Page 1

Art.Nr.

5906703903

5906703850 | 05/2014

GB

Tile-cutting machine

Translat ion from th e origi nal manua l

FS85000

Page 2

DE

Nur für EU-Länder.

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß europäischer Richtlinie 2012/19/EU über Elektro- und ElektronikAltgeräte und Umsetzung in nationales Recht müssen verbrauchte Elektrowerkzeuge getrennt gesammelt und einer umweltgerechten Wiederverwertung zugeführt werden.

GB

Only for EU countries.

Do not dispose of electric tools together with household waste material!

In observance of European directive 2012/19/EC on wasted electrical and

electronic equipment and its implementation in accordance with national

law, electric tools that have reached the end of their life must be collected

separately and returned to an environmentally compatible recycling facility.

FR

Pour les pays européens uniquement.

Ne pas jeter les appareils électriques dans les ordures ménagères!

Conformément à la directive européenne 2012/19/EG relative aux déchets

d’équipements électriques ou électroniques (DEEE) et à sa transposition

dans la législation nationale, les appareils électriques doivent être collectés à part et être soumis à un recyclage respectueux de l’environnement.

IT

Solo per Paesi EU.

Non gettare le apparecchiature elettriche tra i rifi uti domestici!

Secondo la Direttiva Europea 2012/19/CE sui rifi uti di apparrecchiature

elettriche ed elettroniche e la sua attuazione in conformità alle norme

nazionali, le apparecchiature elettriche esauste devono essere raccolte

separatamente, al fi ne di essere reimpiegate in modo eco-compatibile.

NL

Allen voor EU-landen.

Geef elektrisch gereedschap niet met het huisvuil mee!

Volgens de europese richtlijn 2012/19/EG inzake oude elektrische en

elektronische apparaten en de toepassing daarvan binnen de nationale

wetgeving, dient gebruikt elektrisch gereedschap gescheiden te worden

ingezameld en te worden afgevoerd naar en recycle bedrijf dat voldoet aan

de geldende milieu-eisen.

ES

Sólo para países de la EU

¡No deseche los aparatos eléctricos junto con los residuos domésticos!

De conformidad con la Directiva Europea 2012/19/CE sobre residuos

de aparatos eléctricos y electrónicos y su aplicación de acuerdo con la

legislación nacional, las herramientas electricas cuya vida útil haya llegado

a su fi n se deberán recoger por separado y trasladar a una planta de

reciclaje que cumpla con las exigencias ecológicas.

PT

Apenas para países da UE.

Não deite ferramentas eléctricas no lixo doméstico!

De acordo cum a directiva europeia 2012/19/CE sobre ferramentas

eléctricas e electrónicas usadas e a transposição para as leis nacionais,

as ferramentas eléctricas usadas devem ser recolhidas em separado e

encaminhadas a uma instalação de reciclagem dos materiais ecológica.

SE

Gåller endast EU-länder.

Elektriska verktyg får inte kastas i hushållssoporna!

Enligt direktivet 2012/19/EG som avser äldre elektrisk och elektronisk

utrustning och dess tillämpning enligt nationell lagstiftning ska uttjänta

eletriska verktyg sorteras separat och lämnas till miljövänlig återvinning.

FI

Koskee vain EU-maita.

Älä hävitä sähkötyökalua tavallisen kotitalousjätteen mukana!

Vanhoja sähkö- ja elektroniikkalaitteita koskevan EU-direktiivin 2012/19/

ETY ja sen maakohtaisten sovellusten mukaisesti käytetyt sähkötyökalut

on toimitettava ongelmajätteen keräyspisteeseen ja ohjattava ympäristöystävälliseen kierrätykseen.

NO

Kun for EU-land.

Kast aldri elektroverktøy i husholdningsavfallet!

I henhold til EU-direktiv 2012/19/EF om kasserte elektriske og elektroniske

produkter og direktivets iverksettning i nasjonal rett, må elektroverktøy som

ikke lenger skal brukes, samles separat og returneres til et miljøvennlig

gjenvinningsanlegg.

DK

Kun for EU-lande.

Elværktøj må ikke bortskaffes som allmindeligt affald!

I henhold til det europæiske direktiv 2012/19/EF em bortskaffelse af

elektriske og elektroniske produkter og gældende national lovgivning skal

brugt elværktoj indsamles separat og bortskaffes på en måde, der skåner

miljøet mest muligt.

SK

Kun for EU-lande.

Elværktøj må ikke bortskaffes som allmindeligt affald!

I henhold til det europæiske direktiv 2012/19/EF em bortskaffelse af

elektriske og elektroniske produkter og gældende national lovgivning skal

brugt elværktoj indsamles separat og bortskaffes på en måde, der skåner

miljøet mest muligt.

SI

Samo za drzave EU.

Elektricnega orodja ne odstranjujte s hisnimi odpadki!

V skladu z Evropsko direktivo 2012/19/EG o odpani elektricni in elektronski

opremi in z njenim izvajanjem v nacionalni zakonodaji je treba elektricna

orodja ob koncu nijihove zivljenjske dobe loceno zbirati in jih predati v

postopek okulju prijaznega recikliranja.

HU

Csak EU-országok számára.

Az elektromos kéziszerszámokat ne dobja a háztartási szemétbe!

A használt villamos és elektronikai készülékekról szóló 2012/19/EK

irányelv és annak a nemzeti jogba való átültetése szerint az elhasznált

elektromos kéziszerszámokat külön kell gyüjteni, és környezetbarát módon

újra kell hasznositani.

HR

Samo za EU-države.

Električne alate ne odlažite u kućne otpatke!

Prema Europskoj direktivi 2012/19/EG o starim električnim i elektroničkim

strojevima i usklađivanju s hrvatskim pravom istrošeni električni alati

moraju se sakupljati odvojeno i odvesti u pogon za reciklažu.

CZ

Jen pro státy EU.

Elektrické náradi nevyhazujte do komunálniho odpadu!

Podle evropské smêrnice 2012/19/EG o nakládání s použitými elecktrickými a elektronickými zarizeními a odpovídajícich ustanoveni právnich predpisú jednotlivých zemí se použitá elektrická náradí musí sbírat oddêlenê

od ostatniho odpadu a podrobit ekologicky šetrnému

recyklování.

PL

Tylko dla państw UE.

Proszę nie wyrzucać elektronarzędzi wraz z odpadami domowymi!

Zgodnie z europejską Dyrektywą 2012/19/WE dot. zużytego sprzętu elek-

trycznego i elektronicznego oraz odpowiednikiem w prawie narodowym

zużyte elektronarzędzia muszą być oddzielnie zbierane i wprowadzane do

ponownego użytku w sposób nieszkodliwy dla środowiska.

RO

Numai pentru ţările din UE.

Nu aruncaţi echipamentele electrice la fel ca reziduurile menajere!

Conform Directivei Europene 2012/19/EC privitoare la echipamente

electrice şi electronice scoase din uz şi în conformitate cu legile naţionale,

echipamentele electrice care au ajuns la fi nalul duratei de viaţă trebuie să

fi e colectate separat şi trebuie să fi e predate unei unităţi de reciclare.

EE

Kehtib vaid EL maade suhtes.

Ärge kasutage elektritööriistu koos majapidamisjäätmetega!

Vastavalt EÜ direktiivile 2012/19/EC elektri- ja elektroonikaseadmete jäätmete osas ja kooskõlas igas riigis kehtivate seadustega, kehtib kohustus

koguda kasutatud elektritööriistad eraldi kokku ja suunata need keskkonnasõbralikku taasringlusesse.

LV

Tikai attiecībā uz ES valstīm.

Neutilizējiet elektriskas ierīces kopā ar sadzīves atkritumiem!

Ievērojot Eiropas Direktīvu 2012/19/EK par elektrisko un elektronisko

iekārtu atkritumiem un tās ieviešanu saskaņā ar nacionālo likumdošanu,

elektriskas ierīces, kas nokalpojušas savu mūžu, ir jāsavāc dalīti un

jāatgriež videi draudzīgās pārstrādes vietās.

LT

Tik ES šalims.

Nemesti elektros prietaisų kartu su kitomis namų ūkio atliekomis!

Pagal Europos Sąjungos direktyvą 2012/19/EB dėl elektros ir elektroninės

įrangos atliekų ir jos vykdymo pagal nacionalinius įstatymus elektros

įrankius, kurių tinkamumo naudoti laikas pasibaigė, reikia surinkti atskirai ir

perduoti aplinkai nekenksmingo pakartotinio perdirbimo įmonei.

IS

Aðeins fyrir lönd ESB:

Ekki henda rafmagnstækjum með heimilisúrgangi!

Í fylgni við evrópsku tilskipunina 2012/19/EC um fargaðan rafbúnað og

rafrænan búnað og framkvæmd þess í samræmi við innlend lög, verða

rafmagnstæki sem úr sér gengin.

Page 3

GB

Tile-cutting machine

4 - 17

Page 4

4

MANUFACTURER::

scheppach

Fabrikation von Holzbearbeitungsmaschinen GmbH

Günzburger Straße 69

D-89335 Ichenhausen

IMPORTED BY::

Total Tools:

Unit 5B, 730 Lorimer St. Port Melbourne, 3207.

0332611900

DEAR CUSTOMER,

We wish you lots of fun and success in working with your

new scheppach machine.

NOTE:

As per the applicable Product Liability Law, the manu facturer of this device will not be liable for damages that

occur in this device or that are caused by this device in

the following cases:

• Improper handling,

• Non-observation of the operating instructions,

• Repair by third parties, unauthorized technicians,

• Installation and replacement with non-original spare

parts,

• Use not in conformity with the manufacturer‘s speci fications,

• Failures of the electrical system attributable to nonobservation of the electrical specifications and VDE

clauses 0100, DIN 57113 / VDE0113.

WE RECOMMEND THE FOLLOWING:

Please read the instructions in the present manual care fully before using the tile-cutting machine.

Read the Instructions For Use:

Please read the Instructions for Use carefully before set ting up, commissioning or intervening in the machine.

Dangerous electric voltage

Caution! Switch o the mains power supply

before ma -

king any intervention in the tile-cutting machine.

Risk from sudden start

Caution! The tile-cutting machine can restart suddenly

after a power failure.

Please read the entire text of the operating instructions

thoroughly before installation and start-up.

This operating instructions manual will help you get to

know the machine and utilize its use options better. The

operating instructions manual contains important instruc tions of working safely, correctly and economically with

the machine, and on how you can avoid risks, save on

repair costs, reduce downtime and increase the reliability

and shelf-life of the machine.

In addition to the safety clauses of this operating instruc tions manual, you must also observe the specifications of

your country applicable to the operation of the machine

without fail.

Keep the operating instructions manual in a plastic cover

near the machine, protected against dirt and humidity. It

must be read and observed carefully by all machine ope rators before starting work on the machine.

Only persons who are trained to use the machine and who

have been instructed about the risks involved should be

allowed to operate the machine. The required minimum

age of workers must to be observed.

Besides the safety instructions contained in this ope rating instructions manual and the specifications of

your country, the generally recognized technical rules of

engagement for the operation of the machine must also

Page 5

5

be observed.

GENERAL INSTRUCTIONS

• After removing the packing, check the components for

possible transport damage. In case of complaints, please inform the delivery agent immediately. Subsequent

complaints will not be entertained.

• Check the delivery to ensure that it is complete.

• Familiarize yourself with the machine with the help

of the operating instructions manual before using it.

• Use only original parts for accessories as well as consumables and spare parts. Spare parts can be obtained

from your scheppach retailer.

• Please quote our article numbers as well as type and

production year in all your orders.

FS8500

Delivery scope

Tile-cutter

Tub

Cooling water pump

Angled stop

Table extension

4 legs

Handle

14mm w r en ch

Counter torque wrench

Technical d ata

Production dimensions

L x W x H

1250 x 530 x 1090 mm

Cutting table

680 x 465 mm

Diamon d cut ting disc D

180 mm

Hole D

22,2 mm

Water filling quantity

approx.

18,0 l

Speed

5800 1/min

Weight

40, 0 kg

Section dat a

Max. cutting length

850 mm

Max. diagon al cut ting

length

640 x 640 mm

Max 90 ° cut ting height

40 mm

Max. 4 5° cut ting

height

14 mm

Drive

Moto r

230 V/50 Hz

Power intake

1250 W (S3 20%)

Motor speed

2950 1/min

Insulating m aterial

class

B

Protection type

IP54

Technical changes res erv ed!

NOISE CHARACTERISTIC VALUES

Noise at the workplace can exceed 85 dB (A). In this

case, noise protection measures are necessary for the

user (wear hearing protection!).

NOISE OUTPUT LEVEL IN DB

LWA idling / processing of LWA = 108/111 dB (A)

Noise pressure level at workplace in dB

LPA idling / processing of LPA = 95/98 dB (A) according

to DIN EN ISO 3744; EN ISO 11201

USED SYMBOLS

J Wear protective gloves

Page 6

6

I Wear eye protection

N Wear hearing protection

Wear dust protection masks

We have marked the places that affect your safety with the

following signs: m

m Safety instructions

Working with the tile-cutting machine can be risky, if safe and correct work procedures are not followed. As with

all machines, working with the product involves certain

inherent risks. Working at the machine with respect and

caution reduces the risk of physical injury considerably.

Not observing the customary safety measures can lead to

physical injuries to the operators. Safety equipment such

as protective goggles, dust masks and ear protection can

reduce the risks of possible injury. Even the best possible

protection however, cannot match incorrect assessment,

carelessness or negligence. Always use your healthy common sense and caution in the workshop. If you feel an

operation is risky, do not try it out. Think about an alternative method which feels safer. Think of the following:

Your physical integrity is your personal responsibility.

This machine was designed to perform certain jobs.

We recommend urgently that the machine should not be

altered and it should not be used for application areas for

which it was not designed. If you are not sure, please ask

your dealer before working with the product.

Warning: Non-observation of these specifications can lead

to serious injuries.

• For your own safety: Please read this operating instructions manual carefully before starting work. Familiarize

yourself with the uses and restrictions as well as special risks.

• Maintain the protective devices at the workplace in

good condition.

• Always wear a pair of safety goggles.

• Remove the adjusting wrench.

• Familiarize yourself and check whether all the tools have been removed from the machine before switching

it on.

• Keep the workplace clean. Crammed areas can lead to

accidents.

• Do not use the machine in risky conditions.

• Do not use electrical machines on humid or wet places,

and do not expose them to rain.

• Keep children and visitors at a safe distance from the

work area.

• Make the workshop safe for children with the help of

padlocks, master switches, and by removing starter

keys.

• Do not overload the machine. It works better and more

safely at the power for which it was designed.

• Use the correct tool. Do not overstrain the tool or accessory. You get a better result with the correct tool or

accessory.

• Wear suitable clothing: Loose clothing or gloves, ties,

rings, arm-bands or other ornaments can get entangled

Page 7

7

in rotating components. Skid-free shoes are recommen ded. Protect long hair with a net.

• Always wear protective goggles (corresponding to ANSI

Z87.1). A normal pair of glasses cannot provide ade quate protection. In dusty environments, use a face- or

dust mask.

• Never lose your balance. Always remain secure with

both feet planted firmly on the ground.

• Keep your machine in top condition. To achieve the

best and safest output, keep the tools sharp and clean.

Follow the instructions on lubrication and tool change.

• Disconnect the machine from the mains before under taking maintenance or adjustment jobs.

• Use recommended spare parts only. Use of tools or ac cessories not recommended by the dealer can lead to

the risk of physical injury.

• Reduce the risk of unintended activation. Before inser ting the power plug into the mains socket, please ensu re that the switch Is in the O position.

• Before working at the machine, please check for dama ged parts. A damaged protection device or some other

part must be checked carefully to ensure that it is wor king properly and performing the intended function.

Check the alignment of moving parts, breaking points,

installation or other such conditions that could aect

the function adversely. A damaged protection device or

some other part must be repaired properly or replaced.

• Do not leave the running machine unsupervised.

Switch o the power supply. Leave the machine only

after it comes to a complete standstill.

• Never work at the machine under the influence of

drugs, alcohol or medicaments.

• Ensure that the

machine is disconnected from the

mains when you install, connect or shut down the mo tor.

• Tile parts lying around can aect your health adversely.

Operate the machine at well-ventilated places and en sure eective waste disposal.

• Moving disc can injure operators hands or other body parts .

Before starting work all protection and safety guards must

be installed on the machine.

•

•

•

Work piece being cut may y o or particles from the

Cuttering process may y o and strike operator. Do Not

cut under size or over size pieces that cannot be held

securely on the cutting table.

Wear gloves when changing the cutting discs to avoid

accidentically cutting hands.

Never use the machine without the coolant running.

The disc and machiene may over heat and become

dangerours or damaged.

Keep these specifications intact at a safe place.

Page 8

8

OTHER SAFETY INSTRUCTIONS

Please read all the instructions before using this product!

Workplace

To rule out the risk of physical injury, machine damage,

fire and electric shock, please ensure that your workplace

is protected

• against humidity, wetness and rain,

• It is free of Inflammable gases and liquids,

• It is protected from children – use padlocks and the

master switch when the machine is not in use;

• It is clean and empty,

• It is well-ventilated and illuminated.

The operators

Healthy commonsense and caution are factors that cannot be integrated in a machine. These factors are the responsibility of the operator. Please consider the following:

Prevent body contact with grounded surfaces such as

pipes and radiators.

Please be watchful. Do not work at the machine if you

are tired.

Do not operate the product under the influence of alcohol or drugs. Read the warning instructions to determine

whether your judgement or your reflexes could be affected.

Do not wear loose clothing or ornaments which can get

entangled in rotating components.

Anti-skid shoes are recommended.

Protect long hair with suitable means.

Wear eye- and ear protection. Always wear:

• ANSI- approved dust masks.

• Hearing protection.

Always maintain your balance.

Do not stretch yourself over running machines.

m Proper use

The machine corresponds to the valid EU Machine Directive

• Before starting work, all the protection- and safety devices must be installed on the machine.

• The machine is designed for operation by one person.

The operator will be responsible for the presence of

third persons in the work area.

• Observe all safety- and danger instructions on the machine.

• Keep all safety and danger instructions near the machine in complete and readable form.

• The machine is designed exclusively for cutting small

and medium-sized tiles (glazed, ceramic or similar tiles) with the offered tool and accessories. Cutting of

metal and wood is not allowed.

• The dimensions of the workpieces to be machined

should not exceed or fall below the specified maximum and minimum dimensions.

• Please use the machine only if it is in a technically

fault-free condition. Use It properly, conscious of the

involved safety and risk factors and giving due consideration to the operating instructions manual! Faults,

especially those that can affect safety must be recti-

Page 9

9

fied immediately!

• The safety-, workplace- and maintenance specifications of the manufacturer as well as the dimensions

specified in the technical data must be observed.

• The applicable accident prevention measures and the

other generally recognized technical safety rules must

be observed.

• The machine must be used, serviced or repaired only

by persons who are familiar with it and who have been briefed about its risks. Arbitrary alterations to the

machine will make the liability of the manufacturer for

damages resulting there from null and void.

• The machine may be used only with original accessories and original tools of the manufacturer.

Despite proper use, certain residual risk factors cannot be

eliminated fully. The following things can occur, depending on the design and structure of the machine:

• Intervention in the running diamond cutting disc.

• Contact with the diamond cutting disc in exposed area.

• Ejection of work pieces and work piece components.

• Ejection of a faulty diamond attachment in the cutting disc.

• Hearing damage due to non-use of the required hearing protection.

• Injuries to the eyes due to non-use of eye protection

Any use beyond the one specified will be treated as improper. The manufacturer will not be liable for damages

resulting from such improper use; the risk will be borne

by the user alone.

m Residual risks

The machine is built according to the latest technology and

the recognized technical safety-related rules. Nevertheless,

individual residual risks can occur during operation.

• Danger of Injury to fingers and hands from the running

tool if it is used incorrectly.

• Risk to health from steel chips. Wear personal protection equipment such as eye protection without fail.

• Injuries due to defective diamond cutting disc. The

diamond cutting disc must be checked regularly for

physical integrity.

• Risk of injury to fingers and hands during cutting disc

replacement. Wear appropriate working gloves.

• Risk of injury during machine activation from sudden

start of cutting disc.

• Risk from power while using improper electric connecting cables.

• Risk to health from running cutting disc due to long

hair and loose clothing. Wear personal protection

equipment like hair net and tight-fitting working clothes.

• Even after taking all the necessary precautions, not

apparent residual risks cannot be ruled out completely.

• Residual risks can be minimized if the „safety instructions“ and the „proper use“, as well as operating

instructions manual are observed jointly.

Page 10

10

Before start-up

Replace cracked diamond cutting discs.

• Get to know your machine. Familiarize yourself with

its use and its restrictions, but also with the specific

potential risks.

• Check the machine carefully for damages to ensure

that it is able to achieve the intended output. In case

of doubt, please replace the concerned component.

• Ensure that the switch is on Off, before inserting the

power plug into the mains socket.

• Ensure that the machine is cleaned and lubricated

properly.

• Before start-up, check the machine for damaged parts

and find out whether these parts are working properly

and performing their defined function.

• Check the alignment of all moving parts, all broken

or fastening parts, and all other conditions that can

affect smooth operation. Each damaged part should

be repaired or replaced by a technician immediately.

• Do not use the machine if a switch cannot be activated/deactivated correctly.

Operation

• Install the machine on an even, slide-proof floor.

• Check that the voltage on the nameplate matches the

existing voltage; connect the power plug to the mains

power supply only thereafter

• The cutting disc should be free to run before the machine is switched on.

Caution: Cutting disc must always be cooled with water.

Caution: Cutting disc runs with a time lag.

Do not break the cutting disc by applying pressure at the

sides.

• Under normal use conditions, the motor casing can

become hot.

• Do not use force on the machine or on an accessory

to achieve the performance of a bigger Industrial machine. It does a better job at the output for which it

is designed.

• Define all machine settings only when it is switched

off.

• Do not leave the machine unattended as long as it is

running.

• During shutdown, leave the machine only after it comes to a complete standstill.

• Always switch the machine off before pulling out the

power plug from the mains socket.

• Always pull out the power plug. Never disconnect the

power plug from the mains socket by pulling at the

cable.

• Do not use cutting discs that do not meet the size

specifications.

• Do not carry the machine by the cable.

Do not work with the machine if you are not sure whether

a working condition is safe of unsafe.

Page 11

11

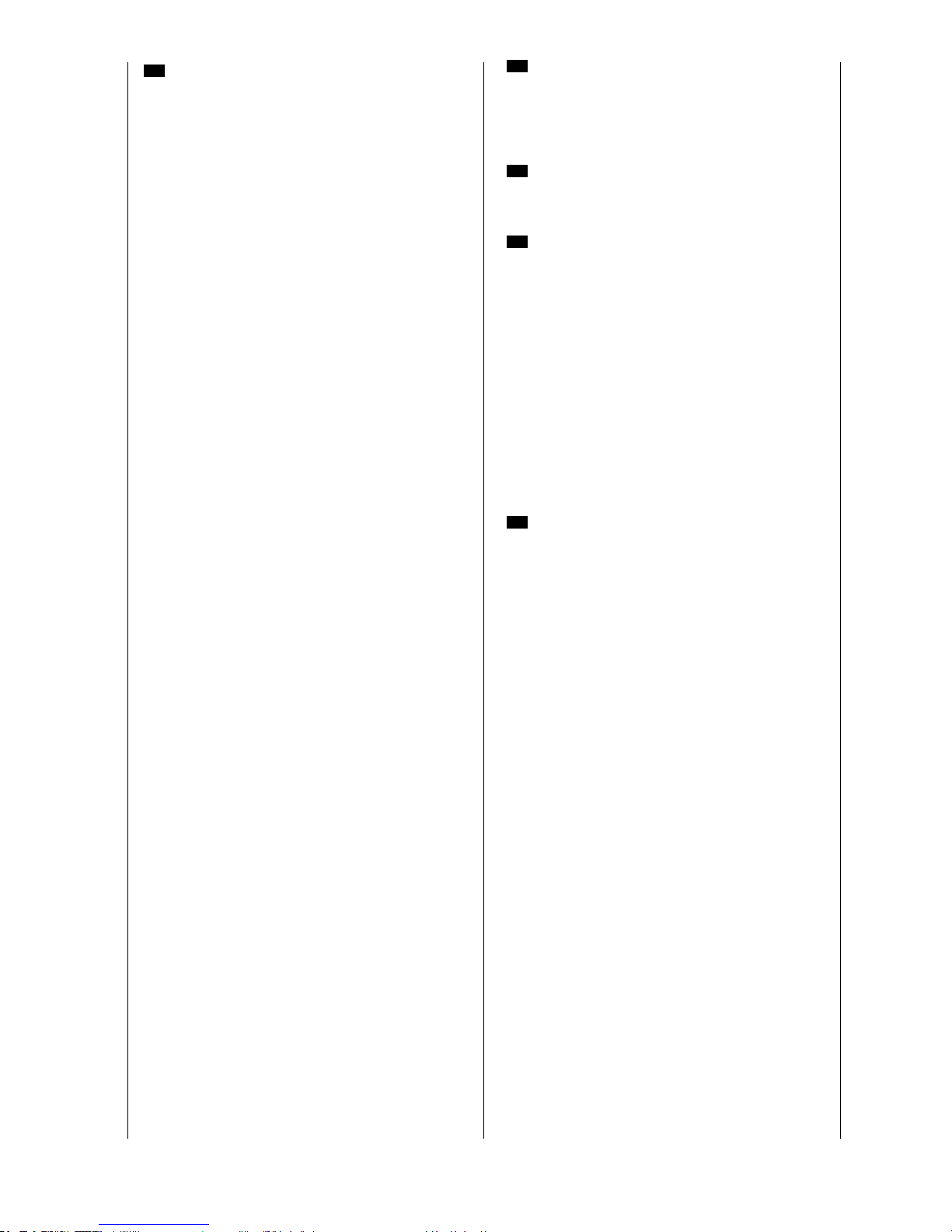

EQUIPMENT FIG.1-2

1 Machine head

2 Base frame

3 Legs

4 Tub

5 Alu. table

6 Angled stop

7 Stop rails

8 Guide rails

9 Cutting disc protection

10 Diamond cutting-disc

11 Handle

12 Star knob screw for angle adjustment

13 Pin for transport lock

14 Cooling water pump

15 Hose

16 Motor

17 ON/OFF switch

18 Angle scale

19 Table extension

20 Saw blade protection

2

3

4

5

6

7

8

9

12

18

Fig. 1

Fig. 2

1

10

11

13

14

15

16

17

19

20

Page 12

12

Assembly

Fig.3-5

For technical packaging reasons, your machine is not assembled fully.

1 Take the machine out of the packing and place it

laterally on the floor very carefully.

2 Introduce the legs (3) into the base frame and lock

them with butterfly nuts (A) (Fig. 3).

3 Set the machine on its legs.

4 Install the handle with 2 cross-recess screws (B) on

the motor casing (Fig. 4).

Note: The handle can also be mounted on the opposite side

5 Place the tub (4) in the base frame (2).

6 Place the cooling water pump (14) in the tub (4)

7 Fill water till the pump (14) is filled completely with

water (Fig.4).

8 Pull out the pin of the transport lock (13) (Fig.5).

Start-up

On/Off switch (Fig. 4)

To activate the machine, press the „I“ of the On/Off

switch (17).

Before starting the cutting operation, you must wait for

the cutting disc to reach its max. speed and for the cooling water pump (14) to pump water to the cutting disc.

To deactivate the machine, press the „0“ of the switch

(16). (Fig. 4).

Operation

90° cutting Fig.6-7

1 Loosen the wing bolt (C)

2 Set angled stop (6) to 90° and tighten the wing bolt

(C) again.

3 Tighten the wing bolt (D) to fix the angled stop (6).

(Fig.6)

4 Push the machine head (1) towards the rear by the

handle (11).

5 Place the tile on the stop rail (7) at the angled stop

(6).

6 Switch the tile-cutting machine on. (Fig.7)

Caution: Wait for the cooling water to reach the cutting

disc (10).

7 Pull the machine head (1) slowly and uniformly by the

handle (11) in the forward direction through the tile.

8 Switch the tile-cutter off again after reaching the end.

Fig. 3

A

A

Fig. 4

11

B

17

Fig. 5

13

6

C

D

7

Fig. 6

Fig. 7

1

6

7

10

11

17

Page 13

13

45° diagonal cutting (Fig. 8)

1 Set angled stop (6) to 45°

2 Carry out cutting as described.

45° longitudinal cutting, (Fig. 9)

1 Loosen the star knob screw (E) on both sides

2 Slant guide rail (8) at the left to 45° of the angle

scale (18).

3 Tighten the star knob screw (E) again.

4 Perform cutting as described.

Changing diamond cutting disc (Fig. 10- 11)

Caution! Disconnect power plug

1 Loosen the 2 bolts (F) and take out the saw blade

protection (20). (Fig.10)

2 Place the wrench (21) on the motor shaft and keep

it there.

3 Loosen the flange nut in the running direction of the

cutting disc (10) with the wrench (22).

4 Remove the outer flange (23) and cutting disc (10).

(Fig.11)

5 Clean the supporting flange carefully before installing

the new cutting disc.

6 Insert the cutting disc in the reverse sequence and

tighten it.

Caution: Pay attention to the running direction of the cutting disc!

7 Reinstall the saw blade protection (20).

Transport

Caution! Disconnect power plug

To transport the machine, set the machine head in front

and engage the locking pin (13) (Fig.5)

m Electric connection

Check electric cables regularly for damage. Ensure that

during the check, the connecting cable is not connected

to the mains.

Electric connecting cables must conform to the common

VDE- and DIN provisions. Only use connecting cables

with the H 07 RN designation.

Keeping a copy of the type designation on the connecting

Fig. 8

6

Fig. 9

6

8

18

E

Fig. 10

F F

Fig. 11

21

22

23

Page 14

14

cable is a specification

DAMAGED ELECTRIC CONNECTING CABLES

Insulation damages frequently occur on electric connecting cables. The reasons are:

• Pressure points, if connecting cables are routed

through window or door gaps.

• Kinks due to improper mounting or routing of connecting cables.

• Intersections due to overruns of connecting cables.

• Insulation damage due to pulling out from wall sockets.

• Cracks due to ageing of insulation.

Such damaged electric connecting cables should not be

used and can be fatal because of the insulation damage

AC motor 230 V/ 50 Hz

Mains voltage 230 Volt / 50 Hz.

Mains connection and extension cable must have 3-wires

= P + N + SL. - (1/N/PE).

Extension cables must have a minimum cross-section of

1.5 mm².

The mains connection is secured with a max. 16A fuse.

Maintenance

Caution! Pull out power plug.

• Clean the machine after each work cycle.

• Replace worn out cutting discs.

• Replace damaged protection device

• Dust and pollution must be removed regularly from the

machine. The best way to clean the machine is with a

piece of cloth or brush.

• All moveable parts must be re-lubricated at periodic

intervals.

• Do not use any corrosive substances to clean the plastic.

• The tub (4) and coolant pump (14) must be cleaned

regularly to remove dirt, as otherwise the cooling of the

diamond cutting disc (10) is not guaranteed.

Spare-part ordering

Please quote the following in your order for spare parts:

• Type of device

• Article No. of device

• Ident. No. of device

• Spare Part No. of the required spare part

Page 15

15

Leakage current circuit-breaker

ADDITIONAL INSTRUCTIONS

FOR LEAKAGE CURRENT CIRCUIT-BREAKER.

Please observe the following important instructions on

start-up and handling.

Pay attention to the instructions even if you hand over the

product to a third party. Preserve this operating Instructions manual for subsequent reference.

SAFETY INSTRUCTIONS!

• Arbitrary alteration and/or modification of the product

is not allowed for safety- and approval reasons (CE).

Never dismantle the product.

• The product is not suitable for handling by children.

Children cannot assess the risks involved in handling

electrical devices. Therefore, pay special attention to

the presence of children.

• The structure of the product corresponds to Protection Class 1. Only a proper mains socket with an earth

wire (230V~/50Hz) of the public power supply should

be used.

• In industrial equipment, the Accident Prevention Specifications of the Federation of Trade Associations for

Electrical Systems and Resources must be observed.

• In schools, training centres, hobby- and self-help workshops, the operation of the product must be monitored

responsibly by trained staff.

• Handle the product carefully. Impacts, hits and drops

from even low heights can damage the machine.

• Never use the product if it is brought from a cold to a

hot room. Under certain circumstances, the resulting

condensed water can destroy the product.

• Let the product come to the room temperature, before

connecting it to the mains power supply. Under certain

circumstances, this can take several hours.

• Do not hold the product with moist or wet hands.

• Ensure that the Insulation of the entire product is neither damaged nor destroyed.

• If the product is not operated over long periods, disconnect it from the mains power supply, pull the plug

out of the socket.

• Avoid the following environmental conditions at the

installation site or during transport:

• Wetness or very high humidity. Extreme cold. Dust or

combustible gases, vapours or solvents. Strong vibrations.

• Strong magnetic fields as in the vicinity of machines

or loudspeakers.

Start-up of the leakage current circuit-breaker:

• The leakage current circuit-breaker is equipped with

a test button.

• The function should be checked before each start-up

and at regular Intervals (min. once every week).

• If the leakage current circuit-breaker does not switch

off properly during this test, there is no personal protection! The device must therefore be switched off

immediately!

• In case of damages caused by the non-observation of

Page 16

16

this operating instructions manual, all warranty claims

will become null and void. We do not accept any liability for consequential damages.

• Check the product for damage before each use! If you

detect a damage, do not connect the product to the

mains power supply!

• After actuating the orange Reset button, the device is

ready for operation. Before operation, please test the

triggering with the help of the Test button (as described in “Operation”).

• Insert the leakage current circuit-breaker into the socket.

• Press the orange Reset button.

• A red symbol is displayed in the window indicating

operational readiness.

• Press the red Test button. This action simulates a

leakage current.

• If the machine is working properly, the circuit-breaker

will disconnect the load from the mains. This is displayed in the window through the disappearance of

the red symbol.

• Protection of man and animal is effective only if the

machine works properly.

• The Reset button must be pressed a second time for

operation.

• The load can now be inserted.

Technical data:

Triggering leakage current: < 30 mA

Power supply: 230V~/50Hz

Load capacity: 16A (3680W)

Number of pins: 2-pin wired

Preliminary fuse: 16 A

Protection type: IP54

Dimensions: 126x50x88mm

USE ACCORDING TO MANUFACTURER‘S INSTRUCTIONS!

The portable leakage current circuit-breaker is designed

for wet grinding machines and similar electrical loads in

the household.

It is simply connected between the mains power supply

and the load, and therefore offers optimum protection

against physical contact with live components and sudden restart of the machine after restoration of power.

• Always operate the machine with the provided leakage

current circuit-breaker installed.

Page 17

17

Trouble shooting

Panne Cause possible Dépannage

Diamond cutting disc comes off

when motor is deactivated.

Fastening nut not tightened properly Tighten fastening nu

when motor is deactivated. a) Failure of mains circuit-breaker a) Check mains circuit-breaker

b) Extension cable defective b) Replace extension cable

c) Connection with motor or switch is

not OK

c) Have it checked by an electrician

d) Motor or switch Is defective d) Have it checked by an electrician

Motor has no output a) Cross-section of the extension cable

Is not sufcient

a) See electrical connection, the fuse

has blown

b) Overloading b) Check tool

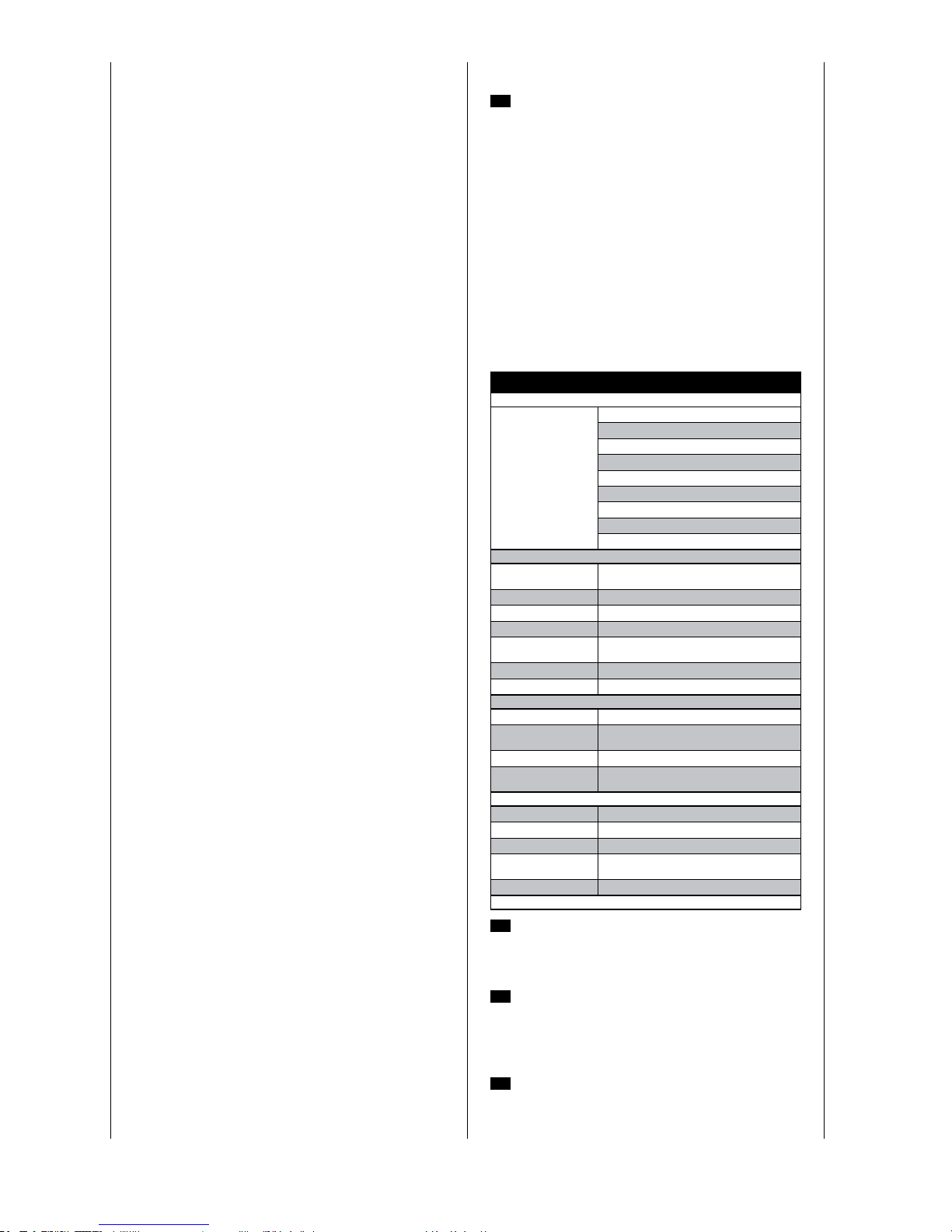

Page 18

78

76

67

66

65

75

64

63

62

61

60

59

58

57

55

54

53

52

51

50

49

48

47

46

70

45

44

43

42

41

39

40

38

37

36

33

26

25

24

21

72

71

70

73

74

69

3

2

1

56

4

5

6

7

8

9

10

11

12

13

14

15

16

17

19

18

20

32

34

35

68

81

82

80

83

22

23

27

28

29

30

31

77

79

Page 19

DE

erklärt folgende Konformität gemäß

EU-Richtlinie und Normen für den Artikel

GB

hereby declares the following conformity under the

EU Directive and standards for the following article

FR

déclare la conformité suivante selon la directive UE

et les normes pour l’article

IT

dichiara la seguente conformità secondo le direttive e le normative UE per l‘articolo

CZ

prohlašuje následující shodu podle smernice EU a

norem pro výrobek

HU

az EU-irányelv és a vonatkozó szabványok szerinti

következo megfeleloségi nyilatkozatot teszi a

termékre

HR

ovime izjavljuje da postoji sukladnost prema EUsmjernica i normama za sljedece artikle

RO

declară următoarea conformitate corespunzător

directivelor şi normelor UE pentru articolul

TR

Normları geregince asagıdaki uygunluk açıkla

masını sunar.

FIN

vakuuttaa täten, että seuraava tuote täyttää ala

esitetyt EU-direktiivit ja standardit

PL

deklaruje, ze produkt jest zgodny z nastepujacymi

dyrektywami UE i normami

SLO

izjavlja sledeco skladnost z EU-direktivo in normami za artikel

SK

prehlasuje nasledujúcu zhodu podla smernice EU a

noriem pre výrobok

EST

kinnitab järgmist vastavus vastavalt ELi direktiivi ja

standardite järgmist artiklinumbrit

LT

pareiškia, taip atitiktis pagal ES direktyvos ir

standartai šį straipsnį

LV

apliecina šādu saskaņā ar ES direktīvu atbilstības

un standarti šādu rakstu

NL

verklaart hierbij dat het volgende artikel voldoet

aan de daarop betrekking hebbende EG-richtlijnen

en normen

RUS

заявляет о соответствии товара следующим

директивам и нормам ЕС

PT

declara o seguinte conformidade com a Directiva

da UE e as normas para o seguinte artigo

ES

declara la conformidad siguiente según la directiva

la UE y las normas para el artículo

DK

erklærer hermed, at følgende produkt er ioverensstemmelse med nedenstående EUdirektiver og

standarder:

SE

försäkrar härmed följande överensstämmelse enligt EU-direktiv och standarder för följande artikeln

NO

erklærer herved følgende samsvar under EUdirektiv og standarder for følgende artikkel

BG

декларира съответното съответствие

съгласно Дирек-тива на ЕС и норми за артикул

Fliesenschneider - FS8500

Standard references: EN 61029-1; EN 12418; EN 55014-1; EN 55014-2;

EN 61000-3-2; EN 61000-3-3

Konformitätserklärung

scheppach Fabrikation von Holzbearbeitungsmaschinen GmbH • Günzburger Str. 69 • D-89335 Ichenhausen

Ichenhausen, den 12.03.2013 _____________________

Unterschrift / Markus Bindhammer / Technical Director

Art.-No. 5906703901 / 5906703903

Subject to change without notice

Documents registar: Christian Drößler

Günzburger Str. 69, D-89335 Ichenhausen

2009/105/EC

X 2006/95/EC

2006/28/EC

2005/32/EC

X 2004/108/EC

2004/22/EC

1999/5/EC

97/23/EC

90/396/EC

X 2011/65/EU

89/686/EC_96/58/EC

X 2006/42/EC

Annex IV

Notied Body:

Notied Body No.:

2000/14/EC_2005/88/EC

Annex V

Annex VI

Noise: measured L

WA

= xx dB(A); guaranteed L

WA

= xx dB(A)

Notied Body:

Notied Body No.:

2004/26/EC

Emission. No:

Page 20

Loading...

Loading...