Schneider Electric ATV61, ATV71 Canopen [EN]

Altivar 61 / 71

CANopen

®

User's manual

11/2010

1755865

www.schneider-electric.com

Contents

While every precaution has been taken in the preparation of this document,

Schneider Electric SA assumes no liability for any omissions or errors it may contain,

nor for any damages resulting from the application or use of the information herein.

The products and options descr ibed in th is document may be changed or modifi ed at

any time, either from a technical point of view or in the way they are operated. Their

description can in no way be considered contractual.

Before you begin_____________________________________________________________________________________________ 4

Documentation structure_______________________________________________________________________________________ 5

Introduction_________________________________________________________________________________________________ 6

Presentation _____________________________________________________________________________________________ 6

Notation ______________________________________________ __________________________________________________ 6

Hardware setup _____________________________________________________________________________________________ 7

Installing the CANopen adapter ______________________________________________________________________________ 7

Connecting to the CANopen bus ____________________________________________________ _________________________ 8

Configuration ________________________________________ ___________________________________________________ ___ 10

Configuring the communication parameters____________________________________________________________________ 10

Control-signal configuration ________________________________________________________________________________ 11

Configuring monitored parameters___________________________________________________________________________ 14

Configuring communication fault management _________________________________________________________________ 15

Diagnostics____________________________________________________________________________________ ____________ 16

LEDs__________________________________________________________________________________________________ 16

Communication diagnostics ________________________________________________________________________________ 17

Control-signal diagnostics__________________________________________________________________________________ 19

Communication faults_____________________________________________________________________________________ 21

Software setup _____________________________________________________________________________________________ 22

Profiles ________________________________________________________________________________________________ 22

PDO (Process Data Objects) _______________________________________________________________________________ 23

SDO (Service Data Objects)________________________________________________________________________________ 26

Other available services___________________________________________________________________________________ 26

Description of identifiers taken into account____________________________________________________________________ 27

Software setup with PL7 and SyCon ____________________________________________________________________________ 28

Detailed description of services ________________________________________________________________________________ 40

NMT commands _________________________________________________________________________________________ 40

CANopen NMT state chart _________________________________________________________________________________ 41

Bootup service __________________________________________________________________________________________ 43

Synchronization object - SYNC _____________________________________________________________________________ 43

Emergency object - EMCY_______________ __________________________________________________________________ 43

PDO1 ________________________________________________ _________________________________________________ 44

PDO2 ________________________________________________ _________________________________________________ 48

PDO3 ________________________________________________ _________________________________________________ 49

SDO service ____________________________________________________________________________________________ 50

Node Guarding service____________________________________________________________________________________ 53

Heartbeat service ________________________________________________________________________________________ 55

Object dictionary____________________________________________________________________________________________ 56

Communication profile zone objects__________________________________________________________________________ 57

1755865 11/2010 3

Before you begin

Read and understand these instructions before performing any procedure with thi s drive.

DANGER

HAZARDOUS VOLTAGE

• Read and understand this manual before insta lling or operating the Alti var drive. Installation, a djustment, repair, and

maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts in this variable speed drive, including printed wiring boards, operate at line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with volta ge present.

• DO NOT short across terminals PA and PC or across the DC bus capacitors.

• Install and close all covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive:

- Disconnect all power

- Place a "DO NOT TURN ON" label on the variable speed drive disconnect

- Lock the disconnect in the open position

• Disconnect all power including external control power that may be present before servicing the drive. WAIT 15

MINUTES for the DC bus capacitors to discharge. Then follow the DC bus voltage measurement procedure given

in the Installation Manual to verify that the DC voltage is less than 45 Vdc. The drive LEDs are not accurate indicators

of the absence of DC bus voltage.

Electric shock will result in death or serious injury

CAUTION

DAMAGED EQUIPMENT

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in equipment damage.

4 1755865 11/2010

Documentation structure

Installation manual

This manual describes:

• How to assemble the drive

• How to connect the drive

Programming manual

This manual describes:

• The functions

• The parameters

• How to use the drive display terminal (integrated display terminal and graphic display terminal)

Communication parameters manual

This manual describes:

• The drive parameters with specific information for use via a bus or communication network

• The operating modes specific to communication (state chart)

• The interaction between communication and local control

Modbus, CANopen®, Ethernet™, Profibus, INTERBUS, Uni-Telway, FIPIO, Modbus Plus,

DeviceNet™ ... manuals

These manuals describe:

• Connection to the bus or network

• Diagnostics

• Configuration of the communication-specific parameters via the integrated display terminal or the graphic display terminal

They describe the protocol communication services in detail.

Altivar 58/58F migration manual

This manual describes the differences between the Altivar 71 and the Altivar 58/58F.

It explains how to replace an Altivar 58 or 58F, including how to replace drives communicating on a bus or network.

Altivar 38 migration manual

This manual describes the differences between the Altivar 61 and the Altivar 38.

It explains how to replace an Altivar 38, including how to replace drives communicating on a bus or network.

1755865 11/2010 5

Introduction

Presentation

The CANopen protocol is available on the Altivar speed drive via a VW3 CAN A71 adapter, which must be ordered separately.

The CANopen adapter features a CANopen-compliant 9-way male SUB-D connector referred to as the “CANopen port” in this manual.

The CANopen port on the Altivar can be used for the following functions:

• Configuration

• Adjustment

• Control

• Monitoring

This manual describes how to set up the Altivar drive on CANopen and also describes the CANopen servi ces that are available on this drive.

Notation

Drive terminal displays

The graphic display terminal menus are shown in square brackets.

Example: [1.9 COMMUNICATION].

The integrated 7-segment display terminal menus are shown in round brackets.

Example: (COM-).

Parameter names are displayed on the graphic display terminal in square brackets.

Example: [Fallback speed]

Parameter codes are displayed on the integrated 7-segment display terminal in round brackets.

Example: (LFF).

Formats

In this manual, hexadecimal values are written as follows: 16#.

6 1755865 11/2010

Hardware setup

Modbus terminal port (HMI)

Example: ATV71HU22M3

VW3 CAN A71

CANopen

adapter

Modbus network port

8........................1

CAN _H -7-

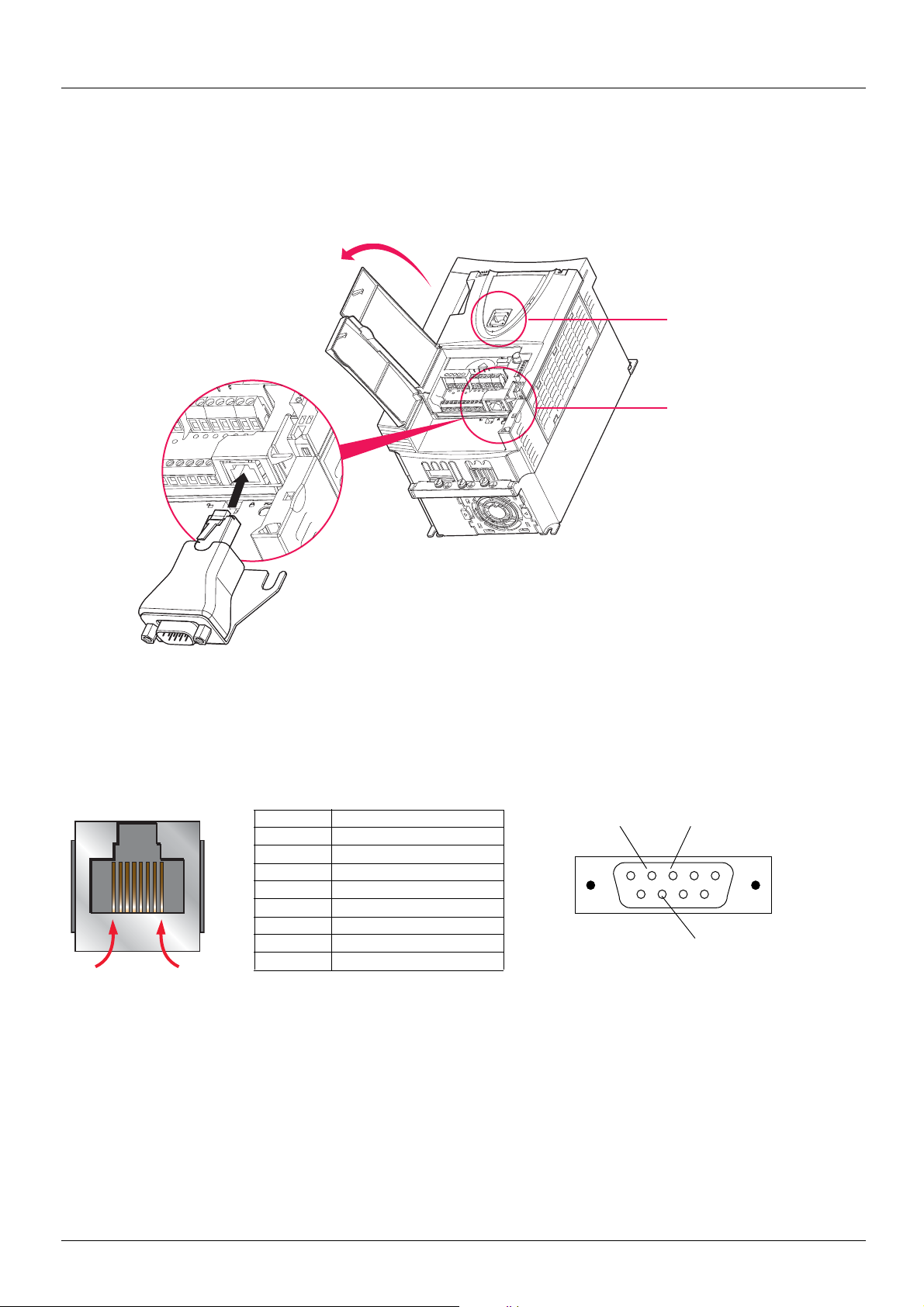

Installing the CANopen adapter

Install the VW3 CAN A71 CANopen adapter in the RJ45 port located on the drive's control terminals.

Note: This adapter MUST be screwed to the drive via its CANopen bus metal groun ding plate.

Modbus network port pinout

View from underneath

Pin Signal

(1)Modbus signal

(2)Power supply for an RS232/RS485 converter (to PC-Software)

1 CAN_H

2 CAN_L

3 CAN_GND

4D1 (1)

5D0 (1)

6 Not connected

7VP (2)

8 Common (1)

Pinout of 9-way male SUB-D connector on

CANopen adapter

CAN_L -2- CAN_GND -3-

1755865 11/2010 7

Hardware setup

2

3

5

4

1

5 5 6

CANopen

TSX CPP 110

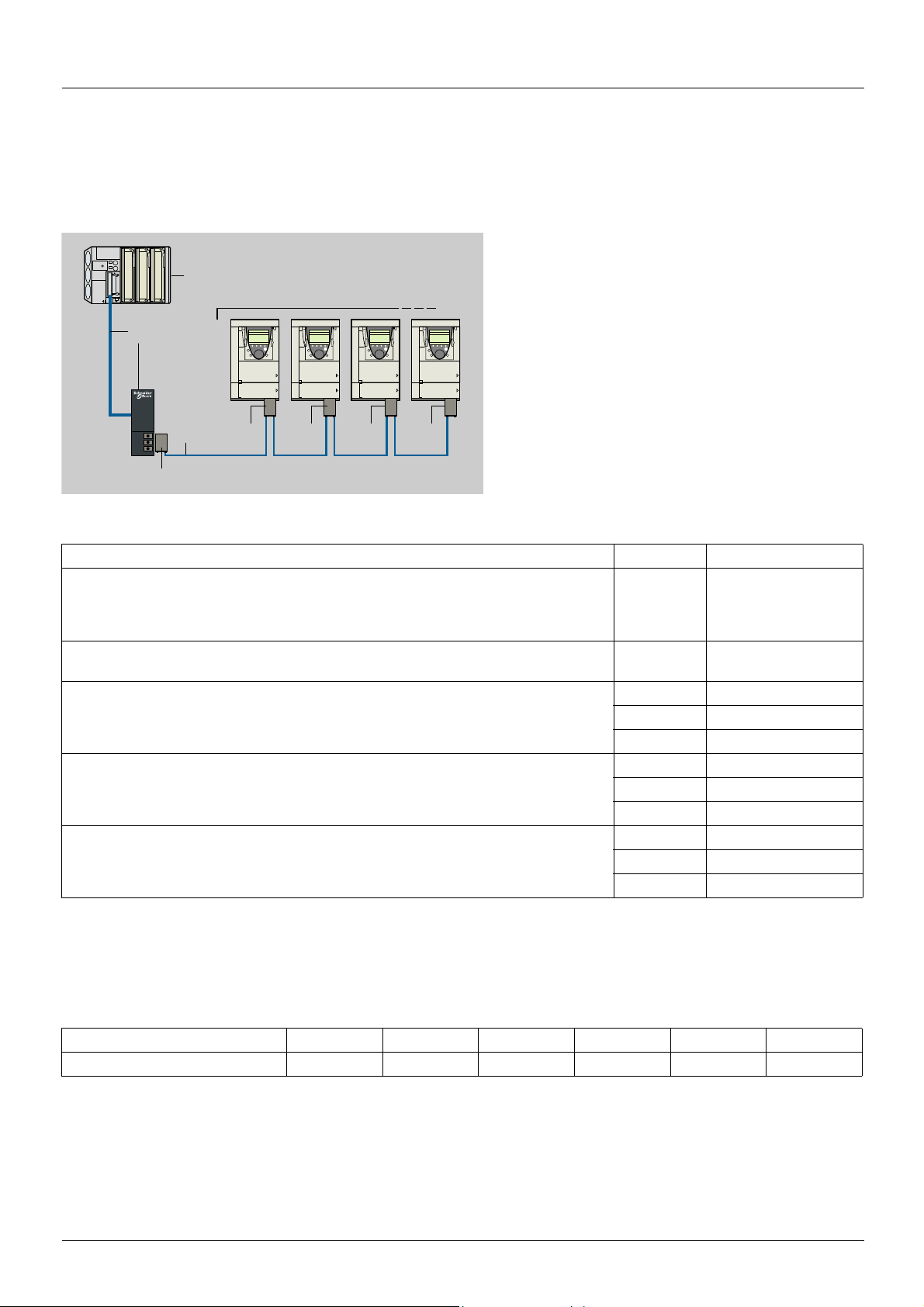

Connecting to the CANopen bus

The diagram below illustra tes an e xampl e conf ig uration co mprisi ng f our Altivar drives connec ted to a TSX Premium mast er PLC fitted with

a TSX CPP 110 CANopen master PCMCIA card.

Connection accessories should be ordered separately (please consult our cat alogs). See also below.

1. TSX Premium PLC + TSX CPP 110 CANopen master

PCMCIA card

2. Drop cable and cable connector supplied with TSX CPP 110

card

3. TSX CAN KCDF 180T 9-way female SUB-D connector with

active line terminator

4. TSX CAN C

100 or 300 m

5. VW3 CAN A71 CANopen adapter + VW3 CAN KCDF 180T

9-way female SUB-D connector with deactivated line

terminator

6. VW3 CAN A71 CANopen adapter + VW3 CAN KCDF 180T

9-way female SUB-D connector with active line terminator

••• CANopen cable, available in lengths of 50,

Description Length (m) Catalog number

CANopen adapter to be installed

in the RJ45 port on the drive's control terminals.

The adapter provides a 9-way male SUB-D connector conforming to the CANopen standard

(CIA DRP 303-1).

CANopen connector (1)

9-way female SUB-D connector with line terminator (can be deactivated)

CANopen cables LSZH

CE certification. Low smoke, halogen free and flame retardant (IEC 60332-1).

CANopen cables UL / IEC 60332-2

UL certification. Non flame propagating (IEC 60332-2).

CANopen cables flexible LSZH HD

For heavy duty or mobile applications. Low smoke, halogen free and flame retardant (IEC

60332-1). Oil resistant.

(1) For ATV 71H

TSX CAN KCDF 180T connector.

•••M3, ATV 71HD11M3X, HD15M3X and ATV 71H075N4 to HD18N4 drives, this connector can be replaced by the

– VW3 CAN A71

– VW3 CAN KCDF 180T

50 TSX CAN CA 50

100 TSX CAN CA 100

300 TSX CAN CA 300

50 TSX CAN CB 50

100 TSX CAN CB 100

300 TSX CAN CB 300

50 TSX CAN CD 50

100 TSX CAN CD 100

300 TSX CAN CD 300

Length of CANopen bus

The maximum length of the bus depends on the communication speed:

Communication speed 20 kbps 50 kbps 125 kbps 250 kbps 500 kbps 1000 kbps

Maximum length of bus 2500 m 1000 m 500 m 250 m 100 m 25 m

These lengths are for a CANopen bus and take into account actual dispersions on the components as well as when certain devices are

optocoupled to the bus.

Schneider-Electric will not accept liability for longer lengths specified in other documents.

8 1755865 11/2010

Hardware setup

7

5

10

max.

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

CAN-GND

CAN-L

CAN-H

CAN-L

CAN-H

CAN-GND

R1

S1

X1

X2

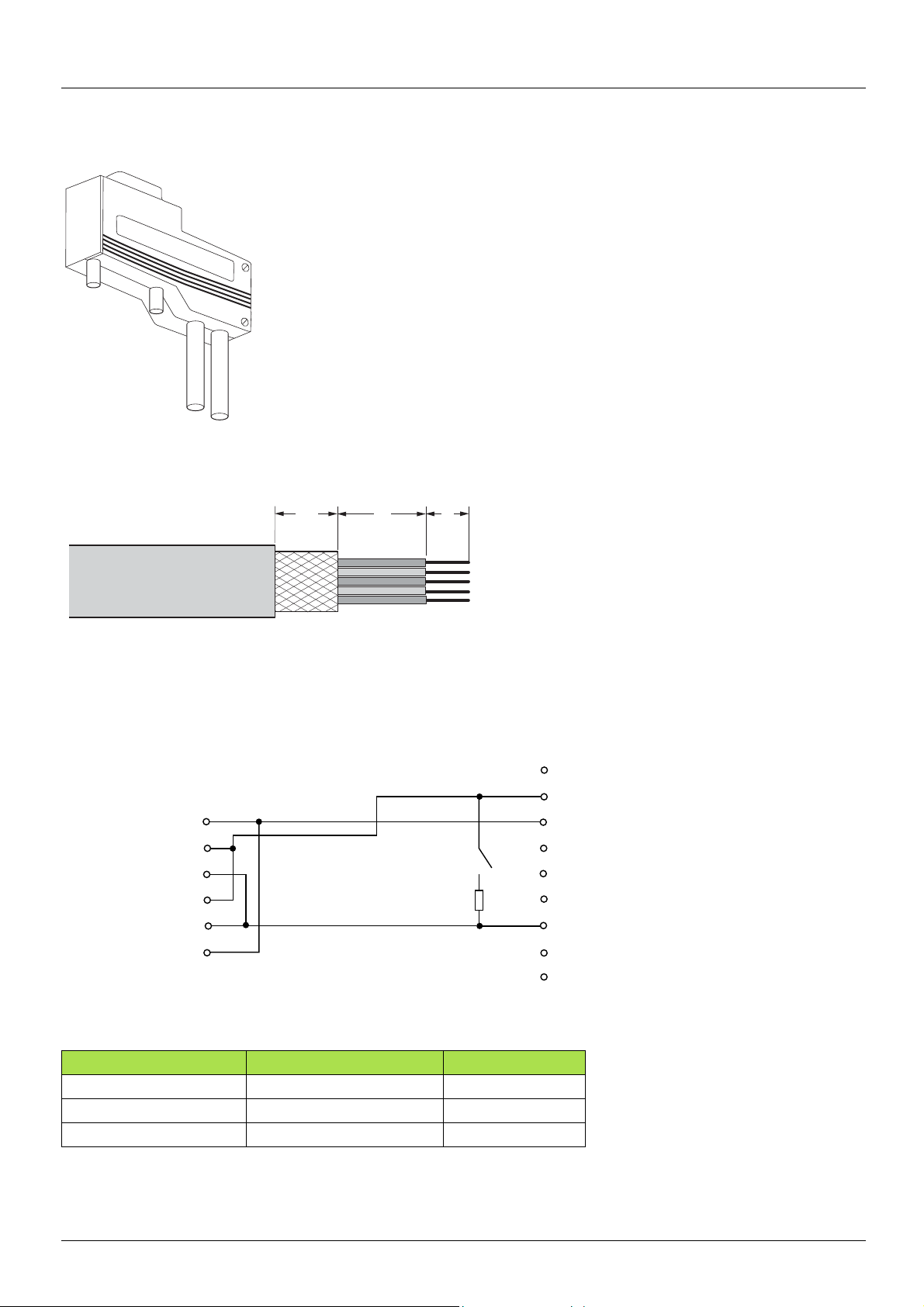

CANopen connector (VW3 CAN KCDF 180T)

How to strip the CANopen cable

Schematic

X1 = Internal screw terminal

X2 = 9-way female SUB-D

1, 6 3 CAN_GND

2, 4 2 CAN_L

3, 5 7 CAN_H

X1 = Internal screw terminal X2 = 9-way female SUB-D Signal

1755865 11/2010 9

Configuration

Configuring the communication parameters

The configuration of the CANopen communication functions on the Altivar is accessed via the [1.9 - COMMUNICATION] (COM-), menu (

[CANopen] (CnO-) submenu) on the graphic display terminal or integrated display terminal.

Note:

The configuration can only be modified when the motor is stopped and the drive locked.

In order for modifications to take effect, the drive must be shut down then restarted.

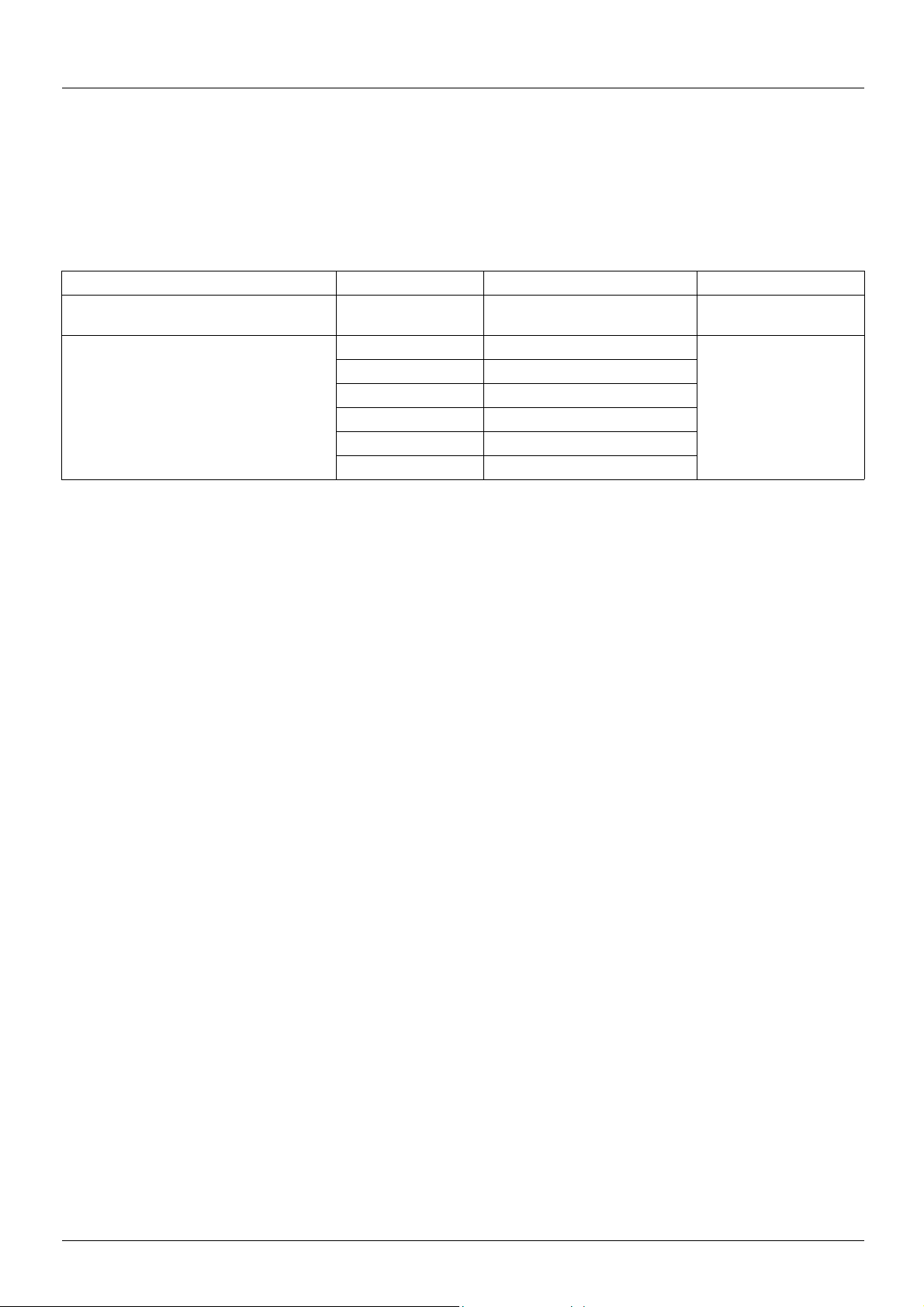

Parameter Possible values Terminal display Default value

[CANopen address] (AdCO) CANopen deactivated

1 to 127

[CANopen bit rate] (bdCO) 00- [20 kbps] (20) (1)

0050 kbps [50 kbps] (50)

0 125 kbps [125 kbps] (125)

0 250 kbps [250 kbps] (250)

0 500 kbps [500 kbps] (500)

1 000 kbps [1000 kbps] (1M)

[OFF] (0FF)

[1] (1)....[127] (127)

[OFF] (0FF)

[125 kbps] (125)

In this user’s manual, the [CANopen address] (AdC0) parameter is referred to as the "NODE-ID".

Set this parameter to its default value, (0FF), to deactivate CANopen communication on the Altivar.

To activate CANopen communication on the Altivar, write a value other than zero to the [CANopen address] (AdC0) parameter.

The value of the [CANopen bit rate] (bdC0) parameter must correspond to the communication speed of all other devices connected to the

CANopen bus.

(1)Do not select [20 kbps] (20), possible malfunction.

10 1755865 11/2010

Configuration

Control-signal configuration

Numerous control-signal configurations are possible. Please consult the Programming Manual.

The following configurations are just some of the possibili ties available.

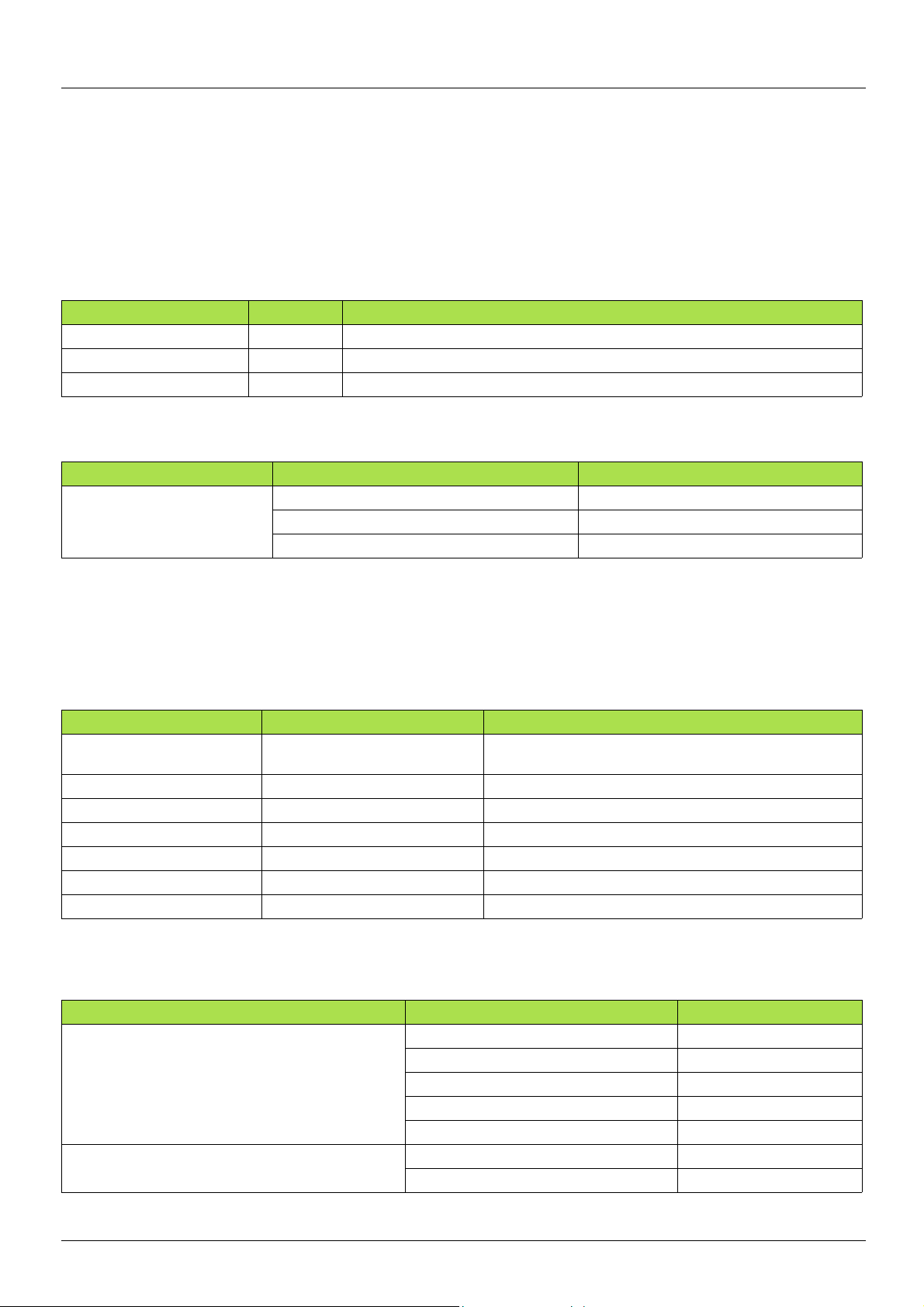

Control via CANopen in I/O profile

The command and target come from CANopen.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile The run command is simply obtained by bit 0 of the control word.

Target 1 configuration CANopen The target comes from CANopen.

Command 1 configuration CANopen The command comes from CANopen.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

[Cmd channel 1] (Cd1) [CANopen] (CAn)

Control via CANopen or the terminals in I/O profile

Both the command and target come from CANopen or the terminals. Input LI5 at t he terminals is used t o switch between CANop en and the

terminals.

The command is in I/O profile.

Configure the following parameters:

Parameter Value Comment

Profile I/O profile

Target 1 configuration CANopen Target 1 comes from CANopen.

Target 1B configuration Analog input 1 on the terminals Target 1B comes from input AI1 on the terminals.

Target switching Input LI5 Input LI5 switches the target (1

Command 1 configuration CANopen Command 1 comes from CANopen.

Command 2 configuration Terminals C ommand 2 comes from the terminals.

Command switching Input LI5 Input LI5 switches the command.

Target 1B is connected to the functions (summing, PID, etc.) that remain active, even after switching.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [I/O profile] (IO)

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

[Cmd channel 1] (Cd1) [CANopen] (CAn)

[Cmd channel 2] (Cd2) [Terminals] (tEr)

[Cmd switching] (CCS) [LI5] (LI5)

[1.7 APPLICATION FUNCT.] (FUn-) [REFERENCE

SWITCH.]

[Ref. 1B chan] (Fr1b) [AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

The run command is simply obtained via bit 0 of the control

word.

↔ 1B).

1755865 11/2010 11

Configuration

Control via CANopen in DSP402 profile

The command and target come from CANopen.

The command is in DSP402 profile (not separate mode).

Configure the following parameters:

Parameter Value Comment

Profile DSP402 profile not separate

Target 1 configuration CANopen The command and the target come from CANopen.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM) (factory setting)

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

The run commands are in DSP402 profile, the command and the

target come from the same channel.

Control via CANopen or the terminals in DSP402 profile

Both the command and target come from CANopen or the terminals. Input LI5 at t he terminals is used t o switch between CANop en and the

terminals.

The command is in DSP402 profile (not separate mode).

Configure the following parameters:

Parameter Value Comment

Profile DSP402 profile not separate

Target 1 configuration CANopen Target 1 comes from CANopen.

Target 2 configuration Analog input 1 on the terminals Target 2 comes from input AI1 on the terminals.

Target switching Input LI5 Input LI5 switches the target (1

Warning: Target 2 is directly connected to the drive reference limit. If switching is performed, the functions that affect the reference

(summing, PID, etc) are inhibited.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM)

The run commands are in DSP402 profile, the command and the

target come from the same channel.

↔ 2) and the command.

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

[Ref. 2 channel] (Fr2) [AI1] (AI1)

[Ref. 2 switching] (rFC) [LI5] (LI5)

12 1755865 11/2010

Configuration

Command in DSP402 profile via CANopen and target switching at the terminals

The command comes from CANopen.

The command comes either from CANopen or from the terminals. Inp ut LI5 at the te rmina ls is us ed to swit ch the targ et bet ween CANopen

and the terminals.

The command is in DSP402 profile (separate mode).

Configure the following parameters:

Parameter Value Comment

Profile Separate DSP402 profile

Target 1 configuration CANopen Target 1 comes from CANopen.

Target 1B configuration Analog input 1 on the terminals Target 1B comes from input AI1 on the terminals.

Target switching Input LI5 Input LI5 switches the target (1

Command 1 configuration CANopen Command 1 comes from CANopen.

Command switching Channel 1 Channel 1 is the command channel.

Target 1B is connected to the functions (summing, PID, etc.), which remain active, even after switching.

The run commands are in DSP402 profile, the command and the

target can come from different channels.

↔ 1B).

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

[Ref. 1 channel] (Fr1) [CANopen] (CAn)

[Cmd channel 1] (Cd1) [CANopen] (CAn)

[Cmd switching] (CCS) [ch1 act iv e ] (Cd1)

[1.7 APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH.]

[Ref. 1B chan] (Fr1b) [AI1] (AI1)

[Ref 1B switching] (rCb) [LI5] (LI5)

1755865 11/2010 13

Configuration

Configuring monitored parameters

It is possible to select up to 4 parameters to display their values in the [1.2 - MONITORING] menu on the graphic display terminal.

The selection is made via the [6 - MONITORING CONFIG.] menu ([6.3 - COM. MAP CONFIG.] submenu).

Each parameter in the range [Address 1 select] ... [Address 4 select] can be

used to select the parameter logic address. An address at zero is used to

disable the function.

In the example given here, the monitored words are:

• Parameter 1 = Motor current (LCR): logic address 3204, signed decimal

format.

• Parameter 2 = Motor torque (OTR): logic address 3205, signed decimal

format.

• Parameter 3 = Last fault occurred (LFT): logic address 7121,

hexadecimal format.

• Disabled parameter: 0; default format: Hexadecimal format

One of the three display formats below can be assigned to each monitored word:

Format Range Term i nal di sp lay

Hexadecimal 0000 ... FFFF [Hex]

Signed decimal -32 767 ... 32 767 [Signed]

Unsigned decimal 0 ... 65 535 [Unsigned]

RDY CAN +0.00Hz 0A

Address 1 select : 3204

FORMAT 1 : Signed

Address 2 select : 3205

FORMAT 2 : Signed

Address 3 select : 7121

Code Quick

FORMAT 3 : Hex

Address 4 select : 0

FORMAT 4 : Hex

6.3 COM. MAP CONFIG.

Note: If a monitored parameter:

- has been assigned to an unknown address

- has been assigned to a protected parameter

- has not been assigned

the value displayed in the [COMMUNICATION MAP] screen is: "-----" (see "Diagnostics" section).

14 1755865 11/2010

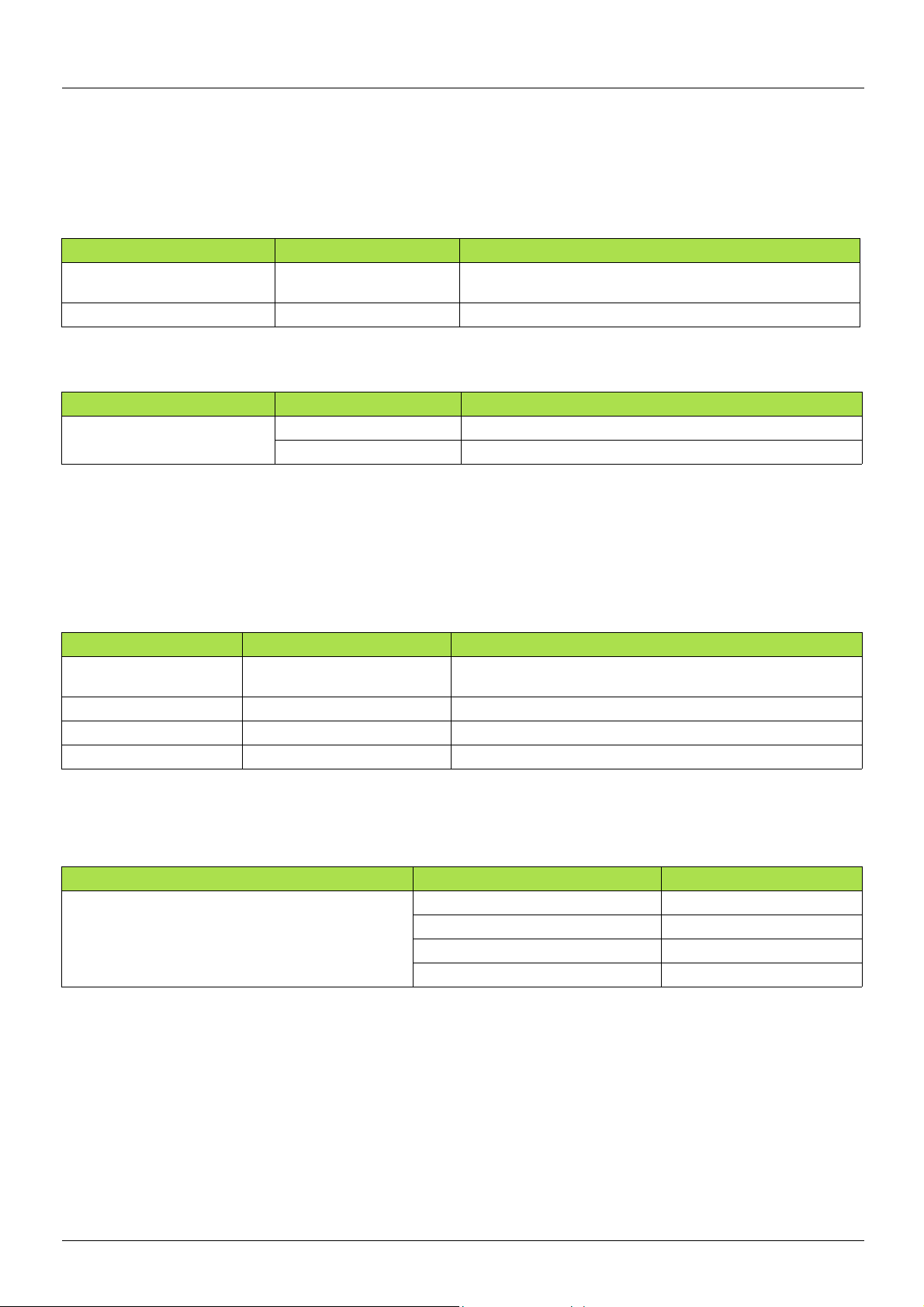

Configuration

Configuring communication fault management

The response of the drive in the event of a CANopen communication fault can be configured.

It can be configured via the graphic display termin al or the integrated display

terminal, from the [1.8 – FAULT MANAGEMENT] (FLt-) menu,

[COM. FAULT MANAGEMENT] (CLL-) submenu, via the

[CANopen fault mgt] (COL) parameter.

The values of the [CANopen fault mgt] (COL) parameter, which trigger a drive fault [CANopen com.] (COF), are:

Value Meaning

[Freewheel] (YES) Freewheel stop (factory setting).

[Ramp stop] (rMP) Stop on ramp.

[Fast stop] (FSt) Fast stop.

[DC injection] (dCI) DC injection stop.

The values of the [CANopen fault mgt] (COL) parameter, which do not trigger a drive fault, are:

Value Meaning

[Ignore] (nO) Fault ignored.

[Per STT] (Stt) Stop according to configuration of [Type of stop] (Stt).

[fallback spd] (LFF)

[Spd maint.] (rLS)

Change to fallback speed, maintained as long as the fault persists and the run command has not been

removed.

The drive maintains the speed at the time the fault occurred, as long as the fault persists and the run

command has not been removed.

RDY CAN +0.00Hz 0A

COM. FAULT MANAGEMENT

Network fault mgt : Freewheel

CANopen fault mgt : Freewheel

Modbus fault mgt : Freewheel

Code Quick

The fallback speed can be configured in the [1.8 – FAULT MANAGEMENT] (FLt-) menu using the [Fallback speed] (LFF) parameter.

1755865 11/2010 15

Diagnostics

LEDs

The two LEDs located on the right-hand side of the 7-segment integrated display

terminal indicate the CANopen communication status.

The two LEDs on the left-hand side are reserved for Modbus and are not described in

this manual.

LED LED state Altivar / CANopen state

The drive CANopen controller is in the "OFF" state.

The Altivar is in the CANopen "Stopped" state.

RUN

The Altivar is in the CANopen "Pre-operational" state.

The Altivar is in the CANopen "Operational" state.

No error signaled

Warning output by the Altivar CANopen controller

ERR

(e.g., too many error frames)

E

RROR due to the occurrence of a "Node Guarding" or "Heartbeat" event or an

"overrun" on the CANopen bus (network overload)

The CANopen controller is in the "OFF" state.

Key:

LED state Visual description of the LED state LED state Visual description of the LED state

The LED flashes at 2.5 Hz

The LED is on

The LED is in single flash mode

(on for 200 ms then off for

1 second)

The LED is in double flash mode

(on for 200 ms then off for

200 ms, on for 200 ms then off for 1 second)

(on for 200 ms then off for

200 ms)

The LED is off

16 1755865 11/2010

Diagnostics

Communication diagnostics

RUN CAN +50.00Hz 80A

COMMUNICATION MAP

Command Channel : CANopen

Cmd value : 000FHex

Active ref. channel : CANopen

Frequency ref. : 500.0Hz

Status word : 8627Hex

Code Quick

W3204 : 53

W3205 : 725

W7132 : 0000Hex

W0 : ----COM. SCANNER INPUT MAP

COM SCAN OUTPUT MAP

CMD. WORD IMAGE

FREQ. REF. WORD MAP

MODBUS NETWORK DIAG

MODBUS HMI DIAG

CANopen MAP

PROG. CARD SCANNER

On the display terminal, the [1.2 - MONITORING] (SUP-) menu ([COMMUNICATION MAP] (CMM-) submenu,

[CANopen MAP] submenu) can be used to display the communication status on CANopen.

LED display

• [RUN LED] LED ("OFF", "Stopped", "Pre-operational" or "Operational" state of the CANopen controller)

• [ERR LED] LED (CANopen error)

These LEDS are equivalent to the "CAN RUN" and "CAN ERR" LEDs on the 7-segment integrated terminal (where supplied together with

the drive).

The display on the screen opposite indicates that the CANopen controller is

in the "Operational" state ([RUN LED] LED permanently lit) and that the

controller has not detected any errors present ([ERR LED] not lit).

indicates an LED, which is not lit;

indicates an LED, which is lit.

RUN CAN +50.00Hz 80A

CANopen MAP

RUN LED :

ERR LED :

PDO1 IMAGE :

PDO2 IMAGE :

PDO3 IMAGE :

Code Quick

Canopen NMT state : Operational

Number of TX PDO : 2438

Number of RX PDO : 2438

Error code 0

RX Error Counter 0

TX Error Counter 0

1755865 11/2010 17

Diagnostics

In each of these screens and for each PDO transmitted or received, only the

[Transmit PDO•-•] or [Received PDO•-•] words actually transmitted and

received on the CANopen bus are displayed.

This means, for example, that for a recei ve PDO2 containing only 4 data bytes

(i.e., RP21 and RP22), the fields [Received PDO2-3] and [Received PDO2-4]

will not be displayed.

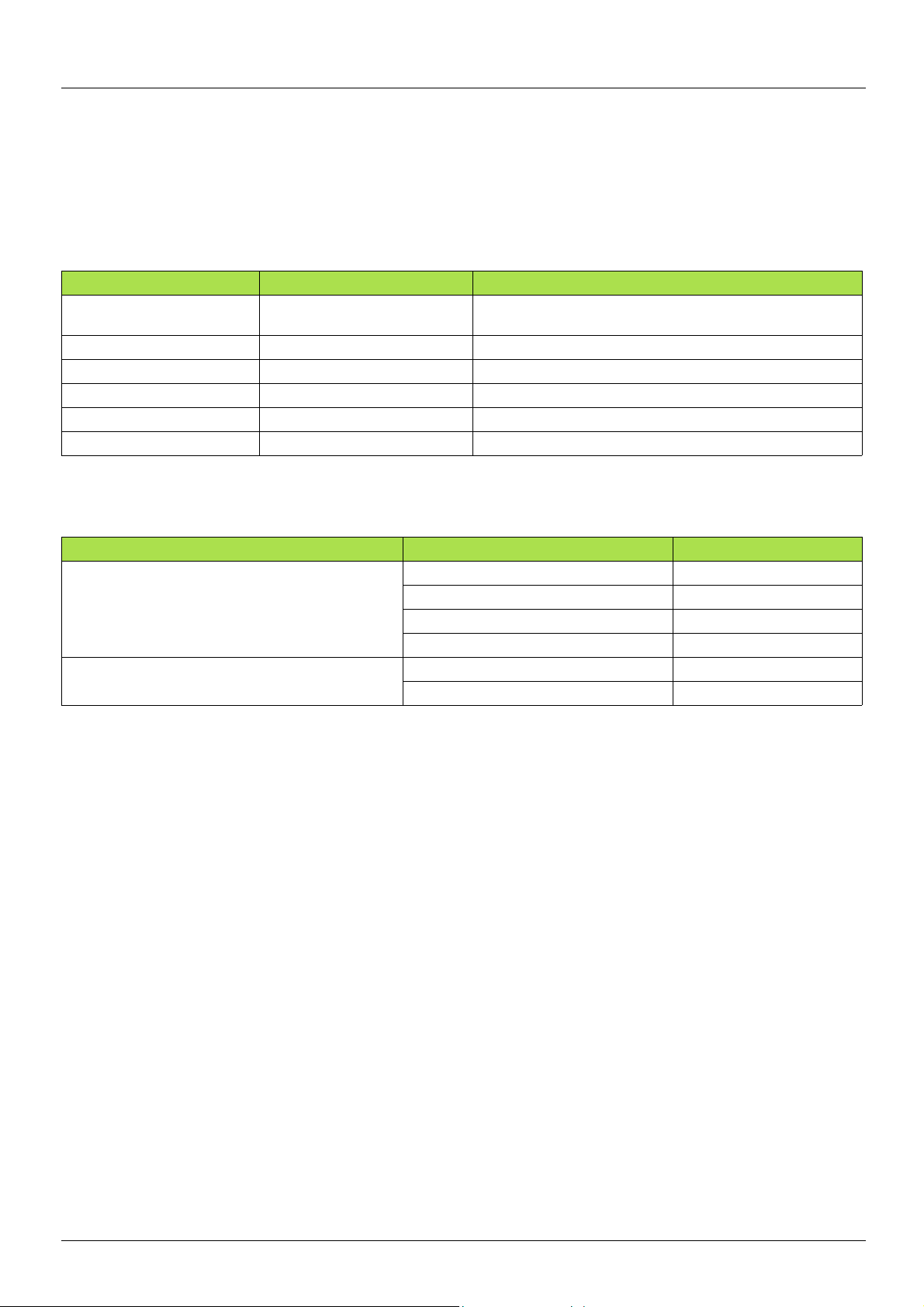

NMT chart display

The [CANopen NMT state] (NMTS) parame ter (logic add ress 6057, CANopen in dex/sub index 16#20 1E/3A) indicat es the NMT chart sta te.

The various possible values are [Boot], [Stopped], [Operational] and [Pre-Op] (Pre-operational).

PDO counter display

[Number of RX PDO] and [Number of TX PDO] indicate the number of PDOs received and the number of PDOs transmitted by the drive

(all PDO sets - PDO1, PDO2 and PDO3 - combined).

These counters are modulo 65 536 counters, i.e., the value is reset to zero once 65 535 is reached.

Last CANopen fault

The [Error code] (ErCO) parameter (index/subindex 16#201E/39) indicates the last active CANopen fault and maintains its value until the

last fault has disappeared.

The possible values are listed below:

Display Description

[0] No errors detected since the start of CANopen communication

[1] "Bus Off" requiring the drive to be restarted

[2] "Life Guarding" fault requiring a return to the NMT "Initialization" state

[3] "CAN overrun" error not requiring any specific action to be taken

[4] "Heartbeat" fault requiring a return to the NMT "Initialization" state

[5] NMT state chart fault (see section "CANopen NMT state chart")

Counters

The [RX Error Counter] (rEC1) parameter (logic address 6059, CANopen index/subindex 16#201E/3C) counts the number of frames

received with errors for all types of frame (PDO, SDO, etc.).

The [TX Error Counter] (tEC1) parameter (logic address 6058, CANopen index 16#201E/3B) counts the number of frames transmitted

with errors for all types of frame (PDO, SDO, etc.).

These types of error can be caused, for example, by network load problems or the short-circuiting of electrical signals on the bus.

The maximum count value supported by these two counters is 65 535.

PDO value display

A second level of submenus can be accessed via the [CANopen map] submenu: [PDO1 IMAGE], [PDO2 IMAGE] and

[PDO3 IMAGE].

Each of these submenus can be used to access a screen displaying the values transmitted and received by each set respectively (PDO1,

PDO2 and PDO3).

RUN CAN +50.00Hz 80A

PDO3 IMAGE

Received PDO3-1 : 1237

Received PDO3-2 : 50

Received PDO3-3 : 0

Received PDO3-4 : 304

Transmit PDO3-1 : 231

Code Quick

Transmit PDO3-2 : 642

Transmit PDO3-3 : 10

Transmit PDO3-4 : 9432

18 1755865 11/2010

Diagnostics

Control-signal diagnostics

On the terminal, the [1.2 - MONITORING] menu ([COMMUNICATION MAP] submenu) can be used to display control-signal diagnostic

information between the Altivar drive and the CANopen master:

• Active command channel

• Value of the control word (CMD) from the active command channel

• Active target channel

• Value of the target from the active target channel

• Value of the status word

• Values of the four param e te rs se l ec t ed by th e u se r

•The [COM. SCANNER INPUT MAP] submenu: is unnecessary for CANopen

•The [COM SCAN OUTPUT MAP] submenu: is unnecessary for CANopen

• In the [CMD. WORD IMAGE] submenu: control words from all channels

• In the [FREQ. REF. WORD MAP] submenu: frequency targets produced by all channels

Example of the display of communication diagnostic information

RUN CAN +50.00Hz 80A

COMMUNICATION MAP

Command Channel : CANopen

Cmd value : 000FHex

Active ref. channel : CANopen

Frequency ref. : 500.0Hz

Status word : 8627Hex

Code Quick

W3204 : 73

W3205 : 725

W7132 : 0000Hex

W0 : ----COM. SCANNER INPUT MAP

COM SCAN OUTPUT MAP

CMD. WORD IMAGE

FREQ. REF. WORD MAP

MODBUS NETWORK DIAG

MODBUS HMI DIAG

CANopen MAP

PROG. CARD SCANNER

Control word display

The [Command Channel] parameter indicates the active command channel.

The [Cmd value] parameter indicates the hexadecimal value of the control word (CMD) used to control the drive.

The [CMD. WORD IMAGE] submenu ([CANopen cmd.] parameter) is used to display the hexadecimal value of the control word sent by

CANopen.

1755865 11/2010 19

Loading...

Loading...