Page 1

2354235 11/2008

Altivar 71

Communication parameters

User manual

Software V2.7

11/2009

1755861

www.schneider-electric.com

Page 2

Contents

Document structure and directions for use__________________________________________________________________________ 5

Presentation _________________________________________________________________________________________________ 7

Software enhancements ________________________________________________________________________________________ 9

Enhancements made to version V1.2 in comparison to V1.1 _____________________________________________________ 9

Enhancements made to version V1.6 in comparison to V1.2 ____________________________________________________ 10

Enhancements made to version V2.5 in comparison to V1.6 ____________________________________________________ 10

Enhancements made to version V2.7 in comparison to V2.5 ____________________________________________________ 10

Notations___________________________________________________________________________________________________ 11

Description of parameters _______________________________________________________________________________ 11

Drive terminal displays __________________________________________________________________________________ 11

Profiles ____________________________________________________________________________________________________ 12

What is a profile? ______________________________________________________________________________________ 12

Functional profiles supported by the Altivar 71 _______________________________________________________________ 13

I/O profile __________________________________________________________________________________________________ 14

Definition ____________________________________________________________________________________________ 14

Control word - run on state [2 wire] (2C) ____________________________________________________________________ 16

Control word - run on edge [3 wire] (3C) ___________________________________________________________________ 17

Status word (ETA) _____________________________________________________________________________________ 18

Example: I/O profile with positioning by sensors function _______________________________________________________ 19

CiA402 profile_______________________________________________________________________________________________ 21

Functional description __________________________________________________________________________________ 21

CiA402 state chart _____________________________________________________________________________________ 22

Description of states ___________________________________________________________________________________ 23

Control word (CMD) ____________________________________________________________________________________ 25

Status word (ETA) _____________________________________________________________________________________ 27

Starting sequence _____________________________________________________________________________________ 28

Sequence for a drive powered by the power section line supply __________________________________________________ 29

Sequence for a drive with separate control section ____________________________________________________________ 31

Sequence for a drive with line contactor control ______________________________________________________________ 34

Command/reference switching__________________________________________________________________________________ 37

Channels ____________________________________________________________________________________________ 37

Not separate mode ____________________________________________________________________________________ 38

Separate mode _______________________________________________________________________________________ 38

Switching in not separate mode ___________________________________________________________________________ 39

Switching in separate mode ____________________________________ __________________________________________ 39

Channel switching _____________________________________________________________________________________ 40

Reference switching principle ____________________________________________________________________________ 42

Command switching principle _______________________________________________________________ _____________ 43

Assigning control word bits ______________________________________________________________________________ 44

Example: I/O profile with positioning by sensors function _______________________________________________________ 47

Copy on switching _____________________________________________________________________________________ 49

Forced local ________________________________________________________________________________________________ 50

Definition ____________________________________________________________________________________________ 50

Forced local mode and reference switching _________________________________________________________________ 51

Forced local mode and command switching _________________________________________________________________ 52

Priority stops________________________________________________________________________________________________ 54

Priority stops on the graphic display terminal ________________________________________________________________ 54

Priority stops via the terminals or the network ________________________________________________________________ 54

Communication monitoring_____________________________________________________________________________________ 56

Principle _____________________________________________________________________________________________ 56

Network monitoring criteria ______________________________________________________________________________ 56

Behavior in the event of a network fault _____________________________________________________________________ 57

Detailed operation _____________________________________________________________________________________ 58

Assignment of setpoints from a network___________________________________________________________________________ 60

Setpoint parameters ___________________________________________________________________________________ 60

Without PID regulator __________________________________________________________________________________ 61

With PID regulator _____________________________________________________________________________________ 62

Configuration saving and switching ______________________________________________________________________________ 63

Saving the configuration ________________________________________________________________________________ 63

Restore configuration ___________________________________________________________________________________ 65

Configuration switching via control word ____________________________________________________________________ 66

Configuration switching by selection _______________________________________________________________________ 70

Parameter set switching_______ ___________________________________________________ _____________________________ 72

Loading drive parameters______________________________________________________________________________________ 77

Requirement _________________________________________________________________________________________ 77

Procedure ___________________________________________________________________________________________ 77

Command parameters ________________________________________________________________________________________ 79

Setpoint parameters__________________________________________________________________________________________ 82

1755861 11/2009 3

Page 3

Sommaire

Status parameters ___________________________________________________________________________________________ 84

Output value parameters ______________________________________________________________________________________ 92

Output values (speed) __________________________________________________________________________________ 92

Output values (torque) ________________________________________ __________________________________________ 93

Output values (motor) __________________________________________________________________________________ 94

Reference parameters ________________________________________________________________________________________ 96

References (speed) ____________________________________________________________________________________ 96

References (torque) ____________________________________________________________________________ ________ 97

Reference (regulator) ___________________________________________________________________________________ 98

Measurement parameters______________________________________________________________________________________ 99

Input measurements ___________________________________________________________________________________ 99

Thermal states ________________________________________________________________________________________ 99

Time _______________________________________________________________________________________________ 100

I/O parameters _____________________________________________________________________________________________ 102

Logic I/O ___________________________________________________________________________________________ 102

Analog inputs ________________________________________________________________________________________ 103

Analog outputs _______________________________________________________________________________________ 104

Encoder ____________________________________________________________________________________________ 105

Fault parameters____________________________________________________________________________________________ 106

Log parameters_____________________________________________________________________________________________ 113

Log of the following faults ______________________________________________________________________________ 117

Identification parameters _____________________________________________________________________________________ 121

CiA402 standard configuration and adjustment parameters_______________________________________________ ____________ 124

ODVA standard configuration and adjustment parameters ___________________________________________________________ 128

Index of parameters codes____________________________________________________________________________________ 129

4 1755861 11/2009

Page 4

Document structure and directions for use

Installation Manual

This manual describes:

• Assembly

• How to connect the drive

Programming Manual

This manual describes:

• Functions

• Parameters

• How to use the drive's display terminal (integrated display terminal and graphi c display terminal)

Communication Parameters Manual

This manual describes:

• The operating modes specific to communication (state chart)

• The interaction between communication and local control

• The control, reference and monitoring parameters, with specific information for use via a bus or communication network

It does not include the drive adjustment and configuration parameters, which are contained in the Excel file supplied as an

appendix to this manual.

All the parameters are grouped together in an Excel file supplied as an appendix, with the following data:

-Code

-Name

- Addresses: logic, CANopen, INTERBUS, Device Net

- Category

- Read/write access

- Type: signed numerical, unsigned numerical, etc.

-Unit

- Factory setting

- Minimum value

- Maximum value

- Display on the graphic display terminal and the 7-segment integrated display termi nal

- Relevant menu

This file offers the option of sorting and arranging the data according to any criterion chosen by the user.

Data relating to operation, interdependences and limits of use are described in the Programming Manual.

The various documents are to be used as follows:

1. For information about the drive and its programming, refer to the Programming Manual.

2. For information about communication and its programming, refer to the Parameters Manual.

3. Use the Parameters file to define any addresses and values of the adj ustment and configuration parameters to be modified through

communication.

The section entitled "Loading drive parameters" on page 77

through communication.

describes the recommended procedure for loading parameters

Modbus, CANopen, Ethernet, Profibus, INTERBUS, Uni-Telway, FIPIO, Modbus Plus and Device Net

manuals

These manuals describe:

• Assembly

• Connection to the bus or network

• Diagnostics

• Configuration of the communication-specific parameters via the integrated display terminal or graphic display terminal

They describe the protocol communication services in detail.

"Controller Inside" Manual

This manual describes, for the "Controller Inside" card:

• Assembly

• Connection

• Functions

• Configuration

1755861 11/2009 5

Page 5

Documentation structure

Altivar 58/58F Migration Manual

This manual describes the differences between the Altivar 71 and the Altivar 58/58F.

It explains how to replace an Altivar 58 or 58F, including how to replace drives communicating on a bus or network.

Note: This Parameters Manual describes the parameters of the Altivar 71 profiles.

It does not describe the Altivar58/58F compatibility parameters (SE8 profile).

These are detailed in the Altivar 58/58F Communication Variables Manual and the Migration Manual.

Altivar 78 Migration Manual

This manual describes the differences between the Altivar 71 and the Altivar 78.

It explains how to replace an Altivar 78.

6 1755861 11/2009

Page 6

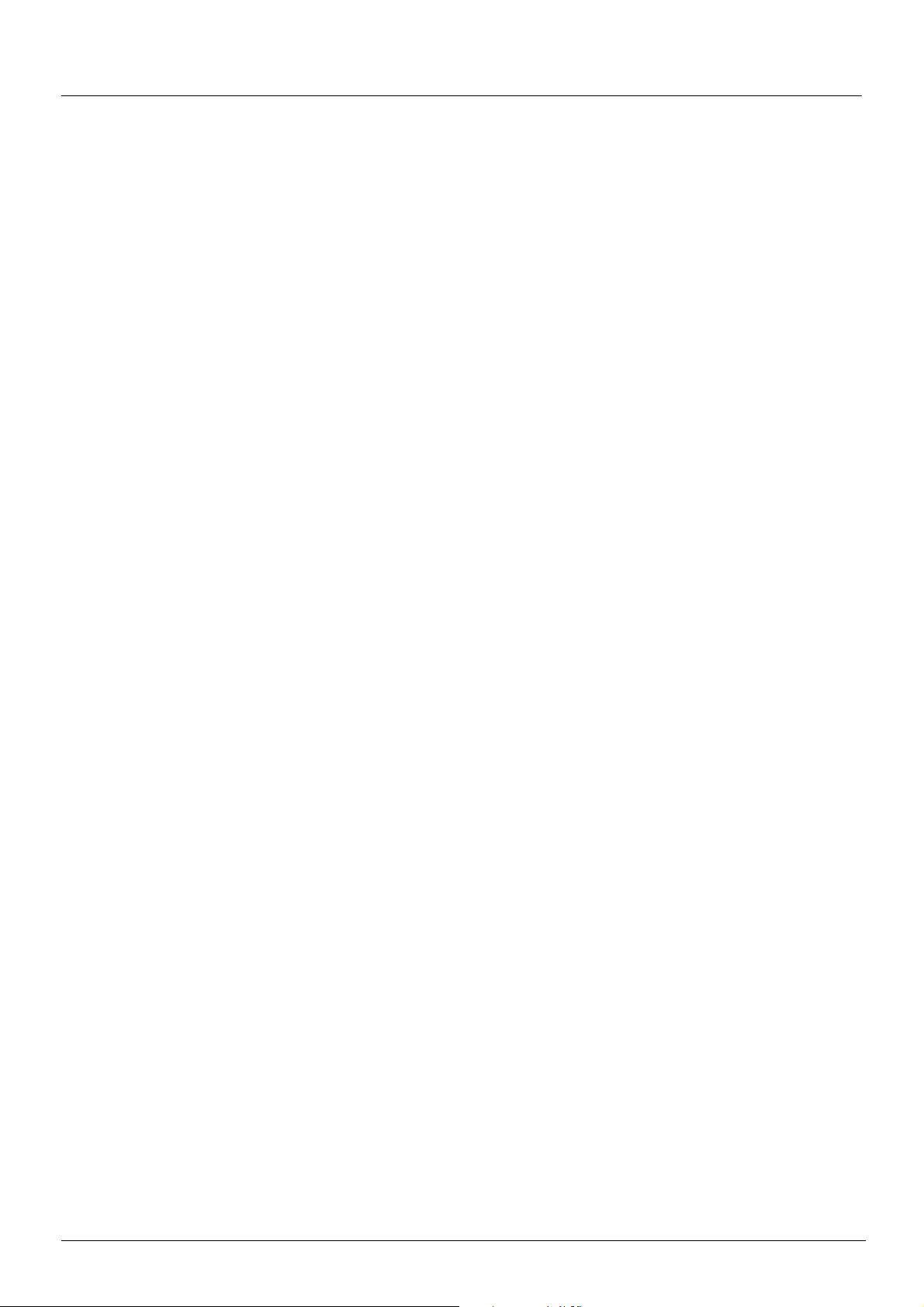

Presentation

2

1

3

1

2

1

3

Magelis XBT Premium

FTM FTM

ATV 31

ATV 71

Sensors Sensors

Example of configuration on the CANopen bus

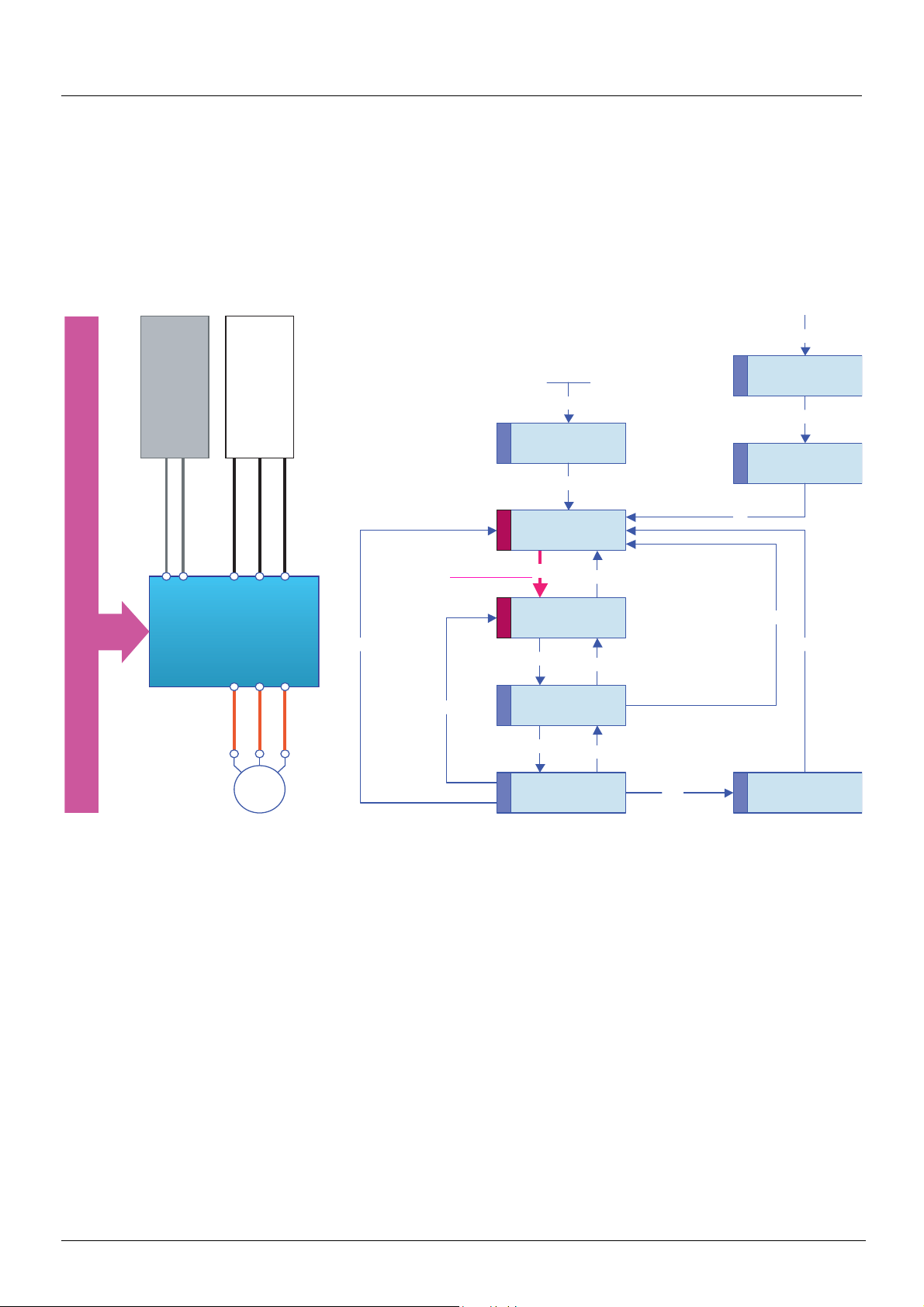

The Altivar 71 drive has been designed to meet all the configuration requirements

encountered within the context of industrial communication installations.

It includes Modbus and CANopen communication protocols as standard.

Two integrated communication ports enable direct access to the Modbus protocol :

• One RJ45 Modbus connector port , located on the drive front panel,

which is used to connect:

• The remote graphic display terminal

• A Magelis industrial HMI terminal

• The PowerSuite software workshop

• One RJ45 Modbus network port , located on the drive’s control terminals,

which is dedicated to control and signaling by a PLC or other type of controller.

It can also be used to connect a display terminal or the PowerSuite software

workshop.

The CANopen protocol can be accessed from the Modbus network port via the

CANopen adapter (1).

The Altivar 71 can also be connected to other networks and industrial communication

buses by using one of the communication option cards:

• Ethernet TCP/IP

• Modbus/Uni-Telway. This card provides access to additional functions, which

complement those of the integrated ports: Modbus ASCII and 4-wire RS 485

•Fipio

• Modbus Plus

•Profibus DP

• DeviceNet

•INTERBUS

• etc. (Please refer to the catalog)

The control section can be powered separately, thus allowing communication

(monitoring, diagnostics) to be maintained even if the power supply section fails.

The main communication functions of Altivar 58 and Altivar 58F drives are compatible

with the Altivar 71 (2):

- Connection

- Communication services

- Drive behavior (profile)

- Control and monitoring parameters

- Basic adjustment parameters

The PowerSuite software workshop supports the transfer of configurations from

Altivar 58 and Altivar 58F drives to the Altivar 71.

(1) If the CANopen adapter is installed, Modbus will not be available on the network port .

(2) Please refer to the ATV 58(F)/ATV 71 Migration Manual supplied on the documentation CD-ROM.

1755861 11/2009 7

Page 7

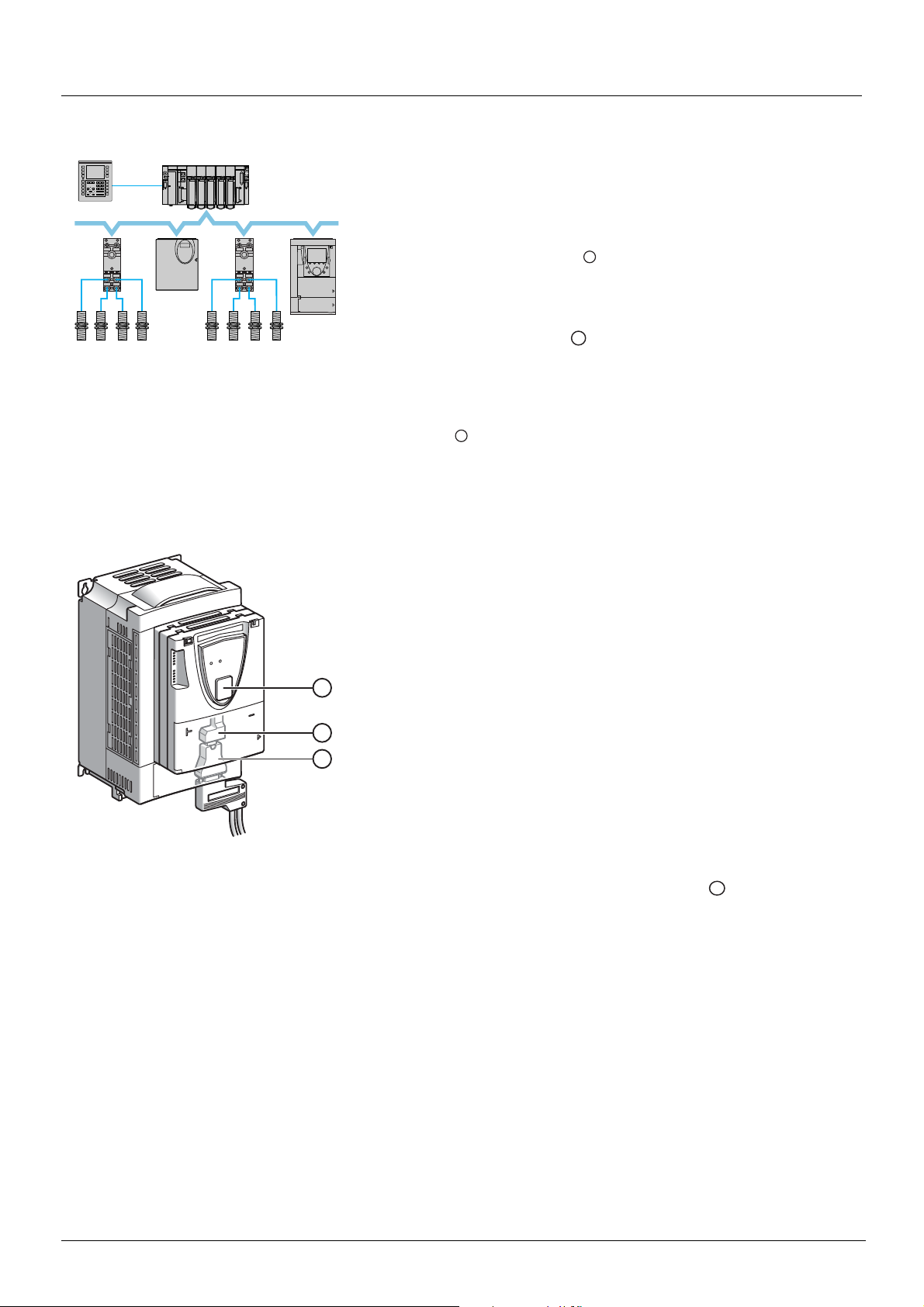

Presentation

All the drive functions are accessible via the network:

• Control

• Monitoring

• Adjustment

• Configuration

If the "Controller Inside" programmable card is installe d on the drive , it s variables (%MW, etc.) can be acce ssed via the integ rated Modb us

ports or the Ethernet option card.

The speed/torque command and reference can come from different sources:

• The I/O terminals

• The communication ne twork

• The "Controller Inside" programmable card

• The remote graphic display terminal

• The PowerSuite software workshop (for commissioning and maintenance)

The Altivar 71 drive's advanced functions can be used to manage switching of these command and reference sources according to

application requirements.

The periodic communication variables can be selected via:

• The network configuration software (Sycon, etc.): CANopen, DeviceNet

• The Altivar 71’s communication scanner function: Profibus DP, Fipio, Modbus Plus

• The network's IO Scanner function: Ethernet TCP/IP

With the exception of DeviceNet, regardless of n etwork type, the Altivar 71 can be controlled:

• In accordance with the Drivecom profile (CANopen CiA DSP 402)

• In accordance with the I/O profile, whereby control is as straightforward and flexible as control via the I/O terminals

The DeviceNet card supports the ODVA standard profile.

Communication is monitored according to criteria specific to each protocol. Regardless of protocol type, the reaction of the drive to a

communication fault can be configured:

• Drive fault involving: Freewheel stop, stop on ramp, fast stop or braked stop

• Stop without drive fault

• Maintain the last command received

• Fallback position at a predefined speed

• Ignore the fault

A command from the CANopen bus is handled with the same priority as an input from the drive termi nals. This enables very good response

times to be achieved on the network port via the CANopen adapter.

8 1755861 11/2009

Page 8

Software enhancements

Since the Altivar ATV71 was first launched, it has benefited from the addition of several new functions. Software version has now been

updated to V2.7. The new version can be substituted to the previous versions without making any changes.

Although this documentation relates to versi on V2.7, it can st ill be used with previ ous versions, as the update s merely invol ves t he additi on

of new values and parameters. None of the previous versions parameters have been modified or removed.

The software version is indicated on the nameplate attached to the body of the drive.

Enhancements made to version V1.2 in comparison to V1.1

Factory setting

Note 1: In version V1.1, the analog input was 0 ± 10 V. For safety reasons, this input is co nfigured as 0 + 10 V in the new versi on.

Note 2: In version V1.1, the analog output AO1 was assigned to the motor frequency. In the new version, this output is not

assigned.

Except for these two parameters, the factory setting of version V1.1 is retained in the new version. The new functions are inactive in the

factory setting.

Motor frequency range

The maximum output frequency range is extended from 1000 to 1600 Hz (depending on rating and selected control profile).

New parameters and functions

[1.2 MONITORING] (SUP-) menu

Addition of states and internal values relating to the new fun ctions described below.

[1.3 SETTINGS] (SEt-) menu

• [High torque thd.] (ttH)

• [Low torque thd.] (ttL)

• [Pulse warning thd.] (FqL)

• [Freewheel stop Thd] (FFt)

[1.4 MOTOR CONTROL] (drC-) menu

• [rpm increment] (InSP)

• Extension to all drive ratings of the following configurat ions, formerly limited to 45 kW for ATV7 1

synchronous motor [Sync. mot.] (SYn), sinus filter [Sinus filter] (OFI), noise reduction [Noise reduction] (nrd), braking balance [Braking

balance] (bbA).

pppM3X and 75 kW for ATV71pppN4:

[1.5 INPUTS / OUTPUTS CFG] (I-O-) menu

• Input AI1 becomes configurable as 0 + 10 V or 0 ± 10 V using [AI1 Type] (AI1t).

• [AI net. channel] (AIC1)

• New options for assigning relays and logic outputs: rope slack, torque greater than high threshold, torque less than low threshold,

motor rotating in forward direction, motor rotating in reverse, measured speed th reshold attained, and load variation detection.

• Analog output AO1 becomes usable as a logic output and can be assigned to the relay and logic output functions.

• New option of modifying the scaling of the analog outputs using the parameters [Scaling AOx min] (ASLx) and [Scaling AOx max]

(ASHx).

• New options for assigning analog outputs: signed motor torque and measured motor speed.

• New options for assigning alarm groups: rope slack, torque greater than high threshold, torque less than low threshold, measured

speed threshold attained, and load variation detection.

1755861 11/2009 9

Page 9

Software enhancements

[1.7 APPLICATION FUNCT.] (Fun-) menu

• The summing, subtraction and multiplier reference functions become assignable to the network analog input [Network AI] (AIU1)

• New parameter [Freewheel stop Thd] (FFt) used to adjust a threshold for switching to freewheel at the end of a stop on ramp or fast stop.

• New parameter: Brake engage at controlled zero speed [Brake engage at 0] (b ECd).

• The weight sensor [Weight sensor ass.] (PES) becomes assignable to the network analog input [Network AI] (AIU1).

• New "rope slack" function, with the parameters [Rope slack config.] (rSd) and [Rope slack trq level] (rStL).

• Use of the ramp [Acceleration 2] (AC2) during PID function starts and wake-ups.

• Torque limitation [TORQUE LIMITATION] (tOL-) becomes configurable as a % or 0.1% using [Torque increment] (IntP) and can be

assigned to the network analog input [Network AI] (AIU1).

• New "stop at calculated distance after end of slowdown travel" function, wit h the parameters [Stop distance] (Std), [Rated linear

speed] (nLS) and [Stop corrector] (SFd).

• Positioning by sensor or limit switch [POSITIONING BY SENSORS] (LPO-) becomes configurable as positive or n egative logic usi ng

[Stop limit config.] (SAL) and [Slowdown limit cfg.] (dAL).

• Parameter switchi ng [PARAM.] (MLP-) becomes assignable to attained frequency thresholds [Freq. Th. attain.] (FtA) and

[Freq. Th. 2 attain.] (F2A).

• New half floor function: [HALF FLOOR] (HFF-) menu.

[1.8 FAULT MANAGEMENT] (FLt-) menu

• Option of reinitializing the drive without switching it off, using [Product reset] (rP).

• Option of reinitializing the drive using a logic input without switching it off, using [Product reset assig.] (r PA).

• Option of configuring the "output phase loss" fault [Output Phase Loss] (OPL) to [Output cut] (OAC) is extended to all drive ratings

(formerly limited to 45 kW for ATV71

• The external fault [EXTERNAL FAULT] (EtF-) becomes configurable as positive or negative logic using [External fault config] (LEt).

• New monitoring function by speed measurement via the "Pulse input", using the [FREQUENCY METER] (FqF-) menu.

• New load variation detection function, using the [DYNAMIC LOAD DETECT.] (dLd-) menu.

• The braking unit short-c i rc uit fault becomes configurable u si n g [Brake res. fault Mgt] bUb).

pppM3X and 75 kW for ATV71pppN4).

[7 DISPLAY CONFIG.] menu

• Addition in [7.4 TERMINAL ADJUSTMENT] of the [CONTRAST] and [STANDBY] parameters for adjusting the contrast of the graphic

display unit and setting it to standby.

Enhancements made to version V1.6 in comparison to V1.2

Extension of the range with addition of the drives ATV71pppY for network 500 to 690 V.

There are no new parameters, but the ranges of adjustment and factory settings of some parameters are adapted to the new voltage.

[1.5 INPUTS / OUTPUTS CFG] (I-O-) menu

Increase in adjustment range of delay parameters for relays and logic outputs : 0 to 600 00 ms instead of 0 to 9999 ms.

Enhancements made to version V2.5 in comparison to V1.6

[1.3 SETTINGS] (SEt-) menu

• New parameters [Skip Frequency] (JPF), [Skip Frequency 2] (JF2) and [3rd Skip Frequency] (JF3) allow to avo id critical speed which

generate resonances.

• New parameter [Skip.Freq.Hysteresis] (JFH) to adjust the range of skip frequency.

• Possibility to adjust the parameter [Torque ratio] (trt) (visible too in [TORQUE CONTROL] (tOr-) menu).

Important :

For V2.5 version, the behaviour of the following functions is different from the previous when type of stop "freewheel" is selected (factory

value):

• [LIMIT SWITCHES] (LSt-) function,

• [POSITIONING BY SENSORS] (LPO-) function,

• "shutdown" command by communication (see CiA402 state chart in communication parameters manual).

Actually, on previous versions, type of stop "freewheel" was not well done.

Enhancements made to version V2.7 in comparison to V2.5

[7 DISPLAY CONFIG.] menu

Addition in [7.4 KEYPAD PARAMETERS] of [Power up menu]. This parameter allows to choose the menu which displays on the drive on

power up.

[1.3 SETTINGS] (SEt-) menu

The adjustment range of [Time to restart] (ttr) can now be configured between 0.00 and 15.00 seconds.

10 1755861 11/2009

Page 10

Notations

Description of parameters

Identification

A parameter is defined by means of various character strings:

• Code: 4 charac

brt, tLIG

• Name: Description in plain text (used by the PowerSuite software workshop)

• Terminal name: Character string in square brackets for the graphic display terminal [Gen. torque lim]

Addresses

There are 4 formats for specifying parameter addresses:

• Logic address: Address for the Modbus messaging (RS485 and Ethernet TCI/IP) and the PKW indexed periodic variables (Fipio,

Profibus DP), in decimal and hexadecimal (preceded by 16#).

To optimize Modbus messaging performance, two addresses are given for the control word and the status word. The addresses

annotated "speed" are for use in rpm; the addresses annotated "frequency" are for use in Hz.

• CANopen index: CANopen index/subindex in hexadecimal fo rmat, to be used for va riabl e assign ment of PDOs and SDO messagi ng

• INTERBUS index: Index/subindex in hexadecimal for PCP messaging

• DeviceNet path: Class/instance/attribute i n hexadecimal

Read/write

• R: Read only

• R/W: Read and write

• R/WS: Read and write, but write only possible when motor is at standstill

ters max. The code makes it possible to identify the parameter on the integrated 7-segment display terminal (Examples:

)

Type

• WORD (bit register): Word where each bit represents an item of command, monitoring or configuration information

• WORD (listing): Word where each value represents a possible choice for a configuration or state

• INT: Signed integer

• UINT: Unsigned integer

• DINT: Signed double integer

• UDINT: Unsigned double integer

Format

Hexadecimal values are written as follows: 16#pppp

Drive terminal displays

The menus that appear on the graphic display terminal are shown in square brackets.

Example: [1.9 COMMUNICATION].

The menus that appear on the integrated 7-segment display terminal always end with a dash and appear between round brackets.

Example: (COM-).

Parameter names are displayed on the remote graphic display terminal in square brackets.

Example: [Fallback speed].

The parameter codes displayed on the integrated 7-segment display terminal are shown in round brackets.

Example: (LFF).

1755861 11/2009 11

Page 11

Profiles

What is a profile?

There are three types of profile:

• Communication profiles

• Functional profiles

• Application profiles

Communication profiles

A communication profile describes the characteristics of the bus or network:

• Cables

• Connectors

• Electrical characteristics

• Access protocol

• Addressing system

• Periodic exchange service

• Messaging service

•...

A communication profile is unique to a type of network (Fipio, Profibus DP, etc.) and is used by various different types of device.

Functional profiles

A functional profile describes the behavior of a type of device. It defines:

• Functions

• Parameters (name, format, unit, type, etc.)

• Periodic I/O variables

• State chart(s)

•...

A functional profile is common to all members of a device family (variable speed drives, encoders, I/O modules, displays, etc.).

Ideally, functional profiles should be network-independent, but in reality they are not. They can feature common or similar parts. The

standardized (IEC 61800-7) functional profiles of variable speed drives are:

• CiA402

• PROFIDRIVE

•CIP

DRIVECOM has been available since 1991.

CiA402 "Device profile for drives and motion control" represents the next stage of this standard’s development and is maintained by

CanInAutomation.

Some protocols also support the ODVA (Open DeviceNet Vendor Association) profile.

Application profiles

Application profiles define in their entirety the services to be provided by the devices on a machine. For example, "CiA DSP 417-2 V 1.01

part 2: CANopen application profile for lift control systems - virtual device definitions".

Interchangeability

The aim of communication and functional profiles is to achieve interchangeability of the devices connected via the network.

Although this aim is not always achieved, the profiles facilitate free competition.

12 1755861 11/2009

Page 12

Profiles

Functional profiles supported by the Altivar 71

I/O profile

Using the I/O profile simplifies PLC programming.

When controlling via the terminals or the display terminal, the I/O profile is used without knowing it.

With an Altivar 71, the I/O profile can also be used when controlling via a network.

The drive starts up as soon as the run command is sent.

The 16 bits of the control word can be assigned to a function or a terminal input.

This profile can be developed for simultaneous control of the drive via:

• The terminals

• The Modbus control word

• The CANopen control word

• The network card control word

• The "Controller Inside" control word

The I/O profile is supported by the drive itself and therefore in turn by all the communication ports (integrated Modbus, CANopen and the

Ethernet, Fipio, ModbusPlus, Modbus, Uni-Telway, Profibus DP, DeviceNet, and INTERBUS communication cards).

CiA402 profile

The drive only starts up following a command sequence.

The control word is standardized.

5 bits of the control word (bits 11 to 15) can be assigned to a function or a terminal input.

The CiA402 profile is supported by the drive itself and therefore in turn by all the communication ports (integrated Modbus, CANopen and

the Ethernet, Fipio, ModbusPlus, Modbus, Uni-Telway, Profibus DP, DeviceNet, and INTERBUS communication cards).

The Altivar 71 supports the CiA402 profile’s "Velocity mode".

In the CiA402 profile, there are two modes that are specific to the Altivar 71 and characterize command and reference management (see

section “Command/reference switching”, page 37

• Separate mode [Separate] (SEP)

• Not separate mode [Not separ.] (SIM)

):

ODVA profile

The drive starts up as soon as the run command is sent.

The control word is standardized.

The ODVA profile is supported by the DeviceNet communication card.

1755861 11/2009 13

Page 13

I/O profile

C201

C202

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

A

B

CANopen control word

Function

C201

C202

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

A

B

LI2

LI10

LI9

LI8

LI7

LI6

LI5

LI4

LI3

LI2

LI1

LI12

LI11

LI14

LI13

C

CANopen control word

Terminals

Function

Definition

The behavior of the drive is identical whether via the network or via the terminals.

The I/O profile is achieved via the following configuration:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

As well as to logic inputs of the terminals, drive functio n s can be assigned to control word bits.

A function input can be assigned to:

• A terminal input (LI2 to LI14)

• A Modbus control word bit (C101 to C115)

• A CANopen control word bit (C201 to C215)

• A network card control word bit (C301 to C315)

• A Controller Inside control word bit (C401 to C415)

• A switched bit (Cd00 to Cd15): See "Command/reference switching" section.

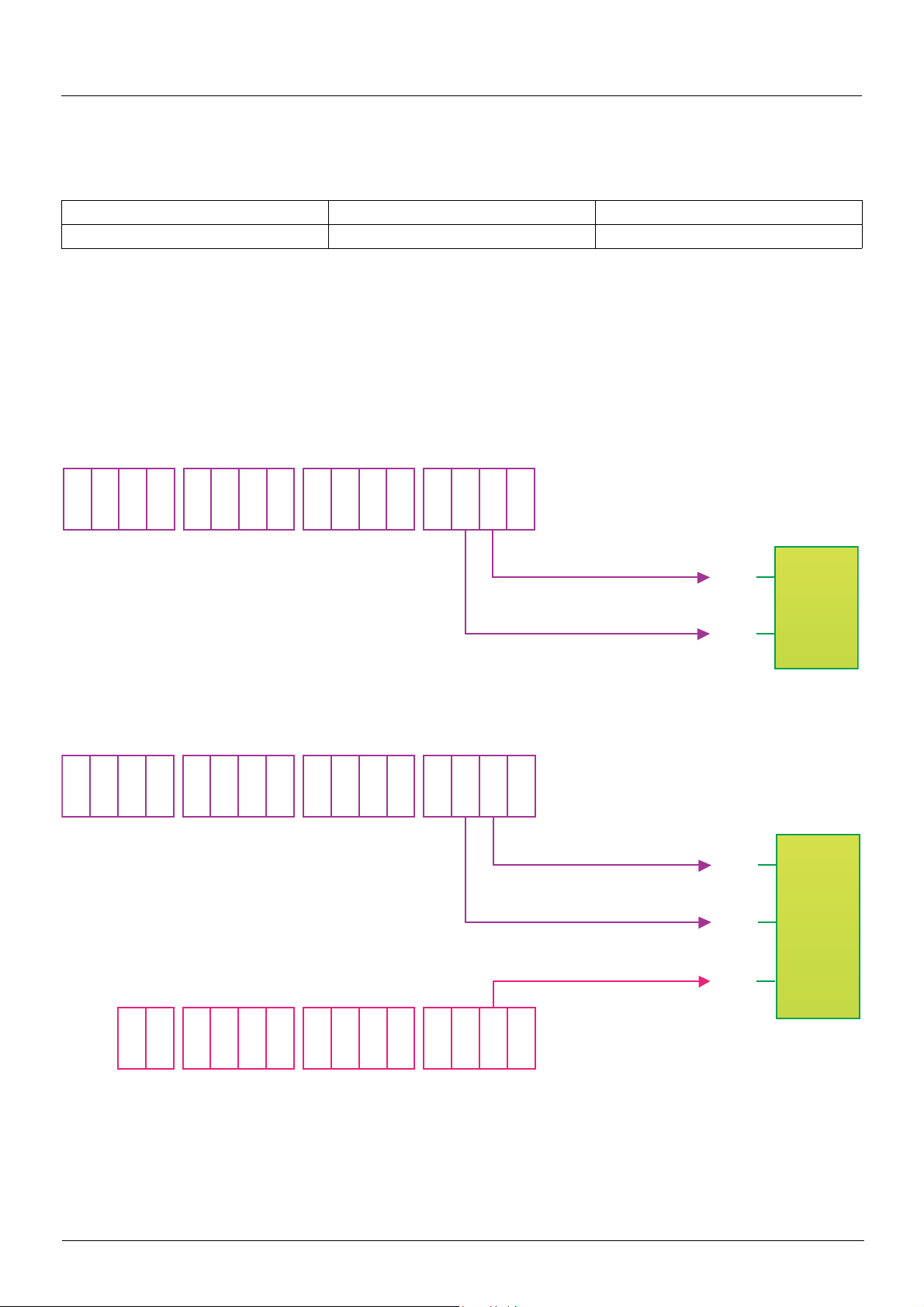

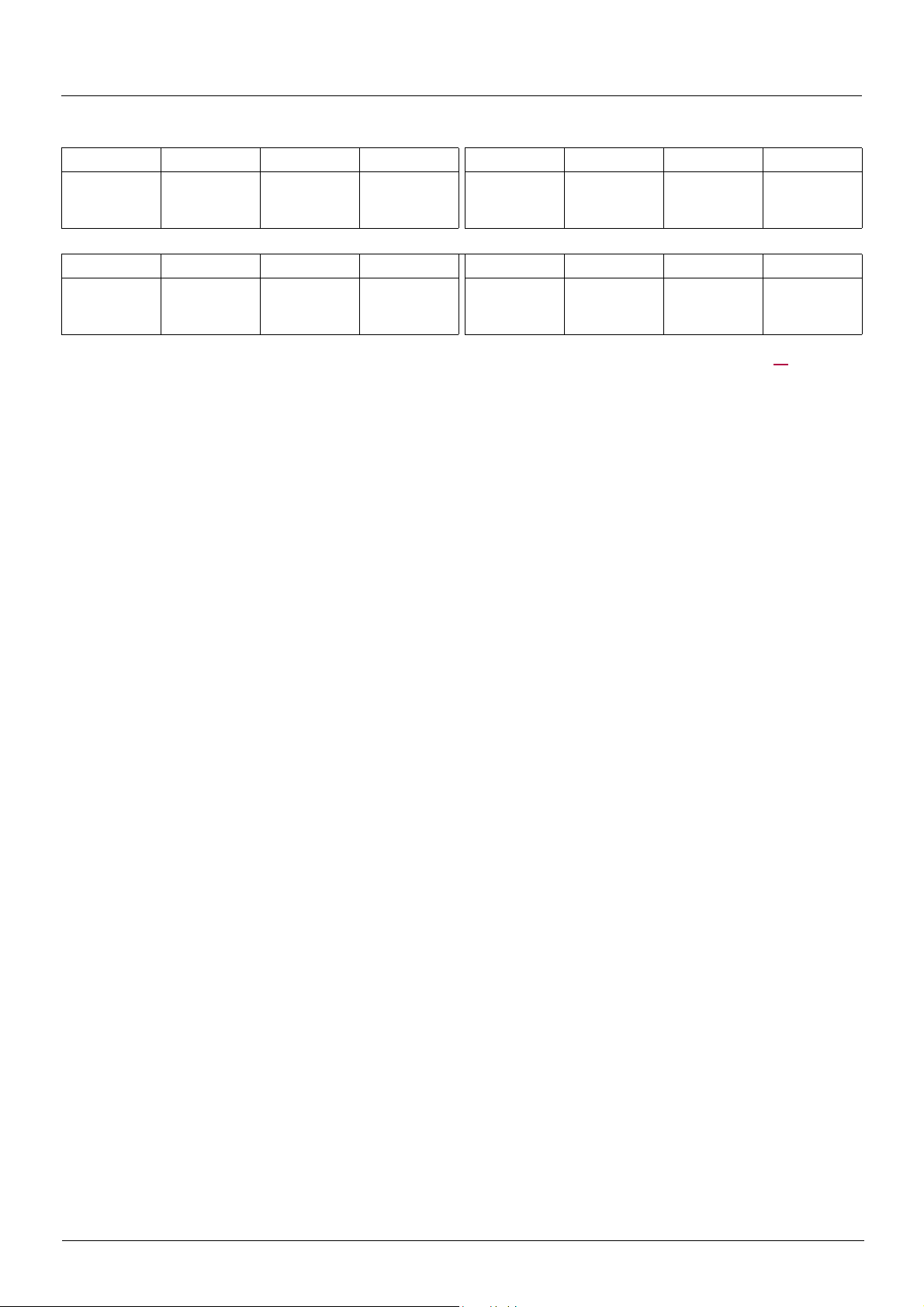

Schematic diagrams:

Fixed assignment on CANopen:

Fixed assignment to terminals and on CANopen: :

14 1755861 11/2009

Page 14

I/O profile

C201

C202

C401

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

A

B

LI2

LI10

LI9

LI8

LI7

LI6

LI5

LI4

LI3

LI2

LI1

LI12

LI11

LI14

LI13

C

Stop

CANopen control word

Terminals

Function

"Controller Inside" control word

Fast stop

C201

Cd02

LI5

LI10

LI9

LI8

LI7

LI6

LI5

LI4

LI3

LI2

LI1

LI12

LI11

LI14

LI13

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

LI2

A

B

C

CANopen control word

Terminals

Function

CANopen

Terminals

Command

switching

CCS

Fixed assignment to terminals, on CANopen and on "Controller Inside" card:

Fixed assignment to terminals and on CANopen with command switching:

1755861 11/2009 15

Page 15

I/O profile

Control word - run on state [2 wire] (2C)

Please refer to the [1.5 INPUTS / OUTPUTS CFG] (I-O-) section of the Programming Manual.

The forward run command is automatically assigned to input LI1 and to bit 0 of the various control wo rds.

This assignment cannot be modified.

The run command is active on state 1:

• Of input LI1, if the terminals are active

• Of bit 0 of the control word, if the network is active

Bits 1 to 15 of the control words can be assigned to drive functions.

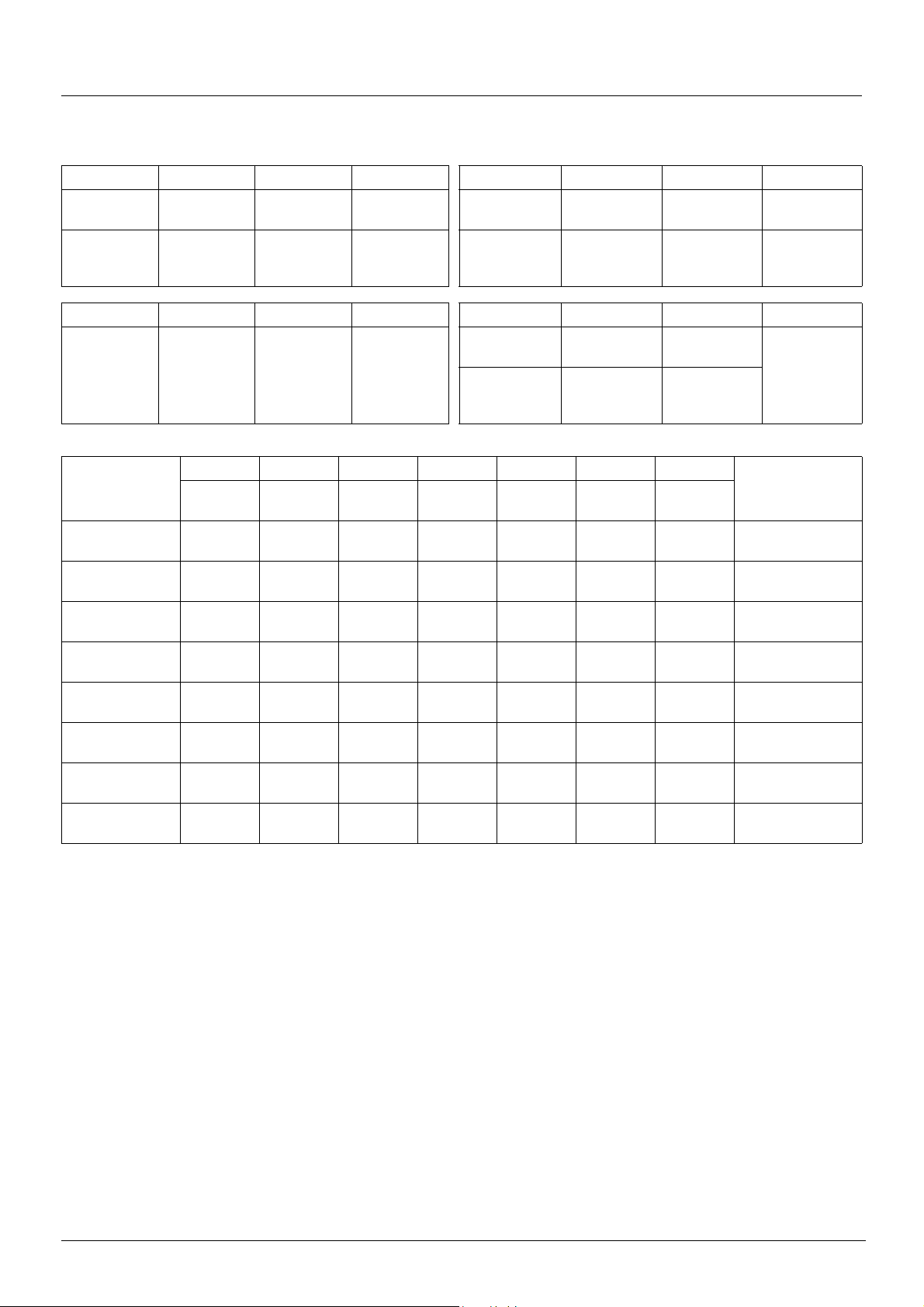

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Configurable Configurable Configurable Configurable Configurable Configurable Configurable Forward

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Configurable Configurable Configurable Configurable Configurable Configurable Configurable Configurable

In the case of a [2 wire] (2C) run on state command and I/O profile, fixed assignment of a function input is possible using the following

codes:

Fixed assignments

Bit

Drive terminals Logic I/O card

bit 0 Forward

bit 1 LI2 --C101 C201 C301 C401

bit 2 LI3 --C102 C202 C302 C402

bit 3 LI4 --C103 C203 C303 C403

bit 4 LI5 --C104 C204 C304 C404

bit 5 LI6 --C105 C205 C305 C405

bit 6 - LI7 - C106 C206 C306 C406

bit 7 - LI8 - C107 C207 C307 C407

bit 8 - LI9 - C108 C208 C308 C408

bit 9 - LI10 - C109 C209 C309 C409

bit10 - - LI11 C110 C210 C310 C410

bit11 - - LI12 C111 C211 C311 C411

bit12 - - LI13 C112 C212 C312 C412

bit13 - - LI14 C113 C213 C313 C413

bit14---C114 C214 C314 C414

bit15---C115 C215 C315 C415

Extended I/O

card

Modbus CANopen Network card

"Controller Inside"

card

For example, to assign the operating direction command to bit 1 of CANopen, simply conf igure the [Reverse ass ign.] (rrS) parameter with

the value [C201] (C201).

16 1755861 11/2009

Page 16

I/O profile

Control word - run on edge [3 wire] (3C)

Please refer to the [1.5 INPUTS / OUTPUTS CFG] (I-O-) section of the Programming Manual.

The stop command is automatically assigned to input LI1 and to bit 0 of the control words.

This assignment cannot be modified.

This command enables running on state 1:

• Of input LI1, if the terminals are active

• Of bit 0 of the control word, if the network is active

The forward run command is automatically assigned to input LI2 and to bit 1 of the control words.

This assignment cannot be modified.

The forward run command is active if the stop command is at 1 and on a rising edge (0 V 1):

• Of input LI2, if the terminals are active

• Of bit 1 of the control word, if the network is active

Bits 2 to 15 of the control words can be assigned to drive functions.

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Configurable Configurable Configurable Configurable Configurable Configurable Forward Stop

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Configurable Configurable Configurable Configurable Configurable Configurable Configurable Configurable

In the case of a [3 wire] (3C) run on state command and I/O profile, fixed assignment of a function input is possible using the following

codes:

Fixed assignments

Bit

Drive terminals Logic I/O card

bit 0 Authorization to run (Stop)

bit 1 Forward

bit 2 LI3 --C102 C202 C302 C402

bit 3 LI4 --C103 C203 C303 C403

bit 4 LI5 --C104 C204 C304 C404

bit 5 LI6 --C105 C205 C305 C405

bit 6 - LI7 - C106 C206 C306 C406

bit 7 - LI8 - C107 C207 C307 C407

bit 8 - LI9 - C108 C208 C308 C408

bit 9 - LI10 - C109 C209 C309 C409

bit10 - - LI11 C110 C210 C310 C410

bit11 - - LI12 C111 C211 C311 C411

bit12 - - LI13 C112 C212 C312 C412

bit13 - - LI14 C113 C213 C313 C413

bit14---C114 C214 C314 C414

bit15---C115 C215 C315 C415

Extended

I/O card

Modbus CANopen Network card

"Controller Inside"

card

For example, to assign the operating direction command to bit 2 of CANopen, simply conf igure the [Reverse ass ign.] (rrS) parameter with

the value [C202] (C202).

1755861 11/2009 17

Page 17

I/O profile

Status word (ETA)

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Alarm

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Direction of

rotation

The status word is identical in the I/O profile and the CiA402 profile. For more information, see section “CiA402 profile”, page21.

Reserved

(= 0 or 1)

Stop via STOP

key

Reserved (=1)

Reserved (=0) Reserved (=0)

Power section

line supply

present

Fault Running Ready

Reference

outside limits

Reference

reached

Command or

reference via

network

Reserved (=0)

Reserved

(= 0 or 1)

18 1755861 11/2009

Page 18

I/O profile

tEr

LCC

CAn

Mdb

nEt

APP

tEr

LCC

CAn

Mdb

nEt

APP

bit 9

bit 8

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

bit 2

bit 1

bit 0

C201

LI4

LI6

LI5

LI8

LI10

LI9

LI8

LI7

LI6

LI5

LI4

LI3

LI2

LI1

LI12

LI11

bit 11

bit 10

bit 13

bit 12

bit 15

bit 14

LI14

LI13

CANopen control word

Terminals

Command channel 1

Cd1

Forward

Positioning

by sensors

Reverse

Disabling of sensors

Forward stop sensor

Reverse stop sensor

Forward slowdown sensor

Reverse slowdown sensor

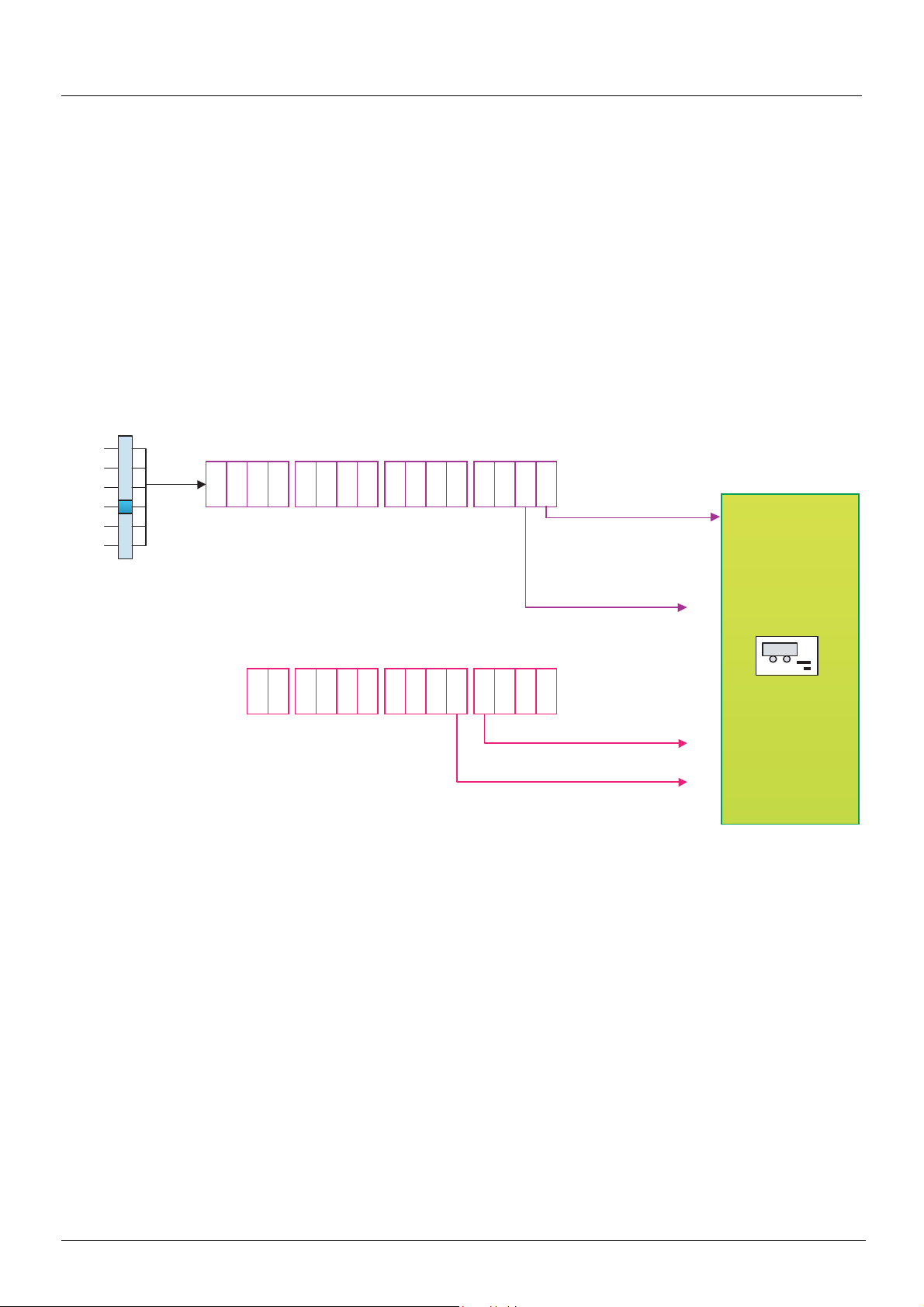

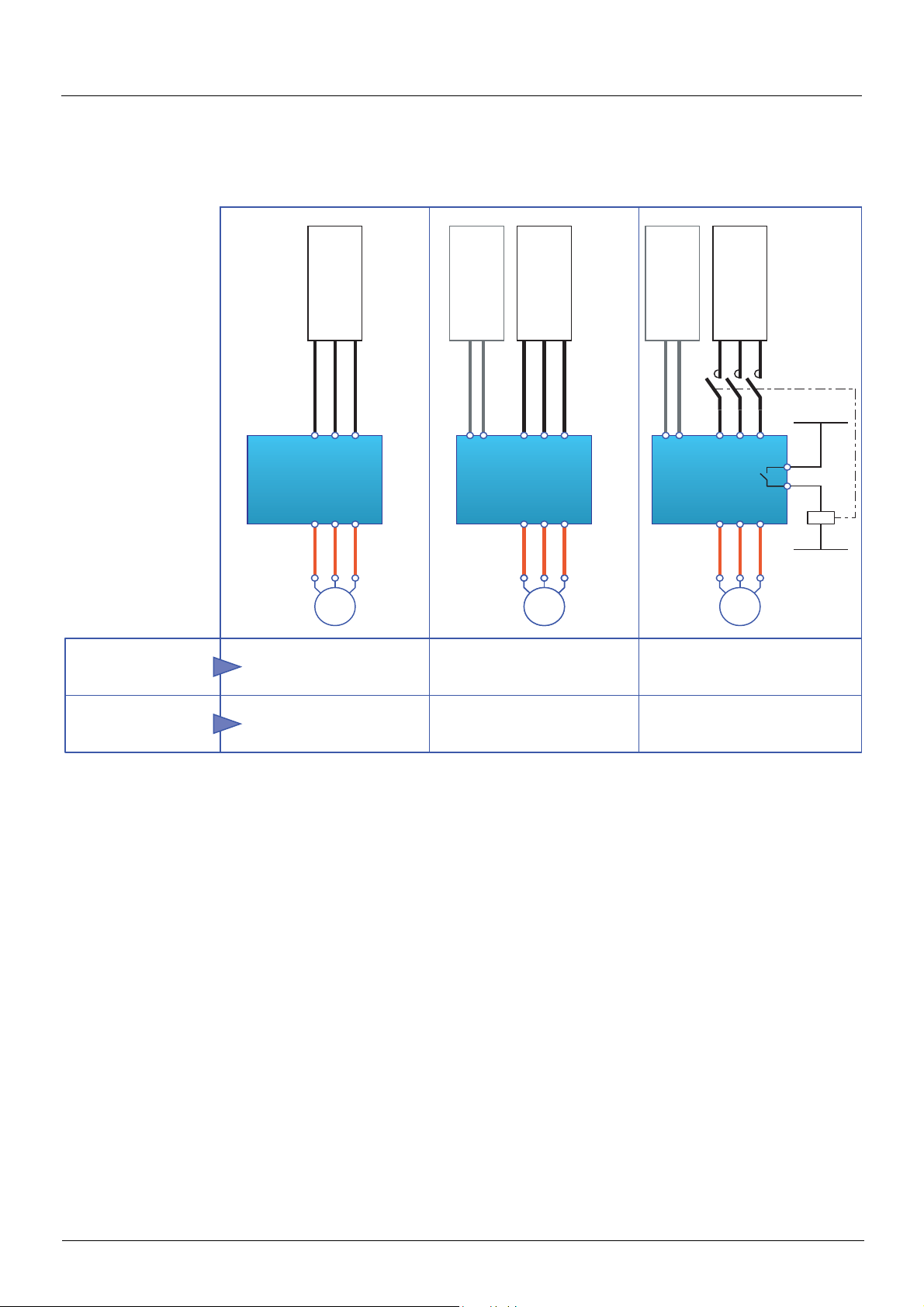

Example: I/O profile with positioning by sensors function

Please refer to the [1.7 APPLICATION FUNCT.] (FUn-) section of the Programming Manual, under "Positioning by sensors".

In this example, a PLC is used to control the transfer of parts on a conveyor composed of transfer tables. Each table is controlled by a

variable speed drive. The PLC and the drives are connected via a CANopen network.

The PLC controls the operation of the installation via the CANopen bus.

The drive uses the stop sensor to inhibit transfer of the part if the next table is unavailable. In this case, the PLC enables the sensors.

If the next table is free, the drive transfers the part without stopping. In this case, the PLC disables the sensors.

The stop sensor is directly connected to the drive terminals.

The slowdown sensor, which is also directly connected (to the drive) enables a more precise st op.

Configuration schematic diagram:

1755861 11/2009 19

Page 19

I/O profile

Configure the following parameters:

Parameter Value Comment

Type of command On state (2 wire) The run command is obtained via bit 0 of the CANopen control

Profile I/O profile

Reference 1 configuration CANopen The reference comes from the CANopen card.

Command 1 configuration CANopen The command comes from the CANopen card.

Assignment of stop sensor Input LI4

Assignment of slowdown sensor Input LI5

Assignment of sensor disable command Bit 1 of CANopen control

word

Configuration via the remote graphic display terminal:

Menu Parameter Value

[1.5 INPUTS / OUTPUTS CFG] (I-O-) [2/3 wire control] (tCC ) [2 wire] (2C)

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

[Cmd channel 1] (Cd1) [CANopen] (CAn)

[1.7 APPLICATION FUNCT.] (FUn-)

[POSITIONING BY SENSORS] (LPO-)

[Stop FW limit sw.] (SAF) [LI4] (LI4)

[Slowdown forward] (dAF) [LI5] (LI5)

[Disable limit sw.] (CLS) [C201] (C201)

word.

Note: On a [2 wire] (2C) state command, the forward command is automatically assigned to bit 0 of the CANopen control word.

20 1755861 11/2009

Page 20

CiA402 profile

Controlword

(6040)

Statusword

(6041)

Statemachine

M

3

vl_target_velocity

(6042)

vl_velocity_demand

(6043)

Limit Ramp

Power device

vl_velocity_acceleration (6048)

vl_velocity_acceleration (6049)

vl_velocity_min_max amount (6046)

vl_control_effort

(6044)

Control word

(CMD)

Status word

(ETA)

State machine

M

3

Speed reference

(LFRD)

Speed reference

after ramp

(FRHD)

Reference limit Ramp

Power

module

Acceleration delta speed (SPAL)

Acceleration delta time (SPAT)

Deceleration delta speed (SPDL)

Deceleration delta time (SPDT)

Velocity min amount (SMIL)

Velocity max amount (SMAL)

Output speed

(RFRD)

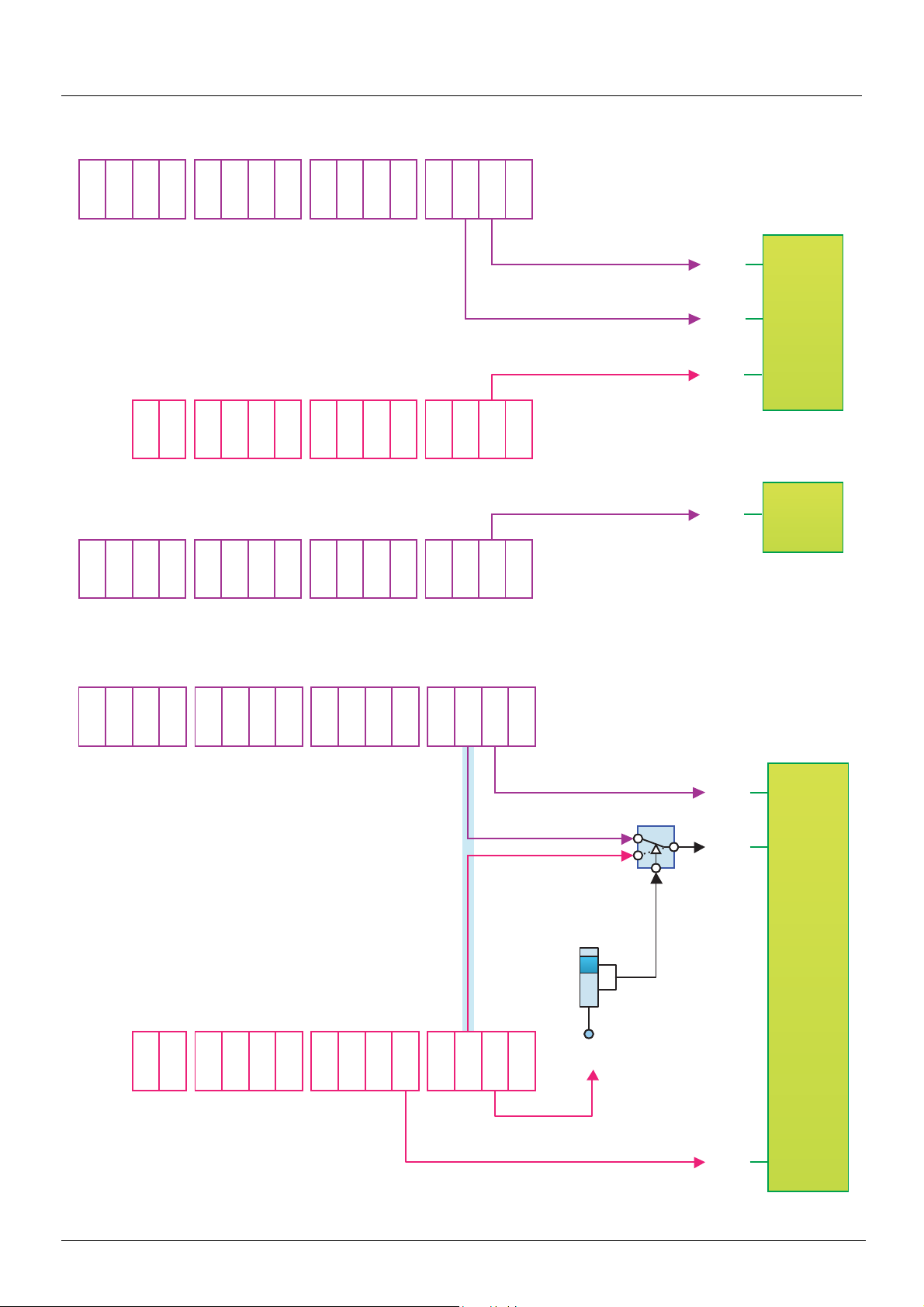

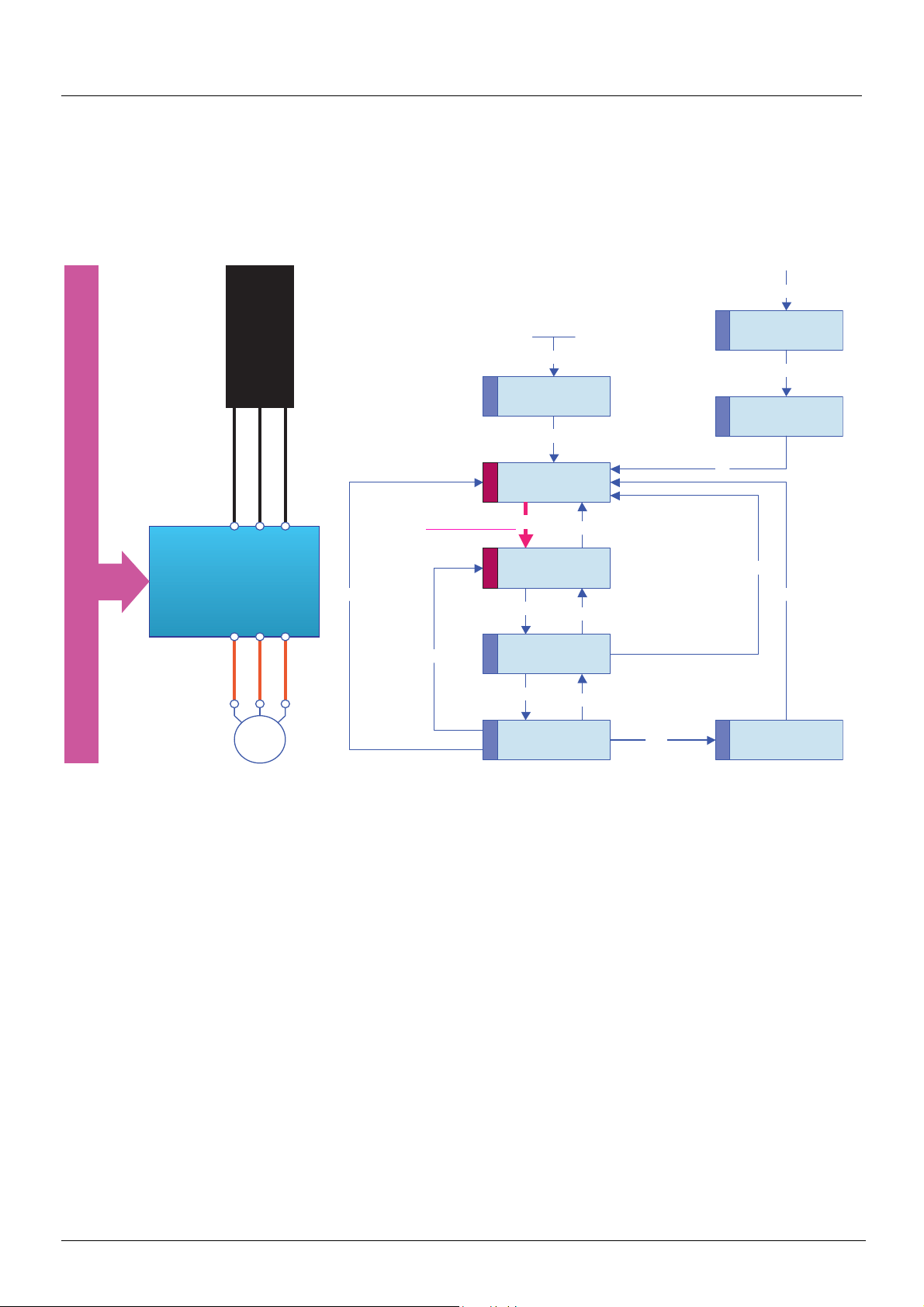

Functional description

b Drive operation involves two main functions, which are illustrated in the two diagrams below (the values in brackets are the CANopen

addresses of the parameters):

• Control diagram:

• Simplified diagram of speed control in "Velocity" mode:

b The main parameters are shown with their CiA402 name and their CiA402/Drivecom index (the values in brackets are the parameter

codes).

These diagrams translate as follows for the Altivar system:

• Control diagram:

• Simplified diagram of speed regulation in "Velocity" mode:

1755861 11/2009 21

Page 21

CiA402 profile

Fault

Power section line supply present or absent

Power section line supply present

Transition condition

with example of command

Value of

status word

Power

absent

Power

present

Status display on

graphic display terminal

State

Key:

Examples:

ETA=16#0637: Stop or forward, speed reached

ETA=16#8637: Stop or reverse, speed reached

ETA=16#0237: For w ar d, acce le ra ti ng or dece le r ati n g

ETA=16#8237: Reverse, accelerating or decelerating

Enable

operation

CMD=16#xxxF

Switched on

Ready to switch on

or

Switched on

Operation enabled

Power absent

or present

Enable

operation

CMD=16#xxxF

Disable

operation

CMD=16#0007

or

fast stop

Quick stop

CMD=16#0002

Quick stop active

Switch on

CMD=16#xxxF

Shutdown

CMD=16#0006

Switch on

CMD=16#0007

Shutdown

CMD=16#0006

Disable

voltage

CMD=16#0000

or

Quick stop

CMD=16#0002

or

STOP key

or

freewheel stop

at the terminals

or

modification

of a configuration

parameter

If Quick stop option code

= 2:

transition after stop.

If Quick stop option code

= 6:

Disable voltage

CMD=16#0000

or

STOP key

or

freewheel stop at

terminals

Disable

voltage

CMD=16#0000

or

Quick stop

CMD=16#0002

or

STOP key

Shutdown

CMD=16#0006

Disable voltage

CMD=16#0000

or

STOP key

or

freewheel stop at

the terminals

or

Power Removal

or

Switch on disabled

Fault disappeared

and faults reset

CMD=16#0080

Not ready to switch on

Entry into

state chart

Fault reaction active

From all states

Fault

Fault

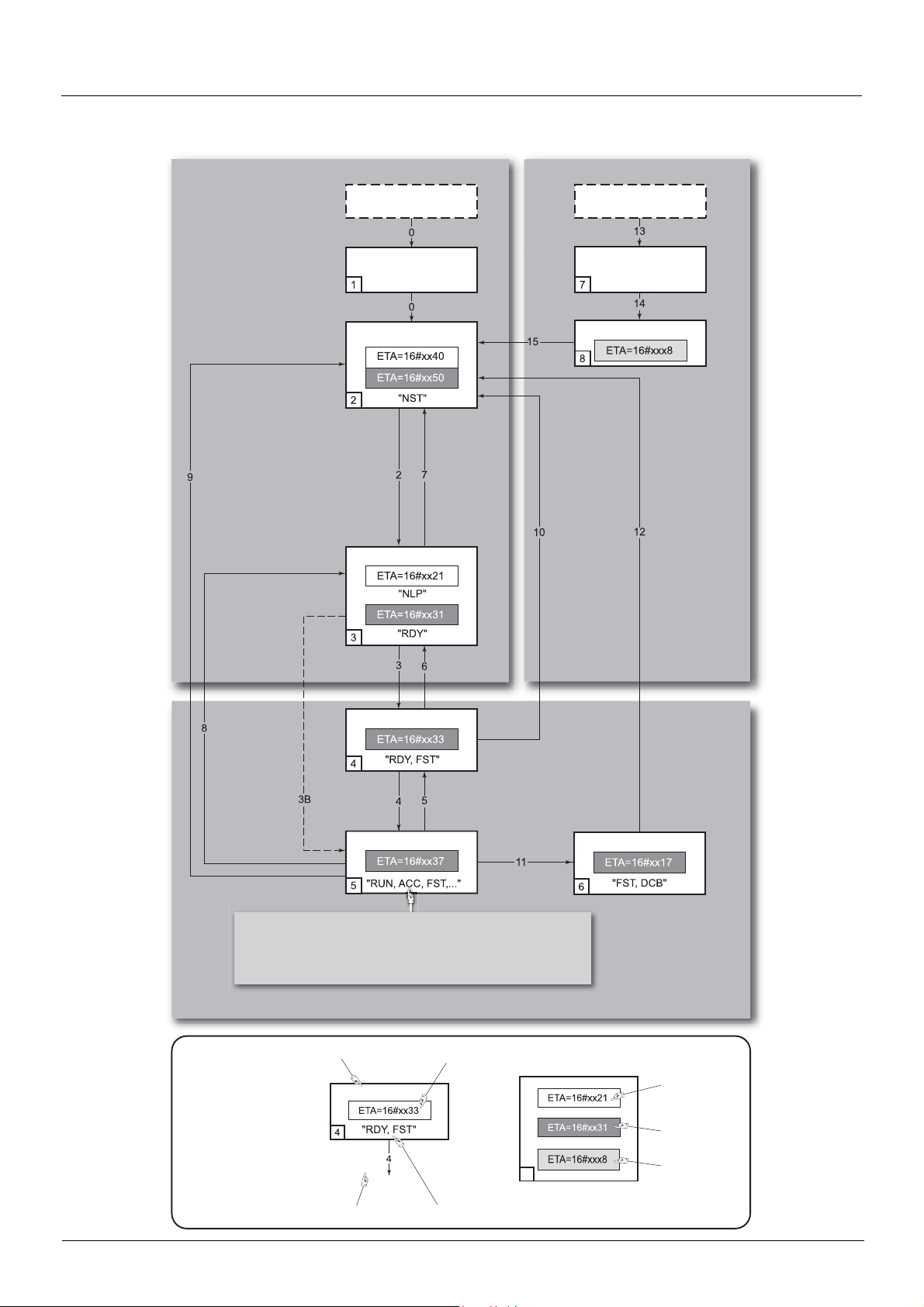

CiA402 state chart

22 1755861 11/2009

Page 22

CiA402 profile

Description of states

Each state represents an internal reaction by the drive.

This chart will change depending on whether the control word is sent (CMD) or an event occurs (a fault, for example).

The drive state can be identified by the value of the status word (ETA).

1 - Not ready to switch on

Initialization starts. This is a transient state invisible to the communication network.

2 - Switch on disabled

The drive is inactive.

The drive is locked, no power is supplied to the motor.

For a separate control section, it is not necessary to supply AC power to the power section.

For a separate control section with line contactor, the contac tor is not controlled.

The configuration and adjustment parameters can be modified.

3 - Ready to switch on

Awaiting power section line supply.

For a separate control section, it is not ne cessa ry to s uppl y AC power to the p ower sec tion, b ut the sy ste m wil l expe ct it i n o rder to chan ge

to state "4 - Switched on".

For a separate control section with line contactor, the contac tor is not controlled.

The drive is locked, no power is supplied to the motor.

The configuration and adjustment parameters can be modified.

4 - Switched on

The drive is supplied with AC power but is stationary.

For a separate control section, the power section line supply must be present.

For a separate control section with line contactor, the contac tor is controlled.

The drive is locked, no power is supplied to the motor.

The power stage of the drive is ready to operate, but voltage has not yet been applied to the output.

The adjustment parameters can be modified.

Modification of a configuration parameter returns the drive to state "2- Switch on disabled".

5 - Operation enabled

The drive is running.

For a separate control section, the power section line supply must be present.

For a separate control section with line contactor, the contac tor is controlled.

The drive is unlocked, power is supplied to the motor.

The drive functions are activated and voltage is applied to the motor terminals.

However, in the case of an open-loop drive, if the reference is zero or the "Halt" command i s applied, no power is suppli ed to the motor and

no torque is applied.

Auto-tuning (tUn) requires an injection of current into the motor. The drive must therefore be in state "5 - Operation enabled" for this

command.

The adjustment parameters can be modified.

The configuration parameters cannot be modified.

Note: The command "4 - Enable operation" must be taken into consideration only if the channel is valid (see Communication monitoring

page 56

reference has been received for the first time.

The reaction of the drive to a "Disable operation" command depends on the value of the "Disable operation opti on code" (DOTD) parameter:

• If the "Disable operation option code" parameter has the value 0, the drive ch anges to "4 - Switche d on" and s tops i n free wheel st op.

• If the "Disable operation option code" parameter has the value 1, the drive stops on ramp and then changes to "4 - Switched on".

1755861 11/2009 23

). In particular, if the channel is involved in the command and the reference, transition 4 will take place only after the

Page 23

CiA402 profile

6 - Quick stop active

Emergency stop

The drive performs a fast stop, after which restarting will only be possible once the drive has changed to the "Switch on disabled" state.

During fast stop, the drive is unlocked and power is supplied to the motor.

The configuration parameters cannot be modified.

The condition for transition 12 to state "2 - Switch on disabled" depends on the value of the parameter "Quick stop option code" (QSTD):

• If the "Quick stop option code" parameter has the value 2, the drive stops according t o the fast st op ramp and then chang es to s tate

"2 - Switch on disabled".

• If the "Quick stop option code" parameter has the value 6, the drive stops according to the fast stop ramp and then remains in state

"6 - Quick stop active" until:

- A "Disable voltage" command is received

- Or the STOP key is pressed

- Or there is a freewheel stop command via the terminals

7 - Fault reaction active

Transient state during which the drive performs an action appropriate to the type of fault.

The drive function is activated or deactivated according t o the type of reaction configured in the fault management parameters.

8 - Fault

Drive faulty.

The drive is locked, no power is supplied to the motor.

Summary

State

1 - Not ready to switch on Not required No Yes

2 - Switch on disabled Not required No Yes

3 - Ready to switch on Not required No Yes

4 - Switched on Required No

5 - Operation enabled Required

6 - Quick stop active Required Yes, during fast stop No

7 - Fault reaction active

8 - Fault Not required No Yes

Power section line supply for

separate control section

Depends on fault management

configuration

Power supplied to motor

Yes, apart from an open-loop

drive with a zero reference or in

the event of a "Halt" command

for an open-loop drive.

Depends on fault management

configuration

Modification of configuration

Yes, return to "2 - Switch on

disabled" state

parameters

No

-

24 1755861 11/2009

Page 24

CiA402 profile

Control word (CMD)

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Fault reset

Enable operation

Quick stop Enable voltage

Switch on

Reserved (=0) Reserved (=0) Reserved (=0)

Ack. fault

Assignable Assignable Assignable Assignable

Command

Shutdown 2, 6, 8

Switch on 3 4 - Switched on x x 1 1 1 16#0007

operation

operation

Disable voltage 7, 9, 10, 12

Quick stop

Fault reset 15

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

bit7 bit3 bit2 bit1 bit0

Fault

reset

x x 1 1 0 16#0006

x 1 1 1 1 16#000F

x x x 0 x 16#0000

x x 0 1 x 16#0002

0 V 1 x x x x 16#0080

Enable

Disable

Transition

address

4

5 4 - Switched on x 0 1 1 1 16#0007

11

7, 10

Final state

3 - Ready to

switch on

5 - Operation

enabled

2-Switch on

disabled

6 - Quick stop

active

2-Switch on

disabled

2-Switch on

disabled

Run command

By default,

direction of

rotation

command.

Enable

operation

Quick

Emergency

stop

Reserved (=0) Reserved (=0)

Enable

stop

voltage

Authorization

to supply AC

power

Switch on

Example value

Contactor

control

Halt

Halt

x: Value is of no significance for this command.

0 V 1: Command on rising edge.

1755861 11/2009 25

Page 25

CiA402 profile

Stop commands:

The "Halt" command enables movement to be int errupted wi t hout ha vin g t o leave t he "5 - Operat ion ena bl ed" stat e. The st op is performed

in accordance with the [Type of stop] (Stt) parameter.

In the case of an open-loop drive, if the "Halt" command is active, no power is supplied to the motor and no torque is applied.

In the case of a closed-loop drive, if the "Halt" command is active , power c ontinues t o be supplie d to the motor and t orque is appl ied during

stopping.

Regardless of the assignment of the [Type of stop] (Stt) parameter ([Fast stop] (FSt), [Ramp stop] (rMP), [Freewheel] (nSt), or [DC

injection] (dCI)), the drive remains in the "5 - Operation enabled" state.

A Fast Stop command at the terminals or using a bit of the control word assigned to Fast Stop causes a change to the "4 - Switched on"

state. A "Halt" command does not cause this transition.

A Freewheel Stop command at the terminals or using a bit of the control word assigned to Freewheel Stop causes a change to the "2 Switch on disabled" state.

WARNING

RISK OF EQUIPMENT DAMAGE

When the braking loop is configured, it is necessary to use the "Halt" command (bit 8 of CMD command word) to stop.

Failure to follow these instructions can result in death, serious injury or equipment damage.

Assigning control word bits

In the CiA402 profile, fixed assignment of a function input is po ssible using the following codes:

Bit Integrated Modbus CANopen Network card "Controller Inside" card

bit 11 C111 C211 C311 C411

bit 12 C112 C212 C312 C412

bit 13 C113 C213 C313 C413

bit 14 C114 C214 C314 C414

bit 15 C115 C215 C315 C415

For example, to assign the DC injection braking to bit 13 of CANopen, simply configure the [DC injection assign.] (dCI) parameter with

the [C213] (C213) value.

Bit 11 is assigned by default to the operating direction command [Reverse assign.] (rrS).

26 1755861 11/2009

Page 26

CiA402 profile

Status word (ETA)

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Warning

Alarm

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Direction of

rotation

Switch on

disabled

Power section

line supply

disabled

Stop via

STOP key

Quick stop

Emergency

stop

Reserved (=0) Reserved (=0)

Voltage

enabled

Power section

line supply

present

Fault

Fault

Internal limit

active

Reference

outside limits

Operation

enabled

Running Ready

Target

reached

Reference

reached

Switched on

Remote

Command or

reference via

network

Ready to

switch on

Awaiting

power section

line supply

Reserved (=0)

bit6 bit5 bit4 bit3 bit2 bit1 bit0

Status

1-Not ready to

switch on

2 -Swi tch on

disabled

3 -Ready to

switch on

4 -Switched on 0 1 1 0 0 1 1 16#0023

5 -Operation

enabled

6 -Qui ck stop

active

7 - Fault reaction

active

8-Fault 0xx1000

x: In this state, the value of the bit can be 0 or 1.

(1)

This mask can be used by the PLC program to test the chart state.

Switch on

disabled

0xx0000 -

1 x x 0 0 0 0 16#0040

0 1 x 0 0 0 1 16#0021

0 1 1 0 1 1 1 16#0027

0 0 1 0 1 1 1 16#0007

0xx1111 -

Quick

stop

Voltage

enabled

Fault

Operation

enabled

Switched onReady to

switch on

ETA

masked by

16#006F

16#0008

or 16#0028

(1)

(2)

(2)

Fault following state "6 - Quick stop active".

1755861 11/2009 27

Page 27

CiA402 profile

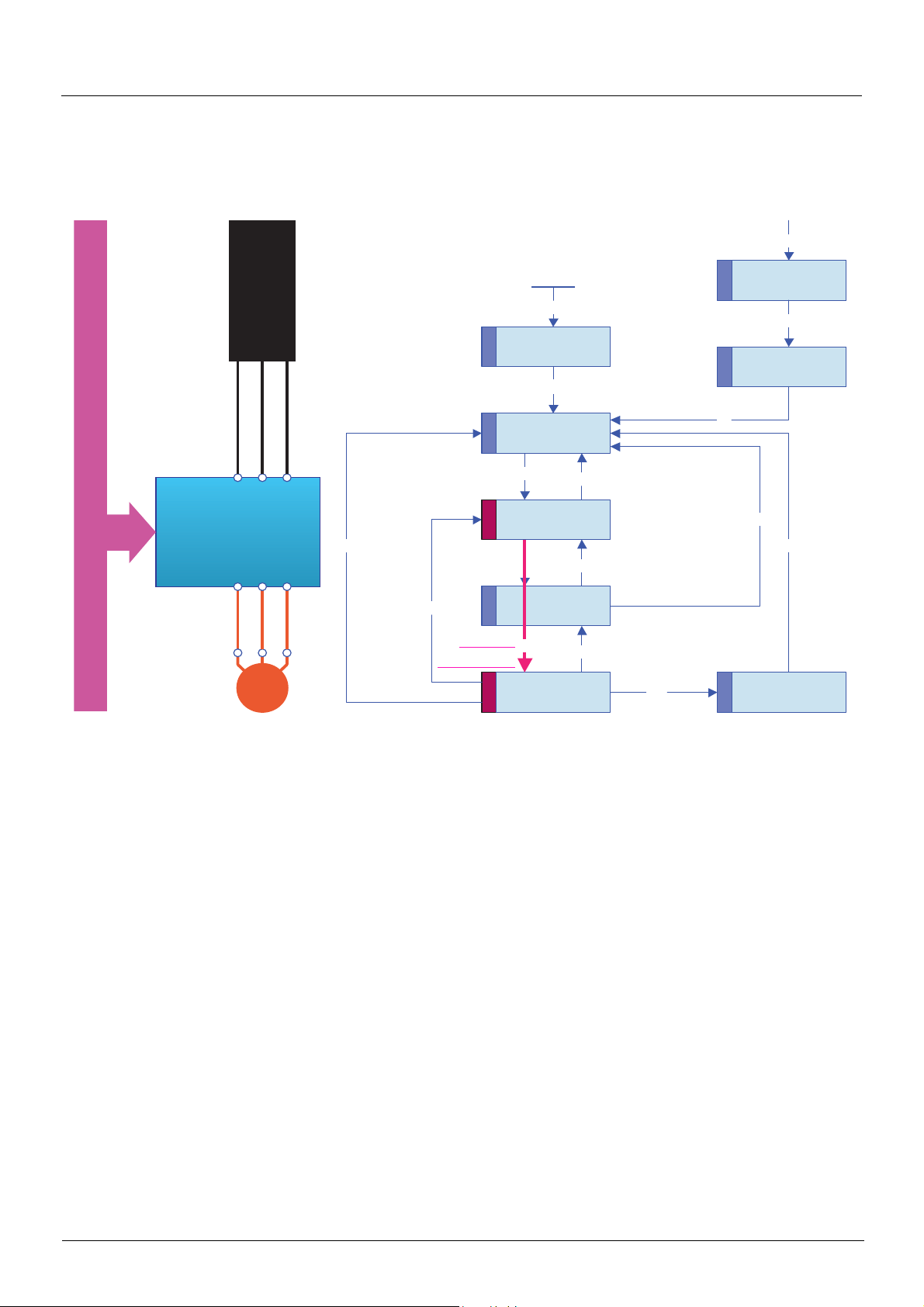

M MM M

Power section

line supply

Power section

line supply

Control section

power supply

Direct

Not separate

(1)

Direct

Separate

Line contactor

controlled by the drive

Separate

DRIVE DRIVE DRIVE

Power section

line supply

Power section

line supply

Control section

power supply

Control section

power supply

Starting sequence

The command sequence in the state chart depends on how power is being supplied to the drive.

There are three possible s cen a r io s :

(1)

The power section supplies the control section.

28 1755861 11/2009

Page 28

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Shutdown

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

Sequence for a drive powered by the power section line supply

Both the power and control sections are powered by the power section line supply.

If power is supplied to the control section, it has to be supplied to the power section as well.

The following sequence must be applied:

b Step 1

• Send the "2 - Shutdown" command

1755861 11/2009 29

Page 29

CiA402 profile

M

2

3

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5

6

8

7

4

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Switch on

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

Power section

line supply

Bus or network

DRIVE

b Step 2

• Check that the drive is in the "3 - Ready to switch on" state.

• Then send the "4 - Enable operation" command.

• The motor can be controlled (send a reference not equal to zero).

Note: It is possible, but not necessary, to send the "3 - Switch on" command followed by the "4 - Enable Operation" command to switch

successively into the states "3 - Ready to Switch on", "4 - Switched on" and then "5 - Operation Enabled".

The "4 - Enable operation" command is sufficient.

30 1755861 11/2009

Page 30

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

Shutdown

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

From all states

Sequence for a drive with separate control section

Power is supplied separately to the power and control sections.

If power is supplied to the control section, it does not have to be supplied to the power section as well.

The following sequence must be applied:

b Step 1

• The power section line supply is not necessarily present.

• Send the "2 - Shutdown" command

1755861 11/2009 31

Page 31

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Shutdown Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

b Step 2

• Check that the drive is in the "3 - Ready to switch on" state.

• Check that the power section line supply is present ("Voltage enabled" of the status word).

Power section line supply Terminal display Status word

Absent nLP 16#pp21

Present rdY 16#pp31

• Send the "3 - Switch on" command

32 1755861 11/2009

Page 32

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Shutdown Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

b Step 3

• Check that the drive is in the "4 - Switched on" state.

• Then send the "4 - Enable operation" command.

• The motor can be controlled (send a reference not equal to zero).

• If the power section line supply is still not pre sent in the "4 - Switched on" st ate after a t ime delay [Mains V. time out] (LCt), the drive

will switch to fault mode (LCF).

1755861 11/2009 33

Page 33

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

Shutdown

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

From all states

Sequence for a drive with line contactor control

Power is supplied separately to the power and control sections.

If power is supplied to the control section, it does not have to be supplied to the power secti on as well. The drive controls the line contactor.

The following sequence must be applied:

b Step 1

• The power section line supply is not present as the line contactor is not being controlled.

• Send the "2 - Shutdown" command

34 1755861 11/2009

Page 34

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

line supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Shutdown

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

b Step 2

• Check that the drive is in the "3 - Ready to switch on" state.

• Send the "3 - Switch on" command, which will close the line contactor and switch on the power section line supply.

1755861 11/2009 35

Page 35

CiA402 profile

M

2

3

4

5

6

7

1

11

9

8

12

10

15

14

13

0

1

2

3

4

5 6

8

7

Power section

ine supply

Bus or network

DRIVE

Control section

power supply

Not ready to

switch on

Entry into state chart

Switch on

disabled

Ready to

switch on

Switched on

Operation

enabled

Quick stop

active

Fault

Fault reaction

active

From all states

Shutdown

Disable voltage

or Quick stop

Shutdown

Disable

operation

Disable

voltage

Enable

operation

Shutdown

Switch on

Disable voltage

or Quick stop

Quick stop

b Step 3

• Check that the drive is in the "4 - Switched on" state.

• Then send the "4 - Enable operation" command.

• The motor can be controlled (send a reference not equal to zero).

• If the power section line supply is still not pre sent in the "4 - Switched on" st ate after a t ime delay [Mains V. time out] (LCt), the drive

will switch to fault mode (LCF).

36 1755861 11/2009

Page 36

Command/reference switching

Channels

A channel is the name given to the source of a command or reference.

The 6 Altivar 71 channels are:

• The terminals

• The graphic display terminal

• The integrated Modbus ports

• The integrated CANopen port

• A network card

• The "Controller Inside" card

The Altivar 71 has 2 integrated Modbus ports. These 2 ports are physicall y independent of one an other but together constitut e a single logic

channel.

The drive does not distinguish between commands and references that come from the Modb us network port and tho se that come from the

Modbus HMI port.

With the Altivar 71 drive, it is possible to select the active command channel and the active reference channel:

• Via configuration

• Via switching at the terminals or via a communication network

Channel commands and references

All the drive’s command and reference parameters are managed on a channel-by-channel basis.

Only the control word (CMd), speed reference (LFrd) and frequency reference (LFr) are switched.

It is possible to identify the last value written for each channel and each command or reference parameter:

Parameter name Parameter code

Taken into

account by the

drive

Control word CMd CMd1 CMd2 CMd3 CMd4

Extended control word CMI CMI1 CMI2 CMI3 CMI4

Speed setpoint (rpm) LFrd LFd1 LFd2 LFd3 LFd4

Frequency setpoint (0.1 Hz) LFr LFr1 LFr2 LFr3 LFr4

Torque setpoint Ltr Ltr1 Ltr2 Ltr3 Ltr4

PID regulator setpoint PISP PIr1 PIr2 PIr3 PIr4

Multiplying coefficient MFr MFr1MFr2MFr3MFr4

Modbus CANopen

Communication

card

Controller

inside

1755861 11/2009 37

Page 37

Command/reference switching

-10V

+10V

TERMINALS

ReferenceCommand

Digital

reference

TERMINALS

ReferenceCommand

CANopen

CANopen

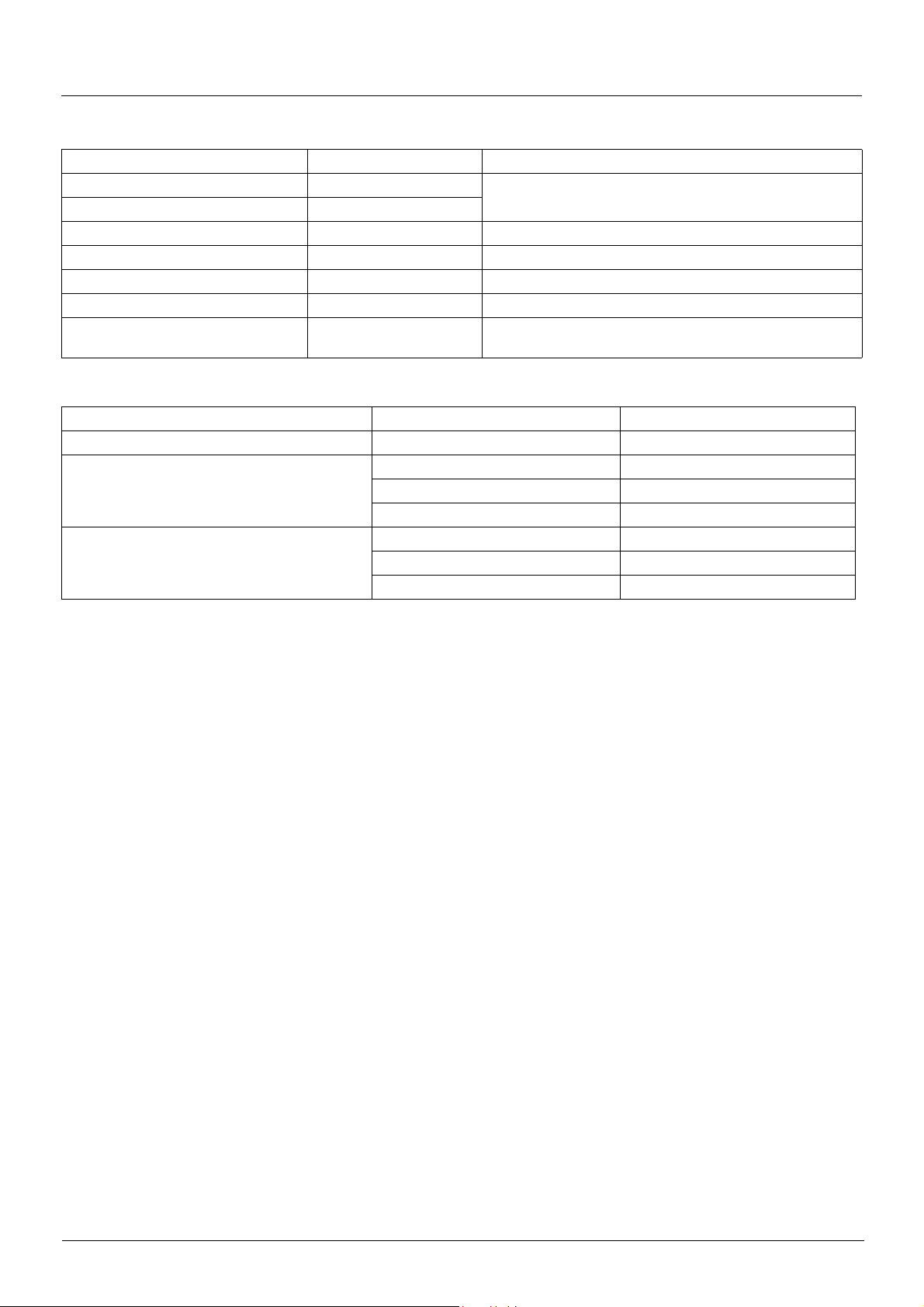

Not separate mode

Command and reference come from the same channel.

In CiA402 profile, not separate mode is configured via the terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM)

Separate mode

Command and reference may come from different channels.

In CiA402 profile, separate mode is achieved via configuration with the terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

In I/O profile, the drive is automatically in separate mode.

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

38 1755861 11/2009

Page 38

Command/reference switching

-10V

+10v

CANopen

CANopen

Control register

TERMINALS

ReferenceCommand

Digital reference

TERMINALS

ReferenceCommand

CANopen

CANopen

Digital reference

-10V

+10V

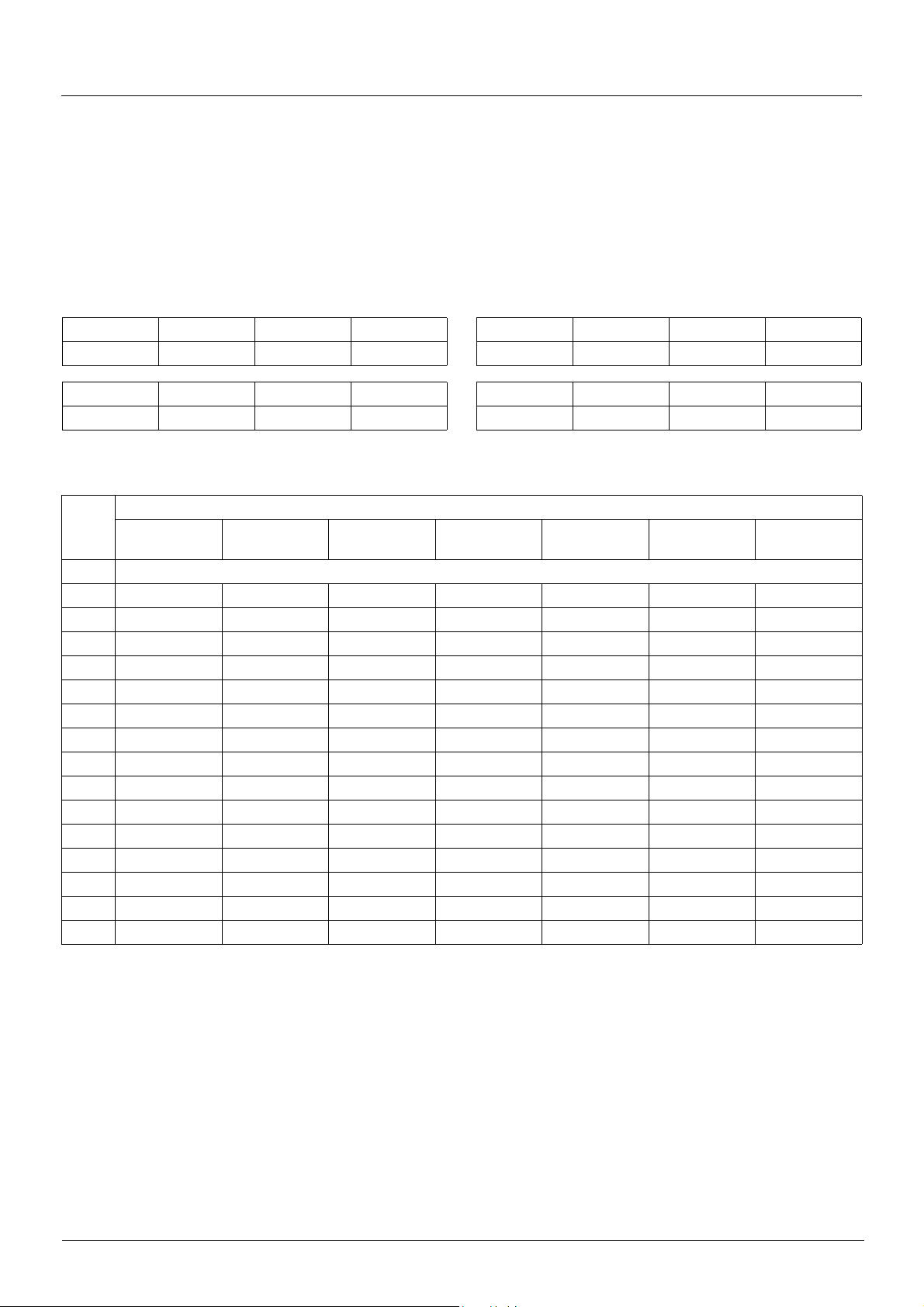

Switching in not separate mode

Switching takes place between 2 channels simultaneously for both reference and command.

In this example, the command and reference come either from CANopen or from the terminals.

Switching in separate mode

Switching can take place between 2 channels independently for the reference and command.

In this example, the command always comes from the terminals; the reference can come either from CANopen or from the terminals.

1755861 11/2009 39

Page 39

Command/reference switching

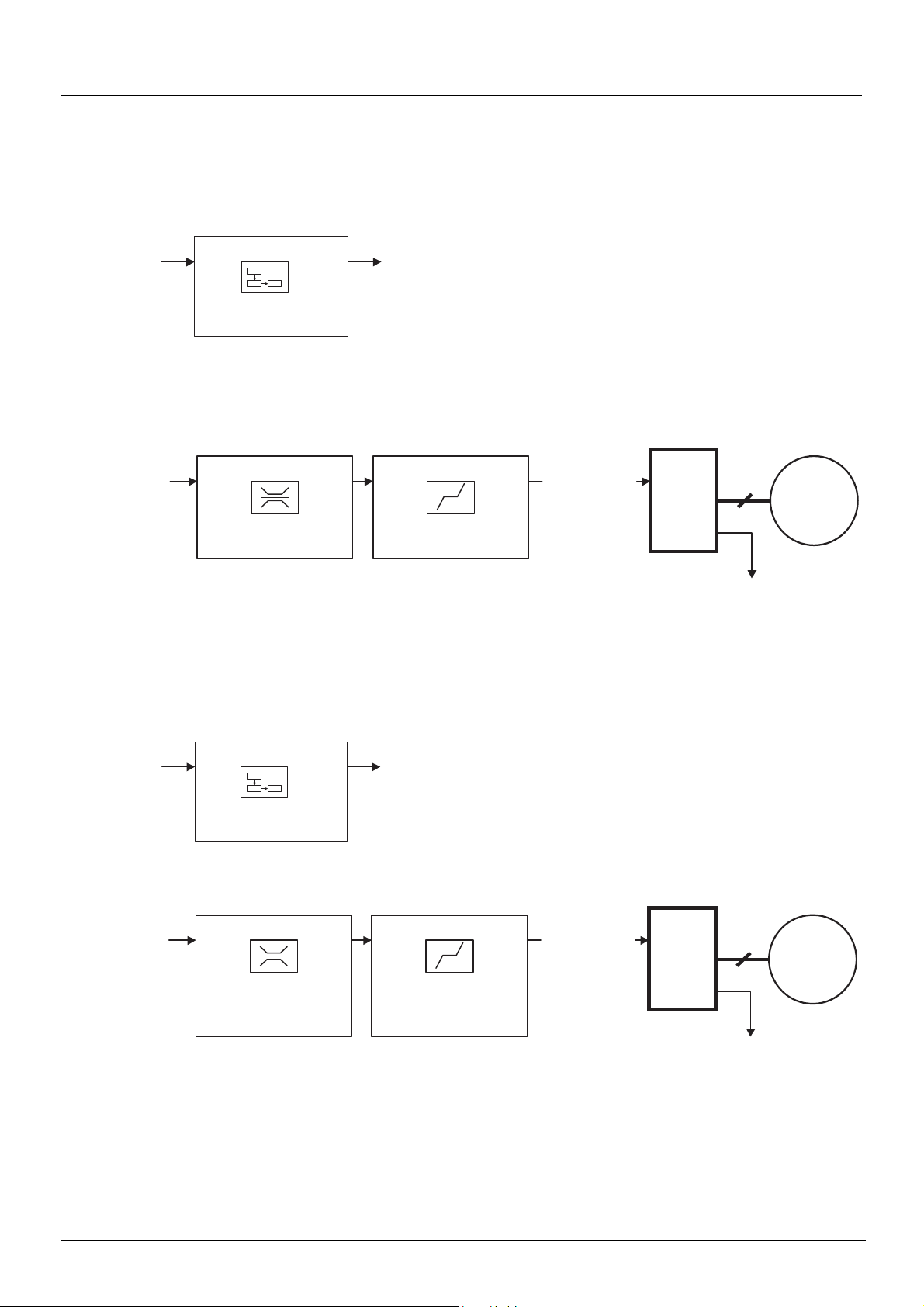

Channel switching

Reference channel configuration

Reference channel configuration enables reference sources to be predefined, which can be modified or switched subsequently via a

command.

There are 3 predefined reference channels:

• Reference channel 1

• Reference channel 1B

• Reference channel 2

Reference channels 1 and 1B are used for drive application functions.

Reference channel 2 is connected directly to the reference limiting function, bypassing the application functions.

The predefined reference channels are assigned via the [Ref. 1 channel] (Fr1), [Ref. 1B channel] (Fr1b) and [Ref. 2 channel] (Fr2)

configuration parameters, which can have the following values:

• [No] (nO): Not assigned

• [AI1] (AI1): Analog input AI1

• [AI2] (AI2): Analog input AI2

• [AI3] (AI3): Analog input AI3 (if extension card present)

• [AI4] (AI4): Analog input AI4 (if extension card inserted)

• [HMI] (LCC): Graphic display terminal

• [Modbus] (Mdb): Integrated Modbus

• [CANopen] (CAn): Integrated CANopen

• [Com. card] (nEt): Communication card (if inserted)

• [C.Insid. card] (APP): Controller Inside card (if inserted)

• [RP] (PI): Frequency input, (if card inserted)

• [Encoder] (PG): Encoder input (if card inserted)

Note: The "+speed/-speed" function is on reference channel 2. See the Programming Manual for more information.

Command channel configuration

Command channel configuration enables command sources to be predefined, which can be modified or switched subsequently via a

command.

There are 2 predefined command channels:

• Command channel 1

• Command channel 2

The predefined command channels are assigned via the [Cmd channel 1] (Cd1) and [Cmd channel 2] (Cd2) configuration parameters,

which can have the following values:

• [Terminals] (tEr): Terminals

• [HMI] (LCC): Graphic display terminal

• [Modbus] (Mdb): Integrated Modbus

• [CANopen] (CAn): Integrated CANopen

• [Com. card](nEt): Communication card (if inserted)

• [C.Insid. card] (APP): Controller Inside card (if inserted)

40 1755861 11/2009

Page 40

Command/reference switching

V

V

V

V

V

V

V

V

V

V

Switches

A channel switch is used to select predefined channels.

It can be:

• Defined via configuration

• Actuated either by an input (terminals) or a control word bit (network)

• Written via a network during operation (modification of a configuration parameter)

The possible switch values are:

Function reference

switching

[Ref 1B switching] (rCb)

Channel 1 Fr1 Fr1 Cd1

Channel 1B Fr1b

Channel 2 - Fr2 Cd2

Drive input LI1 ... LI6

Logic I/O card input LI7 ... LI10

Extended I/O card input LI11 ... LI14

Modbus command bit bit 0 = C100 ... bit 15 = C115

CANopen command bit bit 0 = C200 ... bit 15 = C215

Network command bit bit 0 = C300 ... bit 15 = C315

Controller Inside command bit bit 0 = C400 ... bit 15 = C415

The values Fr1, Fr1b, Fr2, Cd1 and Cd2 are either configured or written via the network during operation.

In I/O and CiA402 (separate mode) profiles, independent switching is possible:

Type Channel 1 Channel 2 Switching

Reference

Command

Function reference 1

[Ref. 1 channel] (Fr1)

Function reference 1 or 1B

[Ref. 1 channel] (Fr1)

[Ref. 1B channel] (Fr1b)

Command 1

[Cmd channel 1] (Cd1)

Function reference 1B

[Ref. 1B channel] (Fr1b)

Direct reference 2

[Ref. 2 channel] (Fr2)

Command 2

[Cmd channel 2] (Cd2)

Direct reference

switching

[Ref. 2 switching] (rFC)

--

Function reference switching

[Ref 1B switching] (rCb)

Direct reference switching

[Ref. 2 switching] (rFC)

Command switching

[Cmd switching] (CCS)

Command switching

[Cmd switching] (CCS)

In CiA402 profile (not separa t e m o de ) switching is simultaneous:

Type Channel 1 Channel 2 Switching

Function reference 1 or 1B

Reference

and

Command

1755861 11/2009 41

[Ref. 1 channel] (Fr1)

[Ref. 1B channel] (Fr1b)

Command 1