Schneider Electric ATV61, ATV71 Instruction Bulletin

30072-451-38 (Rev. 01)

DANGER

09/2009

Instruction Bulletin

Replaces 30072-451-38C dated 07/2008

Raleigh, NC, USA

Altivar® 61 and 71 Supplementary Ratings

Class Number 8800

Retain for future use.

Before you Begin Read and follow these precautions before performing any procedure with

this drive.

The word “drive” as used in this bulletin refers to the controller portion of the

adjustable speed drive as defined in the National Electrical Code

.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the

Altivar 61 or 71 drive. Installation, adjustment, repair, and maintenance

must be performed by qualified personnel.

• The user is responsible for compliance with all international and national

electrical code requirements with respect to grounding of all equipment.

• Many parts of this drive, including the printed circuit boards, operate at

the line voltage. DO NOT TOUCH. Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw

connections with voltage present.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus

capacitors.

• Before servicing the drive:

— Disconnect all power, including external control power that may be

present.

— Place a “DO NOT TURN ON” label on all power disconnects.

— Lock all power disconnects in the open position.

— WAIT 15 MINUTES to allow the DC bus capacitors to discharge.

Then follow the “DC Bus Voltage Measurement Procedure” on

page 2 to verify that the DC voltage is less than 42 V. The drive LED

is not an indicator of the absence of DC bus voltage.

• Install and close all covers before applying power or starting and

stopping the drive.

™

(NEC).

© 2005–2009 Schneider Electric All Rights Reserved

Failure to follow these instructions will result in death or serious

injury.

Released for Manufacturing

Printed on 2009/10/09

Altivar® 61 and 71 Supplementary Ratings 30072-451-38 (Rev. 01)

DANGER

Introduction 09/2009

Introduction This document provides:

• Information regarding short circuit current rating (SCCR) and

overcurrent protection device (OCPD) for the 200–240 Vac,

380–480 Vac, and 500–600 Vac three-phase Altivar

and Altivar 71 (ATV71) drives.

• Information on drives in single-phase installations with and without

line reactors.

Use this information in addition to the ATV61 and ATV71 Simplified Manuals

and as a supplement to the recommendations listed on the drive nameplate.

Only the ATV61 and ATV71 drive part numbers available for each

supplementary rating type are listed in this document.

®

61 (ATV61)

DC Bus Voltage Measurement

Procedure

Measuring the DC bus voltage

Before working on the drive, turn it off and wait 15 minutes to allow the DC

bus to discharge. Then measure the DC bus voltage.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read and understand the instructions on page 1 before performing this

procedure.

Failure to follow these instructions will result in death or serious

injury.

The DC bus voltage can exceed 1,000 Vdc. Use a properly rated voltagesensing device when performing this procedure. To measure the DC bus

voltage:

1. Disconnect the drive power supply.

2. Wait 15 minutes to allow the DC bus to discharge.

3. Measure the voltage of the DC bus between the PA/+ and PC/–

terminals to ensure that the voltage is less than 42 Vdc.

4. If the DC bus capacitors do not discharge completely, contact your local

Schneider Electric representative. Do not repair or operate the drive.

© 2005–2009 Schneider Electric All Rights Reserved2

Released for Manufacturing

Printed on 2009/10/09

30072-451-38 (Rev. 01) Altivar® 61 and 71 Supplementary Ratings

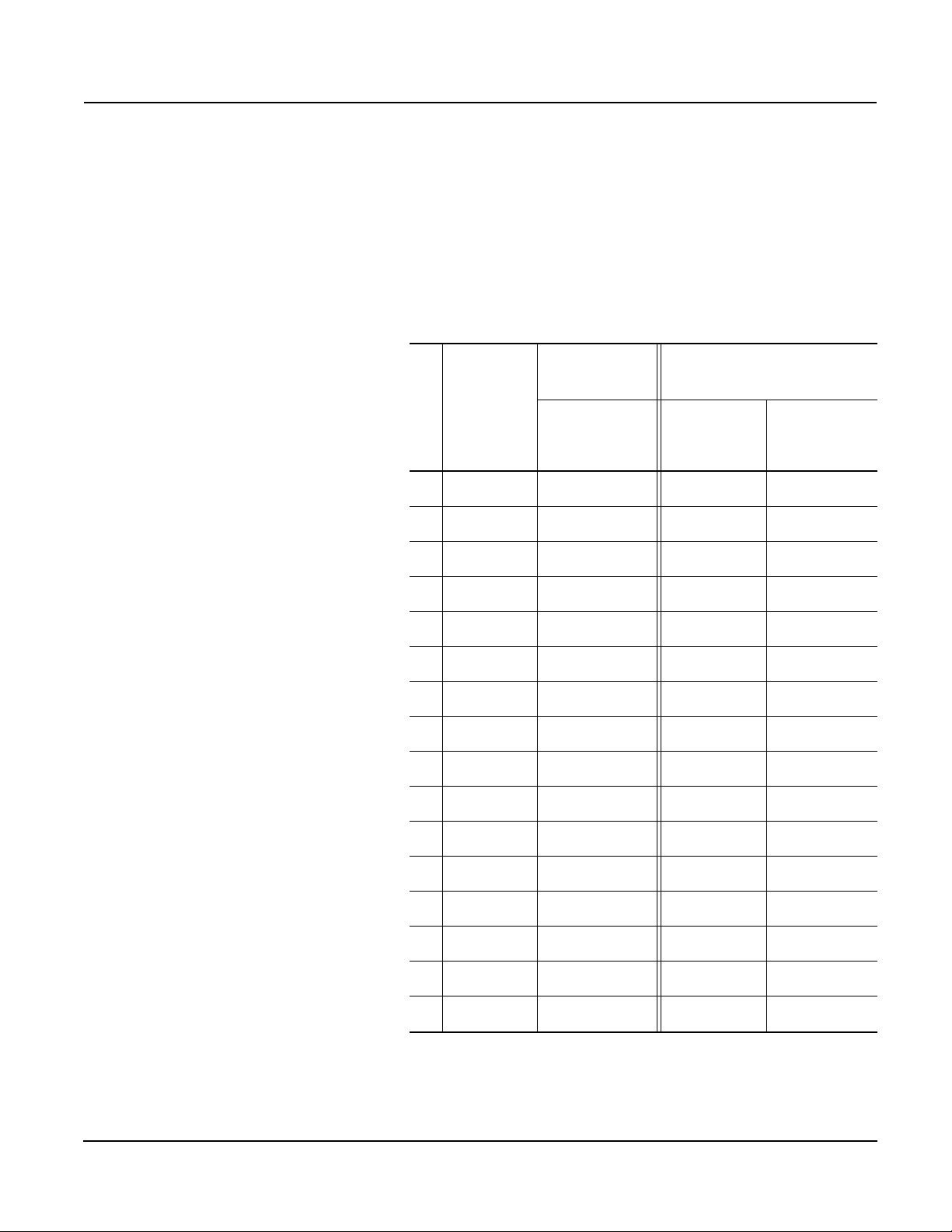

09/2009 100 kA SCCR with Fuses and a Minimum 3% Impedance Line Reactor

100 kA SCCR with Fuses and a

Minimum 3% Impedance Line

Reactor

380–480 V Ratings For drives with a three-phase input line voltage of 380–480 V, a

This section provides fuse values for a drive installed as a Type 1 drive

(open drive with a conduit box) with a 3% line reactor, or for a drive that is

installed in a metallic enclosure with a 3% line reactor.

®

Bussmann

Class J Time Delay or Non-time Delay 600 V Fuse is

required. Table 1 lists the maximum fuse values for a 100 kA SCCR. For

installations requiring an enclosure, the minimum enclosure volume is also

specified in Table 1.

Table 1: Maximum Fuse Values for 100 kA SCCR With a 3% Line

Reactor

Type 1

(Open Drive With

Conduit Box)

Drive Catalog

hp

Number

Maximum Fuse

Value

(A)

A T V 6 1 H 0 7 5 N 4

1

ATV71H075N4

ATV61HU15N4

2

ATV71HU15N4

A T V 6 1 H U 2 2 N 4

3

ATV71HU22N4

A T V 6 1 H U 3 0 N 4

—

ATV71HU30N4

A T V 6 1 H U 4 0 N 4

5

ATV71HU40N4

A T V 6 1 H U 5 5 N 4

7.5

ATV71HU55N4

A T V 6 1 H U 7 5 N 4

10

ATV71HU75N4

ATV61HD11N4

15

ATV71HD11N4

A T V 6 1 H D 1 5 N 4

20

ATV71HD15N4

ATV61HD18N4

25

ATV71HD18N4

ATV61HD22N4

30

ATV71HD22N4

A T V 6 1 H D 3 0 N 4

40

ATV71HD30N4

A T V 6 1 H D 3 7 N 4

50

ATV71HD37N4

A T V 6 1 H D 4 5 N 4

60

ATV71HD45N4

A T V 6 1 H D 5 5 N 4

75

ATV71HD55N4

A T V 6 1 H D 7 5 N 4

100

ATV71HD75N4

1

Minimum enclosure volume allows the specified SCCR. Application specific thermal

requirements may require a larger enclosure.

2

There is no supplementary rating for an ATV61HD11N4 or ATV71HD11N4 drive installed with

a Type 1 conduit box or in a Type 1 enclosure. For the ATV61HD11N4 or ATV71HD11N4 drive

installed in a metallic enclosure, a 100 kA short circuit current rating is possible only in a Type

12 enclosure.

6 6 1078

12 12 1078

15 15 1078

17.5 17.5 1550

25 25 1551

40 40 1987

40 40 1987

2

— 60 2719

2

70 70 4036

70 70 4036

80 80 4900

90 90 7230

110 110 7230

150 150 12044

175 175 12044

225 225 12045

Drive Installed in a

Metallic Enclosure

Maximum Fuse

Value

(A)

Minimum

Enclosure

Volume

(in³)

1

© 2005–2009 Schneider Electric All Rights Reserved

3

Released for Manufacturing

Printed on 2009/10/09

Altivar® 61 and 71 Supplementary Ratings 30072-451-38 (Rev. 01)

100 kA SCCR with Fuses and a Minimum 3% Impedance Line Reactor 09/2009

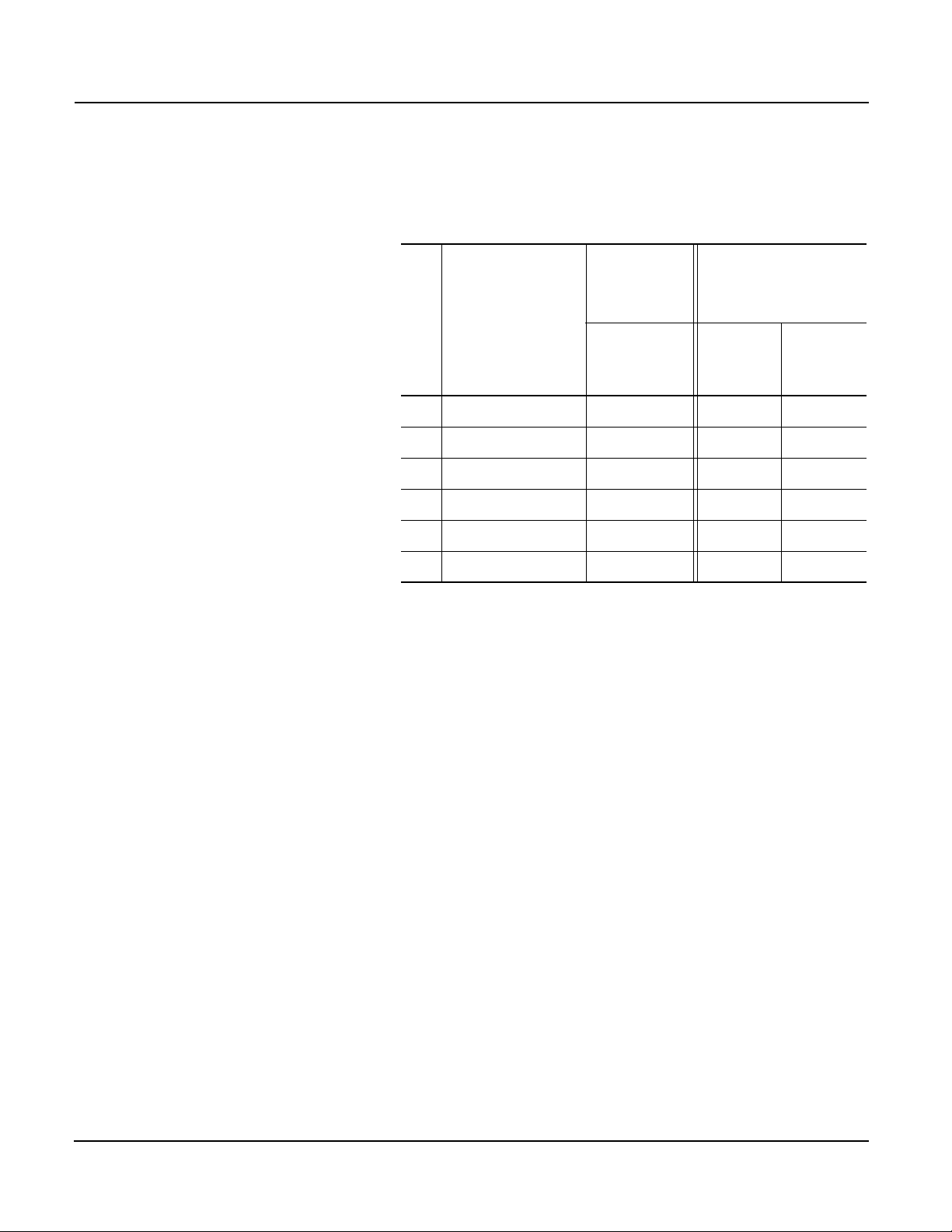

600 V Ratings For drives with a three-phase input line voltage of 600 V, a

Ferraz Shawmut® Class J Non-time Delay 600 V Fuse is required.

Table 2 lists the maximum fuse value for a 100 kA SCCR. For installations

requiring an enclosure, the minimum enclosure volume is also specified.

Table 2: Maximum Fuse Value for 100 kA SCCR With a 3% Line

Reactor

Type 1

(Open Drive With

Conduit Box)

Drive Installed in a Metallic

Enclosure

1

hp Drive Catalog Number

Maximum Fuse

Value

(A)

ATV61HD22Y

25

ATV71HD22Y

ATV61HD30Y

30

ATV71HD30Y

ATV61HD37Y

40

ATV71HD37Y

ATV61HD45Y

50

ATV71HD45Y

ATV61HD55Y

60

ATV71HD55Y

ATV61HD75Y

75

ATV71HD75Y

1

Any NEMA type enclosure can be used.

2

Minimum enclosure volume allows the specified SCCR. Application specific thermal

requirements may require a larger enclosure.

60 60 8640

60 60 8640

90 90 9792

110 110 9792

125 125 9792

150 150 9792

Maximum

Fuse Value

(A)

Minimum

Enclosure

Volume

2

(in³)

© 2005–2009 Schneider Electric All Rights Reserved4

Released for Manufacturing

Printed on 2009/10/09

Loading...

Loading...