Page 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

SK-Relay

SPECIFICATIONS

Normal Operating Voltage: 15 to 32 VDC

Maximum Current Draw: 6.5 mA (LED on)

Average Operating Current: 230μA direct poll; 255μA group poll

EOL Resistance: Not used

Temperature Range: 32˚F to 120˚F (0˚C to 49˚C)

Humidity: 10% to 93% Non-condensing

Dimensions: 41/2˝ H × 4˝ W × 11/4˝ D (Mounts to a 4˝ square by 21/8˝ deep box.)

Accessories: SMB500 Electrical Box

BEFORE INSTALLING

This information is included as a quick reference installation guide. Refer to

the appropriate Silent Knight control panel installation manual for detailed

system information. If the modules will be installed in an existing operational

system, inform the operator and local authority that the system will be temporarily out of service. Disconnect power to the control panel before installing

the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

The SK-Relay is intended for use in intelligent, two-wire systems where the individual address of each module is selected using the built-in rotary switches.

It allows a compatible control panel to switch discrete contacts by code command. The relay contains two isolated sets of Form-C contacts, which operate

as a DPDT switch and are rated in accordance with the table in the manual.

Circuit connections to the relay contacts are not supervised by the module.

The module also has a panel controlled LED indicator.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a compatible

Silent Knight system control panel (list available from Silent Knight).

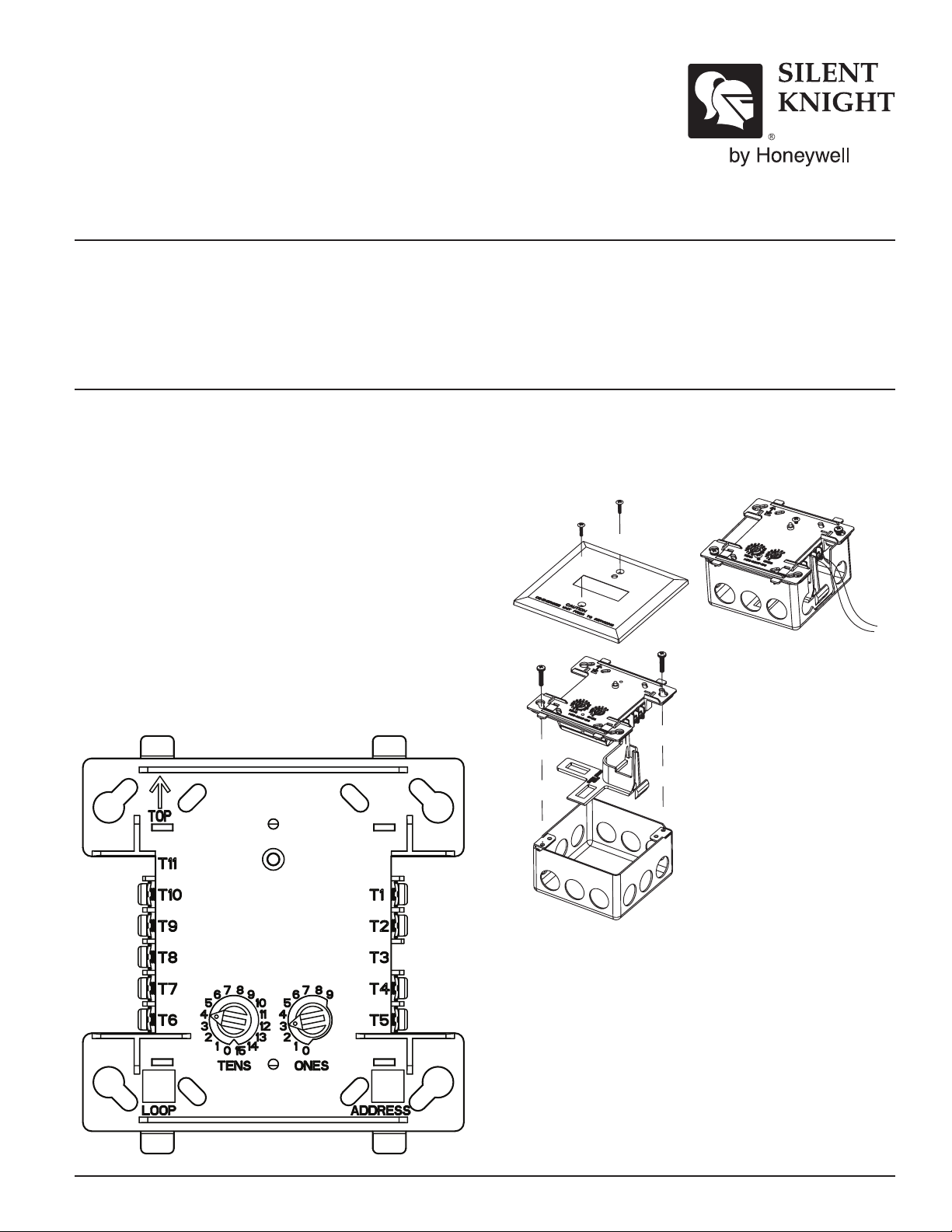

FIGURE 1. CONTROLS AND INDICATORS:

MOUNTING

The SK-Relay mounts directly to 4-inch square electrical boxes (see Figure

2A). The box must have a minimum depth of 21/8 inches. Surface mounted

electrical boxes (SMB500) are available from Silent Knight.

FIGURE 2A. MODULE MOUNTING FIGURE 2B:

WITH BARRIER:

I56-3438-001

12 Clintonville Road, Northford, CT 06472

203.484.7161; Fax: 203.484.7118

www.silentknight.com

C1070-00

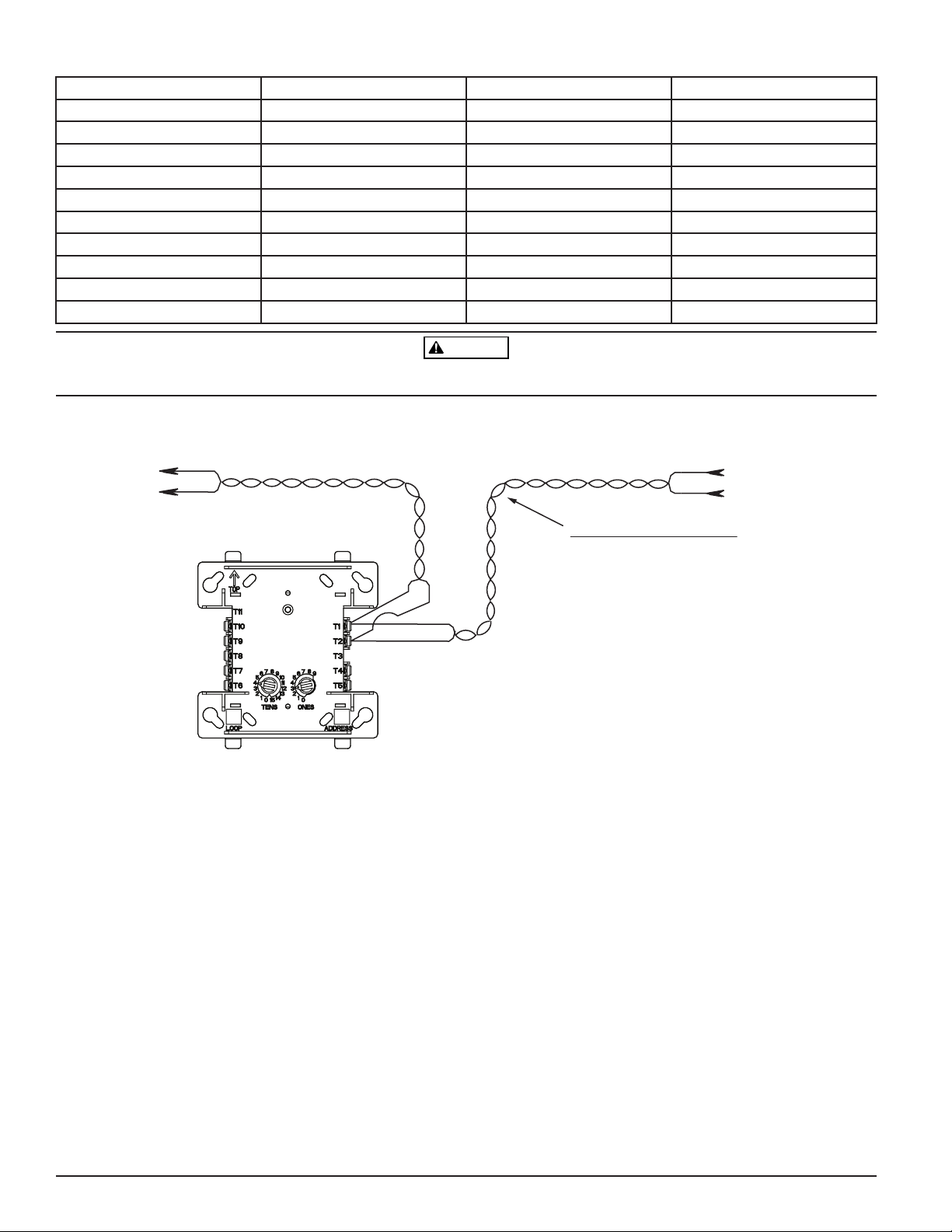

WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and regulations. When using control modules in nonpower limited applications, the

CB500 Module Barrier must be used to meet UL requirements for the separation of power-limited and nonpower-limited terminals and wiring. The barrier

must be inserted into a 4˝ × 4˝ × 21/8˝ junction box, and the control module

must be placed into the barrier and attached to the junction box (Figure 2A).

The power-limited wiring must be placed into the isolated quadrant of the

module barrier (Figure 2B).

1. Install module wiring in accordance with the job drawings and appropriate wiring diagrams.

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as shown in

C1071-00

SK-470-001 1 I56-3438-001

Figure 2A.

Page 2

Relay Contact Ratings:

WARNING

MODULE

FROM PANEL OR

(+)

(–)

TO NEXT

(+)

(–)

DEVICE

(+)

(–)

CONTROL

CONNECT MODULES TO LISTED COMPATIBLE

RELAY COMMON 1

RELAY COMMON 2

NORMALLY CLOSED 1

NORMALLY OPEN 2

NORMALLY CLOSED 2

MODULE DOES NOT SUPERVISE CONTROLLED CIRCUITS

NORMALLY OPEN 1

CONTROL PANELS ONLY

PREVIOUS DEVICE

SIGNAL LINE CIRCUIT (SLC)

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

UNUSED

*NOTE: ANY FAULT IN THE POWER SUPPLY IS LIMITED TO THAT ZONE AND DOES NOT RESULT IN A FAULT IN A SEPARATE ZONE.

IF ANY WIRING TO TERMINALS 4 – 10 IS NONPOWER

LIMITED, THE CB500 BARRIER IS REQUIRED. THE CB500

INCLUDES A NONPOWER LIMITED LABEL, WHICH MUST

BE PLACED OVER THE POWER LIMITED TERMINAL

INFORMATION ON THE NAMEPLATE LABEL.

CURRENT RATING MAXIMUM VOLTAGE LOAD DESCRIPTION APPLICATION

3 A 30 VDC Resistive Non-coded

2 A 30 VDC Resistive Coded

.9 A 110 VDC Resistive Non-coded

.9 A 125 VDC Resistive Non-coded

.5 A 30 VDC Inductive (L/R=5ms) Coded

1 A 30 VDC Inductive (L/R=2ms) Coded

.3 A 125 VAC Inductive (PF=.35) Non-coded

1.5 A 25 VAC Inductive (PF = .35) Non-coded

.7 A 70.7 VAC Inductive (PF=.35) Non-coded

2 A 25 VAC Inductive (PF=.35) Non-coded

All relay switch contacts are shipped in the standby state (open) state, but may have transferred to the activated (closed) state during shipping. To ensure that

the switch contacts are in their correct state, modules must be made to communicate with the panel before connecting circuits controlled by the module.

FIGURE 3. RELAY MODULE WIRING DIAGRAM:

SK-470-001 2 I56-3438-001

©2009 Honeywell International Inc.

C0946-00

Loading...

Loading...