SEW-Eurodrive MOVIFIT FC User Manual

Drive Technology \ Drive Automation \ System Integration \ Services

Manual

MOVIFIT

®

FC – Function Level "Technology"

with Interface for PROFINET IO, PROFIBUS

or Ethernet/IP

Application Solution "Bus Positioning"

Edition 08/2012 19428014 / EN

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General Information ............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.2.1 Meaning of signal words .............................................................. 5

1.2.2 Structure of the section-related safety notes ............................... 5

1.2.3 Structure of the embedded safety notes...................................... 5

1.3 Right to claim under warranty ..................................................................... 6

1.4 Exclusion of liability..................................................................................... 6

1.5 Copyright..................................................................................................... 6

1.6 Product names and brands......................................................................... 6

1.7 Other applicable documentation ................................................................. 7

2 Safety Notes ........................................................................................................ 8

2.1 General information .................................................................................... 8

2.2 Target group ............................................................................................... 9

2.3 Designated use ......................................................................................... 10

2.4 Bus systems.............................................................................................. 10

3 System Description........................................................................................... 11

3.1 Area of application .................................................................................... 11

3.2 Profiles ...................................................................................................... 11

4 Operating Modes............................................................................................... 12

4.1 Jog ............................................................................................................ 12

4.1.1 Jog mode flow diagram.............................................................. 12

4.2 Referencing............................................................................................... 13

4.2.1 Referencing mode flow diagram ................................................ 13

4.3 Positioning ................................................................................................ 14

4.3.1 Positioning mode flow diagram.................................................. 14

5 Project Planning Information ........................................................................... 15

6 Startup................................................................................................................ 16

6.1 Requirements............................................................................................ 16

6.2 Setting the "Bus positioning for MOVIFIT

6.2.1 General settings......................................................................... 16

6.2.2 Scaling ....................................................................................... 18

6.2.3 Monitoring .................................................................................. 19

6.2.4 Reference travel ........................................................................ 22

7 Download ........................................................................................................... 24

8 Operation and Diagnostics .............................................................................. 25

8.1 Monitor mode and control mode ............................................................... 25

8.1.1 Monitor mode............................................................................. 25

8.1.2 Control mode ............................................................................. 26

9 Process Data and Terminal Assignment ........................................................ 27

9.1 Input terminal assignment......................................................................... 27

Manual – Bus Positioning Application Solution for MOVIFIT®

®

" application module ............... 16

3

Contents

9.2 Process data assignment.......................................................................... 27

9.2.1 Overview.................................................................................... 27

9.2.2 8 PD (single-motor operation).................................................... 28

9.2.3 14 PD (dual-motor operation) .................................................... 30

Index................................................................................................................... 34

4

Manual – Bus Positioning Application Solution for MOVIFIT®

1 General Information

1.1 How to use this documentation

The documentation is part of the product and contains important information. The

documentation is for everyone who works with this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently with the

software and the connected units from SEW-EURODRIVE, have read through the documentation carefully and understood it. If you are unclear about any of the information

in this documentation, or if you require further information, contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of signal words

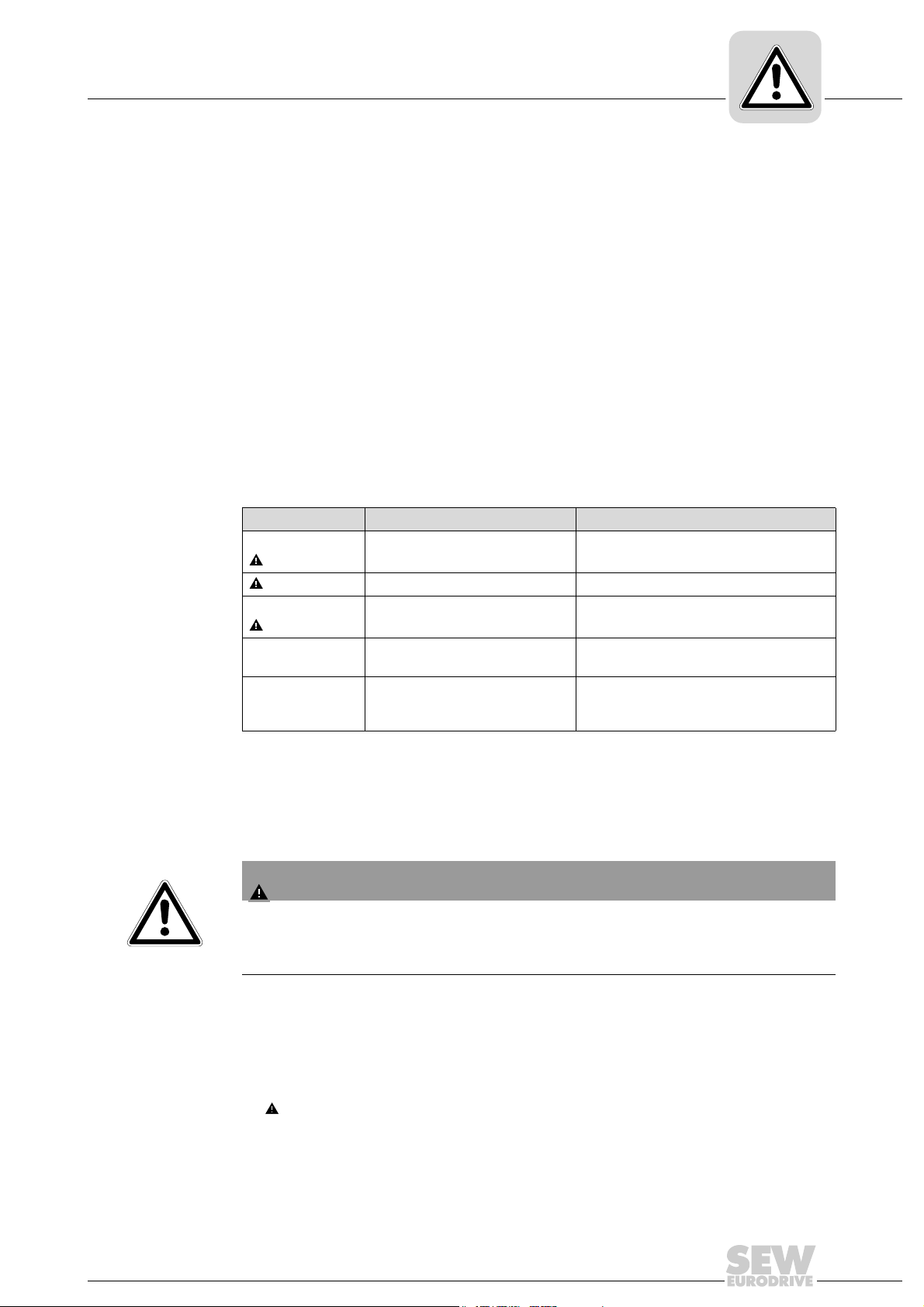

The following table shows the grading and meaning of the signal words for safety notes,

warnings regarding potential risks of damage to property, and other notes.

General Information

How to use this documentation

1

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNIN G Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

IMPORTANT! Possible damage to property Damage to the drive system or its envi-

NOTE Useful information or tip: Simpli-

fies handling of the drive system.

1.2.2 Structure of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to several actions pertaining to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section-related safety note:

SIGNAL WORD

Nature and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to avoid the danger.

ronment

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORDNature and source of danger.

Possible consequence(s) if disregarded.

– Measure(s) to avoid the danger.

Manual – Bus Positioning Application Solution for MOVIFIT®

5

1

General Information

Right to claim under warranty

1.3 Right to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation at hand. Therefore,

read the documentation before you start working with the software and the connected

units from SEW-EURODRIVE.

Make sure that the documentation is available to persons responsible for the machinery

and its operation as well as to persons who work independently on the devices. Also

ensure that the documentation is legible.

1.4 Exclusion of liability

You must adhere to this documentation and the documentation of the connected

devices from SEW-EURODRIVE to ensure safe operation and to achieve the specified

product characteristics and performance features.

SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or

property resulting from non-observance of the documentation. In such cases, any liability for defects is excluded.

1.5 Copyright

© 2012 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized reproduction, modification, distribution, and

use of this instruction manual, in whole or in part.

1.6 Product names and brands

The product names mentioned in this documentation are brands or registered brands of

the titleholders.

6

Manual – Bus Positioning Application Solution for MOVIFIT®

1.7 Other applicable documentation

Depending on the respective fieldbus, observe one of the following applicable fieldbus

manuals:

• For PROFIBUS: MOVIFIT

• For PROFINET IO: MOVIFIT

face

• For Ethernet/IP: MOVIFIT

TCP Interface

Additionally observe the following document if you use the "Dual-motor operation" special design:

• Addendum to the operating instructions "MOVIFIT

Motor Operation"

Make sure you always use the latest documentation and software version.

Our documentation is available in various languages for download from the SEW

homepage (www.sew-eurodrive.com). If you are unclear about any of the information in

this documentation or if you require further information, consult SEW-EURODRIVE.

If required, you can order printed copies of the documentation from SEW-EURODRIVE.

General Information

Other applicable documentation

®

function level "Technology"

®

"Technology" function level with PROFINET IO inter-

®

Function Level "Technology" with EtherNet/IP or Modbus

®

FC Special Design for Dual-

1

Manual – Bus Positioning Application Solution for MOVIFIT®

7

2

Safety Notes

General information

2 Safety Notes

2.1 General information

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to.

Ensure that persons responsible for the machinery and its operation as well as persons

who work independently have read through the documentation carefully and understood

it. If you are unclear about any of the information in this documentation or if you require

further information, please contact SEW-EURODRIVE.

The following safety notes refer to the use of the software. Also adhere to the supplementary safety notes in this document and in the documentation of the connected

devices from SEW-EURODRIVE.

This document does not replace the detailed documentation of the connected devices.

This documentation assumes that the user has access to and is familiar with the

documentation for all connected units from SEW-EURODRIVE.

Never install or start up damaged products. Submit a complaint to the shipping company

immediately in the event of damage.

During operation, the devices may have live, uninsulated, and sometimes moving or

rotating parts as well as hot surfaces depending on their degree of protection.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property. Refer to the

documentation for additional information.

8

Manual – Bus Positioning Application Solution for MOVIFIT®

2.2 Target group

Any work with the software may only be performed by adequately qualified personnel.

Qualified personnel in this context are persons who have the following qualifications:

• Appropriate instruction.

• Knowledge of this documentation and other applicable documentation.

• SEW-EURODRIVE recommends additional product training for products that are op-

Any mechanical work on connected units may only be performed by adequately qualified personnel. Qualified staff in the context of this documentation are persons familiar

with the design, mechanical installation, troubleshooting and servicing of the product

who possess the following qualifications:

• Training in mechanical engineering, e.g. as a mechanic or mechatronics technician

• Knowledge of this documentation and other applicable documentation.

erated using this software.

(final examinations must have been passed).

Safety Notes

Target group

2

Any electrical work on connected units may only be performed by adequately qualified

electricians. Qualified electricians in the context of this documentation are persons familiar with electrical installation, startup, troubleshooting and servicing of the product

who possess the following qualifications:

• Training in electrical engineering, e.g. as an electrician or mechatronics technician

(final examinations must have been passed).

• Knowledge of this documentation and other applicable documentation.

• Knowledge of the relevant safety regulations and laws.

• Knowledge of the other standards, guidelines, and laws mentioned in this documentation.

The above mentioned persons must have the authorization expressly issued by the

company to operate, program, configure, label and ground units, systems and circuits in

accordance with the standards of safety technology.

All work in further areas of transportation, storage, operation and waste disposal must

only be carried out by persons who are trained appropriately.

Manual – Bus Positioning Application Solution for MOVIFIT®

9

2

2.3 Designated use

2.4 Bus systems

Safety Notes

Designated use

SEW-EURODRIVE offers various standardized control programs, so-called application

modules.

The "bus positioning" application module is a single-axis application and used for variable positions in conjunction with different speeds and ramps.

A bus system makes it possible to adapt frequency inverters and/or motor starters to the

particulars of the machinery within wide limits. This results in the risk that a change of

parameters that cannot be detected externally can result in unexpected, though not

uncontrolled, system behavior.

10

Manual – Bus Positioning Application Solution for MOVIFIT®

3 System Description

P

i

f

kVA

Hz

n

3.1 Area of application

The "bus positioning" application module is used for variable positions in conjunction

with different speeds and ramps.

The positioning is carried out via the built-in motor encoder or an optional distance encoder. Only the linear, absolute positioning is supported. You can work with user units.

The following operating modes are supported:

•Jog

• Referencing

• Positioning

3.2 Profiles

The "Bus positioning" application module has the following profiles:

System Description

Area of application

3

Profile Scope of functions

8 PD (single-motor operation) 2 process data words for the state of the controller

6 process data words for the motor

14 PD (dual-motor operation) 2 process data words for the state of the controller

6 process data words for motor 1

6 process data words for motor 2

INFORMATION

Profile "Dual-motor operation"

• With the "Dual-motor operation" profile, you may only operate one motor at a time.

The process data assignment for the profiles is listed in chapter "Process data and terminal assignment".

Manual – Bus Positioning Application Solution for MOVIFIT®

11

4

1

2

3

Mode

Actual speed

Jog positive

Jog negative

P

i

f

kVA

Hz

n

Operating Modes

Jog

4 Operating Modes

4.1 Jog

Functional description

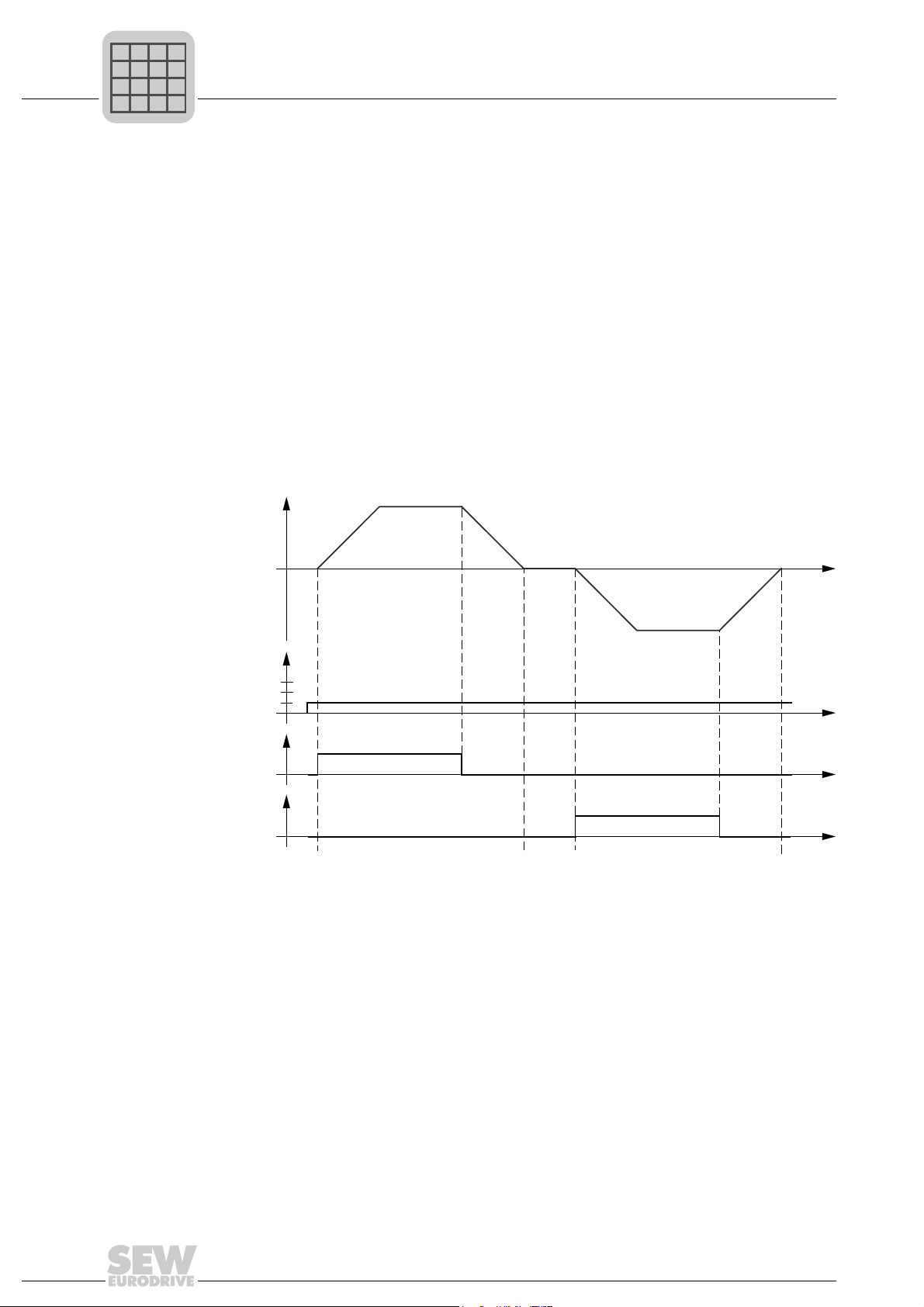

4.1.1 Jog mode flow diagram

The jog mode is required for service. In this operating mode, the drive can be moved

regardless of the automatic operating mode.

In jog mode, you can set the control bits "Jog+" or "Jog-" to move the drive clockwise or

counterclockwise. It is not necessary to set the start bit.

The dynamics parameters (speed and the ramps) are specified dynamically via the corresponding process data words.

The following figure shows the actual speed of the drive against the status of the input

and output signals in jog mode:

12

6050125579

Manual – Bus Positioning Application Solution for MOVIFIT®

Loading...

Loading...