Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

MOVIFIT

Edition 05/2013 20116543 / EN

®

basic

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General information ............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.3 Rights to claim under warranty ................................................................... 6

1.4 Exclusion of liability..................................................................................... 6

1.5 Copyright..................................................................................................... 6

1.6 Product names and trademarks.................................................................. 6

2 Safety notes......................................................................................................... 7

2.1 Preliminary information ............................................................................... 7

2.2 General information .................................................................................... 7

2.3 Target group ............................................................................................... 7

2.4 Designated use ........................................................................................... 8

2.5 Other applicable documentation ................................................................. 8

2.6 Transportation, storage............................................................................... 8

2.7 Installation................................................................................................... 8

2.8 Electrical connection ................................................................................... 9

2.9 Safe disconnection...................................................................................... 9

2.10 Operation .................................................................................................... 9

3 Unit structure..................................................................................................... 10

3.1 MOVIFIT

3.2 Variants..................................................................................................... 10

3.3 Accessories............................................................................................... 11

3.4 Type designations..................................................................................... 12

4 Mechanical installation..................................................................................... 13

4.1 Installation instructions.............................................................................. 13

4.2 Mounting position...................................................................................... 14

4.3 Installing MOVIFIT

5 Electrical installation ........................................................................................ 15

5.1 Installation instructions.............................................................................. 15

5.2 Topology ................................................................................................... 18

5.3 Power bus connection (line cable) ............................................................ 19

5.4 Motor connection ...................................................................................... 24

5.5 Control unit connection ............................................................................. 28

5.6 Connections of MOVIFIT

5.7 Connections of MOVIFIT

5.8 Connection of operator terminals LT-BG and MB-LC ............................... 33

5.9 PC connection........................................................................................... 34

6 Startup................................................................................................................ 35

6.1 Important notes on startup ........................................................................ 35

6.2 Requirements............................................................................................ 36

6.3 Startup procedure for the MOVIFIT

6.4 MOVIFIT

6.5 Assigning the AS-Interface slave address ................................................ 40

®

basic........................................................................................ 10

®

basic......................................................................... 14

®

basic with AS-Interface................................... 29

®

basic with binary control................................. 31

®

basic inverter.................................. 37

®

basic motor starter – startup procedure .................................. 39

Operating Instructions – MOVIFIT® basic

3

Contents

6.6 Parameterization with LT-BG keypad ....................................................... 42

6.7 Parameterization with the PC ................................................................... 45

6.8 Parameter directory of the MOVIFIT

6.9 Functions of MOVIFIT

6.10 Functions of MOVIFIT

®

basic with AS-Interface....................................... 53

®

basic with binary control ..................................... 54

7 Operation ........................................................................................................... 55

7.1 Operating displays of MOVIFIT

7.2 Description of the MB-LC keypad ............................................................. 57

7.3 Operating displays of MB-LC keypad ....................................................... 58

7.4 Manual operation with MB-LC keypad ...................................................... 59

7.5 Operating displays of LT-BG keypad ........................................................ 61

7.6 Manual mode with LT-BG keypad............................................................. 62

8 Service ............................................................................................................... 64

8.1 Diagnostics with LT-BG operator terminal ................................................ 64

8.2 Status and error display ............................................................................ 65

8.3 Inspection/Maintenance ............................................................................ 66

8.4 Shutdown .................................................................................................. 67

8.5 Storage ..................................................................................................... 68

8.6 Extended storage...................................................................................... 68

8.7 Disposal .................................................................................................... 68

®

basic inverter ................................ 49

®

basic (LEDs)......................................... 55

9 Technical data ................................................................................................... 69

9.1 CE marking, UL approval and C-Tick ....................................................... 69

9.2 MOVIFIT

9.3 MOVIFIT

®

basic with AS-Interface............................................................ 70

®

basic with binary control .......................................................... 72

9.4 Accessories............................................................................................... 74

9.5 Dimension drawings.................................................................................. 75

10 Address list........................................................................................................ 77

I

ndex................................................................................................................... 82

4

Operating Instructions – MOVIFIT® basic

1 General information

1.1 How to use this documentation

The documentation is an integral part of the product and contains important information

on operation and service. The documentation is written for all employees who assemble,

install, start up, and service this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of signal words

The following table shows the grading and meaning of the signal words for safety notes,

warnings regarding potential risks of damage to property, and other notes.

General information

How to use this documentation

1

Signal word Meaning Consequences if disregarded

DANGER! Imminent hazard Severe or fatal injuries

WARNING! Possible dangerous situation Severe or fatal injuries

CAUTION! Possible dangerous situation Minor injuries

IMPORTANT! Possible damage to property Damage to the drive system or its envi-

NOTE Useful information or tip: Simpli-

fies handling of the drive system.

1.2.2 Structure of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to several actions pertaining to one subject. The symbols used indicate either a general or a specific hazard.

This is the formal structure of a section-related safety note:

SIGNAL WORD

Type and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the hazard.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated into the instructions just before the description of the dangerous action.

ronment

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the hazard.

Operating Instructions – MOVIFIT® basic

5

1

General information

Rights to claim under warranty

1.3 Rights to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Therefore read the

documentation before you start working with the unit.

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such

cases, any liability for defects is excluded.

1.5 Copyright

© 2013 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any

part of this documentation is strictly prohibited.

1.6 Product names and trademarks

All product names in this documentation are trademarks or registered trademarks of

their respective titleholders.

6

Operating Instructions – MOVIFIT® basic

2 Safety notes

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to. Make sure that persons responsible for the plant and its operation, as well

as persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in

this documentation or if you require further information, please contact SEWEURODRIVE.

2.1 Preliminary information

The following safety notes are primarily concerned with the use of MOVIFIT® basic

drives. If you use other SEW components, also refer to the safety notes for the respective components in the corresponding documentation.

Please also observe the supplementary safety notes in the individual sections of this

documentation.

Safety notes

Preliminary information

2

2.2 General information

Never install or start up damaged products. Submit a complaint to the shipping company

immediately in the event of damage.

During operation, MOVIFIT

surfaces, depending on their enclosure.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property. Refer to the

documentation for additional information.

2.3 Target group

Only qualified electricians are authorized to install, startup or service the units or correct unit faults (observing IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are persons familiar with

installation, assembly, startup and operation of the product who possess the necessary

qualifications.

Any activities regarding transportation, storage, operation, and disposal must be carried

out by persons who have been instructed appropriately.

®

basic drives can have live and bare parts as well as hot

Operating Instructions – MOVIFIT® basic

7

2

2.4 Designated use

2.4.1 Safety functions

Safety notes

Designated use

MOVIFIT® basic drives are components intended for installation in electrical systems or

machines.

®

In case of installation in machines, startup of MOVIFIT

nated operation) is prohibited until it is determined that the machine meets the requirements stipulated in the Machinery Directive 2006/42/EC.

Startup (i.e. the start of designated use) is only permitted under observance of the EMC

directive 2004/108/EC.

®

The MOVIFIT

tive 2006/95/EC. The standards given in the declaration of conformity apply to the

MOVIFIT

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

MOVIFIT

basic units meet the requirements stipulated in the Low Voltage Direc-

®

basic units.

®

basic units may not perform safety functions.

basic units (i.e. start of desig-

2.4.2 Hoist applications

®

MOVIFIT

basic units are not designed for hoist applications.

2.5 Other applicable documentation

Note also the following documentation:

• "DR.71-225, 315 AC Motors" operating instructions

You can download or order this publication on the Internet (http://www.sew-

eurodrive.de, under the heading "Documentation").

2.6 Transportation, storage

You must observe the notes on transportation, storage and proper handling. Comply

with the requirements for climatic conditions stated in section "Technical Data".

2.7 Installation

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

®

Protect the MOVIFIT

The following applications are prohibited unless the unit is explicitly designed for such

use:

basic units from improper strain.

• Use in potentially explosive atmospheres.

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications with strong mechanical oscillation and impact

loads; see section "Technical Data".

8

Operating Instructions – MOVIFIT® basic

2.8 Electrical connection

Perform electrical installation according to the pertinent regulations (e.g. cable cross

sections, fusing, protective conductor connection). For any additional information, refer

to the applicable documentation.

For notes on EMC compliant installation, such as shielding, grounding, arrangement of

filters and routing of lines, refer to chapter "Installation instructions". The manufacturer

of the system or machine is responsible for maintaining the limits established by EMC

legislation.

Protective measures and protection devices must comply with the regulations in force

(e.g. EN 60204 or EN 61800-5-1).

A voltage test according to EN 61800-5-1:2007 chapter 5.2.3.2 is required for the

MOVIFIT

®

basic drives prior to startup in order to ensure the insulation.

2.9 Safe disconnection

The MOVIFIT® basic units meet all requirements for safe disconnection of power and

electronic connections in accordance with EN 61800-5-1. All connected circuits must

also satisfy the requirements for safe disconnection.

Safety notes

Electrical connection

2

2.10 Operation

Systems with integrated MOVIFIT® basic units must be equipped with additional monitoring and protection devices according to the applicable safety guidelines, such as the

law governing technical equipment, accident prevention regulations, etc. Additional protective measures may be necessary for applications with increased potential risk.

Do not touch live components or power connections immediately after disconnecting

MOVIFIT

Wait at least 10 minutes after the supply voltage is switched off.

Once the supply voltages are applied to MOVIFIT

closed, i.e. the cover must be screwed on and all the plugs must be connected.

The fact that the status LEDs and other display elements are no longer illuminated does

not indicate that the unit has been disconnected from the supply system and no longer

carries any voltage.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. If, for safety reasons, this is not permitted for the driven machine,

disconnect the unit from the supply system before correcting the error.

Caution: Danger of burns: The surface temperatures of the MOVIFIT

exceed 60 °C during operation.

®

basic from the supply voltage because some capacitors may still be charged.

®

basic, the connection box must be

®

basic drives can

Operating Instructions – MOVIFIT® basic

9

3

3 Unit structure

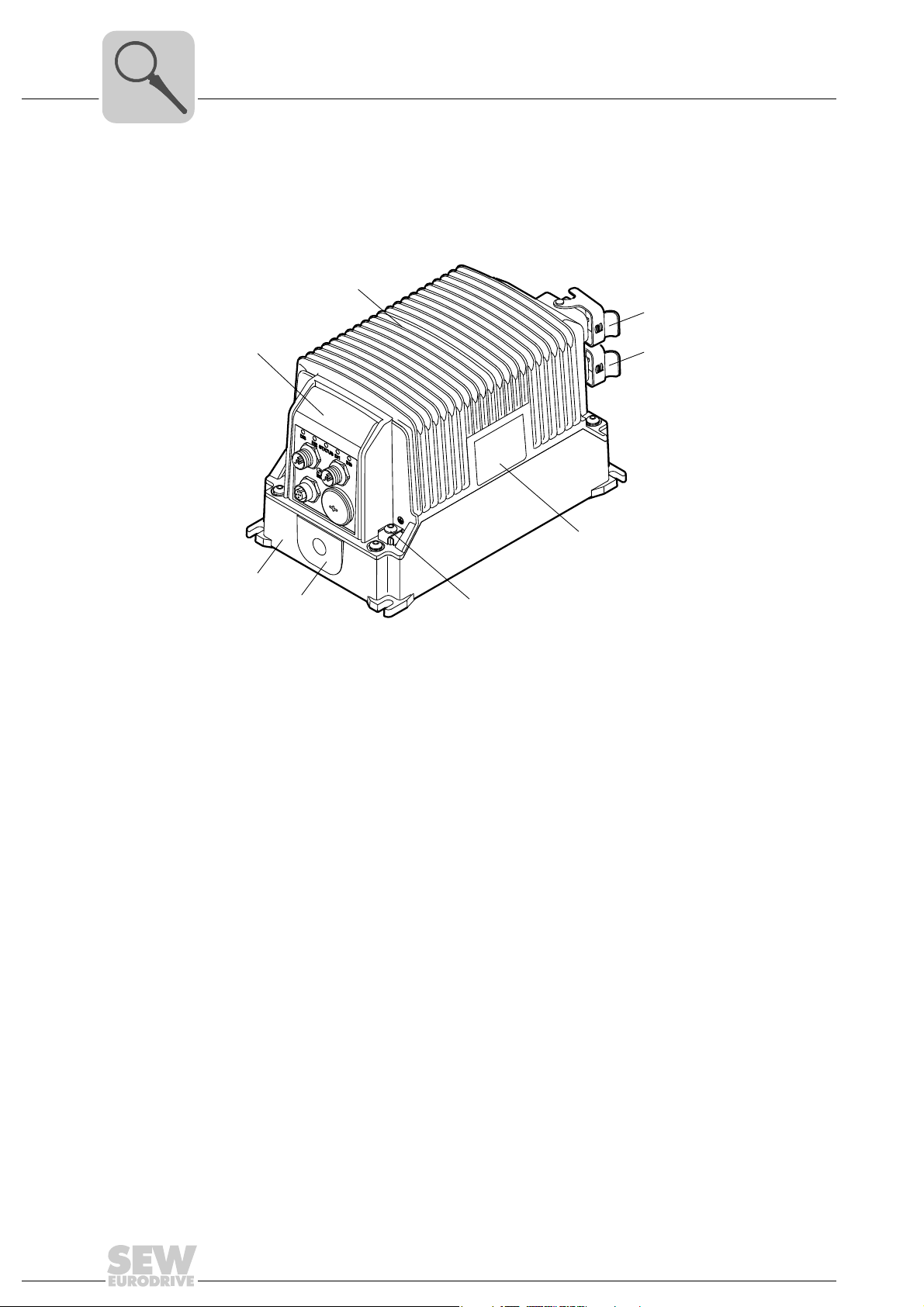

3.1 MOVIFIT® basic

Unit structure

MOVIFIT® basic

MOVIFIT® basic is a decentralized drive unit for controlling AC motors.

[2]

[3]

[1]

[5]

[8]

[7]

[1] Control unit

[2] EBOX with cooling fins and electronics (inverter or motor starter)

[3] X8 connection for motor (only with dual motor starter design)

[4] X9 connection for motor

[5] Nameplate

[6] PE connection

[7] Cable seal for cable diameter 13 – 15 mm

[8] ABOX with FieldPower contact module (connection unit)

댷 (outside)

[6]

[4]

2816397195

3.2 Variants

10

MOVIFIT® basic is available in the following variants:

• Inverter For 1 motor with CW and CCW operation and 4 setpoint speeds

• Dual motor starter For 2 motors with 1 direction of rotation each

The direction of rotation depends on the phase

sequence.

• Reversing starter For 1 motor with CW and CCW operation

®

MOVIFIT

basic is available with the following control units:

• Drives with AS-Interface

• Control unit with binary signal inputs and outputs

Operating Instructions – MOVIFIT® basic

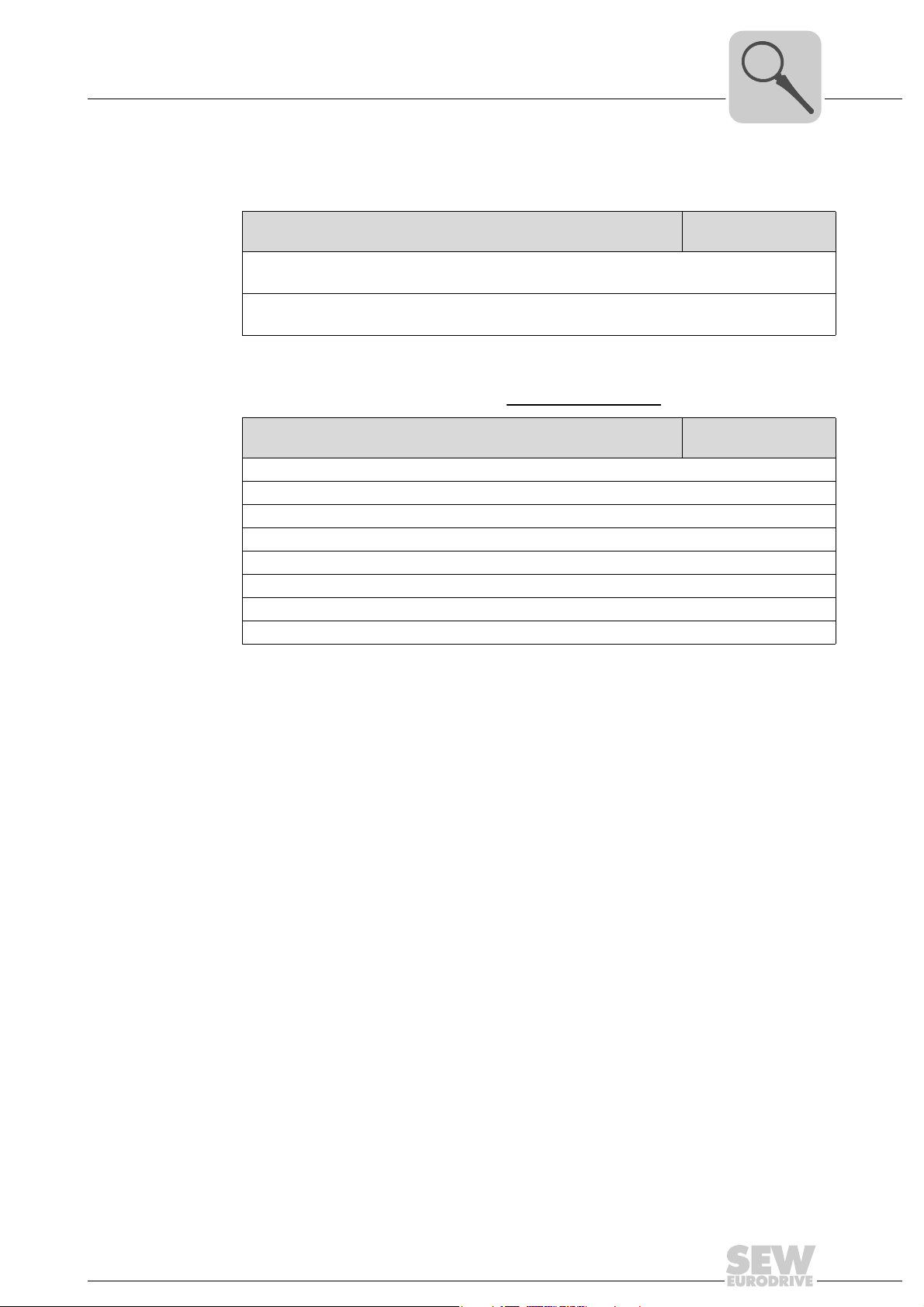

3.3 Accessories

Unit structure

Accessories

You can order the following accessories for MOVIFIT® basic from SEW-EURODRIVE:

Accessories Part number

(SEW-EURODRIVE)

2

Motor connection cable 4 x 2.5 mm

with plug connector Q8/0 – open conductor ends

Motor connection cable 7 x 2.5 mm2, unshielded, length = 3 m

with plug connector Q8/0 – open conductor ends

You can order the following accessories for MOVIFIT

müller Interface GmbH & Co. KG (see www.weidmueller.com

Accessories Part number

Cable seal, for cables with Ø = 7.5 – 9 mm 4329610000

Cable seal, for cables with Ø = 9 – 11 mm 4323210000

Cable seal, for cables with Ø = 11 – 13 mm 4323230000

Cable seal for cables with Ø = 13 – 15 mm

Cable seal, for cables with Ø = 15 – 17 mm 4324010000

Seal (without cable entry) 4323240000

Stripping tool AM 16 (for round cables) 9204190000

Stripping tool AMF 6/10 (for flat cables) 9204180000

1) The scope of delivery of MOVIFIT® basic units comprises 2 of those cable seals.

, unshielded, length = 3 m

®

1)

basic from the company Weid-

):

1 814 874 3

1 814 992 8

(Weidmüller)

4323220000

3

Operating Instructions – MOVIFIT® basic

11

3

Unit structure

Type designations

3.4 Type designations

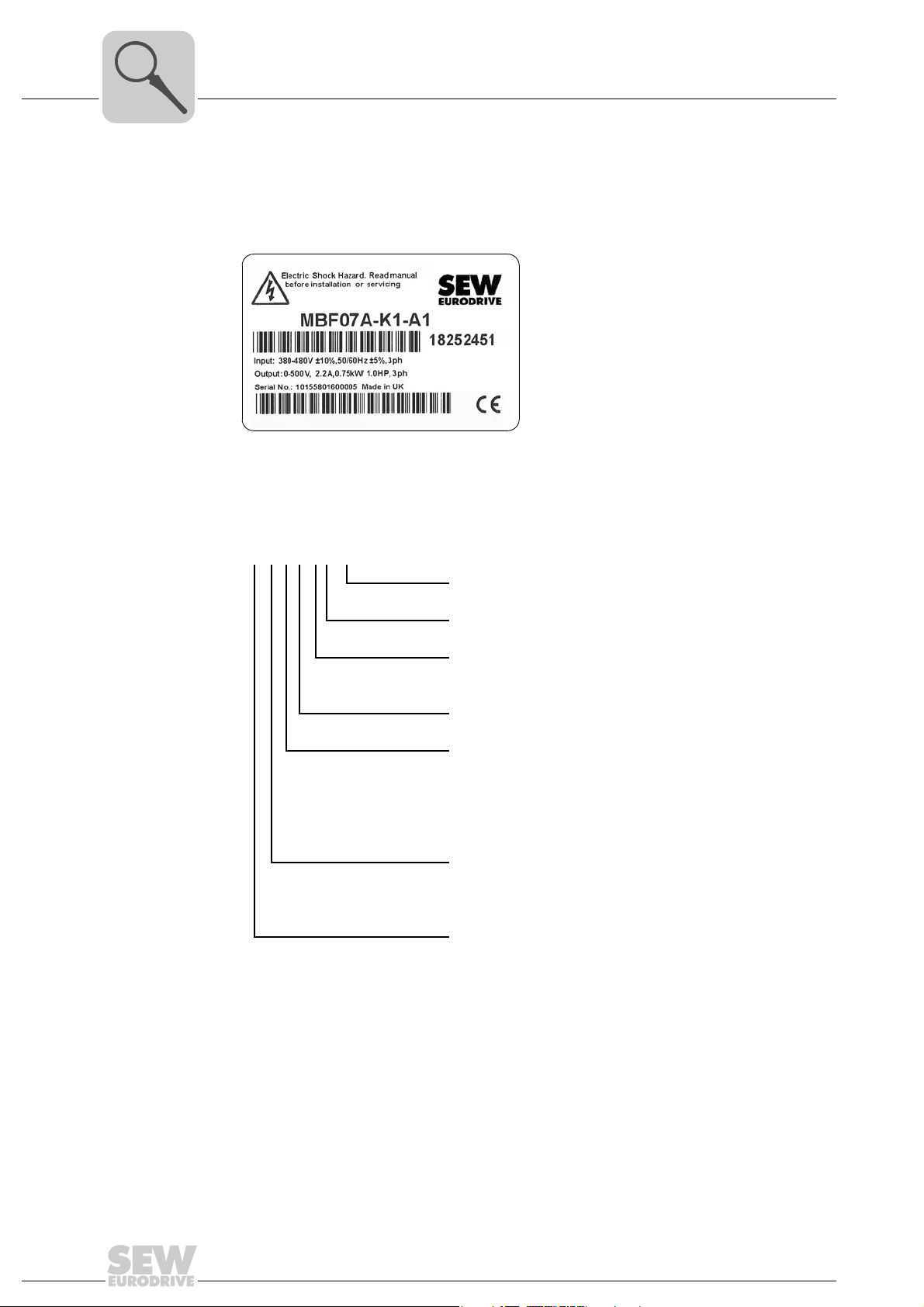

3.4.1 Nameplate

3.4.2 Type designation

The following figure gives an example of a nameplate of the MOVIFIT

®

The following table shows the MOVIFIT

basic type designation:

®

basic inverter:

3782535691

MBF07A-K1-A1

Connection module

Version

Control

K = via AS-Interface

B = binary control

Version

Motor power/variant

07 = 0.75 kW inverter

15 = 1.5 kW inverter

4R = Reversing starter

4D = Dual motor starter

Variant

F = Inverter

S = Motor starter

Unit series

MB = MOVIFIT

®

basic

12

Operating Instructions – MOVIFIT® basic

4 Mechanical installation

4.1 Installation instructions

4.1.1 General information

NOTICE

Loss of warranted degree of protection if the MOVIFIT® basic inverter is installed

incorrectly or not at all.

Damage to the MOVIFIT

• If you remove the EBOX from the ABOX, you have to protect the EBOX and the

ABOX from moisture and dust.

Note the following when installing the MOVIFIT

• Observe the general safety notes.

• Only install the MOVIFIT

support structure.

• Ensure sufficient clearance around the unit to allow for adequate cooling. Warm

outlet air of other units must not be drawn in.

Mechanical installation

Installation instructions

®

basic unit.

®

basic unit:

®

basic unit on a level, low-vibration, and torsionally rigid

4

• Strictly observe all instructions as to the technical data and the permissible conditions regarding the place of installation.

• Do only use provided attachment options when mounting the drive.

• Cover the unused plug connectors with blind caps.

The degree of protection specified in the technical data only applies for a correctly

installed MOVIFIT

4.1.2 Installation requirements

Make sure that the following requirements are met before you start installing the unit:

• The nameplate data of the MOVIFIT

• The MOVIFIT

storage).

• The ambient temperature corresponds to the specifications in chapter "Technical

Data".

• The MOVIFIT

conditions:

– Potentially explosive atmospheres

– Oils

–Acids

– Gases

®

basic unit.

®

basic unit match the voltage supply system

®

basic unit is undamaged (no damage caused by transportation or

®

basic unit must not be installed under the following harmful ambient

– Vapors

– Radiation

–etc.

Operating Instructions – MOVIFIT® basic

13

4

M1

M2

M5

M3

M4

M6

239

134

6

M5

Mechanical installation

Mounting position

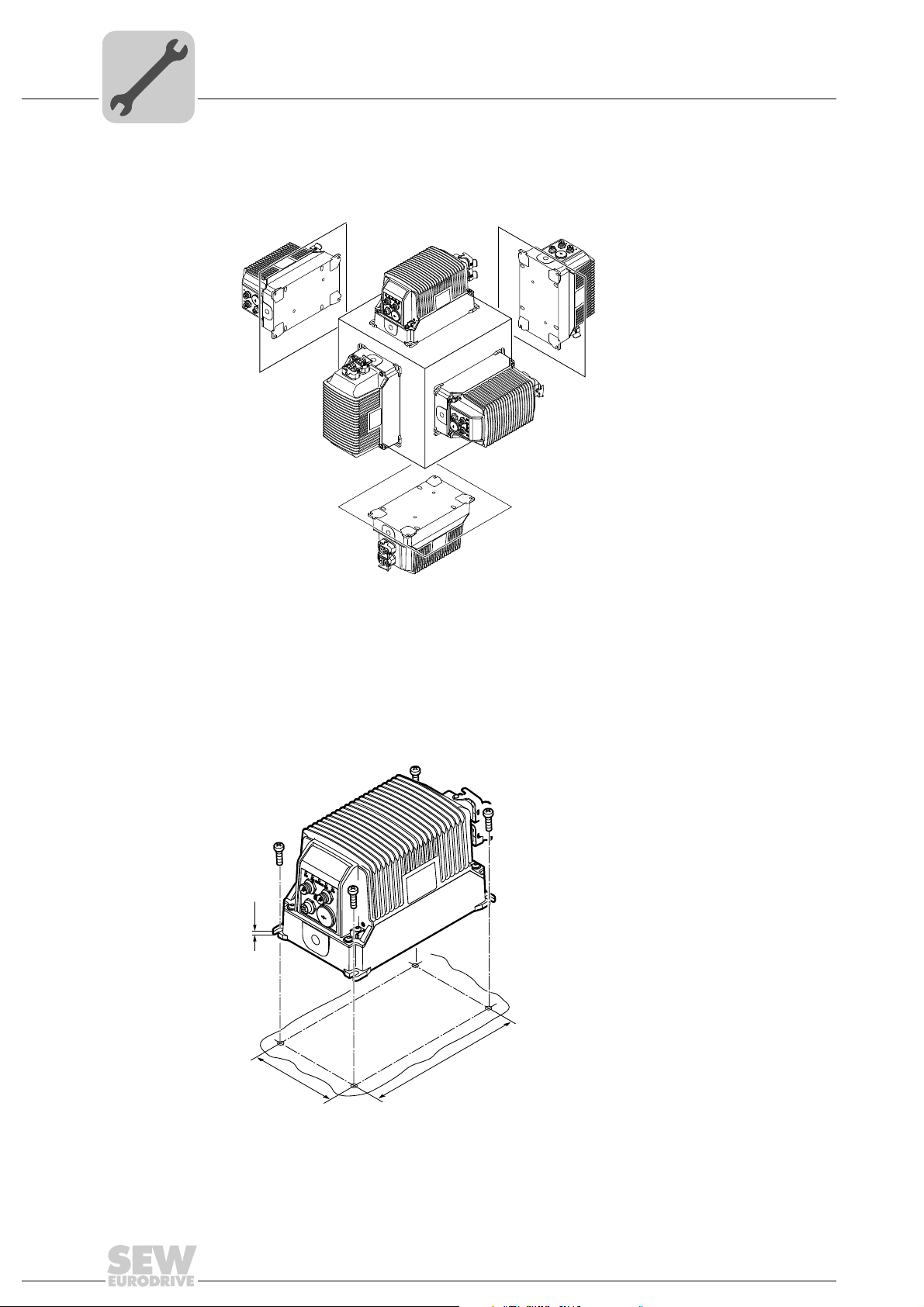

4.2 Mounting position

You can install the MOVIFIT® basic unit in any mounting position.

4.3 Installing MOVIFIT® basic

Mount the MOVIFIT® basic unit with 4 screws according to the following figure:

(Tightening torque 2.0 – 2.4 Nm (18 – 21 lb.in))

2816420235

14

9007202071159307

Operating Instructions – MOVIFIT® basic

5 Electrical installation

5.1 Installation instructions

5.1.1 Residual current device

WARNING

Electric shock due to incorrect RCD type.

Severe or fatal injuries.

®

• MOVIFIT

a residual current device (RCD) is used for protection against direct or indirect contact, only install a type B residual current device on the supply system end of the

MOVIFIT

basic can cause direct current in the protective earth conductor. When

®

basic unit.

Electrical installation

Installation instructions

5

5.1.2 Line contactor

• Do not use a conventional RCD as a protective device. Universal current-sensitive

RCDs are permitted as a protective device. During normal operation of MOVIFIT

basic units, leakage currents > 3.5 mA can occur.

• SEW-EURODRIVE recommends that you do not use RCDs. However, if a residual

current device is stipulated for direct or indirect protection against contact, observe

the above note.

NOTICE

Damage due to jogging.

®

Damage to the MOVIFIT

• Do not use the line contactor for jogging, but only for switching the MOVIFIT

unit on and off. In jog mode, use the control signals (AS-Interface bits or binary inputs).

• Observe a minimum switch-off time of 10 s for the line contactor.

• Use only a contactor of utilization category AC3 (EN 60947-4-1) as a line contactor.

basic unit.

®

basic

®

Operating Instructions – MOVIFIT® basic

15

5

M5

(2,0 – 2,5 Nm)

(18 - 21 lb.in)

Electrical installation

Installation instructions

5.1.3 Notes on PE connection

WARNING

Electric shock due to incorrect connection of PE.

Severe or fatal injuries.

• Observe the following notes regarding PE connection.

PE connection in

the unit

PE connection on

the outside of the

housing

Establish a PE connection in the unit.

BR

BU

BK

GN/YE

GY

3160365451

PE

During normal operation of the MOVIFIT

BK

unused

BK or 1

WT or GY

L1

N

L2

PE

L3

®

basic inverter, earth-leakage currents

BK or 2

GN/YE

BK or 3

WT

GN

RD

≥ 3.5 mA can occur. To meet the requirements of EN 61800-5-1, you must establish 2

PE connections.

Install a second PE conductor

with a cross section of at least the cross section of the

supply system cable:

16

2816416395

Operating Instructions – MOVIFIT® basic

5.1.4 EMC-compliant installation

INFORMATION

This drive system is not designed for operation on a public low voltage supply system

that supplies residential areas.

This is a product with restricted availability in accordance with IEC 61800-3. It may

cause EMC interference. In this case, it is recommended for the operator to take

suitable measures.

For detailed information on EMC compliant installation, refer to the publication

"Electromagnetic Compatibility in Drive Engineering" from SEW-EURODRIVE.

With respect to the EMC regulation, frequency inverters cannot be operated as standalone units. Regarding EMC, they can only be evaluated when they are integrated in a

drive system. Conformity is declared for a described, CE-typical drive system. These

operating instructions contain further information.

5.1.5 Installation above 1000 m asl

®

MOVIFIT

serve the following basic conditions:

• At heights above 1000 m amsl, the nominal continuous power is reduced due to reduced cooling => I

• For heights from 2000 m to max. 4000 m amsl, observe the following notes:

– The safe disconnection of power and electronics connections can no longer be

– Connect an overvoltage protection device upstream of MOVIFIT

basic units can also be operated at an altitude of 1000 – 4000 m amsl. Ob-

assured above 2000 m. For safe disconnection, you have to take measures according to IEC 60664-1 / EN 61800-5-1.

overvoltages from category III to category II.

Electrical installation

Installation instructions

reduction by 1% per100 m.

N

®

basic to reduce

5

5.1.6 Protection devices

®

• MOVIFIT

load of the drive. External motor protection devices are not necessary.

5.1.7 UL compliant installation (in preparation)

UL and cUL approval for the MOVIFIT

basic drives are equipped with integrated protection devices against over-

®

basic unit series is in preparation.

Operating Instructions – MOVIFIT® basic

17

5

A

5.2 Topology

Electrical installation

Topology

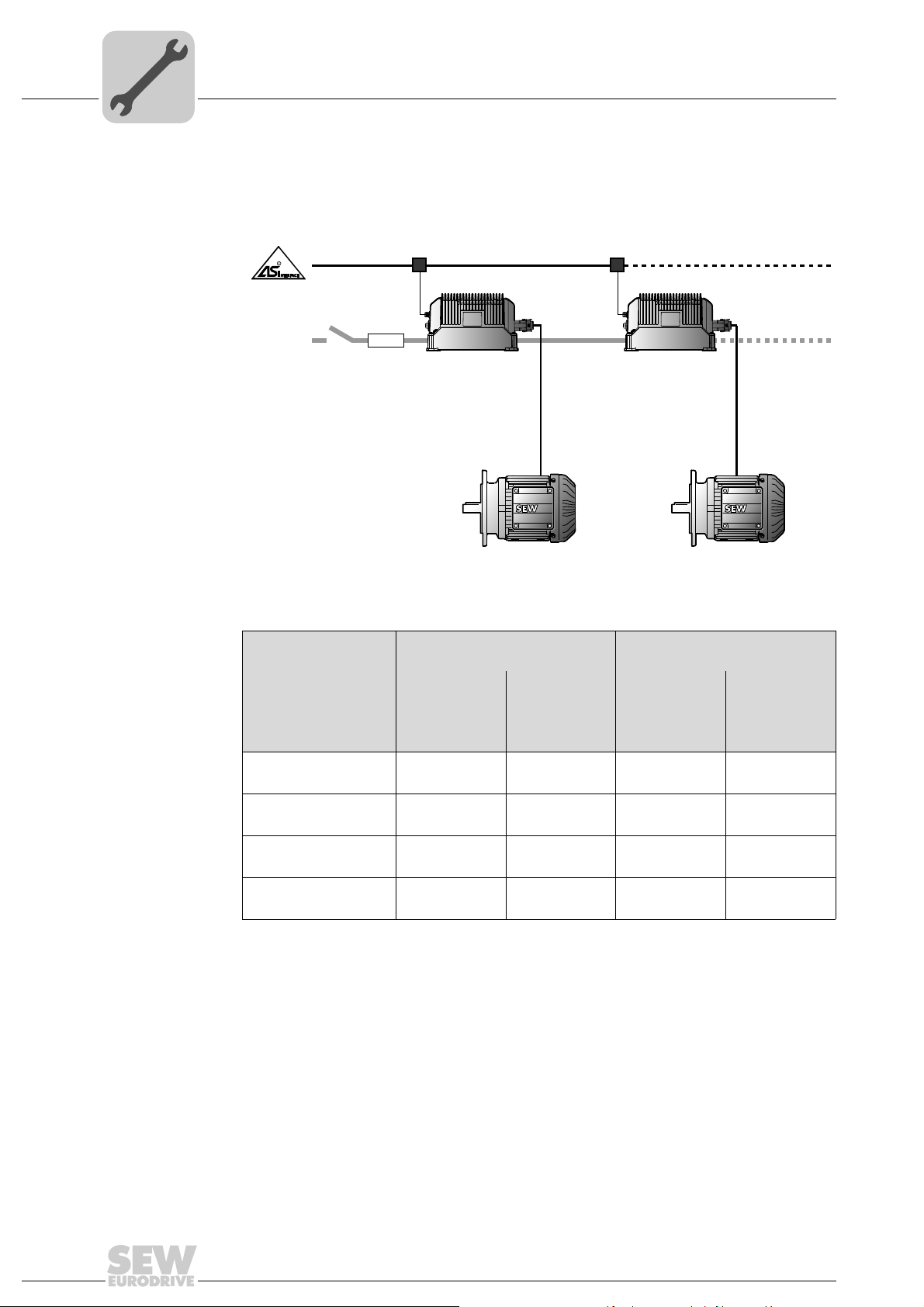

The following figure shows a typical MOVIFIT® basic drive system with AS-Interface

control:

C 3 x

380 - 480 V

K

[1]

[2] [3]

[4]

[5]

K: Line contactor

Circuit breaker for

line protection

Type Minimum con-

[1] [2] [3] [4] [5]

B16 2.5 mm

B16 2.5 mm

B20 4.0 mm

B25 6.0 mm

Power bus (line cable) Motor cable

ductor

cross section

2

AWG14

2

AWG14

2

AWG12

2

AWG10

Maximum

total length

130 m

130 m

170 m

190 m

Minimum

conductor

cross section

1.5 mm

AWG16

2.5 mm

AWG14

2.5 mm

AWG14

2.5 mm

AWG14

[4]

[5]

9007201945761931

Maximum

length

2

2

10 m

2

2

3m

3m

3m

The table shows typical characteristics at an ambient temperature of 40 °C with routing

type B2 according to EN 60204-1.

The applicable country-specific standards and regulations must also be observed for individual project planning and installation.

18

Operating Instructions – MOVIFIT® basic

5.3 Power bus connection (line cable)

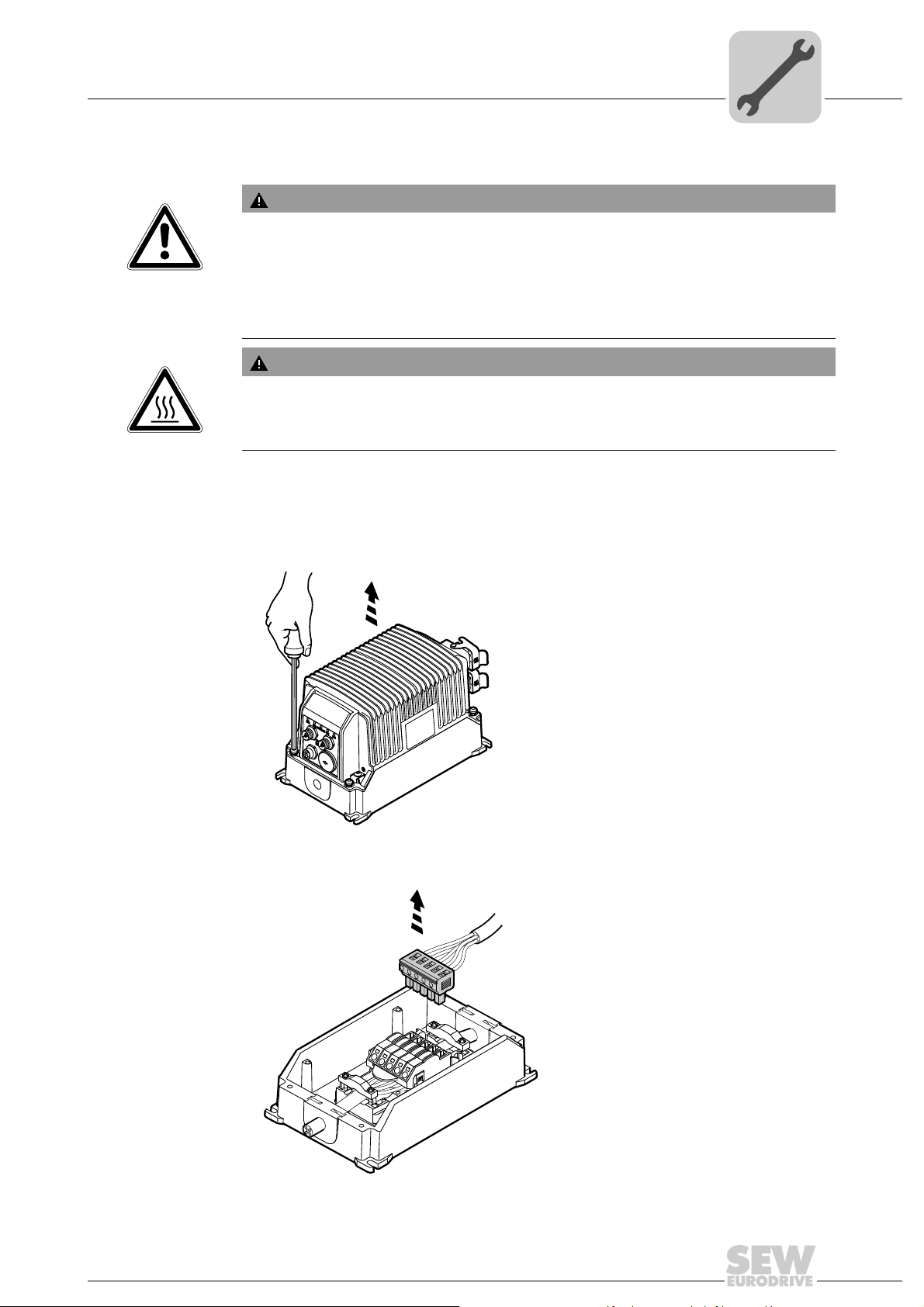

WARNING

Electric shock due to charged capacitors.

Severe or fatal injuries.

• De-energize the MOVIFIT

fore removing the EBOX from the ABOX.

• Secure the drive against unintended re-connection to the voltage supply.

• Then wait at least for 10 minutes.

WARNING

Danger of burns due to hot surfaces of the MOVIFIT® basic unit.

Severe injuries.

• Do not touch the MOVIFIT

Connect the MOVIFIT® basic unit to the power bus (line cable) as follows.

Electrical installation

Power bus connection (line cable)

®

basic drive using a suitable external cut-off device be-

®

basic until it has cooled down sufficiently.

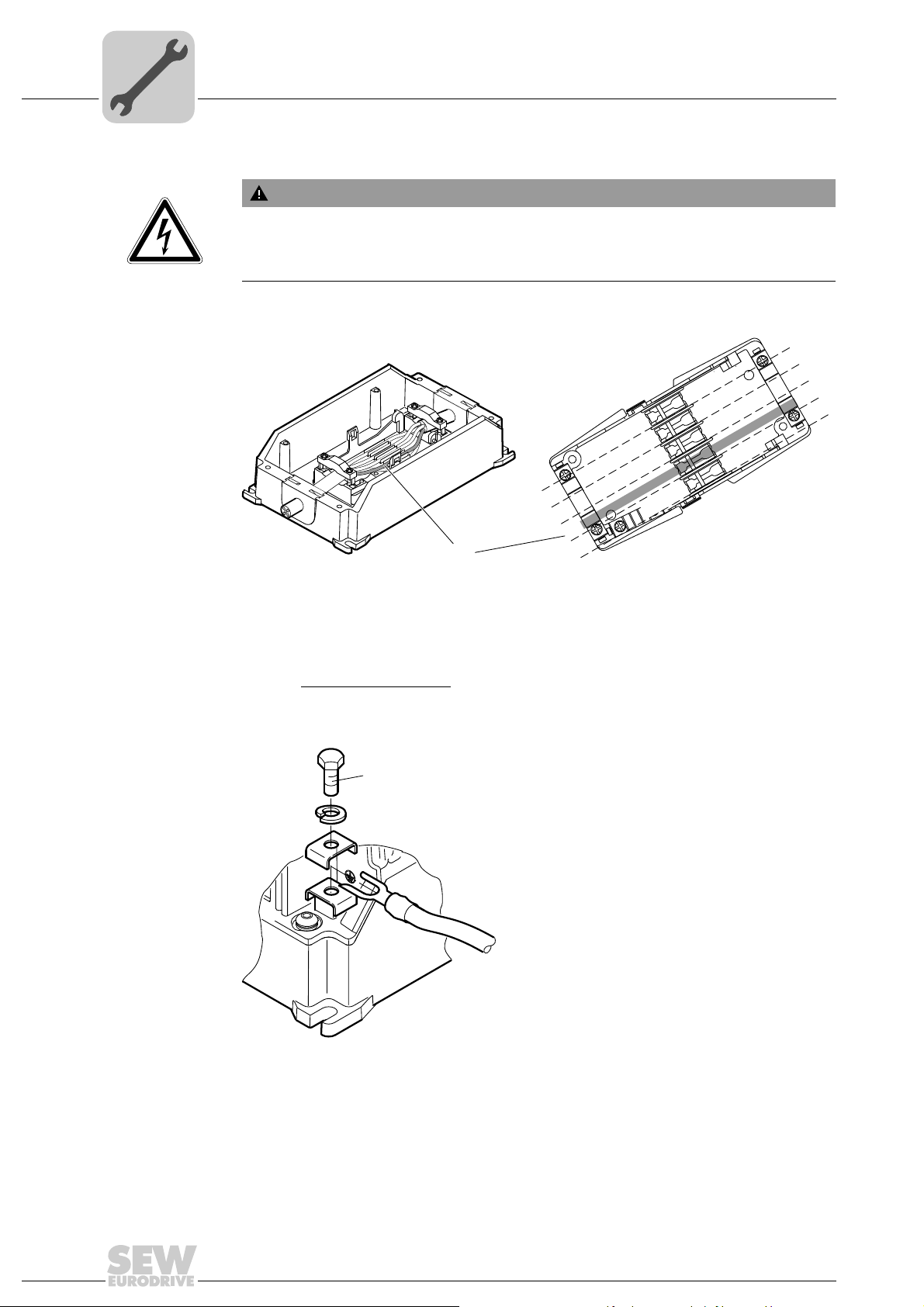

5

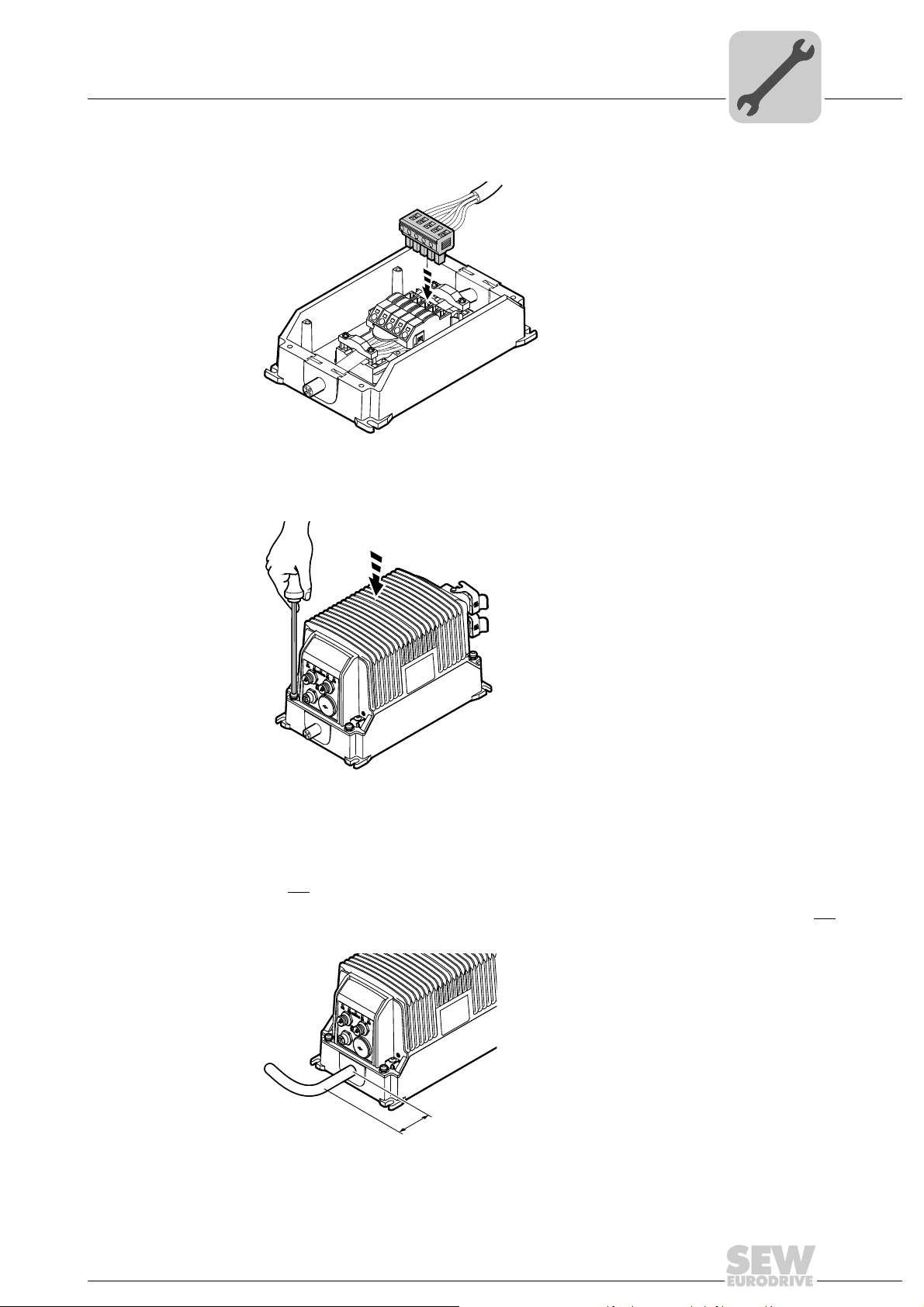

1. Loosen the 4 screws and remove the EBOX from the ABOX.

2. Remove the supply system plug connector from the FieldPower

2839862283

®

contact module.

Operating Instructions – MOVIFIT® basic

9007202094605195

19

5

120

130

Electrical installation

Power bus connection (line cable)

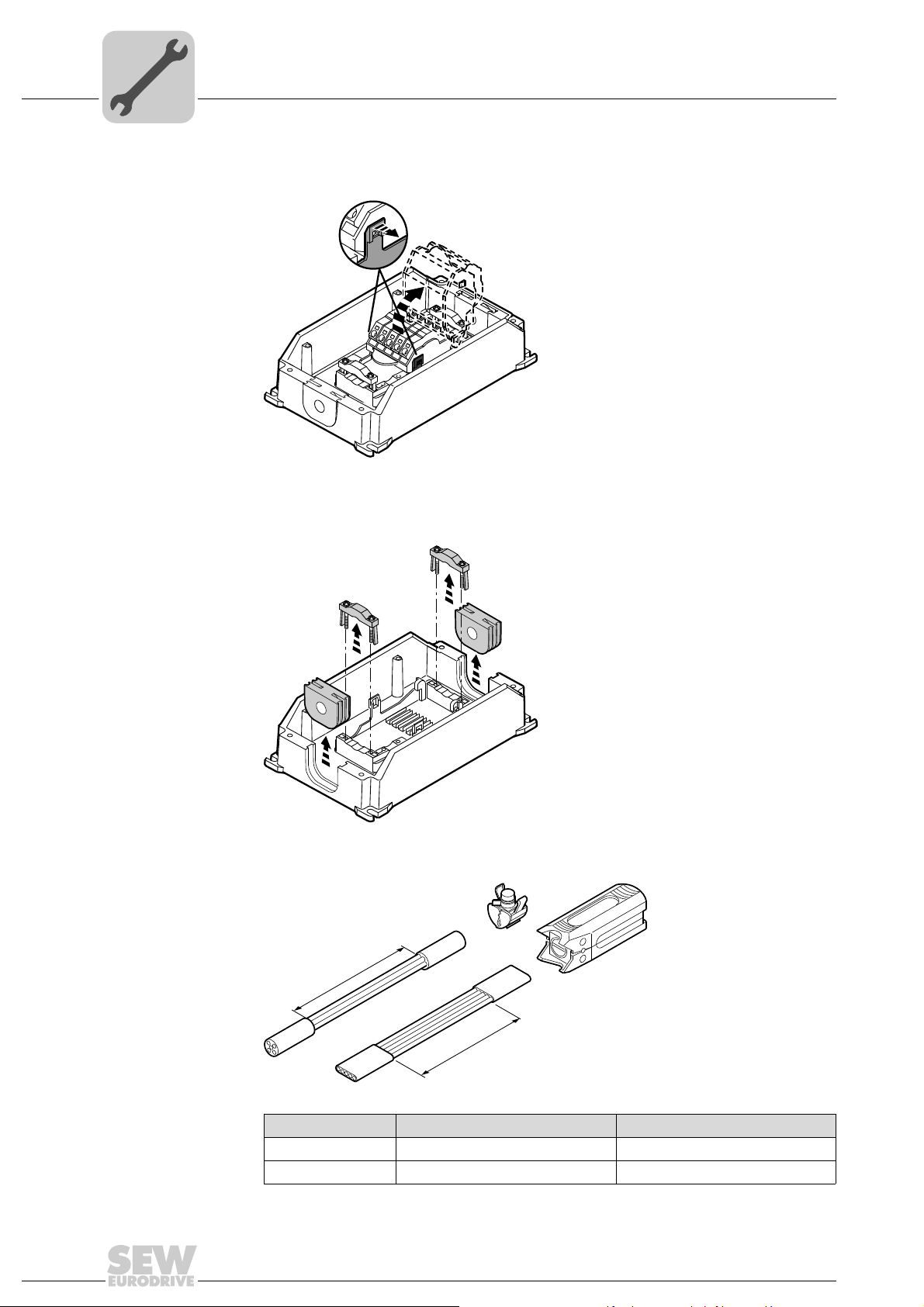

3. Pull both locking tabs to the outside and tilt up the upper part of the FieldPower® contact module.

2839866123

4. Loosen the 4 screws and remove the strain relief brackets.

Remove the two cable seals.

20

5. Remove the sheath of the line cable with a suitable stripping tool.

Line cable Stripping tool Strip length

Round cable AM 16 130 mm

Flat cable AMF 6/10 120 mm

Operating Instructions – MOVIFIT® basic

2839868043

2839869963

Electrical installation

L1

N

L2

PE

L3

L1

N

L2

PE

L3

Power bus connection (line cable)

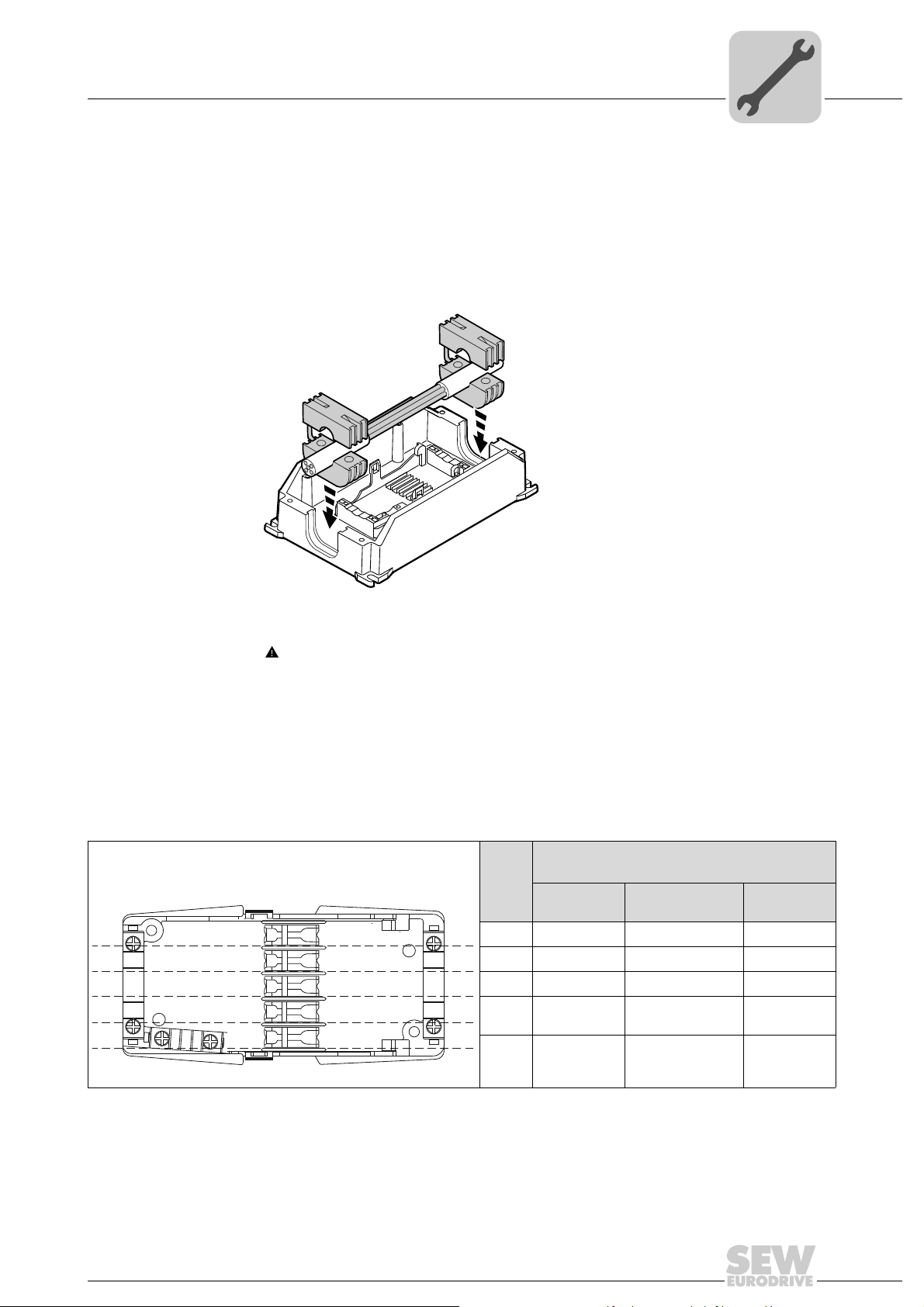

6. Fix the cable seals around the line cable.

NOTICE Ingression of moisture or dust due to incorrect cable seal.

®

Damage to the MOVIFIT

• Only use cable seals approved for the line cable diameter.

Insert the cable seals with the line cable in the recesses in the ABOX.

basic unit.

5

2839871883

7. WARNING Risk of crushing due to wrong sense of rotation or damage due to reverse connection of phases.

Severe or fatal injuries, irreparable damage to the unit.

• Observe the following connection diagram.

• Prevent short circuits.

Insert the conductors of the line cable in the cable guides according to the following

wiring diagram:

Con-

duc-

tor

L1

N

L2

PE

L3

Conductor coloring / conductor marking

According to:

IEC 60757 UL 1277

TC-ER

Brown Black or 1 Black

Blue White or gray –

Black Black or 2 White

Green/yel-

low Green/yellow Green

Gray Black or 3 Red

UL 62

STOOW

Operating Instructions – MOVIFIT® basic

2839873803

21

5

90°

AB

Electrical installation

Power bus connection (line cable)

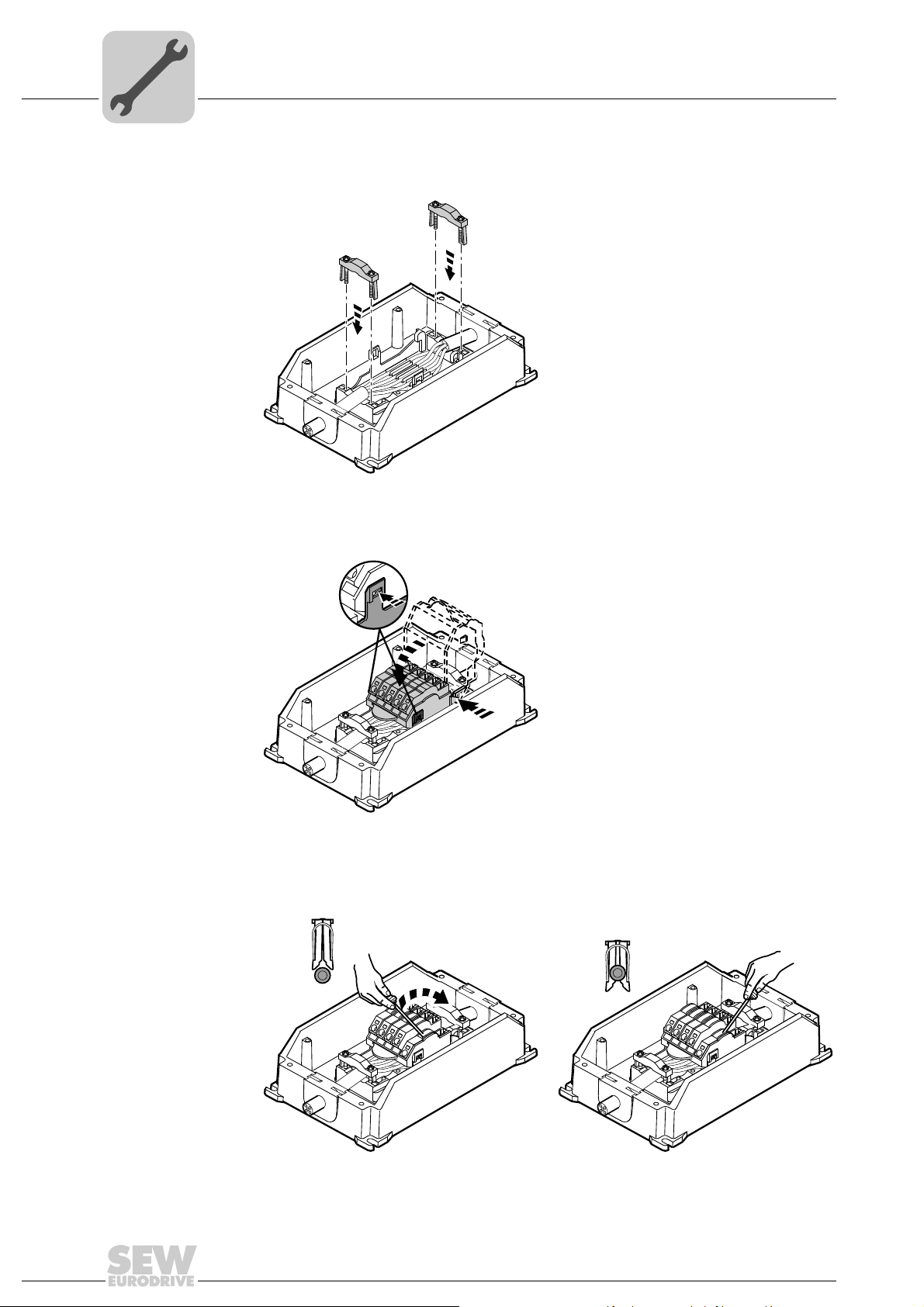

8. Screw the strain relief brackets to the ABOX and fix the line cable with the brackets

(tightening torque: 0.6 Nm, 5.3 lb.in).

2839875723

9. Place the upper part of the contact module on the hinge hooks.

Tilt down the upper part of the contact module until it latches on both sides.

2839877643

10.Use the screwdriver (blade width 3 – 3.5 mm) to lever all contacts of the insulation

displacement connector downwards.

22

Operating Instructions – MOVIFIT® basic

2839879563

Electrical installation

Power bus connection (line cable)

11.Plug in the line connector of the EBOX to the FieldPower® contact module.

2839881483

12.Position the EBOX on the ABOX.

Screw on the EBOX with 4 screws (tightening torque: 2 Nm, 18 lb.in).

5

NOTICE Ingression of moisture or dust when bending the line cable.

®

Damage to the MOVIFIT

• Do not

bend the line cable for the first 50 mm from the unit.

®

The MOVIFIT

bend within 50 mm of the unit.

basic unit only meets the IP54 requirements if the line cable is not

basic unit.

2839860363

3756680203

Operating Instructions – MOVIFIT® basic

23

5

[1]

X8

X9

[2]

[1]

X8

X9

Electrical installation

Motor connection

5.4 Motor connection

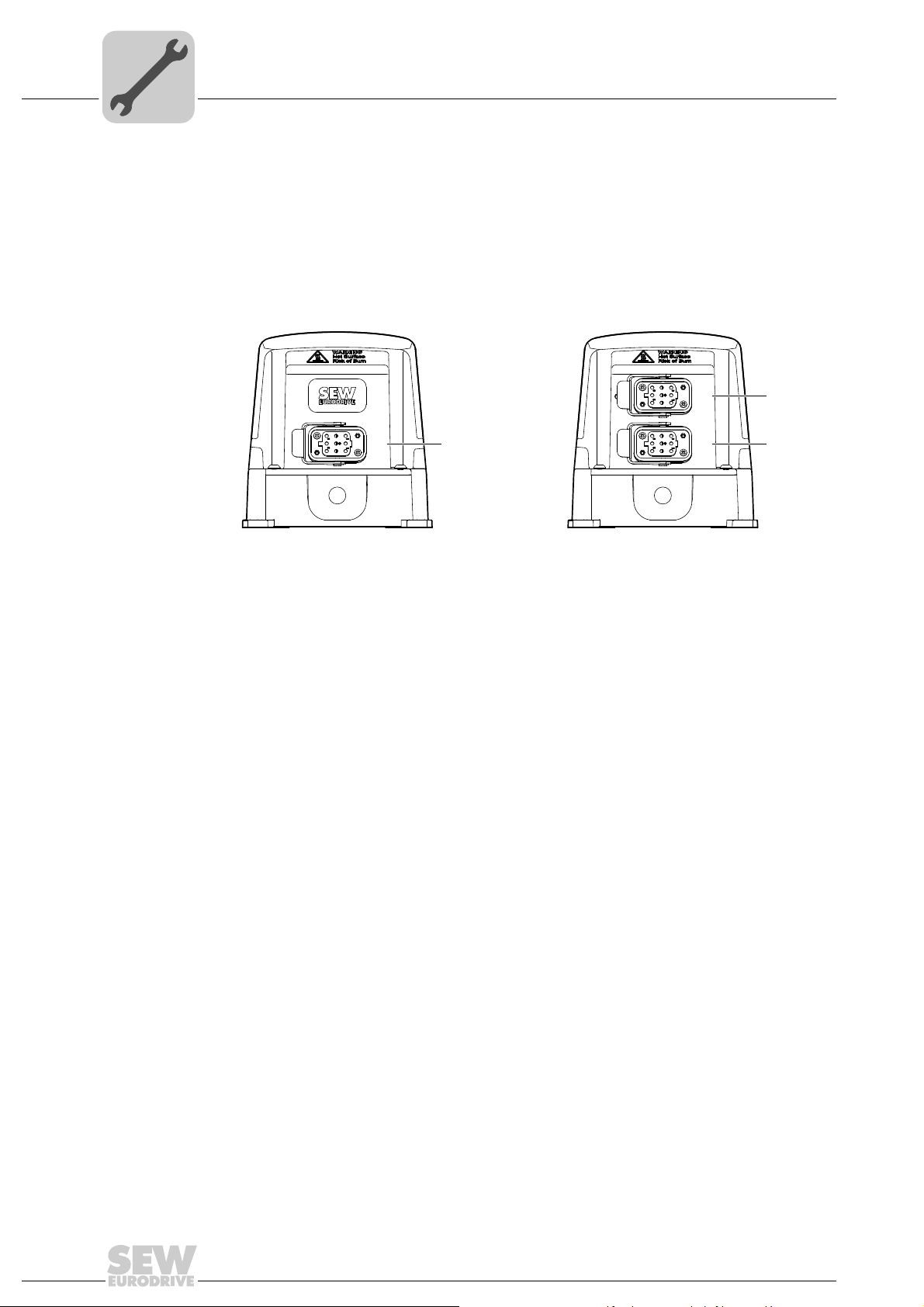

5.4.1 Motor connection variants

The following figure shows the motor plug connector variants for MOVIFIT

®

basic:

MOVIFIT

MOVIFIT

[1] X9 Motor connection

[2] X8 Motor connection

®

basic inverter

®

basic reversing starter

MOVIFIT

2816406795 2816404875

®

basic dual motor starter

24

Operating Instructions – MOVIFIT® basic

Electrical installation

8

5

3

1

2

4

PE

6

7

Motor connection

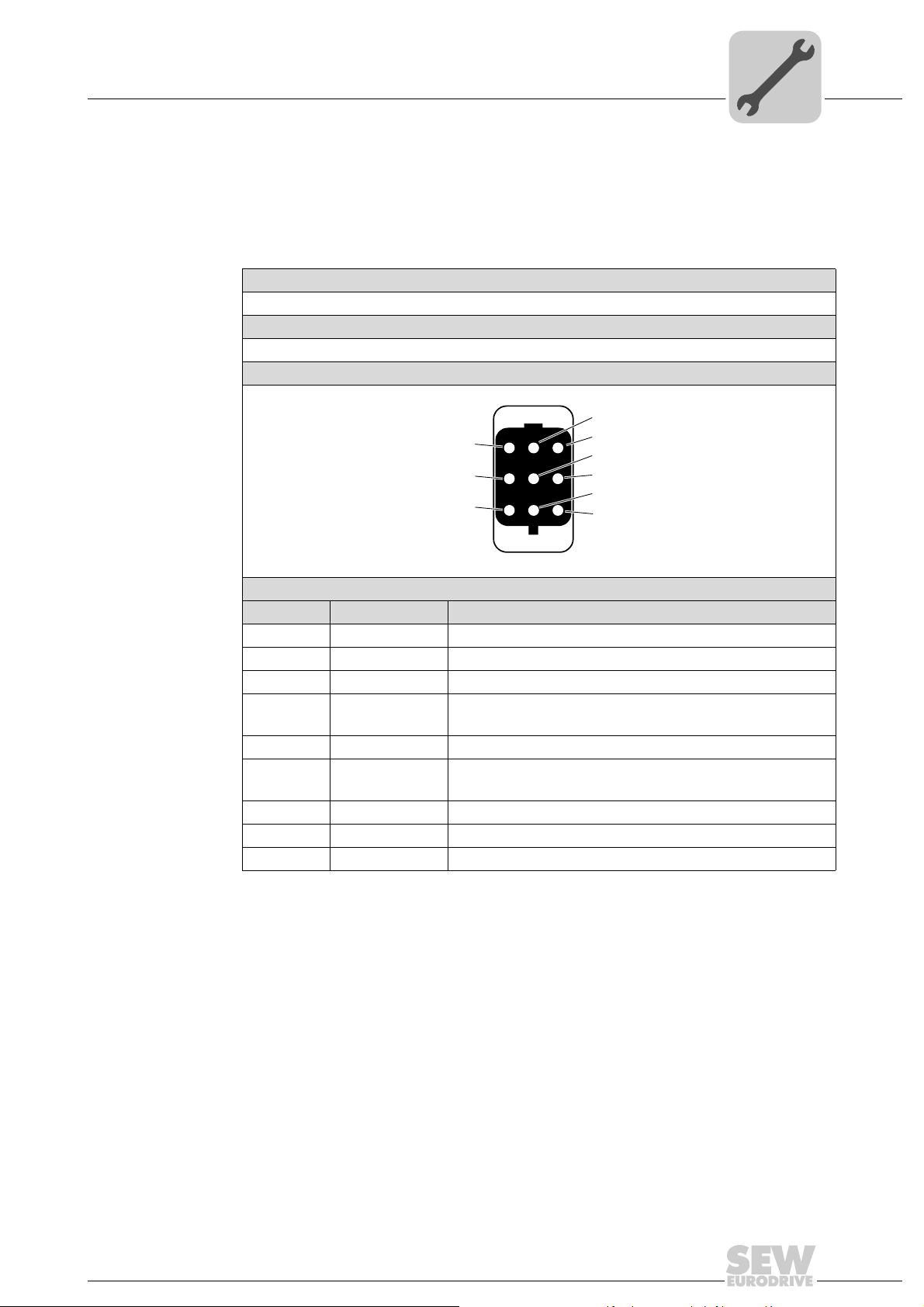

5.4.2 X9, (X8): Motor connection

The X8 plug connector is only available in conjunction with MOVIFIT

motor starter

Connection The following table provides information about this connection:

Function

Power connection for motor with brake

Connection type

Q 8/0, female

Wiring diagram

®

basic with dual-

5

Assignment

No. Name Function

1 U Motor phase U output

2 n. c. Not connected

3 W Motor phase W output

4 L1 Supply of mechanical brake

(only with MOVIFIT

5 n. c. Not connected

6 L2_S Supply of mechanical brake switched

(only with MOVIFIT

7 V Motor phase V output

8 n. c. Not connected

PE PE Protective earth

®

basic inverter)

®

basic inverter)

2441429259

Operating Instructions – MOVIFIT® basic

25

5

123

45

678

W2

U2

V2

U1

V1

W1

123

45

678

W2

U2

V2

U1

V1

W1

Electrical installation

Motor connection

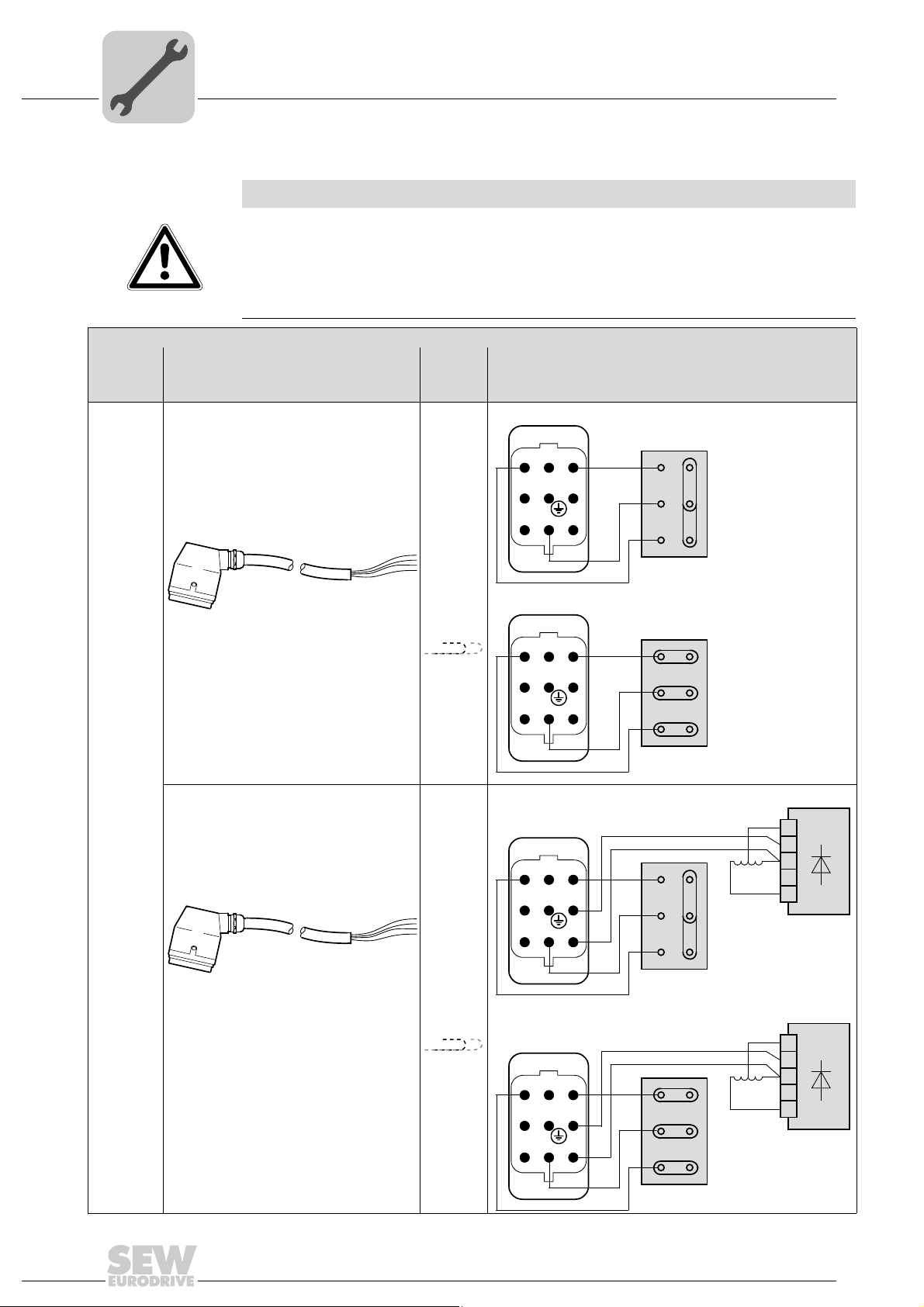

Connection cable The following table shows possible motor cables:

NOTICE

Danger in case of incorrect wiring of U1, V1, and W1 or short circuit. The motor outputs

of MOVIFIT

Irreparable damage to the MOVIFIT

• Observe the following wiring diagrams.

• Prevent any short circuits between the conductors.

Connection cable and component

MOVIFIT®

basic

Motor cable

Cable design: 4G2.5, shielded Max.

®

basic are not protected against short circuits.

Length/

Installa-

tion type

10 m

®

basic unit.

Motor connection

Motor without brake,

댴 connection

MOVIFIT

basic

inverter

Cable design: 4G2.5, unshielded

Part number: 1 814 874 3

Q 8/0 Open

®

Cable design: 7G2.5, shielded

Cable design: 7G2.5, unshielded

Part number: 1 814 992 8

Max. 3 m

Max.

10 m

Max. 3 m

Motor without brake,

Motor with brake,

123

45

U1

V1

쑶 connection

댴 connection

WH

W2

U2

RD

BU

BG

1

2

3

4

5

26

678

W1

V2

Q 8/0 Open

Motor with brake,

123

45

678

U1

V1

W1

Operating Instructions – MOVIFIT® basic

쑶 connection

WH

W2

U2

V2

RD

BU

BG

1

2

3

4

5

Connection cable and component

123

45

678

W2

U2

V2

U1

V1

W1

MOVIFIT®

basic

Motor cable

Cable design: 4G2.5, unshielded Max.

Length/

Installa-

tion type

10 m

Electrical installation

Motor connection

Motor connection

Motor without brake

5

MOVIFIT®

basic

motor

starter

Cable design: 4G2.5, unshielded

Part number: 1 814 874 3

Q 8/0 Open

3m Motor with brake

123

45

678

U1

V1

W1

W2

U2

V2

Motor with brake and BSR brake controller

123

45

678

U1

V1

W1

W2

U2

V2

BU

WH

RD

BU

WH

RD

BGE

1

BG

2

3

4

5

BGE

1

BG

2

3

4

5

For applications with regenerative mode, SEW-EURODRIVE recommends the BSR brake controller.

Mating connector Use a type Q8/0 plug connector for pre-fabricating these motor cables:

INFORMATION

Note the following when using a mating connector with metallic housing:

• Ensure a suitable shield connection.

• Connect the housing of the mating connector with PE.

Operating Instructions – MOVIFIT® basic

27

5

DI3 DI2 DI1 DI0

STATUS

[5]

[8] [7]

[6]

Electrical installation

Control unit connection

5.5 Control unit connection

The following figure shows the control unit variants for MOVIFIT®basic:

MOVIFIT

®

basic with AS-Interface MOVIFIT®basic with binary control

[1]

DI3 DI2

[4] [3]

STATUS

[2]

AS-Interface

9007202071153547 2816402955

[1] X22 Binary input sensor 2 [5] X12 Signal inputs DI2 + DI3

[2] X21 AS-Interface connection [6] X11 Signal inputs DI0 + DI1

[3] X50 Diagnostic interface [7] X50 Diagnostic interface

[4] X23 Binary input sensor 3 [8] X13 Signal outputs DO0 + DO1

28

Operating Instructions – MOVIFIT® basic

Connections of MOVIFIT®basic with AS-Interface

2

1

4

3

5.6 Connections of MOVIFIT

5.6.1 X21: AS-Interface connection

The following table provides information about this connection:

Function

AS-Interface – input

Connection type

M12, 4-pole, male, A-coded

Wiring diagram

Assignment

No. Name Function

1 AS-Interface + AS-Interface +

2 n. c. Not connected

3 AS-Interface − AS-Interface −

4 n. c. Not connected

Electrical installation

®

basic with AS-Interface

5

2384154763

5.6.2 X22: Binary input sensor 2

The following table provides information about this connection:

Function

Binary input sensor 2

Connection type

M12, 5-pole, female, A-coded

Wiring diagram

Assignment

No. Name Function

1 +24 V DC 24 V output (sensor supply)

2 n. c. Not connected

3 0V24 0V24 reference potential

4 DI2 Binary input sensor 2

5 PE Equipotential bonding/protective earth conductor

1

4

2

3

5

2264816267

Operating Instructions – MOVIFIT® basic

29

5

1

6

Electrical installation

Connections of MOVIFIT®basic with AS-Interface

5.6.3 X23: Binary input sensor 3

The following table provides information about this connection:

Function

Binary input sensor 3

Connection type

M12, 5-pole, female, A-coded

Wiring diagram

Assignment

No. Name Function

1 +24 V DC 24 V output (sensor supply)

2 n. c. Not connected

3 0V24 0V24 reference potential

4 DI3 Binary input sensor 3

5 PE Equipotential bonding/protective earth conductor

5.6.4 X50: Diagnostic interface

The following table provides information about this connection:

Function

Diagnostics and programming interface

Connection type

RJ11 (6P6C)

Wiring diagram

1

4

2

3

5

2264816267

3163123211

Assignment

No. Name Function

1 n. c. Not connected

2 RS+ RS-485 data cable (+)

3RS − RS-485 data cable (–)

4 +24 V DC 24 V output for keypad

5 0V24 0V24 reference potential for keypad

6 n. c. Not connected

30

Operating Instructions – MOVIFIT® basic

Connections of MOVIFIT®basic with binary control

2

1

4

3

2

1

4

3

®

5.7 Connections of MOVIFIT

5.7.1 X11: Signal inputs 0 and 1 of MOVIFIT® basic

The following table provides information about this connection:

Function

Binary inputs 0 and 1

Connection type

M12, 4-pole, male, A-coded

Wiring diagram

Assignment

No. Name Function

1 n. c. Not connected

2 DI1 Binary input 1

3 0V24 0V24 reference potential

4 DI0 Binary input 0

basic with binary control

Electrical installation

5

2718233355

5.7.2 X12: Signal inputs 2 and 3 of MOVIFIT

The following table provides information about this connection:

Function

Binary inputs 2 and 3

Connection type

M12, 4-pole, male, A-coded

Wiring diagram

Assignment

No. Name Function

1 n. c. Not connected

2 DI3 Binary input 3

3 0V24 0V24 reference potential

4 DI2 Binary input 2

®

basic

2718233355

Operating Instructions – MOVIFIT® basic

31

5

1

4

3

2

5

1

6

Electrical installation

Connections of MOVIFIT®basic with binary control

5.7.3 X13: Signal outputs 0 and 1 of MOVIFIT® basic

The following table informs about this connection:

Function

Binary outputs 0 and 1

Connection type

M12, 5-pole, female, A-coded

Wiring diagram

Assignment

No. Name Function

1 +24 V DC 24 V output

2 DO1 Binary output 1 (manual mode)

3 0V24 0V24 reference potential

4 DO0 Binary output 0 (ready signal)

5 PE Equipotential bonding/protective earth conductor

0: MOVIFIT

1: Manual control of MOVIFIT

0: MOVIFIT

1: MOVIFIT

®

basic control via control signals

®

basic is not ready

®

basic is ready

®

2264816267

basic

5.7.4 X50: Diagnostic interface

The following table informs about this connection:

Function

Diagnostics and programming interface

Connection type

RJ11 (6P6C)

Wiring diagram

Assignment

No. Name Function

1 n. c. Not connected

2 RS+ RS-485 data line (+)

3RS − RS-485 data cable (–)

4 +24 V DC 24 V output for keypad

5 0V24 0V24 reference potential for keypad

6 n. c. Not connected

3163123211

32

Operating Instructions – MOVIFIT® basic

Electrical installation

Connection of operator terminals LT-BG and MB-LC

5.8 Connection of operator terminals LT-BG and MB-LC

MOVIFIT® basic units are equipped with an X50 diagnostic interface (RJ11 socket).

The diagnostics interface is located in the connection block of the control unit.

You must remove the screw plug before plugging in the connector into the diagnostic

interface.

WARNING Danger of burns due to hot surfaces of the MOVIFIT

Severe injuries.

®

• Wait for the MOVIFIT

NOTICE Loss of the ensured degree of protection if the screw plug of the diagnostic interface X50 is not installed.

Damage to the MOVIFIT

basic unit to cool down sufficiently before touching it.

®

basic unit.

®

basic unit.

5

• If there is no screw plug covering the diagnostic interface, you have to make sure that

no moisture can ingress into the MOVIFIT

Use the cable enclosed with the operator terminal to connect the operator terminal to

the MOVIFIT

Scope of delivery:

Type Part number Scope of delivery

LT-BG 1 820 864 9 – LT-BG operator terminal

MB-LC 2 820 126 4 – MB-LC operator terminal

®

basic unit.

®

basic unit.

– Cable with RJ11 – RJ11 plug connectors

– Cable with RJ45 – RJ11 plug connectors

Operating Instructions – MOVIFIT® basic

18014401325896459

33

5

5.9 PC connection

Electrical installation

PC connection

The MOVIFIT® basic inverter is equipped with an X50 diagnostics interface (RJ-11

socket) for startup, parameterization and service.

The diagnostics interface is located in the connection block of the control unit.

You must remove the screw plug before plugging in the connector into the diagnostic

interface.

®

WARNING Danger of burns due to hot surfaces of the MOVIFIT

Severe injuries.

®

• Wait for the MOVIFIT

basic unit to cool down sufficiently before touching it.

NOTICE Loss of the ensured degree of protection if the screw plug of the diagnostic interface X50 is not installed.

®

Damage to the MOVIFIT

basic unit.

basic unit.

• If no screw plug is covering the diagnostic interface, you have to make sure that no

moisture can ingress into the MOVIFIT

®

basic unit.

The diagnostic interface can be connected to a conventional PC/laptop with the following accessories:

• USB11A interface adapter

•and

OP LT 003 C adapter

Scope of delivery:

Type Part number Scope of delivery

USB11A 0 824 831 1 – USB11A interface adapter

– USB cable

– Cable with RJ10 – RJ10 plug connectors

OP LT 003 C 1 824 368 1 – OP LT 003 C adapter

with DC 24 V -> DC 5 V voltage converter

– Cable with RJ45 – RJ11 plug connectors

34

PC +

MOVITOOLS

USB

®

USB11A

RJ10

OP LT 003 C

Operating Instructions – MOVIFIT® basic

RJ45

RJ11

MOVIFIT basic

9007202071149707

®

6Startup

00

I

6.1 Important notes on startup

INFORMATION

You must comply with the general safety notes in chapter "Safety notes" during

startup.

WARNING

Risk of crushing due to missing or defective protective covers.

Severe or fatal injuries.

• Install the protective covers of the plant according to the instructions, also see the

operating instructions of the gear unit.

• Never start up the drive if the protective covers are not installed.

WARNING

Electric shock due to dangerous voltages in the ABOX.

Severe or fatal injuries.

• De-energize the MOVIFIT

fore removing the EBOX.

• Secure the MOVIFIT

supply.

• Wait for at least 10 minutes before removing the EBOX.

Startup

Important notes on startup

®

basic unit using a suitable external cut-off device be-

®

basic unit against unintended re-connection to the voltage

6

WARNING

Danger of burns due to hot surfaces of the MOVIFIT® basic unit.

Severe injuries.

®

• Do not touch the MOVIFIT

basic until it has cooled down sufficiently.

WARNING

Unit malfunction due to incorrect unit setting.

Severe or fatal injuries.

• Observe the startup notes.

• The installation must only be carried out by qualified personnel.

• Use only settings that are consistent with the function.

INFORMATION

To ensure fault-free operation, do not disconnect or connect power or signal cables

during operation.

Operating Instructions – MOVIFIT® basic

35

6

00

I

6.2 Requirements

Startup

Requirements

The following conditions apply to startup:

®

• The MOVIFIT

cally.

• Appropriate safety measures prevent the drives from starting up unintentionally.

• Appropriate safety measures must be taken to prevent risk of injury or damage to the

machine.

The following hardware must be available for startup and parameterization of the

MOVIFIT

• Operator terminal LT-BG, see chapter "Connecting the operator terminals LT-BG

• or PC/laptop, see chapter "PC connection"

®

basic inverter:

and MB-LC"

basic unit must be installed correctly both mechanically and electri-

The following software must be available on the PC or laptop for startup and parameterization of the MOVIFIT

• LT Shell", version 3.20 or later

®

basic inverter:

INFORMATION

For startup of the MOVIFIT® basic motor starter, you do not require a PC/laptop and

software.

36

Operating Instructions – MOVIFIT® basic

Startup procedure for the MOVIFIT® basic inverter

00

I

6.3 Startup procedure for the MOVIFIT

Proceed as follows to startup the MOVIFIT® basic inverter:

1. Check the connection of the MOVIFIT

See chapter "Electrical Installation".

2. Make sure that the motor cannot start

e.g. by unplugging the motor connector from the MOVIFIT

3. Switch on the line voltage.

The "Status" LED is now illuminated.

4. Connect the LT-BG operator terminal or the PC to the MOVIFIT

See chapter "Connecting the operator terminals LT-BG and MB-LC" (page 33)

or chapter "PC connection" (page 34).

WARNING During the auto-tune phase in vector control, the motor axis briefly

rotates.

If you set the parameter P4-02 Auto-tune = "1", the inverter performs a calibration

process (Auto-tune). The inverter releases the brake and the motor briefly rotates.

®

basic inverter

®

basic unit.

Startup

®

basic unit.

®

6

basic unit.

Severe injuries.

• During the auto-tune phase, observe a sufficient safety distance to all parts driven

by the motor.

5. Set the following parameters:

Motor parameters:

For V/f control

• P1-07 = Nominal motor voltage

• P1-08 = Nominal motor current

• P1-09 = Nominal motor frequency

System parameters:

• P1-03 = Acceleration ramp

• P1-04 = Deceleration ramp

• P1-11 = Speed n1

• P2-02 = Speed n2

• P2-03 = Speed n3

• P2-04 = Speed n4

See chapter "Parameterization with LT-BG operator terminal" (page 43).

or chapter "Parameterization with PC" (page 45).

6. Make sure the screw plug of the diagnostics interface has a seal and screw it in.

For vector control

• P1-07 = Nominal motor voltage

• P1-08 = Nominal motor current

• P1-09 = Nominal motor frequency

• P4-01 = Control mode

• P4-02 = Auto-tune

• P4-05 = motor power factor

NOTICE Loss of the ensured degree of protection if the screw plug of the diagnostic

interface is not installed or not installed correctly.

Damage to the MOVIFIT

• Make sure the screw plug of the diagnostics interface has a seal and screw it in.

7. Switch off the line voltage.

8. Set the AS-Interface slave address of the MOVIFIT

basic with AS-Interface).

See chapter "Assigning the AS-Interface address" (page 40).

Operating Instructions – MOVIFIT® basic

®

basic unit

®

basic unit (only for MOVIFIT

®

37

6

00

I

Startup

Startup procedure for the MOVIFIT® basic inverter

9. Start up the higher-level controller.

®

10.Plug in the motor connector at the MOVIFIT

11.Switch on the line voltage.

®

You can now control the MOVIFIT

signals or AS-Interface).

basic drive with the higher-level controller (via binary

basic.

38

Operating Instructions – MOVIFIT® basic

6.4 MOVIFIT

00

I

MOVIFIT® basic motor starter – startup procedure

®

basic motor starter – startup procedure

WARNING

Electric shock due to dangerous voltages in the ABOX.

Severe or fatal injuries.

®

• De-energize the MOVIFIT

fore removing the EBOX.

• Secure the MOVIFIT

supply.

Proceed as follows to startup the MOVIFIT® basic motor starter:

1. Check the connection of the MOVIFIT

See chapter "Electrical Installation".

basic unit using a suitable external cut-off device be-

®

basic unit against unintended re-connection to the voltage

®

basic unit.

Startup

6

Reversing starter:

Dual motor starter:

2. Set the I

= nominal motor current as listed on the motor nameplate

I

Mot

= nominal output current as listed on the MOVIFIT® basic nameplate

I

N

/ IN ratio at the I

Mot

NOTICE Damage due to incorrect setting of I

potentiometer (factory setting: about 100%).

Motor

potentiometer. The potentiometer

Motor

setting protects the motor against overload.

Damage to the motor.

• When setting the potentiometer, observe the current rating on the nameplates of

®

60

20

basic unit.

60

40

20

80

100

60

40

20

80

100

80

100

I [A]

Motor

10

8

6

4

2

0

0 20 40 60 80 100

9007203014544907

I [A]

Motor

5

4

3

2

the motor and the MOVIFIT

40

[1]

7

7

7

4

0

5

6

7

1

5

[1] Potentiometer setting I

Operating Instructions – MOVIFIT® basic

/ IN in %

Mot

1

0

0 20 40 60 80 100

7774056715

[1]

39

6

00

I

Startup

Assigning the AS-Interface slave address

3. Make sure that the motor cannot start

e.g. by unplugging the motor connector(s) from the MOVIFIT

4. Set the AS-Interface slave address of the MOVIFIT

basic with AS-Interface).

See chapter "Assigning the AS-Interface address" (page 40).

5. Start up the higher-level controller.

6. Plug in the motor connector(s) at MOVIFIT

7. Switch on the line voltage.

You can now control the MOVIFIT

signals or AS-Interface).

6.5 Assigning the AS-Interface slave address

SEW-EURODRIVE supplies MOVIFIT®basic with AS-Interface with address 0.

®

basic unit.

®

basic unit (only for MOVIFIT

®

basic.

®

basic drive with the higher-level controller (via binary

®

You have the following options for assigning the AS-Interface address of MOVIFIT

basic (address 1 - 31):

• Addresses are assigned automatically within a configured AS-Interface system

®

when replacing a MOVIFIT

basic drive.

The following prerequisites must be fulfilled:

®

–The new MOVIFIT

– If you need to replace multiple MOVIFIT

basic drive must have address 0.

®

basic drives, you must exchange them

individually (one after another).

• Manual address assignment via the plant master

Connect the drives to the AS-Interface cable one after another. Doing so prevents

®

several MOVIFIT

basic drives being assigned the same AS-Interface address.

• Manual address assignment using a hand-held AS-Interface programming

device.

®

Observe the notes in the following section when connecting the MOVIFIT

basic

drive to the AS-Interface cable.

®

40

Operating Instructions – MOVIFIT® basic

Assigning the AS-Interface slave address

2

1

4

3

A

B

MOVIFIT basic

[1]

®

MOVIFIT basic

®

00

I

6.5.1 Assigning the slave address using a hand-held programming device

Hand-held AS-Interface programming devices offer the following functions:

• Reading out and changing an AS-Interface slave address

• Reading out the AS-Interface profile

• Reading out and changing the data and parameter bits

• Function check and test run.

Startup

6

When using a hand-held programming device, you need a connection cable that fits onto

®

the AS-Interface plug connector X21 of MOVIFIT

basic (see the following figure).

1: AS-Interface +

2. n. c.

3: AS-Interface −

4: n. c.

2384154763

Example:

1. Disconnect the AS-Interface nodes from the AS-Interface network one at a time and

assign addresses via the hand-held programming device (A).

2. Then reconnect the respective AS-Interface node to the AS-Interface network (B).

9007202092542475

[1] AS-Interface hand-held programming device

Operating Instructions – MOVIFIT® basic

41

6

00

I

Startup

Parameterization with LT-BG keypad

6.6 Parameterization with LT-BG keypad

6.6.1 Description of LT-BG keypad

Function You can use the LT-BG keypad for startup, parameterization and manual operation of

MOVIFIT

about the state of the drive.

Features • Illuminated display

• Keypad with 5 keys

• Connection cable

Key assignment The following figure shows the key assignment of the LT-BG operator terminal:

®

basic inverters. In addition to that, the keypad displays important information

Key Navigate • Switch menu

• Saving parameter values

• Show real-time information

Key Up • Increase speed

• Increase parameter values

Key Down • Decrease speed

• Decrease parameter values

Key Stop • Stop the drive

• Reset the drive

Key Start • Enabling the drive

• Changing the direction of rotation

2669822603

42

Operating Instructions – MOVIFIT® basic

6.6.2 Parameterization

00

I

Proceed as follows to change the parameter values:

Startup

Parameterization with LT-BG keypad

6

1. Check the connection of the MOVIFIT

See chapter "Electrical Installation".

2. Connect the LT-BG operator terminal to the MOVIFIT

See chapter "Connecting the operator terminals LT-BG and MB-LC" (page 33)

3. Make sure that the motor cannot start

e.g. by unplugging the motor connector(s) from the MOVIFIT

Switch on the line voltage.

4.

After initialization, the operator terminal shows the rotational fre-

quency "H", the output current "A", or the motor power "P".

To change the display, briefly press the key.

Use the key to activate the parameter mode.

5.

(Press the key for more than 1 s)

Use the key and the key to select the desired parameter.

6.

Use the key to activate the setting mode.

7.

®

basic unit.

®

basic unit.

®

basic unit.

H 50.0

P 1 - 0 1

P 1 - 0 3

5.0

Use the key and the key to set the required parameter

8.

value.

Use the key to quit the setting mode.

9.

Use the key to quit the parameter mode.

10.

(Press the key for more than 1 s)

The operator terminal shows "StoP", "H ", "A ", or "P ".

11. Switch off the line voltage.

®

12. Plug in the motor connector(s) at the MOVIFIT

13. NOTICE Damage due to missing or incorrectly mounted screw plug of the diagnostics interface X50. The degree of protection of MOVIFIT

"Technical data" only applies if the screw plug of the diagnostic interface is mounted

correctly.

®

Damage to the MOVIFIT

• Once you have finished working with the operator terminal, unplug the connector

from the diagnostics interface.

• Screw the screw plug of the diagnostics interface back in with the seal.

For a description of the parameters, refer to chapter "Parameter list – MOVIFIT

inverter"

basic unit.

basic unit.

®

basic specified in chapter

2.0

P 1 - 0 3

S t o P

®

basic

Operating Instructions – MOVIFIT® basic

43

6

00

I

6.6.3 Reset parameters to default settings

Startup

Parameterization with LT-BG keypad

To reset the parameters to their default value, proceed as follows:

1. Check the connection of the MOVIFIT

See chapter "Electrical Installation".

2. Connect the LT-BG operator terminal to the MOVIFIT

See chapter "LT-BG operator terminal connection".

3. Press the 3 keys , , and simultaneously for at least 2 s.

After 2 s, the display shows "P-def".

4. Press the key to confirm the factory settings.

®

basic unit.

®

basic unit.

44

Operating Instructions – MOVIFIT® basic

6.7 Parameterization with the PC

00

I

(Only for MOVIFIT® basic inverter)

6.7.1 Parameterization with LT Shell software

Proceed as follows to change the parameter values via the PC:

1. Check the connection of the MOVIFIT

See chapter "Electrical Installation".

2. Connect the PC/laptop to the MOVIFIT

See chapter "PC connection".

3. Start the LT Shell V4.0.exe software.

4. Select the COM port of the PC/laptop, the MOVIFIT

Startup

Parameterization with the PC

®

basic unit.

®

basic unit.

®

basic unit is connected to.

6

5. Choose the communication type RS485.

9007203037920011

7828289163

Operating Instructions – MOVIFIT® basic

45

6

00

I

Startup

Parameterization with the PC

6. Read the parameter set with the button of the MOVIFIT® basic.

The parameter menu is displayed:

[1] [2] [3] [4] [5] [6] [7]

[1] Open parameter set

[2] Save parameter set on PC

[3] Shows the units in the network

[4] Restore factory settings of the unit

[5] Read parameter set from MOVIFIT

[6] Transmit parameter set to MOVIFIT

[7] Select parameter group

®

basic unit.

®

basic unit.

7. Select the required parameter group [7].

8. Double-click the required parameter.

9. Enter the new parameter value into the input field.

10.Transmit the parameter set from the PC to the MOVIFIT

ton.

9007203038730891

®

basic using the but-

46

Operating Instructions – MOVIFIT® basic

6.7.2 Real-time edit mode

Add Virtual Drive

Scan Drive Nezwork

Real-Time Edit Mode

Scans for Drives on the Network

Add Virtual Drive

Scan Drive Network

Real-Time Edit Mode

Scans for Drives on the Network

Add Virtual Drive

Offline Mode

Real-Time Edit Mode

Enables Real-Time Edit Mode

Enables Real-Time Edit Mode

Add Virtual Drive

Offline Mode

Real-Time Edit Mode

00

I

Startup

Parameterization with the PC

6

In real-time edit mode, the parameter changes become active immediately in the

®

MOVIFIT

basic inverter.

WARNING

Risk of crushing if the drive starts up unintentionally and risk of impact due to sudden

changes in velocity. When the drive is enabled, a parameter change affects the drive

system immediately.

Severe or fatal injuries.

• Make sure that the drive is inhibited

• Take additional safety precautions depending on the application to avoid injury to

people and damage to machinery.

Proceed as follows to change the parameter values in real-time edit mode:

®

1. If the MOVIFIT

basic unit has not been set up yet in the LT Shell software, carry

out the steps 1 to 5 of chapter "Parameterization with LT Shell software".

2. Scan the network for existing drives.

before you activate the real-time edit mode.

Operating Instructions – MOVIFIT® basic

7832409995

3. Activate the real-time edit mode by clicking the [Real-time edit mode] button.

7828297995

47

6

Add Virtual Drive

Offline Mode

Real-Time Edit Mode

Enter offline mode

Add Virtual Drive

Offline Mode

Real-Time Edit Mode

Enter offline mode

00

I

Startup

Parameterization with the PC

4. Select the required parameter group.

5. Double-click the required parameter.

6. Enter the new parameter value into the input field.

7. Exit the real-time edit mode by activating offline mode with the [Offline mode] button.

7832413579

48

Operating Instructions – MOVIFIT® basic

Parameter directory of the MOVIFIT® basic inverter

00

I

6.8 Parameter directory of the MOVIFIT

®

basic inverter

Startup

6

The following tables show the unit-relevant parameters. The keypad shows additional

parameters that are without function for MOVIFIT

®

basic.

6.8.1 Standard parameters

The following table shows the standard parameters:

No. Name Range Standard Description

P1-01 Upper speed limit

[Hz] or [rpm]

P1-02 Lower speed limit

[Hz] or [rpm]

P1-03 Acceleration ramp 0.0 s – 3000 s 5.0 s Time for acceleration along the

P1-04 Deceleration ramp 0.0 s – 3000 s 5.0 s Time for deceleration from the nom-

P1-06 Energy optimization

(for V/f mode only)

P1-07 Nominal motor voltage 0.2 – 500 V 400 V Set the nominal motor voltage

P1-08 Nominal motor current 0.4 – 2.2 A (with MBF07A..) 2.2 A Set the nominal motor current

P1-09 Nominal motor fre-

quency

P1-10 Nominal motor speed 0 – 30000 rpm 0 Set the nominal motor speed

P1-11 Speed n1 -P1-01 – +P1-01 50 Hz The drive runs with this speed in jog

P1-12 Control mode of the

drive

P1-13 Error log The 4 most recent errors are

P1-02 – P1-09 x 5

(up to 2000 Hz max.)

0 – P1-01 0.0 Hz Setting the lower speed limit.

0: Deactivated 0 With P1-06 = "1", the unit reduces

1: Activated

0.8 – 4.1 A (with MBF15A..) 4.1 A

25 – 500 Hz 50 Hz Set the nominal motor frequency

0: Binary signals or

AS-Interface

1: Manual mode

(only clockwise)

2: Manual mode

(CW and CCW operation)

logged.

50.0 Hz Setting the upper speed limit.

The display in [Hz] or [rpm]

depends on parameter P1-10.

The display in [Hz] or [rpm]

depends on parameter P1-10.

ramp from 0 to the nominal frequency (P1-09).

inal frequency (P1-09) to 0.

At P1-04 = "0", the maximum decel-

eration is realized.

the supplied motor voltage in case

of light loads.

according to the motor nameplate.

With P1-07 = "0", voltage compen-

sation is deactivated.

according to the motor nameplate

[A].

according to the motor nameplate

[Hz].

With P1-10 ≠ 0, all speed-related

parameters are displayed in rpm.

mode, or when the speed n1 was

selected by the higher-level controller.

0 Setting the control mode

Display of

the most

recent error

The most recent error is displayed

first.

Exception: Undervoltage errors are

only logged once.

Operating Instructions – MOVIFIT® basic

49

6

00

I

Startup

Parameter directory of the MOVIFIT® basic inverter

6.8.2 Advanced parameters

The following table shows the advanced parameters:

No. Name Section Standard Description

P2-02 Speed n2 -P1-01 – +P1-01 10 Hz The drive runs with the speed that

P2-03 Speed n3 -P1-01 – +P1-01 25 Hz

P2-04 Speed n4 -P1-01 – +P1-01 50 Hz

P2-16 Zero speed holding

time

P2-19 Keypad restart mode 0: Minimum speed 0 Speed selection when drive is

P2-21 Scaling factor 0.000 – 30.000 0.000 Scaling factor of the display

P2-22 Display variable 1: Motor speed 1 Selection of variables displayed by

P2-24 Effective switching

frequency

P2-38 Parameter lock 0: Enabled 0 Blocking/enabling parameter

P2-39 Operating hours

counter

P2-40 Inverter power – Display Display of the power of

0 – 60 s 0.2 s Time during which the speed "0" is

1: Most recently used

speed

2: Motor torque

3: Motor current

4 kHz 16 kHz Effective switching frequency of the

8 kHz

16 kHz

1: Disabled

0 – 99999 hours Display Total number of operating hours of

was selected by the higher-level

controller.

held at the output before the drive is

inhibited.

restarted.

variable P2-22:

With P2-21 = "0", the display

function is deactivated.

the unit.

This variable is scaled with

parameter P2-21.

power section.

A higher switching frequency

means less motor noise, but also

higher energy losses in the power

section.

changes.

When the lock is active, you cannot

change any parameters.

the drive.

MOVIFIT

®

basic.

50

Operating Instructions – MOVIFIT® basic

Startup

00

I

Parameter directory of the MOVIFIT® basic inverter

6.8.3 Motor control parameters

The following table lists the parameters for motor control:

No. Name Section Standard Description

P4-01 Control modes 0: Speed control

(Vector)

1: Setting can not be used for

MOVIFIT

2: Speed control (V/f)

P4-02 Auto-tune motor

parameters

P4-05 Motor power factor 0.50 – 0.99 Inverter

0: Deactivated 0 If you set parameter P4-02 = "1",

1: Enable

®

basic.

2 Control mode selection

To ensure optimum motor power,

you must perform an auto-tune

process (P4-02) each time you

change the control mode.

the inverter performs a static measurement of the motor parameters.

You must set the parameters P1-07,

P1-08, and P1-09 according to the

data on the motor nameplate before

you can start the auto-tune process.

Auto-tune is performed:

• When receiving the first enable

signal after operation with

factory-set parameters

•Or when P1-08 has been

changed

No hardware enable is required for

this.

Setting the power factor cos Φ of

power

the motor according to the motor

nameplate.

This setting is mandatory for all

vector control modes.

6

Operating Instructions – MOVIFIT® basic

51

6

00

I

Startup

Parameter directory of the MOVIFIT® basic inverter

6.8.4 Monitoring parameters

The following table shows the monitoring parameters:

The parameter group 0 is used to display internal drive parameters for monitoring

purposes. You cannot change these parameters.

No. Name Display range Description

P0-03 Setpoint speed -500% – +500% Speed display (100% = nominal motor frequency)

P0-04 Setpoint speed -P1-01 – +P1-01

[Hz] or [rpm]

P0-13 Output torque 0 - 200% Output torque (100% = nominal motor torque)

P0-20 DC link voltage [V DC] Internal DC link voltage

P0-21 Inverter temperature [°C] Temperature inside the unit

P0-25 Calculated rotor speed [Hz] or [rpm] Calculated motor speed

P0-26 kWh counter 0.0 - 999.9 kWh Energy consumption in [kWh]

P0-27 MWh counter 0.0 - 60000 MWh Energy consumption in [MWh]

P0-28 Software ID, IO processor e.g. "1.00",

"493F"

P0-29 Software ID, motor control e.g. "1.00",

"7A5C"

P0-30 Serial number of the inverter 000000 - 999999

00-000 - 99-999

Speed display in Hz or rpm

(only valid in a vector control mode)

Version number and check sum of the I/O

processor in the unit

Version number and check sum of the motor

controller in the unit

Serial number of the unit

e.g. 540102 / 24 / 003

INFORMATION

In addition to the parameters described above, the keypad or the parameter menu

show other parameters. However, these are irrelevant for the drive, thus they are not

described here.

52

Operating Instructions – MOVIFIT® basic

Functions of MOVIFIT® basic with AS-Interface

00

I

®

6.9 Functions of MOVIFIT

6.9.1 Data transfer AS-Interface master → MOVIFIT® basic

MOVIFIT

inverter

®

basic

The following table shows the 4 data bits that the AS-Interface master sends to the

MOVIFIT

AS-Interface bit Function

DO3 DO2 DO1 DO0 MOVIFIT® basic inverter

XX0 0 Stop

X X 0 1 Enable CW

X X 1 0 Enable CCW

X X 1 1 Stop/reset

0 0 X X Setpoint speed = n1

0 1 X X Setpoint speed = n2

1 0 X X Setpoint speed = n3

1 1 X X Setpoint speed = n4

basic with AS-Interface

®

basic inverter and the functions of the drive:

Startup

6

®

MOVIFIT

basic

motor starter

The following table shows the 4 data bits that the AS-Interface master sends to the

MOVIFIT

AS-Interface bit Function

DO2 DO1 DO0 MOVIFIT® basic

0 0 0 Stop Stop

001

010

011

1 X X Reset Reset

6.9.2 Data transfer MOVIFIT

The following table shows the 4 data bits that MOVIFIT

Interface master:

DI3 DI2 DI1 DI0

X X X 1 / 0

XX1 / 0X

X 1 / 0 X X

1 / 0 X X X

X = any status

®

basic motor starter and the functions of the drive:

Reversing starter

Enable CW Enable signal for motor at terminal

Enable CCW Enable signal for motor at terminal

Stop Enable signal for both motors at X9

®

basic → AS-Interface master

AS-Interface bit Meaning

Ready signal

0: The MOVIFIT® basic drive is not ready

1: The MOVIFIT

Manual mode

0: MOVIFIT®basic control via AS-Interface

1: Manual control of MOVIFIT

Sensor input 2

0: The signal of sensor 2 = "0"

1: The signal of sensor 2 = "1"

Sensor input 3

0: Signal of sensor 3 = "0"

1: Signal of sensor 3 = "1"

®

basic drive is ready for operation

MOVIFIT® basic dual motor

starter

X9

X8

+ X8

®

basic sends back to the AS-

®

basic

Operating Instructions – MOVIFIT® basic

53

6

00

I

Startup

Functions of MOVIFIT® basic with binary control

6.10 Functions of MOVIFIT

6.10.1 Data transfer PLC → MOVIFIT® basic

MOVIFIT

inverter

®

basic

The following table shows the control signal that the higher-level controller (e.g. PLC)

sends to the MOVIFIT

Control signals Function

DI3 DI2 DI1 DI0 MOVIFIT® basic inverter

XX0 0 Stop

X X 0 1 Enable CW

X X 1 0 Enable CCW

X X 1 1 Stop/reset

0 0 X X Setpoint speed = n1