Page 1

T

MOVIMOT

®

Operating Instructions

Category 3D

(Dust Explosion Protection)

Edition 03/2000

0918 581X / 0300

09/011/98

Page 2

Page 3

Contents

1 Important Notes................................................................................................. 4

2 Safety Notes ...................................................................................................... 5

®

2.1 Information for using MOVIMOT

3 Structure of the Unit ......................................................................................... 7

3.1 Type designation, nameplates.................................................................. 7

3.2 Structure of the inverter unit...................................................................... 8

3.3 Description of the controls ............................. ... .... .................................... 9

4 Mechanical Installation................................................................................... 10

5 Electrical Installation ...................................................................................... 11

5.1 Installation guidelines..... ... ... .... ... ....................................... ... ... ... ............ 11

5.2 Protection concept .................................................................................. 13

5.3 Operating modes .................................................................................... 13

5.4 Connection with binary control................................................................ 14

5.5 Connection with MLA12A option....................... .... ... ... ... .... ... ... ... ... .... ... .. 15

5.6 Connection with RS-485 bus mode ............................................ ... .... ... .. 16

in category 3D..................................... 6

kVA

i

6 Startup.............................................................................................................. 17

I

00

n

f

Hz

P

6.1 Important startup instructions.................................................................. 17

6.2 Startup with binary control ...................................................................... 18

6.3 Startup with the MLA12A option ............................................................. 20

6.4 Startup with RS-485 bus operation......................................................... 22

6.5 Serial communication.............................................................................. 24

7 Operation and Service.................................................................................... 26

7.1 Status LED.................................................. ... ... .... .................................. 26

7.2 Status LED messages ............................................................. ... ... .... ..... 26

7.3 List of errors................................... ....................................... ... ... ... ......... 27

8 Inspection and Maintenance.......................................................................... 28

8.1 Inspection and maintenance periods ..................................................... 28

8.2 Inspection and maintenance work on the motor .................................... 29

8.3 Inspection and maintenance of the brake............................................... 31

9 Technical data (relating to 4 kHz PWM frequency)...................................... 36

®

9.1 MOVIMOT

9.2 Technical data MLA12A option............................................................... 37

9.3 Regenerative load capacity of brake coil ................................................ 37

9.4 Work done until adjustment, working air gap, braking torque of brake... 37

9.5 Approved ball bearing types ................................................................... 38

9.6 Operating characteristics ........................................................................ 38

9.7 Declaration by the manufacturer............................................................. 39

in category 3D ............................................................... ... .. 36

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

3

Page 4

1

Important Notes

1 Important Notes

Always following the safety and warning instructions contained in this publication!

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Waste disposal

Harmful situation

Possible consequences: Damage to the unit and the environmen t.

Tips and useful information

Important information about explosion protection

A requirement of fault-free operation and fulfillment of any rights to claim under guarantee is that the information in the operating instructions is adhered to. Co nsequently, read

the operating instructions before you start working with the unit!

The operating instructions contain important information about servicing; as a result,

they should be kept in the vicinity of the unit.

This product consists of

•Iron

• Aluminum

• Copper

• Plastic

• Electronics components

Please dispose of the parts in accordance with the applicable regulations.

4

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 5

2 Safety Notes

• Never install damaged products or take them into operation. Please submit a

•Only electrical specialists with the relevant accident prevention training are

• Make sure that preventive measures and protection devices correspond to the

• Disconnect the unit from the supply system prior to removing the connection

• Keep the connection box cover closed during operation.

Safety Notes

complaint to the transport company immediately in the event of damage.

allowed to perform installation, startup and service work on the unit. They must

also comply with the regulations in force (e.g. EN 60204, VBG 4, DIN-VDE 0100/

0113/0160).

applicable regulations (e.g. EN 60204 or EN 50178).

Necessary protective measures: Grounding the unit

box cover. Dangerous voltages may still be present for up to 1 minute after

mains disconnection.

2

• Just because the status LED and other display elements have gone out does

not mean that the unit has been disconnected from the power supply and is deenergized.

®

• Mechanical blockage or unit internal safety functions of MOVIMOT

a

motor standstill

MOVI

MOT® can result in an automatic restart of the motor. If, for safety reasons,

this is not permissible for the driven machine, the MOVIMOT

nected from the supply system before correcting the fault.

• Important: MOVIMOT

• Important – Danger of burns: The surface temperature of MOVIMOT

particular that of the heat sink) may exceed 60° C during operation!

. The removal of the source of the interruption or a reset of

®

®

is not suitable for hoist applications!

can lead to

must be discon-

®

units (in

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

5

Page 6

2

Safety Notes

2.1 Information for using MOVIMOT® in category 3D

Standards

Enclosure of the

housing

Applications

MOVIMOT® units in category 3D comply with EN 50014 ("Electrical apparatus for potentially explosive atmospheres; general requirements", 2nd edition) and EN 50281-11:1998 ("Electrical apparatus for use in atmospheres containing flammable dust"), and

therefore conform to Directive 94/9/EC (ATEX 100a).

MOVIMOT® units in category 3D are supplied with enclosure IP54 at least. The enclosure has to be maintained over the complete operating time as a precondition for satisfying the requirements for devices in category 3D. For this reason, particular care must

be taken even when connecting the units.

The unit must not be operated in zone 22 atmospheres if the enclosure type is not assured!

• Unit group II

• Category 3D

• For use in zone 22

• Surface temperature 140 °C

• Ambient temperature -20 to +40 °C

6

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 7

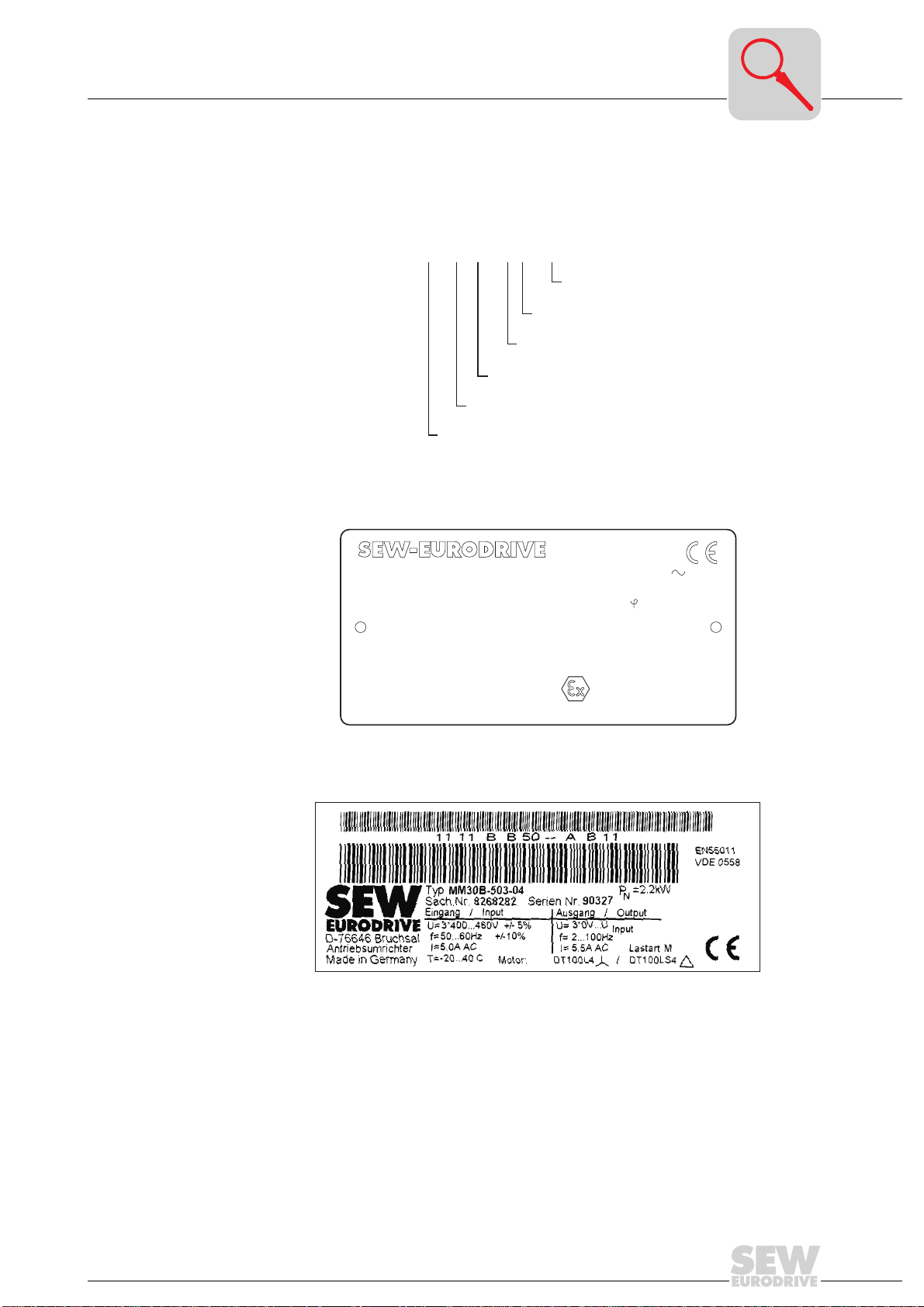

3 Structure of the Unit

3.1 Type designation, nameplates

Type designation

example

MOVIMOT® nameplate (example)

MO VIMOT MM 22 - 503 - 04

®

KA67DT100L4BMGMM30B/MLA

Typ

010012345.6.00.00

Nr.

2,2 / 50Hz

kW

50Hz V

92/1400

r/min

Kg

15,19

i

Schmierstoff

Type designation, nameplates

B

Ver sion (04 = 3D category)

Connection type

Supply voltage

Version B

Motor rating

Nm

®

Series

Bruchsal/Germany

40110

Nm

Made in Germany

400-460

400-460

V

Ma

MOVIMO T

31054

:1

3 IEC 34

B3

IM

0,99

cos

5,0

A

5,0

A60Hz V

54

IP

GleichrichterBremse

II 3 D T 140°C

Kl.

186 853 5.10

3

02883AEN

F

Electronics

nameplate

(example)

03090AXX

02581AXX

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

7

Page 8

3

Structure of the inverter unit

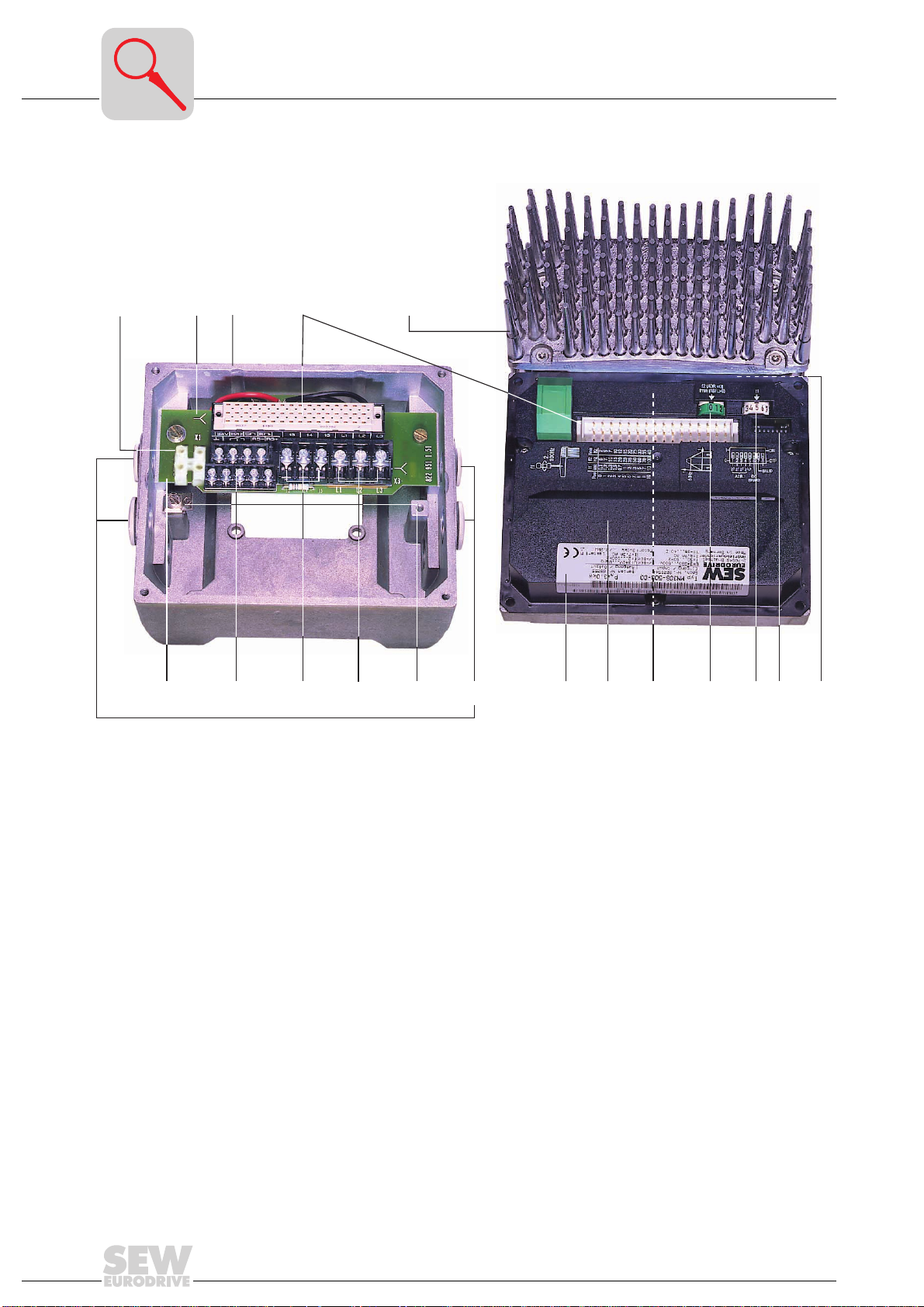

3.2 Structure of the inverter unit

2

18

1

34

5 6 7 8 9 10 111213 141516

®

unit)

02882AXX

Bild 1: Structure of the unit

1 Identification of the circuit type

2 Connection box

3 Connection plug, connection unit with inverter

4 Connection box cover with inverter and heat sink

5 Connection unit with terminals

6 Electronics terminal strip X2

7 Connection of brake coil (X3)

For motors without a brake: Connection of internal braking resistor BW1/BW2 (standard)

8 Power system connection L1, L2, L3 (X3) (suitable for 2 x 4 mm

9 Screws for PE connection y

10 Cable screw fittings MM03B-MM15B: (2 x PG11 and 2 x PG16 / from start of 2000, 2 x M16 and 4 x M25)

(not all visible in picture) MM22B-MM30B: (4 x PG11 and 4 x PG16 / from start of 2000, 4 x M16 and 4 x M25)

11 Electronics nameplat e

12 Safety hood for inverter electronics

13 Setpoint potentiometer f1 (not visible),

accessible from the top of the connection box cover by means of a PG screw fitting

14 Setpoint switch f2 (green)

15 Switch t1 for ramp generator (white)

16 DIP switch S1 for setting the bus address, motor protection, DC braking, PWM frequency

17 Status LED (visible from the top of the connection box cover, see “Status LED” on page 26)

18 Terminals for TH connection (arrangement of terminals varies according to the size of the MOVIMOT

2

)

17

8

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 9

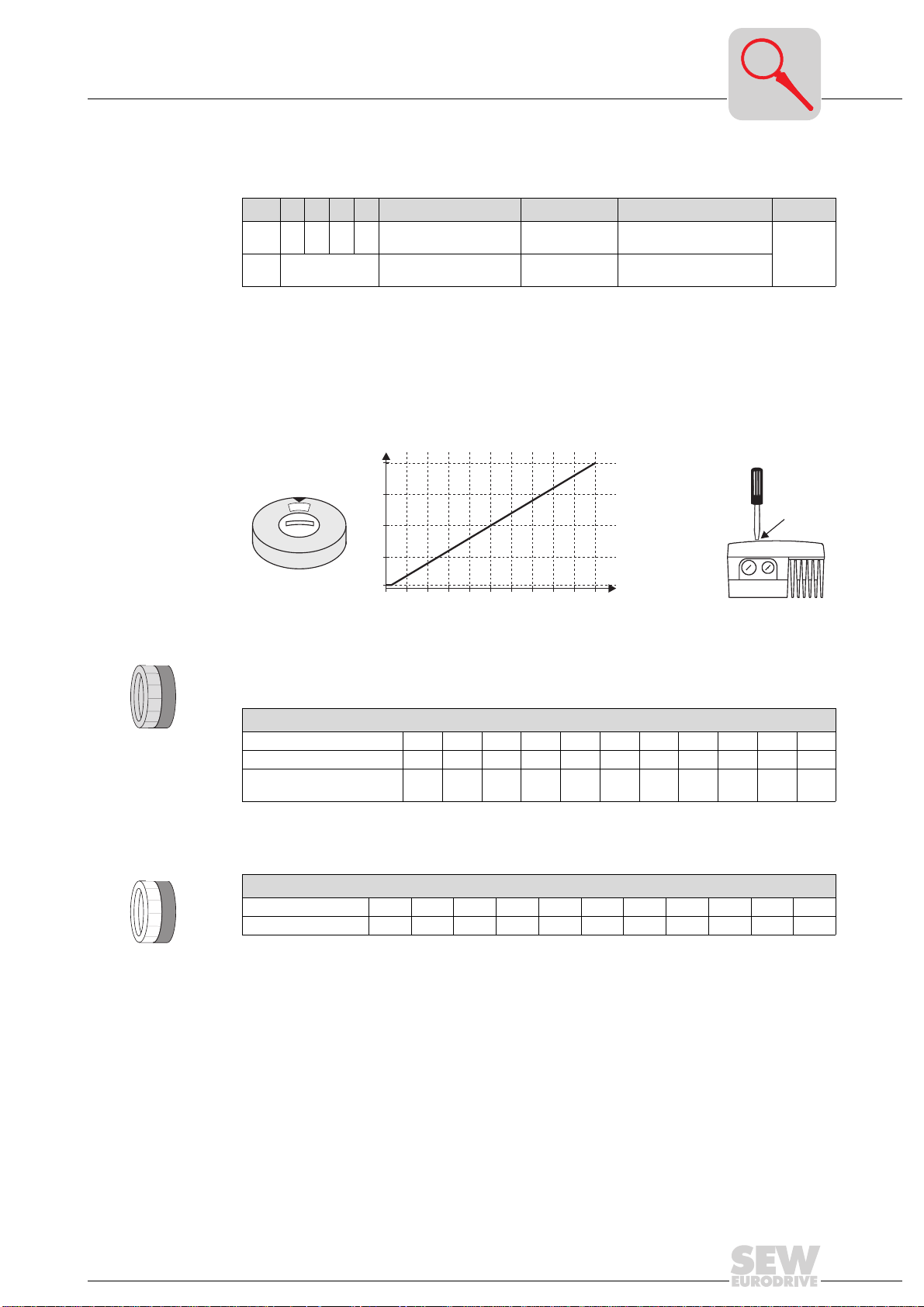

3.3 Description of the controls

DIP SWITCH S1

S1/..

1 2 3 4 5 6 7 8

ON 2021222

OFF RS-485 address

1) 16 kHz PWM frequency (low-noise)

When DIP SWITCH S1/7 = ON, the units operate with a 16 kHz PWM frequency (low noise) and

switch back in steps to lower pulse frequencies depending on the heat sink temperature.

* Factory setting

3

Description of the controls

Motor protection

deactivated

Motor protection

active *

DC braking

4Q operation *

PWM frequency

1)

16 kHz

PWM frequency

variable

4 kHz fix *

3

No func-

tion

Setpoint

potentiometer f1

Setpoint switch f2

3

4

5

6

7

8

The function of the potentiometer changes depending on the unit’s operating mode .

• Control via terminals: Setpoint f1 (selected by tl. f1/f2 = “0”)

• Control via RS-485: Maximum frequency f

100

f[Hz]

6

5

75

50

25

2

123456789100

max

Pot.position

f

1

02704AEN

The function of the switch changes depending on the unit’s operating mode.

• Control via terminals: Setpoint f2 (selected by tl. f1/f2 = “1”)

• Control via RS-485: Minimum frequency f

Setpoint switch f2

Detent position 0 * 12345678910

Setpoint f2 [Hz] 5 * 7 1015202535506070100

Minimum frequency f

[Hz]

min

2 * 5 7 10 12 15 20 25 30 35 40

min

* Factory setting

Switch t1

3

4

5

6

7

8

For ramp generator

Switch t1

Detent position 01234 5 *678910

Ramp time t1 [s] 0.1 0.2 0.3 0.5 0.7 1 * 2 3 5 7 10

Factory setting

*

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

9

Page 10

4

Mechanical Installation

4 Mechanical Installation

Before you begin

Installation tolerances

Setting up

MOVIMOT

®

MOVIMOT® may not be installed unless:

• the entries on the name plate of the drive match the mains power supply,

• the drive is undamaged (no damage caused by transport or storage) and

• it is certain that the following requirements have been fulfilled:

– ambient temperatures between -20 °C and +40 °C (remember that the tempera-

ture range of the gear unit may be restricted → operating instructions for the

gear unit),

– no oil, acid, gas, vapors, radiation, etc.,

– installation altitude max. 1000 m above sea level.

Shaft end Flanges

Diametric tolerance in accordance with DIN 748

• ISO k6 at ∅ ≤ 50 mm

• ISO m6 at ∅ > 50 mm

(Center hole in accordance with DIN 332, shape DR)

→ ”MOVIMOT® Geared Motors” catalog, section ”Notes on Dimension Sheets.”

Centering shoulder tolerance in accordance with DIN

42948

• ISO j6 at ∅ ≤ 230 mm

• ISO h6 at ∅ > 230 mm

The MOVIMOT® may only be mounted or installed in the specified mounting position on

a level, vibration-proof and torsionally rigid support structure.

• Thoroughly remove anti-corrosion agents from the shaft ends (use a commercially

available solvent). Do not allow the solvent to penetrate the bearings and shaft

seals – this could cause material damage!

• Carefully align MOVIMOT

®

and the driven machine to avoid placing any unacceptable strain on the motor shafts (observe permissible overhung load and axial thrust

data!).

• Do not butt or hammer the shaft end.

• Use an appropriate cover to protect motors in vertical mounting positions

from accidental entering of objects or fluids ! (Protection cowl C)

• Ensure an unobstructed cooling air supply and that air heated by other units cannot

be drawn in or reused.

• Balance components for subsequent mounting on the shaft with a half key (output

shafts are balanced with a half key).

10

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 11

5 Electrical Installation

It is essential to comply with the safety notes (see page 5) during installation!

5.1 Installation guidelines

When connecting up, comply with the following ElexV 1 provisions (or other nationally

valid regulations) in addition to the generally applicable installation regulations:

• EN 60 079-14 (“Installation of electrical systems in hazardous areas”)

• EN 50281-1-2 (“Electrical tools and fixtures for use in atmo spheres con taining

flammable dust”)

• DIN VDE 0105-9 (“Operation of electrical systems”)

• DIN VDE 0100 (“Setup of power installations up to 1000 V”)1)

• and provisions specifically relating to the system

Connecting supply system leads

Rated voltage and

frequency

• The rated voltage and frequency of MOVIMOT® must correspond to the data for the

mains supply.

Installation guidelines

1)

5

Selecting the

cables

Permitted line cross

section of the terminals

Conductor end

sleeves

Cable entries

Line protection

Residual-currentoperated circuit

breaker

Contactor switch

contacts

• The cross sections of the cables used must be selected according to the rated current of the unit and the applicable installation regulations.

• The selection of the cable type is based on the applicable installation regulations

and the requirements at the application location.

Power terminals Control terminals

1.0 mm2 – 4.0 mm2 (2 x 4.0 mm2) 0.25 mm2 – 1.0 mm2 (2 x 0.75 mm2)

AWG17 – AWG10 (2 x AWG10) AWG22 – AWG17 (2 x AWG18)

• Use conductor end sleeves without insulating shrouds

(DIN 46228 part 1, material E-CU)

• All cable entries are supplied fitted with a closing plug.

To connect the unit, replac e the req uired nu mbe r of plug s with su itable cable entries

which are fitted with strain relief.

• The cable entries must meet the requirements of EN 50 014, 2nd edition.

• Select the cable entries on the basis of the diameter of the cables used. Please

refer to the documentation provided by the manufacturer of the cable entry for further information.

• Install the line protection at the start of the supply system lead behind the supply

bus junction (

breakers. The fusible rating should be selected in accordance with the cross section

of the cable.

• It is not permissible to use a conventional residual-current-operated circuit breaker

(r.c.c.b.) as a protective device. Universal current-sensitive residual-current-operated circuit breakers (tripping current 300 mA) are permissible as a protective

device. Earth-leakage currents > 3.5 mA may occur during normal operation of the

MOVIMOT

• Contactor switch contacts in utilization category AC-3 to IEC 158 must be used for

switching MOVIMOT

see section 5.4 to section 5.6:

®

.

®

.

F11/F12/F13). Use D, DO, NH or circuit

1. Or other national guidelines

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

11

Page 12

5

Installation guidelines

IT systems

Connecting

24 V

Conventional

control

(using binary

commands)

Control via

RS-485 interface

Cable screw fittings

DC

supply

• SEW recommends using earth-leakage monitors with a pulse code measuring

process in voltage power systems with a non-earthed star point (IT systems). This

avoids faulty tripping of the earth-leakage monitor due to the earth capacitance of

the inverter.

• The MOVIMOT® power supply should be either from an external 24 VDC voltage or

using the MLA12A options.

• Connect the required electronic control leads

(e.g. CW/STOP, CCW/STOP, setpoint changeover f1/f2).

• Use shielded cables as control leads and route them separately from power current

cables.

With PLC bus master or MLA12A option

• Important: Only ever connect one

• Use twisted pair shielded cables as control leads and route them separately fro m

power current cables.

• All cable entries which are not required must be sealed properly using

suitable closing plugs.

bus master.

12

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 13

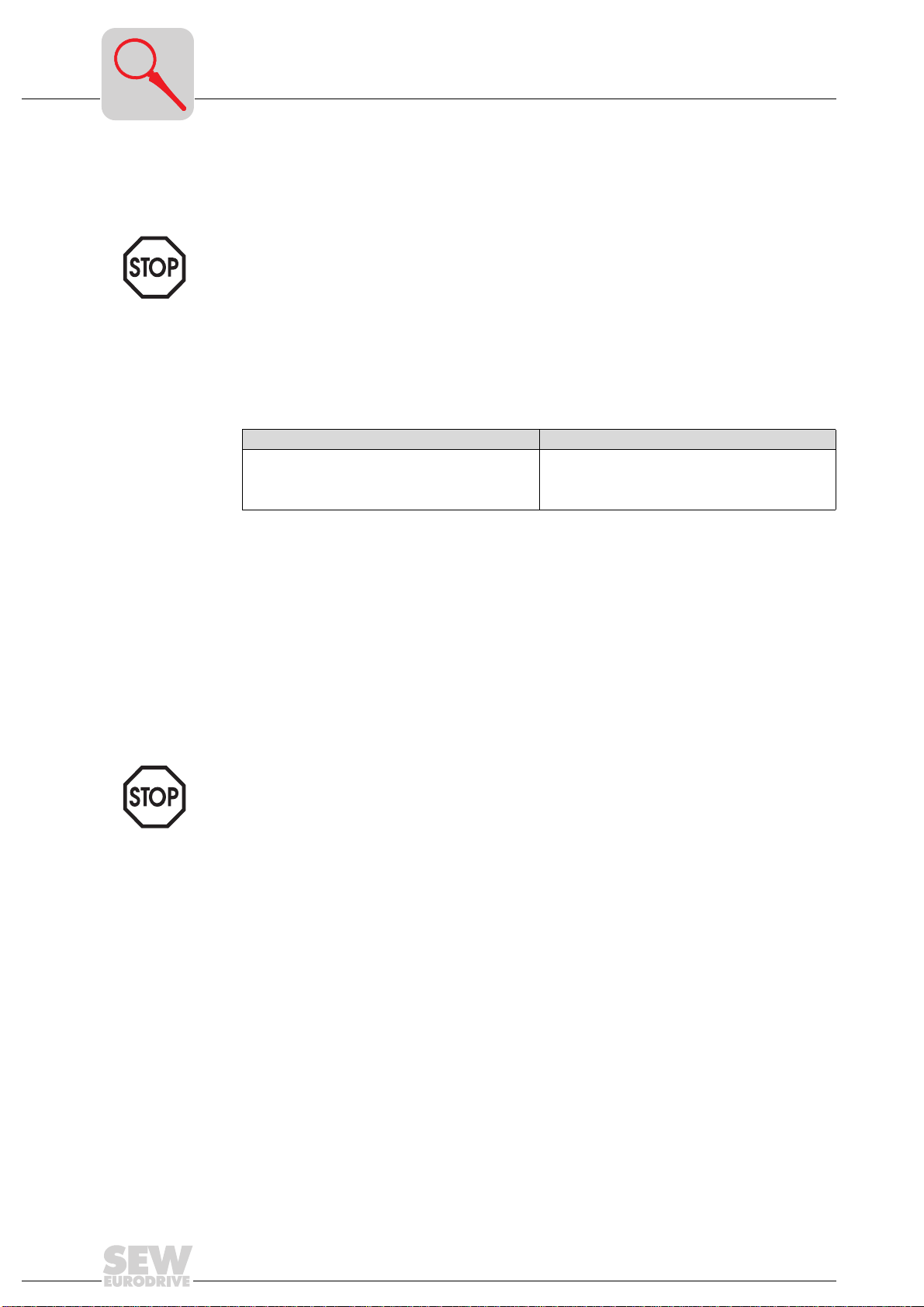

5.2 Protection concept

In order to avoid exceeding the permitted temperature, only operation in accor-

dance with the operating characteristics is permitted (see “Operating characteristics” on page 38)!

• MOVIMOT® units in category 3D are supplied with a temperature switch (TH). The

TH switches off the motor if the winding temperature exceeds the maximum value.

• The switching off process by the TH must be monitored by an independent evaluation unit.

• The independent evaluation unit must be equipped with a base insulation to

securely separated electrical circuits.

• The drive must be disconnected from the supply power system when the TH

trips.

• The TH automatically switches itself back on when the temperature drops

below the maximum value! A restart interlock must prevent the drive from

being energized.

Important: Do not switch the drive back on until the cause of the problem has been

checked. This check must be performed by a trained specialist.

Protection concept

5

In conjunction with

MLA12A

• The unit is supplied with the TH already wired up in conjunction with MLA12A. Consequently, the 24 V power supply of MOVIMOT

and the drive is stopped. At the same time, the ready contact of the MOVIMOT

drops out (ready signal terminals). A restart interlock must prevent the drive

from being energized again automatically when the TH switches back on.

Important: Do not switch the drive back on until the cause of the problem has been

checked. This check must be performed by a trained specialist.

5.3 Operating modes

The following operating modes are permitted with MOVIMOT® units in category 3D:

4Q operation

1Q operation

1. 4Q operation with motors with a mechanical brake

• The brake coil is used as a braking resistor in 4Q operation.

• No external braking resistor is allowed to be connected.

• Regenerative load capacity of the brake coil

2. 1Q operation with motors without a mechanical brake

Important:

Connecting an internal or external braking resistor is not permitted!

®

is interrupted when the TH trips

(see page 37)

®

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

13

Page 14

5

Connection with binary control

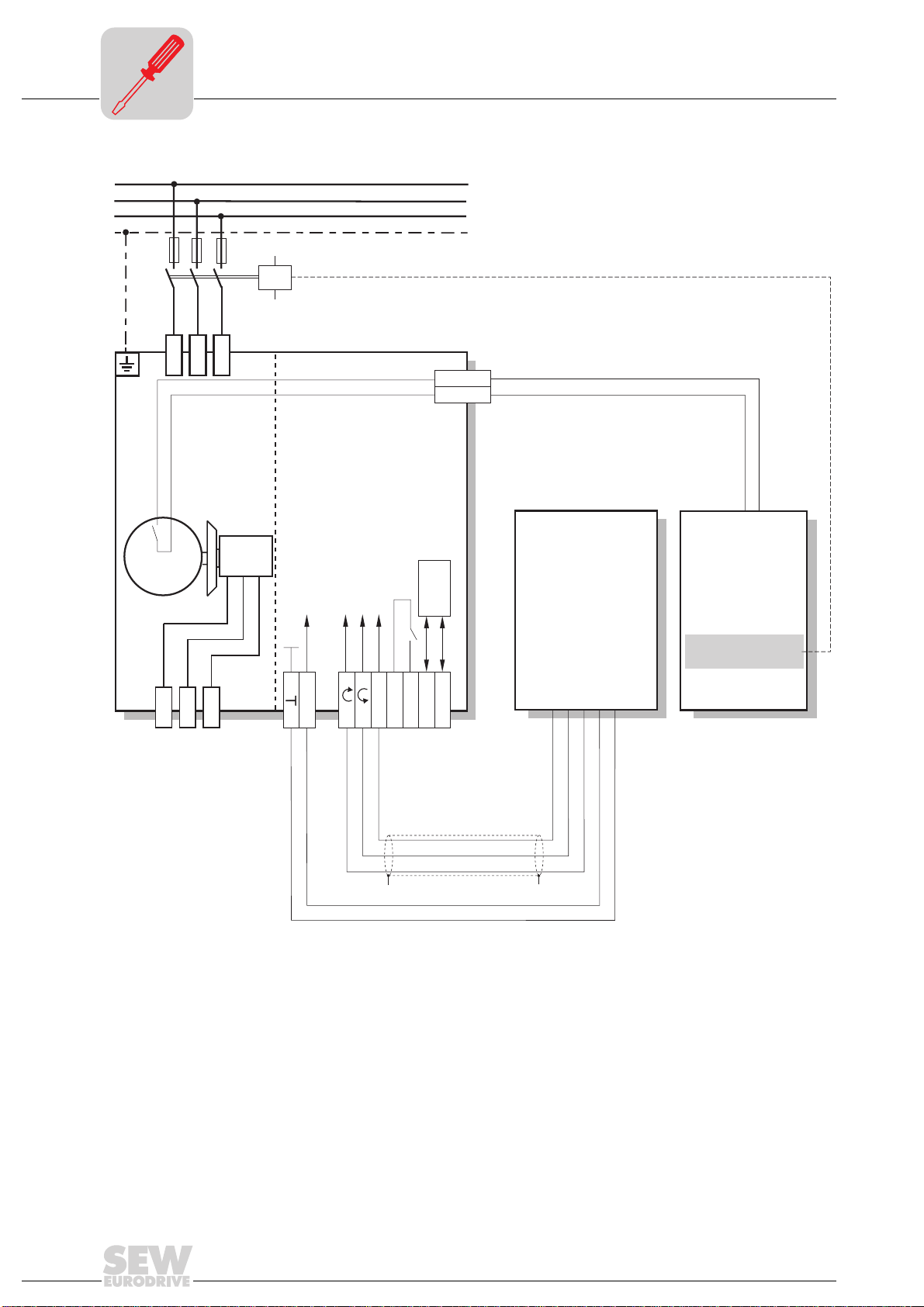

5.4 Connection with binary control

L1

L2

L3

PE

L1

F11/F12/F13

L2

L3

K11

TH

TH

ϑ

14

blue

15

BMG

brake

Terminal Ready signal

Terminal setpoint change

Terminal C CW/Stop

Terminal C W/Stop

Incoming electronics

supply voltage

L

R

24V

1) The independent evaluation unit must have a base insulation to securely separated electrical

circuits.

f1/f2

y

RS-485

K1

RS-

K1a

K1b

Metal cable

entry

RS+

External

control

y

Independent

evaluation unit

restart interlock

1)

with

02844AEN

M

3~

red

white

13

14

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 15

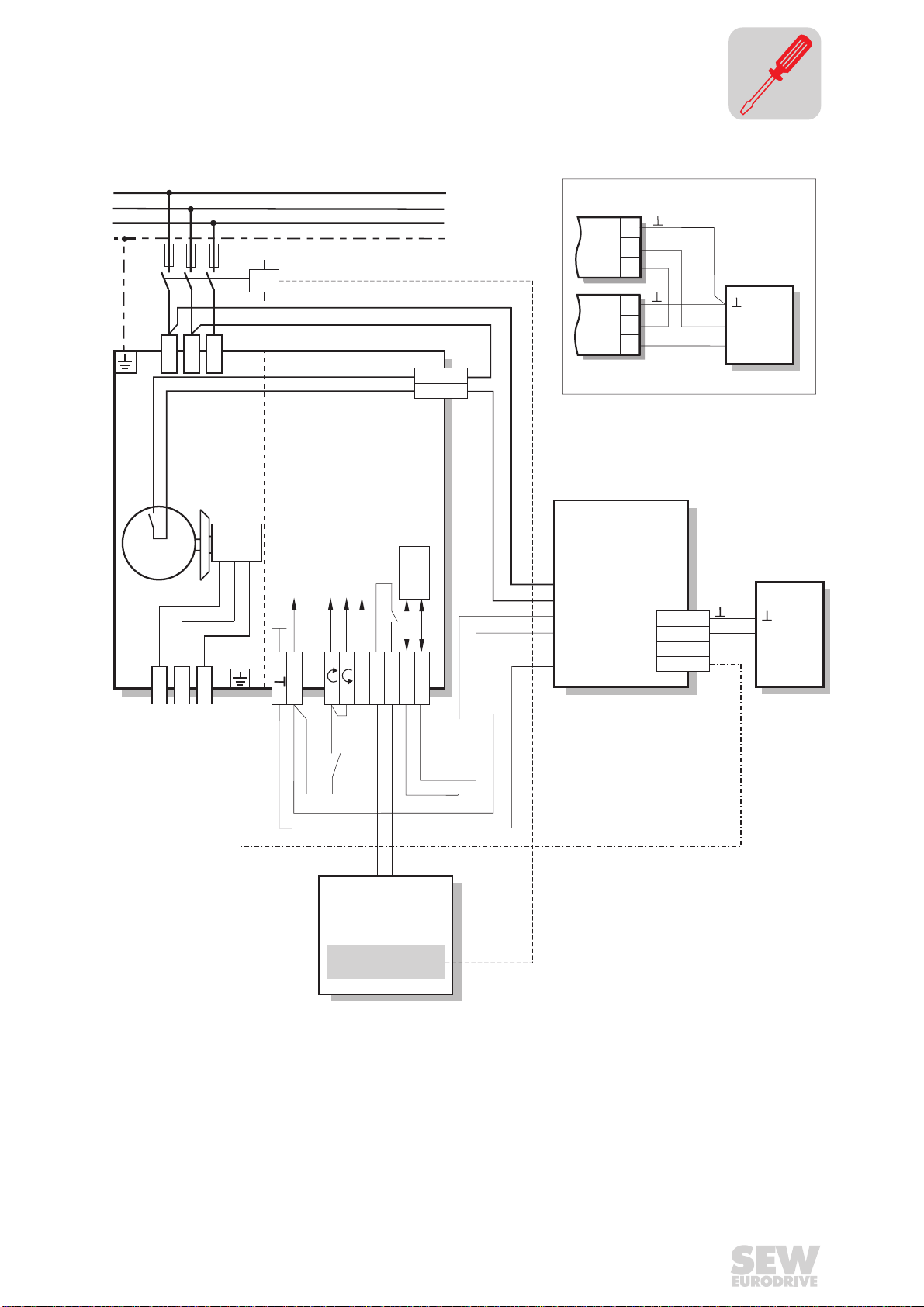

5.5 Connection with MLA12A option

Connection with MLA12A option

5

L1

L2

L3

PE

Connecting several MLA12A units:

4

AI-

MLA12A

3

AI+

2

F11/F12/F13

K11

4

AI-

3

AI+

2

L1

L2

L3

TH

TH

ϑ

M

3 ~

red

13

BMG

brake

yellow

Terminals Ready signal

Terminal Setpoint change

Terminal CC W/Stop

Terminal CW/Stop

Incoming electronics

supply voltage

white

blue

L

R

14

15

24V

f1/f2

K1

K1a

K1b

RS-485

RS-

RS+

yellow

MLA12A

MLA12A

Setpoint converter

with 24V

supply

x10

x9

x8

x7

x6

x5

DC

4

3

2

1

AIAI+

PE

-

PLC

+

PLC

-

+

Start/Stop

Relay

monitoring

with

restart interlock

green

red

orange

blue

02845AEN

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

15

Page 16

5

Connection with RS-485 bus mode

5.6 Connection with RS-485 bus mode

L1

L2

L3

PE

L1

F11/F12/F13

L2

L3

K11

TH

TH

ϑ

M

3~

red

13

BMG

brake

Terminals Ready signal

Terminal Setpoint change

Terminal CCW/Stop

Terminal CW/Stop

Incoming electronics

supply voltage

white

blue

L

R

14

15

24V

Both directions

of rotation

enabled

Potential compensation with the RS-485 master

1) The independent evaluation unit must have a base insulation to safely separated

electrical circuits.

f1/f2

cable entries

K1

K1a

K1b

Metal-

RS-485

RS-

RS+

y

RS-485

bus master

RS-485

y

Independent

evaluation unit

with

restart interlock

1)

02849AEN

16

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 17

6 Startup

6.1 Important startup instructions

Important startup instructions

I

6

00

• It is essential to comply with the safety notes (see page 5) during startup!

• Disconnect MOVIMOT

the terminal box cover.

• Before startup, make sure that

– the drive is not damaged and

– all protective covers have been fitted correctly.

• MOVIMOT

unit. As a result, the parameter settings are fixed.

• Use CW/STOP or CCW/STOP for jog mode.

• A minimum switch-off time of 2 seconds must be maintained for the supply system

contactor K11.

®

is optimally adapted to the motor by means of parameters stored in the

®

from the supply system before removing/replacing

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

17

Page 18

6

00

I

1

ON

432

6

7

5

Startup with binary control

6.2 Startup with binary control

Check connection

Set the DIP

switches

Set the first speed

1. Check MOVIMOT® to see that it is connected correctly (see “Connection with binary

control” on page 14).

2. Make sure DIP switches S1/1 – S1/4 are set to OFF (= address 0).

3. Check the setting for 4Q operation / 1Q operation (DIP switch S1/6 = Off).

ON

1

2

543

6

8

7

02764AEN

to 2.

ON

to 3.

1

2

543

6

8

7

4. Set the first speed with setpoint potentiometer f1 (active when tl. f1/f2 = “0”)

(factory setting: approx. 50 Hz).

100

f[Hz]

6

5

75

50

25

f

1

2

123456789100

Pot.position

Set the second

speed

3

4

5

6

7

8

Setting the ramp

time

3

4

5

6

7

8

Fig. 2: Frequency response of setpoint potentiometer f1

02704AEN

• The first speed is infinitely variable and can be set by using the setpoint

potentiometer f1 which is accessible externally.

• The opening above potentiometer f1 must be closed properly during operation by means of the supplied closing plug. This is the only way in which

explosion-protection can be guaranteed.

• The plug must not be removed, even for adjusting the speed, unless there is

no dangerous dust/air mixture present.

5. Set the second speed with switch f2 (active when tl. f1/f2 = “1”).

Switch f2

Detent position 0 * 12345678910

Setpoint f2 [Hz] 5 * 7 1015202535506070100

* Factory setting

6. Set the ramp time with switch t1.

Switch t1

Detent position 0 1234 5 *678910

Ramp time t1 [s] 0.1 0.2 0.3 0.5 0.7 1 * 2 3 5 7 10

* Factory setting

7. Put on the terminal box cover and secure with bolts.

8. Make sure the cover has a seal and fit the cover back in.

18

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 19

Startup with binary control

I

6

00

Important

The opening above potentiometer f1 must be closed properly during operation by

means of the supplied closing plug. This is the only way in which explosion protection may be guaranteed. The plug must not be removed, even for adjusting the

speed, unless there is no dangerous dust/air mixture present.

9. Switch on the 24 V

control voltage and supply system.

DC

Inverter response according to the terminal level

Network 24 V f1/f2 CW/STOP CCW/STOP Status LED Inverter response

00XXXOffInverter off

10XXXOffInverter off

11X00YellowStop

11010GreenClockwise with f1

11001Green

11110GreenClockwise with f2

11101Green

11X11YellowStop

Key:

0 = No voltage

1 = Voltage

X = Any

Counterclockwise

with f1

Counterclockwise

with f2

Evaluation of the

TH

Functional check

• The TH switch-off must be monitored by an independent eval uation unit.

• The drive must be disconnected from the power supply system when the TH trips.

• The TH automatically switches itself back on when the temperature drops below the

maximum value! An automatic restart must be prevented (restart interlock).

• Do not switch the drive back on until the cause of the problem has been checked.

This check must be performed by a trained specialist.

Check the brake for proper function when brake motors are used. This step will

prevent brake friction and the associated generation of excess heat.

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

19

Page 20

6

00

I

1

ON

2

6

7

5

Startup with the MLA12A option

6.3 Startup with the MLA12A option

Checking connection

Set the DIP

switches

Setting the minimum frequency

3

4

5

6

7

8

Setting the ramp

time

3

4

5

6

7

8

Setting the maximum speed

1. Check to see that MOVIMOT® is connected correctly (see “Connection with

MLA12A option” on page 15).

2. Set DIP switch S1/1 (on MOVIMOT® ) to ON (= address 1).

3. Check the setting for 4Q operation / 1Q operation (DIP switch S1/6 = Off).

ON

to 2.

1

2

4. Set the minimum frequency f

55443

6

8

7

with switch f2

min

to 3.

Switch f2

Detent position 0 * 12345678910

Minimum frequency f

[Hz]

min

2 * 5 7 10 12 15 20 25 30 35 40

ON

1

2

3

6

8

7

02765AEN

* Factory setting

5. Set the ramp time with switch t1.

Switch t1

Detent position 01234 5 *678910

Ramp time t1 [s] 0.10.20.30.50.7 1 *235710

* Factory setting

6. Replace terminal box cover and secure with bolts.

7. Set the required maximum speed using setpoint potentiometer f1.

100

f[Hz]

6

5

75

50

f

1

Important

Selecting the direction of rotation

25

2

123456789100

Pot.position

02704AEN

The opening above potentiometer f1 must be closed properly during operation by

means of the supplied closing plug. This is the only way in which explosion protection may be guaranteed. The plug must not be removed unless there is no dangerous dust/air mixture present.

8. Make sure the cover has a seal and fit it back in place.

9. Select the sign (direction of rotation) for the analog input (tl. 2 and tl. 3) on the

MWA12A option using switch S1.

S1 S2

Clockwise OFF N.C.

Counterclockwise ON N.C.

10. Switch on the voltage.

20

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 21

Startup with the MLA12A option

I

6

00

Control

Setpoint stop

function

Evaluation of the

TH

MOVIMOT® is controlled from f

min

to f

using the analog signal at terminal 2 and ter-

max

minal 3.

[Hz]

5

4

3

f

min

(2 Hz)

Output frequency

1

0

0 0,2 0,4

• The unit is supplied with the TH already wired up in conjunction with the MLA12A

option. Consequently, the 24 V power supply of MOVIMOT

TH trips and the drive is stopped. At the same time, the “Ready contact” of

MOVIMOT

®

drops out (“Ready contact” terminals). An automatic restart must be

0,6

Setpoint

0,8 1

®

is interrupted when the

[mA]

02846AEN

secured by evaluation of the ready contact!

• Do not switch the drive back on until the cause of the problem has been checked.

This check must be performed by a trained specialist.

Functional check

Check proper brake function when using brake motors. This step will prevent

brake friction and the associated generation of excess heat.

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

21

Page 22

6

00

I

6

7

5

24V

L

R

L

R

24V

L

R

24V

L

R

24V

Startup with RS-485 bus operation

6.4 Startup with RS-485 bus operation

Checking connection

Setting the RS-485

address

* Factory setting

Setting the minimum frequency

3

4

5

6

7

8

Setting the ramp

time

3

4

5

6

7

8

1. Check to see that MOVIMOT® is connected correctly (see “Connection with RS-485

bus mode” on page 16).

2. Set the correct RS-485 address on DIP switches S1/1 – S1/4

Address - * 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

S1/1 OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON OFF ON

S1/2 OFF OFF

S1/3 OFF OFF OFF OFF

S1/4 OFF OFF OFF OFF OFF OFF OFF OFF

ON ON OFF OFF ON ON OFF OFF ON ON OFF OFF ON ON

ON ON ON ON OFF OFF OFF OFF ON ON ON ON

ON ON ON ON ON ON ON ON

3. Check the setting for 4Q operation / 1Q operation (DIP switch S1/6 = Off).

ON

to 3.

1

2

4. Set the minimum frequency f

with switch f2

min

Switch f2

Detent position 0 * 12345678910

Minimum frequency f

2 * 5 7 10 12 15 20 25 30 35 40

min

5. Set the ramp time with switch t1 unless it is specified via RS-485.

Switch t1

Detent position 01234 5 *678910

Ramp time t1 [s] 0.10.20.30.50.7 1 *235710

543

6

8

7

02766AEN

* Factory setting

* Factory setting

Enabling the direction of rotation

6. Check whether the required direction of rotation is enabled.

Terminal R Terminals L Meaning

Activated Activated

a)

• Both directions of rotation are enabled

Activated Not activated

b)

• Only clockwise direction of rotation is enabled

• Setpoint entries for counterclockwise lead to the drive

being stopped

Not activated Activated

c)

• Only counterclockwise direction of rotation is enabled

• Setpoint entries for clockwise lead to the drive being

stopped

Not activated Not activated

d)

• Unit is blocked or the drive is stopped

22

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 23

Startup with RS-485 bus operation

7. Replace terminal box cover and secure with bolts.

I

6

00

Setting the maximum speed

Important:

Evaluation of the

TH

8. Set the required maximum speed using setpoint potentiometer f1.

100

f[Hz]

6

5

75

50

25

f

1

2

123456789100

Pot.position

02704AEN

The opening above potentiometer f1 must be closed properly during operation by

means of the supplied closing plug. This is the only way in which explosion protection may be guaranteed. The plug must not be removed unless there is no dangerous dust/air mixture present.

9. Make sure the cover has a seal and fit cover back in.

10. Switch on the voltage.

• The TH switch-off must be monitored by an independent eval uation unit.

• The drive must be disconnected from the power suuply system when the TH trips.

• The TH automatically switches itself back on when the temperature drops below the

maximum value! An automatic restart must be prevented (restart interlock).

• Do not switch the drive back on until the cause of the problem has been checked.

This check must be performed by a trained specialist.

Functional check

Check proper brake function when brake motors are used. This step will prevent

brake friction and the associated generation of excess heat.

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

23

Page 24

6

00

I

Serial communication

6.5 Serial communication

• The control (e.g. PLC) is the master, MOVIMOT® is the slave.

• 1 start bit, 1 stop bit and 1 parity bit (even parity) are used.

• Transmission conforms to the SEW-MOVILINK

Message

structure

Key

Idle = Start pause at least 3.44 ms

SD1 = Start delimiter (start character) 1: Master → MOVIMOT

SD2 = Start delimiter (start character) 2: MOVIMOT® → Master: 1D

ADR = Address 1 – 15

TYPE = User data type

PDU = User data

BCC = Block check character: XOR all bytes

of 9600 baud.

Group address 101 – 115

254 = Point-to-point

255 = Broadcast

TYPE

03

hex

83

hex

05

hex

85

hex

Transfer

variant

Cyclical 2 words

Acyclical 2 words

Cyclical 3 words

Acyclical 3 words

Process

data length

®

protocol with a fixed transfer rate

02754AEN

®

: 02

hex

hex

User data

Control word / Speed [%]

Status word 1 / Output current

Control word / Speed [%] / Ramp

Status word 1 / Output current / Status word 2

24

Note:

If the “cyclic” type is selected, MOVIMOT® expects the next bus activity after maximum

one second (master protocol). If this bus activity is not detected, MOVIMOT

®

rests au-

tomatically (time-out monitoring).

There is no time-out monitoring if the “acyclical” type is selected.

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 25

User data master → Slave

15

14

13

12

11

10

I

Serial communication

6

00

Basic control block

9

8

7

5

6

4

2

3

0

1

Control word

Setpoint

Ramp *

* only with 3 word protocol

Signed percentage / 0.0061 % -80 % / 0.0061 % = -13115 = CCC5Example:

Time from 0 to 50 Hz in ms (range: 100...10000 ms) 2.0 s = 2000 ms = 07D0Example:

User data slave → Master

15

14

State of unit/fault number

Status word 1

Actual current

value

0 = inverter not ready

2 = no enable

4 = enabledV/f-controlled

13

not assigned

12 11

10 9 8

16 Bit signed integer x 0.1% I

Example: 0320 = 800 x 0.1% I = 80% I

h exNN

6

7

N

"1" =

Reset

5

4

3

not assigned

21

0

"1 1 0" = release,

otherwise stop

hex

hex

02758AEN

Controller enabled = "1"

Unit ready = "1"

PO data enabled = "1"

reserved

reserved

Error/Warning = "1"

reserved

reserved

Status word 2*

* (only with 3 word protocol

Controller enabled = "1"

Unit ready = "1"

PO-data enabled = "1"

reserved

reserved

Error/Warning = "1"

reserved

reserved

A1 (brake)

A2 (ready)

E1 (CW)

E2 (CCW)

E3 (setpoint value f2)

reserved 0

reserved 0

reserved 0

)

02760AEN

The following manuals provide more detailed information about startup with RS485 bus operation and about the MOVILINK

Manual and MOVILINK

®

Unit Profile, Communication and Fieldbus Interfaces.

®

unit profile: MOVIMOT® System

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

25

Page 26

7

Status LED

7 Operation and Service

7.1 Status LED

Status LED

7.2 Status LED messages

The 3-color LED indicates the operating and er ro r sta te s.

Color Operational status Description

- Off Not ready to operate No 24 V power supply

Yellow

Yellow

Green/

yellow

Green Steady light Unit enabled Motor operating

Green Steady, flashing rapidly Current limit active Drive has reached the current limit

Red flashing twice, pause Fault 07 DC link voltage too high

Red flashing 3x, pause Fault 11 Excessive temperature in output stage

Red flashing 4x, pause Fault 84 Excessive temperature in motor

Red flashing 5x, pause Fault 89 Excessive temperature in brake

Red flashing 6x, pause Fault 06 Mains phase fault

Steady flashing Not ready to operate Self-test phase active or 24 V power supply

present but supply system voltage not OK

Steady light Ready to operate but unit

blocked

Flashing with alternating colors

Ready to operate but timeout Communication via RS-485 interrupted

24 V power supply and power system supply

OK, but no enable signal

02600AEN

26

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 27

List of errors

7.3 List of errors

Error codes can be evaluated by communicating with the external control using the MOVILINK® profile1) or by

means of the status LED

Errors Cause/Remedy

Communication timeout

(motor stops without error code)

DC link voltage too low, supply system off detected

(motor stops without error code)

Error code 06

Phase fault

Error code 07

DC link voltage

too high

Error code 11

Thermal overload of the output

stage or internal unit fault

Error code 84

Thermal overload of motor

Error code 89

Thermal overload of brake coil

or brake coil defective

(see page 26)

1)

a) No connection ⊥, RS+, RS- between MOVIMOT® and RS-485 master.

b) EMC effects

c) Incorrect type (cyclical) in acyclical protocol

Check supply system leads and supply voltage for interruption.

Motor restarts automatically as soon as the supply voltage reaches normal values.

Check the supply system leads for phase fault. Reset the fault by switching off the

24 V

a) Ramp time too short → Increase ramp time

b) Faulty connection between brake coil and braking resistor

c) Incorrect internal resistance brake coil / braking resistor

d) Thermal overload in braking resistor

Reset error by switching off the 24 V

• Clean heat sink

• Reduce ambient temperature

• Prevent heat accumulation

• Reduce load on drive

Reset error by switching off the 24 V

• Reduce ambient temperature

• Prevent heat accumulation

• Reduce load on the motor

• Increase speed

Reset error by switching off the 24 V

• Extend set ramp time

• Inspect brake (See “Inspection and maintenance of the brake” on page 31)

• Contact SEW service

Reset error by switching off the 24 V

.

Check the connection, in particular the ground, and repair.

Check the shielding of the data cables and improve if necessary.

Time between the individual messages >1 s for protocol type

“cyclical”. Shorten message cycle or select “acyclical”.

supply voltage or use MOVILINK

DC

→ Check connection between braking resistor and brake coil. Correct if necessary.

→ Check internal resistance of brake coil / braking resistor (see page 37)

→ Wrong size of braking resistor selected

®1)

supply voltage or use MOVILINK

DC

supply voltage or use MOVILINK

DC

supply voltage or use MOVILINK

DC

supply voltage or use MOVILINK

DC

®1)

®1)

®1)

®1)

7

1) See the "MOVILINK® Unit Profile, Communication and Fieldbus Interfaces” manual for detailed information about

communication.

If you require assistance from our customer service staff, please state the following:

• Nameplate data

• Time and accompanying circumstances of error

• Type and extent of error

• Presumed cause

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

27

Page 28

8

Inspection and maintenance periods

8 Inspection and Maintenance

Notes:

• Only use genuine spare parts in accordance with the valid spare parts list!

• Important – Danger of burns: Motors can become very hot during operation!

• The IP enclosure of the housing must be maintained in order to ensure protection against explosions. It is therefore very important to make sure that the

housing parts are assembled correctly in accordance with the spare parts list

for all maintenance and inspection work. Elastomer and plastic seals must be

replaced with genuine spare parts.

8.1 Inspection and maintenance periods

Frequency

depending on loading conditions: every 2 to 4 years

(The wear periods are affected by many factors and may be

short. Calculate the required inspection/maintenance intervals

individually in accordance with the project planning documents.)

every 10,000 hours of operation Motor

variable

(depending on external factors)

Unit/unit

component

Brake

What to do?

• Inspect the brake

(working air gap, brake disk, pressure plate, carrier / gearing, pressure rings)

• Remove abraded matter

• Inspect the moto r

(fit new ball bearings/oil seal)

• Clean the cooling air passages

• Touch up or renew the anticorrosion

coating

Checks following

maintenance or

repair work

Perform a safety and functional check after all maintenance or repair work. This check

should be the same as the functional check described for startup.

Perform another routine test prior to startup if you have rep laced any parts on the m otor

which may affect its explosion-proof qualities.

28

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 29

Inspection and maintenance work on the motor

8.2 Inspection and maintenance work on the motor

10

9

8

4

5

7

6

8

12

11

15

3

2

1

Fig. 3: Example: motor DFT.. MM..

1Circlip

2 Oil flinger

3 Oil seal

4 Screw plug

5 Drive end bearing

shield

6 Circlip

7 Ball bearing

8 Circlip

9 Rotor

10 Nilos ring

11 Ball bearing

13

16

14

12 Equalizing ring

13 Stator

14 Non-drive end bearing

shield

15 Hexagon screw

16 V ring

20

19

18

17

02575AXX

17 Fan

18 Circlip

19 Fan guard

20 Housing screw

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

29

Page 30

8

Inspection and maintenance work on the motor

Inspecting the

motor

(Fig. 3)

1. Important: Interrupt power supply to MOVIMOT®, safeguarding it against unintentional power-up.

2. Remove proximity sensor NV16 / NV26 if fitted.

3. Remove the flange cover or fan guard (19).

4. Remove the hexagon head screws (15) from the drive end bearin g shield (5) and the

non-drive end bearing shield (14), releas e the stator (13) from the drive end bearing

shield.

5. a) Motors with a brake:

– open the terminal box cover, remove brake cable from terminals

– push the non-drive end bearing shield and the brake off the stator

and carefully lift them off (if necessary, run the brake cable along with

trailing wire)

b) Pull the stator back by approx. 3 to 4 cm.

6. Visual check:

Are there traces of gear oil or condensation inside the stator?

– no, continue with 9.

– if there is moisture, continue with 7.

– if there is gear oil, have the motor repaired by a specialist workshop

7. a) Geared motors: remove the motor from the gear unit.

b) Motors without a gear unit: remove the drive end flange.

c) Remove the rotor (9).

8. Clean the winding, dry it and check it electrically.

9. Fit new ball bearings (7, 11) (only use approved ball bearings see page 38) .

10. Fit new oil seal (3) in the drive end bearing shield.

11. Reseal the stator seat, reassemble the motor, brake, etc.

Then check gear unit, if applicable

(see the gear unit operating instructions)

.

30

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 31

Inspection and maintenance of the brake

8.3 Inspection and maintenance of the brake

Parts of the brake are subject to wear during operation. As a result, regular inspection and maintenance are essential.

8

Using the brake

as a working

brake

Using the brake

as a holding

brake

If the brake is used as a working brake, the brake pad wear is the determining factor

governing when to service the brake.

Do not allow the maximum permitted working air gap to be exceeded (see “Work done

until adjustment, working air gap, braking torque of brake” on page 37). The inspection

and maintenance intervals can be calculated on the basis of the work done by the brake

in each braking operation and the entire work done until adjustment (see “Work done

until adjustment, working air gap, braking torque of brake” on page 37).

To do this, please calculate the work do ne in ea ch brak ing opera tion indiv idually in a ccordance with the project planning documents. Check the brake at the latest when it has

performed the amount of work until reset at which point an adjustment is due.

The following parts of the brake are subject to wear and should be r eplaced if necessary

(see Fig. 4):

• Brake disk (7)

• Annular spring (6)

• Pressure plate (8)

• Pressure rings and counter springs (10 b, c)

• Brake springs (11)

• Also replace the self-locking hexagon nuts (10e) and the rubber sealing collar (5)

after repeated disassembly/assembly.

Brakes used as holding brakes are only subject to a small amount of lining wear. However, their mechanical transmission elements must also be checked for wear.

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

31

Page 32

8

Inspection and maintenance of the brake

9

8

7

6

23

5

23

4

3

2

1

a

Fig. 4: Type BMG 05 – BMG 4

1 Motor with brake bearing end

shield

2 Carrier

3 Circlip

4 Niro disk (only BMG)

5 Rubber sealing collar

6 Annular spring

7 Brake disk

8 Pressure plate

22

21

e

10

c

b

17

16

15

14

13

12

11

9 Damping plate

10a Stud (3 pcs.)

10b Counter spring

10c Pressure ring

10e Hexagon nut

11 Brake spring

12 Brake coil body

13 Sealing washer

14 Dowel pin

19

18

20

02900AXX

15 Releasing lever with hand lever

16 Stud (2 pcs.)

17 Conical coil spring

18 Setting nut

19 Fan

20 Circlip

21 Fan guard

22 Housing screw

23 Clamping strap

32

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 33

Inspection and maintenance of the brake

8

Inspecting the

brake

(Fig. 4 + Fig. 5)

Checking the

brake disk

Setting the working

air gap

1. Interrupt MOVIMOT® power supply, safeguarding it against unintentional

starting.

2. Remove the following:

– Proximity sensor NV16 / NV26, if fitted

– Flange cover or fan guard (21)

3. Remove the clamping straps (23) and move the rubber sealing collar (5).

Remove any abraded residue with vacuum.

4. Measure the brake disk (7):

If the brake disk is ≤ 9 mm:

Replace brake disk

5. Measure the working air gap A

– with feeler gauge at three points between thepressure plate and the damping

plate (9)offset by approx. 120°.

6. Tighten the hexagon nuts (10e) until working air gap is set correctly

7. Fit rubber sealing collar and clamping straps back in place and re-install removed

parts.

(see page 34)

(see Fig. 5).

.

(see page 37)

A

.

Fig. 5: Measuring the working air gap

02577AXX

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

33

Page 34

8

Inspection and maintenance of the brake

Installing new

brake disk

(Fig. 4 + Fig. 5)

When installing a new brake disk, inspect the other removed parts as well and replace,

if necessary.

®

1. Interrupt power supply to MOVIMOT

tional starting.

2. Remove the following:

– proximity sensor NV16 / NV26, if fitted

– flange cover or fan guard (21), circlip (20) and fan (19)

3. Remove the clamping straps (23) and rubber sealing collar (5) .

Remove the manual brake release: setting nuts (18), conical coil springs (17), studs

(16), releasing lever (15), dowel pin (14).

4. Unscrew hexagon nuts (10e), carefully pull off the coil body (12) (brake cable!) and

remove brake springs (11).

5. Remove the damping plate (9), pressure plate (8) and brake disk (7) and clean the

brake components.

6. Install new brake disk.

7. Re-assemble the brake components (except for the rubber sealing collar, fan and

fan guard).

Set the working air gap

8. For manual brake release (type HF or HR):

Use setting nuts to set the floating clearance between the conical coil springs

(pressed flat) and the setting nuts

(see page 33 / points 5. to 7.)

(→ Fig. 6)

unit, safeguarding it against uninten-

.

.

Important: This floating clearance is necessary so that the pressure plate can move

up as the brake lining wears.

9. Fit the rubber sealing collar and clamping straps back in pl ace and re-install the dismantled parts.

Note:

The lockable manual brake release (type HF) has already been released if a resistance

is encountered when operating the manual brake release screw.

The self-reengaging manual brake release (type HR) can b e operated with normal hand

pressure.

Important:

In brake motors with self-reengaging manual brake release, the manual brake re-

lease lever must be removed after startup/maintenance. A bracket is provided for

storing it on the outside of the motor.

Brake

BMG 05-1 1.5

BMG 2-BMG4 2

Floating clearance mm

34

Fig. 6

01111AXX

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 35

Inspection and maintenance of the brake

8

Changing the

braking torque

(Fig. 4 + Fig. 5)

The braking torque can be altered in steps

• by installing different brake springs,

• by changing the number of brake springs.

1. Interrupt power supply to MOVIMOT

tional start.

2. Remove the following:

– proximity sensor NV16 / NV26, if fitted

– flange cover or fan guard (21), circlip (20) and fan (19)

3. Remove the clamping straps (23) and rubber sealing collar (5) .

Remove the manual brake release:

setting nuts (18), conical coil springs (17), studs (16), releasing lever (15), do wel pin

(14).

4. Unscrew the hexagon nuts (10e) and pull off the brake coil body (12) by about 50

mm (caution: brake cable!).

5. Replace or add brake springs (11).

(Position the brake springs symmetrically.)

6. Re-assemble the brake components (except for the rubber sealing collar, fan and

fan guard).

Set the working air gap

7. With manual brake release:

Use setting nuts to set the floating clearance between the conical coil springs

(pressed flat) and the releasing lever

(see page 33 / points 5. to 7.)

(see page 37)

®

unit, safeguarding it against uninten-

.

(→ Fig. 6)

.

Important: This floating clearan ce is necessary so that the pressure plate can move

up as the brake lining wears.

8. Fit the rubber sealing collar back in place and re-install removed parts.

Note:

Install new setting nuts (18) and hexagon nuts (1 0e) if the removal procedure is rep eated! (due to reduction in the self-locking effect of the nuts!)

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

35

Page 36

9

P

i

f

kVA

Hz

n

MOVIMOT® in category 3D

9 Technical data (relating to 4 kHz PWM frequency)

9.1 MOVIMOT® in category 3D

MOVIMOT® type

Output power

Connection voltages

Approved range

Supply frequency

Supply system rated current

(at V

= 400 VAC)

in

Output voltage

Output frequency

Resolution

Operating point

Rated output current I

Motor power

PWM frequency

Current limitation

External braking resistor

P

V

f

in

I

in

U

f

A

N

P

I

max

R

N

in

A

mot

min

MM 03B-

503-04

0.8 kVA 1.1 kVA 1.4 kVA 1.8 kVA 2.2 kVA 2.8 kVA 3.8 kVA

1.0 AAC 1.3 AAC 1.6 AAC 1.9 AAC 2.4 A

1.2 AAC 1.6 AAC 2.0 AAC 2.5 AAC 3.2 A

0.25 kW 0.37 kW 0.55 kW 0.75 kW 1.1 kW 1.5 kW 2.2 kW

MM 05B-

503-04

MM 07B-

503-04

MM 11B-

503-04

3 x 400 VAC / 415 VAC / 460 V

Vin = 400 VAC -5 %...460 VAC +5 %

50 Hz – 60 Hz ±10 %

0 – V

in

2...100 Hz

0.01 Hz

400 V at 50 Hz / 100 Hz

41) / 8 / 12 / 162)kHz

Motor: 160 % at V, 150 % at ∆

Regenerative: 160 % at V, 150 % at ∆

Not permitted

MM 15B-

503-04

AC

AC

MM22B-

503-04

AC

3.5 A

4.0 A

Interference immunity Complies with EN 50082 – Parts 1+2

Emitted interference

Ambient temperature

Enclosure

(select and specify with order)

q

to EN 55011 and EN 55014, complies with EN 50081 – Part 2

amb

In accordance with limit value class A

-20 °C...+40 °C

IP54, IP55, IP65

Operating mode DB (EN 60149-1-1 and 1-3)

Type of cooling (DIN 41 751) Self-cooling

Altitude

Ext. power supply to control

electronics

Binary inputs

h ≤ 1000 m (P

Tl. 24 V V = +24 V ± 25 %

Isolated by opto-coupler, PLC-compatible (EN 61131-2)

R

≈ 3.0 kΩ, IE ≈10 mA, sampling interval ≤ 5 ms

i

reduction: 1 % per 100 m up to max. 2000 m)

N

≤ 250 mA

I

E

Signal level 13 V...+30 V = “1” = Contact closed

-3 V...+5 V = “0” = Contact open

Control functions Tl. R

Output relay

Contact data

Tl. L

Tl.f1/f2

Tl. K1a

Tl. K1b

“0” = Setpoint 1 / “1” = Setpoint 2

24 V

DC

CW/STOP

CCW/STOP

Response time ≤ 10 ms

/ 0.6 ADC / DC11 to IEC 337-1

Signaling function Normally open contact for ready signal

Serial interface

Tl. RS +

Tl. RS -

Max. 32 stations (1 bus master3) + 31 MOVIMOT® units)

Max. cable length: 200 m (for transmission rate: 9600 baud)

RS-485 (to EIA standard)

30 m (for transmission rate: 31250 baud

1) Factory setting

2) 16 kHz PWM frequency (low-noise)

When DIP SWITCH S1/7 = ON, the units operate with a 16 kHz PWM frequency (low noise) and switch back in steps to lower

pulse frequencies depending on the heat sink temperature.

3) Ext. control or option MLA12A

4) Transmission rate of 31250 baud is set automatically for operation with the MLA12A option.

AC

AC

MM 30B-

503-04

5.0 A

5.5 A

4)

)

AC

AC

36

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 37

Technical data MLA12A option

9.2 Technical data MLA12A option

MLA12A

Part number 823 186 9

Input voltage X9 / X10 380...500 V

Output voltage

Terminals

Analog input:

Serial interface X7 / X8

Enclosure IP65

X6 24 VDC ±25 % (max. 200 mA)

X5 0 V reference potential

Tl. 1 PE

Tl. 2 / tl. 3 0...20 mA

Tl. 4 ⊥ Reference ground for analog input

RS-485 (to EIA standard)

Transmission rate: 9600 / 31250 baud

AC

±10 %

9.3 Regenerative load capacity of brake coil

kVA

i

P

f

Hz

n

9

Load capacity

for

100 % cdf 30 W 57 W 70 W

50 % cdf 39 W 88 W 105 W

25 % cdf 56 W 150 W 175 W

12 % cdf 90 W 270 W 330 W

6 % cdf 150 W 480 W 620 W

Brake coil BMG05/1

(DT71/DT80)

Brake coil BMG2

(DT90)

Brake coil BMG4

(DT 100)

9.4 Work done until adjustment, working air gap, braking torque of brake

Work done

Brake

type

BMG 05 DT 71 60

BMG 1 DT 80 60

BMG 2 DT 90 130

BMG 4 DT 100 130

1) Rated value measured between the red connection (terminal 13) and the blue connection (terminal 15) at

20 °C, temperature-dependent fluctuations in the range of -25 % / +40 % are possible.

2) Please note when checking the working air gap:

Parallelism tolerances on the brake disk may give rise to deviations of ±0.1 mm after a test run.

For

motor size

until adjust-

ment

6

J]

[10

Working air

gap, mm

2)

min.

max.

0.25 0.6

Braking

torque

[Nm]

5.0

4.0

2.5

1.6

1.2

10

7.5

6.0

20

16

10

6.6

5.0

10

30

24

Braking torque settings

Type and number

of springs

Normal Red Normal Red

3

2

-

-

-

6

4

3

3

2

-

-

-

6

4

3

2

6

4

3

2

3

2

6

4

3

2

3

Order numbers

of springs

135 017 X 135 018 8

135 150 8 135 151 6

Resistance

Brake

277 Ω

(230V)

248 Ω

(230V)

216 Ω

(230V)

43.5 Ω

(110V)

1)

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

37

Page 38

9

P

i

f

kVA

Hz

n

Approved ball bearing types

9.5 Approved ball bearing types

Motor

type

DT 71-80 6204-Z-J 6303-Z-J 6204-Z-J 6203-J 6203-RS-J-C3

DT 90-100 6306-Z-J-C3 6205-J 6205-RS-J-C3

9.6 Operating characteristics

Drive end bearing (AC motor, brake motor)

Flange-

mounted

motor

Geared motor

Foot-mounted

motor

Non-drive end bearing

(foot-mounted, flange-mounted,

geared motors)

AC motor Brake motor

50 Hz

100 Hz

V

n

• The operating characteristics provide information about the torque values with

which MOVIMOT

®

units may be loaded depending on the speed.

• Exceeding these values over long periods gives rise to impermissible heat.

• Brief periods above this value are permitted.

1

S1

0,8

0

,

6

nenn

M/M

0,4

0,2

0

05

0

0 1000 1500 2000 2500 3000

n[1/min]

S3 40%

02847AEN

1

0,8

0

,

6

nenn

M/M

0,4

0,2

0

05

0

0 1000 1500 2000 2500 3000

n[1/min]

S1

S3 40%

02848AEN

38

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

Page 39

9.7 Declaration by the manufacturer

Declaration by the manufacturer

kVA

i

P

f

Hz

n

9

Operating Instructions MOVIMOT® MM..B for Use According to Category 3D

39

Page 40

We are available,wherever you needus.

Worldwide.

SEW-EURODRIVE right around the globe is

your competent partner in matters of power

transmission with manufacturing and assembly plants in most major industrial countries.

SEW-EURODRIVE GmbH & Co · P.O.Box 30 23 · D-76642 Bruchsal/Germany

Tel. +49-7251-75-0 · Fax +49-7251-75-19 70 · Telex 7 822 391

http://www.SEW-EURODRIVE.com · sew

sew-eurodrive.com

@

Loading...

Loading...