Scania Opticruise Troubleshooting

05:05-02

Issue 1 en

Opticruise

Description of operation and work description

| <![if ! IE]> <![endif]>100 830 |

1 585 369 |

https://www.truck-manuals.net/ |

|

© S ania CV AB 1995-10 |

Contents

General

Description of operation

Fault codes

Electrical system

Mechanical work

Exploded view drawings

Opticruise in brief .............................................. |

3 |

Introduction ........................................................ |

4 |

Controls and operation ....................................... |

6 |

Gear changing .................................................... |

7 |

Opticruise controls the engine via EDC ............ |

7 |

Gear changing sequence, description ................ |

8 |

Engine brake program ....................................... |

9 |

Starting gear, programming .............................. |

9 |

Kick-down .......................................................... |

9 |

Auxiliary brake system ...................................... |

9 |

EDC cruise control .......................................... |

10 |

ABS/TC ............................................................ |

10 |

Power take-offs ................................................ |

10 |

Configuration, control unit .............................. |

11 |

Power supply and fuses ................................... |

11 |

Interaction with other systems ........................ |

12 |

Opticruise, design ............................................. |

14 |

Warning system ................................................ |

16 |

General ............................................................. |

19 |

Faults that do not generate fault codes ............ |

19 |

Clarifications, new terms ................................ |

20 |

List of fault codes ....................................... |

19-52 |

References to wiring diagrams ........................ |

53 |

Location of electrical components ............. |

54-55 |

Control unit signals .................................... |

56-59 |

Driving mode selector ...................................... |

60 |

Test program .............................................. |

61-71 |

General ............................................................. |

73 |

Instructions for repair and adjustment ....... |

73-76 |

Components on gearbox ............................. |

77-83 |

2 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

General

General

Opticruise in brief

Opticruise is a system which allows a normal manual gearbox to shift automatically. The clutch is retained but is used only when starting, stopping and shunting.

A control unit collects and processes data from controls, sensors and adjacent systems such as EDC, ABS/TC and auxiliary brake (if fitted).

When it is time to change gear, the control unit actuates the solenoid valves, releasing compressed air to the air cylinders. These air cylinders then change to the required gear.

The control unit has an in-built warning system. Fault codes can either be read on the display or using a PC and the Scania Diagnos program. The latter makes fault diagnosis quicker.

<![endif]>05_5338

Opticruise requires that the vehicle be fitted with both EDC and ABS/TC, due to the information exchange requirements between the systems.

When changing gear, the engine speed is controlled so that the speeds of the gearbox input shaft and output shaft correspond for the gear to be engaged. Gear changing is only then completed.

When necessary, the exhaust brake is used to make changing up fast and smooth.

05:05-02 en |

© Scania CV AB 1995 |

3 |

|

https://www.truck-manuals.net/ |

|

General

Introduction

| <![if ! IE]> <![endif]>100 830 |

Normal

Hill

| <![if ! IE]> <![endif]>100 830 |

Scania Opticruise is an automatic gear changing system for manual gearboxes. Opticruise is constructed in more or less the same way as the Scania CAG system, the major difference being that the driver only needs to use the clutch pedal when starting, stopping and shunting.

The system is able to change gear automatically without the clutch because the engine is regulated to synchronous speed for the gear that is to be engaged. This means that the electronics adapt both engine speed and torque to exactly the levels required by the gearbox. This makes all gear changing gentle and precise, increasing the service life of the entire powertrain.

Opticruise requires the engine to be equipped with EDC. It would not be possible, using a mechanical injection pump, to control the engine with the speed and precision required for Opticruise to work smoothly. Opticruise also requires the vehicle to be equipped with ABS/TC in order to select the correct gear, even if the drive wheels lose grip on a slippery road surface.

Using Opticruise, the driver can choose to drive with manual or automatic gear selection. In manual gear selection driving mode, the driver selects the gear and when it is changed (depending on road speed and/or engine speed). The control unit decides whether it is possible to change gear without the driver using the clutch. If this is the case, the gear is immediately changed when the driver moves the driving mode selector sideways. Otherwise, the driver has to depress the clutch pedal in order to change gear.

In automatic gear selection driving mode, the control unit calculates which gear is appropriate and carries out this shift when the calculation is complete. In this case, gear changing always takes place without the driver having to use the clutch pedal. If the EDC cruise control is engaged, gear change is automatic without the cruise control being disengaged. This applies until speed is so low that it is a question of stopping or shunting. The clutch must then be used.

In addition to the driving mode selector and its various positions, the driver can choose between two different driving programs. This is done using a program selector beside the driving mode selector. These programs are called Normal and Hill. The Hill program is for steep upward slopes with more than 5 % gradient.

4 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

General

CLU MODE

LIMPHOME

The control unit varies the point at which it changes gear, depending on the position of the program selector. When driving with the program selector set to Hill, gear changing is faster than when the Normal program is engaged. If necessary, the exhaust brake may also be used in order to quickly reduce the speed of the engine.

Like the older CAG system, Opticruise has a selectable starting gear which is programmed in one of the control unit memories. The driver can easily select the starting gear for the average gross train weight of the vehicle combination. The control unit retains this setting, even when power is interrupted. In addition to this, the driver can temporarily select a starting gear other than the one programmed in the memory. This is fully described in the driver’s manual.

The control unit has a built-in warning system. This has made it possible to reduce the inconvenience in the event of a fault. Opticruise has two built-in emergency driving programs. The first of these, clutch mode, is activated in the case of less serious faults and the driver has to depress the clutch pedal every time a gear is changed. If the driving mode selector is set to automatic, Opticruise still preselects the gear as normal. In this situation, Opticruise works in the same way as Scania CAG.

In the case of more serious faults, the driver should activate a limp home program. This makes it possible to drive the vehicle to a workshop, even if something like a sensor is faulty.

This means that the vehicle can be run, even if the emergency driving program feels basic with its manually-requested compressed air gear changes.

The Opticruise system interacts with the braking effect of the diesel engine, the exhaust brake and the Scania retarder, if the vehicle is fitted with this. This reduces brake wear, reducing running costs. In addition, wear to the entire powertrain is reduced as power is transferred more gently than on vehicles with manual gearboxes.

However, the greatest advantage, not least financially, is of course improved driver comfort. Opticruise enables the driver to maintain concentration longer than when driving a vehicle with manual gear changing. This is an advantage for both running costs and road safety.

05:05-02 en |

© Scania CV AB 1995 |

5 |

|

https://www.truck-manuals.net/ |

|

General

Controls and operation

3

The above drawing shows the controls used for Opticruise. The clutch pedal, controls for EDC cruise control and auxiliary brake control unit also affect the system.

For example, the auxiliary brake may request that the engine brake program be activated in order to increase engine speed and therefore coolant flow. This is essential for optimum retarder performance.

When driving with the cruise control, the system changes gear automatically provided the driving mode selector is set the position A. The cruise control is deactivated using the clutch pedal, brake pedal, retarder lever, cruise control OFF button or using the exhaust brake switch on the floor.

5 4

1

2

2

<![endif]>100 829

1Driving mode selector with positions R, N,

A and M. The driver is able to command up and downshift by moving the selector lever to the side.

2Program selector with Normal and Hill positions. The Hill position is for use on steep slopes, preferably with the driving mode selector set to M (manual).

3Switch for activating engine brake program and exhaust brake.

4Diagnostics switch

5Gear indicator with display and buzzer.

6 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

Description of operation

Gear changing

Driving in automatic position A means that the system changes gear automatically in accordance with the driving program set using the program selector, either ”Normal” or ”Hill”.

However, the gear selected automatically can be changed at any time by the driver by moving the driving mode selector to the side. The control unit always checks that the driver’s selection is within reasonable limits.

The driver can even preselect a gear that appears completely inappropriate under the circumstances, such as 3rd when driving in 7th. There are two conditions that must be met for this to work.

•The vehicle must lose speed (be retarded).

•The driving mode selector must be set to manual and the program selector to Hill.

The gearbox then starts the shift by first going to neutral. The control unit then prepares itself for the correct splitter level, correct lateral stroke and the correct range before road speed is reduced sufficiently for the particular gear change to be requested.

At the same time, engine speed is automatically increased to high idling, about 2500 rpm. When road speed has decreased sufficiently, the gear is engaged smoothly and gently. When gear changing is complete, control of the engine is returned to the driver.

When driving, the driver can at any time move the driving mode selector to neutral (N) when, for example, approaching a traffic light. If he changes his mind and the vehicle is still moving, it is possible to move the driving mode selector back to one of positions A or M. The control unit then selects a suitable gear, based on the speed of the vehicle and other information from sensors etc. It is not necessary to use the clutch unless speed is too low.

From automatic position A, the driver can at any time move the lever to manual position M and vice versa. This can be useful if you, for example, want to ”lock” a gear on a slippery road surface. The same applies if he wants to shift manually, for example on steep hills.

Note: On uphill slopes greater than 8 %, it may be necessary to drive with the driving mode selector set to M and with the program selector set to ”Hill”. This gives the fastest possible gear changing, which means that the vehicle does not lose so much speed during changing.

Opticruise controls the engine via EDC

Gear changing when driving is done by Opticruise controlling the engine via EDC to synchronous speed for the gear that is about to be engaged, without the driver using the clutch pedal. This means that both engine speed and torque are adjusted to precisely the level required by the gearbox.

In order to make gear changing easier, engine torque is reduced in a controlled manner just before the gear is disengaged.

Gear changing takes place after the speed of the moving parts in the gearbox has been synchronized.

Towards the end of gear changing, engine torque increases in a gentle and controlled manner to the level requested by the driver using the throttle pedal. This means that gear changing is always gentle and precise, increasing the service life of the entire powertrain.

This precise control is made possible by communication between the Opticruise and EDC control systems.

05:05-02 en |

© Scania CV AB 1995 |

7 |

|

https://www.truck-manuals.net/ |

|

Description of operation

Description of the gear changing process

1Gear change requested automatically or by the driver.

2Engine regulated so that there is no torque on the gearbox input shaft.

3Gearbox set to neutral.

4Engine regulated to synchronize the speed of the gearbox input shaft and the moving parts for the gear to be engaged.

5Gear engaged.

6The engine is regulated to the required torque. The Opticruise then returns control of the engine to the driver.

•During certain upshifts, the exhaust brake is used to more quickly brake the engine to the correct speed in relation to the gear selected.

•When driving in automatic (A), the control unit continuously calculates which gear is most suitable. When this calculation shows that a gear other than the one engaged would be more suitable, the gear change takes place immediately. This may be either a single change or a block change.

The calculation of appropriate gear is made based on the following data:

-Position of program selector

-Current road speed

-Current acceleration

-Current torque

-Total gear ratio

-Throttle pedal position

-Any request for the activation of the engine brake program from the driver or from the auxiliary brake control unit.

8 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

Engine brake program

The function of the engine brake program is to give optimum engine braking in all driving conditions. The engine brake program has nothing to do with the Normal/Hill program selector, but is controlled by a separate switch on the floor of the cab.

In order to use the engine brake program, the throttle pedal must be fully released.

A short press on the floor switch is all that is required to activate the engine brake program.

This means that upshift is delayed as the control unit maintains the gear for longer before changing up, increasing engine brake output.

However, if the floor switch is held down all the time, the exhaust brake is also engaged and downshift takes place earlier.

If the brake pedal is held down, the upshift points change. The control unit is informed of this via the brake lamp switch.

The engine brake program is connected until the throttle pedal is next depressed.

If the vehicle is equipped with an auxiliary brake system with Scania retarder, the engine brake program can be automatically engaged (if appropriate) when using the retarder. This is done by the auxiliary brake control unit. The intention is to raise engine speed and thus coolant flow, providing the retarder with maximum braking effect and activation time.

Programming start-off gear

The system permits free choice of starting gear between 1st and 4th. 1st or 2nd are normally used, but it may be appropriate to use another one in extreme cases.

Note: When the vehicle is heavily loaded, 1st or 2nd must be used. Otherwise, the clutch will be subjected to excessive wear.

It may sometimes be necessary to start in a gear other than the one programmed. This can be done, irrespective of whether the driving mode selector is set to A or M. Simply move the driving mode selector to the side until the required gear is shown on the display. The vehicle can now be started. The ordinary starting gear remains programmed in the control unit memory. More information can be found in the driver’s manual.

Kick-down

By pressing the throttle pedal from full throttle to kick-down, the gear changing points are raised, usually causing faster downshift.

Auxiliary brake system

See ”Engine brake program”.

05:05-02 en |

© Scania CV AB 1995 |

9 |

|

https://www.truck-manuals.net/ |

|

Description of operation

EDC Cruise control

When driving with the cruise control, the system automatically change gear if the driving mode selector is set to A. It is however still possible to manually control gear selection in both positions A and M, without disengaging the cruise control.

If the driving mode selector is set to N when the vehicle is being driven with the cruise control activated, engine speed is increased to high idling (i.e. the engine surges). The driver should therefore disengage the cruise control before setting the driving mode selector to N.

The cruise control is disengaged using the clutch pedal, brake pedal, retarder lever, cruise control OFF button or the exhaust brake switch on the cab floor.

ABS/TC

The Opticruise control unit communicates with the ABS/TC system. If there is wheel lock (causing ABS control) or spin (causing TC control), the Opticruise is very reluctant to change gear and does so according to special criteria. When the driving mode selector is set to A, the Opticruise endeavours to maintain the engaged gear.

Power take-offs

The control unit is configured for two types of power take-off, PTO EK/ED and PTO EG.

PTO EK/ED provides torque compensation and therefore very smooth gear changing if the vehicle is driven with an enginedriven power take-off engaged (Max. compensation 200 Nm).

If the ED120 is used to drive a hydraulic pump, there may be a lack of space around the longitudinal stroke cylinder. If this is the case, turn the longitudinal stroke cylinder the other way and move the compressed air couplings so that they swap places.

PTO EG is for gearbox-driven power take-offs. If the vehicle is driven with this input signal active, all gear changing is blocked. The text PTO also flashes on the display if the vehicle is driven above a certain speed.

10 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

Miscellaneous

Control unit configuration

The control unit contains all programming necessary for a number of different Scania versions. So that the control unit fits each Scania, it must first be configured so that it uses the correct program for the particular vehicle. This is equivalent to the code plug in other (less modern) control units, such as for CAG.

The required configuration is fed into the control unit at manufacture using a PC. Configuration may be changed later by qualified personnel.

Configuration must contain the following information:

•Vehicle category (e.g. truck)

•Chassis number

•Part No. for control unit software

•Gearbox type

•Engine type and version

•Rear axle ratio

•Wheel rolling radius

•End-of-line data (date, signature)

Power supply and fuses

Generally, Opticruise continues to work if a fuse blows while the vehicle is being driven. It may, however, be impossible to start the system the next time.

The control unit is protected by two fuses:

•Fuse 41 is used for 30 supply.

•Fuse 5 is used for 15 supply.

Power to the control unit is usually interrupted using the starter switch. What happens then is that control unit 15 supply to pin 55 is broken. When this happens, important data is transferred from the RAM to the EEPROM and stored there until the next start. The control unit then goes into rest state, despite the fact that 30 supply from the batteries is still applied to pin 19.

•If fuse 41 for 30 supply blows, or if a battery cable is removed, data cannot be transferred from the RAM to the EEPROM and be stored. The control unit ”forgets” any newly-programmed starting gear as well as new fault codes.

•If fuse 5 for the 15 supply blows, data is transferred as normal from RAM to EEPROM and stored there. In this situation, the control unit believes that the starter key has been set to position 0. This means that it is not possible to restart Opticruise until the fault has been corrected.

05:05-02 en |

© Scania CV AB 1995 |

11 |

|

https://www.truck-manuals.net/ |

|

Description of operation

Interaction with other systems

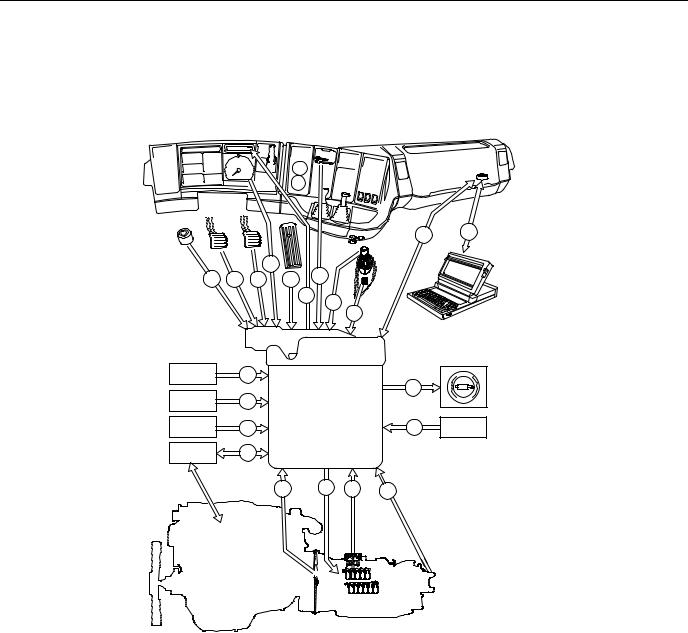

The figure opposite shows which other systems are connected to Opticruise and in which directions data is transferred.

Any faults are transmitted in the same direction. This means that a fault in the ABS/TC system can manifest itself in the Opticruise system, but not vice versa.

Where appropriate, the figure applies to all optional equipment affected.

• The Opticruise is coupled to the EDC system to enable synchronous control of the speed of the gearbox input and output shafts. The particular gear change does not take place until these speeds correspond with each other.

The communication between the Opticruise and the EDC covers a wide range of data, such as engine speed, requested and actual torque, throttle pedal position, coolant temperature and cruise control.

Communication is via two CAN leads and is for such things as executing engine-control- led gear changing and determining which gear should be selected at any particular time.

• The Opticruise is coupled to the ABS/TC system to receive information on ABS control, TC control, wheel speeds etc.

The communication between Opticruise and ABS/TC is used for confirming such things as the suitability of the gear selection. If the wheels are spinning or slipping, Opticruise would be “fooled” into selecting the wrong gear. The speed of each wheel is also used to check that other speed signals appear plausible.

Communication is via the two CAN leads.

• Opticruise is coupled to the auxiliary brake system to make it possible to engage the engine brake program to optimize the retarder and achieve maximum braking power in kW.

When the auxiliary brake has requested the exhaust brake to retard the vehicle, the Opticruise will still be able to control the exhaust brake for gear changing.

When the gear change is complete, the exhaust brake will again be used to retard the vehicle. Prioritization of the various tasks of the exhaust brake is controlled by the exhaust brake control unit (EEB).

If the vehicle has an auxiliary brake, the Opticruise forwards the speed signal from the speed sensor on the gearbox output shaft to the auxiliary brake control unit.

• Opticruise is connected to the tachograph so that it can use the speed information from this to check that other speed signals are reasonable.

12 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

Opticruise

Exhaust brake

EDC

ABS/TC

Auxiliary brake system with Scania retarder

Tachograph

Signal paths between the Opticruise control unit and other computer-controlled systems that may be in the vehicle.

Any faults are transferred from one system to another in the same direction as communication (see arrows).

05:05-02 en |

© Scania CV AB 1995 |

13 |

|

https://www.truck-manuals.net/ |

|

Description of operation

Opticruise, design

Item numbers refer to the drawing opposite.

1The floor switch is used to activate the engine brake program and exhaust brake. In vehicles with no auxiliary brake, the exhaust brake is used in combination with the engine brake program when the floor switch is held down. The signal goes via the auxiliary brake control unit if the vehicle has this. Also see point 14.

2Two switches provide data on the position of the clutch pedal (released, partly or fully depressed).

3EDC informs the control unit that the driver is braking. The engine brake program then uses slightly shifted upshift points.

4The tachograph provides a speed signal which Opticruise compares with the other speed signals. These come from ABS/TC and the gearbox output shaft.

5The throttle pedal sensor provides data on requested throttle and kick-down. The potentiometer signal goes via the EDC control unit.

6The gear indicator with display and buzzer is used to display driving program, which gear is engaged, fault messages etc.

8The driving mode selector informs the control unit about requested driving mode and if the driver wants to actuate the automatic system by commanding a change up or down.

9The program selector has two positions. The Normal position provides optimum fuel economy and the box changes gear calmly and comfortably. The Hill mode provides a faster gear changing cycle at higher engine speed.

10Diagnostic socket for PC via interface (Scania VCI).

11PC with Scania Diagnos 2 fault tracing program provides the fastest result when fault tracing.

12The diagnostic switch is used to activate the test program built into the control unit and for erasing fault codes.

13Opticruise receives information from ABS/TC on speed, slip and possible wheel spin in order to select the correct gear at any moment. In addition, Opticruise must be able to prevent gear change if the drive wheels lose grip. This is for safety.

14Opticruise uses the exhaust brake to adapt engine speed during certain gear changing procedures, but the exhaust brake is normally used to brake the vehicle.

The exhaust brake control unit prioritizes requests depending on driving conditions. The exhaust brake can be activated automatically, manually or by the auxiliary brake control unit.

15The engine speed sensor is used to be able to synchronize the speeds of the gearbox input and output shafts when changing gear. The signal goes via the EDC and through the communications circuit.

16The solenoid valves on the gearbox carry out each gear change by releasing compressed air to the longitudinal and lateral stroke cylinders. In turn, the cylinders activate the gear selector shaft.

17The hall effect sensor and the confirmation switches monitor and confirm gear changing movement.

14 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

The drawing below is general and applies to all optional equipment affected. Only relevant sections apply to vehicles with less equipment.

10 11

4

1 2 3 5 12

6 8

9

PTO EK/ED

21

14

PTO EG |

22 |

|

OPTI− |

|

|

|

RETARDER |

20 |

CRUISE |

13 |

ABS/TC |

||

|

|

|

|

|

||

EDC |

19 |

|

|

|

|

|

|

|

15 |

16 |

17 |

18 |

|

<![endif]>100862

18The speed sensor on the gearbox output shaft is used to calculate vehicle speed and to confirm other speed signals from ABS/TC and the tachograph. A corresponding output signal is relayed to the auxiliary brake control unit.

19Control of engine torque and speed is requested by Opticruise but carried out by EDC. Just when Opticruise is controlling the engine, the control unit continuously checks that actual torque corresponds to the requested level.

20The auxiliary brake system control unit can request Opticruise to activate the engine brake program.

21PTO EK/ED provides torque compensation during engine-controlled gear changing and therefore an excellent level of comfort if the vehicle is driven with an engine-driven power take-off engaged.

22PTO EG is for gearbox-driven power takeoffs. When this input signal is active, all gear changing is blocked and the clutch cannot be used.

05:05-02 en |

© Scania CV AB 1995 |

15 |

|

https://www.truck-manuals.net/ |

|

Description of operation

CLU MODE

C

NORMAL

FAILURE

CHK CODE

ERROR1

ERROR2

CONFIG

Warning system

The control unit takes various action in the case of faults. This is to prevent the fault having expensive consequences. For example, the control unit has two different emergency gear changing programs. The first of these still provides good drivability while the second requires more from the driver. The intention of this is that minor faults should not cause too much inconvenience.

Certain types of less-serious fault cause the control unit to switch from normal operation to the simpler of the two emergency gear changing programs. The text ”CLU MODE” (clutch mode) is shown on the gear indicator display. In this case, the driver is required to use the clutch for each gear change. While the control unit is working in this mode, the letter C will be displayed near the left of the display.

If the fault disappears on its own, the control unit immediately returns to normal operation. The display then shows ”NORMAL”.

In the case of more serious faults, ”FAILURE” is displayed. If this happens when driving, the control unit locks the engaged gear. This gear alone is shown on the display. The driver must then stop the vehicle and activate the ”LIMPHOME” emergency gear changing program. This process is described in detail in the Opticruise driver’s manual.

Fault code messages

When the driver switches off the power, the message ”CHK CODE” is displayed if the control unit has stored any fault codes during driving. This message is repeated when the power is switched back on again.

”ERROR1” or ”ERROR2” means that the control unit has supplied faulty signals or no signals to the display. A PC must be used to read any fault codes.

”CONFIG” means that the configuration of the control unit is not correct. In this case, change the configuration of the control unit using a PC and Scania Programmer.

16 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Description of operation

TESTING

ECU NO

PROG NO

CHASSNO

F CODES

E010 003

A B

Reading fault codes

Fault codes are read in the first part of the Opticruise test program. This test program is described in full on pages 59 - 69 of this booklet.

However, describing how to read fault codes would be a suitable introduction to the list of fault codes in the next chapter and the method is therefore also shown here.

1Stop the vehicle and switch off the engine.

2Switch on the power using the starter key. Wait for five seconds and then hold the diagnostic switch depressed for at least a half second. Release it. ”TESTING” is shown on the display and the buzzer sounds.

Do not touch the diagnostic switch for the moment. The test program has now started. All parts of the display light for one second and the buzzer sounds.

3”ECU NO” is displayed, directly followed by the part number of the control unit hardware.

4”PROG NO” is displayed, directly followed by the part number of the control unit software.

5”CHASSNO” is displayed, directly followed by the vehicle chassis number.

6”F CODES” is displayed, directly followed by any fault codes stored. More on this below.

•The fault codes are displayed one at a time, with two seconds between them.

•When all stored fault codes have been displayed, the buzzer sounds briefly. The stored fault codes are then displayed again. This may be repeated any number of times, so there is no danger if you should lose concentration.

The display can, for example, look like the figure to the left. A shows the number of the fault code (10 in this case) and B shows how many times this fault code has been registered (3).

7Make a note of the fault codes. Run through the test program. Press the diagnostic switch to switch between the various stages of the test. See pages 59 - 69.

05:05-02 en |

© Scania CV AB 1995 |

17 |

|

https://www.truck-manuals.net/ |

|

Description of operation

Erasing fault codes

It may be necessary to reset the warning system every now and then. Someone may, for example, have unplugged a cable while the power was switched on. This can easily happen and the control unit will then believe that a genuine fault has arisen.

The warning system is either reset using the diagnostic switch, concealed behind the cover on the instrument panel, or using a PC connected to the vehicle’s diagnostic socket in the central electric unit.

Fault codes are extremely useful in the workshop as they facilitate fault diagnosis.

• In the driver’s manual, there is an explanation of how to erase fault codes. However, it is also advised that they should not be erased unnecessarily and that it is preferable, if possible, to seek advice at a workshop.

The symbols for the various switches are on the inside of the lid. These can be seen when the lid is opened. The Opticruise symbol is shown to the right.

When the warning system is reset, all fault |

ERASED! |

codes are erased. Proceed as follows: |

1Switch off the power using the starter key.

2Press the diagnostic switch and hold it down. Switch on the power.

3The buzzer gives a short signal. When the text ”ERASED” is displayed, erasure is complete.

<![endif]>05_5161

18 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault codes

General

The control unit acts fast and accurately, according to certain instructions. It has no imagination and no judgement. When it discovers a fault, or anything it interprets as abnormal, it reacts immediately and generates fault codes. The warning system is capable of generating around 70 different fault codes.

Despite the advanced and ”farsighted” software, a fault can arise which the control unit is unable to distinguish from something which might happen during normal operation. If this is the case, no fault code is generated. There is always a limit to how complete monitoring can be. This applies to all types of control unit.

Limitations

It is not only ”genuine” faults that lead to the generation of fault codes. It is sufficient that someone has unplugged a cable while the power was on. This can easily happen and the control unit will then believe that a fault has arisen.

As for cases of loose contact, the fault may no longer be present, but the fault code is stored in the control unit memory until it is erased. It is at least possible then to see which circuit the fault was in and look for the cause there, even if there is currently no fault.

Faults that do not generate fault codes

The following are the faults which do not cause a fault code to be generated that we are aware of at the time of going to press.

•Fuse 5 blown (15 supply).

•Break in the diagnostics switch circuit.

•Break in the floor switch circuit.

•Break or continuous signal from program selector (Normal/Hill).

•Break in circuit to the exhaust brake control unit. Fault code 14 is generated in some, but not all, cases.

•Break to gear indicator.

•Broken lamp in gear indicator.

05:05-02 en |

© Scania CV AB 1995 |

19 |

|

https://www.truck-manuals.net/ |

|

Fault codes

Explanations

Several new terms are used in the fault code list or in the connection diagram in group 16. These terms are explained below.

EEPROM: Stands for electrically erasable programmable read only memory. Memory is retained, even if power is broken using the starter key. The contents can be erased and updated during service, using a PC and Scania Programmer.

This memory contains the control unit configuration, programmed starting gear, any fault codes etc.

FLASH memory: This memory contains the complete basic programming of the control unit. The content remains, even if power is switched off using the starter key. The basic program can be changed during service using a PC connected to the diagnostic socket.

RAM: Stands for random access memory. The content disappears every time the power is switched off using the starter key or if power is lost for any other reason.

This memory stores and processes the various control unit driving data from such things as sensors, controls and adjacent systems (EDC, ABS and the retarder).

CAN: Stands for controller area network. CAN communication is used to reduce the number of cables in the vehicle. This is intended to increase reliability.

Vehicles with Opticruise have a communications circuit consisting of two cables, CAN high (pin 38) and CAN low (pin 20).

In simple terms, CAN communication can be likened to radio technology. Data signals through a CAN cable can be likened to radio waves through the air.

When listening to the radio, the receiver is set so that one radio station is heard at one time. This is the only station that can be heard, despite the fact that there are many radio stations broadcasting at the same time.

A control unit does more or less the same thing with the data coming through a CAN cable. It listens for things such as information from EDC on coolant temperature, receives this value and uses it in calculations.

The control unit receives all CAN signals that are sent through the communications circuit in a special memory. This memory can be likened to a number of radio receivers, set to different radio stations in order to hear several, particular radio programmes at the same time. In this way, the control unit always knows what is happening.

This is nothing that a mechanic needs to worry about. The only thing to remember is that it is not possible to check CAN signals using a multimeter. This is not even necessary as we have precise fault codes.

20 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault code 1

Fault code 2

Fault code 3

Fault: Fault in integrated control unit memory.

Cause: Test calculation of content of FLASH memory did not provide the result the control unit was expecting.

Comment: FLASH memory itself contains basic control unit program. The control unit checks that the FLASH memory is working as follows. All memory addresses are added together to provide a sum. This sum is then used in a test calculation which must provide the ”correct answer”. Otherwise, this fault code is generated.

Action: Change control unit.

Fault: Fault in integrated control unit memory.

Cause: Test calculation of content of EEPROM memory did not provide the result expected by the control unit.

Comment: EEPROM memory contains the configuration of the control unit. Configuration controls which parts of the basic program are used for the particular vehicle. When the control unit checks that the EEPROM memory is working, the following happens. All values that are important for configuration are added up to a sum. This sum is then used in a test calculation which must provide the ”correct answer”. Otherwise, this fault code is generated.

Action: Correctly configure the control unit using a PC. If this does not help, change the control unit.

Fault: Fault in integrated control unit memory.

Cause: The control unit’s test of the RAM has shown that some of the memory cells are not working properly.

Comment: The RAM is the actual working memory of the control unit. It is here that all calculations are made.

When the control unit checks that the RAM is working properly, the following happens. Firstly, the control unit writes certain values into the RAM and then reads these same values to check that they have not become confused . If the control unit interprets any deviation, this fault code is generated.

Action: Change control unit.

05:05-02 en |

© Scania CV AB 1995 |

21 |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault: Break or short in circuit for UX supply.

Fault code 4

Cause: Control unit has detected that power consumption from pin 36 on the control unit (the so-called UX feed, +24V) is either too low or too high.

Comment: The control unit gives UX supply on pin 36 to supply the sensors, controls and display with power. The UX supply enables the control unit to sense both open and short circuits as they cause abnormal power consumption. It is this abnormal power consumption from pin 36 which causes fault code 4 to be generated.

Open circuit: The circuit consumes no current. Short circuit:

The circuit consumes high current.

In order for the fault code to be regenerated, power consumption must suddenly change, due to something such as loose contact. If the fault remains, the fault code is regenerated each time the control unit attempts to activate the UX supply.

High current in the UX circuit can be caused by such things as shorted sensors.

Action: Check the UX circuit, wiring and components.

Fault: Fault in voltage supply in control unit.

Fault code 5

Cause: Control unit could not confirm its own internal U15 supply when the driver switched on the power using the starter key.

Comment: The control unit started working when the power was switched on, despite it not being possible to confirm U15 supply in the test circuit monitoring this.

When this fault arises, it is not possible for the EEPROM to store new information. This means that the control unit ”forgets” any newly-programmed starting gear, and any newlygenerated fault codes. The number of faults is displayed as 1, even if there are several. It is possible to drive the vehicle, but it should be repaired as soon as possible as certain safety features may be jeopardized.

Action: Change control unit.

22 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault code 7

Fault code 14

Fault code 15

Fault: Fault in monitoring feature inside control unit.

Cause: The integrated watchdog relay does not activate when the control unit starts working, or this relay is already activated when the driver switches on the starter power (this should not be the case).

Comment: The control unit has detected a malfunction in one of its internal safety features. Each malfunction of this type causes the watchdog relay to alarm, generating fault code 7.

If the watchdog relay does not activate, power supply is lost to all control unit outputs. Not even the starter gear can be engaged, making the vehicle unusable.

Action: Change control unit.

Fault: Not possible to regulate engine speed to correct level when changing gear.

Cause: The control unit has received a message from the EDC via the communications circuit (pins 20 and 38) which indicated an incorrect response from the engine. The exhaust brake may have been activated during gear changing without the Opticruise requesting this.

Comment: Requested torque exceeds permitted value for engine-controlled gear changing when the gearbox has been confirmed to be in neutral. This can happen if a gear is engaged when the control unit is not expecting it. A possible cause of this might be the slider in the gearbox breaking. If this fault arises, the driver must use the clutch for every gear change. CLU_MODE is displayed.

Action: Start by checking the sensor signals for gear position and then the gearbox itself.

Fault: EDC gives a torque which does not correspond to the requested torque.

Cause: When the Opticruise control unit requested a particular torque via the communications circuit (pins 20 and 38), EDC responded with a response which Opticruise considered to indicate impossible values.

Continued >

05:05-02 en |

© Scania CV AB 1995 |

23 |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault code 19

Comment: Requested torque from Opticruise is ”translated” in this manner to actual control rack position in the injection pump. The Opticruise control unit continuously checks that each response of this type from EDC corresponds with the expected result. If this fault arises, the driver has to use the clutch whenever changing gear. CLU_MODE is displayed.

Action: Check whether the EDC control unit has generated any fault codes. Check that the EDC control unit has the correct part number. Check connectors and wiring. End by checking the position of the control rack in the injection pump.

Fault: NO signal or impossible signal from driving mode selector.

Cause: The control unit has received a signal on at least two of pins 10, 11, 28, 29, 47 and 48 at the same time, or there is no signal at all from the driving mode selector. These signals are provided with UX voltage (+24V).

Comment: These signals are impossible as the driving mode selector can only be in one position at a time.

If this fault arises, the control unit does not ”obey” the driving mode selector. Either there is no signal at all, or the control unit has received conflicting signals in one of the following combinations:

Upshift and downshift at the same time (pins 10 and 28).

Reverse and automatic position at the same time (pins 48 and 29).

Reverse and manual position at the same time (pins 48 and 47).

Neutral and manual position at the same time (pins 11 and 47).

Continued >

24 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault code 22

Fault code 23

Action: Check the driving mode selector, connectors and wiring. Use wiring diagrams and a multimeter to check the driving mode selector.

Fault: Impossible signals from clutch switches.

Cause: Control unit has sensed that pin 8 received a signal when there was no signal on pin 45.

Comment: The lower clutch pedal switch has been closed despite the upper clutch pedal switch not being closed. It should not be possible for something like this to happen when driving.

When these switches are activated, they are closed to system earth (0V).

The gearbox cannot change gear automatically if this fault has arisen. The vehicle can, however, be operated using the LIMPHOME emergency gear changing program.

Action: Check both clutch pedal switches, connectors and wiring.

Fault: Uninterrupted signal from the lower clutch pedal switch.

Cause: Control unit has sensed that there was a signal for too long on pin 8.

Comment: The clutch pedal switch cannot be closed for this long when driving normally.

When this switch is activated, it is closed to system earth (0V).

The gearbox cannot change gear automatically if this fault has arisen. The vehicle can, however, be operated using the LIMPHOME emergency gear changing program.

Action: Check the lower clutch pedal switch, connectors and wiring.

05:05-02 en |

© Scania CV AB 1995 |

25 |

|

https://www.truck-manuals.net/ |

|

Fault codes

Fault code 24

Fault code 26

Fault: Uninterrupted signal from upper clutch pedal switch.

Cause: Control unit has sensed that the signal remained for too long on pin 45.

Comment: The clutch pedal switch cannot be closed for this long when driving normally, unless the driver rests his foot on the clutch pedal when driving.

When this switch is activated, it is closed to system earth (0V).

The gearbox cannot carry out engine-controlled gear changing in manual position if this fault arises.

Action: Check the upper clutch pedal switch, connectors and wiring.

Fault: Uninterrupted signal from floor switch for engine brake program.

Cause: Control unit has sensed that the signal remained for too long on pin 27.

Comment: The floor switch cannot be closed for this long during normal driving.

When this switch is activated, it is closed to +24V. Note that the signal to pin 27 does not always come from the floor switch. The retarder control unit can also send the same signal.

If this fault arises, the control unit is forced to use the engine brake program.

Action: Check the floor switch, connectors and wiring. Check if there are any fault codes stored in the retarder control unit (if the vehicle has a retarder).

26 |

© Scania CV AB 1995 |

05:05-02 en |

|

https://www.truck-manuals.net/ |

|

Loading...

Loading...