Installation Instructions

Specifications

Actuator Inputs

Control Signal

Power Input

Connections

Actuator Outputs

Electrical

Position Feedback Voltage

(proportional or floating only)

Mechanical

Timing

Travel

Manual Override

See Table-1 thru 4 for actuator mod-

els and control types.

See Table-1 thru 4. All 24 Vac circuits

are Class 2. All circuits 30 Vac and

above are Class 1.

3 ft (91 cm) appliance or plenum ca-

bles, enclosure accepts 1/2” (13 mm)

conduit connector. For M20 Metric

conduit, use AM-756 adaptor.

For voltage ranges, the feedback

signal is the same range as the input

signal. The 4 to 20 mA current range

and floating actuators have a 2 to 10

Vdc feedback signal. The feedback

signal can supply up to 0.5 mA to

operate up to four additional slave

actuators.

See Figure-1 to Figure-4.

93° nominal.

Allows positioning of damper or valve

using manual crank.

Environment

Ambient Temperature Limits

Shipping & Storage

Operating

Humidity

Location

Agency Listings

UL 873

CUL

European Community

Australia

-40 to 160°F (-40 to 71°C).

-22 to 140°F (-30 to 60°C).

15 to 95% RH, non-condensing.

NEMA 1. NEMA 2, UL Type 2 (IEC

IP54) with customer supplied water

tight conduit connectors. Enclosure is

air plenum rated.

Underwriters Laboratories (File

#E9429 Category Temperature-Indi-

cating and Regulating Equipment).

UL Listed for use in Canada by

Underwriters Laboratories. Canadian

Standards C22.2 No. 24-93.

EMC Directive (89/336/EEC). Low

Voltage Directive (72/23/EEC). This

product fits in Installation Category

(Overvoltage Category) II per EN

61010-1.

This product meets requirements to

bear the RCM according to the terms

specified by the Communications

Authority under the Radiocommuni-

cations Act 1992.

RA/DA Jumper

Permits reverse acting/direct acting

control (MS4D models only).

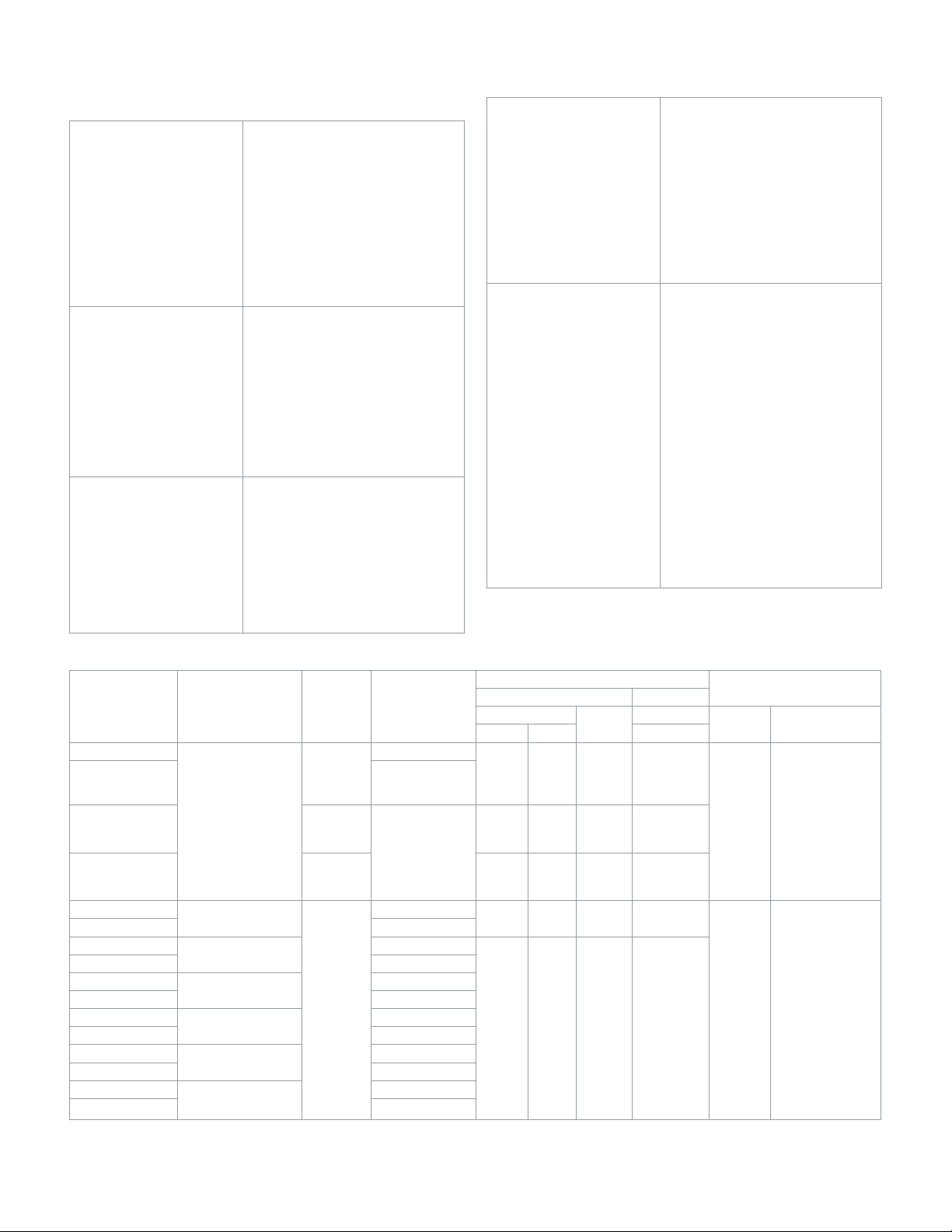

Table 1. 30 in-lb (3.4 N-m) Spring Return CCW Actuators (Viewed from cover side)

Part Number Control Signal Voltage Wiring System

50/60 Hz

VA W W

MA4D-7033-000

MA4D-7033-100 Plenum Cable

2

MA4D-7030-000

Position

SPST

MA4D-7031-000

24 VAC

+/-20%

or 20-30

Vdc

120 Vac ±

10%

50/60 Hz

230 Va ±

10%

Appliance Wire

5.1 3.6 0.14 1.3

7.8 5.0 — 2.5

Appliance Wire

7.2 5.2 — 2.4

50/60 Hz

MF4D-7033-000

MF4D-7033-100 Plenum Cable

MS4D-7033-000

MS4D-7033-100 Plenum Cable

MS4D-7033-020

MS4D-7033-120 Plenum Cable

MS4D-7033-030

MS4D-7033-130 Plenum Cable

MS4D-7033-050

MS4D-7033-150 Plenum Cable

MS4D-7033-060

MS4D-7033-160 Plenum Cable

a Timing was measured with no load applied to actuator.

b 4 to 20 mAdc with field-installed 500 ohm resistor.

Floating

2 to 10 Vdcb

Proportional

0 to 3 Vdc

Proportional

6 to 9 Vdc

Proportional

0 to 10 Vdc

Proportional

4 to 20 mAdc

Proportional

24 Vac

+/-20%

or 20-30

Vdc

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

6.8 4.2 0.15 1.9

6.1 3.4 0.12 1.4

Actuator Power Input

Running Holding

DC

50/60 Hz

Amps

Approximate Timinga in

Sec. @ 70 °F (21 °C)

Pow-

ered

Spring Return

(CCW)

56 23

85 21

November, 2018 tc © 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries S AS or its af filiat ed companies.

Document Number: F-27170-7

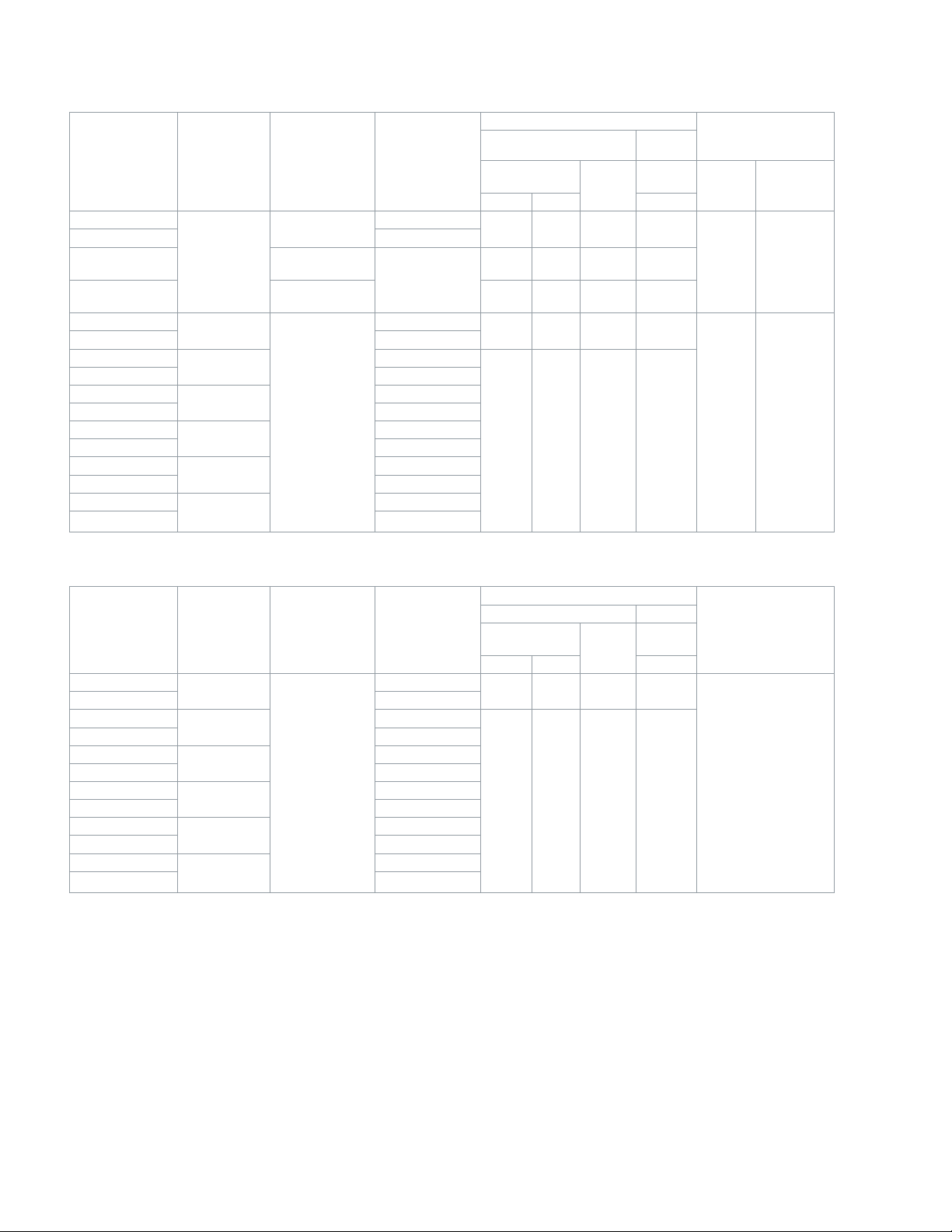

Table 2. 30 in-lb (3.4 N-m) Spring Return CW Actuators (Viewed from cover side)

Part Number

Control

Signal

Voltage Wiring System

50/60 Hz

VA W W

MA4D-8033-000

MA4D-8033-100 Plenum Cable

MA4D-8030-000

2

Position

SPST

MA4D-8031-000

MF4D-8033-000

MF4D-8033-100 Plenum Cable

MS4D-8033-000

MS4D-8033-100 Plenum Cable

MS4D-8033-020

MS4D-8033-120 Plenum Cable

MS4D-8033-030

MS4D-8033-130 Plenum Cable

MS4D-8033-050

MS4D-8033-150 Plenum Cable

MS4D-8033-060

MS4D-8033-160 Plenum Cable

a Timing was measured with no load applied to actuator.

b 4 to 20 mAdc with field-installed 500 ohm resistor.

Floating

2 to 10 Vdcb

Proportional

0 to 3 Vdc

Proportional

6 to 9 Vdc

Proportional

0 to 10 Vdc

Proportional

4 to 20 mAdc

Proportional

24 VAC +/-20%

or 20-30 Vdc

120 Vac ± 10%

50/60 Hz

230 Va ± 10%

50/60 Hz

24 Vac +/-20%

or 20-30 Vdc

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

Appliance Wire

5.1 3.6 0.14 1.3

7.8 5.0 — 2.5

7.2 5.2 — 2.4

6.8 4.2 0.15 1.9

6.1 3.4 0.12 1.4

Actuator Power Input Approximate Timing

Running Holding

DC

50/60

Hz

Amps

in Sec. @ 70 °F (21

°C)

Pow-

ered

Spring Re-

turn (CW)

56 23

85 21

Installation Instructions

a

Table 3. Non-Spring Return 35 in-lb (4 N-m) Actuators.

Part Number

MF4D-6043-000

MF4D-6043-100 Plenum Cable

MS4D-6043-000

MS4D-6043-100 Plenum Cable

MS4D-6043-020

MS4D-6043-120 Plenum Cable

MS4D-6043-030

MS4D-6043-130 Plenum Cable

MS4D-6043-050

MS4D-6043-150 Plenum Cable

MS4D-6043-060

MS4D-6043-160 Plenum Cable

a Timing was measured with no load applied to actuator.

b 4 to 20 mAdc with field-installed 500 ohm resistor.

Control

Signal

Floating

2 to 10 Vdcb

Proportional

0 to 3 Vdc

Proportional

6 to 9 Vdc

Proportional

0 to 10 Vdc

Proportional

4 to 20 mAdc

Proportional

Voltage Wiring System

Appliance Wire

Appliance Wire

Appliance Wire

24 Vac +/-20%

or 20-30 Vdc

Appliance Wire

Appliance Wire

Appliance Wire

Actuator Power Input

Running Holding

50/60 Hz

VA W W

DC

Amps

4.4 2.7 0.1 1.7

4.2 2.2 0.08 1.2

50/60

Hz

Approximate Timinga

in Sec. @ 70 °F (21

°C)

85

© 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries SAS or its af filiat ed companies. Novemb er, 2018 tc

Docume nt Number : F-27170-7

Installation Instructions

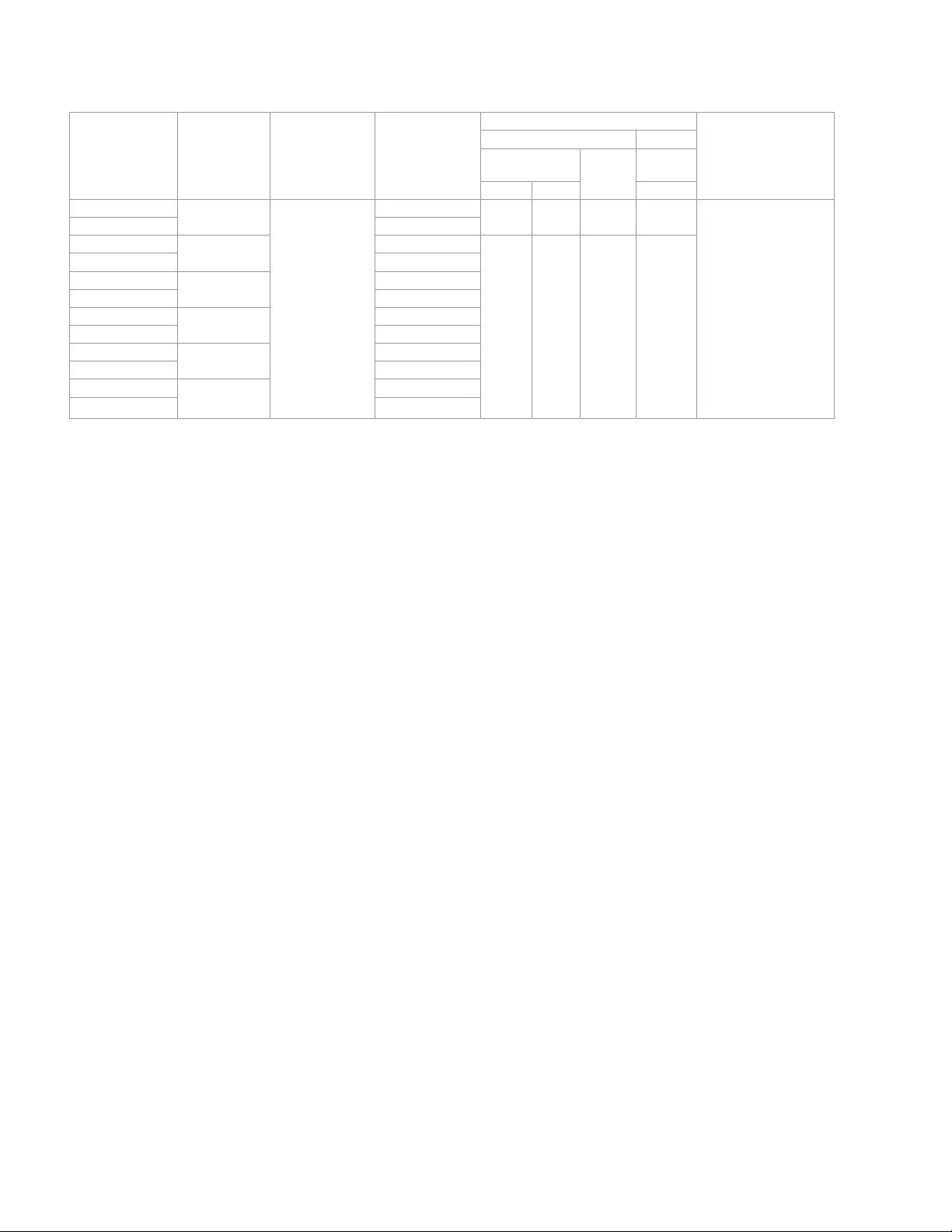

Table 4. Non-Spring Return 70 in-lb (8 N-m) Actuators.

Part Number

MF4D-6083-000

MF4D-6083-100 Plenum Cable

MS4D-6083-000

MS4D-6083-100 Plenum Cable

MS4D-6083-020

MS4D-6083-120 Plenum Cable

MS4D-6083-030

MS4D-6083-130 Plenum Cable

MS4D-6083-050

MS4D-6083-150 Plenum Cable

MS4D-6083-060

MS4D-6083-160 Plenum Cable

a Timing was measured with no load applied to actuator.

b 4 to 20 mAdc with field-installed 500 ohm resistor.

Control

Signal

Floating

2 to 10 Vdcb

Proportional

0 to 3 Vdc

Proportional

6 to 9 Vdc

Proportional

0 to 10 Vdc

Proportional

4 to 20 mAdc

Proportional

Voltage Wiring System

Appliance Wire

Appliance Wire

Appliance Wire

24 Vac +/-20%

or 20-30 Vdc

Appliance Wire

Appliance Wire

Appliance Wire

Actuator Power Input

Running Holding

50/60 Hz

VA W W

5.9 3.6 0.13 1.6

5.2 2.7 0.10 1.4

DC

Amps

50/60

Hz

Approximate Timing

in Sec. @ 70 °F (21

°C)

85

a

Ball Valve Close-Off Pressures: For close-off pressure ratings on Schneider Electric VB2000 ball valves, consult Schneider Electric VB2000 Ball Valve Assemblies Ball Valve Body/Linkage Selection Guide F-27086.

Accessories

AM-763 1/8” Hexcrank for manual override

AM-756 Metric Conduit Adapter M20 x 1.5 to 1/2” NPT

AM-771 Crank Arm and bracket kit

AM-772 Bracket for reverse mounting

AM-714 Weathershield Kit

MS4D-xxx3-xxx

AM-703 Input rescaling module, adjust signals to 2-10 Vac, zero and span adjust

AM-704 Interface, pulse width modulation (PWM)

AM-705 Positioner (NEMA 4 housing)

AM-706 Min and/or manual positioner for flush panel mount

AM-708 500 Ω resistor for 4 to 20 mA control signal

November, 2018 tc © 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries S AS or its af filiat ed companies.

Document Number: F-27170-7

Installation Instructions

Installation

Inspect the package for damage. If damaged, notify the appropriate carrier immediately. If undamaged, open the package and

inspect the device for obvious damage. Return damaged products.

Requirements

• Job wiring diagrams

• Appropriate accessories

• Installer must be a qualified, experienced technician

• 1/8” hex allen wrench (not provided)

• #8 Torx screwdriver (not provided)

• #8 sheet metal screws (2) (not provided)

• Appropriate drill bits (not provided

Precautions

Warning:

• Electrical shock hazard! Disconnect the power supply (line power) before installation to prevent electric shock and equipment

damage.

• Make all connections in accordance with the job wiring diagram and in accordance with national and local electrical codes.

Use copper conductors only.

• Floating and Proportional Models: These products contain a half-wave rectifier power supply. They must not be powered with

transformers that are used to power other devices utilizing non-isolated full-wave rectifier power supplies. Refer to EN-206,

Guidelines For Powering Devices From A Common Transformer, F-26363 for detailedinformation.

Caution:

• Avoid electrical noise interference. Do not install near large contactors, electrical machinery, or welding equipment.

• Manual override to be used only when power is not applied to unit.

• When operating manual override (observe position indicator), back off 5° from full extended mechanical stop to ensure proper

release.

Federal Communications Commission (FCC)

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in residential installations.

This equipment generates, uses, and can radiate radio frequency energy and may cause harmful interference if not installed and

used in accordance with the instructions. Even when instructions are followed, there is no guarantee that interference will not

occur in a particular setting—Which can be determined by turning the equipment off and on—the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

Canadian Department of Communications (DOC)

Note: This Class B digital apparatus meets all requirements of the Canadian Interference- Causing Equipment Regulations.

Cet appareil numerique de la classe B respecte toutes les exigences du Reglement sur le material broilleur du Canada.

European Standard EN 55022

Note: This is a Class B digital (European Classification) product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

Location

Caution: Avoid locations where excessive moisture, corrosive fumes, vibration, or explosive vapors are present.

November, 2018 tc © 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries S AS or its af filiat ed companies.

Document Number: F-27170-7

Installation Instructions

Ball Valve Mounting

Installation of Mx4D-xxxx-xxx Actuators on 1/2” to 3” Schneider Electric VB2000 Ball Valves

Install the actuator onto the ball valve according to Figure-16.

Note: If space constraints do not allow the actuator to be installed in the standard position, reposition the mounting plate

before mounting the actuator.

The valve should be mounted in a weather-protected area, in a location that is within the ambient temperature limits of the

actuator. The installation of the actuator assembly should provide clearance on all sides to allow for any maintenance that

may be needed (see Figure-13 thru Figure-15).

1. Follow the general piping practices.

2. Apply pipe sealant sparingly to all but the last two threads of a properly threaded, reamed, and cleaned pipe. Make sure

the pipe chips, scale, etc. do not get into the pipe since this material may lodge in the valve seat and prevent proper

operation of the valve. The valve must be piped with an inlet and an outlet.

3. Start the joint hand-threading the pipe into the valve. If the thread alignment feels normal, continue to turn the pipe by

hand as far as it will go.

4. Use a pipe wrench to fully tighten the pipe to the valve.

5. Caution: Do not over-tighten the pipe, which may cause stripped threads. Avoid twisting or crushing the valve while tight-

ening the pipe.

6. Insulate only the valve body and associated piping. Do not insulate the actuator.

7. In chilled or cold water systems where the environment is humid, use a drip pan under the valve to catch condensate.

Caution: The Schneider Electric SmartX Actuator is designed to effectively support its own weight. No load or weight should

be resting on the actuator. Long term damage may occur to the actuator, mounting connection, or valve.

• Do not insulate the actuator/linkage. Doing so will result in excess heat buildup within the actuator.

• For non-steam applications the ball valve assembly must be mounted so the actuator is at least 5° above horizontal

(Figure-13) to ensure that any condensate that forms will not travel into the mounting bracket or actuator.

• On steam applications, the ball valve assembly must be mounted approximately 45° from horizontal (Figure-14).

• Temperature Restrictions: To maintain the maximum ambient temperature 140 °F (60 °C) of the actuator/valve, the

maximum allowable fluid temperature should not exceed the 250 °F(121 °C) ball valve maximum rating.

85˚

Max

0˚

3-7/8" (99 mm) Min.

Clearance

85˚

Max

Figure-13 Acceptable Mounting Orientations.

November, 2018 tc © 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries S AS or its af filiat ed companies.

Document Number: F-27170-7

Wiring

Requirements

Control Leads

See Table-5 for power wiring data. Refer to Figure-1 through Figure-8 for typical wiring.

Table-5 Power Wiring.

SmartX

Actuator

Voltage

24 Vac and

22-30 Vdc

Part Number

MA4D-7033

MA4D-8033

MF4D-7033

MF4D-8033

MS4D-7033

MS4D-8033

MF4D-6083

MS4D-6083

MF4D-6043

MS4D-6043

12 AWG 14 AWG 16 AWG 18 AWG 20 AWG 22 AWG

1744

(532)

1308

(399)

1458

(444)

1508

(459)

1710

(521)

2021

(616)

2118

(645)

Maximum Wire Run in ft. (m)

1097

(534)

822

(251))

917

(279)

948

(289)

1075

(328)

1271

(387)

1331

(406)

690

(210)

517

(158)

577

(276)

596

(182)

676

(206)

799

(244)

837

(255)

434

(132)

325

(99)

325

(99)

375

(114)

425

(130)

503

(153)

527

(161)

273

(83)

205

(62))

228

(70)

236

(72)

268

(82)

268

(82)

331

(101)

216

(66)

162

(49)

181

(55)

187

(57)

212

(65)

251

(76)

263

(80)

Installation Instructions

Checkout

With the correct control signals applied, power the actuator. Observe movement of the output shaft to check for proper operation. If a spring return model, removing power should cause the actuator to spring return to its rest position. If problems are

encountered, check the suggestions below.

Note: Check that the transformer(s) are sized properly.

• If a common transformer is used with multiple actuators, make sure that polarity is observed on the secondary. This means

connecting all black wires to one leg of the transformer and all red wires to the other leg of the transformer.

• If multiple transformers are used with one control signal, make sure all black wires are tied together and tied to control

signal negative (-).

• If the controller uses a full-wave power supply and does not provide isolated outputs, a separate transformer is required to

power the actuator.

© 2018 Schneider Elect ric. All r ights res erved. A ll trade marks are o wned by Schneider Ele ctric Ind ustries SAS or its af filiat ed companies. Novemb er, 2018 tc

Docume nt Number : F-27170-7

Loading...

Loading...