Page 1

Compact® NSF and NSJ

150 to 600 A Circuit Breakers

Class 615

CONTENTS Page

Section 1—The Compact

Section 2—General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 3—Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 4—Trip Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 5—Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 6—Motor Circuit Protectors . . . . . . . . . . . . . . . . . . . . . . . . . 19

Section 7—Mounting Configurations . . . . . . . . . . . . . . . . . . . . . . . . 21

Section 8—Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 9—Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Section 10—Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Section 11—Connection Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 53

Section 12—Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Section 13—Supplementary Technical Information . . . . . . . . . . . . . 57

®

Circuit Breaker Line . . . . . . . . . . . . . . . . . 4

Page 2

Page 3

TABLE OF CONTENTS

THE COMPACT® CIRCUIT BREAKER LINE ....................................................................................... 4

GENERAL CHARACTERISTICS .......................................................................................................... 5

Compliance with Standards ............................................................................................................. 5

CIRCUIT BREAKERS ........................................................................................................................... 8

Ratings and Interrupting Ratings ..................................................................................................... 8

TRIP UNITS ........................................................................................................................................ 10

Trip Units for Compact® NSF150 and NSF250 Circuit Breakers .................................................. 10

Trip Units for Compact

Electronic Trip Unit Test Kits ......................................................................................................... 16

SWITCHES ......................................................................................................................................... 17

Ratings and Interrupting Ratings ................................................................................................... 17

MOTOR CIRCUIT PROTECTORS ..................................................................................................... 19

Ratings and Interrupting Ratings ................................................................................................... 19

MOUNTING CONFIGURATIONS ....................................................................................................... 21

Fixed Mounting .............................................................................................................................. 21

Connections .................................................................................................................................. 21

Plug-in Mounting ........................................................................................................................... 21

Drawout Mounting ......................................................................................................................... 22

CONNECTIONS ................................................................................................................................. 24

Front Connection ........................................................................................................................... 24

Rear Connection ........................................................................................................................... 25

ACCESSORIES .................................................................................................................................. 26

Location ......................................................................................................................................... 26

Connections .................................................................................................................................. 26

Automatic Secondary Disconnecting Blocks ................................................................................. 27

Auxiliary and Alarm Switches ........................................................................................................ 28

Shunt Trip and Undervoltage Trip ................................................................................................. 30

Motor Operator .............................................................................................................................. 31

Rotary Operating Handles ............................................................................................................. 33

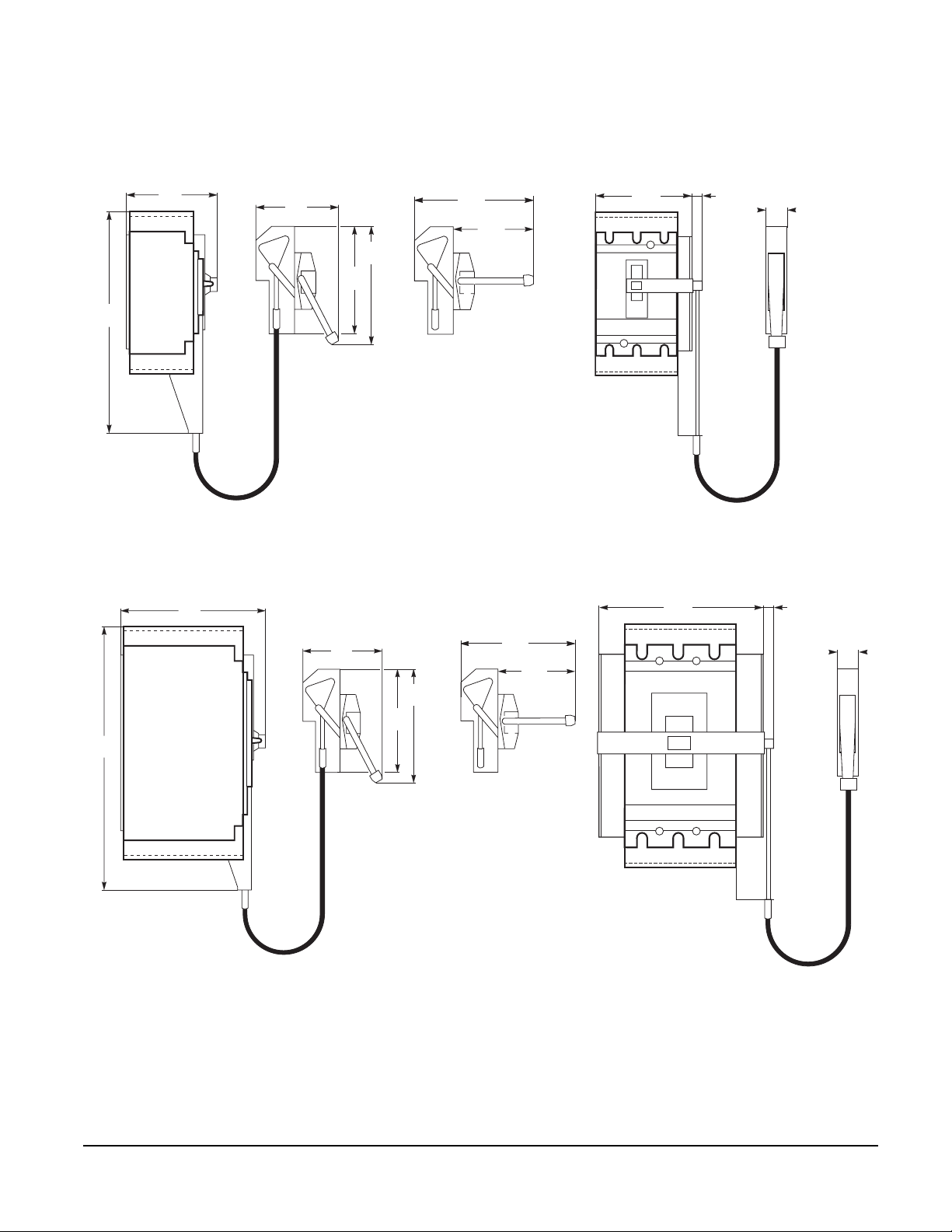

Cable Operating Handles .............................................................................................................. 35

Locking Systems ........................................................................................................................... 36

Interlocking Accessories ................................................................................................................ 37

Front Panel Escutcheons .............................................................................................................. 39

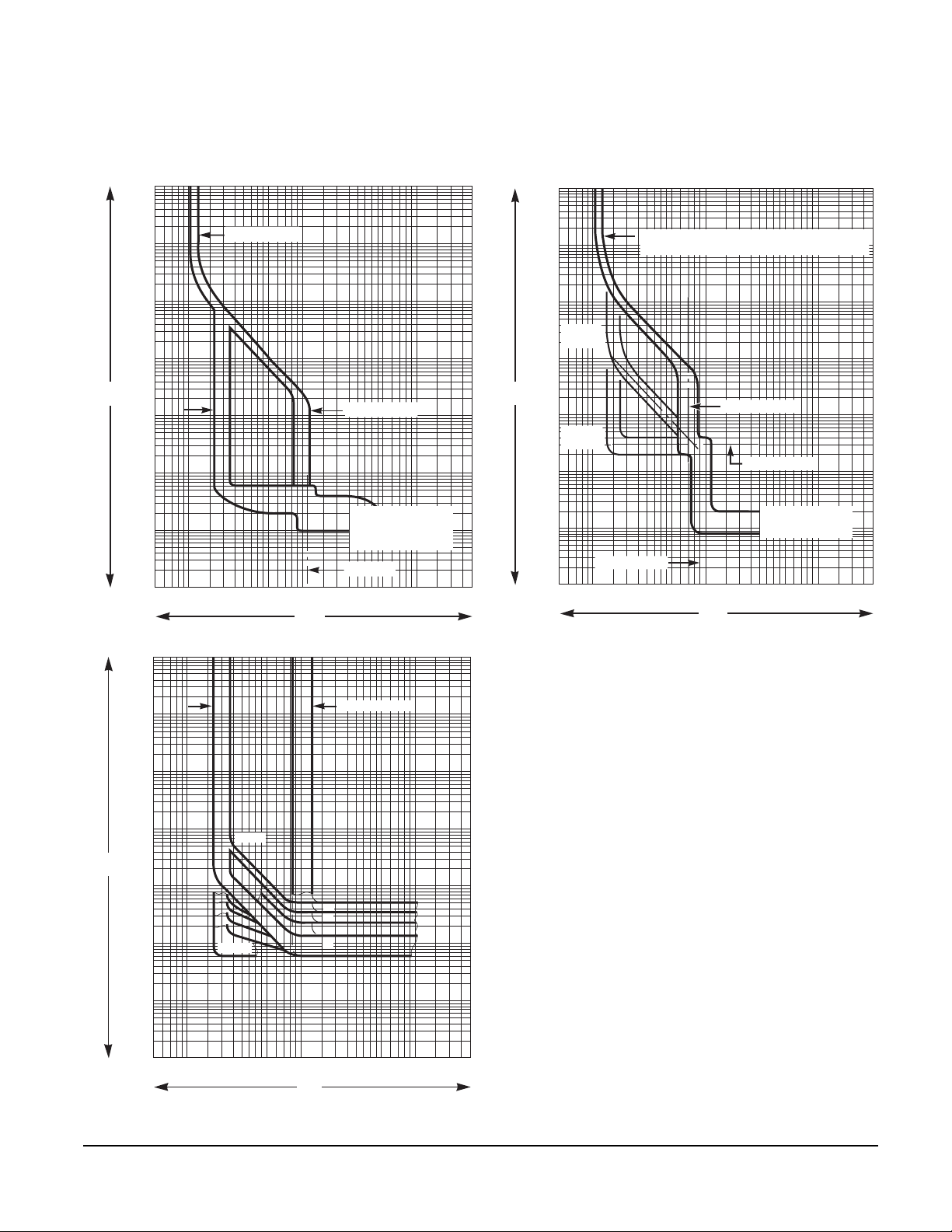

DIMENSIONS ..................................................................................................................................... 41

Fixed Mounted ............................................................................................................................... 41

Plug-in and Drawout Mounting ...................................................................................................... 43

Cable Operating Handles .............................................................................................................. 47

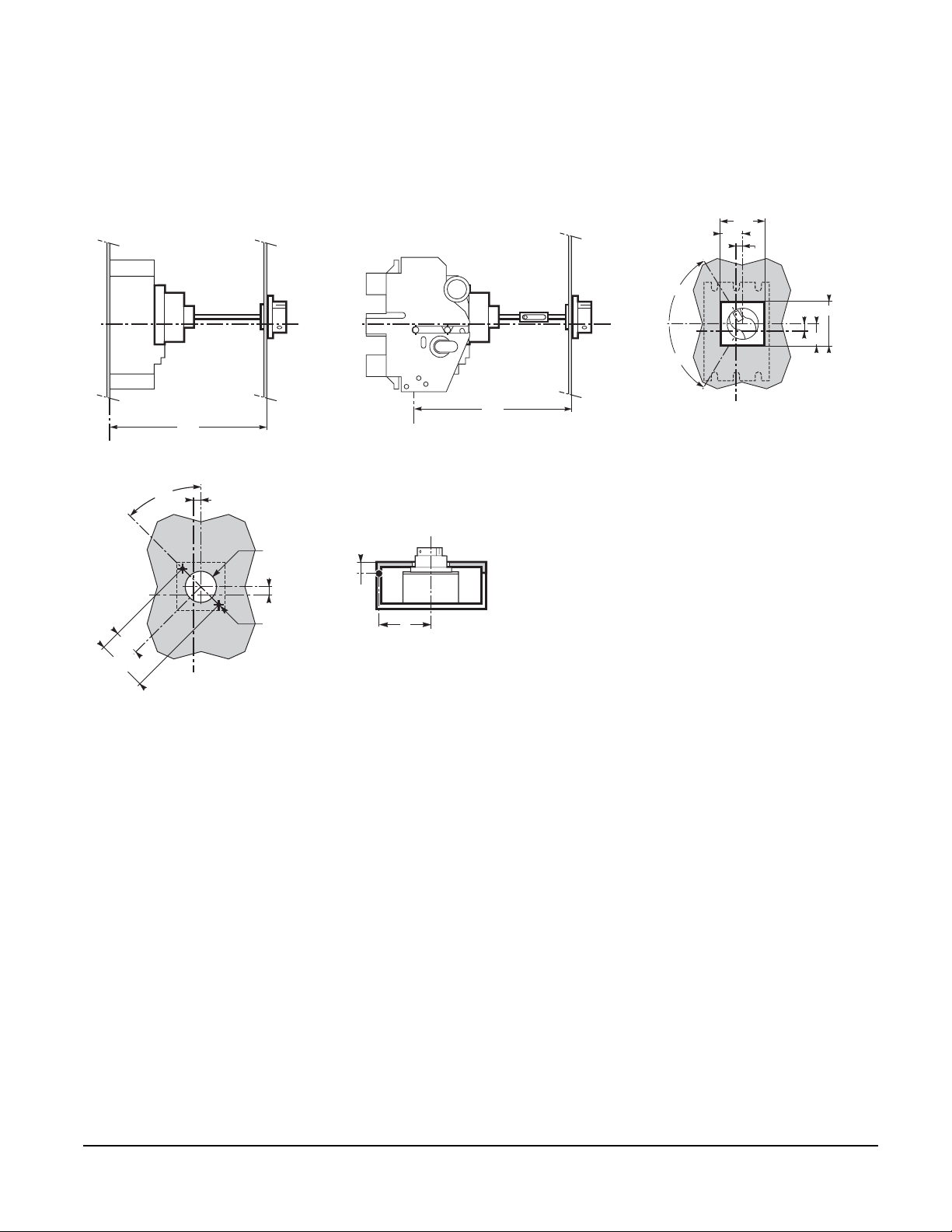

Rotary Operating Handles ............................................................................................................. 48

Front Accessories .......................................................................................................................... 51

Interlocking Systems ..................................................................................................................... 52

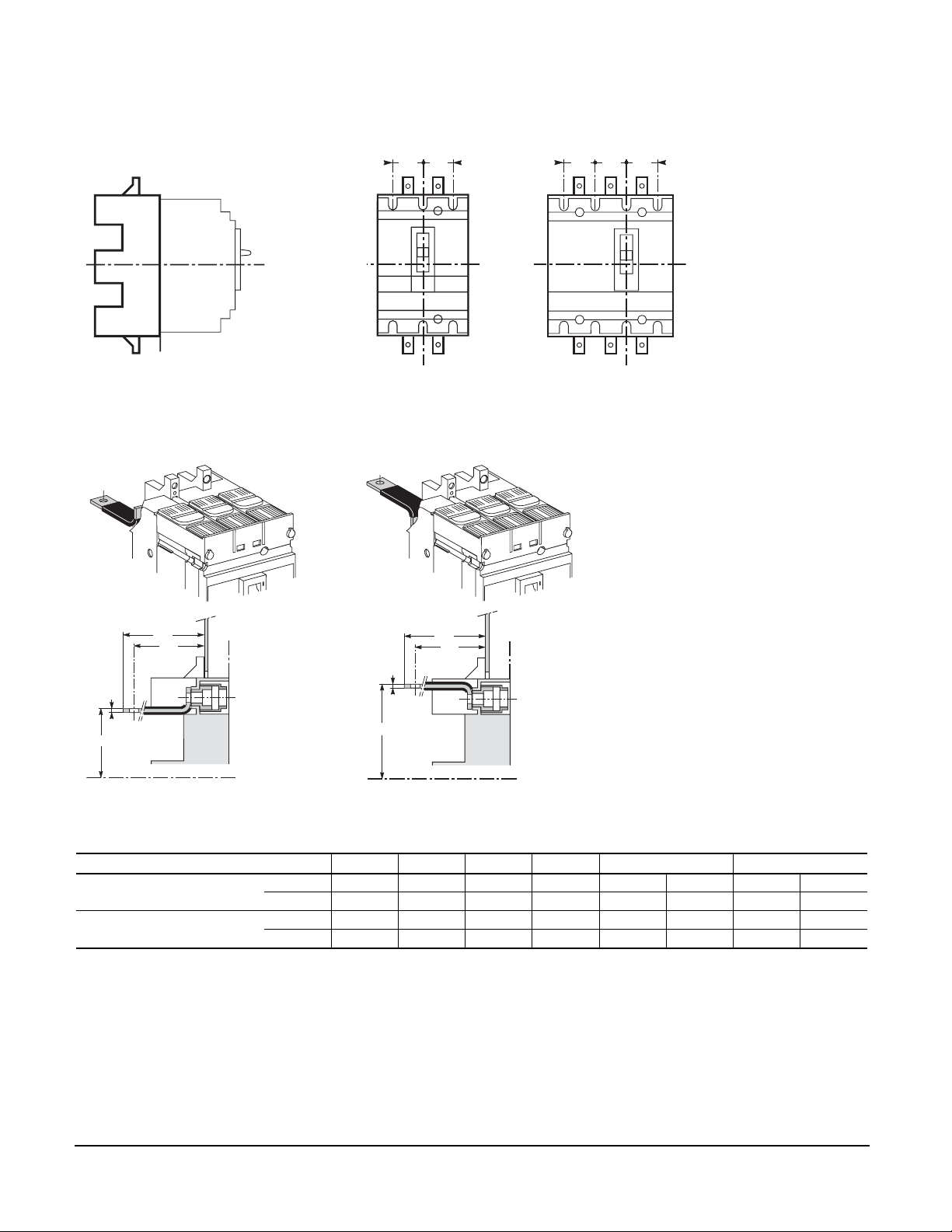

CONNECTION DIMENSIONS ............................................................................................................ 53

WIRING DIAGRAMS .......................................................................................................................... 55

SUPPLEMENTARY TECHNICAL INFORMATION ............................................................................. 57

Reflex Tripping .............................................................................................................................. 62

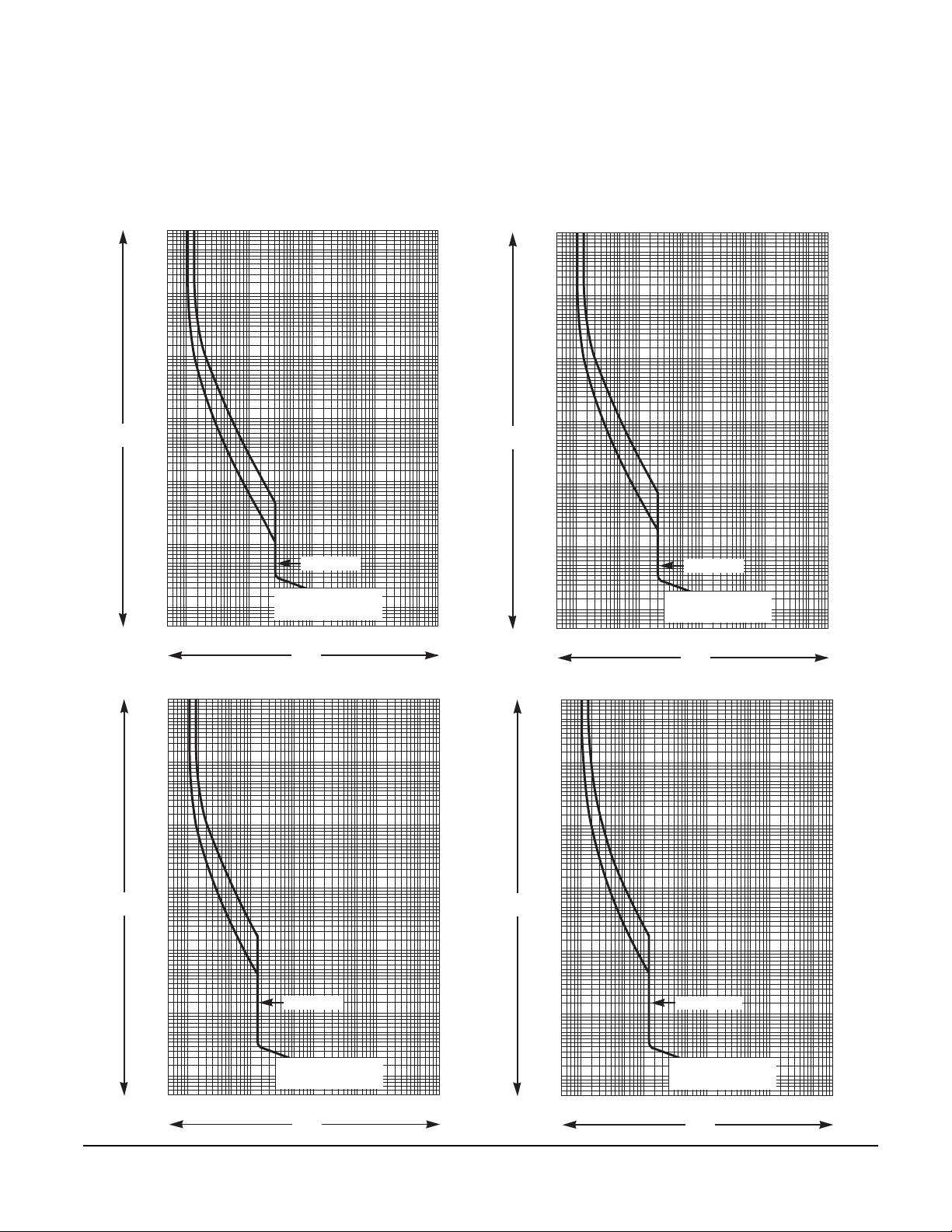

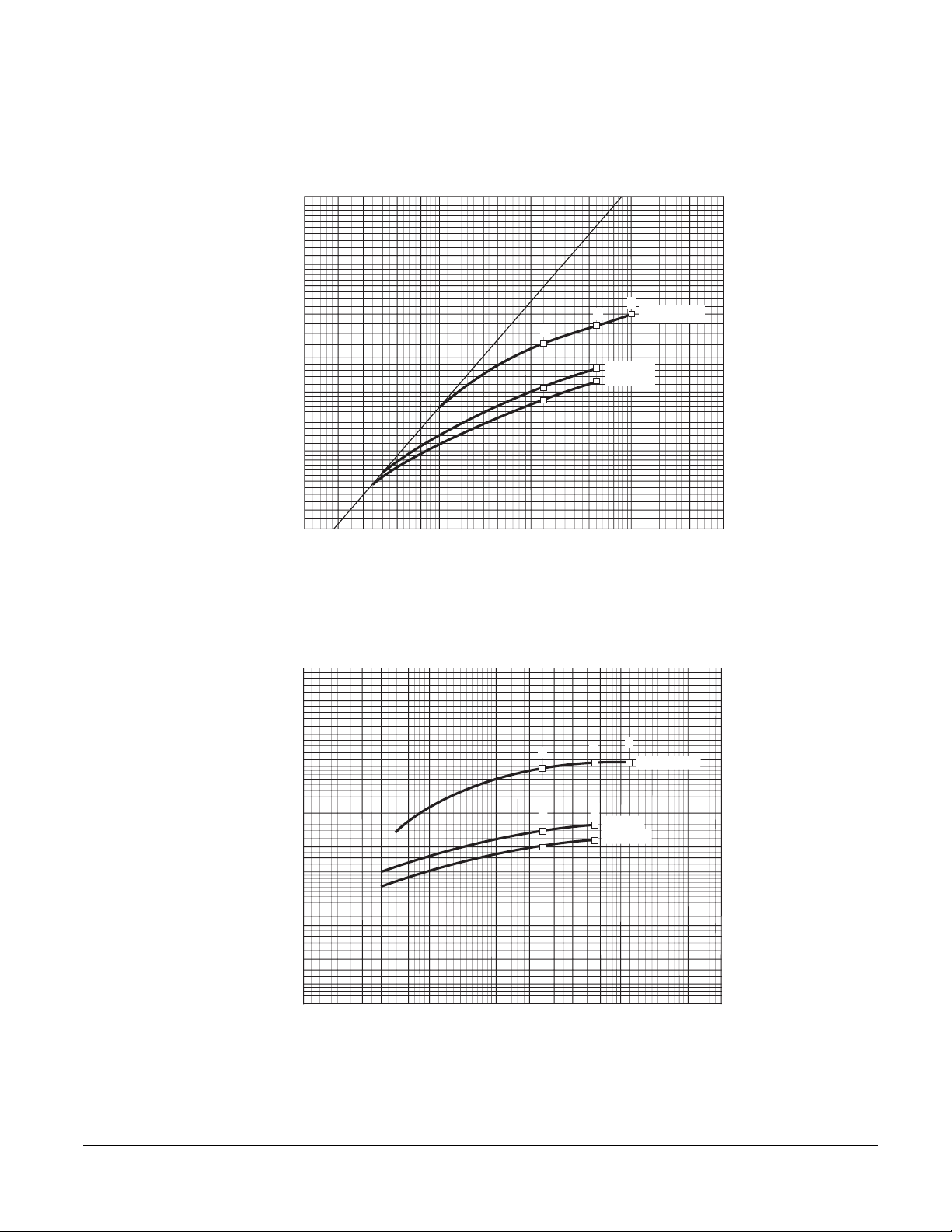

Let-through Curves ........................................................................................................................ 63

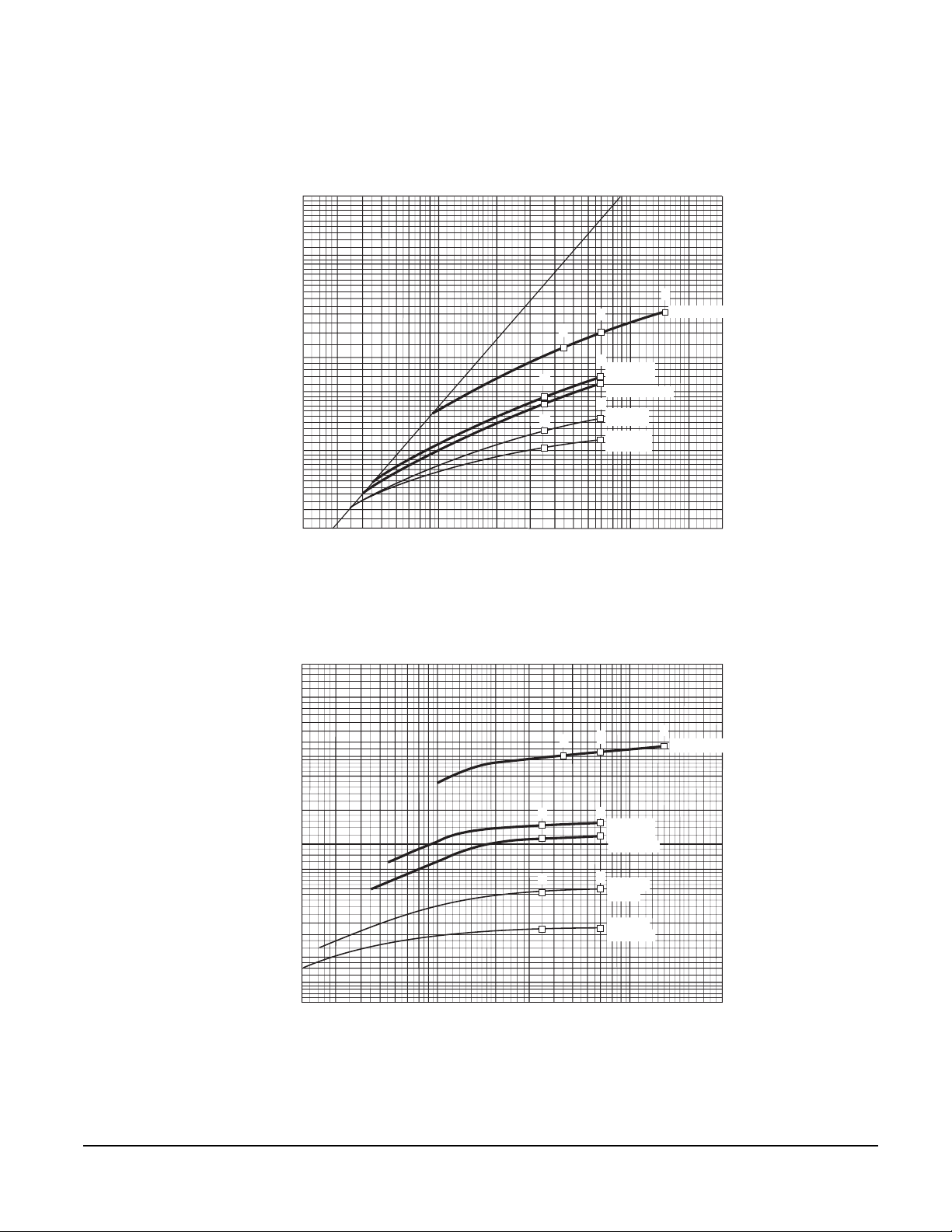

Current Limiting Curves ................................................................................................................. 65

UL 489 Test Procedure ................................................................................................................. 67

IEC 947-2 Test Procedure ............................................................................................................. 70

Routine and Maintenance Guidelines ........................................................................................... 73

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Table of Contents

®

NSJ400 and NSJ600 Circuit Breakers ................................................... 11

© 1995–2003 Schneider Electric All Rights Reserved

3

Page 4

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

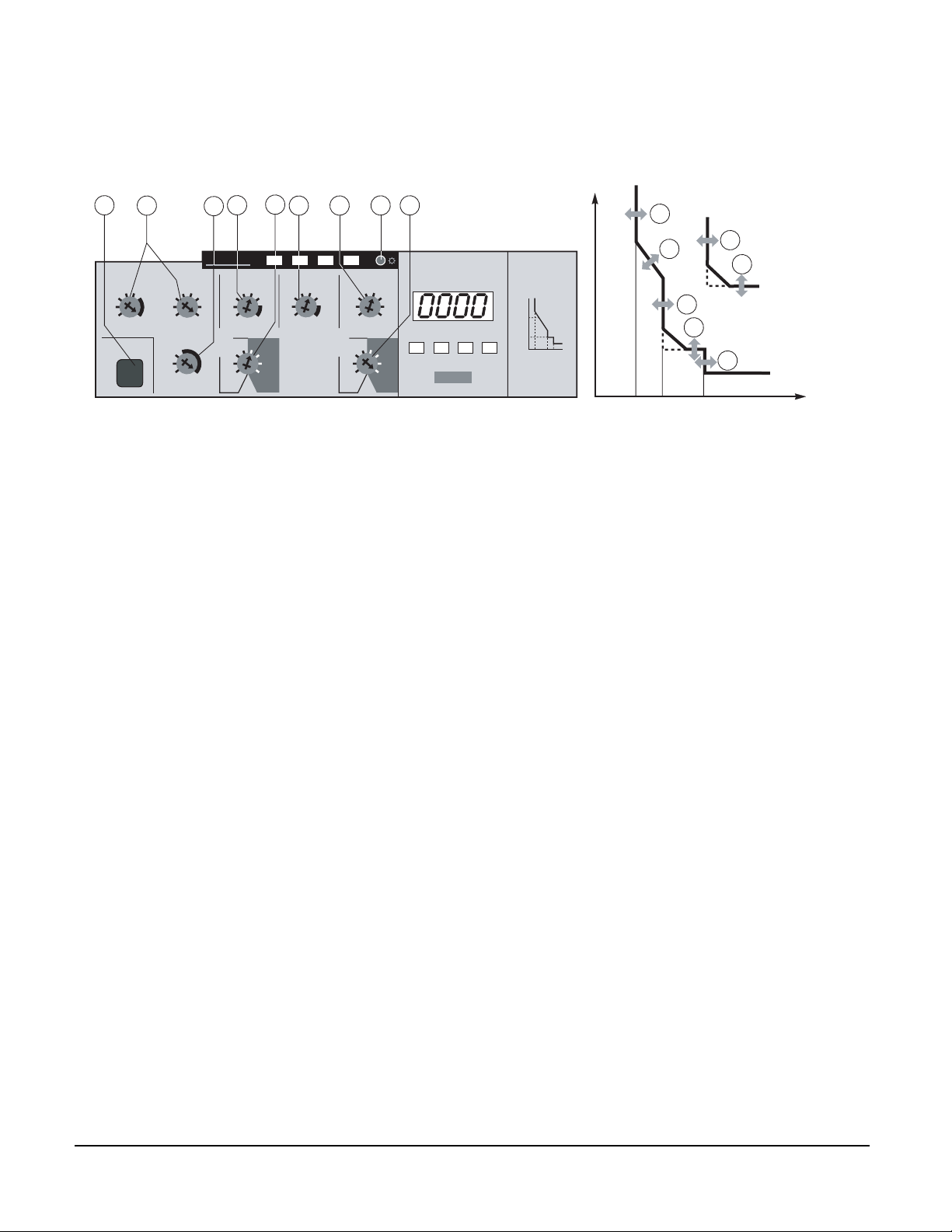

Section 1—The Compact® Circuit Breaker Line

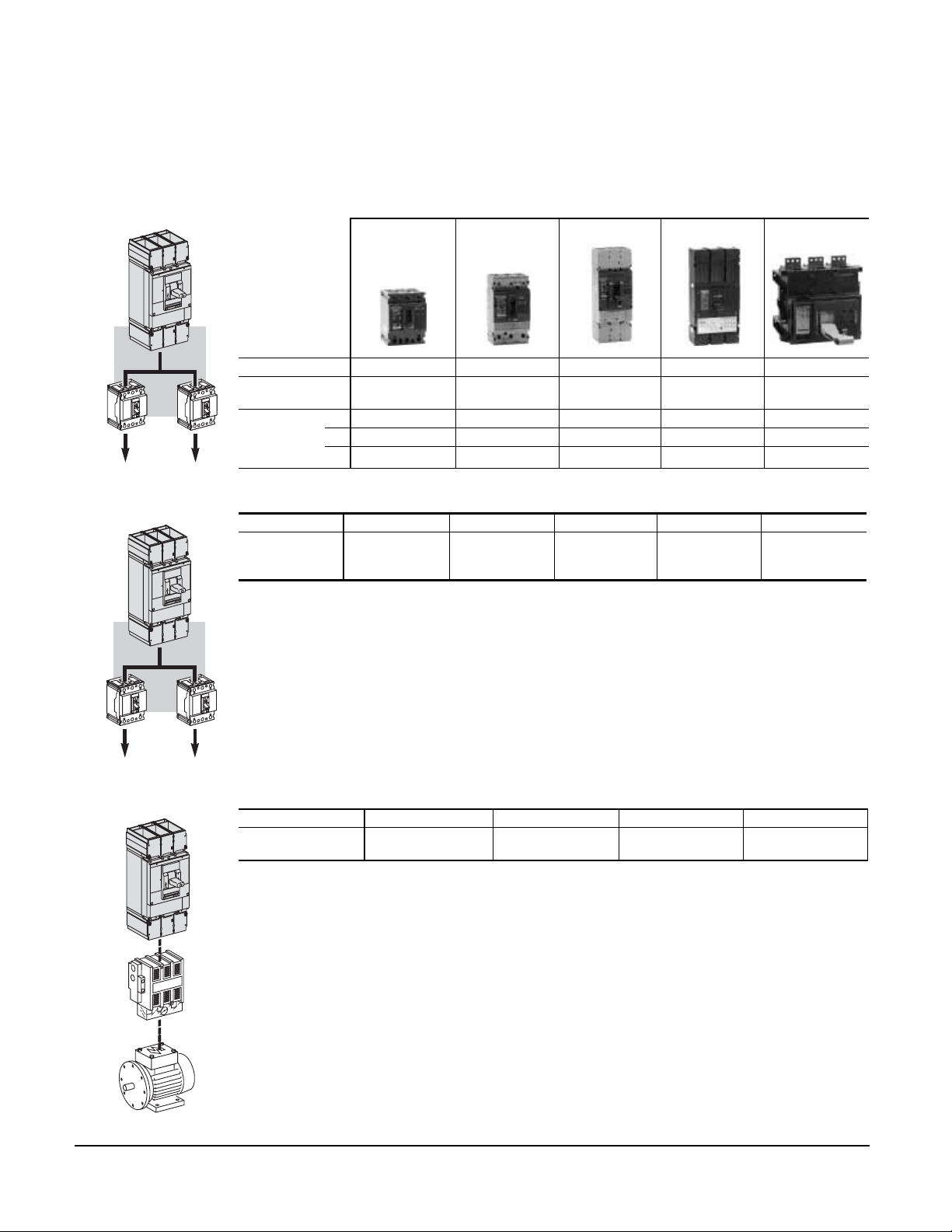

SECTION 1—THE COMPACT® CIRCUIT BREAKER LINE

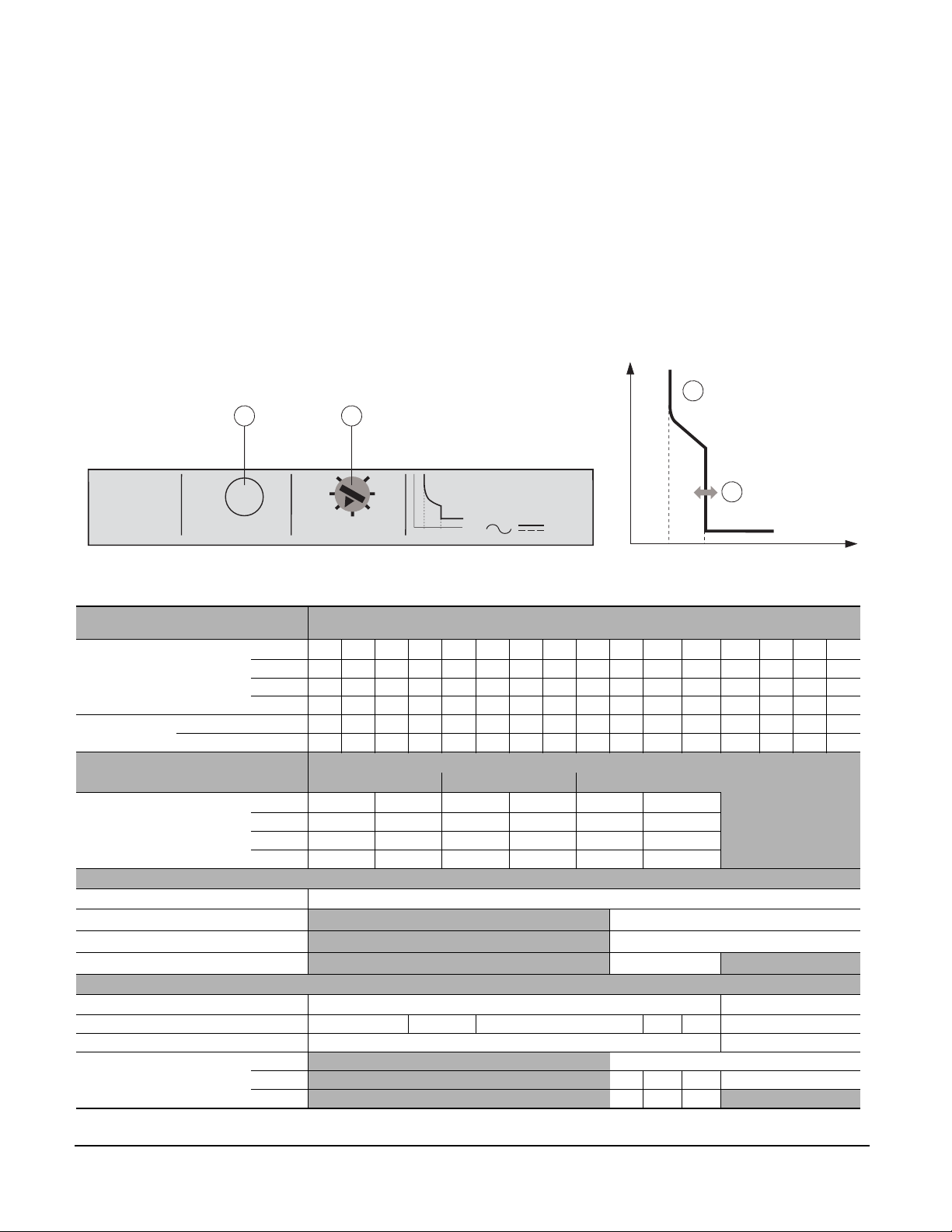

CIRCUIT BREAKERS—PAGE 8

06153032

h

s

u

p

o

t

p

i

r

t

Rated Current (A)

COMPACT

Interrupting

Rating at 480 V

®

15–100 15–250 150–600 400–1200 1250–2500

NSE100

18 35 35 50 —

N

—65656585

H

——100150—

L

SWITCHES—PAGE 17

Rated Current (A)

06153032

h

s

u

p

o

t

p

i

tr

COMPACT

®

70 150, 250 400, 600 800, 1200 1600–2500

NSE100A

MOTOR CIRCUIT PROTECTORS—PAGE 19

3–75 100–250 400–600 800–1200

NSE100A

06153033

Rated Current (A)

COMPACT

®

NSF150

NSF250

NSF150A

NSF250A

NSF150A

NSF250A

NSJ400

NSJ600

NSJ400A

NSJ600A

CK400–CK1200 CM1250–CM2500

CK800NA

NSJ400A

NSJ600A

CK800NA

CM1600HA

CM2000HA

CM2500HA

h

s

u

p

o

t

ip

tr

For NSE, CK and CM circuit breakers see appropriate catalog.

4

© 1995–2003 Schneider Electric All Rights Reserved

Page 5

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

SECTION 2—GENERAL CHARACTERISTICS

COMPLIANCE WITH STANDARDS

MERLIN

compact

06153060

NSF 250 N

600Y/347V 50/60Hz

UL/CSA

interrupting ratings

RMS sym. Amps

240V ac

480V ac

600Y/347V ac

current limiting

(see curves in catalog)

IEC947.2

220/240V

380/415V~

Ics=100% Icu

Ui 750V

cat A

UTE VDE BS CEI UNE NEMA

~

65k

35k

18k

85kA

36kA

Uimp 8kV

Icu

Section 2—General Characteristics

Compliance with

North American

Standards

Compliance with

International

Standards

Compliance with

the Specifications

of Marine

Classification

Organizations

Compact® NS circuit breakers are built in accordance with Underwriters Laboratories Inc. UL 489

Standard and Canadian Standards Association CSA C22.2 No. 5.02 Standard. Circuit breakers,

switches and their accessories, except where noted, are Listed under UL files E63335, E103740,

E103955, and Certified under CSA files LR69561 and LR88980.

Compact NS circuit breakers and their accessories comply also with the following international

standards:

• IEC 60947-1: general rules

• IEC 60947-2: circuit breakers

• IEC 60947-3: switches, disconnectors, switch disconnectors, etc.

In that these standards are applied in most countries, Compact circuit breakers and their accessories

comply with European (EN 60947-1 and EN 60947-2) and the corresponding national standards:

• France NF

• Germany VDE

• U.K. BS

• Australia AS

• Italy CEI

Compact NS circuit breakers have been approved for marine application by the American Bureau of

Shipping, Bureau Veritas, Lloyd’s Register of Shipping, Registro Italiano Navale, Germanischer Lloyd’s

and Det Norske Veritas.

They comply with the following standards:

• UL 489 Supplement SA. Marine use on vessels over 65 feet in length

• US Coast Guard specifications

• IEC 92-504 and marine specifications: inclination, vibrations, insulation resistance

• IEC 803 Electromagnetic Disturbance Immunity

© 1995–2003 Schneider Electric All Rights Reserved

5

Page 6

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 2—General Characteristics

Tropicalization Compact

humidity at 45° C or 80% at 55° C, hot and humid climate conditions). The materials used in Compact

NS circuit breakers will not support the growth of fungus or mold.

They also comply with the following standards:

®

NS circuit breakers comply with NF C 63-100 standard level 2 conditions (95% relative

• IEC 68-2-30 damp heat

• IEC 68-2-2 dry heat

• IEC 68-2-11 salt spray

• IEC 68-2-1 low temperatures

Pollution Degree Compact NS circuit breakers are certified for operation in pollution degree III environments as defined

by IEC standard 947 (industrial environments).

Environmental

Protection

Compact NS circuit breakers take into account concerns for environmental protection. Most

components are recyclable and parts are marked as specified in applicable standards.

Suitability for

Isolation (Positive

Contact Indication)

06153037

Installation in

Class II

Switchboards

All Compact NS circuit breakers and switches are suitable for isolation as defined in the IEC 947-2

Standard:

• The isolation position corresponds to the O (OFF position).

• The operating handle cannot indicate the OFF position unless the contacts are open.

• Padlocks may not be installed unless the contacts are open

Installation of a rotary handle or a motor mechanism does not alter the functionality of the position

indication system.

The isolation function is certified by tests guaranteeing:

• The mechanical reliability of the position indication system

• The absence of leakage currents

• Overvoltage withstand capacity between upstream and downstream connections

Circuit Breaker Marking

06153038

All Compact NS circuit breakers, even when fitted with a rotary handle or a motor mechanism, can be

installed through the door of Class II IEC switchboards (as per IEC 664 Standard). Refer to circuit

breaker installation instructions prior to installing circuit breaker.

Installation requires no special insulation because Compact NS circuit breakers provide Class II

insulation between the front face and all internal circuits.

Switch Marking

06153039

6

© 1995–2003 Schneider Electric All Rights Reserved

Page 7

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 2—General Characteristics

Suitability for

Isolation (Positive

Contact Indication)

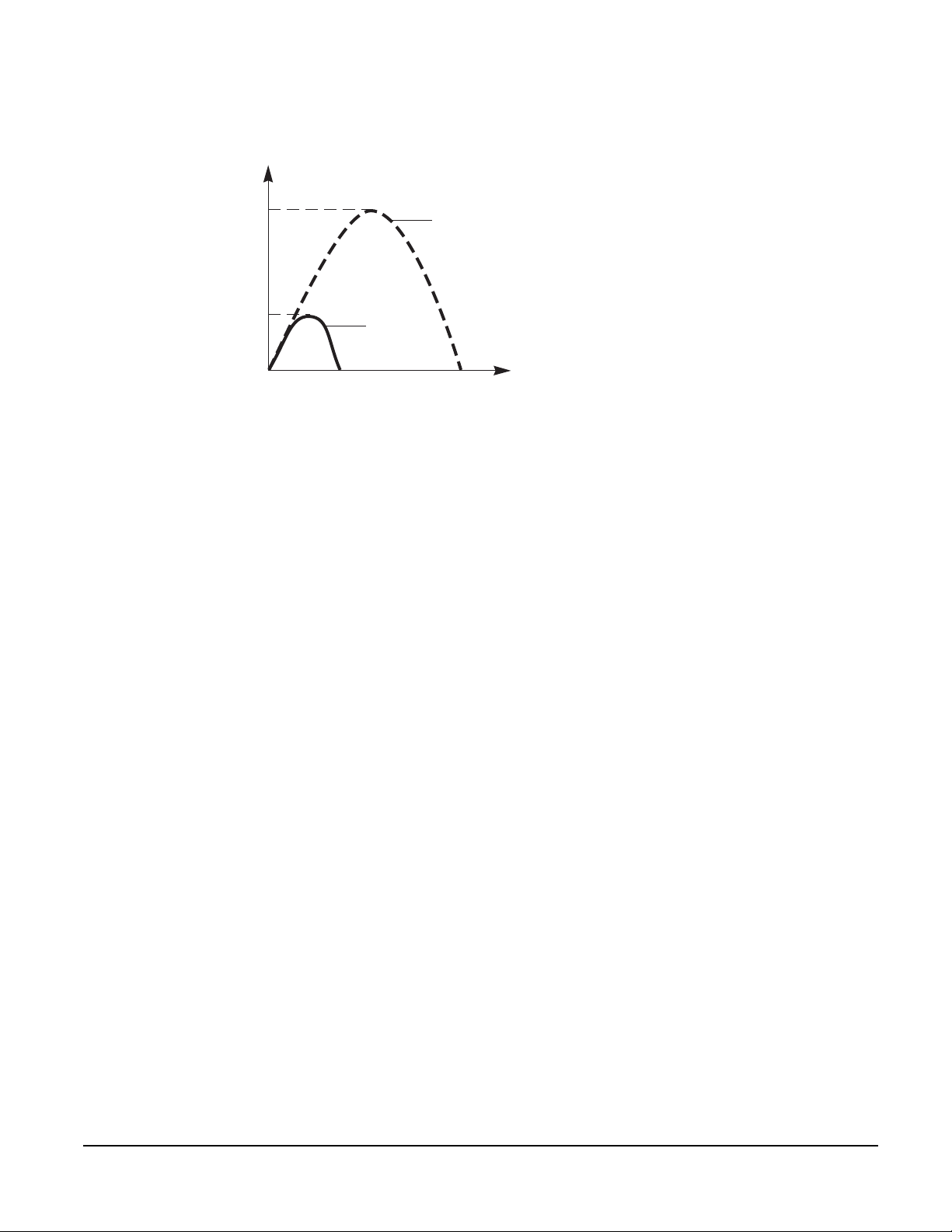

The limiting capacity of a circuit breaker is its ability to limit short-circuit currents.

Isc

06153040

The exceptional limiting capacity of the Compact

Prospective

Isc Peak

Limited

Isc Peak

Limited

Isc

tsc

Actual

Current

Prospective

Current

Prospective

Isc

t

®

NS line is due to the double break technique (rapid

natural repulsion of contacts and the appearance of two arc voltages in series with a steep wavefront).

The limiting capacity of the Compact NS line greatly reduces the forces created by fault currents in

devices. The result is a major increase in breaking performance. In particular, the service breaking

capacity Ics is equal to 100% of Icu.

The Ics value, defined by IEC 947-2, is guaranteed by tests comprising the following operations:

• Breaking a fault current equal to 100% of Icu three times consecutively

• Checking that the device continues to function normally

• Conduction of rated current without abnormal temperature rise

• Protection functions perform within the limits specified by the standard

• Suitability for isolation is not impaired

Longer Service

Current limiting circuit breakers greatly reduce the negative effects of short circuits on installations.

Life of Electrical

Installations

Thermal Effects Less temperature rise in conductors, therefore longer service life for cables.

Mechanical Effects Reduced electrodynamic forces, therefore less risk of electrical contacts or busbars being distorted or

broken.

Electromagnetic

Effects

Less disturbance for measuring devices located near electrical circuits.

© 1995–2003 Schneider Electric All Rights Reserved

7

Page 8

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 3—Circuit Breakers

SECTION 3—CIRCUIT BREAKERS

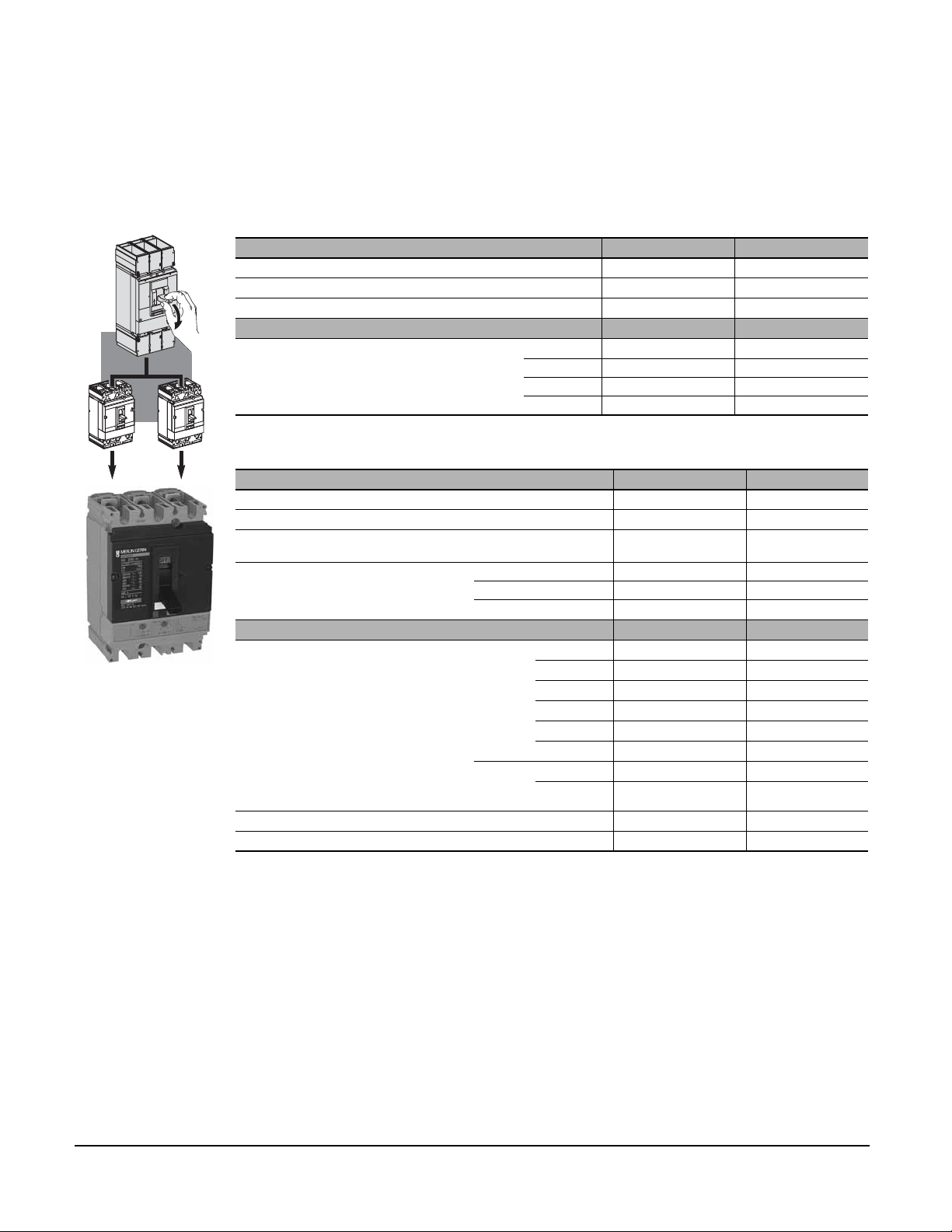

RATINGS AND INTERRUPTING RATINGS

UL 489 Listed Ratings

Compact® Circuit Breakers NSF150 NSF250

06153061

06153062

Number of Poles

Rated Voltage (V)

h

s

u

p

o

t

p

i

r

t

Rated Current (A) In

Interrupting Ratings (kA rms)

*Oversized Neutral Protection: four-pole OSN 125/250N and 150/250N are same ratings as NSF250A.

AC 50/60 Hz 600Y/347 600Y/347

40° C 150 250

240 V 65 100 65 100

480 V 35 65 35 65

600 Y/ 347 V 18 25 18 25

600 V — — — —

IEC 947-2 and EN 60947-2 Ratings

Compact® Circuit Breakers NSF150 NSF250

Number of Poles

Rated Insulation Voltage (V) Ui

Rated Impulse

Withstand Voltage (kV)

Rated Operational Voltage (V) Ue

Rated Current (A) In

Ultimate Breaking Capacity (kA rms) Icu

Service Breaking Capacity Ics

Utilization Category

*Oversized Neutral Protection: four-pole OSN 125/250N and 150/250N are same ratings as NSF250A.

Uimp

AC 50/60 Hz 690 690

DC 500 500

40° C 150 250

AC 50/50 Hz 220/ 240 V 85 100 85 100

380/ 415 V 36 70 36 70

440 V 35 65 35 65

500 V 30 50 30 50

525 V 22 35 22 35

600/ 690 V 8 10 8 10

DC 250 V (1 pole) 50 85 50 85

500 V (2 pole in

series)

(% Icu) 100% 100% 100% 100%

3, 4, 4 OSN* 3, 4

N H N H

3, 4, 4 OSN* 3, 4

750 750

88

N H N H

50 85 50 85

A A A A

8

© 1995–2003 Schneider Electric All Rights Reserved

Page 9

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 3—Circuit Breakers

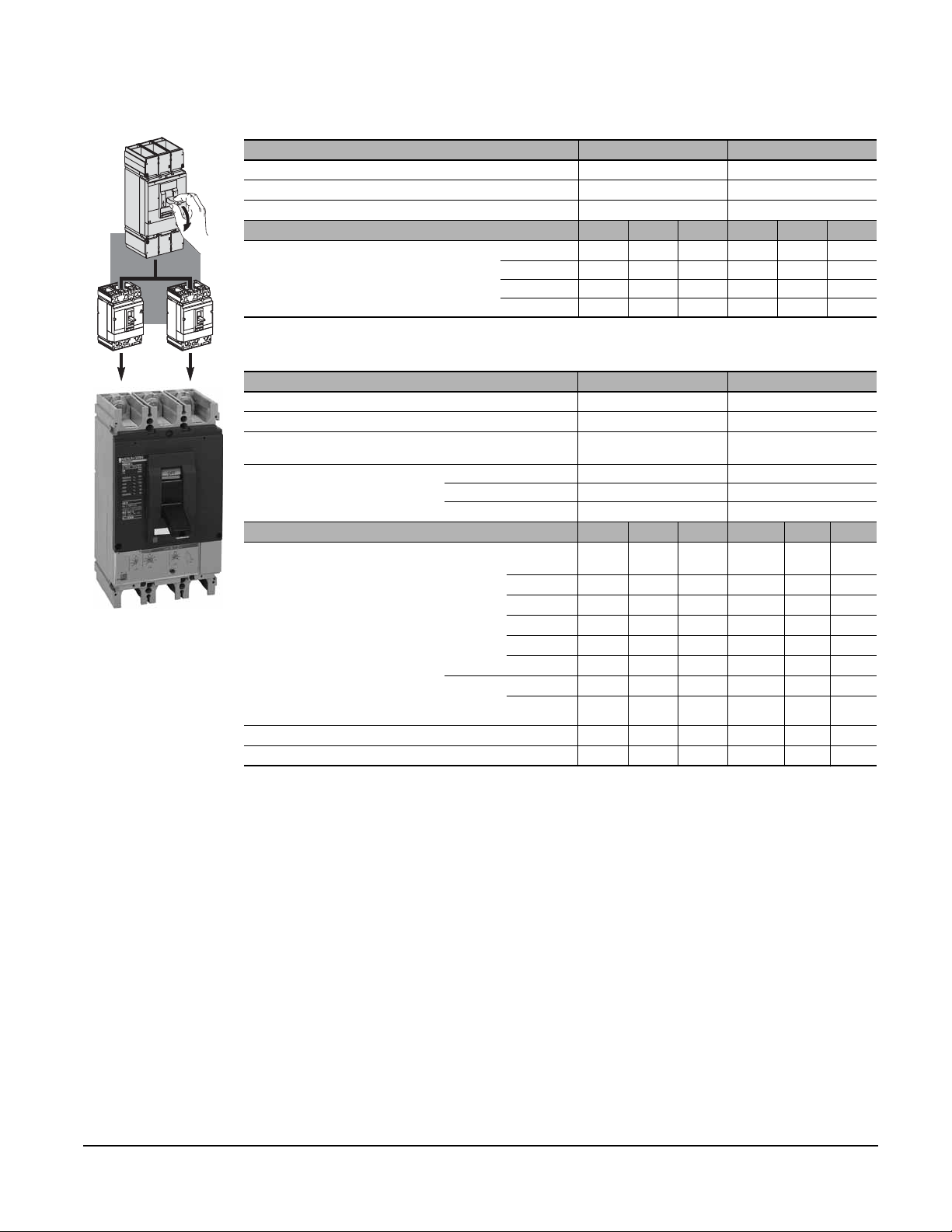

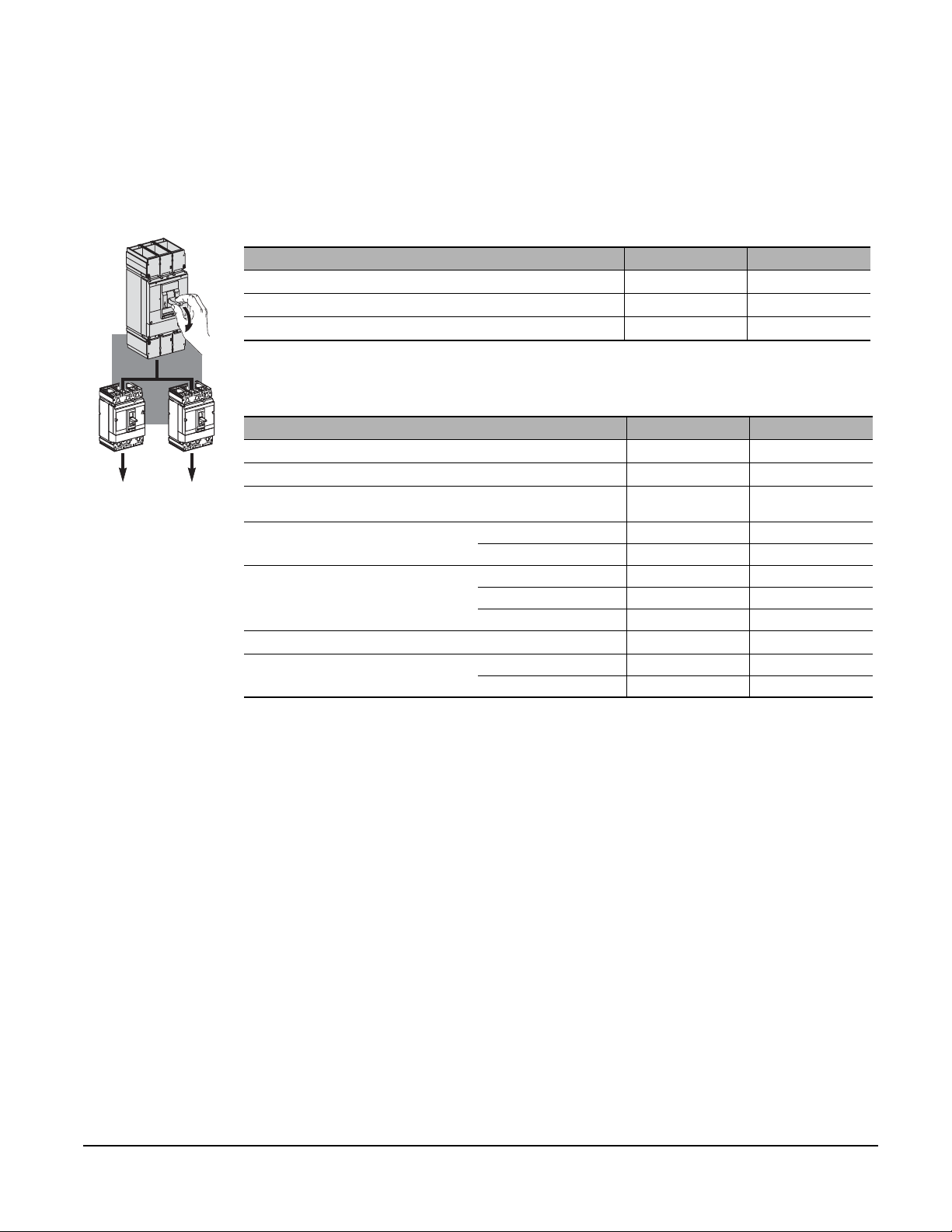

UL 489 Listed Ratings

Compact® Circuit Breakers NSJ400 NSJ600

06153061

h

s

u

p

o

t

p

i

r

t

Number of Poles

Rated Voltage (V)

Rated Current (A) In

Interrupting Ratings (kA rms)

AC 50/60 Hz 600 600

40° C 400 (100% Rated Circuit Breaker) 600

240 V 65 100 150 65 100 150

480 V 35 65 100 35 65 100

600 Y/ 347 V — — — — — —

600 V 182525182525

*Oversized Neutral

IEC 947-2 and EN 60947-2 Ratings

Compact® Circuit Breakers NSJ400 NSJ600

Number of Poles

06153063

Rated Insulation Voltage (V) Ui

Rated Impulse

Withstand Voltage (kV)

Uimp

Rated Operational Voltage (V) Ue

Rated Current (A) In

Ultimate Breaking Capacity

(kA rms)

Icu

Service Breaking Capacity Ics

Utilization Category

*Oversized Neutral

AC 50/60 Hz 690 690

DC 500 500

40° C 400 600

AC 50/50 Hz 220/240 V 85 100 150 85 100 150

380/415 V 45 70 150 45 70 150

440 V 42 65 130 42 65 130

500 V 30 50 70 30 50 70

525 V 22 35 50 22 35 50

600/690 V 10 20 35 10 20 35

DC 250 V (1 pole) — 85 — — 85 —

500 V (2 pole

in series)

(% Icu) 100% 100% 100% 100% — 100%

3, 4, 4 OSN* 3, 4

N H L N H L

3, 4, 4 OSN* 3, 4

750 750

88

N H L N H L

—85—— 85—

A A A A — A

© 1995–2003 Schneider Electric All Rights Reserved

9

Page 10

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

SECTION 4—TRIP UNITS

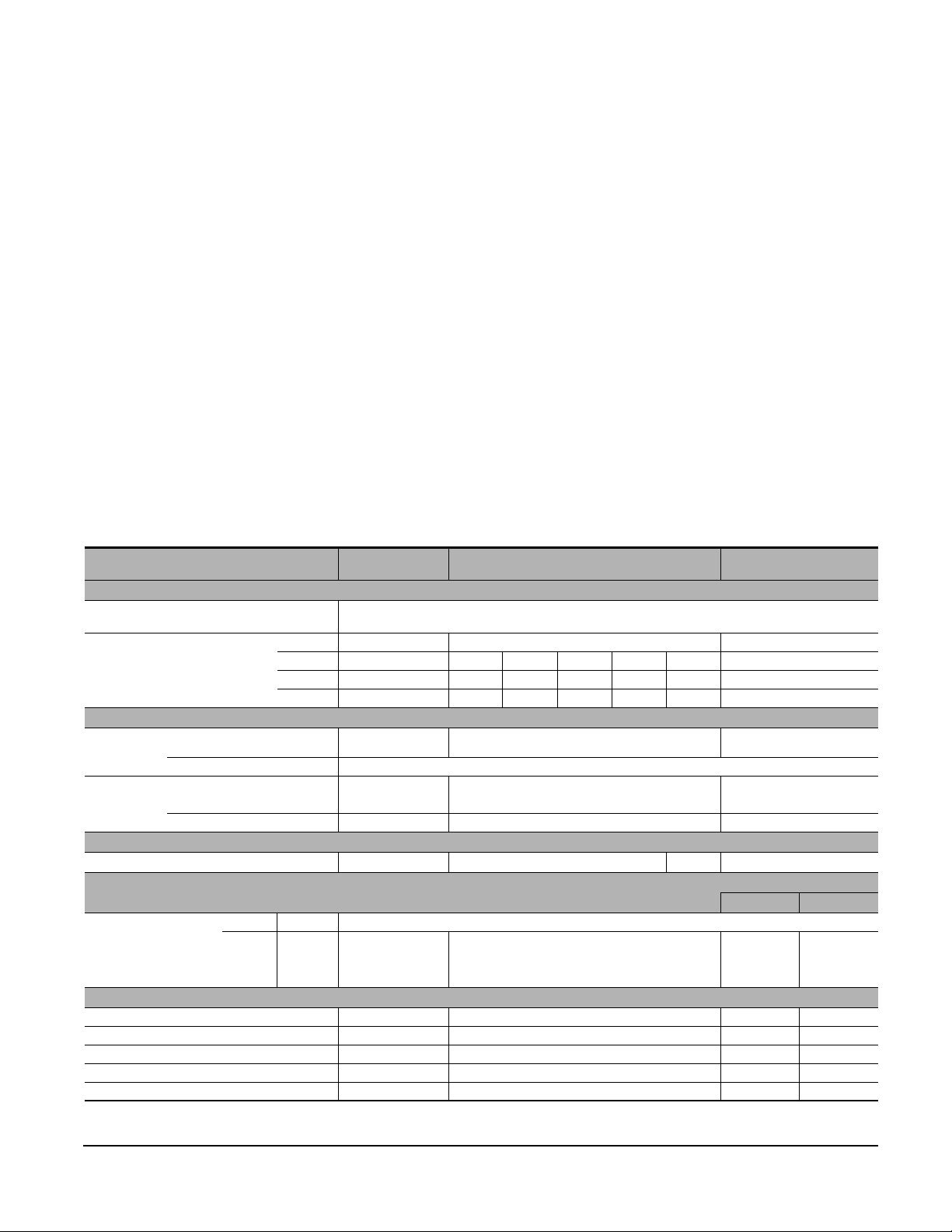

TRIP UNITS FOR COMPACT® NSF150 AND NSF250 CIRCUIT BREAKERS

Compact NSF150 and NSF250 circuit breakers are equipped with thermal-magnetic (TM) trip units.

Protection • Against overload (1) with a fixed thermal protection

• Against short circuits (2) with fixed (on NSF150) or adjustable (on NSF250) magnetic protection

t

06153064

21

1

Ir

250 A

Trip Units for Compact® NSF150–NSF250

Circuit Breakers

Rating (A) In

3P 50° C 14.2 19 28.5 38 47.5 57 66.5 76 85 95 118 142 166 190 213 237

4P3T 60° C 13.5182736455463728190112 135158180203225

4P4T 70° C 12.8 17 25.6 34.2 43 51 60 68 77 85 107 128 150 171 192 214

Circuit Breaker

Rating (A) In

4P OSN 50° C 95 142 118 237 142 237

Overload Protection

Thermal

Short-circuit Protection

Magnetic

Neutral Protection

*Oversized Neutral

Compact® NSF150 N/H ■■■■■■■■■■ ■ ■

Compact® NSF250 N/H ■ ■■■

®

Compact

NSF150 400 500 1000 1250 1500

Compact® NSF250 5–10 x In

Im

10

9

TM15DP–TM250DP Trip Units

40° C 152030405060708090100125150 175200225250

TM100OSN–TM150OSN Trip Units

Phase Neutral Phase Neutral Phase Neutral

40° C 100 150 125 250 150 250

60° C 90 135 112 225 135 225

70° C 85 128 107 214 128 214

3P Non-adjustable

4P3T

4P4T

4P OSN*

Non-adjustable Adjustable

4P3T No Neutral Protection

4P4T 1000 1250 1500 5–10 x In

4P OSN*

8

7

x 250 A

5

6

Ir Im

TM 250 D

250A / 40°C

2

0

Ir Im

Non-adjustable, No Neutral Protection

Non-adjustable

Non-adjustable

1000 1250 1500

I

10

© 1995–2003 Schneider Electric All Rights Reserved

Page 11

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

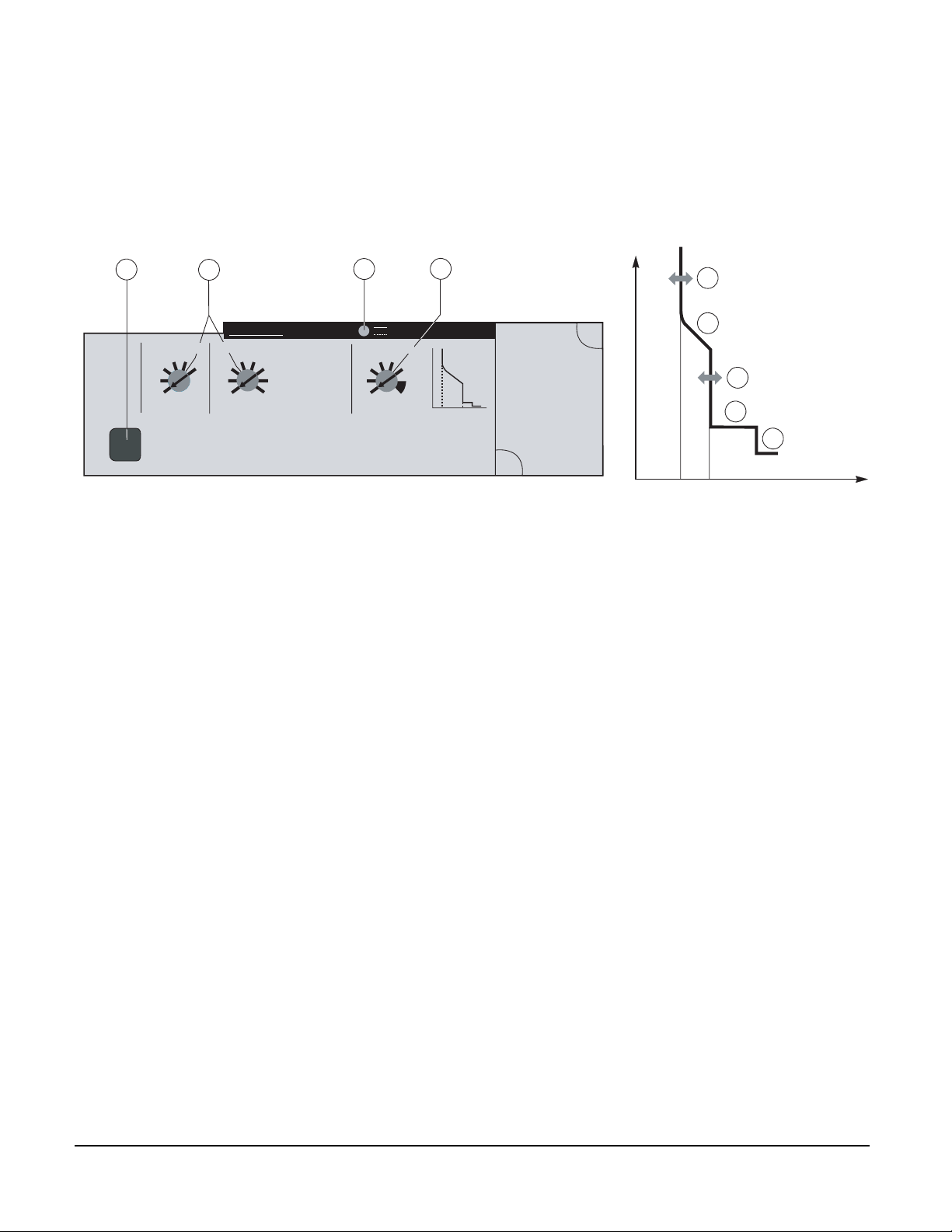

TRIP UNITS FOR COMPACT® NSJ400 AND NSJ600 CIRCUIT BREAKERS

Compact NSJ400 and NSJ600 circuit breakers are equipped with current sensors and electronic trip

units.

Current Sensors Four different sizes are available and can be mounted with all trip units:

• NSJ400—150, 250 and 400 A

• NSJ600—600 A

Trip Units

STR23SP,

STR53UP and

STR23SP-OSN

•

Protection for loads, from 60 to 600 A

— STR23SP and STR53UP for standard protection

— STR23SP-OSN for oversized neutral protection (factory-installed only)

— STR53UP for generator supplied network protection and long cable runs

• Trip units STR23SP and STR53UP can be mounted on all Compact NSJ400 and NSJ600 circuit

breaker types N, H and L

• Trip unit STR53UP offers a greater number of optional indication and measurement functions,

protection settings and ground-fault protection

• STR23SP and STR53UP available on four-pole circuit breakers with sealable, 3-position neutral

protection setting:

— 4P 3D (neutral unprotected)

— 4P 3D + N/2 (neutral protection at 0.5 x Ir) where Ir is trip unit current setting

— 4P 4D (neutral protection at Ir) where Ir is trip unit current setting

Trip Units for Compact® NSJ400 and NSJ600

Circuit Breakers

Overload Protection (Long Time)

Tripping

Threshold (A)

Tripping Time (s)

(Min–Max)

Short-circuit Protection (Short Time)

Tripping

Time Delay

(ms)

Short-circuit Protection (Instantaneous)

Tripping Threshold (A)

Adjustable Neutral Protection (Three Position Switch)

Other Functions

Indication of Fault Type ■ (Standard)

Equipment Ground-fault Protection (T) ■

Built-in Ammeter (I) ■

Zone-selective Interlocking (ZSI) ■

Communication (COM) ■

Ir

Im / Isd

Accuracy ± 15%

Max. Overcurrent Time Before Tripping Fixed ≤ 40

Total Breaking Time ≤ 60 ≤ 60 ≤ 140 ≤ 230 ≤ 350 ≤ 60

Switch Settings Protection Level

Position 1 4P 3D No Protection No Protection No Protection No Protection

Position 2 4P 3D + N/2 0.5 x Ir 0.5 x Ir 0.8 x Ir 0.75 x Ir

Position 3 4P 4D 1.0 x Ir 1.0 x Ir 1.6 x Ir 1.5 x Ir

20–70° C Adjustable (48 Settings) 0.4–1 x In

At 1.5 x Ir 120–180 17–25 34–50 69–100 138–200 277–400 120–180

At 6 x Ir 5–7.5 0.8–1 1.6–2 3.2–4 6.4–8 12.8–16 5–7.5

At 7.2 x Ir 3.2–5.0 0.5–0.7 1.1–1.4 2.2–2.8 4.4–5.5 8.8–11 3.2–5.0

STR23SP STR53UP

Fixed Adjustable Fixed

Adjustable (7 Settings)

2–9 x Ir

Fixed ≥ 9 x In Adjustable (7 Settings) 1.5–9 x In Fixed ≥ 9 x In

Adjustable (7 Settings) 1.5–7 x Ir Adjustable (7 Settings) 2–9 x Ir

Adjustable (4 Settings + Constant I2t Function)

≤ 15 ≤ 60 ≤ 140 ≤ 230

STR23SP OSN

(Oversized Neutral)

Fixed ≤ 40

NSJ250/400N NSJ400/600N

© 1995–2003 Schneider Electric All Rights Reserved

11

Page 12

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

Electronic Trip

Unit STR23SP and

STR23SP-OSN

(Oversized

Neutral)

t

7

06153065

1

6

3

1

2

3

4

5

Ir Im

test

+

Io = sensor

.7

.63

.5

-

short time

Im

56

4

3

2

90

%Ir

105

7

9

x Ir

ImIr

STR 23 SP

long time

Ir

.8

x In

.9

1

.85

.88

.93

.9

.95

.98

.8

1

x Io

alarm

0

Protection • Long-time (LT) overload protection, adjustable threshold, based on the actual rms current

— Adjustable threshold (1) using six lo base settings (0.5–1) and fine adjustment Ir with eight

settings ranging from (0.8–1)

— Non-adjustable tripping time (2)

• Short-time (ST) short-circuit protection

— Adjustable threshold Im (3)

— Fixed time delay (4)

• Instantaneous (I) short-circuit protection, fixed threshold (5)

• Neutral protection available on standard four-pole circuit breakers; protection level controlled using

three-position switch

— 4P 3D: no protection

— 4P 3D + N/2: neutral protection at 0.5 Ir

— 4P 4D: neutral protection at Ir

• Neutral protection for STR23SP-OSN (oversized neutral) available on four-pole circuit breakers

equipped with oversized neutral protection; protection level controlled using three-position switch

I

12

NSJ250/400N: NSJ400/600N:

— 4P 3D: no protection — 4P 3D: no protection

— 4P 3D + N/2: neutral protection at 0.8 x Ir — 4P 3D + N/2: neutral protection at 0.75 x Ir

— 4P 4D: neutral protection at 1.6 x Ir — 4P 4D: neutral protection at 1.5 x Ir

© 1995–2003 Schneider Electric All Rights Reserved

Page 13

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

Indications Load indication (LED) in front (6):

• Lights solid at 90% of Ir threshold

• Flashes at >105% or greater of Ir threshold

Test Test connector in front (7) for connection to test kit to check circuit breaker operation after fitting the trip

unit or other accessories.

Setting Example Question: What is the overload protection threshold of a Compact NSJ400 circuit breaker equipped

with trip unit STR23SP where Io = 0.5 and Ir = 0.8?

Answer: In x Io x Ir = 400 x 0.5 x 0.8 = 160 A

The same trip unit with the same settings, mounted on an NSJ600 circuit breaker will have the following

tripping threshold: In x Io x Ir = 600 x 0.5 x 0.8 = 240 A.

.7

.8

Io

.9

1

06153066

.63

.5

x In

400 x 0.5 x 0.8 = 160 A

.88

.85

.8

.9

Ir

.93

.95

.98

1

x Io

© 1995–2003 Schneider Electric All Rights Reserved

13

Page 14

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

Electronic Trip

Unit STR53UP

t

4

8

test

1

Io

.7

.6

.5

Ir

.9

.8

x In

+

.90 .93

.88

1

.85

1

.8

x Io

tr

8

4

-

2

0,5

(s) @ 6 Ir

06153067

Protection • Long-time (LT) overload protection, adjustable threshold, based on actual rms current, as defined

2

STR 53 UP

.95

.98

1

tsd

8

Isd

(s)

3

4 5

3

6

2

7

1.5

x Ir

.3 .3

.2

.2

.1

0

0

on

I2t

off

5

%Ir >Ir >Isd >Ig

Ii

4 6

3

8

9

2

7

.1

9

1.5

x In

6

Ig

.4

.3

.2

tg

.3

(s)

.2

.1

on

.4 .4

.5

x In

I2t

9

.6

.7

.8

1

.3

.2

.1

off

7

test

μ P

> Ir

> Im

> Ih

In I1 I2 I3

1

2

6

7

A

tr

tsd

IsdIr li

0

Ir Isd I

3

4

5

by IEC 947-2, appendix F

— Adjustable threshold (1) using six lo base settings (0.5–1) and fine adjustment Ir with eight

settings ranging from (0.8–1)

— Adjustable tripping time (2)

• Short-time (ST) short-circuit protection

— Adjustable threshold Isd (3)

— Adjustable time delay (4), with or without constant I

2

t function

• Instantaneous (Ii) short-circuit protection, adjustable threshold (5)

• Neutral protection available on standard four-pole circuit breakers; protection level controlled using

three-position switch

— 4P 3D: no protection

— 4P 3D + N/2: neutral protection at 0.5 Ir

— 4P 4D: neutral protection at Ir

I

Overload Indications

(%Ir)

• LED (9) lights solid when current exceeds 0.9 Ir

• LED (9) flashes when current exceeds long-time threshold Ir

Fault Indications LEDs indicate the type of fault that caused tripping:

• Overload (LT protection) or abnormal component temperature (>Ir)

• Short-circuit (ST or instantaneous protection) (>Isd)

• Ground-fault (if earth-fault protection option is present) (>Ig)

• Microprocessor malfunction—both (>Ir) and (>Isd) LEDs go on, plus the (>Ig) LED, if the ground-

fault protection option is present

The LEDs are battery powered with spare batteries supplied in the adapter box. When a fault occurs,

the LED indicating type of fault shuts off after approximately 10 minutes to conserve battery power. The

fault data is stored in memory and the LED can be re-illuminated by pressing the battery/LED test

button (9). The LED automatically goes off and memory is cleared when the circuit breaker is reset.

Test

• Test connector in front (8) for connection to test kit (see page 16); used to check circuit breaker

operation after fitting trip unit or other accessories

• Test button (9) for (%Ir), (>Ir), (>Im) and (>Ig) LEDs and battery

Self-monitoring The circuit breaker trips for both microprocessor faults and abnormal temperatures.

14

© 1995–2003 Schneider Electric All Rights Reserved

Page 15

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

Options for

Electronic Trip

Unit STR53UP

Equipment Ground-fault Protection (T)—see (6) and (7), page 14

Type

Tripping threshold

Tripping time (ms)

Ig Adjustable (8 Settings) 0.2–1 x In

Accuracy ± 15%

Max. overcurrent time before tripping (Tg) Adjustable (4 Settings + Constant I2t Function) 60, 140, 230, 350

Total Breaking Time -140, -230, -350, -500

Residual Current

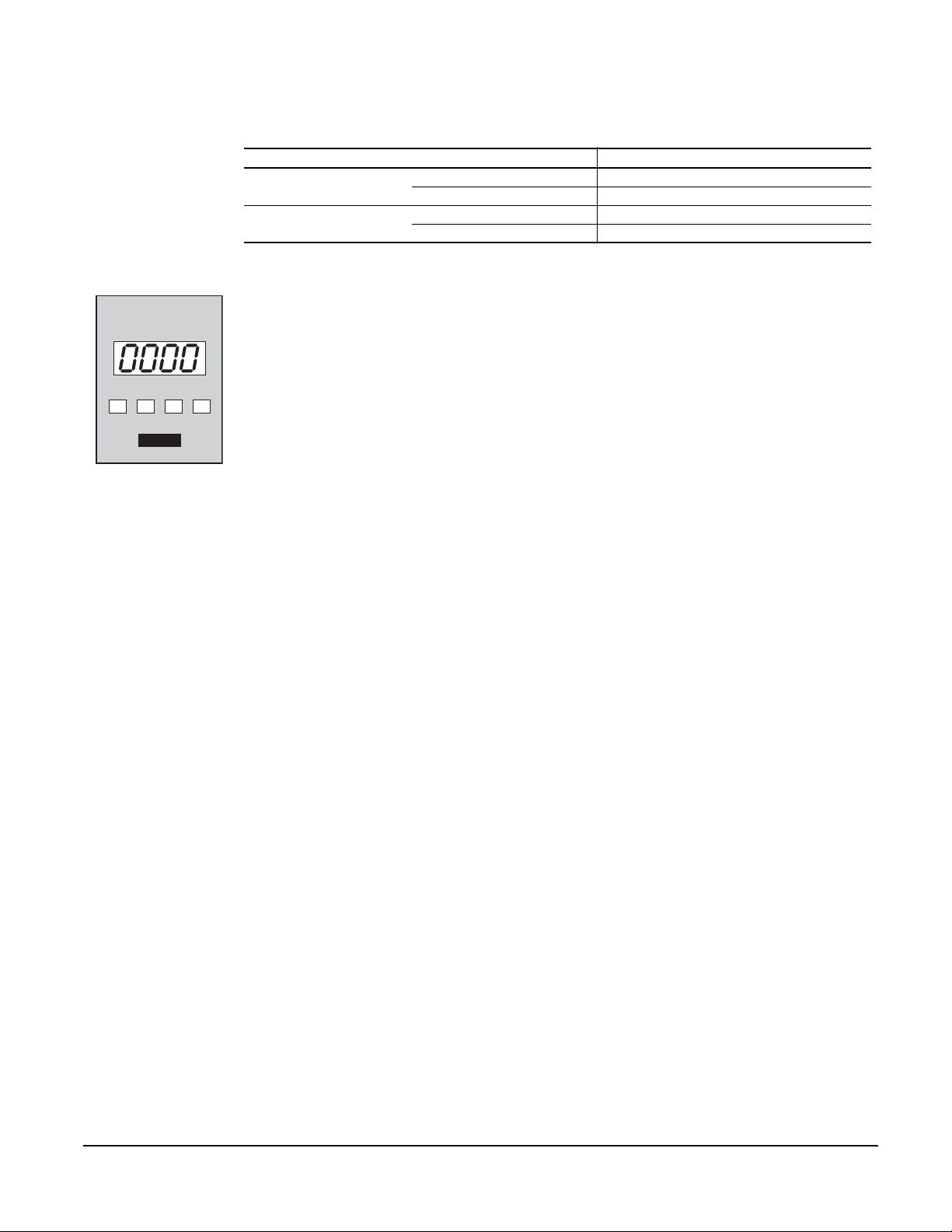

Ammeter (I) A digital display continuously indicates the current of the phase with the greatest load. By pressing a

scroll button, it is also possible to display successively the readings of I1, I2, I3 and I neutral. LEDs

indicate the phase for which the current is displayed.

06153068

A

In I1 I2 I3

Zone-selective

Interlocking (ZSI)

A number of circuit breakers are interconnected one after another by a pilot wire. In the event of a

short-time or earth fault:

• If a given trip unit STR53UP detects the fault, it informs the upstream circuit breaker which applies

the set time delay

• If the trip unit STR53UP does not detect the fault, the upstream circuit breaker trips after its shortest

time delay

Opto-electronic

Outputs

Communication

(COM)

Possible

Combinations

In this way, the fault is cleared rapidly by the nearest circuit breaker. In addition, thermal stresses on

the circuits are minimized and time discrimination is maintained throughout the installation.

The use of opto-transistors ensures total isolation between the internal circuits of the trip unit and the

circuits wired by the user.

®

Transmission of the following data to Digipact

distribution monitoring and control modules:

• Settings

• Phase and neutral currents (rms values)

• Highest current of the three phases

• Overload condition alarm

• I

• T

• I + T

• I + COM

• I + T + COM

• ZSI

• ZSI + I

• ZSI + T

• ZSI + I + T

• ZSI + I + COM

• ZSI + I + T + COM

© 1995–2003 Schneider Electric All Rights Reserved

15

Page 16

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 4—Trip Units

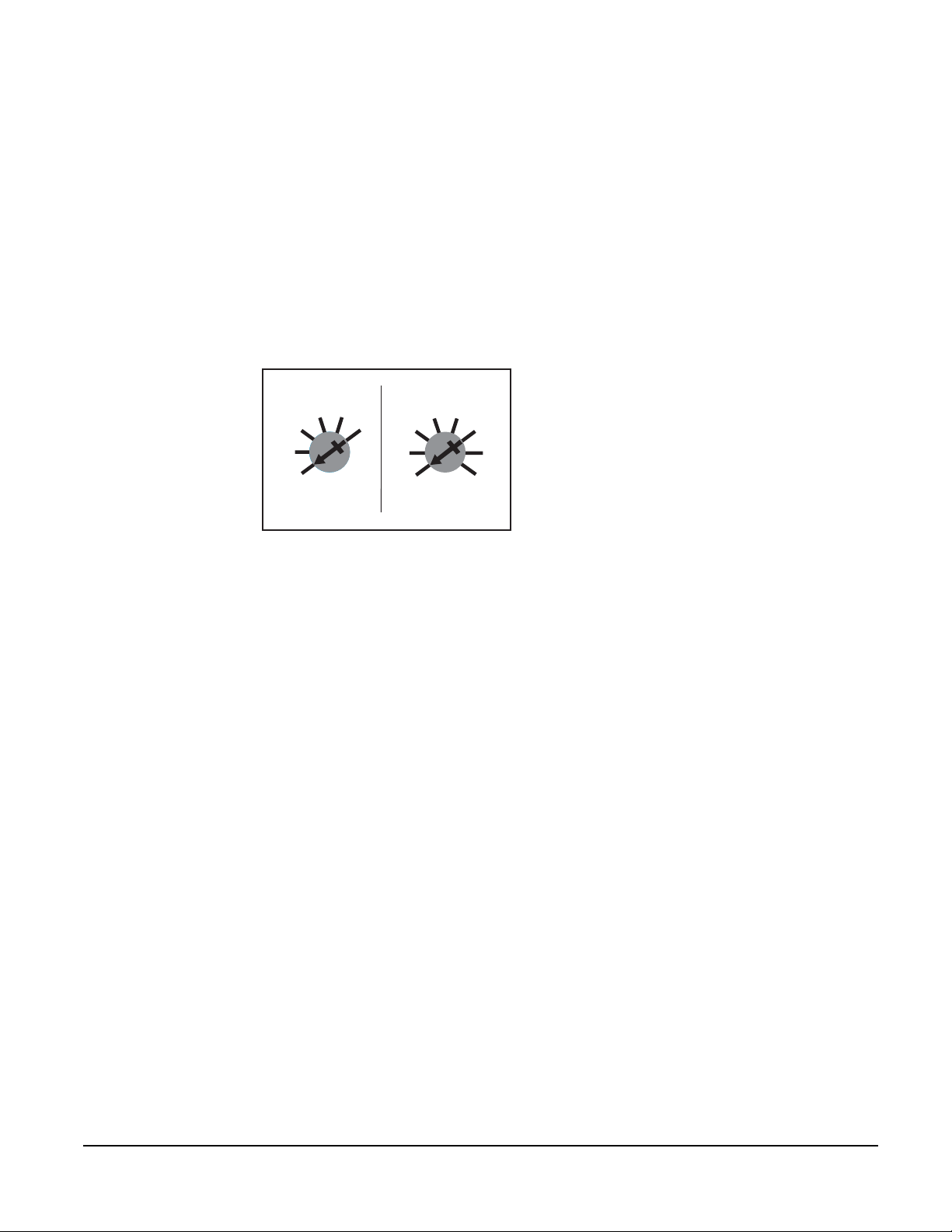

ELECTRONIC TRIP UNIT TEST KITS

The test kits presented below are compatible with Compact® and Masterpact® MP/MC/M circuit

breakers.

Tests performed by test kits are only functional tests designed to electrically test the operating integrity

of the trip unit, the flux shifter and the mechanical operation of the circuit breaker. Tests are not

designed to calibrate the circuit breaker.

Mini Test Kit and

Hand-held Test Kit

Portable Test Kit

and Full-function

Test Kit

The Mini Test Kit and the new generation Hand-held Test Kit are portable units which require no

external power supply. Both are powered by five 9 V alkaline batteries, not supplied. These test kits are

used to check operation of the electronic trip unit and circuit breaker tripping. Connection of either test

kit is made via the test port on the front of the trip unit.

06153069

Mini Test Kit

06133786

Hand-held Test Kit

The Portable Test Kit and the new generation Full-function Test Kit are calibration units. Both require a

power supply of 110 or 240 Vac, 50/60 Hz (two-position selector). These test kits are used to check the

operation of the trip unit by measuring actual trip times:

• At 1.5 x Ir for long-time protection

• At 15 x Ir for short-time protection

• At 0.8 x In for ground-fault protection

16

06153070

Portable Test Kit

06133014

Full-function Test Kit

© 1995–2003 Schneider Electric All Rights Reserved

Page 17

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

SECTION 5—SWITCHES

RATINGS AND INTERRUPTING RATINGS

UL 1087 Listed Ratings

Section 5—Switches

06153061

h

s

u

p

o

t

p

i

tr

Number of Poles

Rated Voltage (V)

Rated Current (A)

AC 50/60 Hz 600Y/ 347 600Y/ 347

*Oversized Neutral Protection: four-pole OSN 125/250 and 150/250 are same ratings as NSF250A.

3, 4, 4P OSN* 3, 4

150 250

IEC 947-3 Ratings

Compact® Switches NSF150A NSF250A

Compact® Switches NSF150A NSF250A

Number of Poles

Rated Insulation Voltage (V) Ui

Rated Impulse Withstand

Voltage (kV)

Uimp

Rated Operational Voltage (V) Ue

Rated Operational Current (V) Ie

Making Capacity (kA peak)

Short-time Withstand Current

(kA rms)

*Oversized Neutral Protection

Icw

AC 50/60 Hz 690 690

DC 500 500

AC23A 690 V 160 250

DC23A 250 V 160 250

DC23A 500 V (2 poles in series) 160 250

Icw (kA rms) 2.5 3.5

Duration (s) 3 3

3, 4, 4P OSN* 3, 4

750 750

88

3.6 4.9

© 1995–2003 Schneider Electric All Rights Reserved

17

Page 18

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 5—Switches

UL 489 Listed Ratings

06153061

h

s

u

p

o

t

p

i

r

t

Number of Poles

Rated Voltage (V)

AC 50/60 Hz 600 600

Rated Current (A)

*Oversized Neutral Protection: four-pole OSN 125/250 and 150/250 are same ratings as NSF250A.

3, 4, 4P OSN* 3, 4

400 600

IEC 947-3 Ratings

Compact® Switches NSF150A NSF250A

Compact® Switches NSJ400A NSJ600A

Number of Poles

Rated Insulation Voltage (V) Ui

Rated Impulse Withstand

Voltage (kV)

Uimp

Rated Operational Voltage (V) Ue

Rated Operational Current (V) Ie

Making Capacity (kA peak)

Short-time Withstand Current

(kA rms)

*Oversized Neutral Protection

Icw

AC 50/60 Hz 690 690

DC 500 500

AC23A 690 V 400 630

DC23A 250 V 400 630

DC23A 500 V (2 poles in series) 400 630

Icw (kA rms) 5 8

Duration (s) 3 3

3, 4, 4P OSN* 3, 4

750 750

88

7.1 8.5

Short-circuit

Withstand Current

Molded case switches are identical to molded case circuit breakers, except they are not equipped with

trip units and sensors. Molded case switches open when the handle is switched to the OFF position or

in response to an auxiliary tripping device such as a shunt trip or an undervoltage release.

These switches open instantaneously at a non-adjustable, factory preset, magnetic trip point calibrated

to protect only the molded case switch itself. Magnetic settings:

• NSF150/250 A switches: 2000 A

• NSJ 400/600 A switches: 6000 A

These switches are suitable for use on a circuit capable of delivering not more than:

• 240 V: 100 kA for NSF switches and 150 kA for NSJ switches

• 480 V: 65 kA for NSF switches and 100 kA for NSJ switches

• 600 V (600Y/347 for NSF switches): 25 kA

Switches are Listed under UL file E103740 and Certified under CSA file LR 88980.

18

© 1995–2003 Schneider Electric All Rights Reserved

Page 19

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

SECTION 6—MOTOR CIRCUIT PROTECTORS

RATINGS AND INTERRUPTING RATINGS

UL 489 Recognized Component

Compact® Circuit Breakers NSF150HC NSF250HC

06153033

h

s

u

p

o

t

p

i

tr

Number of Poles

Rated Voltage (V)

Rated Current (A) In

AC 50/60 Hz 600Y/347 600Y/347

40° C 150 200 250

Magnetic Trip Setting Im

IEC 947-2 and EN 60947-2 Ratings

Compact® Circuit Breakers NSF150HC NSF250HC

Number of Poles

Rated Insulation Voltage (V) Ui

Rated Impulse Withstand

Voltage (kV)

Rated Operational Voltage (V) Ue

Rated Current (A) In

Ultimate Breaking Capacity Icu

(kA rms) 380/415 V 70 70

Service Breaking Capacity Ics

Utilization Category

Uimp

AC 50/60 Hz 690 690

DC 500 500

40° C 150 200 250

AC 50/60 Hz 220/240 V 100 100

440 V 65 65

500 V 50 50

525 V 35 35

660/690 V 10 10

DC 250 V (1 pole) 85 85

500 V (2 poles in series) 85 85

(% Icu) 100% 100%

Section 6—Motor Circuit Protectors

33

900-1800

33

750 750

88

1000–

2000

HC HC

AA

1250–

2500

© 1995–2003 Schneider Electric All Rights Reserved

19

Page 20

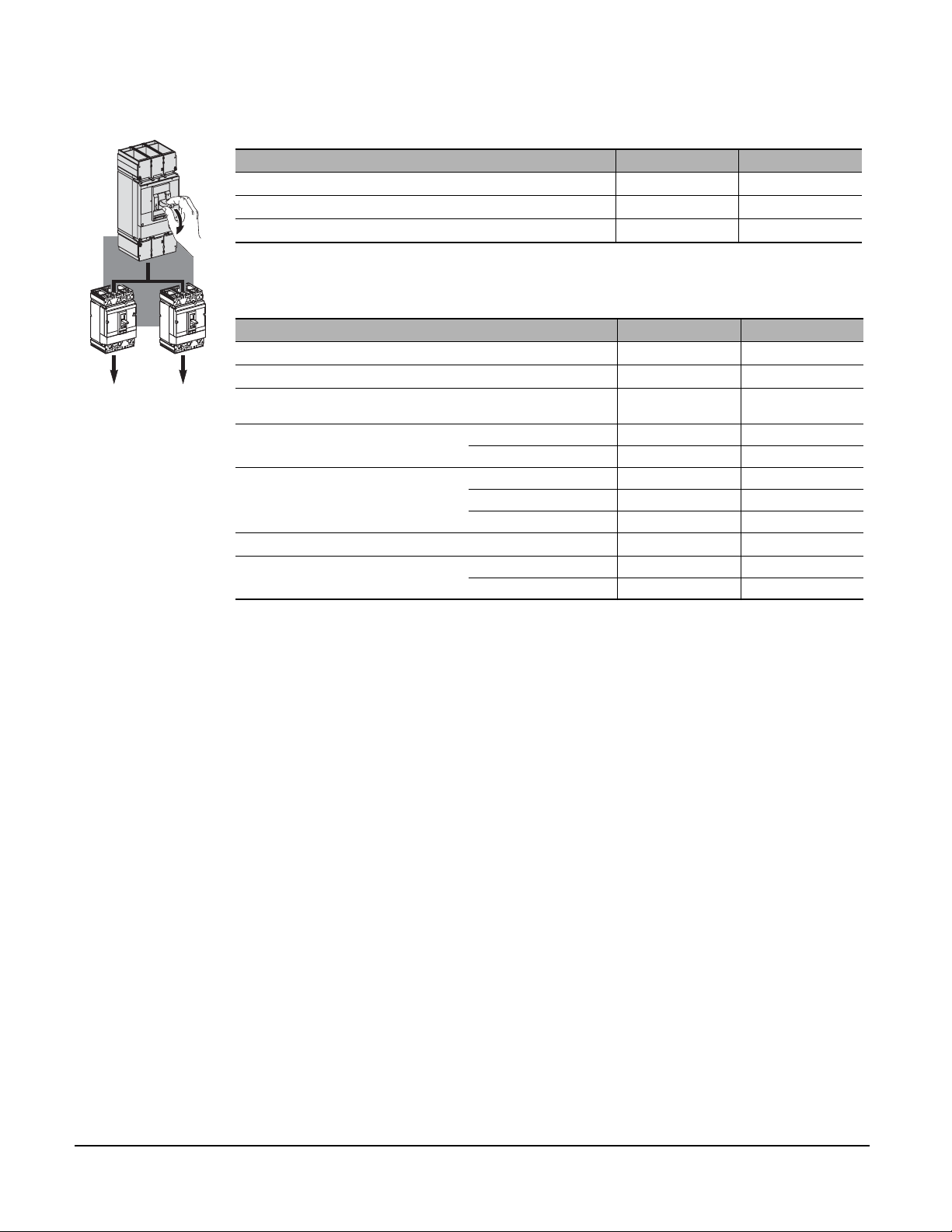

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 6—Motor Circuit Protectors

UL 489 Recognized Component

Compact® Circuit Breakers NSJ400HC NSJ600HC

06153033

h

s

u

p

o

t

p

i

tr

Number of Poles

Rated Voltage (V)

Rated Current (A) In

AC 50/60 Hz 600 600

40° C

Magnetic Trip Setting Im

IEC 947-2 and EN 60947-2 Ratings

Compact® Circuit Breakers NSF150HC NSF250HC

Number of Poles

Rated Insulation Voltage (V) Ui

Rated Impulse Withstand

Voltage (kV)

Rated Operational Voltage (V) Ue

Rated Current (A) In

Ultimate Breaking Capacity Icu

(kA rms) 380/415 V 70 70

Service Breaking Capacity Ics

Utilization Category

Uimp

AC 50/60 Hz 690 690

DC 500 500

40° C 400 600

AC 50/60 Hz 220/240 V 100 100

440 V 65 65

500 V 30 30

525 V 35 35

660/690 V 20 20

DC 250 V (1 pole) 85 85

500 V (2 poles in series) 85 85

(% Icu) 100% 100%

33

400 (100% Rated

Circuit Breaker)

600

2000–4000 3000–6000

33

750 750

88

HC HC

AA

20

© 1995–2003 Schneider Electric All Rights Reserved

Page 21

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

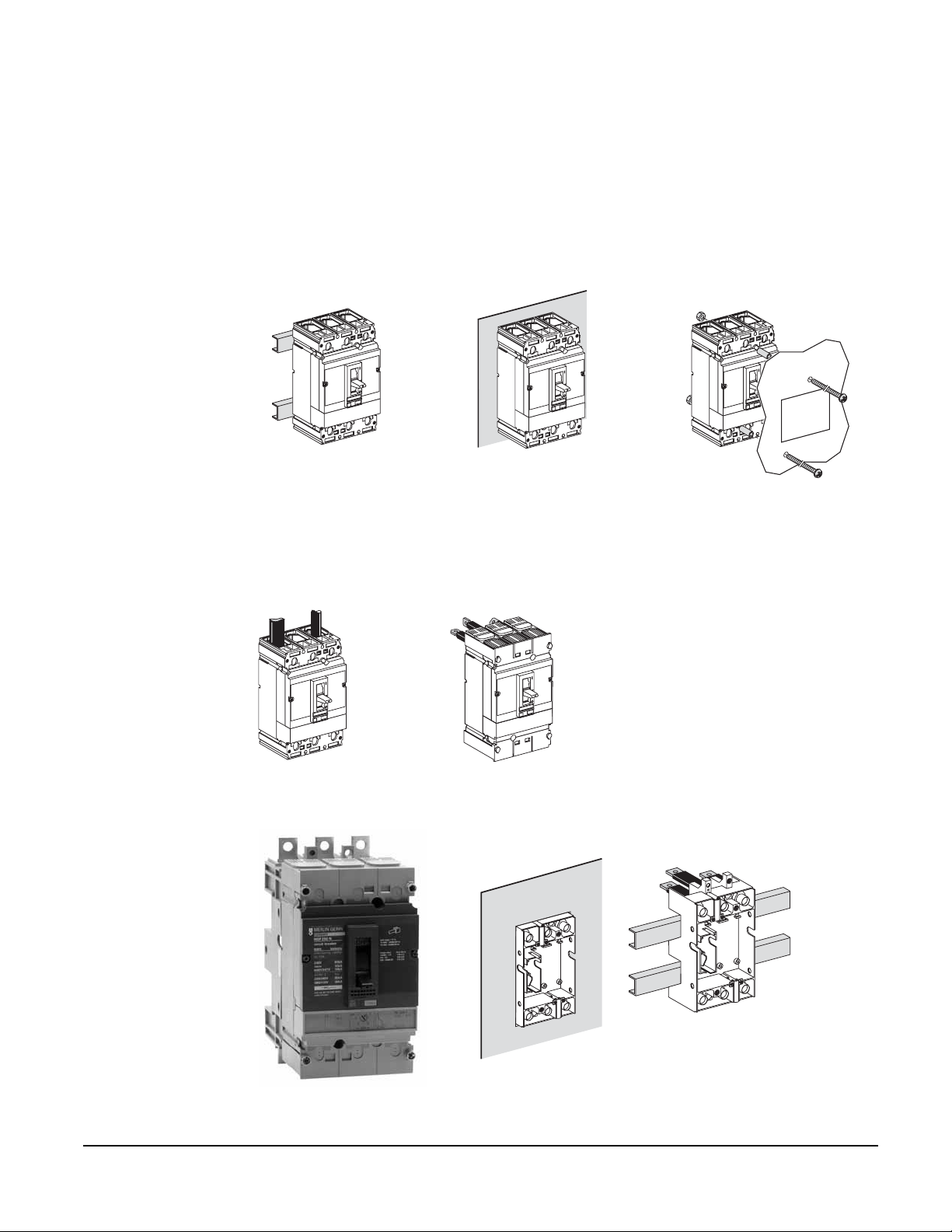

SECTION 7—MOUNTING CONFIGURATIONS

Refer to circuit breaker installation instructions before installing circuit breaker, accessories or wiring.

FIXED MOUNTING

Section 7—Mounting Configurations

CONNECTIONS

Mounting on Rails

06153071

h

s

pu

to

trip

Mounting on Backplate

06153072

h

s

u

p

o

t

p

i

r

t

Flush Mounting

06153073

h

s

pu

to

ip

r

t

See Section 8—Connections for details. Compact® NSF and NSJ circuit breakers suitable for reverse

feeding.

Front Connection

06153074

h

s

u

p

to

p

i

tr

Rear Connection

06153075

h

s

u

p

o

t

p

i

r

t

PLUG-IN MOUNTING

06153076

© 1995–2003 Schneider Electric All Rights Reserved

Mounting through

Front Panel

06153077

Mounting on Rails

06153078

21

Page 22

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 7—Mounting Configurations

The plug-in configuration makes it possible to:

• Extract and/or rapidly replace the circuit breaker without having to touch connections

• Allow for addition of future circuits at a later date

When the circuit breaker is in the connected position, the primary voltage is fed through the circuit

breaker by means of multiple finger disconnects. Control voltage of internal accessories is provided

through secondary disconnects.

Parts of a Plug-in

Configuration

Compact® circuit breaker (fixed mounted)

• Set of power and secondary disconnects that are added to the circuit breaker

• Plug-in base for mounting through a front panel or on rails

• Safety trip, to be installed on the circuit breaker, which causes automatic tripping if the circuit

breaker is ON before engaging or withdrawing it; the safety trip does not prevent circuit breaker

operation, even when the circuit breaker is disconnected

• Mandatory short terminal shields

The plug-in mounting is Listed under UL file E113555 and Certified under CSA file LR 69561.

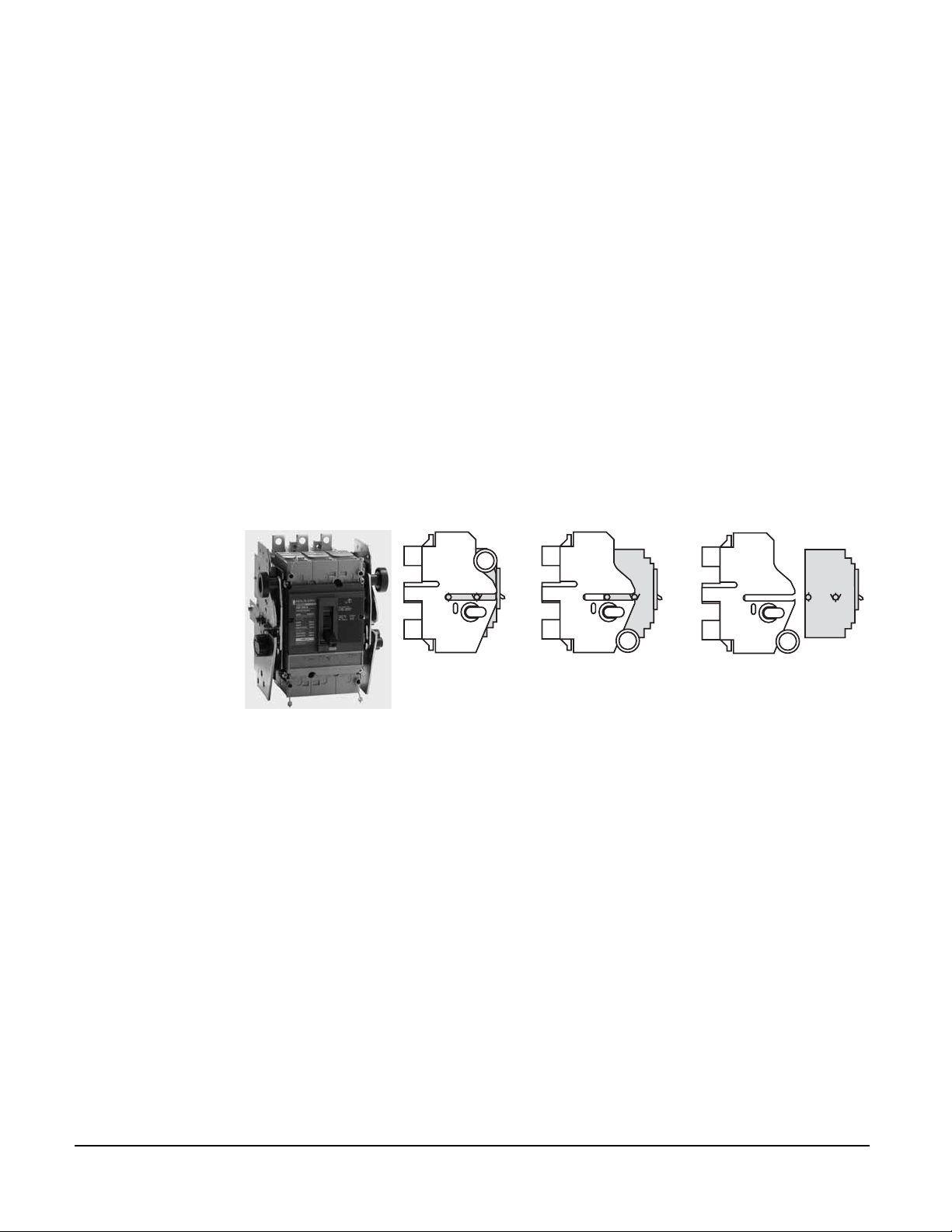

DRAWOUT MOUNTING

The chassis is made up of two side plates installed on the base and two other plates mounted on the

circuit breaker.

06153079

06153080

Connected

RemovedDisconnected

Chassis Functions All functions of the plug-in base, plus:

• Disconnected position: the power circuits are disconnected, the circuit breaker is simply

"withdrawn" and may still be operated (on, off, push-to-trip)

• Circuit breaker may be locked using 1 to 3 padlocks—diameter 0.19 to 0.31 inch (5 to 8 mm)—to

prevent connection

• Auxiliaries can be tested using manual auxiliary connector

Mounting • On a backplate, through a front panel or on rails

• Horizontally or vertically

22

© 1995–2003 Schneider Electric All Rights Reserved

Page 23

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 7—Mounting Configurations

Accessories • Auxiliary switches for installation on the fixed part of the chassis, indicating the "connected" and

"disconnected" positions

• Toggle collar for circuit breakers with toggle through front panel, intended to maintain the degree of

protection whatever the position of the circuit breaker (supplied with a toggle extension)

• Keylock which, depending on the bolt fitted, can be used to:

— Prevent insertion for connection

— Lock the circuit breaker in connected or disconnected position

• Telescopic shaft for extended rotary handles

Connection of

Auxiliaries

Control voltage is provided through automatic secondary disconnects in the connected position only.

See Section 8—Connections for more details. Electrical accessories can be tested in the disconnected

position with an external wiring harness.

The drawout-mounted chassis is Listed under UL file E113555 and Certified under CSA file LR 69561.

© 1995–2003 Schneider Electric All Rights Reserved

23

Page 24

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 8—Connections

SECTION 8—CONNECTIONS

FRONT CONNECTION

Connection to

Cables

06153081

h

s

pu

o

t

p

i

tr

Copper or Aluminum

Cable

Cable connectors for Compact® NSF150 and NSF250 circuit breakers surround the circuit breaker

terminals. They are positioned by an insulating lug pack which is anchored to the circuit breaker case.

06153082

06153083

Cable connectors for Compact NSJ400 and NSJ600 circuit breakers bolt onto the circuit breaker

terminals or the terminals of the plug-in base.

06153084

One-wire Cable

NSF150 NSF150/250

Steel Lug (15–60 A) Aluminum Lug (70–250 A)

S

06153086

06153085

Two-wire Cable

#14 AWG–#3/0 AWG Cu (Solid or Stranded)

#12 AWG–#4/0 AWG Al (Stranded Only)

2.5–95 mm

2

CU/AL

#2/0 AWG–250 kcmil Cu (Stranded Only)

S

70–120 mm

#4/0 AWG–300 kcmil Al (Stranded Only)

95–150 mm

2

2

L

L

S

NSJ400 NSJ600

1 Cable 1–2 Cable

S

L

0.79 in.

20 mm

#2 AWG–600 kcmil Cu (Stranded Only)

35–300 mm

#2 AWG–500 kcmil Al (Stranded Only)

35–240 mm

1.2 in.

31 mm

2

2

Cu/AL

L

S

L

0.79 in.

20 mm

#2/0 AWG–350 kcmil Cu (Stranded Only)

70–185 mm

#2/0 AWG–500 kcmil Al (Stranded Only)

70–240 mm

1.2–2.4 in.

31–61 mm

2

2

24

© 1995–2003 Schneider Electric All Rights Reserved

Page 25

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 8—Connections

Connection to

Bars

Compact® NSF150 to NSJ600 circuit breakers are equipped as standard with captive nuts and screws

for direct connection to bars:

• Compact NSF150/250 circuit breakers—M8 screws

• Compact NSJ400/600 circuit breakers—M10 screws

06153087

06153088

e

h

s

u

p

to

trip

∅

L

Compact®Circuit Breaker NSF150/250 NSJ400/600

Pole Pitch

L

d

D

e

∅

D

d

REAR CONNECTION

in. / mm 1.4 / 35 1.8 / 45

in. / mm -1 / 25 -1.3 / 32

in. / mm -0.4 / 10 -0.64 / 16

in. / mm < 0.35 / 9 < 0.51 / 13

in. / mm -0.23 / -6 0.11–0.39 / 3–10

in. / mm < 0.32 / 8 < 0.4 / 10

Fixed Mounting For connection of bars or cables with compression lugs. Rear connections are easily installed on the

circuit breaker terminals. The same connection may be installed flat, edgewise or at a 45° angle. All

combinations are possible. The circuit breaker is mounted on a backplate.

Plug-in Mounting

and Drawout

06153089

sh

u

p

o

t

trip

For connection of bars or cables with compression lugs. Rear connections are installed flat. The plug-in

base or the chassis are mounted through a front panel.

06153090

One Long + Two Short

06153091

Four Positions

Mounting

06153092

06153093

Plug-in Mounting Drawout Mounting

© 1995–2003 Schneider Electric All Rights Reserved

push

to

p

ri

t

25

Page 26

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

SECTION 9—ACCESSORIES

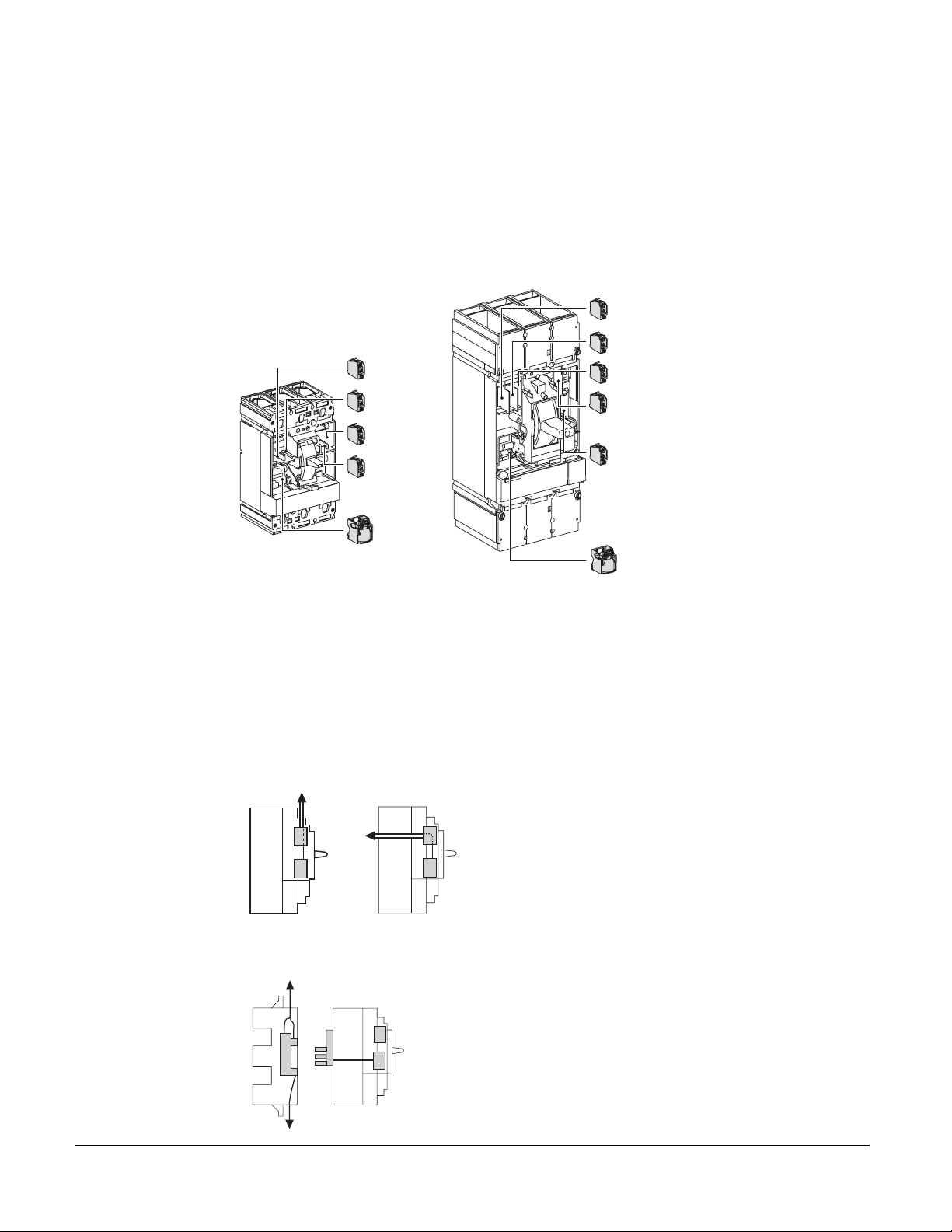

LOCATION

Internal accessories comply with requirements of Underwriters Laboratories Inc. UL 489 and Canadian

Standard Association C22.2 No. 5.1 Standards. All internal accessories are Listed for fixed installation

per UL file E103955 and Certified under CSA file LR 69561.

Auxiliary Switch

(OF1)

06153094

Auxiliary Switch

(OF1)

Alarm Switch

(SD)

Auxiliary Switch

(OF2)

Overcurrent

Trip Switch (SDE)

Shunt Trip (MX)

or Undervoltage

Trip (MN)

Auxiliary Switch

(OF2)

Auxiliary Switch

(OF3)

Alarm Switch

(SD)

Overcurrent

Trip Switch (SDE)

Shunt Trip (MX)

or Undervoltage

Trip (MN)

NSF150/250 NSJ400/600

CONNECTIONS

Each electrical accessory is fitted with numbered terminal blocks for wires with the following maximum

size:

• #16 AWG (1.5 mm

• #14 AWG (2.5 mm

Fixed Mounting Auxiliary circuits exit the device through a knock-out in the front cover.

06153095

Plug-in and

Drawout Mounting

06153097

2

) for auxiliary switches, undervoltage and shunt trip or undervoltage trip

2

) for the motor operator

06153096

26

© 1995–2003 Schneider Electric All Rights Reserved

Page 27

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

AUTOMATIC SECONDARY DISCONNECTING BLOCKS

Accessory circuits exit the circuit breaker via one to three secondary disconnecting blocks (nine wires

each). For Compact

unit STR53UP also exit via the automatic secondary disconnecting blocks. These are made up of:

• A moving part connected to the circuit breaker via a support (one support per circuit breaker)

• A fixed part mounted on the plug-in base, equipped with connectors for wires up to

#14 AWG (2.5 mm

06153098

®

NSJ400/600 circuit breakers connection wires for the options installed with trip

2

)

06153099

Section 9—Accessories

OF1

SD

MN/MX

®

Compact

06153100

Nine-wire Manual Auxiliary Connector

OF2

SDE

MT

NSF150 and NSF250 Circuit Breakers

OF1

SD

MN/MX

Compact

OF2

SDE

MT

®

NSJ400 and NSJ600 Circuit Breakers

OF3

SDV

COM

R/T

© 1995–2003 Schneider Electric All Rights Reserved

27

Page 28

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

AUXILIARY AND ALARM SWITCHES

06153101

Changeover

Switches

Auxiliary switches provide remote information of the circuit breaker status and can thus be used for

indications, electrical locking, relays, etc.

Functions • OF (open/closed): auxiliary switch—indicates position of the circuit breaker contacts

• SD (trip indication): bell alarm—indicates that the circuit breaker has tripped due to

— Overload

— Short circuit

— Ground fault

— The operation of a shunt trip or undervoltage trip or the "push-to-trip" button which resets when

the circuit breaker is reset

• Operation of a plug-in base or chassis when attempting to withdraw the circuit breaker in ON

position; SDE (fault indication): indicates the circuit breaker has tripped due to an overload, short

circuit or ground fault; resets when circuit breaker is reset

• CAM (early-make or early-break function): indicates the position of the rotary handle; used in

particular for advanced-opening safety trip devices

• Connected/disconnected: indicates the position of a drawout circuit breaker

• Switching of very low loads: all above auxiliary switches are also available in low-level versions

capable of switching very low loads (e.g., for controlling PLCs or electronic circuits)

Standards Auxiliary switches comply with UL 489, CSA C22.2 No. 5.1 and IEC 947-5 Standards. “Low-level"

switches are not UL Listed.

Installation • Functions OF, SD and SDE:

— Switches snap into cavities under front accessory cover of the circuit breaker

— For Compact

depending on where it is fitted in the circuit breaker

®

NSF150–NSJ600 circuit breakers, one model serves for all indication functions

• SDE function of a circuit breaker equipped with a thermal-magnetic trip unit requires the SDE

actuator

• CAM: to be fitted in the rotary handle module; depending on how it is installed, it ensures either the

CAO (early-break) or the CAF (early-make) function "Connected/disconnected" function; two parts

to be fitted on the chassis and the drawout circuit breaker

28

© 1995–2003 Schneider Electric All Rights Reserved

Page 29

Electrical Ratings

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

UL 489 and CSA C22.2 No. 5.1 Ratings

Minimum Rating

Maximum Current and Voltage

Maximum Rating

IEC 947 Ratings

Rated Thermal Current (A)

Minimum Rating

Maximum Current and Voltage

Utilization Category

(IEC 947-4)

Operational Current (A)

50/60 Hz 240 V 5 6

480 V 5 6

DC 48 V 2.5 2.5

600 V — 3

125 V 0.8 0.8

250 V 0.3 0.3

Low-level Switches Regular Switches

56

1 mA–4 V 10 mA–24 V

100 mA–10 V 6 A–480 V

If the maximum voltage and current are

exceeded, the low-level characteristics of

the switch will be compromised.

However, the switch will still function as a

standard switch to the following

specifications:

ac dc ac dc

AC12 AC15 DC12 DC14 AC12 AC15 DC12 DC14

24 V 5351662.51

48 V 5 3 2.5 0.2 6 6 2.5 0.2

110 V 5 2.5 0.8 0.05 6 5 0.8 0.05

220/240 V 5 2 — — 6 4 — —

250 V — — 0.3 0.03 — — 0.3 0.03

380/415 V 5 1.5 — — 6 3 — —

440 V 5 1.5 — — 6 3 — —

660/690 V — — — — 6 0.1 — —

Section 9—Accessories

Low-level Switches Regular Switches

1 mA–4 V 10 mA–24 V

100 mA–10 V 6 A–480 V

If the maximum voltage and

current are exceeded, the lowlevel characteristics of the switch

will be compromised. However,

the switch will still function as a

standard switch to the following

specifications:

© 1995–2003 Schneider Electric All Rights Reserved

29

Page 30

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

SHUNT TRIP AND UNDERVOLTAGE TRIP

A voltage release can be used to trip the circuit breaker via a control signal.

06153102

Undervoltage trip

(MN)

• Trips circuit breaker when the control voltage drops below a tripping threshold

• Drops out between 35% and 70% of rated voltage

• Circuit breaker closing is possible only if the voltage exceeds 85% of rated voltage

• Permanent type

• If an overvoltage condition exists, operation of circuit breaker closing mechanism will not permit the

main contacts to touch, even momentarily

Shunt trip (MX) • Trips the circuit breaker when control voltage rises above 70% of its rated voltage

• Impulse type ≥ 20 ms or maintained control signals

• AC shunt trips can be operated at 55% of their rated voltage, making them suitable for ground-fault

protection when combined with a Class I ground-fault sensing element

Operation • The circuit breaker must be reset locally after being tripped by shunt trip or undervoltage trip

(MN or MX)

• MN or MX tripping has priority over manual (or motor operator) closing; in the presence of a

standing trip order such an action does not result in any closing, even temporarily, of the main

Installation and

Connection

contacts

• Endurance: 50% of the rated mechanical endurance of the circuit breaker for Compact

NSJ600 circuit breakers

• Accessories are common to NSF and NSJ circuit breakers and are located within the circuit breaker

behind front accessory cover

• Each terminal may be connected by one #18–#14 AWG (1.0–2.5 mm

Electrical Characteristics

2

) stranded copper wire

®

NSF150–

30

Rated Voltage (V)

Consumption

Clearing Time (ms)

AC DC

24, 48, 110–130, 208–277, 380–480, 525, 600 12, 24, 30, 48, 60, 125, 250

Pickup (MX) < 10 VA < 5 W

Seal-in (MN) < 5 VA < 5 W

< 50 < 50

© 1995–2003 Schneider Electric All Rights Reserved

Page 31

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

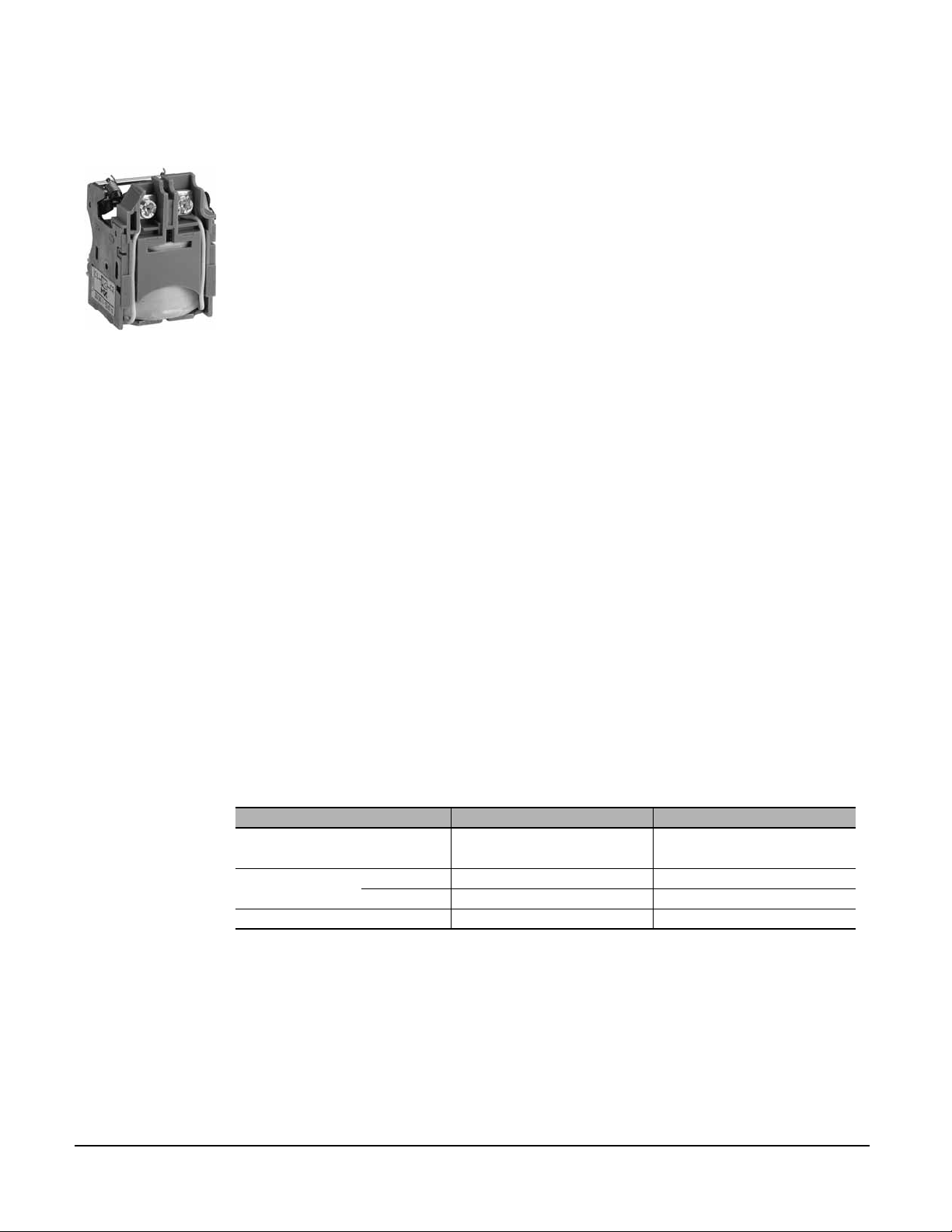

MOTOR OPERATOR

The motor operator remotely operates the circuit breaker featuring easy and sure operation:

• All circuit breaker indications and information remain visible and accessible, including trip units

06153103

Applications • Local motor-driven operation, centralized operation, automatic distribution control

settings and circuit breaker connection

• Suitability for isolation is maintained and padlocking remains possible

• Double insulation front face

• Normal/standby source changeover or switching to a replacement source to optimize energy costs

• Load shedding and reconnection to optimize energy costs

• Synchrocoupling—less than five cycle closing time

Automatic

Operation

• On and off by two impulse type or continuous control signals

• Depending on the wiring, resetting can be done locally, remotely or automatically

• Mandatory manual reset following tripping due to an electrical fault

Manual Operation • Transfer to manual mode using switch with possibility of remote mode indication

• On and off by two push buttons

• Recharging of stored-energy system by pumping the lever nine times

• Padlocking in off position

Installation and

Connection

• All installation (fixed, plug-in/drawout mounting) and connection capabilities are maintained

• Connection of the motor operator module behind its front cover to a built-in terminal block, for

stranded copper wire #14 AWG (2.5 mm

2

)

© 1995–2003 Schneider Electric All Rights Reserved

31

Page 32

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

Accessories for

NSJ400/600

• Keylock for locking in OFF position

• Operations counter, indicating the number of ON and OFF cycles; the counter must be installed on

the front of the motor operator module.

Characteristics

NSF NSJ

Response Time (ms)

Max. Cycles Frequency Per Minute

Control Voltage (V)

Consumption

Minimum Operating Order

Operating Voltage

AC 50/60 Hz 48–60 48–60

DC 24–30 24–30

AC (VA) Opening -500 —

DC (W) Opening -500 —

Opening < 500 —

Closing < 80 —

4—

110–130 110–130

208–277 208–277

380–480 380–415

440–480

48–60 48–60

110–130 110–130

250 250

Closing -500 —

Closing -500 —

700 ms —

85–110% Rated Voltage —

06153104

10

MERLIN GERIN

compact

NSJ 400 N

circuit breaker

600V

UL inter. ratings

RMS Sym Amps

240V

480V

600V

IEC947

.2

220/240V

380/415V

Ics = 100% Icu

Uimp = 8kV

UTE VDE BS CEI UNE NEMA

In = 400A

manu

1 3

50/60Hz

65k

35k

25k

Ic

u

85kA

45kA

auto

2

O OFF

O

push OFF

89

charged

I

push ON

7

4

5 6

2

2

1

1

1. Contact position indicator (suitability for isolation)

2. Outgoing circuit identification labels

3. Spring status indicator (charged, dischar ged)

4. Locking device (keylock) on NSJ400/600

5. Locking device (off position) using one to three padlocks, diameter

0.2–0.32 in. (5–8 mm), not supplied

6. Manual spring-charging handle

7. ON push button

8. OFF push button

9. Manual/auto mode selection switch; the position of the switch can be indicated

remotely

10. Operations counter (Compact

®

NSJ400/600 circuit breaker)

32

© 1995–2003 Schneider Electric All Rights Reserved

Page 33

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

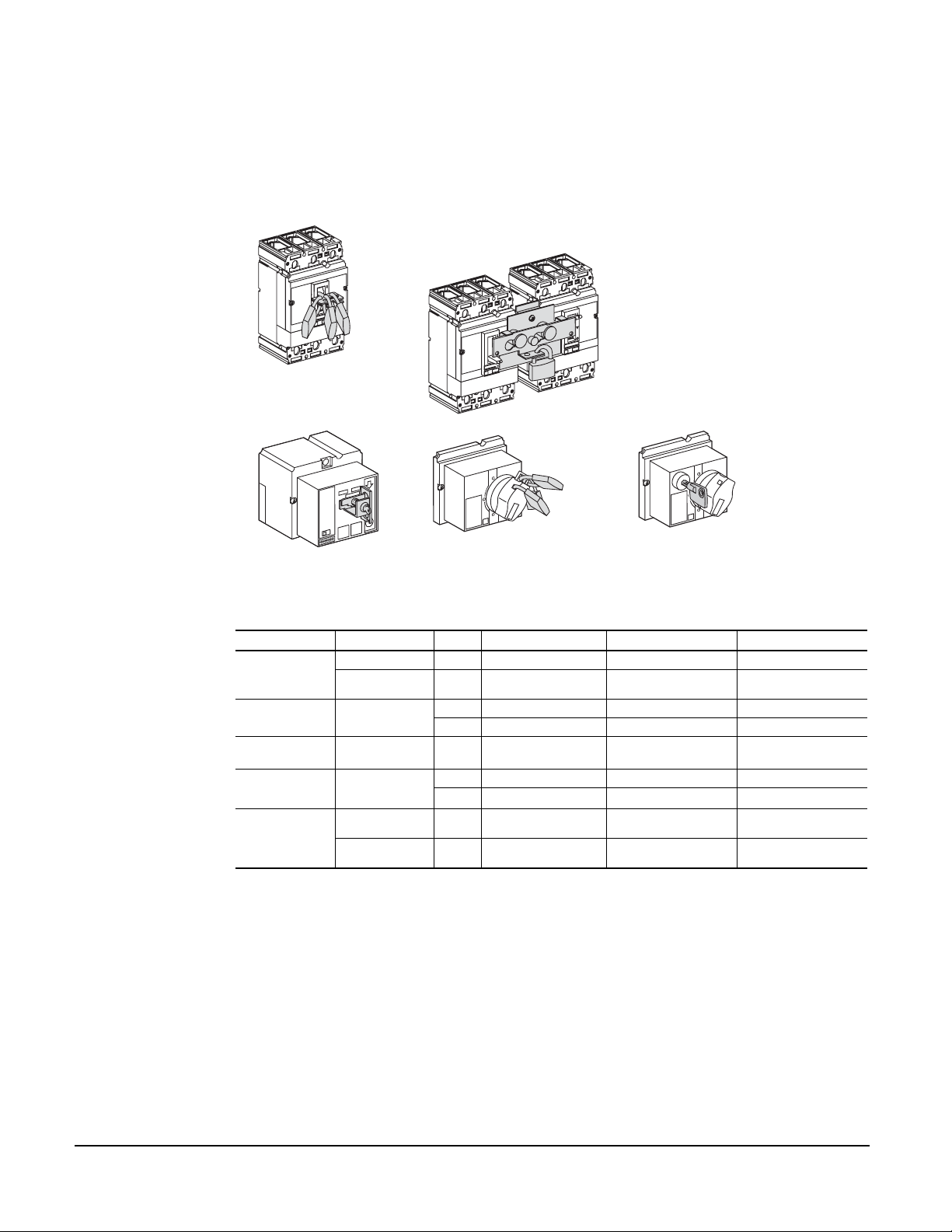

ROTARY OPERATING HANDLES

Operation • The direct rotary handle maintains

— Suitability for isolation

— Indication of three positions: O (off), I (on) and tripped

— Access to the "push-to-trip" button

— Visibility of, and access to, trip unit settings

Section 9—Accessories

Directly Mounted

tripped

ON

I

reset

O

OFF

06153105

Closing

I/ON

(Closed)

Tripped

Reset

O/OFF

(Open

Isolated)

• The circuit breaker may be locked in the off position by using one to three padlocks, padlock

shackle diameter 0.19–0.31 in. (5–8 mm); padlocks are not supplied

06153106

Installation Replaces the circuit breaker front accessory cover (secured by screws).

Models

• Standard with black handle

• VDE type with red handle and yellow bezel for machine tool control

Variations for

Compact

®

NSF150–

NSJ600 Circuit

Breakers

Accessories transform the standard direct rotary handle for the following situations:

• Motor control centers (MCCs)

— Opening of door prevented when circuit breaker is on

— Closing of circuit breaker inhibited when door is open

• Machine tool control; complies with CNOMO E03.81.501N; degree of protection IP54

The directly-mounted rotary operating handle is Listed under UL file E103955 and Certified under CSA

file LR 69561.

© 1995–2003 Schneider Electric All Rights Reserved

33

Page 34

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

Door Mounted Makes it possible to operate circuit breakers installed inside an enclosure from the front. The handle

mechanism can be used in NEMA 3R and 12 enclosure applications. Degree of protection: IP40 as per

IEC 529.

06153107

Operation

• The unit maintains:

— Suitability for isolation

— Indication of the three positions: O (off), I (on) and tripped

— Visibility of and access to trip unit settings when door is open

• Defeatable interlock prevents opening of door when circuit breaker is on

• Circuit breaker may be locked in the off position by using one to three padlocks, padlock shackle

diameter 0.19–0.31 in. (5–8 mm); padlocks are not supplied; locking prevents opening of the

switchboard door

Models

• Standard with black handle

• VDE type with red handle and yellow bezel for machine tool control

Installation The extended rotary operating handle is made up of:

• A unit that replaces the front accessory cover of the circuit breaker (secured by screws)

• An assembly (handle and front plate) on the door that is always secured in the same position,

whether the circuit breaker is installed vertically or horizontally

• An extension shaft that must be adjusted; the distances between back of circuit breaker and door

Variation for

Compact

NSJ600 Circuit

Breakers

®

NSF150–

are

— Compact

— Compact NSJ400/600 circuit breakers: 8.4–25 in. (210–625 mm)

For withdrawable configurations, the extended rotary handle is also available with a telescopic shaft

containing two stable positions. The extended rotary operating handle is Listed under UL file E103955

and Certified under CSA file LR 69561.

®

NSF150/250 circuit breakers: 7.4–24 in. (185–600 mm)

34

© 1995–2003 Schneider Electric All Rights Reserved

Page 35

CABLE OPERATING HANDLE

The extended rotary operating handle is Listed under UL file E103955 and Certified under CSA file LR

69561.

06153108

h

s

u

p

o

t

p

tri

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

O

O

FF

Flange-mounted

Handle Cable

Operating

Mechanism

•

The cable operator maintains:

— Suitability for isolation

— Indication of three positions: O (Off), I (On) and tripped

— Access to push-to-test

• The circuit breaker may be locked in the off position by one to three padlocks, padlock shackle

diameter 0.19–0.31 in. (5–8 mm); padlocks are not supplied

• Door can be locked closed due to interlocking features of handle operator

Installation Handle is mounted on flange of enclosure using specified mounting dimensions while circuit breaker

and operating mechanism are mounted to inside of enclosure using two screws.

Cable lengths available in 3-, 5- or 10-foot lengths to accommodate a variety of mounting locations.

Handles are available in painted Nema 1, 3, 3R, 4 (sheet steel) and 12 ratings or chrome (Nema 4, 4x).

© 1995–2003 Schneider Electric All Rights Reserved

35

Page 36

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

LOCKING SYSTEMS

Padlocking systems can receive up to three padlocks with diameters ranging from

0.19–0.31 in. (5–8 mm) ; padlocks not supplied.

Locking In the Off

Position

06153109

06153110

push

to

trip

push

to

trip

push

to

trip

Locking of the Toggle Using a

Fixed Device

Locking of the Toggle Using a

Stationary Device

06153111

I

ush

p

manu/auto

O

ON

ush

p

OFF

Locking of the Motor Operator

Using a Keylock

2

1

06153112

Locking of the Rotary Handle Using

a Padlock or a Keylock

ON

I

O

OFF

06153113

Locking of the Rotary Handle Using

a Keylock

profalux

profalux

ON

I

O

F

OF

Control Device Function Means Required Accessories Compact® NSF150/250 Compact® NSJ400/600

Toggle

Direct Rotary

Handle

MCC Rotary

Operating Handle

Extended Rotary

Operating Handle

Motor Operator

Lock In Off Position Padlock Removable Device ■■

Lock In Off or On

Position

Lock In Off Position

Padlock Stationary Device ■■

Padlock — ■■

Keylock Locking Device + Keylock

Lock In Off Position Padlock — ■■

Lock In Off Position,

Door Opening

Prevented

Lock In Off Position,

Motor

Mechanism Locked

Out

Padlock — ■■

Keylock Keylock

Padlock —

Keylock

Locking Device (Keylock

Incorporated)

■■

■

36

© 1995–2003 Schneider Electric All Rights Reserved

Page 37

INTERLOCKING ACCESSORIES

Interlocking prevents simultaneous closing of two circuit breakers.

Control Device Means NSF150–NSJ600

Toggle

Rotary Handle (Directly or Door Mounted)

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

Sliding Bar Interlocking Mechanical Device ■

Mechanical Interlocking ■

2 Keylocks and 1 Key ■

Interlocking of

Circuit Breakers

with Toggle

Control

Interlocking of

Circuit Breakers

with Rotary

Handles

Two models:

• For Compact

• For Compact

®

NSF150–NSF250 circuit breakers (three-pole or four-pole)

®

NSJ400–NSJ600 circuit breakers (three-pole or four-pole)

Padlocking systems can receive one or two padlocks with diameters ranging from

0.19–0.31 inch (5–8 mm). Both interlocked circuit breakers should be fixed version or plug-in version.

Two sliding interlocking bars can be used to interlock three circuit breakers installed side-by-side, in

which case one circuit breaker is in the ON position and the two others in the OFF position.

06153114

push

to

trip

push

to

trip

Interlocking with Toggle Control

For Compact® NSF150–NSJ600 circuit breakers

06153115

ON

I

ON

I

tripped

push

to

trip

reset

O

OFF

O

OFF

ON

I

ON

I

ripped

t

push

to

p

ri

t

reset

O

OFF

O

OFF

Interlocking with Rotary Handles

© 1995–2003 Schneider Electric All Rights Reserved

37

Page 38

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

Interlocking with

Keys

For circuit breakers equipped with rotary handles or a motor mechanism. Interlocking with keys may be

easily implemented by equipping each of the Compact

®

circuit breakers, either fixed or drawout

mounted, with a directly mounted rotary operating handle and a standard keylock, but with only one key

for the two keylocks. This solution enables interlocking between two circuit breakers that are

geographically distant or that have significantly different characteristics.

Use:

• A keylock adapter (different for each device)

• Two identical keylocks with a single key

06153116

ON

I

ON

I

O

OFF

h

s

u

p

o

t

trip

sh

u

p

o

set

t

e

r

p

i

tr

O

OFF

Interlocking with Keys

38

© 1995–2003 Schneider Electric All Rights Reserved

Page 39

FRONT-PANEL ESCUTCHEONS

∅

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

For Fixed or Plugin Mounting

Front-panel

Escutcheons for

Toggle

Front-panel

Escutcheon for

Motor Operator

Module or Rotaryoperating Handle

Door escutcheon provides better appearance of the door contact.

Secures to the panel, from the front.

06153117

h

s

pu

to

trip

Secures to the panel by four screws, from the front.

06153118

2

2

d

rge

d

scha

i

d

rge

scha

i

d

F

OF

O

OFF

O

5...8

5...8

∅

1

1

I

I

O

O

ON

push ON

sh

pu

push OFF

OFF

sh

pu

06153119

ON

I

O

h

us

p

F

to

OF

trip

Toggle Boot

• Protection up to NEMA 3M

• Fits on front of circuit breaker

06153120

© 1995–2003 Schneider Electric All Rights Reserved

39

Page 40

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 9—Accessories

For Drawout

Mounting

Toggle Collars The toggle collars make it possible to maintain degrees of protection regardless of the circuit breaker

position (connected, disconnected).

• Front panel escutcheons are obligatory (identical to those for rotary handle and ammeter module)

• Toggle collars secured by two screws on the circuit breaker

• Front panel escutcheons secured on the switchboard

• Toggle extension is supplied with the toggle collar

Front panel escutcheons for motor operator, rotary operating handles are the same as for the fixedmounted circuit breaker with the same equipment.

06153121

push

to

trip

Outgoing Circuit

Compact® NS circuit breakers come with labels designed for handwritten indications.

Identification

06153122

N

I

A

M

AIN

PUMP

M

push

trip

P

to

It is also possible to use preprinted Telemecanique labels, catalog No. AB1

• Compact

• Compact

®

NSF150–NSF250 circuit breakers: eight characters

®

NSJ400–NSJ600 circuit breakers: sixteen characters

Sealing Accessory This accessory includes the elements required to fit lead seals to prevent:

• Front accessory cover removal

• Rotary handle removal

06153123

• Opening of the motor operator

• Access to accessories

• Access to trip unit settings

06153124

• Access to ground-fault protection settings

• Trip unit removal

• Terminal cover removal

• Access to power connections

40

06153125

© 1995–2003 Schneider Electric All Rights Reserved

Page 41

SECTION 10—DIMENSIONS

FIXED MOUNTED

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 10—Dimensions

Dimensions

06153126

H1

H3

H54

X

H

H2

H53

P1

P2

P4

Z

Mounting on Backplate

2P, 3P 4P

06153129

G1

G

∅T

K1 K1

K

K1

G5

X

G4

2P, 3P 4P

06153127

X

A

Y

L

L1

A—Short Terminal Covers

for Rear Connection

K1 K1 K1

K2

K

Electrical Clearances

13.8

35

06153128

X

13.8

35

0.4

10

0.4

10

Y

L

L2

Mounting on Rails

2P, 3P 4P

U (E)

06153130

X

∅T

G

K1

K

X

K2

K

X

∅T4 (D)

D—Only For Rear Connected Circuit Breakers

Y

Front Panel Cutouts

For Fixed or Plug-in Circuit Breakers

Cutout A

06153131

B/C

P5

P6

Z

A

X

© 1995–2003 Schneider Electric All Rights Reserved

06153132

R1

Y

E—U ≤ 0.78 in. (20 mm) When Using

Secondary Disconnecting Blocks

®

NSF150 and NSF250

(Compact

Circuit Breakers)

Cutout B

06153133

C1

X

C

Y

R

Y

R4(3P)

R5(4P)

R2

Y

Cutout C

06153134

C3

X

C2

Y

X

C2

Y

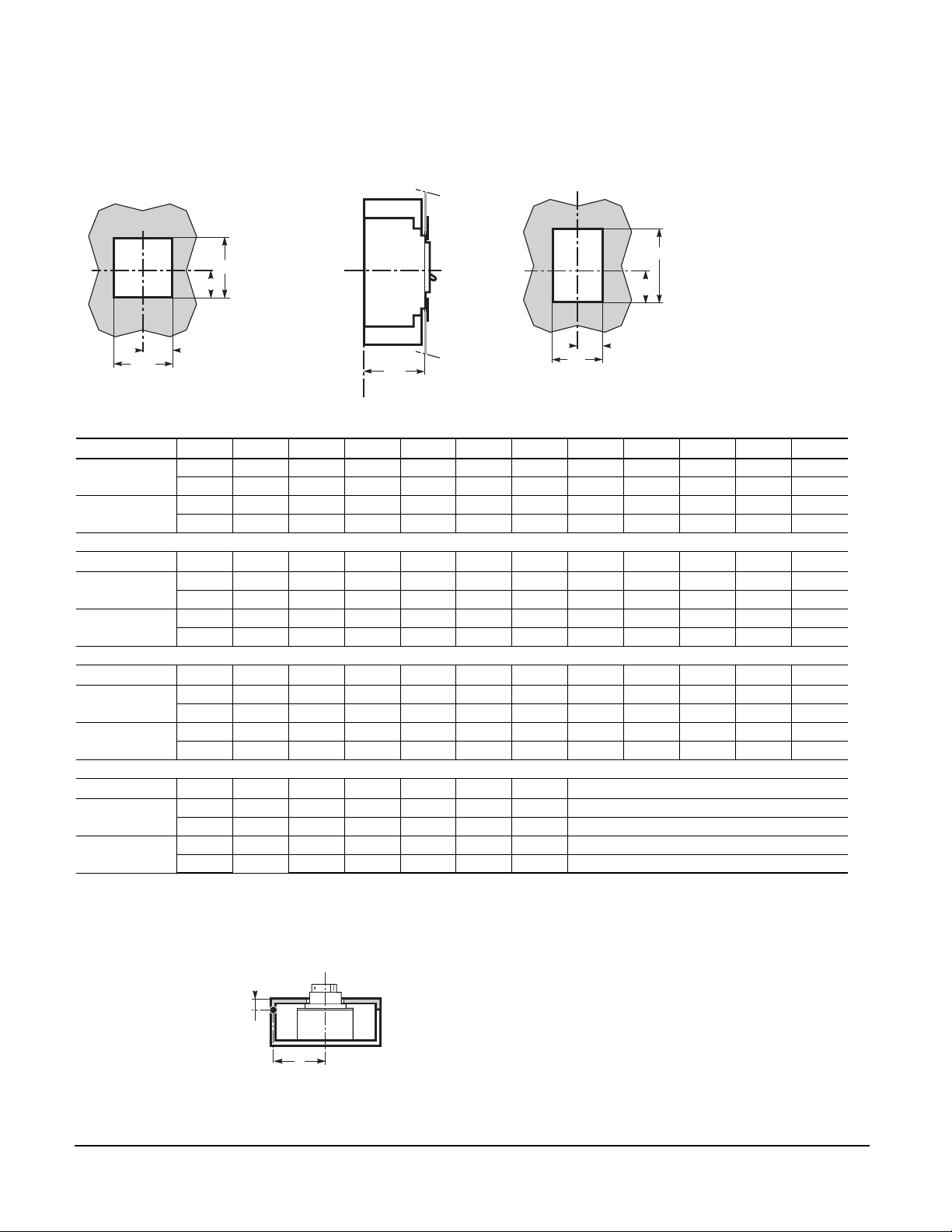

Dimensions: in. / mm

C3

41

Page 42

Compact® NSF and NSJ 150 to 600 A Circuit Breakers

Section 10—Dimensions

Front-panel Cutouts

With Toggle Boot

06153135

Y

R12

R13

Front Accessories: See Page 39

NSF150/250N/H/L

NSJ400/600N/H/L

NSF150/250N/H/L

NSJ400/600N/H/L

Inch 1.14 2.99 2.12 4.25 1.69 4.09 1.33 3.38 2.46 4.92 2.75

mm 29 76 54 108 43 104 34 86 62,5 125 70

Inch 1.63 4.56 3.64 7.24 2.08 5.74 1.83 4.96 3.93 7.87 4.46

mm 41.5 116 92.5 184 53 146 46.5 126 100 200 113.5

Inch 5.51 3.16 6.33 3.70 7.40 3.74 7.48 0.68 1.37 2.06 4.13

mm 140 80.5 161 94 188 95 190 17.5 35 52.5 105

Inch 8.93 5.01 10.03 5.61 11.22 6.69 13.38 0.88 1.77 2.75 5.51

mm 227 127.5 255 142.5 285 170 340 22.5 45 70 140

With Escutcheon

06153136

X

C21

X

C20

P6

Z

C C1C2C3C6C7C20C21G G1G4

G5H H1H2H3H53H54K K1 L L1

06153137

C7

X

C6

Y

R6

R7

Dimensions: in. / mm

L2 P1 P2 P4 P5 P6 R R1 R2 R4 R6

NSF150/250N/H/L

NSJ400/600N/H/L

Inch 5.51 3.18 3.38 4.37(*) 3.26 3.46 0.57 1.14 2.12 4.25 1.14

mm1408186111(*)838814.52954108 29

Inch 7.28 3.75 4.33 6.61 4.21 4.40 1.24 2.48 2.81 5.62 1.83

mm 185 95.5 110 168 107 112 31.5 63 71.5 143 46.5

R7 R12 R13 ØT ØT4 U**

NSF150/250N/H/L

NSJ400/600N/H/L

* P4 = 4.96 in./126mm for Compact® NSF250N/H/L Circuit Breaker

** U ≤ 0.78 in./20mm When Using Secondary Disconnecting Blocks (Compact® NSF150 and NSF250 Circuit Breakers)

Inch 2.28 1.69 3.38 0.23 0.86 - 1.25

mm 58 43 86 6 22 - 32

Inch 3.66 2.48 4.96 0.23 1.25 - 1.25

mm 93 63 126 6 32 - 32

NOTE: Door cutouts require a minimum distance between the center of the circuit breaker and the door

hinge point

06153138