SILENT KNIGHT INTELLIKNIGHT 5820XL, INTELLIKNIGHT 5820XL-EVS Installation And Operation Instruction Manual

Page 1

INTELLIKNIGHT

5820XL

5820XL-EVS

Addressable Fire System

Emergency Voice System

Installation and

Operations Manual

Document LS10061-001SK-E

10/30/2014 Rev:

P/N LS10061-001SK-E:E ECN: 14-0724

E

Page 2

Installation Procedure

Installation Precautions - Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected to the fire alarm control panel. Disconnect all sources

of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserti ng card s,

modules, or interconnecting cables while the unit is energized. Do not attempt to install, service, or operate this unit until

manuals are read and understood. CAUTION - System Re-acceptance Test after Software Changes: To ensure proper

system operation, this product must be tested in accordance with NFPA 72 after any programming operation or change in

site-specific software. Re-acceptance testing is required after any change, addition or deletion of system components, or

after any modification, repair or adjustment to system hardware or wiring. All components, circuits, system operations, or

software functions known to be affected by a change must be 100% tested. In addition, to ensure that other operations are

not inadvertently affected, at least 10% of initiating devices that are not directly affected by the change, up to a maximum

of 50 devices, must also be tested and proper system operation verified. This system meets NFPA requirements for

operation within the range of 0°C-49°C (32°F-120°F) or humidity within the range of 10%-93% at 30°C (86°F) noncondensing. However, the useful life of the system's standby batteries and the electronic components may be adversely

affected by extreme temperature ranges and humidity. Therefore, it is recommended that this system and its peripherals be

installed in an environment with a normal room temperature of 15-27º C/60-80º F . Verify that wire sizes are adequate for

all initiating and indicating device loops. Most devices cannot tolerate more than a 10% I.R. drop from the specified device

voltage. Like all solid state electronic devices, this system may operate erratically or can be damaged when subjected to

lightning induced transients. Although no system is completely immune from lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to an increased

susceptibility to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated

or encountered. Disconnect AC power and batteries prior to removing or inserting circuit boards. Failure to do so can

damage circuits. Remove all electronic assemblies prior to any drilling, filing, reaming, or punching of the enclosure.

When possible, make all cable entries from the sides or rear. Before making modifications, verify that they will not

interfere with battery, transformer, or printed circuit board location. Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced terminal contact pressure and difficulty with screw terminal

removal. fire alarm control panels contain static-sensitive components. Always ground yourself with a proper wrist strap

before handling any circuits so that static charges are removed from the body. Use static suppressive packaging to protect

electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. Th ese instructions must be followed to

avoid damage to the control panel and associated equipment. Fire Alarm Control Panel (FACP) operation and reliability

depend upon proper installation.

While installing a fire alarm system may make lower insurance rates possible, it is not a substitute for fire insurance! An

automatic fire alarm system - typically made up of smoke detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control with remote notification capability - can provide early warning of a developing fire. Such

a system, however, does not assure protection against property damage or loss of life resulting from a fire. Any fire alarm

system may fail for a variety of reasons: Smoke detectors may not sense fire where smoke cannot reach the detectors such

as in chimneys, in walls, or roofs, or on the other side of closed doors. Smoke detectors also may not sense a fire on

another level or floor of a building. A second floor detector, for example, may not sense a first floor or basement fire.

Furthermore, all types of smoke detectors, including ionization and photoelectric types, have sensing li mitations. No type

of smoke detector can sense every kind of fire caused by carelessness and safety hazards like smoking in bed, violent

explosions, escaping gas, improper storage of flammable materials, overloaded electrical circuits, children playing with

matches, or arson.

IMPORTANT! Smoke detectors must be installed in the same room as the control panel and in rooms used by the

system for the connection of alarm transmission wiring, communications, signaling, and/or power. If detectors are not so

located, a developing fire may damage the alarm system, crippling its ability to report a fire. Audible warning devices

such as bells may not alert people if these devices are located on the other side of closed or partly open doors or are located

on another floor of a building. A fire alarm system will not operate without any electrical power. If AC power fails, the

system will operate from standby batteries only for a specified time. Rate-of-Rise heat detectors may be subject to

reduced sensitivity over time. For this reason, the rate-of-rise feature of each detector should be tested at least once per

year by a qualified fire protection specialist. Equipment used in the system may not be technically compatible with the

control. It is essential to use only equipment listed for service with your control panel. Telephone lines needed to transmit

alarm signals from a premise to a central monitoring station may be out of service or temporarily disabled. The most

common cause of fire alarm malfunctions, however, is inadequate maintenance. All devices and system wiring should be

tested and maintained by professional fire alarm installers following written procedures supplied with each device. System

inspection and testing should be scheduled monthly or as required by national and/or local fire codes. Adequate written

records of all inspections should be kept.

Page 3

Contents

Section 1

Introduction ..................................................................................................................................................1

1.1 Overview of Basic System ...........................................................................................................1

1.1.1 Addressable Fire Alarm Control/Communicator Hardware Features ...................................1

1.1.2 5820XL-EVS Emergency Voice Hardware Features ............................................................1

1.1.3 Software Features ................................................................................................................2

1.2 About this Manual ........................................................................................................................2

1.2.1 Terms Used in this Manual ...................................................................................................2

1.3 Compatible Products .................................................... ... ... ....................................... ... ... ............3

1.4 How to Contact Silent Knight .......................................................................................................4

Section 2

Agency Listings, Approvals, and Requirements .......................................1

2.1 Federal Communications Commission (FCC) .............................................................................1

2.2 Underwriters Laboratories (UL) ...................................................................................................2

2.2.1 Requirements for All Installations .........................................................................................2

2.2.2 Requirements for Central Station Fire Alarm Systems ................ ......................................... 2

2.2.3 Requirements for Local Protected Fire Alarm Systems ......... .......................... .....................3

2.2.4 Requirements for Remote Station Protected Fire Alarm Systems .......................................3

Section 3

Before You Begin Installation ..............................................................................................1

3.1 What’s in the Box? ......................................................................................................................1

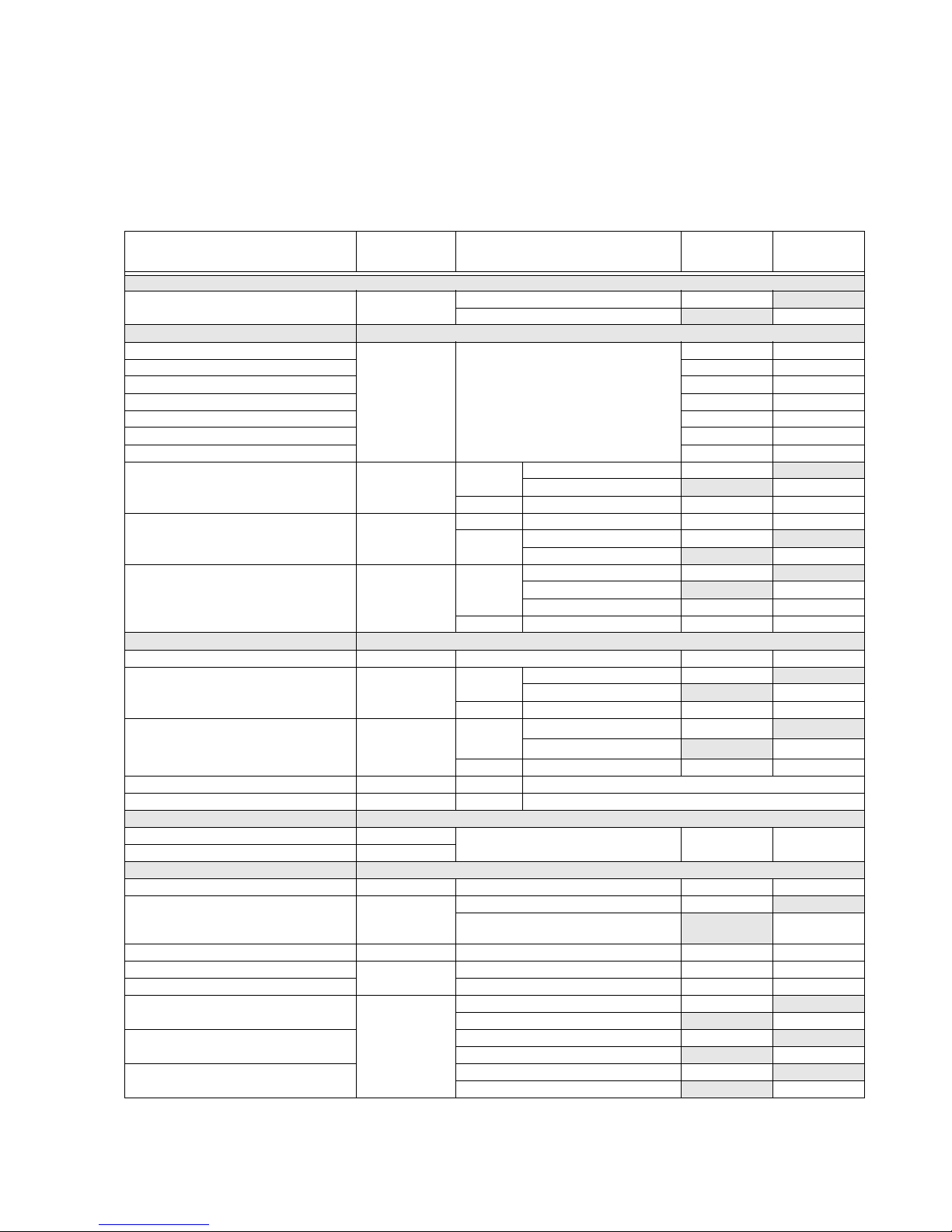

3.2 Environmental Specifications ................... .... .......................................... .....................................1

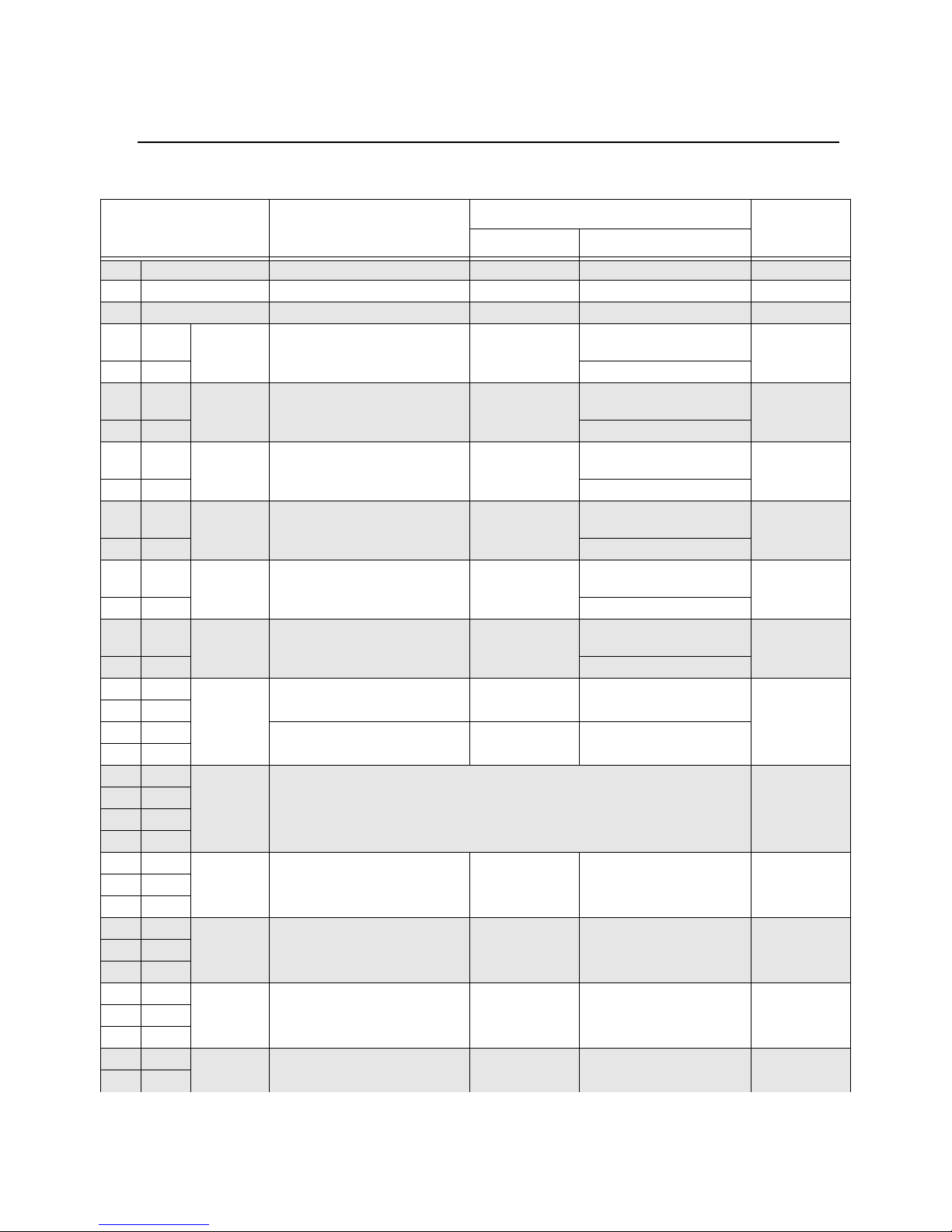

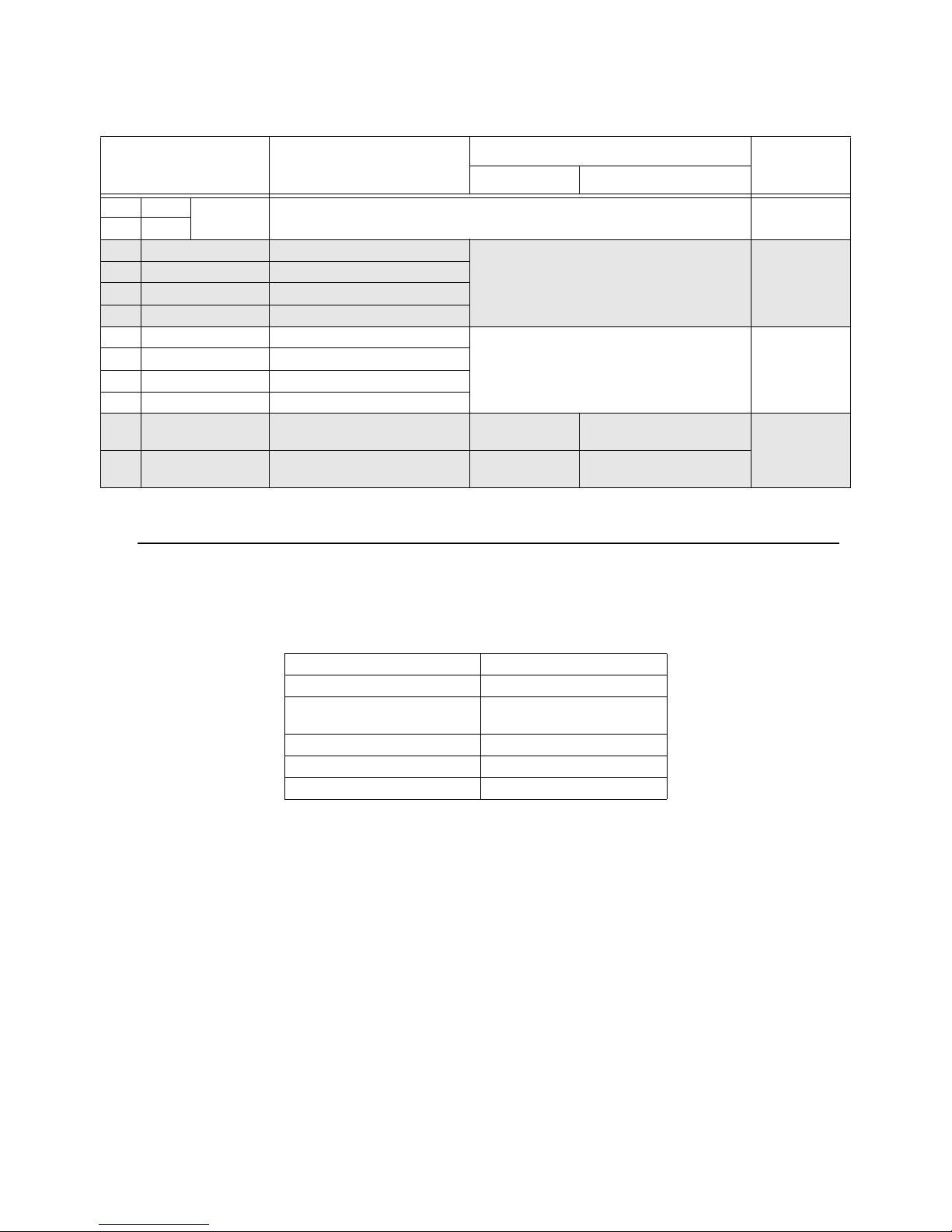

3.3 Electrical Specifications ................... ... .........................................................................................2

3.4 Wiring Specifications ...................................................................................................................3

3.5 Board Assembly Diagram ...................... ... .... ...............................................................................5

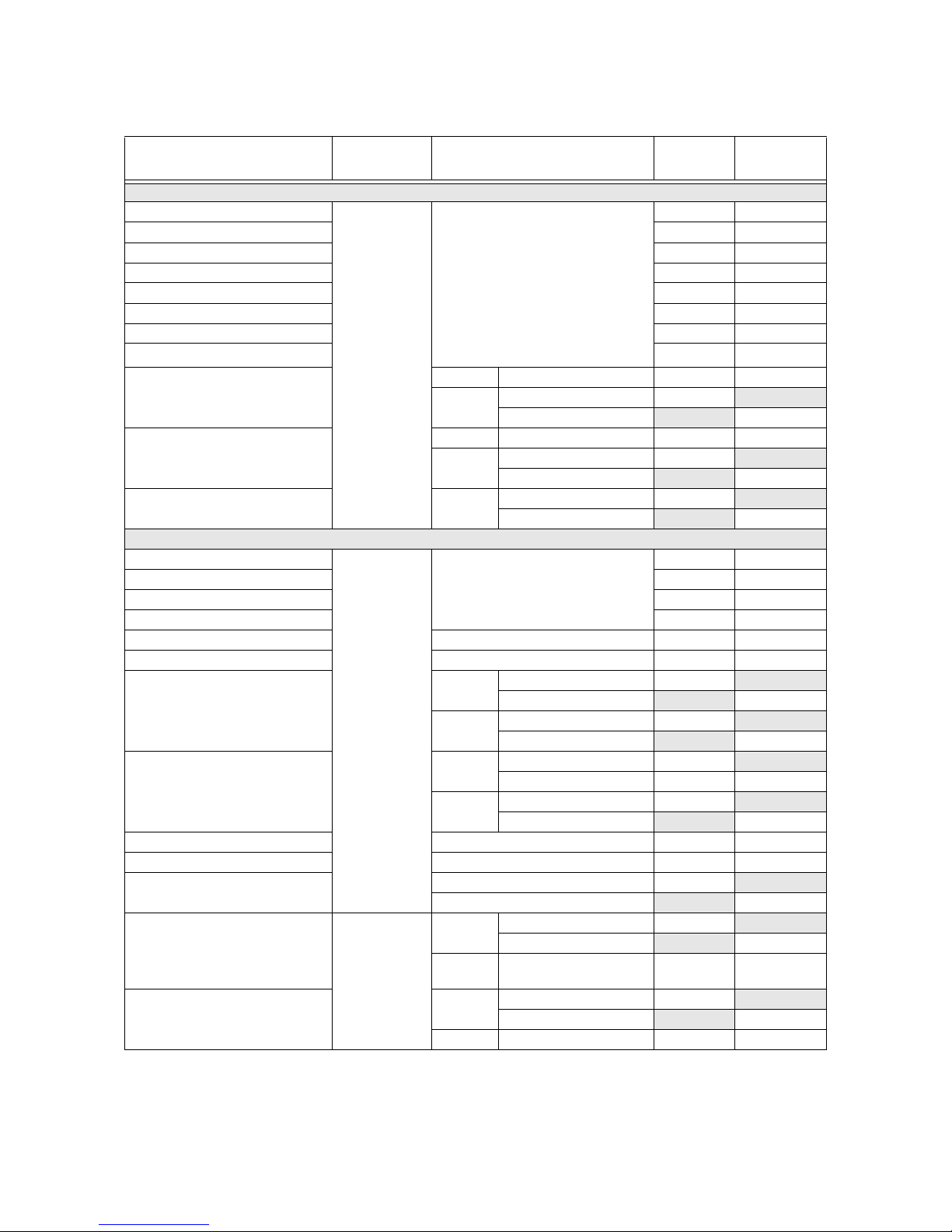

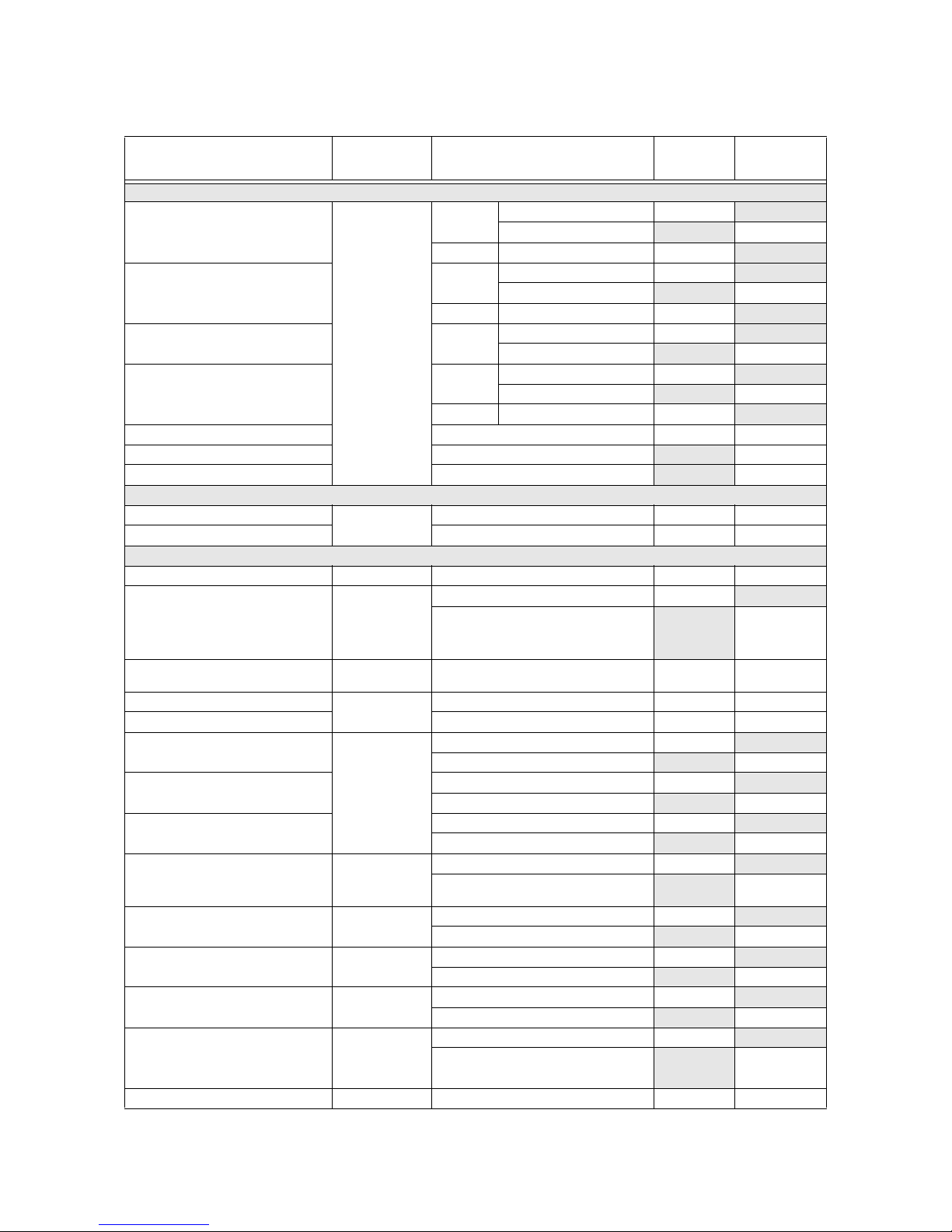

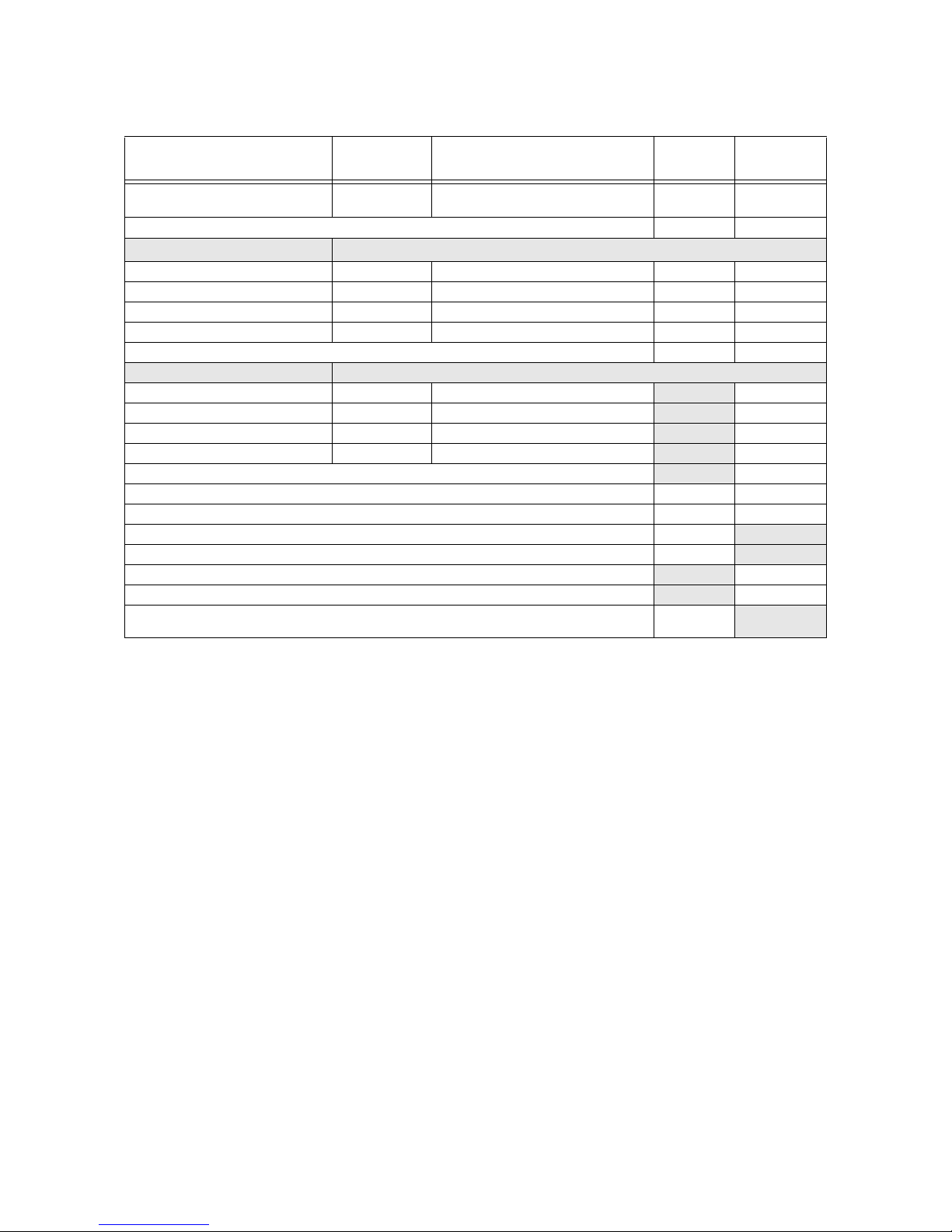

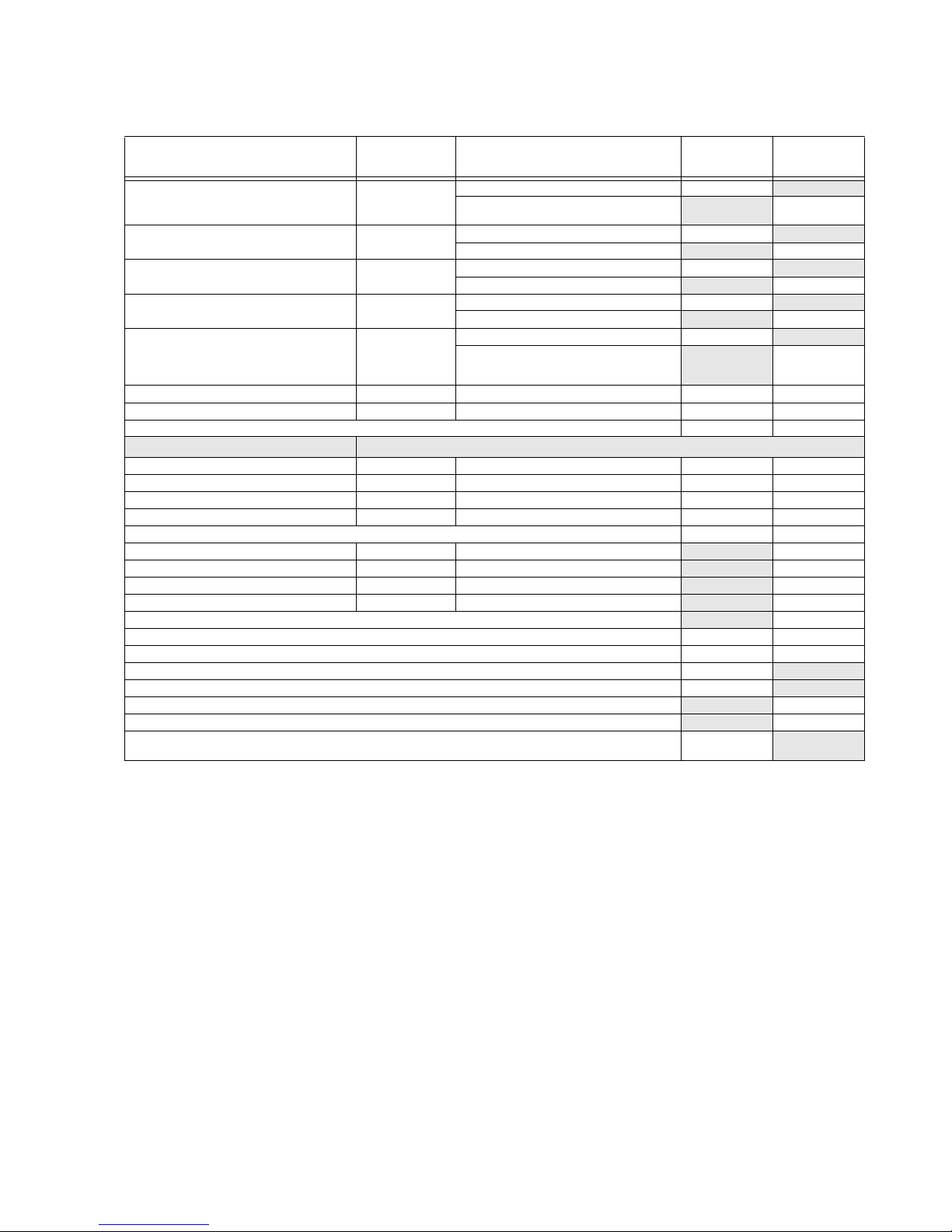

3.6 Calculating Current Draw and Standby Battery ...........................................................................6

3.6.1 Current Draw Worksheet Requirements .......................... ......................... .......................... ..6

3.6.2 Current Draw Worksheet for SK SLC Devices ...... ... ... .... ... ... ... ... .... ... ... ... ............................6

3.6.3 Current Draw Worksheet for SD SLC Devices ...................................................................10

3.6.4 Maximum Battery Standby Load ........................................................................................12

3.7 Installation Tasks Overview .......................................................................................................12

Section 4

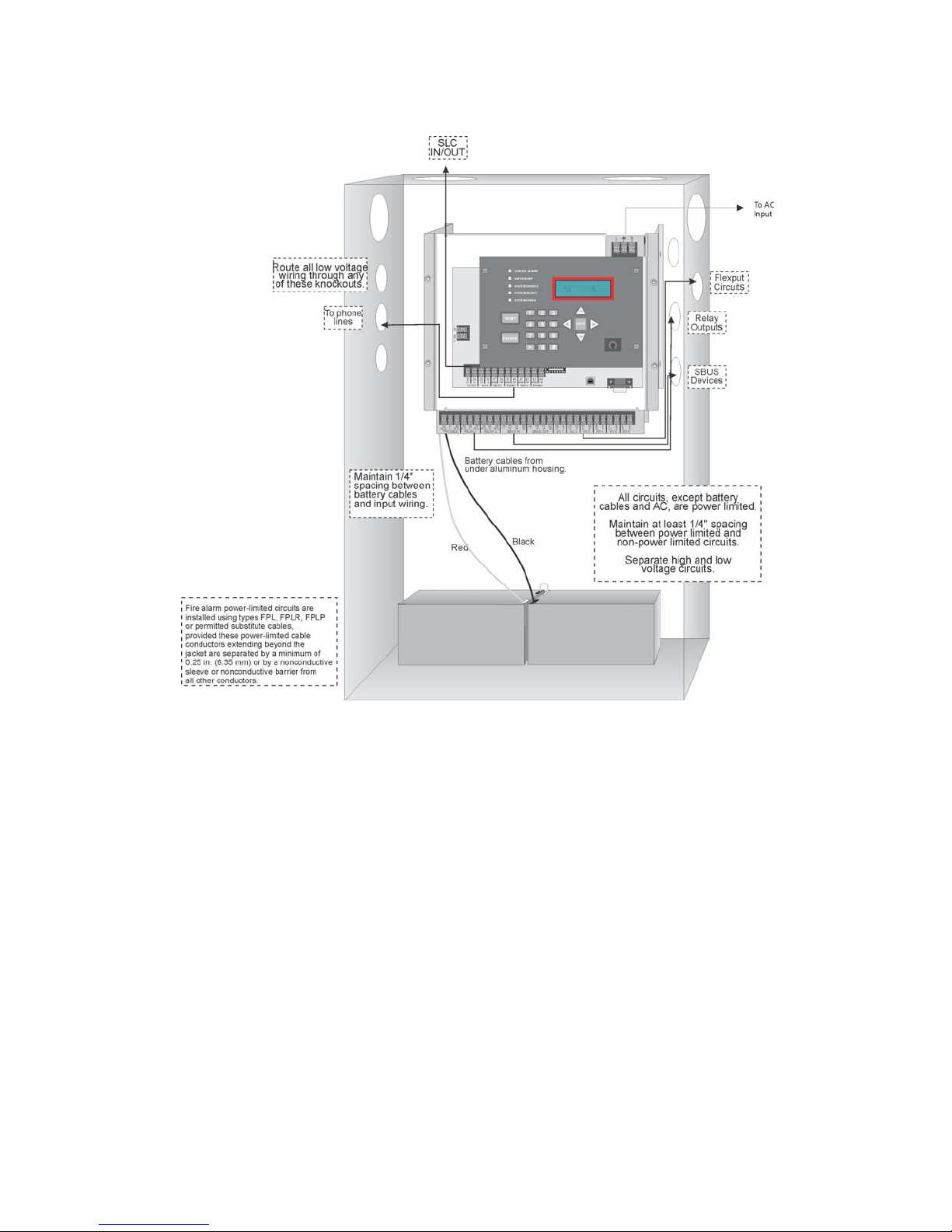

Control Panel Installation ..........................................................................................................1

4.1 Mounting the Control Panel Cabinet ...........................................................................................1

4.1.1 Preventing Water Damage ...................................................................................................1

4.1.2 Removing the 5820XL / 5820XL-EVS Assembly from the Housing .....................................1

4.2 AC Connection ................... ... ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... .....................1

1

Page 4

Model 5820XL/ 5820XL-EVS Installation Manual

4.3 Battery Connection ......................................................................................................................2

4.3.1 RBB Accessory Cabinet ........... ....................................... ... ... ... ... .... ... ..................................3

4.3.1.1 Installing the RBB Accessory Cabinet and Batteries ..................................................3

4.4 SBUS Wiring ......................................................... .... ... ... ....................................... ... ..................4

4.4.1 Calculating Wiring Distance for SBUS Modules ................................................................... 5

4.4.2 Wiring Configurations ...........................................................................................................7

4.5 5860 Remote Annunciator Installation ........................................................................................8

4.5.1 Mounting the 5860 ................................................................................................................9

4.5.1.1 Flush Mounting ..........................................................................................................10

4.5.1.2 Surface Mounting ......................................................................................................12

4.5.2 Model 5860 Connection to the Panel ................................................. ... ... .... ... ... ... ... .... ......12

4.6 5815XL Installation ....................................................................................................................12

4.6.1 5815XL Connection to the Panel ........................................................................................13

4.7 5824 Serial/Parallel Interface Module Installation .....................................................................14

4.7.1 Selecting 5824 Options ......................................................................................................15

4.8 5880 LED I/O Module ................................................................................................................16

4.8.1 5880 Board Layout ................... ... ... ....................................... ... ... .... ... ... ... ..........................16

4.8.2 5880 Connection to Panel ..................................................................................................16

4.8.3 LED Wiring .........................................................................................................................18

4.8.4 Dry Contact Wiring .............................................................................................................18

4.9 5865-3 / 5865-4 LED Annunciator Installation ........................ ................ ................ ................ ...20

4.9.1 5865 Connection to Panel ..................................................................................................20

4.9.2 5865 Mounting ................... .... ...................................... .... ... ... .............................................21

4.10 Configuring Modules .................................................................................................................22

4.10.1 Assigning SBUS Module IDs ............................................................................................22

4.11 Telephone Connection ..............................................................................................................23

4.12 Flexputs

™

I/O Circuits ...............................................................................................................23

4.12.1 Conventional Notification Appliance .................................................................................23

4.12.1.1 Class B Notification Wiring .......................................................................................24

4.12.1.2 Class A Notification Wiring .......................................................................................24

4.12.2 Conventional Input Switch Circuits ...................................................................................25

4.12.2.1 Class B Inputs ..........................................................................................................26

4.12.2.2 Class A Inputs ..........................................................................................................26

4.12.3 Installing 2-Wire Smoke Detectors ................................................................................... 27

4.12.3.1 Installing 2-Wire Class B Smoke Detectors .............................................................27

4.12.3.2 Installing 2-Wire Class A Smoke Detectors .............................................................28

4.12.4 Installing 4-Wire Smoke Detectors ................................................................................... 28

4.12.4.1 Installing 4-Wire Class B Smoke Detectors .............................................................28

4.12.4.2 Installing 4-Wire Class A Smoke Detectors .............................................................29

4.12.5 Auxiliary Power Installation .............. .......................... ....................... ...................... ..........30

4.12.5.1 Door Holder Power ...................................................................................................30

4.12.5.2 Constant Power ........................................................................................................30

4.12.5.3 Resettable Power ........................ ...................................... .......................................30

4.12.5.4 Sounder Sync Power ...............................................................................................31

4.13 On-Board Relays (Conventional) ..............................................................................................31

4.13.1 Trouble Relay .................. .... ...................................... .... ... ... ... ... .... ...................................31

4.13.2 Programmable Relays ......................................................................................................31

4.14 Remote Station Applications .....................................................................................................31

4.14.1 Keltron Model 3158 Installation ........................................................................................31

4.14.2 City Box Connection Using the 5220 Module ...................................................................32

4.14.3 NFPA 72 Polarity Reversal ...............................................................................................33

4.14.3.1 Using the 5220 Module ............................................................................................33

4.14.3.2 Using the 7644* Module ...........................................................................................34

4.14.4 Using the SD500-ARM Addressable Relay Module .........................................................35

2

Page 5

4.14.5 Using a MR-201/T Control Relay From Air Products ........................ .......................... ......35

4.14.6 Transmitter Activated by Dry Contacts ...................................... .... ... ... ... .... ... ... ... ... ..........37

Section 5

SK SLC Device Installation .....................................................................................................1

5.1 List of SK SLC Devices ...............................................................................................................1

5.2 List of SD SLC Devices ...............................................................................................................2

5.3 Maximum Number of Devices .....................................................................................................2

5.4 Wiring Requirements for SLC Devices ........................................................................................3

5.4.1 Wiring 5815XL in Style 4 (Class B) Configuration ................................................................ 3

5.4.2 Wiring 5815XL in Style 6 & 7 (Class A) Configuration ........................................... ...............5

5.5 Wiring SK SLC Detectors ............................................................................................................5

5.6 Addressing SK SLC Devices .......................................................................................................6

5.7 Wiring SD SLC Detectors ............................................................................................................7

5.8 Addressing SD Devices ...............................................................................................................7

5.8.1 SD505-APS, SD505-AHS, and SD505-AIS ..........................................................................7

5.8.2 SLC Devices with DIP Switches ...........................................................................................9

Section 6

Programming Overview ...............................................................................................................1

6.1 Security and Data Protection .................... ................. ................ ................ ................ ..................1

6.2 JumpStart Autoprogramming ......................................................................................................1

6.2.1 Input Points ............... ...................................... .... ... ....................................... ... ... ..................2

6.2.2 Output Points ........................................................................................................................2

6.2.3 Running JumpStart AutoProgramming .................................................................................2

6.3 Mapping Overview .......................................................................................................................4

6.3.1 Input Point Mapping .................. ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ... ............5

6.3.2 Output Circuit Mapping .........................................................................................................6

6.3.3 Zone Event Mapping ............................................................................................................7

6.3.4 Mapping LED Points .............................................................................................................9

6.4 Programming Using the 5660 Silent Knight Software Suite ......................................... ... .... ... ... ..9

6.5 Programming Using an Annunciator .........................................................................................10

6.5.1 Entering / Exiting the Program Menu ..................................................................................10

6.5.1.1 Moving through the Menus ........................................................................................11

6.5.1.2 Selecting Options and Entering Data ........................................................................11

6.5.1.3 Editing Keys ..............................................................................................................12

6.6 Programming Menu Quick Reference ....................................................................................... 13

Section 7

Programming .............................................................................................................................................1

7.1 UL 864 / UL 2572 Programming Requirements ..................... ... ... ... ... .... .....................................1

7.2 Modules ................................. ............................................. .........................................................1

7.2.1 Edit Modules .........................................................................................................................2

7.2.1.1 Naming Modules .........................................................................................................2

7.2.1.2 Editing Module Features .............................................................................................2

7.2.2 Adding a Module ................ .... ...................................... .... ... ... ...............................................2

7.2.3 Deleting a Module .................................................................................................................3

3

Page 6

Model 5820XL/ 5820XL-EVS Installation Manual

7.2.4 View Module List ..................................................................................................................3

7.3 Zone ............................................................................................................................................3

7.3.1 Edit Zone ..............................................................................................................................3

7.3.1.1 Edit Zone Name ..........................................................................................................4

7.3.1.2 Edit Zone Properties ...................................................................................................4

7.3.1.3 Zone Outputs ..............................................................................................................5

7.3.1.4 Cadence Patterns .......................................................................................................7

7.3.1.5 Zone Accessory Options .............................................................................................8

7.3.2 Add Zone .................................................................................. ... .........................................9

7.3.3 Delete Zone ........................................... ... ....................................... ... ..................................9

7.3.4 View Zone Points ..................................................................................................................9

7.4 Group ........................................................................................................................................10

7.4.1 Edit Group ..........................................................................................................................10

7.4.1.1 Edit Group Name ......................................................................................................10

7.4.1.2 Edit Group Properties ................................................................................................11

7.4.2 Add Group ................... ....................................... ... ... ... ....................................... ... .............12

7.4.3 Delete Group ............... ... ... ....................................... ... .... ... ................................................12

7.4.4 View Group Points ..............................................................................................................13

7.4.5 Edit Output Group Templates .............................................................................................13

7.5 Point ..........................................................................................................................................14

7.5.1 Point Programming For 5815XL Module ............................................................................14

7.5.2 Point Programming For Internal or External Power Module ......................... ... ... ... ... .... ... ...18

7.5.3 Point Programming For 5880, 5865, EVS-50W, EVS-100W,

EVS-125W and EVS-CE4 Modules ....................................................................................20

7.5.4 Point Programming For EVS-VCM and EVS-RVM Modules ..............................................20

7.5.5 Assigning a Name to Points ...............................................................................................21

7.6 System Options ............................................... ... ... .... ... ... ....................................... ... ... .............22

7.6.1 Reporting Account ..............................................................................................................22

7.6.1.1 Edit Accounts ............................................................................................................22

7.6.1.2 Auto Test Time ..........................................................................................................24

7.6.2 Phone Lines ........................................................................................................................24

7.6.2.1 Dialing Prefix .............................................................................................................25

7.6.2.2 Number of Answer Rings ................... ... .... ... ... ... .... ...................................... ... .... ... ...25

7.6.2.3 Dial Option (TouchTone or Pulse) .............................................................................26

7.6.2.4 Rotary Format ...........................................................................................................26

7.6.2.5 Line Monitor ..............................................................................................................26

7.6.2.6 Answering Machine Bypass ......................................................................................26

7.6.3 System Event Outputs ................. ... ... .... ... ... ....................................... ... ... .... ... ... ... .............26

7.6.3.1 Trouble Events ..........................................................................................................27

7.6.3.2 System Alarm Cadence ............................................... ... ... .... ... ... ... ..........................27

7.6.4 Time Options ......................................................................................................................28

7.6.4.1 Water Flow Delay ......................................................................................................28

7.6.4.2 Alarm Verification Time .............................................................................................28

7.6.4.3 Low AC Report Delay ................... ... ... ... .... ... ... ... .... ...................................... ... .... ... ...29

7.6.4.4 Clock Display Format (AM/PM or Military) ................................................................29

7.6.4.5 Change AC Line Frequency ......................... ................................................ ............. 29

7.6.5 Miscellaneous Options ............................................. ... .... ...................................... ... .... ......29

7.6.5.1 Synchronize Strobes Active During Silence ..............................................................29

7.6.5.2 Auto Display Oldest Event ........................................................................................30

7.6.5.3 Report by Zone or by Point .......................................................................................30

7.6.5.4 Plex Door Option .......................................................................................................30

7.6.5.5 Single Key Acknowledge ..........................................................................................30

7.6.6 Daylight Savings .................................................................................................................30

7.6.6.1 Automatic Daylight Savings Adjustment ............................................. ... ... ... ... .... ... ...30

4

Page 7

7.6.6.2 Daylight Saving Time Start and End .........................................................................30

7.6.7 Edit Banner .........................................................................................................................31

7.6.8 SLC Family .........................................................................................................................32

7.7 JumpStart Autoprogramming ....................................................................................................32

7.8 Computer Account .....................................................................................................................33

7.9 Access Codes ...........................................................................................................................34

7.9.1 Profile Edit Menu ................................................................................................................35

7.9.1.1 Edit Name .................................................................................................................35

7.9.1.2 Edit Access Code ......................................................................................................35

7.9.1.3 Panel Functions ........................................................................................................35

7.10 Voice Options . .... ...................................... .... ... ... ....................................... ... ... .... ......................35

7.10.1 EVS-VCM Maintenance ....................................................................................................35

7.10.1.1 PC Connection .........................................................................................................36

7.10.1.2 Local Recording .......................................................................................................36

7.10.2 Edit Voice Commands ......................................................................................................36

7.10.3 EVS System Options ........................................................................................................36

7.10.3.1 Enable EVS System .................................................................................................36

7.10.3.2 Edit Command Priority ............................................................................................. 37

7.10.3.3 Edit Command Mapping ...........................................................................................37

7.10.3.4 Edit Timers ...............................................................................................................38

7.10.3.5 Edit Event Names ....................................................................................................38

Section 8

System Operation ................................................................................................................................1

8.1 User and Installer Default Codes ................................................................................................1

8.2 Annunciator Description ..............................................................................................................1

8.2.1 LCD Display ..........................................................................................................................1

8.2.2 Banner ............................................... .... ...................................... .... ... ... ...............................1

8.3 Key Operation .............................................................................................................................2

8.4 Menu System .................................................. ... ....................................... ... ... ............................2

8.4.1 Main Menu Overview ............................................................................................................3

8.4.2 Using the Menus ...................................................................................................................3

8.5 Basic Operation ...........................................................................................................................3

8.5.1 Setting Time and Date ..........................................................................................................3

8.5.2 Disable / Enable a Point .......................................................................................................3

8.5.2.1 Disable / Enable NACs by Template ...........................................................................4

8.5.3 Disable / Enable NACs by Group .........................................................................................4

8.5.3.1 Disable / Enable Zone Points ......................................................................................4

8.5.4 View Event History ...............................................................................................................4

8.5.5 To clear the event history ............ ....................................... ... ... ... .... ... ... ...............................4

8.5.6 Conduct a Fire Drill ................... ... ... ....................................... ... ... .... .....................................4

8.5.7 Conduct an Indicator Test ....................................................................................................4

8.5.8 Conduct a Walk Test ......... .... ... ... ... ... .... ...................................... .... ... ... ...............................5

8.5.9 Conduct a Dialer Test .................. ... ... ....................................... ... .... ... ..................................5

8.5.10 Silence alarms or troubles ..................................................................................................5

8.5.11 Reset alarms ......................................................................................................................6

8.5.12 Check Detector Sensitivity Through Point Status ...............................................................6

8.5.13 View Status of a Point ........................................................................................................7

8.5.14 View Alarms, Supervisories or Troubles .............................................................................7

8.5.15 View System Information ....................................................................................................7

8.5.16 Reset Items ........................................................................................................................7

5

Page 8

Model 5820XL/ 5820XL-EVS Installation Manual

8.5.16.1 Reset Dialer ...............................................................................................................7

8.5.16.2 Reset DSP USB .........................................................................................................7

8.5.17 Communicating with a Remote Computer ..........................................................................8

8.5.18 Working with a Printer ........................................................................................................9

8.6 Operation Mode Behavior ............................................................ ... ... .......................................10

8.7 Releasing Operations ............................ ... .... ...................................... .... ... ... ... .... ... ...................15

8.7.1 Single Interlock Zone Releasing .........................................................................................16

8.7.2 Double Interlock Zone Releasing ................................ .... ... ... ... ... .... ... ................................17

8.8 Smoke Alarm Verification ................................................ ... .... ... ... ... ... .... ... ... ... ..........................18

Section 9

Emergency Voice System Operation .........................................................................1

9.1 Overview .....................................................................................................................................1

9.2 LOC Functionality ......................... ... ... ... ... .... ...................................... .... ... ... ... .... ... .....................1

9.2.1 Keys and LEDs ............... ... .... ... ... ... ... .... ...................................... .... .....................................1

9.2.1.1 EVS Control Key .........................................................................................................1

9.2.1.2 EVS Control LED ........................................................................................................2

9.2.1.3 ALL CALL Key .............................................................................................................2

9.2.1.4 NON-ACTIVE CALL Key .............................................................................................2

9.2.1.5 EVS Message Keys ....................................................................................................2

9.2.1.6 EVS Message LEDs ....................................................................................................2

9.2.1.7 Select Keys .................................................................................................................2

9.2.1.8 Select Key LEDs .........................................................................................................2

9.2.2 Gaining EVS Control ............................................................................................................3

9.2.2.1 LOC Priority .................................................................................................................3

9.2.2.2 LOC Lockout ...............................................................................................................3

9.2.2.3 User Profile Access Control ........................................................................................4

9.2.3 Manual EVS ..........................................................................................................................4

9.2.3.1 Switching between Microphone Mode and Message Mode ........................................4

9.2.3.2 Activating/Deactivating Output Groups Dynamically .............................. ..................... 4

9.2.4 Microphone Mode .................................................................................................................4

9.2.5 Message Mode .....................................................................................................................5

9.2.6 Custom EVS Event ...............................................................................................................5

9.2.7 Passing EVS Control ............................................................................................................5

9.2.8 Exit EVS Control Menu .........................................................................................................5

9.2.9 Relinquish EVS Control ........................................................................................................5

9.2.10 EVS Reset .............................................................................................................

9.2.11 Access Control ...................................................................................................................6

9.3 EVS Super User ..........................................................................................................................6

9.4 EVS Point Functionality ...............................................................................................................6

9.4.1 EVS Point Activations ...........................................................................................................6

9.4.2 EVS-VCM Points ..................................................................................................................7

9.5 EVS 5880 ....................................................................................................................................7

9.5.1 EVS (1-8) 5880 Module ........................................................................................................7

9.5.2 Enable 5880 EVS .................................................................................................................7

9.6 EVS LOC Programming ..............................................................................................................7

9.6.1 Adding an LOC ............................................... .... ... ... ... .... ... ...................................... ............7

9.6.2 Editing an LOC .....................................................................................................................8

9.6.2.1 LOC Priority .................................................................................................................8

9.6.2.2 LOC Association .........................................................................................................8

9.7 Amplifier Programming ................................................................................................................9

.............6

6

Page 9

9.7.1 Adding an Amplifier ..............................................................................................................9

9.7.2 Editing an Amplifier ...............................................................................................................9

9.8 Event Priority .............................................................................................................................10

9.8.1 System Control ............................................ ... ....................................... ... .... ... ...................10

9.8.2 System Override ............. ... ....................................... ... .... ... ...................................... ..........10

9.8.3 EVS Event Priority ..............................................................................................................10

9.8.4 View Active Alarms, Troubles and Supervisory Signals .....................................................11

9.9 Using the Microphone ...............................................................................................................11

9.9.1 Microphone Functionality ....................................................................................................11

9.9.2 Custom EVS Event .............................................................................................................11

9.9.3 Fire Page ............................................................................................................................12

9.9.4 Emergency Page ................................................ ... ... ... .... ... ... .............................................12

9.9.5 Paging ............................................ ... .... ... ... ... .... ...................................... .... ......................12

9.10 Recording Custom Messages ...................................................................................................13

9.10.1 Recording Messages 1-15 Using Aux Audio Input ...........................................................14

9.10.2 Recording Messages 1-15 Using the Microphone ............................................................16

9.10.3 Erasing User Message ................. ... .... ... ... ....................................... ... ... .... ... ... ... ... .... ......17

9.10.4 Using EVS Message Manager Software ..........................................................................18

9.11 EVS Priority ...............................................................................................................................19

9.11.1 Priority Rules ....................................................................................................................19

9.12 Defining Output Group Type .....................................................................................................20

9.13 Voice Command Mapping .........................................................................................................21

9.13.1 Voice System Mapping .....................................................................................................21

9.13.2 EVS Voice Aux Inputs (Dynamic with VCM/RVM in the system) .....................................21

9.13.3 Edit Command Mapping ...................................................................................................23

9.13.3.1 Mapping for Voice Commands .............................. ............................................. ...... 23

9.14 EVS Timer Options ....................................................................................................................24

9.14.0.2 Timers include ..........................................................................................................24

9.14.0.3 EVS Timer Menu ......................................................................................................24

Section 10

Reporting .........................................................................................................................................................1

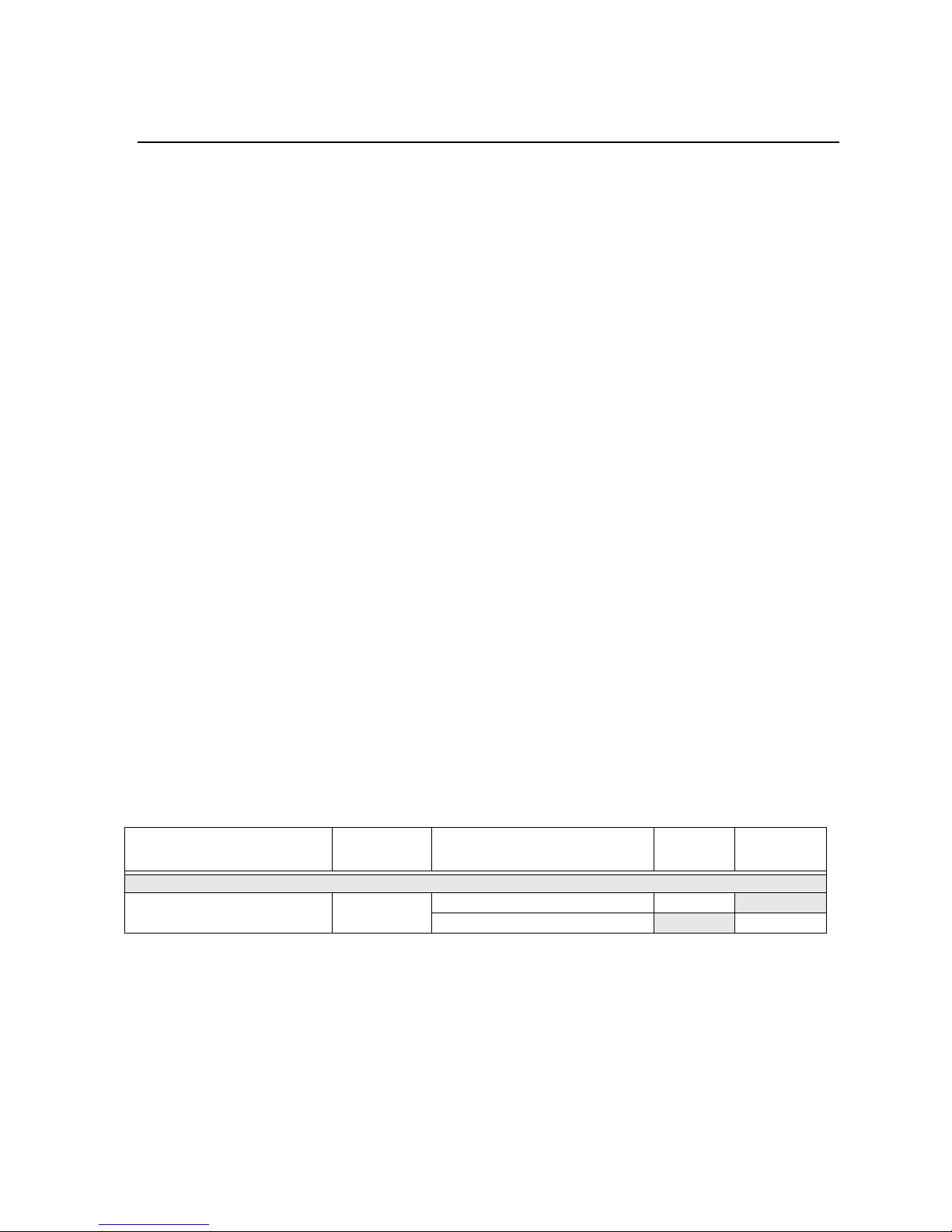

10.1 Receivers Compatible with the Control Panel .............................................................................1

10.2 Reporting Formats Table .............................................................................................................1

Section 11

Testing and Troubleshooting ...............................................................................................1

11.1 Troubleshooting ........................................ ................. ................... ................ ...............................1

11.2 Common Problems .......................... ... ... ... .... ... ....................................... ... ... ... .... ... ... ... ... ............1

11.3 Periodic Testing and Maintenance ..............................................................................................3

11.4 Event History ...............................................................................................................................3

11.5 Built-in Troubleshooting and Testing Tools .................................................................................3

11.5.1 SLC Device Locator ............................................................................................................3

11.5.2 SLC Multiple Locator ..........................................................................................................5

11.5.3 I/O Point Control .................................................................................................................6

11.5.4 Earth Fault Resistance .......................................................................................................7

7

Page 10

Model 5820XL/ 5820XL-EVS Installation Manual

Section 12

Installation Records .......................................................................................................................... 1

12.1 Detector and Module Point Record .............................................................................................1

12.2 Conventional Output Point Record ............................... ............................................. ..................5

Appendix A

Compatible Device ..............................................................................................................................1

Appendix B

Special Characters Lists .............................................................................................................1

Silent Knight Fire Product Warranty and Return Policy

Manufacturer Warranties and Limitation of Liability

IntelliKnight 5820XL Basic Operating Instructions

5820XL-EVS Basic Operating Instructions

8

Page 11

LS10061-001SK-E

Section 1

Introduction

The IntelliKnight 5820XL Fire Alarm Control/Communicator is an addressable fire control system that meets

the requirements of UL 864.

The 5820XL/EVS integrates an Emergency Voice System that meets the requirements of UL 864 and UL 2572.

1.1 Overview of Basic System

The IntelliKnight 5820XL and 5820XL-EVS base system is packaged as an assembled stack of 3 circuit boards

mounted to an aluminum housing.

1.1.1 Addressable Fire Alarm Control/Communicator Hardware

Features

• The IntelliKnight 5820XL and 5820XL-EVS panel has one signaling line circui t (SLC). Up to three

additional SLC loops can be added using the 5815XL SLC expander. The SLC(s) supports SK addressable

detectors and modules or SD protocol detectors and modules.

• Each SLC supports 99 SK detectors and 99 SK modules for a total of 396 SK detectors and 396 SK modules

per 5820XL/EVS or 127 SD devices for a total of 508 SD devices per 5820XL/EVS.

• 6.0A of output power is available through 6 sets of terminals for notification and auxiliary applications.

Each circuit is power limited per UL 864 and can source up to 3.0A (total output power must not exceed

6.0A).

• Built-in dual phone line, digital alarm communicator/transmitter (D ACT).

• Reports events to central station by point or by zone.

• UL Listed for pre-action and deluge releasing systems.

• Dedicated Form C trouble relay and two general purpose Form C programmable relays.

• Basic system operation can be performed using a key or a user code.

• Can be used with up to twelve Model 5860s Remote Annunciators (sold separately).

• Supports the 5865-3, 5865-4, and 5880 in any combination for a total of eight devices on one control panel.

• Printing of detector status, event history, and real time event log available through the Model 5824 Serial/

Parallel Printer Interface Module (sold separately).

• Supports conventional 2-wire & 4-wire detectors using the 6 Flexput™ circuits.

• Add six Flexput™ circuits with each 5895XL Intelligent Power Module (up to eight 5895XLs per system).

See note below.

• Add four notification/auxiliary power circuits with each 5496 Intelligent Power Module. See note below.

Note: The system can support a maximum of eight Intelligent Power modules, either the 5895XL or 5496, in any

combination.

1.1.2 5820XL-EVS Emergency Voice Hardware Features

• The EVS-VCM has a built-in Digital Message Repeater.

• 15 EVS messages.

• Single enclosure for system control components.

• SBUS addressable amplifier. The system can support a combination of up to four EVS-50W, EVS-125W or

EVS-100W amplifiers for a maximum of 500 watts per system.

• On-board supervised microphone.

• 5820XL/EVS can support up to four EVS-RCU's (Remote Command Units).

1-1

Page 12

Model 5820XL/ 5820XL-EVS Installation Manual LS10061-001SK-E

• Up to 32 mappable speaker circuits using a combination of EVS-50W, EVS-100W, EVS-125W and

EVS-CE4's.

• Supports 25 Vrms or 70.7 Vrms speaker circuits using EVS-50W or EVS-100W.

• Supports 25 Vrms speaker circuits using EVS-125W.

1.1.3 Software Features

• Advanced smoke detector features:

Automatic drift compensation

Maintenance alert region

Point status meets calibrated smoke test requirements for NFPA 72

• “JumpStart” feature for easy programming.

• 125 software zones, 250 output groups.

• Non-volatile event history stores 1000 events.

• A choice of output patterns available for notification outputs, including ANSI 3.41 temporal signal.

• Built-in synchronization appliance support for AMSECO, Faraday, Gentex

Wheelock.

®

®

, System Sensor®, and

1.2 About this Manual

This manual is intended to be a complete reference for all installation and operation tasks for the 5820XL* and

5820XL/EVS**. Please let us know if the manual does not meet your needs in any way. We value your feedback!

* All references to 5820XL within this manual are applicable to the 5820XL-EVS.

** Further installation instructions for the 5820XL-EVS and accessories can be found in the EVS Series

installation manual P/N LS10062-001-SK-E.

1.2.1 Terms Used in this Manual

The following terminology is used with the above mentioned control panels:

Term Description

SLC Signaling line circuit

Module The term module is used for all hardware devices except for SLC

addressable devices and notification appliances. This includes the 5820XL/

EVS panel itself and the built-in 5897 power supply. It also refers to any

(optional) 5815XL SLC expansion modules.

Input Point An addressable sensing device, such as a smoke or heat detector or a

contact monitor device.

Input Zone A protected area made up of input points.

Output Point

(or “Output Circuit”)

Output Group (OPG) A group of output points. Operating characteristics are common to all output

Output (or “Cadence”) Pattern The pattern that the output will use, for example, Constant, March Code,

Mapping Mapping is the process of specifying which outputs are activated when

EVS Emergency Voice System.

A notification point or circuit for notification appliances. Relay circuits and

auxiliary power circuits are also considered output points.

points in the group.

ANSI 3.41. Applies to zones and special system events. See Section 7.6.3.2

for additional information.

certain events occur in the system. Section 6.3 explains mapping in detail.

1-2

Page 13

LS10061-001SK-E Introduction

1.3 Compatible Products

Table 1-1 lists the products available from Silent Knight for use with the 5820XL and 5820XL-EVS.

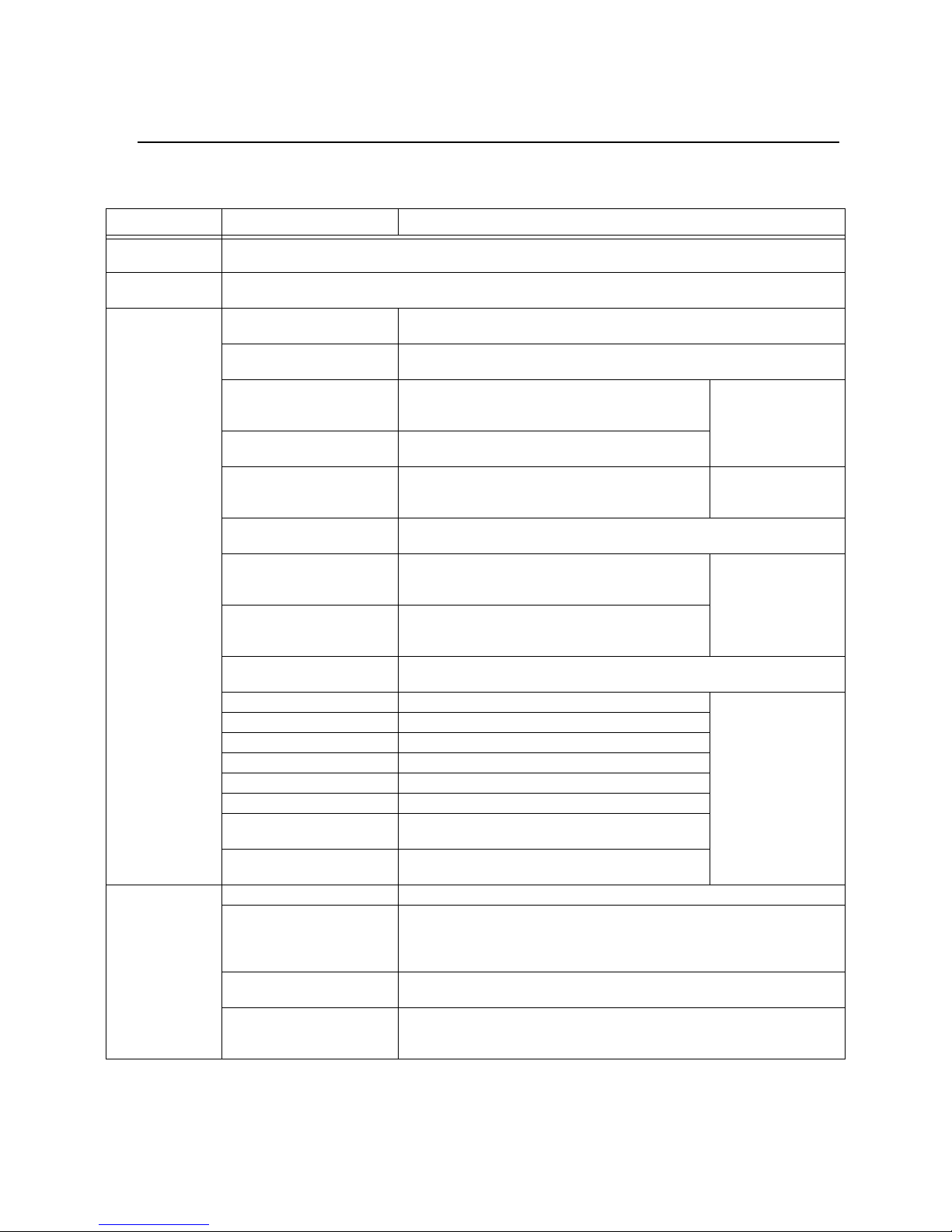

Table 1-1: 5820XL/EVS Compatible Products

Type of Device Model Description

SK Addressable

SLC Devices

SD Addressable

SLC Devices

Other Modules

Misc.

See Section 5.1 for a list of compatible devices.

See Section 5.2 for a list of compatible devices.

5815XL SLC Expander Allows an additional 127 SD devices or 99 SK detectors and 99 SK modules to

5824 Serial/Parallel Printer

Interface Module

5895XL Intelligent Power

Module

5496 Intelligent Power Module Provides 4 additional Notification Appliance Circuits/

5860 and 5860R Remote Fire

Alarm Annunciator

5860TG and 5860TR Trim

Ring Kit

5865-3 and 5865-4 LED

Annunciator

5880 LED I/O Module Driver for up to 40 LEDs. Interfaces with customized

5883 General Purpose Relay

Module

EVS-VCM Voice Control Module used with the 5820XL-EVS.

EVS-SW24 24 switch expander used with the 5820XL-EVS.

EVS-50W 50 watt audio amplifier.

EVS-125W 125 watt audio amplifier.

EVS-100W 50/100 watt Intelligent amplifier

EVS-50WBU External backup amplifier

EVS-CE4 Provides 4 additional audio circuits for the EVS-50W or

EVS-RVM Remote Voice Microphone used with the

7860 Telephone Cord RJ31X cord for connecting phone line to the 5820XL/EVS.

5660 Silent Knight Software

Suite (SKSS)

5670 Silent Knight Software

Suite (SKSS)

RBB Remote Battery Box for mounting backup batteries that are too large to fit into

be added to the system. Up to three 5815XLs per system.

Allows a printer to be attached for the system for on-site event logging, detector

status and event history reports. Two maximum per system.

Provides additional power, six Flexput™ circuits, and

two Form C relays. Max. 8 per system see Model

5895XL Installation Instructions P/N 151142.

Auxiliary power. (Up to 8 per system).

Same operation, similar appearance as on-board

annunciator. Up to 12 5860s per system. 5860 is gray;

5860R is red.

Trim ring kits for surface mounting the 5860 annunciator. 5860TG is gray;

5860TR is red.

LED annunciator can display up to 30 LEDs (15 red

and 15 yellow). 5865-4 has key switches for silence

and reset, and a system trouble LED.

annunciator boards. In addition, the 5880 has eight

generic switch input points.

Provides 10 Form C relays. Designed to be driven by the 5880. Up to four,

5883s can be used with each 5880 module.

EVS-125W.

5820XL-EVS.

“For communication and panel programming with a Windows-based computer.

Remote access requires a modem.” (not sold by Silent Knight, see Table 1-2 for

compatible modems). Enables remote viewing of detector status and event

history.

Facility management software. For remote viewing of detector status and event

history. Remote access requires a modem (not sold by Silent Knight).

the main FACP cabinet. Dim.: 16" W x 10" H x 6" D (40.64 cm W x 25.4 cm H x

15.24 cm D)

5895XLs and 5496s

can be used in any

combination, up to a

total of twelve devices

on one system.

up to a total of 12

5860s on one system.

5865-3, 5865-4, and

5880 can be used in

any combination, up to

a total of eight devices

on one panel.

For use with 5820XLEVS only. Refer to the

EVS-Series

Installation Manual P/

N LS10062-001SK-E

for more information

on these accessories.

1-3

Page 14

Model 5820XL/ 5820XL-EVS Installation Manual LS10061-001SK-E

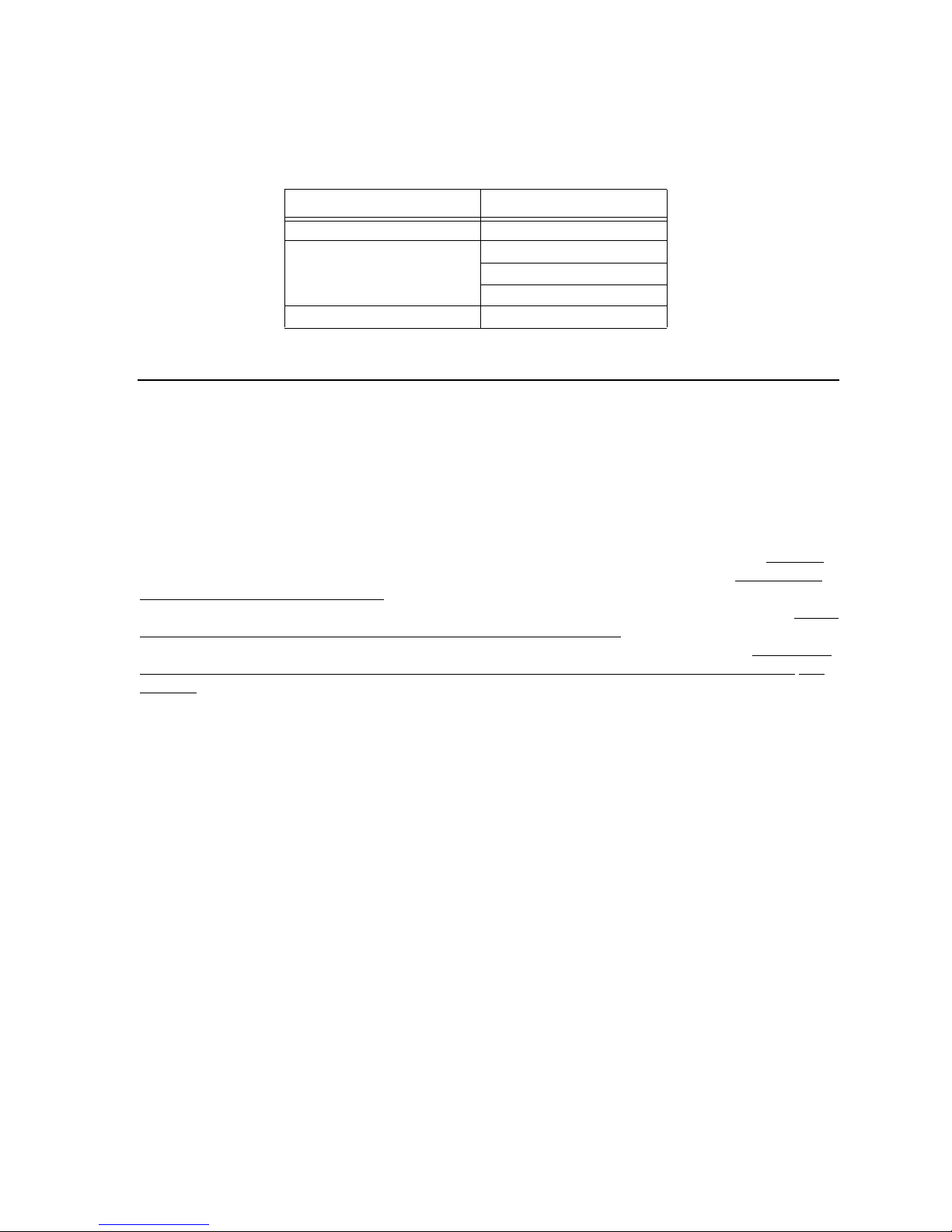

The following modems have been tested by Silent Knight for compatibility with the IntelliKni ght 5820XL and

5820XL-EVS and the Silent Knight Software Suite software packages:

Table 1-2: Compatible Modems

Manufacturer Model

US Robotics 28.8

LifeStyle

Motorola

MultiTech MT19321ZDX

28.8, 3400 series

Premier 33.6

1.4 How to Contact Silent Knight

If you have a question or encounter a problem not covered in this manual, contact Silent Knight Technical

Support at 800-446-6444.

To order parts, contact Silent Knigh t Sal e s at 800-328-0103.

IntelliKnight

Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise following

the recommendations of the current edition of the National Fire Protection Association Standard 72 (NFPA 72

manufacturer’s recommendations, state and local codes, and the recommendations contained in Guide for the

Proper Use of System Smoke Detectors, which is made available at no charge to all installing dealers. A study by

the Federal Emergency Management Agency (an agency of the United States government) indicated that smoke

detectors may not go off or give early warning in as many as 35% of all fires. While fire alarm systems are

designed to provide warning against fire, they do not guarantee warning or protection against fire. A fire alarm

system may not provide timely or adequate warning, or simply may not function, for a variety of reasons. For

example:

®

is a registered trademark of Silent Knight; Flexput™ is a trademark of Silent Knight

Limitations of Fire Alarm Systems

),

• Particles of combustion or smoke from a developing fire may not reach the sensing chambers of smoke

detectors because:

Barriers such as closed or partially closed doors, walls, or chimneys may inhibit particle or smoke flow.

Smoke particles may become cold, stratify, and not reach the ceiling or upper walls where detectors are

located.

Smoke particles may be blown away from detectors by air outlets

Smoke particles may be drawn into air returns before reaching the detector.

In general, smoke detectors on one level of a structure cannot be expected to sense fires developing on another

level.

• The amount of smoke present may be insufficient to alarm smoke detectors. Smoke detectors are designed to

alarm at various levels of smoke density. If such density levels are not created by a developing fire at the

location of detectors, the detectors will not go into alarm.

• Smoke detectors, even when working properly, have sensing limitations. Detectors that have photoelectronic

sensing chambers tend to detect smoldering fires better than flaming fires, which have little visible smoke.

Detectors that have ionizing-type sensing chambers tend to detect fast flaming fires better than smoldering

fires. Because fires develop in different ways and are often unpredictable in their growth, neither type of

detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

• Smoke detectors are subject to false alarms and nuisance alarms and may have been disconnected by users.

For example, a smoke detector located in or near a kitchen may go into nuisance alarm during normal

operation of kitchen appliances. In addition, dusty or steamy environments may cause a smoke detector to

falsely alarm. If the location of a smoke detector causes an abundance of false alarms or nuisance alarms, do

1-4

Page 15

LS10061-001SK-E Introduction

not disconnect the smoke detector; call a professional to analyze the situation and recommend a solution.

• Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children playing

with matches (especially within bedrooms), smoking in bed, violent explosions (caused by escap ing gas,

improper storage of flammable materials, etc.).

• Heat detectors do not sense particles of combustion and are designed to alarm only when heat on their

sensors increases at a predetermined rate or reaches a predetermined level. Heat detectors are designed to

protect property, not life.

• Warning devices (including horns, sirens, and bells) may not alert people or wake up sleepers who are

located on the other side of closed or partially open doors. A warning device that activates on a different

floor or level of a dwelling or structure is less likely to awaken or alert people. Even persons who are awake

may not notice the warning if the alarm is muffled by noise from a stereo, radio, air conditioner or other

appliance, or by passing traffic. Audible warning devices may not alert the hearing-impaired (strobes or

other devices should be provided to warn these people). Any warning device may fail to alert people with a

disability , deep sleepers, people who have recently used alcohol or drugs, or people on medication or

sleeping pills.

Please note that:

i) Strobes can, under certain circumstances, cause seizures in people with conditions such as epilepsy.

ii) Studies have shown that certain people, even when they hear a fire alarm signal, do not respond or com-

prehend the meaning of the signal. It is the property owner’s responsibility to conduct fire drills and

other training exercises to make people aware of fire alarm signals and instruct on the proper reaction to

alarm signals.

iii) In rare instances, the sounding of a warning device can cause temporary or permanent hearing loss.

• Telephone lines needed to transmit alarm signals from a premises to a central station may be out of service

or temporarily out of service. For added protection against telephone line failure, backup radio transmission

systems are recommended.

• System components, though designed to last many years, can fail at any time. As a precautionary measure, it

is recommended that smoke detectors be checked, maintained, and replaced per manufacturer’s

recommendations.

• System components will not work without electrical power. If system batteries are not serviced or replaced

regularly, they may not provide battery backup when AC power fails.

• Environments with high air velocity or that are dusty or dirty require more frequent maintenance.

In general, fire alarm systems and devices will not work without power and will not function properly unless they

are maintained and tested regularly.

While installing a fire alarm system may make the owner eligible for a lower insurance rate, an alarm system is

not a substitute for insurance. Property owners should continu e to act prud ently in protecting the premises and

the people in their premises and should properly insure life and property and buy sufficient amounts of liability

insurance to meet their needs.

1-5

Page 16

Model 5820XL/ 5820XL-EVS Installation Manual LS10061-001SK-E

Requirements and recommendations for proper use of fire alarm systems including smoke detectors and other fire alarm devices:

Early fire detection is best achieved by the installation and maintenance of fire detection equipment in all rooms

and areas of the house or building in accordance with the requirements and recommendations of the current

edition of the National Fire Protection Association Standard 72, National Fire Alarm Code (NFPA 72), the

manufacturer’s recommendations, State and local codes and the recommendations contained in Guide for the

Proper Use of System Smoke Detectors, which is made available at no charge to all installing dealers. For

specific requirements, check with the local Authority Having Jurisdiction (ex. Fire Chief) for fire protection

systems.

Requirements and recommendations include:

• Smoke detectors shall be installed in sleeping rooms in new construction and it is recommended that they

shall also be installed in sleeping rooms in existing construction.

• It is recommended that more than one smoke detector shall be installed in a hallway if it is more than 30 feet

long.

• It is recommended that there shall never be less then two smoke detectors per apartment or residence.

• It is recommended that smoke detectors be located in any room where an alarm control is located, or in any

room where alarm control connections to an AC source or phone lines are made. If detectors are not so

located, a fire within the room could prevent the control from reporting a fire.

• All fire alarm systems require notification devices, including sirens, bells, horns, and/or strobes. In

residential applications, each automatic alarm initiating device when activated shall cause the operation of

an alarm notification device that shall be clearly audible in all bedrooms over ambient or background noise

levels (at least 15dB above noise) with all intervening doors closed.

• It is recommended that a smoke detector with an integral sounder (smoke alarm) be located in every

bedroom and an additional notification device be located on each level of a residence.

• T o keep your fire alarm system in excellent working order, ongoing maintenance is required per the

manufacturer’s recommendations and UL and NFPA standards. At a minimum the requirements of Chapter

7 of NFPA 72 shall be followed. A maintenance agreement should be arranged through the local

manufacturer’s representative. Maintenance should be performed annually by authorized personnel only.

• The most common cause of an alarm system not functioning when a fire occurs is inadequate maintenance.

As such, the alarm system should be tested weekly to make sure all sensors and transmitters are working

properly.

1-6

Page 17

LS10061-001SK-E

Section 2

Agency Listings, Approvals, and Requirements

2.1 Federal Communications Commission (FCC)

1. The following information must be provided to the telephone company before the 5820XL or 5820XL-EVS

can be connected to the phone lines:

A Manufacturer: Silent Knight by Honeywell

B Model Number: IntelliKnight 5820XL and

5820XL-EVS

C FCC registration number: AC6USA-23901-AL-E

Ringer equivalence: 0.8B

D Type of jack: RJ31X

E Facility Interface Codes: Loop Start: 02LS2

F Service Order Code: 9.0F

This equipment complies with Part 68 of the FCC rules and the requirements adopted by ACTA. On the inside

cover of this equipment is a label that contains, among other information, a product identifier. If requested, this

information must be provided to the telephone company.

A plug and jack used to connect this equipment to the premises wiring and telephone network must comply with

the applicable FCC Part 68 rules and requirements adopted by the ACTA. A compliant telephone cord (not

provided) and modular jack must be utilized with this product. It is designed to be used with a modular jack that

is also compliant.

The REN (ringer equivalence number) provided on this installation sheet is used to determine the number of

devices that may be connected to the public switched telephone network. This number must not exceed 5.0.

Since this product has an REN of .8, the number of devices is limited. The REN number is embedded in the FCC

registration number as 10B.

If the 5820XL or 5820XL-EVS causes harm to the telephone network, the telephone company will notify you in

advance that the temporarily discontinuance of service may be required. But if advance notice is not practical,

the telephone company will notify the customer as soon as possible. Also, you will be advised of your right to

file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations or procedures that could affect

the operation of the equipment. If this happens the telephone company will provide advance notice in order for

you to make necessary modifications to maintain uninterrupted service.

If trouble is experienced with the 5820XL or 5820XL-EVS, for repair or warranty information, please contact

Silent Knight at 1-800-328-0103 or www.silentknight.com. If the equipment is causing harm to the telephone

network, the telephone company may request that you disconnect the 5820XL or 5820XL-EVS until the problem

has been resolved.

This product cannot be adjusted or repaired in the field. It must be returned to the factory for service.

This equipment is not designed for use with party line service. Connection to party line service is subject to state

tariffs. You may contact the state public utility com mission, public service commission or corporation

commission for information.

Since the 5820XL/5820XL-EVS is a commercial fire alarm panel, it must be connected upstream of all other

equipment utilizing the phone lines. If you have questions about the installation, contact your telephone company

2-1

Page 18

LS10061-001SK-E Agency Listings, Approvals, and Requirements

or a qualified installer.

Warning

This device has been verified to comply with FCC Rules Part 15. Operation is subject to the following conditions: (1)

This device may not cause radio interference, and (2) This device must accept any interference received, including

interference that may cause undesired operation.

2.2 Underwriters Laboratories (UL)

2.2.1 Requirements for All Installations

General requirements are described in this section. When installing an individual device, refer to the specific

section of the manual for additional requirements. The following subsections list specific requirements for each

type of installation (for example, Central Station Fire Alarm systems, Local Protected Fire Alarm systems, and

so on). See Section 8.7 for information on releasing operation.

1. All field wiring must be installed in accordance with NFPA 70 National Electric Code.

2. Use the addressable smoke detectors specified in Section 5.2 (SD devices) or

Section 5.1 (SK devices) of this manual and/or conventional detectors listed in the compatibility chart. (See

Appendix A).

3. Use UL listed notification appliances compatible with the 5820XL/EVS from those specified in Appendix A

of this manual.

4. A full system checkout must be performed any time the panel is programmed.

Restricted Options:

• The loss of AC signal is defaulted to 3 hours, however the system allows settings from 0 - 30 hours. For UL

certified installations this number must be set from 1 to 3 hours.

• The system allows the use of non-latching spot type smoke detectors. This feature may not be used in

commercial applications whereby a general alarm is sounded. It is intended for elevator recall, door holding

applications, and hotel/motel room applications.

• The system allows the Alarm V erification time to be set from 1 to 255 seconds. For UL certified installations

the setting must be a minimum of 60 seconds.

• Call forwarding shall not be used.

• When two count is used: detector spacing shall be cut in half, you shall not use the alarm verification feature,

and no delay shall be used.

• P.A.S. (positive alarm sequence) feature shall be used only with automatic detectors.

2.2.2 Requirements for Central Station Fire Alarm Systems

1. Use both phone lines. Enable phone line monitors for both lines.

2. You must program a phone number and a test time so that the 5820XL/5820XL-EVS sends an automa ti c

daily test to the central station.

3. The AC Loss Hours option must be set from 1-3 hours.

4. The Attempts to Report option must be set for 5.

2-2

Page 19

Model 5820XL/ 5820XL-EVS Installation Manual LS10061-001SK-E

2.2.3 Requirements for Local Protected Fire Alarm Systems

At least one UL listed supervised notification appliance must be used.

2.2.4 Requirements for Remote Station Protected Fire Alarm

Systems