Siemens SINUMERIK 840, SINUMERIK 880 GA2 T/M, SINUMERIK 840C, SINUMERIK 880, SINUMERIK 880 GA2 Planning Manual

...

SINUMERIK 840/840C

SINUMERIK 880/880 GA2

Computer Link

General Description

Planning Guide 09.95 Edition

Manufacturer Documentation

SINUMERIK 840/840C

SINUMERIK 880/880 GA2

Computer Link

General Description

Planning Guide

Manufacturer Documentation

Valid for:

Control Software version

SINUMERIK 840 from 1

SINUMERIK 840C from 1

SINUMERIK 880 T/M from 3

SINUMERIK 880 GA2 T/M from 1

September 1995 Edition

SINUMERIK® documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” column.

Status code in

”Remarks”

column

:

A . . . New documentation B . . . Unrevised reprint with new Order No.

C . . . Revised edition with new status. If factual changes have been made on the page since

the last edition, this is indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

08.89 6ZB5 410-0CB02-0BA0 A

06.91 6ZB5 410-0CB02-0AA1 C

09.95 6FC5 197-0AB20-0BP0 C

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

This publication was produced on the Siemens 5800 Office

System.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

©

Siemens AG 1989, 1991, 1995 All Rights Reserved

Preliminary Remarks

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

Reader guidance

This documentation is intended for manufacturers and users who wish to obtain information on

the computer link with SINUMERIK 840/880.

The description provides a general overview of the computer link, focussing on the computer

link with SINUMERIK 840/880.

It is meant as a first introduction for users who are not yet familiar with the computer link with

SINUMERIK 880 as it describes the basics for the message frame traffic. The manual

"SINUMERIK 840/880 Computer Link General Description" is part of a documentation set on

the 840/880 computer link that is organized as follows:

• General documentation

• Configuration documentation

• Installation and service documentation

The term ”SINUMERIK 8X0” is used in this description as a short form for

”SINUMERIK 840/880”.

Technical information

This documentation applies to software version 1 and higher in the case

of SINUMERIK 840 and 840C to software version 3 and higher in the case

of SINUMERIK 880 GA2 to software version 1.

General 1

Local Area Networks 2

Interface Modules 3

COM 4

PLC 5

Message Frames 6

Configuration and Test 7

Abbreviations 8

Appendix 9

Contents

Page

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1 Definition of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.1.1 Computer link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.1.2 ISO reference model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1.1.3 LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.1.4 MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.1.5 SINEC AP 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.1.6 Transport connection TPV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.1.7 Logical peer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

2 Local Area Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1 Bus connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1.1 The ISO seven layer model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.1.2 Access methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.1.3 SINEC H1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

2.2 Serial connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

2.2.1 Point-to-point connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

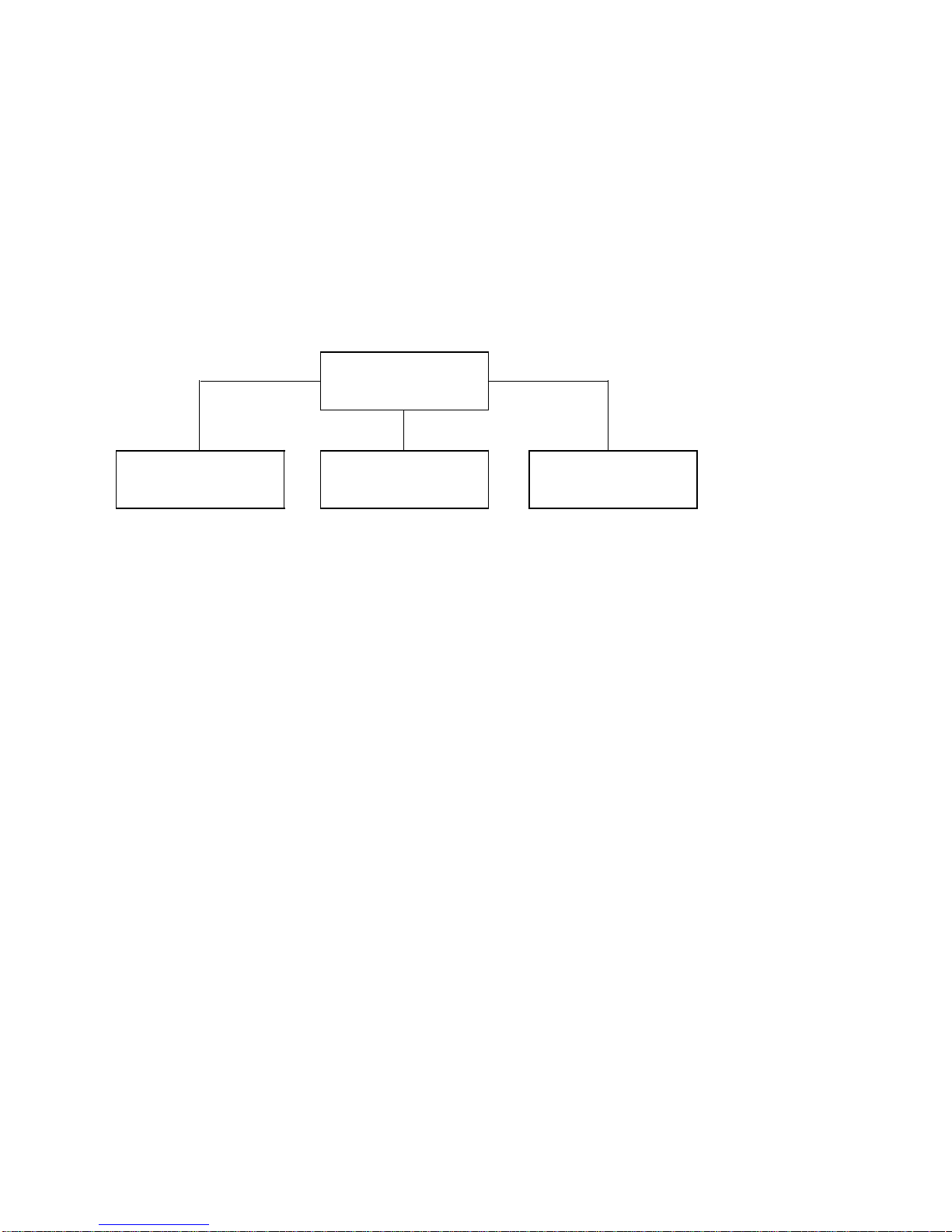

2.2.2 Star connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

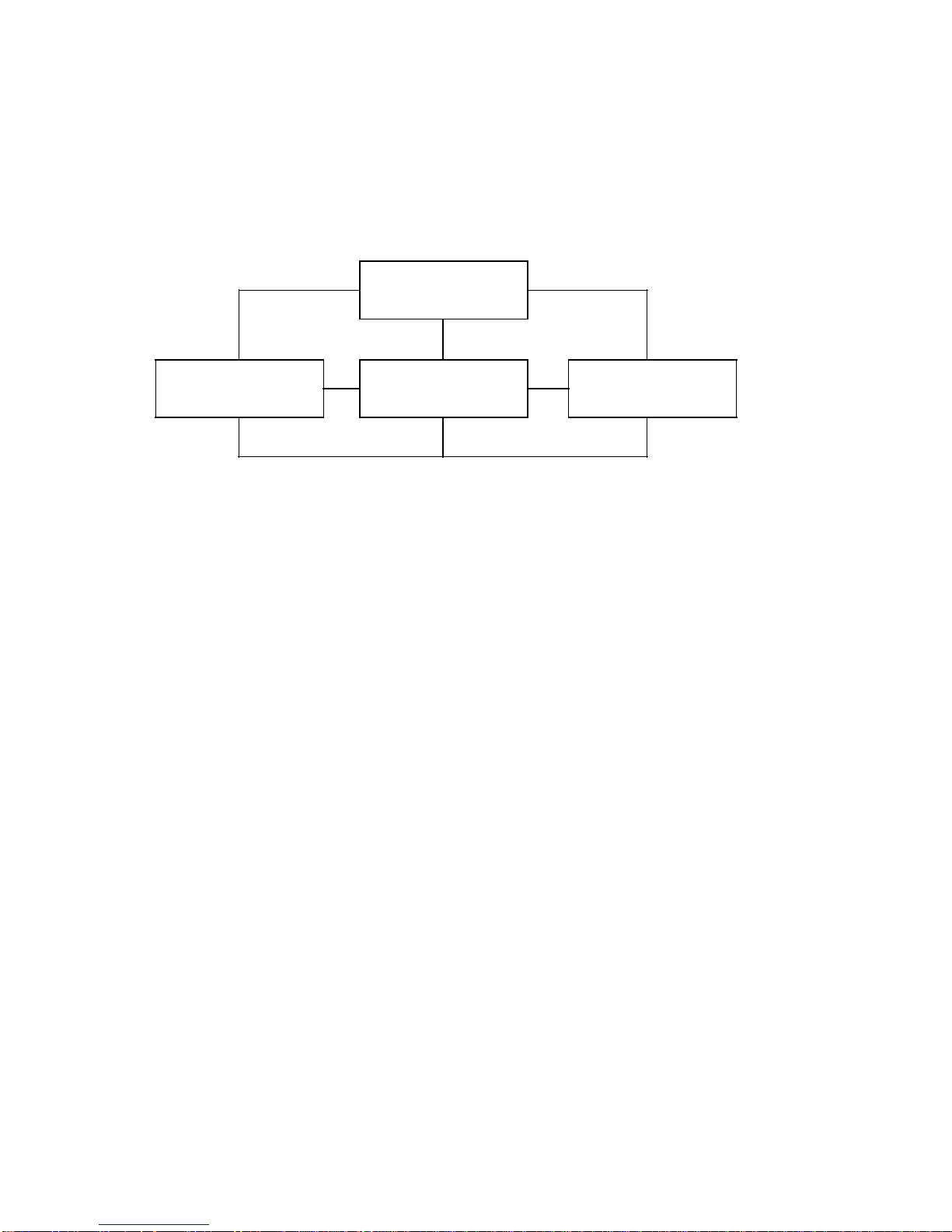

2.2.3 Meshed network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

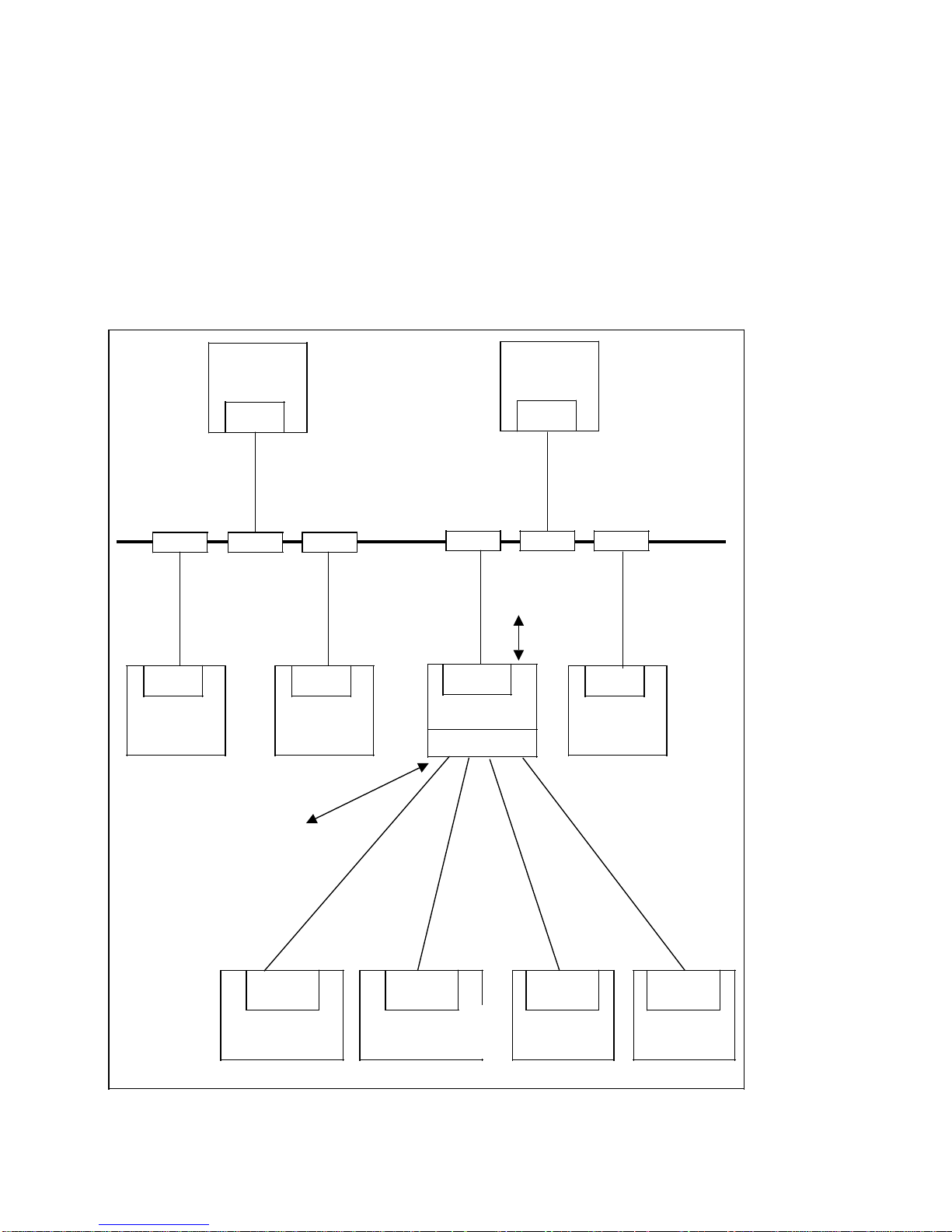

2.3 Bus and serial connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

3 Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.1 Bus interface module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3.2 Serial interface modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.2.1 Communication with the CP 315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

3.2.2 Requirements for the use of ”flexible communication” . . . . . . . . . . . . . 3–12

3.2.3 Brief description of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–12

3.2.4 Possible communication links within the framework of

the ISO 7-layer model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–13

3.3 Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–15

3.3.1 3964R procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–15

3.3.2 LSV2 procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–17

3.3.3 XON/XOFF procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–20

3.3.3.1 Communication nodes between ”intelligent” and”non-intelligent”

(unequal) nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–20

3.3.3.2 Communication between ”intelligent” (equal) nodes . . . . . . . . . . . . . . . 3–21

3.3.3.3 Signal chart for the XON/XOFF procedure . . . . . . . . . . . . . . . . . . . . . . 3–22

3.3.3.3.1 Read data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–22

3.3.3.3.2 Data output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–23

3.3.4 RTS-LINE (RTS/CTS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–24

3.3.4.1 Signal charts for the RTS/CTS procedure . . . . . . . . . . . . . . . . . . . . . . 3–25

3.3.4.1.1 Data input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–25

3.3.4.1.2 Data output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–26

3.3.5 Communication control in the Transparent Mode . . . . . . . . . . . . . . . . . 3–27

3.4 Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–27

3.4.1 SINEC AP1 protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–28

3.4.2 Transparent data exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–31

3.4.3 AS 512 protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–34

3.4.4 Communication with SIMATIC S5 systems . . . . . . . . . . . . . . . . . . . . . 3–41

3.4.4.1 STF extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–41

3.4.4.2 Requirements for the application of STF . . . . . . . . . . . . . . . . . . . . . . . 3–43

3.4.5 Remote communication with programmers via SINEC H1 . . . . . . . . . . . 3–43

3.4.5.1 Scope of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–43

3.4.5.2 Requirements for the use of the PG REMOTE function . . . . . . . . . . . . 3–44

3.5 Addressing lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–45

3.5.1 Addressing lists of the bus interface module . . . . . . . . . . . . . . . . . . . . 3–45

3.5.1 Addressing lists of the serial interface module . . . . . . . . . . . . . . . . . . . 3–47

3.5.2.1 For message frames with AS 512 protocol and

with identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–47

3.5.2.2 For message frames without AS 512 protocol and

with identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–48

3.5.2.3 For message frames with AS 512 protocol and

without identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–48

3.5.2.4 For message frames without AS 512 protocol and

without identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–49

4 COM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.2.1 Standard routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

5 PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.1 User interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5.1.2 Standard functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

6 Message Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6.1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6.1.1. Meaning of the characters in the message frame identification

for SINUMERIK message frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6.1.2 Meaning of the characters used in the identifications of

”free message frames” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6.2 Standard message frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6.3 Kernel sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6.4 Configurable message frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

6.5 Message frame overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

6.6 Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–14

7 Configuration and Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7.1.1 SINEC NM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

7.1.2 SINEC NML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

7.1.3 SINPS 231 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

7.1.4 SINPS 315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

7.2 Test and simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–11

7.2.1 SINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

7.2.2 SIM 850 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

7.2.3 FOX PG-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

7.2.4 FOX PG-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

7.2.5 SIPRA H1 (SINEC Protocol Analyzer) . . . . . . . . . . . . . . . . . . . . . . . . . 7–15

8 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.1 Reception using the 3964R procedure . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.2 LSV2 procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

9.3 XON/XOFF procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

9.4 RTS-LINE procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

9.5 Error coding of remote AP protocol processing systems and AP users . 9–18

06.91 1 General

1

Communication systems are used in various areas and, depending on their application and

environment, they must meet specific quality requirements in order to fulfil their tasks.

Local communication networks are used in three major fields of application:

• Laboratory

• Factory

• Office

This description deals only with communication in the factory environment via industrial bus

and serial connections.

Industrial bus according to MAP

Let us briefly review the history of the MAP industrial bus. General Motors (GM) approached

all electronics manufacturers at the end of the seventies asking them to cooperate. GM have

worked on LANs since 1979. As early as 1980 they started to develop the MAP protocol.

During the NCC 84 US computer show in July 1984, GM introduced a local area network on

the basis of a broad band token bus. They showed a MAP network up to the fourth (transport)

layer, using different computer and control systems of IBM, Hewlett Packard, Digital

Equipment, Motorola, Allen Bradley, Gould and Concord Data Systems. At the September

1985 Autofact in Detroit, Siemens was represented on the bus with a programmable controller

together with other companies. The SIMATIC S5-150S was connected to the token bus via a

301 EU interface module and the 310 Intel development system.

General

SINEC H1

The SINEC H1 industrial bus (ETHERNET) has been implemented by the Siemens Automation

Group. This bus ensures the heterogeneous integration of Siemens programmable controllers.

A uniform protocol is necessary to enable communication to take place with different

automation equipment such as numerical controls, personal computers, process control

computers etc. in a production automation environment.

For SINEC H1 the framework protocol architecture has been implemented using international

standards in the transport-oriented layers (1 to 4) and the SINEC-AP1 Siemens standard in the

application-oriented layers (5 to 7).

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 1–1

©

SINUMERIK 840/880 (PJ)

1 General 06.91

Industrial buses

General quality specifications

• Security

Data must not be falsified or get lost without an error message being displayed

• Performance

The communication performance must meet the requirements

• Functionality

The functions (services) required by the user have to be provided in the required

quality

• Uptime

Communication systems are often major parts of a system, and the uptime of the

entire system can depend on them to a large extent

• Cost-effectiveness

The cost / performance ratio must be reasonable.

In addition to the general quality specifications, additional requirements apply to communication

systems in the process automation environment.

Additional quality specifications for process data communication systems

• Ability to respond

Data must proceed from the transmitter to the receiver within a defined period of time,

which is usually very short.

• Trouble-free operation

Operation in close proximity to power installations must be possible. The system must

adequately resist mechanical and climatic stresses.

1.1 Definition of terms

1.1.1 Computer link

A computer link enables the exchange of data and control information between computers and

controls (e.g. CAD, FMS, ... , NC, RC, SPS ... , as shown in figure SINEC H1) on the initiative

of a computer, control system or operator. The data exchange mainly covers workpiece

programs, tool data, workpiece data, control functions (e.g. NC start, NC stop), operating data

such as status messages, alarm and error messages.

A computer link can be realised using a bus connection or using one of many serial

connections.

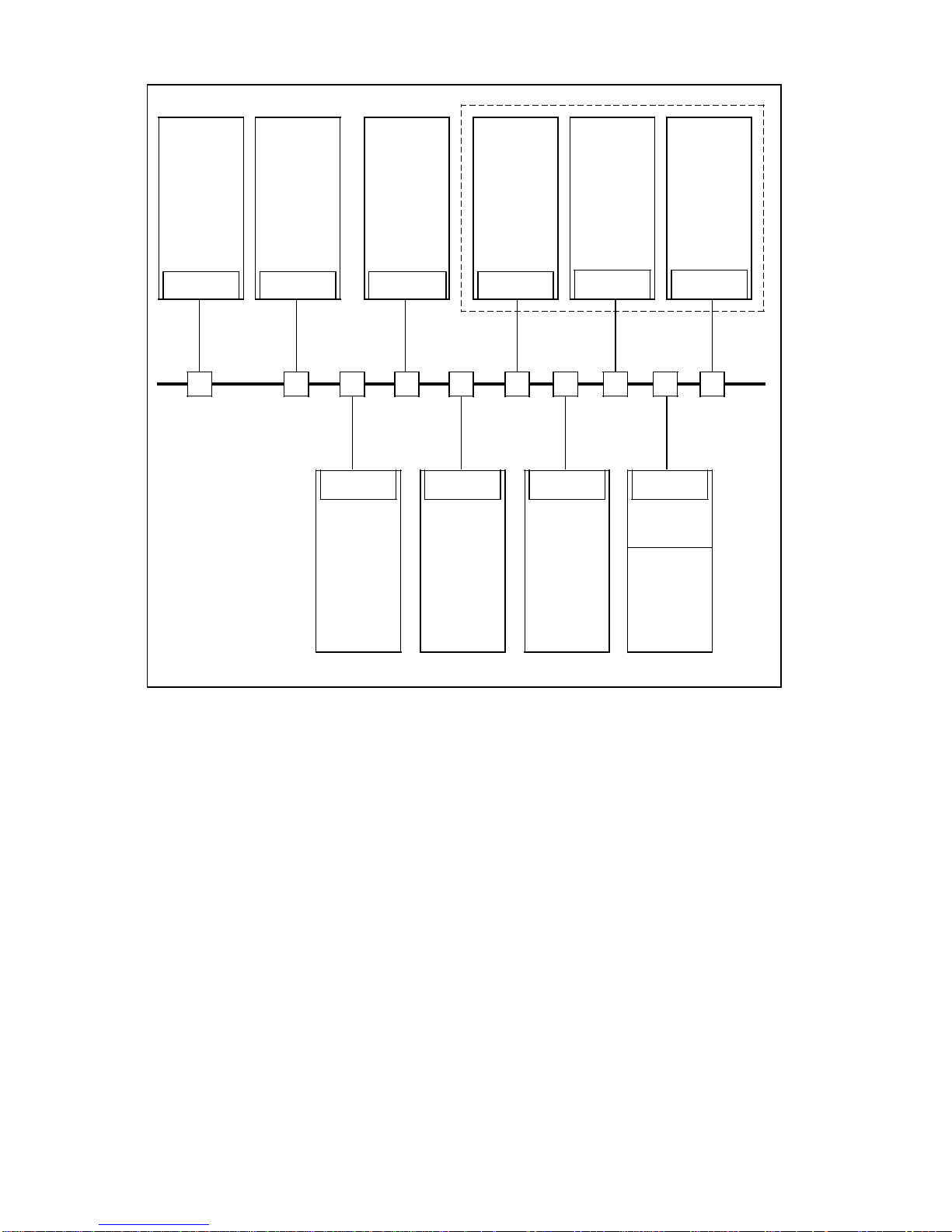

The following figure shows the SIEMENS computer systems used for CAD, FMS,

NC Archive and PPC as well as the RC, NC and PLC systems on a common bus cable. If

older systems are to be connected to the bus, e.g. SINUMERIK System 8, this is done via a

gateway station.

1–2

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 1 General

1.1.1 Computer link

PPC

SINEC

CAD

NC

FMS

Archive

SICOMP

WS 30

WS20/32

SINEC SINEC SINEC

SINEC

SPS

SIMATIC

S5-115U,

135U, 150U

SINUMERIK

SICOMP M

WS20/32

SINEC

NC

850/880

SICOMP M,

SINEC

RC

SIROTEC

RCM 3

Tool

Tool

flow

Presetting

WS20/32

SINEC SINEC

Gateway

SINUMERIK

System 8

device

SINEC

NC

Bus system: SINEC H1

1.1.2 ISO reference model

For the data exchange between systems various prerequisites have to be met by the two

communication partners. Both stations must have compatible physical interfaces, and the form

of information routing, addressing, the type of error checking and the format of the information

have to be agreed by both communication partners.

For this reason, the International Standards Organization (ISO) has established a model for

communication procedures known as the ISO reference model.

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 1–3

©

SINUMERIK 840/880 (PJ)

1 General 08.89

1.1.2 ISO reference model

It consists of a seven-layer hierarchy which is organized as follows:

• Layer 1 Physical layer

• Layer 2 Data Link layer

• Layer 3 Network layer

• Layer 4 Transport layer

• Layer 5 Session layer

• Layer 6 Presentation layer

• Layer 7 Application layer

Further information on the individual layers and their functions are contained in Section 2.1.1,

”The ISO seven layer model”.

1.1.3 LAN

ISO defines local area networks (LAN) as networks for bit-serial transmission of information

between interconnected independent devices (e.g. computers, microcomputers, programmable

controllers, numerical controls), i.e. the interconnection of autonomous systems.

”These are completely controlled by the users and limited to their site”.

In factory plants, communication and exchange of information between the individual devices is

to take place in such a way that direct data access to all stations is ensured.

1.1.4 MAP

MAP (Manufacturing Automation Protocol) is a new communication protocol which is based on

international and US standards as well as additional specifications by GM. This protocol allows

an open communication in the factory (open networks) i.e. devices of different manufacturers

can be interconnected (opposite: closed networks).

1.1.5 SINEC AP 1

SINEC AP 1 is the Siemens Network Architecture Automation Protocol Version 1, a Siemens

automation protocol. It was developed for the integration of the following systems in a factory

automation system:

• SICOMP computers

• SINUMERIK

• SIROTEC

• SIMATIC S5

• Programmers

• MMC 216

• Concentrators

• Personal computers

• Workstations

The protocol covers the OSI layers 5 to 7. For further information please refer to Section 3.3.1,

”SINEC AP 1 protocol”.

1–4

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

06.91 1 General

1.1.6 Transport connection TPV

1.1.6 Transport connection TPV

The term transport connection describes a virtual connection between two nodes in a network

which, in accordance with the ISO reference model, is also referred to as layer 4 connection

since it reaches to layer 4 of the respective communication partner.

In the case of a serial link, the transport connection need not be specified since an

unambiguous hardware allocation is made by the interface used.

The transport connection is determined by addresses which are clearly assigned when the

network is configured. By means of the addresses the two end points of the transport

connection are allocated.

In the case of a computer link with SINUMERIK 8X0, a transport connection is determined by

the address pair's own Ethernet address, the internal TSAP (Transport Service Access Point)

and the Ethernet and TSAP address of the partner. The addresses or the allocations for the

corresponding transport connection are stored in the interface module of the SINUMERIK 8X0.

The transport connection provides a reliable communication connection to transfer the

application-oriented information and it manages the transfer-specific services.

Several transport connections can be configured for one system. For example, a different

transport connection can be used for the file transfer (NC data exchange) than for the

loading/unloading of tools.

Access to the transport connection is from the application-oriented layers via the transport

service access point (TSAP), which has its own unique address (TSAP address).

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 1–5

©

SINUMERIK 840/880 (PJ)

1 General 06.91

1.1.7 Logical peer

1.1.7 Logical peer

Logical peer is the symbolic designation for a technological function module in a system, e.g.

in the SINUMERIK 8X0.

A system can contain one or several function modules.

In the case of a bus connection, a "logical peer" is identified by the combination of transport

connection and addressing in the application layer.

One or several logical peers can be served via a TPV transport connection. (When connecting

the SINUMERIK 8X0 to the Siemens FMS only one logical peer per transport connection is

allowed.)

The ”logical peer” is determined by the addressing in the application layer alone in the case of

a serial connection.

If the AS 512 protocol is used, several logical peers can be allocated to one interface.

If an interface is configured without the AS 512 protocol, only one logical peer can be allocated

to it.

In the communication process, a distinction is made between the transmitting and the receiving

logical peer.

The transmitting logical peer is the symbolic designation for the functional unit by which the

message frame was sent whereas the receiving logical peer refers symbolically to the function

module by which the message frame is to be received.

In input direction, the SINUMERIK 8X0 recognizes the sender and/or receiver by means of the

address information contained in the application part of the message frames.

In output direction, the logical peer to which the message frame is to be sent is assigned to

the corresponding connection.

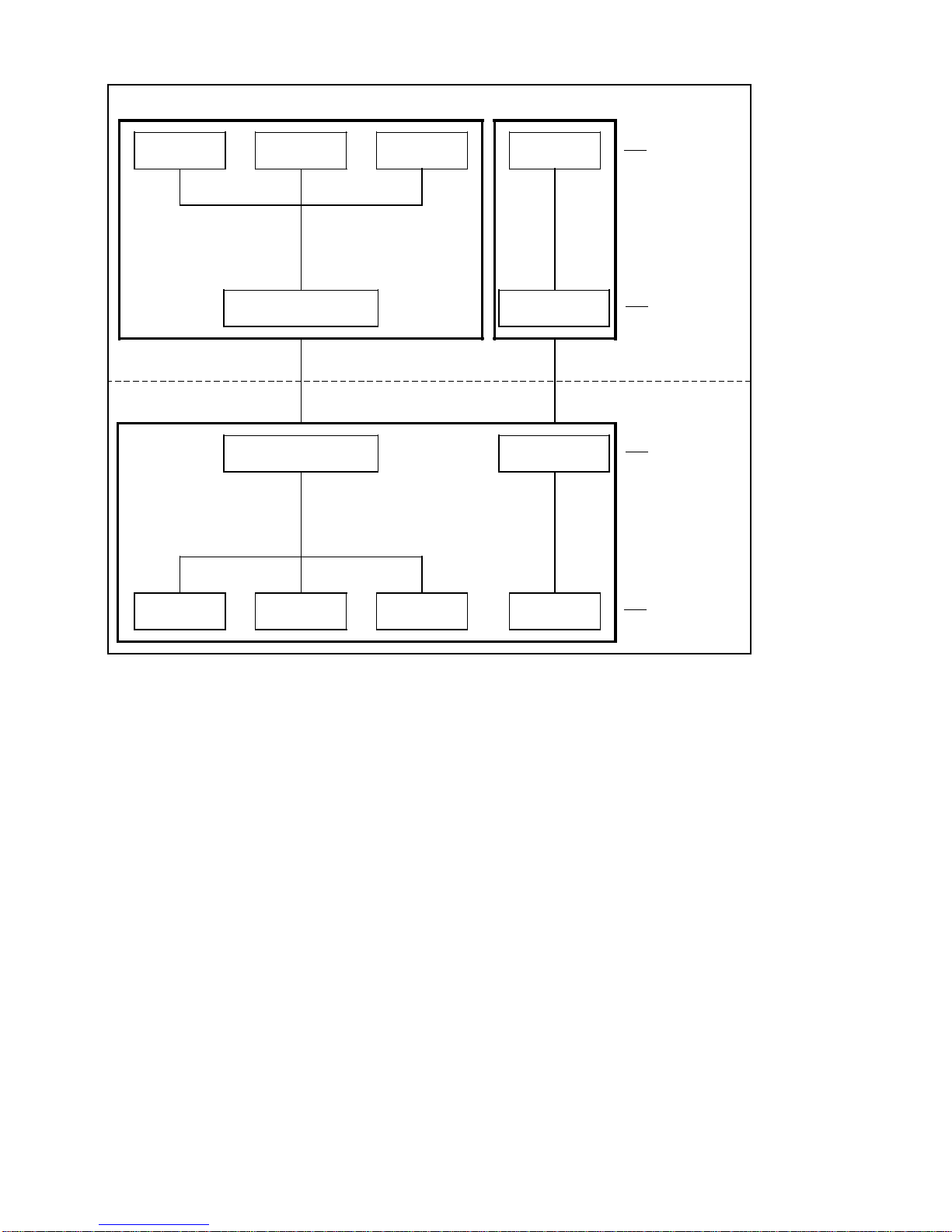

The diagrams below give examples of logical peers both for a production control computer and

for an NC, first for the bus and then for the serial connection.

1–6

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

06.91 1 General

1.1.7 Logical peer

FMS

NCLADE

log.p.1

(TSAP addr.)

NC

TPV5

(TSAP addr.)

BAZSTE

log. p.2

TPV4

(TSAP addr.)

(Ethernet addr.)

(Ethernet addr.)

TPV1

(TSAP addr)

UEBERW

TPV2

log.p.3

TPV6

(TSAP addr.)

TPV3

(TSAP

layer 7

logical peer

layer 4

transport connection

layer 2

Bus

layer 2

layer 4

transport connection

Logical peer in bus connection

log. p.1

NCDAT

log. p.2

GLOBA

log. p.3

MELDG

layer 7

logical peer

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 1–7

©

SINUMERIK 840/880 (PJ)

1 General 06.91

1.1.7 Logical peer

FMS

NC

NCLADE

log. p. 1

BAZSTE

or or

log. p. 2

Interface 1

Interface 1

UEBERW

log. p. 3

PERI 1

log. p.

Interface 2

Interface 2

Layer 7

logical peer

Layer 2

Layer 2

log. p. 1

NCDAT

Logical peer in serial connection

or or

log. p. 2

GLOBA

log. p. 3

MELDG

Configuring interface 1:

• with AS 512 protocol

• with system 800 ID

Configuring interface 2: (depends on peripheral device)

• with/without AS 512 protocol

• with/without system 800 ID

log. p.

PLC 1

Layer 7

logical peer

1–8

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

06.91 1 General

1.1.7 Logical peer

For the computer (FMS):

Logical peer 1: "Functional unit load NC program,

retransmit and erase NCLADE"

Logical peer 2: "Functional unit manufacturing session, synchronization, end-of-work,

BAZSTE message"

Logical peer 3: "Functional unit line monitoring UEBERW"

For the numerical control:

Logical peer 1: "Functional unit transfer of programs / data to the NC,

messages, initiation of transfer using NCDAT screen form"

Logical peer 2: "Functional unit synchronization, end-of-work, mode switchover GLOBA"

Logical peer 3: "Functional unit alarms, operator interrupt, status message MELDG"

Logical peer: PLC1

For the peripheral device:

Logical peer: PERI1 (any name may be selected).

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 1–9

©

SINUMERIK 840/880 (PJ)

06.91 2 Local Area Networks

2.1 Bus connection

2

As automation in manufacturing increases, so does the necessity to exchange data between

different manufacturing systems such as controls, robots, conveyor systems and higher-level

systems as for instance host computers.

In the past, information was transferred between the individual systems by people. This

method is time-consuming and prone to errors.

Local area networks (LANs), interconnecting all systems involved in the manufacturing and

planning process, provide a remedy for this problem. LANs ensure secure and quick data

transfer within manufacturing facilities as well as to higher-level systems.

Special requirements must be met by LANs in the tough environment of industrial

manufacturing:

• A universal basis for different stations (terminals)

• Insensitivity to external mechanical and electric stresses

• High availability

• Simple extendability

Various configurations are possible for local area networks. They are different in the type of

connection and of data transmission.

For the computer link with SINUMERIK 8X0, bus and star connections are of special

importance. These are described below in greater detail.

Local Area Networks

2.1

Networks with bus architectures generally use serial data transmission and often a timedivision multiplex method to maintain the data flow. The bus topology has the following

advantages:

• Passive transport medium, only needs a coaxial cable terminating with the correct

• Depending on the allocation procedure, the network control is concentrated at one station

• Easy reconfiguration, stations can be connected or disconnected as desired;

• The failure of one station does not affect the operation of the network, provided the

The only disadvantage of the bus topology is that it uses a common transport medium: if the

cable is damaged, all nodes are affected.

Suitable transport media for local networks are:

• twisted copper lines,

• coaxial cables,

• broad band coaxial cables

• fibre optic cables.

The bus consists of a common resource, the bus cable, and branches to each station.

Bus connection

impedance;

or distributed over all connected stations;

allocation method is suited for the purpose.

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–1

©

SINUMERIK 840/880 (PJ)

2 Local Area Networks 08.89

2.1 Bus connection

Since the bus cable can be run throughout the facility, only short branch cables are necessary.

The cable costs are thus reduced, and the expenditure for extending the system remains

linear.

Basically, each connected station can communicate with another one over the common bus

cable. However, since the bus is a common resource for all stations, its use has to be

controlled by an access method in order to prevent one station from interfering with the

operation of another one.

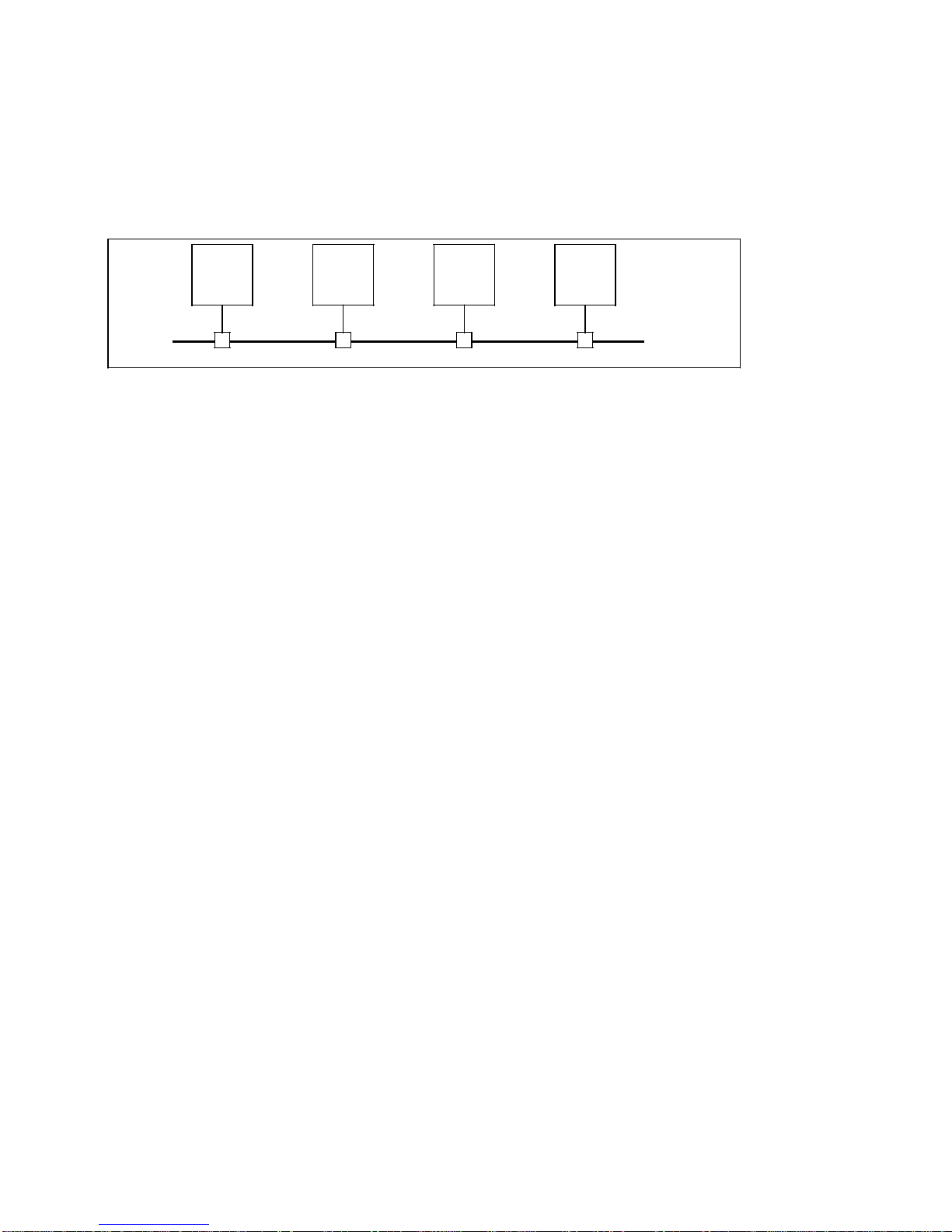

Process communication bus topology

Advantages of bus systems:

• Low cable expenses

• Cost-saving even with few nodes connected

• Extension costs are linear

• Any traffic between all units is possible simultaneously

• Bus is a common resource access method

2.1.1 The ISO seven layer model

Various specifications have to be observed for the communication between systems. Both

partners must have compatible physical interfaces, they must speak the same "language", and

they must "mean" the same thing when they say something.

To ensure this between the peers on a local area network, ISO (International Standardisation

Organization) has defined a hierarchical layer model.

In this model, a layer is defined as a program or a process that communicates with the

corresponding process of its peer on the same layer .

The layers function as follows:

A layer receives a job from the next higher layer. It processes the job with its own resources

and then passes a job to the next lower level. This means that to handle the job the layer uses

its own resources as well as the services made available by the next lower layer.

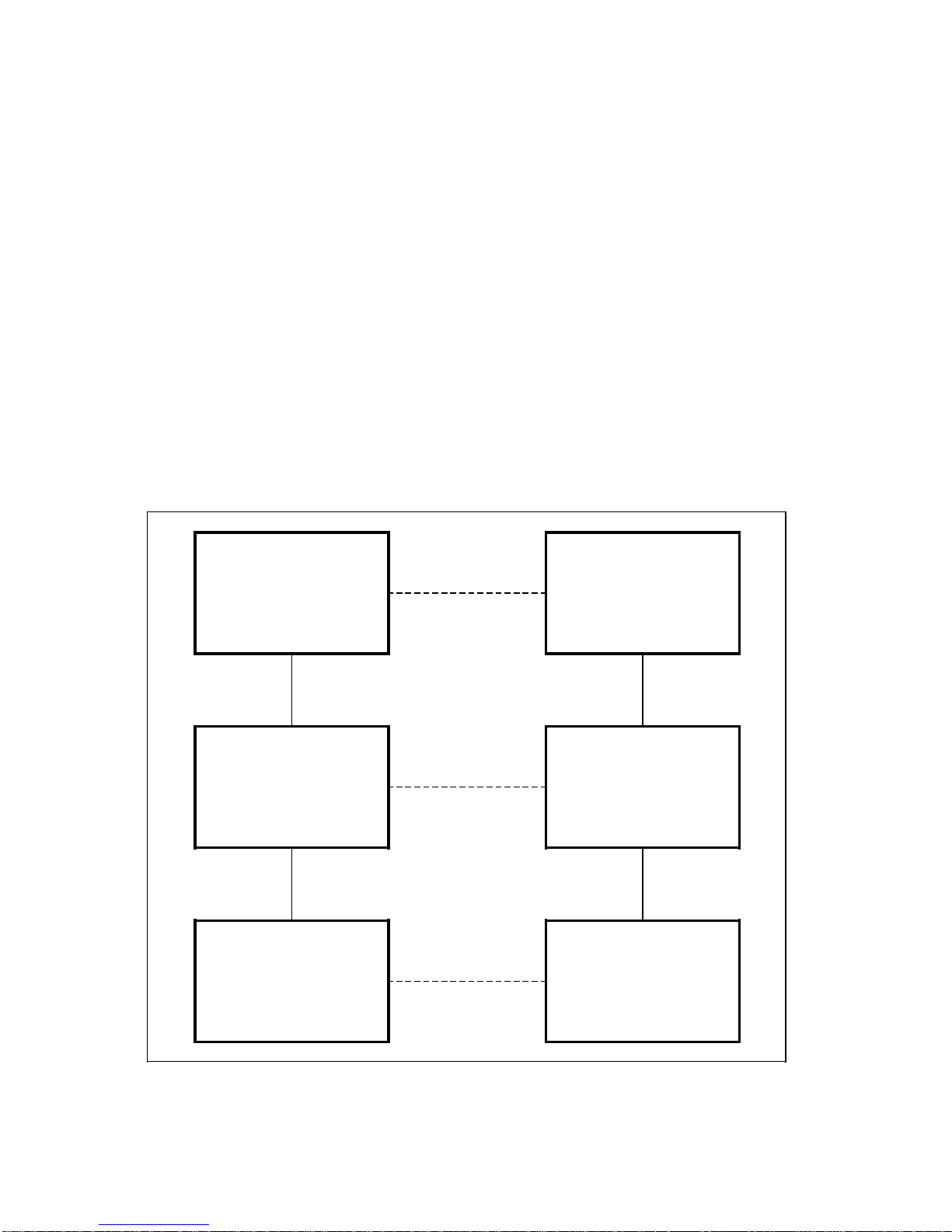

Example: 3 layer model

A "humanized" example of a 3 layer model may help to explain the layer structure:

Two scientists would like to exchange their findings. Scientist 1 lives in Japan and speaks

Japanese, scientist 2 lives in Spain and speaks Spanish. The two scientists represent layer 3.

2–2

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 2 Local Area Networks

2.1.1 The ISO seven layer model

In order to exchange information, each of them hires a translator. To understand each other,

the translators must agree on a common language, e.g. English. The translators constitute

layer 2.

In order to transmit the information, the translators deliver their texts to the respective post

office.

To send the texts, the employees of the post offices agree on a common transmission method

(e.g. telex or fax). They constitute layer 1.

The procedure is as follows:

Scientist 1 (layer 3) hands the message written in Japanese to his translator (layer 2). The

translator translates the text into English and delivers it to the post office (layer 1). The post

office in Japan transmits the text by fax to the respective post office in Spain. The translator in

Spain (layer 2) receives the fax from the post office employee and translates it from English

into Spanish. Scientist 2 (layer 3) receives a Spanish text from his translator which contains

the thoughts of his Japanese colleague.

Irrespective of the common language the translators have chosen (e.g. French instead of

English) or the type of transmission selected by the post (e.g. telex instead of fax) the

scientists receive the message in a language they understand.

This example shows that individual layers can change their agreements (protocols) without

affecting the other layers. This is the main reason for using the layer structure for networks.

Scientist 1

(Japanese)

Translator 1

(Japanese/English)

Post office 1

(fax)

layer 3

layer 2

layer 1

Scientist 2

(Spanish)

Translator 2

(English/Spanish)

Post office 2

(fax)

3 layer model

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–3

©

SINUMERIK 840/880 (PJ)

2 Local Area Networks 08.89

2.1.1 The ISO seven layer model

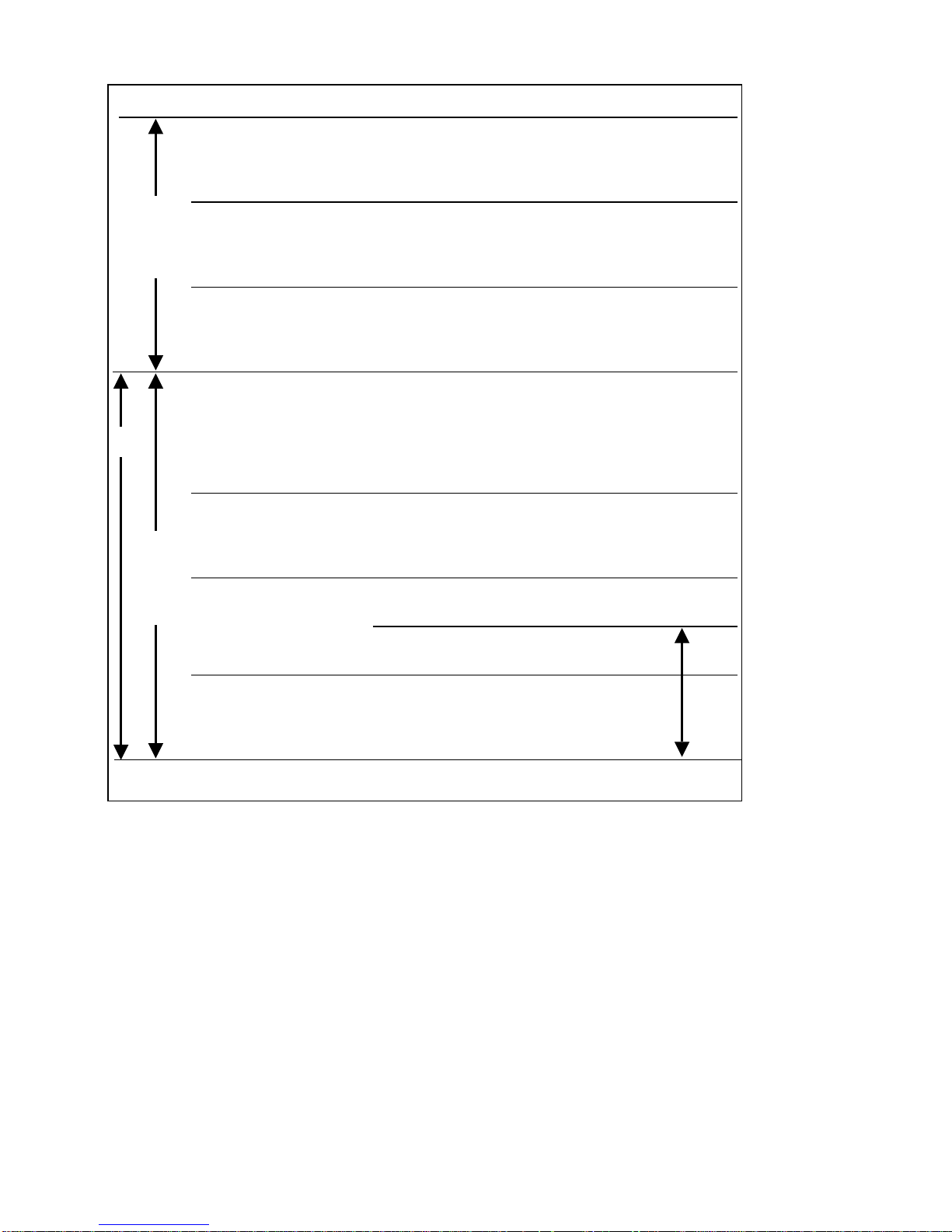

Layer Designation Function Example

Applicationoriented

layer

CP

Transportoriented

layer

Application Application functions

7

6

5

4

3

2

1

Layer (Information processing

Presentation Data representation • Common

Layer language

Session Communication control (open,

Layer Synchronization end, abort)

Transport Transport control

Layer Flow control

Network Network connections X.25

Layer Addressing of other

Data Link

Layer

Physical Physical characteristics of

Layer the transmission path Yellow Cable

• File transfer

•

)

Blocking conversation text

Acknowledgement

Connection establishment/release

networks

Reliable transfer CRC check

Allocation method CSMA/CD

Remote

Control

• Coordination

•

Transmission of

IEEE*

802.3

Protocol architecture for local area networks according to ISO

2–4

* Ethernet

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 2 Local Area Networks

2.1.1 The ISO seven layer model

ISO layers

The layer model defined by ISO includes 7 layers:

The transport-oriented layers (1 to 4) and the user-oriented layers (5 to 7). Each of these 7

layers provides services. In order to make its services available, a layer of a network entity

must communicate with the same layer of its peer. This communication process, including the

means used for it, is referred to as a protocol.

Layer 1: Physical Layer = Physical characteristics of the transmission path, e.g.

Yellow Cable

This layer defines the physical operation such as electrical (current-voltage level) and

mechanical parameters between 2 peers, in order to be able to transmit data.

It provides services in order to activate, maintain and deactivate physical connections for

transmission of data between two data-link entities.

"A medium must be available, for example air, telephone line etc.".

Layer 2: Data Link Layer = 2a Access method,

such as CSMA/CD 2b Reliable transfer, e.g CRC check

On this level, the access mechanism is defined that ensures that only one node sends data

over the bus at a given time. The layer provides functional and procedural services in order to

establish, maintain and release data link connections. It detects and possibly corrects errors

which may occur in the subordinate physical layer. It enables the network layer to control the

interconnection of data circuits within the physical layer, e.g. to interconnect partial sections

and to switch to alternate paths using different combinations.

Layer 1 and 2 ensure that information can be transmitted and that access to the transmission

medium is controlled.

Layer 3: Network Layer = Network connections/addressing of other networks

The network layer provides the means to establish, maintain and terminate connections

between systems as well as networks.

"Rules for routing must be specified when using several transmission sections, e.g. route

switching of several sections in a communication network".

Layer 4: Transport Layer = Transport control: Flow control, blocking,

acknowledgement, establishment and release of connection, transmission

of the conversation text.

The function of the transport layer is to provide a universal transport service in cooperation

with the services of the lower-level layers.

It separates the application-oriented from the transmission-oriented layers.

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–5

©

SINUMERIK 840/880 (PJ)

2 Local Area Networks 08.89

2.1.1 The ISO seven layer model

The transport layer ensures data security and data consistency. It manages the transport

control requirements and provides the following services:

• Flow control:

A message frame is sent only if the remote station is able to receive it, e.g. if sufficient

receive buffer is available.

• Blocking:

Message frames longer than e.g. 512 bytes are blocked automatically so that long

message frames do not block the line.

• Acknowledgement:

Acknowledgement of a message frame received without error by the transport layer (no

user acknowledgement).

To implement these functions transport connections (logical channels) are established.

Establishment/release of these connections are effected automatically by the services of

layer 4.

Layer 5: Session Layer = Communication control/synchronization e.g. coordination

of the conversation (opening, end, abort)

The session layer provides means necessary for cooperating entities of the higher-level

presentation layer (layer 6) to organize and synchronize their dialogue and manage their data

exchange. For this purpose the session layer provides services to establish a session

connection between two entities of the higher-level presentation layer and to support actions

required for a proper data exchange.

The session layer can be designed with more or less comfortable functions.

There are only user-specific aspects for these and the higher layers.

Layer 6: Presentation Layer = Data representation e.g. common language

The Presentation Layer is concerned with the representation

• of the data which are transmitted between corresponding entities of the higher-level

application layer. This data representation is also called data syntax.

• of the data structure to which entities of the application layer refer in order to perform

actions.

The presentation layer is concerned only with the representation (syntax), but not with its

meaning (semantics). The semantics is only known to the application layer.

"Receiver and transmitter must have the information represented in a form known to everyone

(common language). If the representation forms differ (the transmitter speaks Japanese, the

receiver speaks Spanish), a translator is required, e.g. an interpreter for Japanese and

Spanish. However, an intermediate language, for example English, might be chosen, and both

the transmitter and the receiver employ an interpreter; the transmitter for Japanese-English

and the receiver for English-Spanish".

2–6

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 2 Local Area Networks

2.1.1 The ISO seven layer model

Layer 7: Application Layer = Application function (information processing) e.g. File

Transfer, Remote Job Control

The application layer is the highest of the 7 layers of the OSI model and does not provide any

services to a higher layer with regard to the integration of open systems (OSI environment). It

rather provides the means for the application processes, so that these can access the OSI

environment. The application layer serves as a window between corresponding application

processes which are using the integration of (open) systems to exchange meaningful

information.

Each application process is represented to its peer by the application layer entity.

"Even when the same language is spoken and the same terms are used, a term can have

different meanings, when for example the same terms are used in a different environment. It

must therefore be ensured that the meaning of one or a combination of terms is identical for

both the transmitter and the receiver".

2.1.2

Access methods

Two access methods are today at the centre of both theory and practice:

The token principle and the collision principle (CSMA/CD, Ethernet). There are already several

variants of both procedures, however one variant of each has been standardized.

Process communication/access methods

Allocation systems/ Contention systems/

token procedures collision principle

(CSMA/CD, Ethernet)

• An authorization to send • Theoretically, all stations

(token) exists, which is held by in a network can transmit simultaneously.

one station onlyat any time.

• In case of a collision,

• The authorization to transmit is this is recognized and the stations

passed on to another station repeat transmission after

after a given period of time. different times.

• Each station receives one • High transmission capacity

authorization to transmit keeps the number of

after a defined time interval. collisions low

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–7

©

SINUMERIK 840/880 (PJ)

• A probability factor

can be specified with which a

message will be transmitted.

2 Local Area Networks 06.91

2.1.3 SINEC H1

2.1.3 SINEC H1

SINEC (Siemens Network Architecture) stands for the integrated communication system of the

Siemens automation systems.

This includes:

• The communication network

• The respective module which establishes the connection to the communication network

(interface module)

• Protocols and services used for transmission of data between the systems.

SINEC H1 is a baseband transmission communication system to IEEE 802.3 (Ethernet).

It is based on the reference model of the international standard committee ISO for open

communication aiming at operating different types of devices together.

The SINEC H1 layers 1 and 2a (transmission procedure and network access) are based on the

IEEE 802.3 standard. These layers are concerned with data transmission and the access of

the nodes to the network. The access method is based on the collision principle used by

Ethernet. SINEC H1 provides for the higher layers a standardardized interface which is

independent of the access method.

Layer 3 of the ISO reference model is required for large networks. This layer is inactive with

SINEC H1.

For layer 4, SINEC H1 has implemented the ISO transport protocol (ISO-8073 class 4).

The functions of layers 1 to 4 are implemented by SINEC H1 on communication processors

which are located on the interface module. They offer the user a series of services which

relieve him/her from work-intensive procedures.

At present there are no uniform international standards for layers 5 to 7 of the OSI model for

the NC applications. As a first step to standardization of OSI layers 5 to 7 within the company,

Siemens have therefore defined the AP 1 automation protocol. It is suitable for use on all

Siemens automation devices.

For more details on the SINEC AP 1 protocol please refer to Section 3.4, Protocols.

The most important features of SINEC H1 are:

• Topology: bus (line) consisting of one or several segments

• Transmission medium: shielded coaxial cable; 50 ohms

• Segment length: max. 500 metres

• Connectable nodes per segment: max. 100

• Transmission method: baseband

• Data transfer rate: 10 Mbits/sec.

• Bus access method: collision principle

2–8

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 2 Local Area Networks

2.2 Serial connection

2.2 Serial connection

In contrast to bus connection, with which all nodes are physically connected in parallel to a

common bus cable, every connection between two peers is implemented with a separate

connection cable in the case of serial connection.

Procedures agreed between the two nodes ensure the controlled data exchange between the

connected peers.

2.2.1 Point-to-point connection

The point-to-point connection ensures the communication between two peers. This is the

simplest form of process communication if it is established as direct connection (separate line)

between two nodes.

Complex communication relations can be logically traced back (to a large extent) to a

combination of these simplest relationships.

If exactly this case occurs in practice, even the simplest type of connection is adequate.

Process communication point-to-point connection

Station 1 Station 2

• Data transfer between two peers

• Simplest case of process communication

• Simplest type of connection is adequate (4-wire)

• Example: PLC/PG traffic on SIMATIC systems

Exactly one physical point-to-point connection corresponds to each connection i.e. each

existing request of a unit to exchange data with a partner station.

Depending on the number of nodes involved, cabling expenditure is high and costs will

increase progressively if a further station is to be connected and wishes to communicate with

all other stations. Larger networks cannot be implemented due to the required number of

interfaces per unit increasing considerably.

Fault diagnosis is relatively simple since an unambiguous allocation is possible according to

communication request and physical implementation.

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–9

©

SINUMERIK 840/880 (PJ)

2 Local Area Networks 08.89

2.2.2 Star connection

2.2.2 Star connection

The star topology is today probably the most widely used type of connection in a hierarchically

organized process.

Although the cabling expenditure is lower than with meshed networks, it is still relatively high,

as in most cases the distances between master and the lower-level controls are rather long.

The master station must have one interface for every node; with larger systems, the masters

themselves can form a hierarchical structure.

The internode communication between two lower-level systems has to be executed over the

master which results in an additional burden and an availability bottleneck.

Process communication star topology

• Corresponds to the hierarchical organization of the process

• Linear extension cost

• Only at the master station are many interfaces necessary

• Internode communication is executed via the master node

• Master station is availability bottleneck

• Simple diagnostics

• Simple to configure

• Different transmission media can be used

2–10

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

SINUMERIK 840/880 (PJ)

08.89 2 Local Area Networks

2.2.3 Meshed network

2.2.3 Meshed network

Meshed networks have the advantage that the individual stations are connected with several

nodes via point-to-point connections.

Internode communication is possible, due to which the availability increases, since - in contrast

to the star network - the master does not cause an availability bottleneck.

Process communication meshed network

• 1 to 1 allocation of logical connections to physical communication channels

• High cable cost

• Extension costs highly progressive

• Very large number of interfaces required per unit

• Simple diagnostics

• Failsafe

• Internode communication is possible

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 2–11

©

SINUMERIK 840/880 (PJ)

2 Local Area Networks 08.89

2.3 Bus and serial connections

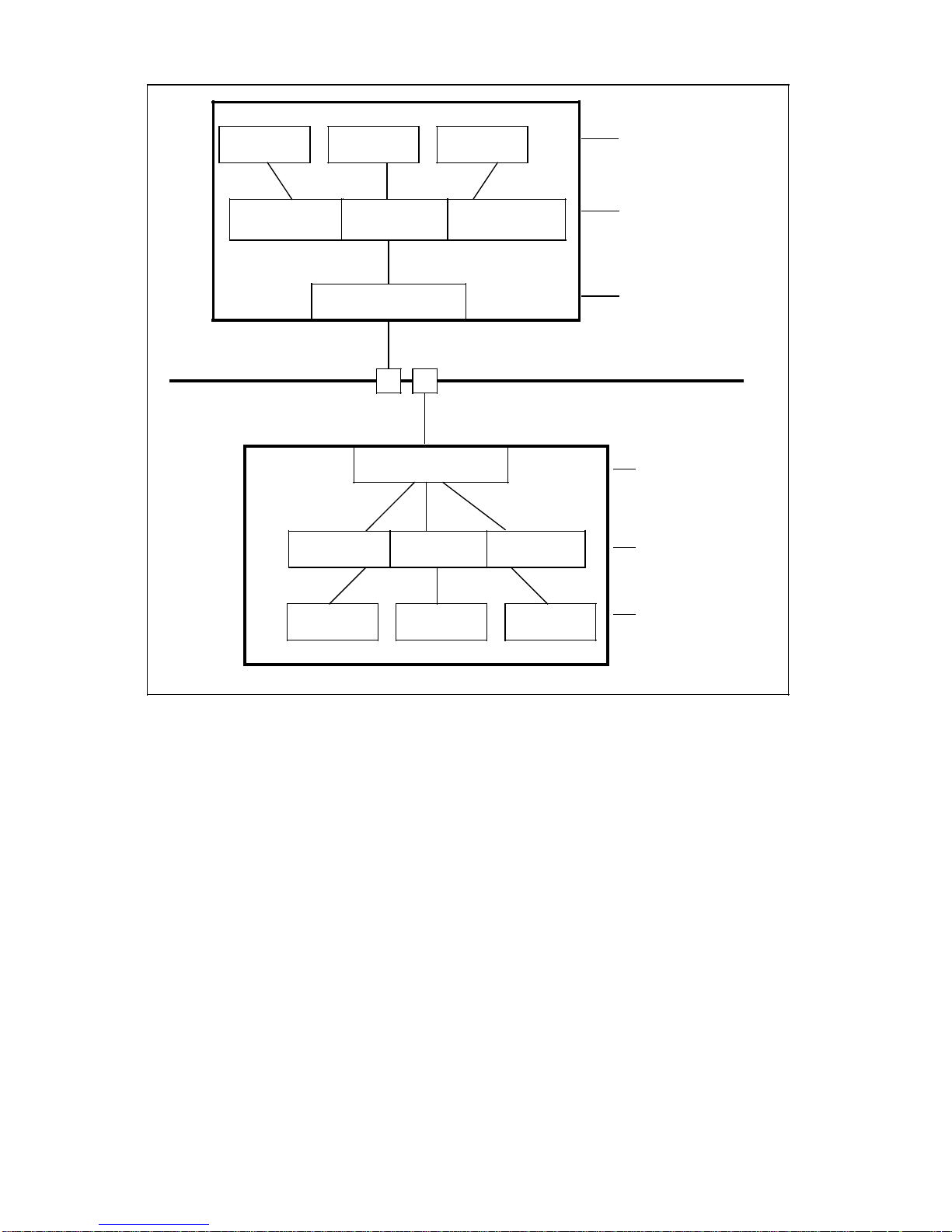

2.3 Bus and serial connections

In addition to local area networks featuring either only bus connections or only serial

connections, there are mixed forms of networks.

The following figure shows a network with different connection types, using the example of a

NC system. In this example the CNC is the master station of a star network and at the same

time a node on the bus network.

The CNC is connected to the higher-level host systems (e.g. host computer) and the systems

at the same level (e.g. RC controls) via bus connection.

Data transfer between the CNC and the secondary systems (e.g. read stations) is via serial

connections.

SINEC

TPS

FMS

SINEC

SINEC

RC

Programmer

connection

CP231A

CNC

CP315/373

PPC

SINEC

Bus

SINEC H1

SINEC

Measuring

machine

Programmer

connection

Serial

interface

Read station 1

Tool data

2–12

Serial

interface

Read station 2

Tool data

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0

©

Serial

interface

Read stat.

Pal. - data

Serial

interface

. . .

SINUMERIK 840/880 (PJ)

06.91 3 Interface Modules

3 Interface Modules

For the computer link with SINUMERIK 8X0, there are corresponding interface modules which

are plugged in the COM area.

The modules are the interface between the local area networks or point-to-point connections

and the control system. The services at the physical layer through to the application layer such

as procedures, test methods, access mechanisms etc. required for communication are

implemented on the interface modules.

The connection-specific and application-oriented parameters are stored on the interface

modules in lists which are compiled by means of a configuring software executable on the PG

685.

The following interface modules are available:

• Bus interface module (CP 231A)

The bus interface module is referred to as CP 231A. It allows connection to the SINEC H1

bus.

• Basic board for serial connection (CP 315)

The basic board for serial connections provides a serial interface conforming with

RS 232C/TTY. The connector pin assignment determines whether the serial interface is

used as RS 232C or TTY interface. The board is called CP 315.

• Expansion board for serial connection (CP 373)

To complement the CP 315 basic board there is an expansion board with the designation

CP 373. It is mounted on the side of the basic board and can be operated only together

with it. The CP 373 offers three further serial interfaces.

Dependent on the frame variant or the SINUMERIK 880 configuration, various configurations

are possible for the interface modules.

The following figure and table show examples of typical variants.

At application layer, the addressing concept of the computer link message frames is identical

for both bus and serial interface modules. It is implemented on the interface module by means

of SINUMERIK-specific input and output lists. In the case of a serial interface module,

message frames not corresponding to the SINUMERIK specifications can also be processed.

The addressing is carried out via internal lists.

Message frames can be transmitted between the bus interface and the serial interface module,

i.e. the message frames are not processed in the SINUMERIK but are passed from one

interface module to the other.

Siemens AG 1989 All Rights Reserved 6FC5 197-0AB20-0BP0 3–1

©

SINUMERIK 840/880 (PJ)

Loading...

Loading...