SINGER WSL2000 User Manual

WHITE

SUPERLOCK

OWNERS WORKBOOK

2000 ATS

Copyright 1995

Education Department

White Sewing Machine Company

11760 Berea Road

Cieveland OH 44111

TABLE OF CONTENTS

INTRODUCTION

SECTION I - Know Your Machine - Model 2000 ATS

Accessories

Superlock Set Up and Maintenance

Foot Control

Power/Light Switch

Opening Front Cover

Closing Front Cover

Opening Swing-Away Side Cover

Handwheel

Presser Foot Lift

Changing Presser Foot

Adjustment of the Presser Foot Pressure

Disengaging Upper Cutter

Exclusive Built-in Thread Cutter

Adjustable Fabric Guide

Waste Tray

Oiling

Cleaning

Storage

Hints for Successful Stitching

Needle Replacement

Needles, Thread & Fabric Chart

3

4

5

5

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

9

10

11

SECTION II - Threading & Tension

Preparation for Threading

Spool Holders

Spool Caps

Spool Nets

Threading Upper Looper

Threading Lower Looper

Threading Needles

Needle Threader

Helpful Hints - Changing Thread

Testing Stitch

Thread Tensions

Adjusting Thread Tension

SECTION III - Basic Sewing Techniques

Superlock Seams & Seam Finishing

Adjusting Stitch Length

Adjusting Cutting Width & Balance of Stitch

Adjusting Cutting Width

Securing Beginning & End of Seam

Outside Corners

Inside Corners

Corded Overlook

Ribbing

Casing or Hem Fold

12

12

12

12

12

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

SECTION IV - Differential Feed

Positive Differential Feed

Minimal Differential Feed

Normal Differential Feed

Serging Lightweight Fabrics

Serging Stretch or Bulky Knits

Gathering

33

34

34

34

35

36

37

SECTION V - 3-Thread Sewing Techniques

3-Thread Seam or Edge Finish

Rolled Edge

Picot Edge

Spaghetti Straps

Slit or Placket

Rolled Edge - "Pokies"

Narrow Edge

Safelock

Decorative Edges

Decorative Braids

Flatlock/Ladder Stitching & Seams

Flatlock Technique - Lace Application

Flatlock Technique - Lingerie Elastic Application

Flatlock Technique - Fringe

Rolled Edge - Novelty Threads

Rollled Edge - Fishline Ruffles or Wire Edges

Narrow or Shell Edge

SECTION VI - 2-Thread Sewing Techniques

Threading for 2-thread Sewing

Two Thread Overcast

Two Thread Flatlock

Two Thread Wrapped Edge

Two Thread Rolled Edge

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

56

57

58

59

60

SECTION VII - Optional Accessory Feet

Blind Hem Foot

Piping/Cording Foot

Elastic Foot

Shirring Foot

SECTION vm - Special Hints

Puckery Fabric

Skipped Stitches

Stitiches Show Through on the Right Side of Seam

Thread Continues to Break

Cannot Get a Tight Stitch at the Cut Edge of the Fabric

Adjusting Tensions

Machine is Jamming

INDEX

61

61

62

63

64

65

65

65

65

65

66

66

66

67-69

II

tNTRODUCTtON

Welcome to the world of easy, speed sewing. The White Superlock was designed with

the home sewer in mind. It is simple to thread, simple to change from regular sewing to specialty

sewing, such as flatlock and rolled edge. The automatic thread tension release will help you

in easy removal of your projects and creative sewing. This workbook is compiled in a method

so you will thoroughly understand the machine and its potential. After following these

instructions, you will marvel at how easy your new White Superlock is to operate.

SECTION I

KNOW YOUR MACHINE - MODEL 2000 ATS

Top of the line Superlock model 20CXÌ ATS is a 2/3/4 thread serger with adjustable

cutting width, built in rolled edge and differential feed. It is capable of two, three or four

thread sewing plus many decorative and specialty applications. A section of this workbook

outlines many different techniques, specialty feet, and simple quick projects for you to try

on your new Superlock.

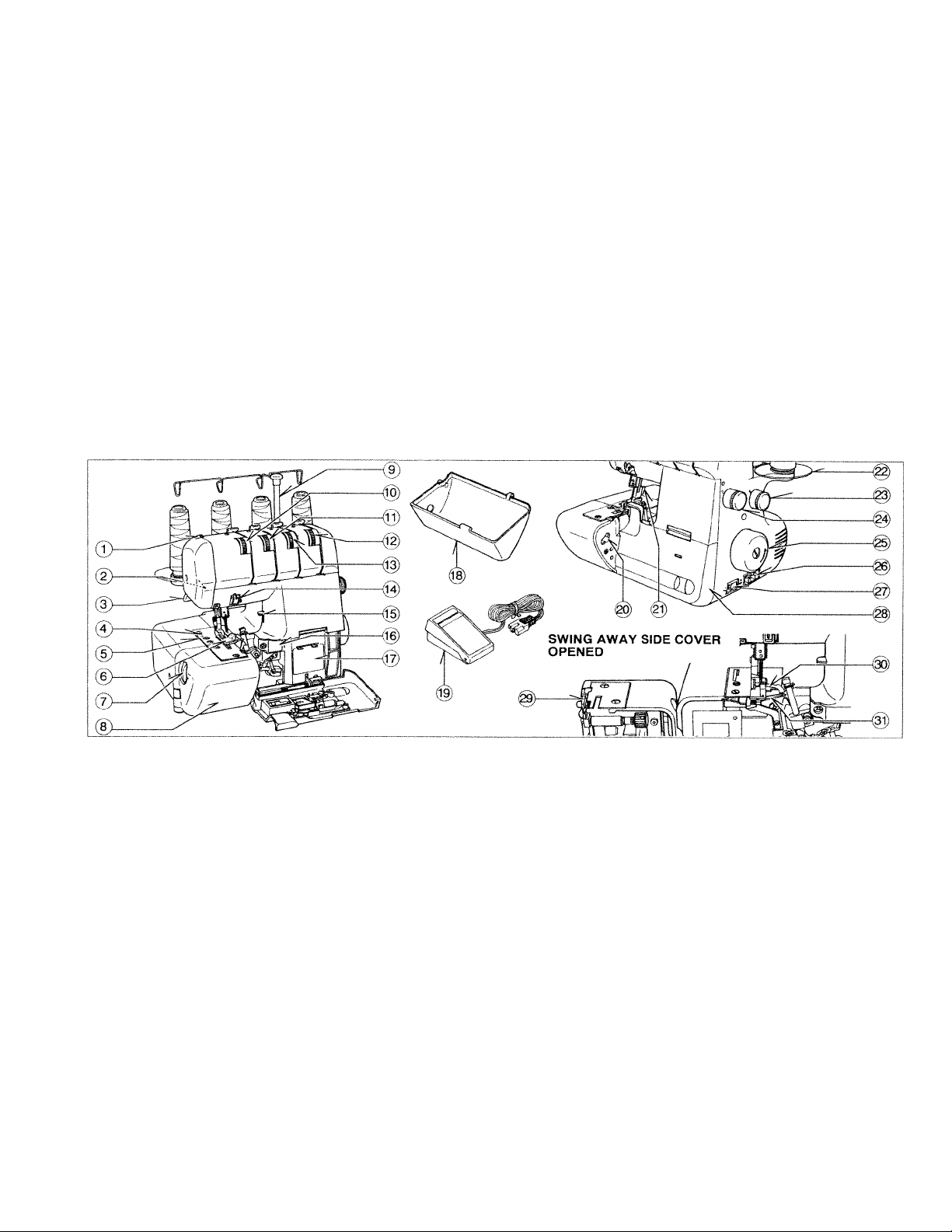

1. KNOWING YOUR MACHINE

IDENTIFICATION CHART

1. Foot pressure regulator

2. Sewing light

3. Presser foot lift lever

4. Thread cutter (Model 2000 only)

5. Needle plate

6. Presser foot

7. Overedge cutting width dial

8. Swing away side cover

9. Thread guide pole

10. Left needle thread tension dial

11. Right needle thread tension dial

12. Lower looper thread tension dial

13. Upper looper thread tension dial

14. Needle thread guides

15. Thread cutter lever (Model 2000 only)

16. Two thread convertor Instruction

17. Threading chart

18. Waste tray (Model 2000 only)

19. Foot control

20. Release lever side cover

21. Foot release lever

22. Thread extension plate

23. Differential feed control dial

24. Stitch length dial

25. Hand wheel

26. Plug connector socket

27. Light and power switch

28. Front cover

29. Moving cutter

30. Upper looper

31. Lower looper

(Model 2000 only)

ACCESSORIES

All parts listed may be obtained from your nearest dealer.

(D (D

^

P

I I

*

1. Two-thread convertor

(Model 2000 only)

2. Needle set

3. Brush

4. Screwdriver (small)

5. Needle threader

6. Machine cover

7. Screwdriver (large)

8. Oiler

*Only Model 2000 has storage of accessories at the back of front cover.

9. Moving cutter

10. Spanner

11. Thread net

12. Tweezers

13. Thread extension plate

14. Cone holder

15. Cord guide

16. Accessory bag

SUPERLOCK SET UP & MAINTENANCE

1. Set your Superlock on a sturdy, flat surface.

2. Your Superlock has been thoroughly oiled at the

factory so be sure to wipe the needle and bed

plate areas carefully before sewing a garment.

Practice on a scrap of fabric so any surplus oil

is absorbed.

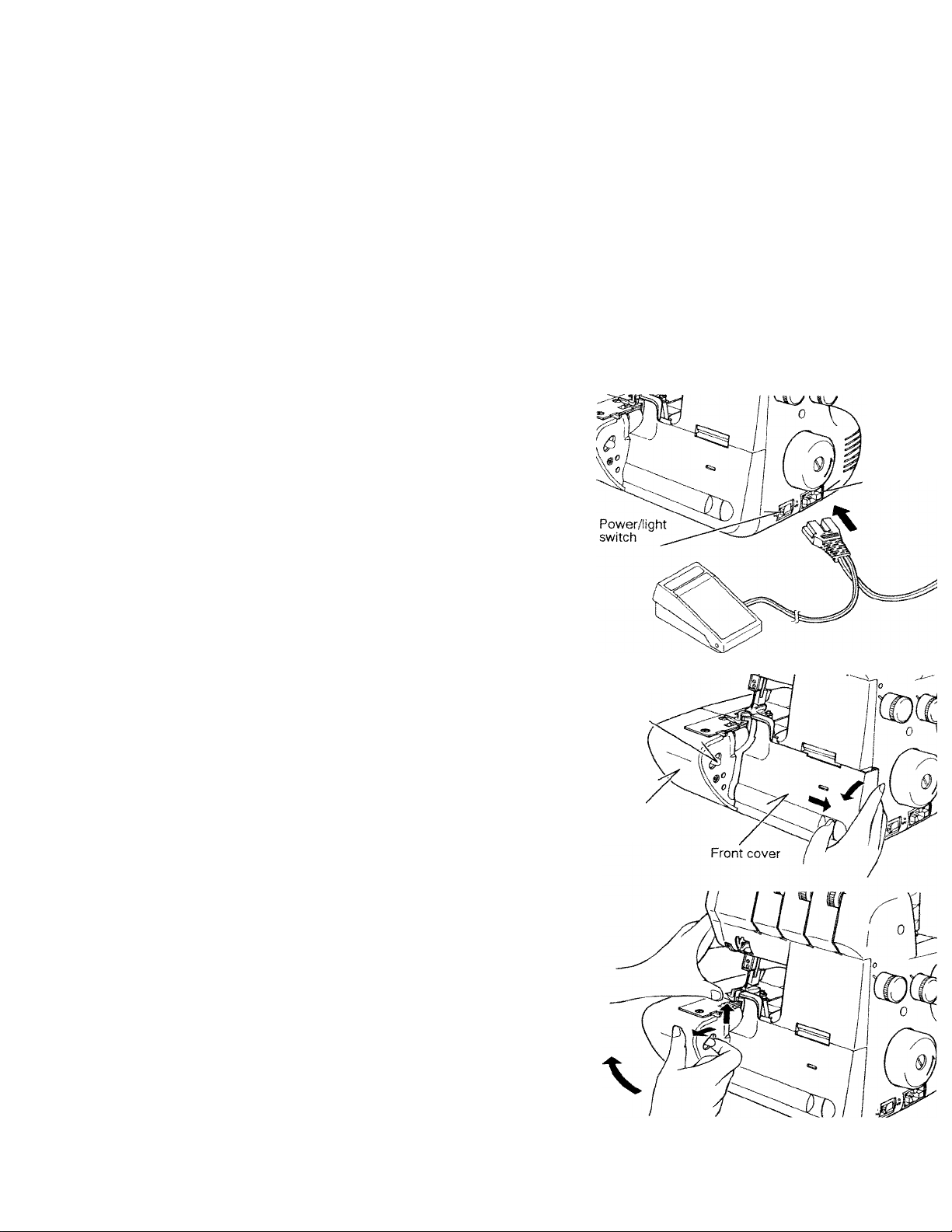

3. FOOT CONTROL

Push foot control plug into the connector socket

at the bottom right side of your Superlock.

4. POWER/LIGHT SWITCH

To operate your machine, turn the power switch

on. It is located at the bottom right hand side.

The same switch controls both power and light.

If leaving your Superlock unattended, turn

switch off.

Connector

socket

5. OPENING FRONT COVER

To open front cover, push part B of cutter cover

to right and pull the cover down toward you.

To open the side cover, press down on the

silver knob located to the inside of the side cover,

and swing the lower left portion of the Superlock

to the left.

6. CLOSING FRONT COVER

Push part B and lower left cover toward the

center of the front to close it.

Note: Always close front cover when sewing.

7. OPENING SWING-AWAY SIDE COVER

To open side cover, pull the release lever toward

you with your right hand and swing out to left.

NOTE: Always close side cover when sewing.

Release lever

Swing away

side cover

8. HANDWHEEL

Always turn handwheel toward you.

9. PRESSER FOOT LIFT

Raise the presser foot lift to lift up the

presser foot.

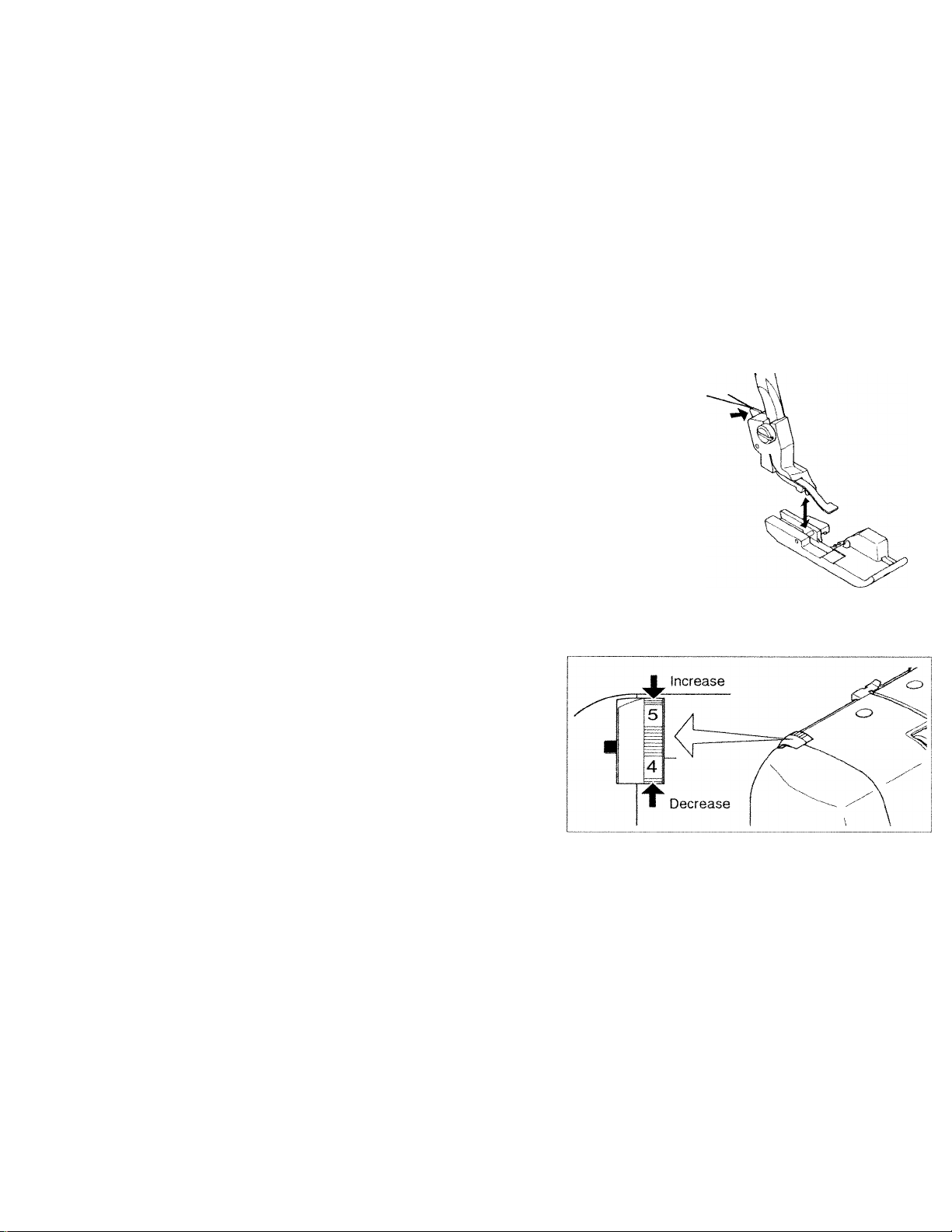

10. CHANGING PRESSER FOOT

Switch off your Superlock.

Raise presser foot.

Raise needles to their highest position by

turning handwheel toward you.

Push lever A and foot will come off.

Position the new foot with pin right under

the groove of the ankle. Lower presser foot

lift so that holder catches the presser foot.

11. ADJUSTMENT OF THE PRESSER

FOOT PRESSURE

The presser foot pressure is pre-adjusted

for materials of medium thickness.

Adjustment is necessary only when

you work on very thin or very thick

materials. Accordingly, sew thinner

materials with less pressure (2 - 3)

and thicker materials with more pressure

(4 - 5). Increase the pressure of the presser

foot by turning the dial to the desired number.

Foot release lever

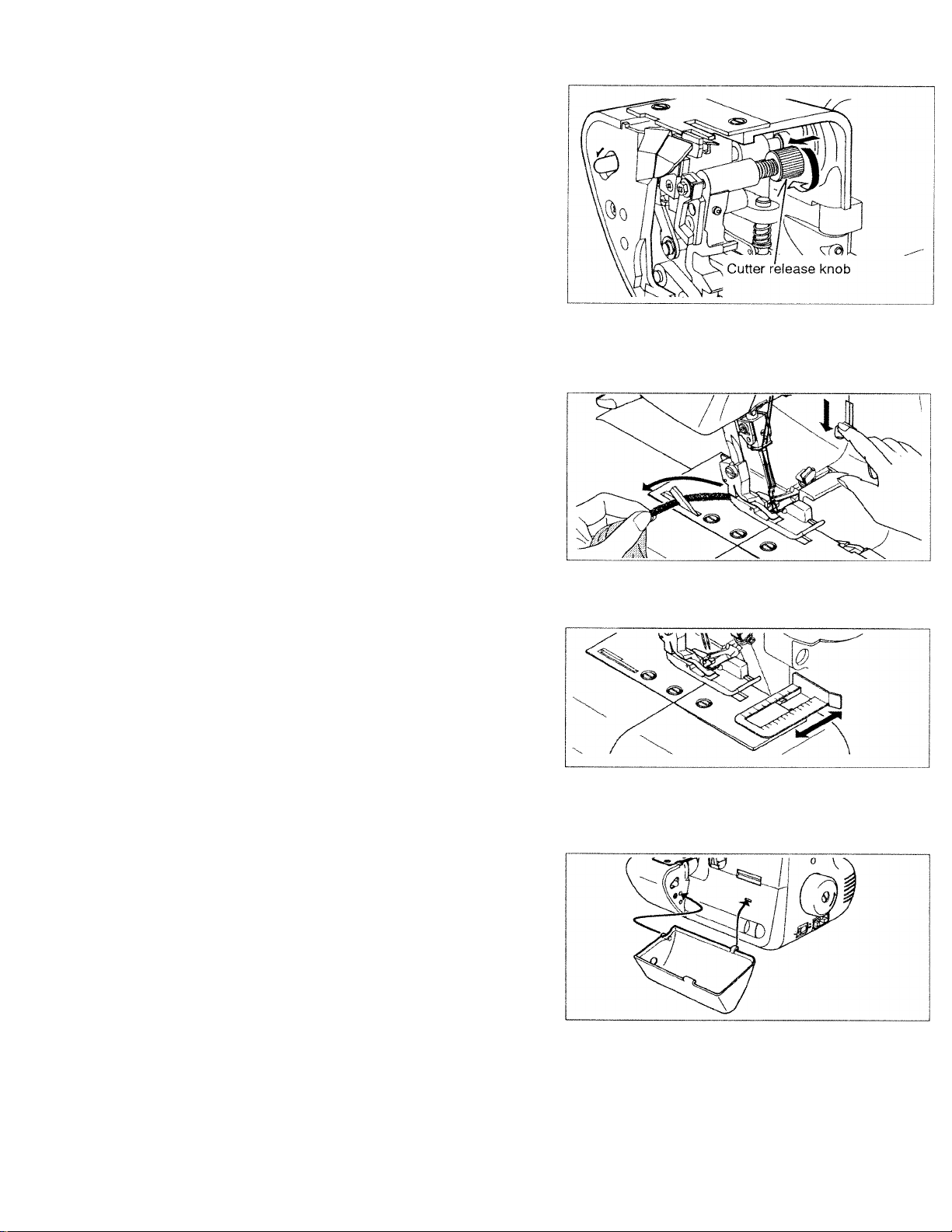

12. DISENGAGING UPPER CUTTER

To lower the upper cutter, open the left

front cover and turn the cutter knob toward

you until the cutter is all the way in the

down position. BE SURE TO PUT CUTTER

BACK UP BEFORE SEWING.

13. EXCLUSIVE BUILT-IN THREAD CUTTER

The built-in scissor conveniently cuts your

thread tail simply by pressing down on the

lever as illustrated, then releasing to cut.

14. ADJUSTABLE FABRIC GUIDE

The adjustable seam guide can slide to the

left or right as needed to keep fabric straight

while serging seams.

15. WASTE TRAY

Place the large waste tray on the front of

your Superlock by hooking over the slot on

the right front cover and inserting the peg

on the left into the hole on the side cover,

as illustrated.

16. OILING

Lubrication is not required often for

this machine since the important parts are all

made of a special oil impregnated sintered

metal. You will want to occasionally put one

or two drops of oil on moving metal parts will

increase durability.

17. CLEANING

First disconnect machine from power supply

by removing plug from the electric outlet.

Open front cover and side cover (see pg. 3).

Using the brush provided, remove all the dust

and lint that has accumulated. Remember to

also clean between the cutters often.

18. STORAGE

When the machine is not in use, disconnect

it from the power supply by removing plug

from the electric outlet.

Using the vinyl cover provided, cover

your machine when not in use.

8

)

HINTS FOR SUCCESSFUL STITCHING

An understanding of the following variables will make your Superlock run smoothly and

your work will look professional. Before sewing, always test the compatibility of your fabric,

thread, pressure, stitch length, and tension.

Thread Selection

When selecting the proper thread, choose one that is compatible with the fashion and

the fabric. Polyester threads (or polyester based) are most commonly used for general

sewing purposes. Threads of different fibers (cotton, rayon, silk, etc.) are available for

special sewing.

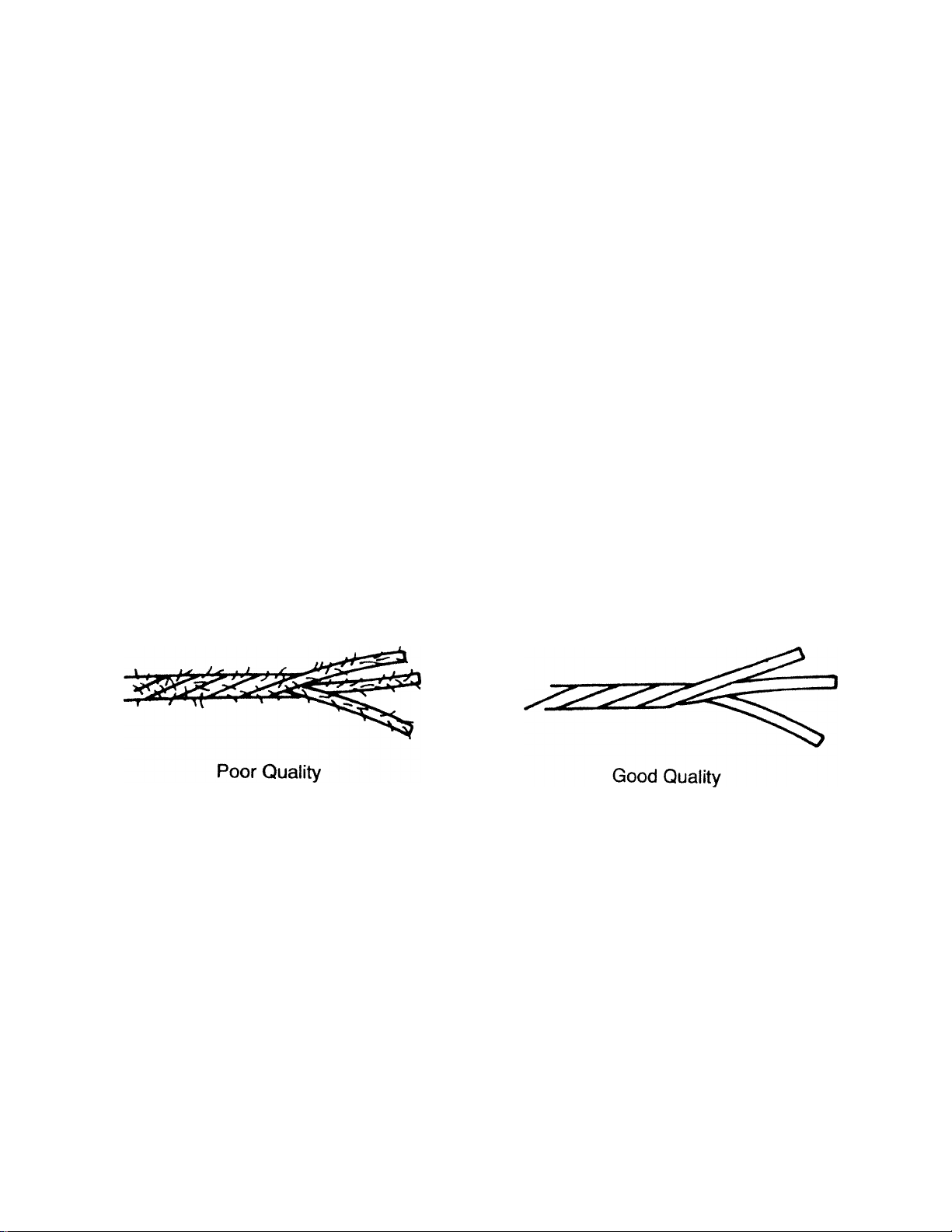

Quality is a very important consideration when selecting a thread. A thread of poor

quality will result in operating and stitching problems on any type of sewing machine. Syn

thetic threads are made by twisting filaments together. Lower quality synthetic threads are

made by twisting short, leftover filaments of polyester together. The result is a "hairy*

appearance and a weaker thread. Better quality threads are made by twisting long continu

ous filaments together. This thread is stronger and smoother, thus fewer operating prob

lems will occur. Brand name and price do not necessarily represent quality in a thread.

The only true test of thread quality is close examination.

A variety of threads are available for overlooks. They may be of cotton, cottonwrapped polyester, polyester or nylon (Wooly Nylon®). These are most often put up on

cones or tubes. Threads for the overlock are generally finer and lighter in weight than

standard sewing machine thread. This is because of the large amount of thread that builds

up in an overlook seam. Finer thread makes for a less bulky seam. Your Superlock will

handle thread on cones or spools. Many decorative threads will be discussed later in this

workbook.

Loading...

Loading...