Page 1

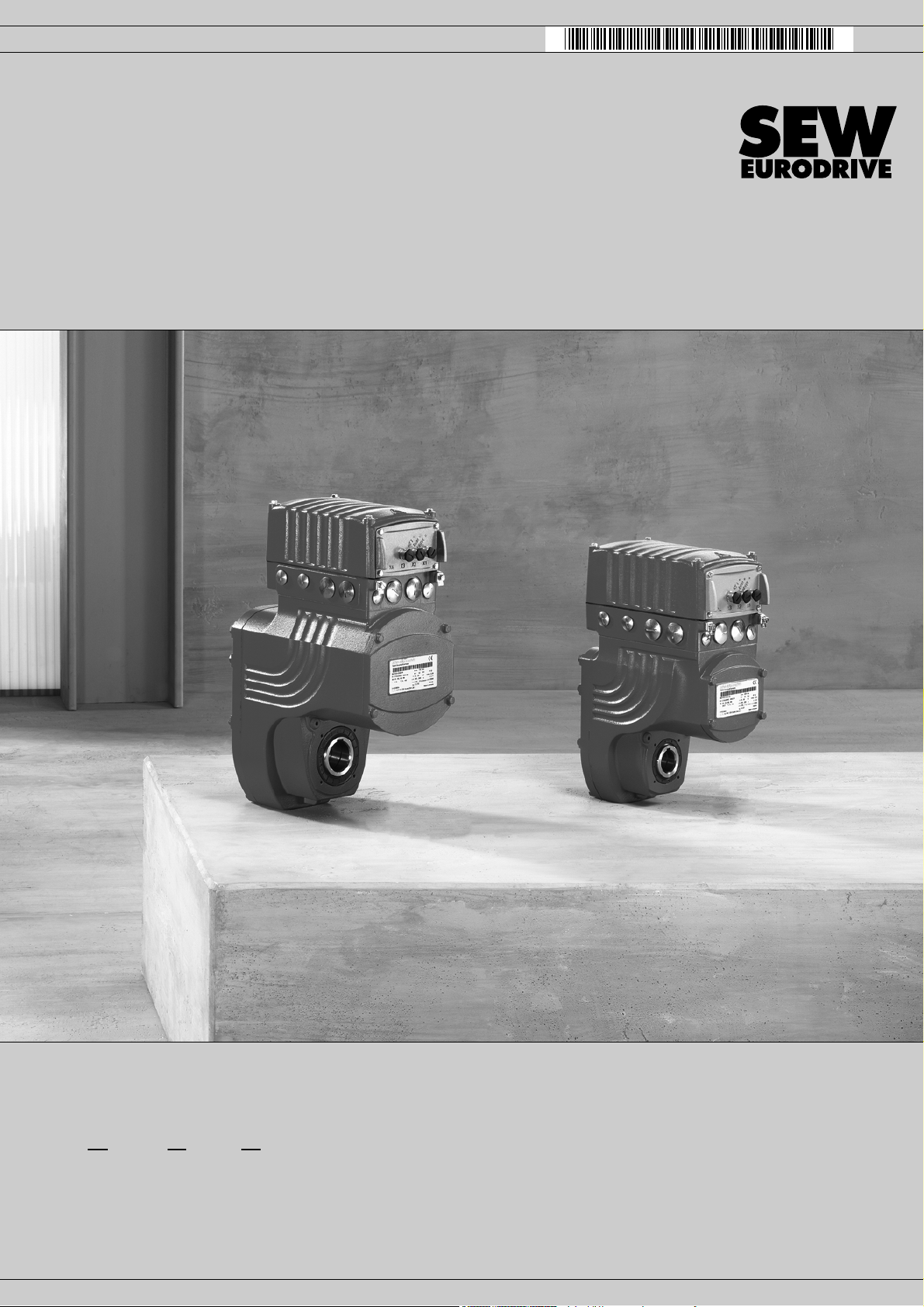

Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

Mechatronic Drive System

MOVIGEAR

®

DSC-B

Direct SBus Communication

Edition 04/2010 16889215 / EN

Page 2

SEW-EURODRIVE—Driving the world

Page 3

1 Important Information......................................................................................... 6

1.1 How to use the operating instructions......................................................... 6

1.2 Structure of the safety notes ....................................................................... 6

1.3 Rights to claim under limited warranty ........................................................ 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright notice .......................................................................................... 7

2 Safety Notes ........................................................................................................ 8

2.1 General ....................................................................................................... 8

2.2 Target group ............................................................................................... 8

2.3 Designated use ........................................................................................... 9

2.4 Transportation and storage......................................................................... 9

2.5 Installation................................................................................................. 10

2.6 Electrical connection ................................................................................. 10

2.7 Safe disconnection.................................................................................... 10

2.8 Operation .................................................................................................. 11

3 Unit Design ........................................................................................................ 12

3.1 MOVIGEAR

®

drive unit............................................................................. 12

3.2 Shaft variants ............................................................................................ 13

3.3 Housing mounting ..................................................................................... 14

3.4 Position of the cable entry......................................................................... 15

3.5 Sample nameplate and type designation of drive unit .............................. 16

3.6 MOVIGEAR

®

electronics .......................................................................... 17

3.7 Application options.................................................................................... 19

3.8 Sample nameplate and type designation for electronics .......................... 21

3.9 MOVIGEAR

®

with optional package for wet areas ................................... 23

4 Mechanical Installation..................................................................................... 24

4.1 Installation notes ....................................................................................... 24

4.2 Required tools and resources ................................................................... 24

4.3 Installation prerequisites ........................................................................... 25

4.4 Installing MOVIGEAR

®

............................................................................. 26

4.5 Application options.................................................................................... 29

4.6 Shaft-mounted gear unit with keyway ....................................................... 31

4.7 Shaft-mounted gear unit with TorqLOC

®

(customer shaft without contact shoulder) ................................................ 35

4.8 Shaft-mounted gear unit with TorqLOC

®

(customer shaft with contact shoulder) ..................................................... 40

4.9 Installing the protective cover ................................................................... 45

4.10 Torque arm ............................................................................................... 46

4.11 Tightening torques .................................................................................... 47

4.12 MOVIGEAR

®

with optional package for wet areas ................................... 50

Operating Instructions – MOVIGEAR® DSC-B

3

Page 4

5 Electrical Installation ........................................................................................ 55

5.1 Installation planning considering EMC aspects ........................................ 55

5.2 Installation instructions.............................................................................. 56

5.3 Installation topology (example) ................................................................. 64

5.4 Terminal assignment................................................................................. 65

5.5 Connection of MOVIGEAR

®

..................................................................... 67

5.6 Cable routing and cable shielding............................................................. 68

5.7 Plug connectors ........................................................................................ 75

5.8 Optional plug connector assignment......................................................... 78

5.9 Application options.................................................................................... 91

6 Startup................................................................................................................ 93

6.1 Startup notes............................................................................................. 93

6.2 Description of the DIP switches ................................................................ 94

6.3 Startup of the MOVIGEAR

®

drive units .................................................... 98

6.4 Startup of application option GIO13A ..................................................... 101

6.5 Deactivating DynaStop

7 Operation of MOVITOOLS

7.1 About MOVITOOLS

®

for startup ........................................................ 104

®

MotionStudio .................................................... 105

®

MotionStudio ........................................................ 105

7.2 First steps ............................................................................................... 106

7.3 Connection mode.................................................................................... 108

7.4 Executing functions with the units........................................................... 110

8 Parameters....................................................................................................... 111

8.1 Overview of parameters for command pcb ............................................. 111

8.2 Overview of parameters for application options...................................... 113

8.3 Overview of power section parameters................................................... 115

8.4 Description of command pcb parameters ............................................... 128

8.5 Description of application option parameters.......................................... 130

8.6 Description of power section parameters................................................ 134

9 Operation ......................................................................................................... 162

9.1 Manual mode with MOVITOOLS

®

MotionStudio .................................... 162

9.2 Local mode (only in conjunction with optional plug connector)............... 166

9.3 DynaStop

9.4 Deactivating DynaStop

®

.............................................................................................. 167

®

......................................................................... 168

10 Service ............................................................................................................. 171

10.1 Malfunctions of the mechanical MOVIGEAR

®

drive ............................... 171

10.2 Evaluating error messages ..................................................................... 172

10.3 Switch-off responsess............................................................................. 173

10.4 Resetting error messages....................................................................... 173

10.5 Description of status and operating indicators ........................................ 174

10.6 Unit replacement..................................................................................... 179

10.7 SEW-EURODRIVE Service .................................................................... 180

10.8 Extended storage.................................................................................... 181

10.9 Disposal .................................................................................................. 182

4

Operating Instructions – MOVIGEAR® DSC-B

Page 5

11 Inspection and Maintenance .......................................................................... 183

11.1 Determining the operating hours............................................................. 183

11.2 Inspection and maintenance intervals..................................................... 184

11.3 Lubricant change intervals ...................................................................... 185

11.4 Inspection and maintenance work on the MOVIGEAR

®

drive ................ 186

12 Technical Data and Dimension Sheets ......................................................... 190

12.1 Technical data of MOVIGEAR

®

.............................................................. 190

12.2 Technical data of application options...................................................... 193

12.3 Integrated braking resistor BW1 ............................................................. 195

12.4 Deceleration torques DynaStop

®

............................................................ 196

12.5 Torque characteristics............................................................................. 197

12.6 Surface protection................................................................................... 205

12.7 Package for applications in wet areas .................................................... 207

12.8 Screw connections.................................................................................. 211

12.9 Connection cables .................................................................................. 212

12.10 Mounting positions .................................................................................. 216

12.11 Lubricants ............................................................................................... 218

12.12 Design notes for gear units with hollow shaft and key ............................ 221

12.13 Dimension drawings................................................................................ 223

13 EC Declaration of Conformity .................................................................... 231

14 Address List .................................................................................................... 232

Index................................................................................................................. 242

Operating Instructions – MOVIGEAR® DSC-B

5

Page 6

1

Important Information

How to use the operating instructions

1 Important Information

MOVIGEAR® DSC-B

1.1 How to use the operating instructions

The operating instructions are an integral part of the product and contain important

information for operation and service. The operating instructions are written for all

employees who assemble, install, startup, and service this product.

The operating instructions must be legible and accessible at all times. Make sure that

staff responsible for the plant and its operation, as well as persons who work independently on the unit, have read the operating instructions carefully and understood them.

If you are unclear about any of the information in this documentation, or if you require

further information, contact SEW-EURODRIVE.

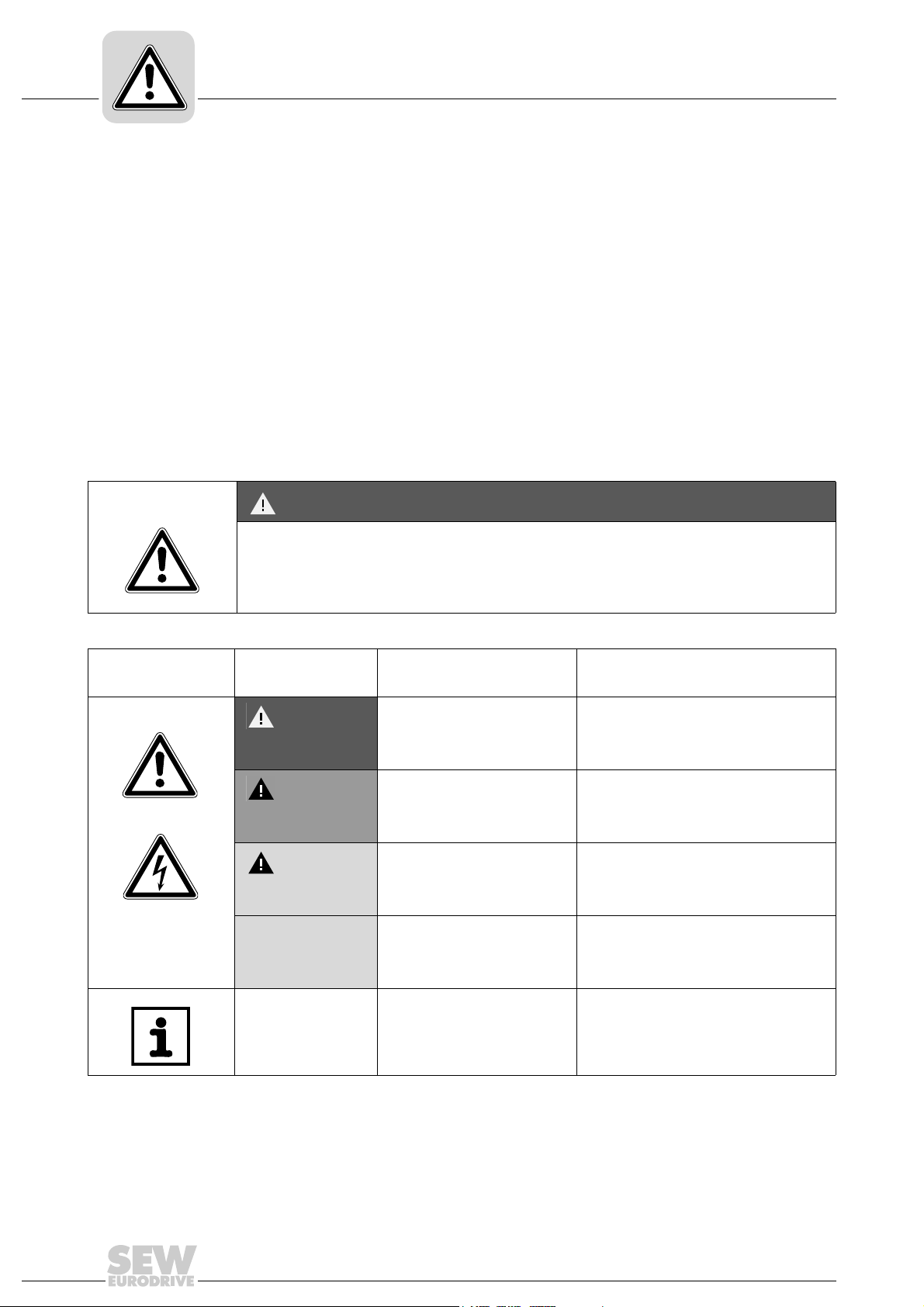

1.2 Structure of the safety notes

The safety notes in these operating instructions are designed as follows:

Pictogram SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

Pictogram Signal word Meaning Consequences if

disregarded

Example:

General danger

Specific danger,

e.g. electric shock

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

INFORMATION

Useful information or tip.

Simplifies the handling of the

drive system.

environment

6

Operating Instructions – MOVIGEAR® DSC-B

Page 7

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the operating instructions. Therefore,

read the operating instructions before you start working with the unit.

Make sure that the operating instructions are available to persons responsible for the

plant and its operation, as well as to person who work independently on the unit. You

must also ensure that the documentation is legible.

1.4 Exclusion of liability

Important Information

1

You must comply with the information contained in the operating instructions to ensure

safe operation of MOVIGEAR

features. SEW-EURODRIVE does not assume liability for injury to persons or damage

to equipment or property resulting from non-observance of these operating instructions.

In such cases, any liability for defects is excluded.

1.5 Copyright notice

© 2010 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

®

and to achieve the specified product and performance

Operating Instructions – MOVIGEAR® DSC-B

7

Page 8

2

2 Safety Notes

2.1 General

Safety Notes

General

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

observed. Ensure that persons responsible for the system and its operation, as well as

persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in

this documentation, please contact SEW-EURODRIVE.

Never install or start up damaged products. Submit a complaint to the shipping company

immediately in the event of damage.

During operation, MOVIGEAR

parts as well as hot surfaces, depending on their enclosure.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property.

Refer to the documentation for additional information.

®

drive units can have live, bare and movable or rotating

2.2 Target group

Only qualified electricians are authorized to install, startup or service the units or

correct unit faults (observing IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are: All persons familiar

with installation, assembly, startup and operation of the product who possess the

necessary qualifications.

Any activities regarding transportation, storage, operation, and disposal must be carried

out by persons who have been instructed appropriately.

8

Operating Instructions – MOVIGEAR® DSC-B

Page 9

2.3 Designated use

MOVIGEAR® drive units are components intended for installation in electrical systems

or machines.

In case of installation in machines, startup of the MOVIGEAR

designated operation) is prohibited until it is determined that the machine meets the

requirements stipulated in the EC Directive 2006/42/EC (machine directive).

Startup (i.e. the start of designated use) is only permitted under observance of the

EMC (2004/108/EC) directive.

MOVIGEAR

95/EC. The standards given in the declaration of conformity are applied to the

MOVIGEAR

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

2.3.1 Safety functions

The MOVIGEAR

are described and expressly permitted.

Safety Notes

Designated use

®

drive units (i.e. start of

®

drive units comply with the regulations of the Low Voltage Directive 2006/

®

drive units.

®

drive units may not perform safety functions unless these functions

2

2.3.2 Hoist applications

MOVIGEAR

MOVIGEAR

performed a risk assessment. For further information, consult the information in the

documentation.

®

drive units must not be used for hoist applications.

®

drive units may only be used for inclining tracks after the operator has

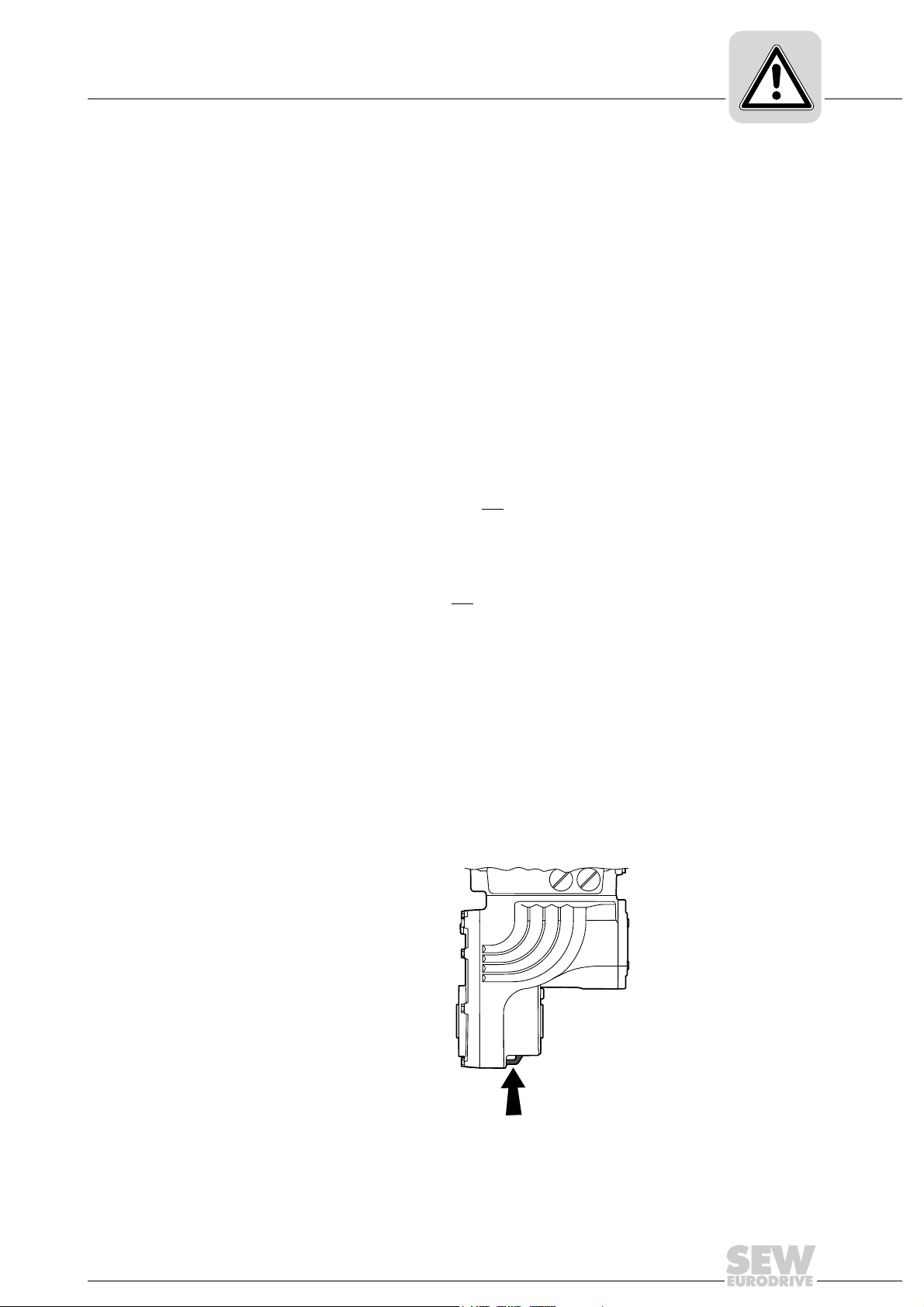

2.4 Transportation and storage

You must observe the notes in the documentation regarding transportation, storage and

proper handling. Use suitable, sufficiently rated handling equipment (e.g. rope guides)

if required. Do not attach any additional loads. Observe climatic conditions in accordance with the documentation.

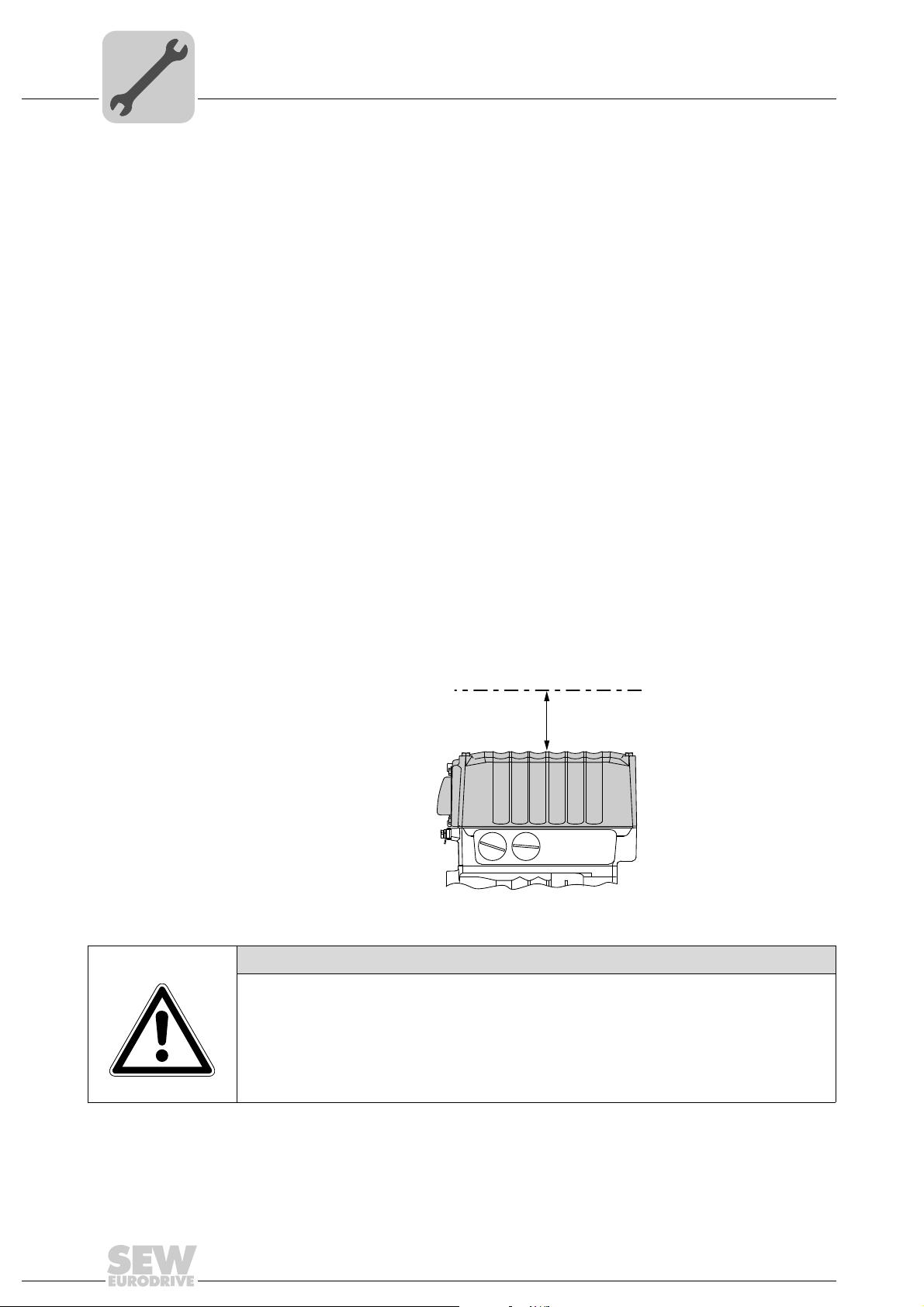

The following figure shows the eyebolt of MOVIGEAR

®

:

Operating Instructions – MOVIGEAR® DSC-B

2770620811

9

Page 10

2

2.5 Installation

Safety Notes

Installation

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

®

Protect the MOVIGEAR

The following applications are prohibited unless the unit is explicitly designed for such

use:

• Use in potentially explosive atmospheres.

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

drive units from improper strain.

• Use in non-stationary applications that are subject to mechanical vibration and shock

loads as stated in the documentation for MOVIGEAR

Important: MOVIGEAR

protrude into footways.

2.6 Electrical connection

Working on live parts of MOVIGEAR® drive units is not permitted.

The drive is operated as a generator due to the kinetic energy of the plant/machine.

Secure the output shaft against rotation before you open the wiring compartment.

Electrical installation is to be carried out in compliance with pertinent regulations (e.g.

cable cross sections, fusing, protective conductor connection). For any additional

information, refer to the applicable documentation.

You will find notes on EMC-compliant installation, such as shielding, grounding,

arrangement of filters and routing of lines, in the documentation of the MOVIGEAR

drive units. The manufacturer of the system or machine is responsible for maintaining

the limits established by EMC legislation.

Protective measures and protection devices must comply with the regulations in force

(e.g. EN 60204-1 or EN 61800-5-1).

®

drive units.

®

drive units and corresponding mount-on parts must not

®

2.7 Safe disconnection

10

MOVIGEAR® drive units meet all requirements for safe disconnection of power and

electronic connections in accordance with EN 61800-5-1. All connected circuits must

satisfy the requirements for safe disconnection as well.

Operating Instructions – MOVIGEAR® DSC-B

Page 11

2.8 Operation

Safety Notes

Operation

Systems with integrated MOVIGEAR® drive units must be equipped with additional

monitoring and protection devices according to the applicable safety guidelines, such as

the law governing technical equipment, accident prevention regulations, etc. Additional

protective measures may be necessary for applications with increased potential risk.

Changes to the MOVIGEAR

Do not touch live components and power connections immediately after separation of

the MOVIGEAR

still be charged. Wait at least 10 minutes after the supply voltage has been switched off.

®

drive units from the supply voltage because some capacitors might

®

drive units using the operating software are permitted.

2

The connection boxes must be closed and screwed on before the supply voltages are

connected to MOVIGEAR

The unit may still be live and connected to the supply, even if the operation LEDs and

other display elements are no longer illuminated.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. If, for safety reasons, this is not permitted for the driven machine,

disconnect the unit from the supply system before correcting the error.

Caution: Danger of burns: The surface temperatures of the MOVIGEAR

be more than 60 °C during operation.

®

.

®

drive units can

Operating Instructions – MOVIGEAR® DSC-B

11

Page 12

3

Unit Design

MOVIGEAR® drive unit

3 Unit Design

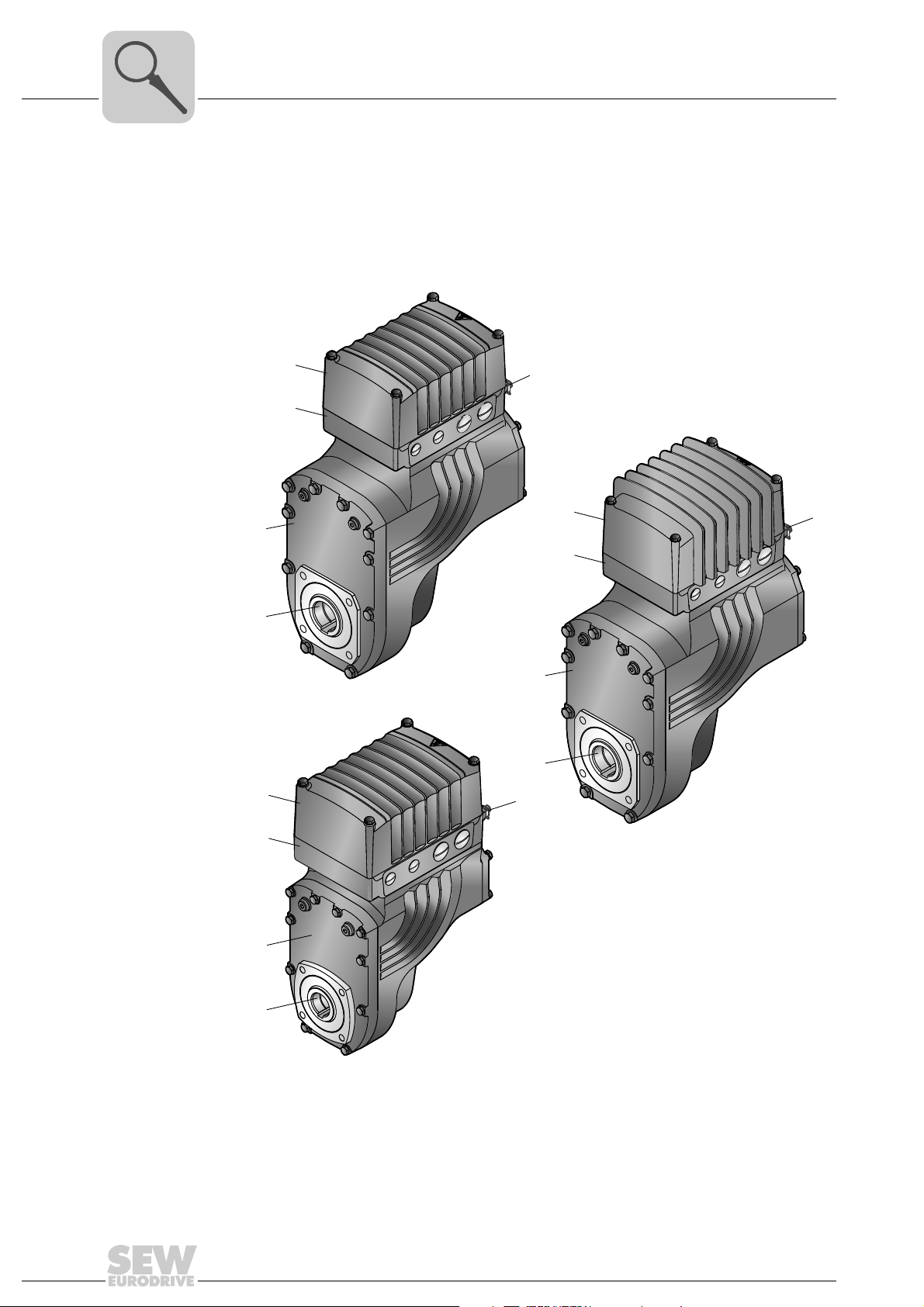

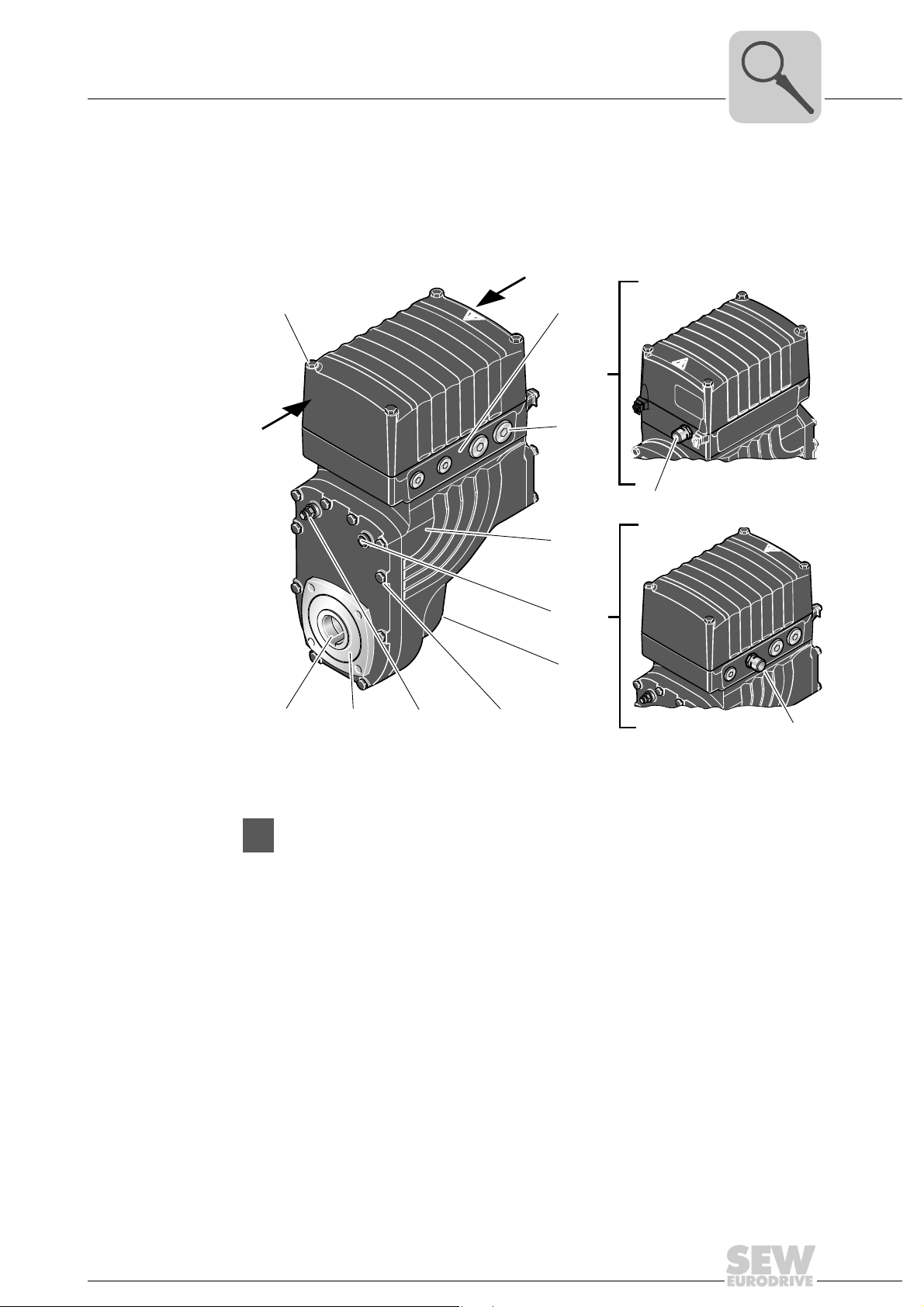

3.1 MOVIGEAR® drive unit

MOVIGEAR® drive units are made up of 3 core components: gear unit, motor and drive

electronics. These 3 core components are included in one cast aluminum housing (see

following figure).

MGF..4

[3]

[4]

[1]

[1]

[2]

MGF..2

[5]

[3]

[4]

[5]

MGF..4/ET

[1]

[2]

[5]

12

[2]

[3]

[4]

2363886987

[1] MOVIGEAR® electronics cover

[2] Connection ring for cable glands

[3] Gear unit cover

[4] Output shaft version (pictured here: hollow shaft with keyway)

[5] Grounding screws

Operating Instructions – MOVIGEAR® DSC-B

Page 13

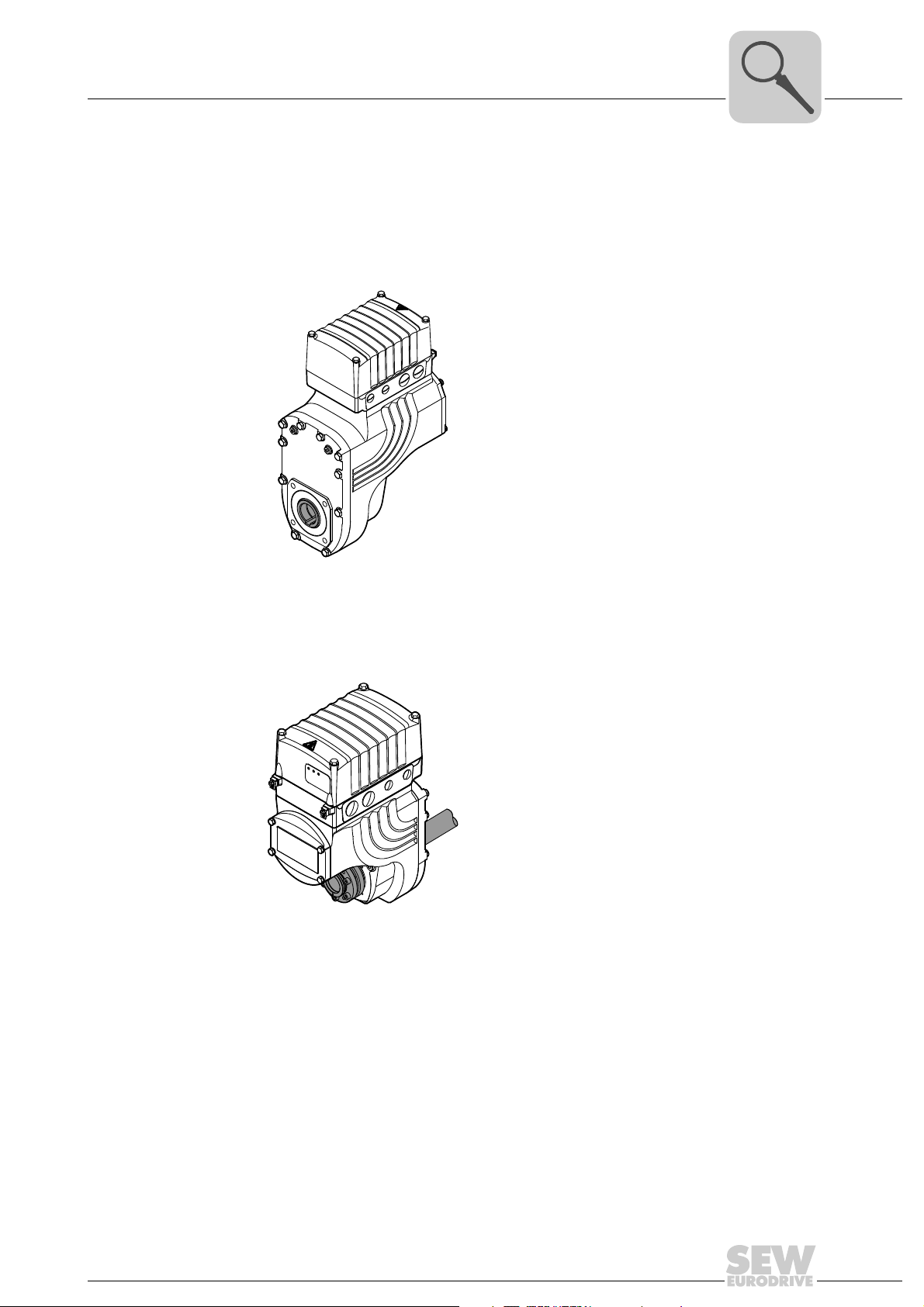

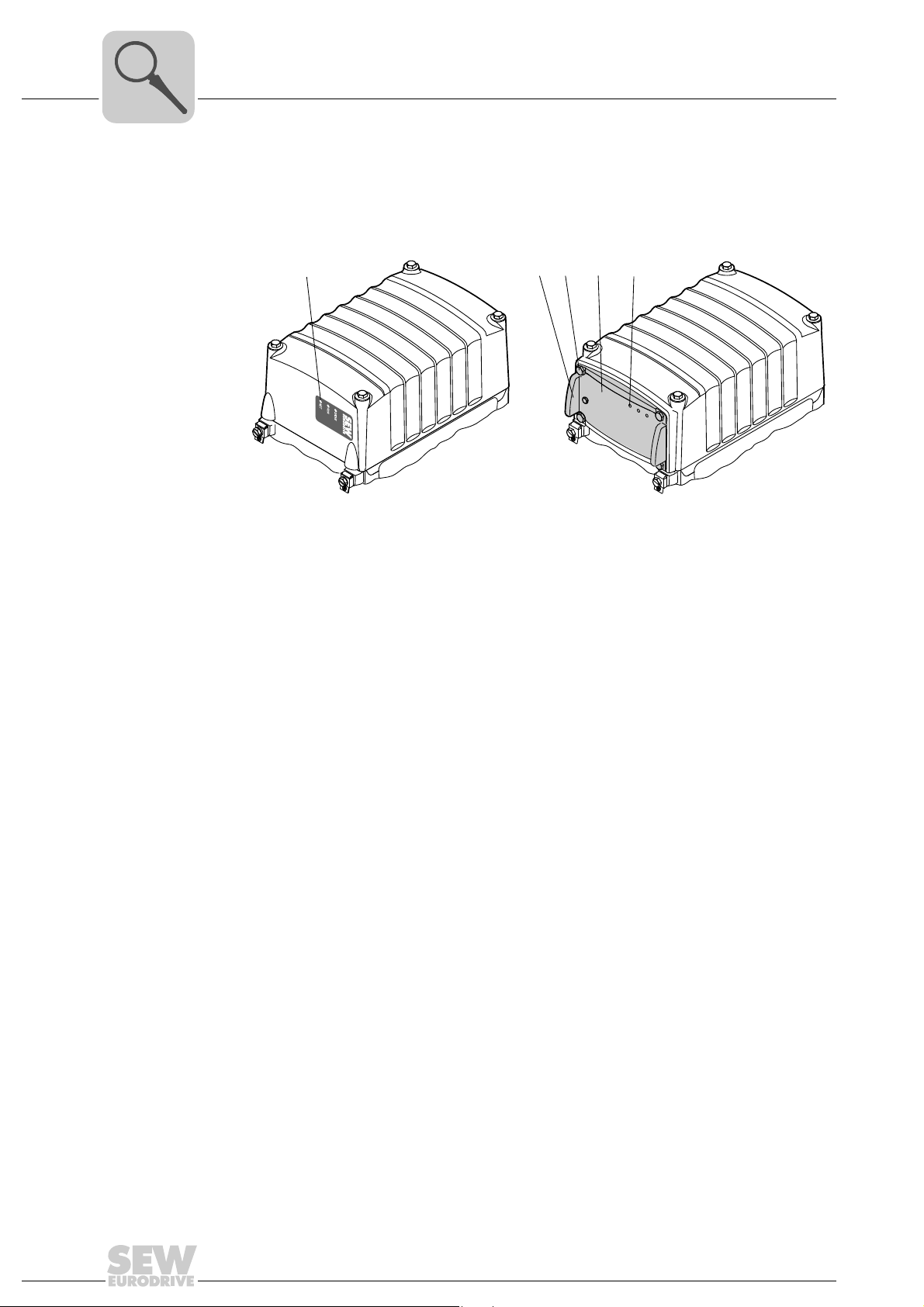

3.2 Shaft variants

MOVIGEAR® is available with the following shaft variants:

®

3.2.1 MOVIGEAR

with hollow shaft and keyway (MGFA..)

The following figure shows a MOVIGEAR

Unit Design

Shaft variants

®

unit with hollow shaft and keyway:

3

3.2.2 MOVIGEAR

2690820619

®

with TorqLOC® hollow-shaft mounting system (MGFT..)

The following figure shows a MOVIGEAR

system

2690822539

®

unit with TorqLOC® hollow shaft mounting

Operating Instructions – MOVIGEAR® DSC-B

13

Page 14

3

Unit Design

Housing mounting

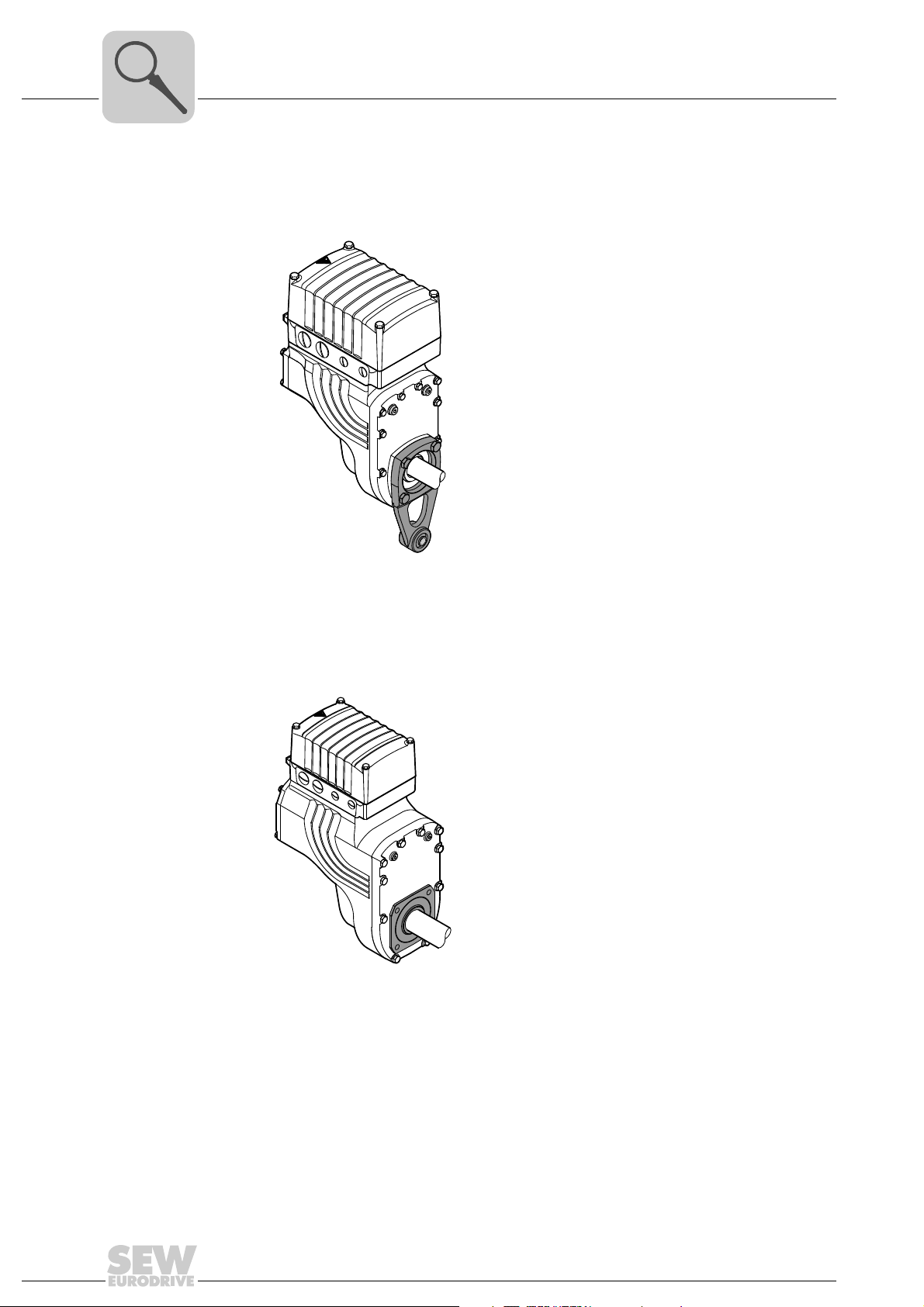

3.3 Housing mounting

3.3.1 Torque arm (MGF.T)

The following figure shows the torque arm for MGF.T:

3.3.2 Housing with threads (MGF.S)

The following figure shows the housing type with threads for mounting a torque arm.

This type does not include a centering shoulder, which means it is not suitable for direct

installation to the machine:

2690826379

2690824459

14

Operating Instructions – MOVIGEAR® DSC-B

Page 15

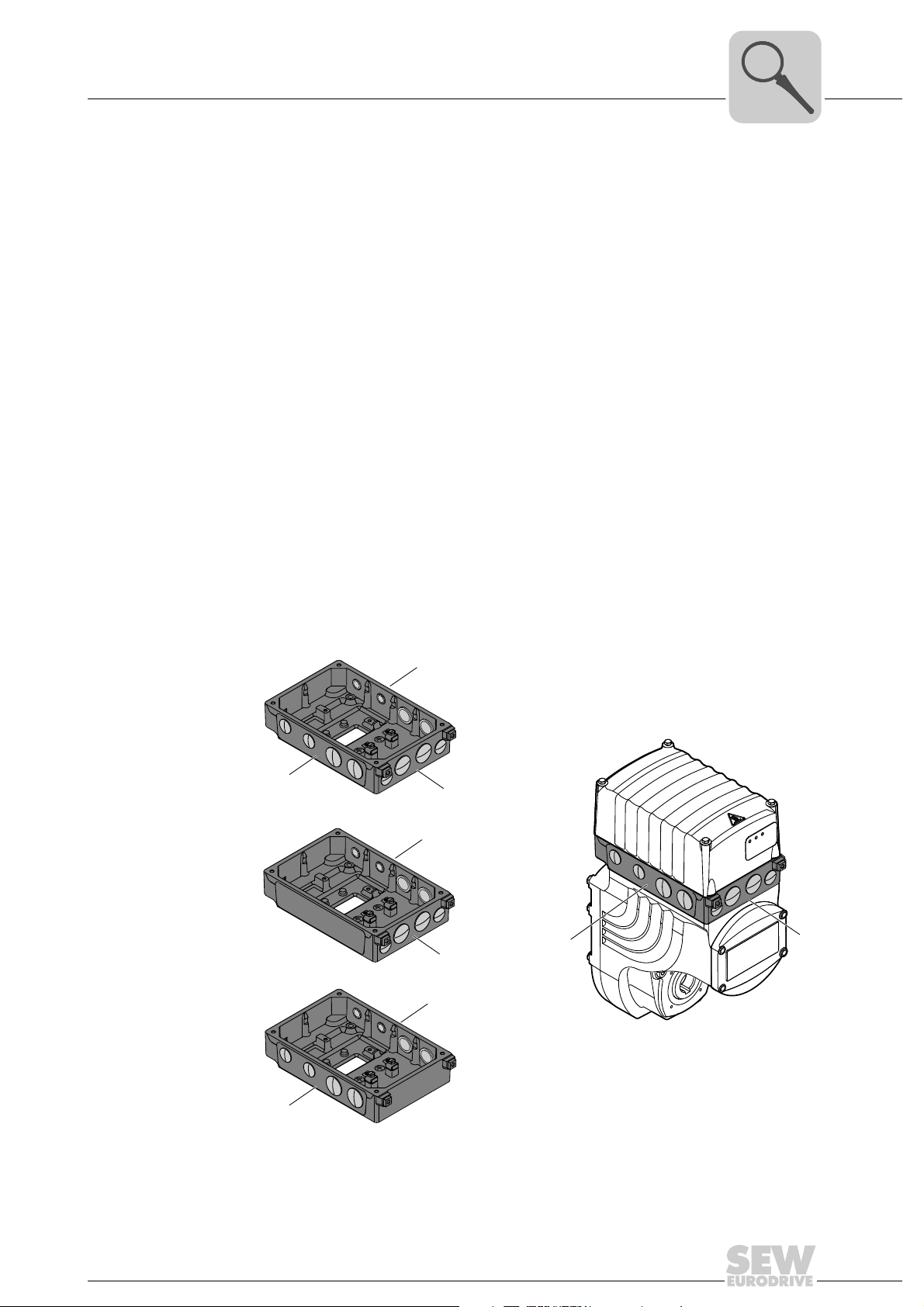

3.4 Position of the cable entry

The following cable entries are possible for MOVIGEAR®:

• Position X + 2

– X: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

– 2: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

• Position X + 2 + 3

– X: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

– 2: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

• Position X + 3

– X: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

• Position 2 + 3

– 2: 2 x M25 x 1.5 + 1 x M16 x 1.5 + 1 x M16 x 1.5

Unit Design

Position of the cable entry

1)

1)

1)

1)

1)

1)

3

3.4.1 Overview

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

The following figure shows the possible cable entries:

2

X

3

2

X

3

2

3

X

1) 1 x M16 x 1.5 reserved for pressure compensation fitting in connection with the package for wet areas

Operating Instructions – MOVIGEAR® DSC-B

2690896779

15

Page 16

3

76646 Bruchsal/Germany

Nm

°C

n

R

U

N

f

N

Nm

n

A

A

M

A

M

a pk

i

Made in Germany

IM

kg

cos

IP

r/min

Hz

V

13356887

MGFAT2-DSM-DSC-B/DSP

01.1233697403.0001.08

5,4...53,7

37,24

M1,M2,M5,M6 50...60

380...500

65

0,99

1,52

1/10

16.000

CLP HC 220 Synth.Öl/0,55l

-25 ... +40

[1]

3~ EN61800

TENV

M.L.

143

220

Unit Design

Sample nameplate and type designation of drive unit

3.5 Sample nameplate and type designation of drive unit

3.5.1 Nameplate

The following figure gives an example of a MOVIGEAR

of the type designation, refer to chapter "Type designation".

[1] Unique serial number

®

nameplate. For the structure

2368165003

3.5.2 Type designation

16

Bar code:

The bar code on the nameplate (code 39) according to ISO/IEC 16388 represents the

unique serial number (with period as separator).

The following table shows the type designation of MOVIGEAR

®

:

MGFAS2–DSM–DSC–B / DSP

MOVIGEAR® option

DSP = Electrodynamic

deceleration function DynaStop

ECR = Extended control range

ET = Extended torque

IV = Plug connector

MOVIGEAR

MOVIGEAR

DSC = D

®

version

®

installation technology

irect SBus Communication

Motor type

Size

2 = Torque class 200 Nm

4 = Torque class 400 Nm

Housing mounting

T = Drive with torque arm

S = Housing with threads for

mounting a torque arm

Shaft variant

A = Shaft-mounted gear unit

(hollow shaft with keyway)

T = TorqLOC

®

hollow shaft mounting system

Gear unit type

F = Parallel-shaft helical gear unit

Product series

MG = MOVIGEAR

Operating Instructions – MOVIGEAR® DSC-B

®

®

Page 17

MOVIGEAR® electronics

OFF

ON

S1

OFF

ON

S1

[1]

[2]

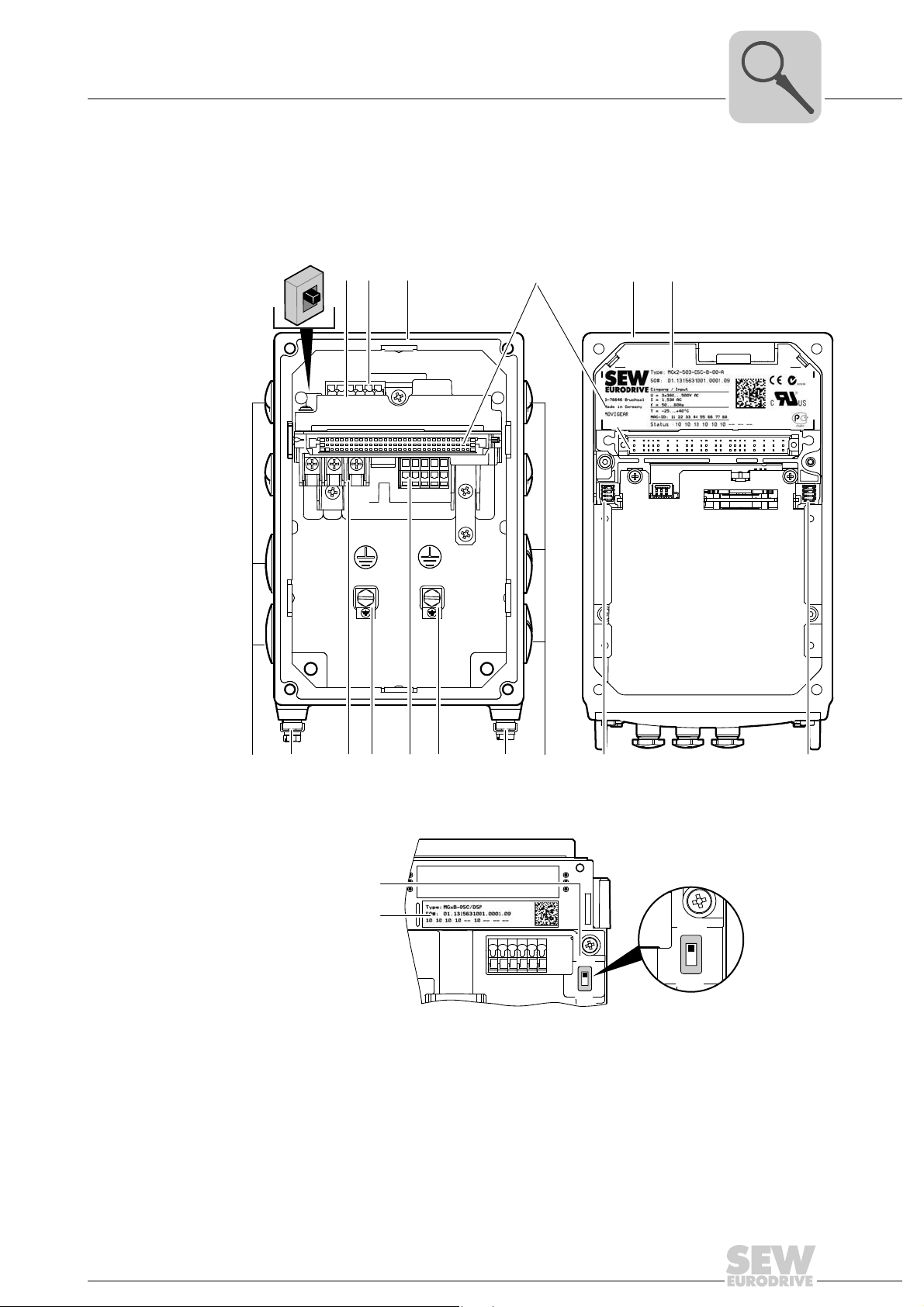

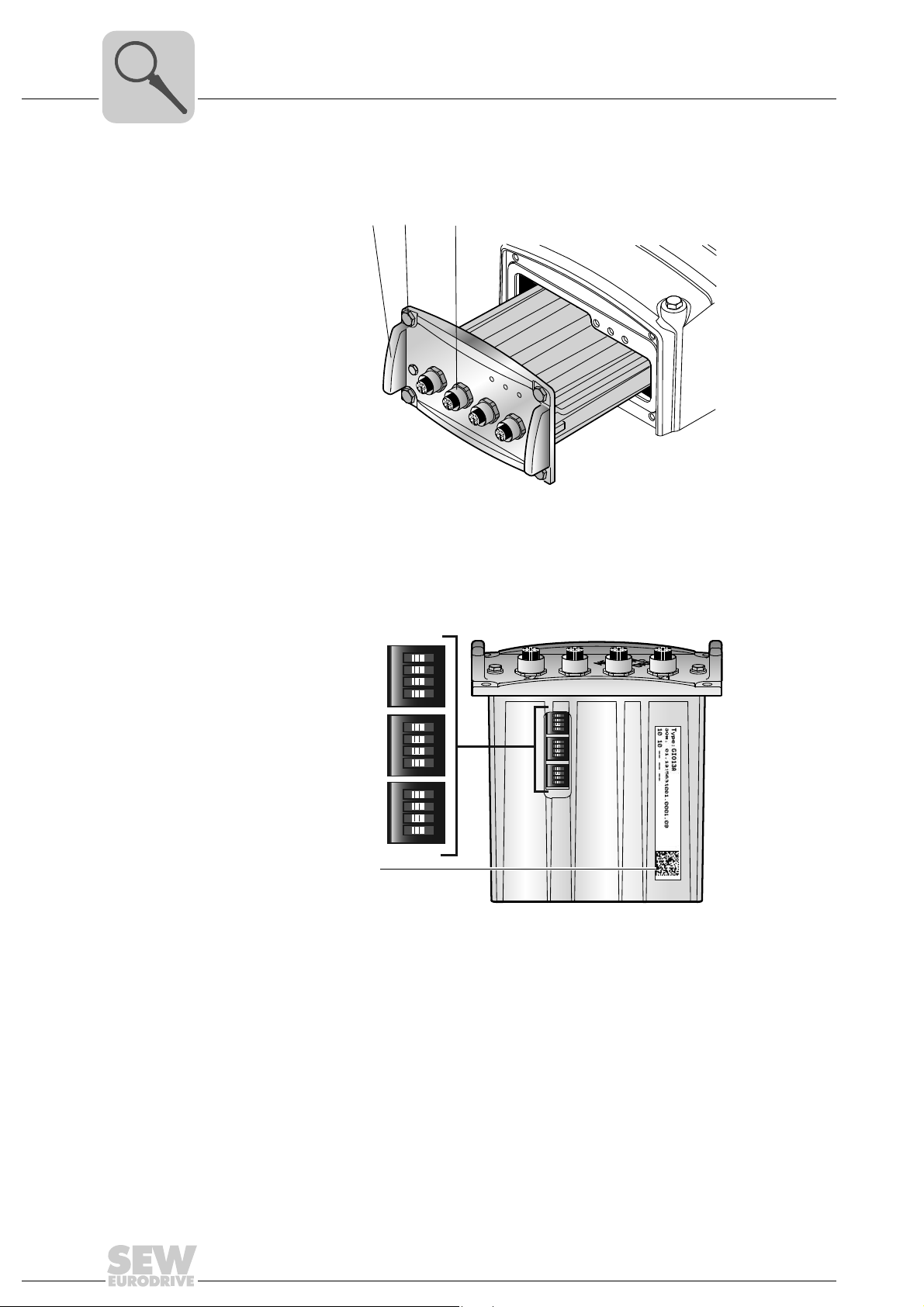

3.6 MOVIGEAR® electronics

3.6.1 MOVIGEAR® electronics cover (inside) and connection box

The following figure shows the connection box and the bottom side of the MOVIGEAR

electronics cover:

Unit Design

3

®

[1]

[2]

[3]

[4]

[5] [6] [7]

[9] [9][9]

[8]

[1] DIP switch S1 for bus termination, see following detailed view

[2] Nameplate of drive unit, see following detailed view

[3] SBus connection

[4] Connection ring

[5] Plug connector connection unit for MOVIGEAR

[6] MOVIGEAR

[7] Electronics cover nameplate

[8] Cable glands

[9] Screw for PE connection

[10] Supply system connection L1, L2, L3

[11] Electronics terminal strips

[12] DIP switches S2/1 – S2/4

[13] DIP switches S1/1 – S1/4

[9]

[10]

®

electronics cover

[11]

[8]

®

electronics cover

[12]

[13]

2389455499

2490703499

Operating Instructions – MOVIGEAR® DSC-B

17

Page 18

3

Unit Design

MOVIGEAR® electronics

3.6.2 MOVIGEAR® electronics cover (outside)

The following figure shows possible types of the MOVIGEAR

MOVIGEAR® electronics cover

without application slot

[1]

[1]

MOVIGEAR

with application slot

and application cover

[2]

[3]

®

electronics cover:

®

electronics cover

[4]

NET

RUN

DRIVE

2367948939

[1] LED displays [1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] Application cover

[4] LED displays

18

Operating Instructions – MOVIGEAR® DSC-B

Page 19

3.7 Application options

DRIVE

RUN

NET

[3]

[1]

[2]

[1]

3.7.1 GIO12A application option

The following figure shows the GIO12A application option:

Unit Design

Application options

3

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital I/Os

The following figure shows the position of the GIO12A nameplate:

[1] Nameplate

2368100235

2701486347

Operating Instructions – MOVIGEAR® DSC-B

19

Page 20

3

DRIVE

RUN

NET

[3]

[1]

[2]

Unit Design

Application options

3.7.2 GIO13A application option

The following figure shows the GIO13A application option:

2585028875

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital/analog I/Os

The following figure shows the DIP switches S1 to S3 of the GIO13A application option:

ON

1234

S1

ON

1234

ON

1234

ON

1234

S2

ON

1234

ON

1234

S3

[1]

2736188299

[1] Nameplate

20

Operating Instructions – MOVIGEAR® DSC-B

Page 21

Unit Design

[1]

[3]

[2]

Sample nameplate and type designation for electronics

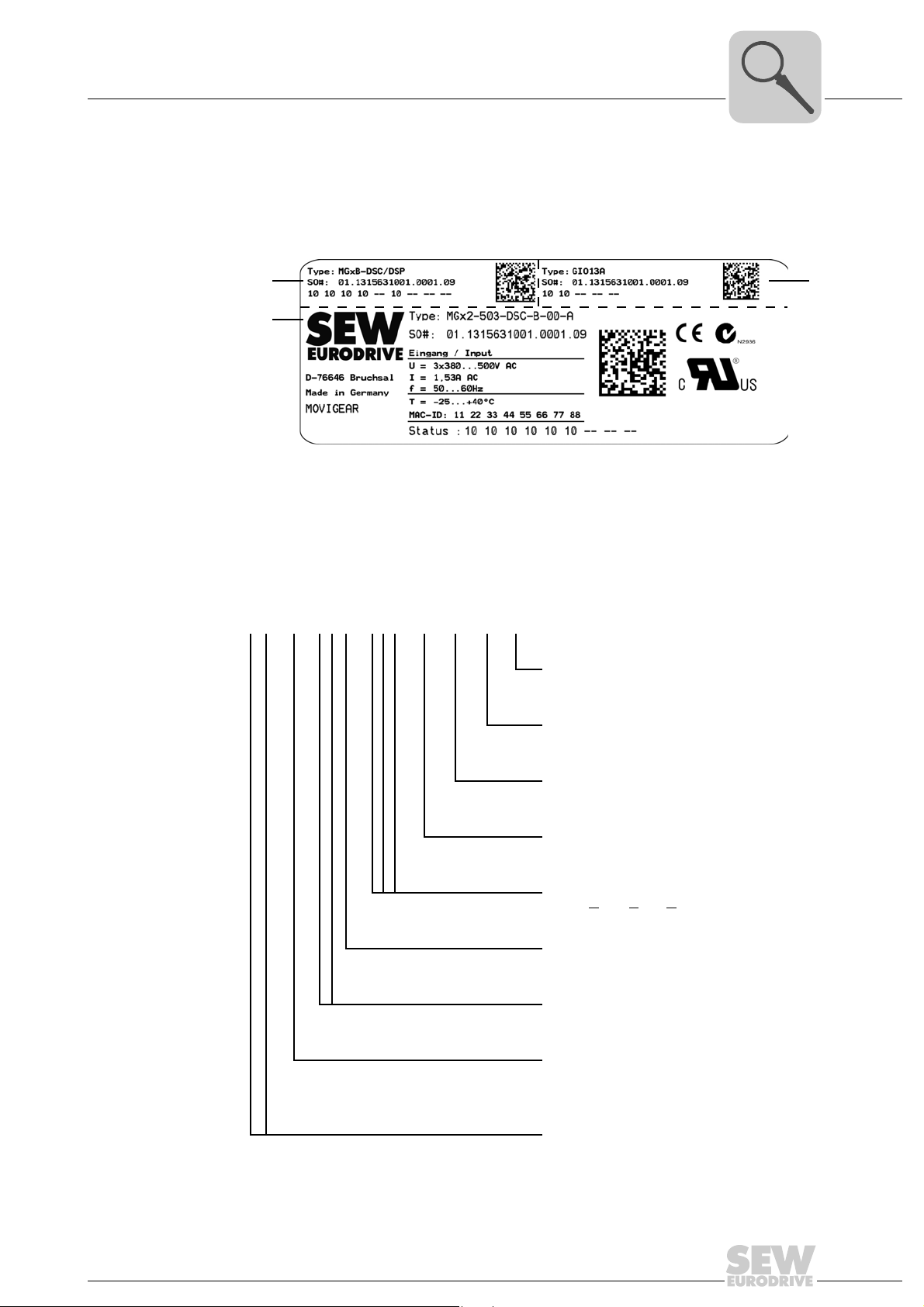

3.8 Sample nameplate and type designation for electronics

3.8.1 Nameplate

The following figure gives an example of a MOVIGEAR

of the type designation, refer to chapter "Type designation".

[1] Nameplate of connection unit

[2] Nameplate of application option

[3] Electronics cover nameplate

®

nameplate. For the structure

2585099787

3

3.8.2 Type designation of electronics cover

The following table shows the type designation of the electronics cover:

M G x 4 – 5 0 3 – DSC – B – 00 – A / ET

Electronics cover option

ET = Extended torque

Electronics cover variant

A = With application slot

Variant

00 = Standard

MOVIGEAR

Version

MOVIGEAR

DSC = D

Connection type

3 = 3-phase

Supply voltage

50 = AC 380 – 500 V

®

®

installation technology

irect SBus Communication

Operating Instructions – MOVIGEAR® DSC-B

Size

2 = Torque class 200 Nm

4 = Torque class 400 Nm

Product series

MG = MOVIGEAR

®

21

Page 22

3

Unit Design

Sample nameplate and type designation for electronics

3.8.3 Type designation of connection unit

The following table shows the type designation of the connection unit:

M G x B – DSC / DSP

Connection unit option

DSP = Electrodynamic

deceleration function DynaStop

®

MOVIGEAR

DSC = D

installation technology

irect SBus Communication

®

3.8.4 Type designation of application options

The following table shows the unit designation for the available application options:

G IO 1 2 A

MOVIGEAR

Version

Product series

MG = MOVIGEAR

Version

Variant

2 = 4 digital inputs + 2 digital outputs

3 = 4 digital inputs

(2 inputs can be used as primary frequency input)

+ 1 digital output

+ 1 analog input

+ 1 analog output

Version

Functionality

IO = Digital inputs/outputs

®

®

22

Product series

G = Option for MOVIGEAR

Operating Instructions – MOVIGEAR® DSC-B

®

Page 23

MOVIGEAR® with optional package for wet areas

[12]

[4]

[5]

[6]

[7]

[8]

B

B

A

A

[10] [9]

[11]

[2]

[1]

[3]

3.9 MOVIGEAR® with optional package for wet areas

3.9.1 Properties

The following figure shows the additional features of MOVIGEAR

optional package for wet areas:

Unit Design

®

drive units with

3

2368838155

3.9.2 Legend

All illustrations regarding MOVIGEAR® drive units with optional package for wet areas are

displayed with a shading (= HP200 surface protection) in this publication

[1] Mounting screws for electronics cover made of stainless steel

[2] Connection ring only possible with cable outlet "at the bottom" or "on the side":

[3] Screw plugs made of stainless steel installed at the factory

[4] HP200 surface protection, see chapter "Technical data and dimension sheets"

[5] Oil screw plug made of stainless steel (hexagon)

[6] Additional cover opposite the output side

[7] Mounting screws for gear unit housing made of stainless steel

[8] Breather valve mounted and activated according to mounting position, see chapter

[9] FKM oil seal (Viton)

[10] Output shaft made of stainless steel (can be deselected)

[11] Pre-installed pressure compensation fitting (M16) with mounting positions M5, M6

[12] Pre-installed pressure compensation fitting (M16) with mounting position M1, M2, M4, M4

– In connection with mounting position M1 and M2: 2 + 3, 2 + X, X + 3, 2 + X + 3

– In connection with mounting position M4: 2 + X

– In connection with mounting position M5: X + 3

– In connection with mounting position M6: 2 + 3

"Technical data and dimension sheets"

Optional plug connectors (see chapter "Electrical installation") are available in connection

with the package for wet areas.

Operating Instructions – MOVIGEAR® DSC-B

23

Page 24

4

Mechanical Installation

Installation notes

4 Mechanical Installation

4.1 Installation notes

INFORMATION

Comply with the safety notes during installation.

Improper installation/disassembly of MOVIGEAR® and mount-on components.

Risk of injury.

• Note the information about installation and disassembly in this chapter.

• Before releasing shaft connections, make sure that there are no active torsional

moments present (tensions within the system).

CAUTION

DANGER

Risk of crushing if the drive starts up unintentionally and danger of electrical voltage.

Dangerous voltages may still be present for up to 10 minutes after disconnection from

the power supply.

Severe or fatal injuries.

• Completely disconnect the MOVIGEAR

provide for suitable external measures to secure against unintentional

reconnection!

• Secure the output shaft against rotation.

• Then wait for at least 10 minutes

4.2 Required tools and resources

• Set of wrenches

• Torque wrench

• Mounting device

• Compensation elements (shims and spacing rings), if necessary

• Mounting materials for output components

• Lubricant (e.g. NOCO

®

fluid)

®

drive unit from the power supply and

• Standard parts are not included in the delivery

4.2.1 Installation tolerances for shaft ends

Diameter tolerance in accordance with DIN 748:

• ISO H7 for hollow shafts

24

Operating Instructions – MOVIGEAR® DSC-B

Page 25

4.3 Installation prerequisites

Check that the following conditions have been met:

• The entries on the nameplate of the MOVIGEAR

system.

• The drive is undamaged (no damage caused by transportation or storage)

• Ambient temperature according to the operating instructions, nameplate and lubricant table in chapter "Technical data and dimension sheets / Lubricants".

• The drive must not be assembled in the following ambient conditions:

– Potentially-explosive atmosphere

– Oils

–Acids

– Gases

– Vapors

– Radiation

Mechanical Installation

Installation prerequisites

®

unit match the voltage supply

4

• For special designs: The drive is designed in accordance with the actual ambient

conditions.

• You must clean the output shafts and flange surfaces thoroughly to ensure they are

free of anti-corrosion agents, contamination or the like. Use conventional solvents.

Do not expose the sealing lips of the oil seals to the solvent – damage to the material.

• When the drive is installed in abrasive ambient conditions, protect the output end oil

seals against wear.

Operating Instructions – MOVIGEAR® DSC-B

25

Page 26

4

100

Mechanical Installation

Installing MOVIGEAR

4.4 Installing MOVIGEAR®

• Clean the output shafts thoroughly to ensure they are free of anti-corrosion agents

• Carefully align the MOVIGEAR

• Do not butt or hammer the shaft end.

• Ensure that cooling air supply is unobstructed and that air discharged by other units

• Use suitable cable glands for the supply leads (use reducing adapters if necessary).

• Seal the cable entry well.

• Clean the sealing faces of the MOVIGEAR

• Restore the corrosion protection if necessary.

• Check the validity of the degree of protection using the information in the operating

®

(use a commercially available solvent). Do not expose the bearings and sealing rings

to the solvent – damage to the material!

®

unit and the driven machine to avoid placing any

unacceptable strain on the motor shafts (observe permissible overhung loads).

does not influence cooling.

®

cover well before reassembling the unit.

instructions and the data on the nameplate.

• When changing the mounting position: Adjust position of breather valve.

Observe chapter "Technical data and dimension sheets / Mounting positions".

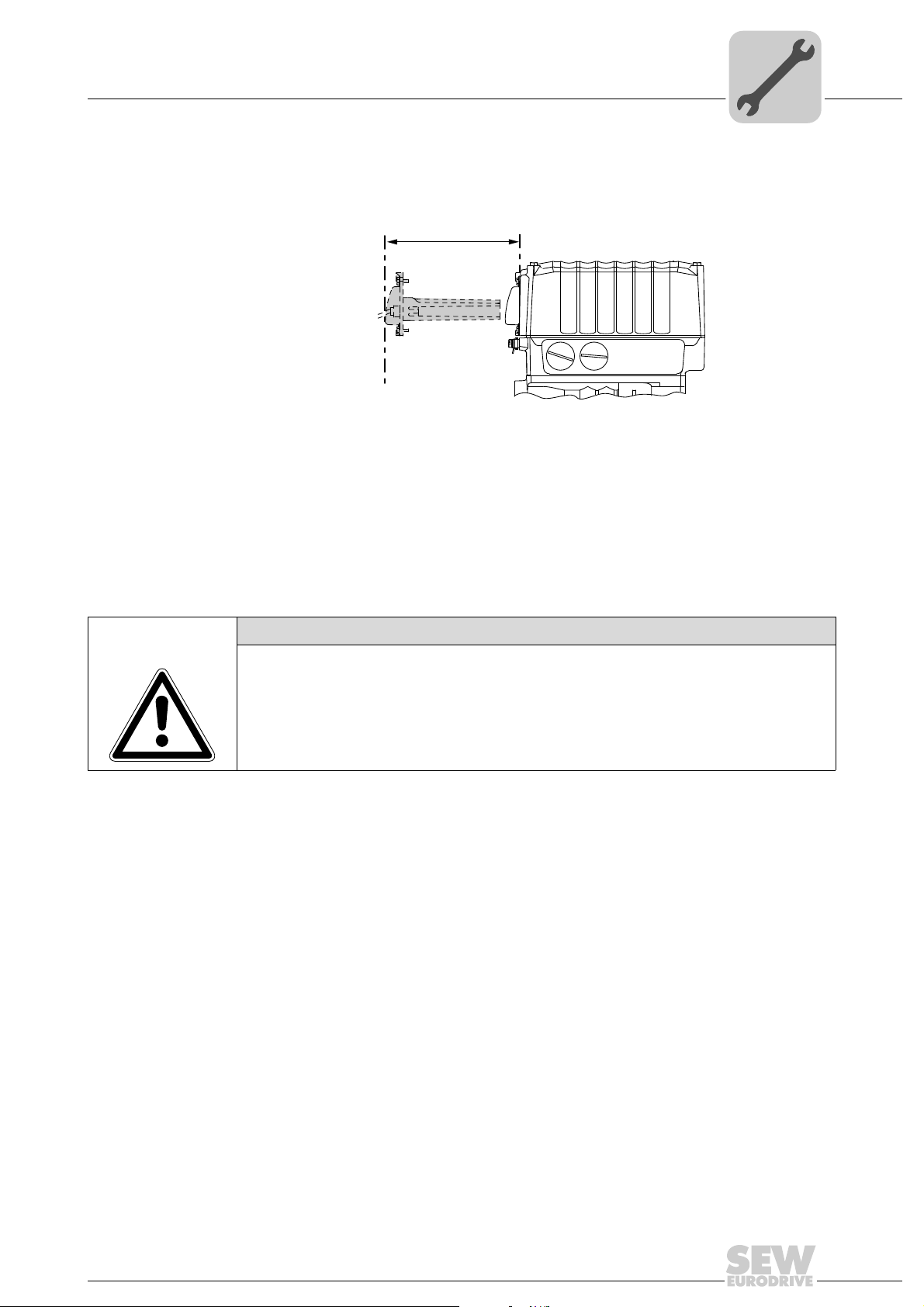

4.4.1 Minimum installation clearance of electronics cover

Note the minimum installation clearance (see following figure) required to remove the

MOVIGEAR

"Technical data and dimension sheets".

®

electronics cover. For detailed dimension drawings, see chapter

NOTICE

The degree of protection specified in the technical data only applies if the MOVIGEAR

electronics cover is properly installed.

When the MOVIGEAR

be damaged by humidity, dust or foreign particles.

• Protect the MOVIGEAR

box.

®

electronics cover is removed from the connection box, it might

®

electronics cover when it is removed from the connection

2350097419

®

26

Operating Instructions – MOVIGEAR® DSC-B

Page 27

Mechanical Installation

200

Installing MOVIGEAR

4.4.2 Minimum installation clearance of application options

Note the minimum installation clearance (see following figure) required to install and

remove the application options.

4.4.3 Installation in damp locations or in the open

Drives are supplied in corrosion-resistant versions for use in damp areas or in the open.

Repair any damage to the paint work if necessary.

For variants with HP200 surface treatment, observe the notes in chapter "MOVIGEAR

with optional package for wet areas".

®

2350130571

4

®

4.4.4 Painting MOVIGEAR

NOTICE

Breather valves and oil seals may be damaged during painting or re-painting.

Potential damage to property.

• The surface of the drive must be clean and free from grease.

• Thoroughly cover the breather valves and the sealing lip of the oil seals with strips

prior to the painting process.

• Remove the strips after the process.

®

Operating Instructions – MOVIGEAR® DSC-B

27

Page 28

4

Mechanical Installation

Installing MOVIGEAR

4.4.5 MOVIGEAR® gear unit venting

®

MOVIGEAR

with

installed breather

valve

SEW-EURODRIVE delivers all MOVIGEAR® drive units ordered for a specific mounting

position with a breather valve that is activated and installed according to the mounting

position.

MOVIGEAR

with the activated breather valve installed corresponding to the respective mounting

position.

®

®

drive units with optional "package for wet areas" are generally delivered

®

MOVIGEAR

with

separately

included breather

valve

Activating the

breather valve

MOVIGEAR

®

drive units ordered for a universal mounting position are delivered by

SEW-EURODRIVE with a separately included breather valve.

In this case, the breather valve is delivered in the hollow shaft of the drive unit. Before

startup, you must replace the highest oil screw plug with the provided breather valve.

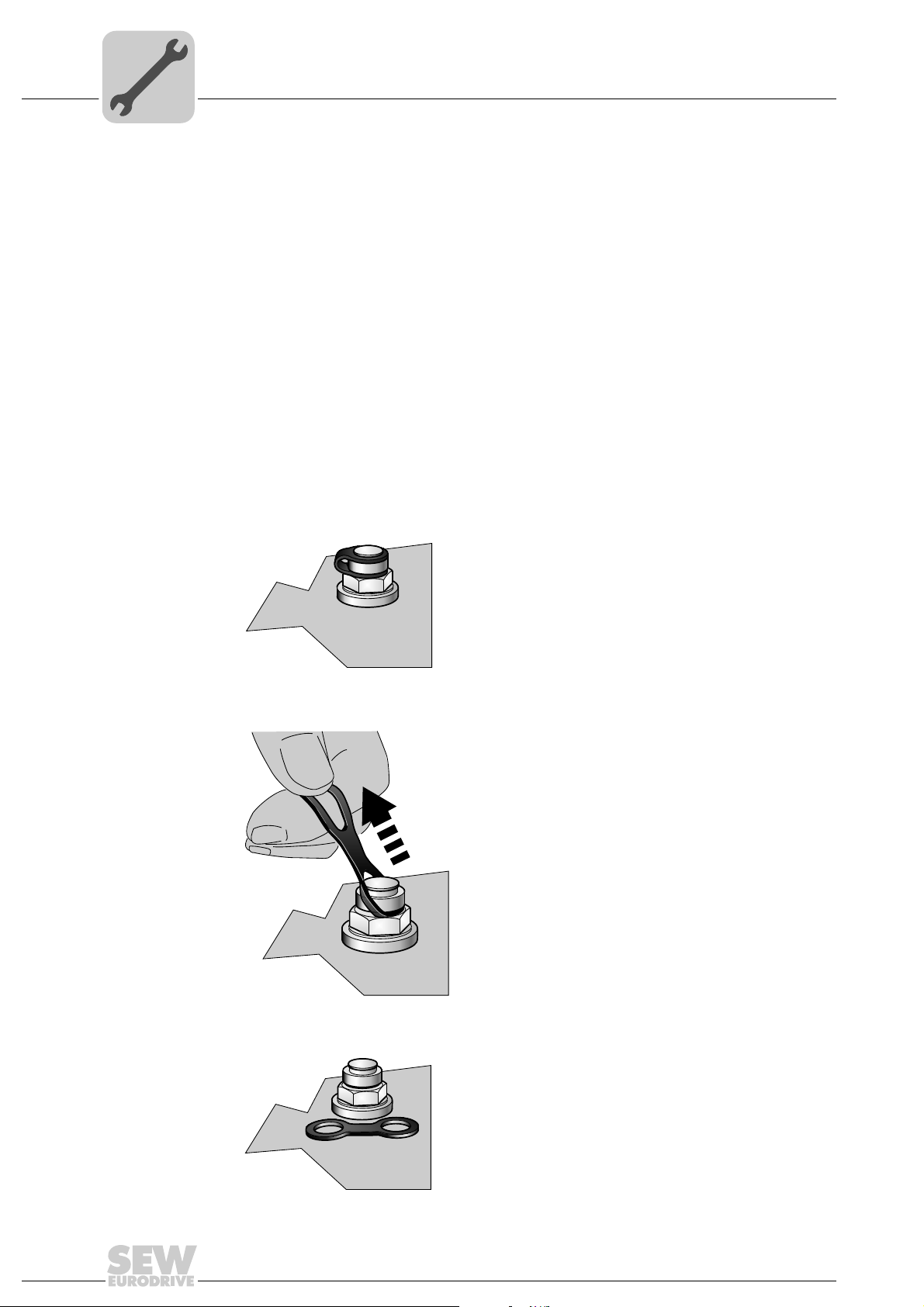

After installing the breather valve, you must activate it as follows. For designs with the

breather valve screwed in: Check whether the breather valve is activated. If not, you

have to remove the transport fixture of the breather valve prior before you start up the

drive unit!

1. Breather valve with transport fixture

2350149003

2. Remove transport fixture

28

2350216203

3. Activated breather valve

2350269835

Operating Instructions – MOVIGEAR® DSC-B

Page 29

4.5 Application options

DRIVE

RUN

NET

WARNING

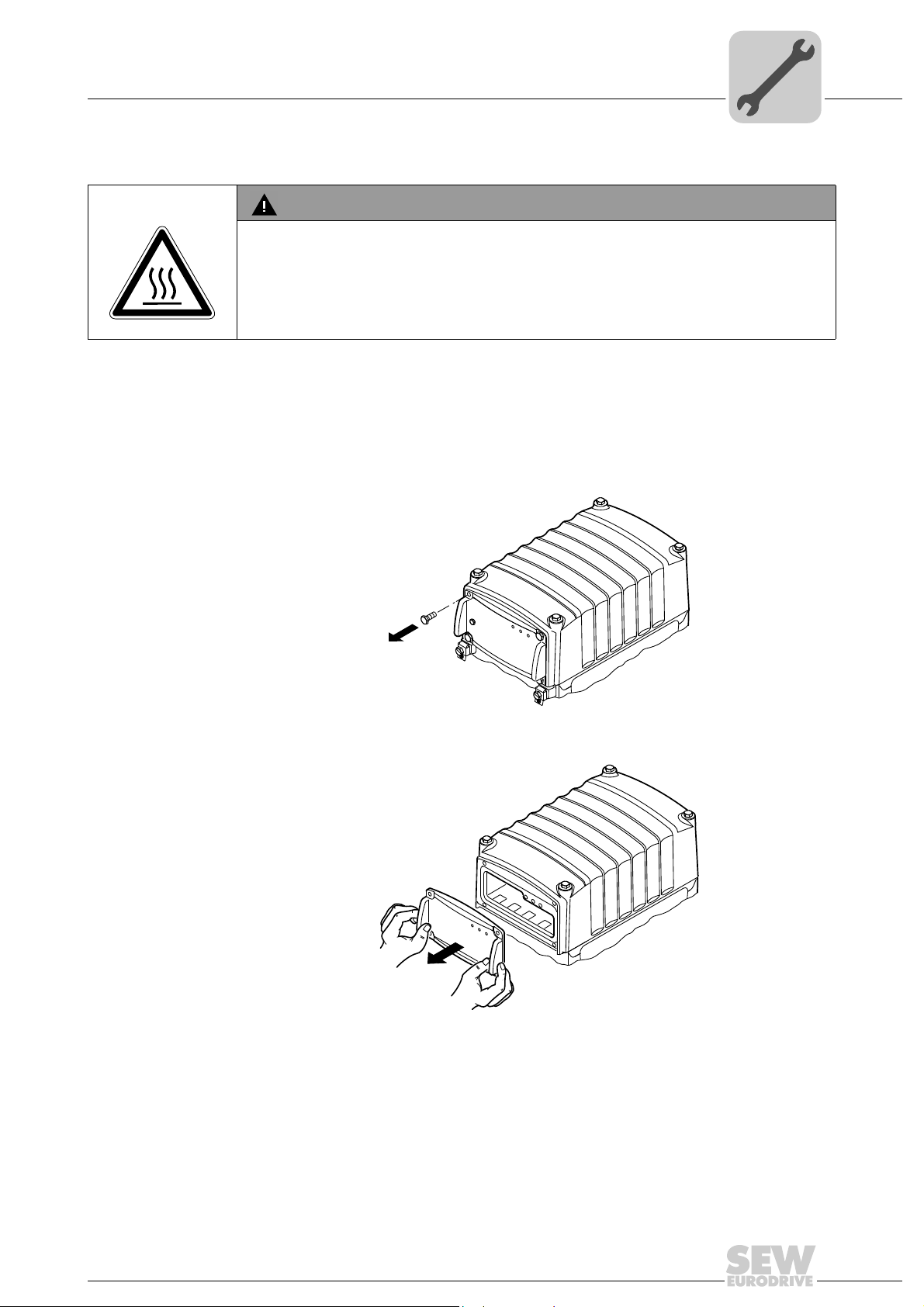

The surface temperatures of the MOVIGEAR® and the application options can be very

high during operation.

Danger of burns.

• Do not touch the MOVIGEAR

down sufficiently.

4.5.1 Removing the application cover

MOVIGEAR

application cover as standard.

You have to remove the application cover in order to install an application option:

1. Loosen the 4 retaining screws.

®

drives with application slot in the electronics cover are delivered with an

Mechanical Installation

Application options

®

drive and application options until they have cooled

4

4 x

2. Remove the application cover.

NET

RUN

DRIVE

2350325003

2350345355

Operating Instructions – MOVIGEAR® DSC-B

29

Page 30

4

Mechanical Installation

Application options

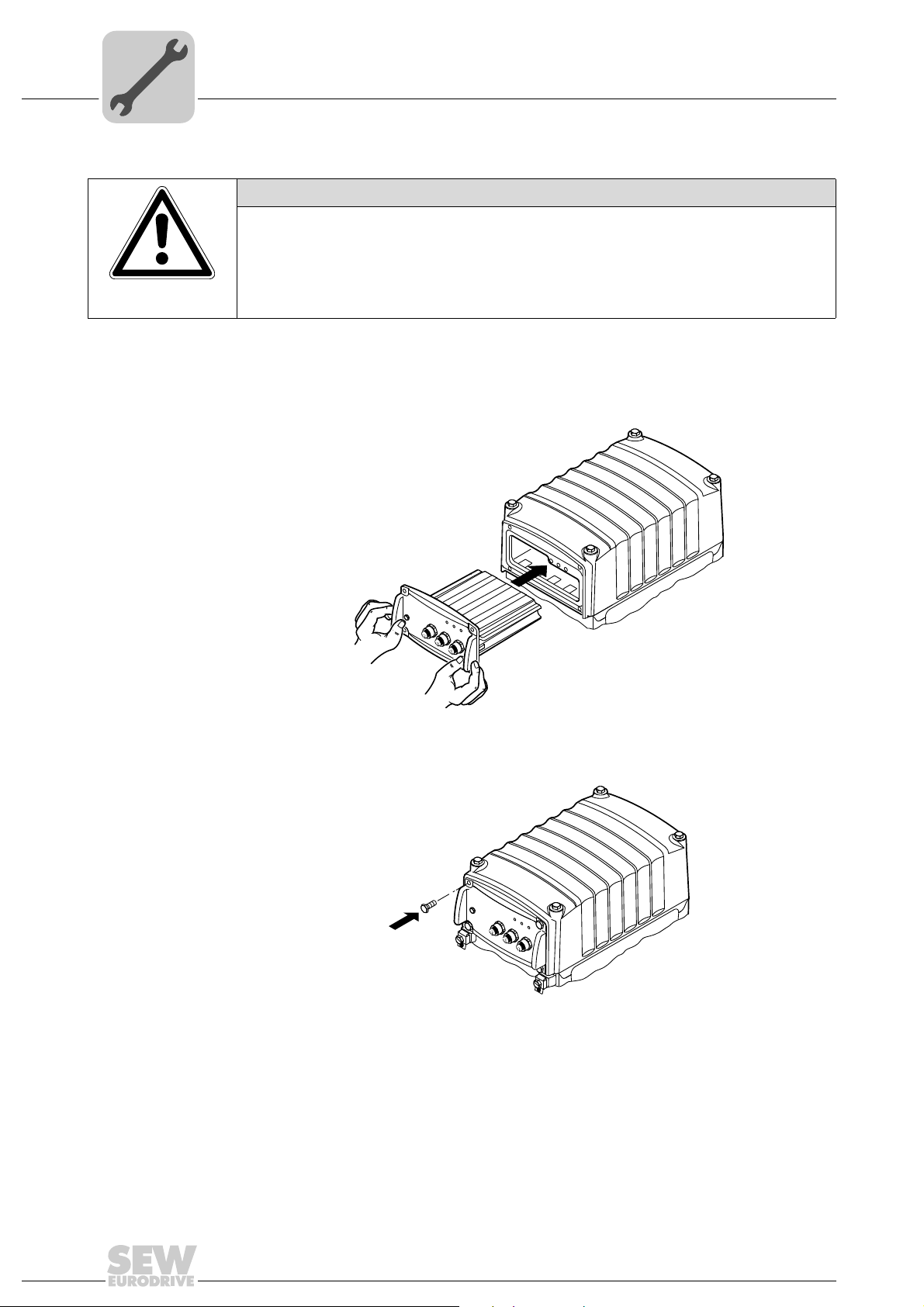

4.5.2 Installing application options

NOTICE

The degree of protection specified in the technical data only applies if the GIO13A

application option is properly installed.

In a disassembled state, the option can be damaged by moisture, dust, or foreign

objects entering through the openings for the DIP switches.

• Protect the GIO13A application option in a disassembled state.

1. You have to remove the application cover or, depending on the design, the paint

2. Insert the option into the application slot.

protector in order to install an application option:

NET

NET

RUN

DRIVE

2350364555

3. Secure the option with the 4 retaining screws. The permitted tightening torque for the

retaining screws is 1.2 - 1.4 Nm.

4 x

NET

RUN

DRIVE

2350383755

30

Operating Instructions – MOVIGEAR® DSC-B

Page 31

Shaft-mounted gear unit with keyway

N

O

C

O

F

L

U

I

NO

C

O

F

L

U

I

4.6 Shaft-mounted gear unit with keyway

INFORMATION

Observe the design notes in chapter "Technical data and dimension sheets" for the

customer shaft design.

4.6.1 Assembly instructions

1. Apply NOCO

®

fluid

Mechanical Installation

4

2. Distribute NOCO

®

fluid carefully

2348641291

2348643211

Operating Instructions – MOVIGEAR® DSC-B

31

Page 32

4

[1]

[2]

[3]

[4]

A

[6]

[1]

[2]

[3]

[4]

B

[6]

Mechanical Installation

Shaft-mounted gear unit with keyway

3. Insert the shaft and secure it axially (installation is made easier by using a mounting

device).

3A: Installation with standard scope of delivery

2348639371

[1] Short retaining bolt (standard delivery scope)

[2] Lock washer

[3] Washer

[4] Retaining ring

[6] Customer shaft

3B: Installation with the SEW-EURODRIVE assembly/disassembly kit. Observe

chapter "Technical data and dimension sheets/ Design notes for gear units

with hollow shaft and key".

Customer shaft with contact shoulder

2348637451

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[6] Customer shaft with contact shoulder

32

Operating Instructions – MOVIGEAR® DSC-B

Page 33

Mechanical Installation

Shaft-mounted gear unit with keyway

3C: Installation with the SEW-EURODRIVE assembly/disassembly kit: Observe

chapter "Technical data and dimension sheets/ Design notes for gear units

with hollow shaft and key".

Customer shaft without contact shoulder

C

[1]

[2]

[3]

[4]

[5]

[6]

2348213131

4

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Spacer tube

[6] Customer shaft without contact shoulder

4. Tighten the retaining bolt to the appropriate torque (see table).

2348211211

Drive Screw Tightening torque

[Nm]

MGFA.2 M10 20

MGFA.4 M16 40

INFORMATION

To avoid contact corrosion, SEW-EURODRIVE recommends that the customer shaft

should additionally be lathed down between the 2 contact surfaces.

Operating Instructions – MOVIGEAR® DSC-B

33

Page 34

4

[1]

[2]

[3]

[4]

[5]

[6]

4.6.2 Disassembly notes

Mechanical Installation

Shaft-mounted gear unit with keyway

The following description only applies when the drive is disassembled using the SEWEURODRIVE assembly/disassembly kit (see previous description, points 3B or 3C).

INFORMATION

For information on the SEW-EURODRIVE assembly/disassembly kit, see chapter

"Technical data and dimension sheets / Design notes".

1. Loosen the retaining screw [1].

2. Remove parts [2] to [4] and, if applicable, the distance piece [5].

2348647051

[1] Retaining screw

[2] Lock washer

[3] Washer

[4] Retaining ring

[5] Spacer tube

[6] Customer shaft

3. Insert the forcing disk [8] and the fixed nut [7] from the SEW-EURODRIVE installation/removal kit between the customer shaft [6] and the retaining ring [4].

4. Re-install the retaining ring [4].

5. Screw the retaining screw [1] back in. Now you can force the drive off the shaft by

tightening the bolt.

[1]

[4]

[7]

[8]

[6]

34

2348645131

[1] Retaining screw

[4] Retaining ring

[6] Customer shaft

[7] Fixed nut

[8] Forcing disk

Operating Instructions – MOVIGEAR® DSC-B

Page 35

Shaft-mounted gear unit with TorqLOC

N

O

C

O

F

L

U

I

D

®

4.7 Shaft-mounted gear unit with TorqLOC® (customer shaft without contact shoulder)

1. Clean the inside of the hollow shaft and the customer shaft carefully. Ensure that all

traces of grease or oil are removed. Install the stop ring and the bushing on the

customer shaft.

Mechanical Installation

®

4

2. Mount the torque arm to MOVIGEAR

®

3. Apply NOCO

fluid to the bushing and distribute it carefully.

®

; observe chapter "Torque arm".

2348651531

2348976011

Operating Instructions – MOVIGEAR® DSC-B

2348653451

35

Page 36

4

Mechanical Installation

Shaft-mounted gear unit with TorqLOC®

4. Push the gear unit onto the customer shaft.

2348983691

5. Preassemble the torque arm (do not tighten the screws).

36

2348979851

6. Push the busing onto the gear unit up to the stop.

2348972171

Operating Instructions – MOVIGEAR® DSC-B

Page 37

Mechanical Installation

Shaft-mounted gear unit with TorqLOC

7. Secure the bushing with the split ring. Tighten the split ring on the bushing using the

appropriate torque as specified in the following table.

®

2348974091

4

Typ e Tightening torque [Nm]

Standard design Stainless steel

MGFT.2 18 7.5

MGFT.4 18 7.5

8. Slide the shrink disk onto the hollow shaft. Ensure that all bolts have been loosened.

2348657291

Operating Instructions – MOVIGEAR® DSC-B

37

Page 38

4

NO

C

O

F

L

UI

D

®

Mechanical Installation

Shaft-mounted gear unit with TorqLOC®

9. Push the counter bushing onto the customer shaft and into the hollow shaft all the

way to the seat.

2348981771

10.Tap lightly on the collar of the counter bushing to ensure that the bushing is fitted

securely in the hollow shaft.

2348970251

11.Manually tighten the screws of the shrink disk and ensure that the end rings of the

shrink disk are parallel.

2348655371

38

Operating Instructions – MOVIGEAR® DSC-B

Page 39

Mechanical Installation

> 0 mm

> 0 mm

Shaft-mounted gear unit with TorqLOC

12.Tighten the locking bolts by working round several times from one bolt to the next

(not in diametrically opposite sequence). See the table for tightening torques.

®

NOTICE

After installation, the remaining gap between the outer rings of the shrink disks must be

> 0 mm.

4

16

5

Typ e Tightening torque [Nm]

Standard design Stainless steel

MGFT.2 10 6.8

MGFT.4 12 6.8

2

5

34

> 0 mm

13

6

42

2348659211

13.The distance between the counter bushing and the hollow shaft end must match the

values in the following figure:

Operating Instructions – MOVIGEAR® DSC-B

2348661131

39

Page 40

4

Mechanical Installation

Shaft-mounted gear unit with TorqLOC®

14.Tighten the torque arm; observe chapter "Torque arm".

2348977931

4.8 Shaft-mounted gear unit with TorqLOC® (customer shaft with contact shoulder)

1. Clean the inside of the hollow shaft and the customer shaft carefully. Ensure that all

traces of grease or oil are removed.

2348994315

40

Operating Instructions – MOVIGEAR® DSC-B

Page 41

Mechanical Installation

0 mm

N

O

C

O

FL

UI

D

®

Shaft-mounted gear unit with TorqLOC

2. Slide the bushing onto the customer shaft.

®

3. Apply NOCO

fluid to the bushing and distribute it carefully.

®

2349377035

4

4. Push the gear unit onto the customer shaft.

2349367435

2348992395

Operating Instructions – MOVIGEAR® DSC-B

41

Page 42

4

NO

C

O

FL

UID

®

Mechanical Installation

Shaft-mounted gear unit with TorqLOC®

5. Slide the shrink disk onto the hollow shaft. Ensure that all screws have been

loosened.

2349371275

6. Push the counter bushing onto the customer shaft and into the hollow shaft all the

way to the seat.

2348990475

7. Tap lightly on the flange of the counter bushing to ensure that the socket is fitted

securely in the hollow shaft.

2349375115

42

Operating Instructions – MOVIGEAR® DSC-B

Page 43

Mechanical Installation

Shaft-mounted gear unit with TorqLOC

8. Manually tighten the screws of the shrink disk and ensure that the end rings of the

shrink disk are parallel.

9. Tighten the locking screws by working round several times from one screw to the

next (not in diametrically opposite sequence). See the table for tightening torques.

®

2349369355

4

NOTICE

After installation, the remaining gap between the outer rings of the shrink disks must be

> 0 mm.

16

5

Typ e Tightening torque [Nm]

Standard design Stainless steel

MGFT.2 10 6.8

MGFT.4 12 6.8

2

5

34

> 0 mm

13

6

42

2349373195

Operating Instructions – MOVIGEAR® DSC-B

43

Page 44

4

> 0 mm

> 0 mm

Mechanical Installation

Shaft-mounted gear unit with TorqLOC®

10.The distance between the counter bushing and the hollow shaft end must match the

values in the following figure:

2348661131

11.Preassemble the torque arm (do not tighten the screws).

44

2352754955

12.Tighten the torque arm; observe chapter "Torque arm".

2352757259

Operating Instructions – MOVIGEAR® DSC-B

Page 45

4.9 Installing the protective cover

15°

NOTICE

During operation, output components are in fast motion.

Risk of jamming and crushing.

• Disconnect the drive from the power supply and safeguard it against accidental

startup before starting work and.

• Cover input and output components with a touch guard.

4.9.1 Installing the fixed cover

1. Place the cover offset by 15° counterclockwise

Mechanical Installation

Installing the protective cover

4

2. Turn the cover clockwise until it locks in position.

3. The following figure shows the installed cover:

2349379723

2349381643

Operating Instructions – MOVIGEAR® DSC-B

2349383563

45

Page 46

4

[1]

90°

[B]

[A]

Mechanical Installation

Torque arm

4.9.2 Installation without cover

4.10 Torque arm

In certain individual cases (e.g. through-shaft), you cannot install the cover. In these

cases, the cover is not necessary if the system or unit manufacturer provides

corresponding components to guarantee for the compliance with the required degree of

protection.

If this results in additional maintenance, you have to describe this in the operating

instructions for the system or component.

NOTICE

Inappropriate installation might damage the MOVIGEAR® drive unit.

Possible damage to property.

• Do not place torque arms under strain during installation.

• Always use bolts of quality 8.8 to fasten torque arms.

4.10.1 MGF.T2 and MGF.T4 torque arm

Installation options The following figure shows the MGF.T2 and MGF.T4 torque arm:

[1] Apply bearings to both ends of the bushing

2350520459

46

Tightening

torques

The following table shows the required tightening torques:

Drive Screw A Screw B

Size Tightening torque

[Nm]

MGF.T2 M10 48 Nm M10 20 Nm

MGF.T4 M12 70 Nm M10 20 Nm

Operating Instructions – MOVIGEAR® DSC-B

Size Tightening torque

[Nm]

Page 47

Mechanical Installation

Tightening torques

4.11 Tightening torques

Warning

The surface temperatures of the MOVIGEAR® and the application options can be very

high during operation.

Danger of burns.

• Do not touch the MOVIGEAR

down sufficiently.

4.11.1 Blanking plugs

Tighten the blanking plugs included in the delivery

Example The following figure shows an example. The number and position of the cable entries

depends on the ordered variant.

®

drive and application options until they have cooled

with 2.5 Nm:

4

Operating Instructions – MOVIGEAR® DSC-B

2350608651

47

Page 48

4

Mechanical Installation

Tightening torques

4.11.2 Cable glands

Tightening

torques

Tighten the EMC cable glands optionally included in the delivery

tightening torques:

Screw fitting Part number Size Tightening torque

EMC cable glands (nickel-plated

brass)

EMC cable glands (stainless

steel)

1820 478 3 M16 x 1.5 3.5 Nm to 4.5 Nm

1820 480 5 M25 x 1.5 6.0 Nm to 7.5 Nm

1821 636 6 M16 x 1.5 3.5 Nm to 4.5 Nm

1821 638 2 M25 x 1.5 6.0 Nm to 7.5 Nm

with the following

The cable retention in the cable gland must withstand the following removal force of the

cable from the cable gland:

• Cable with outer diameter > 10 mm: ≥ 160 N

• Cable with outer diameter < 10 mm: = 100 N

Example The following figure shows an example. The number and position of the cable entries

depends on the ordered variant.

48

2350588171

Operating Instructions – MOVIGEAR® DSC-B

Page 49

4.11.3 MOVIGEAR® electronics cover

1

2

4

3

4

2

3

1

Tighten the screws on the MOVIGEAR

diagonally across.

Mechanical Installation

Tightening torques

®

electronics cover using 6.0 Nm working

4

2350592011

Operating Instructions – MOVIGEAR® DSC-B

49

Page 50

4

Mechanical Installation

MOVIGEAR® with optional package for wet areas

4.12 MOVIGEAR® with optional package for wet areas

INFORMATION

SEW-EURODRIVE guarantees that the HP200 special surface is free from faults when

delivered. Report any transportation damage immediately.

Although the housing surfaces have a high impact resistance, they are to be handled

with care. The corrosion protection can be affected by damage to the surface as a

result from improper handling during transport, installation, operation, cleaning, etc.

SEW-EURODRIVE is not liable for such damage.

4.12.1 Installation notes

Observe the following additional notes when installing MOVIGEAR

optional package for applications in wet areas:

• Make sure to prevent moisture an dirt from entering the unit during the installation.

• After electrical installation, make sure that the sealing and sealing surfaces are clean

during assembly.

®

drive units with

• Check the state of the gasket during maintenance. If damaged: Consult SEWEURODRIVE.

• Make sure to install the cables with a drip loop.

• Only use the metal cable glands/screw plugs provided or offered by SEWEURODRIVE, see chapter "Technical data and dimension sheets".

• You must seal unused cable bushings and plug connectors with suitable screw plugs,

see chapter "Technical data and dimension sheets".

Example The following figure is an example of cable routing with drip loop:

50

2350617739

Operating Instructions – MOVIGEAR® DSC-B

Page 51

Mechanical Installation

MOVIGEAR® with optional package for wet areas

4

Mounting

positions

Mounting

positions

MOVIGEAR® drive units with optional package for wet areas are delivered with pressure

compensation and breather valve installed according to the mounting position.

This is why MOVIGEAR

mounting position specified in the order:

• Mounting position

–M1

–M2

– M3 (only after consultation with SEW-EURODRIVE)

–M4

–M5

–M6

• Cable entries

– Position 3 (not possible in conjunction with M4)

– Position 2 (not possible in conjunction with M5)

– Position X (not possible in conjunction with M6)

The following figure shows the position of MOVIGEAR

x

®

with optional package for wet areas must only be used in the

®

in mounting positions M1 to M6.

M1

2

3

2

3

x

M6

x

2

M5

3

2

M4

x

M3*

2

3

= Mounting position M3 only after consultation with SEW-EURODRIVE

*

x

M2

3

2

3

x

2351031563

Operating Instructions – MOVIGEAR® DSC-B

51

Page 52

4

Mechanical Installation

MOVIGEAR® with optional package for wet areas

4.12.2 Tightening torques regarding the optional package for applications in wet areas

WARNING

The surface temperature of the MOVIGEAR® can be very high during operation.

Danger of burns.

• Do not touch the MOVIGEAR

®

drive until it has cooled down sufficiently.

Blanking plugs Tighten the blanking plugs included in the delivery

Example The following figure shows an example. The number and position of the cable entries

depends on the ordered variant.

with 2.5 Nm.

52

2357713291

Operating Instructions – MOVIGEAR® DSC-B

Page 53

Mechanical Installation

1

2

4

3

4

2

3

1

MOVIGEAR® with optional package for wet areas

4

MOVIGEAR®

Proceed as follows when installing the MOVIGEAR® electronics cover:

electronics cover

Steps 1. Fix the MOVIGEAR

of 2 Nm

2351658251

®

cover in position on the connection box with a tightening torque

2. Tighten screws diagonally with 4 Nm.

3. Tighten screws with 6 Nm.

Operating Instructions – MOVIGEAR® DSC-B

53

Page 54

4

Mechanical Installation

MOVIGEAR® with optional package for wet areas

EMC cable glands Tighten the EMC cable glands optionally included in the delivery with the following

tightening torques:

Screw fitting Part number Size Tightening torque

EMC cable glands (nickel-plated

brass)

EMC cable glands (stainless

steel)

The cable retention in the cable gland must withstand the following removal force of the

cable from the cable gland:

• Cable with outer diameter > 10 mm: ≥ 160 N

• Cable with outer diameter < 10 mm: = 100 N

Example The following figure shows an example. The number and position of the cable entries

depends on the ordered variant.

1820 478 3 M16 x 1.5 3.5 Nm to 4.5 Nm

1820 480 5 M25 x 1.5 6.0 Nm to 7.5 Nm

1821 636 6 M16 x 1.5 3.5 Nm to 4.5 Nm

1821 638 2 M25 x 1.5 6.0 Nm to 7.5 Nm

54

2351663371

Operating Instructions – MOVIGEAR® DSC-B

Page 55

Electrical Installation

Installation planning considering EMC aspects

5 Electrical Installation

INFORMATION

Comply with the safety notes during installation.

5.1 Installation planning considering EMC aspects

5.1.1 Notes on arranging and routing installation components

Successful installation of decentralized drives depends on selecting the correct cables,

providing correct grounding and a functioning equipotential bonding.

You must always apply the relevant standards. Also observe the following points in

particular:

5.1.2 Equipotential bonding

5

• Regardless of the protective earth connection, it is essential that low-impedance, HFcapable equipotential bonding is provided (see also VDE 0113 or VDE 0100

part 540):

– Establish a connection over a wide surface area between the MOVIGEAR

unit and the mounting rail.

– To do so, use a ground strap (HF litz wire) to connect the MOVIGEAR

and the plant's grounding point.

• Do not use cable shields for equipotential bonding.

5.1.3 Cable routing and cable shielding

It is essential that you observe the detailed information in chapter "Cable routing and

cable shielding".

WARNING

®

drive

®

drive unit

2377213963

Faulty installation.

Severe or fatal injuries from electric shock.

• Installation must be carried out with great care.

• Note the connection examples in chapter "Installation instructions / Cable routing

and cable shielding".

INFORMATION

Additional information is available in the SEW-EURODRIVE publication "Drive

Engineering – Practical Implementation, EMC in Drive Engineering".

Operating Instructions – MOVIGEAR® DSC-B

55

Page 56

5

Electrical Installation

Installation instructions

5.2 Installation instructions

5.2.1 Connecting the supply system leads

• The rated voltage and rated frequency of MOVIGEAR

supply system data.

®

must correspond with the

• Cable cross section: according to input current I

"Technical data and dimension sheets").

• Install line fuses at the beginning of the supply system line behind the supply bus

junction. Select the fuse size according to the cable cross section.

• Use only copper cables with a minimum temperature range of 85 °C as the

connection cable.

• MOVIGEAR

star point (TN and TT systems).

®

is intended to be operated on voltage supply systems with grounded

at rated power (see chapter

supply

56

Operating Instructions – MOVIGEAR® DSC-B

Page 57

Electrical Installation

Installation instructions

5.2.2 Permitted cable cross section of the terminals

Supply system

terminals

Control terminals Observe the permitted cable cross sections for installation:

Observe the permitted cable cross sections for installation:

Supply system terminals

2

- 4.0 mm

Connection cross section

2

)

(mm

Connection cross section

(AWG)

Conductor end sleeves • For single assignment:

Control terminals

Connection cross section

2

)

(mm

Connection cross section

(AWG)

Stripping length 6 mm

Conductor end sleeves When using conductor end sleeves, the permitted cross section is

1.0 mm

AWG17 - AWG12

Only connect single-wire conductors or flexible conductors with

conductor end sleeve (DIN 46228 part 1, material E-CU) with or

without insulating shrouds

• For double assignment:

Only connect flexible conductors with conductor end sleeve

(DIN 46228 part 1, material E-CU) without insulating shrouds

• Permitted length of the conductor end sleeve: At least 8 mm

2

0.08 mm

AWG 28 - AWG 14

reduced by one unit (e.g. 2.5 mm

- 2.5 mm

2

2

2

to 1.5 mm2)

5

Communication

terminals

Observe the permitted cable cross sections for installation:

Communication terminals

Connection

cross section

2

(mm

)

Connection

cross section

(AWG)

Conductor end

sleeves

Single-wire

conductor

(bare wire)

Only connect single-wire conductors or flexible conductors with or without conductor end

sleeve (DIN 46228 part 1, material E-CU)

Flexible conductor

(bare litz wire)

2

0.5 mm

– 1.0 mm

AWG20 – AWG17 AWG20 – AWG18

Conductor with

conductor end

without insulating

shrouds

2

sleeve

Conductor with

conductor end

sleeve

with insulating

shroud

0.5 mm2 – 0.75 mm

2

Operating Instructions – MOVIGEAR® DSC-B

57

Page 58

5

5.2.3 Actuating the control terminal clamps

Electrical Installation

Installation instructions

Note the following information for actuating the control terminal clamps:

Control terminals (the following figure shows a schematic illustration)

3.

1.

2.

2378449419

58

Operating Instructions – MOVIGEAR® DSC-B

Page 59

5.2.4 Actuating the communication terminal clamps

Note the following information for actuating the communication terminal clamps:

Electrical Installation

Installation instructions

5

Connecting the conductor

without pushing the actuation button

2378468875 2378488843

Single-wire conductors and flexible conductors with

conductor end sleeves can be installed directly

(without tool) up to two cross section sizes below

the nominal cross section.

Connecting the conductor

after pressing the actuation button

1.

2.

You will need to press the actuation button on top to

open the clamping spring for installing untreated,

flexible conductors or those with a small cross

section that cannot be installed directly.

Removing the conductor,

after pressing the actuation button

1.

2.

Before removing the conductor, first press the actuation button on top.

2378520459

Operating Instructions – MOVIGEAR® DSC-B

59

Page 60

5

5.2.5 Line protection and earth-leakage circuit breakers

Electrical Installation

Installation instructions

• Install the fuses at the beginning of the supply system leads behind the supply bus

junction.

• SEW-EURODRIVE recommends that you do not use earth-leakage circuit breakers.

However, if an earth-leakage circuit breaker is stipulated for direct or indirect protection against contact, observe the following note in accordance with EN 61800-5-1:

WARNING

Wrong type of earth-leakage circuit breaker installed.

Severe or fatal injuries.

• MOVIGEAR

leakage circuit breaker is used for protection against direct or indirect contact, only

install a type B earth-leakage circuit breaker on the power supply end of the

MOVIGEAR

5.2.6 Line contactor

®

can cause direct current in the protective earth. When an earth-

®

unit.

Jog mode

• Use contactor switch contacts of utilization category AC-3 according to IEC 158 to

connect the supply system cable.

NOTICE

• Do not use the K11 input contactor for jog mode, but only for switching the inverter

on and off. Use control commands for jog mode.

• Observe a minimum switch-off time of 2 s for the supply system contactor K11.

60

Operating Instructions – MOVIGEAR® DSC-B

Page 61

5.2.7 Notes on PE connection of MOVIGEAR®

[1]

M5

2.5 mm²

M5

DANGER

Incorrect connection of PE.

Death, severe injuries or damage to property from electric shock.

• The permitted tightening torque for the screw fitting is 2.0 to 2.4 Nm (18...21 lb.in).

• Observe the following notes regarding the PE connection:

Electrical Installation

Installation instructions

5

Prohibited assembly sequence Recommendation:

Assembly with forked cable lug

Permitted for all cross sections

2377711243

[1] Forked cable lug suitable for M5 PE screws

2377688075

Assembly with thick solid wire

Permitted for cross sections up to

max. 2.5 mm

2

2377672587

Earth-leakage currents ≥ 3.5 mA may occur during normal operation. To meet the

requirements of EN 61800-5-1 observe the following note:

• Route a second PE conductor with the cross section of the supply system lead in

parallel to the protective earth via separate terminals or use a copper protective earth

conductor with a cross section of 10 mm

Operating Instructions – MOVIGEAR® DSC-B

2

.

61

Page 62

5

5.2.8 EMC-compliant installation

Electrical Installation

Installation instructions

This drive system is not designed for operation on a public low voltage supply system

that supplies residential areas.

With respect to the EMC regulation, frequency inverters cannot be operated as standalone units. Regarding EMC, they can only be evaluated when they are integrated in a

drive system. Conformity is declared for a described, CE-typical drive system. These

operating instructions contain further information.

INFORMATION

• This is a product with restricted availability in accordance with IEC 61800-3. It may

cause EMC interference. In this case, it may be recommended for the operator to

carry out suitable measures.

• For detailed information on EMC compliant installation, refer to the publication

"Electromagnetic Compatibility in Drive Engineering" from SEW-EURODRIVE.

WARNING

5.2.9 Installation altitudes above 1000 m asl

MOVIGEAR

under the following conditions:

• The nominal continuous power is reduced due to the reduced cooling above 1000 m

(see chapter "Technical data and dimension sheets").

• Above 2000 m asl, the air and creeping distances are only sufficient for overvoltage

class 2. If the installation calls for overvoltage class 3, you will have to install

additional external overvoltage protection to limit overvoltage peaks to 2.5 kV phaseto-phase and phase-to-ground.

• If safe electrical disconnection is required, it must be implemented outside the device

at altitudes of 2,000 msl (safe electrical disconnection in accordance with EN 618005-1).

• In installation altitudes between 2,000 m to 4,000 msl, the permitted rated power

supply voltages are reduced as follows:

– By 6 V per 100 m

5.2.10 Protection devices

• MOVIGEAR

overload.

• Cable protection must be implemented using external overload devices.

®

drive units can be used at altitudes above 1000 m asl up to 4000 m asl

®

drive units are equipped with integrated protection devices against

1)

62

• Observe the relevant standards concerning the cable cross section, voltage drop and

installation type.

1) The maximum altitude is limited by creeping distances and flameproof components such as capacitors.

Operating Instructions – MOVIGEAR® DSC-B

Page 63

5.2.11 Information regarding UL

Field wiring power

terminals

Observe the following notes for UL-compliant installation:

• Use 75 °C copper wire only

• Tighten power terminals to 10.6 – 12.4 lb.in (1.2 – 1.4 Nm)

Electrical Installation

Installation instructions

5

Short circuit

current rating

Branch circuit

protection

Suitable for use on a circuit capable of delivering not more than 200,000 rms

symmetrical amperes:

• MOVIGEAR

®

, max. voltage is limited to 500 V.

Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the National Electrical

Code and any additional local codes.

For maximum fuse rating see table below.

Series Max. fuse rating

Motor overload

protection

Ambient

temperature

MOVIGEAR

MOVIGEAR

®

®

is provided with motor overload protection with a trip current adjusted to

150% of the rated motor current.

MOVIGEAR

®

is suitable for an ambient temperature of 40 °C, max. 60 °C with derated

output current. To determine the output current rating at higher than 40 °C, the output

40 A / 600 V

current should be derated 3.0 % per °C between 40 °C and 60 °C.

Wiring diagrams For wiring diagrams, please refer to chapter "Electrical installation".

Operating Instructions – MOVIGEAR® DSC-B

63

Page 64

5

Hybrid cable (power + SBus)

[1]

MOVIGEAR® DSC B

MOVIGEAR

®

DSC B

MOVIGEAR

®

DSC B

Communication

Power

Power

Communication

Controller - SBus

Control/PLC

Control cabinet level

Field level

SBus-Controller

Power

Electrical Installation

Installation topology (example)

5.3 Installation topology (example)

INFORMATION

The following figure shows the basic installation topology with MOVIGEAR® DSC.

It is essential that you observe the installation instructions in the documentation of the

controller that you use.

64

[1] Permitted cable length between controller and last MOVIGEAR® when using the

recommended hybrid cable:

• 1 Mbaud: 25 m

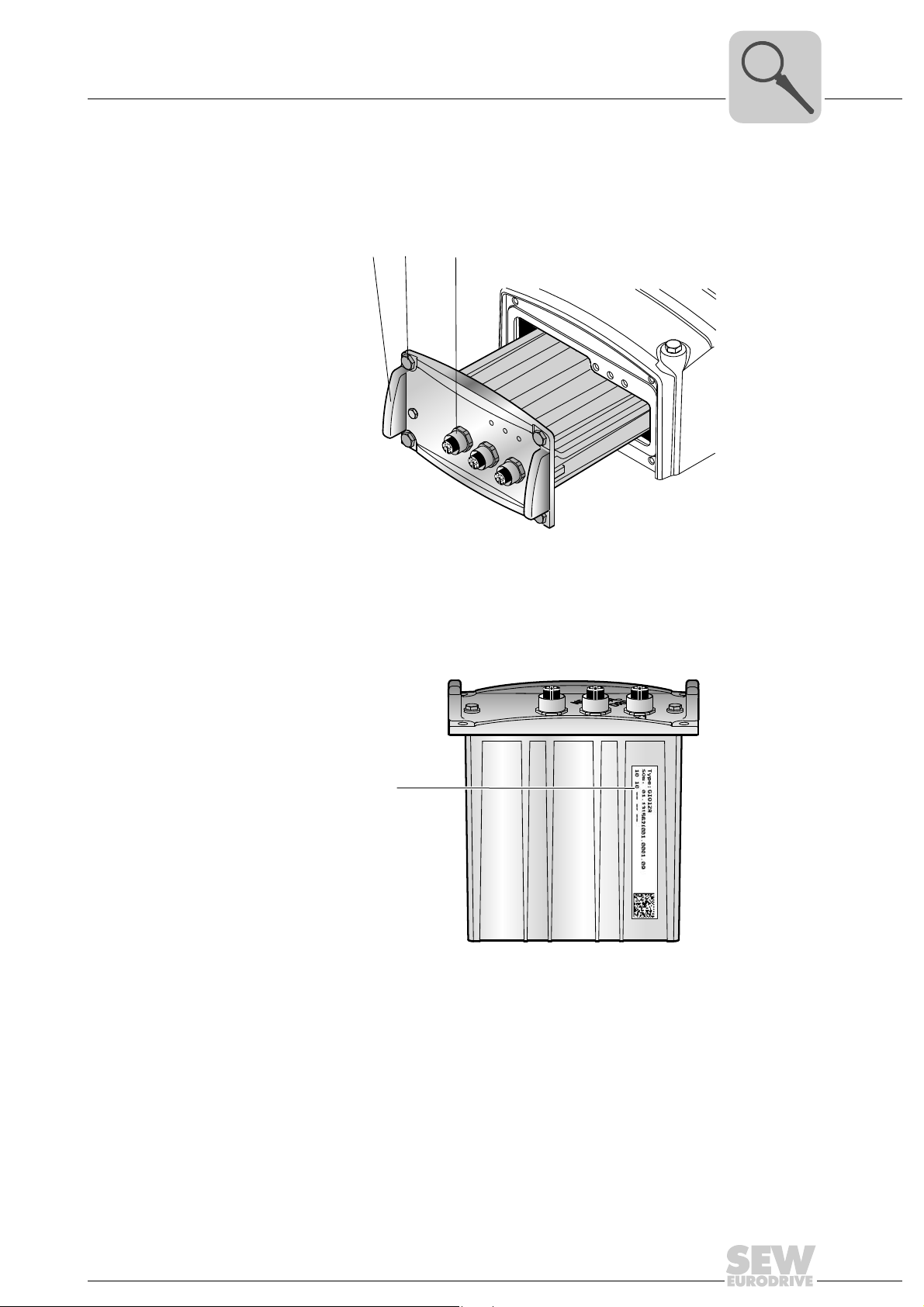

• 500 kbaud: 50 m