Scania DI13 Operator's Manual

Important information Serious risk of injury

When working on the engine, for example when adjusting drive belts and the clutch, or when changing the oil, it is important not to start the engine. The engine could be damaged, but more importantly there is a serious risk of injury.

For this reason, always secure the starting device or disconnect a battery cable before working on the engine. This is especially important if the engine has a remote starter or automatic starting.

WARNING!

WARNING!

This warning symbol and text can be found next to those maintenance items where it is particularly important to bear in mind the risk of injury.

Operator's manual DI13

PDE Marine engine

en-GB 2 453 210

Issue 4.0

Start-up Report – Warranty

The warranty starts when the start-up report has been filled in and sent to Scania. The normal warranty period is 1 year, but other conditions can apply.

Fill in the particulars from the start-up report below as well. This can make things easier if you need to contact a workshop, for example.

Engine serial number

Date of entry into service

User's name and address

Signature

Engine type

Variant

Engine type and variant are indicated on the engine data plate.

Downloaded from www.Manualslib.com manuals search engine

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Power classes . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Environment and safety . . . . . . . . . . . . . . . . . . 5

Environmental responsibility . . . . . . . . . . . . . 5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Warnings and advisories . . . . . . . . . . . . . . . . . 6 Certification . . . . . . . . . . . . . . . . . . . . . . . . . 12

Engine data plate . . . . . . . . . . . . . . . . . . . . . . . 13 Component identification . . . . . . . . . . . . . . . . 14 Starting and running . . . . . . . . . . . . . . . . . . . . 15

Checks before first start . . . . . . . . . . . . . . . . 15 Checks before running . . . . . . . . . . . . . . . . . 15 Starting the engine . . . . . . . . . . . . . . . . . . . . 15 Running. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Engine shutdown. . . . . . . . . . . . . . . . . . . . . . 18 Checks after running . . . . . . . . . . . . . . . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance intervals . . . . . . . . . . . . . . . . . . 20

Lubrication system . . . . . . . . . . . . . . . . . . . . . 21

Oil grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Oil analysis . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Checking oil level . . . . . . . . . . . . . . . . . . . . . 22 Changing the oil . . . . . . . . . . . . . . . . . . . . . . 23 Oil grade labels . . . . . . . . . . . . . . . . . . . . . . . 24 Cleaning the centrifugal oil cleaner . . . . . . . 25 Operational testing . . . . . . . . . . . . . . . . . . . . 29 Renewing the oil filter. . . . . . . . . . . . . . . . . . 30 Renewing the double, commutative oil filter 30

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . 32

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Checking coolant level . . . . . . . . . . . . . . . . . 35 Checking coolant antifreeze and corrosion protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Checking sacrificial anodes . . . . . . . . . . . . . 37 Checking the sea water pump impeller . . . . . 37 Changing the coolant and cleaning the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Reading the air cleaner vacuum indicator. . . 48 Renewing the air cleaner filter element . . . . 48 Renewing the air cleaner safety cartridge . . . 49 Renewing an air filter with a non-renewable element. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Checking fuel level . . . . . . . . . . . . . . . . . . . . 50 Renewing the fuel filter. . . . . . . . . . . . . . . . . 51 Renewing and bleeding double, commutative fuel filters . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Renewing the water separating fuel filter . . . 53 Bleeding the fuel system using a hand pump 54 Bleeding the fuel system using a suction tool55

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Checking the drive belt . . . . . . . . . . . . . . . . . 56

Checking for leaks . . . . . . . . . . . . . . . . . . . . .57 Checking and adjusting the valve clearance .58

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Composition of the fuel . . . . . . . . . . . . . . . . .64 Sulphur content of fuel. . . . . . . . . . . . . . . . . .64 Using DMX and DMA fuels in marine engines. 64

Temperature dependency of the fuel . . . . . . .65 Biodiesel (FAME) . . . . . . . . . . . . . . . . . . . . .65

Preparing the engine for storage . . . . . . . . . . .66

Handling the engine . . . . . . . . . . . . . . . . . . . .66 Preservative coolant . . . . . . . . . . . . . . . . . . . .66 Preservative fuel. . . . . . . . . . . . . . . . . . . . . . .66 Preservative oil. . . . . . . . . . . . . . . . . . . . . . . .66 Preparations for storage . . . . . . . . . . . . . . . . .67

EC declaration of conformity . . . . . . . . . . . . .69 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . .70

General data . . . . . . . . . . . . . . . . . . . . . . . . . .70 Lubrication system . . . . . . . . . . . . . . . . . . . . .71 Injection system . . . . . . . . . . . . . . . . . . . . . . .71 Cooling system. . . . . . . . . . . . . . . . . . . . . . . .72 Intake system . . . . . . . . . . . . . . . . . . . . . . . . .72 Electrical system . . . . . . . . . . . . . . . . . . . . . .72 Material content . . . . . . . . . . . . . . . . . . . . . . .73

Scania Assistance . . . . . . . . . . . . . . . . . . . . . . .74

OPM 250 en-GB |

2 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Introduction

Introduction

This Operator's manual describes the operation and maintenance of Scania marine engines.

The engines are direct-injection, liquid-cooled, four-stroke turbocharged diesel engines.

The engines are available with different output and speed settings. The engine power of the engine ordered is indicated on the engine data plate.

Note:

Only standard components are described in the operator's manual. Information about special equipment is contained in instructions from the various manufacturers.

To ensure the maximum performance and the longest service life for the engine remember the following:

•Read through the Operator's Manual before starting to use the engine. Even regular users of Scania engines will get new information from the Operator's manual.

•Always follow the maintenance instructions.

•Read the section on safety carefully.

•Get to know your engine so that you know what it can do and how it works.

•Always contact an authorised Scania workshop for maintenance and repairs.

The information in this Operator's manual was correct at the time of going to press. Scania reserves the right to make alterations without prior notice.

Note:

Always use Scania spare parts for maintenance and repair.

OPM 250 en-GB |

3 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Power classes

Power classes

Scania supplies engines in 4 different power classes:

ICFN – continuous operation: Intended for unlimited number of operational hours per year at a total load factor of 100%.

IFN – periodic operation: Intended for periodic operation, where full power is available 1 h/3 h. The accumulated load factor must not exceed 80% of the calculated load. Unlimited number of hours per year.

Patrol Craft Long: Intended for periodic operation, where full power is available 1 h/6 h. In between periods of operation at full load, the engine speed must be reduced by at least 10% of the maximum engine speed attained. The maximum accumulated operating time must be 2,000 hours per year.

Patrol Craft Short: Intended for periodic operation where the calculated power is available 1h/12h. In between periods of operation at full load, the engine speed must be reduced by at least 10% of the maximum engine speed attained. The maximum accumulated operating time must be 1,200 hours per year.

The engine serial numbers and power classes for the engines that are used in this installation should be listed below:

Engine serial number:

Engine type:

Engine power: |

|

kW at |

|

rpm |

Indicate below the type of operation, and enter it on page 1.

ICFN – continuous operation

IFN – periodic operation

Patrol Craft Long

Patrol Craft Short

OPM 250 en-GB |

4 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Environment and safety

Environmental responsibility

Scania develops and produces engines that are as environmentally-friendly as possible. Scania has made major investments in the reduction of harmful exhaust emissions in order to fulfil the environmental requirements in force in almost every market.

At the same time, we have been able to maintain a high level of performance and operating economy for Scania marine engines. To maintain these throughout the entire service life of the engine, it is important for the user to follow the instructions on running, maintenance and fuel and lubricating oil as outlined in the Operator's manual.

Other green initiatives taken include ensuring that, following maintenance and repair, waste that is harmful to the environment (for example oil, fuel, coolant, filters and batteries) is disposed of accordance with the applicable environmental requirements.

Different types of advisory

Warning!

All advisories preceded by Warning! are very important. They warn of serious faults and incorrect operation that could lead to personal injury. Example:

WARNING!

WARNING!

Block the starting device when working on the engine. If the engine starts unexpectedly, there is a serious risk of injury.

Important!

Advisories preceded by Important! warn of faults and incorrect operation that could lead to equipment being damaged. Example:

IMPORTANT!

IMPORTANT!

An excessively high coolant temperature can damage the engine.

Safety

The following pages contain a summary of the safety precautions to be complied with when operating and maintaining Scania engines. The equivalent text can also be found under the relevant maintenance item.

To prevent damage to the engine and to ensure that it runs optimally, follow the instructions in the warnings and advisories.

If the instructions are not followed, the warranty can cease to apply.

OPM 250 en-GB |

5 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Note:

Advisories preceded by Note: refer to information important to ensure the best possible operation and functionality. Example:

Note:

Leave the engine off for at least 1 minute before you check the oil level.

Environment

This Operator’s Manual contains specially highlighted text with instructions to help protect the environment during maintenance. Example:

Environment

Use a suitable container. Used fuel must be disposed of as specified in national and international laws and regulations.

Warnings and advisories

Safety precautions for running the engine

Daily maintenance

Always carry out a visual inspection of the engine and engine compartment before starting the engine or when the engine has been switched off after operation.

This inspection should be done to detect fuel, oil or coolant leaks, or anything else that may require corrective action.

Fuel

WARNING!

The wrong fuel grade can cause breakdowns or stoppages by causing the injection system to malfunction. This can cause damage to the engine and, possibly, personal injury.

IMPORTANT!

IMPORTANT!

Smoking

WARNING!

WARNING!

Smoking is prohibited

•in the vicinity of flammable or explosive material, e.g. fuel, oils, batteries, chemicals

•when refuelling and in the vicinity of the filling station

•when working on the fuel system

The operator is responsible for using the correct type of fuel to ensure that local laws and regulations are complied with.

For further information on fuel, see the section Composition of the fuel.

OPM 250 en-GB |

6 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Refuelling

WARNING!

WARNING!

During refuelling there is a risk of fire and explosion. The engine must be switched off and smoking is prohibited.

Never overfill the tank as the fuel needs space to expand. Make sure that the filler cap is fully closed.

Starter lock

IMPORTANT!

IMPORTANT!

If the instrument panel is not fitted with a starter lock, the engine compartment should be locked to prevent unauthorised personnel from starting the engine. Alternatively, a lockable master switch or battery master switch can be used.

Starter gas

Hazardous gases

WARNING!

WARNING!

Only start the engine in a well ventilated area. The exhaust gases contain carbon monoxide and nitrogen oxides, which are toxic.

If it is run in an enclosed space, there should be an effective device to extract exhaust gases and crankcase gases.

WARNING!

WARNING!

Never use starter gas or similar agents to help start the engine. This can cause an explosion in the intake manifold and possible injury.

OPM 250 en-GB |

7 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Running |

Batteries |

||||||||

|

|

|

|

WARNING! |

|

|

|

|

WARNING! |

|

|

|

|

|

|

|

|

|

|

The engine must not be run in environments where there is a risk of explosion, as all of the electrical or mechanical components can generate sparks.

Approaching a running engine always poses a safety risk. Parts of the body, clothes or dropped tools can get caught in rotating parts such as the fan and cause injury. For personal safety all rotating parts and hot surfaces must be fitted with guards.

Safety precautions for handling materials

Fuel and lubricating oil

WARNING!

WARNING!

All fuels and lubricants as well as many chemicals are flammable. Always follow the instructions on the relevant packaging.

The work must be carried out on a cold engine. Fuel leaks and spillage on hot surfaces can cause fire.

Store used rags and other flammable materials safely so as to avoid spontaneous combustion.

The batteries contain and form oxyhydrogen gas, particularly during charging. Oxyhydrogen gas is flammable and highly explosive.

There must be no smoking, naked flames or sparks near the batteries or the battery compartment. Incorrect connection of a battery cable or jump lead can cause a spark, which can cause the battery to explode.

Chemicals

WARNING!

WARNING!

Most chemicals such as glycol, anti-corrosive agents, preservative oils and degreasing agents, are hazardous to health.

Some chemicals, such as preservative oil, are also flammable.

Always follow the safety precautions on the relevant packaging.

Store chemicals and other materials which are hazardous to health in approved and clearly marked containers, where they are inaccessible to unauthorised persons.

Environment

Always hand in leftover and used chemicals to an authorised waste disposal contractor.

OPM 250 en-GB |

8 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Safety precautions for maintenance |

Lifting the engine |

||||||||

and repair |

|

|

|

|

WARNING! |

||||

Switch off the engine |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||

|

|

|

|

WARNING! |

Never work underneath a suspended engine! |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Working with a running engine always poses a safety risk. Parts of the body, clothes or dropped tools can get caught in rotating parts and cause injury.

Always switch off the engine before carrying out maintenance and repairs, unless otherwise indicated.

Always use the engine lifting eyes. Always check that lifting accessories are in good condition and are designed to lift the weight.

Optional equipment on the engine can change the centre of gravity. This means that it may be necessary to use additional lifting devices to balance the engine correctly and lift it safely.

Make it impossible to start the engine: Remove any starter key, or cut the power using the main power switch or battery master switch and lock them.

Fix a warning plate somewhere appropriate, showing that work is being carried out on the engine.

Hot surfaces and fluids

WARNING!

WARNING!

There is always a risk of sustaining burns when an engine is hot. Particularly hot parts are engine manifolds, turbochargers, oil sumps, hot coolant and oil in pipes and hoses.

Batteries

WARNING!

WARNING!

The batteries contain highly corrosive sulphuric acid. Take care to protect your eyes, skin and clothes when charging or handling batteries. Wear protective gloves and goggles.

If sulphuric acid comes in contact with the skin: Wash with soap and plenty of water. If it gets in your eyes: Rinse immediately with plenty of water and seek medical attention.

Environment

Always hand in used batteries to an authorised waste disposal contractor.

OPM 250 en-GB |

9 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Electrical system

IMPORTANT!

IMPORTANT!

Always use Scania spare parts for the fuel and electrical systems. Scania spare parts are designed to minimise the risk of fire and explosion.

The engine must be switched off and the power disconnected using the master switch or battery master switch before working on the electrical system. External power supplies to extra equipment on the engine must also be disconnected.

Electric welding

IMPORTANT!

IMPORTANT!

When carrying out welding work on and near the engine, disconnect the battery and alternator leads. Pull out the multi-pin connector for the engine control unit as well.

Connect the welding clamp close to the component to be welded. The welding clamp must not be connected to the engine, or so that the current can cross a bearing.

When welding is finished:

Lubrication system

WARNING!

WARNING!

Hot oil can cause burns and skin irritation. Wear protective gloves and goggles when changing hot oil.

Make sure that there is no pressure in the lubrication system before starting work on it.

The oil filler cap must always be in place when starting and running the engine to prevent oil being ejected.

Environment

Use a suitable container. Used oil must be disposed of as specified in national and international laws and regulations.

1.Connect the alternator and engine control unit cables first.

2.Then connect the batteries.

OPM 250 en-GB |

10 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Cooling system |

Fuel system |

||||||||

|

|

|

|

WARNING! |

|

|

|

|

WARNING! |

|

|

|

|

|

|

|

|

|

|

Never open the coolant filler cap when the engine is hot. Hot coolant and steam may spray out and cause burns.

If the cap has to be opened do it slowly and carefully to release the pressure before removing the cap. Wear gloves as the coolant is still very hot.

Environment

Use a suitable container. Used coolant must be disposed of as specified in national and international laws and regulations.

Maintenance and repairs of injection equipment are to be carried out by an authorised Scania workshop.

Always use Scania spare parts for the fuel and electrical systems. Scania spare parts are designed to minimise the risk of fire and explosion.

Environment

Use a suitable container. Used fuel must be disposed of as specified in national and international laws and regulations.

Before starting

WARNING!

WARNING!

Never start the engine without the air filter being in place. If you do, this could cause injury and severe engine damage.

Ensure that all guards are in place before starting the engine. Ensure that no tools or other objects have been left on the engine.

OPM 250 en-GB |

11 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Environment and safety

Certification

IMPORTANT!

IMPORTANT!

For Scania to guarantee that the engine corresponds to its certified configuration, and take responsibility for any damage and injuries that occur, maintenance must be carried out in accordance with the instructions in this Operator's manual.

An emissions certified engine fulfils the emissions requirements for a particular range of application.

On each emissions certified engine there is a label which shows which requirements the engine fulfils. Scania guarantees that each such engine fulfils the emissions requirements for the range of application for which it is certified.

The following are required for the certified engine to fulfil the emissions requirements once it has been taken into service:

•Maintenance is to be carried out in accordance with the instructions in this Operator's manual.

•Maintenance and repairs of injection equipment are to be carried out by an authorised Scania workshop.

•The engine may only be modified with equipment that has been approved by Scania.

•Seals may be broken and setting data edited only once approval has been granted by Scania. Modifications may be made by authorised personnel only.

•Modifications affecting the exhaust and intake systems must be approved by Scania.

Otherwise, the instructions in the Operator's manual for the running and maintenance of the engine shall apply. Follow the safety precautions on the previous pages.

OPM 250 en-GB |

12 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Engine data plate

Engine data plate

The engine data plate indicates, in the form of a code, the engine type, its size and applications. It also indicates the engine power and operating speed. The engine EU type approval for exhaust emissions is indicated under Output.

The engine serial number is stamped onto the top of the cylinder block at the front right.

Example: DI13 070M

DI |

Supercharged diesel engine with water-cooled charge air cooler. |

13 |

Displacement in whole dm3. |

070Performance and certification code. The code indicates, together with the application code, the normal gross engine output.

M Code for application. M means for marine use.

|

Made b y |

Type |

DI13 070M |

Engine No |

6950106 |

Output. 405 |

kW 1800 r pm. |

348 329

Example of an engine data plate

OPM 250 en-GB |

13 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

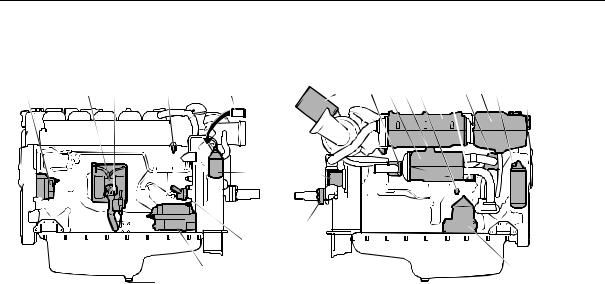

Component identification

1 |

2 |

3 |

4 |

|

5 |

6 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Component identification

1 2 1 3 1 4 1 5 1 6 1 7 1 2 1 8 1 9 2 0 2 1 2 2

7 |

25 |

|

8 |

24 |

|

|

|

|

9 |

23 |

190 |

10 |

|

343 |

The illustration shows a normal version of a DI13 engine with heat exchanger. The engine ordered may have different equipment.

1. |

Alternator |

14. |

Heat exchanger |

2. |

Oil filler cap |

15. |

Holes for draining condensation in charge air cooler |

3. |

Engine control unit |

16. |

Valve for draining coolant |

4. |

Oil dipstick |

17. |

Charge air cooler |

5. |

Fuel manifold bleed nipple |

18. |

Thermostat |

6. |

Engine data plate |

19. |

Expansion tank |

7. |

Fuel filter |

20. |

Oil filter |

8. |

Fuel pump with hand pump |

21. |

Filling coolant |

9. |

Starter motor |

22. |

Level glass for checking coolant level |

10. |

Oil plug |

23. |

Centrifugal oil cleaner |

11. |

Air filter |

24. |

Sea water intake |

12. |

Sacrificial anodes (2) |

25. |

Sea water pump |

13. |

Sea water outlet |

|

|

OPM 250 en-GB |

14 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

Starting and running

Starting and running

Checks before first start

Before the engine is started for the first time, carry out the maintenance items listed under First start in the maintenance schedule. The following must be checked:

•Oil level

•Coolant

•Fuel level

•Fluid level in batteries

•State of battery charge

•Condition of the drive belt

See also Maintenance intervals.

Checks before running

Carry out daily maintenance as described in the maintenance schedule prior to operation. See Maintenance intervals.

Starting the engine

WARNING!

WARNING!

Never use starter gas or similar agents to help start the engine. This can cause an explosion in the intake manifold and possible injury.

Only start the engine in a well ventilated area. When the engine is run in an enclosed space, there must be effective devices to extract exhaust gases and crankcase gases.

IMPORTANT!

IMPORTANT!

The starter motor must only be cranked twice for 30 seconds at a time. After that, it must rest for at least 5 minutes before the next attempt to start it.

For environmental reasons the Scania engine has been developed to be started with a low fuel feed. Using unnecessarily large amounts of fuel when starting the engine always results in emissions of unburnt fuel.

1.Open the fuel cock if fitted.

2.Disengage the engine.

3.If the engine has a battery master switch: Switch on the power by means of the battery master switch.

4.Start the engine.

If the fuel tank has been run dry or if the engine has not been used for a long time, bleed the fuel system. See section Bleeding the fuel system using a hand pumpor Bleeding the fuel system using a suction tool.

OPM 250 en-GB |

15 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Starting and running

Starting at low temperatures |

Limp home mode |

Take the local environmental requirements into account. Use a fuel heater and engine heater to avoid starting problems and white smoke.

Scania recommends that an engine heater should be used if the engine will be used at temperatures below -10°C.

A low engine speed and a moderate load on a cold engine limits white smoke, gives better combustion and warms up the engine more quickly than warming it up with no load.

Avoid running it longer than necessary at idling speed.

Running

Check instruments and warning lamps at regular intervals.

Engine speed range

The engine operating speed range is between low idling and the nominal engine speed. The nominal engine speed is indicated on the engine data plate. Low idling can be set between 500 and 1,050 rpm.

If there is a fault in the normal throttle opening or if CAN communication is interrupted, the following emergency operation option is provided:

A CAN fault or throttle opening fault in an allspeed engine (both signal and idling switch):

•The throttle opening value is 0% and the engine is running at normal idling speed.

•The throttle opening value is 0% and the engine is running at raised idling speed (750 rpm) if this function is activated.

Throttle opening fault, but the idling switch is working:

•The throttle opening value can be increased slowly between 0 and 50% by using the idling switch.

CAN fault:

•The engine is switched off if the shutdown function is activated.

Driving at high altitude

When driving at high altitudes engine power is reduced automatically due to the lower oxygen content in the air. It is then not possible to run the engine at maximum power.

•ICFN and PRP engines may be used at an altitude of up to 2,000 metres.

•IFN, Patrol Craft Long and Patrol Craft Short engines must not be used at an altitude of more than 1,000 metres.

•Contact Scania if the operating conditions deviate from these.

OPM 250 en-GB |

16 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Starting and running

Coolant temperature

IMPORTANT!

IMPORTANT!

An excessively high coolant temperature can damage the engine.

Normal coolant temperature during operation is approximately 94°C/200°F.

The alarm levels are set in the engine control unit. The default setting for the lowest and highest limit values for high coolant temperature are 95°C/203°F and 105°C/221°F respectively.

The high coolant temperature alarm has the following functions:

•Alarm only.

•Alarm and torque reduction at the lowest limit value.

•Alarm at the lowest limit value and engine shutdown at the highest limit value.

•Alarm, torque reduction at the lowest limit value and engine shutdown at the highest limit value.

•Alarm at the lowest limit value and engine shutdown at the highest limit value with the possibility of engine shutdown override control.

•Alarm, torque reduction at the lowest limit value and engine shutdown at the highest limit value, with the possibility of engine shutdown override control.

If run for extended periods under an extremely light load, the engine may have difficulty in maintaining the coolant temperature. At an increased load the coolant temperature rises to the normal value.

Oil pressure

Information about the normal oil pressure and lowest permitted oil pressure is contained in the Lubrication systemsection in the Technical Data chapter.

The engine management system has the following alarm levels:

•At an engine speed below 1,000 rpm and an oil pressure below 0.7 bar/10.2 psi.

•At an engine speed above 1,000 rpm and an oil pressure below 2.5 bar/36.3 psi for longer than 3 seconds.

The incorrect oil pressure alarm has the following functions:

•Alarm only.

•Alarm and torque reduction by 30%.

•Alarm and engine shutdown.

•Alarm and engine shutdown override control.

Note:

High oil pressure (above 6 bar/87 psi) is normal when starting a cold engine.

Charging indicator lamp

If the lamp comes on during operation:

•Check and adjust the drive belt according to the section Checking the drive belt.

If the charging indicator lamp is still on, this could be due to an alternator fault or a fault in the electrical system.

Belt transmission

When the belt transmission is new, it may make a squeaking noise when running. The noise is normal and disappears after 50-100 hours of operation. The noise does not affect the service life of the belt transmission.

OPM 250 en-GB |

17 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Starting and running

Engine shutdown

IMPORTANT!

IMPORTANT!

There is risk of post boiling and of damage to the turbocharger if the engine is switched off without cooling. The power must not be switched off before the engine has stopped.

Note:

The battery voltage must remain on for a few seconds after the 15 voltage is switched off so that the control units can store the values and switch to standby mode.

10 prohibited engine shutdowns will cause a torque reduction (70% of fuel quantity). Reset the engine by switching it off correctly once.

1.Run the engine without a load for a few minutes if it has been run continuously with a heavy load.

2.Switch off the engine.

Checks after running

WARNING!

WARNING!

Block the starting device when working on the engine. If the engine starts unexpectedly, there is a serious risk of injury.

There is always a risk of sustaining burns when an engine is hot. Particularly hot parts are turbochargers, oil sumps, hot coolant and oil in pipes and hoses.

IMPORTANT!

IMPORTANT!

Check the coolant level following the first start. Top up with coolant as necessary.

1.Check that the power supply has been cut.

2.Fill the fuel tank. Make sure that the filler cap and the area round the filler opening are clean to avoid contamination of the fuel.

3.If there is a risk of freezing, the cooling system must contain enough glycol. See the section Coolant resistance to cold.

4.If the temperature is below 0°C/32°F: Prepare for the next start by connecting the engine heater (if fitted).

OPM 250 en-GB |

18 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Maintenance

The maintenance programme covers a number of points that are divided into the following sections:

•Lubrication system

•Cooling system

•Air cleaner

•Fuel system

•Miscellaneous

WARNING!

WARNING!

Block the starting device when working on the engine. If the engine starts unexpectedly, there is a serious risk of injury.

There is always a risk of sustaining burns when an engine is hot. Particularly hot parts are turbochargers, oil sumps, hot coolant and oil in pipes and hoses.

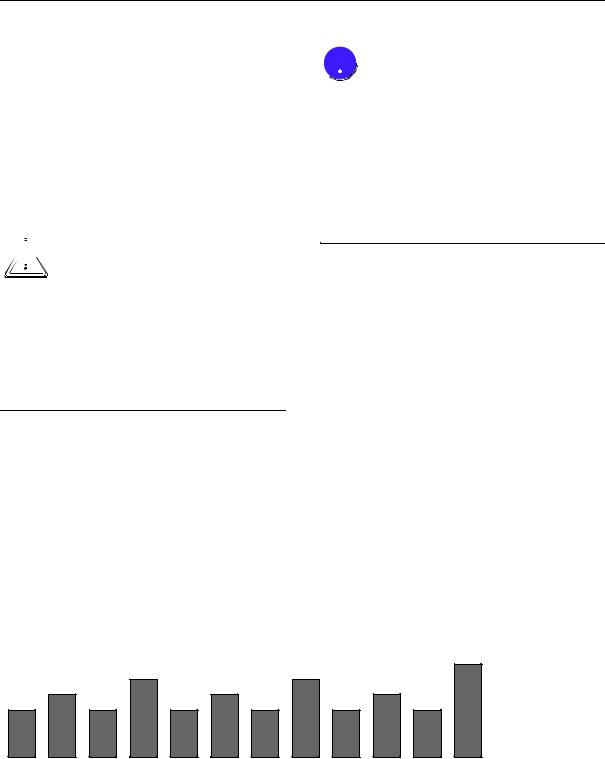

The maintenance programme includes the following:

•S maintenance: Minimum basic maintenance.

•M maintenance: More extensive maintenance.

•L maintenance: Includes nearly all maintenance items.

•XL maintenance: Includes all maintenance items.

IMPORTANT!

IMPORTANT!

On delivery a Scania engine is optimised for its application. However, regular maintenance is necessary to

•prevent unplanned stops

•extend the service life of the engine

•maximise the long-term emission performance of the engine

•give the best possible operating economy.

During a period, the sequence is S-M-S-L-S-M- |

|

|

|

|

|

||||||

S-L-S-M-S-XL. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

L |

|

|

|

XL |

|

M |

|

|

M |

|

|

M |

|

|

||

S |

S |

|

S |

S |

|

S |

S |

|

|||

|

|

|

|

|

|

||||||

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

5500 |

6000 |

|

|

|

|

|

|

|

|

|

|

|

313 153 |

OPM 250 en-GB |

19 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Maintenance intervals

|

Daily |

First time at |

|

Interval (hours) |

|

At least |

||||

|

|

first start |

500 |

500 |

|

1,000 |

2,000 |

6,000 |

annu- |

every |

|

|

|

|

|

|

|

|

|

ally |

5 |

|

|

|

R |

S |

|

M |

L |

XL |

||

|

|

|

|

|

|

|

|

|

|

years |

Lubrication system |

|

|

|

|

|

|

|

|

|

|

Checking oil level |

X |

X |

|

|

|

|

|

|

|

|

Changing the oil |

|

|

X |

X |

|

X |

X |

X |

X |

|

Cleaning the centrifugal oil |

|

|

X |

X |

|

X |

X |

X |

X |

|

cleaner |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Renewing the oil filter |

|

|

X |

X |

|

X |

X |

X |

X |

|

Cooling system |

|

|

|

|

|

|

|

|

|

|

Checking coolant level |

X |

X |

X |

X |

|

X |

X |

X |

|

|

Checking coolant antifreeze and |

|

X |

|

|

|

|

X |

X |

X |

|

corrosion protection |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Checking sacrificial anodes |

|

|

X |

X |

|

X |

X |

X |

X |

|

Checking the sea water pump |

|

|

|

X |

|

X |

X |

X |

X |

|

impeller |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Changing the coolant and clean- |

|

|

|

|

|

|

|

X |

|

X |

ing the cooling system |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Air cleaner |

|

|

|

|

|

|

|

|

|

|

Reading the air cleaner vacuum |

X |

|

X |

X |

|

X |

X |

X |

|

|

indicator |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Renewing the air cleaner filter |

|

|

|

|

|

|

X |

X |

|

X |

element |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Renewing the air cleaner safety |

|

|

|

|

|

|

X |

X |

|

X |

cartridge |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Renewing an air filter with a |

|

|

|

|

|

|

X |

X |

|

X |

non-renewable element |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Fuel system |

|

|

|

|

|

|

|

|

|

|

Checking fuel level |

X |

X |

|

|

|

|

|

|

|

|

Renewing the fuel filters |

|

|

|

|

|

X |

X |

X |

|

X |

Miscellaneous |

|

|

|

|

|

|

|

|

|

|

Checking the drive belt |

|

X |

|

|

|

X |

X |

X |

X |

|

Checking for leaks |

X |

|

|

X |

|

X |

X |

X |

|

|

Checking and adjusting the valve |

|

|

X |

|

|

|

X |

X |

|

|

clearance |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

OPM 250 en-GB |

20 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Lubrication system

Lubrication system

Oil grade

Scania LDF stands for the Scania Long Drain Field test standard. Scania LDF oils have been carefully selected after extensive testing. The approval is only granted to the highest quality engine oils available on the market.

Recommended oil

Scania Oil LDF-3

Scania Oil LDF-2

Scania Oil LDF

Scania Oil E7

The engine oil must fulfil the following quality requirements:

•ACEA E5/API CI-4.

•ACEA E7/API CI-4 +.

•For engines not run on low-sulphur fuel, the TBN (Total Base Number) should be at least 12 (ASTM D2896).

•Oils with a low ash content (ACEA E9/API CJ4) are not recommended.

Check with your oil supplier that the oil meets these requirements.

If the engine is used in areas of the world where lubricating oil with ACEA or API classification is not available, the oil grade must be measured in actual operation. In this case contact the nearest Scania workshop.

For operation at extremely low outdoor temperatures: Consult your nearest Scania representative on how to avoid starting difficulties.

Viscosity class |

Outdoor temperature |

||

SAE 20W-30 |

-15°C (5°F) |

- |

+30°C (86°F) |

SAE 30 |

-10°C (14°F) |

- |

+30°C (86°F) |

SAE 40 |

-5°C (23°F) |

- |

> +45°C (113°F) |

SAE 50 |

0°C (32°F) |

- |

> +45°C (113°F) |

SAE 5W-30 |

< -40°C (-40°F) |

- |

+30°C (86°F) |

SAE 10W-30 |

-25°C (-13°F) |

- |

+30°C (86°F) |

SAE 15W-40 |

-20°C (-4°F) |

- |

> +45°C (113°F) |

|

|

|

|

OPM 250 en-GB |

21 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Lubrication system

Oil analysis

To be able to extend the oil change intervals using an oil analysis, Scania LDF-2 and LDF-3 oils must be used. Oil companies can offer analysis of the engine oil.

The following conditions must remain fulfilled when the oil is changed:

•Viscosity at 100°C (212°F): max ±20% of original value of the fresh oil.

•TBN (in accordance with ASTM D4739): > 3.5.

•TBN (in accordance with ASTM D4739): > TAN (in accordance with ASTM D664).

•Soot (in accordance with DIN 51452): < 3%.

Such analysis measures the oil's TBN (Total Base Number), TAN (Total Acid Number), fuel dilution, water content, viscosity and the quantity of particles and soot in the oil. The result of a series of analyses is used as the basis for establishing a suitable oil change interval.

If the conditions are changed, a new oil analysis programme must be carried out to establish new oil change intervals.

Checking oil level

Checking the oil level with the engine switched off

Note:

Leave the engine off for at least 1 minute before you check the oil level.

1. Remove the oil dipstick (1) and check the oil

level. The correct level is between the mini- 2 mum and maximum marks on the oil dip-  stick.

stick.

2. Top up with more oil via the oil filler (2)

when the oil level is at or below the mini- 1 mum mark.

For information on the correct oil type, see the section Oil grade.

312 506

OPM 250 en-GB |

22 |

|

© Scania CV AB 2016, Sweden |

Downloaded from www.Manualslib.com manuals search engine

Lubrication system

Changing the oil

WARNING!

WARNING!

Hot oil can cause burns and skin irritation. Wear protective gloves and goggles when changing hot oil. Make sure that there is no pressure in the lubrication system before starting work on it. The oil filler cap must always be in place when starting and running the engine to prevent oil being ejected.

362 865

Max. 45 litres (11.9 US gallons).

Min. 39 litres (10.3 US gallons).

362 866

Note:

Renew the oil filter and clean the centrifugal oil cleaner when changing oil.

Change oil more often if the engine is subjected to particularly demanding operation, such as a dusty environment, or if deposits in the centrifugal oil cleaner are thicker than 28 mm (1.1 in).

Environment

Use a suitable container. Used oil must be disposed of as specified in national and international laws and regulations.

1.Unscrew the oil plug and drain the oil when the engine is hot. In certain engines the oil is pumped out by means of a bilge pump.

When draining with the valve, the oil should be hot. Alternatively, use a pump. This so that draining occurs more quickly.

2.Clean the magnet on the oil plug.

3.Refit the oil plug.

4.Top up with oil.

5.Check the level on the oil dipstick.

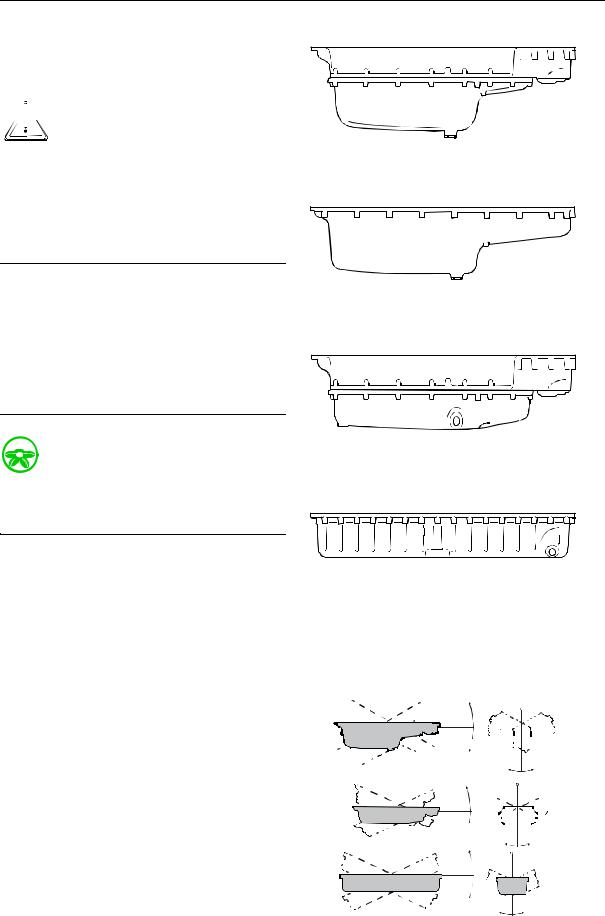

Maximum angles of inclination during operation

Maximum permissible angles during operation vary, depending on the type of oil sump. See illustration.

OPM 250 en-GB |

23 |

Max. 36 litres (9.5 US gallons).

Min. 30 litres (7.9 US gallons).

Max. 34 litres (9.0 US gallons).

Min. 28 litres (7.4 US gallons).

Max. 30 litres (7.9 US gallons).

Min. 25 litres (6.6 US gallons).

30°

30°

30°

30°

25°

25°

30°

30°

25°

25°

30°

30°

© Scania CV AB 2016, Sweden

362 867

362 868

30°

30°

30° |

842 |

|

343 |

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...