Schneider Electric ATV61, ATV71 Controller inside [EN]

Altivar 61 / 71

"Controller Inside" Card

User’s manual

VW3 A3 501

11/2010

1757062

www.schneider-electric.com

Contents

While every precaution has been taken in the preparation of this document,

Schneider Electric SA assumes no liability for any omissions or errors i t may contain,

nor for any damages resulting from the application or use of the information herein.

The products and options descr ibed in th is document may be changed or modifi ed at

any time, either from a technical point of view or in the way they are operated.

Their description can in no way be considered contractual.

Before you begin_____________________________________________________________________________________________ 4

Documentation structure_______________________________________________________________________________________ 5

Introduction_________________________________________________________________________________________________ 6

Presentation _____________________________________________________________________________________________ 6

Description ______________________________________________________________________________________________ 6

Dialog __________________________________________________________________________________________________ 7

Master CANopen communication_____________________________________________________________________________ 7

Communication with a PLC ___________________________________________ ______________________________________ 7

Clock______________________________________________________________________ _____________________________ 8

Programming ____________________________________________________________________________________________ 8

Hardware setup _____________________________________________________________________________________________ 9

Receipt _________________________________________________________________________________________________ 9

Installing the card in the drive________________________________________________________________________________ 9

Description of terminals _____________ ______________________________________________________________________ 10

Characteristics __________________________________________________________________________________________ 11

Schemes_______________________________________________________________________________________________ 12

Connection to a CANopen bus______________________________________________________________________________ 13

Example of connection to a CANopen bus_____________________________________________________________________ 14

Connecting the "Controller Inside" card to a PC_________________________________________________________________ 15

Data backup battery ______________________________________________________________________________________ 16

Configuration ______________________________________________________________________________________________ 17

Configuring the switches___________________________________________________________________________________ 17

Diagnostics____________________________________________________________________________________ ____________ 18

LEDs__________________________________________________________________________________________________ 18

I/O monitoring___________________________________________________________________________________________ 19

Card fault ______________________________________________________________________________________________ 20

Operation using the graphic display terminal ______________________________________________________________________ 21

Factory-loaded program___________________________________________________________________________________ 21

Example of a special program ______________________________________________________________________________ 23

Operation using the integrated display terminal ____________________________________________________________________ 24

Factory-loaded program___________________________________________________________________________________ 24

Special program _________________________________________________________________________________________ 24

1757062 11/2010 3

Before you begin

Read and understand these instructions bef ore performing any procedure on this drive.

DANGER

HAZARDOUS VOLTAGE

• Read and understand the Installation manual before installing or operating the Altivar 61 / 71 drive. Installation,

adjustment, repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts of this variable speed drive, including the printed circuit boards, operate at the line voltage.

DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with volta ge present.

• DO NOT short across terminals PA and PC or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive

- Disconnect all power

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect

- Lock the disconnect in the open position

• Disconnect all power including external control power that may be present before servicing the drive.

WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement

procedure given in the installation manual to verify that the DC voltage is less than 45 VDC. The drive LEDs are not

accurate indicators of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

CAUTION

DAMAGED EQUIPMENT

Do not install or operate any drive that appears damaged.

Failure to follow this instruction can result in equipment damage.

4 1757062 11/2010

Documentation structure

Installation manual

This manual describes:

• Assembly

• How to connect the drive

Programming manual

This manual describes:

• The functions

• The parameters

• How to use the drive display terminal (integrated display terminal and graphic display terminal)

Communication parameters manual

This manual describes:

• The drive parameters with specific information (addresses, formats, etc) for use via a bus or communication network

• The operating modes specific to communication (state chart)

• The interaction between communication and local control

Modbus®, CANopen®, Ethernet™, Profibus™, INTERBUS, Uni-Telway, DeviceNet®, Modbus® Plus,

FIPIO...

These manuals describe:

• Connection to the bus or network

• Configuration of the communication-specific parameters via the integrated display terminal or the graphic display terminal

• Diagnostics

• Software setup

• The communication services specific to the protocol

Altivar 58/58F compatibility manual

This manual describes the differences between the Altivar 71 and the Altivar 58/58F.

It explains how to replace an Altivar 58 or 58F, including how to replace drives communicating on a bus or network.

Altivar 38 compatibility manual

This manual describes the differences between the Altivar 61 and the Altivar 38.

It explains how to replace an Altivar 38, including how to replace drives communicating on a bus or network.

1757062 11/2010 5

Introduction

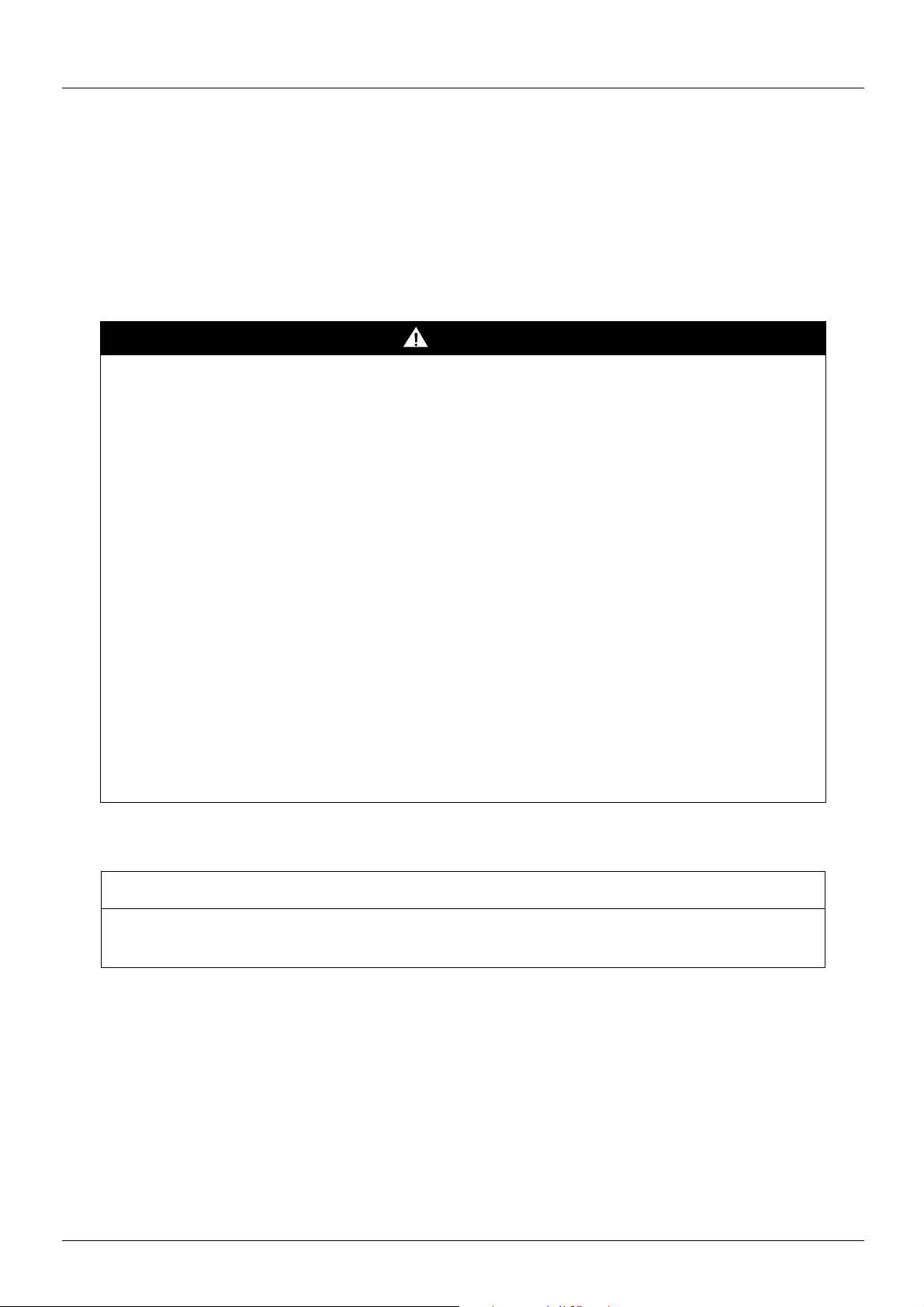

1 23

4

5

6

Presentation

The “Controller Inside” programmable card is used to adapt the variable speed drive to specific applications by integrating control system

functions.

Various predefined configurable applications are sold by Schneider-Electric and its partners.

The PS 1131 software workshop for PC is used for programming and debugging new applica tions, qui ckly and in a n open-ende d manner.

It is not possible to transfer the program from the card to the PC, which enables us to protect our know-how.

Only one “Controller Inside” pr ogrammable card can be instal led in the Altivar 61 or Altivar 7 1 drive. It can be combined with ano ther option card

(I/O extension or communication). Consult the tables summarizing the possible combinations: drives, options and accessories,

see catalogue.

The “Controller Inside” programmable card has:

• 10 logic inputs, 2 of which can be used for 2 counters or 4 of which can be used for 2 incremental encoders

• 2 analog inputs

• 6 logic outputs

• 2 analog outputs

• A master port for the CANopen bus

• A PC port for programming with the PS 1131 software workshop

• If the power consumption table does not exceed 200 mA, this card can be powered by the drive. Otherwise, an external 24 V c power

supply must be used.

The “Controller Inside” programmable card can also use:

• The drive I/O

• The I/O extension card I/O

• The encoder interface card points counter

• The drive parameters (speed, current, torque, etc)

Description

1 RJ45 connector for connecting the PS 1131 software workshop via an RS 485 serial link.

Connection to the PC is via a cable and an RS 232/RS 485 converter included in the PCSoftware for PC connection kit, VW3 A8 106.

2 9-way male SUB-D connector for connection to the CANopen bus.

3 Connector with removable screw terminals, 6 contacts at intervals of 3.81 for the

24 V c power supply and 4 logic inputs.

4 3 connectors with removable screw terminals, 6 contacts at intervals of 3.81 for 6 logic

inputs, 6 logic outputs, 2 analog inputs, 2 analog outputs and 2 commons.

5 5 LEDs, comprising:

• 1 to indicate the presence of the 24 V c power supply

• 1 to indicate a program execution fault

• 2 to indicate the CANopen bus communication status

• 1 controlled by the application program

6 Block of 4 configuration switches

6 1757062 11/2010

Introduction

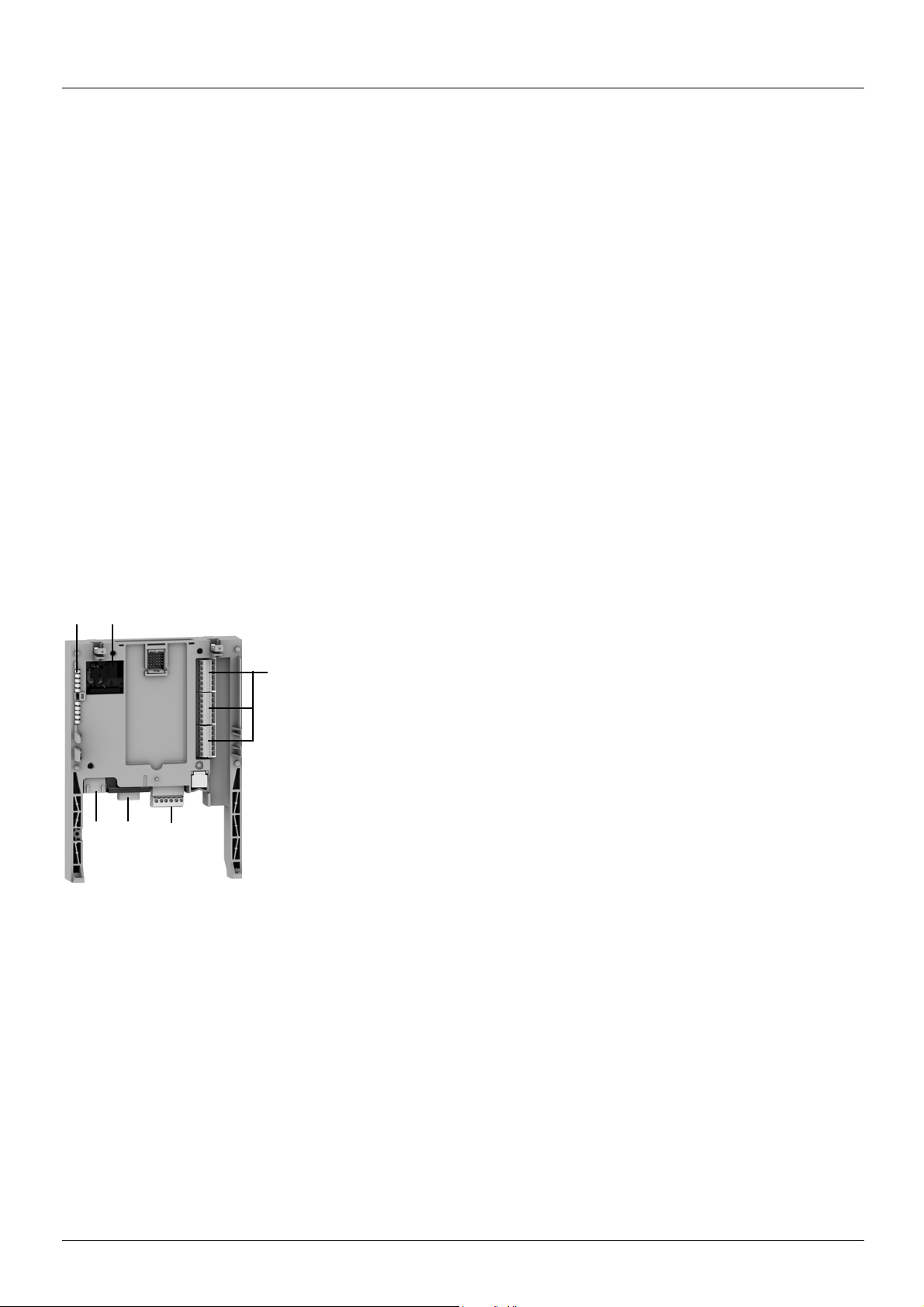

Sensors

XBT Magelis

ATV 61 / 71

Modbus bus

Independent machine with multiwire system

ATV 31

ATV 31 Advantys STB

distributed I/O

FTB 1CN

XBT Magelis

CANopen bus

Independent machine with CANopen bus

ATV 61 / 71

Modbus bus

Sensors ATV 31 FTB 1CN

CANopen bus

Ethernet TCP/IP network

Premium

ATV 61 / 71

ATV 61 / 71

XBT Magelis

Modular machine with Ethernet TCP/IP network

Dialog

Human-machine dialog with the application programmed in the “Controller Inside”

programmable card is possible using:

• The Altivar 61 / 71 graphic display terminal

• A Magelis industrial HMI terminal connected to the drive Modbus port

• A Magelis industrial HMI terminal connected to the Ethernet TCP/IP netwo rk (if the drive is

equipped with an Ethernet TCP/IP communication card)

One graphic terminal menu is dedicated to the “Controller Inside” programmable card. This

menu can be customized by the card program according to the application.

Any industrial HMI terminal which supports the Modbus protocol can be used to display and

modify the “Controller Inside” programmable card parameters. The card Modbus server

provides access to 2048 Kwords (% MW, etc).

Master CANopen communication

The master CANopen port on the “Controller Inside” programmable card can be

used to extend the I/O capacity (using CANopen I/O modules) and to control other

CANopen slave devices.

Communication with a PLC

The Altivar 61 / 71 drive equipped with a “Controller Inside” programmable card fits

easily into complex architectures.

Regardless of which bus or network is being used (Ethernet TCP/IP, Modbus/

Uni-Telway, FIPIO, Modbus Plus, Profibus DP, InterBus, etc), the PLC can

communicate with the “Controller Inside” progra mmable card and the drive. The periodic

variables can still be configured as required.

1757062 11/2010 7

Introduction

Clock

A clock backed up by a lithium battery makes it possible to have a log of events that have occurred. When the “Controller Inside”

programmable card is installed in the drive, the drive faults are automatically time and date-stamped without special programming.

Programming

In factory settings mode, the "Controller Inside" card only contains the clock function.

For other applications, the program must be loaded:

• By loading an existing program (procedure described in the PS 1131documentation)

• Or by loading a custom-built program, with the aid of the PS 1131 software workshop, using the function libraries dedicated to

programming the "Controller Inside" card.

In order to program the "Controller Inside" card, it is necessary to undergo training.

The PS1131 CD-Rom contains:

• This manual, already available on the CD-Rom supplied with ea ch Altivar 61 / 71

• The PS 1131 software workshop

• The online help

• The standard function library

• Program examples

• The Altivar 61 / 71 parameters manual

The standard function library contains:

• Logic functions (AND, OR, etc)

• Mathematical functions (Cos, Sin, Exp, etc)

• Functions dedicated to drives which simplify data exchanges between t he drive and the "Controller Inside" programmable card (example:

sending the speed reference)

• Functions for managing the CANopen bus

• Graphic terminal display functions

This manual does not describe programming using PS 1131.

Note: PS 1131 is also called CoDeSys.

CoDeSys V2.2 can be used on the Controller Inside for Altivar 58 (VW3A581131), but must not be used for programming the Controller

Inside for Altivar 61 / 71 (VW3 A3 501).

8 1757062 11/2010

Loading...

Loading...