Page 1

ILA2K EtherNet/IP

0198441113670 08/2020

ILA2K EtherNet/IP

Integrated Drive

User Guide

Original instructions

08/2020

0198441113670.00

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 0198441113670 08/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview of Integrated Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components and Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft-Specific Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data for Safety-Related Function STO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditions for UL 508C and CSA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Engineering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.1 Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Power Supply Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Functional Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements for Using the Safety-Related Function STO. . . . . . . . . . . . . . . . . . . . . . . . . .

Application Examples STO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 EtherNet/IP Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Messaging and Message Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 EtherNet/IP Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication via I/O Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Assembly, Instance 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Assembly, Instance 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handshake via the Bit "MT" (Mode Toggle). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.1 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the Integrated Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Via Cable Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Via Industrial Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of CN1 - Vdc Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of CN2 - Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of CN3 - RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of CN4 - 24 V Signal Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of CN5 - Safety-Related Function STO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of Accessories for 24 V Signals and Safety-Related Function STO. . . . . . . . . .

4.3 Verifying Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

15

17

18

20

22

23

26

27

28

29

32

32

34

35

36

37

38

39

40

42

44

45

47

48

49

50

51

53

56

57

58

60

61

63

64

67

68

70

72

74

76

78

80

80

0198441113670 08/2020 3

Page 4

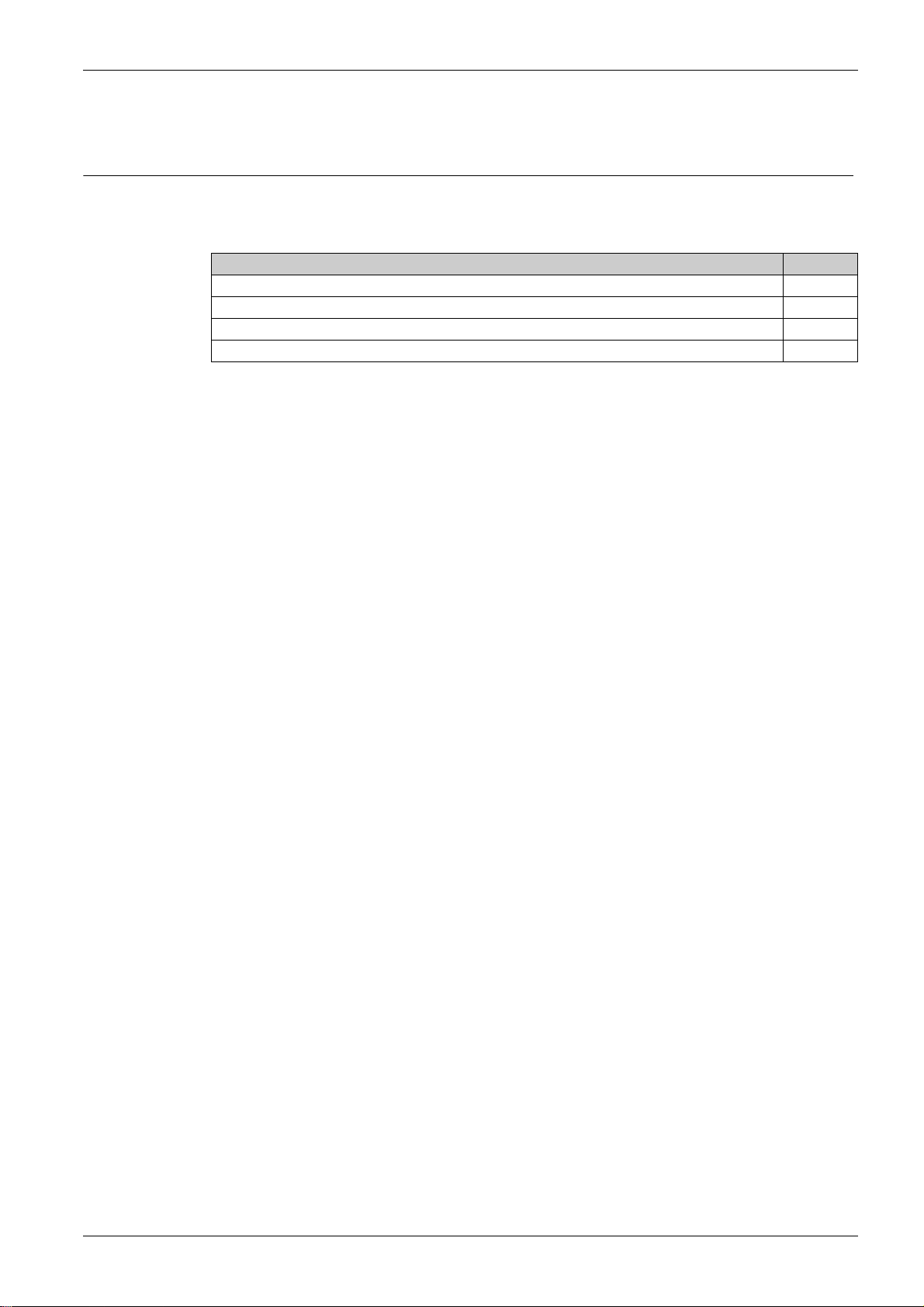

Chapter 5 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Fieldbus Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Commissioning Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Limit Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs and Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying the Signals of the Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying the Safety-Related Function STO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Holding Brake (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direction of Movement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Parameters for Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Controller Optimization with Step Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation of Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the Velocity Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying and Optimizing the P Gain of the Velocity Controller . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the Position Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Parameter Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restoring Factory Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

82

83

85

86

87

90

92

93

94

95

96

97

99

100

102

103

104

105

108

109

111

112

113

Chapter 6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Access Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Movement Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization of the Signal Input Functions and the Signal Output Functions. . . . . . . . .

116

117

118

120

Chapter 7 Operating States and Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7.1 Operating States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State Diagram and State Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicating the Operating State via Signal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indication of the Operating State via Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Operating State via Signal Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Operating State via Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Indicating, Starting and Changing an Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicating the Operating Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Changing an Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Operating Mode Jog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Operating Mode Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Operating Mode Profile Velocity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Operating Mode Profile Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

124

125

128

129

130

131

132

133

134

135

136

139

140

141

142

143

144

145

146

147

148

149

150

152

153

4 0198441113670 08/2020

Page 5

7.7 Operating Mode Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Movement to a Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Movement to the Reference Switch in Positive Direction . . . . . . . . . . . . . . . . . .

Reference Movement to the Reference Switch in Negative Direction. . . . . . . . . . . . . . . . . .

Reference Movement to the Index Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

154

155

157

160

161

162

163

164

165

Chapter 8 Functions for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

8.1 Functions for Target Value Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Profile for the Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping a Movement with Halt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping a Movement with Quick Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting a Signal Output via Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position Capture Via Signal Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Functions for Monitoring Movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load-Dependent Position Deviation (Following Error) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standstill Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Functions for Monitoring Internal Device Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Monitoring (I2t Monitoring) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

168

169

171

172

174

175

177

178

180

181

183

185

187

188

189

Chapter 9 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

191

Chapter 10 Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

10.1 Diagnostics via LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating State LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fieldbus Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Diagnostics via the Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fieldbus Communication Error Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Most Recent Detected Error - Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Most Recent Detected Error - Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Response to Incorrect Realtime Ethernet Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronous Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

194

195

196

197

198

199

201

202

204

205

206

207

208

Chapter 11 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Representation of the Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

214

216

Chapter 12 Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

239

Chapter 13 Service, Maintenance, and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Service Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping, Storage, Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

242

243

245

246

247

251

0198441113670 08/2020 5

Page 6

6 0198441113670 08/2020

Page 7

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

QUALIFICATION OF PERSONNEL

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product. These persons

must have sufficient technical training, knowledge and experience and be able to foresee and detect

potential hazards that may be caused by using the product, by modifying the settings and by the

mechanical, electrical and electronic equipment of the entire system in which the product is used.

The qualified person must be able to detect possible hazards that may arise from parameterization,

modifying parameter values and generally from mechanical, electrical, or electronic equipment.

The qualified person must be familiar with the standards, provisions, and regulations for the prevention of

industrial accidents, which they must observe when designing and implementing the system.

0198441113670 08/2020 7

Page 8

INTENDED USE

The products described in or affected by the present document are, along with software, accessories and

options, motors with an integrated drive. The products are intended for industrial use according to the

instructions, directions, examples, and safety information contained in the present user guide and other

supporting documentation.

The product may only be used in compliance with all applicable safety regulations and directives, the

specified requirements and the technical data.

Prior to using the products, you must perform a risk assessment in view of the planned application. Based

on the results, the appropriate safety-related measures must be implemented.

Since the products are used as components in an overall machine or process, you must ensure the safety

of persons by means of the design of this overall machine or process.

Operate the products only with the specified cables and accessories. Use only genuine accessories and

spare parts.

Any use other than the use explicitly permitted as described herein is prohibited and may result in

unanticipated hazards.

8 0198441113670 08/2020

Page 9

About the Book

At a Glance

Document Scope

This manual describes technical characteristics, installation, commissioning, operation, and maintenance

of the integrated drive ILA2K.

Validity Note

This manual is valid for the standard products listed in the type code, see chapter Type Code

(see page 18)

For product compliance and environmental information (RoHS, REACH, PEP, EOLI, etc.), go to

www.schneider-electric.com/green-premium

The technical characteristics of the devices described in the present document also appear online. To

access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

The characteristics that are described in the present document should be the same as those characteristics that appear online. In line with our policy of constant improvement, we may revise content over time

to improve clarity and accuracy. If you see a difference between the document and online information, use

the online information as your reference.

Product Related Information

The use and application of the information contained herein require expertise in the design and

programming of automated control systems.

Only you, the user, machine builder or integrator, can be aware of all the conditions and factors present

during installation and setup, operation, repair and maintenance of the machine or process.

You must also consider any applicable standards and/or regulations with respect to grounding of all

equipment. Verify compliance with any safety information, different electrical requirements, and normative

standards that apply to your machine or process in the use of this equipment.

The motor itself generates voltage when the motor shaft is rotated.

.

.

.

DANGER

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any covers or

doors, or installing or removing any accessories, hardware, cables, or wires.

Place a "Do Not Turn On" or equivalent hazard label on all power switches and lock them in the non-

energized position.

Block the motor shaft to prevent rotation prior to performing any type of work on the drive system.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a proper

ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

If the power stage is disabled unintentionally, for example as a result of power outage, errors or functions,

the motor is no longer decelerated in a controlled way. Overload, errors or incorrect use may cause the

holding brake to no longer operate properly and may result in premature wear.

0198441113670 08/2020 9

Page 10

WARNING

UNINTENDED EQUIPMENT OPERATION

Verify that movements without braking effect cannot cause injuries or equipment damage.

Verify the function of the holding brake at regular intervals.

Do not use the holding brake as a service brake.

Do not use the holding brake for safety-related purposes.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Drive systems may perform unanticipated movements because of incorrect wiring, incorrect settings,

incorrect data or other errors.

WARNING

UNINTENDED MOVEMENT OR MACHINE OPERATION

Carefully install the wiring in accordance with the EMC requirements.

Do not operate the product with undetermined settings and data.

Perform comprehensive commissioning tests that include verification of configuration settings and

data that determine position and movement.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for certain critical control functions, provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop and overtravel stop, power outage

and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1

1

For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control” and to NEMA ICS 7.1 (latest edition), “Safety

Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive

Systems” or their equivalent governing your particular location.

Machines, controllers, and related equipment are usually integrated into networks. Unauthorized persons

and malware may gain access to the machine as well as to other devices on the network/fieldbus of the

machine and connected networks via insufficiently secure access to software and networks.

10 0198441113670 08/2020

Page 11

WARNING

UNAUTHORIZED ACCESS TO THE MACHINE VIA SOFTWARE AND NETWORKS

In your risk assessment, take into account all hazards that result from access to and operation on the

network/fieldbus and develop an appropriate cyber security conceptual framework.

Verify that the hardware infrastructure and the software infrastructure into which the machine is

integrated, as well as all organizational measures and rules covering access to this infrastructure, take

into account the results of the hazard and risk analysis.

Implement your cyber security framework according to the best practices and standards of IT security

and cyber security, such as ISO/IEC 27000 series, Common Criteria for Information Technology

Security Evaluation, ISO/IEC 15408, IEC 62351, ISA/IEC 62443, NIST Cybersecurity Framework,

Information Security Forum - Standard of Good Practice for Information Security.

Verify the effectiveness of your IT security and cyber security systems using appropriate, proven

methods.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Schneider Electric adheres to industry best practices in the development and implementation of control

systems. This includes a "Defense-in-Depth" approach to secure an Industrial Control System. This

approach places the controllers behind one or more firewalls to restrict access to authorized personnel and

protocols only.

WARNING

UNAUTHENTICATED ACCESS AND SUBSEQUENT UNAUTHORIZED MACHINE OPERATION

Evaluate whether your environment or your machines are connected to your critical infrastructure and,

if so, take appropriate steps in terms of prevention, based on Defense-in-Depth, before connecting the

automation system to any network.

Limit the number of devices connected to a network to the minimum necessary.

Isolate your industrial network from other networks inside your company.

Protect any network against unintended access by using firewalls, VPN, or other, proven security

measures.

Monitor activities within your systems.

Prevent subject devices from direct access or direct link by unauthorized parties or unauthenticated

actions.

Prepare a recovery plan including backup of your system and process information.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

For more information on organizational measures and rules covering access to infrastructures, refer to

ISO/IEC 27000 series, Common Criteria for Information Technology Security Evaluation, ISO/IEC 15408,

IEC 62351, ISA/IEC 62443, NIST Cybersecurity Framework, Information Security Forum - Standard of

Good Practice for Information Security.

For reasons of Internet security, TCP/IP forwarding is disabled by default. Therefore, you must manually

enable TCP/IP forwarding. However, doing so may expose your network to possible cyberattacks if you do

not take additional measures to protect your enterprise. In addition, you may be subject to laws and

regulations concerning cybersecurity.

WARNING

UNAUTHENTICATED ACCESS AND SUBSEQUENT NETWORK INTRUSION

Observe and respect any and all pertinent national, regional and local cybersecurity and/or personal

data laws and regulations when enabling TCP/IP forwarding on an industrial network.

Isolate your industrial network from other networks inside your company.

Protect any network against unintended access by using firewalls, VPN, or other, proven security

measures.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Consult the

Use the latest firmware version. Visit

Schneider Electric Cybersecurity Best Practices

https://www.se.com

for information on firmware updates that may involve Ethernet connections.

for additional information.

or contact your Schneider Electric representative

0198441113670 08/2020 11

Page 12

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or that

appear in or on the products themselves, are generally derived from the terms or definitions of international

standards.

In the area of functional safety systems, drives and general automation, this may include, but is not limited

to, terms such as

,

message

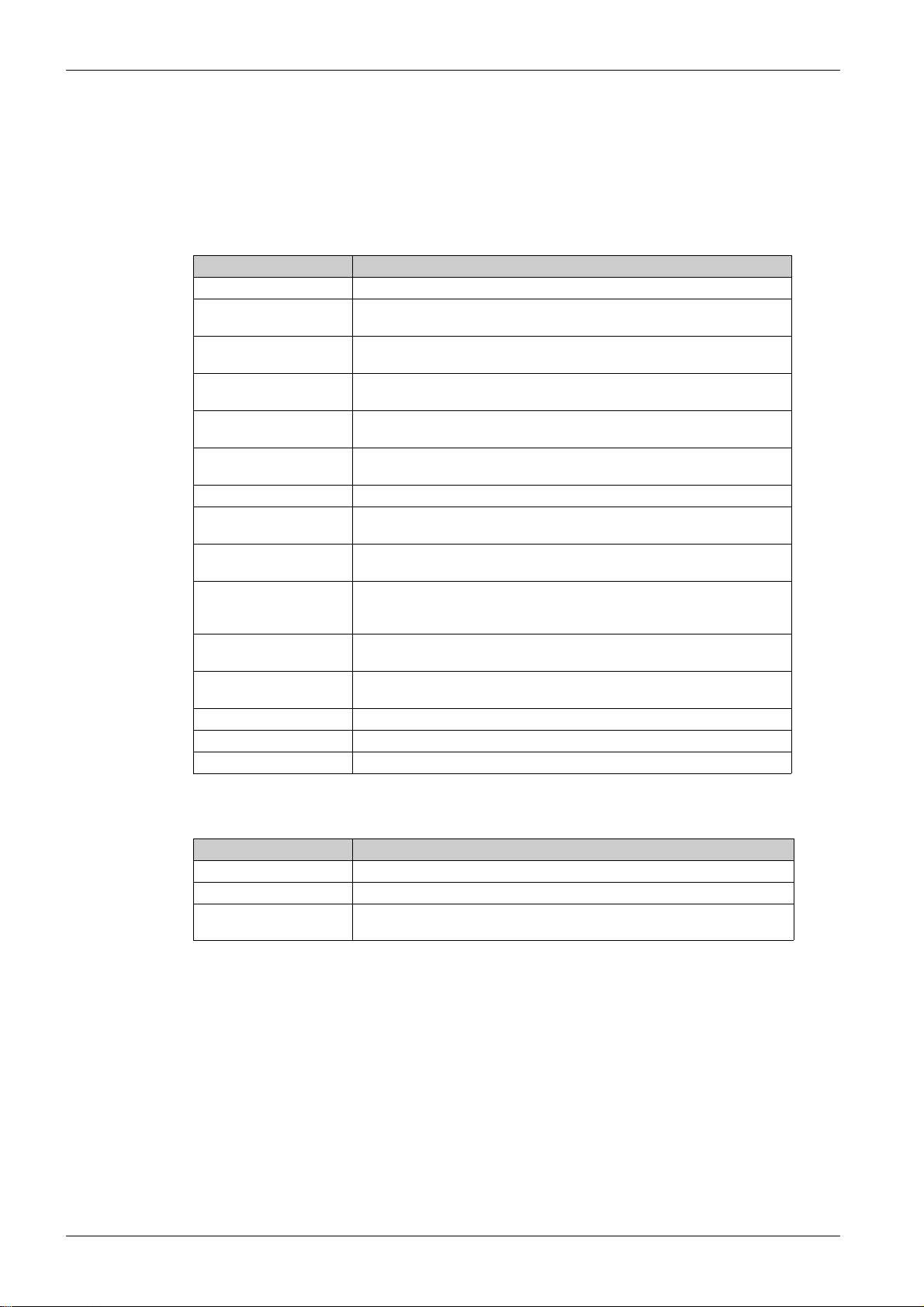

dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

safety, safety function, safe state, fault, fault reset, malfunction, failure, error, error

, etc.

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

In addition, terms used in the present document may tangentially be used as they are derived from other

standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

Finally, the term

zone of operation

is defined as it is for a

ISO 12100:2010

.

industrial control systems

may be used in conjunction with the description of specific hazards, and

hazard zone

or

danger zone

in the

Machinery Directive (2006/42/EC

) and

NOTE: The aforementioned standards may or may not apply to the specific products cited in the present

documentation. For more information concerning the individual standards applicable to the products

described herein, see the characteristics tables for those product references.

12 0198441113670 08/2020

Page 13

ILA2K EtherNet/IP

Introduction

0198441113670 08/2020

Introduc tion

Chapter 1

Introduction

What Is in This Chapter?

This chapter contains the following topics:

Overview of Integrated Drive 14

Components and Interfaces 15

Nameplate 17

Type Code 18

Topic Page

0198441113670 08/2020 13

Page 14

Introduction

Overview of Integrated Drive

Lexium Integrated Drive

The Lexium integrated drive consists of a servo motor and an integrated drive. The product integrates

interfaces, control electronics, a holding brake (optional) and the power stage.

Minimum wiring as well as a comprehensive portfolio of options and accessories allows you to implement

compact, high-performance drive solutions for a wide range of power requirements.

Features

Overview of some of the features:

Fieldbus interface for EtherNet/IP.

The drive is commissioned via a PC with the commissioning software “Lexium CT” or the fieldbus.

Two Drive Profiles are supported:

“Generic Profile” (CIP)

“Drive Profile Lexium” (manufacturer-specific)

Four digital 24 V signals. Each of these signals can be used as an input or output.

The integrated safety-related function Safe Torque Off (STO) as per IEC 61800-5-2 allows for a stop

with stop category 0 as per IEC 60204-1 without external power contactors.

14

0198441113670 08/2020

Page 15

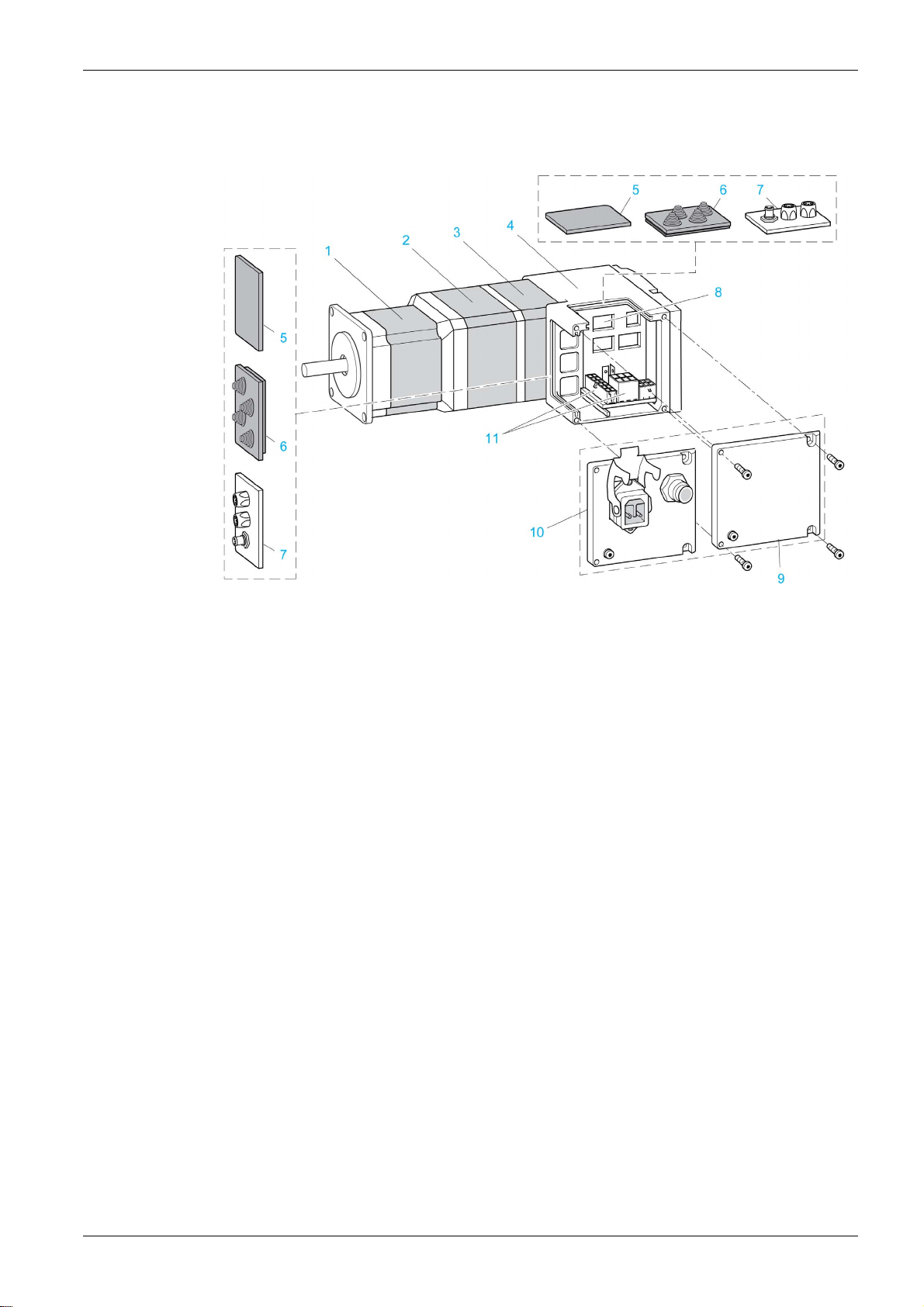

Components and Interfaces

Overview

Introduction

Motor

Electronics

Encoder

1 AC synchronous servo motor

2 Holding brake (optional)

3 Encoder

4 Electronics housing

5 Insert for sealing (accessory)

6 Insert with cable entry (accessory)

7 I/O insert with industrial connectors (accessory)

8 Switches for settings

9 Cover with connector for functional ground, to be removed for installation

10 Cover with industrial connector for Vdc supply voltage and IN/OUT fieldbus connection and with

connector for functional ground (optional)

11 Electrical interfaces

The motor is a brushless AC synchronous servo motor.

The electronic system comprises control electronics and power stage.

The drive can be parameterized and controlled via the fieldbus interface.

Four digital 24 V signals are also available. Each of these signals can be used as an input or output.

The integrated drive features a singleturn or a multiturn encoder, depending on the drive version.

The singleturn encoder has an internal resolution of 32768 increments per revolution.

The scaling of the integrated drive is set to 16384 user-defined units per revolution.

The multiturn encoder covers a range of 4096 motor revolutions.

Holding Brake

The integrated drive is available with an optional integrated holding brake. The holding brake is controlled

automatically.

0198441113670 08/2020 15

Page 16

Introduction

Vdc Supply Voltage

The Vdc supply voltage supplies the control electronics and the power stage.

Fieldbus Interface

The integrated drive features an EtherNet/IP fieldbus interface.

The fieldbus interface is used for parameterizing and controlling the drive. The fieldbus interface allows the

integrated drive to be operated on a fieldbus via a master controller, for example, a logic controller.

Communication Interface RS-485

The RS-485 interface is used for commissioning the drive by means of the commissioning software.

The firmware can be updated via the RS-485 interface. Contact your Schneider Electric service representative for any firmware update.

24 Vdc Signal Interface

Four digital 24 Vdc signals are available. Each of these signals can be used as an input or output.

The 24 Vdc signals are available to the master controller.

16

0198441113670 08/2020

Page 17

Nameplate

Overview

Introduction

The nameplate contains the following data:

1 Type code

2 Type code (previous)

3 Nominal voltage

4 Nominal torque

5 Maximum input current

6 Nominal speed of rotation

7 Date of manufacture

8 Thermal class

9 Maximum surrounding air temperature

10 Firmware version

11 Hardware version

12 Firmware number

13 Commercial reference

14 Serial number

0198441113670 08/2020 17

Page 18

Introduction

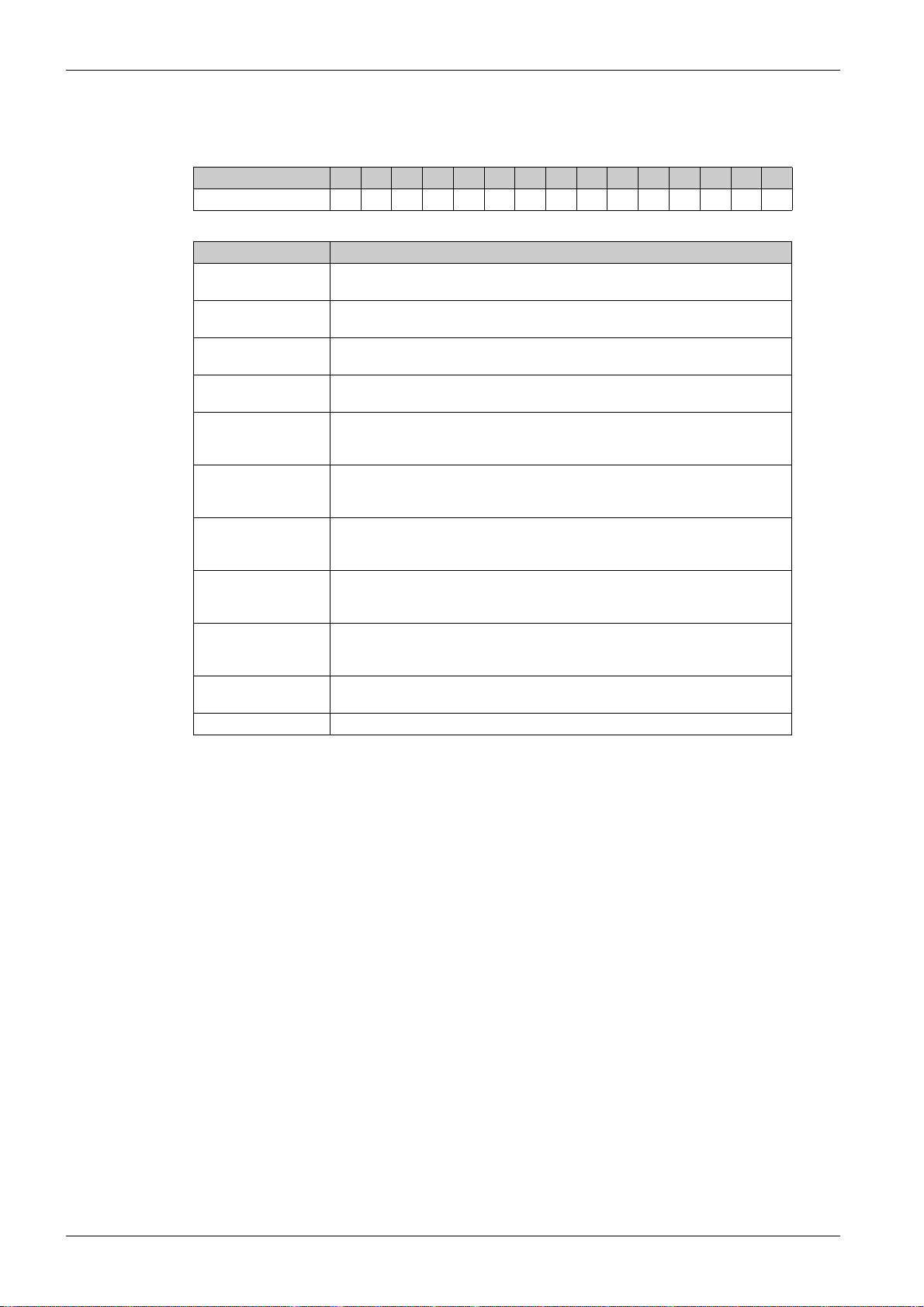

Type Code

Overview

Item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Type code (example) I L A 2 K 5 7 1 P B 1 A 0 • •

Item Meaning

1 ... 3 Product family

ILA = Servo motor

4 Supply voltage

2 = 24 ... 48 Vdc

5 Fieldbus interface

K = EtherNet/IP

6 ... 7 Size

57 = 57 mm

8 Length

1 = 1 stack

2 = 2 stacks

9 Winding

P = Medium speed of rotation/medium torque

T = High speed of rotation/medium torque

10 Connection version

B = Printed circuit board connector

C = Industrial connector

11 Encoder

1 = Servo Singleturn

2 = Servo Multiturn

12 Holding brake

A = Without holding brake

F = With holding brake

13 Gearbox

0 = Without gearbox

14 ... 15 Reserved

If you have questions concerning the type code, contact your Schneider Electric representative.

Designation Customized Version

In the case of a customized version, position 9 of the type code is an "S". The subsequent number defines

the customized version. Example: IL••••••S1234--

Contact your local Schneider Electric service representative if you have questions concerning customized

versions.

18

0198441113670 08/2020

Page 19

ILA2K EtherNet/IP

Technical Data

0198441113670 08/2020

Technical Data

Chapter 2

Technical Data

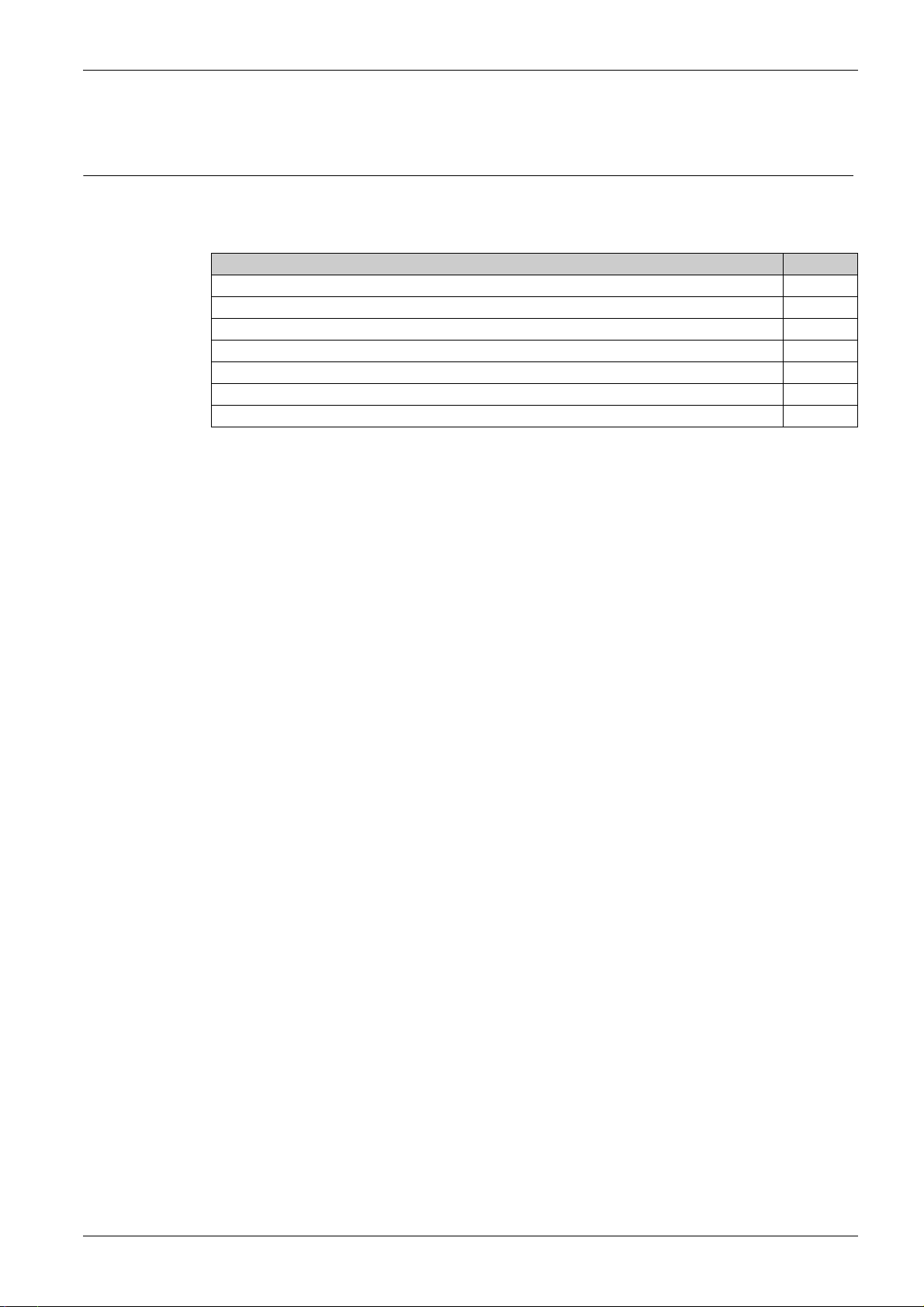

What Is in This Chapter?

This chapter contains the following topics:

Environmental Conditions 20

Mechanical Data 22

Electrical Data 23

Electromagnetic Compatibility 26

Shaft-Specific Data 27

Data for Safety-Related Function STO 28

Conditions for UL 508C and CSA 29

Topic Page

0198441113670 08/2020 19

Page 20

Technical Data

Environmental Conditions

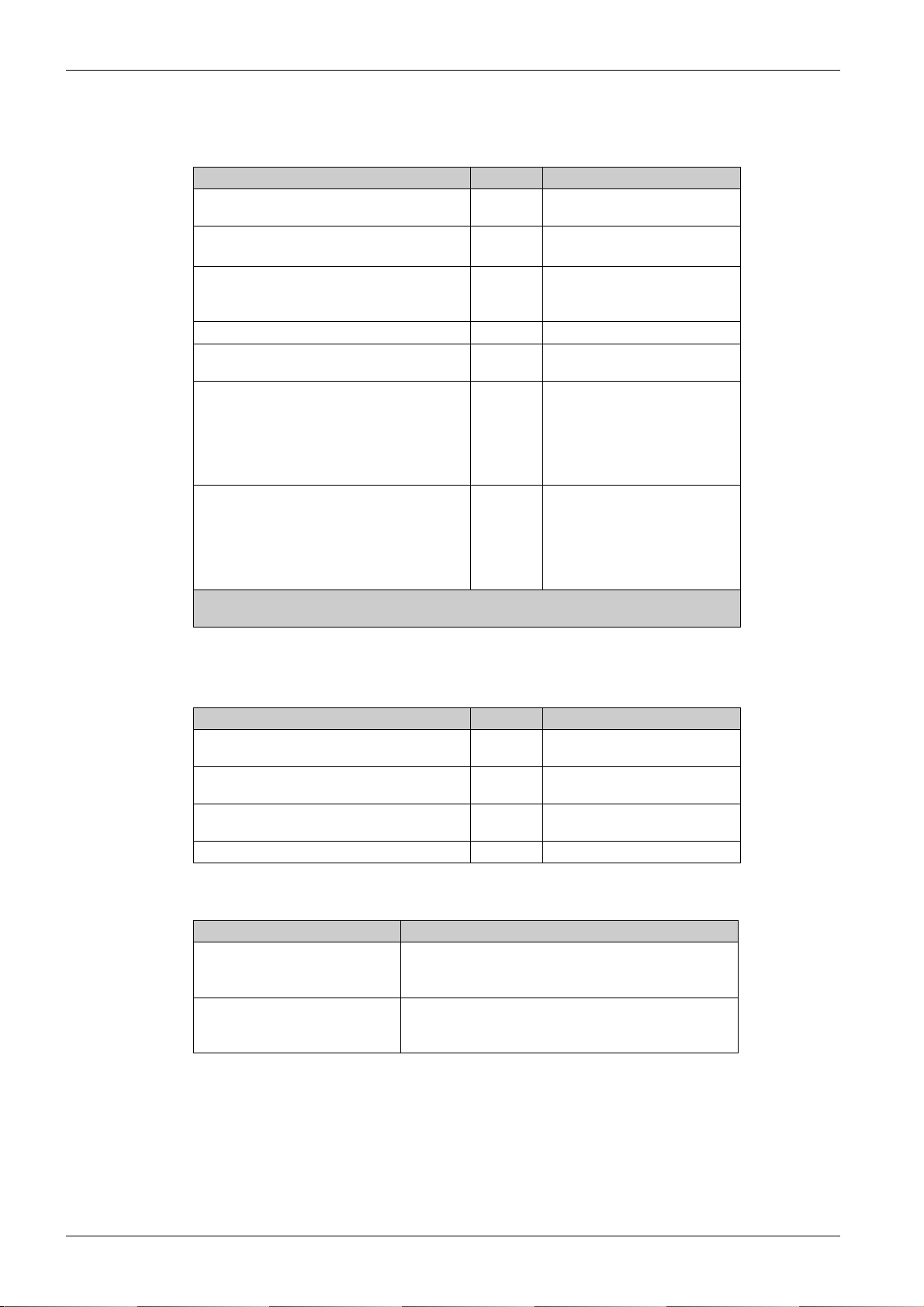

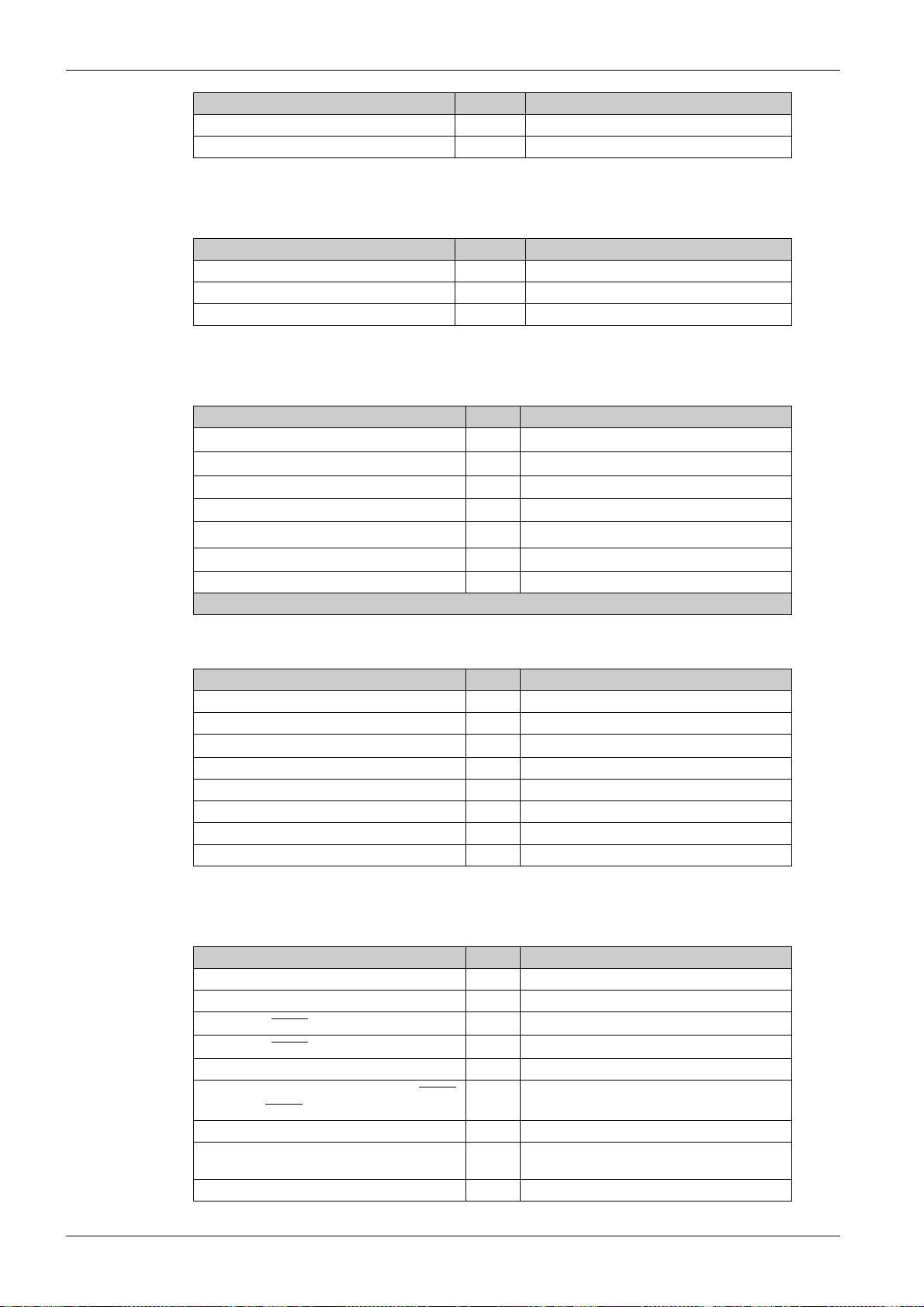

Environmental Conditions for Operation

Characteristic Unit Value

Chemically active substances as per IEC 607213-3, operation

Ambient temperature (no icing, non-

condensing)

Ambient temperature with current derating of 2 %

per one degree Celsius (per 1.8 degrees

Fahrenheit)

Relative humidity % 15 ... 85

Installation altitude

Installation altitude

conditions are met:

45 °C (113 °F) maximum ambient

temperature

Reduction of the continuous power by 1% per

100 m (328 ft) above 1000 m (3281 ft)

Installation altitude

of the following conditions are met:

40 °C (104 °F) maximum ambient

temperature

Reduction of the continuous power by 1% per

100 m (328 ft) above 1000 m (3281 ft)

(1) Limit values with flanged motor (for example, steel plate 300 x 300x10 mm).

(2) The installation altitude is defined in terms of altitude above mean sea level.

(1)

(1)

(2)

(2)

if all of the following

(2)

above mean sea level if all

°C

(°F)

°C

(°F)

m

(ft)

m

(ft)

m

(ft)

3C1

0...40

(32 ... 104)

40 ... 55

(104 ... 131)

< 1000

(< 3281)

1000 ... 2000

(3281 ... 6562)

2000 ... 3000

(6562 ... 9843)

Environmental Conditions for Transportation and Storage

The environment during transportation and storage must be dry and free from dust.

Characteristic Unit Value

Chemically active substances as per IEC 607213-2, transportation

Chemically active substances as per IEC 607213-1, storage

Ambient temperature (no icing, non-condensing) °C

Relative humidity (non-condensing) % 5 ... 80

Vibration and Shock

Characteristic Value

Vibration, sinusoidal Type test with 10 runs as per IEC 60068-2-6

0.15 mm (10 Hz ... 60 Hz)

20 m/s

Shock, semi-sinusoidal Type test with 3 shocks in each direction as per IEC 60068-

2-27

150 m/s

(°F)

2

(60 Hz 500 Hz)

2

(11 ms)

3C1

3C1

-25 ... 70

(-13 ... 158)

20

0198441113670 08/2020

Page 21

IP Degree of Protection

The integrated drive has the following IP degree of protection as per IEC 60529:

Item Component Degree of protection

1 Shaft bushing

2 Housing, except shaft bushing IP54

(1) In the case of mounting position IM V3 (shaft vertical, shaft end upward), the degree of protection is IP

The total degree of protection is determined by the component with the lowest degree of protection.

Pollution Degree

Technical Data

(1)

Shaft bushing with GBX gearbox (accessory)

40. The degree of protection does not relate to mounted components such as, for example, a gearbox.

IP41

IP54

Characteristic Value

Pollution degree 2

0198441113670 08/2020 21

Page 22

Technical Data

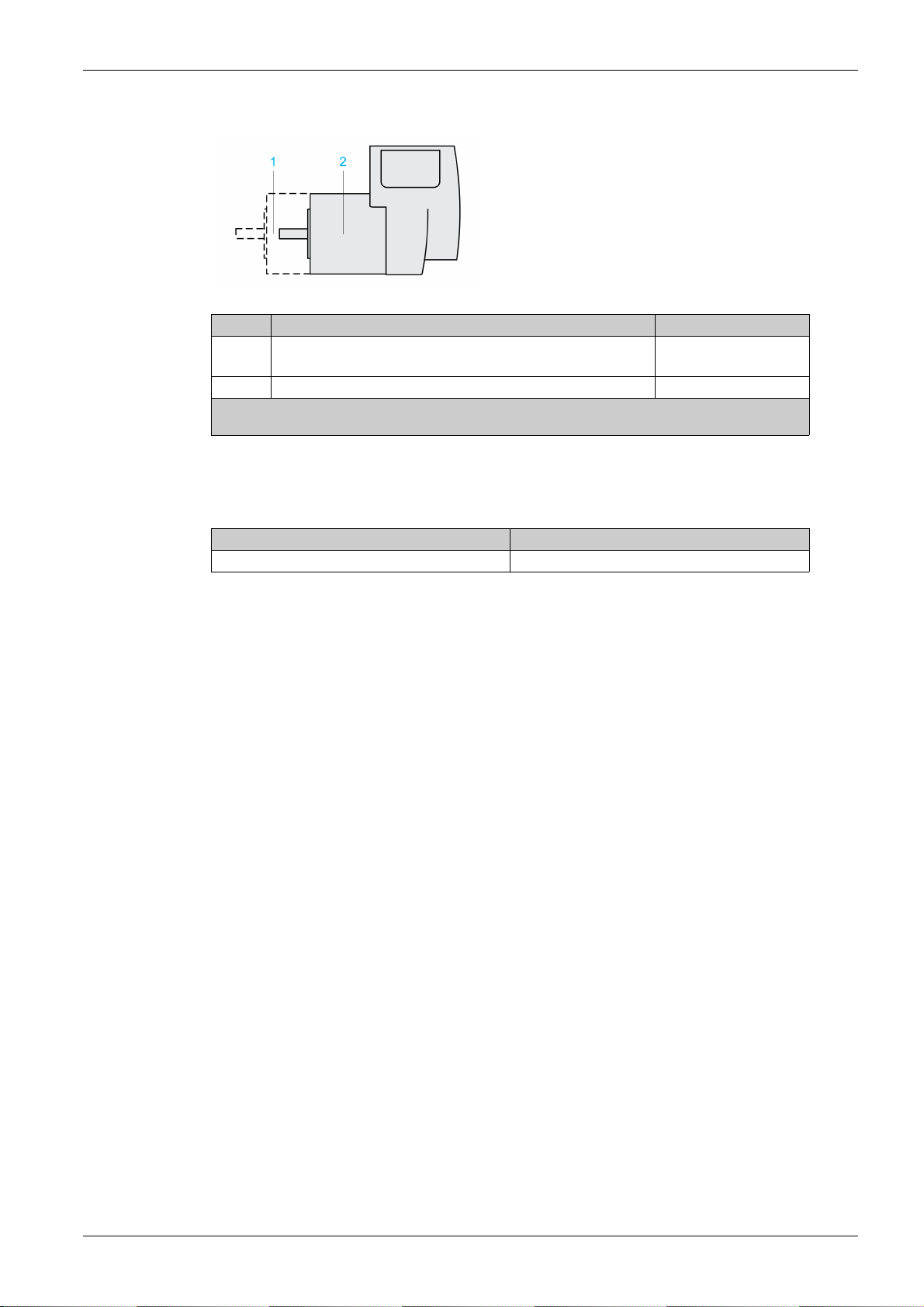

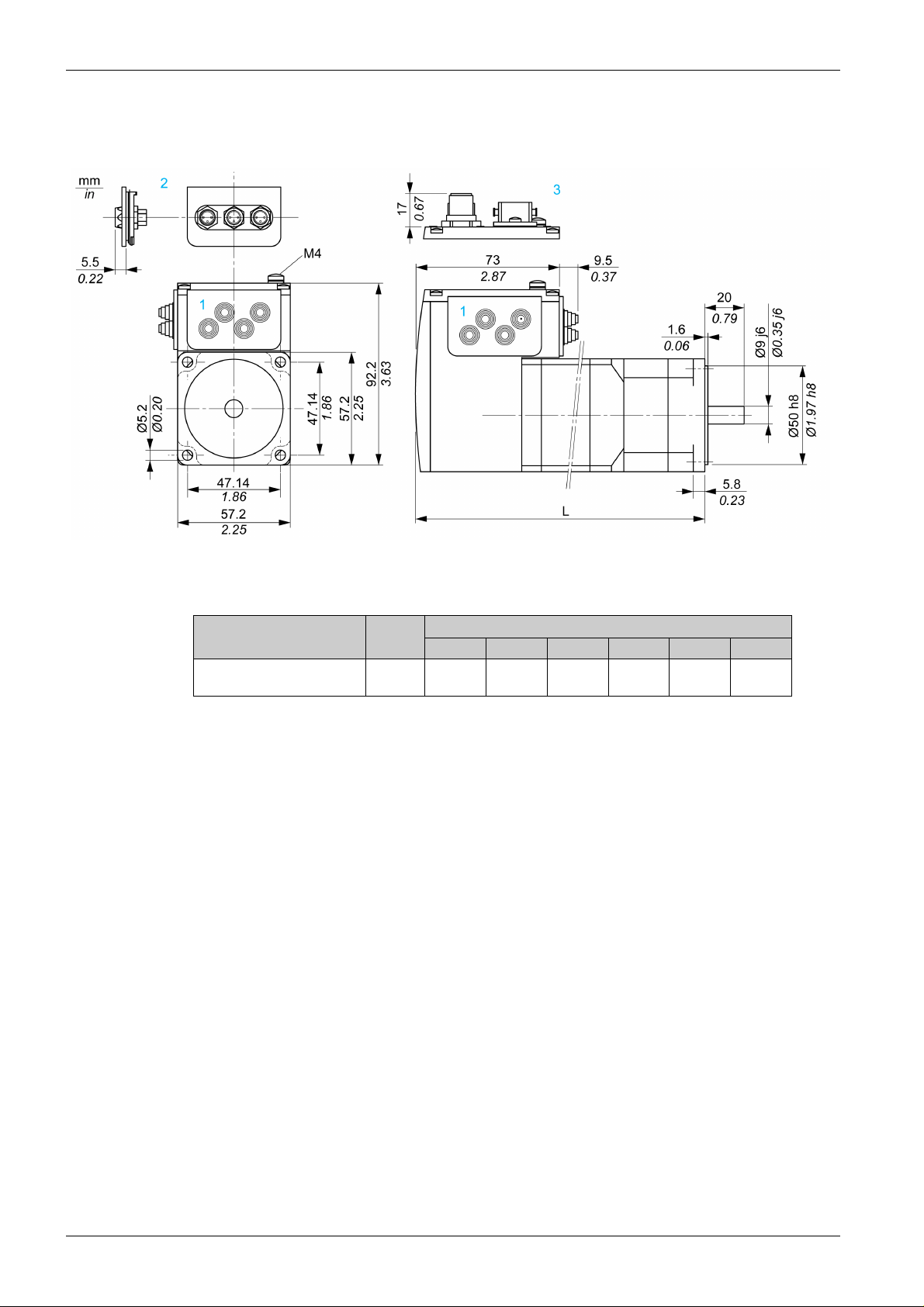

Mechanical Data

Dimensions

1 Insert with cable entry (accessory)

2 Insert kit (accessory)

3 Industrial connector (option)

Dimension Unit ILA••57...

1••1A0 1••2A0 1••1F0 2••1A0 2••2A0 2••2F0

Total length L mm

(in)

145.3

(5.72)

179.3

(7.06)

190.8

(7.51)

163.8

(6.45)

197.8

(7.79)

209.3

(8.24)

22

0198441113670 08/2020

Page 23

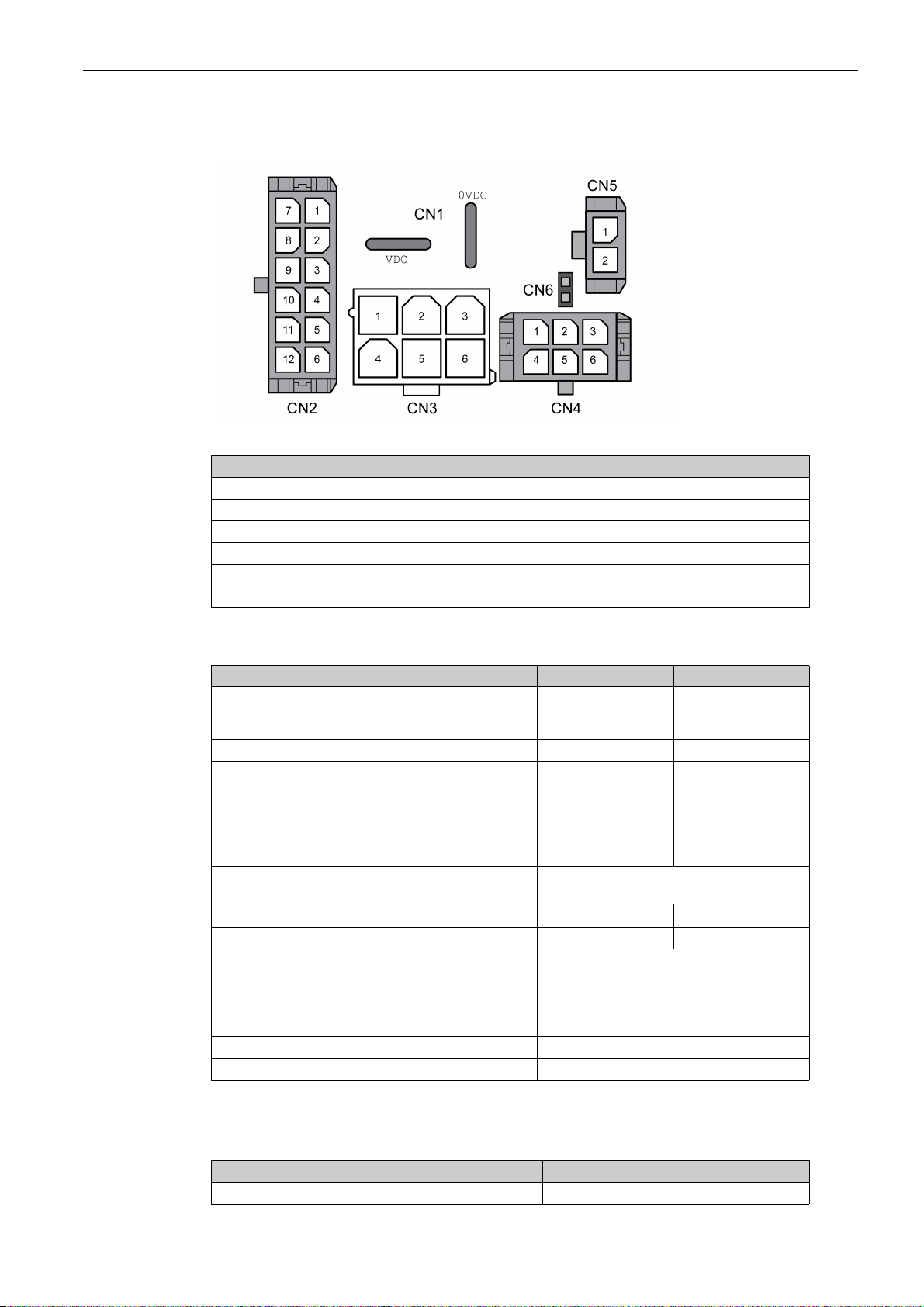

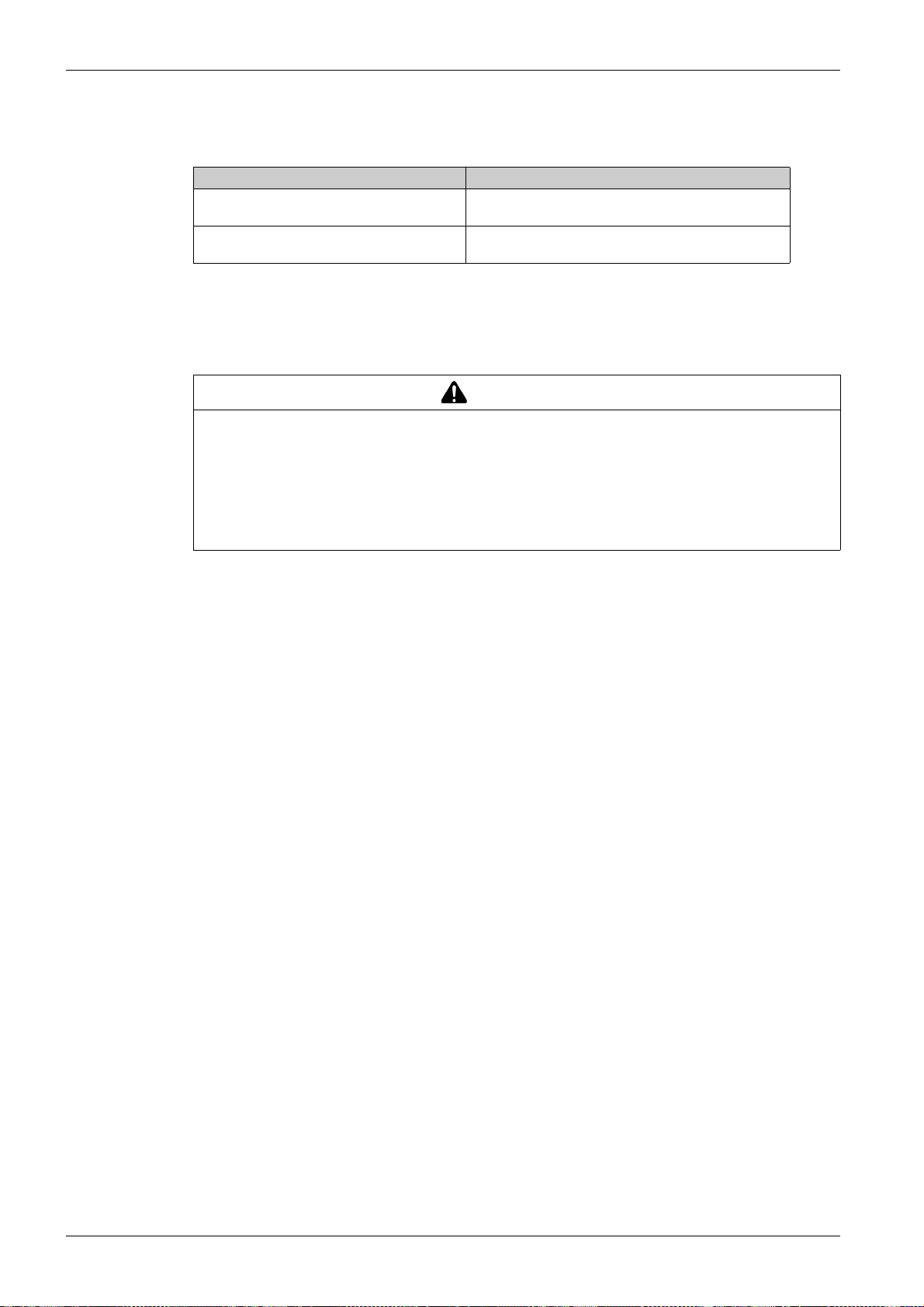

Electrical Data

Overview of Connectors

Connection Assignment

CN1 Connectors for Vdc supply voltage

CN2 Fieldbus interface for EtherNet/IP

CN3 Commissioning interface

CN4 24 V signal interface

CN5 Connector for the safety-related function STO

CN6 Jumper for activating and deactivating the safety-related function STO

Technical Data

CN1: Vdc Supply Voltage

Characteristic Unit ILA••571 ILA••572

Nominal voltage

Minimum voltage

Maximum voltage

Ripple at nominal voltage Vpp ≤3.6 ≤3.6

Maximum input current

Winding type P

Winding type T

Peak input current

Winding type P

Winding type T

Overvoltage category - III at input of power supply unit, II at output of

Capacitance at VDC to 0VDC (for inrush current) µF 1500 1500

Fuse rating of fuse to be connected upstream A ≤15 ≤15

Type of fuse or circuit breaker to be connected

upstream

PELV - Required

Galvanic isolation - No

Vdc 24 / 48

18

55.2

A

5

7.5

A

7

11

power supply unit (as per IEC 61800-5-1)

-

Circuit-breaker (type Multi 9 - C60BP,

M9F42115 by Schneider Electric, 15 A,

tripping characteristic C), or

Blade fuse (FKS, 15 A maximum), or

Fuse (5 x 20 mm, 10 A, slow-blow)

24 / 48

18

55.2

7

7.5

8.5

9

CN2: Fieldbus Interface

The EtherNet/IP signals comply with the IEEE 802.3 standard.

Characteristic Unit Value

Transmission rate MBit 10 / 100

0198441113670 08/2020 23

Page 24

Technical Data

Characteristic Unit Value

Transmission protocol - EtherNet/IP

Galvanic isolation - Yes

CN3: Commissioning Interface

The RS485 signals comply with the RS485 standard.

Characteristic Unit Value

Transmission rate kBaud 9.6 / 19.2 / 38.4

Transmission protocol - Modbus RTU

Galvanic isolation - No

CN4: 24 V Signals

The signal inputs are not protected against reverse polarity.

Characteristic Unit Value

Logic 0 (U

Logic 1 (U

Input current at 24 Vdc mA 2

Debounce time LIO1 ... LIO4 ms 1.25 ... 1.5

Debounce time LIO1 and LIO2

Jitter LIO1 and LIO2 ms <2

Galvanic isolation - No

(1) When the function "Fast Position Capture" is used

) V -3 ... 4.5

low

)V15...30

high

(1)

ms 0.01

The internal 24 V power supply and the signal outputs are short-circuit protected.

Characteristic Unit Value

Nominal voltage V 24

Voltage range V 23 ... 25

Maximum current +24VDC_OUT mA 200

Maximum current per output mA 100

Maximum total current mA 200

Suitable for inductive loads mH 1000

Voltage drop at 50 mA load V ≤1

Galvanic isolation - No

CN5 and CN6: Safety-Related Function STO

Jumper CN6 to deactivate the safety-related function STO.

Characteristic Unit Value

Voltage for logic level 0 V -3 ...4.5

Voltage for logic level 1 V 15 ... 30

Input current STO_A

Input current STO_B

Debounce time ms 1

Detection of difference between level of STO_A

and level of STO_B

Response time of safety-related function STO ms <50

Permissible duration of test pulses from

upstream devices

PELV - Required

at 24 Vdc mA ≤10

at 24 Vdc mA ≤3

s>1

ms <1

24

0198441113670 08/2020

Page 25

Characteristic Unit Value

Galvanic isolation - No

Technical Data

0198441113670 08/2020 25

Page 26

Technical Data

Electromagnetic Compatibility

Electromagnetic Compatibility (EMC)

Characteristic Value

Emission Category C2 as per IEC 61800-3

Immunity Use permissible in second environment as per EN 61800-

NOTE: The emission category is independent of immunity. For example, if a power drive system has

emission category 2, this does not imply that it is only suitable for the first environment.

The equipment described in the present document is not intended for use in domestic, residential

environments and may not provide adequate protection to radio reception in such environments.

INSUFFICIENT ELECTROMAGNETIC COMPATIBILITY

Verify compliance with all EMC regulations and requirements applicable in the country in which the

device is to be operated and with all EMC regulations and requirements applicable at the installation

site.

Do not install and operate the devices described in the present document in residential environments.

Implement all required radio interference suppression measures and verify their effectiveness.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Compliant with IEC 61000-6-4

3

WARNING

NOTE: Compliance of the product described in the present manual with Directive 2014/30/EU of the

European Parliament and the Council (EMC Directive) is declared with reference to the harmonized

standard EN 61800-3 “Adjustable speed power drive systems - Part 3: EMC requirements and specific test

methods”. With regard to equipment of category 2, this harmonized standard and the Directive itself oblige

manufacturers to include the following statement in their product documentation: “In a domestic

environment this product may cause radio interference in which case supplementary mitigation measures

may be required.”

26

0198441113670 08/2020

Page 27

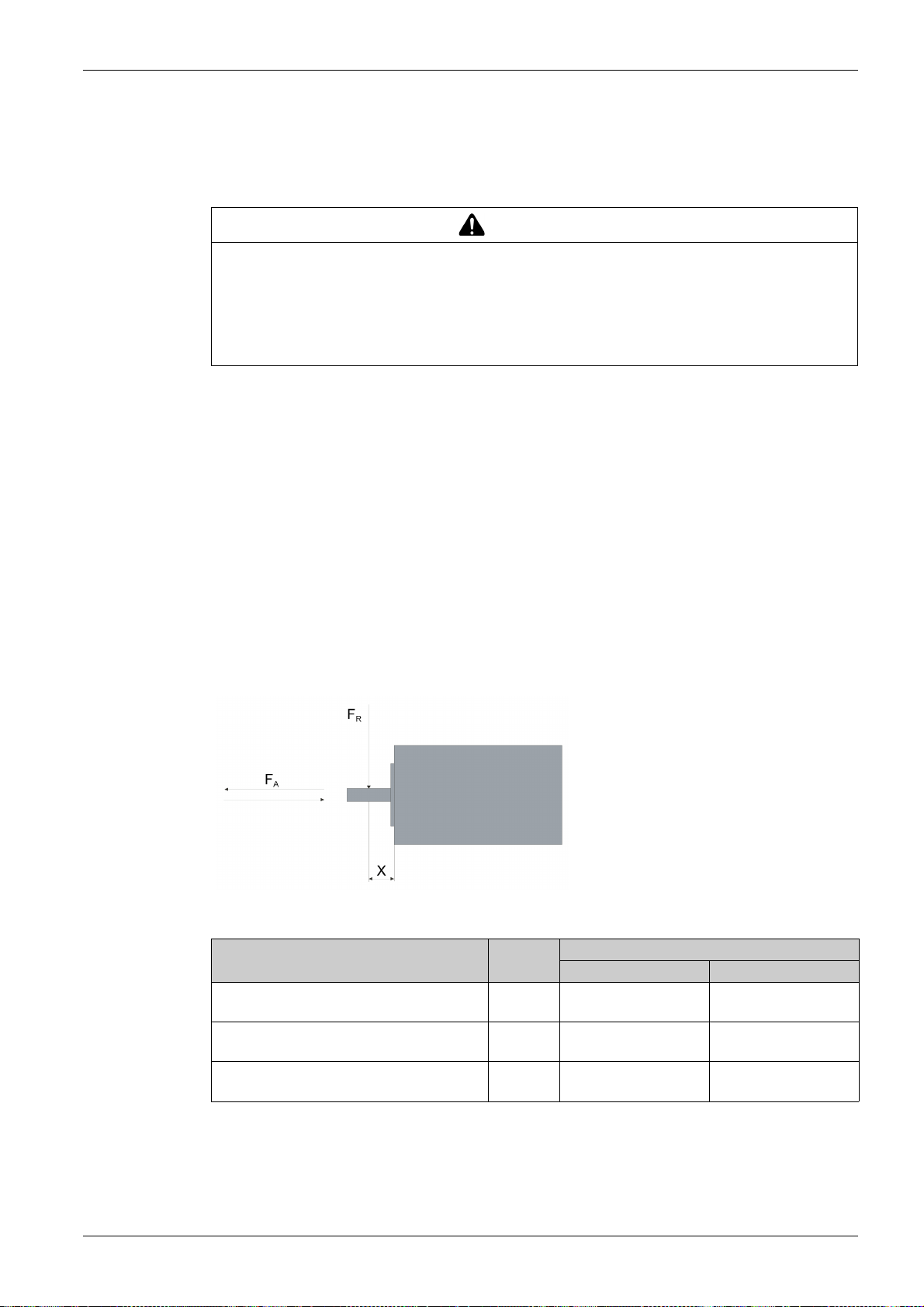

Shaft-Specific Data

Overview

If the maximum permissible forces at the motor shaft are exceeded, this will result in premature wear of the

bearing or shaft breakage.

UNINTENDED EQUIPMENT OPERATION DUE TO MECHANICAL DAMAGE TO THE MOTOR

Do not exceed the maximum permissible axial and radial forces at the motor shaft.

Protect the motor shaft from impact.

Do press output components onto the shaft unless the shaft has a thread that can be used for pressing

on.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Mounting Output Components

If the shaft has a thread, use it to press on the component to be mounted. This way there is no axial force

acting on the rolling bearing.

It is also possible to shrink-fit, clamp, or glue the component to be mounted.

Shaft Load

The following conditions apply:

The permissible force applied during pressing on must not be exceeded.

The maximum permissible radial force and the maximum permissible axial force must not be applied

simultaneously.

Nominal bearing service life in operating hours at a probability of failure of 10% (L

Mean speed of rotation n = 4000 RPM

Ambient temperature = 40 °C (104 °F)

Nominal torque = Duty type S1, 100% duty cycle

The following figure shows the points of application of forces:

WARNING

Technical Data

= 20000 hours)

10h

The following table shows the maximum radial and axial forces:

Characteristic Unit Value

ILA2•571 ILA2•572

Maximum radial force F

X = 10 mm (0.39 in)

Maximum axial force F

tension

Maximum axial force F

compression

0198441113670 08/2020 27

at 100% duty cycle and

R

at 100% duty cycle,

A

at 100% duty cycle,

A

N (lbf) 89 (20.01) 107 (24.05)

N (lbf) 104 (23.38) 104 (23.38)

N (lbf) 104 (23.38) 104 (23.38)

Page 28

Technical Data

Data for Safety-Related Function STO

Data for Safety-Related Calculations and Maintenance Plan

The safety-related function must be triggered at regular intervals. The interval depends on, among other

things, the risk assessment for the overall system. The minimum interval is one year (high demand mode

as per IEC 61508).

Use the following data of the safety-related function STO for the maintenance plan of your machine and

for the calculations for functional safety:

Lifetime of the safety-related function STO

(IEC 61508)

SFF (IEC 61508)

Safe Failure Fraction

HFT (IEC 61508)

Hardware Fault Tolerance

Type A subsystem

Safety Integrity Level (IEC 61508)

Safety Integrity Level Claim Limit (IEC 62061)

PFH (IEC 61508)

Probability of Dangerous Hardware Failure per

Hour

PL (ISO 13849-1)

Performance Level

MTTF

Mean Time to Dangerous Failure

DC (ISO 13849-1)

Diagnostic Coverage

Demand Mode (IEC 61508) - High Demand Mode (safety-related function

(1) Refer to the chapter Lifetime Safety-Related Function STO

(1)

(ISO 13849-1)

d

Years 20

%47

-1

-SIL2

1/h

- d (category 3)

Years 1995

%90

SILCL2

5.223*10

must be triggered at least once per year)

-9

(see page 244)

.

Contact your local Schneider Electric representative for additional data, if required.

28

0198441113670 08/2020

Page 29

Conditions for UL 508C and CSA

Description

If the product is used to comply with UL 508C, the following conditions must also be met:

PELV Power Supply

Use only power supply units that are approved for overvoltage category III.

Motor Overload Protection

This equipment provides Solid State Motor Overload Protection at 200 % of maximum FLA (Full Load

Ampacity).

Fuses

The product was tested with a UL-listed 15 A circuit breaker. The product must be fused either with a ULlisted circuit breaker or a fuse for "Branch Circuit Protection" as per UL 248 with a maximum current of 15 A

and DC rating.

Wiring

Use at least 60/75 °C copper conductors.

Technical Data

0198441113670 08/2020 29

Page 30

Technical Data

30

0198441113670 08/2020

Page 31

ILA2K EtherNet/IP

Engineering

0198441113670 08/2020

Engineering

Chapter 3

Engineering

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

3.1 Electromagnetic Compatibility (EMC) 32

3.2 Power Supply 34

3.3 Functional Safety 37

3.4 EtherNet/IP Fieldbus 44

3.5 EtherNet/IP Communication 48

0198441113670 08/2020 31

Page 32

Engineering

Electromagnetic Compatibility (EMC)

Section 3.1

Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC)

EMC-Compliant Wiring

This product meets the EMC requirements according to the standard EN 61800-3 if the measures

described in this manual are implemented during installation.

Signal interference can cause unexpected responses of the drive system and of other equipment in the

vicinity of the drive system.

SIGNAL AND EQUIPMENT INTERFERENCE

Install the wiring in accordance with the EMC requirements described in the present document.

Verify compliance with the EMC requirements described in the present document.

Verify compliance with all EMC regulations and requirements applicable in the country in which the

product is to be operated and with all EMC regulations and requirements applicable at the installation

site.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

Shielded Cables

WARNING

ELECTROMAGNETIC DISTURBANCES OF SIGNALS AND DEVICES

Use proper EMI shielding techniques to help prevent unintended device operation in accordance with the

standard IEC 61800-3.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Refer to the chapter Electromagnetic Compatibility

NOTE: The emission category is independent of immunity. For example, if a power drive system has

emission category 2, this does not imply that it is only suitable for the first environment.

The equipment described in the present document is not intended for use in domestic, residential

environments and may not provide adequate protection to radio reception in such environments.

(see page 26)

for technical data on EMC.

WARNING

INSUFFICIENT ELECTROMAGNETIC COMPATIBILITY

Verify compliance with all EMC regulations and requirements applicable in the country in which the

device is to be operated and with all EMC regulations and requirements applicable at the installation

site.

Do not install and operate the devices described in the present document in residential environments.

Implement all required radio interference suppression measures and verify their effectiveness.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

32

EMC measures Objective

Connect large surface areas of cable shields, use cable clamps and

ground straps.

Ground shields of digital signal wires at both ends by connecting them to

a large surface area or via conductive connector housings.

Reduces emissions.

Reduces interference affecting the

signal wires, reduces emissions

0198441113670 08/2020

Page 33

Cable Installation

EMC measures Objective

Do not route fieldbus cables and signal wires in a single cable duct

Reduces mutual interference

together with lines with DC and AC voltages of more than 60 V. (Fieldbus

cables, signal lines and analog lines may be in the same cable duct)

Use separate cable ducts at least 20 cm (7.87 in) apart.

Keep cables as short as possible. Do not install unnecessary cable

loops, use short cables from the central grounding point in the control

Reduces capacitive and inductive

interference.

cabinet to the external ground connection.

Use equipotential bonding conductors in the following cases: wide-area

installations, different voltage supplies and installation across several

Reduces current in the cable

shield, reduces emissions.

buildings.

Use fine stranded equipotential bonding conductors. Diverts high-frequency

interference currents.

If motor and machine are not conductively connected, for example by an

insulated flange or a connection without surface contact, you must

Reduces emissions, increases

immunity.

ground the motor with a ground strap or a ground wire. The conductor

2

cross section must be at least 10 mm

(AWG 6).

Engineering

0198441113670 08/2020 33

Page 34

Engineering

Power Supply

Section 3.2

Power Supply

What Is in This Section?

This section contains the following topics:

External Power Supply Units 35

Wiring Information 36

Topic Page

34

0198441113670 08/2020

Page 35

External Power Supply Units

General Information

UNINTENDED EQUIPMENT OPERATION

Use power supply units that meet the PELV (Protective Extra Low Voltage) requirements.

Connect the 0 Vdc outputs of all power supply units to FE (functional earth/functional ground), for

example, for the VDC supply voltage and for the 24 Vdc voltage for the safety-related function STO.

Interconnect all 0 Vdc outputs (reference potentials) of all power supply units used for the drive.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The motor regenerates energy during deceleration and when external driving forces act on the motor shaft.

This can increase the VDC voltage up to 60 Vdc. The DC bus can absorb a limited amount of energy via

the capacitors. If the capacity of the capacitors is exceeded, this results in overvoltage on the DC bus.

Overvoltage on the DC bus causes the power stage to be disabled. The motor is no longer actively

decelerated.

LOSS OF CONTROL DUE TO REGENERATION CONDITION

Verify that the integrated drive can absorb the entire energy generated during deceleration by

performing test runs under maximum load conditions.

Install an external Braking Resistor Controller (UBC60) if the integrated drive cannot absorb the entire

energy generated under maximum load conditions.

Verify that all equipment is properly isolated from high Vdc voltage for which it is not rated, or use

properly rated equipment.

Only use power supply units that can withstand the voltage that may be present during regeneration

conditions.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Engineering

WARNING

WARNING

Fusing

Refer to the chapter Accessories

of the braking resistor controller for additional details.

Reverse polarity of the Vdc supply voltage leads to a short-circuit.

(see page 239)

for a braking resistor controller. Refer to the user guide

NOTICE

INCORRECT POLARITY

Verify correct polarity of the Vdc supply voltage before applying power.

Failure to follow these instructions can result in equipment damage.

The external power supply unit must be rated for the power requirements of the drive. Refer to the chapter

Electrical Data

Install the fusing specified in the chapter Electrical Data

(see page 23)

for the input current.

(see page 23)

.

0198441113670 08/2020 35

Page 36

Engineering

Wiring Information

Description

The reference potential of interfaces without galvanic isolation is internally connected via 0VDC. If the

negative connection (0VDC) between the power supply and the drive is interrupted, the current of the

power stage flows via the negative connection of the interfaces without galvanic isolation.

WARNING

LOSS OF CONTROL

Do not interrupt the negative connection between the power supply unit and the drive, for example, by

means of a switch or a fuse.

Connect the reference potential of interfaces with galvanic isolation to 0VDC.

Do not connect the reference potential of interfaces without galvanic isolation to 0VDC.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Wiring the product:

Keep the voltage drop on the supply cables for the Vdc supply voltage to less than 1 V. The reference

potential of some interfaces are connected to 0VDC. At higher potential differences, the communication

and control signals can be disturbed.

Decentralized power supply units for VDC close to the drives are advisable if the drives are installed at

greater distances from each other. Connect 0VDC of the individual power supply units with the largest

possible conductor cross section.

Do not connect any other power supply in parallel with the internal 24 V power supply (+24VDC_OUT).

This may cause overloads of the internal 24 V power supply.

Equipotential Bonding Conductors

Potential differences can result in excessive currents on the cable shields. Use equipotential bonding

conductors to reduce currents on the cable shields. The equipotential bonding conductor must be rated for

the maximum current.

36

0198441113670 08/2020

Page 37

Functional Safety

Section 3.3

Functional Safety

What Is in This Section?

This section contains the following topics:

Definitions 38

Function 39

Requirements for Using the Safety-Related Function STO 40

Application Examples STO 42

Engineering

Topic Page

0198441113670 08/2020 37

Page 38

Engineering

Definitions

Integrated Safety-Related Function "Safe Torque Off" STO

The integrated safety-related function STO (IEC 61800-5-2) allows for a category 0 stop as per IEC 602041 without external power contactors. It is not necessary to interrupt the supply voltage for a category 0 stop.

This reduces the system costs and the response times.

Category 0 Stop (IEC 60204-1)

In stop category 0 (Safe Torque Off, STO), the drive coasts to a stop (provided there are no external forces

operating to the contrary). The safety-related function STO is intended to help prevent an unintended startup, not stop a motor, and therefore corresponds to an unassisted stop in accordance with IEC 60204-1.

In circumstances where external influences are present, the coast down time depends on physical

properties of the components used (such as weight, torque, friction, etc.), and additional measures such

as external safety-related brakes may be necessary to help prevent any hazard from materializing. That is

to say, if this means a hazard to your personnel or equipment, you must take appropriate measures.

UNINTENDED EQUIPMENT OPERATION

Make certain that no hazards can arise for persons or material during the coast down period of the

axis/machine.

Do not enter the zone of operation during the coast down period.

Ensure that no other persons can access the zone of operation during the coast down period.

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

Category 1 Stop (IEC 60204-1)

For stops of category 1 (Safe Stop 1, SS1), you can initiate a controlled stop via the control system, or

through the use of specific functional safety-related devices. A Category 1 Stop is a controlled stop with

power available to the machine actuators to achieve the stop.

The controlled stop by the control/safety-related system is not safety-relevant, nor monitored, and does not

perform as defined in the case of a power outage or if an error is detected. This has to be implemented by

means of an external safety-related switching device with safety-related delay.

38

0198441113670 08/2020

Page 39

Function

General

Function Principle

Engineering

The safety-related function STO integrated into the product can be used to implement an "EMERGENCY

STOP" (IEC 60204-1) for category 0 stops. With an additional, approved EMERGENCY STOP safety relay

module, it is also possible to implement category 1 stops.

The safety-related function STO is triggered via two redundant signal inputs. The wiring of the two signal

inputs must be separate.

The safety-related function STO is triggered if the level at one of the two signal inputs is 0. The power stage

is disabled. The motor can no longer generate torque and coasts down without braking. An error of error

class 3 is detected.

If, within one second, the level of the other output also becomes 0, the error class remains 3. If, within one

second, the level of the other output does not become 0, the error class changes to 4.

0198441113670 08/2020 39

Page 40

Engineering

Requirements for Using the Safety-Related Function STO

General

The safety-related function STO (Safe Torque Off) does not remove power from the DC bus. The safetyrelated function STO only removes power to the motor. The DC bus voltage and the mains voltage to the

drive are still present.

ELECTRIC SHOCK

Do not use the safety-related function STO for any other purposes than its intended function.

Use an appropriate switch, that is not part of the circuit of the safety-related function STO, to

disconnect the drive from the mains power.

Failure to follow these instructions will result in death or serious injury.

After the safety-related function STO is triggered, the motor can no longer generate torque and coasts

down without braking.

WARNING

UNINTENDED EQUIPMENT OPERATION

Install a dedicated, external safety-related brake if coasting does not meet the deceleration requirements

of your application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

Logic Type

The inputs for the safety-related function STO (inputs STO_A and STO_B) can only be wired for positive

logic.

Holding Brake and Safety-Related Function STO

When the safety-related function STO is triggered, the power stage is immediately disabled. Applying the

holding brake requires a certain amount of time. In the case of vertical axes or external forces acting on

the load, you may have to take additional measures to bring the load to a standstill and to keep it at a

standstill when the safety-related function STO is used, for example, by using a service brake.

FALLING LOAD

Ensure that all loads come to a secure standstill when the safety-related function STO is used.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

If the suspension of hanging / pulling loads is a safety objective for the machine, then you can only achieve

this objective by using an appropriate external brake as a safety-related measure.

UNINTENDED AXIS MOVEMENT

Do not use the internal holding brake as a safety-related measure.

Only use certified external brakes as safety-related measures.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

WARNING

40

NOTE: The drive does not provide its own safety-related output to connect an external brake to use as a

safety-related measure.

0198441113670 08/2020

Page 41

Unintended Restart

WARNING

UNINTENDED EQUIPMENT OPERATION

Verify that your risk assessment covers all potential effects of automatic or unintended enabling of the

power stage, for example, after power outage.

Implement all measures such as control functions, guards, or other safety-related functions, required

to reliably protect against all hazards that may result from automatic or unintended enabling of the

power stage.

Verify that a master controller cannot enable the power stage in an unintended way.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

UNINTENDED EQUIPMENT OPERATION

Set the parameter IO_AutoEnable to "off" if the automatic enabling of the power stage presents

hazards in your application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Degree of Protection when the Safety-Related Function STO is Used

You must ensure that conductive substances cannot get into the product (pollution degree 2). Moreover,

conductive substances may cause the safety-related function to become inoperative.

Engineering

INOPERABLE SAFETY-RELATED FUNCTION

Ensure that conductive substances (water, contaminated or impregnated oils, metal shavings, etc.)

cannot get into the drive.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Protected Cable Installation

If short circuits and other wiring errors such as a cross circuit between the signals of the safety-related

function STO can be expected in connection with safety-related signals, and if these short circuits and