying into standard containers. Discharging can be done through the discharge valve or through the opened lid. A sieve integrated in the lid enable discharge of cooking water through the valve. I

|

|

|

|

|

|

|

|

|

|

|

|

|

g |

! |

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

|

t |

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

h |

|

|

|

|

|

|

|

|

|

|

|

|

v |

|

|

|

|

|

|

|

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

|

t |

|

|

|

|

|

|

|

|

|

|

|

|

|

c |

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

f |

|

|

|

|

|

|

|

|

|

|

|

|

|

f |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...