ModiconTM3

EIO0000003125 06/2020

Modicon TM3

Digital I/O Modules

Hardware Guide

06/2020

EIO0000003125.03

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000003125 06/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part I TM3 General Overview. . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 TM3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 TM3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1 TM3 General Rules for Implementing . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 TM3 Expansion Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Maintenance Requirements . . . . . . . . . . . . . . . . . . . .

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top Hat Section Rail (DIN rail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembling a Module to a Controller or Receiver Module . . . . . . . . .

Disassembling a Module from a Controller or Receiver Module . . . . .

Direct Mounting on a Panel Surface . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TM3 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Supply Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II TM3 Digital Input Modules . . . . . . . . . . . . . . . . . . . .

Chapter 3 TM3DI8A Module 8 Inputs 120 Vac . . . . . . . . . . . . . . . . 57

TM3DI8A Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI8A Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI8A Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc . . 63

TM3DI8 / TM3DI8G Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI8 / TM3DI8G Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI8 / TM3DI8G Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 TM3DI16 / TM3DI16G Module 16 Regular Inputs 24 Vdc 69

TM3DI16 / TM3DI16G Presentation . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI16 / TM3DI16G Characteristics . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI16 / TM3DI16G Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .

15

18

22

24

28

29

32

33

34

37

38

41

43

44

46

47

53

55

58

59

61

64

66

68

70

72

75

EIO0000003125 06/2020 3

Chapter 6 TM3DI16K Module 16 Regular Inputs 24 Vdc . . . . . . . . . 77

TM3DI16K Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI16K Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI16K Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 TM3DI32K Module 32 Regular Inputs 24 Vdc . . . . . . . . . 85

TM3DI32K Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI32K Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DI32K Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III TM3 Digital Output Modules. . . . . . . . . . . . . . . . . . .

Chapter 8 TM3DQ8R / TM3DQ8RG Module 8 Relay Outputs 2A

24 Vdc/240 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

TM3DQ8R / TM3DQ8RG Presentation . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8R / TM3DQ8RG Characteristics . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8R / TM3DQ8RG Wiring Diagram . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 TM3DQ8T / TM3DQ8TG Module 8 Regular Transistor

Source Outputs 0.5A 24 Vdc . . . . . . . . . . . . . . . . . . . . . . 103

TM3DQ8T / TM3DQ8TG Presentation. . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8T / TM3DQ8TG Characteristics . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8T / TM3DQ8TG Wiring Diagram . . . . . . . . . . . . . . . . . . . . . .

Chapter 10 TM3DQ8U / TM3DQ8UG Module 8 Regular Transistor

Sink Outputs 0.5A 24 Vdc . . . . . . . . . . . . . . . . . . . . . . . . 109

TM3DQ8U / TM3DQ8UG Presentation . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8U / TM3DQ8UG Characteristics . . . . . . . . . . . . . . . . . . . . . .

TM3DQ8U / TM3DQ8UG Wiring Diagram . . . . . . . . . . . . . . . . . . . . . .

Chapter 11 TM3DQ16R / TM3DQ16RG Module 16 Relay Outputs 2A

24 Vdc/240 Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

TM3DQ16R / TM3DQ16RG Presentation . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16R / TM3DQ16RG Characteristics . . . . . . . . . . . . . . . . . . . .

TM3DQ16R / TM3DQ16RG Wiring Diagram . . . . . . . . . . . . . . . . . . . .

Chapter 12 TM3DQ16T / TM3DQ16TG Module 16 Regular

Transistor Source Outputs 0.5A 24 Vdc . . . . . . . . . . . . . . 123

TM3DQ16T / TM3DQ16TG Presentation. . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16T / TM3DQ16TG Characteristics . . . . . . . . . . . . . . . . . . . . .

TM3DQ16T / TM3DQ16TG Wiring Diagram . . . . . . . . . . . . . . . . . . . .

78

80

83

86

88

91

93

96

98

102

104

105

107

110

111

113

116

118

121

124

126

128

4 EIO0000003125 06/2020

Chapter 13 TM3DQ16TK Module 16 Regular Transistor Source

Outputs 0.1A 24 Vdc. . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

TM3DQ16TK Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16TK Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16TK Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 14 TM3DQ16U / TM3DQ16UG Module 16 Regular

Transistor Sink Outputs 0.5A 24 Vdc . . . . . . . . . . . . . . . 135

TM3DQ16U / TM3DQ16UG Presentation . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16U / TM3DQ16UG Characteristics . . . . . . . . . . . . . . . . . . . .

TM3DQ16U / TM3DQ16UG Wiring Diagram. . . . . . . . . . . . . . . . . . . .

Chapter 15 TM3DQ16UK Module 16 Regular Transistor Sink Outputs

0.1A 24 Vdc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

TM3DQ16UK Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16UK Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ16UK Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 16 TM3DQ32TK Module 32 Regular Transistor Outputs 0.1A

24 Vdc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

TM3DQ32TK Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ32TK Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ32TK Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 17 TM3DQ32UK Module 32 Regular Transistor Outputs 0.1A

24 Vdc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

TM3DQ32UK Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ32UK Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM3DQ32UK Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV TM3 Digital Mixed Input/Output Modules . . . . . . . . .

Chapter 18 TM3DM8R / TM3DM8RG Mixed I/O Module 4 Inputs/4

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

TM3DM8R / TM3DM8RG Presentation . . . . . . . . . . . . . . . . . . . . . . . .

TM3DM8R / TM3DM8RG Characteristics . . . . . . . . . . . . . . . . . . . . . .

TM3DM8R / TM3DM8RG Wiring Diagram . . . . . . . . . . . . . . . . . . . . .

Chapter 19 TM3DM24R / TM3DM24RG Mixed I/O Module 16

Inputs/8 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

TM3DM24R / TM3DM24RG Presentation. . . . . . . . . . . . . . . . . . . . . .

TM3DM24R / TM3DM24RG Characteristics . . . . . . . . . . . . . . . . . . . .

TM3DM24R / TM3DM24RG Wiring Diagram . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

130

132

134

136

138

140

142

144

146

148

150

152

156

158

160

163

166

168

174

176

178

184

187

189

EIO0000003125 06/2020 5

6 EIO0000003125 06/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000003125 06/2020 7

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

QUALIFICATION OF PERSONNEL

Only appropriately trained persons who are familiar with and understand the contents of this

manual and all other pertinent product documentation are authorized to work on and with this

product.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying parameter values and generally from mechanical, electrical, or electronic equipment.

The qualified person must be familiar with the standards, provisions, and regulations for the

prevention of industrial accidents, which they must observe when designing and implementing the

system.

INTENDED USE

The products described or affected by this document, together with software, accessories, and

options, are expansion modules, intended for industrial use according to the instructions,

directions, examples, and safety information contained in the present document and other

supporting documentation.

The product may only be used in compliance with all applicable safety regulations and directives,

the specified requirements, and the technical data.

Prior to using the product, you must perform a risk assessment in view of the planned application.

Based on the results, the appropriate safety-related measures must be implemented.

Since the product is used as a component in an overall machine or process, you must ensure the

safety of persons by means of the design of this overall system.

Operate the product only with the specified cables and accessories. Use only genuine accessories

and spare parts.

Any use other than the use explicitly permitted is prohibited and can result in unanticipated

hazards.

8 EIO0000003125 06/2020

About the Book

At a Glance

Document Scope

This guide describes the hardware implementation of TM3 digital I/O expansion modules. It

provides the parts description, characteristics, wiring diagrams, and installation details for TM3

digital I/O expansion modules.

Validity Note

This document has been updated for the release of EcoStruxureTM Machine Expert V1.2.4.

The technical characteristics of the devices described in the present document also appear online.

To access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

.

.

EIO0000003125 06/2020 9

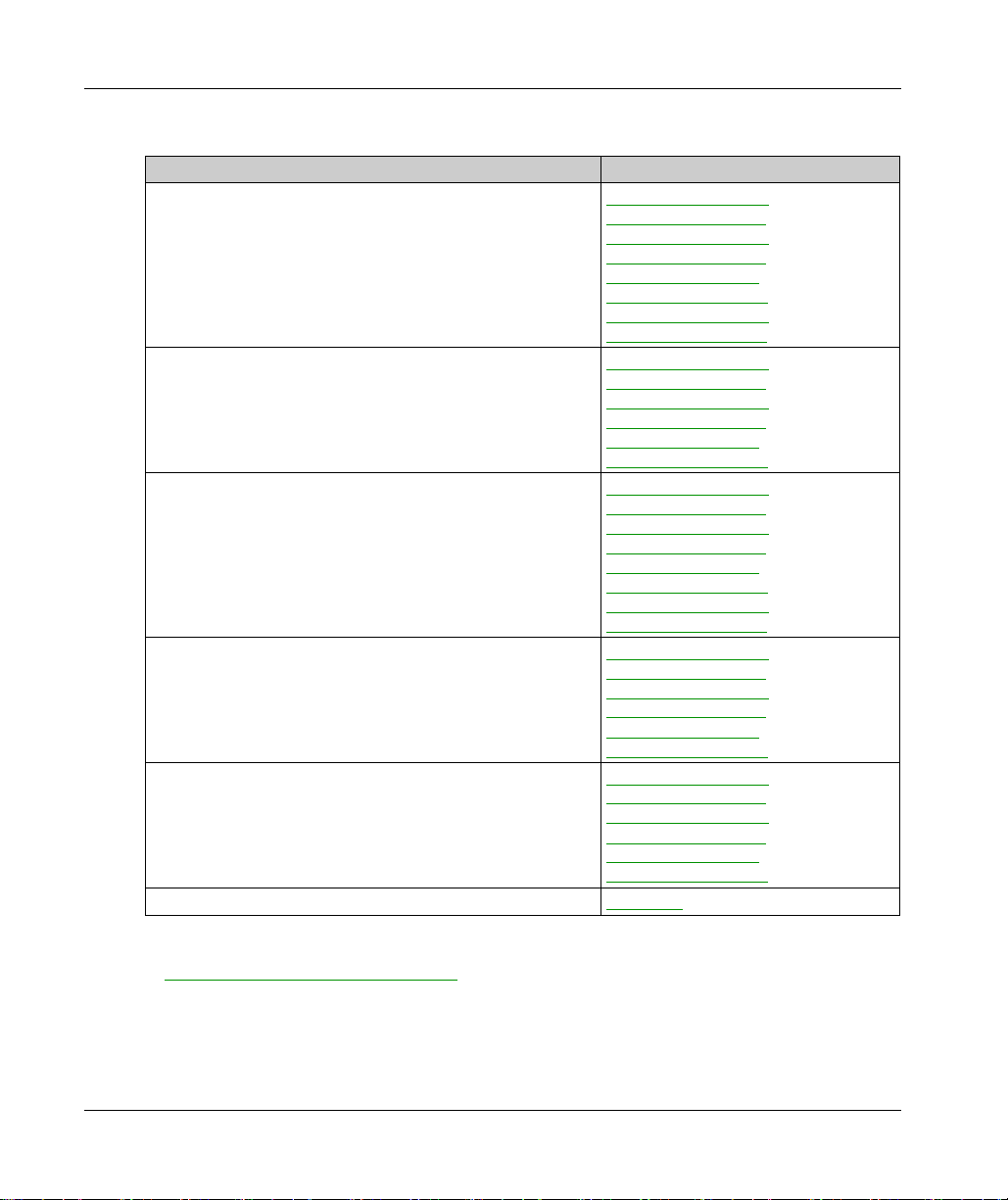

Related Documents

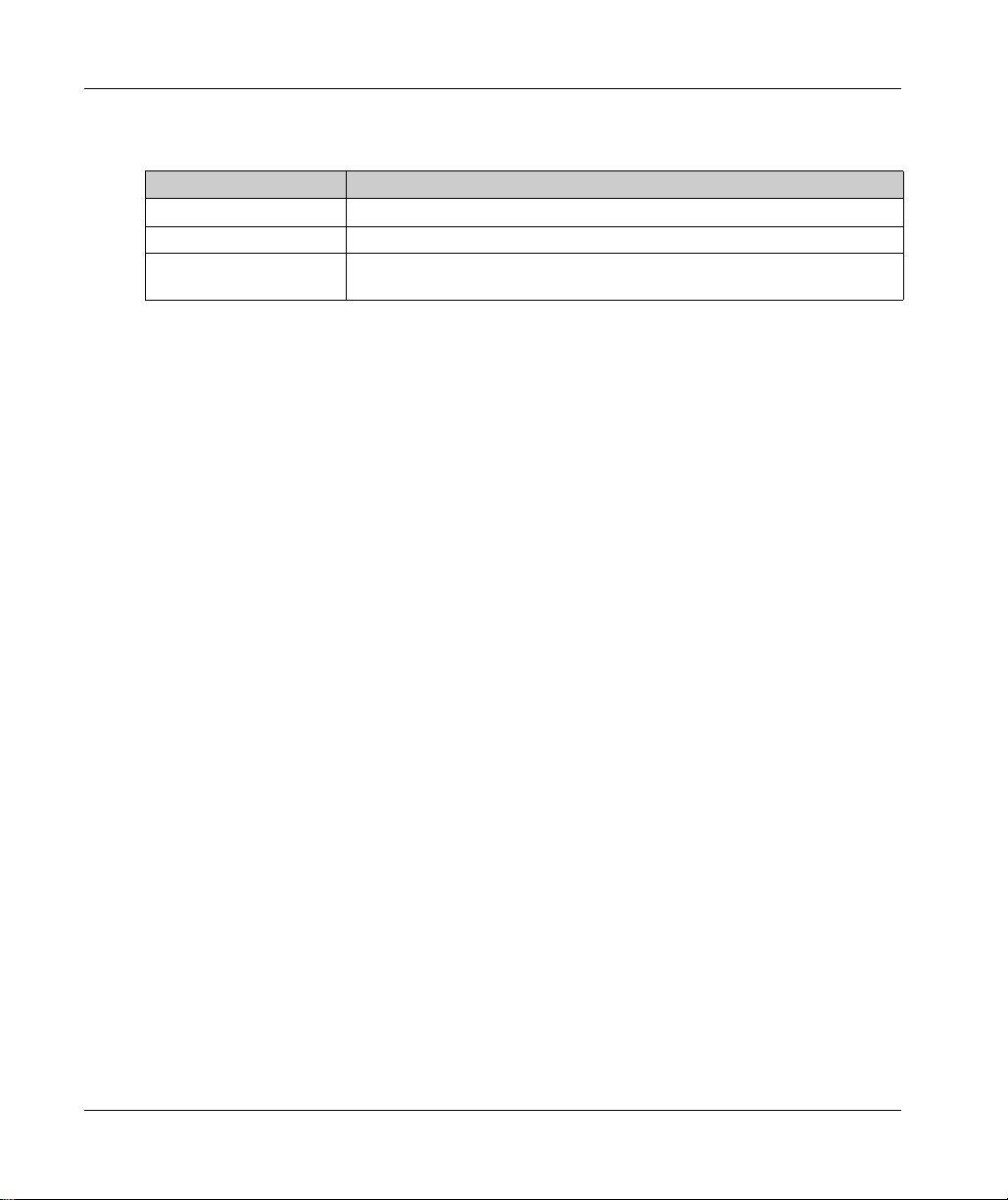

Title of Documentation Reference Number

Modicon TM3 Expansion Modules Configuration - Programming

Guide (EcoStruxure Machine Expert - Basic)

Modicon TM3 Expansion Modules Configuration - Programming

Guide (EcoStruxure Machine Expert)

Modicon M221 Logic Controller - Hardware Guide

Modicon M241 Logic Controller - Hardware Guide

Modicon M251 Logic Controller - Hardware Guide

TM3 Digital I/O Modules Instruction Sheet

EIO0000003345 (ENG)

EIO0000003346 (FRE)

EIO0000003347 (GER)

EIO0000003348 (SPA)

EIO0000003349 (ITA)

EIO0000003350 (CHS)

EIO0000003351 (POR)

EIO0000003352 (TUR)

EIO0000003119 (ENG)

EIO0000003120 (FRE)

EIO0000003121 (GER)

EIO0000003122 (SPA)

EIO0000003123 (ITA)

EIO0000003124 (CHS)

EIO0000003313 (ENG)

EIO0000003314 (FRE)

EIO0000003315 (GER)

EIO0000003316 (SPA)

EIO0000003317 (ITA)

EIO0000003318 (CHS)

EIO0000003319 (POR)

EIO0000003320 (TUR)

EIO0000003083 (ENG)

EIO0000003084 (FRE)

EIO0000003085 (GER)

EIO0000003086 (SPA)

EIO0000003087 (ITA)

EIO0000003088 (CHS)

EIO0000003101 (ENG)

EIO0000003102 (FRE)

EIO0000003103 (GER)

EIO0000003104 (SPA)

EIO0000003105 (ITA)

EIO0000003106 (CHS)

HRB59605

You can download these technical publications and other technical information from our website

https://www.se.com/ww/en/download/

at

10 EIO0000003125 06/2020

.

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

POTENTIAL FOR EXPLOSION

Only use this equipment in non-hazardous locations, or in locations that comply with Class I,

Division 2, Groups A, B, C and D.

Do not substitute components which would impair compliance to Class I, Division 2.

Do not connect or disconnect equipment unless power has been removed or the location is

known to be non-hazardous.

Do not use the USB port(s), if so equipped, unless the location is known to be non-hazardous.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

EIO0000003125 06/2020 11

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

1

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

12 EIO0000003125 06/2020

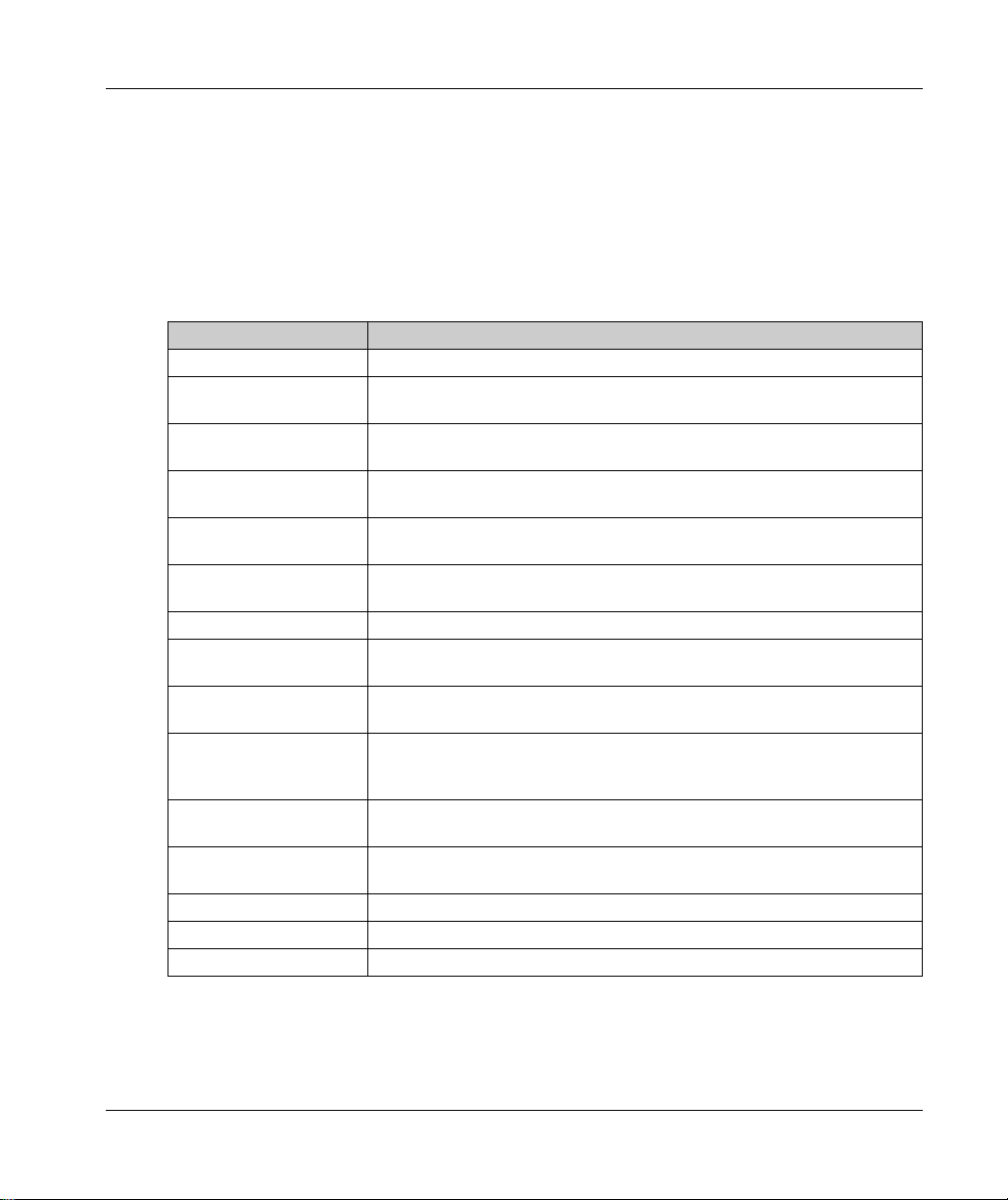

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

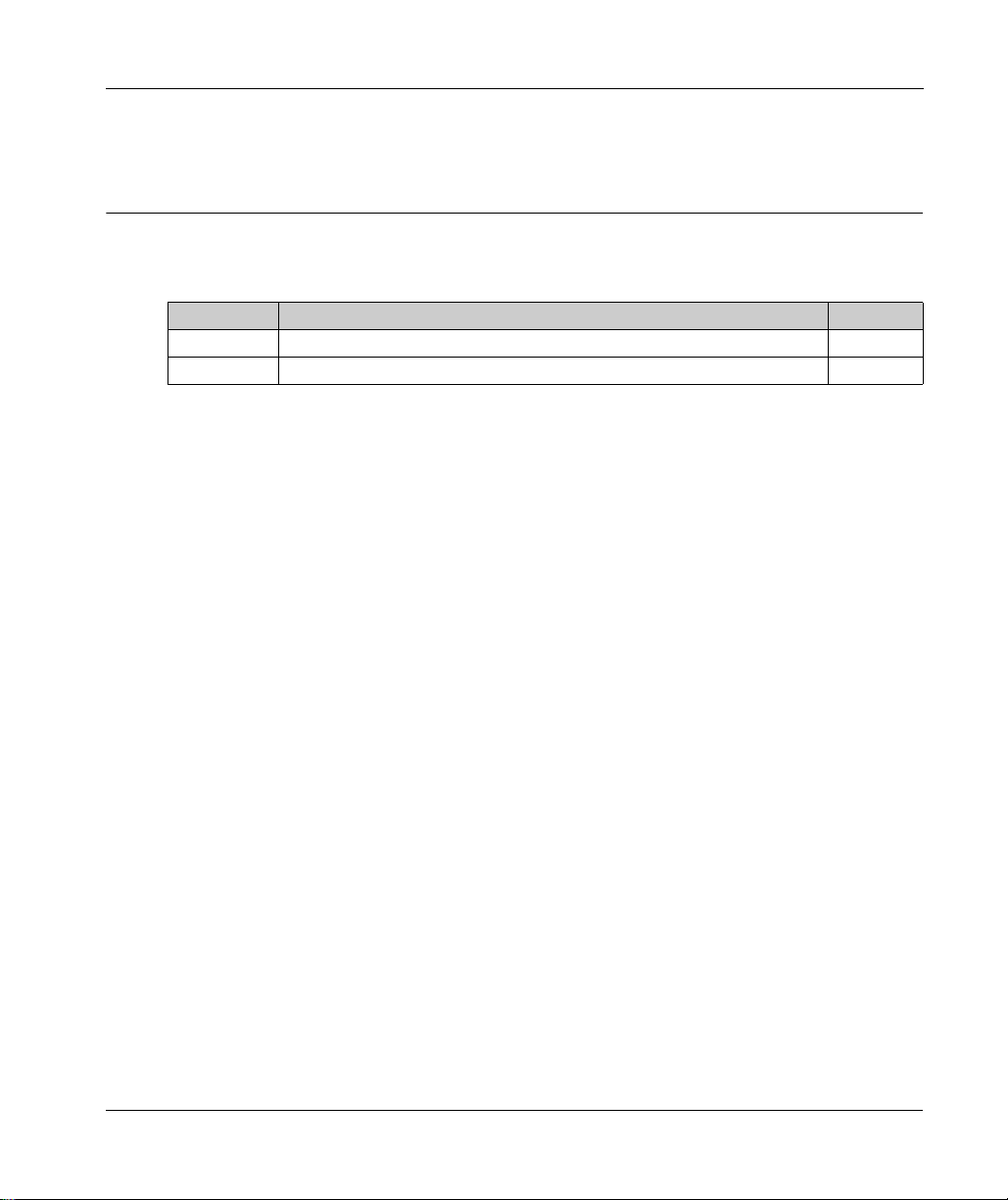

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

,

, etc.

EIO0000003125 06/2020 13

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

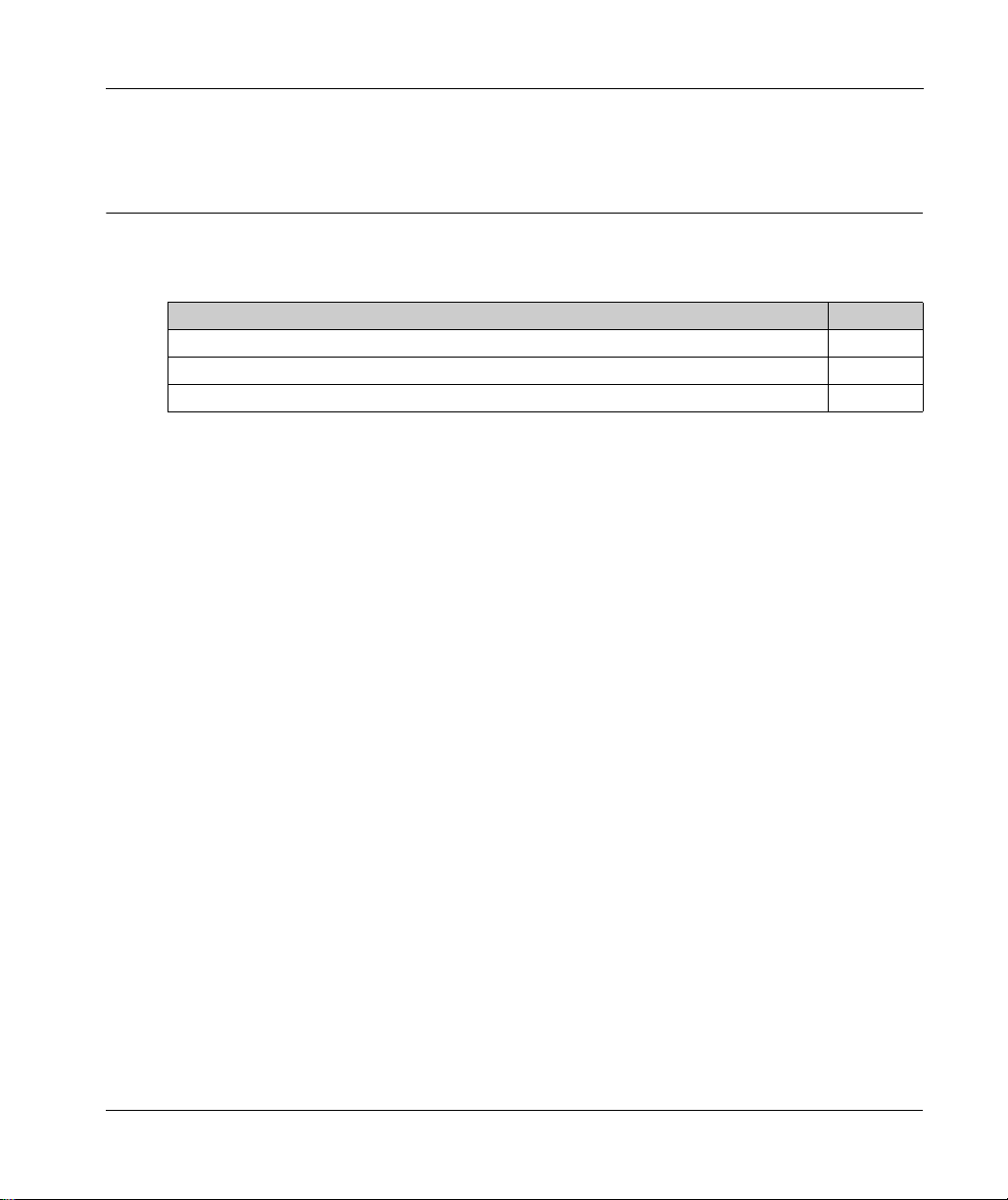

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

14 EIO0000003125 06/2020

ModiconTM3

TM3 General Overview

EIO0000003125 06/2020

TM3 General Overview

Part I

TM3 General Overview

What Is in This Part?

This part contains the following chapters:

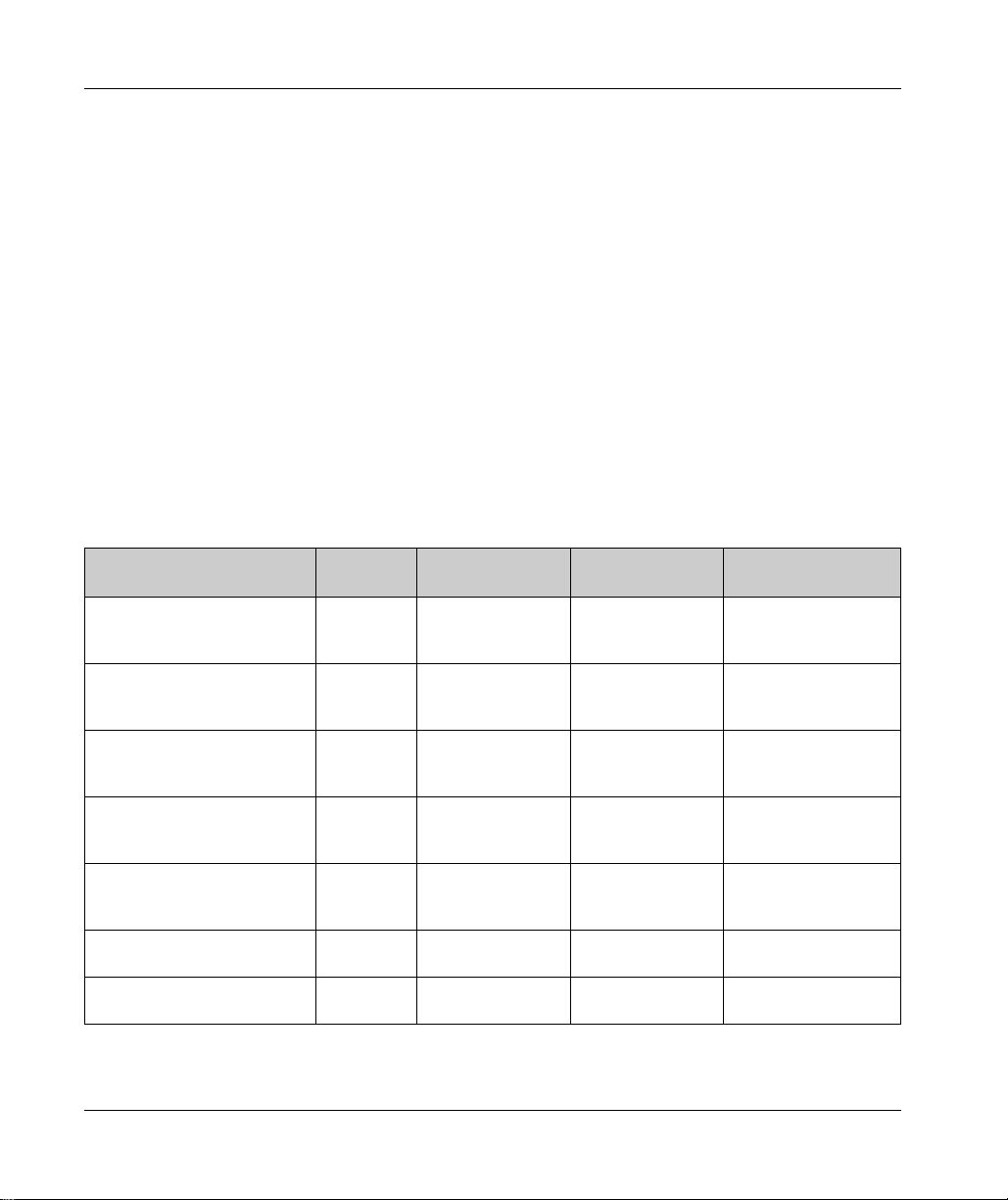

Chapter Chapter Name Page

1 TM3 Description 17

2 TM3 Installation 27

EIO0000003125 06/2020 15

TM3 General Overview

16

EIO0000003125 06/2020

ModiconTM3

TM3 Description

EIO0000003125 06/2020

TM3 Description

Chapter 1

TM3 Description

What Is in This Chapter?

This chapter contains the following topics:

General Description 18

Physical Description 22

Accessories 24

Topic Page

EIO0000003125 06/2020 17

TM3 Description

General Description

Introduction

The range of TM3 digital I/O expansion modules includes:

Input modules

Output modules

Mixed input/output modules

All TM3 digital I/O expansion modules are equipped with (depending on the reference):

Removable screw terminal blocks

Removable spring terminal blocks

HE10 (MIL 20) connectors

For modules with HE10 (MIL 20) connectors, a group of products known as Telefast 2 are a v ailable

that enable these modules to be quickly connected to sensors and actuators.

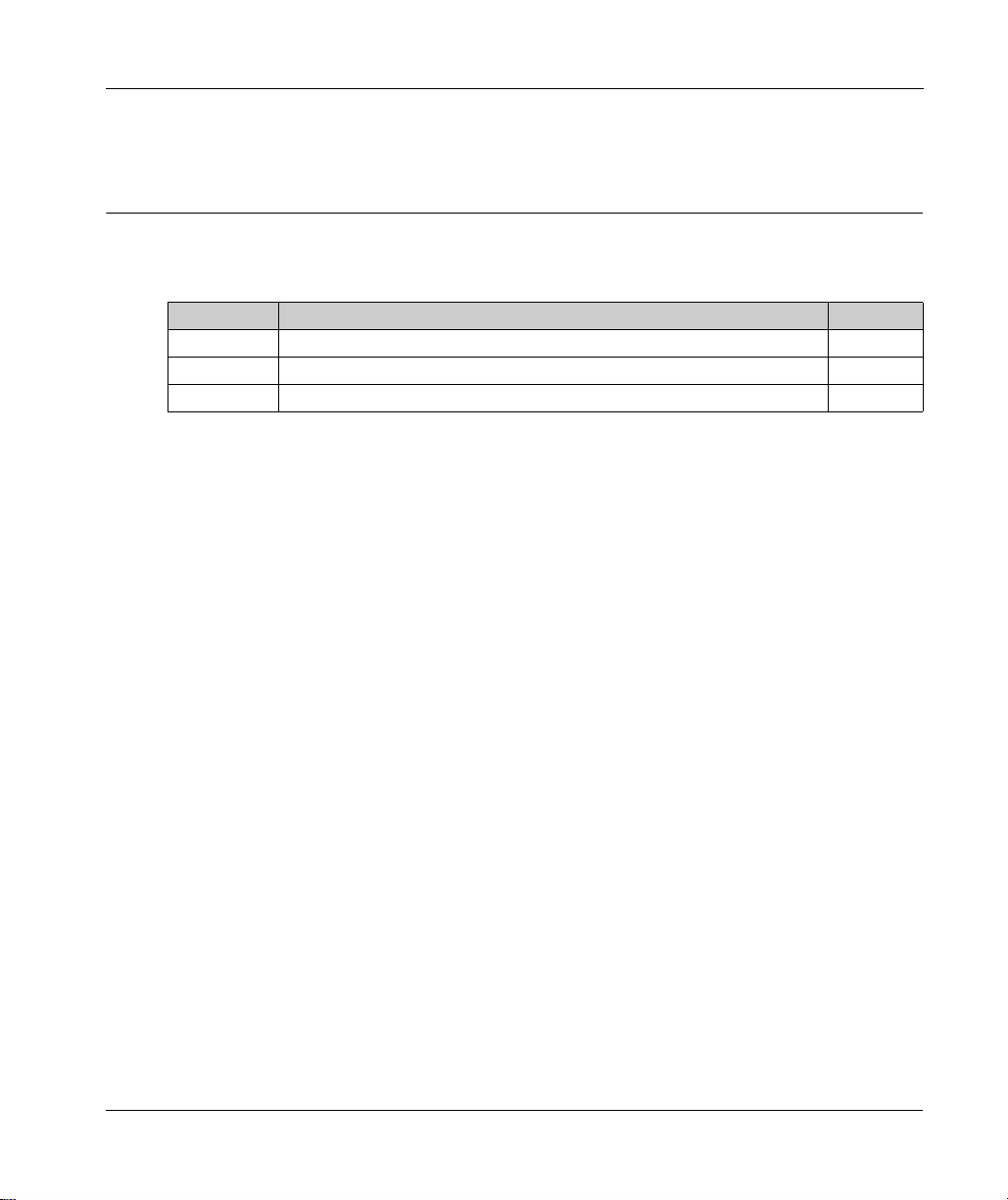

TM3 Digital Input Modules

The following table shows the TM3 digital input expansion modules

corresponding channel type, nominal voltage/current, and terminal type:

(see page 55)

, with

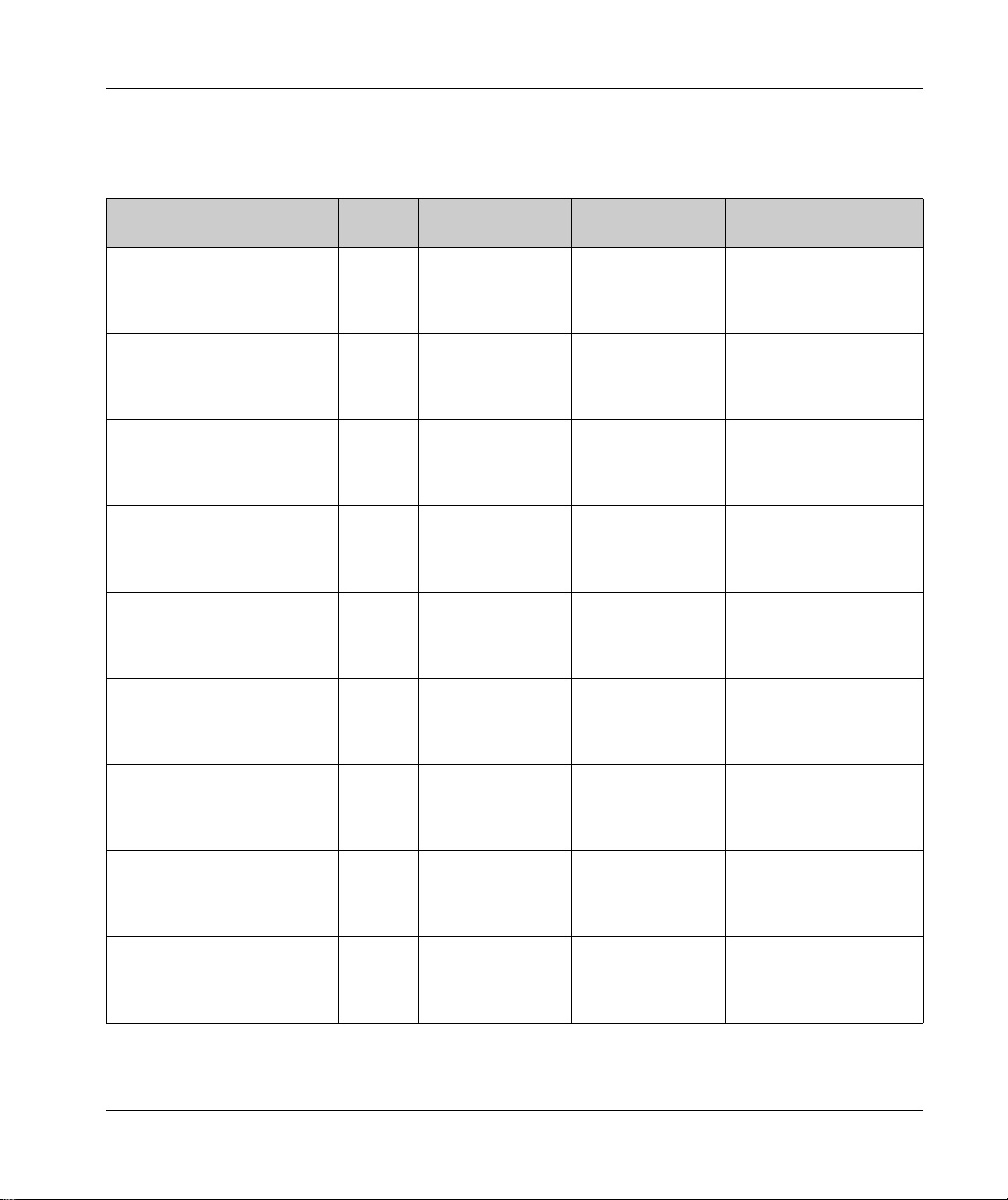

Reference Channels Channel Type Voltage

Current

TM3DI8A

TM3DI8

TM3DI8G

TM3DI16

TM3DI16G

TM3DI16K

TM3DI32K

18

(see page 57)

(see page 63)

(see page 63)

(see page 69)

(see page 69)

(see page 77)

(see page 85)

8 Regular inputs 120 Vac

7.5 mA

8 Regular inputs 24 Vdc

7mA

8 Regular inputs 24 Vdc

7mA

16 Regular inputs 24 Vdc

7mA

16 Regular inputs 24 Vdc

7mA

16 Regular inputs 24 Vdc

5mA

32 Regular inputs 24 Vdc

5mA

Terminal Type / Pitch

Removable screw

terminal block /

5.08 mm

Removable screw

terminal block /

5.08 mm

Removable spring

terminal block /

5.08 mm

Removable screw

terminal blocks /

3.81 mm

Removable spring

terminal blocks /

3.81 mm

HE10 (MIL 20)

connector

HE10 (MIL 20)

connector

EIO0000003125 06/2020

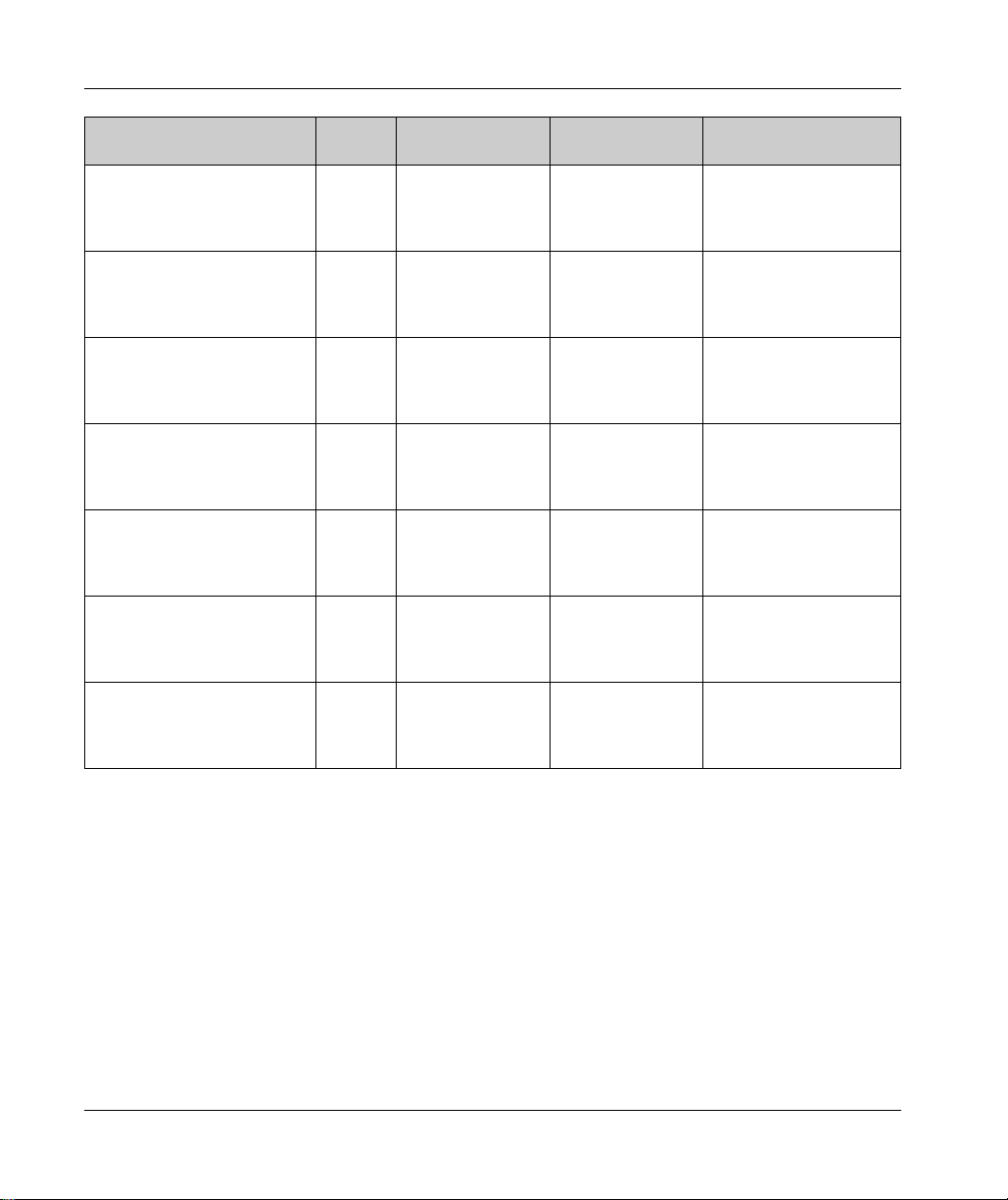

TM3 Digital Output Modules

The following table shows the TM3 digital output expansion modules

corresponding channel type, nominal voltage/current, and terminal type:

(see page 93)

TM3 Description

, with

Reference Channels Channel Type Voltage

Current

TM3DQ8R

TM3DQ8RG

TM3DQ8T

TM3DQ8TG

TM3DQ8U

TM3DQ8UG

TM3DQ16R

TM3DQ16RG

TM3DQ16T

(see page 95)

(see page 95)

(see page 103)

(see page 103)

(see page 109)

(see page 109)

(see page 115)

(see page 115)

(see page 123)

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

8 Regular transistor

outputs (source)

8 Regular transistor

outputs (source)

8 Regular transistor

outputs (sink)

8 Regular transistor

outputs (sink)

16 Relay outputs 24 Vdc / 240 Vac

16 Relay outputs 24 Vdc / 240 Vac

16 Regular transistor

outputs (source)

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

24 Vdc

4 A maximum per

common line/0.5 A

maximum per output

8 A maximum per

common line / 2 A

maximum per output

8 A maximum per

common line / 2 A

maximum per output

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

Terminal Type / Pitch

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block / 5.08 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

Removable screw terminal

blocks / 3.81 mm

EIO0000003125 06/2020 19

TM3 Description

Reference Channels Channel Type Voltage

Current

TM3DQ16TG

TM3DQ16U

TM3DQ16UG

TM3DQ16TK

TM3DQ16UK

TM3DQ32TK

TM3DQ32UK

(see page 123)

(see page 135)

(see page 135)

(see page 129)

(see page 141)

(see page 147)

(see page 155)

16 Regular transistor

outputs (source)

16 Regular transistor

outputs (sink)

16 Regular transistor

outputs (sink)

16 Regular transistor

outputs (source)

16 Regular transistor

outputs (sink)

32 Regular transistor

outputs (source)

32 Regular transistor

outputs (sink)

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

24 Vdc

8 A maximum per

common line / 0.5 A

maximum per output

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

24 Vdc

2 A maximum per

common line / 0.1 A

maximum per output

Terminal Type / Pitch

Removable spring terminal

blocks / 3.81 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

HE10 (MIL 20) connector

HE10 (MIL 20) connector

HE10 (MIL 20) connectors

HE10 (MIL 20) connectors

20

EIO0000003125 06/2020

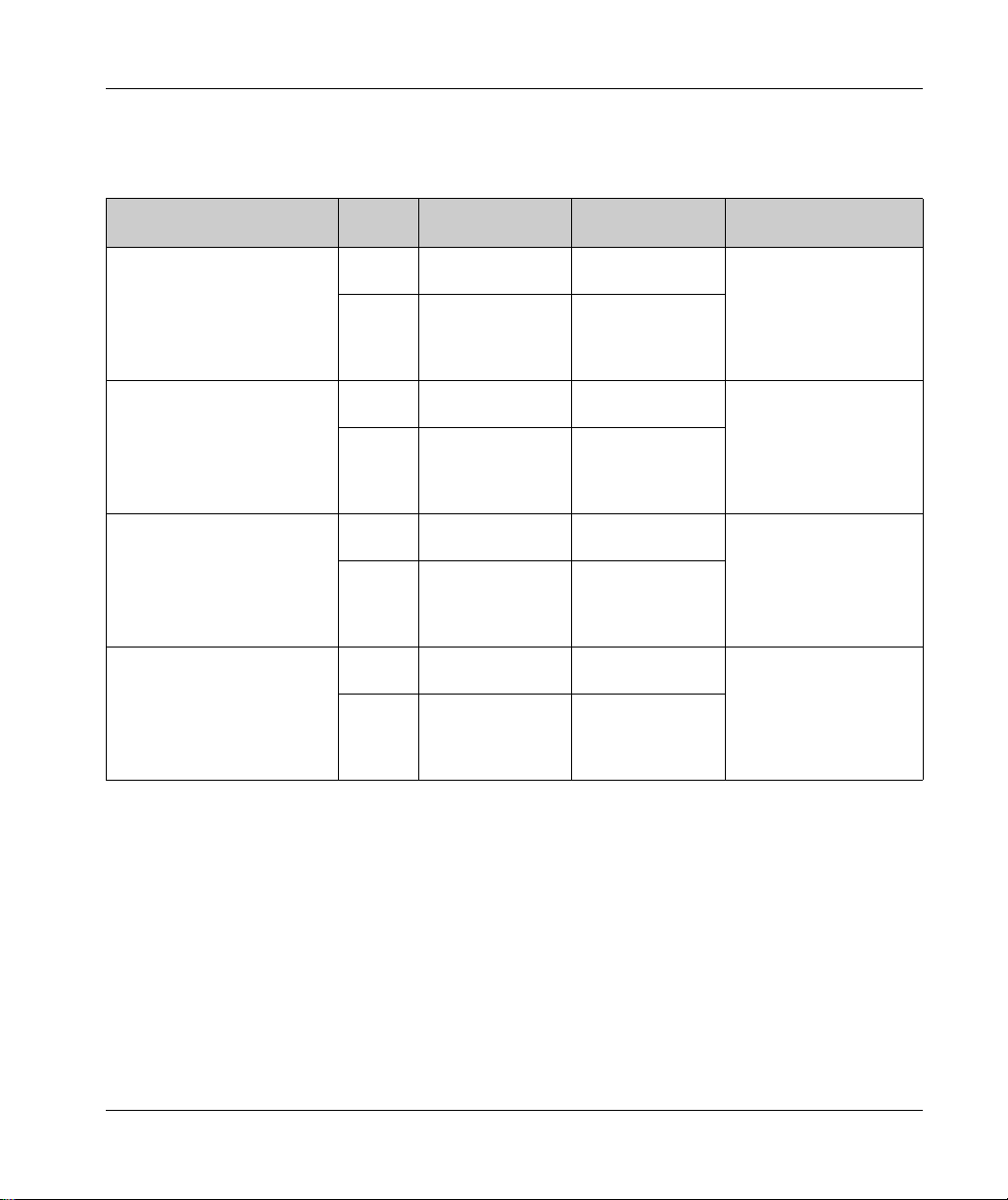

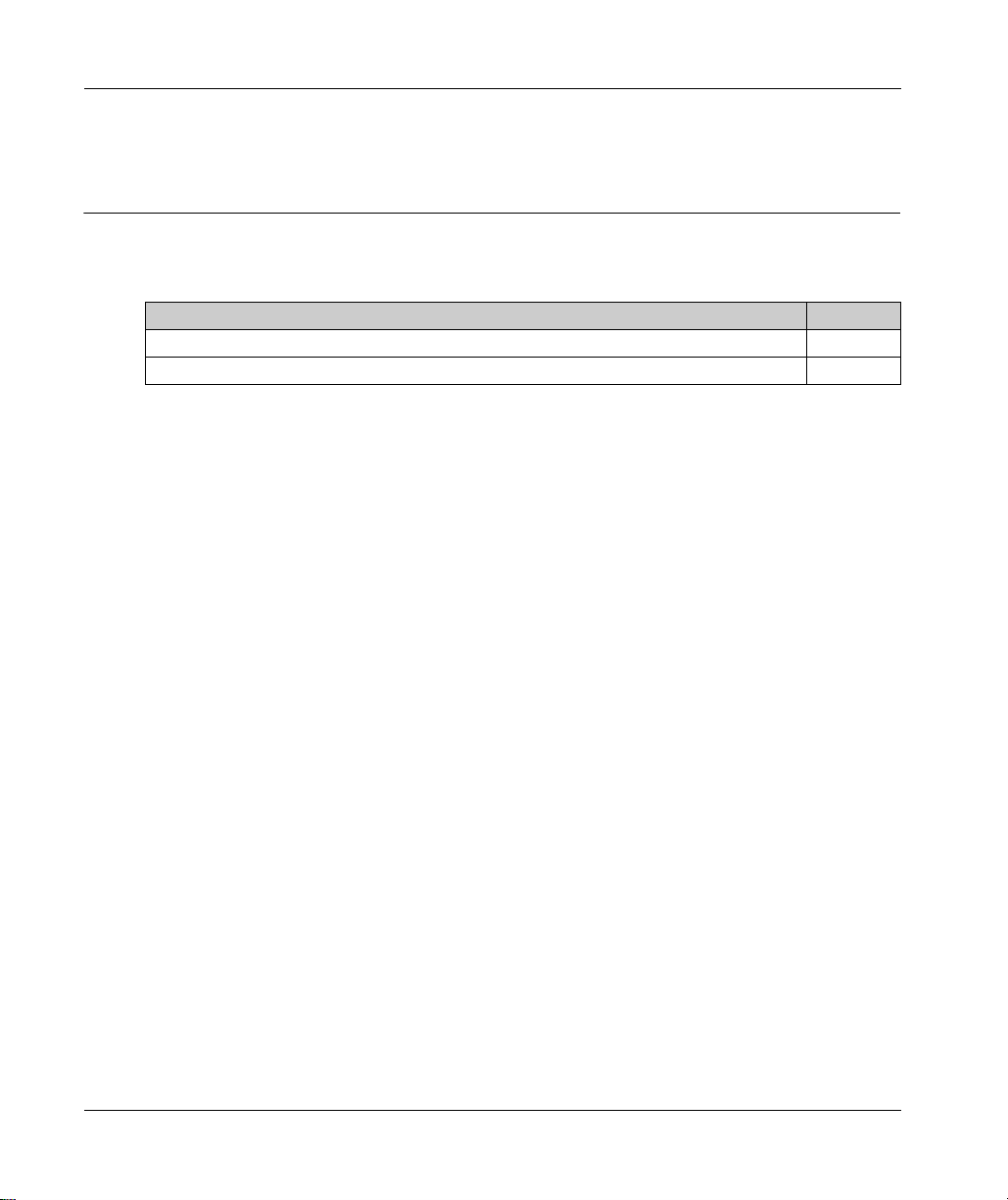

TM3 Digital Mixed Input/Output Modules

This following table shows the TM3 mixed I/O modules

channel type, nominal voltage/current, and terminal type:

(see page 163)

TM3 Description

, with corresponding

Reference Channels Channel Type Voltage

Current

TM3DM8R

TM3DM8RG

TM3DM24R

TM3DM24RG

(see page 165)

(see page 165)

(see page 175)

(see page 175)

4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

4 Regular inputs 24 Vdc

7mA

4 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

16 Regular inputs 24 Vdc

7mA

8 Relay outputs 24 Vdc / 240 Vac

7 A maximum per

common line / 2 A

maximum per output

Terminal Type / Pitch

Removable screw terminal

block / 5.08 mm

Removable spring terminal

block /5.08 mm

Removable screw terminal

blocks / 3.81 mm

Removable spring terminal

blocks / 3.81 mm

EIO0000003125 06/2020 21

TM3 Description

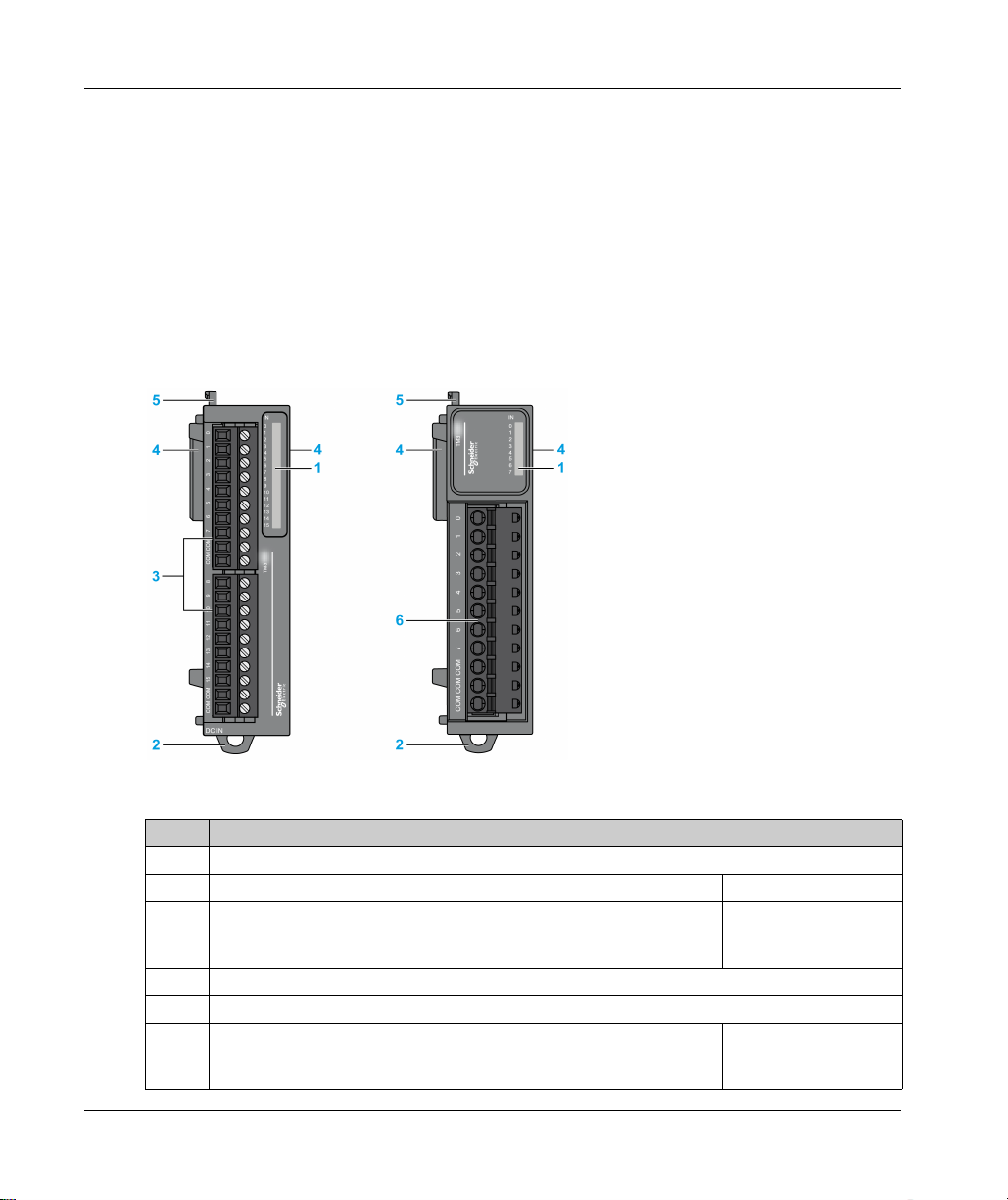

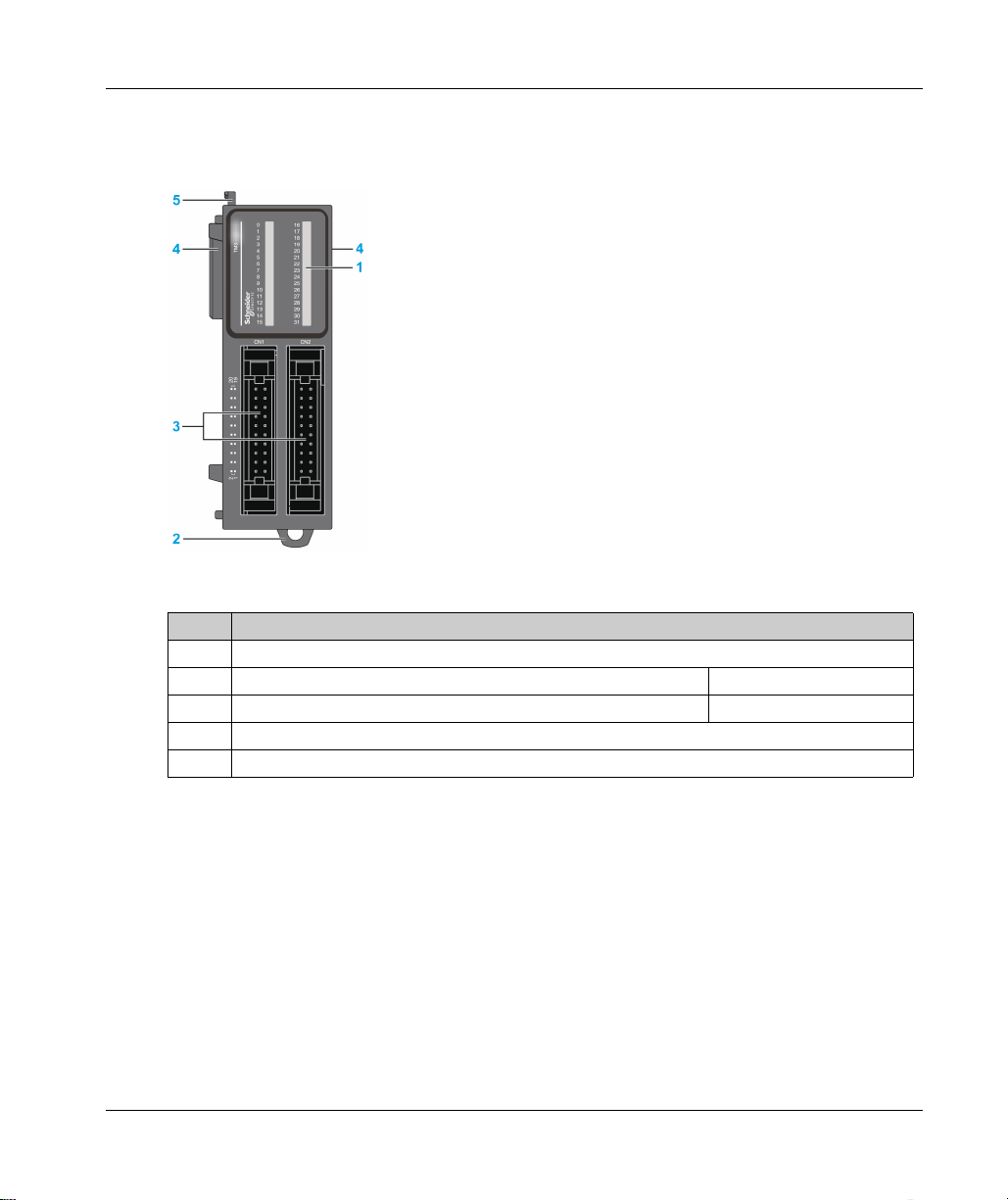

Physical Description

Introduction

This section describes the physical characteristics of the TM3 modules. The modules, depending

on the reference, support one of two different types of connectors:

Removable screw or spring terminal block

HE10 (MIL 20) connector

TM3 with Removable Screw or Spring Terminal Block

The following figure shows the main elements of a TM3 expansion module with removable screw

or spring terminal block:

22

This table describes the main elements of the TM3 expansion modules shown above:

Label Elements

1 LEDs for displaying the state of the I/O channel.

2 Clip-on lock for 35 mm (1.38 in.) top hat section rail (DIN-rail). DIN Rail

3 Removable terminal block. Rules for Removable

Screw Terminal Block

(see page 38)

(see page 49)

4 Expansion connector for TM3 I/O bus (one on each side).

5 Locking device for attachment to the previous module.

6 Removable terminal block. Rules for Removable

Spring Terminal Block

(see page 50)

EIO0000003125 06/2020

TM3 with HE10 (MIL 20) Connector

The following figure shows the main elements of a TM3 expansion module with HE10 (MIL 20)

connector:

This table describes the main elements of the TM3 expansion module shown above:

Label Elements

1 LEDs for displaying the state of the I/O channel.

2 Clip-on lock for 35 mm (1.38 in.) top hat section rail (DIN-rail). DIN Rail

3 HE10 (MIL 20) connector socket. Cable list

4 Expansion connector for TM3 I/O bus (one on each side).

5 Locking device for attachment to the previous module.

TM3 Description

(see page 38)

EIO0000003125 06/2020 23

TM3 Description

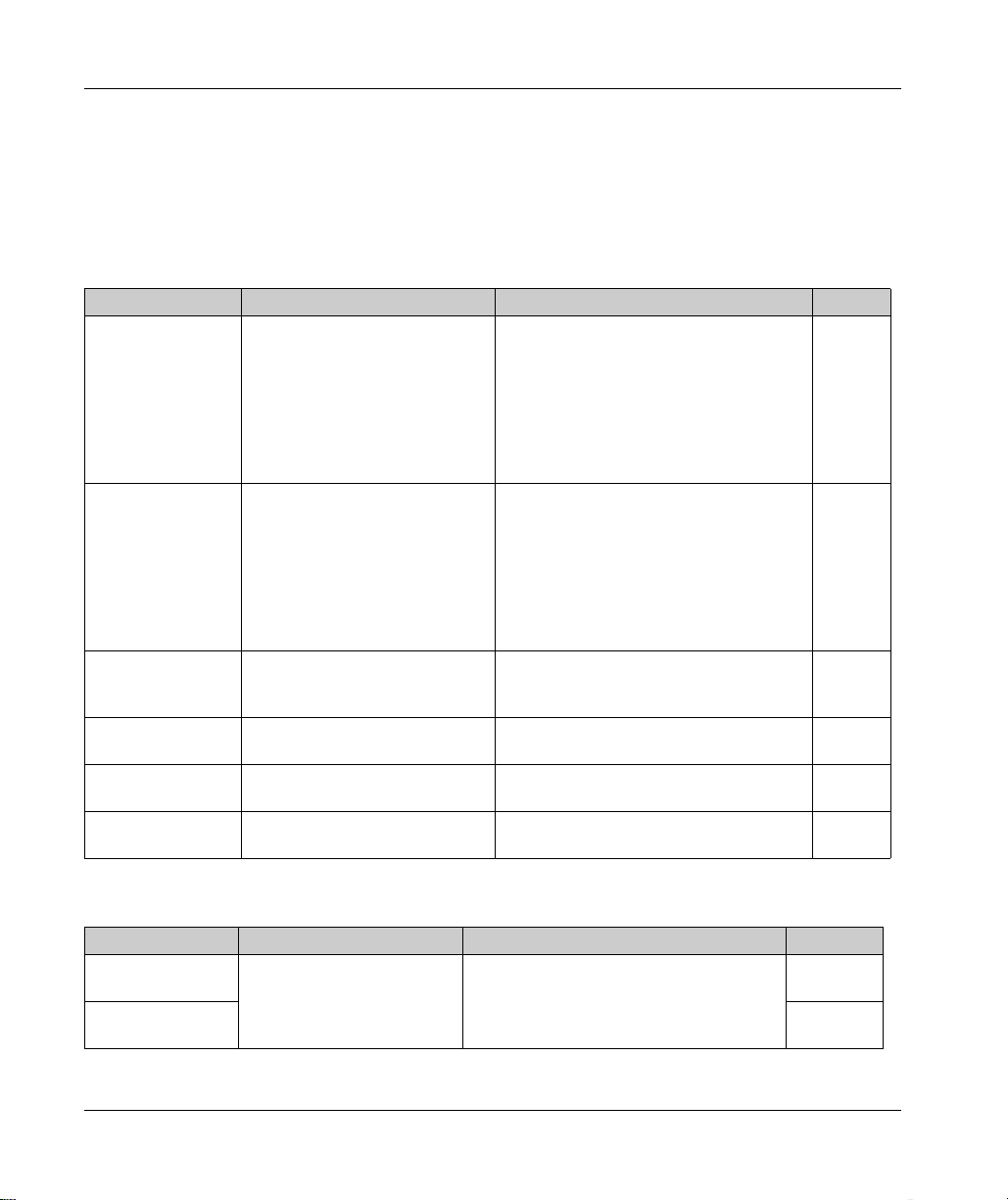

Accessories

Overview

This section describes the accessories, cables, and Telefast.

Accessories

Reference Description Use Quantity

TMAT2MSET Set of 8 removable screw terminal

blocks:

4 x Removable screw terminal

blocks (pitch 3.81 mm) with 11

terminals for inputs/outputs

4 x Removable screw terminal

blocks (pitch 3.81 mm) with 10

terminals for inputs/outputs

TMAT2MSETG Set of 8 removable spring terminal

blocks:

4 x Removable spring terminal

blocks (pitch 3.81 mm) with 11

terminals for inputs/outputs

4 x Removable spring terminal

blocks (pitch 3.81 mm) with 10

terminals for inputs/outputs

NSYTRAAB35 End brackets Helps secure the controller or receiver

TM2XMTGB Grounding Bar Connects the cable shield and the module to

TM200RSRCEMC Shielding take-up clip Mounts and connects the ground to the

TMAM2 Mounting Kit Mounts the controller and I/O modules

Connects the module I/Os. 1

Connects the module I/Os. 1

1

module and their expansion modules on a

top hat section rail (DIN rail).

1

the functional ground.

25 pack

cable shielding.

1

directly to a flat, vertical panel.

Cables

Reference Description Details Length

TWDFCW30K Digital I/O cables with free

wires for 20-pin Modular

TWDFCW50K 5m

controller

24

Cable equipped at a one end with an HE10

connector. (AWG 22 / 0.34 mm

2

).

3m

(9.84 ft)

(16.4 ft)

EIO0000003125 06/2020

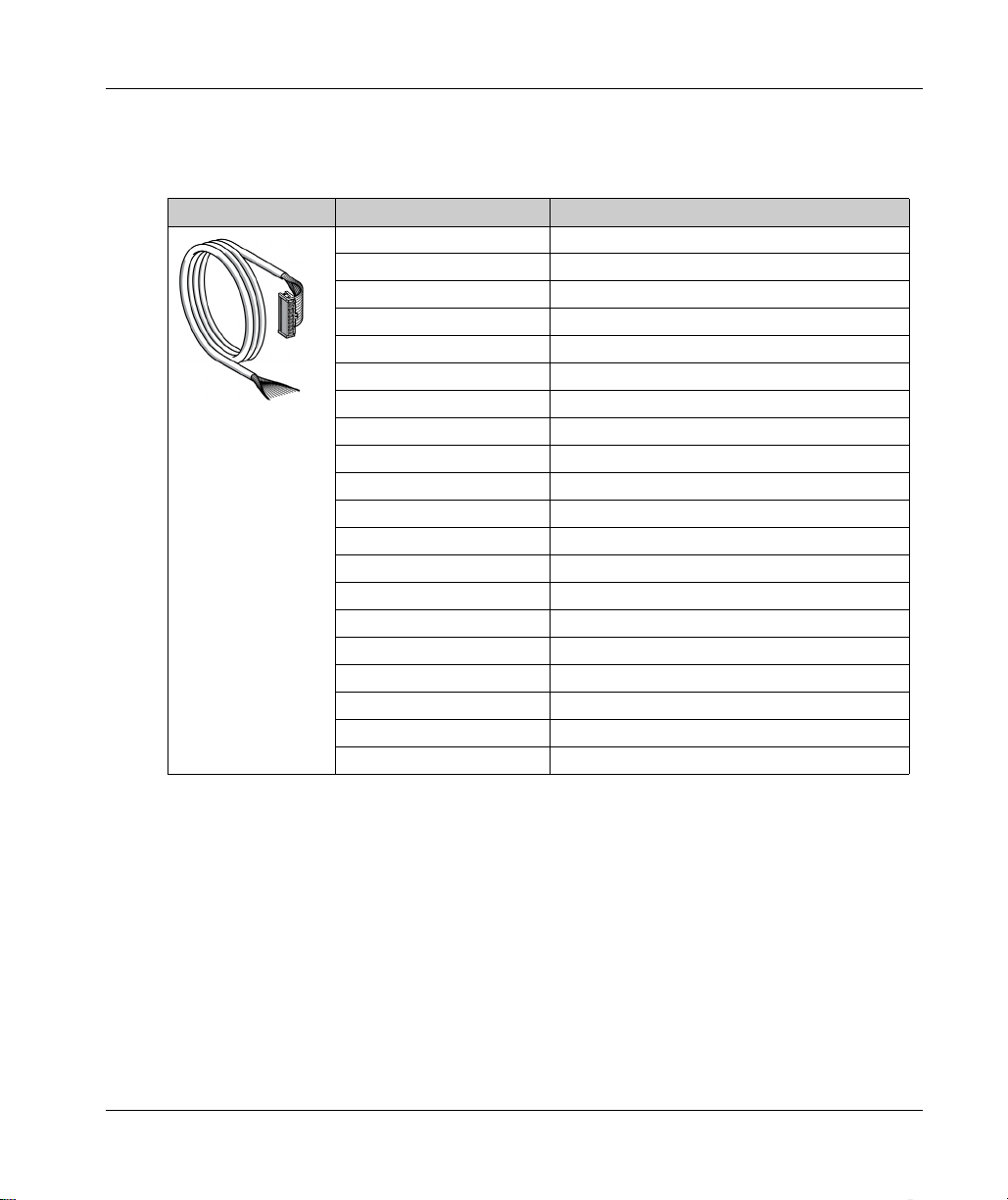

TWDFCW••K Cable Description

The following table provides specifications for the TWDFCW30K/50K with free wires for 20-pin

connectors (HE10 or MIL20):

Cable illustration Pin Connector Wire Color

TM3 Description

1White

2Brown

3 Green

4Yellow

5Grey

6Pink

7Blue

8Red

9Black

10 Violet

11 Grey and pink

12 Red and blue

13 White and green

14 Brown and green

15 White and yellow

16 Yellow and brown

17 White and grey

18 Grey and brown

19 White and pink

20 Pink and brown

EIO0000003125 06/2020 25

TM3 Description

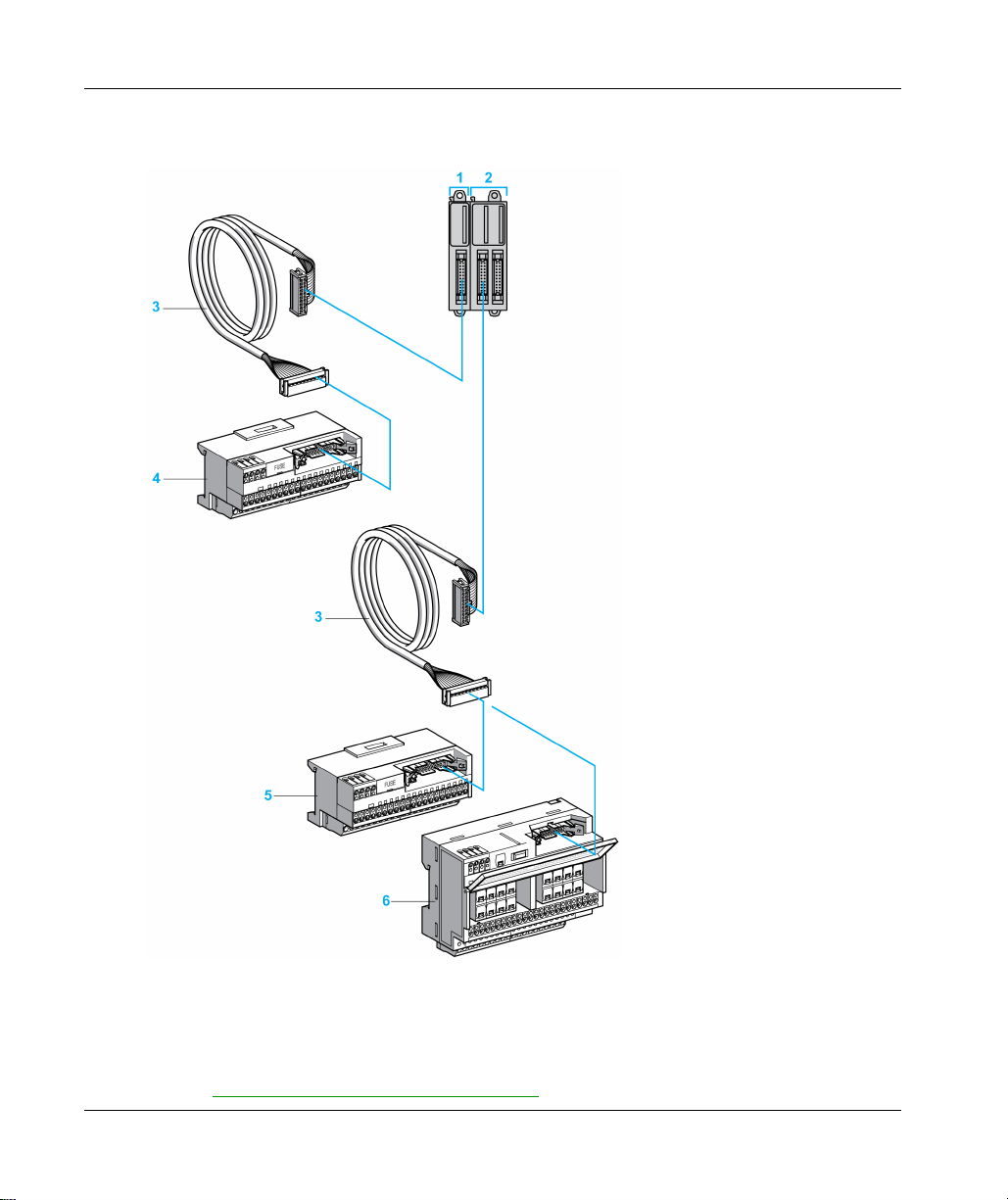

Telefast Pre-Wiring Sub-bases

The following illustration shows the Telefast system:

26

1 TM3DI16K / TM3DI32K

2 TM3DQ16TK / TM3DQ32TK

3 Cable equipped with a 20-way HE 10 connector at each end.)

4 16 channel sub-base for input extension modules.

5–6 16 channel sub-base for output extension modules.

Refer to

TM3 Digital I/O Modules Instruction Sheet

.

EIO0000003125 06/2020

ModiconTM3

TM3 Installation

EIO0000003125 06/2020

TM3 Installation

Chapter 2

TM3 Installation

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

2.1 TM3 General Rules for Implementing 28

2.2 TM3 Expansion Module Installation 33

2.3 TM3 Electrical Requirements 46

EIO0000003125 06/2020 27

TM3 Installation

TM3 General Rules for Implementing

Section 2.1

TM3 General Rules for Implementing

What Is in This Section?

This section contains the following topics:

Environmental Characteristics 29

Certifications and Standards 32

Topic Page

28

EIO0000003125 06/2020

Environmental Characteristics

Enclosure Requirements

TM3 expansion module components are designed as Zone B, Class A industrial equipment

according to IEC/CISPR Publication 11. If they are used in environments other than those

described in these standards, or in environments that do not meet the specifications in this manual

the ability to meet electromagnetic compatibility requirements in the presence of conducted and/or

radiated interference may be reduced.

All TM3 expansion module components meet European Community (CE) requirements for open

equipment as defined by IEC/EN 61131-2. You must install them in an enclosure designed for the

specific environmental conditions and to minimize the possibility of unintended contact with

hazardous voltages. Use metal enclosures to improve the electromagnetic immunity of your TM3

expansion module components. Use enclosures with a keyed locking mechanism to minimize

unauthorized access.

Environmental Characteristics

All the TM3 expansion module components are electrically isolated between the internal electronic

circuit and the input/output channels. This equipment meets CE requirements as indicated in the

table below. This equipment is intended for use in a Pollution Degree 2 industrial environment.

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the environmental and electrical characteristics

tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM3 Installation

WARNING

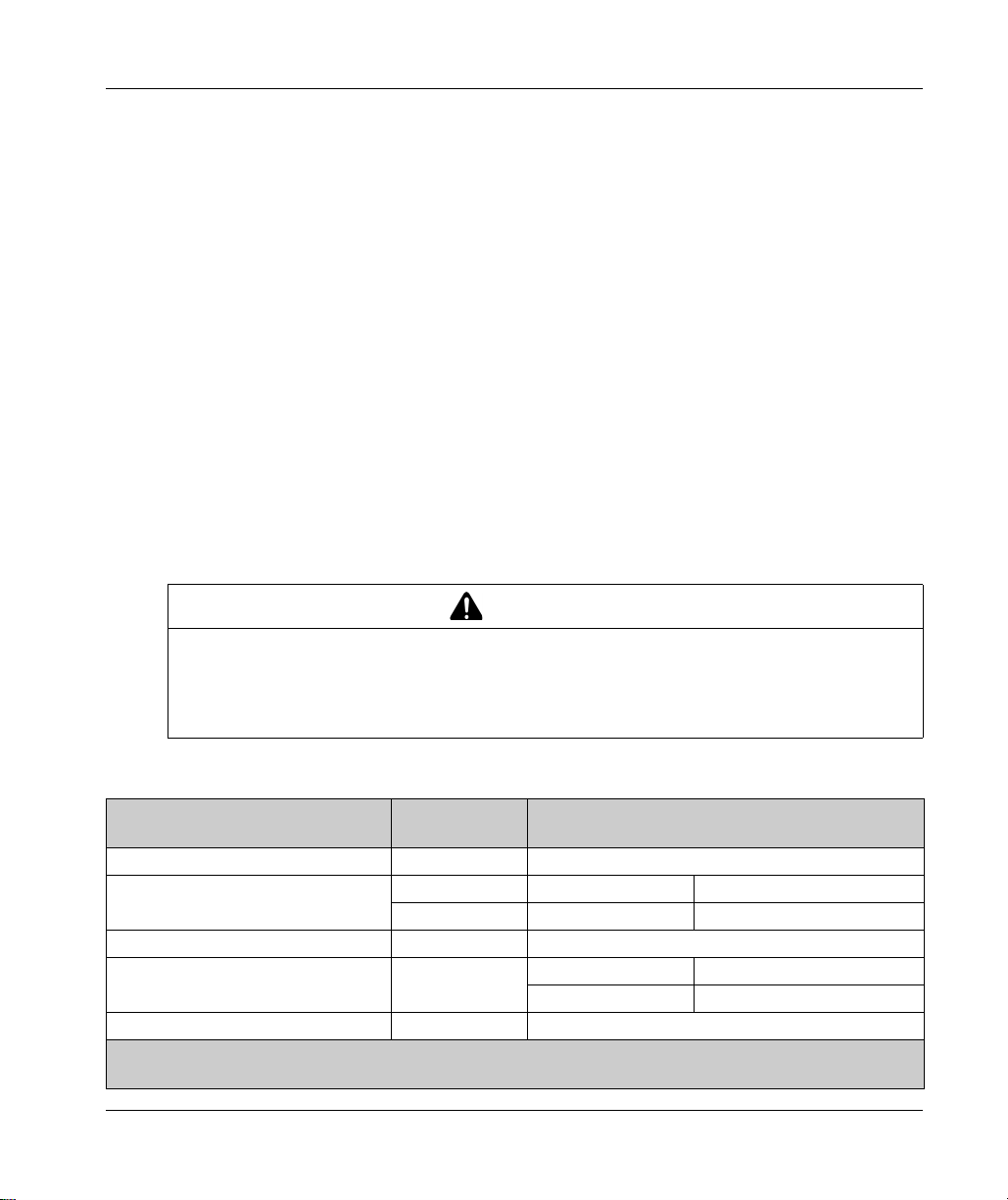

The following table shows the general environmental characteristics:

Characteristic Minimum

Specification

Standard compliance IEC/EN 61131-2 –

Ambient operating temperature – Horizontal installation –10...55 °C (14...131 °F)

– Vertical installation –10...35 °C (14...95 °F)

Storage temperature – –25...70 °C (- 13...158 °F)

Relative humidity – Transport and storage 10...95 % (non-condensing)

Degree of pollution IEC/EN 60664-1 2

Tested Range

Operation 10...95 % (non-condensing)

NOTE: The tested ranges may indicate values beyond that of the IEC Standard. However, our internal standards

define what is necessary for industrial environments. In all cases, we uphold the minimum specification if indicated.

EIO0000003125 06/2020 29

TM3 Installation

Characteristic Minimum

Tested Range

Specification

Degree of protection IEC/EN 61131-2 IP20

Corrosion immunity – Atmosphere free from corrosive gases

Operating altitude – 0...2000 m (0...6560 ft)

Storage altitude – 0...3000 m (0...9843 ft)

Vibration resistance IEC/EN 61131-2 Panel mounting or

mounted on a top hat

section rail (DIN rail)

10 mm (0.39 in) fixed amplitude

from 5...8.7 Hz

29.4 m/s

2

(96.45 ft/s2) (3 gn)

fixed acceleration from

8.7...150 Hz

Mechanical shock resistance –

147 m/s

2

or 482.28 ft/s2 (15 gn) for a duration of 11 ms

NOTE: The tested ranges may indicate values beyond that of the IEC Standard. However, our internal standards

define what is necessary for industrial environments. In all cases, we uphold the minimum specification if indicated.

Electromagnetic Susceptibility

The TM3 expansion module components meets electromagnetic susceptibility specifications as

indicated in the following table:

Characteristic Minimum Specification Tested Range

Electrostatic discharge IEC/EN 61000-4-2 8 kV (air discharge)

4 kV (contact discharge)

Radiated electromagnetic

field

Magnetic field IEC/EN 61000-4-8 30 A/m 50 Hz, 60 Hz

Fast transients burst IEC/EN 61000-4-4 –

1 Common Mode

2 Differential Mode

IEC/EN 61000-4-3 10 V/m (80...1000 MHz)

3 V/m (1.4...2 GHz)

1 V/m (2...3 GHz)

AC/DC Power lines –

Relay Outputs 2 kV

24 Vdc I/Os 1 kV

Analog I/Os –

Communication line –

CM

1

and DM

2

NOTE: The tested ranges may indicate values beyond that of the IEC Standard. However, our internal standards

define what is necessary for industrial environments. In all cases, we uphold the minimum specification if indicated.

30

EIO0000003125 06/2020

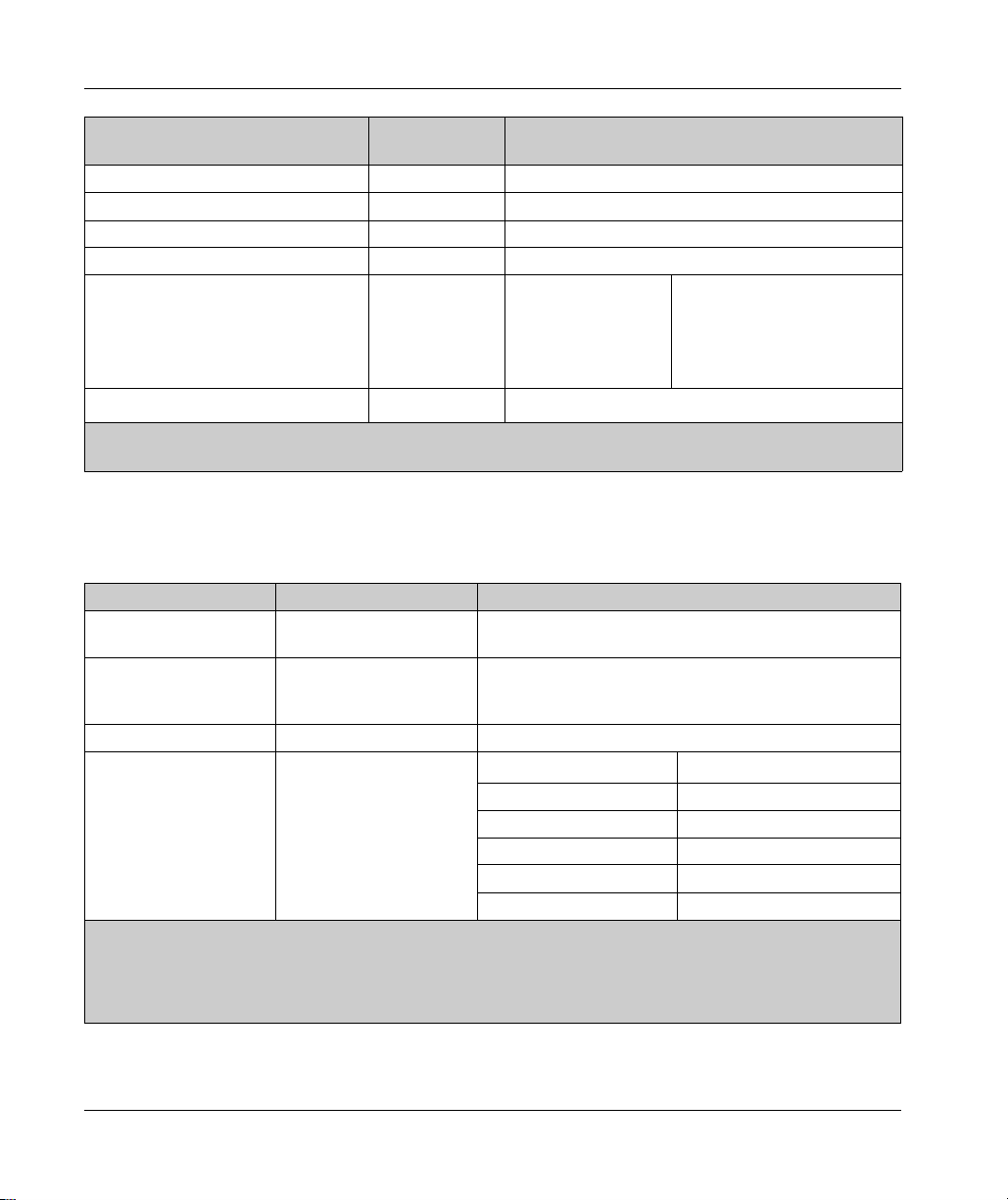

Characteristic Minimum Specification Tested Range

Surge immunity IEC/EN 61000-4-5

IEC/EN 61131-2

–

DC Power lines 1 kV 0.5 kV

AC Power lines 2 kV 1 kV

Relay Outputs 2 kV 1 kV

24 Vdc I/Os 1 kV –

Shielded cable (between

shield and ground)

Induced electromagnetic

IEC/EN 61000-4-6 10 Vrms (0.15...80 MHz)

field

Conducted emission IEC 61000-6-4 AC power line:

0.15...0.5 MHz: 79 dBμV/m QP / 66 dBμV/m AV

0.5...300 MHz: 73 dBμV/m QP / 60 dBµV/m AV

AC/DC power line:

10...150 kHz: 120...69 dBμV/m QP

150...1500 kHz: 79...63 dBμV/m QP

1.5...30 MHz: 63 dBμV/m QP

Radiated emission IEC 61000-6-4 30...230 MHz: 40 dBμV/m QP

230...1000 MHz: 47 dBμV/m QP

1 Common Mode

2 Differential Mode

TM3 Installation

1

CM

1kV –

DM

2

NOTE: The tested ranges may indicate values beyond that of the IEC Standard. However, our internal standards

define what is necessary for industrial environments. In all cases, we uphold the minimum specification if indicated.

EIO0000003125 06/2020 31

TM3 Installation

Certifications and Standards

Introduction

The TM3 expansion modules are designed to conform to the main national and international

standards concerning electronic industrial control devices:

IEC/EN 61131-2

SV ≥ 2.0

UL 61010-1

UL 61010-2-201

SV < 2.0

UL 508

ANSI/UL 121201

CSA 22.2 n° 213

The TM3 have obtained the following conformity marks:

CE

cULus/CSA

EAC

RCM

cULus/CSA Hazardous Location

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

.

32

EIO0000003125 06/2020

TM3 Expansion Module I nstallation

Section 2.2

TM3 Expansion Module Installation

What Is in This Section?

This section contains the following topics:

Installation and Maintenance Requirements 34

Installation Guidelines 37

Top Hat Section Rail (DIN rail) 38

Assembling a Module to a Controller or Receiver Module 41

Disassembling a Module from a Controller or Receiver Module 43

Direct Mounting on a Panel Surface 44

TM3 Installation

Topic Page

EIO0000003125 06/2020 33

TM3 Installation

Installation and Maintenance Requirements

Before Starting

Read and understand this chapter before beginning the installation of your system.

The use and application of the information contained herein require expertise in the design and

programming of automated control systems. Only you, the user, machine builder or integrator, can

be aware of all the conditions and factors present during installation and setup, operation, and

maintenance of the machine or process, and can therefore determine the automation and

associated equipment and the related safeties and interlocks which can be effectively and properly

used. When selecting automation and control equipment, and any other related equipment or

software, for a particular application, you must also consider any applicable local, regional or

national standards and/or regulations.

Pay particular attention in conforming to any safety information, different electrical requirements,

and normative standards that would apply to your machine or process in the use of this equipment.

Disconnecting Power

All options and modules should be assembled and installed before installing the control system on

a mounting rail, onto a mounting plate or in a panel. Remove the control system from its mounting

rail, mounting plate or panel before disassembling the equipment.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

DANGER

34

EIO0000003125 06/2020

Programming Considerations

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Operating Environment

In addition to the Environmental Characteristics, refer to Product Related Information in the

beginning of the present document for important information regarding installation in hazardous

locations for this specific equipment.

UNINTENDED EQUIPMENT OPERATION

Install and operate this equipment according to the conditions described in the Environmental

Characteristics.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM3 Installation

WARNING

WARNING

EIO0000003125 06/2020 35

TM3 Installation

Installation Considerations

UNINTENDED EQUIPMENT OPERATION

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Install and operate this equipment in an enclosure appropriately rated for its intended

environment and secured by a keyed or tooled locking mechanism.

Use the sensor and actuator power supplies only for supplying power to the sensors or

actuators connected to the module.

Power line and output circuits must be wired and fused in compliance with local and national

regulatory requirements for the rated current and voltage of the particular equipment.

Do not use this equipment in safety-critical machine functions unless the equipment is

otherwise designated as functional safety equipment and conforming to applicable regulations

and standards.

Do not disassemble, repair, or modify this equipment.

Do not connect any wiring to reserved, unused connections, or to connections designated as

No Connection (N.C.).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTE: JDYX2 or JDYX8 fuse types are UL-recognized and CSA approved.

WARNING

36

EIO0000003125 06/2020

Installation Guidelines

Introduction

TM3 expansion modules are assembled by connecting them to a logic controller or receiver

module.

The logic controller or receiver module and their expansion modules can be installed on a top hat

section rail (DIN rail).

Mounting Position and Minimum Clearances

The mounting position and minimum clearances of the expansion modules must conform with the

rules defined for the appropriate hardware system. Refer to the

Hardware

UNINTENDED EQUIPMENT OPERATION

Place devices dissipating the most heat at the top of the cabinet and ensure adequate

Avoid placing this equipment next to or above devices that might cause overheating.

Install the equipment in a location providing the minimum clearances from all adjacent

Install all equipment in accordance with the specifications in the related documentation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

documentation for your specific controller.

ventilation.

structures and equipment as directed in this document.

WARNING

Installation chapter

TM3 Installation

in th e

Controller

EIO0000003125 06/2020 37

TM3 Installation

Top Hat Section Rail (DIN rail)

Dimensions of Top Hat Section Rail (DIN Rail)

You can mount the controller or receiver and their expansions on a 35 mm (1.38 in.) top hat section

rail (DIN rail). The DIN rail can be attached to a smooth mounting surface or suspended from a EIA

rack or mounted in a NEMA cabinet.

Symmetric Top Hat Section Rails (DIN Rail)

The following illustration and table indicate the references of the top hat section rails (DIN rail) for

the wall-mounting range:

38

Reference Type Rail Length (B)

NSYSDR50A A 450 mm (17.71 in.)

NSYSDR60A A 550 mm (21.65 in.)

NSYSDR80A A 750 mm (29.52 in.)

NSYSDR100A A 950 mm (37.40 in.)

EIO0000003125 06/2020

TM3 Installation

The following illustration and table indicate the references of the symmetric top hat section rails

(DIN rail) for the metal enclosure range:

Reference Type Rail Length (B-12 mm)

NSYSDR60 A 588 mm (23.15 in.)

NSYSDR80 A 788 mm (31.02 in.)

NSYSDR100 A 988 mm (38.89 in.)

NSYSDR120 A 1188 mm (46.77 in.)

The following illustration and table indicate the references of the symmetric top hat section rails

(DIN rail) of 2000 mm (78.74 in.):

Reference Type Rail Length

NSYSDR200

NSYSDR200D

1

2

A 2000 mm (78.74 in.)

A

1 Unperforated galvanized steel

2 Perforated galvanized steel

EIO0000003125 06/2020 39

TM3 Installation

Double-Profile Top Hat Section Rails (DIN rail)

The following illustration and table indicate the references of the double-profile top hat section rails

(DIN rails) for the wall-mounting range:

Reference Type Rail Length (B)

NSYDPR25 W 250 mm (9.84 in.)

NSYDPR35 W 350 mm (13.77 in.)

NSYDPR45 W 450 mm (17.71 in.)

NSYDPR55 W 550 mm (21.65 in.)

NSYDPR65 W 650 mm (25.60 in.)

NSYDPR75 W 750 mm (29.52 in.)

40

The following illustration and table indicate the references of the double-profile top hat section rails

(DIN rail) for the floor-standing range:

Reference Type Rail Length (B)

NSYDPR60 F 588 mm (23.15 in.)

NSYDPR80 F 788 mm (31.02 in.)

NSYDPR100 F 988 mm (38.89 in.)

NSYDPR120 F 1188 mm (46.77 in.)

EIO0000003125 06/2020

Assembling a Module to a Controller or Receiver Module

Introduction

This section describes how to assemble an expansion module to a controller, Receiver module or

other modules.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

After connecting new modules to the controller, either directly or through a transmitter/receiver,

update and redownload your application program before placing the system back in service. If you

do not revise your application program to reflect the addition of new modules, I/O located on the

expansion bus may no longer operate normally.

TM3 Installation

WARNING

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003125 06/2020 41

TM3 Installation

Assembling a Module to a Controller or Receiver Module

The following procedure shows how to assemble a controller or receiver module and a module

together.

Step Action

1 Remove all power and dismount any existing controller I/O assembly from its DIN mounting.

2 Remove the expansion connector sticker from the controller or the outermost installed expansion

module.

3 Verify that the locking device

Guide)

on the new module is in the upper position.

4 Align the internal bus connector on the left side of the module with the internal bus connector on the

right side of the controller, Receiver module or expansion module.

5 Press the new module towards the controller, Receiver module or expansion module until it is

securely in place.

6 Push down the locking device

Guide)

on the top of the new module to lock it to the controller, Receiver module or previously

installed expansion module.

(see Modicon TM3, Transmitter and Receiver Modules, Hardware

(see Modicon TM3, Transmitter and Receiver Modules, Hardware

42

EIO0000003125 06/2020

Disassembling a Module from a Controller or Receiver Module

Introduction

This section describes how to disassemble a module from a controller or receiver module.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

Disassembling a Module from a Controller or Receiver Module

The following procedure describes how to disassemble a module from a controller or receiver

module.

TM3 Installation

Step Action

1 Remove all power from the control system.

2 Dismount the assembled controller and modules from the mounting rail.

3 Push up the locking device

controller or receiver module.

4 Pull apart module from the controller or receiver module.

EIO0000003125 06/2020 43

(see page 22)

from the bottom of the module to disengage it from the

TM3 Installation

Direct Mounting on a Panel Surface

Overview

This section shows how to install TM3 expansion module using the Panel Mounting Kit. This

section also provides mounting hole layout for all modules.

Installing the Panel Mount Kit

The following procedure shows how to install a mounting strip:

Step Action

1 Insert the mounting strip TMAM2 into the slot at the top of the module.

Mounting Hole Layout

The following diagram shows the mounting holes for TM3 with 8 I/Os ,16 I/Os ,TM3XTRA1 ,

TM3XREC1 and TM3XTYS4 expansion modules:

44

EIO0000003125 06/2020

TM3 Installation

The following diagram shows the mounting holes for TM3 with 24 screw or spring I/O channels:

The following diagram shows the mounting holes for TM3 with 32 HE10 (MIL 20) I/O channels:

EIO0000003125 06/2020 45

TM3 Installation

TM3 Electrical Requirements

Section 2.3

TM3 Electrical Requirements

What Is in This Section?

This section contains the following topics:

Wiring Best Practices 47

DC Power Supply Characteristics 53

Topic Page

46

EIO0000003125 06/2020

Wiring Best Practices

Overview

This section describes the wiring guidelines and associated best practices to be respected when

using the TM3 system.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power is off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM3 Installation

DANGER

WARNING

1

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

EIO0000003125 06/2020 47

TM3 Installation

Functional Ground (FE) on the DIN Rail

The DIN Rail for your TM3 system is common with the functional ground (FE) plane and must be

mounted on a conductive backplane.

UNINTENDED EQUIPMENT OPERATION

Connect the DIN rail to the functional ground (FE) of your installation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Protective Ground (PE) on the Backplane

The protective ground (PE) is connected to the conductive backplane by a heavyduty wire, usually

a braided copper cable with the maximum allowable cable section.

Wiring Guidelines

The following rules must be applied when wiring a TM3 system:

I/O and communication wiring must be kept separate from the power wiring. Route these 2 types

of wiring in separate cable ducting.

Verify that the operating conditions and environment are within the specification values.

Use proper wire sizes to meet voltage and current requirements.

Use copper conductors.

Use twisted-pair, shielded cables for analog, and/or fast I/O.

Use twisted-pair, shielded cables for networks, and field bus.

WARNING

48

WARNING

UNINTENDED EQUIPMENT OPERATION

Use shielded cables for all fast I/O, analog I/O, and communication signals.

Ground cable shields for all fast I/O, analog I/O, and communication signals at a single point

Route communications and I/O cables separately from power cables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

Multipoint grounding is permissible if connections are made to an equipotential ground plane

dimensioned to help avoid cable shield damage in the event of power system short-circuit currents.

NOTE: Surface temperatures may exceed 60 °C (140 °F).

To conform to IEC 61010 standards, route primary wiring (wires connected to power mains)

separately and apart from secondary wiring (extra low voltage wiring coming from intervening

power sources). If that is not possible, double insulation is required such as conduit or cable gains.

EIO0000003125 06/2020

1

.

Rules for Removable Screw Terminal Block

The following tables show the cable types and wire sizes for a 3.81 pitch removable screw terminal

block (I/Os and power supply):

The following tables show the cable types and wire sizes for a 5.08 pitch removable screw terminal

block (I/Os and power supply):

The use of copper conductors is required.

TM3 Installation

DANGER

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the I/O channels and

power supplies.

For relay output (2 A) wiring, use conductors of at least 0.5 mm

rating of at least 80 °C (176 °F).

For common conductors of relay output wiring (7 A), or relay output wiring greater than 2 A,

use conductors of at least 1.0 mm2 (AWG 16) with a temperature rating of at least 80 °C

(176 °F).

Failure to follow these instructions will result in death or serious injury.

EIO0000003125 06/2020 49

2

(AWG 20) with a temperature

TM3 Installation

Rules for Removable Spring Terminal Block

The following tables show the cable types and wire sizes for a 3.81 pitch removable spring terminal

block (I/Os and power supply):

The following tables show the cable types and wire sizes for a 5.08 pitch removable spring terminal

block (I/Os and power supply):

The use of copper conductors is required.

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the I/O channels and

power supplies.

For relay output (2 A) wiring, use conductors of at least 0.5 mm

rating of at least 80 °C (176 °F).

For common conductors of relay output wiring (7 A), or relay output wiring greater than 2 A,

use conductors of at least 1.0 mm

(176 °F).

Failure to follow these instructions will result in death or serious injury.

DANGER

2

(AWG 20) with a temperature

2

(AWG 16) with a temperature rating of at least 80 °C

50

The spring clamp connectors of the terminal block are designed for only one wire or one cable end.

Two wires to the same connector must be installed with a double wire cable end to help prevent

loosening.

DANGER

LOOSE WIRING CAUSES ELECTRIC SHOCK

Do not insert more than one wire per connector of the spring terminal blocks unless using a

double wire cable end (ferrule).

Failure to follow these instructions will result in death or serious injury.

EIO0000003125 06/2020

Protecting Outputs from Inductive Load Damage

Depending on the load, a protection circuit may be needed for the outputs on the controllers and

certain modules. Inductive loads using DC voltages may create voltage reflections resulting in

overshoot that will damage or shorten the life of output devices.

OUTPUT CIRCUIT DAMAGE DUE TO INDUCTIVE LOADS

Use an appropriate external protective circuit or device to reduce the risk of inductive direct

current load damage.

Failure to follow these instructions can result in injury or equipment damage.

If your controller or module contains relay outputs, these types of outputs can support up to

240 Vac. Inductive damage to these types of outputs can result in welded contacts and loss of

control. Each inductive load must include a protection device such as a peak limiter, RC circuit or

flyback diode. Capacitive loads are not supported by these relays.

RELAY OUTPUTS WELDED CLOSED

Always protect relay outputs from inductive alternating current load damage using an

appropriate external protective circuit or device.

Do not connect relay outputs to capacitive loads.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM3 Installation

CAUTION

WARNING

AC-driven contactor coils are, under certain circumstances, inductive loads that generate

pronounced high-frequency interference and electrical transients when the contactor coil is deenergized. This interference may cause the logic controller to detect an I/O bus error.

WARNING

CONSEQUENTIAL LOSS OF CONTROL

Install an RC surge suppressor or similar means, such as an interposing relay, on each TM3

expansion module relay output when connecting to AC-driven contactors or other forms of

inductive loads.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003125 06/2020 51

TM3 Installation

Protective circuit A: this protection circuit can be used for both AC and DC load power circuits.

C represents a value from 0.1 to 1 μF.

R represents a resistor of approximately the same resistance value as the load.

Protective circuit B: this protection circuit can be used for DC load power circuits.

Use a diode with the following ratings:

Reverse withstand voltage: power voltage of the load circuit x 10.

Forward current: more than the load current.

Protective circuit C: this protection circuit can be used for both AC and DC load power circuits.

52

In applications where the inductive load is switched on and off frequently and/or rapidly, ensure

that the continuous energy rating (J) of the varistor exceeds the peak load energy by 20 % or

more.

EIO0000003125 06/2020

DC Power Supply Characteristics

Overview

This section provides the characteristics of the DC power supply.

Power Supply Voltage Range

If the specified voltage range is not maintained, outputs may not switch as expected. Use

appropriate safety interlocks and voltage monitoring circuits.

FIRE HAZARD

Use only the correct wire sizes for the maximum current capacity of the I/O channels and power

supplies.

Failure to follow these instructions will result in death or serious injury.

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the environmental and electrical characteristics

tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

TM3 Installation

DANGER

WARNING

EIO0000003125 06/2020 53

TM3 Installation

DC Power Supply Characteristics

The 24 Vdc power supplies must be rated at least Protective Extra Low Voltage (PELV) according

to IEC 61140. These power supplies are isolated between the electrical input and output circuits

of the power supply.

POTENTIAL OF OVERHEATING AND FIRE

Do not connect the equipment directly to line voltage.

Use only isolating PELV power supplies to supply power to the equipment

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

For compliance to UL (Underwriters Laboratories) requirements, the power supply must also

conform to the various criteria of NEC Class 2, and be inherently current limited to a maximum

power output availability of less than 100 VA (approximately 4 A at nominal voltage), or not

inherently limited but with an additional protection device such as a circuit breaker or fuse meeting

the requirements of clause 9.4 Limited-energy circuit of UL 61010-1. In all cases, the current limit

should never exceed that of the electric characteristics and wiring diagrams for the equipment

described in the present documentation. In all cases, the power supply must be grounded, and you

must separate Class 2 circuits from other circuits. If the indicated rating of the electrical characteristics or wiring diagrams are greater than the specified current limit, multiple Class 2 power

supplies may be used.

WARNING

1

.

54

EIO0000003125 06/2020

ModiconTM3

TM3 Digital Input Modules

EIO0000003125 06/2020

TM3 Digital Input Modules

Part II

TM3 Digital Input Modules

What Is in This Part?

This part contains the following chapters:

Chapter Chapter Name Page

3 TM3DI8A Module 8 Inputs 120 Vac 57

4 TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc 63

5 TM3DI16 / TM3DI16G Module 16 Regular Inputs 24 Vdc 69

6 TM3DI16K Module 16 Regular Inputs 24 Vdc 77

7 TM3DI32K Module 32 Regular Inputs 24 Vdc 85

EIO0000003125 06/2020 55

TM3 Digital Input Modules

56

EIO0000003125 06/2020

ModiconTM3

TM3DI8A Module 8 Inputs 120Vac

EIO0000003125 06/2020

TM3DI8A Module 8 Inputs 120Vac

Chapter 3

TM3DI8A Module 8 Inputs 120 Vac

Overview

This chapter describes the TM3DI8A expansion modules, its characteristics, and its connection to

the different sensors.

What Is in This Chapter?

This chapter contains the following topics:

TM3DI8A Presentation 58

TM3DI8A Characteristics 59

TM3DI8A Wiring Diagram 61

Topic Page

EIO0000003125 06/2020 57

TM3DI8A Module 8 Inputs 120 Vac

TM3DI8A Presentation

Overview

TM3DI8A (screw) digital expansion module:

8 channels

120 Vac digital input

2 common lines

removable screw terminal block

Main Characteristics

Characteristic Value

Number of input channels 8

Input type Type 1 (IEC/EN 61131-2)

Logic type N/A

Rated input voltage 120 Vac

Connection type Removable screw terminal block

Cable type and length Type stranded wire 2,5 mm²

Status LEDs

The following figure shows the status LEDs:

Length -

58

This table describes the status LEDs:

LED Color Status Description

0...7 Green On The input channel is activated.

Off The input channel is deactivated.

EIO0000003125 06/2020

TM3DI8A Characteristics

Introduction

This section provides a general description of the characteristics of the TM3DI8A expansion

module.

See also Environmental Characteristics

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the environmental and electrical characteristics

tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Dimensions

The following diagrams show the external dimensions for the TM3DI8A module:

(see page 29)

.

WARNING

TM3DI8A Module 8 Inputs 120 Vac

* 8.5 mm (0.33 in.) when the clamp is pulled out.

EIO0000003125 06/2020 59

TM3DI8A Module 8 Inputs 120 Vac

Input Characteristics

The table below describes the inputs characteristics of the TM3DI8A expansion module:

Characteristic Value

Number of input channels 8 inputs

Number of channels groups 2 common lines of 4 channels each

Input type Type 1 (IEC/EN 61131-2))

Logic type N/A

Rated input voltage 120 Vac

Input voltage range 0...132 Vac

Rated input current 7.5 mA at 100 Vac

Input impedance 11 kΩ

Turn on time 25 ms

De-rating -10...55 °C

(14...131 °F)

Input limit values Voltage at state 1 > 79 Vac (79...132 Vac)

Voltage at state 0 < 20 Vac (0...20 Vac)

Current at state 1 2 mA < I < 15 mA

Isolation Between input and internal logic 1500 Vac

Between input groups 1500 Vac

Connector type Removable screw terminal block

Connector insertion/removal durability Over 100 times

Current draw on 5 Vdc internal bus 60 mA (all inputs on)

Current draw on 24 Vdc internal bus 0 mA (all inputs on)

No de-rating

25 mA (all inputs off)

0 mA (all inputs off)

60

EIO0000003125 06/2020

TM3DI8A Wiring Diagram

Introduction

This expansion module has a built-in removable screw terminal block for the connection of inputs

and power supply.

Wiring Rules

See Wiring Best Practices

Wiring Diagram

The following figure illustrates the connection between the inputs, the sensors, and their commons:

(see page 47)

TM3DI8A Module 8 Inputs 120 Vac

.

The COM0 and COM1 terminal are not connected internally.

WARNING

UNINTENDED EQUIPMENT OPERATION

Do not connect wires to unused terminals and/or terminals indicated as “No Connection (N.C.)”.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000003125 06/2020 61

TM3DI8A Module 8 Inputs 120 Vac

62

EIO0000003125 06/2020

ModiconTM3

TM3DI8 / TM3DI8G Module 8 Regula r Inputs 24 Vdc

EIO0000003125 06/2020

TM3DI8 / TM3DI8G Module 8 Regula r Inputs 24 Vdc

Chapter 4

TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc

Overview

This chapter describes the TM3DI8 / TM3DI8G expansion modules, its characteristics and its

connection to the different sensors.

What Is in This Chapter?

This chapter contains the following topics:

TM3DI8 / TM3DI8G Presentation 64

TM3DI8 / TM3DI8G Characteristics 66

TM3DI8 / TM3DI8G Wiring Diagram 68

Topic Page

EIO0000003125 06/2020 63

TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc

TM3DI8 / TM3DI8G Presentation

Overview

TM3DI8 (screw) and TM3DI8G (spring) digital expansion module:

8 channels

24 Vdc digital input

1 common line

Sink/source

removable screw or spring terminal block

Main Characteristics

Characteristic Value

Number of input channels 8 inputs

Input type Type 1 (IEC/EN 61131-2)

Logic type Sink/Source

Rated input voltage 24 Vdc

Connection type TM3DI8 Removable screw terminal block

TM3DI8G Removable spring terminal block

Cable type and length Type Unshielded

Length Max. 30 m (98 ft)

Weight 85g (3 oz)

64

EIO0000003125 06/2020

Status LEDs

The following figure shows the status LEDs:

This table describes the status LEDs:

LED Color Status Description

0...7 Green On The input channel is activated

TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc

Off The input channel is deactivated

EIO0000003125 06/2020 65

TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc

TM3DI8 / TM3DI8G Characteristics

Introduction

This section provides a description of the input characteristics of TM3DI8 / TM3DI8G expansion

modules.

See also Environmental Characteristics

UNINTENDED EQUIPMENT OPERATION

Do not exceed any of the rated values specified in the environmental and electrical characteristics

tables.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Dimensions

The following diagrams show the external dimensions for the TM3DI8 / TM3DI8G expansion

modules:

(see page 29)

.

WARNING

66

* 8.5 mm (0.33 in.) when the clamp is pulled out.

EIO0000003125 06/2020

TM3DI8 / TM3DI8G Module 8 Regular Inputs 24 Vdc

Input Characteristics

The table below describes the inputs characteristics of the TM3DI8 / TM3DI8G:

Characteristic Value

Number of input channels 8 inputs

Number of channels groups 1 common line on three terminals for 8 channels

Input type Type 1 (IEC/EN 61131-2)

Logic type Sink/Source

Rated input voltage 24 Vdc

Input voltage range 19.2...28.8 Vdc

Rated input current 7 mA

Input impedance 3.4 kΩ

Turn on time

Turn off time

Input limit values Voltage at state 1 > 15 Vdc (15...28.8 Vdc)

Voltage at state 0 < 5 Vdc (0...5 Vdc)

Current at state 1 > 2.5 mA

Current at state 0 <1 mA

Isolation Between input and

internal logic

Between input groups N/A