Page 1

1689 Rover 214 & 414 Updated Version 09/97

Rover 214 & 414

Service and Repair Manual

Mark Coombs and Christopher Rogers

Models covered

Rover 214 and 414 models fitted with eight or sixteen-valve 1397 cc ‘K-series’ engine

Covers major mechanical features of Cabriolet

Does not cover Diesel engine models

(1689-288-9AA3)

© Haynes Publishing 1997

A book in the Haynes Service and Repair Manual Series

All rights reserved. No part of this book may be reproduced or transmitted

in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the copyright holder.

ISBN 1 85960 458 7

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Printed by J H Haynes & Co. Ltd, Sparkford, Nr Yeovil,

Somerset BA22 7JJ

Haynes Publishing

Sparkford, Nr Yeovil, Somerset BA22 7JJ, England

Haynes North America, Inc

861 Lawrence Drive, Newbury Park, California 91320, USA

Editions Haynes S.A.

147/149, rue Saint Honoré, 75001 PARIS, France

Haynes Publishing Nordiska AB

Fyrisborgsgatan 5, 754 50 Uppsala, Sverige

Page 2

1689 Rover 214 & 414 Updated Version 09/97

REPAIRS AND OVERHAUL

Engine and Associated Systems

Engine in-car repair procedures Page 2A•1

Engine removal and general overhaul procedures Page 2B•1

Cooling, heating and ventilation systems Page 3•1

Fuel and exhaust systems - carburettor engines Page 4A•1

Fuel and exhaust systems - single-point fuel injected engines Page 4B•1

Fuel and exhaust systems - multi-point fuel injected engines Page 4C•1

Emission control systems Page 4D•1

Ignition system - carburettor engines Page 5A•1

Ignition system - fuel injected engines Page 5B•1

Starting and charging systems Page 5C•1

Transmission

Clutch Page 6•1

Gearbox Page 7•1

Driveshafts Page 8•1

Brakes and Suspension

Braking system Page 9•1

Suspension and steering Page 10•1

Body Equipment

Bodywork and fittings Page 11•1

Body electrical systems Page 12•1

Wiring Diagrams Page 12•20

REFERENCE

Dimensions and Weights Page REF•1

Conversion Factors Page REF•2

Buying Spare Parts and Vehicle Identification Page REF•3

General Repair Procedures Page REF•4

Jacking and Vehicle Support Page REF•5

Radio/cassette Anti-theft System - precaution Page REF•5

Tools and Working Facilities Page REF•6

MOT Test Checks Page REF•8

Fault Finding Page REF•12

Glossary of Technical Terms Page REF•19

Index Page REF•24

Contents

Page 3

2A

1689 Rover 214 & 414 Updated Version 09/97

Chapter 2 Part A

Engine in-car repair procedures

Camshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Camshafts and hydraulic tappets - removal, inspection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compression test - description and interpretation . . . . . . . . . . . . . . 3

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 13

Cylinder head cover - removal and refitting . . . . . . . . . . . . . . . . . . . 5

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine/gearbox mountings - inspection and renewal . . . . . . . . . . . . 19

Flywheel - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 18

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . . 16

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Timing belt - removal, inspection, refitting and adjustment . . . . . . . 8

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Timing belt tensioner and sprockets - removal, inspection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Top Dead Centre (TDC) for number one piston - locating . . . . . . . . 4

Valve clearances - general information . . . . . . . . . . . . . . . . . . . . . . . 12

2A•1

Contents

Specifications

General

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder in-line, four-stroke, liquid-cooled

Designation:

1.4 8-valve sohc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K8

1.4 16-valve dohc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K16

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.00 mm

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1396 cc

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Compression ratio:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.75 : 1

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.50 : 1

Minimum compression pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3 bar

Maximum compression pressure difference between cylinders . . . . . . 1.4 bar

Maximum power (EEC):

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 ps (56 kW) @ 5700 rpm

K8 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 ps (55 kW) @ 5500 rpm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 ps (70 kW) @ 6250 rpm

K16 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 ps (66 kW) @ 6250 rpm

Maximum torque (EEC):

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 Nm (86 lbf ft) @ 3500 rpm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 Nm (91 lbf ft) @ 4000 rpm

K16 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Nm (89 lbf ft) @ 4000 rpm

Cylinder block/crankcase

Note: Service liners are Grade B

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminium alloy

Cylinder liner bore diameter - 60 mm from top of bore:

Standard - grade A (Red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.975 to 74.985 mm

Standard - grade B (Blue) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.986 to 74.995 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.045 mm

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

5

4

3

2

1

Page 4

Crankshaft

Number of main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.979 to 48.000 mm

Main bearing journal size grades:

Grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.993 to 48.000 mm

Grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.986 to 47.993 mm

Grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.979 to 47.986 mm

Crankpin journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.986 to 43.007 mm

Crankpin journal size grades:

Grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43.000 to 43.007 mm

Grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.993 to 43.000 mm

Grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.986 to 42.993 mm

Main bearing and crankpin journal maximum ovality . . . . . . . . . . . . . . . 0.010 mm

Main bearing and big-end bearing running clearance . . . . . . . . . . . . . . 0.021 to 0.049 mm

Crankshaft endfloat:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 0.30 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 mm

Thrustwasher thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.61 to 2.65 mm

Gudgeon pins

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.0 mm

Fit in connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Interference

Pistons and piston rings

Note: Service pistons are Grade B

Piston diameter: Grade A Grade B

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.940 to 74.955 mm 74.956 to 74.970 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.945 to 74.960 mm 74.960 to 74.975 mm

Piston-to-bore clearance:

K8 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 to 0.045 mm

K16 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.010 to 0.040 mm

Service limit - all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.080 mm

Piston ring end gaps (fitted 20 mm from top of bore):

Top compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.45 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.50 mm

Second compression ring - all models . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.50 mm

Oil control ring:

K8 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 1.00 mm

K16:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.50 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.60 mm

Piston ring-to-groove clearance:

Top compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.09 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.07 mm

Second compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.08 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.07 mm

Oil control ring - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.06 mm

Cylinder head

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminium alloy

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118.95 to 119.05 mm

Reface limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Maximum acceptable gasket face distortion . . . . . . . . . . . . . . . . . . . . . 0.05 mm

Valve seat angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Valve seat width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Seat cutter correction angle:

Upper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30°

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60°

Valve stem installed height:

K8:

new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.95 to 40.81 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.06 mm

K16:

new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.93 to 39.84 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.10 mm

2A•2 Engine in-car repair procedures

1689 Rover 214 & 414 Updated Version 09/97

Page 5

Valves

Seat angle:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44° 30’

Head diameter:

Inlet:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0 mm

Exhaust:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.0 mm

Stem outside diameter:

Inlet:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.967 to 6.975 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.952 to 5.967 mm

Exhaust:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.952 to 6.967 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.947 to 5.962 mm

Guide inside diameter:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.000 to 7.025 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.000 to 6.025 mm

Stem-to-guide clearance:

Inlet:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.04 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 mm

Exhaust:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 to 0.08 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.11 mm

Valve timing:

K8:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13° BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47° ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53° BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7° ATDC

K16:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15° BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45° ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55° BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5° ATDC

Valve spring free length:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46.2 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.0 mm

Valve guide fitted height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 mm

Camshaft

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Toothed belt

Number of bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bearing journal running clearance:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 to 0.094 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.150 mm

Camshaft endfloat:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 to 0.190 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.500 mm

Valve lift:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2 mm

Hydraulic tappet outside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.959 to 32.975 mm

Lubrication system

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 bar @ idle speed

Oil pump type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Trochoidal, eccentric-rotor

Oil pump clearances:

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.06 mm

Outer rotor-to-body clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.28 to 0.36 mm

Rotor lobe clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 to 0.13 mm

Pressure relief valve operating pressure . . . . . . . . . . . . . . . . . . . . . . . . 4.1 bar

Oil pressure warning lamp lights at . . . . . . . . . . . . . . . . . . . . . . . . . . . . Below 0.3 to 0.5 bar

Engine in-car repair procedures 2A•3

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 6

Torque wrench settings Nm lbf ft

Spark plug (HT) lead clip screws - K8 . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Air intake duct support bracket-to-cylinder head screws . . . . . . . . . . . 4 3

Spark plug cover screws - K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1.5

Cylinder head cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Camshaft bearing cap/carrier-to-cylinder head bolts . . . . . . . . . . . . . . 9 7

Cylinder head bolts:

1st stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

2nd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through 180°

3rd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through (a further) 180°

Timing belt cover fasteners:

Upper right-hand (outer) cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Lower and upper left-hand (inner) covers . . . . . . . . . . . . . . . . . . . . . . 9 7

Timing belt tensioner backplate clamp bolt . . . . . . . . . . . . . . . . . . . . . . 25 19

Timing belt tensioner pulley Allen screw . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 24

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 118

Oil pump-to-cylinder block/crankcase bolt and screws . . . . . . . . . . . . . 9 7

Alternator mounting bracket-to-cylinder block/crankcase bolts . . . . . . 45 33

Dipstick tube-to-cylinder block/crankcase bolts . . . . . . . . . . . . . . . . . . 9 7

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Transmission-to-engine bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Flywheel cover plate screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Flywheel rear cover plate bolt and nut . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Big-end bearing cap bolts:

1st stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

2nd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through 45°

Main bearing ladder-to-cylinder block/crankcase bolts . . . . . . . . . . . . . 10 7

Oil rail-to-main bearing ladder nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Oil pump pick-up/strainer pipe bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Sump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 31

Engine/transmission right-hand mounting:

Bracket-to-cylinder block/crankcase bolts . . . . . . . . . . . . . . . . . . . . . 45 33

Mounting-to-bracket nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 74

Mounting-to-body through-bolt and nut . . . . . . . . . . . . . . . . . . . . . . . 85 63

Engine/transmission left-hand mounting:

Mounting-to-body bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Mounting-to-transmission bracket bolts . . . . . . . . . . . . . . . . . . . . . . 60 44

Transmission bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 74

Engine/transmission rear mounting:

Mounting bracket-to-transmission bolt . . . . . . . . . . . . . . . . . . . . . . . 85 63

Connecting link-to- transmission bracket bolt . . . . . . . . . . . . . . . . . . 60 44

Connecting link-to-body bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Anti-beaming bracket-to-support bracket bolt . . . . . . . . . . . . . . . . . . . 45 33

2A•4 Engine in-car repair procedures

1689 Rover 214 & 414 Updated Version 09/97

1 General information and

precautions

How to use this Chapter

This Part of the Chapter describes those

repair procedures that can reasonably be

carried out on the engine whilst it remains in

the vehicle. If the engine has been removed

from the vehicle and is being dismantled as

described in Part B of this Chapter, any

preliminary dismantling procedures can be

ignored.

Note that whilst it may be possible

physically to overhaul items such as the

piston/connecting rod assemblies with the

engine in the vehicle, such tasks are not

usually carried out as separate operations

and usually require the execution of several

additional procedures (not to mention the

cleaning of components and of oilways). For

this reason, all such tasks are classed as

major overhaul procedures and are described

in Part B of this Chapter.

Engine information

The engine is of four-cylinder, in-line type,

mounted transversely at the front of the

vehicle with the clutch and transmission on its

left-hand end. The engine is available in two

forms - the K8 engine, which is the eight-valve

single overhead camshaft engine fitted to the

carburettor-equipped 214 S model, and the

K16 engine, which is a sixteen-valve double

overhead camshaft engine which is fitted to all

fuel-injected models. Apart from the different

cylinder head designs, both engines are of

identical construction.

Apart from the pressed steel sump, the

plastic timing belt covers and the aluminium

alloy cylinder head cover, the engine consists

of three major castings which are the cylinder

head, the cylinder block/crankcase and the

crankshaft main bearing ladder. There is also

an oil rail underneath the main bearing ladder

and the camshaft carrier/bearing caps.

All major castings are of aluminium alloy

and are clamped together by ten long

through-bolts which perform the dual role of

cylinder head bolts and crankshaft main

bearing fasteners. Since these bolts pass

through the cylinder block/crankcase and the

main bearing ladder, the oil rail is secured also

to the main bearing ladder (by two nuts) and

the main bearing ladder is secured also to the

cylinder block/crankcase (by ten smaller bolts)

so that the cylinder head can be removed

without disturbing the rest of the engine. The

passages provided for the bolts in the major

castings are used as breather passages or as

returns for the oil to the sump.

Page 7

The crankshaft runs in five main bearings.

Thrustwashers are fitted to the centre main

bearing (upper half) to control crankshaft

endfloat.

The connecting rods rotate on horizontallysplit bearing shells at their big-ends. The

pistons are attached to the connecting rods

by gudgeon pins which are an interference fit

in the connecting rod small-end eyes. The

aluminium alloy pistons are fitted with three

piston rings, comprising two compression

rings and an oil control ring.

The cylinder bores are formed by

replaceable wet liners which are located from

their top ends. Two sealing rings are fitted at

the base of each liner to prevent the escape of

coolant into the sump.

The inlet and exhaust valves are each

closed by coil springs and operate in guides

pressed into the cylinder head. The valve seat

inserts are pressed into the cylinder head and

can be renewed separately if worn.

On the K8 engine, the camshaft is driven by

a toothed timing belt and operates the eight

valves via self-adjusting hydraulic tappets,

thus eliminating the need for routine checking

and adjustment of the valve clearances. The

camshaft rotates in six bearings that are linebored direct in the cylinder head and the

(bolted-on) bearing caps. This means that the

bearing caps are not available separately from

the cylinder head and must not be

interchanged with others from another engine.

The distributor is driven from the left-hand

end of the camshaft and the mechanical fuel

pump is operated by an eccentric on the

camshaft.

Apart from the fact that it has two

camshafts, one inlet and one exhaust, each

controlling eight valves and both retained by a

single camshaft carrier, the same applies to

the K16 engine. On the K16 engine, the

distributor is driven from the left-hand end of

the inlet camshaft. The fuel pump is

electrically-operated.

On both engine types, the coolant pump is

driven by the timing belt.

Lubrication is by means of an eccentricrotor trochoidal pump mounted on the

crankshaft right-hand end. It draws oil

through a strainer located in the sump and

then forces it through an externally-mounted

full-flow cartridge-type filter into galleries in

the oil rail and cylinder block/crankcase, from

where it is distributed to the crankshaft

(main bearings) and camshaft(s). The big-end

bearings are supplied with oil via internal

drillings in the crankshaft, while the camshaft

bearings and the hydraulic tappets receive a

pressurised supply. The camshaft lobes and

valves are lubricated by splash, as are all

other engine components.

Repair operations possible with

the engine in the car

The following work can be carried out with the

engine in the vehicle:

a) Compression pressure - testing.

b) Cylinder head cover - removal and

refitting.

c) Crankshaft pulley - removal and refitting.

d) Timing belt covers - removal and refitting.

e) Timing belt - removal, refitting and

adjustment.

f) Timing belt tensioner and sprockets -

removal and refitting.

g) Camshaft oil seal(s) - renewal.

h) Camshaft(s) and hydraulic tappets -

removal, inspection and refitting.

i) Cylinder head - removal and refitting.

j) Cylinder head and pistons -

decarbonising.

k) Sump - removal and refitting.

l) Oil pump - removal, overhaul and refitting.

m) Crankshaft oil seals - renewal.

n) Engine/transmission mountings -

inspection and renewal.

o) Flywheel - removal, inspection and

refitting.

Precautions

Note that a side-effect of the above

described engine design is that the crankshaft

cannot be rotated once the cylinder head and

block through-bolts have been slackened.

During any servicing or overhaul work the

crankshaft always must be rotated to the

desired position before the bolts are

disturbed.

2 Engine oil and filter - renewal

1 Details of checking the engine oil levels and

renewing both the oil and filter are contained

in “Weekly Checks” and Chapter 1.

3 Compression test -

description and interpretation

2

1 When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly it can give warning of trouble before

any other symptoms become apparent.

2 The engine must be fully warmed up to

normal operating temperature, the battery

must be fully charged and the spark plugs

must be removed. The aid of an assistant will

be required.

3 Disable the ignition system by

disconnecting the ignition HT coil lead from

the distributor cap and earthing it on the

cylinder block. Use a jumper lead or similar

wire to make a good connection.

4 Fit a compression tester to the No 1

cylinder spark plug hole. The type of tester

which screws into the plug thread is preferred

(see illustration).

5 Have the assistant hold the throttle wide

open and crank the engine on the starter

motor. After one or two revolutions, the

compression pressure should build up to a

maximum figure and then stabilise. Record

the highest reading obtained.

6 Repeat the test on the remaining cylinders,

recording the pressure in each.

7 All cylinders should produce very similar

pressures. Any difference greater than that

specified indicates the existence of a fault.

Note that the compression should build up

quickly in a healthy engine. Low compression

on the first stroke, followed by gradually

increasing pressure on successive strokes,

indicates worn piston rings. A low

compression reading on the first stroke, which

does not build up during successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause). Deposits on the undersides of

the valve heads can also cause low

compression.

8 If the pressure in any cylinder is reduced to

the specified minimum or less, carry out the

following test to isolate the cause. Introduce a

teaspoonful of clean oil into that cylinder

through its spark plug hole and repeat the

test.

9 If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear is responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

10 A low reading from two adjacent cylinders

is almost certainly due to the head gasket

having blown between them and the presence

of coolant in the engine oil will confirm this.

11 If one cylinder is about 20 percent lower

than the others and the engine has a slightly

rough idle, a worn camshaft lobe could be the

cause.

12 If the compression reading is unusually

high, the combustion chambers are probably

coated with carbon deposits. If this is the

case, the cylinder head should be removed

and decarbonised.

13 On completion of the test, refit the spark

plugs and reconnect the ignition system.

Engine in-car repair procedures 2A•5

3.4 Measuring compression pressure

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 8

4 Top Dead Centre (TDC) for

number one piston - locating

2

General

1 The crankshaft pulley, crankshaft and

camshaft sprockets are provided by the

factory with clear marks which align only at

90° BTDC. This positions the pistons half-way

up the bores so that there is no risk of

damage as the engine is reassembled. These

marks do not indicate TDC. Use only the

ignition timing marks, as described in this

Section, to find TDC.

2 Top dead centre (TDC) is the highest point

in its travel up-and-down the cylinder bore

that each piston reaches as the crankshaft

rotates. While each piston reaches TDC both

at the top of the compression stroke and

again at the top of the exhaust stroke, for the

purpose of timing the engine, TDC refers to

the piston position (usually No 1) at the top of

its compression stroke.

3 While all engine reassembly procedures use

the factory timing marks (90° BTDC), it is

useful for several other servicing procedures

to be able to position the engine at TDC.

4 No 1 piston and cylinder is at the right-hand

(timing belt) end of the engine. Note that the

crankshaft rotates clockwise when viewed

from the right-hand side of the vehicle.

Locating TDC

5 Disconnect the battery negative lead and

remove all the spark plugs.

6 Trace No 1 spark plug (HT) lead from the

plug back to the distributor cap and use chalk

or similar to mark the distributor body or

engine casting nearest to the cap’s No 1

terminal. Undo the distributor cap retaining

screws and remove the cap.

7 Apply the handbrake and ensure that the

transmission is in neutral, then jack up the

front of the vehicle and support it on axle

stands. Remove the right-hand roadwheel.

8 From underneath the front of the vehicle,

slacken and remove the three bolts securing

the bumper flange to the body. Remove the

seven bolts securing the front undercover

panel to the body and remove the panel to

gain access to the crankshaft pulley and

ignition timing marks.

9 Using a spanner, or socket and extension

bar, applied to the crankshaft pulley bolt,

rotate the crankshaft clockwise until the notch

on the crankshaft pulley’s inboard (left-hand)

rim is aligned with the TDC mark on the timing

belt lower cover (see Chapter 1 for details of

ignition timing marks).

10 With the crankshaft in this position, Nos 1

and 4 cylinders are now at TDC, one of them

on the compression stroke. If the distributor

rotor arm is pointing at (the previously-marked)

No 1 terminal, then No 1 cylinder is correctly

positioned. If the rotor arm is pointing at No 4

terminal, rotate the crankshaft one full turn

(360°) clockwise until the arm points at the

marked terminal. No 1 cylinder will then be at

TDC on the compression stroke.

11 Once No 1 cylinder has been positioned

at TDC on the compression stroke, TDC for

any of the other cylinders can then be located

by rotating the crankshaft clockwise 180° at a

time and following the firing order.

5 Cylinder head cover -

removal and refitting

2

Removal

1 Disconnect the battery negative lead.

2 Remove the air cleaner assembly and metal

intake duct.

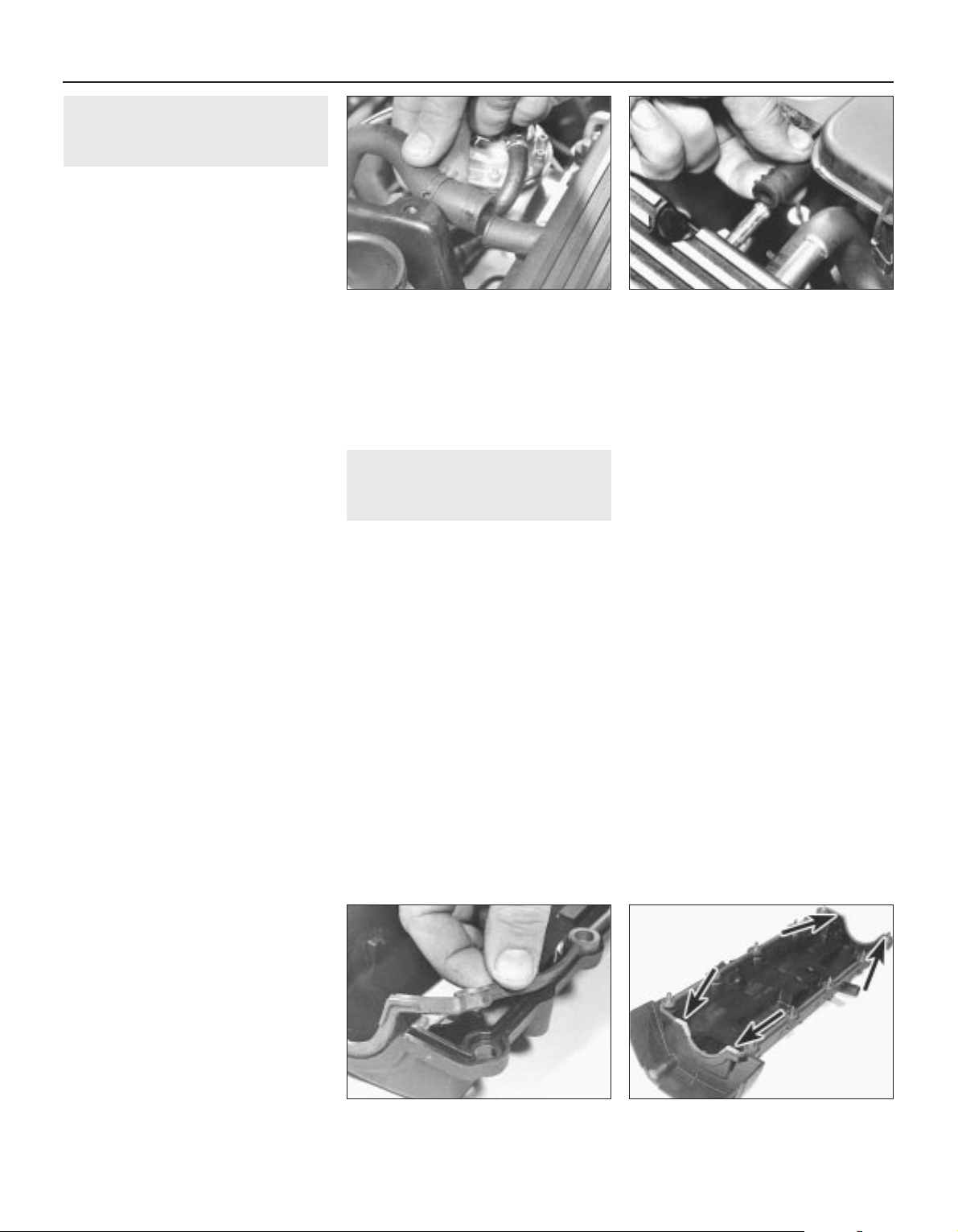

3 Using a suitable pair of pliers, release the

retaining clip(s) and disconnect the breather

hose(s) from the cylinder head cover (see

illustrations).

K8 engines

4 Undo the bolts securing the HT lead

mounting and air intake support brackets to

the cylinder head cover, then remove the

brackets and position the HT leads clear of

the cover.

5 Remove the two uppermost retaining

screws securing the timing belt upper righthand/outer cover to the cylinder head cover,

then slacken the remaining screws and bolts,

as necessary, until the timing belt cover can

be prised clear of the cylinder head cover

without damaging it.

6 Working progressively and in the reverse of

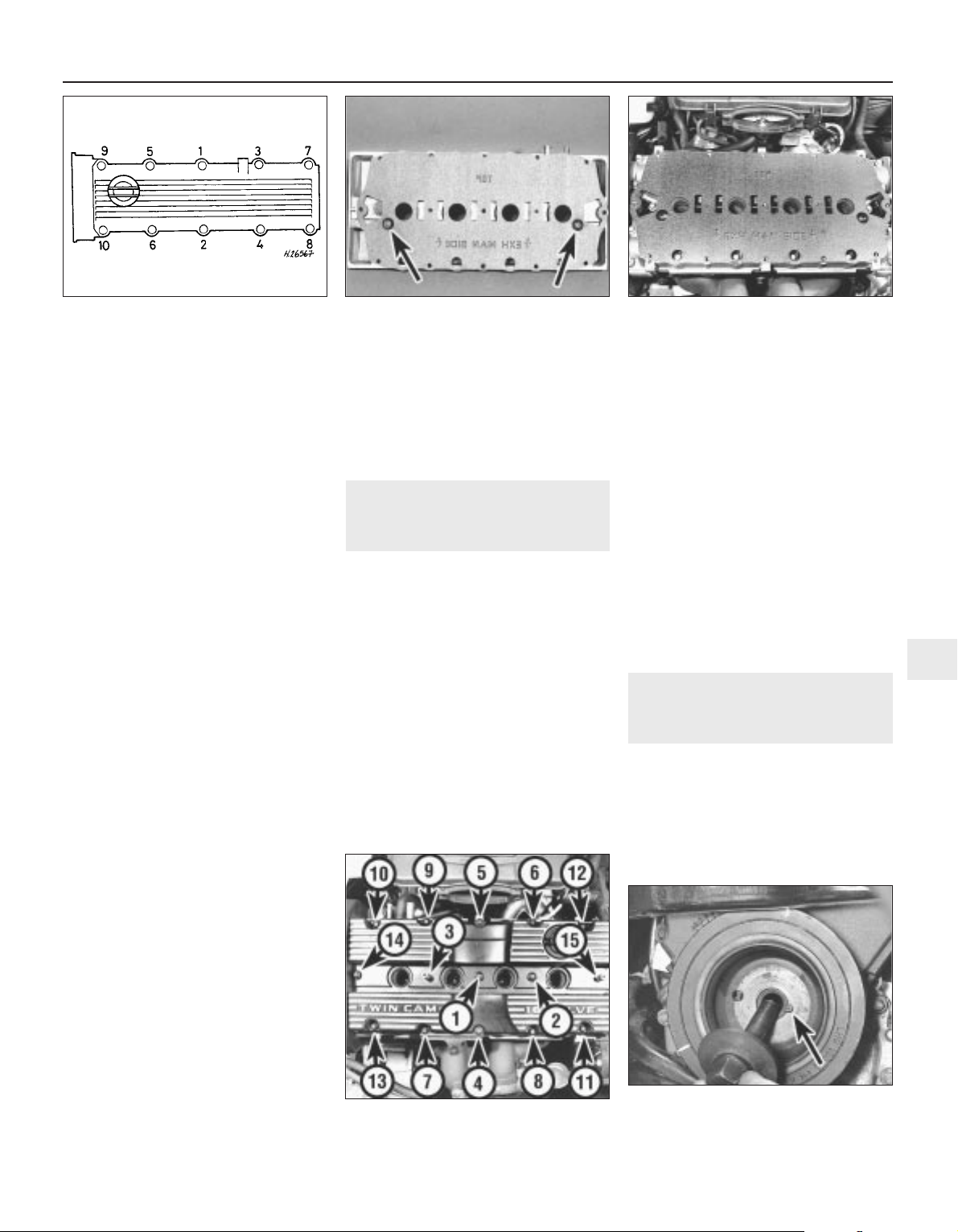

the tightening sequence (see illustration 5.14),

slacken and remove the cylinder head cover

retaining bolts.

7 Remove the cover, peel off the rubber seal

and check it for cuts, other damage or

distortion. Renew the seal if necessary.

K16 engines

8 Undo the two spark plug cover retaining

screws and lift off the cover. Disconnect the

HT leads from the plugs and withdraw them

from the cylinder head, along with the clip

plate and the grommet which is fitted to the

left-hand end of the cylinder head cover.

9 Working progressively and in the reverse of

the tightening sequence (see illustration 5.22),

slacken and remove the cylinder head cover

retaining bolts, noting the correct fitted position

of the air intake duct support bracket.

10 Carefully lift off the cylinder head cover,

taking care not to damage the gasket. Check

that the gasket sealing path is undamaged

and is attached to the gasket all around its

periphery. If the sealing path is undamaged,

then the gasket is re-usable and should

remain in place on the cover until reassembly,

unless its removal is necessary for other

servicing work.

Refitting

K8 engines

11 On reassembly, carefully clean the

cylinder head mating surfaces and the cover

seal’s groove and remove all traces of oil.

12 Seat the seal in its groove in the cover and

refit the bolts, pushing each through the seal,

then apply a smear of silicone-RTV sealant to

each corner of the seal (see illustrations).

2A•6 Engine in-car repair procedures

5.12b . . . then refit bolts and apply sealant

at locations arrowed - K8 engine

5.12a Ensure seal is correctly seated in

cylinder head cover groove . . .

5.3b Disconnecting breather hoses from

cylinder head cover - K16 engine

5.3a Disconnecting breather hose from

cylinder head cover - K8 engine

1689 Rover 214 & 414 Updated Version 09/97

Page 9

13 Refit the cover to the cylinder head,

ensuring that the seal remains seated in its

groove. Fit all bolts, finger-tight.

14 Tighten the cylinder head cover bolts in

the sequence shown to the specified torque

wrench setting (see illustration).

15 Refit the timing belt upper righthand/outer cover to the cylinder head cover

and tighten all the disturbed screws and bolts

to the specified torque setting.

16 Refit the HT lead mounting clips and air

cleaner intake support brackets to the

cylinder head, then tighten the retaining bolts

to the specified torque. Ensure the HT leads

are correctly routed.

17 Connect the breather hose to the cylinder

head cover and secure it in position with the

retaining clip.

18 Refit the air cleaner housing and

reconnect the battery negative lead.

K16 engines

19 On reassembly, carefully clean the mating

surfaces, removing all traces of oil. If the

gasket has been removed, the oil separator

elements can be cleaned by removing them

from the cover and washing them in solvent.

Use compressed air to blow dry the elements

before refitting them to the cover.

20 If a new gasket is to be fitted, press it onto

the cover locating dowels so that if it were laid

on the camshaft carrier its stamped markings

would be legible. The TOP mark should be

nearest the inlet manifold and the EXH MAN

SIDE mark should have its arrows pointing to

the exhaust manifold (see illustrations).

21 Lower the cover onto the cylinder head,

ensuring that the gasket is not damaged or

displaced. Install the cover retaining bolts, not

forgetting to refit the air intake duct support

bracket to its original position, and tighten

them finger-tight.

22 Working in the sequence shown, tighten

the cylinder head cover retaining bolts to the

specified torque setting (see illustration).

23 Reconnect the HT leads to the spark

plugs, then locate the clip plate and grommet

in the left-hand end of the cylinder head

cover. Ensure the HT leads are correctly

routed then refit the spark plug cover and

tighten its retaining screws to the specified

torque. Tighten the air intake support bracket

screws.

24 Connect both the breather hoses to the

cylinder head cover and secure them in

position with the retaining clips.

25 Refit the air cleaner housing and

reconnect the battery negative lead.

6 Crankshaft pulley -

removal and refitting

2

Removal

1 Apply the handbrake then jack up the front

of the vehicle and support it on axle stands.

Remove the right-hand roadwheel.

2 From underneath the front of the vehicle,

slacken and remove the three bolts securing

the bumper flange to the body. Remove the

seven bolts securing the front undercover

panel to the body and remove the panel.

3 If necessary, rotate the crankshaft until the

relevant timing marks align.

4 Remove the power steering pump and/or

alternator drivebelt(s) (as applicable).

5 To prevent crankshaft rotation while the

pulley bolt is unscrewed, select top gear and

have an assistant apply the brakes firmly. If

the engine has been removed from the

vehicle, lock the flywheel using the

arrangement shown (see illustration 18.2).

6 Unscrew the pulley bolt, noting the special

washer behind it, then remove the pulley from

the crankshaft.

Refitting

7 Align the crankshaft pulley centre notch

with the locating lug on the crankshaft timing

belt sprocket then refit the washer, ensuring

that its flat surface is facing the pulley. Fit the

retaining bolt (see illustration).

8 Lock the crankshaft by the method used on

removal and tighten the pulley retaining bolt to

the specified torque setting.

9 Refit the power steering pump and/or

alternator drivebelt(s) (as applicable) and

adjust them as described in Chapter 1.

10 Refit the undercover panel and roadwheel

then lower the vehicle to the ground.

7 Timing belt covers -

removal and refitting

4

Removal

Upper right-hand (outer) cover

1 Slacken the bolt situated at the cover’s

bottom corner, immediately behind the

engine/gearbox unit right-hand mounting

bracket.

Engine in-car repair procedures 2A•7

5.20b . . . stamped markings would appear

as shown if gasket were placed on

camshaft carrier

5.20a Fit gasket to cylinder head cover

dowels (arrowed) so that . . .

5.14 Cylinder head cover bolt tightening

sequence - K8 engine

6.7 Ensure notch in crankshaft pulley

centre fits over crankshaft timing belt

sprocket locating lug (arrowed)

5.22 Cylinder head cover bolt tightening

sequence - K16 engine

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 10

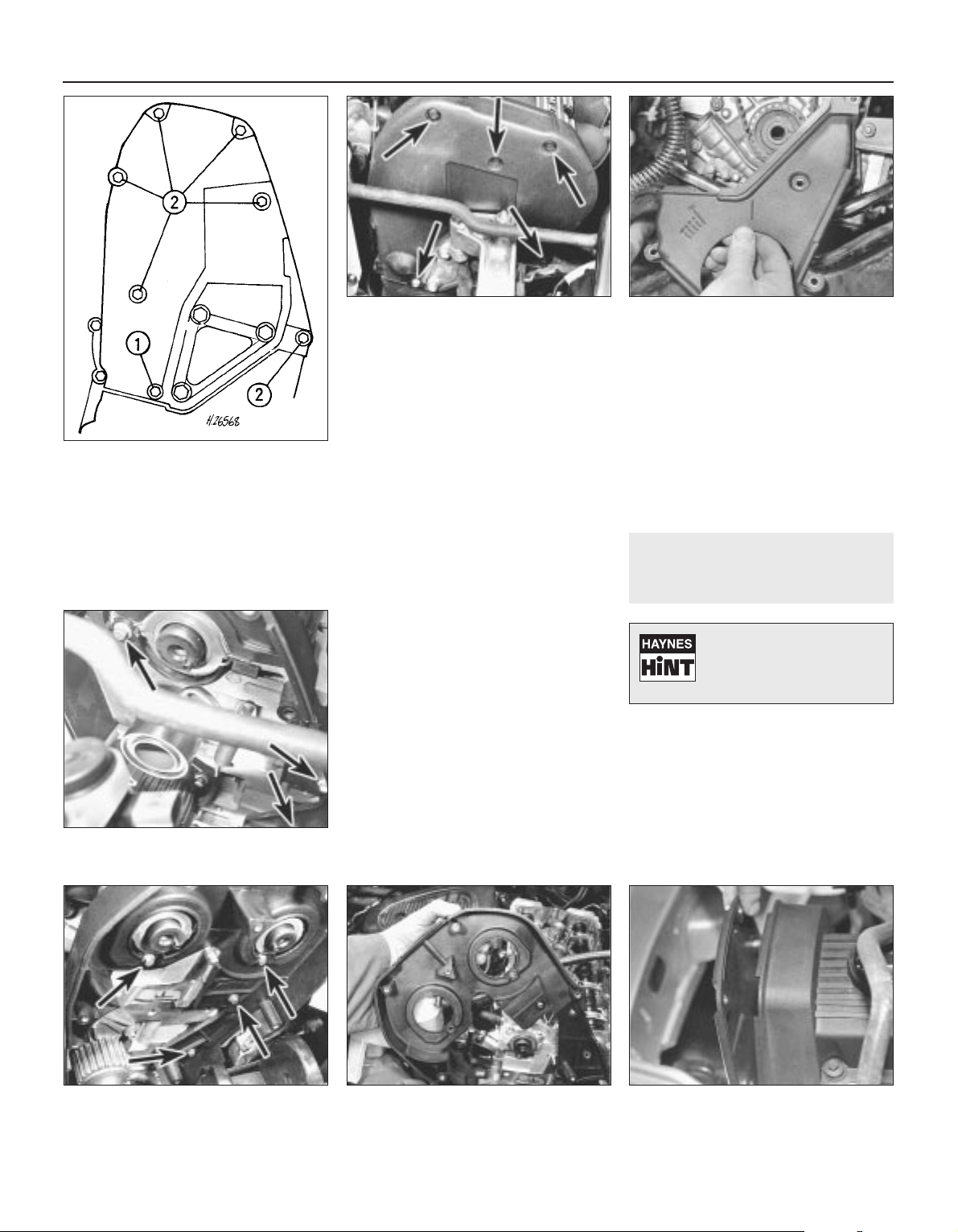

2 Unscrew the remaining cover retaining

bolts and withdraw the cover, noting the

rubber seal fitted to the mounting bracket

edge. Note that if the cover is not slotted at

the bottom corner screw’s location, the screw

will have to be removed fully. If this is the

case, the cover can be slotted to ease future

removal and refitting (see illustrations).

Lower cover

3 Remove the crankshaft pulley.

4 Remove the cover retaining screws,

including the one which also secures the

upper cover’s bottom front corner. Remove

the cover whilst noting the rubber seal fitted to

its mounting bracket edge (see illustration).

Upper left-hand (inner) cover

5 Remove the timing belt.

6 Remove the camshaft sprocket(s) and the

timing belt tensioner.

7 Unscrew the bolt securing the cover to the

coolant pump.

8 On K16 engines, unbolt the engine/gearbox

unit right-hand mounting bracket from the

cylinder block/crankcase.

9 Remove the remaining cover retaining bolts

and withdraw the cover (see illustrations).

Refitting

Upper right-hand (outer) cover

10 Refitting is the reverse of the removal

procedure. Ensure that the seal fits correctly

between the cover and the mounting bracket

and that the cover edges mate correctly with

those of the inner cover and (K8 engines only)

cylinder head cover (see illustration).

11 Tighten the cover fasteners to the

specified torque setting.

Lower cover

12 Refitting is the reverse of the removal

procedure. Ensure that the seal fits correctly

between the cover and the mounting bracket

and tighten the cover fasteners to the

specified torque setting.

Upper left-hand (inner) cover

13 Refitting is the reverse of the removal

procedure. Tighten all disturbed fasteners to

their specified torque wrench settings.

8 Timing belt - removal,

inspection, refitting and

adjustment

4

Removal

1 Disconnect the battery negative lead.

2 To improve access to the timing belt,

remove the expansion tank mounting bolts

then free the coolant hose from any relevant

retaining clips and position the tank clear of

the engine. On models equipped with powerassisted steering, undo all the power steering

hose retaining clip bolts then slide the fluid

reservoir out of its retaining clip and position it

2A•8 Engine in-car repair procedures

7.10 Ensure timing belt upper right-hand

(outer) cover engages correctly with

cylinder head cover - K8 engine

7.9c Removing timing belt upper left-hand

(inner) cover - K16 engine

7.9b Timing belt upper left-hand (inner)

cover fasteners (arrowed) - K16 engine

7.9a Timing belt upper left-hand (inner)

cover fasteners (arrowed) - K8 engine

7.4 Removing timing belt lower cover7.2b Timing belt upper right-hand (outer)

cover fasteners (arrowed) - K16 engine,

raised for clarity

7.2a Timing belt upper right-hand (outer)

cover fasteners - K8 engine

1 Slacken screw - cover should be slotted

2 Remove fasteners

1689 Rover 214 & 414 Updated Version 09/97

If the timing belt is to be reused, use white paint or

similar to mark the direction

of rotation on the belt.

Page 11

clear of the timing belt covers. Take great care

not to place any undue strain on hoses and

mop up any spilt fluid immediately.

3 Remove the timing belt upper right-hand

(outer) cover.

4 Firmly apply the handbrake then jack up the

front of the vehicle and support it on axle

stands. Remove the right-hand roadwheel

5 From underneath the front of the vehicle,

slacken and remove the three bolts securing

the bumper flange to the body. Remove the

seven bolts securing the front undercover

panel to the body and remove the panel to

gain access to the crankshaft pulley bolt.

6 Using a suitable spanner or socket on the

crankshaft pulley bolt, rotate the crankshaft in

a clockwise direction until the long whitepainted mark on the crankshaft pulley’s

outboard (right-hand) face is aligned with the

single, separate mark on the timing belt lower

cover so that the crankshaft is in the 90°

BTDC position (see Chapter 1 for details of

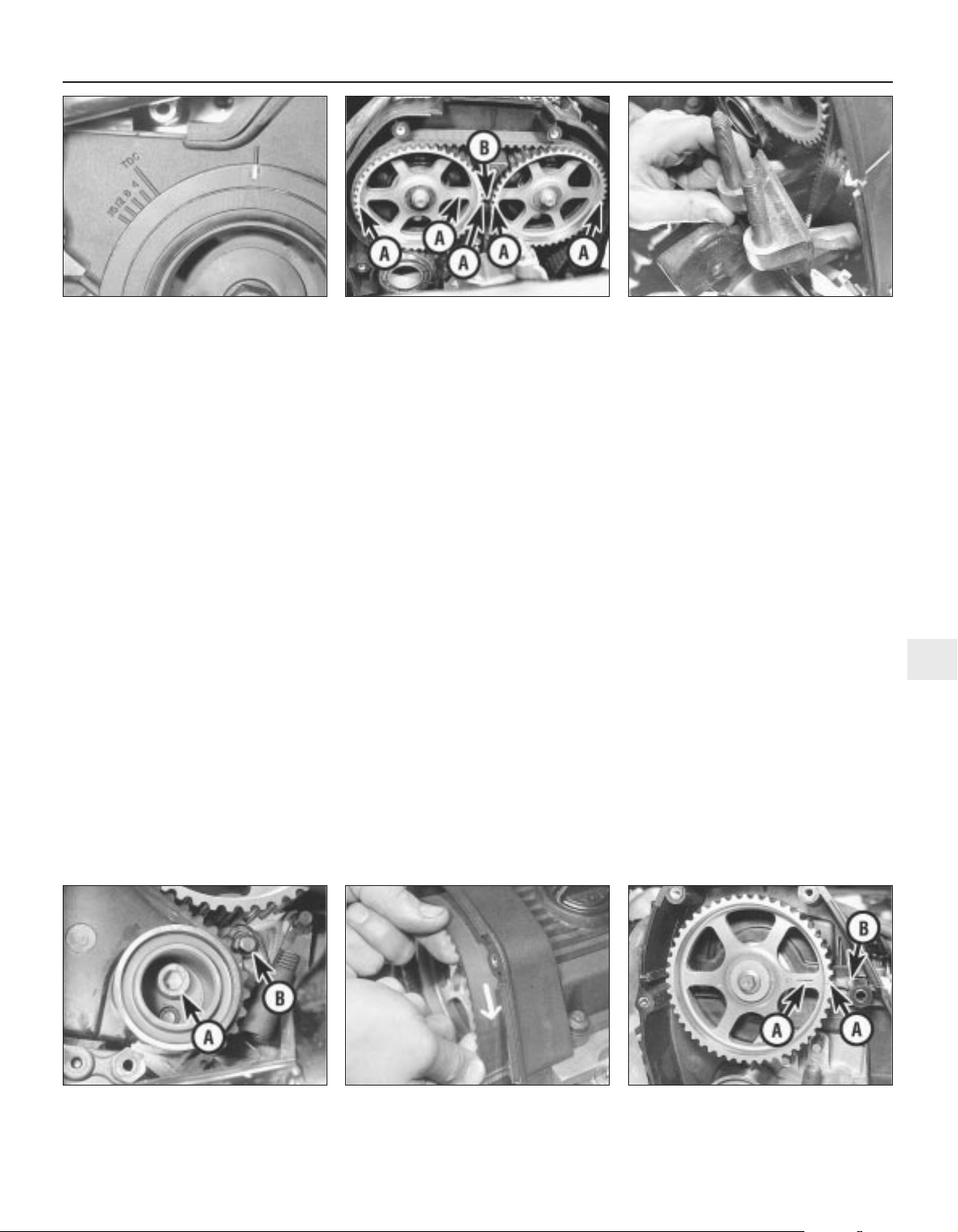

the pulley/cover marks) (see illustration).

7 Check that the camshaft sprocket mark(s)

align as described in paragraph 15, showing

that Nos 1 and 4 cylinders are at 90° BTDC

so that there is no risk of the valves contacting

the pistons during dismantling and

reassembly. If the camshaft sprocket mark(s)

are 180° out, rotate the crankshaft through

one complete turn (360°) to align the marks as

described (see illustration).

8 On K16 engines, use the tool described in

Section 9 to lock up the camshaft sprockets

so that they cannot move under valve spring

pressure when the timing belt is removed.

9 Remove the crankshaft sprocket and timing

belt lower cover.

10 Position a trolley jack with a wooden

spacer beneath the sump then gently jack it

up to take the weight of the engine.

11 Slacken and remove the engine/gearbox

unit right-hand mounting through-bolt and nut

and the mounting-to-bracket nuts. Remove

the mounting, along with the two rubber

washers which are fitted on each side of the

mounting. On K8 engines only, unscrew the

retaining bolts securing the bracket to cylinder

block/crankcase and remove it from the

engine unit (see illustration).

12 Slacken both the timing belt tensioner

pulley Allen screw and the tensioner

backplate clamp bolt through half a turn each,

then push the pulley assembly downwards to

remove all the tension from the timing belt.

Hold the tensioner pulley in this position and

re-tighten the backplate clamp bolt securely

(see illustration).

13 Slip the belt off the sprockets (see

illustration). Do not rotate the crankshaft until

the timing belt has been refitted.

Inspection

14 Check the timing belt carefully for any

signs of uneven wear, splitting or oil

contamination and renew it if there is the

slightest doubt about its condition. If the

engine is undergoing an overhaul and has

covered more than 48 000 miles (80 000 km)

since the original belt was fitted, renew the

belt as a matter of course, regardless of its

apparent condition. If signs of oil

contamination are found, trace the source of

the oil leak and rectify it, then wash down the

engine timing belt area and all related

components to remove all traces of oil.

Refitting

15 On reassembly, thoroughly clean the

timing belt sprockets and check that they are

aligned as follows. It is most important that

these marks are aligned exactly as this sets

valve timing. Note that in this position, Nos 1

and 4 cylinders are at 90° BTDC so that there

is no risk of the valves contacting the pistons

during dismantling and reassembly.

a) Camshaft sprocket on K8 engine - The EX

line and the mark stamped on the

sprocket rim must be at the front (looking

at the sprocket from the right-hand side

of the vehicle) and aligned exactly with

the cylinder head top surface (see

illustration).

b) Camshaft sprockets on K16 engine - Both

EXHAUST arrow marks must point to the

rear (looking at the sprockets from the

right-hand side of the vehicle) with the IN

lines and the sprocket rim marks aligned

exactly with the line on the timing belt

upper left-hand/inner cover (representing

the cylinder head top surface). See

illustration 8.7.

Engine in-car repair procedures 2A•9

8.11 Removing engine/gearbox unit righthand mounting bracket - K8 engine

8.7 Camshaft sprocket marks (A) aligned

with timing belt upper left-hand (inner)

cover mark (B) - K16 engine

8.6 Crankshaft pulley mark aligned with

timing belt lower cover mark at 90° BTDC

8.15a Camshaft sprocket marks (A)

aligned with cylinder head top surface (B) -

K8 engine

8.13 Mark direction of rotation of timing

belt before removal

8.12 Timing belt tensioner pulley bolt (A)

and tensioner backplate clamp bolt (B)

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 12

c) Crankshaft sprocket - The two dots must

be positioned on each side of the raised

rib on the oil pump body (see

illustration).

16 If a used belt is being refitted, ensure that

the arrow mark made on removal points in the

normal direction of rotation. Fit the timing belt

over the crankshaft and camshaft sprockets,

ensuring that the belt front run (and, on K16

engines, the top run) is taut, ie: all slack is

on the tensioner pulley side of the belt, then fit

the belt over the coolant pump sprocket and

tensioner pulley. Do not twist the belt sharply

during refitting and ensure that the belt teeth

are correctly seated centrally in the sprockets

and that the timing marks remain in alignment

(see illustration)..

17 Slacken the tensioner backplate clamp

bolt and check that the tensioner pulley

moves to tension the belt. If the tensioner

assembly is not free to move under spring

tension, rectify the fault or the timing belt will

not be correctly tensioned.

18 On K16 engines, remove the camshaft

sprocket locking tool.

19 On K8 engines, refit the engine/gearbox

unit right-hand mounting bracket, tightening

its bolts to the specified torque wrench

setting.

20 On all engines, refit the timing belt lower

cover and the crankshaft pulley.

21 Using a suitable spanner or socket, rotate

the crankshaft two full turns clockwise to

settle and tension the belt. Realign the

crankshaft pulley (90° BTDC) mark and check

that the sprocket timing mark(s) are still

correctly aligned.

22 If all is well, first tighten the tensioner

pulley backplate clamp bolt to the specified

torque, then tighten the tensioner pulley Allen

screw to the specified torque.

23 Reassemble the engine/gearbox unit

right-hand mounting, ensuring that the rubber

washers are correctly located, then tighten

the mounting nuts and bolts to their specified

torque settings. Remove the jack from

underneath the engine unit.

24 Refit the front undercover panel and

roadwheel, then lower the vehicle to the ground.

25 Refit the timing belt upper right-hand

(outer) cover.

26 Where necessary, refit the power steering

fluid reservoir to the mounting bracket and

secure the hydraulic hose clamps in position

with the retaining bolts.

27 Refit the coolant expansion tank and

tighten the mounting bolts securely. Secure

the coolant hose in position with any

necessary retaining clips and reconnect the

battery negative lead.

Adjustment

28 As the timing belt is a ‘fit-and-forget’ type,

the manufacturer states that tensioning need

only be carried out when a belt is (re)fitted. No

re-tensioning is recommended once a belt

has been fitted and therefore this operation is

not included in the manufacturer’s

maintenance schedule.

29 If the timing belt is thought to be

incorrectly tensioned, then adjust the tension

as described in paragraphs 1 to 7, 17, 21, 22

and 24 to 27 above.

30 If the timing belt has been disturbed,

adjust its tension following the same

procedure, omitting as appropriate the

irrelevant preliminary dismantling/reassembly

steps.

9 Timing belt tensioner and

sprockets - removal,

inspection and refitting

4

Note: This Section describes as individual

operations the removal and refitting of the

components concerned. If more than one

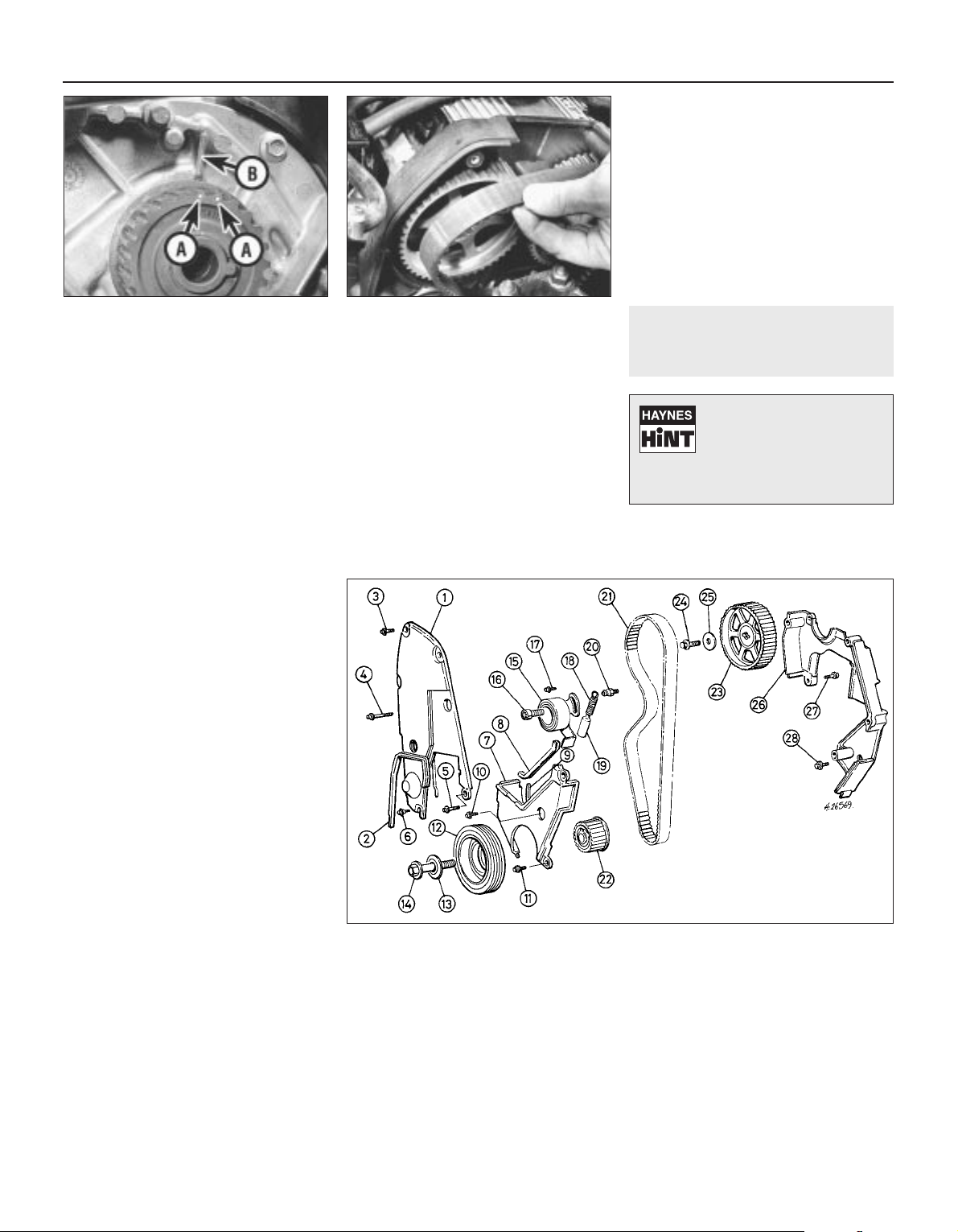

2A•10 Engine in-car repair procedures

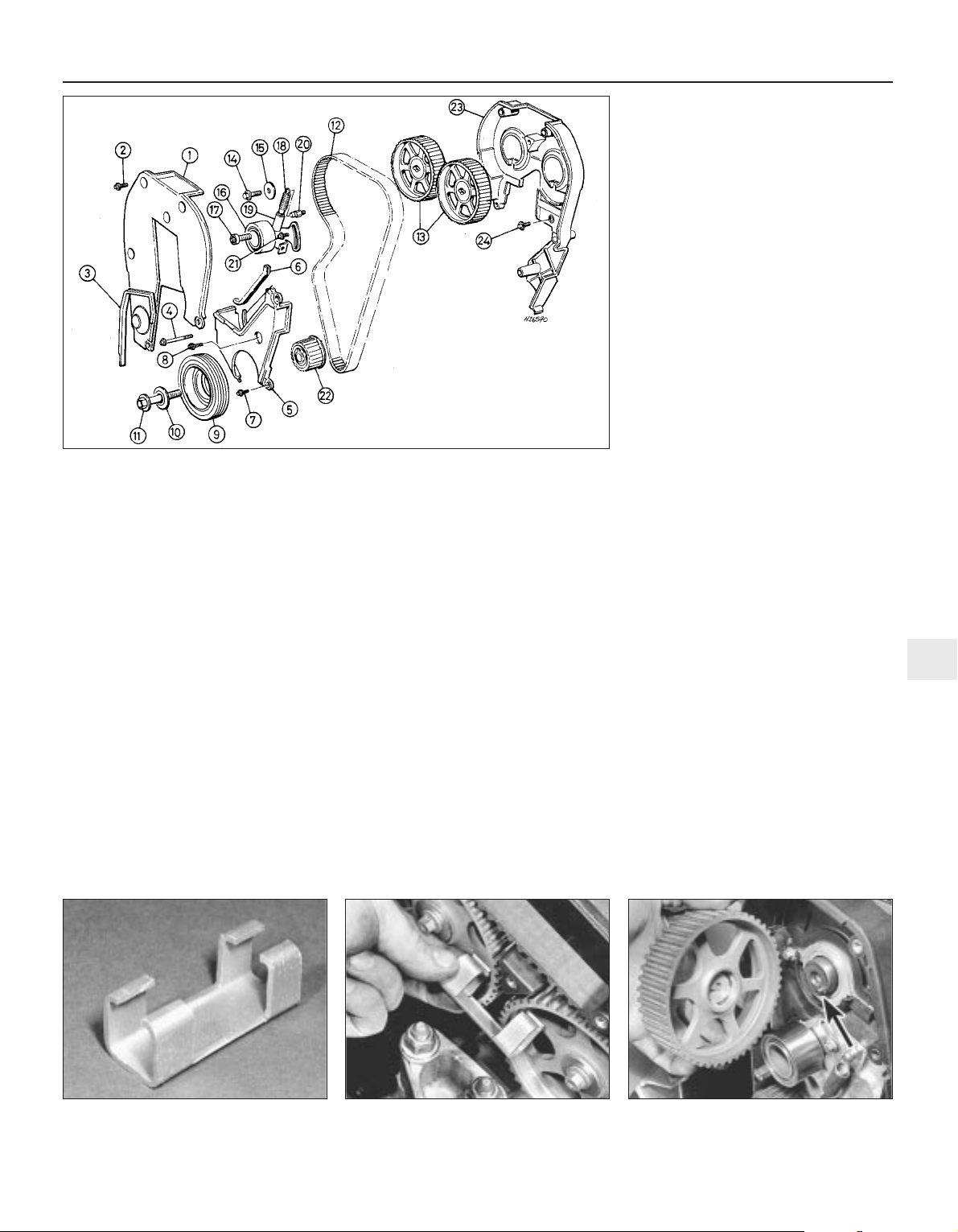

9.2a Timing belt, sprockets and covers - K8 engine

1 Timing belt upper right-

hand (outer) cover

2 Seal

3 Bolt

4 Bolt

5 Bolt

6 Shouldered bolt

7 Timing belt lower cover

8 Seal

9 Seal

10 Bolt

11 Bolt

12 Crankshaft pulley

13 Washer

14 Crankshaft pulley bolt

15 Timing belt tensioner

pulley assembly

16 Tensioner pulley Allen

screw

17 Tensioner backplate

clamp bolt

18 Tensioner pulley spring

19 Sleeve

20 Pillar bolt

21 Timing belt

22 Crankshaft sprocket

23 Camshaft sprocket

24 Camshaft sprocket bolt

25 Washer

26 Timing belt upper left-

hand (inner) cover

27 Bolt - cover to water

pump

28 Bolt

8.16 Refitting timing belt K16 engine

8.15b Crankshaft sprocket dots (A)

aligned on each side of oil pump raised

rib (B)

1689 Rover 214 & 414 Updated Version 09/97

If both camshaft sprockets

on K16 engines are to be

removed, it is good practice

to mark them (inlet or

exhaust) so that they can be returned to

their original locations on reassembly.

Page 13

component needs to be removed at the same

time, start by removing the timing belt, then

remove each component as described below

whilst ignoring the preliminary dismantling

steps.

Removal

1 Disconnect the battery negative lead.

2 To improve access to the timing belt

components (see illustrations), remove the

expansion tank mounting bolts then free the

coolant hose from any relevant retaining clips

and position the tank clear of the engine. On

models equipped with power-assisted

steering, undo all the power steering hose

retaining clip bolts then slide the fluid

reservoir out of its retaining clip and position it

clear of the timing belt covers. Take great care

not to place any undue strain on hoses and

mop up any spilt fluid immediately.

3 Remove the timing belt upper right-hand

(outer) cover.

4 Apply the handbrake then jack up the front

of the vehicle and support it on axle stands.

Remove the right-hand roadwheel.

5 From underneath the front of the vehicle,

slacken and remove the three bolts securing

the bumper flange to the body. Remove the

seven bolts securing the front undercover

panel to the body and remove the panel.

6 Using a suitable spanner or socket on the

crankshaft pulley bolt, rotate the crankshaft in

a clockwise direction until the long whitepainted mark on the crankshaft pulley’s

outboard (right-hand) face is aligned with the

single, separate mark on the timing belt lower

cover so that the crankshaft is in the 90°

BTDC position (see Chapter 1 for details of

the pulley/cover marks).

7 Check that the camshaft sprocket mark(s)

align as described in Section 8, paragraph 15

then proceed as described under the relevant

sub-heading.

Camshaft sprocket(s)

8 Slacken through half a turn each, the timing

belt tensioner pulley Allen screw and the

tensioner backplate clamp bolt. Push the

pulley assembly down to release all tension

from the timing belt, then re-tighten the

backplate clamp bolt securely.

9 Remove the belt from the camshaft

sprocket(s), taking care not to twist it too

sharply. Use fingers only to handle the belt.

Do not rotate the crankshaft until the timing

belt is refitted.

10 On K8 engines, slacken the camshaft

sprocket retaining bolt and remove it, along

with its washer. To prevent the camshaft from

rotating, use Rover service tool 18G 1521 to

retain the sprocket. If the tool is not available,

then an acceptable substitute can be

fabricated from two lengths of steel strip (one

long, the other short) and three nuts and bolts.

One nut and bolt should form the pivot of a

forked tool with the remaining two nuts and

bolts at the tips of the forks to engage with

the sprocket spokes, as shown in illustration 9.23a.

11 On K16 engines, unscrew the appropriate

camshaft sprocket retaining bolt and remove it,

along with its washer. To prevent a camshaft

from rotating, lock together both sprockets

using Rover service tool 18G 1570. This tool is

a metal sprag shaped on both sides to fit

the sprocket teeth and is inserted between the

sprockets. If the tool is not available, then an

acceptable substitute can be cut from a length

of square-section steel tube or similar to fit as

closely as possible around the sprocket

spokes (see illustrations).

12 On all engines, remove the sprocket(s)

from the camshaft end(s), noting the locating

roll pin(s) (see illustration). If a roll pin is a

Engine in-car repair procedures 2A•11

9.12 Removing camshaft sprocket (roll pin

arrowed) - K8 engine

9.11b . . . to fit sprocket spokes as closely

as possible - K16 engine

9.11a Camshaft locking tool cut from steel

section . . .

2A

1689 Rover 214 & 414 Updated Version 09/97

9.2b Timing belt, sprockets and covers - K16 engine

1 Timing belt upper right-

hand (outer) cover

2 Bolt

3 Seal

4 Bolt

5 Timing belt lower cover

6 Seal

7 Bolt

8 Bolt

9 Crankshaft pulley

10 Washer

11 Crankshaft pulley bolt

12 Timing belt

13 Camshaft sprockets

14 Bolt

15 Washer

16 Timing belt tensioner

pulley assembly

17 Tensioner pulley Allen

screw

18 Tensioner pulley spring

19 Sleeve

20 Pillar bolt

21 Tensioner backplate

clamp bolt

22 Crankshaft sprocket

23 Timing belt upper left-

hand (inner) cover

24 Bolt

Page 14

loose fit in the camshaft end, remove it and

store it with the sprocket for safe-keeping.

Crankshaft sprocket

13 On K16 engines, use the tool described in

paragraph 11 to lock together the camshaft

sprockets so that they cannot move under

valve spring pressure when the timing belt is

removed.

14 Remove the crankshaft pulley and timing

belt lower cover.

15 Slacken through half a turn each the

timing belt tensioner pulley Allen screw and

the tensioner backplate clamp bolt, push the

pulley assembly down to release all the

tension from the timing belt, then re-tighten

the backplate clamp bolt securely.

16 Work the belt clear of the crankshaft

sprocket, taking care not to twist it too

sharply. Use fingers only to handle the belt.

Do not rotate the crankshaft until the timing

belt is refitted.

17 Remove the sprocket from the crankshaft.

Tensioner assembly

18 On K16 engines, use the tool described in

paragraph 11 to lock together the camshaft

sprockets so that they cannot move under

valve spring pressure when the timing belt is

removed.

19 Using a suitable pair of pliers, unhook the

tensioner spring from the pillar bolt. Unscrew

the tensioner pulley Allen screw and the

tensioner backplate clamp bolt then withdraw

the tensioner assembly from the engine unit.

Do not rotate the crankshaft until the timing

belt is re-tensioned.

Inspection

20 Clean thoroughly the camshaft/crankshaft

sprockets and renew any that show signs of

wear, damage or cracks.

21 Clean the tensioner assembly but do not

use any strong solvent which may enter the

pulley bearing. Check that the pulley rotates

freely on the backplate, with no sign of

stiffness or of free play. Renew the assembly

if there is any doubt about its condition or if

there are any obvious signs of wear or

damage. The same applies to the tensioner

spring, which should be checked with great

care as its condition is critical for the correct

tensioning of the timing belt.

Refitting

Camshaft sprocket(s)

22 If removed, refit the roll pin to the

camshaft end, ensuring that its split is facing

the centre of the camshaft, then refit the

sprocket so that the timing marks are facing

outwards (to the right). On K16 engines,

ensure that the appropriate sprocket keyway

engages with the camshaft locating pin (ie: if

refitting the inlet camshaft sprocket, engage

its IN keyway with the roll pin and so on) then

refit the sprocket retaining bolt and washer

(see illustration). Where necessary, repeat

the procedure for the second sprocket.

23 Prevent the sprocket(s) from rotating by

using the method employed on removal, then

tighten the sprocket retaining bolt(s) to the

specified torque setting. Check that the

sprocket timing marks align as described in

Section 8, paragraph 15 (see illustrations).

24 Fit the timing belt over the camshaft

sprockets, ensuring that the belt front run

(and, on K16 engines, the top run) is taut, that

is, all slack is on the tensioner pulley side of

the belt. Do not twist the belt sharply while

refitting it and ensure that the belt teeth are

correctly seated centrally in the sprockets and

that the timing marks remain in alignment.

25 Slacken the tensioner backplate clamp

bolt and check that the tensioner pulley

moves to tension the belt. If the tensioner

assembly is not free to move under spring

tension, rectify the fault or the timing belt will

not be correctly tensioned.

26 On K16 engines, remove the camshaft

sprocket locking tool.

27 Using a suitable spanner or socket, rotate

the crankshaft two full turns clockwise to

settle and tension the belt. Realign the

crankshaft pulley (90° BTDC) mark and check

that the sprocket timing mark(s) are still

correctly aligned.

28 If all is well, first tighten the tensioner

pulley backplate clamp bolt to the specified

torque, then tighten the tensioner pulley Allen

screw to the specified torque.

29 Refit the front undercover panel and

roadwheel, then lower the vehicle to the

ground.

30 Refit the timing belt upper right-hand

(outer) cover.

31 Where necessary, refit the power steering

fluid reservoir to the mounting bracket and

secure the hydraulic hose clamps in position

with the retaining bolts.

32 Refit the coolant expansion tank and

tighten the mounting bolts securely. Secure

the coolant hose in position with any

necessary retaining clips and reconnect the

battery negative lead.

Crankshaft sprocket

33 Refit the sprocket to the crankshaft so

that it locates correctly on the crankshaft’s

flattened section, noting that the sprocket

flange must be innermost so that the two

timing marks are on the outside (right-hand

side) of the sprocket. Check that the sprocket

timing marks align as described in Section 8,

paragraph 15.

34 Fit the timing belt over the crankshaft

sprocket, ensuring that the belt front run (and,

on K16 engines, the top run) is taut, that is, all

slack is on the tensioner pulley side of the

belt. Do not twist the belt sharply

while refitting it and ensure that the belt teeth

are correctly seated centrally in the

sprockets and that the timing marks remain in

alignment.

35 Slacken the tensioner backplate clamp

bolt and check that the tensioner pulley

moves to tension the belt. If the tensioner

assembly is not free to move under spring

tension, rectify the fault or the timing belt will

not be correctly tensioned.

36 On K16 engines, remove the camshaft

sprocket locking tool.

37 Refit the lower timing belt cover and the

crankshaft pulley.

38 Carry out the operations described in

paragraphs 27 to 32.

2A•12 Engine in-car repair procedures

9.23b Locking camshafts in position with

fabricated tool - K16 engine

9.23a Using fabricated tool to hold

camshaft pulley in position - K8 engine

9.22 Camshaft sprockets have two

keyways. Engage EX keyway with exhaust

camshaft roll pin and IN keyway with inlet

camshaft roll pin - K16 engine

1689 Rover 214 & 414 Updated Version 09/97

Page 15

Tensioner pulley

39 Refit the tensioner pulley assembly and

tighten the pulley Allen screw and the

backplate clamp bolt lightly. Hook the

tensioner spring over the pillar bolt and check

that the tensioner is free to move under spring

tension and that the pulley bears correctly

against the timing belt (see illustration).

40 On K16 engines, remove the camshaft

sprocket locking tool.

41 Carry out the operations described above

in paragraphs 27 to 32.

10 Camshaft oil seals - renewal

4

Note: If a right-hand oil seal is to be renewed

with the timing belt still in place, then check

that the belt is free from oil contamination.

Renew the belt if signs of oil contamination

are found. Cover the belt to protect it from

contamination while work is in progress and

ensure that all traces of oil are removed from

the area before the belt is refitted.

Right-hand seal(s)

1 Remove the camshaft sprocket(s).

2 Punch or drill two small holes opposite

each other in the oil seal. Screw a self-tapping

screw into each and pull on the screws with

pliers to extract the seal.

3 Clean the seal housing and polish off any

burrs or raised edges which may have caused

the seal to fail in the first place.

4 Lubricate the lips of the new seal with clean

engine oil and drive it into position until it

seats on its locating shoulder. Use a suitable

tubular drift, such as a socket, which bears

only on the hard outer edge of the seal (see

illustration). Take care not to damage the

seal lips during fitting and note that the seal

lips should face inwards.

5 Refit the camshaft sprocket(s).

Left-hand seals - K16 engines

6 Disconnect the battery negative lead.

7 To reach the inlet camshaft seal, remove

the distributor.

8 To reach the exhaust camshaft seal,

unfasten the rubber strap securing the air

intake duct to its support bracket, disconnect

the vacuum pipe from the air temperature

control valve and unclip the pipe from the

support bracket. Undo the bracket’s retaining

bolts and remove the bracket from the

cylinder head (see illustration).

9 Remove the old seal and install the new one

as described above in paragraphs 2 to 4.

10 On the inlet camshaft, refit the distributor.

11 On the exhaust camshaft, refit the air

intake duct support bracket, tightening its

screws to the specified torque wrench setting.

Reconnect and secure the air temperature

control valve vacuum pipe and refit the rubber

strap to secure the air intake duct.

12 Connect the battery negative lead.

11 Camshafts and hydraulic

tappets - removal, inspection

and refitting

4

Note: Prior to removing the camshaft(s), obtain

Rover sealant kit LVV 10002 which also

contains a plastic scraper. Read the

instructions supplied with the kit and take care

not to allow the sealant to contact the fingers,

as it will bond the skin. If difficulty is

experienced with the removal of hardened

sealant from mating surfaces, it will be

necessary to use a foam action gasket remover.

Removal

K8 engines

1 Remove the cylinder head cover (see

illustration 11.0a overleaf).

2 Remove the distributor.

3 Remove the camshaft sprocket.

4 Carefully prise the oil feed tube away from

the camshaft bearing caps and remove it

from the head assembly. Remove the

O-rings from the oil rail and discard them.

The O-rings must be renewed whenever they

are disturbed.

5 The camshaft right and left-hand end

bearing caps are noticeably different and

cannot be confused. The intermediate bearing

caps (which are all similar) are marked by the

manufacturer with a number (1, 2, 3, or 4)

stamped in the boss next to the oil feed hole.

Before unbolting any of the caps, make

written notes to ensure that each can be

easily identified and refitted in its original

location.

6 Working in the reverse of the tightening

sequence (see illustration 11.29), slacken the

camshaft bearing cap bolts progressively, by

one turn at a time. Work only as described to

release the pressure of the valve springs on

the bearing caps gradually and evenly.

7 Withdraw the bearing caps, noting the

presence of the locating dowels on the end

caps, then remove the camshaft and withdraw

the oil seal.

8 Obtain eight small, clean plastic containers,

number them 1 to 8, and then fill them with

clean engine oil. Using a rubber sucker,

withdraw each hydraulic tappet in turn (see

illustration), and place it in its respective

container, to prevent oil loss. Do not

interchange the hydraulic tappets or the rate

of wear will be much increased and do not

allow them to lose oil or they will take a long

Engine in-car repair procedures 2A•13

10.8 Remove air intake duct support

bracket to reach exhaust camshaft left-

hand oil seal - K16 engine

10.4 Fitting a new camshaft right-hand oil

seal - K16 engine

9.39 Ensure timing belt tensioner spring is

correctly hooked onto pillar bolt

2A

1689 Rover 214 & 414 Updated Version 09/97

If faulty tappets are

diagnosed and the engine’s

service history is unknown,

it is always worth trying the

effect of renewing the engine oil and

filter (using only good quality engine oil

of the recommended viscosity and

specification) before going to the

expense of renewing any of the

tappets.

11.8 Use a valve-grinding sucker to

extract hydraulic tappets

Page 16

2A•14 Engine in-car repair procedures

1689 Rover 214 & 414 Updated Version 09/97

11.0a Top end components - K8 engine

11.0b Top end components - K16 engine

1 Cylinder head cover

2 Seal

3 Engine oil filler cap

4 Seal

5 Bolt

6 HT lead retaining clip

bracket

7 Screw

8 HT lead retaining clip

9 HT lead retaining clip

10 HT lead retaining clip

bracket

11 Air intake duct support

bracket

12 Fastener insert

13 Bolt

14 Oil seal

15 Roll pin

16 Camshaft

17 Camshaft right-hand

bearing cap*

18 Dowel

19 Bolt

20 Camshaft intermediate

bearing cap*

21 Bolt

22 Camshaft left-hand

bearing cap*

23 Oil feed tube

24 O-ring

25 Cylinder head bolt

26 Cylinder head

27 Cylinder head gasket

28 Hydraulic tappet

29 Split collets

30 Spring retainer

31 Valve spring

32 Valve stem seal/ spring

lower seat

33 Valve guide

34 Inlet valve

35 Valve seat insert

36 Exhaust valve