Scania DC16, DC13, DC09 Service Manual

INSTALLATION

MANUAL

Fuel system

Industrial engines

DC09, DC13, DC16

333 381

01:03 Issue 6.1 en-GB |

1 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION |

|

MANUAL |

|

Fuel tank................................................................................................................... |

3 |

Position................................................................................................................ |

4 |

Fuel tank design .................................................................................................. |

6 |

Main tank and buffer tank ................................................................................... |

8 |

Fuel pipes.................................................................................................................. |

9 |

Fuel filter ................................................................................................................ |

11 |

XPI engines ....................................................................................................... |

11 |

PDE engines ...................................................................................................... |

13 |

Fuel heater for XPI engines.................................................................................. |

14 |

Feed pump flow rates ............................................................................................ |

16 |

XPI engines ....................................................................................................... |

16 |

PDE engines ...................................................................................................... |

16 |

Flow and pressure ................................................................................................. |

17 |

XPI engines ....................................................................................................... |

17 |

PDE engines ...................................................................................................... |

17 |

Risk of fire.............................................................................................................. |

18 |

Fuel grade and power for PDE engines............................................................... |

19 |

01:03 Issue 6.1 en-GB |

2 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

Fuel tank

Fuel tank

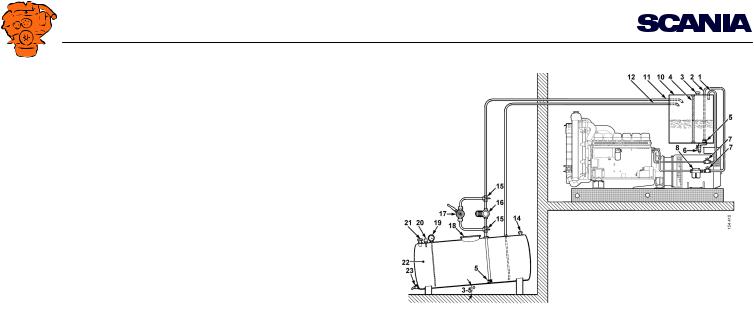

1.Return pipe. Note: For XPI engines, it should enter below the lowest fuel level

2.Suction pipe

3.Venting

4.Level indication and level sensor

5.Bottom strainer

6.Drain tap with water separator

7.Shut-off cocks

8.Additional water separating fuel filter. Note: Not for XPI engines

9.Flexible fuel hoses

10.Buffer tank

11.Supply line

12.Return pipe

13.Injection pump with feed pump

14. |

Ventilating valve |

Example of a fuel system for a stationary industrial engine |

|

15. |

3-way valves |

||

|

|||

16. |

Feed pump |

|

|

17. |

Hand pump |

|

|

18. |

Inspection hatch |

|

|

19. |

Fuel gauge |

|

|

20. |

Overfill protection |

|

|

21. |

Filler cap |

|

|

22. |

Main tank |

|

|

23. |

Drain tap |

|

01:03 Issue 6.1 en-GB |

3 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

Fuel tank

Position

PDE and XPI engines

If the fuel tank is placed higher than the engine feed pump, a shut-off cock should be installed in the fuel line to the feed pump. During stoppages, this cock should be closed.

REQUIREMENT!

REQUIREMENT!

The highest fuel level in the tank is 3 m in relation to the feed pump.

REQUIREMENT!

REQUIREMENT!

Maximum permitted suction height is 2 m for PDE engines and 1 m for XPI engines. The risk of air leaks in the suction pipe increases with increased vacuum. Suction height is calculated from the bottom of the tank.

If the fuel tank is mounted lower than the maximum permitted suction height, or if a large tank is required which cannot be mounted close to the engine, a buffer tank must be installed at a suitable distance and height.

On stand-by generator sets, it is recommended that the tank always be positioned above the level of the fuel manifold to prevent the engine's fuel system being drained in the event of leakage.

If the tank(s) are built in, the space should be well ventilated.

01:03 Issue 6.1 en-GB |

4 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

Fuel tank

XPI engines

If the tank is positioned so that suction height exceeds 1 m, a feed pump must be mounted directly after the tank. The flow for the auxiliary feed pump must be minimum 15% higher than the flows specified in the table found in the section Feed pump flow rates.

To prevent fuel leakage during filter renewal, a shut-off cock must be installed on the return pipe if the fuel tank is positioned higher than the engine.

To prevent unfiltered fuel from entering the engine during an inspection, a shut-off cock must also be installed on the fuel pipe to the feed pump if fuel tank is placed higher than the engine.

All XPI engines are equipped with a water-separating fuel filter. The water that is separated follows with the return fuel. For this reason, all tanks must be fitted with a drain tap for draining water.

The tank should normally be drained once a year, but this may vary depending on the quality of the fuel.

If the customer requires extra water separation so that the water is not led back to the fuel tank, a water separating fuel filter can be fitted on the return pipe.

IMPORTANT!

IMPORTANT!

Fitting an extra water separating fuel filter in addition to the Scania prefilter is not permitted on the fuel pipe to the engine.

01:03 Issue 6.1 en-GB |

5 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

Fuel tank

Fuel tank design

The material for the fuel tank should be corrosion-resistant, such as stainless steel or aluminium.

Note:

Some other materials, such as copper or hot dip galvanised sheet steel, are unsuitable for use with diesel fuel.

The fuel tanks must be fully welded. When used in mobile installations, the fuel tanks must be equipped with baffle plates.

Both fuel filling components and the fuel tank must be grounded to prevent sparking from static electricity.

The fuel tank must have the following devices:

•A drain tap for emptying sludge and water that has sunk to the bottom.

•A connection with the outside air at the upper part of the tank to avoid a vacuum in the tank. This can consist of a special bleed pipe or a ventilation hole in the filler pipe cover. In dusty environments, this connection should be connected via a filter to prevent dirt from entering the tank.

•Protection or filter to prevent contaminants entering during filling.

•Fuel pick-up unit with electronic overfill protection to prevent any diesel spillage.

•Main tanks must be fitted with inspection hatches so that they can be inspected and cleaned inside.

REQUIREMENT!

REQUIREMENT!

By law, the label "Ultra Low Sulfur Fuel Only" must be affixed at the filler cap on all engines certified in accordance with Tier 4. The label is supplied with all industrial engines from Scania.

01:03 Issue 6.1 en-GB |

6 |

© Scania CV AB 2016, Sweden

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...