Scania instrumentation Operator's Manual

Operator's manual

Scania

Instrumentation

en-GB 2 374 015

Issue 2.0

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Analogue instrument panel . . . . . . . . . . . . . . . 5

Analogue instrument panel for engines without

SCR system . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Analogue instrument panel for engines with SCR

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Display in tachometer . . . . . . . . . . . . . . . . . . . 7

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Starter lock . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine speed setting 1 and 2. . . . . . . . . . . . . 11

Idling speed adjustment . . . . . . . . . . . . . . . . 12

Limp home mode . . . . . . . . . . . . . . . . . . . . . 12

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . 13

Digital display . . . . . . . . . . . . . . . . . . . . . . . . . 14

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display structure . . . . . . . . . . . . . . . . . . . . . . 15

Favourite screens. . . . . . . . . . . . . . . . . . . . . . 16

Information (4) . . . . . . . . . . . . . . . . . . . . . . . . . 19

Statistics trip (4.1) . . . . . . . . . . . . . . . . . . . . . 19

Performance (4.2) . . . . . . . . . . . . . . . . . . . . . 19

Fault codes (5). . . . . . . . . . . . . . . . . . . . . . . . . . 21

Information about the highlighted fault code 22

Clear fault codes . . . . . . . . . . . . . . . . . . . . . . 22

Update the fault code list . . . . . . . . . . . . . . . 23

Settings (6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contrast/brightness (6.1). . . . . . . . . . . . . . . . 23

Button beep (6.2). . . . . . . . . . . . . . . . . . . . . . 24

Language (6.3) . . . . . . . . . . . . . . . . . . . . . . . 24

Units (6.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Engine (6.5). . . . . . . . . . . . . . . . . . . . . . . . . . 26

Examples of setting. . . . . . . . . . . . . . . . . . . . 32

Base system (6.6) . . . . . . . . . . . . . . . . . . . . . 33

Alarm and fault code generation . . . . . . . . . . 33

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

External alarm signal . . . . . . . . . . . . . . . . . . 35

Fault code generation . . . . . . . . . . . . . . . . . . 35

OPM 500 en-GB 2

©

Scania CV AB 2014, Sweden

Introduction

Note:

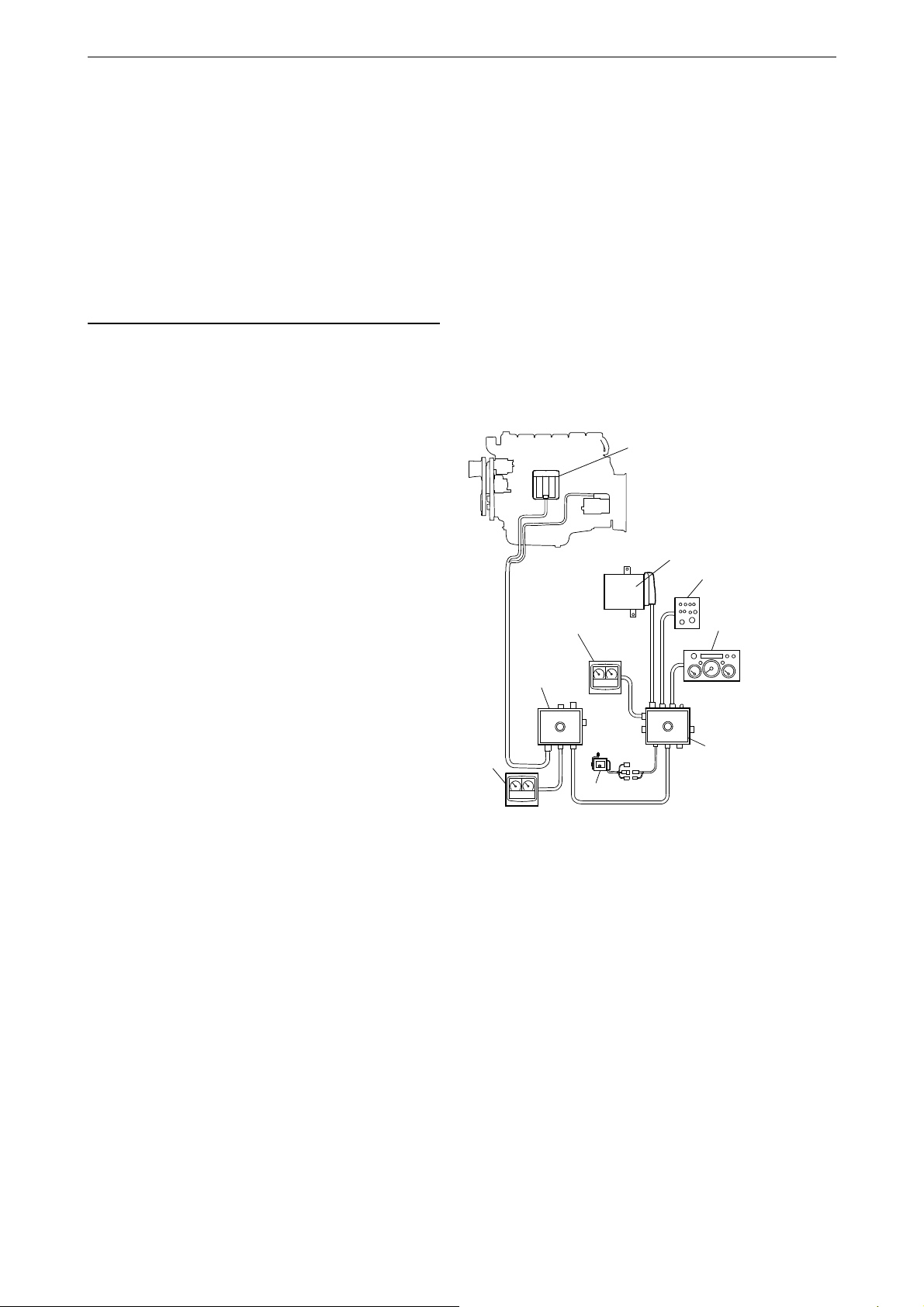

321 034

1

2

3

4

5

6

7

8

4

Base system for industrial engines

1. Engine control unit

2. Main junction box

3. Coordinator

4. Digital display

5. Coordinator junction box

6. Control panel

7. Analogue instrument panel

8. Accelerator pedal sensor

This Operator's manual describes operation of

Scania instrumentation.

The information in this manual was correct at the

time of going to press. Scania reserves the right

to make alterations without prior notice.

Always use Scania spare parts for repair work.

Overview

The base system consists of a coordinator, coordinator junction box and main junction box. The

main junction box is connected directly to the engine control unit. There are a number of different

options for the base system that can be connected

to the system:

Introduction

• A digital display together with a control panel

with starter key.

• An analogue instrument panel that can be

used instead of the digital display or together

with it.

• An accelerator pedal sensor.

• A remote control (for marine engines only).

The entire instrumentation system is Plug and

Play which makes it very easy to install.

This Operator's manual only describes the analogue instrument panel, remote control, digital

display and control panel.

OPM 500 en-GB 3

©

Scania CV AB 2014, Sweden

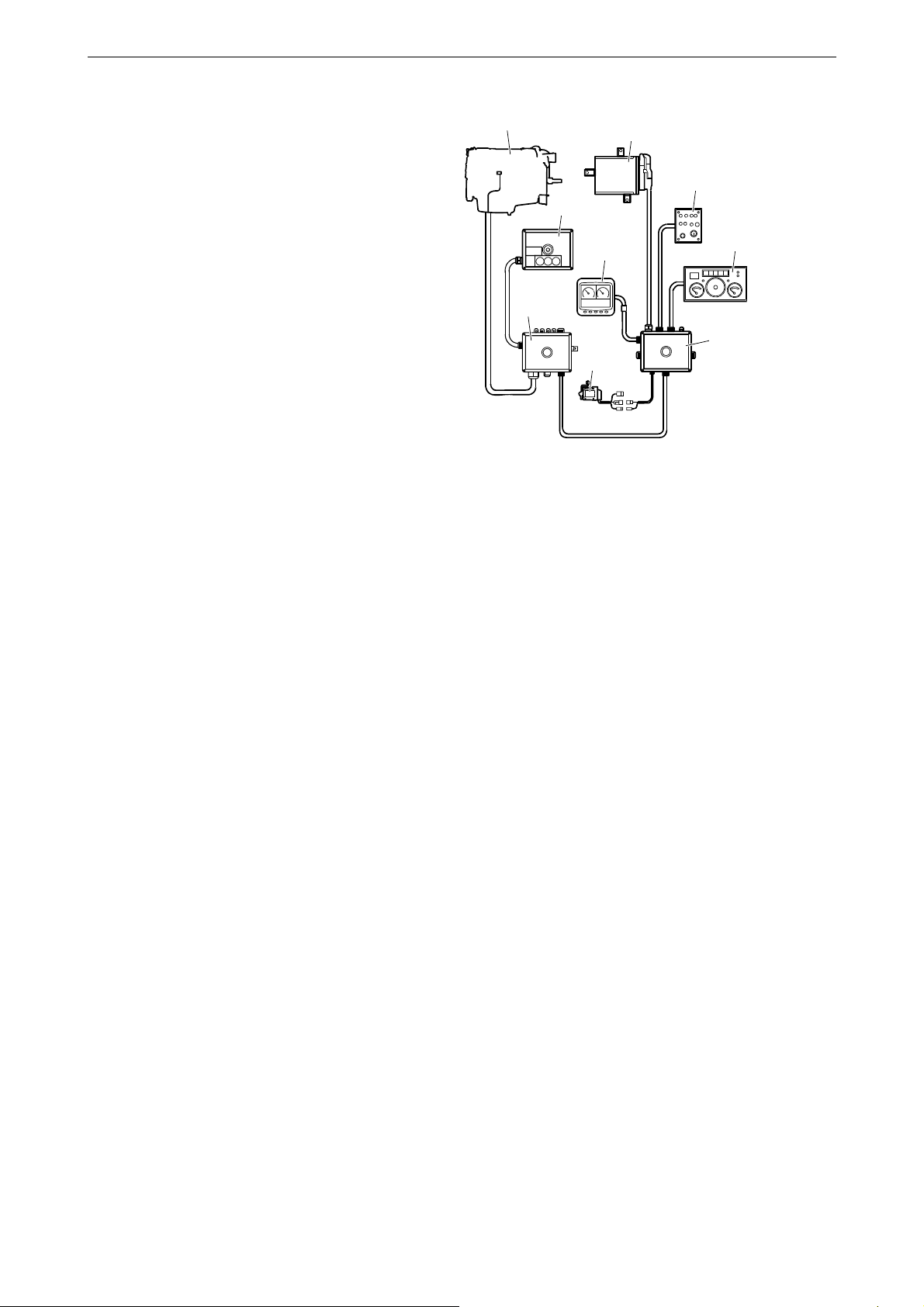

Overview

1

2

3

4

5

6

7

8

9

343 188

Base system for marine engines

1. Engine control unit

2. Remote control

3. Main junction box

4. Accelerator pedal sensor

5. Coordinator junction box

6. Analogue instrument panel

7. Control panel

8. Coordinator

9. Digital display

OPM 500 en-GB 4

©

Scania CV AB 2014, Sweden

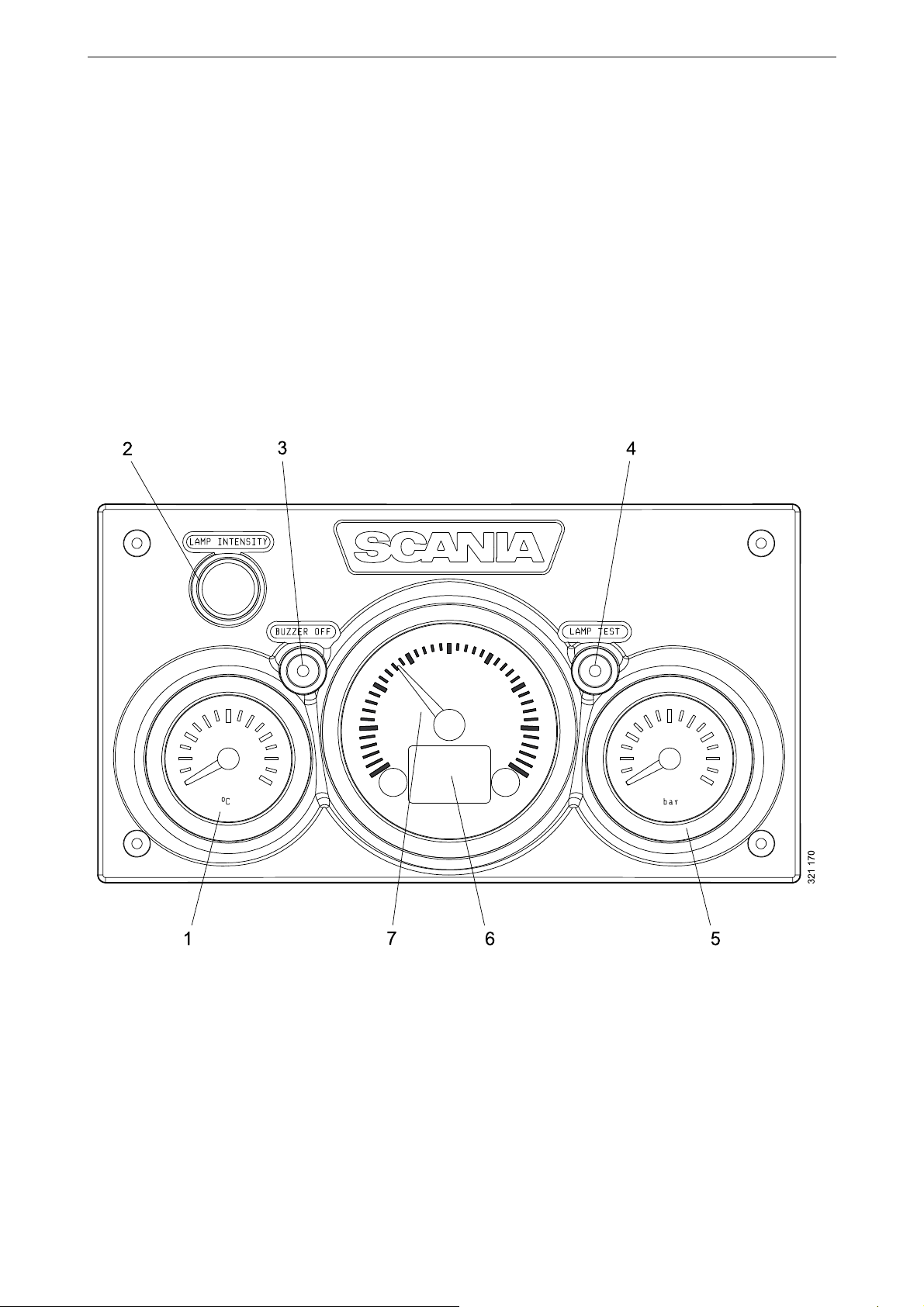

Analogue instrument panel

1. Coolant temperature display

2. Adjusting instrument lighting brightness (Lamp intensity)

3. Buzzer deactivation (Buzzer off)

4. Lamp test (Lamp test)

5. Display for oil pressure

6. Display showing engine data, alarms and fault codes

7. Tachometer

The analogue instrument panel has instruments

for reading engine speed, coolant temperature

and oil pressure. It also has hour counting and diagnostic and alarm switches and lamps.

The analogue instrument panel is available in 2

versions, depending on whether the engine is

equipped with an SCR system or not.

Analogue instrument panel

for engines without SCR system

Analogue instrument panel

OPM 500 en-GB 5

©

Scania CV AB 2014, Sweden

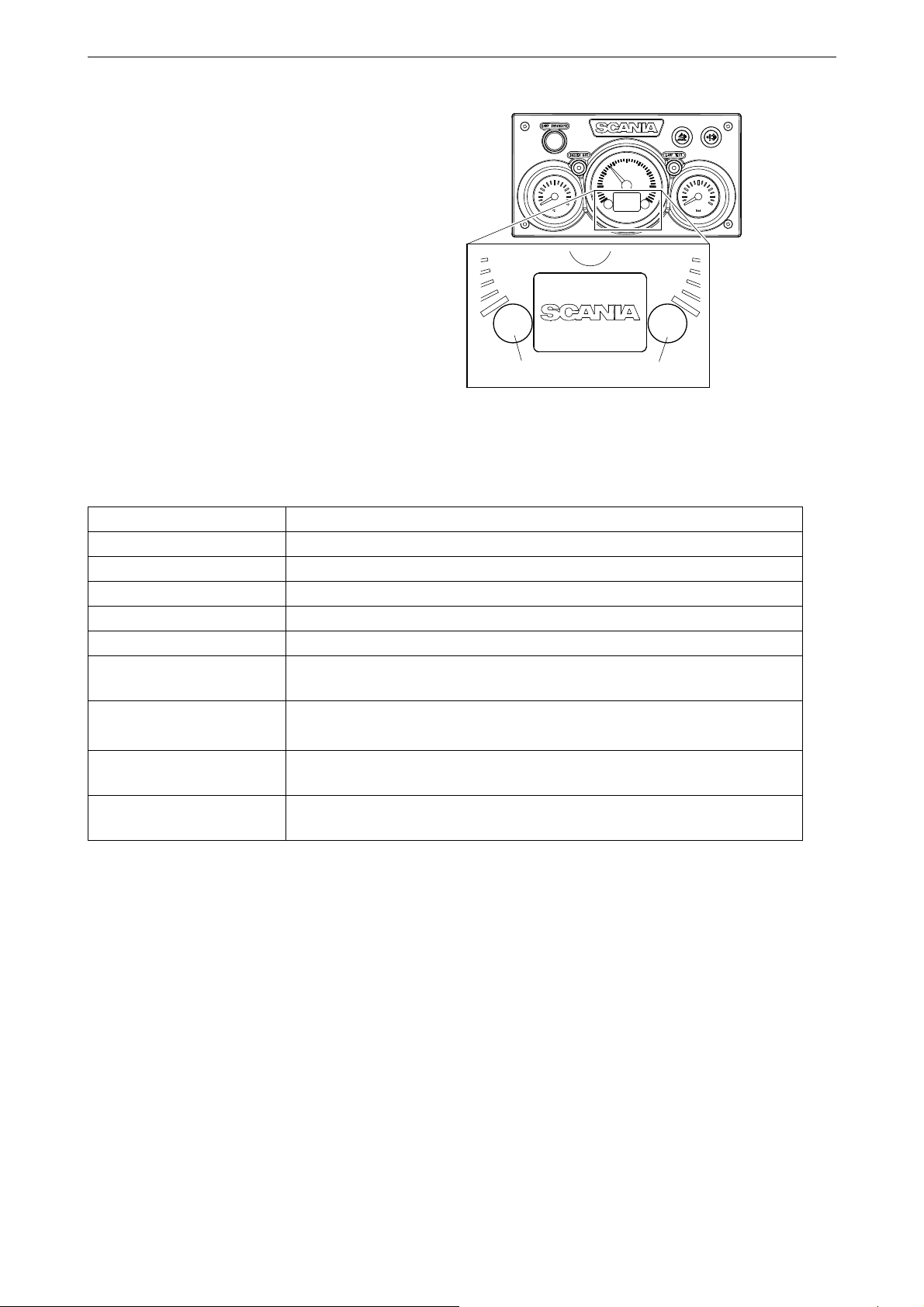

Analogue instrument panel

1. Coolant temperature display

2. Adjusting instrument lighting brightness (Lamp intensity)

3. Buzzer deactivation (Buzzer off)

4. Lamp test (Lamp test)

5. Display for oil pressure

6. Display showing engine data, alarms and fault codes

7. Tachometer

8. Warning lamp for low reductant level

9. Warning lamp for SCR system faults.

for engines with SCR system

Analogue instrument panel

OPM 500 en-GB 6

©

Scania CV AB 2014, Sweden

Display in tachometer

322 253

12

Integrated in the tachometer is a digital display

that shows engine data, alarms and fault codes.

Button 1 displays the previous page and button 2

displays the next page. The table below describes

how to go down a level in the structure.

Engine data shown on the display

Analogue instrument panel

Engine data Explanation

Coolant temperature

Oil pressure

Fuel level

Fuel consumption

Charge air pressure

Trip meter

Adjusting instrument lighting brightness

Reset the trip meter by holding buttons 1 and 2 down at the same time for

3 seconds.

Reduce the brightness by holding button 1 down for 3 seconds

Increase the brightness by holding button 2 down for 3 seconds

Settings No settings can be changed. The only available language is English and the

only available unit is metric

Fault codes Display an explanation of active fault codes by holding buttons 1 and 2

down at the same time for 3 seconds.

OPM 500 en-GB 7

©

Scania CV AB 2014, Sweden

Alarms

On the display in the tachometer, the following

alarms are shown:

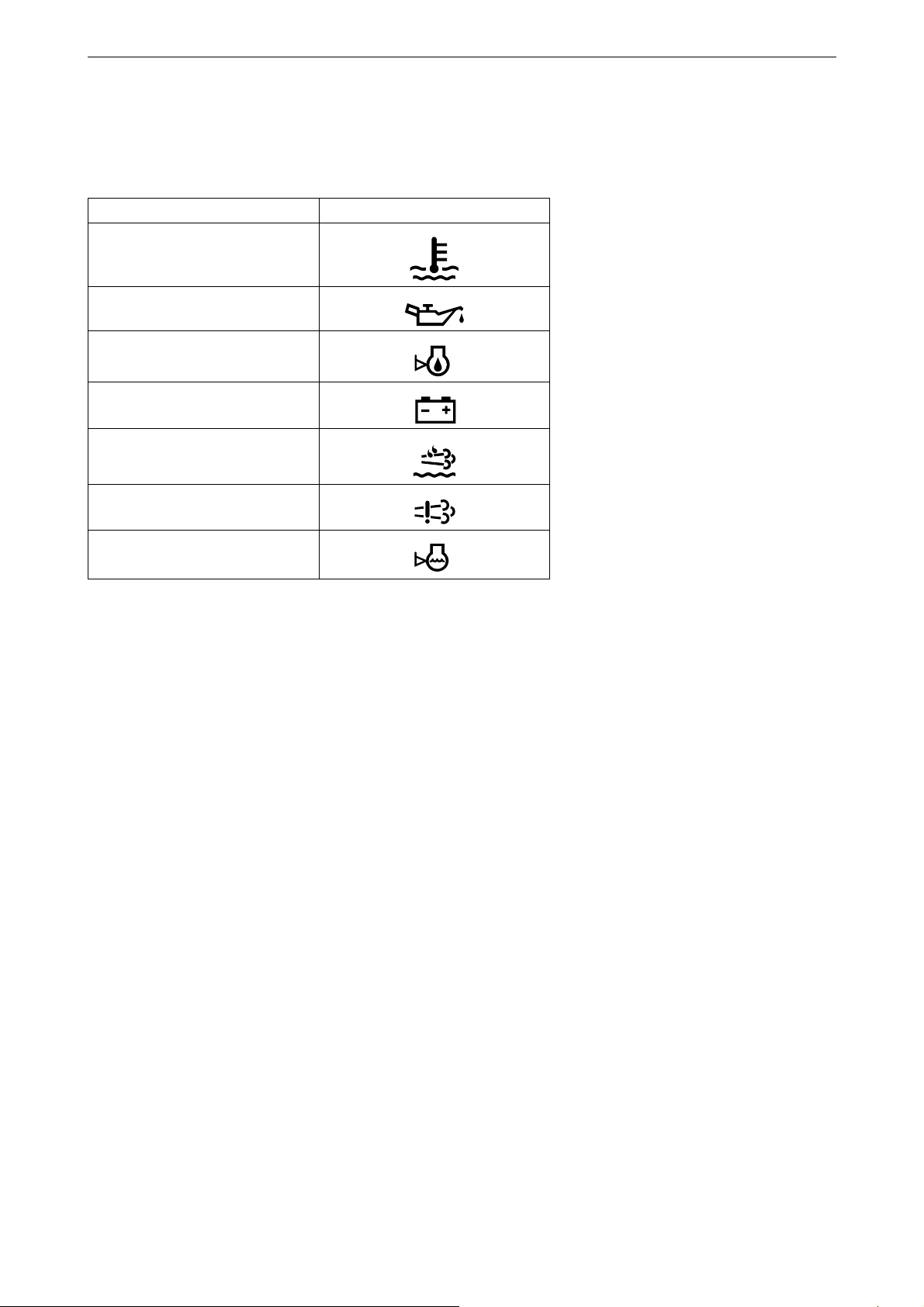

Alarm Symbol

High coolant temperature

Low oil pressure

Analogue instrument panel

Oil level too high or low

1

Alternator not charging

Low reductant level

SCR fault

1

Low coolant level

1. Depending on how the engine is equipped.

1

1

OPM 500 en-GB 8

©

Scania CV AB 2014, Sweden

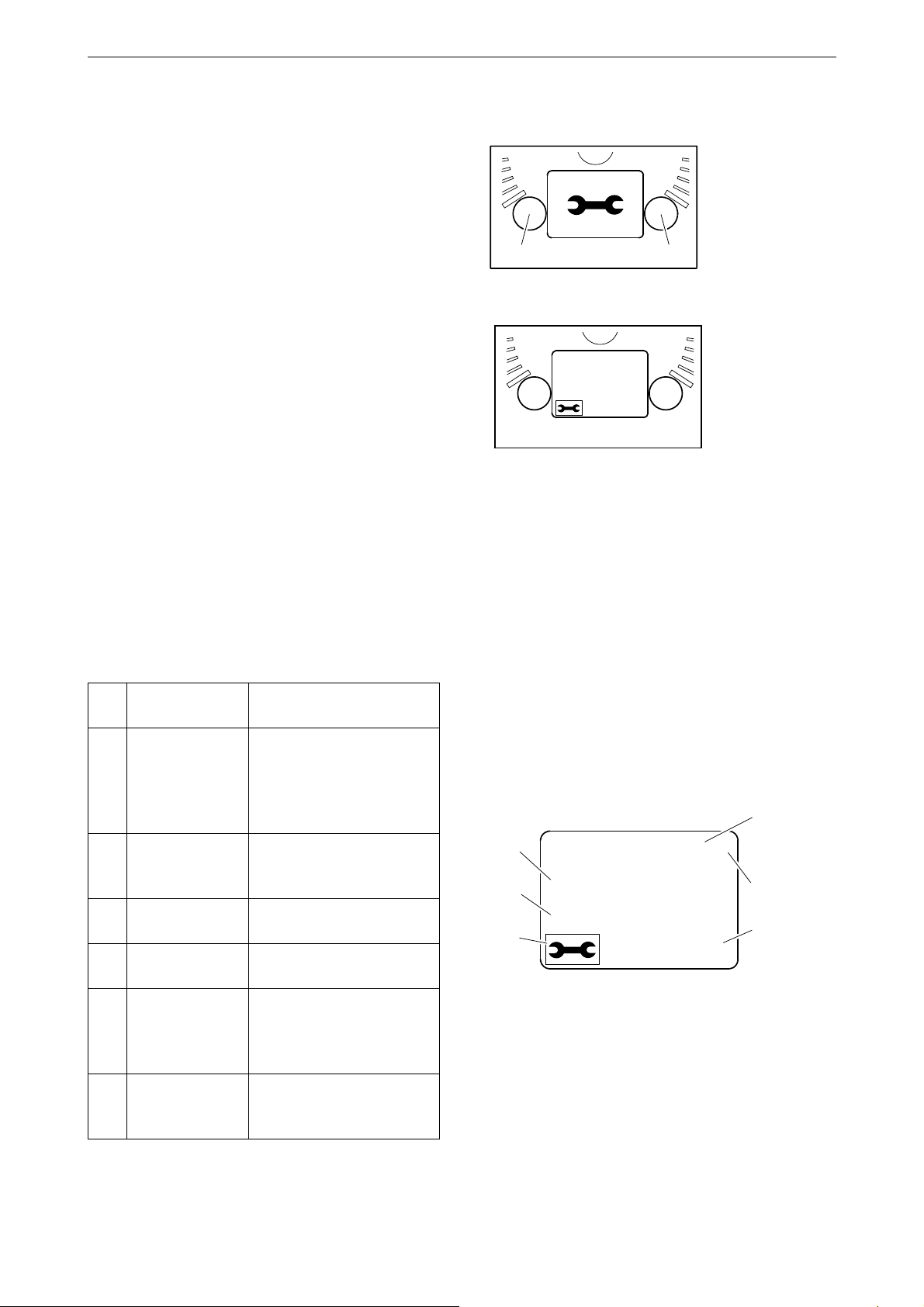

Fault codes

343 928

21

322 255

92.2

Coolant [C˚]

322 256

DTC:

EMS

11

1/16

2100!

1

2

3

4

5

6

When a fault code is generated, a symbol is

shown on the display in the tachometer. Acknowledge the fault code by pressing button 1 or

2.

Once the fault code has been acknowledged, the

fault code symbol remains (refer to illustration)

as long as the fault code is active.

Analogue instrument panel

Fault code description

If you want to see a more detailed description of

the fault code, hold buttons 1 and 2 down at the

same time for 3 seconds.

The fault code contains the following information:

Pos.Information Explanation

1 Shows the con-

trol unit in

which the fault

code was registered

2 Counter Shows how many times

3 Fault code sym-

bol

4 Fault code Shows the fault code in

5 Active fault

code

6 Page Shows which page is ac-

The engine management

system (EMS), coordinator (COO) or SCR control

unit (SCR)

the displayed fault has occurred

hexadecimal form

! is shown if the fault code

is active. If the fault code

is inactive, no ! is displayed

tive and how many pages

there are

OPM 500 en-GB 9

©

Scania CV AB 2014, Sweden

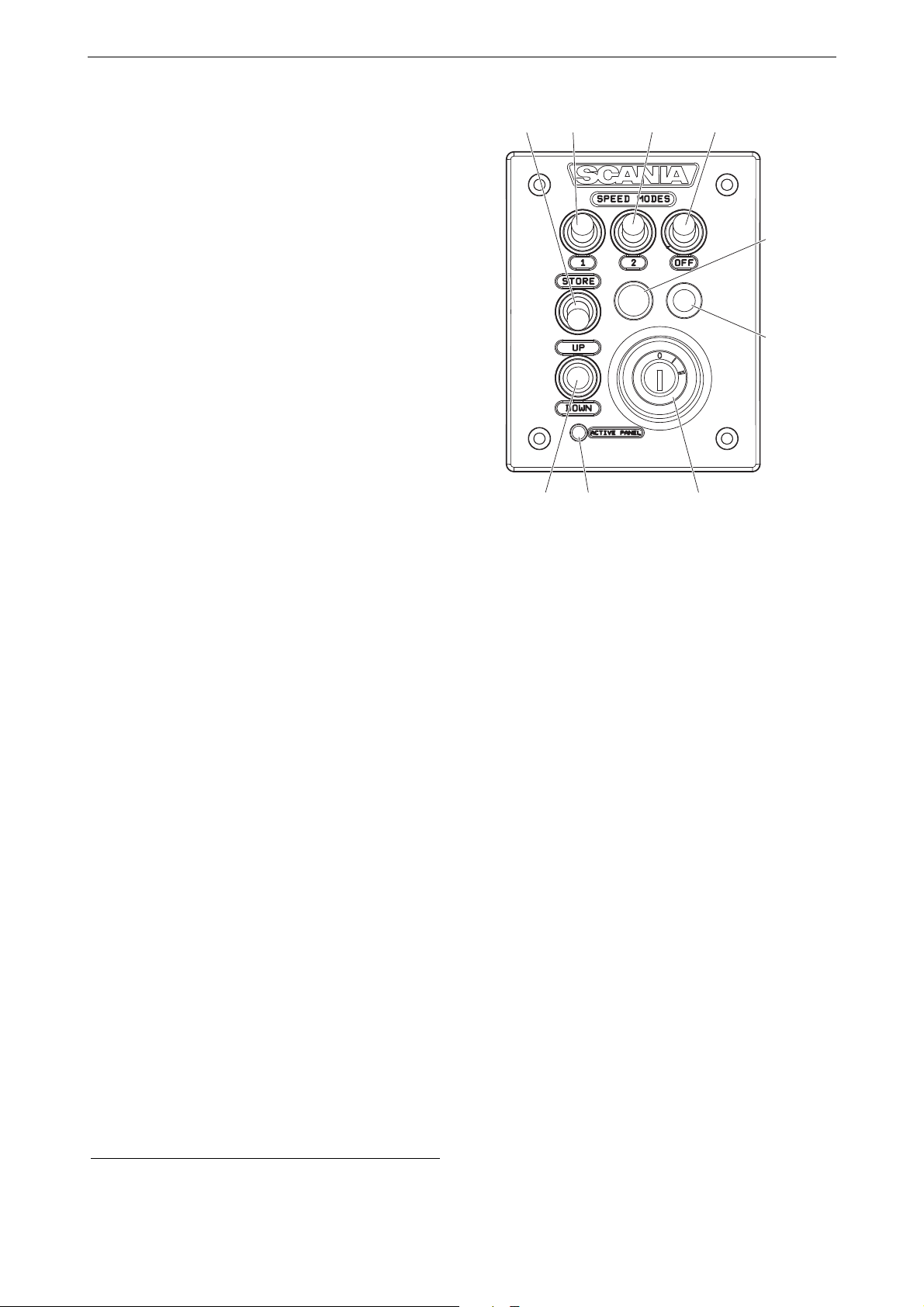

Control panel

23 4 5

19 8

6

7

321 169

The engine is started and shut down from the

control panel, which has a starter lock and functions for engine speed setting and idling setting.

1. Control for adjusting engine speed and idling

speed

2. Control for storing new engine speed and

idling speed

3. Control for activating engine speed setting 1

4. Control for activating engine speed setting 2

5. Control for deactivating engine speed setting

1 (marine engines) or 2 (industrial engines).

6. Indicator lamp for limp home throttle con-

1

trol

7. Limp home throttle control (Limp home)

8. Starter lock

9. Indicator lamp for active panel (Active pan-

el)

1

Control panel

Starter lock

The starter lock (8) is used to start and shut down

the engine.

Position 0: The engine electrical system and the

engine are switched off.

Position 1: The engine electrical system is activated.

Position 2: The starter motor is activated.

1. Only available for marine engines.

OPM 500 en-GB 10

©

Scania CV AB 2014, Sweden

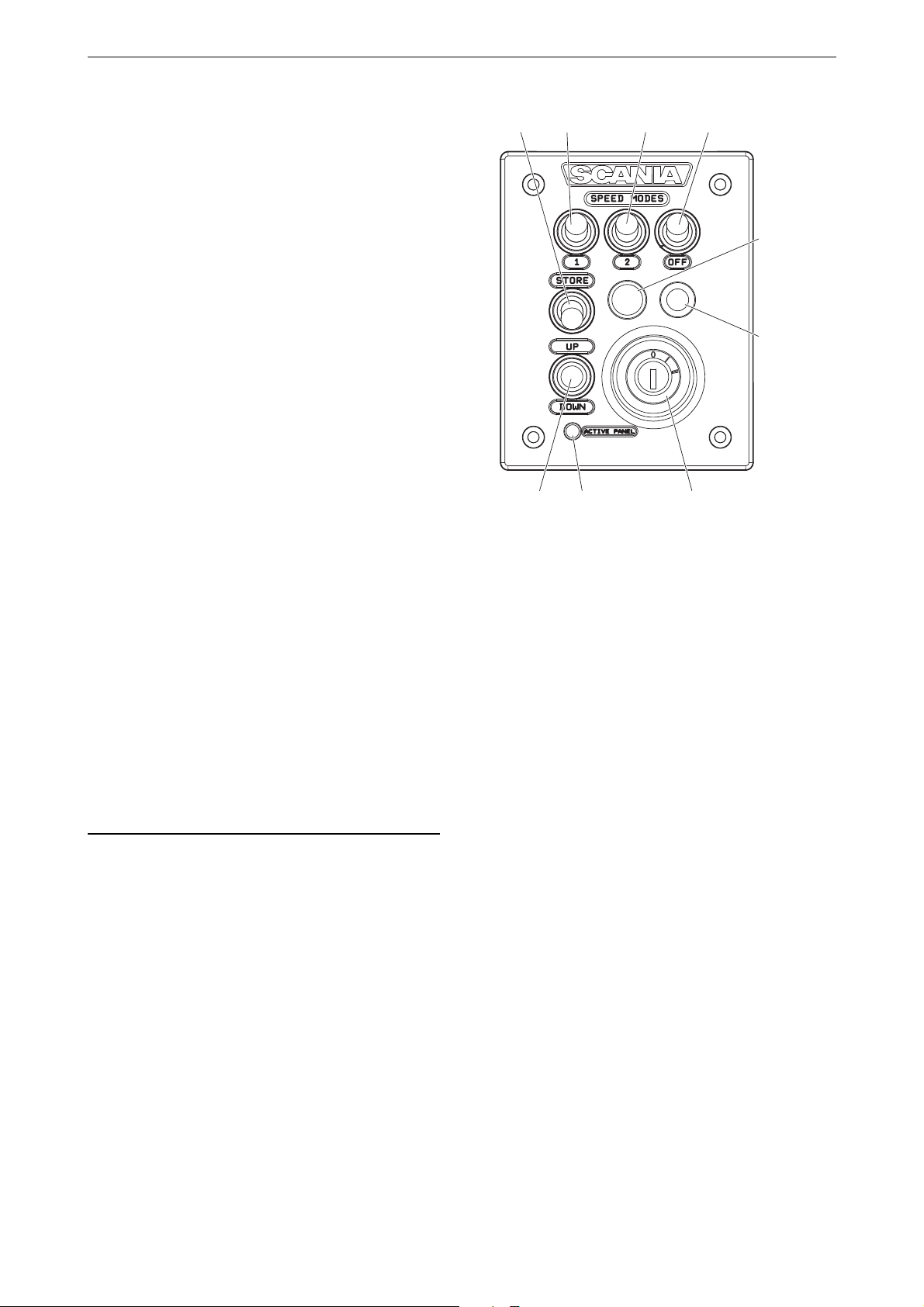

Engine speed setting 1 and 2

Note:

23 4 5

19 8

6

7

321 169

Engine speed setting 1 is an engine speed set between high and low idling. High and low idling

vary depending on the engine. The engine speed

is set with control 3.

Engine speed setting 2 is an engine speed that is

set between 450 and 2,000 rpm. The engine

speed is set with control 4.

For both engine speed settings, torque limitation

can be set via either the digital display or using

SDP3. The engine speed settings are isochronous, i.e. the engine speed is held constant irrespective of load.

When either of the engine speed settings is activated, the engine speed goes up or down to the

last saved engine speed.

Control panel

In order to activate engine speed setting 1 or 2,

the engine must be running, the active panel indicator lamp must be on and the throttle must be

at 0%.

Change the engine speed:

• Activate engine speed setting 1 or 2 with control 3 or 4.

• Adjust engine speed up or down with control

1.

• Save the new setting by holding control 2

down for 3 seconds.

If the setting is not saved, the engine uses the last

saved value next time engine speed setting is activated.

This is how to switch off the engine speed settings:

• Press control 5, touch the accelerator pedal or

switch off the engine.

OPM 500 en-GB 11

©

Scania CV AB 2014, Sweden

Loading...

Loading...