Schneider Electric atv61 Bacnet [EN]

Altivar 61

BACnet card

User’s manual

VW3 A3 319

06/2010

1765274

www.schneider-electric.com

Contents

While every precaution has been taken in the preparation of this document, Schneider

Electric SA assumes no liability for any omissions or errors it may contain, nor for any

damages resulting from the application or use of the information herein.

The products described in this document may be changed or modified at any time,

either from a technical point of view or in the way they are operated. Their de scription

can in no way be considered contractual.

1. Important Information _______________________________________________________________________________________ 4

2. Before you begin________________________________ ___________________________________________________________ 5

3. Introduction___________________________________________________________________________________________ ____ 6

4. Documentation structure_____________________________________________________________________________________ 7

5. Notation _________________________________________________________________________________________________ 8

6. Quick start________________________________________________________________________________________________ 9

7. Hardware setup _________________________________________________ _________________________________________ 10

7. 1. Receipt ____________________________________________________________________________________________ 10

7. 2. Hardware description _________________________________________________________________________________ 10

7. 3. Installing the card in the drive___________________________________________________________________________ 10

7. 4. Switch coding ______________________________________________________ _________________________________ 11

8. Connecting to the bus______________________________________________________________________________________ 13

8. 1. Cable routing practices________________________________________________________________________________ 13

8. 2. Card connector pinout _______________________________________ _________________________________________ 13

8. 3. RS485 schematic for the card _________________________________________ _________________________________ 14

8. 4. Dsub 9-pin connector ____________________________________________ _____________________________________ 15

9. Configuration ____________________________________________________________________________________________ 16

9. 1. Communication parameters ____________________________________________________________________________ 16

9. 2. Control ____________________________________________________________________________________________ 17

9. 3. Communication scanner_______________________________________________________________________________ 24

9. 4. Communication faults_________________________________________________________________________________ 25

9. 5. Monitored parameters_________________________________________________________________________________ 26

10. Diagnostics_____________________________________________________________________________________________ 27

10. 1. Checking the address________________________________________________________________________________ 27

10. 2. Checking the communication _________________________________ _________________________________________ 27

10. 3. LEDs_____________________________________________________________________________________________ 27

10. 4. Control - Command _________________________________________________________________________________ 28

10. 5. Communication scanner______________________________________________________________________________ 29

10. 6. Communication fault_________________________________________________________________________________ 30

10. 7. Card fault _________________________________________________________________________________________ 30

11. Network objects _________________________________________________________________________________________ 31

11. 1. List of type supported by ATV61______________ __________________________________________________________ 31

11. 2. Drive I/O __________________________________________________________________________________________ 31

11. 3. Control objects _____________________________________________________________________________________ 32

12. Network services ________________________________________________________________________________________ 34

12. 1. List of services _____________________________________________________________________________________ 34

12. 2. List of available BACnet services. ______________________________________________________________________ 35

12. 3. Additional functions__________________________________________________________________________________ 36

2 1765274 06/2010

1. Important Information

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result

in personnal injury if the instruction are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

NOTICE

Read these instructions carefully, and look at th e equip ment to bec ome fami liar with t he devi ce before t rying to insta ll, operat e, or maintain

it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifie s a procedure.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death, serious injury, or

equipment damage.

WARNING

Warning indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment

damage.

PLEASE NOTE

Electrical equipment should be serviced only by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material. This document is not intended as an instruction manual for untrained persons.

© 2005 Schneider Electric. All Rights Reserved.

3 1765274 06/2010

2. Before you begin

Read and understand these instructions before performing any procedure with thi s drive.

DANGER

HAZARDOUS VOLTAGE

• Read and understand the Installation Ma nual before inst alling or op erating the Al tivar 61 drive. Installati on, adjustme nt,

repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts of this variable speed drive, including the printe d circuit cards, operate at the line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage prese nt.

• DO NOT short across terminals PA and PC or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive

- Disconnect all power.

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect.

- Lock the disconnect in the open position.

• Disconnect all power including external control power that may be present before servicing the drive. WAIT 15

MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement procedure given

in the Installation Manual to verif y that t he DC vol tage is l ess than 45 VDC. Th e drive LEDs are not accurate indic ators

of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

CAUTION

DAMAGED EQUIPMENT

Do not install or operate any drive that appears damaged.

Failure to follow this instruction can result in equipment damage.

1765274 06/2010 4

3. Introduction

Thank you for purchasing the BACnet option card (VW3A3319) for Altivar 61 drive.

IMPORTANT : This communication opti on card is only supported with the version V1.2 and above of the Altivar 61 firmware.

By Installing this board into the Altivar 61, data communi cation can be made with a host computer or other device via BACnet network.

The communication card has a 4-pole open style connector for connection t o the network: A, B, GND, SCR.

Data exchanges give access to all Altivar 61 functions:

• Control (start, stop, reset, setpoint),

• Monitoring (status, current, voltage, thermal state...),

• Diagnostics (alarms).

The graphic display terminal or the integrated display terminal can be used to acce ss numerous functi ons for commun ication con figuration

and diagnostics.

5 1765274 06/2010

4. Documentation structure

b BACnet manual

The present BACnet user manual describes:

• connection to BACnet,

• configuration of the communication-specific parameters via the integrated HMI or the graphic HMI,

• diagnostics,

• networks variables.

You will also find important information in other Altivar 61 t echnical documents. They are available on the Web site

www.schneider-electric.com and on the CDROM delivered with each drive.

b Installation manual

The installation manual describes:

• how to assemble the drive (particularly how to mount the BACnet card),

• how to connect the drive.

b Programming manual

The programming manual describes:

• the functions and parameters of the drive,

• how to use the drive HMI (integrated HMI and graphic HMI).

b Communication parameters manual

The Communication parameters manual describes:

• the operating modes specific to communication (CiA 402 state chart),

• the interaction between communication and local control (HMI and termi nals),

• the drive parameters with specific information for use via a communication network (addresses, formats, etc).

When using the BACnet card, some sections of the Communication parameters manual are not relevant :

-profiles,

- I/O profile

- DSP 402 profile.

The description of drive parameters is useful only if you use the parameters access function of the BACnet card (MBOX PARAM, MBOX

DATA) or the communication scanner function (COM SCAN OUT1, COM SCAN IN1).

1765274 06/2010 6

5. Notation

b Drive terminal displays

The graphic display terminal menus are shown in square brackets.

Example: [1.9 COMMUNICATION].

The integrated 7-segment display terminal menus are shown in round brackets with a "-" at the end.

Example: (COM-).

Parameter names displayed on the graphic display terminal are written in square brackets.

Example: [Fallback speed]

Parameter codes displayed on the integrated 7-segment display terminal are written in round brackets.

Example: (LFF).

b Formats

Hexadecimal values are written as follows: 16# or 0x

Binary values are written as follows: 2#

b Abbreviations

O = Optional

M = Mandatory

7 1765274 06/2010

6. Quick start

Operation Refer to

A How to realize a factory setting of the drive

In the menu:

[1 DRIVE MENU]

[1.12 FACTORY SETTINGS]

• Select [Config. Source]: Macro-conf,

• Select [PARAMETER GROUP LIST]: All

B How to configure main BACnet communication parameters:

In the menu:

[1 DRIVE MENU]

[1.9 COMMUNICATION]

[BACnet]

• Check [Address] (BACnet MAC address)

• Configure [Bit rate]

• Configure [Instance number] (also called "Device node ID")

You must power cycle the drive to apply these parameters to the BACnet card.

•

C How to configure control is from BACnet

In the menu:

[1 DRIVE MENU]

[1.6 COMMAND]

Programming manual

[1.12 FACTORY SETTINGS]

(FCS-)

7. Configuration

7. 1. Communication parameters

7. Configuration

7. 3. Control

• Change [Ref.1 channel] from "AI1" to "Com. card"

D Handle the drive by the BACnet controller

• Control start / stop by the binary value RUN/STOP CMD,

• Control the velocity setpoint by the analog value INPUT REF 1,

• Control direction of rotation by the binary value FWD/REV CMD,

• Monitor if the drive is controlled l ocal or remote (BACnet) by the binary value HAND/AUTO ACT,

• Monitor the running / stopped state by the binary value RUN/STOP ACT,

• Monitor the actual direction of rotation by the binary value FWD/REV ACT,

• Monitor the actual speed or frequency by the analog val ue OUTPUT SPEED or ACTUAL FREQ.

Fault handling:

• Monitor the fault state by the binary value FAULT ACT,

• Monitor the fault detail by the analog value LAST FLT,

• Remote reset the fault by the binary value FAULT RESET.

E Switch local / remote by the drive HMI

Press F4 key (marked TK) to switch alternately from between BACnet and HMI.

The right of the upper display line:

- REM: control by BACnet,

- LOC: control by HMI.

F Diagnose BACnet communication by the drive HMI

In the menu:

[1 DRIVE MENU]

[1.2 - MONITORING]

[COMMUNICATION MAP]

[DIAG NETWORK]

• Monitor the frame and error frame counters.

G Diagnose BACnet communication by the drive HMI

In the menu:

[1 DRIVE MENU]

[1.2 - MONITORING]

[COMMUNICATION MAP]

• Check that the Command Channel is Com. card,

• Check that Active ref. channel is Com. card.

H Disable network fault for testing

In the menu:

[1 DRIVE MENU]

[1.8 FAULT MANAGEMENT] (FLt-)

Configure [COM. FAULT MANAGEMENT] to [Ignore].

Programming manual

Graphic display terminal

Description of the graphic screen

8. Diagnostics

8. 3. Control - Command

8. Diagnostics

8. 9. Communication

Programming manual

[1.8 FAULT MANAGEMENT]

(FLt-)

1765274 06/2010 8

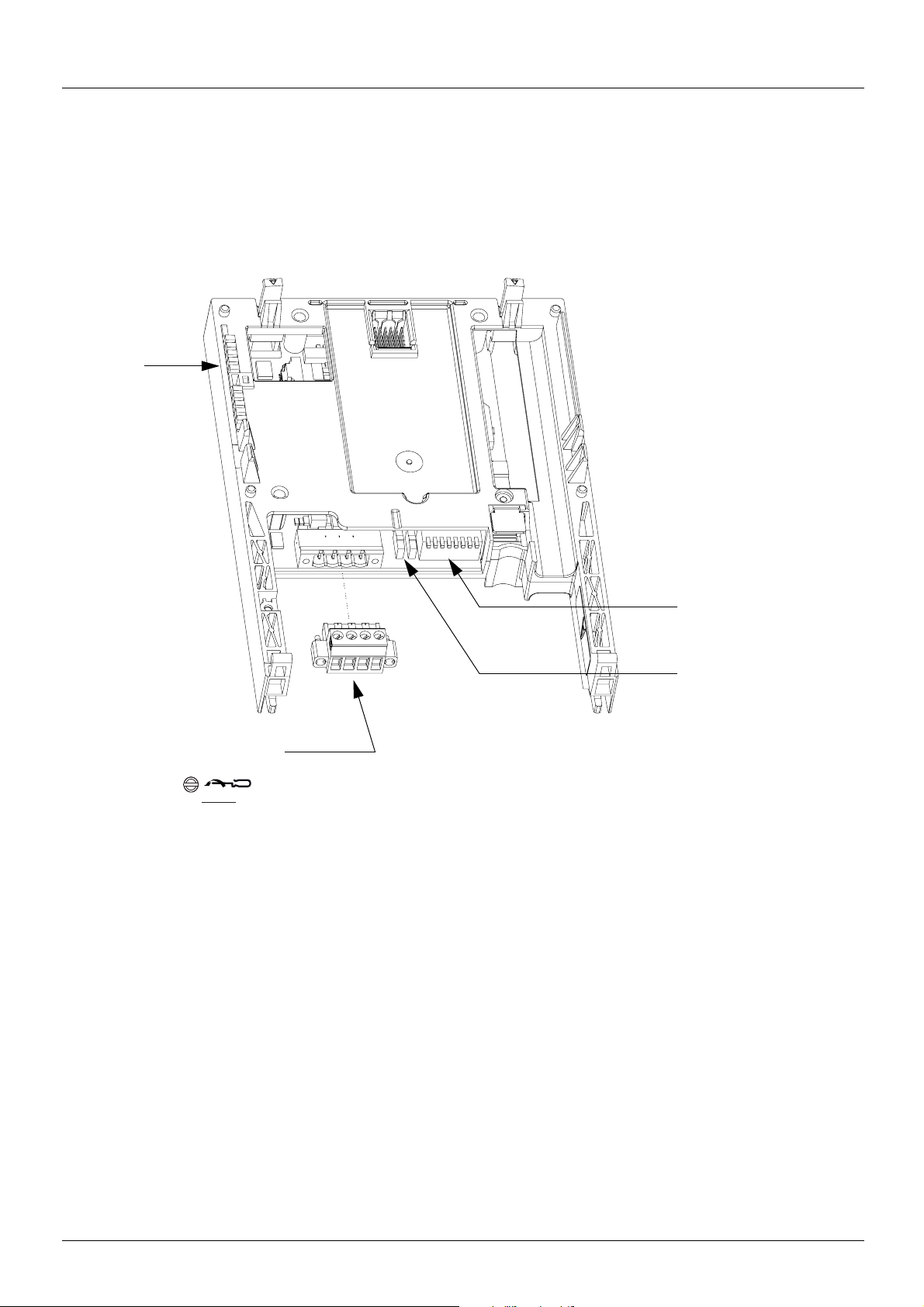

7. Hardware setup

4-pole open style connector

Max. tightening torque:

Address switches

LEDs

Polarization switches

7. 1. Receipt

• Check that the card reference printed on the label is the same as that on the delivery note corresponding to the purchase order.

• Remove the option card from its packaging and check that it has not been damag ed in transit.

7. 2. Hardware description

0,6 N.m

5.3 lb.in

7. 3. Installing the card in the drive

Refer to the "Installation manual".

9 1765274 06/2010

7. Hardware setup

Address 11 = 2#000 1011

Address 110 = 2#110 1110

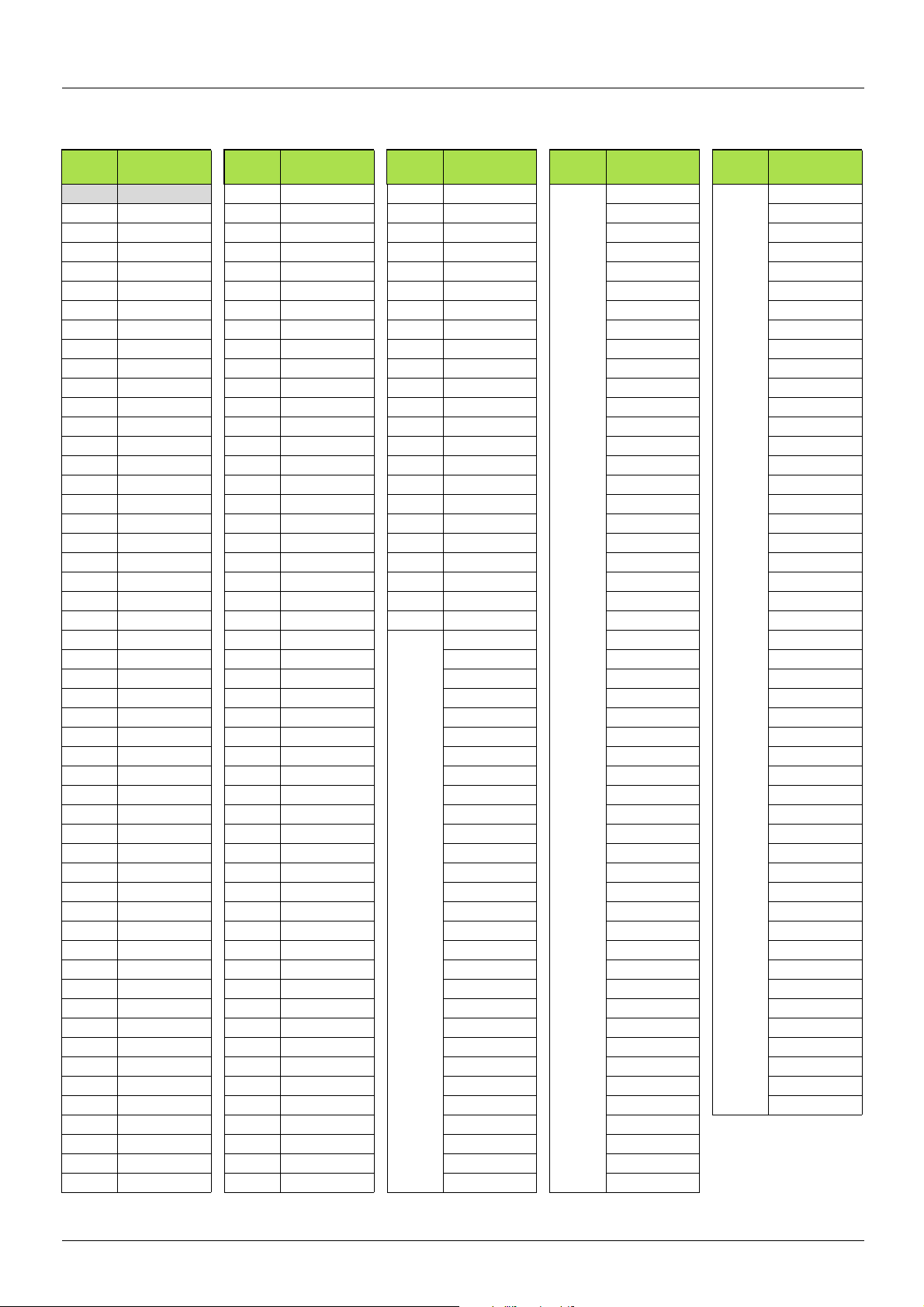

7. 4. Switch coding

b Choosing polarization

Set both switches to the lower position.

Polarization to the RS 485 line at 4.7 k

Ω.

b Coding the address

The switches are used to encode the address (1 to 127) of the drive on the bus.

The switch settings must not be changed when the drive is powered on.

The correspondence between the value and the position of the switch is as follows:

• 0 = OFF = Switch in upper position,

• 1 = ON = Switch in lower position.

The address is binary-coded.

Examples :

1765274 06/2010 10

7. Hardware setup

The table below indicates the positions of the switches for all configurable addresses:

Address

0 0000 0000 052 0011 0100 104 0110 1000

001 0000 0001 053 0011 0101 105 0110 1001 1001 1101 1101 0001

002 0000 0010 054 0011 0110 106 0110 1010 1001 1110 1101 0010

003 0000 0011 055 0011 0111 107 0110 1011 1001 1111 1101 0011

004 0000 0100 056 0011 1000 108 0110 1100 1010 0000 1101 0100

005 0000 0101 057 0011 1001 109 0110 1101 1010 0001 1101 0101

006 0000 0110 058 0011 1010 110 0110 1110 1010 0010 1101 0110

007 0000 0111 059 0011 1011 111 0110 1111 1010 0011 1101 0111

008 0000 1000 060 0011 1100 112 0111 0000 1010 0100 1101 1000

009 0000 1001 061 0011 1101 113 0111 0001 1010 0101 1101 1001

010 0000 1010 062 0011 1110 114 0111 0010 1010 0110 1101 1010

011 0000 1011 063 0011 1111 115 0111 0011 1010 0111 1101 1011

012 0000 1100 064 0100 0000 116 0111 0100 1010 1000 1101 1100

013 0000 1101 065 0100 0001 117 0111 0101 1010 1001 1101 1101

014 0000 1110 066 0100 0010 118 0111 0110 1010 1010 1101 1110

015 0000 1111 067 0100 0011 119 0111 0111 1010 1011 1101 1111

016 0001 0000 068 0100 0100 120 0111 1000 1010 1100 1110 0000

017 0001 0001 069 0100 0101 121 0111 1001 1010 1101 1110 0001

018 0001 0010 070 0100 0110 122 0111 1010 1010 1110 1110 0010

019 0001 0011 071 0100 0111 123 0111 1011 1010 1111 1110 0011

020 0001 0100 072 0100 1000 124 0111 1100 1011 0000 1110 0100

021 0001 0101 073 0100 1001 125 0111 1101 1011 0001 1110 0101

022 0001 0110 074 0100 1010 126 0111 1110 1011 0010 1110 0110

023 0001 0111 075 0100 1011

024 0001 1000 076 0100 1100 1000 0000 1011 0100 1110 1000

025 0001 1001 077 0100 1101 1000 0001 1011 0101 1110 1001

026 0001 1010 078 0100 1110 1000 0010 1011 0110 1110 1010

027 0001 1011 079 0100 1111 1000 0011 1011 0111 1110 1011

028 0001 1100 080 0101 0000 1000 0100 1011 1000 1110 1100

029 0001 1101 081 0101 0001 1000 0101 1011 1001 1110 1101

030 0001 1110 082 0101 0010 1000 0110 1011 1010 1110 1110

031 0001 1111 083 0101 0011 1000 0111 1011 1011 1110 1111

032 0010 0000 084 0101 0100 1000 1000 1011 1100 1111 0000

033 0010 0001 085 0101 0101 1000 1001 1011 1101 1111 0001

034 0010 0010 086 0101 0110 1000 1010 1011 1110 1111 0010

035 0010 0011 087 0101 0111 1000 1011 1011 1111 1111 0011

036 0010 0100 088 0101 1000 1000 1100 1100 0000 1111 0100

037 0010 0101 089 0101 1001 1000 1101 1100 0001 1111 0101

038 0010 0110 090 0101 1010 1000 1110 1100 0010 1111 0110

039 0010 0111 091 0101 1011 1000 1111 1100 0011 1111 0111

040 0010 1000 092 0101 1100 1001 0000 1100 0100 1111 1000

041 0010 1001 093 0101 1101 1001 0001 1100 0101 1111 1001

042 0010 1010 094 0101 1110 1001 0010 1100 0110 1111 1010

043 0010 1011 095 0101 1111 1001 0011 1100 0111 1111 1011

044 0010 1100 096 0110 0000 1001 0100 1100 1000 1111 1100

045 0010 1101 097 0110 0001 1001 0101 1100 1001 1111 1101

046 0010 1110 098 0110 0010 1001 0110 1100 1010 1111 1110

047 0010 1111 099 0110 0011 1001 0111 1100 1011 1111 1111

048 0011 0000 100 0110 0100 1001 1000 1100 1100

049 0011 0001 101 0110 0101 1001 1001 1100 1101

50 0011 0010 102 0110 0110 1001 1010 1100 1110

0

051 0011 0011 103 0110 0111 1001 1011 1100 1111

Switches

1234 5678

Address

Switches

1234 5678

Address

127

Switches

1234 5678

0111 1111 1011 0011 1110 0111

Address

127

Switches

1234 5678

1001 1100

Address

127

Switches

1234 5678

1101 0000

Address 0 generally reserved.

11 1765274 06/2010

Loading...

Loading...