Schneider Electric TC-200 Series Data Sheet

SPECIFICATIONS

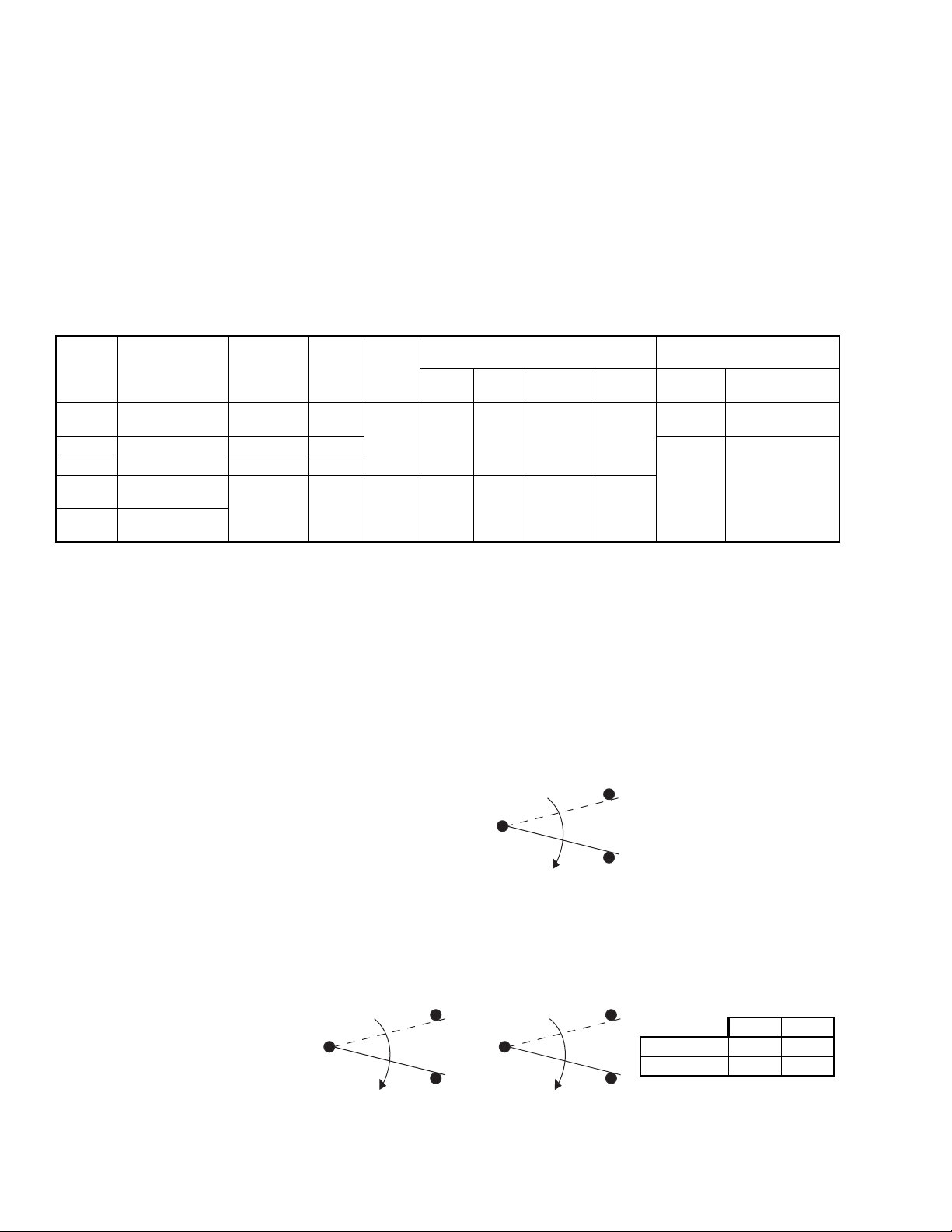

Figure-1 Typical of TC-202, Single Stage.

B

R

C

Temp. Drop

Figure-2 Typical of TC-252 and TC-271, Two Stage.

B

R

C

Temp. Drop

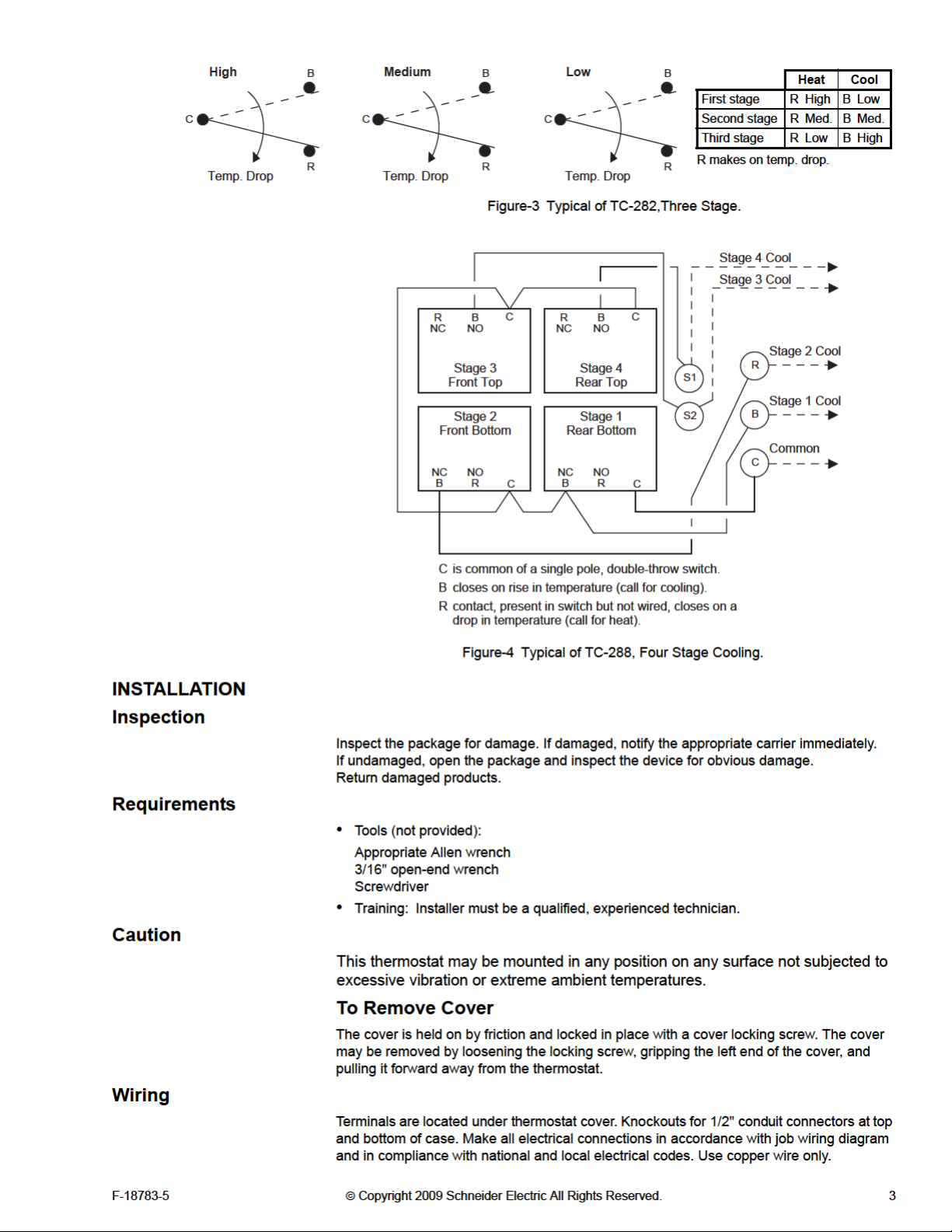

High

B

R

C

Temp. Drop

Low

R makes on temp. drop.

Heat Cool

First stage R High B Low

Second stage R Low B High

Setpoint Adjustment Range: Setpoint dial marked in °F. See Table-1 for specific ranges.

Sensing Element: Liquid-filled thermal element.

Electrical Switch: One snap-acting SPDT per stage.

Ratings, See Table-1.

Connection

Case: Rugged die cast with metal cover. Half inch conduit openin

Ambient Temperature Limits:

Case, -40 to 140°F (-40 to 60°C).

Bulb, 230°F (110°C).

t: Switch action is adjustable. See Table-1.

Outpu

Dimensions:

Case, See Figure-18.

Thermal Elem

Table-1 Specifications.

Part

Number

TC-202

TC-252

TC-271 10' armored 0 to

TC-282

TC-

288

*20' (6 m) and 45' (14 m) capillary lengths are available.

**Celsius scale is available as an option. Specify -216 suffix.

†1600 VA maximum load.

Description Capillary*

Single stage

heating or cooling

Two stage

heating or cooling

Three stage

heating or cooling

Four stage

cooling only

6' copper 10 to 90

6' copper 10 to 90

6' copper 10 to 90

Scale

(°F)**

s: Coded terminals.

ent, 3/8" diameter x 9-1/2" long (9

Vol ts

120

240

160

24

120

240

277

Switch Ratings (AC Only)†

FLA

Amps

—

—

3.8

3.8

2.9

—

LRA

Amp

—

—

22.8

22.8

17.4

—

50/60 Hz

Resistive

s

Amps

.5 mm x 241 mm).

Duty VA

12

6

15

15

15

15

Pilot

125

125

26

125

125

—

gs at top and bottom.

Thermal Diff

°F (°C)

Factory

Set

2 (

1.1)

1.1)

2 (

per stage

3 (1.66)

between

stages

Adjustable

(0.55 to 8.3)

(1.1 to 3.8)

per stage

0 to 2

between high and

low

erential

1 to 15

2 to 7

0 (0 to 11)

stages

TYPICAL APPLICATIONS

ACCESSORIES

AT-201 Copper bulb well (provided)

AT-203 Stainless steel bu b well (provided)

AT-208 Bulb duct mounting kit (order separately)

AT-211 Outside bulb shield (order separately)

AT-401 Housing for hazardous locations

2 © Copyright 2009 Schneider Electric All Rights Reserved. F-18783-5

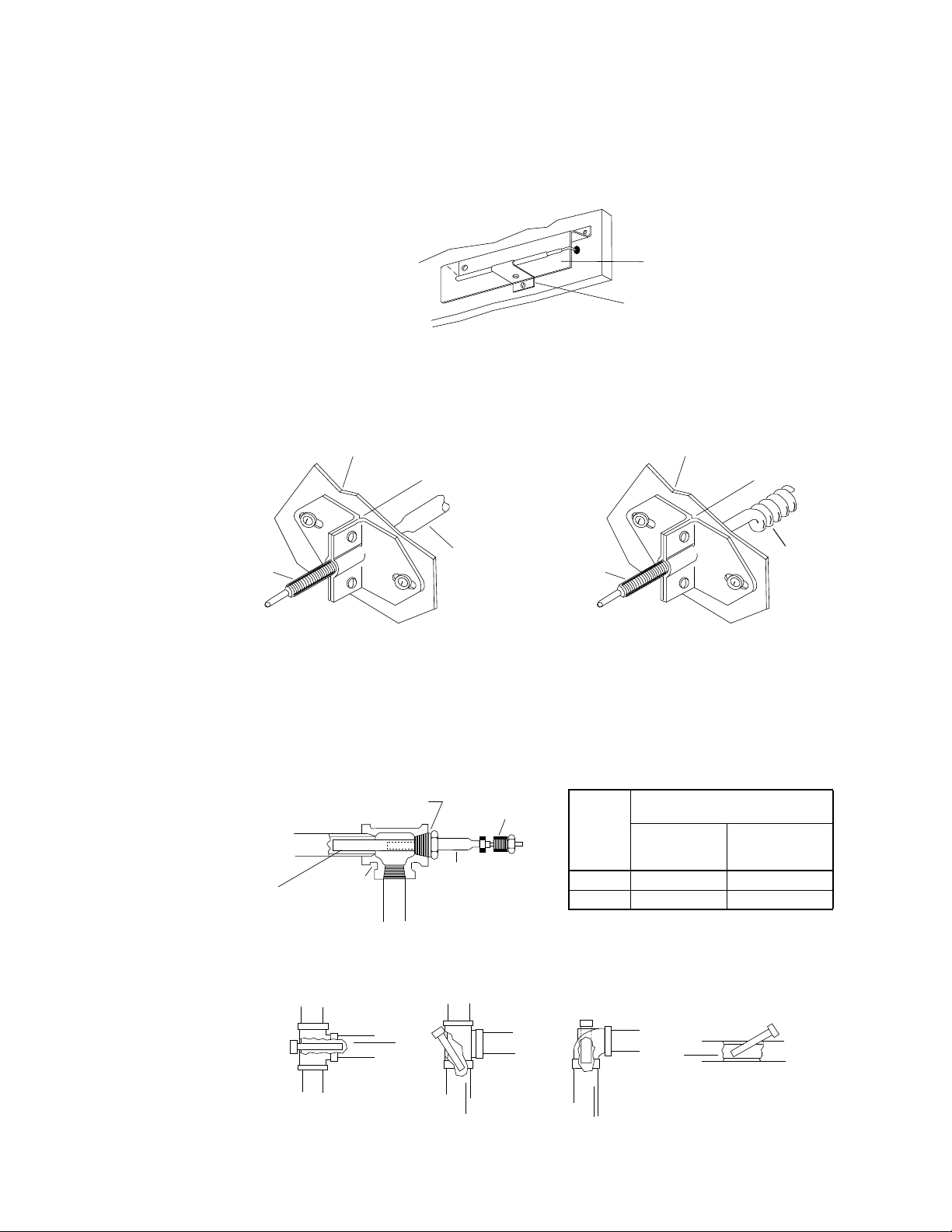

Bulb Mounting

Figure-5 Ou tdoor Bulb Mounting.

Shield

Clip

▲

▲

Figure-6 Duct Bulb Mounting.

Cut 7/8" Dia.

Hole in Duct

Sealing Gasket

(AT-208)

Coiled

Bu b

Mounting Bracket

(AT-208)

Support Spring

on Capillary

▲

▲

▲

▲

Cut 3/4" Dia.

Hole in Duct

Sealing Gasket

(AT-208)

Straight

Bulb

Mounting Bracket

(AT-208)

Support Spring

on Capillary

▲

▲

▲

▲

Figure-7 Liquid Line and Tank Bulb Mounting.

3/4" MNPT Fitting

of AT-201 or AT-203

Pipe Tee

Bulb Well

AT-201 or AT-203

▲

Sealing

Bushing

Bu b

▲

▲

▲

▲

Part

Number

Application Limitations at 250°F

Fluid Temp. (Max. 350°F)

Max. Recom.

Velocity (FPS)

Max. Recom.

Static Pressure

(psig)

AT-201 11 250

AT-203 20 500

Figure-8 Bulb Well Installation Limitations.

▲

FLOW

Straight Pipe Mounting

Note: Angle must not allow

end of well to contact

side of pipe.

E bow

Mounting

F

L

O

W

▲

F

L

O

W

▲

Tee

Mounting

Tee

Mounting

▲

FLOW

The remote sensing bulb may be mounted in ducts or liquid lines.

Outdoor

Install with AT-211 kit as shown in Figure-5.

1. Mount bulb to outside wall or surface with bulb clip.

2. Place shield over bulb and fasten to mounting surface.

Duct

Install bulb with AT-208 kit as shown in Figure-6 below.

Liquid Line and Tank

1. Install AT-201 or AT-203 bulb well.

2. Install thermal bulb and tighten sealing bushing.

Bulb Well Installation Limitations

4 © Copyright 2009 Schneider Electric All Rights Reserved. F-18783-5

Loading...

Loading...