Scania Retarder Service Manual

0

88

10:05-08

Issue 1

Scania Retarder

Troubleshooting

Mechanical system and hydraulic system

en

1 712 029

:22

1

©

Scania CV AB 1999, Sweden

Contents

Contents

Before starting troubleshooting

Troubleshooting

Test report

General............................................................ 3

Road test .........................................................4

Renewing components.................................... 4

Poor braking.................................................... 5

External oil leakage ...................................... 23

Cover for temporarily blocking the

retarder shaft output on the gearbox............. 27

Test report for test of

proportional valve......................................... 28

Test report for test of

hydraulic pressure......................................... 28

Valve housing and retarder housing ............. 30

2

©

Scania CV AB 1999, Sweden

10:05-08 en

Before starting troubleshooting

Retarder

Before starting

troubleshooting

General

The same retarder is used in trucks and buses

but the installation differs with respect to the

location of the oil cooler and accumulator, for

example. These troubleshooting instructions

apply to trucks and two-axle buses. Three-axle

buses are covered where applicable.

This description covers the troubleshooting

procedure for the retarder itself. The objective

is to determine whether dismantling is

necessary or not.

Troubleshooting the auxili ary brake system can

also be achieved with the help of the diagnostic

lamp marked Retarder on the vehicle's

diagnostic panel.

Spot repairs are often sufficient to make the

vehicle operable again.

All work on the retarder must be carried out

with the most thorough cleanliness possible.

The retarder is extremely sensitive to

impurities.

WARNING!

!

Hot fluid and coolant can cause

personal injury. This applies also to

spot repairs.

Wiring and similar components are often the

cause of a fault rather than the retarder.

Therefore, always start by checking for fault

codes.

Troubleshooting the entire auxiliary brake

system, i.e. with accompanying controls and

electrical equipment, is best achieved using

SD.

1050t14b.mkr

©

Scania CV AB 1999, Sweden

3

Before starting trouble shooting

Road test

The following applies when road testing the

vehicle to check, for example, whether a spot

repair has given the desired result.

1

Drive the vehicle at a speed of at least

60 kph

2

Select a gear so that the engine speed is at

least 1500 rpm.

3

Brake with the retarder lever in position 5,

max position.

If retarder braking capacity is still insufficient,

there is still a fault somewhere. Continue with

the troubleshooting as directed.

Renewing components

Use preferably SD for troubleshooting rather

than the Workshop Manual in order to avoid

renewing components that are not defective.

The following components are often renewed

despite them not being defective: hand control

assembly, pedal travel sensor and proportional

valve.

©

4

Scania CV AB 1999, Sweden

1050t14b.mkr

Troubleshooting

Troubl eshooting

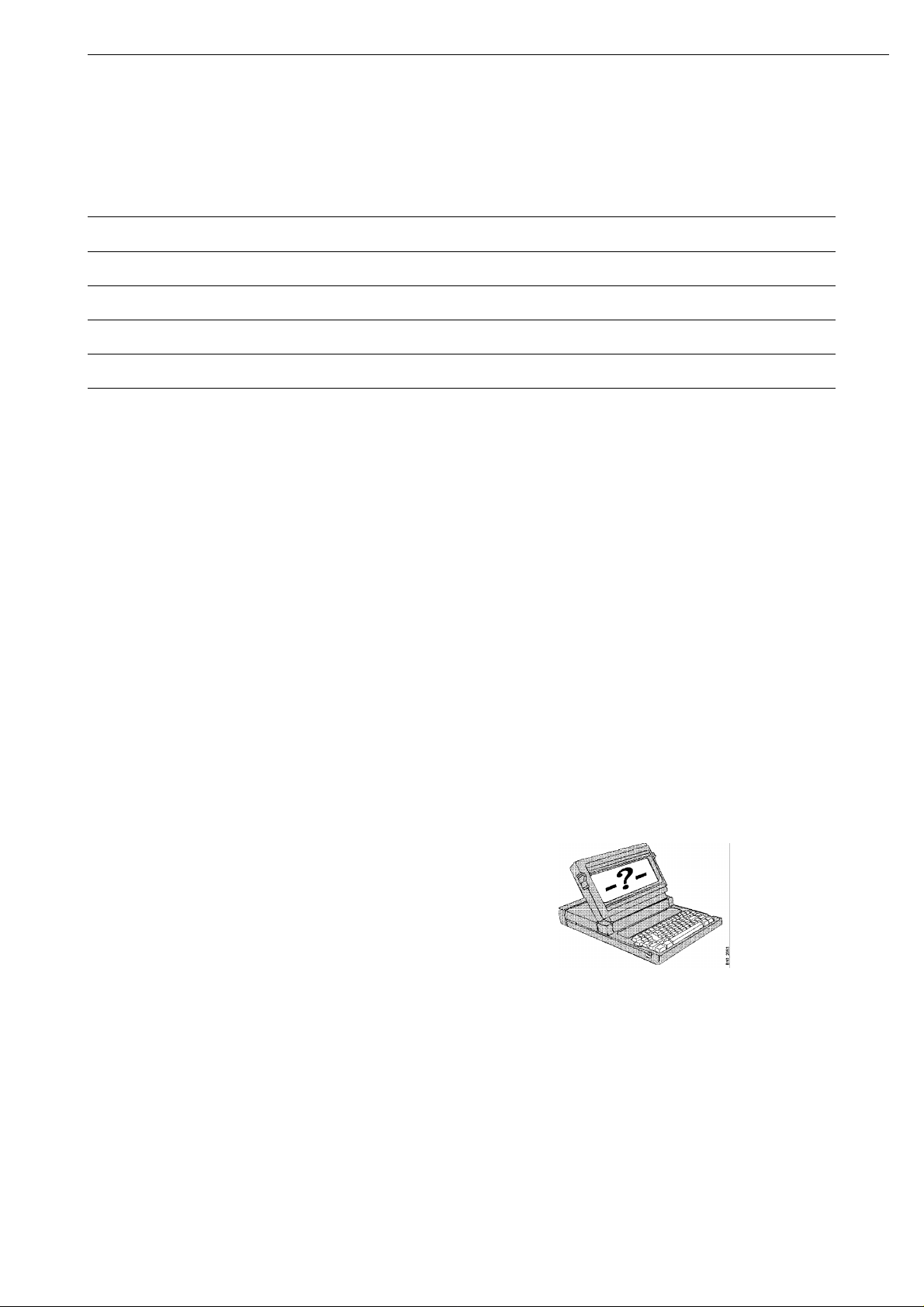

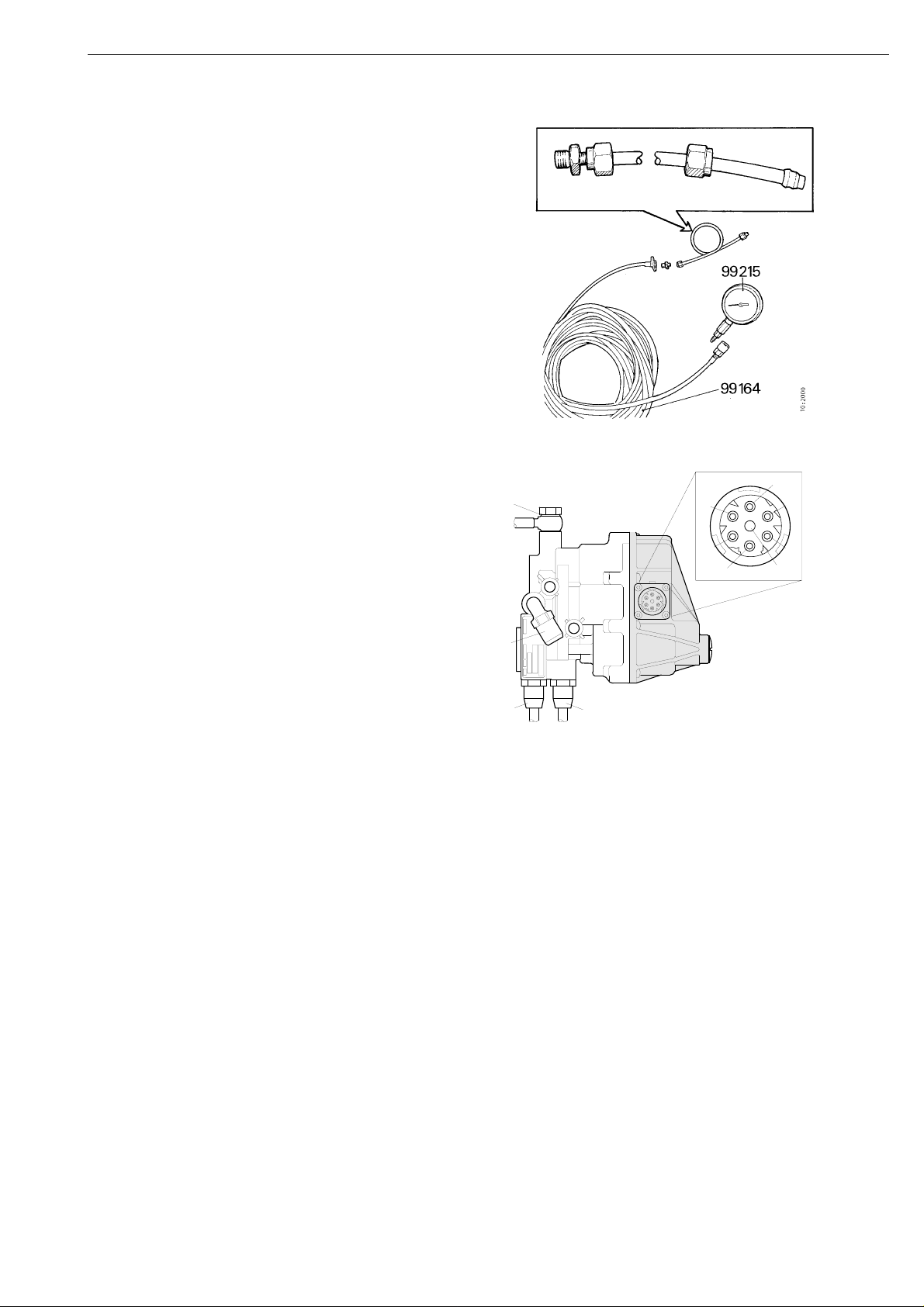

Special tools

No. Description Illustration Tool board

99 164 Hose - B

99 215 Pressure gauge - B

99 362 Measuring set - 99 378 Cover with test outlet - 99 404 T adapter - -

Poor braking

Check fault codes and oil level

Checking fault codes

Action

Check for stored fault codes. Use preferably SD;

it will then be possible to see how many times

each fault code has been registered. Then, repair

any faults.

1050t14b.mkr

©

Scania CV AB 1999, Sweden

5

Troubleshooting

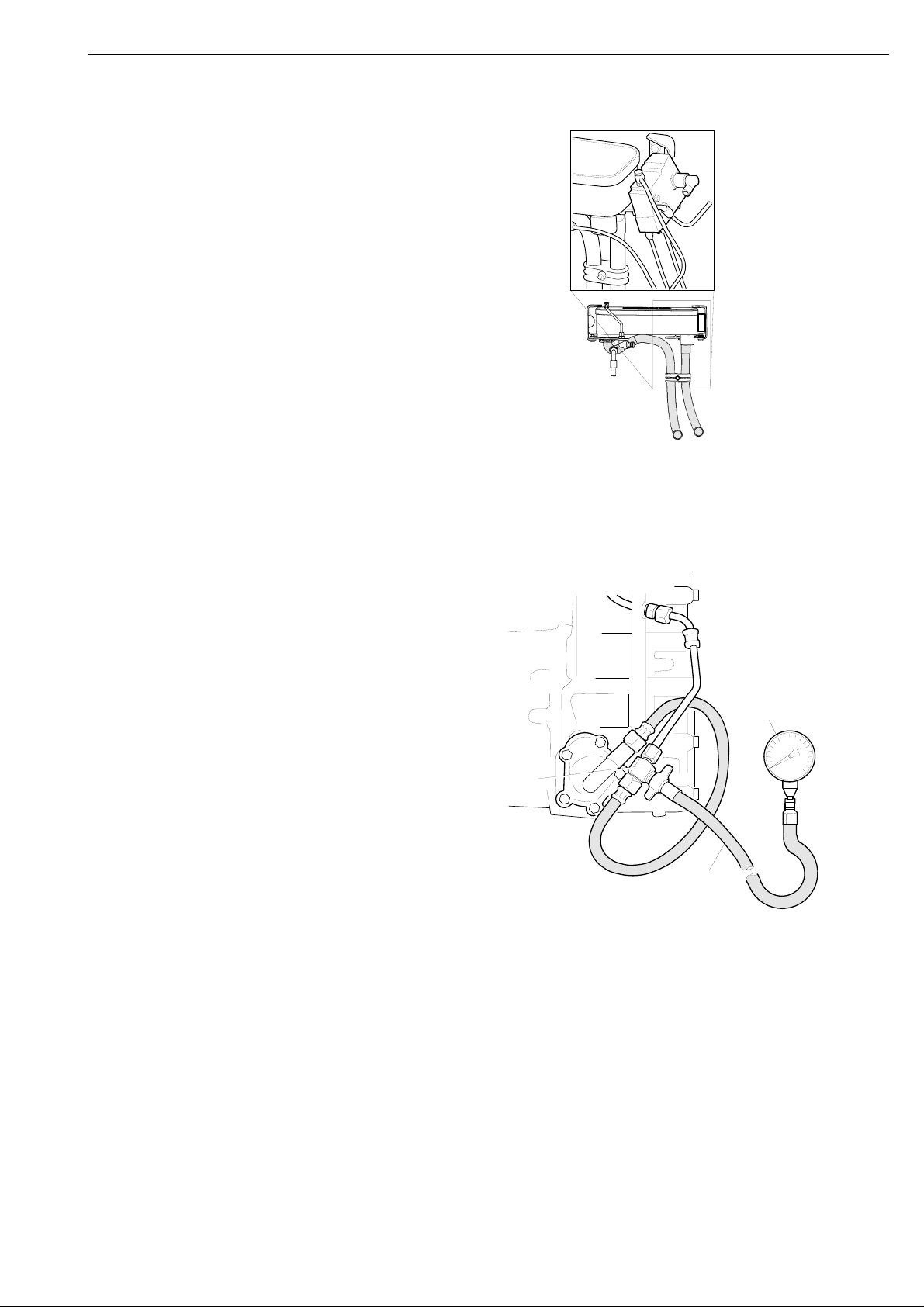

Check the oil level.

Action

Check and adjust the oil level in the retarder.

Press the diagnostic switch to empty the oil

accumulator. Top up if necessary.

Do not remove the level plug only. The oil

accumulator may contain oil and the level

check will be unreliable or directly misleading.

IMPORTANT! Empty the oil accumulator

with the diagnostic switch before checking the

oil level. Otherwise, the oil level will be too

high, resulting in foaming and leakage.

10_2188

©

6

Scania CV AB 1999, Sweden

1050t14b.mkr

Proportional valve

115 741

5

9

Checking the proportional valve

Action

The proportional valve increases the air

pressure, and consequently the oil pressure, after

which the operating current increases in

strength. This can be checked in two ways;

either with or without SD.

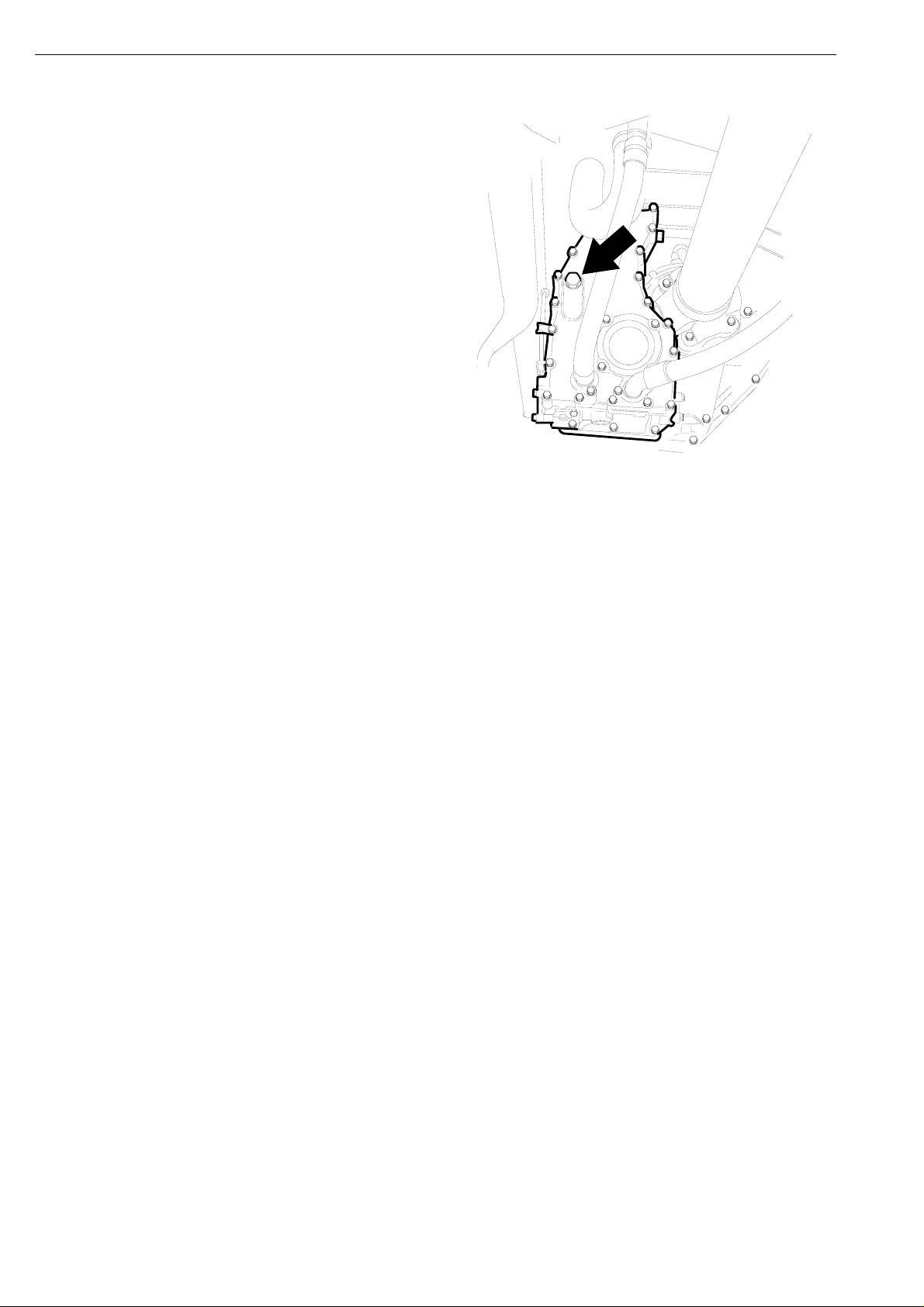

Troubleshooting

Location of new proportional valve in trucks,

introduced from 9908 on trucks and 9910 on

buses.

Before chec ki n g

• Fit T adapter 99 404 to the compressed air

line between the valve block V97 or the

proportional valve V76, and the retarder

control piston.

• Connect the hose 99 164 and pressure gauge

99 215.

Note: Make sure the pressure gauge has been

calibrated. Refer to Main Group 10 Brake

system testing for calibrating.

Note: In order to include the hysteresis of the

proportional valve, test readings must be taken

both when the pressure is rising and when it is

falling.

99 404

99 164

99 215

bar

MPa

1

4

11

1050t14b.mkr

©

Scania CV AB 1999, Sweden

7

Troubleshooting

Checking with SD

1

Activate the solenoid valve for feed air and

control of the proportional valve. Then,

check the air pressure in relation to the

current strength.

2

Use the test report, see Test report for test

of proportional valve. Activate the

proportional valve with 200 mA. The

pressure gauge should read 1.6 - 2.0 bar.

3

Increase the activation to 400 mA. The

reading should be 5.4 - 6.0 bar.

4

Increase to maximum current. Decrease to

400 mA. The reading should be 5.4 - 6.0

bar.

5

Decrease further to 200 mA. The reading

should be 1.6 - 2.0 bar.

Checking without SD (requires two

persons)

1

Drive the vehicle at 50 kph and brake with

the retarder lever in position 5, max

position.

2

Correct air pressure is 5.0 bar or higher.

If the value is incorrect

• Check the compensation setting of the

proportional valve in Scania Programmer.

It may be set incorrectly.

©

8

Scania CV AB 1999, Sweden

1050t14b.mkr

If the air pressure stated above is not

obtained

• Make sure that at least 6 bar is reaching the

proportional valve. Use pressure gauge

99 215, hose 99 164, union 1 319 272 and

an 8 mm adapter hose.

• Make the adapter from a 0.5 metre long

piece of 8 mm hose. The adapter hose is to

be fitted with sleeve 814 809, ferrule

813 221 and nut 812 888 on both ends.

These will then fit to union 1 319 272.

• Fit the adapter to hose 99 164 and connect

pressure gauge 99 215. Ta ke a reading at the

distributor piece that supplies the

proportional valve with compressed air.

Troubleshooting

• If there is no pressure, the fault may be in

the solenoid valve for the compressed air

supply, ON/OFF valve.

Note: A minor and controlled air leakage from

the proportional valve vent is normal. A hissing

noise, therefore, does not indicate a fault.

4

A

4

56

7

B

C

D

5

6

7

3

2

3

2

1

115 682

Valve block V97 with integrated proportional

valve. The new valve block requires a higher

pilot frequency, 360 Hz, which is obtained from

control units manufactured from 9902.

1

Pin for proportional valve (+)

2

Pin for proportional valve (-)

3

Pin for solenoid valve for compressed air

supply

If oil appears from the proportional valve vent,

check the sealing rings for the control piston and

the safety valve. Clean also the proportional

valve filter.

1050t14b.mkr

©

Scania CV AB 1999, Sweden

4

Pin for earth

5

Pin for solenoid valve for oil accumulator

6

Pin for earth

A Air connection to oil accumulator

B Air supply

C Air connection to retarder

D Venting

9

114 687

A

B

C

3

83

Troubleshooting

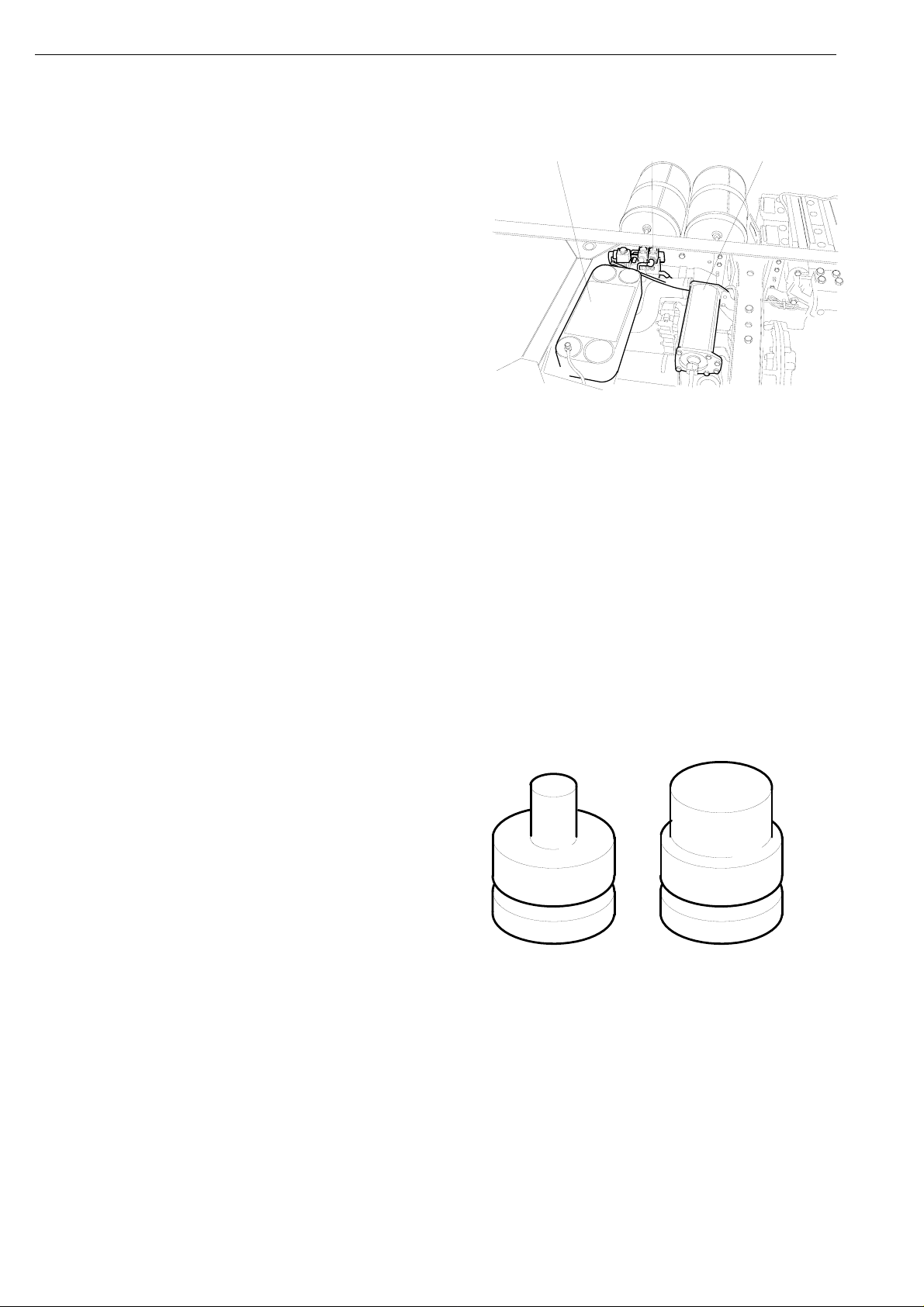

Reasons for improvements introduced

on the old proportional valve.

Impurities entering the valve

Action

The proportional valve on trucks has

occasionally broken due to impurities entering.

A new exchangeable valve with integrated air

filter has been introduced in production from

chassis number SS1238870, SN4391326,

SA9031574 and SLA3503385.

A. Location of proportional valve

Air leakage due to defective check valve

Action

There have been occurrences of air leakage from

the proportional valve vent on trucks and buses.

This is due to a defective rubber check valve.

The fault is easiest to locate in SD. The ON/OFF

valve must be activated. If air leaks through the

vent 4, the check valve is probably defective.

The proportional valve support sleeve has been

modified and was introduced in production from

chassis number SS1246832, SN4405293 and

SA9038846.

AB

A. Old version of support sleeve.

B. New version of support sleeve.

7

11

10

©

Scania CV AB 1999, Sweden

1050t14b.mkr

Loading...

Loading...