Page 1

Page 2

ther e rem ai ns references to TAC as a corpor a te brand in the body copy. As ea ch document is updated, the body copy wi ll be changed to reflect a ppropriate cor porate bran d

g

1. Fasten to wall or duct with two #8 sheet metal screws or

equivalent.

2. Rotate the solenoid enclosure to position the wiring

compartment, if necessary.

Warning: Do not over-tighten as this may cause distortion of

plunger tube or damage coil.

CHECKOUT - Go, No Go Test

1. Connect solenoid ports to plastic tubing.

2. Apply air to port 3. Ports 3 and 2 should be connected.

3. Apply power to the solenoid. Ports 3 and 1 should be

connected.

4. If ports

3 and 1 are not connected, check to see if the proper

voltage is applied.

5. Replace the solenoid with a functional unit if solenoid is

powered and ports 3 and 1 are not connected.

MAINTENANCE

Regular maintenance of the total system is recommended to

assure sustained optimum performance.

FIELD REPAIR

None. Replace with a functional solenoid.

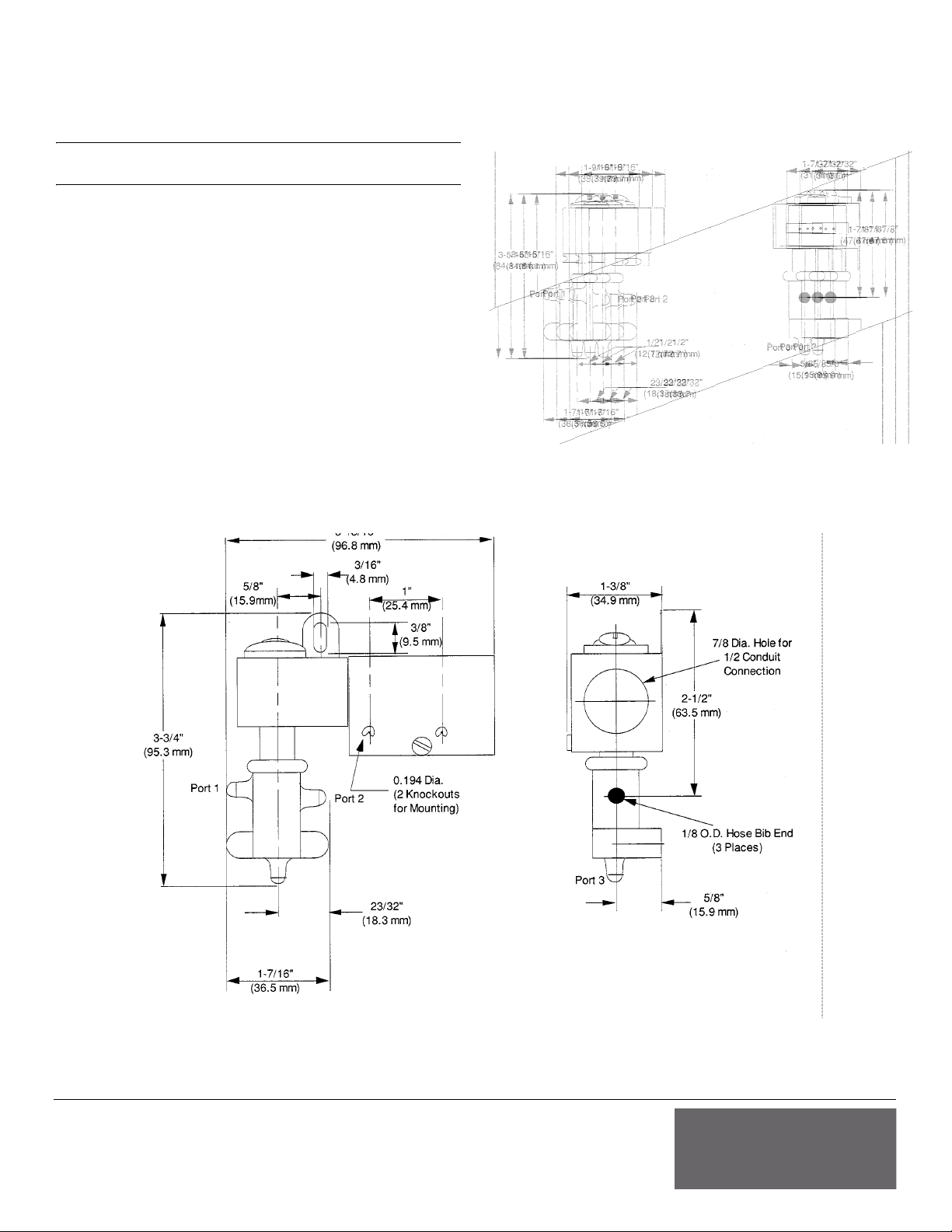

DIMENSIONAL DATA

Figure-2 AL-17 0 Dimensional Drawing.

Figure-3 AL-180 Dimensional Drawing.

On October 1 st, 2009, TAC became the B uildings business o f its parent comp a ny Schneider El ectric. This document reflects the vi sual identity of Schnei der Electric, howev e r

chan

es.

Copyright 2009, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained wihin this

document is subject to change wi hout notice.

F-24748-5

Loading...

Loading...