Scania 4Electrycal Service Manual

Electrical system 11

© Scania CV AB 2003

1

ELECTRICAL SYSTEM ................................ 2

PROTECTION AND SAFETY

REQUIREMENTS ......................................... 3

Preventative measures.............................. 3

CONNECTORS ............................................. 4

Moisture-proof connectiors ...................... 4

POWER CONSUMPTION ............................. 5

SIZING FUSES AND CABLES AND

VOLTAGE LOSS........................................... 7

CENTRAL ELECTRIC UNIT ......................... 8

Extra central electric unit (accessories/

bodywork) .................................................. 9

FACTORY-FITTED WIRING........................ 10

Factory-fitted wiring in cab ..................... 11

Factory-fitted wiring for FM/AM radio ....13

Factory-fitted wiring for CB radio .......... 13

Factory-fitted wiring for cell phone........ 13

Factory-fitted extra voltage converter

24/12 V ...................................................... 13

Factory-fitted wiring for electrically

operated rear-view mirrors ..................... 13

Connecting extra lights ........................... 14

Power socket in cab ................................ 14

Extra direction indicators ....................... 14

Extra brake light lamps ........................... 14

Electrical items for front-mounted

equipment ................................................ 15

EXTRA CONTROL BOX ............................. 17

JUNCTION BOX IN FRAME ....................... 18

PLACE FOR OPTIONAL ELECTRICAL

ACCESSORIES IN TOPLINE CAB ............ 19

POWER TAKE-OFFS IN COMBINATION

WITH OPTICRUISE .................................... 20

EDC ............................................................. 21

Hand throttle (normal) ............................. 22

Limited hand throttle ............................... 22

Raised idling speed ................................. 23

Fixed engine speed ................................. 23

Example of setting three fixed engine

speeds ...................................................... 24

Torque limitation ...................................... 25

Speed limiter ............................................ 26

Engine stop .............................................. 26

External control of engine speed ........... 27

ADR............................................................. 28

Bodywork on ADR-equipped vehicle .....28

SWITCHES ................................................. 29

APPENDIX:

Wiring diagrams manual

Connection diagrams sheets 1-4

Contents

Electrical system 11

© Scania CV AB 2003

2

ELECTRICAL SYSTEM

This chapter provides general information about

the electrical system in the Scania 4 series which is

relevant to bodywork.

Supplementing this chapter as attachments are

Manual: Wiring diagram with list of components

and Basic electrical systems.

For further information about components,

diagrams, etc. contact a Scania dealer.

For further information concerning the illustration,

see the Manual: Wiring diagram attachment.

Electrical system 11

© Scania CV AB 2003

3

PROTECTION AND SAFETY

REQUIREMENTS

Preventative measures

When working on the electrical system

Detach the battery earth lead and fit a line fuse

between the negative battery terminal and the

chassis in order to avoid accidents in the case of

short circuit.

In and under the instrument panel, close to hot air

ducts, temperatures can reach 90 °C. Always use

cables which resist at least 105 °C in the cab.

Electronic control units and components for such

things as ABS, Opticruise and automatic gearboxes

can be sensitive to heat during oven drying after

painting and to current during such things as arc

welding. Prevent damage as follows:

When oven-drying

See Chapter 2 Painting

When arc welding

See Chapter 2 General recommendations for

bodywork section Welding, general.

When charging

Vehicle system voltage must not exceed 30 volts.

This means that jump starting should only be

carried out using batteries in order to prevent a

voltage surge which could damage electronic

components.

Protection against transients

Solenoid valves can give rise to high transients

when the ignition switch is turned off. For this

reason, always use solenoid valves with transient

protection.

The electrical system can cope with transients up to

150 V.

Batteries

The batteries should be trickle-charged to avoid

deterioration while the vehicle is under bodywork

construction.

If the specific gravity of the electrolyte falls too

low, sulphation of the lead plates will result and lead

to a drastic reduction of battery life and capacity.

See Chapter 2 General recommendations for

bodywork section Batteries.

Electrical system 11

© Scania CV AB 2003

4

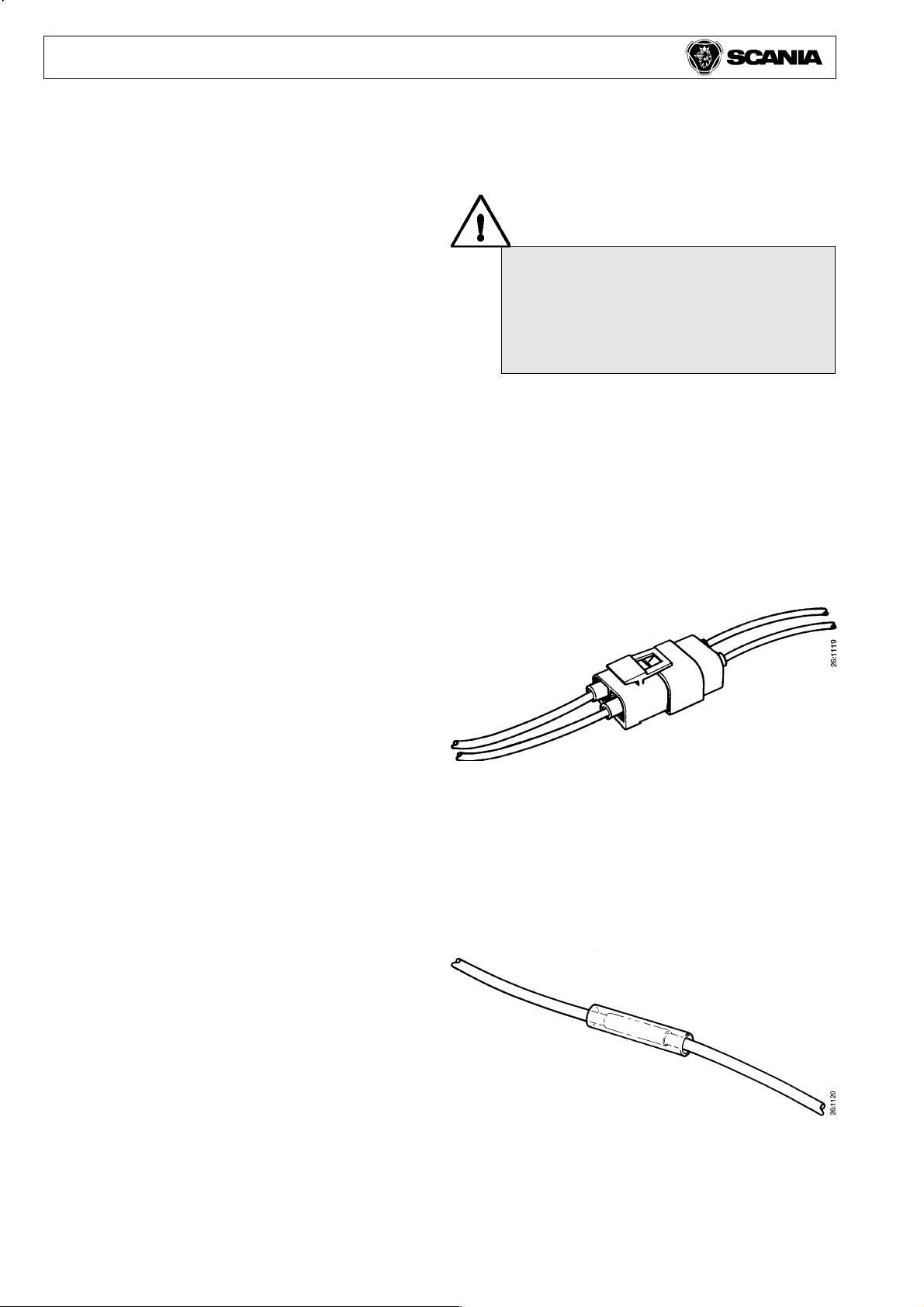

Many connectors have a double latching

mechanism for cable terminals.

It is important to release or secure the

double latching mechanism after

changing or adding connectors.

CONNECTORS

A standard electrical system contains about 200

connectors of different shape and material.

When working on the electrical system, changing

or adding components, it is important to use the

same types of connector in order to avoid the risk

of causing interference.

Moisture-proof connectiors

The Scania spare parts department can supply a

number of different types of moisture-proof

connector. Some examples are given below.

Moisture-proof, moulded connectors with 1 m of

1.5 mm

2

cable.

Part No.

389202 Female connector, 2-pole with cable

389203 Male connector, 2-pole with cable

1117327 Cable with female terminal, red

1117328 Cable with female terminal, black

1117329 Cable with male terminal, red

1117330 Cable with male terminal, black

Splice connector

Use splice connector part No. 341333 for splicing

cable 1-2.6 mm

2

. This is wound with vulcanising

tape part No. 380128 and cover tape part No.

380129.

Alternatively, use a splice connector with adhesive

lined heat shrink tubing.

Part No. 1112499 0.75 mm

2

1112500 2.5 mm

2

1112501 3-6 mm

2

Electrical system 11

© Scania CV AB 2003

5

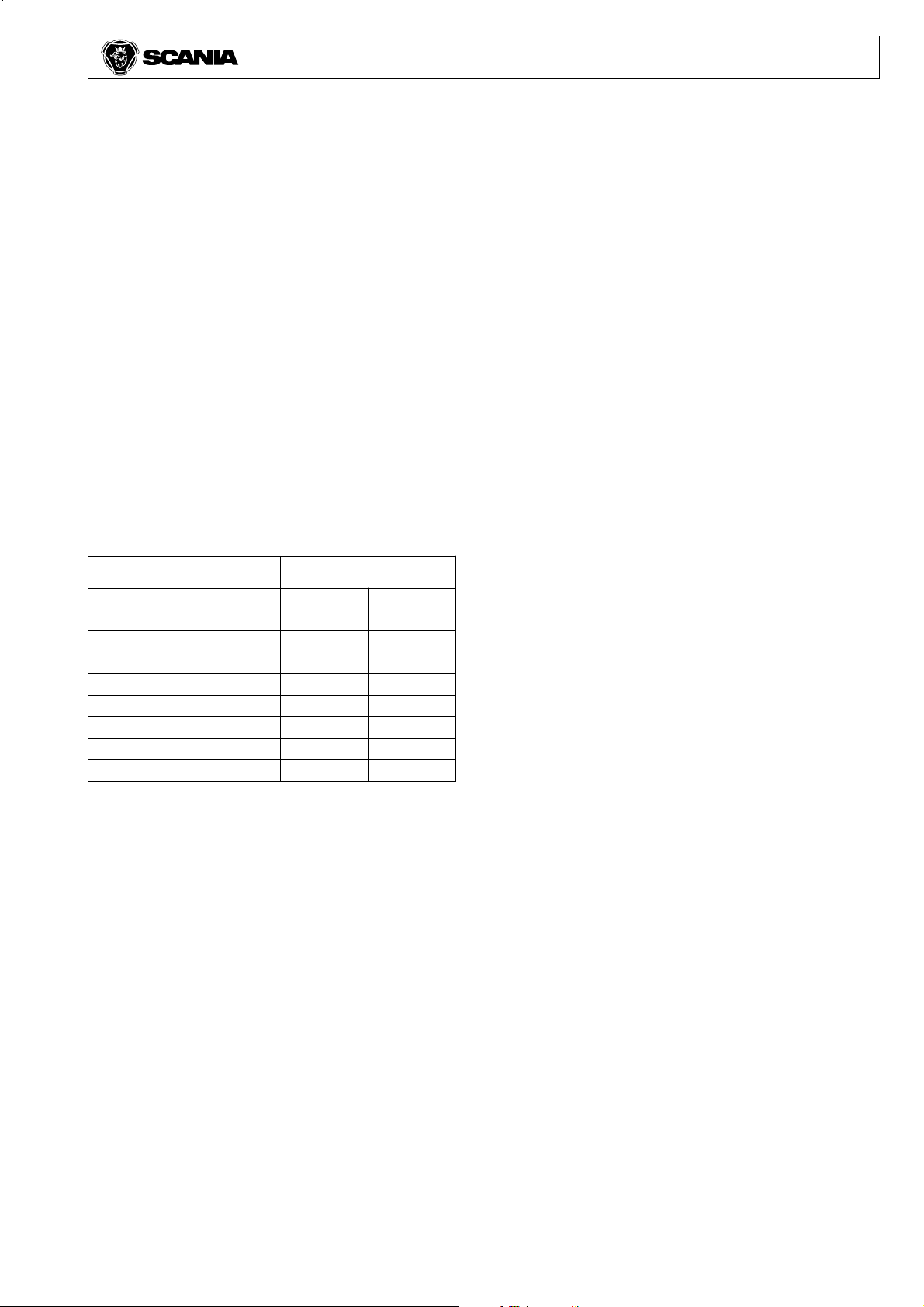

Temperature is also important. A battery is much

less able to accept a charge at low temperatures. To

achieve charging balance the alternator should have

an overcapacity of about 15-25 A. In general, it

could be said that an overcapacity of about 15 A

suffices for a vehicle driven over long distances

without stopping (e.g. long-haul runs) while an

overcapacity of about 25 A is needed for a vehicle

making frequent stops (e.g. a delivery van).

To check whether the alternator has sufficient

capacity, obtain the total current consumption using

the tables below and then add the overcapacity.

Note that this is a very approximate calculation.

Engine speed

Alternator

(rpm)

65A

(A)

90A

(A)

500 30 42

600 40 58

700 46 68

800 50 76

1000 56 82

1200 60 88

1600 64 92

POWER CONSUMPTION

Batteries, alternator and current consumption must be

matched to each other. There should be a charging

equilibrium.

Alternator capacity should be matched to current

consumption so that battery damage is avoided.

The time aspect is important. The current taken from

the batteries must restored within a day or two.

What is the driving cycle like? Frequent starting and

lengthy idling periods will not charge up the batteries

as efficiently as long-haul runs. The alternator genera-

tes less current at low engine speeds.

Some examples are given below.

Electrical system 11

© Scania CV AB 2003

6

Guide values for extra equipment

Operating

time

Extra lights 2-4 x 3 A = 6-12 A 50%

Side marker lights 4-6 x 0.5 A = 2-3 A 100%

Roof lighting, external 1 x 4 A = 4 A 50%

Loading lights 2 x 4 A = 8 A 50%

Electrically-heated seats 2 x 2.5 A = 5 A 25%

Electrically-heated mirrors 2 x 2 A = 4 A 25%

Refrigerator 1 x 2 A = 2 A 60%

Extra cab heaters: 25%

a) Engine cab heater (Webasto) = 6 A

b) Cab heater (Eberspächer) = 3 A

c) Short stop heater = 4 A

Retarder (Electric) 1 x 100-200 A = 100-200 A 5-10 %

Battery heater 1 x 10 A = 10 A 25-50 %

Tail lift 1 x 100 A = 100 A ----

Normal power consumption, truck

Electric fuel injection 1 x 5 A = 5 A

Main beam headlights 2 x 3 A = 6 A

Rear lights 4 x 0.25 A = 2 A

Front position lights 2 x 0.25 A = 0.5 A

Width marker lights 2 x 0.25 A = 0.5 A

Instrument illumination 20-30 x 0.05 A = 1.5 A

Fan motor 1 x 5 A = 5 A

Windscreen wipers 1 x 4 A = 4 A

Air dryer 1 x 3 A = 3 A

Radio ( std ) 1 x 2 A = 2 A

Normal power consumption, trailer

Rear lights 4 x 0.5 A = 2 A

Side marker lights 8 x 0.5 A = 4 A

Width marker lights 2 x 0.25 A = 0.5 A

Box interior lighting 4 x 2 A = 8 A

To avoid shortening the useful life of the batteries,

the radio position on the ignition switch should be

used whenever possible for supplying power. In the

drive position the entire electrical system is

engaged, which increases current consumption and

with it a bigger drain on the battery.

Electrical system 11

© Scania CV AB 2003

7

SIZING FUSES AND CABLES AND

VOLTAGE LOSS

If cables are long, it may be necessary to use a

thicker cable to reduce voltage loss.

Normally, a voltage loss of 5 % (1.2 V) is acceptable.

Voltage loss in copper conductors is calculated

using the following formula:

U = I x (0.0175 x L) / A

U = Voltage loss (V).

I = Current in amps (A).

L = Length of cable.

A = Cross-section of conductor (mm

2

).

Calculate how many amps are consumed when

extra equipment is connected in order to size the

fuses and cables.

Use the following equation:

I = P/U

I = Current in amps (A)

P = Power in watts (W)

U = Voltage (V)

If two of P, U and I are known, the third can be

calculated as follows:

U = P/I, I = P/U, P = U x I

Example

Power P = 200 W

Voltage U = 24 V

I = 200 W / 24 V = 8.3 A

The calculated total current through a fuse should

not exceed 60 % of the amp rating.

Sizing cables

Current, power and the distance to the load

determine the cross-section of the conductor.

Current Power Cross-section

10 A 200W 0.75-1 mm

2

15 A 400W 1.5 mm

2

20 A 500W 2.5 mm

2

25 A 650W 4.0 mm

2

40 A 850W 6.0 mm

2

50 A 1200W 10.0 mm

2

Cables outside the cab should be at least 1.5 mm

2

These values are based on the heat generated in the

cable with continuous current.

Always use the correct fuse. An

oversized fuse can cause fire in the

electrical system.

Electrical system 11

© Scania CV AB 2003

8

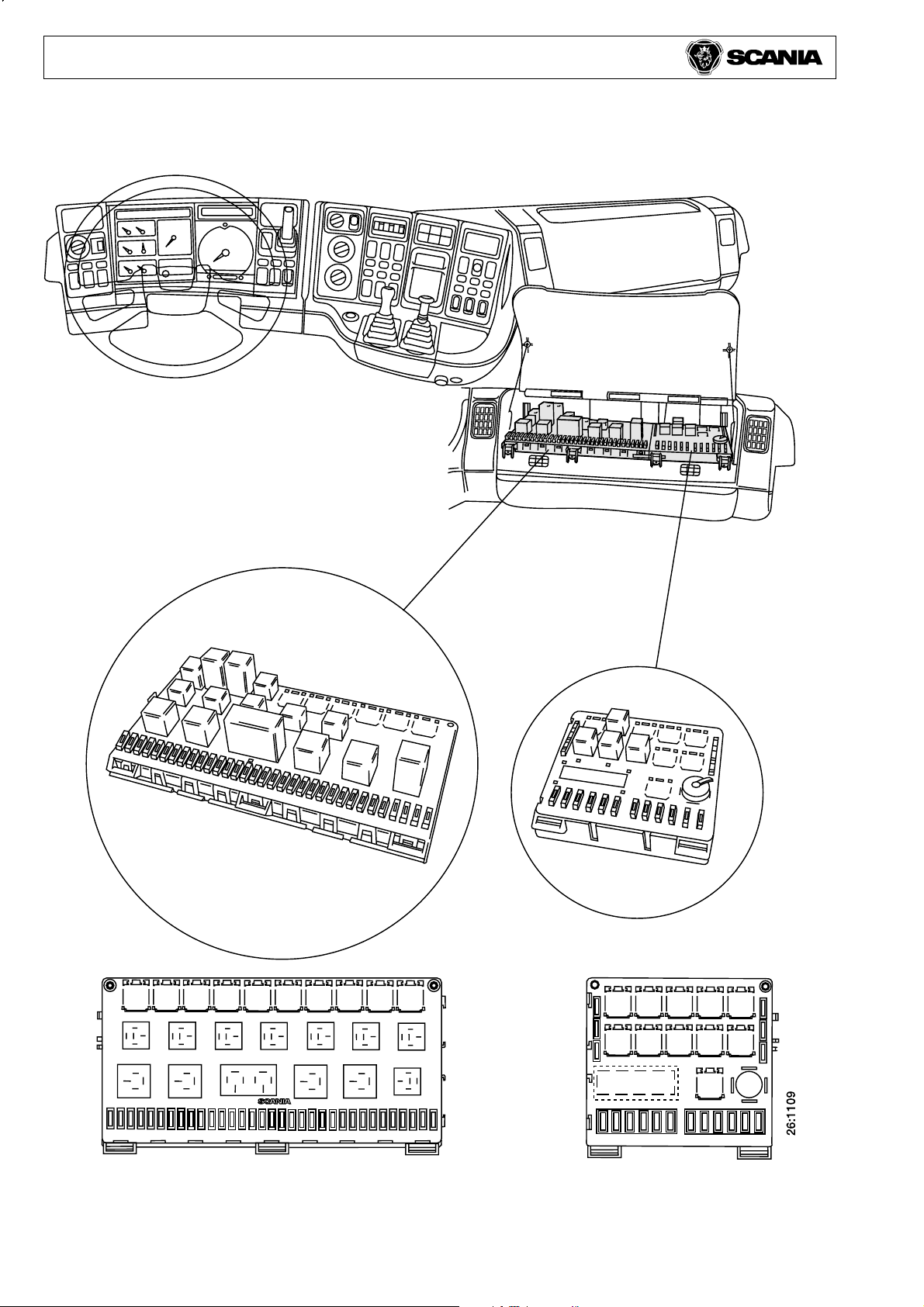

CENTRAL ELECTRIC UNIT

Central electric unit Extra central electric unit

(accessories/bodywork)

Electrical system 11

© Scania CV AB 2003

9

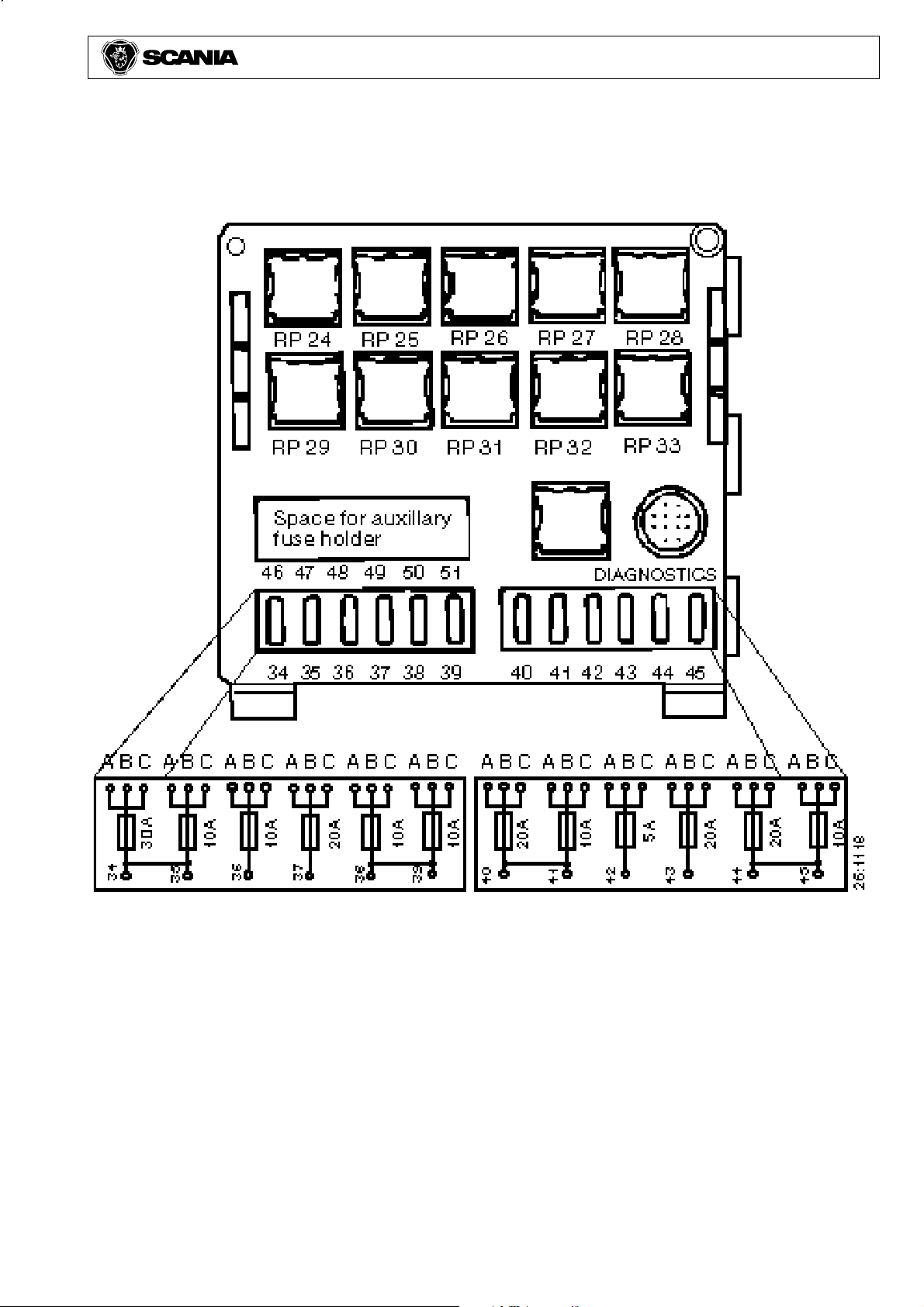

Extra central electric unit (accessories/bodywork)

The extra central electric unit can have a varying

number of positions occupied from factory,

depending on what extra equipment, such as fuel/

battery heater and flame start, is fitted.

Extra fuse holder for positions 46-51, part number

1320852.

Extra relay holder, 9-pole, part number 1320851.

Electrical system 11

© Scania CV AB 2003

10

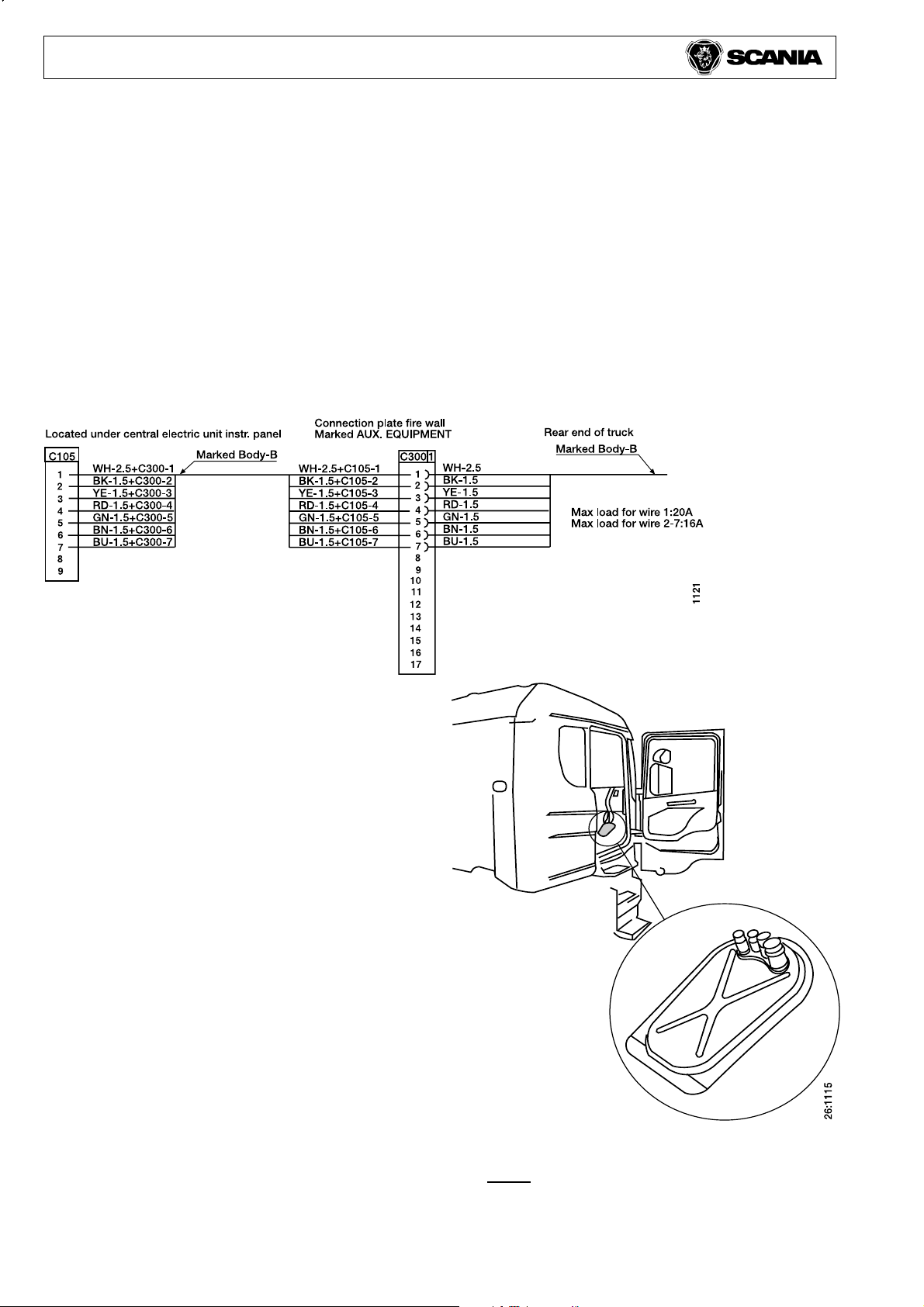

FACTORY-FITTED WIRING

With the exception of tractors, all vehicles can be

ordered with a seven-core cable running from the

cab to the rear end of the frame. Via a connector in

the bulkhead marked C300 this cable is wired to a

white connector marked C105 located under the

central electric unit and terminates without a

connector about 1 metre behind the junction box at

the rear end of the frame.

The cable is of ADR design on vehicles ordered

with ADR.

If the 7-core cable is not enough, or if it is

necessary to route cables to the cab of tractor units,

there are four lead-throughs of varying diameter in

the floor on the passenger side.

Cable lead-throughs

Note: The floor panel is illustrated upside

down to show the rubber plugs.

Cable cross- Colour Max. load

section area

1 2.5 mm

2

white 20 A

2 1.5 mm

2

black 16 A

3 1.5 mm

2

yellow 16 A

4 1.5 mm

2

red 16 A

5 1.5 mm

2

green 16 A

6 1.5 mm

2

brown 16 A

7 1.5 mm

2

blue 16 A

Suitable connector housing for C105: part. no. 813556

Suitable round female terminals

Cable cross-section: 1.5 mm

2

part no. 813925

Cable cross-section: 2.5 mm

2

part no. 813927

Loading...

Loading...