Page 1

Easergy P3

Universal Relays P3U10, P3U20 and P3U30

User Manual

P3U/en M/F005

01/2020

www.schneider-electric.com

Page 2

Page 3

Table of Contents

Table of Contents

1. About this manual....................................................................... 12

1.1. Purpose..........................................................................................................12

1.2. Related documents........................................................................................12

1.3. Abbreviations and terms................................................................................ 13

2. Product introduction.................................................................... 18

2.1. Warranty.........................................................................................................18

2.2. Product overview........................................................................................... 18

2.3. Product selection guide..................................................................................19

2.4. Access to device configuration...................................................................... 27

2.4.1. User accounts......................................................................................27

2.4.2. Logging on via the front panel............................................................. 28

2.4.3. HTTP and FTP logon details............................................................... 28

2.4.4. Password management....................................................................... 29

2.4.5. Changing passwords for administrator and configurator accounts via

PuTTY............................................................................................................29

2.4.6. Password restoring.............................................................................. 31

2.5. Front panel.....................................................................................................32

2.5.1. Push-buttons........................................................................................32

2.5.2. LED indicators..................................................................................... 33

2.5.3. Controlling the alarm screen................................................................34

2.5.4. Accessing operating levels.................................................................. 34

2.5.5. Adjusting the LCD contrast.................................................................. 34

2.5.6. Testing the LEDs and LCD screen.......................................................35

2.5.7. Controlling an object with selective control..........................................35

2.5.8. Controlling an object with direct control............................................... 35

2.5.9. Menus..................................................................................................35

2.6. Easergy Pro setting and configuration tool.................................................... 38

Universal Relays P3U10, P3U20 and P3U30

2.5.9.1. Moving in the menus ............................................................. 37

2.5.9.2. Local panel messages............................................................38

3. Measurement functions...............................................................40

3.1. Primary, secondary and per unit scaling........................................................ 42

3.1.1. Frequency adaptation mode................................................................ 44

3.1.2. Current transformer ratio..................................................................... 45

3.1.3. Voltage transformer ratio..................................................................... 47

3.2. Measurements for protection functions..........................................................49

3.3. RMS values....................................................................................................50

3.4. Harmonics and total harmonic distortion (THD).............................................50

3.5. Demand values..............................................................................................51

3.6. Minimum and maximum values..................................................................... 53

3.7. Maximum values of the last 31 days and 12 months..................................... 54

3.8. Power and current direction........................................................................... 56

3.9. Symmetrical components...............................................................................57

P3U/en M/F005 3

Page 4

Universal Relays P3U10, P3U20 and P3U30

4. Control functions......................................................................... 59

4.1. Digital outputs................................................................................................ 59

4.2. Digital inputs.................................................................................................. 61

4.3. Virtual inputs and outputs...............................................................................63

4.4. Matrix............................................................................................................. 66

4.4.1. Output matrix....................................................................................... 66

4.4.2. Blocking matrix.................................................................................... 67

4.4.3. Object block matrix.............................................................................. 68

4.4.4. Auto-recloser matrix.............................................................................69

4.5. Releasing latches...........................................................................................69

4.5.1. Releasing latches using Easergy Pro.................................................. 69

4.5.2. Releasing latches using buttons and local panel display.....................69

4.5.3. Releasing latches using F1 or F2 buttons........................................... 70

4.6. Controllable objects....................................................................................... 70

4.6.1. Object control with digital inputs.......................................................... 72

4.6.2. Local or remote selection.....................................................................72

4.6.3. Object control with Close and Trip buttons.......................................... 73

4.6.4. Object control with F1 and F2..............................................................73

4.7. Logic functions...............................................................................................74

4.8. Local panel.....................................................................................................82

4.8.1. Mimic view........................................................................................... 83

4.8.2. Local panel configuration.....................................................................85

Table of Contents

5. Protection functions.....................................................................90

5.1. Maximum number of protection stages in one application.............................90

5.2. General features of protection stages............................................................90

5.3. Application modes..........................................................................................98

5.4. Current protection function dependencies..................................................... 98

5.5. Dependent operate time................................................................................ 98

5.5.1. Standard dependent delays using IEC, IEEE, IEEE2 and RI curves.100

5.5.2. Custom curves................................................................................... 114

5.5.3. Programmable dependent time curves.............................................. 115

5.6. Synchronism check (ANSI 25)..................................................................... 116

5.7. Undervoltage (ANSI 27)...............................................................................120

5.8. Directional power (ANSI 32) ....................................................................... 123

5.9. Phase undercurrent (ANSI 37).....................................................................125

5.10. Broken conductor (ANSI 46BC) ................................................................ 126

5.11. Negative sequence overcurrent (ANSI 46) ................................................127

5.12. Incorrect phase sequence (ANSI 46) ........................................................129

5.13. Negative sequence overvoltage protection (ANSI 47)............................... 130

5.14. Motor start-up supervision (ANSI 48) ........................................................131

5.15. Thermal overload (ANSI 49 RMS)............................................................. 136

5.16. Breaker failure 1 (ANSI 50BF)................................................................... 140

5.17. Breaker failure 2 (ANSI 50BF)................................................................... 141

5.18. Switch-on-to-fault (ANSI 50HS) ................................................................ 147

5.19. Phase overcurrent (ANSI 50/51)................................................................149

4 P3U/en M/F005

Page 5

Table of Contents

Universal Relays P3U10, P3U20 and P3U30

5.20. Ground fault overcurrent (ANSI 50N/51N) ................................................ 153

5.20.1. Ground fault phase detection...........................................................157

5.21. Capacitor bank unbalance (ANSI 51C) .....................................................158

5.22. Locked rotor (ANSI 51LR)..........................................................................164

5.23. Voltage-dependent overcurrent (ANSI 51V) ............................................. 166

5.24. Overvoltage (ANSI 59)...............................................................................168

5.25. Capacitor overvoltage (ANSI 59C) ............................................................171

5.26. Neutral overvoltage (ANSI 59N)................................................................ 176

5.27. Motor restart inhibition (ANSI 66) ..............................................................178

5.28. Directional phase overcurrent (ANSI 67) .................................................. 181

5.29. Directional ground fault overcurrent (ANSI 67N)....................................... 185

5.29.1. Ground fault phase detection...........................................................191

5.30. Transient intermittent ground fault (ANSI 67NI).........................................192

5.31. Second harmonic inrush detection (ANSI 68F2)........................................197

5.32. Fifth harmonic detection (ANSI 68H5)....................................................... 198

5.33. Auto-recloser function (ANSI 79) .............................................................. 199

5.34. Overfrequency and underfrequency (ANSI 81) .........................................204

5.35. Rate of change of frequency (ANSI 81R).................................................. 206

5.36. Lockout (ANSI 86)......................................................................................211

5.37. Programmable stages (ANSI 99)............................................................... 212

6. Supporting functions................................................................. 215

6.1. Event log......................................................................................................215

6.2. Disturbance recording..................................................................................217

6.3. Cold load start and magnetizing inrush........................................................223

6.4. System clock and synchronization...............................................................224

6.5. Voltage sags and swells...............................................................................230

6.6. Voltage interruptions....................................................................................232

6.7. Current transformer supervision (ANSI 60) .................................................234

6.8. Voltage transformer supervision (ANSI 60FL)............................................. 236

6.9. Circuit breaker wear.....................................................................................237

6.10. Circuit breaker condition monitoring.......................................................... 243

6.11. Energy pulse outputs..................................................................................245

6.12. Running hour counter................................................................................ 249

6.13. Timers........................................................................................................250

6.14. Combined overcurrent status.....................................................................252

6.15. Main short-circuit fault locator.................................................................... 254

6.16. Feeder fault locator (ANSI 21FL)............................................................... 259

6.17. Trip circuit supervision (ANSI 74) ..............................................................263

6.17.1. Trip circuit supervision with one digital input....................................263

6.17.2. Trip circuit supervision with two digital inputs.................................. 269

7. Communication and protocols...................................................273

7.1. Cybersecurity...............................................................................................273

7.2. Communication ports...................................................................................273

7.2.1. Remote and extension ports..............................................................274

P3U/en M/F005 5

Page 6

Universal Relays P3U10, P3U20 and P3U30

7.2.2. Ethernet port......................................................................................274

7.2.3. Disabling the Ethernet communication.............................................. 274

7.3. Communication protocols............................................................................ 275

7.3.1. Modbus RTU and Modbus TCP.........................................................276

7.3.2. Profibus DP........................................................................................276

7.3.3. SPA-bus.............................................................................................277

7.3.4. IEC 60870-5-103 (IEC-103)...............................................................277

7.3.5. DNP 3.0............................................................................................. 278

7.3.6. IEC 60870-5-101 (IEC-101)...............................................................278

7.3.7. IEC 61850..........................................................................................279

7.3.8. HTTP server – Webset...................................................................... 279

7.4. IP filter..........................................................................................................279

7.4.1. Configuring the IP filter...................................................................... 280

7.4.2. Unexpected packets.......................................................................... 282

7.4.3. Alarms................................................................................................282

8. Applications and configuration examples..................................284

Table of Contents

8.1. Substation feeder protection........................................................................284

8.2. Industrial feeder / motor protection.............................................................. 286

8.3. Using CSH120 and CSH200 with core balance CTs................................... 286

9. Installation................................................................................. 289

9.1. Safety in installation.....................................................................................289

9.2. Checking the consignment...........................................................................290

9.3. Product identification....................................................................................291

9.4. Storage........................................................................................................ 292

9.5. Mounting...................................................................................................... 293

9.6. Connections.................................................................................................296

9.6.1. Rear panel......................................................................................... 297

9.6.2. Auxiliary voltage.................................................................................309

9.6.3. Local port...........................................................................................309

9.6.4. Connection data.................................................................................310

9.6.5. External option modules.................................................................... 316

9.6.5.1. VSE-001 fiber optic interface module...................................316

9.6.5.2. VSE-002 RS-485 interface module...................................... 317

9.6.5.3. VSE-009 DeviceNet interface module..................................319

9.6.5.4. VPA-3CG Profibus interface module.................................... 320

9.6.5.5. VIO 12A RTD and analog input / output modules................ 321

9.6.6. Block diagrams.................................................................................. 322

9.6.7. Connection examples........................................................................ 329

9.7. Voltage system configuration.......................................................................339

9.8. CSH120 and CSH200 Core balance CTs.................................................... 346

10. Test and environmental conditions..........................................350

10.1. Disturbance tests....................................................................................... 350

10.2. Electrical safety tests................................................................................. 351

10.3. Mechanical tests........................................................................................ 352

10.4. Environmental tests................................................................................... 352

6 P3U/en M/F005

Page 7

Table of Contents Universal Relays P3U10, P3U20 and P3U30

10.5. Environmental conditions...........................................................................353

10.6. Casing........................................................................................................353

11. Maintenance............................................................................ 354

11.1. Preventive maintenance.............................................................................354

11.2. Periodic testing...........................................................................................355

11.3. Hardware cleaning..................................................................................... 355

11.4. System status messages........................................................................... 355

11.5. Spare parts.................................................................................................355

11.6. Self-supervision..........................................................................................355

11.6.1. Diagnostics.......................................................................................356

12. Order codes and accessories................................................. 358

12.1. Order codes............................................................................................... 358

12.2. Accessories................................................................................................360

13. Firmware revision....................................................................362

P3U/en M/F005 7

Page 8

Universal Relays P3U10, P3U20 and P3U30 Legal information

Legal information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the

owner's permission, given in writing. This guide and its content are protected,

within the meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications and designs change from time to time, please ask for

confirmation of the information given in this publication.

8 P3U/en M/F005

Page 9

Safety information

Safety information

Important information

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this publication or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

Universal Relays P3U10, P3U20 and P3U30

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

The addition of either symbol to a “Danger” or “Warning” safety

label indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please note

Electrical equipment must only be installed, operated, serviced, and maintained

by qualified personnel. A qualified person is one who has skills and knowledge

related to the construction, installation, and operation of electrical equipment and

has received safety training to recognize and avoid the hazards involved.

No responsibility is assumed by Schneider Electric for any consequences arising

out of the use of this material.

Protective grounding

The user is responsible for compliance with all the existing international and

national electrical codes concerning protective grounding of any device.

P3U/en M/F005 9

Page 10

Universal Relays P3U10, P3U20 and P3U30 North America regulatory compliance

North America regulatory compliance

Certificate number: 20190829-E215590

Issue date: 2019-August-29

UL certifies that the Easergy P3 products comply with the following standards:

• UL 508 Industrial Control Equipment

• CSA C22.2 No. 14-13 Industrial Control Equipment

• IEEE C37.90-2005 Guide for Power System Protection Testing

• IEEE C37.90.1-2012 Standard for Surge Withstand Capability (SWC) Tests

for Relays and Relay Systems Associated with Electrical Power Apparatus

• IEEE C37.90.2-2004 Standard for Withstand Capability of Relay Systems to

Radiated Electromagnetic Interference from Trancievers

10 P3U/en M/F005

Page 11

EU directive compliance Universal Relays P3U10, P3U20 and P3U30

EU directive compliance

EMC compliance

2014/30/EU

Compliance with the European Commission's EMC Directive. Product Specific

Standard was used to establish conformity:

• EN 60255-26 2013

Product safety

2014/35/EU

Compliance with the European Commission's Low Voltage Directive. Product

Specific Safety Standard was used to establish conformity:

• EN 60255-27 2014

P3U/en M/F005 11

Page 12

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

1. About this manual

1.1. Purpose

This document contains instructions on the installation, commissioning and

operation of Easergy P3U10, P3U20 and P3U30.

This document is intended for persons who are experts on electrical power

engineering, and it covers the relay models as described by the order code.

Related topics

Order codes on page 358

1.2. Related documents

Table 1 - Related documents

Document

Easergy P3 Universal Relay P3U Quick Start P3U/EN QS/xxxx

Easergy Pro Setting and Configuration Tool User Manual P3eSetup/EN M/xxxx

RTD and mA Output/Input Modules User Manual P3VIO12A/EN M/A001

Profibus Interface Module User Manual P3VPA3CG/EN M/A001

IEC 61850 configuration instructions P3APS17001EN

Rapid Spanning Tree Protocol (RSTP) P3APS17002EN

Parallel Redundancy Protocol for Easergy P3 relays with dualport 100 Mbps Ethernet interface

Communication parameter protocol mappings P3TDS17005EN

Easergy P3 protection functions' parameters and recorded

values

DeviceNet data model P3APS17008EN

Identification

P3APS17004EN

P3TDS17006EN

1

IEC103 Interoperability List P3TDS17009EN

DNP 3.0 Device Profile Document P3TDS17010EN

P3 Standard Series facia label instruction P3TDS17011EN

Principles of numerical protection techniques P3INS17019EN

1

xxxx = revision number

12 P3U/en M/F005

Page 13

1. About this manual Universal Relays P3U10, P3U20 and P3U30

1.3. Abbreviations and terms

AFD Arc flash detection

ANSI American National Standards Institute

A standardization organisation

bps Bits per second

CB Circuit breaker

CBFP Circuit breaker failure protection

CLPU Cold load pickup

CM Common mode

Controlling output Heavy duty output rated for the circuit breaker controlling

CPU Central processing unit

cosφ Active power divided by apparent power = P/S

(See power factor PF.)

Negative sign indicates reverse power.

CT Current transformer

CT

PRI

CT

SEC

Dead band See hysteresis.

DI Digital input

Digital output Relay's output contact

DM Differential mode

DMS Distribution management system

Nominal primary value of current transformer

Nominal secondary value of current transformer

DO Digital output

Document file Stores information about the relay settings, events and fault logs

DSR Data set ready

An RS232 signal. Input in front panel port of Easergy P3 devices

to disable rear panel local port.

DST Daylight saving time

Adjusting the official local time forward by one hour for summer

time.

DT Definite time

P3U/en M/F005 13

Page 14

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

DTR Data terminal ready

An RS232 signal. Output and always true (+8 Vdc) in front panel

port of Easergy P3 relays.

Easergy P3 Standard P3U10, P3U20 and P3U30 relays

Easergy P3

P3F30, P3L30, P3M30/32, P3G30/32 and P3T32 relays

Advanced

eSetup Easergy Pro Setting and configuration tool for Easergy P3 protection relays,

later called Easergy Pro

F2BIO 2 x optical BIO interfaces, fibre

GOOSE Generic object-oriented substation event

A specific definition of a type of generic substation event, for

peer-peer communication.

Hysteresis I.e. dead band

Used to avoid oscillation when comparing two nearby values.

IDMT Inverse definite minimum time

I

MODE

Nominal current of the selected mode

In feeder mode, I

In motor mode, I

MODE

MODE

= CT

= I

MOT

PRIMARY

.

.

I

MOT

I

NOM

Nominal current of the protected motor

Nominal current

Rating of CT primary or secondary

I

SET

I

N(nom)

I

0 SET

Start setting value I> (50/51)

Nominal current of IN input in general

Start setting value I0>

IEC International Electrotechnical Commission

An international standardization organisation

IEC-101 Communication protocol defined in standard IEC 60870-5-101

IEC-103 Communication protocol defined in standard IEC 60870-5-103

IEEE Institute of Electrical and Electronics Engineers

IRIG-B Inter-Range Instrumentation Group time code B

Standard for time transfer

IT Instrument transformer (current or voltage transformer): electrical

device used to isolate or transform voltage or current levels

14 P3U/en M/F005

Page 15

1. About this manual Universal Relays P3U10, P3U20 and P3U30

LAN Local area network

Ethernet-based network for computers and devices

Latching Digital outputs and indication LEDs can be latched, which means

that they are not released when the control signal is releasing.

Releasing of latched devices is done with a separate action.

LCD Liquid crystal display

LED Light-emitting diode

NTP Network Time Protocol for LAN and WWW

OVF Indication of the event overflow

P Active power

Unit = [W]

PF Power factor

The absolute value is equal to cosφ, but the sign is 'IND' for

inductive i.e. lagging current and 'CAP' for capacitive i.e. leading

current.

PLC Programmable logic controller

P

M

Nominal power of the prime mover

(Used by reverse/under power protection.)

POC signals

Binary signals that are transferred in the communication channel

of two P3L30 line differential relays in both directions. POC

signals are used to transfer statuses of the DI, VI, VO and logic

outputs.

pu

PU

Per unit

Depending of the context, the per unit refers to any nominal

value.

For example, for overcurrent setting 1 pu = 1 x I N .For example,

for overcurrent setting 1 pu = 1 x I

MOT

.

P3U P3U10, P3U20 and P3U30 protection relay

Q Reactive power

Unit = [var]

RELxxxxx Short order code

RH Relative humidity

RMS Root mean square

RS232 or RS485

(EIA-232 or EIA-485)

Standard defining the electrical characteristics of a serial

communication interface

P3U/en M/F005 15

Page 16

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

RTU Remote terminal unit

S Apparent power

Unit = [VA]

SCADA Supervisory control and data acquisition

SF Alarm duty watchdog output is energized when the auxiliary

power supply is on and the product status is operative. This

output is referenced as "service status output" in the setting tool.

Signaling output Alarm duty output rated, not suitable for direct circuit breaker

controlling

SNTP Simple Network Time Protocol for LAN and WWW

SOTF Switch on to fault

SPST Single pole single throw

SPDT Single pole double throw

TCS Trip circuit supervision

THD Total harmonic distortion

V Voltage V

V

NSEC

Voltage at input Vc at zero ohm ground fault. (Used in voltage

measurement mode “2LL+VN”)

V

A

Voltage input for VAB or VA depending on the voltage

measurement mode

V

B

Voltage input for VBC or VB depending on the voltage

measurement mode

V

C

Voltage input for VCA or VN depending on the voltage

measurement mode

V

N

Neutral voltage

Rating of VT primary or secondary

V

NOM

Nominal voltage

Rating of VT primary or secondary

UMI User-machine interface

USB Universal serial bus

UTC Coordinated Universal Time

Used to be called GMT = Greenwich Mean Time

Webset http configuration interface

16 P3U/en M/F005

Page 17

1. About this manual Universal Relays P3U10, P3U20 and P3U30

VI Virtual input

VO Virtual output

VT Voltage transformer

VT

VT

PRI

SEC

Nominal primary value of voltage transformer

Nominal secondary value of voltage transformer

Parameter names in user manual and Easergy Pro

Some parameters may have a different name in this user manual compared to the

Easergy Pro setting tool.

Table 2 - Parameter names in user manual and Easergy Pro

User manual Easergy Pro

Base angle setting range Angle offset

Characteristic curve / curve type Delay type

Cooling time coefficient Rel. cooling time coefficient

Dependent time coefficient Inv. time coefficient

Operate angle Pick-up sector size

Operate time Operation delay

Self-blocking value of undervoltage Low voltage blocking

Start value Pick-up setting

Start voltage

Time multiplier Inv. time coefficient / Inverse delay

3BIO 3 x hard-wired BIO interfaces

VN setting for INDir stage > (67N)

P3U/en M/F005 17

Page 18

Universal Relays P3U10, P3U20 and P3U30

2. Product introduction

2.1. Warranty

This product has a standard warranty of 10 years.

2.2. Product overview

The relay communicates with other systems using common protocols, such as the

Modbus RTU, ModbusTCP, IEC 60870-5-103, IEC 60870-5-101, IEC 61850, SPA

bus, and DNP 3.0.

User interface

The relay can be controlled in three ways:

2. Product introduction

• Locally with the push-buttons on the relay front panel

• Locally using a PC connected to the USB port on the front

• Via remote control over the optional remote control port on the relay rear

panel.

Easergy P3U10, P3U20 and P3U30 include all the essential protection functions

needed to protect feeders and motors in distribution networks of utilities, industry

and power plants for all level of voltage below 132 kV. Further, the relay includes

several programmable functions, such as trip circuit supervision and circuit

breaker protection and communication protocols for various protection and

communication situations.

Protection functions

• Universal, adaptive protection functions for user-configurable applications like

feeder, motor and voltage protection from basic non-directional to directional

overcurrent protection, thermal overload, and auto-recloser

• Neutral overvoltage, overvoltage and frequency protection including

synchronism check for two breakers

• Single-line diagram, measurements and alarms in the user-machine interface

(UMI)

• User-configurable interlocking for primary object control

• Optional arc flash detection utilizing point sensors and a fiber loop that can

provide system wide arc flash detection.

Virtual injection

• Current and voltage injection by manipulating the database of the product by

setting tool disturbance recorder file playback through the product's database

Robust hardware

• User-selectable Ethernet, RS485 or RS232 -based communication interfaces

• Designed for demanding industrial conditions with conformal-coated printed

circuit boards

• Standard USB connection (type B) for Easergy P3 setting software

18 P3U/en M/F005

Page 19

1

4

3

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Common technology for cost efficiency

• Powerful CPU supporting IEC 61850

• Thanks to four setting groups, adaptation to various protection schemes is

convenient

User-machine interface (UMI)

• Clear LCD display for alarms and events

• Single-line diagram mimic with control, indication and live measurements

• Programmable function keys and LEDs

• Circuit breaker ON/OFF control

• Common firmware platform with other Easergy P3 range protection relays

NOTE: If the device has been powered off for more than about one week, the

UMI language after starting is IEC but after about two minutes, it is

automatically updated to ANSI.

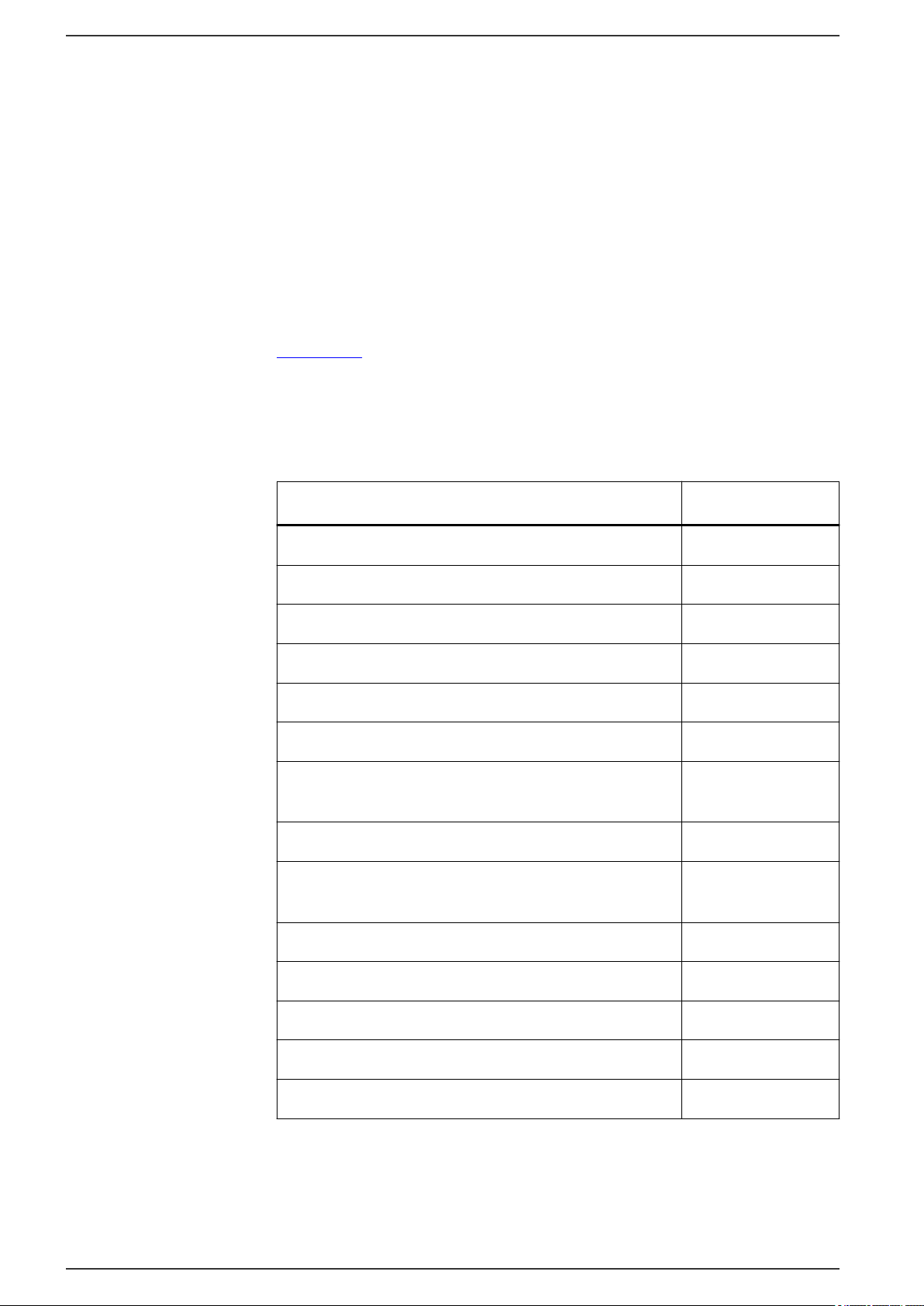

2.3. Product selection guide

The selection guide provides information on the Easergy P3 platform to aid in the

relay selection. It suggests Easergy P3 types suitable for your protection

requirements, based on your application characteristics. The most typical

applications are presented along with the associated Easergy P3 type.

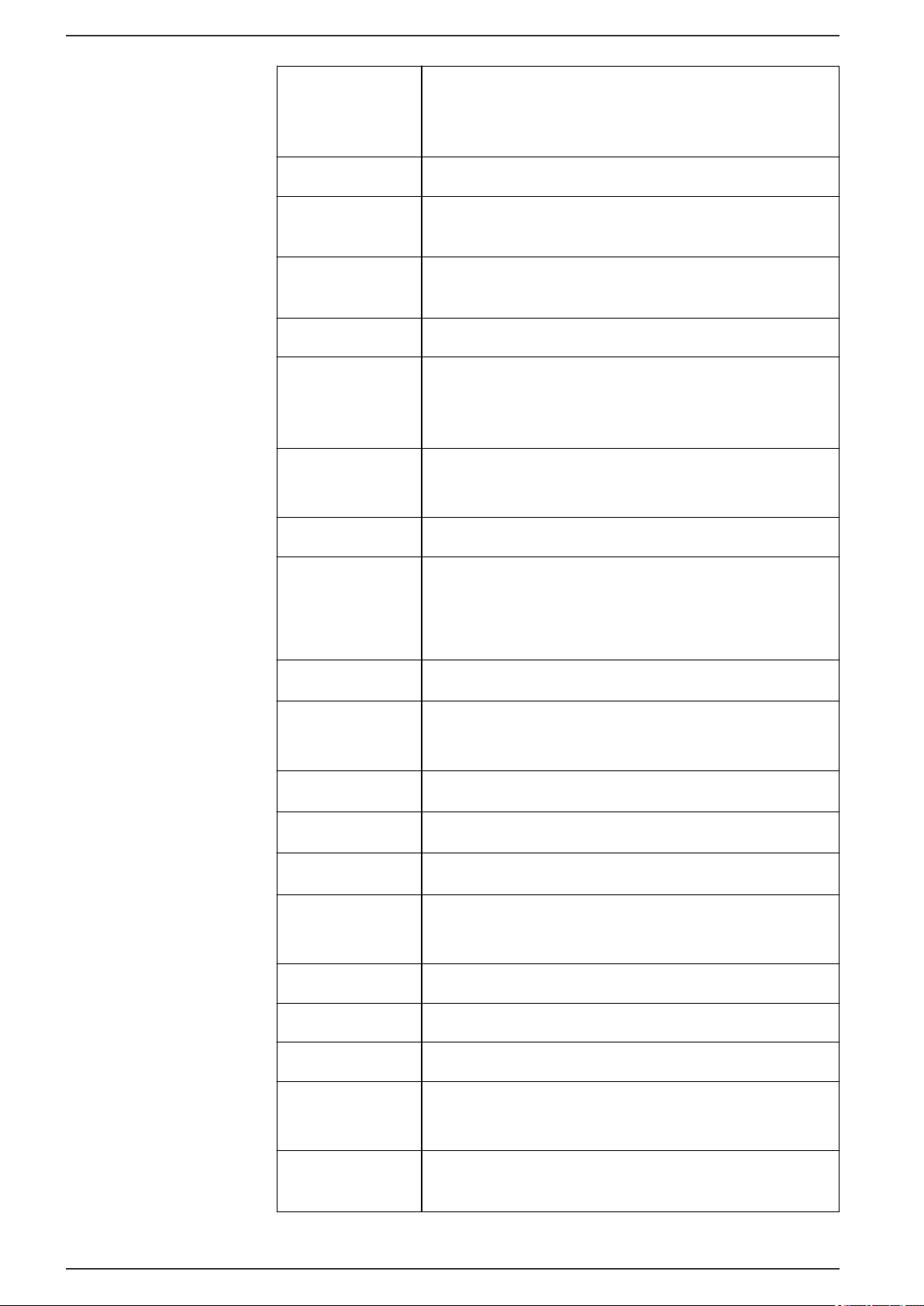

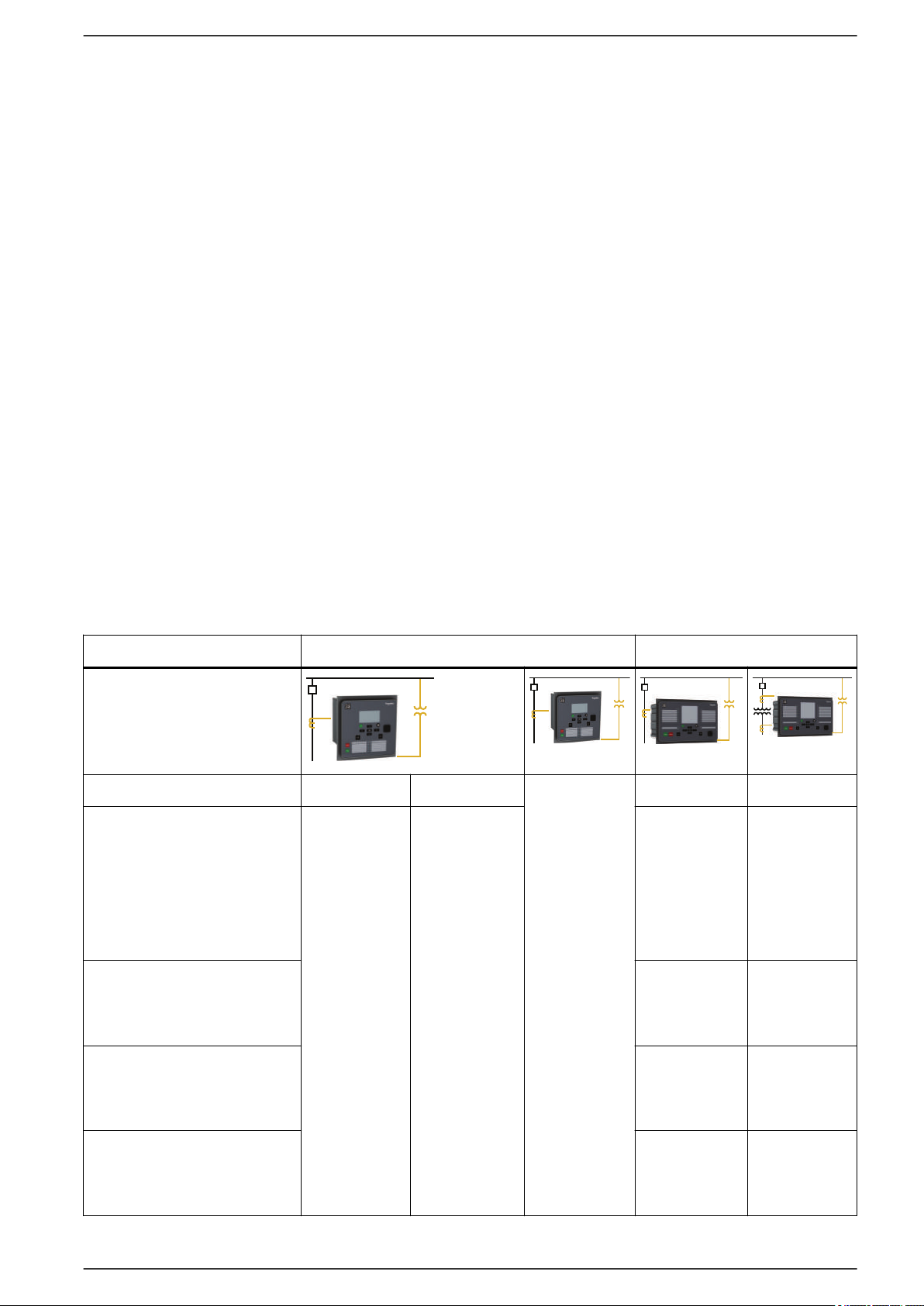

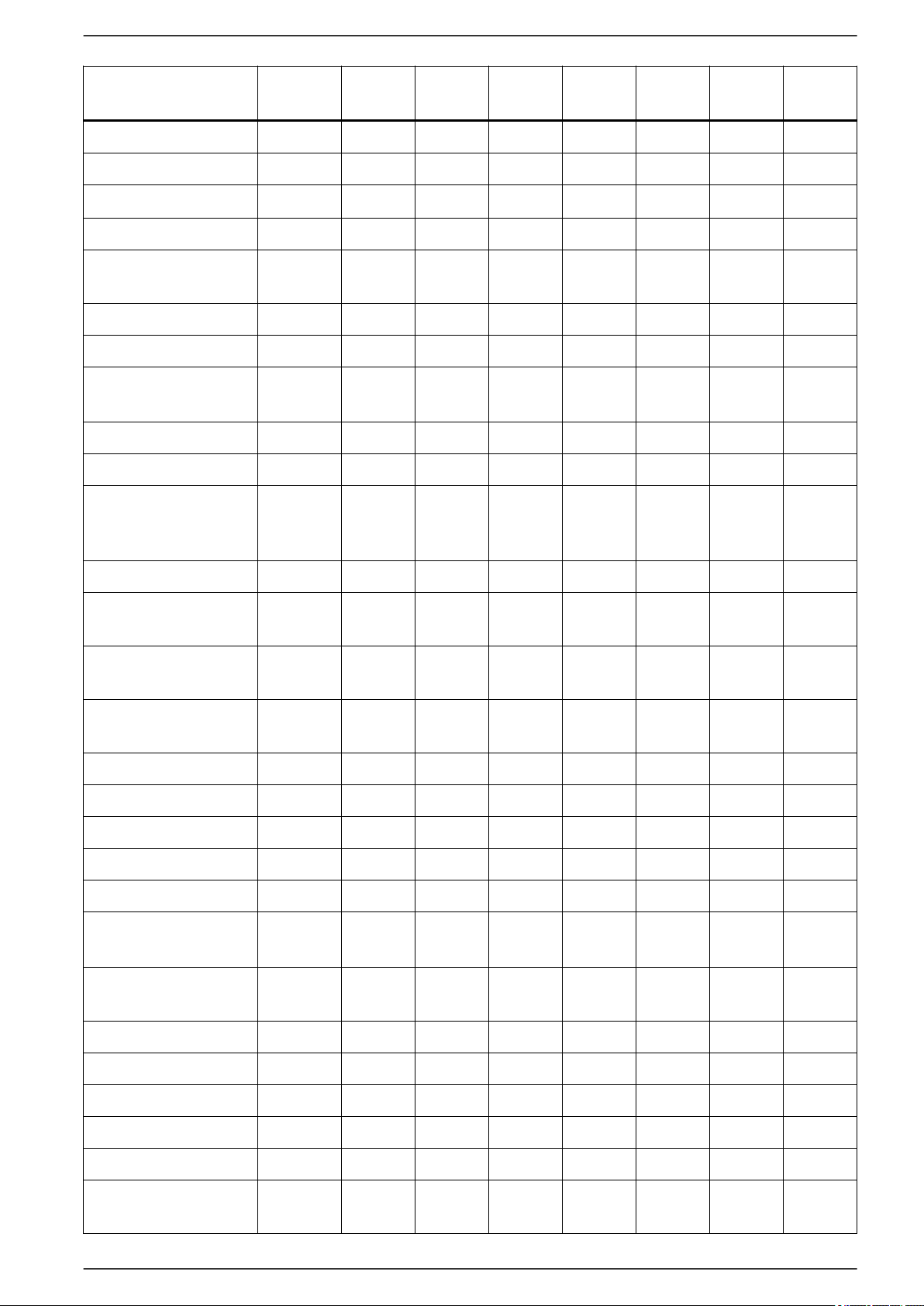

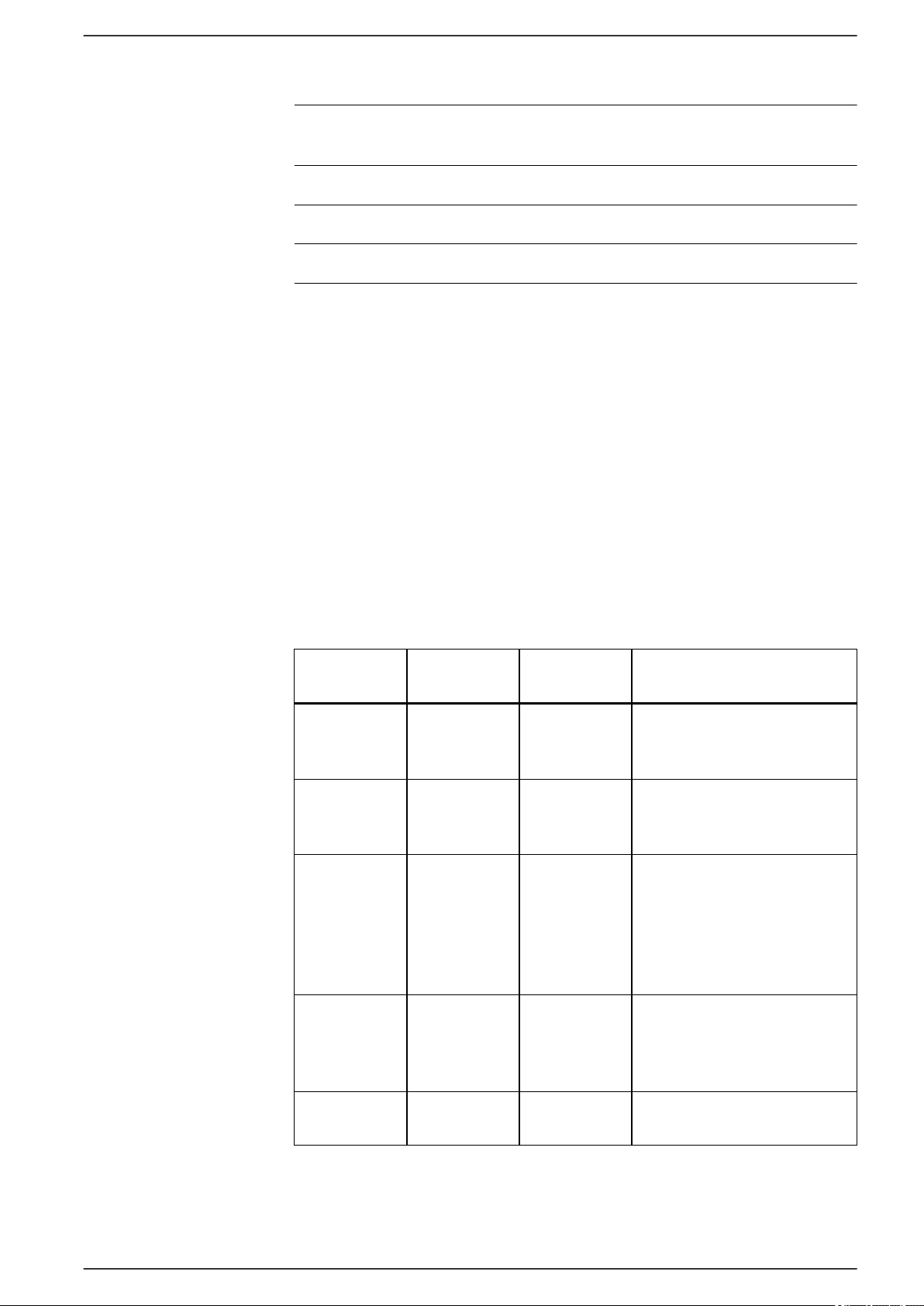

Table 3 - Applications

Easergy P3 Standard Easergy P3 Advanced

Voltage – –

Feeder

Transformer

P3U10 P3U20

Motor

P3U30

with

directional

o/c

with voltage

protection

P3F30

w.

directional

P3L30

w. line diff. &

distance

–

P3M30

–

–

P3T32

with

differential

P3M32

with

differential

Generator

P3G30

P3U/en M/F005 19

P3G32

with

differential

Page 20

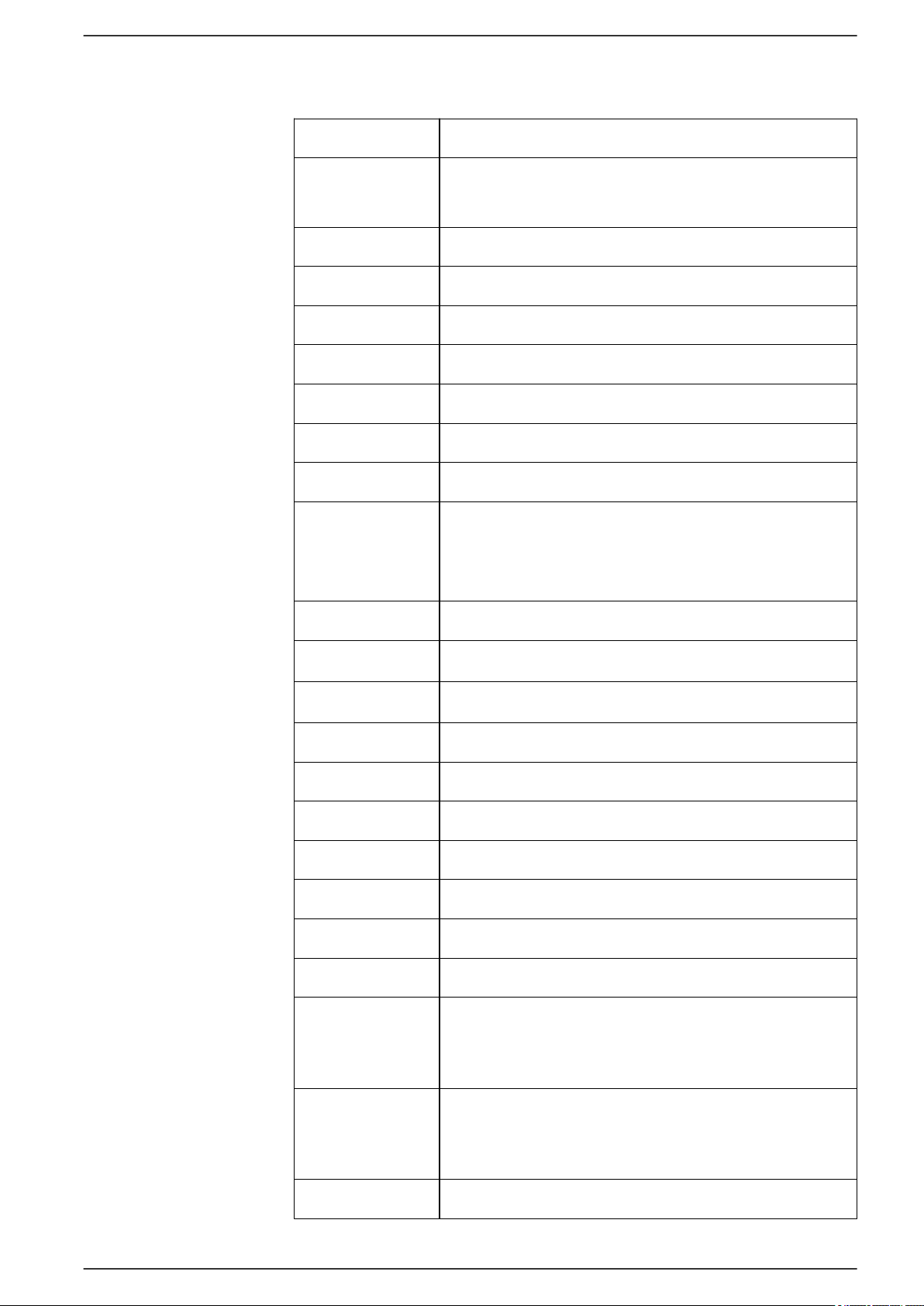

1

4

3

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Easergy P3 Standard Easergy P3 Advanced

Measuring

inputs

Phase current 1/5A CT (x3) 1/5A CT (x3) 1/5A CT (x6)

Residual current 1/5A CT or 0.2/1A CT 5/1A+1/0.2A 5/1A+1/0.2A +

5/1A CT

Voltage VT (x1) VT (x4) VT (x4) VT (x4)

Arc-flash sensor input – 0 to 4 point

sensor

0 to 4 point

sensor

Digital I/O Input 2 8/10 16 6 to 36 6 to 16

Output 5 + WD 5/8 + WD 8 + WD 10 to 21 + WD 10 to 13 + WD

Analog I/O Input –

Output –

Temperature sensor input –

2

0 or 4

2

0 or 4

0 or 8 or 12

2

0 or 8 or 12

0 or 4

0 or 4

2

2

2

Front port USB USB

Nominal power supply

24 V dc or 24...48 V dc or 48...230 V ac/dc

3

24...48 V dc or 110...240 V ac/dc

Ambient temperature, in service -40...60°C (-40...140°F) -40...60°C (-40...140°F)

2

Using external RTD module

3

Check the available power supply range from the device's serial number label.

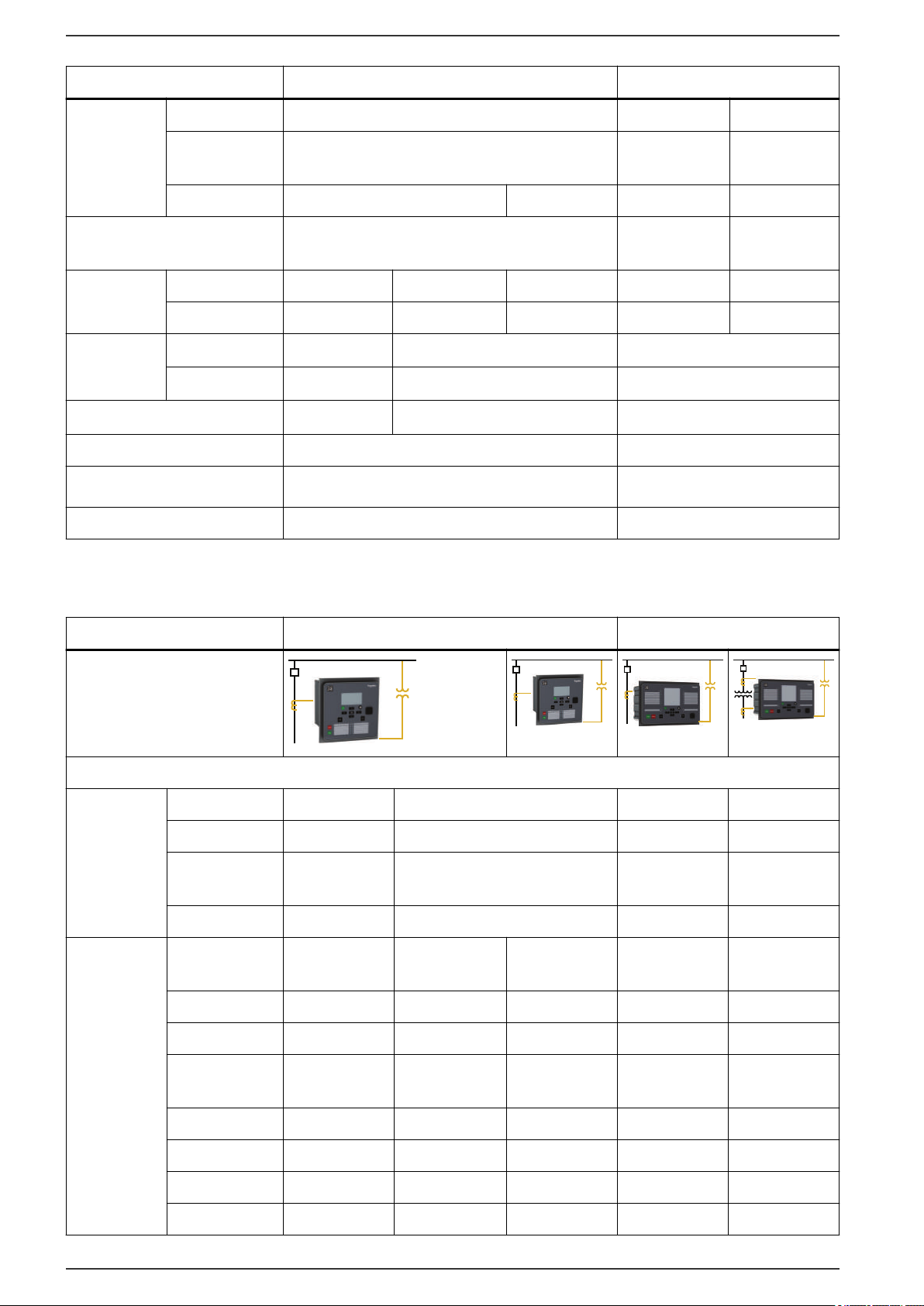

Table 4 - Communication & others

Easergy P3 Standard Easergy P3 Advanced

Communication

Rear ports RS-232 – ■ ■ ■

IRIG/B ■ ■ ■

RS-485 – ■ Using external

ETHERNET – ■ ■ ■

Protocols IEC 61850 Ed1

& Ed2

IEC 60870-5-101 – ■ ■ ■ ■

IEC 60870-5-103 – ■ ■ ■ ■

I/O module

– ■ ■ ■ ■

Using external

I/O module

DNP3 Over

– ■ ■ ■ ■

Ethernet

Modbus serial – ■ ■ ■ ■

Modbus TCP/IP – ■ ■ ■ ■

DeviceNet – ■ ■ ■ ■

Profibus DP – ■ ■ ■ ■

20 P3U/en M/F005

Page 21

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Easergy P3 Standard Easergy P3 Advanced

SPAbus – ■ ■ ■ ■

Redundancy

protocols

Others

Control

Logic Matrix ■ ■

Cyber security Password Password

Withdrawability (Pluggable

connector)

Remote UMI – ■

RSTP – ■ ■ ■ ■

PRP – ■ ■ ■ ■

1 object

Mimic

Logic equations ■ ■

8 objects

Mimic

■ –

8 objects

Mimic

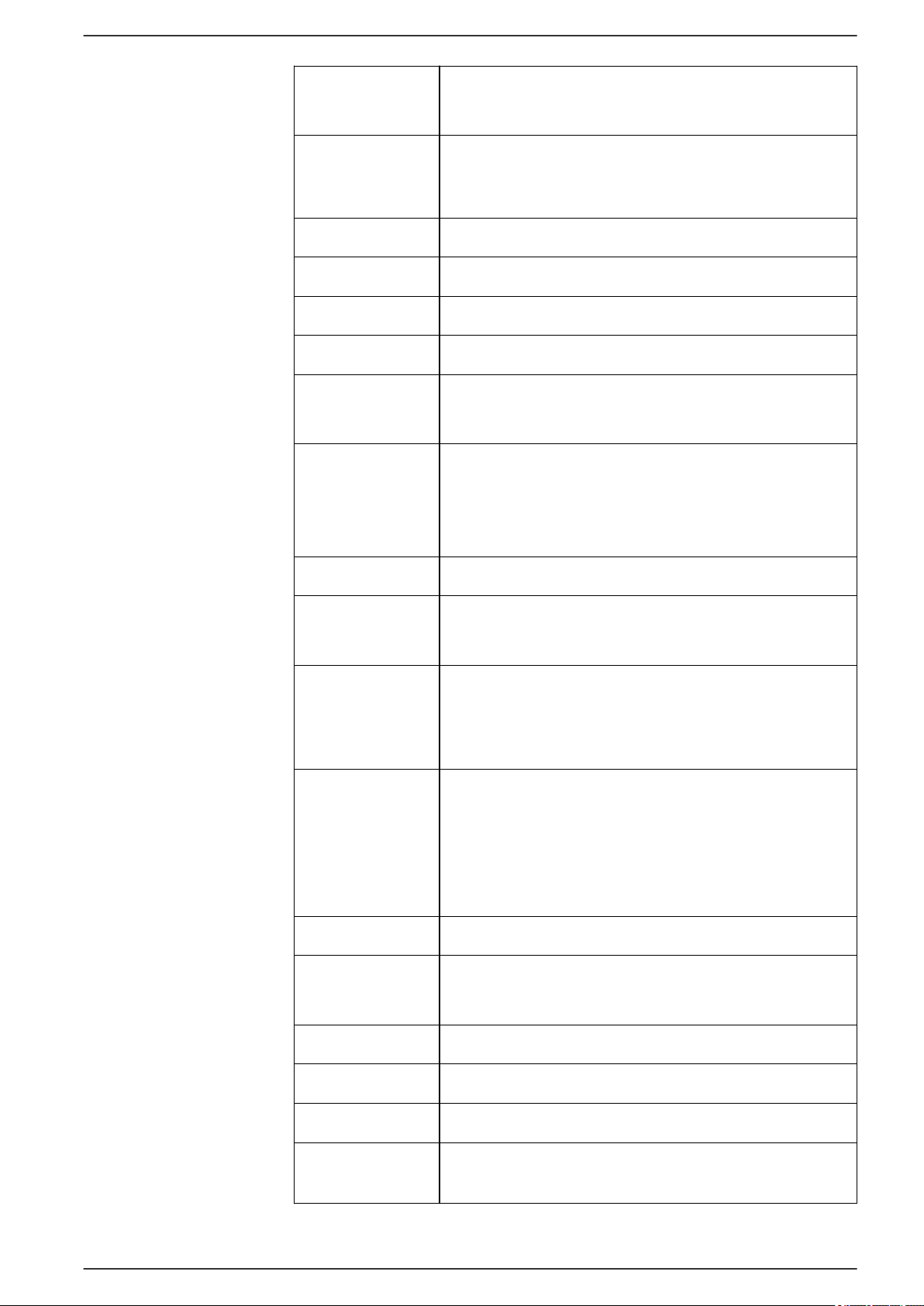

NOTE: The numbers in the following tables represent the amount of stages

available for each Easergy P3 type.

Table 5 - Protection functions for P3U

Protection functions ANSI

code

Feeder

P3U10/20

Feeder P3U30 Motor P3U10/20 Motor P3U30

Fault locator 21FL – 1 – 1

Synchronism check

Undervoltage 27 – 3 – 3

Directional power 32 – 2 – 2

Phase undercurrent 37 1 1 1 1

RTD temperature

monitoring

Negative sequence

overcurrent (motor,

generator)

Incorrect phase sequence 46 – – 1 1

Cur. unbalance, broken

conductor

Negative sequence

overvoltage protection

Excessive start time,

locked rotor

5

4

25 – 2 – 2

38/49T 12 12 12 12

46 – – 2 2

46BC 1 1 – –

47 – 3 – 3

48/51LR – – 1 1

Thermal overload 49 1 1 1 1

Phase overcurrent 50/51 3 3 3 3

Ground fault overcurrent 50N/51N 5 5 5 5

Breaker failure 50BF 1 1 1 1

P3U/en M/F005 21

Page 22

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Protection functions ANSI

code

Feeder

P3U10/20

Feeder P3U30 Motor P3U10/20 Motor P3U30

SOTF 50HS 1 1 1 1

Capacitor bank

unbalance

6

Voltage-dependent

51C 2 2 2 2

51V – 1 – 1

overcurrent

Overvoltage 59 – 3 – 3

Capacitor overvoltage 59C 1 1 – –

Neutral overvoltage 59N 3 3 3 3

CT supervision 60 1 1 1 1

VT supervision 60FL – 1 – 1

Starts per hour 66 – – 1 1

Directional phase

67 – 4 – 4

overcurrent

Directional ground fault

67N 3 3 3 3

o/c

Transient intermittent 67NI 1 1 – –

Second harmonic inrush

68F2 1 1 1 1

detection

Fifth harmonic detection 68H5 1 1 1 1

Auto-Recloser 79 5 5 – –

Over or under frequency 81 – 2/2 – 2/2

Rate of change of

81R – 1 – 1

frequency

Under frequency 81U – 2 – 2

Lockout 86 1 1 1 1

Programmable stages 99 8 8 8 8

Cold load pickup (CLPU) – 1 1 1 1

Programmable curves – 3 3 3 3

Setting groups

4

The availability depends on the selected voltage measurement mode (in the Scaling setting view in Easergy Pro)

5

Using external RTD module

6

Capacitor bank unbalance protection is connected to the ground fault overcurrent input and shares two stages with the ground fault

overcurrent protection.

7

Not all protection functions have 4 setting groups. See details in the manual.

7

– 4 4 4 4

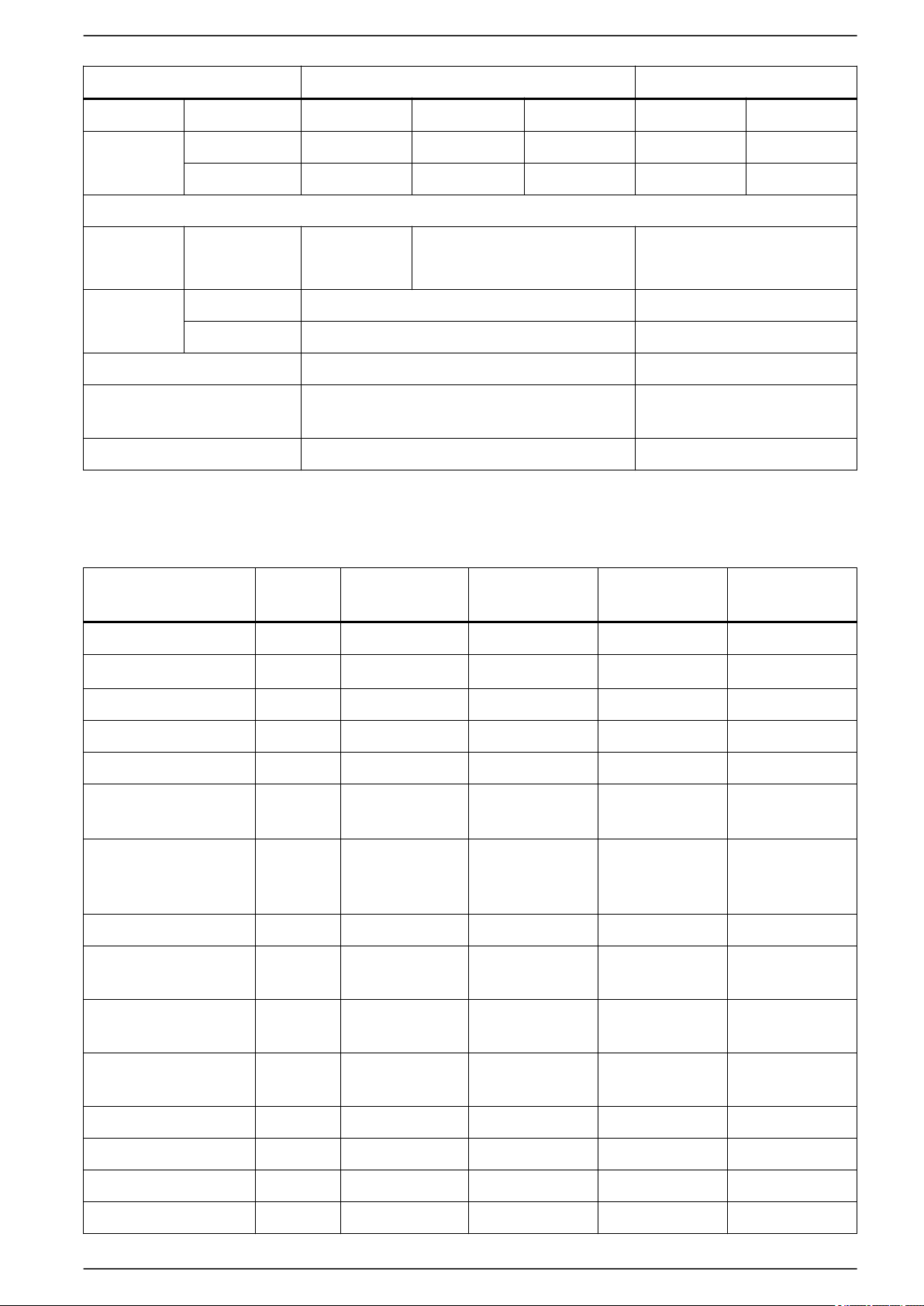

Table 6 - Protection functions for Px3x

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Distance 21 – 1 – – – – –

Under-impedance 21G – – – – 2 2 –

22 P3U/en M/F005

Page 23

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Fault locator 21FL 1 1 – – – – –

Overfluxing 24 – – – – 1 1 1

Synchronism check

8

Undervoltage 27 3 3 3 3 3 3 3

Positive sequence undervoltage

Directional power 32 2 2 2 2 2 2 2

Phase undercurrent 37 – – 1 1 – – –

RTD temperature

monitoring

9

Loss of field 40 – – – – 1 1 –

Under-reactance 21/40 – – – – 2 2 –

Negative sequence

overcurrent (motor,

generator)

25 2 2 2 2 2 2 2

27P – – – – 2 2 –

38/49T 12 12 12 12 12 12 12

46 – – 2 2 2 2 2

Incorrect phase sequence 46 – – 1 1 – – –

Cur. unbalance, broken

46BC 1 1 – – – – –

conductor

Negative sequence

47 3 3 3 3 3 3 3

overvoltage protection

Excessive start time,

48/51LR – – 1 1 – – –

locked rotor

Thermal overload 49 1 1 1 1 1 1 1

Phase overcurrent 50/51 3 3 3 3 3 3 3

Ground fault overcurrent 50N/51N 5 5 5 5 5 5 5

Breaker failure 50BF 1 1 1 1 1 1 1

SOTF 50HS 1 1 1 1 1 1 1

Capacitor bank

unbalance

10

Voltage-dependent

51C 2 2 2 2 2 2 2

51V 1 1 – – 1 1 –

overcurrent

Overvoltage 59 3 3 3 3 3 3 3

Capacitor overvoltage 59C 1 1 – – – – –

Neutral overvoltage 59N 2 2 2 2 2 2 2

CT supervision 60 1 1 1 1 1 2 2

VT supervision 60FL 1 1 1 1 1 1 1

Restricted ground fault

64REF – – – – – 1 1

(low impedance)

P3U/en M/F005 23

Page 24

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Stator ground fault 64S – – – – 1 1 –

Starts per hour 66 – – 1 1 – – –

Directional phase

overcurrent

Directional ground fault

o/c

Transient intermittent 67NI 1 1 – – – – –

Second harmonic inrush

detection

Fifth harmonic detection 68H5 1 1 1 1 1 1 1

Pole slip 78PS – – – – 1 1 –

Auto-Recloser 79 5 5 – – – – –

Over or under frequency 81 2/2 2/2 2/2 2/2 2/2 2/2 2/2

Rate of change of

frequency

67 4 4 4 4 4 4 4

67N 3 3 3 3 3 3 3

68F2 1 1 1 1 1 1 1

81R 1 1 1 1 1 1 1

Under frequency 81U 2 2 2 2 2 2 2

Lockout 86 1 1 1 1 1 1 1

Line differential 87L – 2 – – – – –

Machine differential 87M – – – 2 – 2 –

Transformer differential 87T – – – – – – 2

Programmable stages 99 8 8 8 8 8 8 8

Arc flash detection (AFD) – 8 8 8 8 8 8 8

Cold load pickup (CLPU) – 1 1 1 1 1 1 1

Programmable curves – 3 3 3 3 3 3 3

Setting groups

8

The availability depends on the selected voltage measurement mode (in the Scaling setting view in Easergy Pro)

9

Using external RTD module

10

Capacitor bank unbalance protection is connected to the ground fault overcurrent input and shares two stages with the ground fault

overcurrent protection.

11

Not all protection functions have 4 setting groups. See details in the manual.

11

– 4 4 4 4 4 4 4

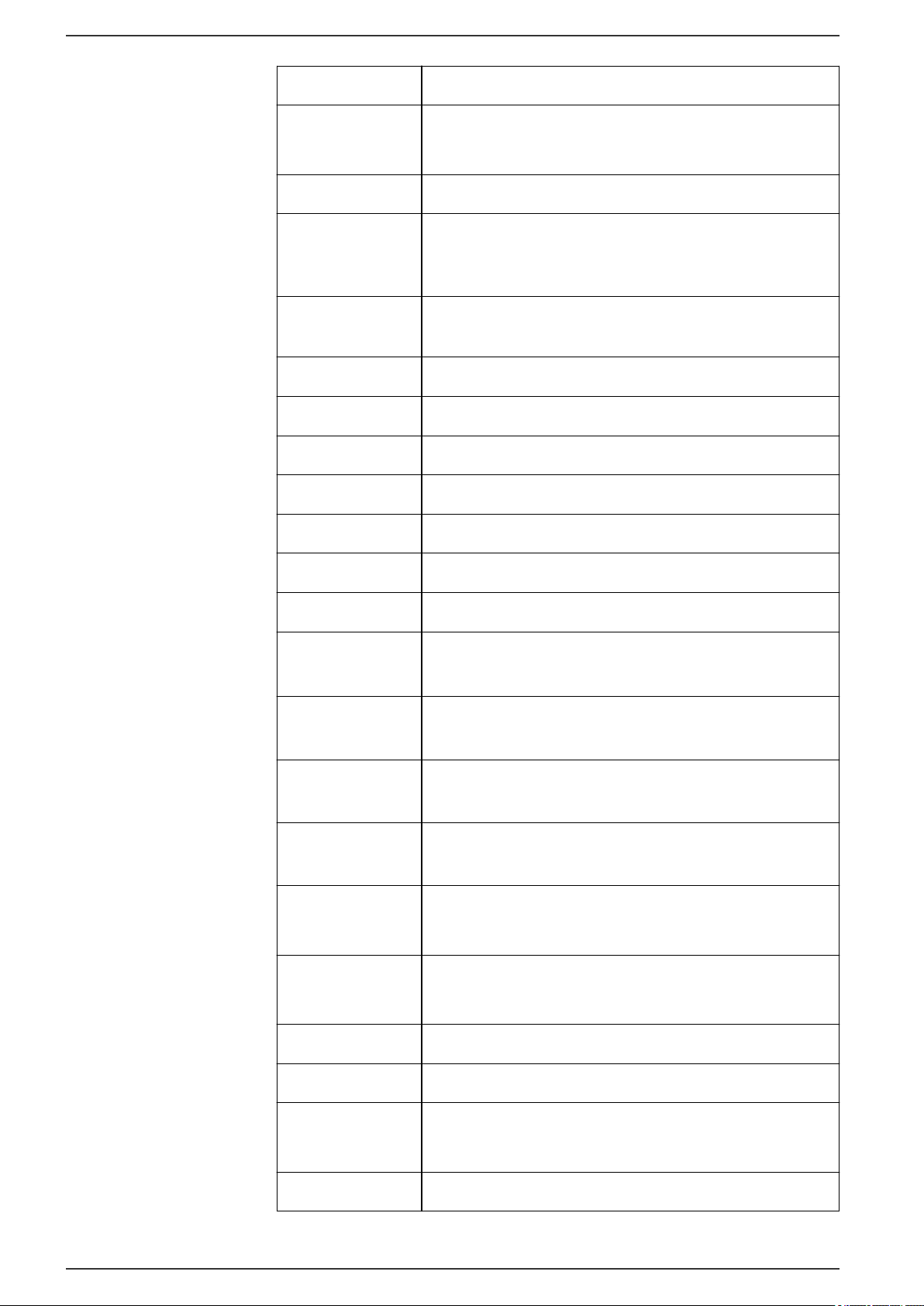

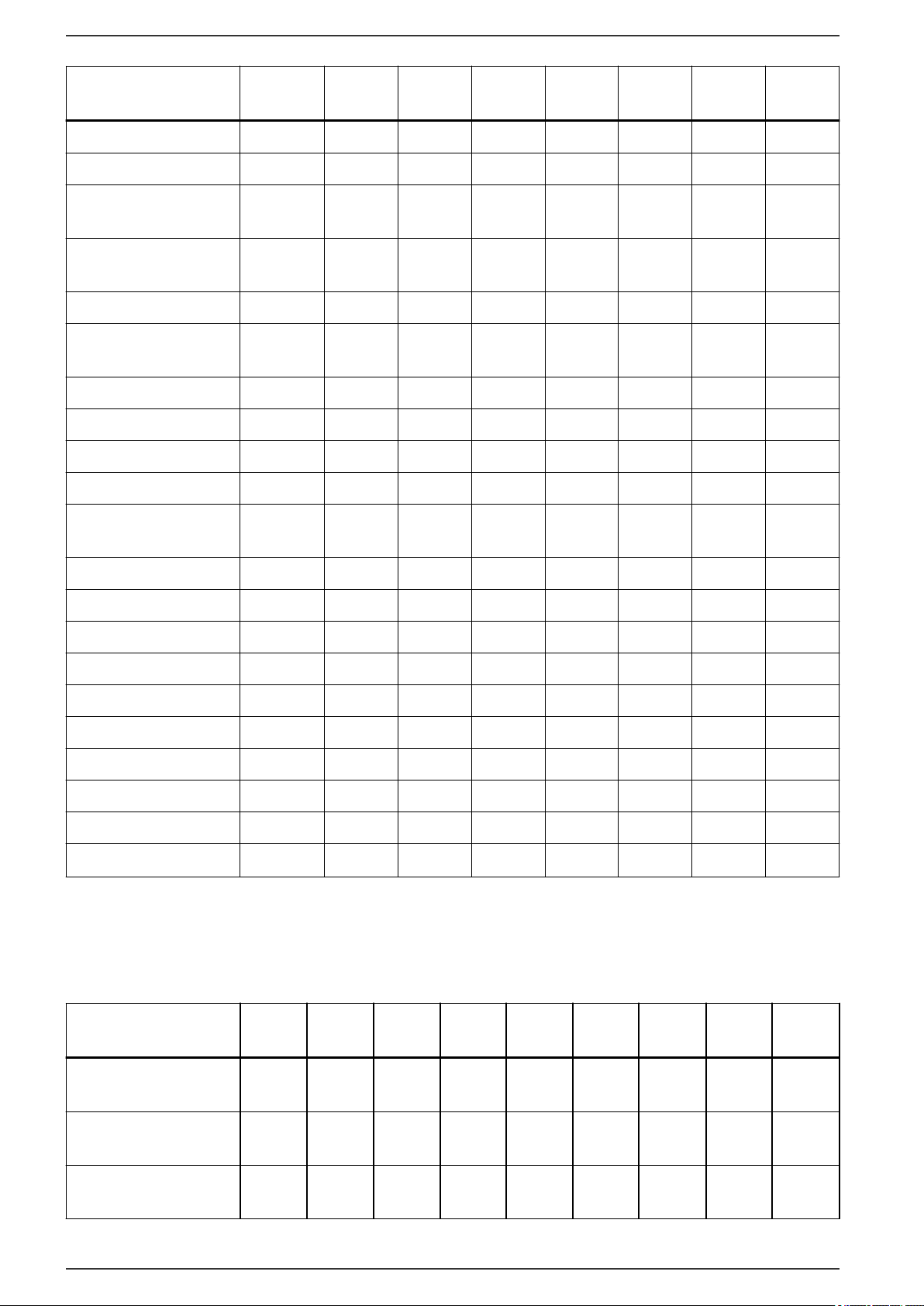

Table 7 - Control functions

Control functions P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Switchgear control and

1/2 4 6 6 6 6 6 6 6

monitoring

Switchgear monitoring

– – 2 2 2 2 2 2 2

only

Programmable switchgear

■ ■ ■ ■ ■ ■ ■ ■ ■

interlocking

24 P3U/en M/F005

Page 25

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Control functions P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Local control on single-

■ ■ ■ ■ ■ ■ ■ ■ ■

line diagram

Local control with O/I keys ■ ■ ■ ■ ■ ■ ■ ■ ■

Local/remote function ■ ■ ■ ■ ■ ■ ■ ■ ■

Function keys 2 2 2 2 2 2 2 2 2

Custom logic (logic

■ ■ ■ ■ ■ ■ ■ ■ ■

equations)

Control with Smart App ■ ■ ■ ■ ■ ■ ■ ■ ■

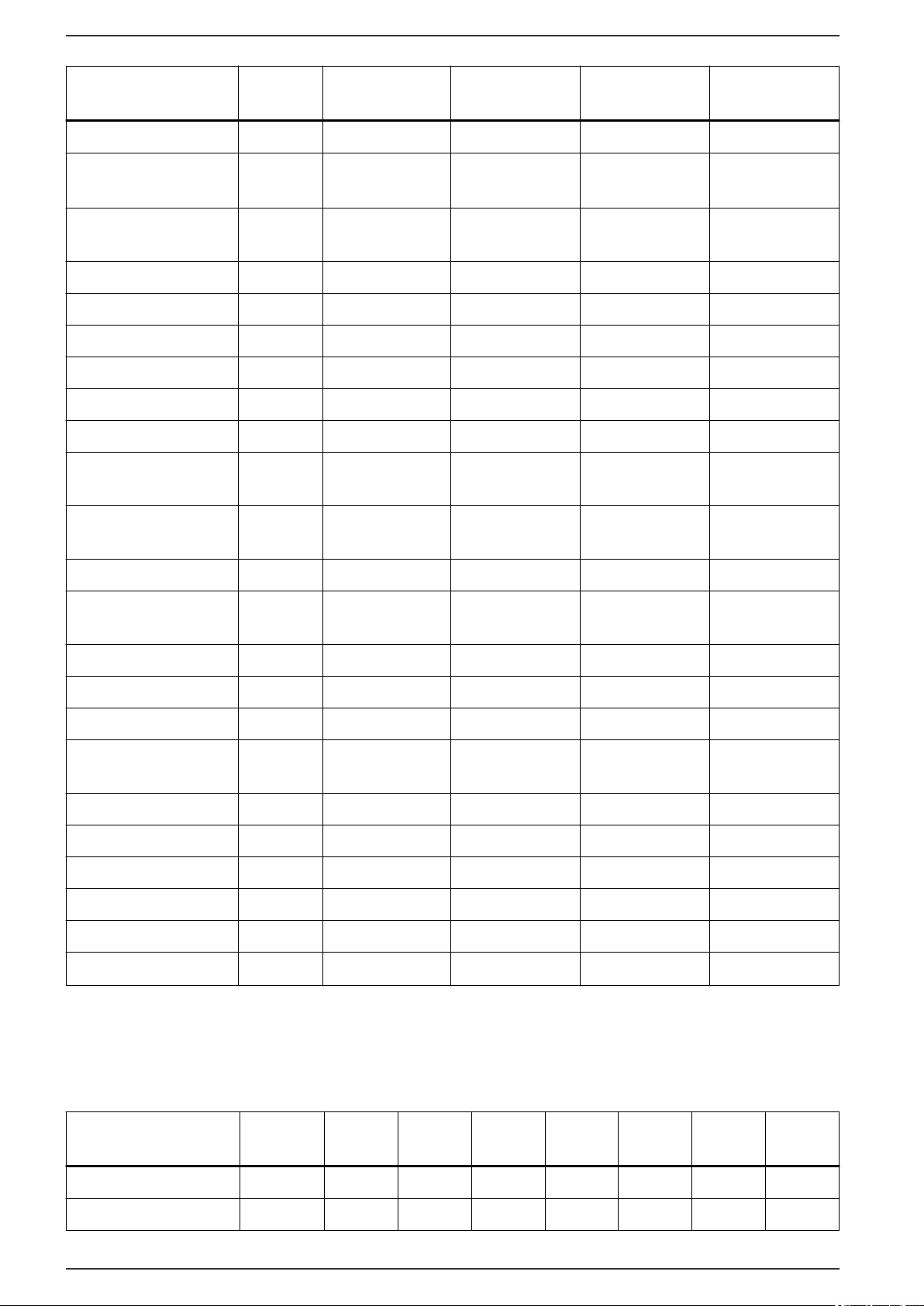

Table 8 - Measurements

Measurement P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

RMS current values ■ ■ ■ ■ ■

12

■

■

RMS voltage values ■ ■ ■ ■ ■ ■ ■ ■ ■

RMS active, reactive and

– ■ ■ ■ ■ ■ ■ ■ ■

apparent power

12

■

12

■

Frequency ■ ■ ■ ■ ■ ■ ■ ■ ■

Fundamental frequency

■ ■ ■ ■ ■

12

■

■

12

■

■

current values

Fundamental frequency

– ■ ■ ■ ■ ■ ■ ■ ■

voltage values

Fundamental frequency

– ■ ■ ■ ■ ■ ■ ■ ■

active, reactive and

apparent power values

Power factor – ■ ■ ■ ■ ■ ■ ■ ■

Energy values active and

– ■ ■ ■ ■ ■ ■ ■ ■

reactive

Energy transmitted with

– ■ ■ ■ ■ ■ ■ ■ ■

pulse outputs

Demand values: phase

■ ■ ■ ■ ■ ■ ■ ■ ■

currents

Demand values: active,

– ■ ■ ■ ■ ■ ■ ■ ■

reactive, apparent power

and power factor

12

Min and max demand

■ ■ ■ ■ ■ ■ ■ ■ ■

values: phase currents

Min and max demand

■ ■ ■ ■ ■ ■ ■ ■ ■

values: RMS phase

currents

P3U/en M/F005 25

Page 26

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Measurement P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Min and max demand

values: active, reactive,

apparent power and

power factor

Maximum demand values

over the last 31 days and

12 months: active,

reactive, apparent power

Minimum demand values

over the last 31 days and

12 months: active,

reactive power

Max and min values:

currents

Max and min values:

voltages

Max and min values:

frequency

– ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■ ■ ■

Max andmin values:

– ■ ■ ■ ■ ■ ■ ■ ■

active, reactive, apparent

power and power factor

Harmonic values of phase

■ ■ ■ ■ ■

12

■

■

12

■

12

■

current and THD

Harmonic values of

– ■ ■ ■ ■ ■ ■ ■ ■

voltage and THD

Voltage sags and swells – ■ ■ ■ ■ ■ ■ ■ ■

12

Function available on both sets of CT inputs

Table 9 - Logs and records

Logs and Records P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Sequence of event record ■ ■ ■ ■ ■ ■ ■ ■ ■

Disturbance record ■ ■ ■ ■ ■ ■ ■ ■ ■

Tripping context record ■ ■ ■ ■ ■ ■ ■ ■ ■

Table 10 - Monitoring functions

Monitoring functions

Trip circuit supervision

P3U10/

20

P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

1 1 1 1 1 1 1 1 1

(ANSI 74)

Circuit breaker monitoring 1 1 1 1 1 1 1 1 1

Relay monitoring ■ ■ ■ ■ ■ ■ ■ ■ ■

26 P3U/en M/F005

Page 27

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

NOTE:

(1) Capacitor bank unbalance protection is connected to the ground fault overcurrent

input and shares two stages with the ground fault overcurrent protection.

(2) Not all protection functions have four setting groups. See details in the manual.

(3) Function available on both sets of CT inputs

(4) Using external RTD module

(5) The availability depends on the selected voltage measurement mode (in the Scaling

setting view in Easergy Pro).

2.4. Access to device configuration

You can access the device configuration via:

• the Easergy Pro setting tool

• the device’s front panel

2.4.1. User accounts

By default, the Easergy P3 device has five user accounts.

Table 11 - User accounts

User account User name Default

Use

password

User user 0 Used for reading parameter

values, measurements, and

events, for example

Operator operator 1 Used for controlling objects and

for changing the protection stages’

settings, for example

Configurator conf 2 Needed during the device

commissioning. For example, the

scaling of the voltage and current

transformers can be set only with

this user account. Also used for

logging on to the HTTP server

Administrator admin 3 Needed for changing the

passwords for other user accounts

and for creating new user

accounts

Easergy easergy 2 Used for logging on to the FTP

server

P3U/en M/F005 27

Page 28

***************

0

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

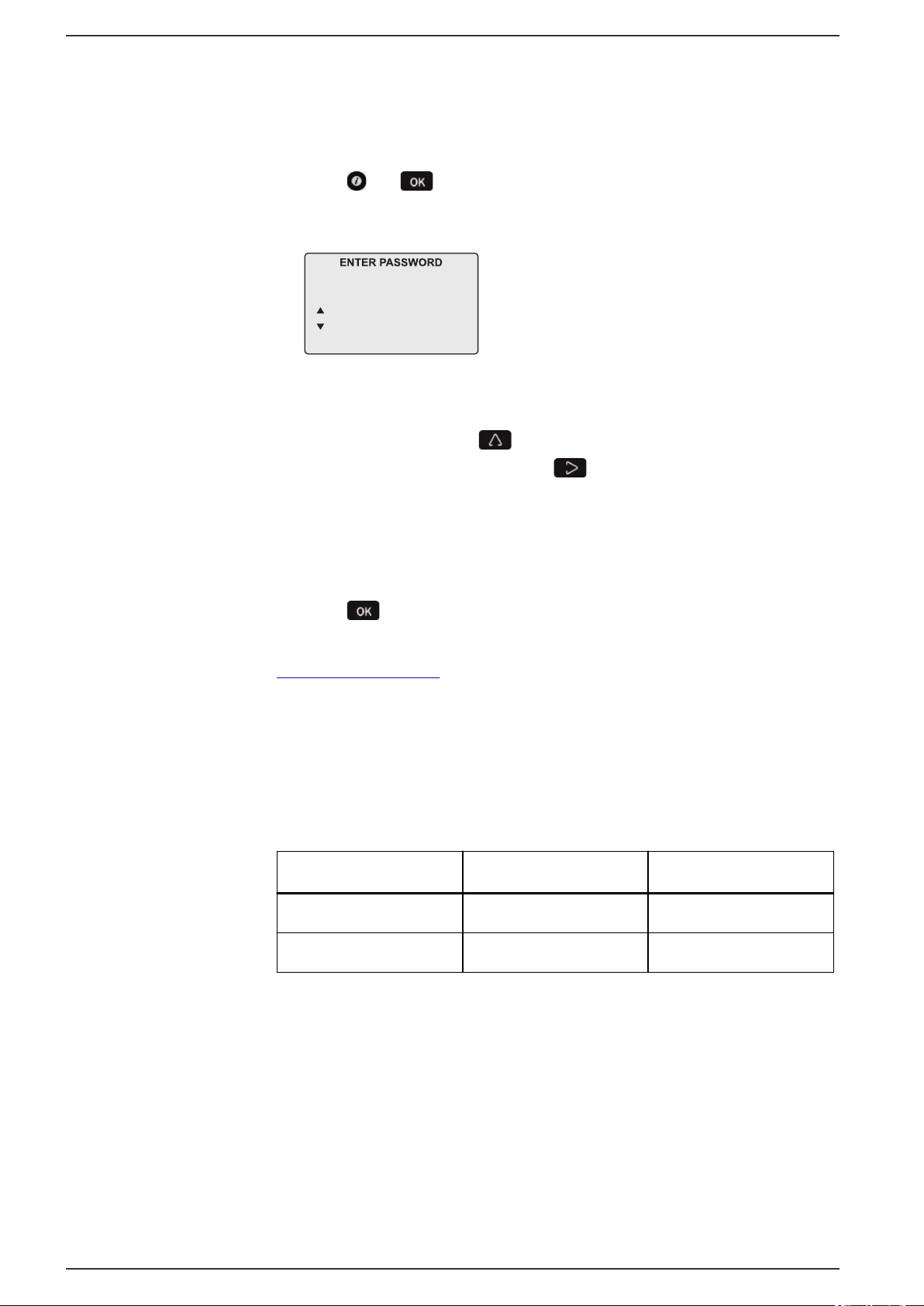

2.4.2. Logging on via the front panel

NOTE: To log on via the front panel, you need a password that consists of

digits only.

1. Press and on the front panel. The Enter password view opens.

Figure 1 - Enter password view

2. Enter the password for the desired access level.

Select a digit value using

move to the next digit position using

NOTE: There are 16 digit positions in the Enter password view. Enter the

password starting from the first digit position.

For example, if the password is 2, you can enter 2***, **2*, ***2, or 0002

to log on.

3. Press

Related topics

Password management on page 29

to confirm the password.

2.4.3. HTTP and FTP logon details

You can log on to the HTTP server and FTP using these user names and

passwords.

Table 12 - HTTP and FTP logon details

Protocol User name Password

, and if the password is longer than one digit,

.

28 P3U/en M/F005

HTTP conf 2

FTP easergy 2

Page 29

2. Product introduction

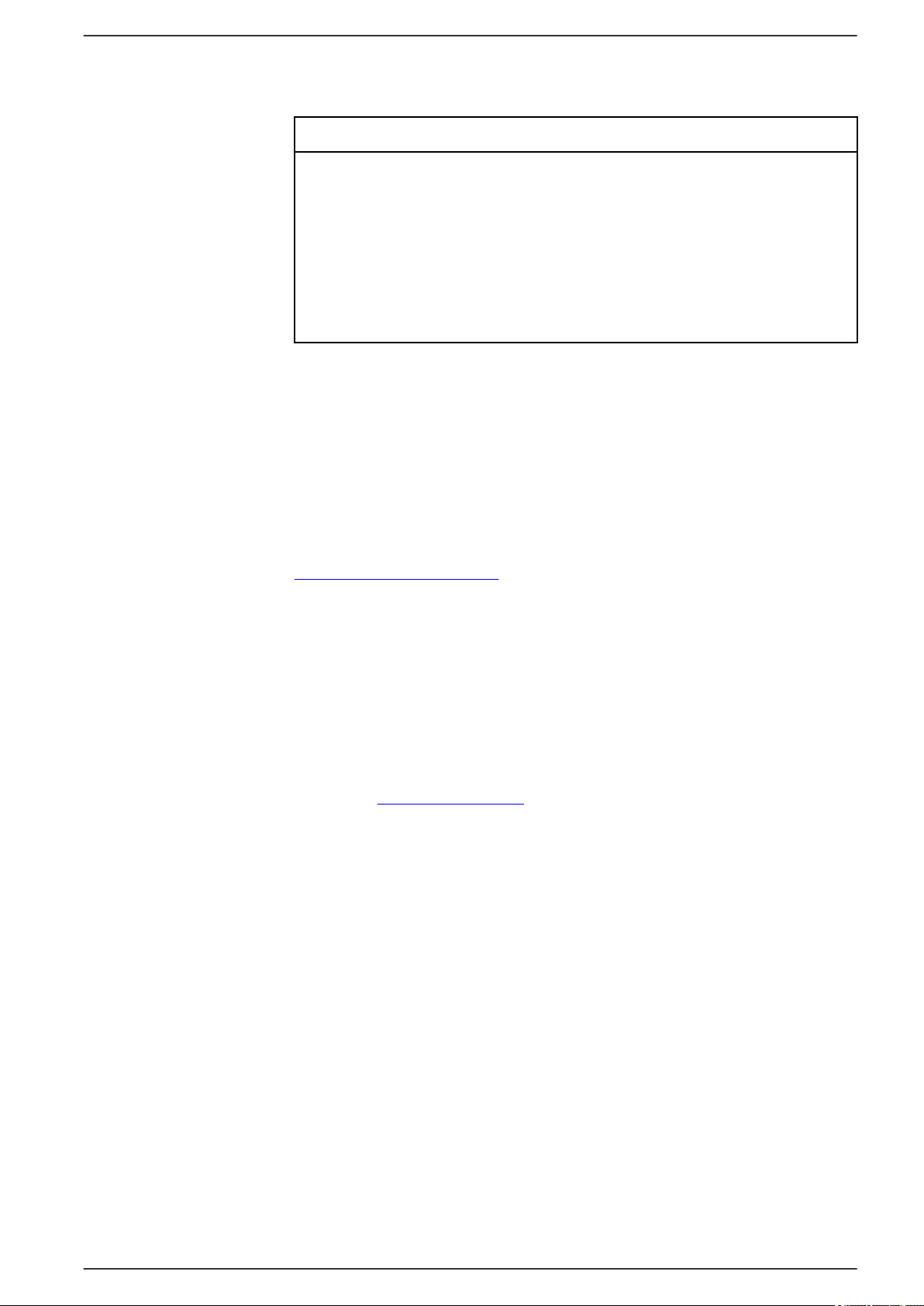

2.4.4. Password management

CYBERSECURITY HAZARD

To improve cybersecurity:

• Change all passwords from their default values when taking the protection

device into use.

• Change all passwords regularly.

Failure to follow these instructions can increase the risk of unauthorized

access.

You can change the password for the operator or configurator user accounts in

the General > Device info setting view in Easergy Pro.

The password can contain letters, digits or any other UTF-8 characters (total 1–32

characters). However, the new password cannot be any of the default passwords

(digits 0–4 or 9999).

Universal Relays P3U10, P3U20 and P3U30

NOTICE

NOTE: To log on via the front panel, you need a password that consists of

digits only.

Related topics

Logging on via the front panel on page 28

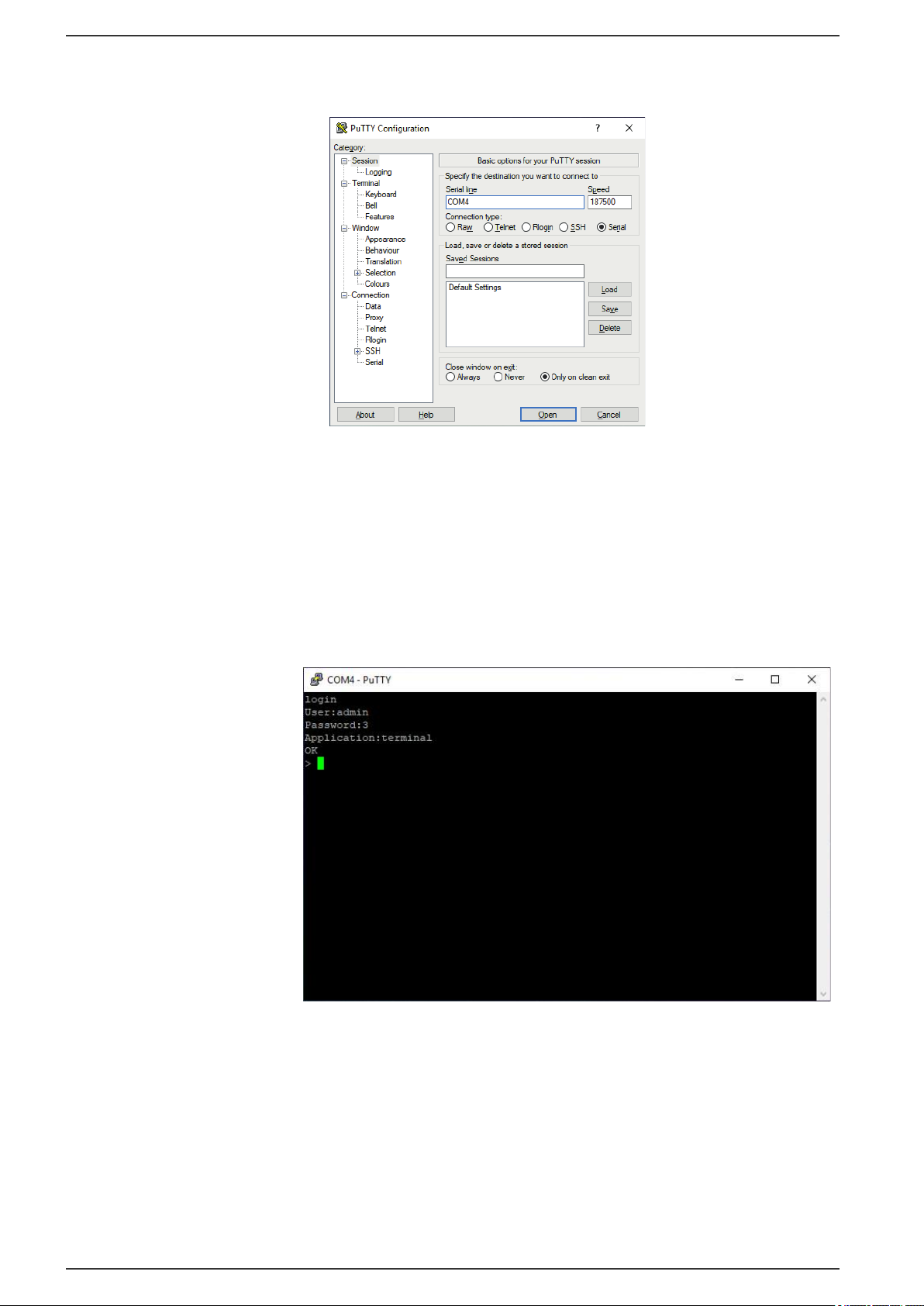

2.4.5. Changing passwords for administrator and configurator accounts via PuTTY

Change the password for the administrator and configurator user accounts to

reach an optimal cybersecurity level. To log on as the administrator user, you

need to use either a serial terminal software or a Telnet client software. This

instruction describes how to change the passwords using PuTTY which is freely

available at https://www.putty.org/.

1. Download and install PuTTY.

2. Connect the Easergy P3 device to your PC via the USB port in the device's

front panel.

3. Find the COM port number for the device (for example, with Easergy Pro).

4. Connect to the device’s COM port via PuTTY.

a. Open PuTTY.

The PuTTY Configuration dialog box opens.

P3U/en M/F005 29

Page 30

Universal Relays P3U10, P3U20 and P3U30

2. Product introduction

Figure 2 - PuTTY Configuration dialog box

b. In the Serial line field, type the COM port name.

c. In the Speed field, set the communication speed to 187500 bps.

d. Click Open.

The PuTTY command window opens.

5. Log on as the administrator by giving command login.

Figure 3 - PuTTY login

6. Change the password for the administrator account by giving the command

passwd.

30 P3U/en M/F005

Page 31

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Figure 4 - Changing the administrator password in PuTTY

7. Change the password for the configurator account by giving the command

passwd conf.

Figure 5 - Changing the configurator password in PuTTY

8. Log out by giving the command logout.

2.4.6. Password restoring

If you have lost or forgotten all passwords, contact Schneider Electric to restore

the default passwords.

P3U/en M/F005 31

Page 32

A

B

C

G

E

F

C

D

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

2.5. Front panel

Figure 6 - Easergy P3U10, P3U20 and P3U30 front panel

2.5.1. Push-buttons

A. LCD

B. Navigation push-buttons

C. Object control buttons

D. LED indicators

E. Local port

F. Function push-buttons and LEDs showing their status

G. INFO push-button

Symbol Function

HOME/CANCEL push-button for returning to the previous menu. To return to

the first menu item in the main menu, press the button for at least 3 seconds.

INFO push-button for viewing additional information, for entering the password

view and for adjusting the LCD contrast.

Programmable function push-button.

13

Programmable function push-button.

32 P3U/en M/F005

13

Page 33

2. Product introduction

Universal Relays P3U10, P3U20 and P3U30

ENTER push-button for activating or confirming a function.

UP navigation push-button for moving up in the menu or increasing a numerical

value.

DOWN navigation push-button for moving down in the menu or decreasing a

numerical value.

LEFT navigation push-button for moving backwards in a parallel menu or

selecting a digit in a numerical value.

RIGHT navigation push-button for moving forwards in a parallel menu or

selecting a digit in a numerical value.

Circuit breaker close push-button

Circuit breaker trip push-button

13

The default names of the function buttons are Function button 1 and 2. You can change the names

of the buttons in the Inputs/outputs > Names for logic outputs setting view.

2.5.2. LED indicators

The relay has 12 LED indicators on the front panel:

• two LEDs for function buttons (F1 and F2)

• two LEDs represent the unit's general status (power and service)

• eight user-configurable LEDs (A-H)

When the relay is powered, the power LED is green. During normal use, the

service LED is not active, it activates only when an error occurs or the relay is not

operating correctly. Should this happen, contact your local representative for

further guidance. The service LED and watchdog contact are assigned to work

together. Hardwire the status output into the substation's automation system for

alarm purposes.

To customize the LED texts on the front panel for the user-configurable LEDs, the

text may be created using a template and then printed. The printed text may be

placed in the pockets beside the LEDs.

You can also customize the LED texts that are shown on the screen for active

LEDs via Easergy Pro.

P3U/en M/F005 33

Page 34

Universal Relays P3U10, P3U20 and P3U30

Table 13 - LED indicators and their information

2. Product introduction

LED indicator

Power LED lit

Service LED lit

A–H LED lit Yellow Application-related

F1 or F2 LED lit Yellow Corresponding

LED color

Green

Red

Meaning Measure /

The auxiliary power

has been switched

on

Internal fault.

Operates in parallel

with the selfsupervision output

status indicators.

function key

pressed / activated

Remarks

Normal operation

state

The relay attempts

to reboot. If the

service LED remains

lit, call for

maintenance.

Configurable in the

Matrix setting view

Depending on the

function

programmed to F1 /

F2

2.5.3. Controlling the alarm screen

You can enable or disable the alarm screen either via the relay's local display or

using Easergy Pro:

• On the local display, go to Events > Alarms.

• In Easergy Pro, go to General > Local panel conf.

2.5.4. Accessing operating levels

1. On the front panel, press

2. Enter the password, and press

2.5.5. Adjusting the LCD contrast

Prerequisite: You have entered the correct password.

1. Press

, and adjust the contrast.

and .

.

◦ To increase the contrast, press

◦ To decrease the contrast, press

2. To return to the main menu, press

.

.

.

NOTE: By nature, the LCD display changes its contrast depending on the

ambient temperature. The display may become dark or unreadable at low

temperatures. However, this condition does not affect the proper operation of

the protection or other functions.

34 P3U/en M/F005

Page 35

2. Product introduction

2.5.6. Testing the LEDs and LCD screen

You can start the test sequence in any main menu window.

To start the LED and LCD test:

1. Press .

Universal Relays P3U10, P3U20 and P3U30

2. Press

The relay tests the LCD screen and the functionality of all LEDs.

.

2.5.7. Controlling an object with selective control

Prerequisite: You have entered the correct password and enabled selective

control in the Objects setting view.

When selective control is enabled, the control operation needs confirmation

(select before operate).

1. Press

◦ Press

◦ Press

2. Press

◦ Press

◦ Press

to close an object.

again to confirm.

to cancel.

to trip an object.

again to confirm.

to cancel.

2.5.8. Controlling an object with direct control

Prerequisite: You have entered the correct password and enabled selective

control in the Objects setting view.

When direct control is enabled, the control operation is done without confirmation.

1. Log into the system.

2. Press

3. Press

to close an object.

to trip an object.

2.5.9. Menus

This section gives an overview of the menus that you can access via the device's

front panel.

The main menu

Press the right arrow to access more measurements in the main menu.

P3U/en M/F005 35

Page 36

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Table 14 - Main menu

Menu name Description

Active LEDs User-configurable texts for active LEDs

Measurements User-configurable measurements

Single line Single line or Single line mimic, measurements and control view. This

is a default start view. To return to this view from any location, press

the HOME/CANCELL button for at least 3 seconds.

Info Information about the relay: relay's name, order code, date, time and

firmware version

P Power: power factor and frequency values calculated by the relay.

Press the right arrow to view more energy measurements.

E Energy: the amount of energy that has passed through the protected

line, calculated by the relay from the currents and voltages. Press the

right arrow to view more energy measurements.

I Current: phase currents and demand values of phase currents. Press

the right arrow to view more current measurements.

V Line-to-line voltages. Press the right arrow to view other voltage

measurements.

Dema Minimum and maximum phase current and power demand values

Vmax Minimum and maximum values of voltage and frequency

Imax Minimum and maximum voltage values

Pmax Minimum and maximum power values

Month Monthly maximum current and power values

FL Short-circuit locator applied to incomer or feeder

Evnt Event log: event codes and time stamps

DR Disturbance recorder configuration settings

Runh Running hour counter

TIMR Timers: programmable timers that you can use to preset functions

DI Digital input statuses and settings

DO Digital output statuses and settings

Prot Protection: settings and statuses for various protection functions

50/51-1–50/51-4 Protection stage settings and statuses. The availability of the menus

are depends on the activated protection stages.

AR Auto-reclosure settings, statuses and registers

36 P3U/en M/F005

Page 37

Main menu Submenus

Arc detection settings

I pick-up setting

ARC

OK

OK OK

2. Product introduction

Universal Relays P3U10, P3U20 and P3U30

Menu name Description

OBJ Objects: settings related to object status data and object control (open/

closed)

Lgic Logic events and counters

CONF General device setup: CT and VT scalings, frequency adaptation,

units, device info, date, time, clock, etc.

Bus Communication port settings

OPT Slot info: card ID (CID) that is the name of the card used by the relay

firmware

Diag Diagnosis: various diagnostic information

2.5.9.1. Moving in the menus

Figure 7 - Moving in menus using the front panel

• To move in the main menu, press or .

• To move in the submenus, press

• While in the submenu, press

• To enter a submenu, press

or .

or to jump to the root.

and use or for moving down or up

in the menu.

• To edit a parameter value, press

• Enter the password, and press

• To go back to the previous menu, press

P3U/en M/F005 37

and .

.

.

Page 38

Universal Relays P3U10, P3U20 and P3U30

• To go back to the first menu item in the main menu, press for at least three

seconds.

NOTE: To enter the parameter edit mode, enter the password. When the

value is in edit mode, its background is dark.

2.5.9.2. Local panel messages

Table 15 - Local panel messages

Value is not editable: The value can not be edited or password is not given

Control disabled: Object control disabled due to wrong operating level

Change causes autoboot: Notification that if the parameter is changed the relay boots

itself

2.6. Easergy Pro setting and configuration tool

2. Product introduction

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC

FLASH

Only qualified personnel should operate this equipment.

Such work should be performed only after reading this

entire set of instructions and checking the technical

characteristics of the device.

Failure to follow this instruction will result in death or

serious injury.

Easergy Pro is a software tool for configuring Easergy P3 relays. It has a

graphical interface where the relay settings and parameters are grouped under

seven tabs:

• General

• Measurements

• Inputs/outputs

• Protection

• Matrix

• Logs

• Communication

The contents of the tabs depend on the relay type and the selected application

mode.

Easergy Pro stores the relay configuration in a setting file. The configuration of

one physical relay is saved in one setting file. The configurations can be printed

out and saved for later use.

For more information, see the Easergy Pro user manual.

NOTE: Download the latest version of the software from www.schneider-

electric.com/en/product-range/64884-easergy-p3.

38 P3U/en M/F005

Page 39

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

NOTICE

RISK OF SYSTEM SHUTDOWN

After writing new settings or configurations to a relay, perform a test to verify that

the relay operates correctly with the new settings.

Failure to follow these instructions can result in unwanted shutdown of

the electrical installation.

P3U/en M/F005 39

Page 40

Universal Relays P3U10, P3U20 and P3U30 3. Measurement functions

3. Measurement functions

Easergy P3 has various amounts of analog inputs depending on the model in use.

Table 16 - Measurement functions in Easergy P3 on page 40 introduces directly

measured and calculated quantities for the power system monitoring. Also see

2.3. Product selection guide on page 19.

The relay has two operational modes: feeder and motor. In the feeder mode, the

secondary currents are proportional to the CT values whereas in the motor mode,

all protection stages use the motor's nominal current values.

The current scaling impacts the following functions:

• Protection stages

• Measurements

• Disturbance recorder

• Fault location calculation

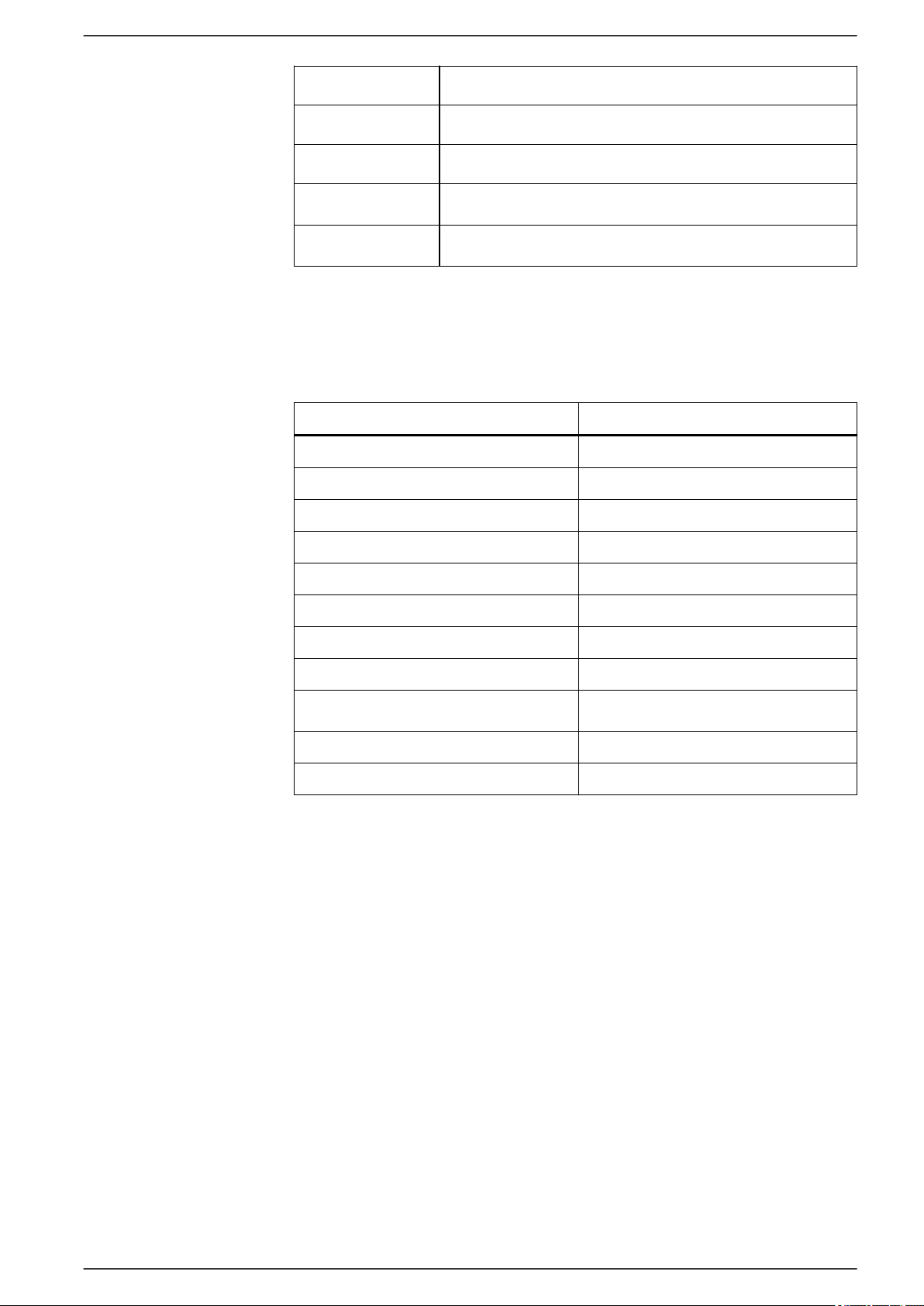

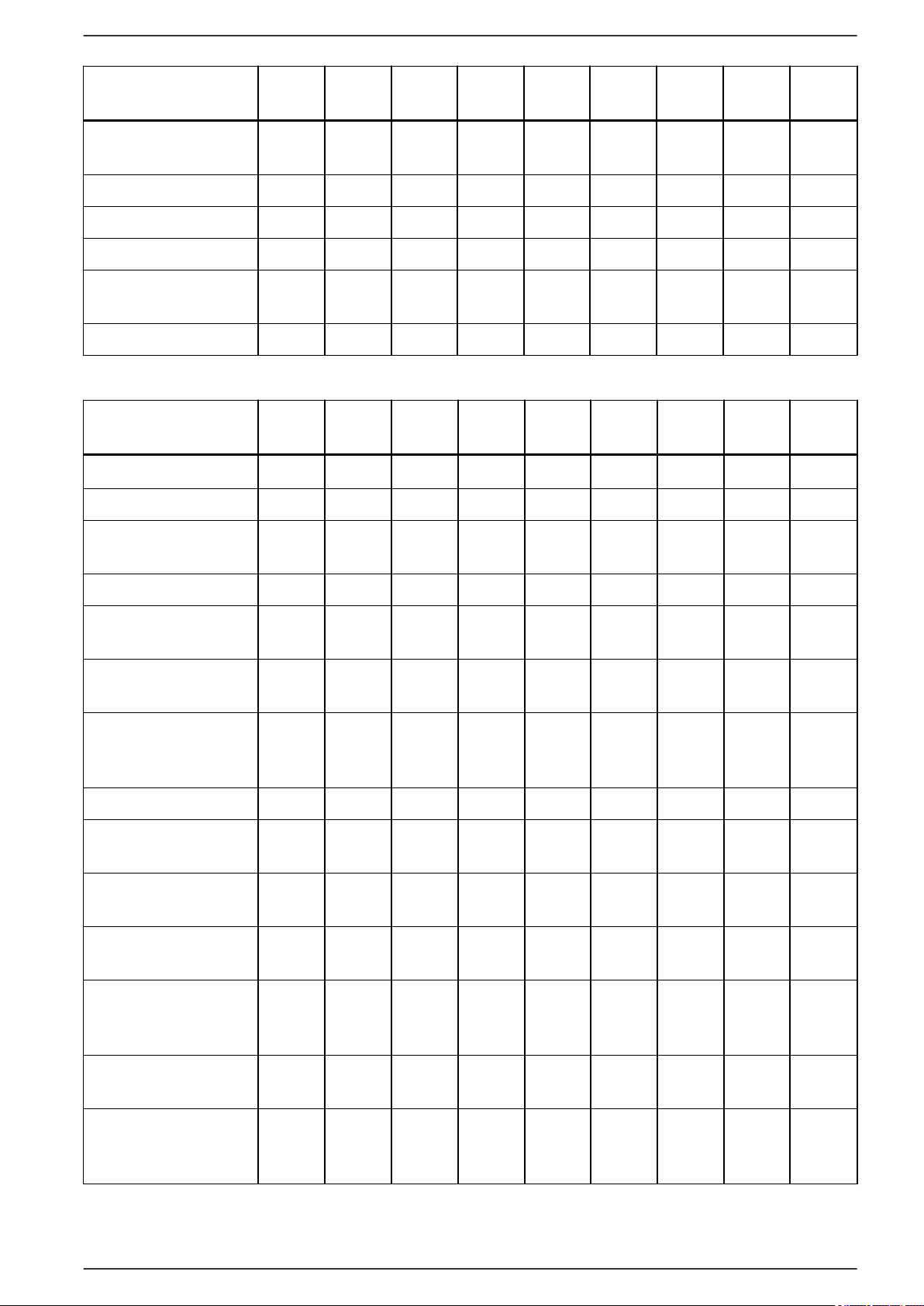

Table 16 - Measurement functions in Easergy P3

Measurements

Specification

P3U10/20 P3U30 P3x3x Measurement

range

RMS phase current ■ ■ ■ 0.025-50 x I

RMS ground fault

■ ■ ■ 0.003-2 x I

overcurrent

RMS line-to-line voltage — ■ ■

RMS phase-to-neutral

— ■ ■

0.005-1.7 x V

0.005-1.7 x V

voltage

RMS active power (PF >0.5) — ■ ■ ±0.1-1.5 x P

RMS reactive power (PF

— ■ ■ ±0.1-1.5 x Q

>0.5)

Inaccuracy

N

N

N

N

N

N

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

I > 1.5 x IN: ±3 % of value

I ≤ 1.5 xI0N: ±0.3 % of value or ±0.2

% of I0N

I > 1.5 xI0N: ±3 % of value

±0.5 % or ±0.3 V

±0.5 % or ±0.3 V

±1 % for range 0.3-1.5xP

±3 % for range 0.1-0.3xP

±1 % for range 0.3-1.5xQ

±3 % for range 0.1-0.3xQ

N

N

N

N

RMS apparent power (PF

— ■ ■ ±0.1-1.5 x S

N

±1 % for range 0.3-1.5xS

N

>0.5)

±3 % for range 0.1-0.3xS

N

Frequency ■ ■ ■ 16 Hz – 75 Hz ±10 mHz

Fundamental frequency

current values

■ ■ ■ 0.025-50 x I

N

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

I > 1.5 x IN: ±3 % of value

Fundamental frequency

— ■ ■

0.005-1.7 x V

N

±0.5 % or ±0.3 V

voltage values

40 P3U/en M/F005

Page 41

3. Measurement functions Universal Relays P3U10, P3U20 and P3U30

Measurements

Specification

Fundamental frequency

P3U10/20 P3U30 P3x3x Measurement

range

— ■ ■ ±0.1-1.5 x P

N

Inaccuracy

±1 % for range 0.3-1.5xP

active, reactive and apparent

power values

Fundamental frequency

— ■ ■ ±0.1-1.5 x Q

N

±3 % for range 0.1-0.3xP

±1 % for range 0.3-1.5xQ

active power values

±3 % for range 0.1-0.3xQ

Fundamental frequency

— ■ ■ ±0.1-1.5 x S

N

±1 % for range 0.3-1.5xS

reactive power values

±3 % for range 0.1-0.3xS

Power factor — ■ ■ 0.02-1 ±2° or ±0.02 for PF > 0.5

Active energy — ■ ■

Reactive energy — ■ ■

±1 % for range 0.3-1.5xEP

±1 %/1h for range 0.3-1.5xEQ

±3 %/1h for range 0.1-0.3xEQ

Energy transmitted with

— ■ ■

±1 %/1h for range 0.3-1.5xEP

pulse outputs

±3 %/1h for range 0.1-0.3xEP

N

N

N

N

N

N

N

N

N

N

N

Demand values: phase

currents

■ ■ ■ 0.025-50 x I

N

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

I > 1.5 x IN ±3 % of value

Active power demand — ■ ■ ±0.1-1.5 x P

N

±1 % for range 0.3-1.5xP

±3 % for range 0.1-0.3xP

Reactive power demand — ■ ■ ±0.1-1.5 x Q

N

±1 % for range 0.3-1.5xQ

±3 % for range 0.1-0.3xQ

Apparent power demand — ■ ■ ±0.1-1.5 x S

N

±1 % for range 0.3-1.5xS

±3 % for range 0.1-0.3xS

Power factor demand — ■ ■ ±2° or ±0.02 for PF > 0.5

Min and max demand

values: phase currents

■ ■ ■

0.025-50 x I

N

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

I > 1.5 x IN ±3 % of value

Min and max demand

values: RMS phase currents

■ ■ ■

0.025-50 x I

N

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

N

N

N

N

N

N

I > 1.5 x IN ±3 % of value

Min and max demand

— ■ ■

±1 % for range 0.3-1.5xPN, QN, S

N

values: active, reactive,

apparent power and power

±3 % for range 0.1-0.3xPN, QN, S

N

factor

P3U/en M/F005 41

Page 42

Universal Relays P3U10, P3U20 and P3U30

3. Measurement functions

Measurements

Specification

Maximum demand values

over the last 31 days and 12

months: active, reactive,

apparent power

Minimum demand values

over the last 31 days and 12

months: active, reactive

power

Max and min values:

currents

Max and min values:

voltages

Max and min values:

frequency

P3U10/20 P3U30 P3x3x Measurement

range

— ■ ■

— ■ ■

■ ■ ■

— ■ ■

■ ■ ■

0.025-50 x I

0.005-1.7 x V

N

N

16 Hz-75 Hz ±10 mHz

Inaccuracy

±1 % for range 0.3-1.5xPN, QN, S

±3 % for range 0.1-0.3xPN, QN, S

±1 % for range 0.3-1.5xPN, QN, S

±3 % for range 0.1-0.3xPN, QN, S

I ≤ 1.5 x IN: ±0.5 % of value or ±15

mA

I > 1.5 x IN ±3 % of value

±0.5 % or ±0.3 V

N

N

N

N

Max andmin values: active,

— ■ ■

±0.1-1.5 x PN, QN, SN±1 % for range 0.3-1.5xPN, QN, S

reactive, apparent power

and power factor

Harmonic values of phase

■ ■ ■

2nd-15th

current and THD

Harmonic values of voltage

— ■ ■

2nd-15th

and THD

Voltage sags and swells — ■ ■

0.005-1.7 x V

N

NOTE: Measurement display's refresh rate is 0.2 s.

3.1. Primary, secondary and per unit scaling

Many measurement values are shown as primary values although the relay is

connected to secondary signals. Some measurement values are shown as

relative values - per unit or percent. Almost all start setting values use relative

scaling.

±3 % for range 0.1-0.3xPN, QN, S

±2° or ±0.02 for PF > 0.5

±2° or ±0.02 for PF > 0.5

N

N

42 P3U/en M/F005

Page 43

3. Measurement functions Universal Relays P3U10, P3U20 and P3U30

Scaling settings

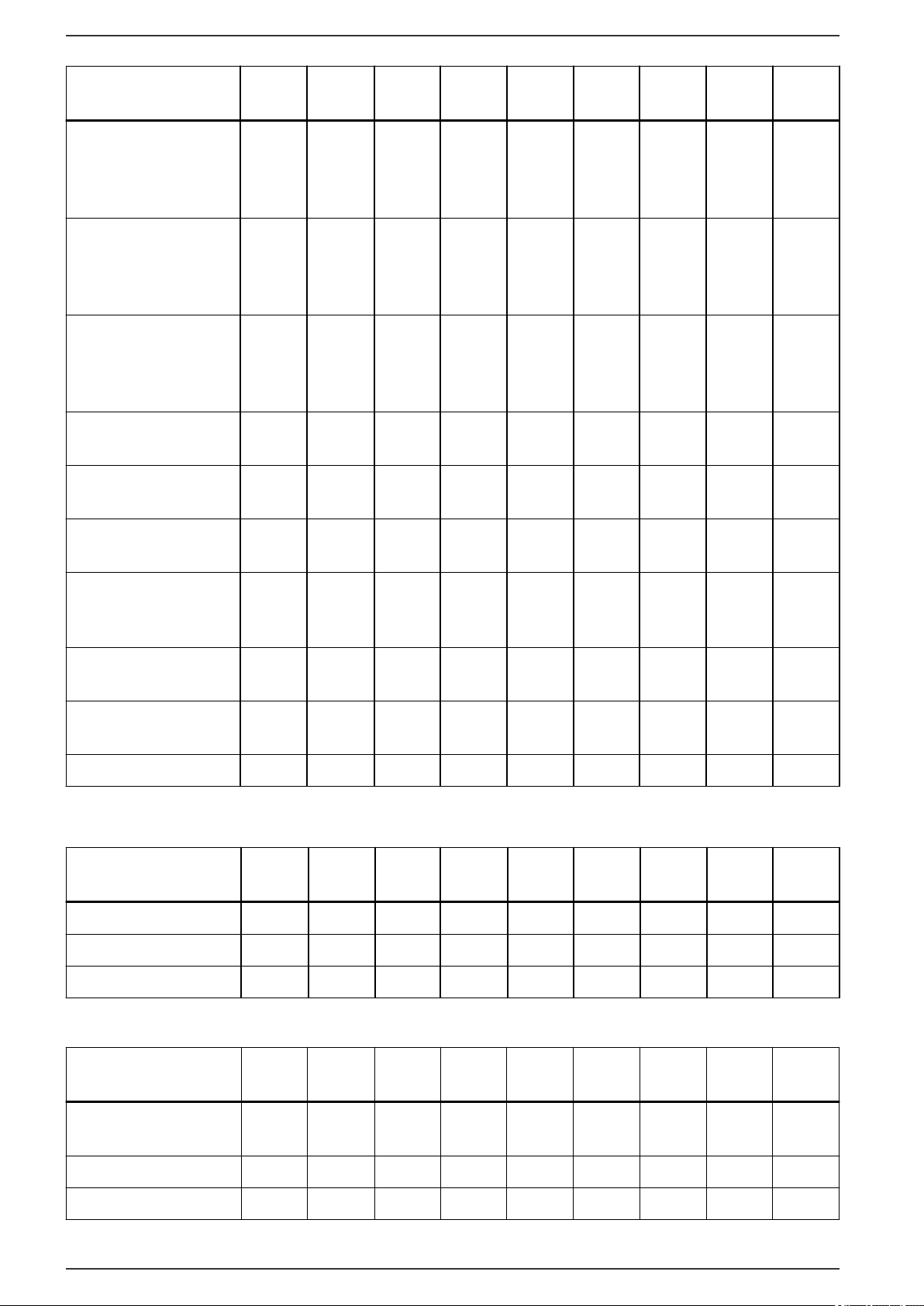

Table 17 - Phase current and ground fault overcurrent scaling parameters

Parameter Description

Nominal input (IL side) Rated value of the phase current input. The given

thermal withstand, burden and impedance are

based on this value.

See Table 130 - Measuring circuits on page 315 for

details.

CT primary Primary current value of the IL current transformer

CT secondary Secondary current value of the IL current

transformer

IN1 CT primary Primary current value of the ground fault I

N1

overcurrent transformer

IN1 CT secondary Secondary current value of the ground fault I

N1

overcurrent transformer

Nominal IN1 input

Selectable nominal input rating for the ground fault

overcurrent input. Select either 5A or 1A depending

on which Io input is used. The given thermal

withstand, burden and impedance are based on this

value.

See Table 130 - Measuring circuits on page 315 for

details.

VT primary Primary voltage value of the voltage transformer

(only P3U30 relays)

VT secondary Secondary voltage value of the voltage transformer

(only P3U30 relays)

VTo secondary Secondary voltage value of the neutral voltage

displacement voltage transformer

Voltage measurement mode The relay can be connected either to zero-

sequence voltage, line-to-line voltage or line-toneutral voltage. Set the voltage measurement mode

according to the type of connection used.

Frequency adaptation mode Parameter used to set the system frequency. There

are three modes available: manual, auto and fixed.

For more information, see section Frequency

adaptation mode.

Adapted frequency When the frequency adaption mode is set to

manual, you can set the frequency in the Adapted

frequency field, and it is not be updated even if the

measured frequency is different.

Angle memory duration Time setting for the directional overcurrent stage to

keep the phase angle fixed if the system voltage

collapses

P3U/en M/F005 43

Page 44

Universal Relays P3U10, P3U20 and P3U30

Figure 8 - Scaling setting view in Easergy Pro

3. Measurement functions

The scaling equations presented in 3.1.2. Current transformer ratio on page 45

and 3.1.3. Voltage transformer ratio on page 47 are useful when doing

secondary testing.

3.1.1. Frequency adaptation mode

You can set the system frequency in General > Scaling in Easergy Pro.

There are three frequency adaptation modes available:

• Manual: When the adaption mode is set to manual, you can set the frequency

in the Adapted frequency field, and it will not be updated even if the

measured frequency is different. However, the relay monitors the system