Page 1

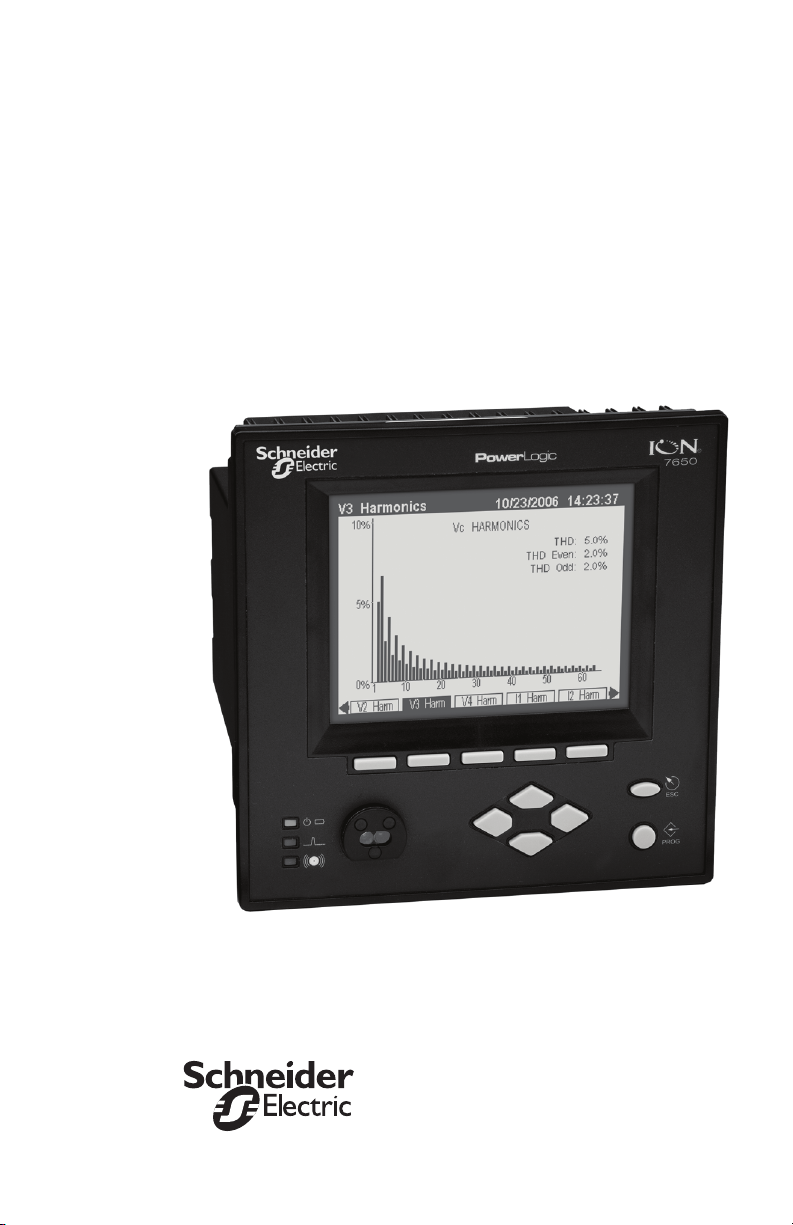

PowerLogic® ION7550 / ION7650

Energy & Power Quality Meter

Installation Guide

December 2007

Page 2

Page 3

Danger

DANGER

CAUTION

PowerLogic ION7550 / ION7650 Installation Guide

This symbol indicates the presence of dangerous voltage within and outside the product enclosure

that may constitute a risk of electric shock, serious injury or death to persons if proper precautions

are not followed.

Caution

This symbol alerts the user to the presence of hazards that may cause minor or moderate injury to

persons, damage to property or damage to the device itself, if proper precautions are not followed.

Note

This symbol directs the user’s attention to important installation, operating and maintenance

instructions.

Installation Considerations

Installation and maintenance of the PowerLogic ION7550 / ION7650 meter should only be performed by qualified,

competent personnel that have appropriate training and experience with high voltage and current devices. The meter

must be installed in accordance with all local and national electrical codes.

Failure to observe the following instructions may result in severe injury or death.

During normal operation of the ION7550 / ION7650 meter, hazardous voltages are present on its termi-

nal strips, and throughout the connected potential transformer (PT), current transformer (CT), digital (status) input, control power and external I/O circuits. PT and CT secondary circuits are capable of generating

lethal voltages and currents with their primary circuit energized. Follow standard safety precautions while

performing any installation or service work (i.e. removing PT fuses, shorting CT secondaries, etc.).

The terminal strips on the meter base should not be user-accessible after installation.

Do not use digital output devices for primary protection functions. These include applications where the

devices perform energy limiting functions or provide protection of people from injury. Do not use the

ION7550 / ION7650 in situations where failure of the devices can cause injury or death, or cause suffi-

cient energy to be released that can start a fire. The meter can be used for secondary protection functions.

Do not HIPOT/Dielectric test the digital (status) inputs, digital outputs, or communications terminals. Refer

to the label on the ION7550 / ION7650 meter for the maximum voltage level the device can

withstand.

Observe the following instructions, or permanent damage to the meter may occur.

The ION7550 / ION7650 meter offers a range of hardware options that affect input ratings. The

ION7550 / ION7650 meter’s serial number label lists all equipped options. Applying current levels incom-

patible with the current inputs will permanently damage the meter. This document provides installation

instructions applicable to each hardware option.

The ION7550 / ION7650 meter’s chassis ground must be properly connected to the switchgear earth

ground for the noise and surge protection circuitry to function correctly. Failure to do so will void the

warranty.

Terminal screw torque: Barrier-type (current, voltage, and relay terminal screws: 1.35 Nm (1.00 ft-lbf)

max. Captured-wire type (

digital inputs/outputs, communications, power supply: 0.90 Nm

(0.66 ft.lbf) max.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

© 2007 Schneider Electric. All rights reserved. 3

Page 4

PowerLogic ION7550 / ION7650 Installation Guide

This equipment generates, uses, and can radiate radio frequency e nerg y and , i f n ot installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

The Ringer Equivalence Number (REN) for the ION7550 / ION7650 optional internal modem is 0.6. Connection to

the ION7550 / ION7650 internal modem should be made via an FCC Part 68 compliant telephone cord (not

supplied). The ION7550 / ION7650 cannot be used on a public coin phone service or party line services.

Network Compatibility Notice for the Internal Modem

The internal modem in meters equipped with this option is compatible with the telephone systems of most countries

in the world. Use in some countries may require modification of the internal modem’s initialization strings. If problems

using the modem on your phone system occur, please contact Schneider Electric Technical Support.

Standards Compliance

CSA: Certified to CAN/

CSA C22.2 No.1010-1

Made by Power Measurement Ltd.

PowerLogic, ION, ION Enterprise, MeterM@il, WebMeter and Modbus are either trademarks or registered

trademarks of Schneider Electric.

Covered by one or more of the following patents:

U.S. Patent No's 7010438, 7006934, 6990395, 6988182, 6988025, 6983211, 6961641, 6957158,

6944555, 6871150, 6853978, 6825776, 6813571, 6798191, 6798190, 6792364, 6792337, 6751562,

6745138, 6737855, 6694270, 6687627, 6671654, 6671635, 6615147, 6611922, 6611773, 6563697,

6493644, 6397155, 6236949, 6186842, 6185508, 6000034, 5995911, 5828576, 5736847, 5650936,

D505087, D459259, D458863, D443541, D439535, D435471, D432934, D429655, D427533.

Certified to

UL 3111

4 © 2007 Schneider Electric. All rights reserved.

Page 5

PowerLogic ION7550 / ION7650 Installation Guide

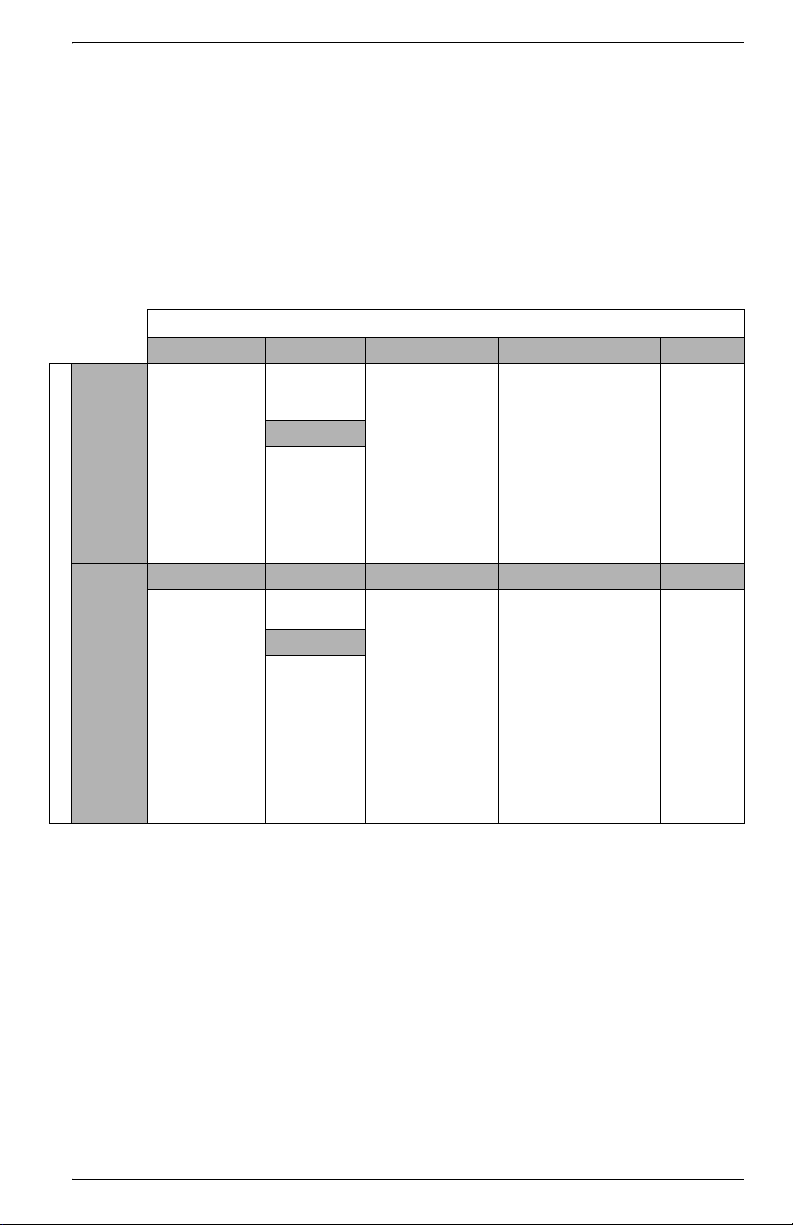

PowerLogic ION7550 / ION7650 Models

Integrated Display Model

Comes with front optical port.

TRAN (transducer) Model

The TRAN model has no display.

Available Options

Option

Form Factor Current Inputs COM I/O Security

ION7550

Model

ION7650

Integ. Display

TRAN

5 MB memory

10 MB memory

Up to 256

sampling rate

Form Factor Current Inputs COM I/O Security

Integ. Display

TRAN

5 MB memory

10 MB memory

Up to 512

sampling rate

(standard)

1024 sampling

rate (optional)

EN50160

compliance

IEC61000-4-30

Class A

compliance

Standard

(5 Amp)

1 Amp

Power Supply

Standard

Low Voltage

DC

Same as

ION7550

Power Supply

Same as

ION7550

Standard (RS-232,

RS-485, optical)

Ethernet RJ45

Ethernet Fiber

Modem

Same as

ION7550

Standard (8 digital

inputs, 3 Form C relays,

4 Form A outputs)

Extra 8 digital inputs

Four 0-1mA analog

inputs

Four 0-20 mA analog

inputs

Four -1 to 1mA analog

outputs

Four 0-20 mA analog

outputs

Same as ION7550 Same as

Standard

RMANSI

ION7550

1

2

Notes

1

Standard = password protected, no locking or sealing.

2

RMANSI = ANSI C12.16 approved revenue meter; meets ANSI C12.20

class 0.2 accuracy standards.

© 2007 Schneider Electric. All rights reserved. 5

Page 6

PowerLogic ION7550 / ION7650 Installation Guide

DANGER

Navigation

Buttons

PROG/SELECT

Button

Softkeys

ESC Button

Communications

Card

Form C

Digital Outputs

Digital

Inputs

Form A

Digital Outputs

Digital Inputs Analog Inputs Analog Outputs

Voltage and Current Inputs

Power

Supply

Ground

Te rm i n al

Meter Front

Meter Back

Optical Port

I/O Expansion

Card

Operational

LEDs

ESC

PROG

Before You Begin

Before installing the meter, familiarize yourself with the steps in this guide and

read the safety precautions presented on the “Installation Considerations”

page.

Do not power up the meter until the current and voltage wiring is completed.

Recommended Tools

Phillips screwdriver

Precision flat-head screwdriver

Wire cutters / stripper

Meter Overview

Front Panel Button Functions

PROG/SELECT: Press the PROG/SELECT (program or select) button to enter Setup

mode. In Setup mode, press the

ESC: Press the ESC (Escape) button to return to a higher menu or discontinue a

configuration change.

NAVIGATION: Press the UP / DOWN arrow buttons to highlight menu items, or

increment / decrement numbers.

Press the

SOFTKEY: Press a SOFTKEY button to select the parameter that you want to

LEFT or RIGHT arrow buttons to move to an adjacent digit.

configure from the sub-menus.

6 © 2007 Schneider Electric. All rights reserved.

PROG/SELECT button to accept changes.

Page 7

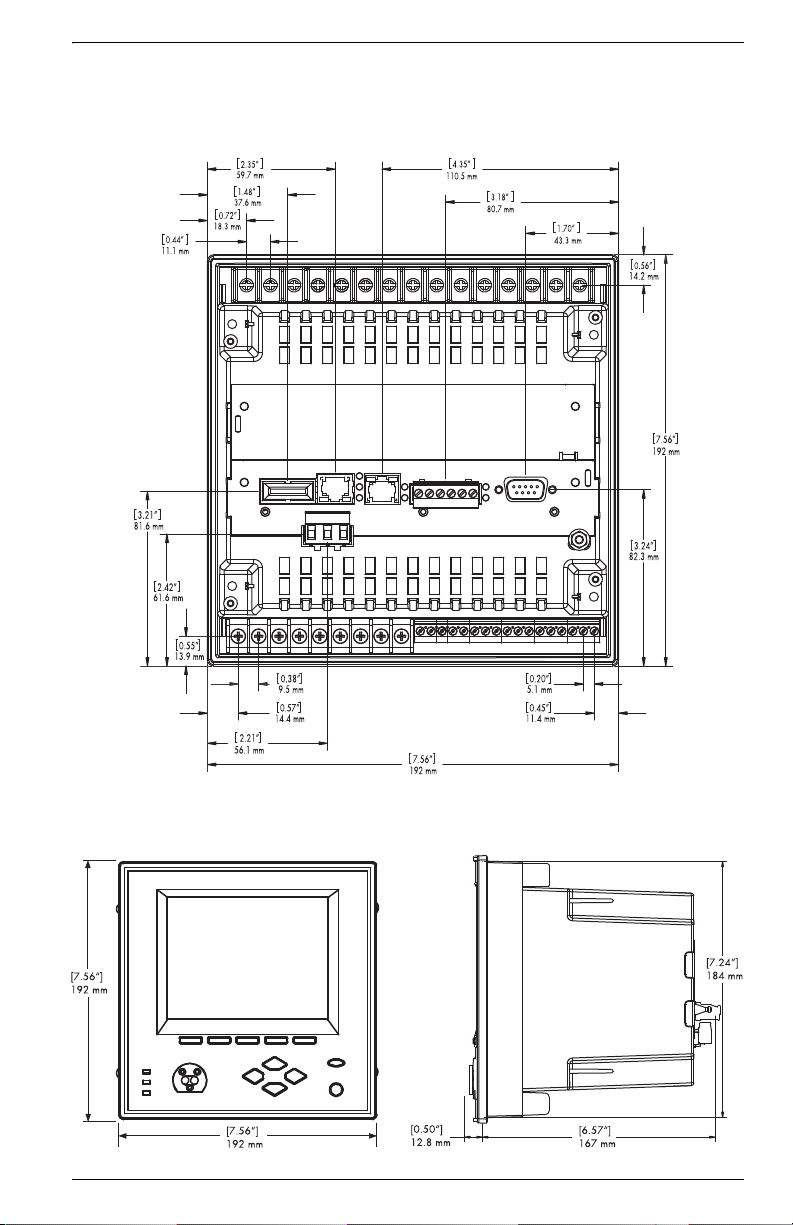

Unit Dimensions

Basic Model — Rear View

Basic Model — Front View

Basic Model — Side View

PowerLogic ION7550 / ION7650 Installation Guide

© 2007 Schneider Electric. All rights reserved. 7

Page 8

PowerLogic ION7550 / ION7650 Installation Guide

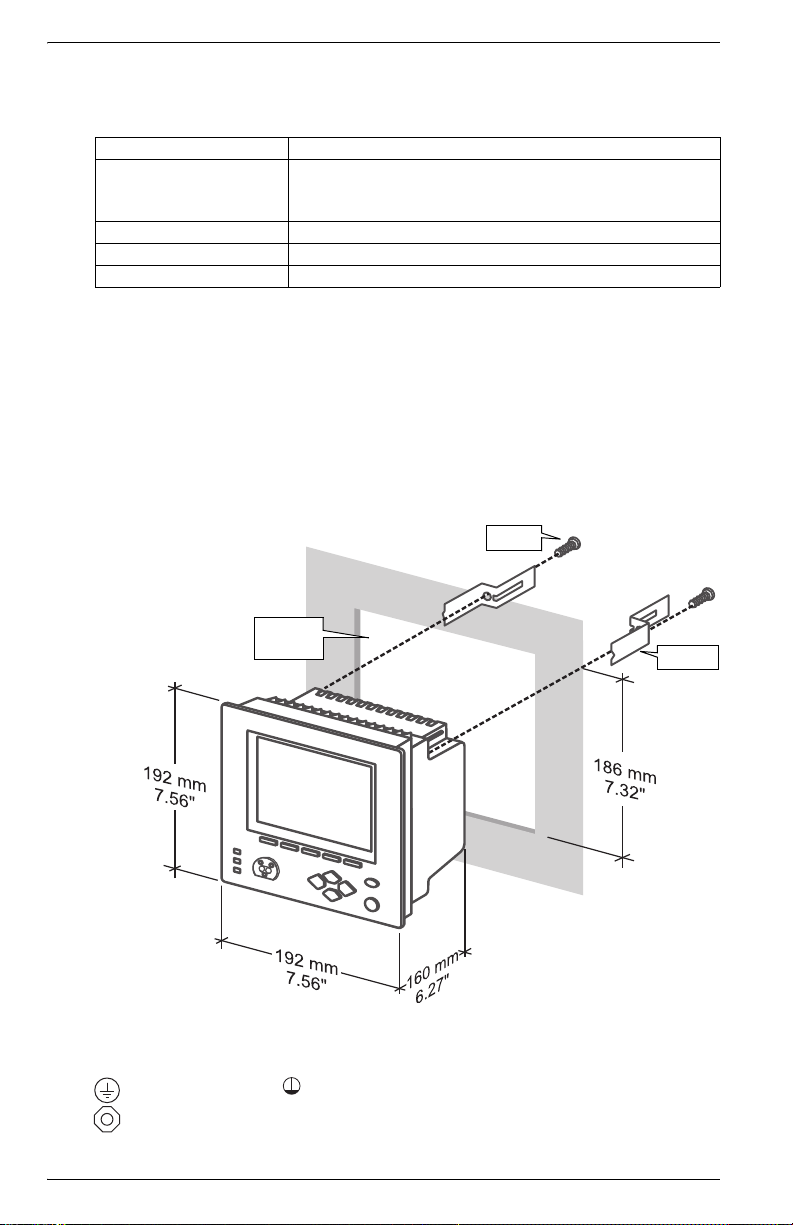

Screw

Bracket

DIN 192

Cutout

Step 1: Mount the Meter

Environmental Specifications

Mounting Location Indoor use

-20 to +70ºC (-4 to +158ºF) Standard Power Supply

Operating Range

Display Operating Range -20 to +70ºC (-4 to +158ºF)

Storage Range -40 to +85ºC (-40 to +185ºF)

Relative Humidity Range 5 to 95% non-condensing

Meter Battery Considerations

The meter’s battery life expectancy depends on both temperature and the

amount of time the meter is without power. For typical installations, the

battery should last 20 years or more. If the meter is not powered, the battery

will last a minimum of 7 years at room temperature.

Integrated Display Model

1. Fit the meter into the DIN standard 192 cutout (186 mm by 186 mm).

2. Slide the four brackets into their slots on the back of the meter and secure

using the four Phillips head screws. Do not overtighten.

-20 to +50ºC (-4 to +122ºF) Low Voltage DC Power Supply

No formation of ice

Step 2: Wire the Ground Terminal

Connect the terminal to a good earth ground with a 2.1 mm2 (14 AWG)

wire. Ensure that the terminal nut is tightened down securely onto the ground

wire. Do not use metal door hinges as a grounding point.

8 © 2007 Schneider Electric. All rights reserved.

Page 9

PowerLogic ION7550 / ION7650 Installation Guide

R11R

12

R

13

R

21

R12

R11

R13

Internal Form C

Mechanical

Relay

External Supply

Alarm Lamp

NCNO

Load

Meter

K

Mechanical

relays should

always be

protected by

external fuses

DIGITAL OUTPUTS

D3

-

+

D2

-

+

D4

-

+

D1

-

+

1.8 Wh

+

_

D1

Internal Form A

Solid State Relay

+

+

_

D3

_

D2

+

_ _

+

_

+

_

+

_

D1

+

D4 output is factory-configured to pulse once every 1.8 Wh for Class 20 meters,

or once every 0.18 Wh for Class 2 meters (for calibration testing purposes).

Meter

External

Relays

External Supply

30VDC max

Step 3: Wire the Digital I/O and Analog I/O

Form C Digital Outputs: Mechanical Relays R1 - R3

Type Form C (R1, R2, R3)

Contacts K (common), Y (NO), Z (NC)

Wire Use wiring that is appropriate for the application

Connector Ring or split ring connector

Voltage Rating 250 VAC / 30 VDC

Rated Load @

Rated Voltage

Max. Voltage 380 VAC / 125 VDC between K and NO/NC

MOV Protection 300 V max. between NO and NC

Max. Load @

Max. Voltage

Turn-On Time 15 ms max.

Isolation 5,000 VAC for 60 s

Turn-Off Time 5 ms max.

Lifetime

Update time ½ cycle or 1 s

Resistive: 10 A (AC/DC)

Inductive (PF=0.4): 7.5 A (AC) / 5 A (DC)

3 A (AC) / 0.2 A (DC)

No load = 10,000,000 operations

Rated voltage and load = 100,000 operations

Form A Digital Outputs: Solid State Relays D1 - D4

Typ e Fo r m A (D1, D2, D3, D4)

Wire

1.3 to 0.1 mm

2

(16 to 28 AWG)

Signal Type Continuous or pulse

Max. Load Voltage 30 VDC

Max. Load Current 80 mA per channel

Isolation

Optically isolated; max. 5,000 V RMS isolation

(UL-E91231)

Scan Time ½ cycle or 1 s

© 2007 Schneider Electric. All rights reserved. 9

Page 10

PowerLogic ION7550 / ION7650 Installation Guide

S

C

O

M

S1S2S3S4S5S

6

S

7

S

8

DIGITAL INPUTS

_

+

S8

S7

SCOM

+

_

30 VDC

+

_

+

_

S8

S7

SCOM

+

_

30 VDC

+

_

+

_

Internal Excitation External Excitation

Opticallycoupled switch

External Supply

130 VDC max

Meter Meter

Opticallycoupled switch

Internal Excitation

External Excitation

Opticallycoupled switch

Opticallycoupled switch

External Supply

50 VDC max

Meter

Meter

Digital Inputs: S1 - S8

Type Self-excited (internal 30 VDC supply)

Application Dry contact sensing, or with external excitation

Wire

Min. Pulse Width

Max. Pulse Rate 20 pulses per second

Timing Resolution 1 ms

Updated ½ cycle (after timing resolution)

Isolation to Ground max. 200 VDC for 10s

Max. External Voltage 130 VDC continuous

1.3 to 0.1 mm

1 ms

2

(16 to 28 AWG)

Digital Inputs (Meter Ordering Option): DI1 - DI8

Type Self excited (internal 30 VDC supply)

Application Dry contact sensing, or with external excitation

Wire

1.3 to 0.1 mm

Min. Pulse Width 20 ms

Max. Pulse Rate 25 pulses per second

Timing Resolution 2 ms

Updated ½ cycle (after timing resolution)

Isolation to Ground 750 VDC

Max. External Voltage 50 VDC continuous

10 © 2007 Schneider Electric. All rights reserved.

2

(16 to 28 AWG)

Page 11

PowerLogic ION7550 / ION7650 Installation Guide

NOTE

NOTE

AI4

AI3

AI2

AI1

AI3

+

-

AI1

+

-

mV

mA

Example

application:

temperature

sensing

Thermocoupler

Vol ta ge- to-

Current

Transducer

Meter

AO3

OUT COM

AO4

A03

A02

AO1

AO1

OUT

COM

+

Example application: driving an

analog meter with the DC

current output

Meter

Analog

Meter

Analog Inputs (Meter Ordering Option): AI1 to AI4

Type Captured wire connector

Wire

1.3 to 0.1 mm

Signal Type DC current

Available Options

0 to 20 mA (scalable 4-20 mA) or 0 to 1 mA

Input Impedance 24 Ω (0-20 mA option) or 475 Ω (0-1 mA option)

Accuracy +/– 0.3% of full scale

Update Rate 1 s

Isolation to Ground 750 V

Isolation Impedance max 400 kΩ (channel/channel)

Do not connect the analog inputs of the I/O card to the analog outputs on

the same I/O card.

2

(16 to 28 AWG)

Analog Outputs (Meter Ordering Option): AO1 to AO4

Type Captured wire connector

Wire

1.3 to 0.1 mm

Signal Type DC current

Available Options

Driving Capability

0 to 20 mA (scalable 4-20 mA) or -1 to 1 mA

(scalable 0-1 mA)

500 Ω (0-20 mA option) or 10 kΩ (-1 to 1 mA

option)

Accuracy +/– 0.30% of full scale

Update Rate ½ cycle or 1 s

Latency

min. 1 cycle for measurement + ½ cycle for ION

+ 1 s delay for hardware

Isolation to Ground 750 V

2

(16 to 28 AWG)

© 2007 Schneider Electric. All rights reserved. 11

Do not connect the analog outputs of the I/O card to the analog inputs on

the same I/O card.

Page 12

PowerLogic ION7550 / ION7650 Installation Guide

NOTE

3~ VOLTAGE INPUTS 3~ CURRENT INPUTS

V

3

V

4

V

ref

I11I12I21I

22

I31I

32

I41I

42

I

51

V1V

2

I

52

Step 4: Wire the Voltage and Current Inputs

Voltage Inputs

Connector Type Ring or split ring connector

Wire Gauge

3.3 to 2.1 mm

Rated Inputs 347 V L-N RMS /600 V L-L RMS

Fault Capture 1200 V L-N peak

Overload 1500 VAC RMS continuous

Dielectric Withstand 2500 VAC RMS at 60 Hz for 60 s

Input Impedance 5 MΩ/phase (phase - Vref)

Current Inputs: Class 20 Current Inputs (5A Option)

Connector Type Ring or split ring connector

Wire Gauge

Input Rating 5 A, 10 A, and/or 20 A RMS

Starting Current 0.005 A RMS

Fault Capture 70 A peak

Max. Voltage 600 V RMS (CAT III IEC61010-1)

Overload 500 A RMS for 1 s, non-recurring

Dielectric Withstand 2500 VAC RMS at 60 Hz for 60 s

Burden 0.05 VA per phase (at 5 A)

Impedance 0.002 Ω per phase

5.3 to 3.3 mm

Use 8.4 mm

2

(12 to 14 AWG)

2

(10 to 12 AWG):

2

(8 AWG) for 10-20 A applications

Current Inputs: Class 2 Current Inputs (1A Option)

Connector Type Ring or split ring connector

Wire Gauge

5.3 to 3.3 mm

Input Rating 1 A, 2 A, 5 A, and/or 10 A RMS

Starting Current 0.001 A RMS

Fault Capture 17.5 A peak

Max. Voltage 600 V RMS (CAT III IEC61010-1)

Overload 50 A RMS for 1s, non-recurring

Dielectric Withstand 2500 VAC RMS at 60 Hz for 60 s

Burden 0.015 VA per phase (at 1 A)

Impedance 0.015 Ω per phase

The appropriate Volts Mode setting is included with each wiring diagram.

Refer to Step 8 to learn how to configure Volts Mode on the meter.

12 © 2007 Schneider Electric. All rights reserved.

2

(10 to 12 AWG)

Page 13

PowerLogic ION7550 / ION7650 Installation Guide

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

I4 Optional

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

I4 Optional

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

I4 Optional

4-Wire Wye, 3-Element, Direct Connection Diagram

347 V L-N / 600 V L-L max.

VOLTS MODE = 4W-Wye

4-Wire Wye, 3-Element, 3 PTs Connection Diagram

Use PTs for voltages over 347 V L-N / 600 V L-L.

Wye (Star) wiring for PT primaries and secondaries.

VOLTS MODE = 4W-Wye

4-Wire Wye, 2½-Element, 2 PTs Connection

Phase B voltage (V2) displayed by meter is derived from phase A and

phase C, not measured. V2 will display a value even if no voltage is

present on Phase B. V2 values are only accurate for balanced loads.

VOLTS MODE = 3W-Wye

© 2007 Schneider Electric. All rights reserved. 13

Page 14

PowerLogic ION7550 / ION7650 Installation Guide

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

V1 V2

V3

Vref

I11

I12

I21

I22

I31

I32

N/-L/+

G

3A

A

B

C

2A

Do not

connect

V4

I41

I42

I51

I52

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

V1 V2

V3

Vref

I11

I12

I21

I22

I31

I32

N/-L/+

G

3A

A

B

C

2A

V4

I41

I42

I51

I52

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

3-Wire Solid-Grounded Wye, 3-Element, Direct Connection

When the common or star point of a 3-wire Wye system is grounded,

the meter may be connected directly without using PTs, provided that the

phase voltages are within the meter’s range.

VOLTS MODE = 4W-Wye

3-Wire Delta, 2½-Element, Direct Connection

600 V L-L max.

VOLTS MODE = Delta

3-Wire Delta, 2-Element 2 PTs & 2 CTs

Use PTs for voltages over 600 V L-L.

14 © 2007 Schneider Electric. All rights reserved.

VOLTS MODE = Delta

Page 15

PowerLogic ION7550 / ION7650 Installation Guide

2A

V1 V2

V3

Vref

I11

I12

I21

I22

I31

I32

N/-L/+

G

3A

A

B

C

V4

I41

I42

I51

I52

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

LINE

LOAD

Fuse for N/- terminal

required if its supply

source is ungrounded

Connect G terminal

to ground for AC

power source

I4 Optional

3-Wire Delta, 2½-Element, 2 PTs & 3 CTs

Use PTs for voltages over 600 V L-L

VOLTS MODE = Delta

Single Phase Connection Diagram

277 V L-N / 554 V L-L max. Use PTs for higher voltages.

VOLTS MODE = Single

Using Potential Transformers

System Mode Voltage Range Requires PTs

120 V L-N or 208 V L-L no

Wye

Single Phase

Delta

© 2007 Schneider Electric. All rights reserved. 15

277 V L-N or 480 V L-L no

347 V L-N or 600 V L-L no

over 347 V L-N or 600 V L-L yes

120 V L-N or 240 V L-L no

277 V L-N or 554 V L-L no

over 277 V L-N or 554 V L-L yes

up to 600 V L-L no

over 600 V L-L yes

Page 16

PowerLogic ION7550 / ION7650 Installation Guide

Null modem

cable pinout

Pin 3 - Transmit Data - Pin 2

Pin 2 - Receive Data - Pin 3

Pin 7 - Reque

st to Send- Pin 8

Pin 8 - Clear to Send- Pin 7

Pin 5 - Signal Ground- Pin 5

Pin 6 - Data Se

t Ready- Pin 4

Pin 4 - Data Terminal Ready- Pin 6

DB9 Null Modem

Wiring Diagram

DTE

(computer)

DTE

(meter)

Connect SH at

one end only

Step 5: Wire the Communications

RS-232 Connections (COM1)

Specification Meter Connected to Computer

Connector Type DB9 female end for mating with male connector on the meter

Wire Null modem RS-232 cable Straight-through RS-232 cable

Maximum Cable Length

Data Rate 300 – 115,200 bps

Isolation Optical

Duplex Full

Compliance ANSI/IEEE C37.90.1-2002 surge withstand and fast transient tests

15.2 m (50 ft)

Meter Connected to External

Modem

RS-485 Connections (COM1 and COM2)

SH RS-485 Shield (electrically connected to chassis ground)

– RS-485 Data Minus

+ RS-485 Data Plus

Connector Type Captured wire

Wire

Maximum Cable Length 1219 m (4000 ft) total for entire bus

Data Rate 300 – 115,200 bps

Maximum Devices (per bus) 32

Isolation Optical

Duplex Half

Compliance

Shielded twisted pair RS-485 cable,

0.33 mm

ANSI/IEEE C37.90.1-2002 surge withstand

and fast transient tests

2

(22 AWG) or larger

Infrared Connections (COM4)

Interface ANSI C12.18 Type II optical port

Location Front of meter

Data Rate 1,200 – 19,200 bps

Duplex Half

16 © 2007 Schneider Electric. All rights reserved.

Page 17

PowerLogic ION7550 / ION7650 Installation Guide

Pin 1: Transmit Data +

Pin 2: Transmit Data Pin 3: Receive Data +

Pin 6: Receive Data -

SC type fiber cable

Only one EtherGate

connection per port

is allowed at a time

Pin 3: Ring

Pin 4: Tip

Ethernet Connections (if equipped)

10BASE-T / 100BASE-TX

Wire Type High quality Category 5 or 6 unshielded twisted pair cable

Connector Type RJ45 modular

Maximum Length 100 m (328 ft)

Ty pe

Data Rate 10/100 Mbps

Isolation Transformer isolated to 1500 V RMS

Max. Connections Allowed 4 simultaneous (32 via Modbus TCP/IP)

100BASE-FX (Fiber)

Ethernet TCP/IP Service Ports

IEEE 802.3 10/100BASE-T for 10/100 Mbps base band CSMA/CD

LANs

Wire Type

Connector Type SC

Maximum Length

Data Rate 100 Mbps

Isolation Optical

ION 7700

Modbus RTU 7701

Modbus TCP 502

EtherGate (COM1) 7801

EtherGate (COM2) 7802

DNP TCP 20,000

SMTP 25 (configurable)

62.5/125 or 50/125 micrometer multimode fiber optic

cable

2000 m (6562 ft) full duplex

400 m (1312 ft) half duplex

Protocol Port

Internal Modem Connection (COM3 if equipped)

© 2007 Schneider Electric. All rights reserved. 17

Connector Type RJ11

Wire Type

Data Rate 300 bps – 56 kbps

Error Correction V.42 LAPM, MNP 2-4, V.44

Data Compression V.42 bis/MNP 5

FCC Part 68 compliant telephone cord (two male

RJ11 ends)

Page 18

PowerLogic ION7550 / ION7650 Installation Guide

G

N

_

L

+

BASIC SETUP

COM1 SETUP

COM2 SETUP

COM3 SETUP

COM4 SETUP

NETWORK SETUP

PQ SETUP

FORMAT SETUP

DISPLAY SETUP

TIME SETUP

SECURITY SETUP

METER RESETS

Press PROG/SELECT to

enter Setup Mode

from Display Mode.

Use arrow buttons to

move up and down in

list. Press PROG/SELECT

to select Basic Setup.

Use arrow buttons to

move up and down in

list. Press PROG/SELECT

to select PT/CT Setup.

Press Mode softkey.

Use arrow buttons to

move up and down in

list. Press PROG/SELECT

to select Delta.

Press

Press

Press

Press

Press

Press

Step 6: Wire the Power Supply

Specification Standard Power Supply Low Voltage DC

Type Captured wire connector

Wire

Rated Inputs

3.3-2.1 mm

85-240 VAC ±10%

or 110-300 VDC ±10%

2

(12-14 AWG) 2.1-0.8 mm2 (14-18 AWG)

(47-63 Hz),

20-60 VDC ±10%

Dielectric Withstand 2500 VAC RMS at 60 Hz for 60s

Burden 35 VA max. (15 VA typical) 18 W max. (12 W typical)

Ride-through 100 ms (6 cycles at 60 Hz) min. None

Step 7: Power Up the Meter

1. Ensure the ground wire is securely connected on both ends.

2. Ensure the meter’s power supply voltage is within the allowed range.

3. Power up the meter.

Step 8: Set Up the Meter Using the Front Panel

The following Setup screens are available for meter configuration via the

front panel:

Use the

PROG/SELECT, ESC, softkeys and arrow buttons to configure settings.

The following example shows Volts Mode setup using the meter front panel.

18 © 2007 Schneider Electric. All rights reserved.

Page 19

Password

NOTE

A password is required for all front panel configuration changes and to enter

the Security Setup menu. The password is set to 0 (zero) in the factory. The

front panel only prompts you for the meter password once, before you make

your first configuration change. You can disable the password via the Security

Setup menu.

Selecting the Front Panel Language

Meters are shipped with English as the default front panel language.

To select another language:

1. Press

2. Scroll through the language list and select the language you want.

PROG/SELECT and the right arrow buttons, hold for two seconds

then release.

PowerLogic ION7550 / ION7650 Installation Guide

3. Press

You can also access this setting via the Display Setup menu.

The meter only communicates to software in English.

PROG/SELECT to confirm.

© 2007 Schneider Electric. All rights reserved. 19

Page 20

PowerLogic ION7550 / ION7650 Installation Guide

Front Panel Setup Menu Settings

The following table lists all settings that can be configured via the front panel.

Menu Setting Description Range (Values) Default

VOLTS MODE

PT PRIMARY

PT SECONDARY

CT PRIMARY

CT SECONDARY

V4 PRIMARY

V4 SECONDARY

I4 PRIMARY

I4 SECONDARY

I5 PRIMARY

I5 SECONDARY

V NOMINAL

BASIC SETUP

V4 NOMINAL

Va POLARITY

Vb POLARITY

Vc POLARITY

V4 POLARITY

Ia POLARITY

Ib POLARITY

Ic POLARITY

I4 POLARITY

I5 POLARITY

CURRENT PROBE

TYPE

The power system’s configuration –

WYE, DELTA, etc.

The Potential Transformer’s primary

winding voltage rating

The Potential Transformer’s

secondary winding voltage rating

The Current Transformer’s primary

winding current rating

The Current Transformer’s

secondary winding current rating

The Potential Transformer’s primary

winding voltage rating on V4

The Potential Transformer’s

secondary winding voltage rating

on V4

The Current Transformer’s primary

winding current rating on I4

The Current Transformer’s

secondary winding current rating

on I4

The Current Transformer’s primary

winding current rating on I5

The Current Transformer’s

secondary winding current rating

on I5

The V1, V2 and V3 nominal voltage

used for harmonics calculations

The V4 nominal voltage used for

harmonics calculations

The polarity of the Potential

Transformer on Va

The polarity of the Potential

Transformer on Vb

The polarity of the Potential

Transformer on Vc

The polarity of the Potential

Transformer on V4

The polarity of the Current

Transformer on Ia

The polarity of the Current

Transformer on Ib

The polarity of the Current

Transformer on Ic

The polarity of the Current

Transformer on I4

The polarity of the Current

Transformer on I5

The type of current probes being

used with the meter

4W-WYE, DELTA, 3W-WYE,

SINGLE, DEMO

1 to 999,999.99 120.00

1 to 999,999.99 120.00

1 to 999,999.99 5.00

1 to 999,999.99 5.00

1 to 999,999.99 120.00

1 to 999,999.99 120.00

1 to 999,999.99 5.00

1 to 999,999.99 5.00

1 to 999,999.99 5.00

1 to 999,999.99 5.00

1.000 to 999,999.000 120.00

1.000 to 999,999.000 120.00

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Normal or Inverted Normal

Factory Default, User Defined 1,

or User Defined 2

4W-WYE

Factory

Default

20 © 2007 Schneider Electric. All rights reserved.

Page 21

PowerLogic ION7550 / ION7650 Installation Guide

Menu Setting Description Range (Values) Default

ION, Modbus RTU, Modbus

PROTOCOL The communications protocol

BAUD RATE The data rate, in bits per second

TRAN DELAY The transmit delay in seconds 0 to 1 0.010

UNIT ID

COM1 SETUP

SERIAL PORT Parity and stop bits for the port 8N1, 8N2, 8E1, 8E2, 8O1, 8O2 8N1

Every meter on an RS-485 network

must have a unique Unit ID number

MODE Hardware mode for the port RS232 or RS485 RS232

FLOW CONTROL

RS485 BIAS

Specifies the handshake mode

when COM1 is set to RS232

Turns on biasing when Mastering

on the RS-485 bus

PROTOCOL The communications protocol See COM1 protocol ION

BAUD RATE The data rate, in bits per second

TRAN DELAY The transmit delay in seconds 0 to 1 0.010

UNIT ID

SERIAL PORT Parity and stop bits for the port 8N1, 8N2, 8E1, 8E2, 8O1, 8O2 8N1

COM2 SETUP

RS485 BIAS

Every meter on an RS-485 network

must have a unique Unit ID number

Turns on biasing when Mastering

on the RS-485 bus

PROTOCOL The communications protocol

BAUD RATE The data rate, in bits per second

TRAN DELAY The transmit delay in seconds 0 to 1 0.010

UNIT ID

COM3 SETUP

ANSWER HR

RINGS

NON-ANSWER

HR RINGS

Every meter on an RS-485 network

must have a unique Unit ID number

The number of rings during defined

answer hours

The number of rings during defined

non-answer hours

PROTOCOL The communications protocol

BAUD RATE The data rate, in bits per second

TRAN DELAY The transmit delay in seconds 0 to 1 0.010

UNIT ID

COM4 SETUP

Every meter on an RS-485 network

must have a unique Unit ID number

SERIAL PORT Parity and stop bits for the port 8N1, 8N2, 8E1, 8E2, 8O1, 8O2 8N1

Master, DNP V3.00,

GPS:Truetime/Datum,GPS:

Arbiter, GPS:Arbiter-Vorne,

Factory, Ethergate, ModemGate

1

300

, 1200, 2400, 4800, 9600,

19200, 38400, 57600, 115200

1 to 9999

RTS + DELAY or RTS/CTS

ION

19,200

From serial

number

RTS +

DELAY

ON or OFF OFF

1

300

, 1200, 2400, 4800, 9600,

19200, 38400, 57600, 115200

19,200

1 to 9999 101

ON or OFF OFF

ION, Modbus RTU, Modbus

Master, DNP V3.00,

GPS:Truetime/Datum,GPS:

Arbiter, GPS:Arbiter-Vorne,

Factory

1

, 1200, 2400, 4800, 9600,

300

19200, 38400, 57600, 115200

ION

19,200

1 to 9999 102

0 to 255 1

0 to 255 5

ION, Modbus RTU, DNP V3.00,

Factory

1200, 2400, 4800, 9600,

19200

ION

9600

1 to 9999 103

2

© 2007 Schneider Electric. All rights reserved. 21

Page 22

PowerLogic ION7550 / ION7650 Installation Guide

Menu Setting Description Range (Values) Default

IP ADDRESS Sets the IP address for the meter

SUBNET MASK

GATEWAY

Used if subnetting applies to your

network

Used in multiple network

configurations

Sets the address for the primary

DNS PRIMARY

DNS

SECONDARY

NETWORK SETUP

10/100BT

CONFIG

DNS Server that is configured to

resolve domain names

Sets the address for the secondary

DNS Server that is configured to

resolve domain names

Sets the BASE-T Ethernet max. link

speed and duplexing

000.000.000.000 to

999.999.999.999

000.000.000.000 to

999.999.999.999

000.000.000.000 to

999.999.999.999

000.000.000.000 to

999.999.999.999

000.000.000.000 to

999.999.999.999

Auto, 10BT half, 10BT full,

100BTX half, 100BTX full

100BFX CONFIG Sets the Fiber Ethernet duplexing Full Duplex or Half Duplex Full Duplex

SNMP SERVER

SWELL LIMIT

Determines whether SNMP protocol

is enabled on the meter or not

Specifies the magnitude above

which an input must rise for a swell

Enabled or Disabled Disabled

100 to 1000 106

to be recorded

SAG LIMIT

Specifies the magnitude below

which an input must fall for a sag to

0 to 100 88

be recorded

CHANGE

CRITERIA

PQ SETUP

NOMINAL

VOLTAGE

EVENT PRIORITY

DIGIT GROUP

VOLTS DECIMAL

CURRNT

DECIMAL

POWER DECIMAL

MEAS SYMBOL

Specifies the amount by which an

input must change during a

disturbance to be considered a new

sub-disturbance

Specifies the nominal voltage of the

4

power system

Assigns a priority level to sag/swell

events

Specifies symbols used to delimit

thousands & decimal place holder

Number of decimal places

displayed for voltages

Number of decimal places

displayed for currents

Number of decimal places

displayed for power measurements

Specifies the convention used for

displaying measurements

0 to 100 10

0 to 1,000,000 0

0 to 255 200

1000.0 or 1,000.0 or 1000,0 1000.0

1. to 123456789.XXX 1.XX

1. to 123456789.XXX 1.XXX

1. to 123456789.XXX 1.XXX

IEEE or IEC IEEE

PHASE LABEL Specifies how phases are labelled ABC, RST, XYZ, RYB, RWB, 123 ABC

PF SIGN

FORMAT SETUP

PF SYMBOL

DATE FORMAT Specifies how dates are displayed

TIME FORMAT

DISPLAY DST

Specifies the power factor sign

convention used

Sets how power factor is labelled

(LD = leading/LG = lagging)

Specifies whether time is displayed

in 12 hour or 24 hour clock format

Specifies whether or not DST is

displayed

IEEE or IEC IEEE

LD/LG, +/-, CAP/IND LD/LG

MM/DD/YYYY, DD/MM/YYYY,

YYYY/MM/DD

12 H or 24 H 24 H

Yes or No Ye s

3

varies

255.240.0.0

0.0.0.0

none

none

Auto

MM/DD/

YYYY

22 © 2007 Schneider Electric. All rights reserved.

Page 23

PowerLogic ION7550 / ION7650 Installation Guide

Menu Setting Description Range (Values) Default

UPDATE RATE Sets when the display updates 1 to 6 (seconds) 1

CONTRAST Higher numbers are sharper 0 to 9 7

DELTA VECTORS

SETUP

DISPLAY

LANGUAGE

TZ OFFSET

DST OFFSET

SYNC SOURCE

SYNC TYPE

TIME SETUP

CLOCK SOURCE Specifies time sync source Internal, Line Freq or COMM Line Freq

LOCAL DATE Sets the local date Same as Date Format setting

LOCAL TIME Sets the local time

PASSWORD Sets the meter password 00000000 to 99999999 00000000

ENABLED Enables or disables meter security Yes or No No

WEB CONFIG

SETUP

SECURITY

WEB ACTIVE

Specifies how vector diagrams are

displayed when in Delta mode

Specifies the language used on the

meter’s front panel

Sets the time zone of the meter’s

location, relative to UTC

Sets the daylight savings time offset

of the meter’s location

Sets the port to receive time

synchronization signals

Specifies whether time sync signals

are received in local time or UTC

Enables or disables web browser

configuration of the meter

Enables or disables internal web

server on the meter

1

A baud rate of 300 bps is only intended for paging applications.

2

Serial number = PA-0302B222-01, Unit ID = 2222

3

Default IP ADDRESS = 172.16.xxx.xxx, where the last two bytes (decimal)

System or Instrument System

English, Spanish, French,

Russian

- 12:00 to +13:00 +00:00

-3:00 to +3:00 +00:00

Ethernet, COM1, COM2,

COM3, COM4

Local Time or UTC UTC

Enabled or Disabled Enabled

Yes or No Ye s

English

COM1

match the last two bytes of the meter’s MAC address (hex).

4

NOMINAL VOLTAGE must be set to your system’s nominal voltage to

activate the meter’s power quality features.

Step 9: Verify Meter Operation

The LEDs on the back of the meter flash during communications.

LED Color Function

Ethernet 100 (Speed) Green Off = link at 10 Mb, On = link at 100 Mb

Ethernet TX Green Blinking indicates Ethernet transmission

Ethernet RX/LINK Green

Modem DCD Green

Modem RI Green Indicates a ring is detected by the modem

COM3 (Modem) TX Yellow Indicates serial transmission on COM3

COM3 (Modem) RX Yellow Indicates serial reception on COM3

COM2 TX Yellow Indicates serial transmission on COM2

COM2 RX Yellow Indicates serial reception on COM2

COM1 TX Yellow Indicates serial transmission on COM1

COM1 RX Yellow Indicates serial reception on COM1

© 2007 Schneider Electric. All rights reserved. 23

On = link up, Off = link down

Blinking indicates Ethernet reception

Indicates a carrier signal is detected (active

connection to the modem)

Page 24

PowerLogic ION7550 / ION7650 Installation Guide

NOTE

Top (green) LED indicates the meter is operational. The light

should always remain on when the meter is in service.

Middle (red) LED is a watt-hour pulser. During normal

operations this LED should blink intermittently as the meter

measures power.

Bottom (red) LED is user programmable. It can be used for

Alarm notification. See the

ION7550 / ION7650 User

Guide

for more information.

Watt-hour

pulsing

Front Panel

ABC Rotation

ACB Rotation

The LEDs on the front panel indicate the following:

Phasor Diagrams

You can also view the meter’s phasor diagram in real time. Use the Phasor

Viewer available in PowerLogic ION Setup v2.1 and later (free download

from the PowerLogic website) to verify your meter’s wiring. See the ION Setup

online help for details.

The following DELTA phasor diagrams are represented in System mode view.

DELTA phasors for UNITY Power Factor (resistive load)

Applicable Volts Mode = DELTA

VCA

IC

IB

VBC

VBC

IB

VAB

IA

VCA

IA

VAB

IC

24 © 2007 Schneider Electric. All rights reserved.

Page 25

PowerLogic ION7550 / ION7650 Installation Guide

r

W

A

-kW

Reactive Power

+kVAR

r

-

R

Q1: Lagging PF (-) Q2: Leading PF (+)

Q4: Leading PF (+) Q3: Lagging PF (-)

Rotation

Rotation

Rotation

Rotation

Rotation

Rotation

Rotation

Rotation

Activ

r

A

r

-kW

Reactive Power

+kVAR

r

-

Q1: Lagging PF (-) Q2: Leading PF (+)

Q4: Leading PF (+) Q3: Lagging PF (-)

WYE - ABC Rotation

Applicable Volts Mode = 4W-WYE and 3W-WYE

VC

IB

IA

VB

VA

IC

ctive Power

VC

IA

IB

Reactive Powe

VA

kVA

IC

VB

WYE - ACB Rotation

Applicable Volts Mode = 4W-WYE and 3W-WYE

VB

IC

ctive Powe

© 2007 Schneider Electric. All rights reserved. 25

IA

IA

VC

VB

VC

IB

VA

IB

IC

Reactive Powe

VA

kVAR

VC

IC

VA

IB

VB

IA

Active Powe

+k

VC

IC

VB

VB

IC

VC

IA

VA

IB

IB

VA

IA

e Powe

+kW

VB

IB

VC

IA

VA

IC

Page 26

PowerLogic ION7550 / ION7650 Installation Guide

Rotation

Rotation

Rotation

Rotation

Active Power

+kW

Active Power

-kW

Reactive Power

+kVAR

Reactive Power

-kVAR

Q1: Lagging PF (-)

Q4: Leading PF (+) Q3: Lagging PF (-)

Q2: Leading PF (+)

Rotation Rotation

Rotation Rotation

Active Power

+kW

Active Power

-kW

Reactive Power

+kVAR

Reactive Power

-kVAR

Q4: Leading PF (+) Q3: Lagging PF (-)

Q2: Leading PF (+) Q1: Lagging PF (-)

2 Element (3Wire) DELTA - ABC Rotation

Applicable Volts Mode = DELTA

VCA

VCA

IB

IA

VBC

IA

IC

VBC

VAB

IC

VAB

IB

VCA

VCA

IC

IB

IA

VBC

IC

VBC

IA

IB

2 Element (3Wire) DELTA - ACB Rotation

Applicable Volts Mode = DELTA

26 © 2007 Schneider Electric. All rights reserved.

VBC

VCA

VBC

VCA

IC

IB

IA

VAB

VBC

IB

IA

IC

VCA

IC

IA

IB

VAB

VBC

IB

VCA

IA

IC

VAB

VAB

VAB

VAB

Page 27

Step 10: View Meter Data

Use the softkeys to select which data to display. Use the left and right arrow

buttons to scroll through the available display screens.

Display Screens

Softkey Contents

V, I , P F Volts , Am ps, Pow er Fac tor

Volts Vo lts

Amps Amps

Pow er Tot a l Po w e r

Energy1 Energy delivered

Demand1 Demand delivered

Pk Dmd1 Peak D ema nd del ivered

V Bar, I Bar, P Bar Voltage, Current and Power Bar Graphs

Summary1, Summary2 Volts/Amps Summary, Power Summary

D Inputs Digital Inputs

DI - I/O Digital I/O on expansion I/O card

D-Output Digital Outputs

Anlg - I/O Analog In and Out

Phasors Phasors

Name Plt Nameplate information

Events Events

Setpoint Setpoint status

Energy2 Energy received

Demand2 Demand received

Pk Dmd2 Peak D ema nd rec eived

THD Volts and Amps Total Harmonic Distortion

V1 Harm, V2 Harm,... V1, V2, V3, V4 harmonics

I1 Harm, I2 Harm,... I1, I2, I3, I4, I5 harmonics

TOU Time Of Use Active Rate / Season

TOU Eg y TOU E nergy del ivere d

TOU Dmd1 & TOU D md2 TOU Peak Demand 1 and 2

*PQ Freq Power Qua lity Po wer Fr equen cy

*PQ Vmag1 PQ Supply Voltage 1

*PQ Vmag2 PQ Supply Voltage 2

*PQ Flk1 PQ Flicker 1

*PQ Flk2 PQ Flicker 2

*PQ Vdist PQ Voltage Disturbance

*PQ Vunb PQ Voltage Unbalance

*PQ Vhrm1 PQ Voltage Harmonics 1

*PQ Vhrm2 PQ Voltage Harmonics 2

V-Tr e n d , I-Tr e n d, P-Tr e nd Voltage, Current, Power Trends

* Additional display screens for ION7650 meters with EN50160 option.

PowerLogic ION7550 / ION7650 Installation Guide

© 2007 Schneider Electric. All rights reserved. 27

Page 28

PowerLogic ION7550 / ION7650

with WebMeter and MeterM@il

Installation Guide

For further assistance

please contact us at:

Schneider Electric

Power Monitoring and Control

2195 Keating Cross Road

Saanichton, BC

Canada V8M 2A5

Tel: 1-250-652-7100

295 Tech Park Drive, Suite 100

Lavergne, TN 37086

USA

Tel: 1-615-287-3400

Electropole (38 EQI)

31, rue Pierre Mendès France

F - 38050 Grenoble Cédex 9

Tel : + 33 (0) 4 76 57 60 60

Getting technical support:

Contact your local Schneider Electric sales

representative for assistance or go to the

www.powerlogic.com website.

PowerLogic, ION, ION Enterprise, MeterM@il, WebMeter

and Modbus are either trademarks or registered

trademarks of Schneider Electric.

Electrical equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

70002-0247-10

© 2007 Schneider Electric. All rights reserved.

12/2007

Loading...

Loading...