Page 1

DTAM Micro

Operator Interface

Module

Catalog Numbers 2707-M232P3,

2707-M485P3

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment

and electromechanical devices that should be taken into consideration when

applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley, DTAM Micro and SLC are trademarks of Rockwell Autom ation

PLC is a registered trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Table of Contents

DT AM Micro Operator Interface Module

User Manual

Using this Manual

DTAM Micro Overview

Chapter 1

Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of this Manual 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Key Operations 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODE Key Operations 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switches 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Port 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Version (Catalog No. 2707-M232P3) 2–9. . . . . . . . . . . . . . . . . . . . . .

RS-232 Communications 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Version (Catalog No. 2707-M485P3) 2–10. . . . . . . . . . . . . . . . . . . . . .

RS-485 Communications 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the DTAM Micro 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT AM Plus Programming Software (DPS) 2–12. . . . . . . . . . . . . . . . . . . . . . . .

Upload/Download Connections 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Settings 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating System 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Settings 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Parameters 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Options 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Accessories 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Setup and Mode

Menu

Chapter 3

Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Apply Power 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powerup Sequence 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Menu 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the DTAM Micro 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Communication Parameters Manually 3–6. . . . . . . . . . . . . . . . . . . . . . .

Special Functions forController Operations 3–7. . . . . . . . . . . . . . . . . . . . . . . . .

Entering a New Master Security Code 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling / Disabling Scaling 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

DT AM Micro Operator Interface Module

User Manual

Using the Simulate Mode 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Functions 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transferring Applications

Running Applications

Chapter 4

Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upload / Download DIP Switch Settings 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upload / Download Connections 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Setup 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading an Application 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Uploading an Application 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Setting 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Documentation 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Write Mode 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Types 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Navigation 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Links 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advisor Option 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Keys 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu and Sub-Menu Screens 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sub-Menus 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Screens 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Display Screens 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Screens 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recipe Screens 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Screens 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

ii

Chapter 6

Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Guidelines 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosures 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearances 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Dimensions 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutout Template 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire and Cable Length Restrictions 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting DC Power 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents

DT AM Micro Operator Interface Module

User Manual

Communication

Connections and Setup

Troubleshooting and

Maintenance

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Guidelines 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting RS-232 Devices 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting RS-485 Devices 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating with a Logic Controller 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Parameters 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating With a PLC-5 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating With an SLC 5/03 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating With an SLC or Network 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232 Communications with a MicroLogix 1000 7–10. . . . . . . . . . . . . . . . . . . . .

RS485/DH–485 Communications with a MicroLogix 1000 7–11. . . . . . . . . . . . . . .

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TroubleshootingRecommendations 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common OperatingProblems 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CommunicationError Codes 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Test Functions 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Test 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Test 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Test 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Port Test 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM Test 8–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Memory Test 8–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Memory Test 8–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TXEN Test 8–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Display Window 8–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Appendix A

DT AM Micro Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agency Ratings A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

European Union Directive Compliance A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

DT AM Micro Operator Interface Module

User Manual

DTAM Micro Cable

Diagrams

DTAM Micro Special

Controller Functions

Appendix B

DT AM Micro Cables B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 2707-NC2 B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 2707-NC3 B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 2707-NC4 B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 2707-NC5 B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 2707-NC10 B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog No. 1747-CP3 B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Objectives C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Special Functions C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the P-A/D Function C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading ControllerInput and Output Files C–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller Status Files C–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller Bit and Integer Files C–5. . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller T imer Files C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller Counter Files C–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller Control Files C–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller ASCII Files C–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / Writing Controller BCD Files C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading / WritingController Message Files C–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Reading Controller ASCII String Files C–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Mode Function C–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Memory Transfer Function C–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Clear Fault Function C–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Page 7

Chapter

Objectives

Contents of this Manual

A–B

1

Using this Manual

Read this chapter to familiarize yourself with the rest of the manual.

You will learn about:

• Contents of this manual

• Intended audience

• Conventions

• Related publications

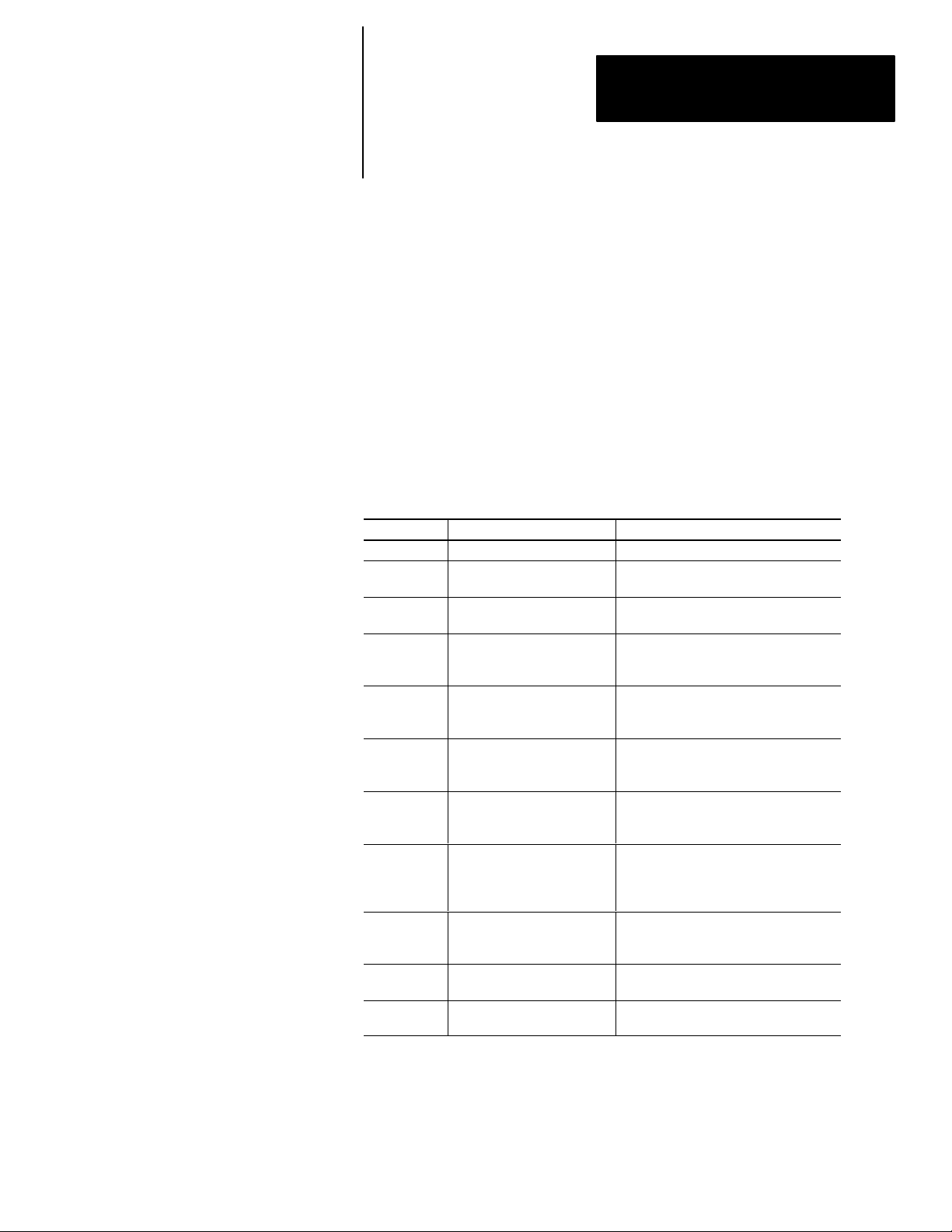

The following table lists the contents of each chapter:

Chapter Title Purpose

1 Using this Manual Provides an overview of the manual.

2 Overview of DTAM Micro

3 Initial Setup and Main Menu

4 Transferring Application Files

5 Running Applications

6 Installation

7

8

Appendix A Specifications

Appendix B Cable Diagrams

Appendix C

Communication

Connections and Setup

Troubleshooting

and Maintenance

DTAM Micro Special

Controller Functions

Contains a description of the DTAM

Micro and accessory devices.

Describes initial desktop setup of the

DTAM Micro using main menu functions.

Describes how to upload and download

application files between the DTAM Micro

and a personal computer.

Describes the basic screen types.

Also describes the different function

key operations.

Provides procedures for mounting the

DTAM Micro. Also provided are wiring

instructions and recommendations.

Describes RS-232 and RS-485

connections. Setup guidelines are

provided for SLC and PLC controllers.

Provides assistance in identifying

and correcting common operating

problems. Cleaning recommendations

are also provided.

Provides the specifications, agency

ratings, and European Union Directive

Compliance.

Provides the DTAM Micro cable

diagrams.

Provides the special control functions.

1–1

Page 8

Chapter 1

Using this Manual

Intended Audience

Conventions

No special knowledge is required to operate the DTAM Micro. If you are

installing the DTAM Micro, you must be familiar with the standard panel

cutout and installation techniques. If you are wiring the DTAM Micro, you

must be familiar with the electrical codes in your area (see inside front

cover).

You should be familiar with the DTAM Programming Software (see related

publications below).

This manual uses the following conventions:

• Keys that you press on the DTAM Micro are enclosed in brackets [ ].

For example: [NEXT] refers to the NEXT key on the DTAM Micro.

• References to menus are initial cap followed by the word Menu.

For example: Special Menu, Main Menu, Other Menu

• All DTAM Micro displays are shown inside a rectangular box.

1 Reset 3 Special

2 Com-Port 4 Other

Related Publications

1–2

The following publications may be helpful for additional reference.

DT AM Micro Publications

Publication Number Title

2707-801

Wiring Publications

1770-6.2.2

SLC Publications

Publication Number Title

1747-6.21

1747-UM011

1747-RM001 SLC 500 Reference Manual

DTAM Programming Software Programming Manual

(Series J or later Software)

Data Highway / Data Highway Plus / Data Highway-485

Cable Installation Manual

SLC 500 Fixed Hardware Style

Installation and Operation Manual

SLC 500 Modular Hardware Style

Installation and Operation Manual

Page 9

Chapter 1

Using this Manual

PLC-5 Publications

Publication Number Title

1785-6.1 PLC-5 Instruction Set Reference

1785-6.2.1 1785 PLC-5 Programmable Controllers Design Manual

1785-6.6.1

1785-7.1 PLC-5 Programmable Controllers Quick Reference

PLC-5 Family Programmable Controllers Hardware

MicroLogix Publications

Publication Number Title

1747-6.3 MicroLogix 1000 User Manual

1747-6.2.1 MicroLogix 1000 Quick Reference Guide

Installation Manual

1–3

Page 10

Chapter 1

Using this Manual

1–4

Page 11

Chapter

Objectives

A–B

2

DTAM Micro Overview

This chapter describes the DTAM Micro and accessories.

It contains these sections:

Section Page

General Information 2–1

Package Contents 2–2

Description 2–2

Keypad 2–5

DIP Switches 2–7

Communications Port 2–8

RS-232 Communications 2–9

RS-485 Communications 2–10

Compatibility NO TAG

Programming the DTAM Micro 2–11

Default Settings 2–12

Product Options 2–13

Product Accessories 2–13

General Information

The DTAM Micro interfaces with the PLC-5 and SLC 500 family of

processors. The DTAM Micro allows operators to monitor and manipulate

process data on the plant floor.

RS-232 or RS-485 Port. The DTAM Micro has either an RS-232 port

(Catalog No. 2707-M232P3) or an RS-485 port (Catalog No. 2707-M485P3).

The RS-232 port allows point-to-point connections with a PLC-5 or SLC

5/03, 5/04, 5/05. The RS-485 port provides network or point-to-point

capability with a PLC-5 (over RS-422), SLC or other DH485 device.

Memory Capability. Storage of the PLC-5 DF1 or SLC DH-485 driver

(communications protocol), configuration information, and user-programmed

screens are maintained in nonvolatile memory providing storage for

approximately 244 screens.

Recipe Operations. Recipe type functions allow operators to quickly

modify blocks of data. Download data to a maximum of 10 non-sequential

register addresses per screen. Link multiple recipe screens to download data

to more than 10 addresses.

Flexible Function Key Operations. Eight function keys provide a

convenient way to trigger screen displays and change display screens.

Point-Access/Display Function. Allows you to monitor or modify data files

in SLC or PLC controllers. Use this function to setup and debug application

programs.

2–1

Page 12

Chapter 2

DTAM Micro Overview

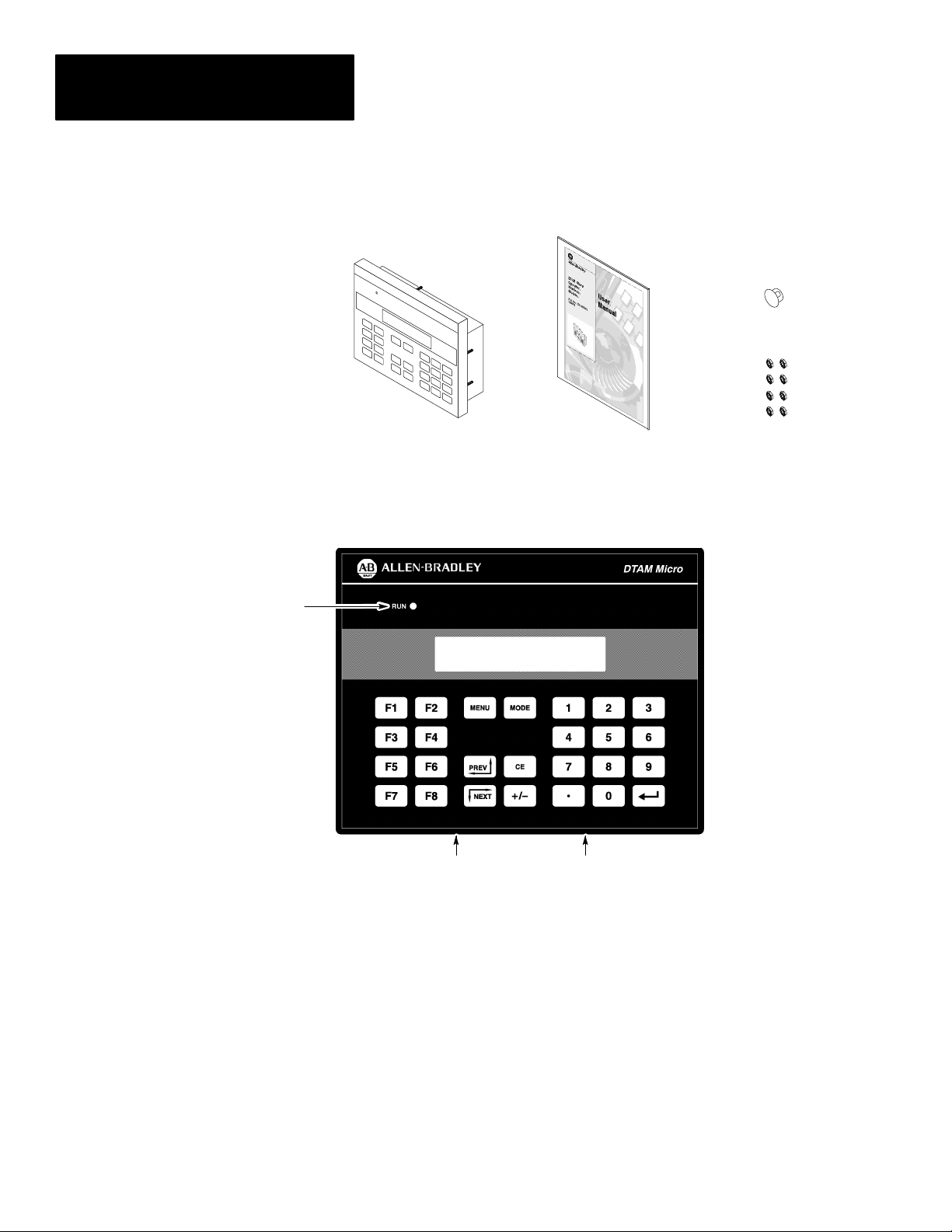

Package Contents

Description

LED Indicator

The DTAM Micro shipping box contains the following:

DIP Switch Cover

DTAM Micro

User Manual

(Catalog No. 2707–UM002)

Mounting Nuts (8)

The front panel of the DTAM Micro terminal is shown below.

Figure 2.1

DT AM Micro (front view)

Display Window

(2 Spare)

2–2

Power Connector

Communications Port

Display

The 2 line by 20 character display uses high contrast LCD technology with

LED backlighting.

Keypad

The keypad is separated by color into easily identified groups or functions. In

addition, each key has a raised dome in the center to provide tactile feedback.

The keypad is designed for hand operation. Using any other object or tool

may damage the overlay or key.

LED Indicator

A RUN LED in the upper left corner of the terminal indicates proper

operation of the DTAM Micro. This LED illuminates after the DTAM Micro

passes the self diagnostic tests.

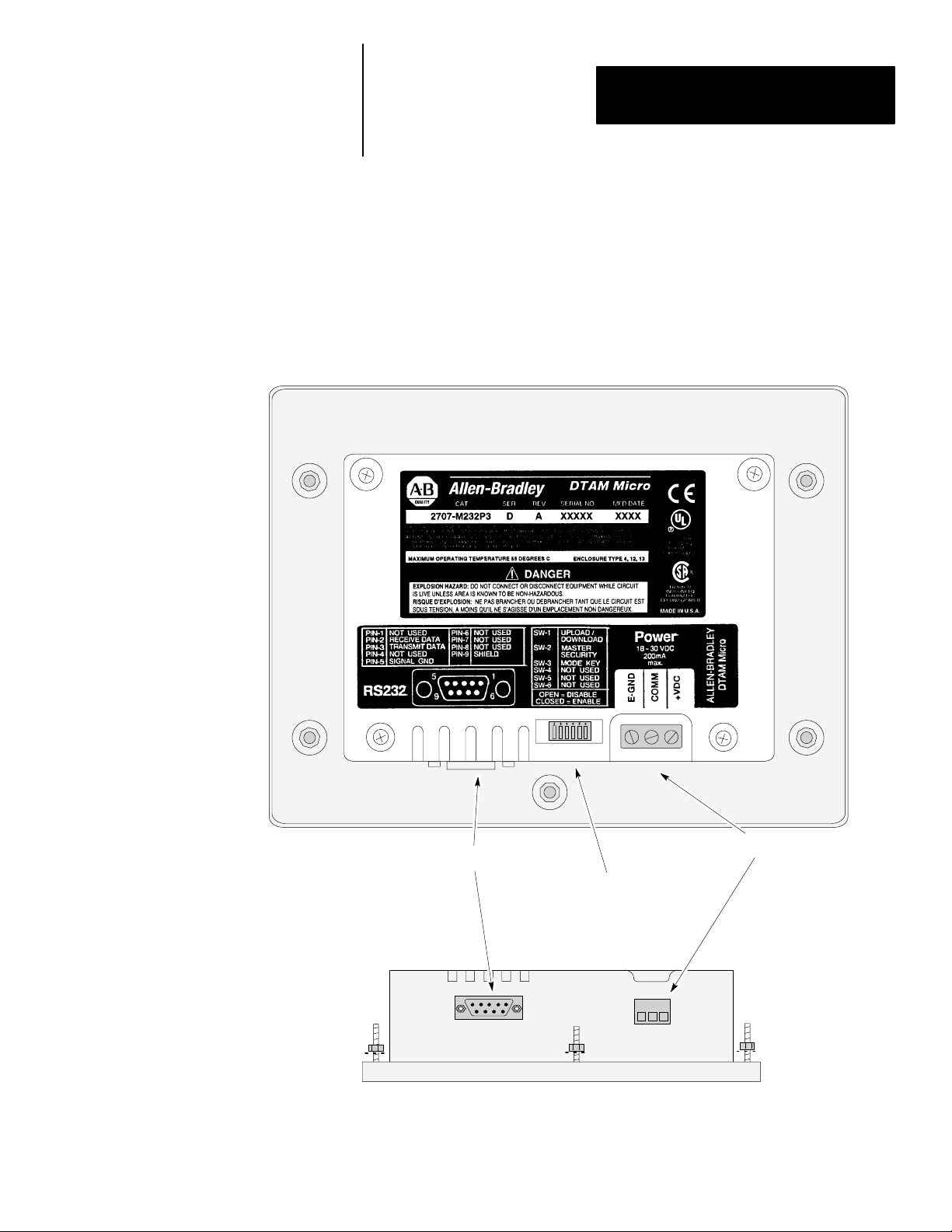

Page 13

Figure 2.2

DT AM Micro (back & bottom view)

Back View (RS-232 version shown)

Chapter 2

DTAM Micro Overview

Communications Port

Power Connector

DIP Switch

(Behind Removable Cover)

Bottom View

2–3

Page 14

Chapter 2

DTAM Micro Overview

Communications Port

The DTAM Micro has either an RS-232 or RS-485 port.

• Catalog No. 2707-M232P3 has RS-232 port

• Catalog No. 2707-M485P3 has RS-485 port

DIP Switch

A six position DIP switch selects various operating settings. This switch is

located under a removable cover on the back. To remove cover, align cover

tabs with notches in hole.

Power Connector

The power connector is a non-removable, screw terminal block located on

the bottom of the unit. Connect 24 VDC to these terminals or use the

optional AC to DC Adapter.

2–4

Page 15

Chapter 2

DTAM Micro Overview

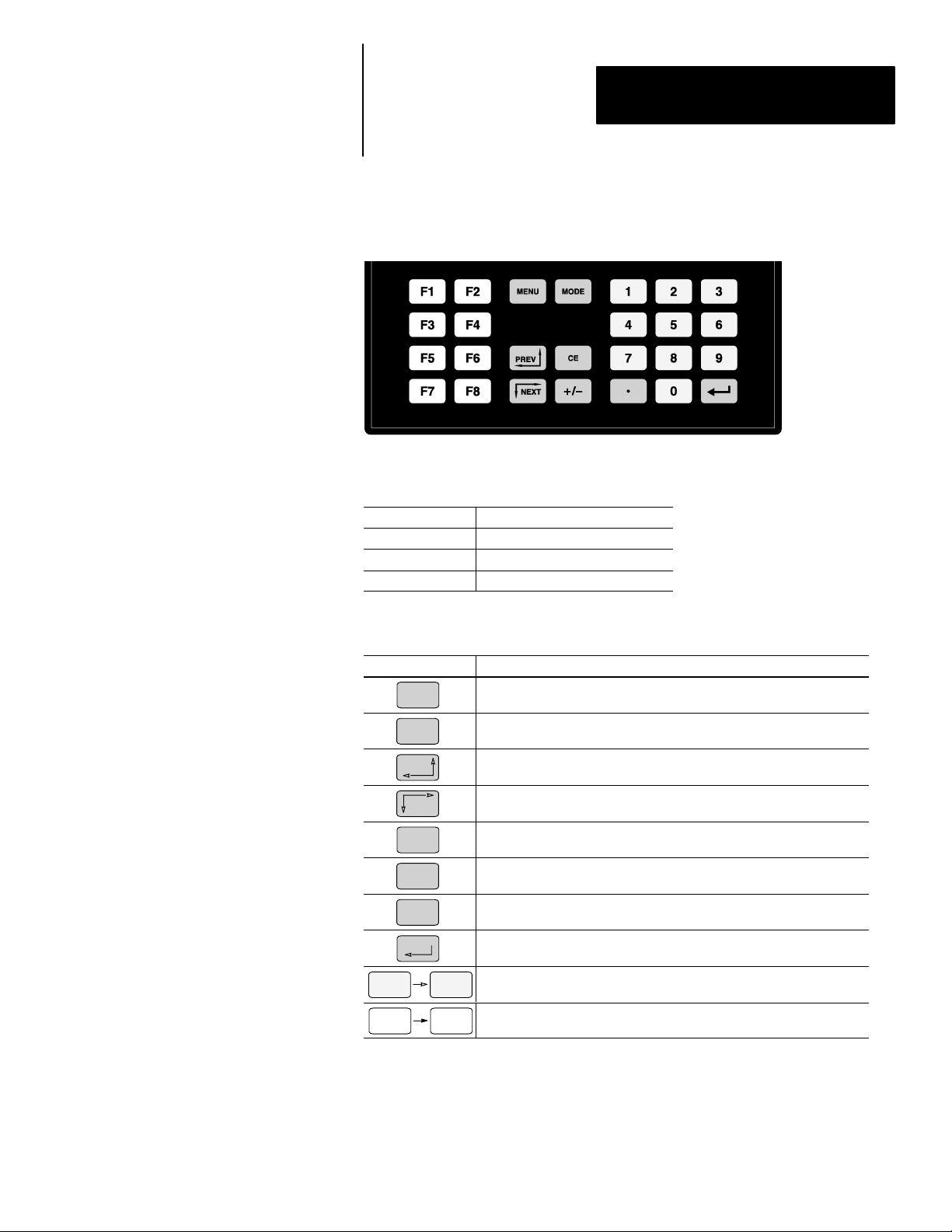

Keypad

Figure 2.3

Keypad

The DTAM Micro uses a sealed membrane, tactile feedback keypad. The

keys are color coded to easily identify key functions.

Key Color Function

Blue Movement/Operator Response

Dark Grey Display/Format Control

Light Grey Numeric Entry

The following table defines the function of each keypad key.

Key Function

MENU

MODE

PREV

NEXT

CE

+ \ –

D

Returns to the main menu of an application. If an alarm screen is triggered, the MENU key is not functional until the alarm is acknowledged.

Accesses special features and configuration operating parameters. DIP

switch SW-3 enables or disables the MODE key.

Steps back through a sequence of linked screens.

Steps forward through a sequence of linked screens.

Clears an entire value during data entry.

Toggles a data entry value between positive or negative.

Enters a decimal point.

Sends data to the controller. Data includes default values or data entered

at the keyboard. Also used to acknowledge alarm screens.

0 9

F1 F8

Enters numbers 0 to 9 during data entry or selects a numbered item

shown on the display.

Displays any application screen assigned to the key. These keys can also

set or clear bits at eight consecutive registers in the controller data table.

2–5

Page 16

Chapter 2

DTAM Micro Overview

Function Key Operations F1 F8

Function keys can be linked to application screens allowing quick access to

critical data display or data entry screens. For example, the F1 function key

is linked to Recipe Screen 10. The operator can press F1 at any point in the

application to download recipe registers on screen 10 to the processor.

A control mode can be assigned to each function key linked to a screen.

Control Mode Function

Auto Return Returns to the screen displayed before the function key was pressed.

Continue

Bit Write Mode

Continues to the next screen in the link regardless of the screen displayed

before the function key was pressed.

Allows the function key when pressed to set or clear a bit in the controller.

Bit Write Mode operates with either Auto Return or Continue mode.

The function keys access 8 contiguous word data elements defined by the

user. For example, assign function keys F1 to F8 to N7:20 → N7:27.

MODE Key Operations

MODE

The MODE key accesses a menu of options allowing you to set features and

operating parameters of the DTAM Micro.

1 Reset 3 Special

2 Com-Port 4 Other

1 Baud Rate 3 Parity

2 Data Bits 4 Exit

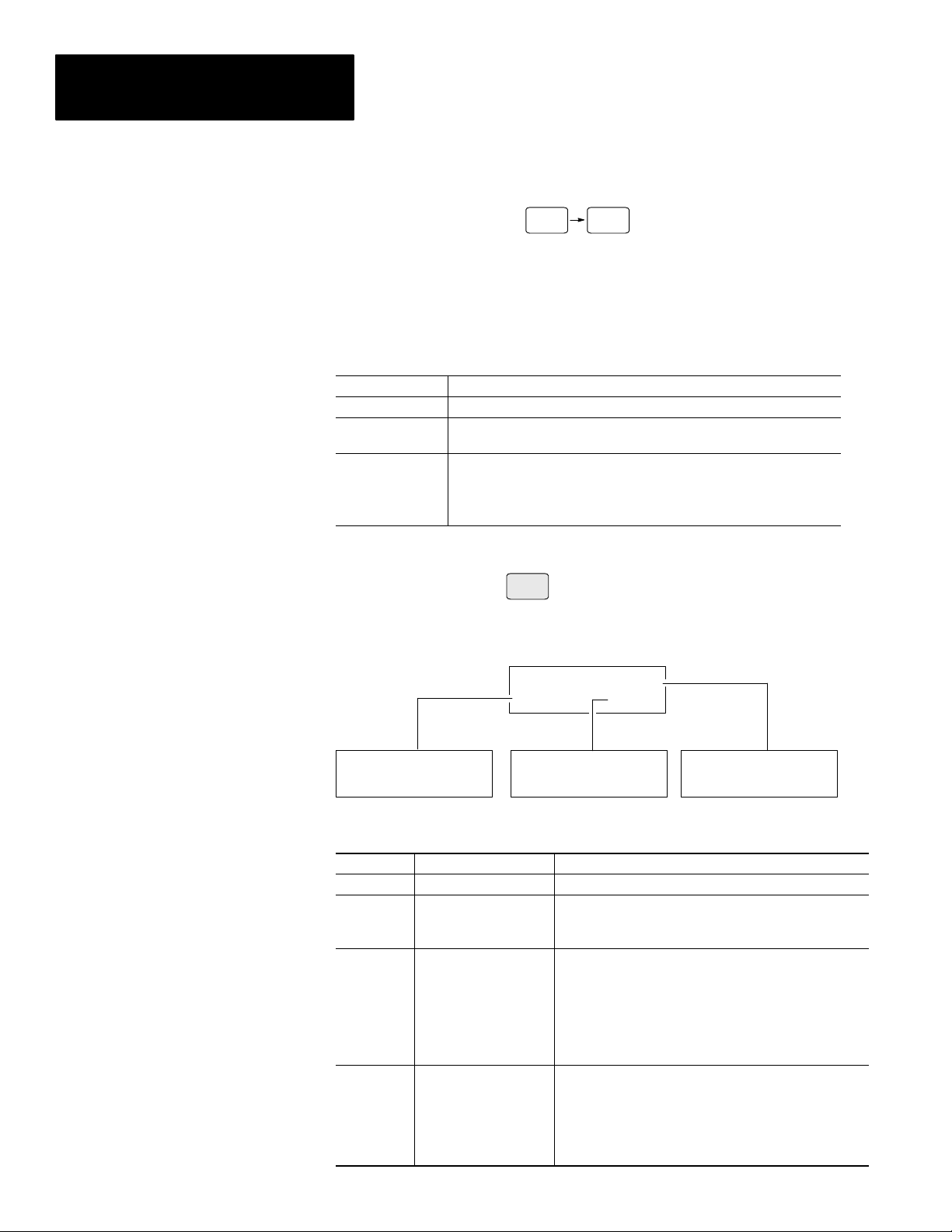

Mode Menu Select this option: To perform this function:

1 Reset Performs a system reset.

1 Baud Rate

2 Com-Port

3 Special

2 Data Bits

3 Parity

1 P-A/D

2 Mode

3 Memory Xfr

1 Master 3 Simulate

2 Scale 4 Test 5 Ex

Specifies 300, 1200, 2400, 4800, 9600, 19200, 38400

Specifies 7 or 8 data bits.

Specifies even, odd or none parity.

Displays and/or modifies data files in the processor.

Places processor in RUN mode or PROGRAM mode.

Transfers memory between a memory module and an SLC

or PLC5. The processor must be in PROGRAM mode.

1 P-A/D 3 Mem Xfr

2 Mode 4 Clr Flt

2–6

4 Other

4 Clr Flt

1 Master

2 Scale

3 Simulate

4 Test

Clears all processor faults in the PLC-5 or SLC 500.

Modifies the master security code of the DTAM Micro.

Converts controller values to engineering units.

Verifies an application without controller connected.

Tests memory, communications, keyboard and display.

Page 17

Chapter 2

DTAM Micro Overview

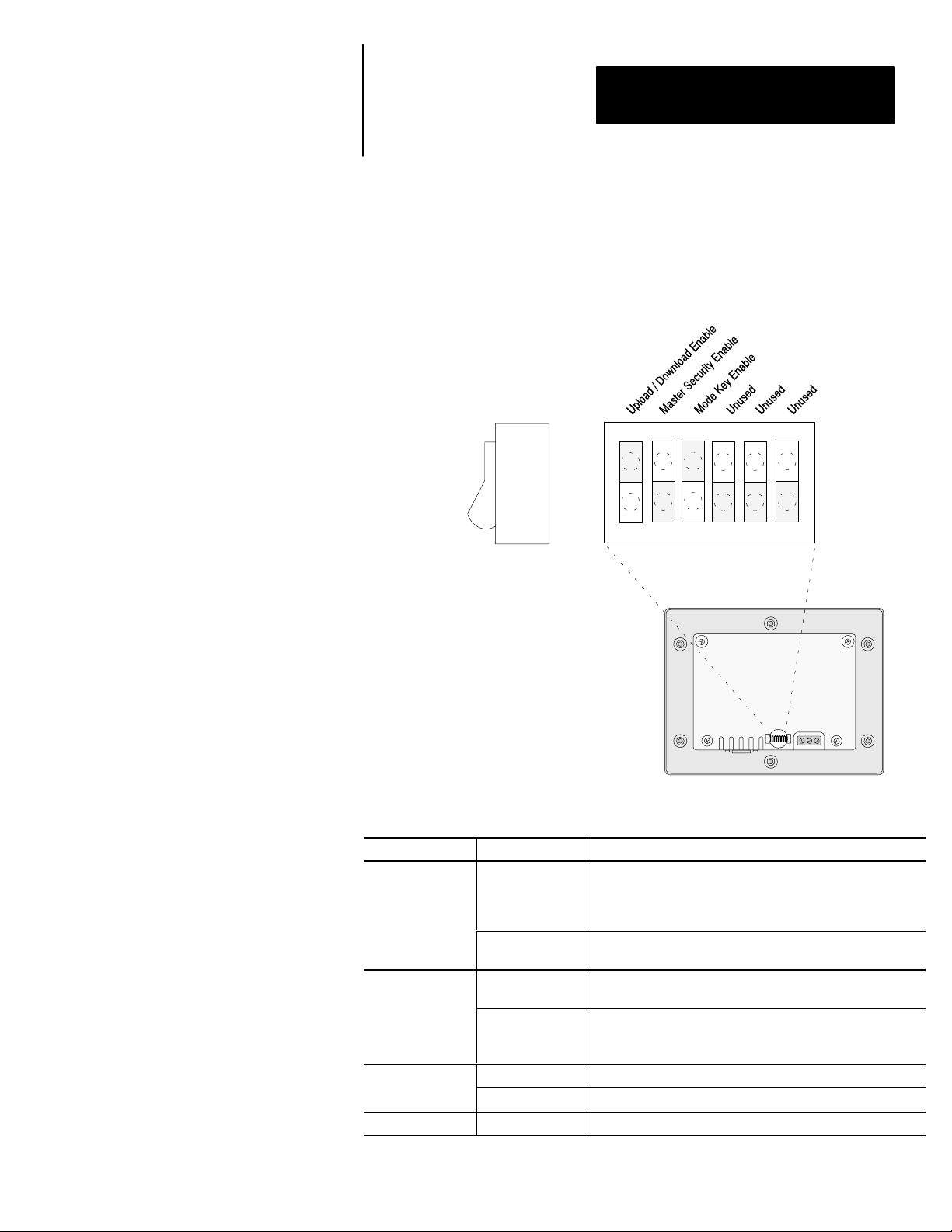

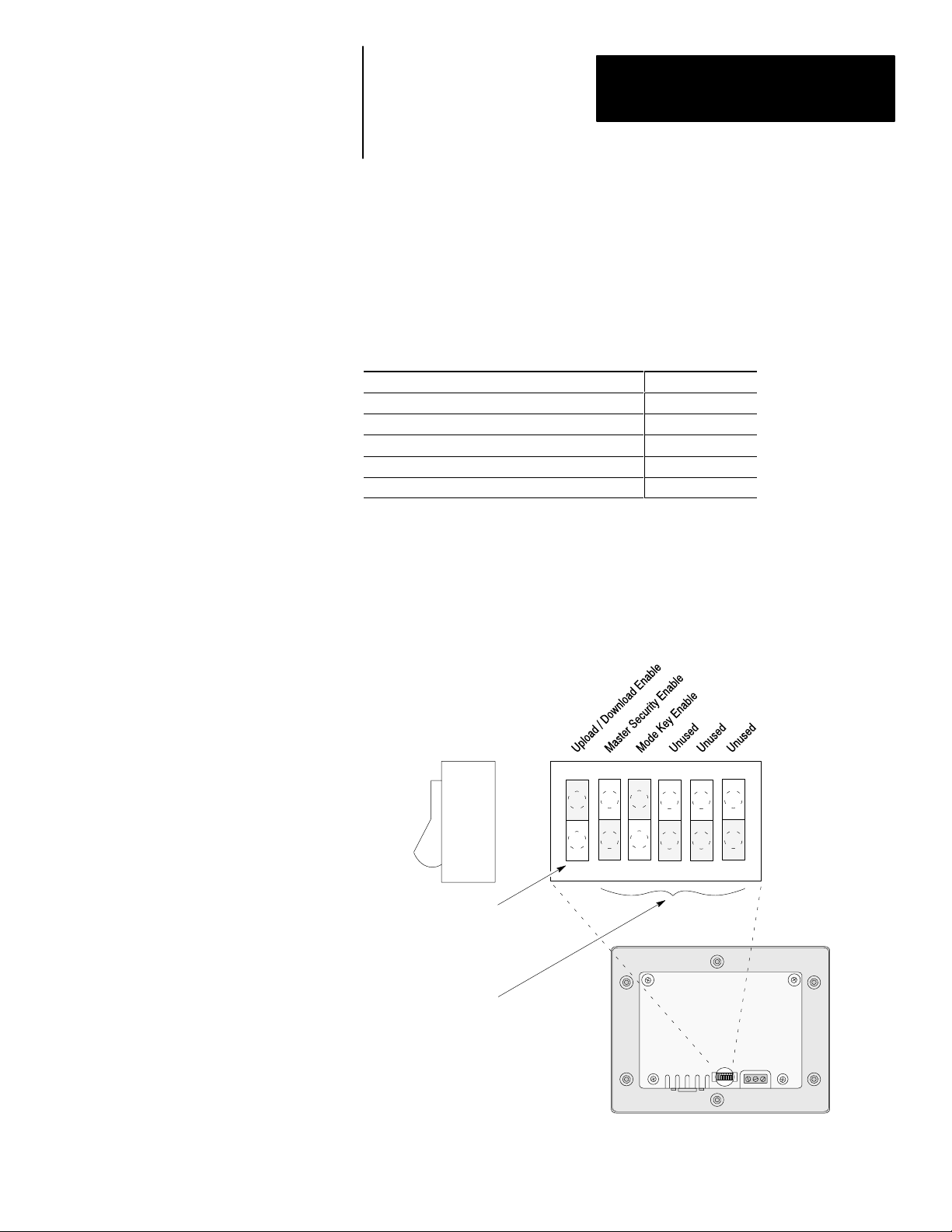

DIP Switches

The 6 position DIP switch allows you to enable or disable certain functions.

The DIP switch is accessed by removing the access cover on the back (access

cover is shipped in the hardware bag on new units).

Figure 2.4

DIP Switch

Side View

123456

ON =

OPEN

Back of DTAM Micro

Switch Position Setting Function

ON position allows the transfer of application files between

ON

1➀

OFF

ON

2

OFF

3

4, 5, 6 ON or OFF Reserved for future use.

➀ DTAM Micro is reset each time this switch position is changed.

ON ON enables the Mode key on the front panel.

OFF OFF disables the Mode key on the front panel.

the DTAM Micro and personal computer running DPS. All

communication between the DTAM Micro and controller are

disabled. Keypad entry is also disabled.

OFF enables communication between the DTAM Micro and

controller.

ON enables the master code. Enabling the master code

allows any security code to be accessed or modified.

OFF disables the master code. Disabling the master code

still allows access to a security screen or special functions

but does not allow security codes to be modified.

2–7

Page 18

Chapter 2

DTAM Micro Overview

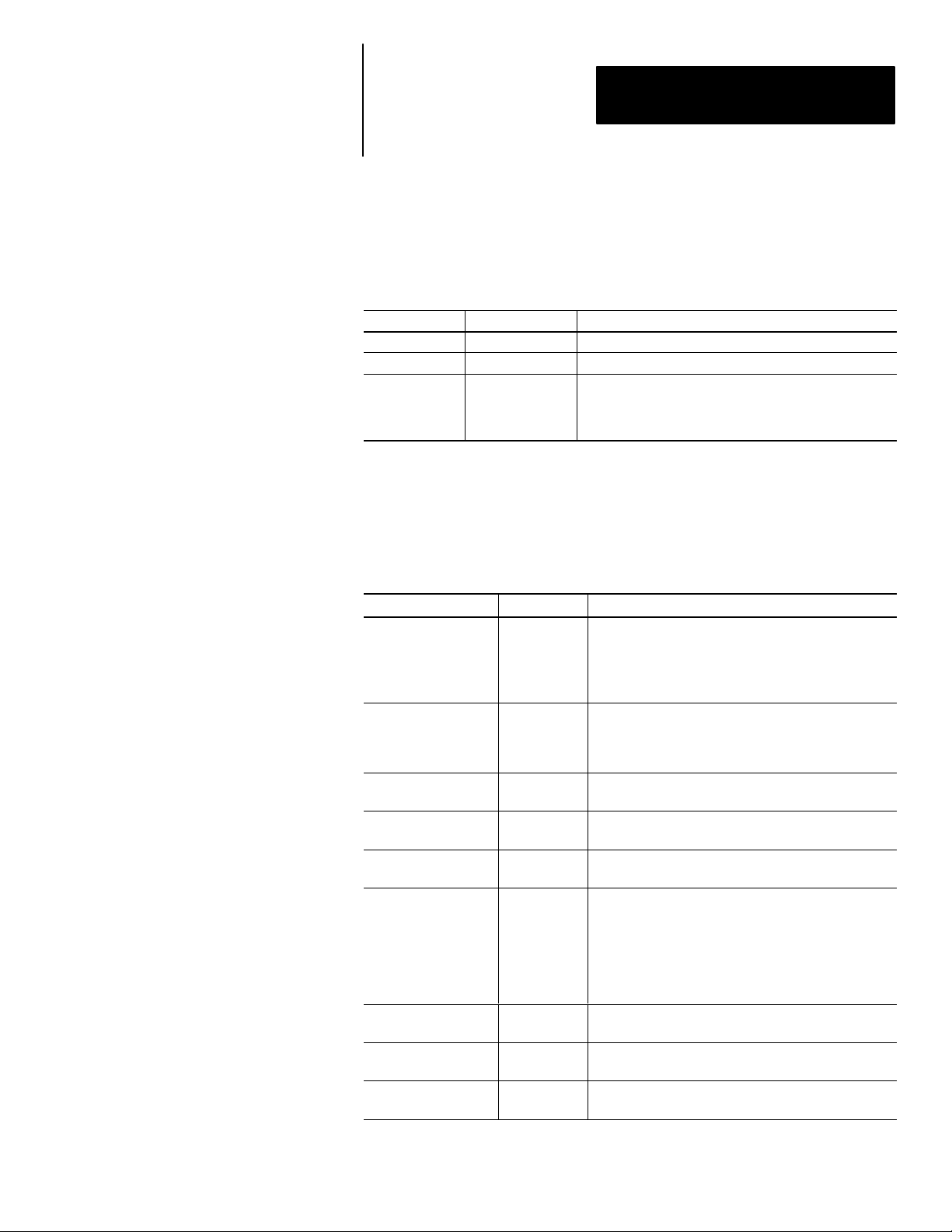

Communications Port

All communications are through a 9 pin connector on the bottom of the

DTAM Micro. The connector is either an RS-232 port or RS-485 port

depending upon the version catalog number.

Figure 2.5

Communications Port

DTAM Micro

(Bottom View)

RS-485 Version

(Catalog No. 2707-M485P3)

9 Pin Female

PIN # Signal Name

1 Data Out –

2 Data Out +

3 Data In 4 Data In +

5 Signal Ground

6 Transmit Enable

7 Not Used

8 Signal Ground

9 Shield

DTAM Micro

(Bottom View)

9 Pin Female

PIN # Signal Name

1 Not Used

2 Receive Data (RD)

3 Transmit Data (TD)

4 Not Used

5 Signal Ground

6 Not Used

7 Not Used

8 Not Used

9 Shield

RS-232 Version

(Catalog No. 2707-M232P3)

2–8

Page 19

Chapter 2

DTAM Micro Overview

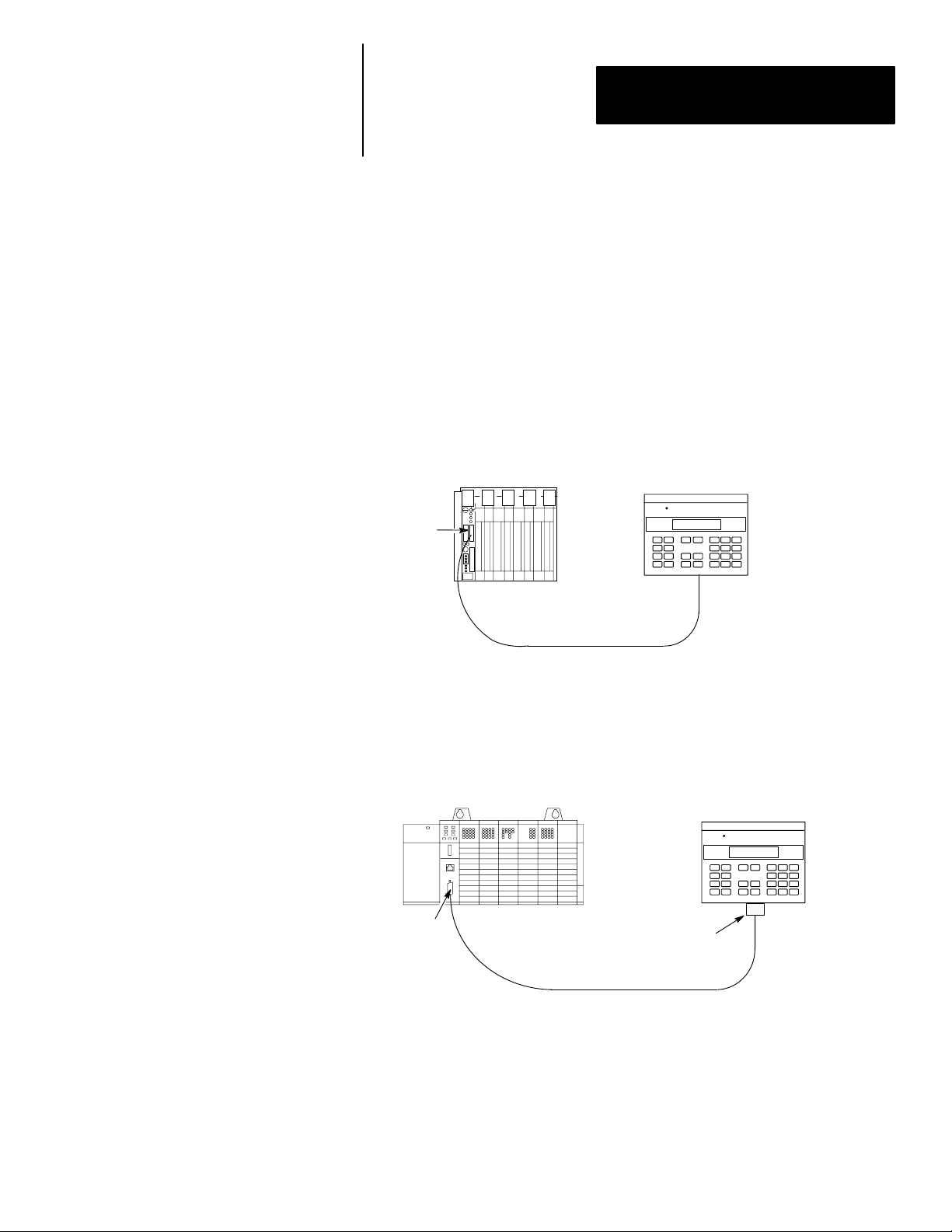

RS-232 Communications

RS-232 Version (Catalog No. 2707-M232P3)

The RS-232 port allows point-to-point communications with:

• PLC-5 Channel 0 (configured as RS-232 port, DF1 protocol)

• SLC 5/03, 5/04, 5/05 RS-232 port (DH485 protocol)

• MicroLogix 1000

Figure 2.6

Typical RS-232 Communications

DTAM Micro to PLC-5 Channel 0

PLC-5

Channel 0

RS-232

Cable (Catalog No. 2707-NC3)

DTAM Micro

DTAM Micro

RS-232 Port

Channel 0

SLC 5/03

DTAM Micro to SLC 5/03, 5/04, 5/05

Gender

Adapter

RS-232

Cable (Catalog No. 1747-CP3)

Gender Adapter Required

DTAM Micro

DTAM Micro

RS-232 Port

2–9

Page 20

Chapter 2

DTAM Micro Overview

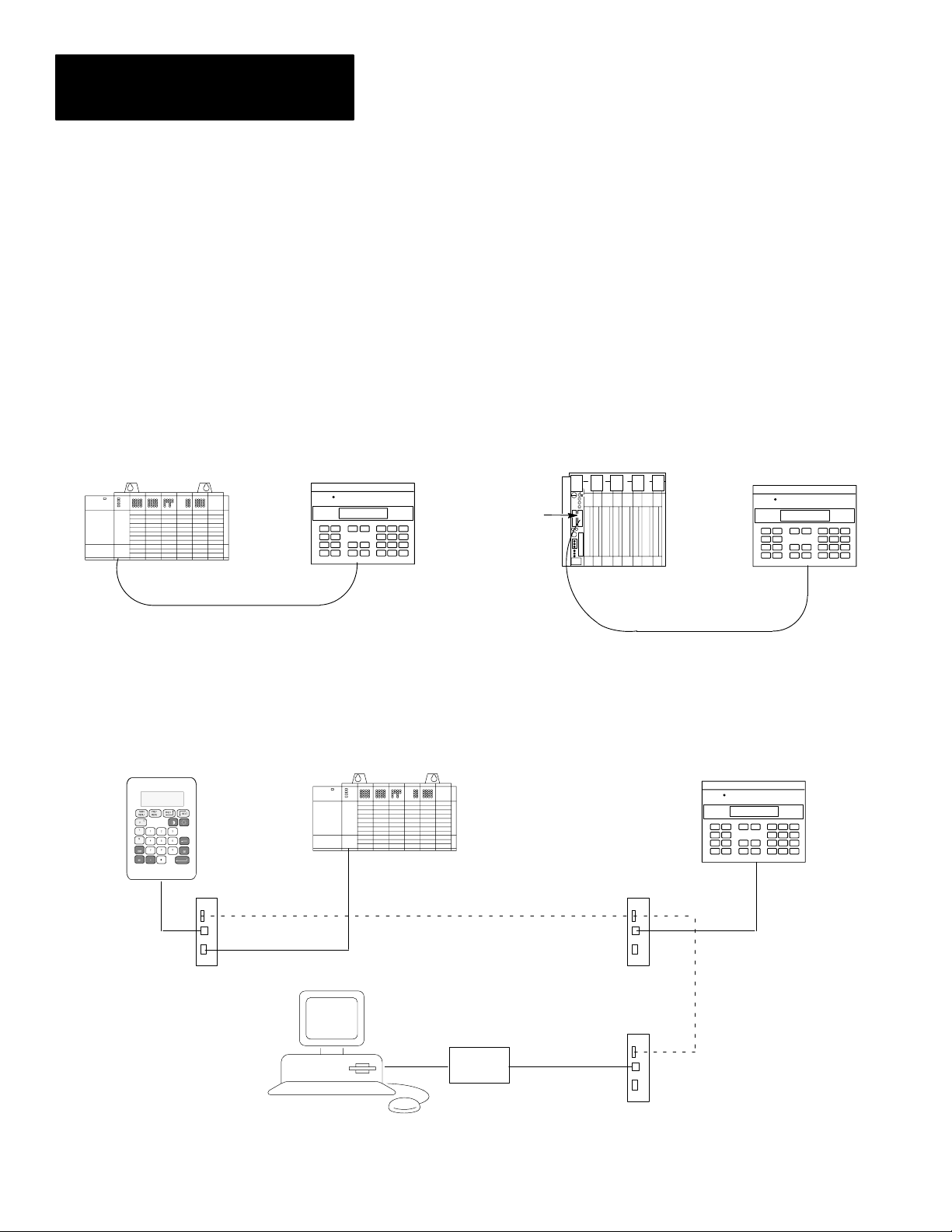

RS-485 Communications

DTAM Micro to Single SLC DTAM Micro to PLC-5 Channel 0

SLC

RS-485

Cable (Catalog No. 2707-NC1)

RS-485 Version (Catalog No. 2707-M485P3)

The RS-485 port allows point-to-point and multi-drop communications with:

• PLC-5 Channel 0 (configured as RS-422 port, DF1 protocol)

• SLC 500 DH-485 port

• MicroLogix 1000 using the AIC+ Interface

Figure 2.7

Typical RS-485 Communications

DTAM Micro

DTAM Micro

RS-485 Port

Channel 0

PLC-5

RS-422

Cable (Catalog No. 2707-NC4)

DTAM Micro

DTAM Micro

RS-485 Port

2–10

DTAM Plus

Link Coupler

Programming Terminal

DTAM Micro to DH-485 Network

SLC

DH-485

Interface

Converter

RS-232 to RS-422

Link Coupler

Link Coupler

DTAM Micro

DTAM Micro

RS-485 Port

RS-485

Cable

(Catalog No. 2707-NC1)

Page 21

Chapter 2

DTAM Micro Overview

Programming the DTAM Micro

The DTAM Micro is programmed off-line using a personal computer running

DTAM Plus Programming Software (DPS). Operating system upgrades are

also transferred using a personal computer.

DTAM Programming Software (DPS)

Use DPS software (Catalog No. 2707-NP, Series H or later) to create

application screens for both the DTAM Micro and DTAM Plus Operator

Terminals. For a description of DPS, refer to the Programming Manual

(Publication No. 2707-801).

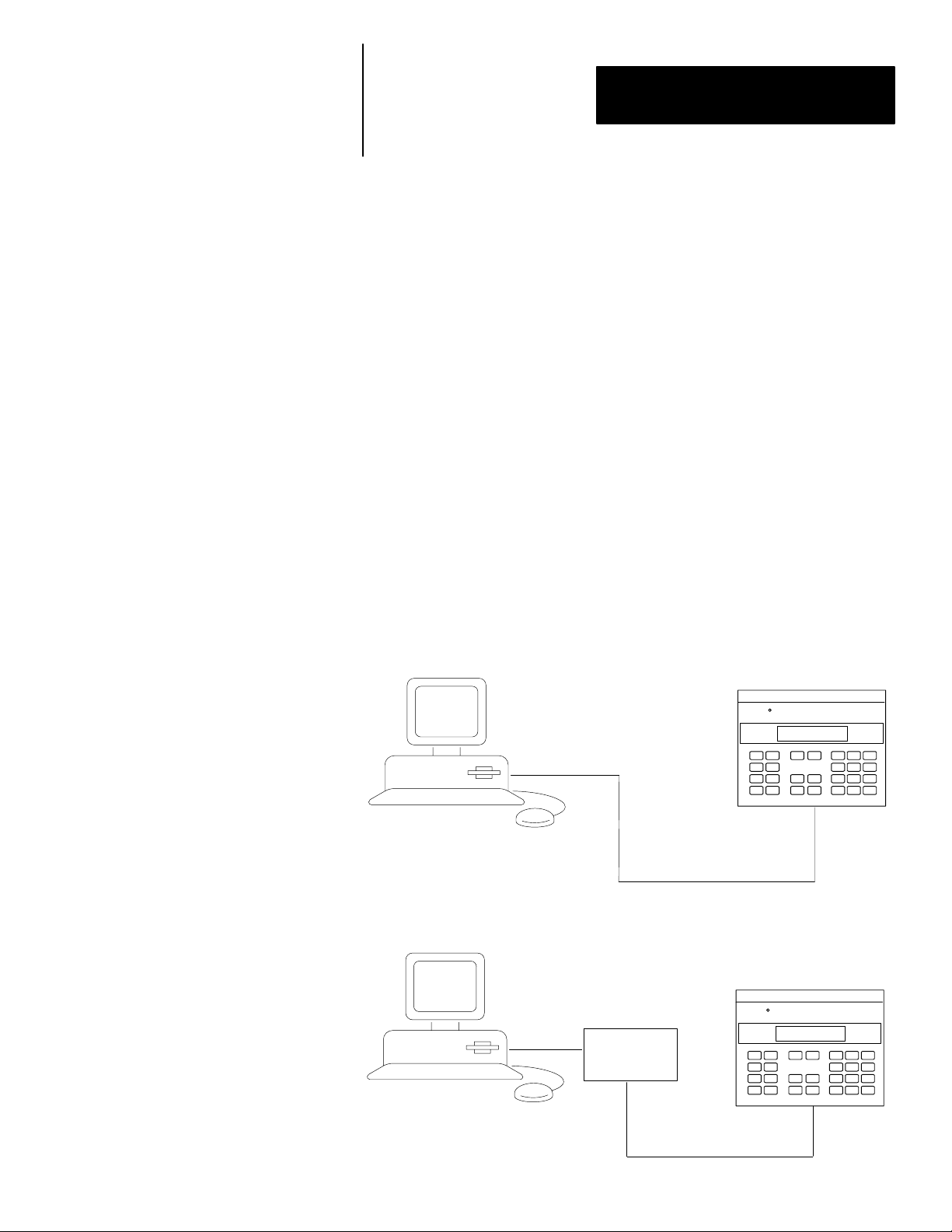

Upload/Download Connections

For programming and configuration, the DTAM Micro is connected to your

computer’s RS-232 port. If you have a DTAM Micro RS-485 version, an

RS-232 to RS-422 converter cable (Catalog No. 2707-NC5) is required. The

RS-485 version of the DTAM Micro is compatible with the converter cable’s

RS-422 output.

Upload/Download Connection to RS-232 DTAM Micro

Programming Terminal

(Catalog No. 2707-NC2)

Upload/Download Connection to RS-485 DTAM Micro

RS-232 to RS-422

Interface

Converter

Built Into Cable

Programming Terminal

(Catalog No. 2707-NC5)

Cable

Cable

DTAM Micro

RS-232 Port

DTAM Micro

RS-485 Port

2–11

Page 22

Chapter 2

DTAM Micro Overview

Default Settings

The DTAM Micro is preset at the factory with the following defaults:

Operating System

The DTAM Micro is provided with a default application file:

• RS-485 version has DH-485 operating system file

• RS-232 version has PLC-5 DF1 operating system file

The application file displays a screen with the message:

Bul 2707 DTAM Micro

No Program loaded

DIP Switch Settings

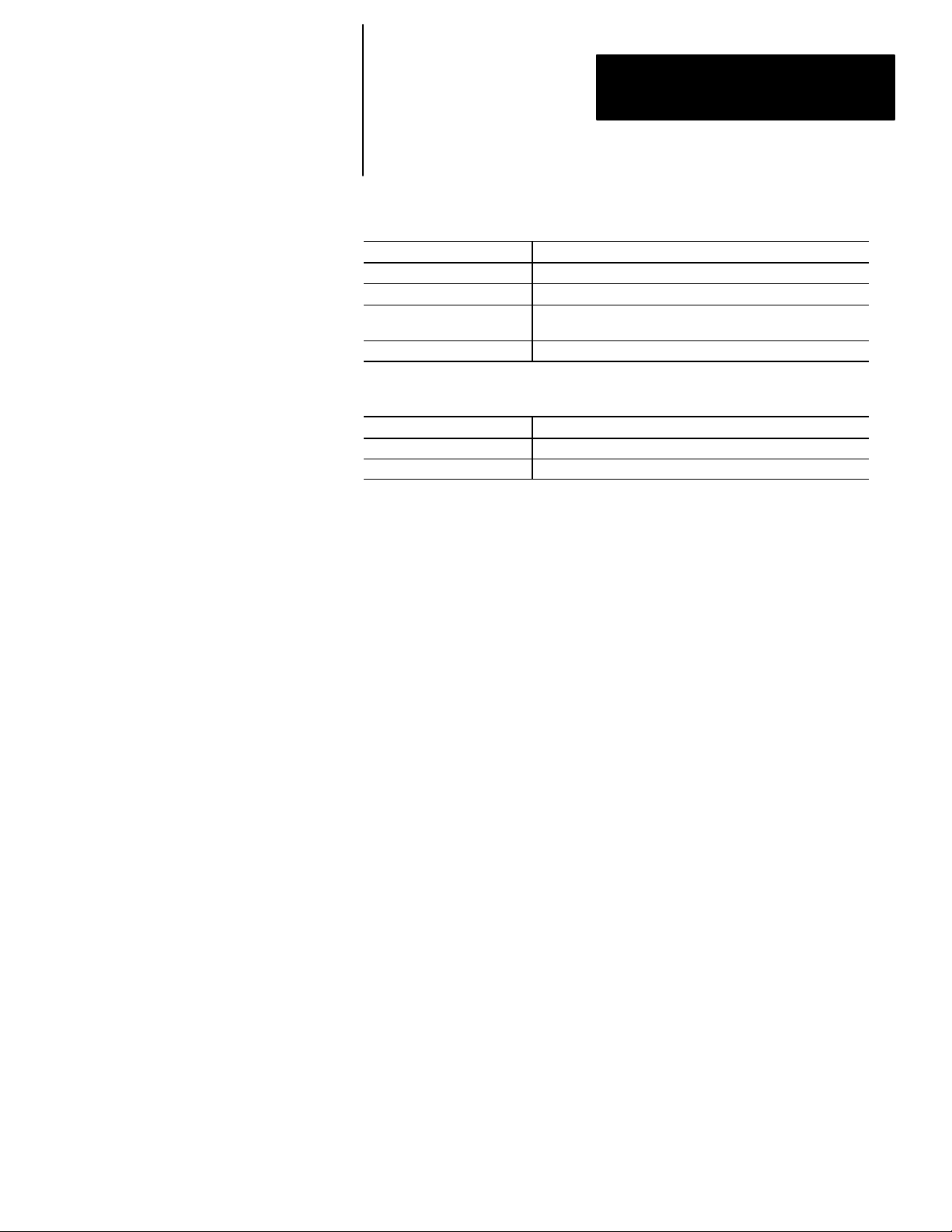

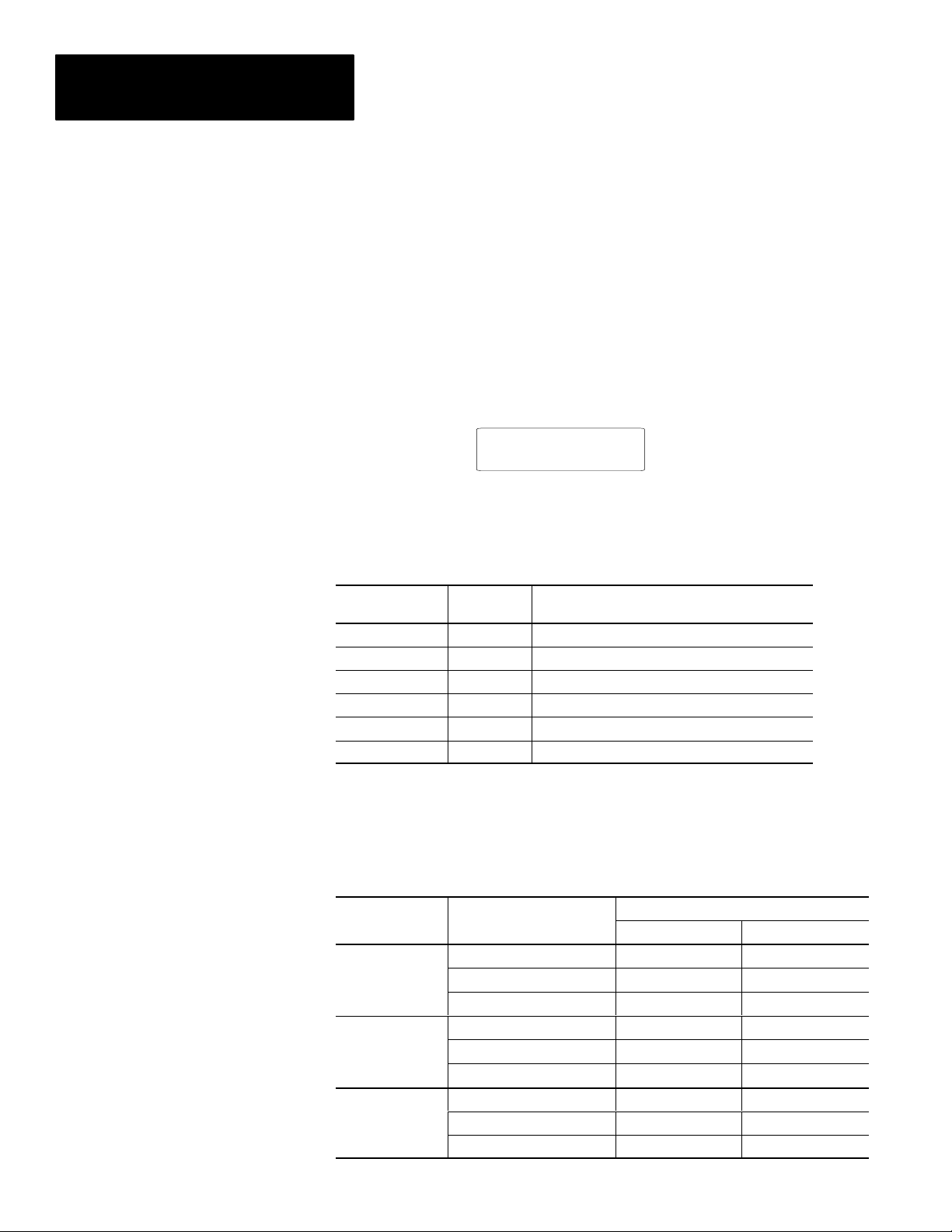

The DTAM Micro is shipped with the following DIP Switch settings:

DIP Switch

Position

1 ON Upload/Download Enabled

2 OFF Master Security Disabled

3 ON Mode Key enabled

4 OFF Not Used

5 OFF Not Used

6 OFF Not Used

Default

Setting

Function

2–12

Operating Parameters

The following operating functions can be set using the DTAM Micro menu

functions. Refer to Chapter 3.

Function Parameter

Baud 19200 2400

C-Port

Special

Other

Data Bits

Parity Even None

DTAM Micro Node 00 N/A

Max. Node 02 N/A

Controller Node 01 N/A

Simulate Off Off

Master Code

Scale On On

RS-485 Version RS-232 Version

00000000 00000000

Default Value

8 8

Page 23

Chapter 2

DTAM Micro Overview

Product Options

Product Accessories

The table below lists the options available for the DTAM Micro.

Table 2.A

DT AM Micro Base Items

Item Catalog No. Description

DTAM Micro 2707-M485P3 DTAM Micro with RS-485 Communications Port

DTAM Micro 2707-M232P3 DTAM Micro with RS-232 Communications Port

Programming

Software

2707-NP

(Series H or later)

Use to create application screens for the DTAM Micro on

a personal computer. Software allows completed applications to be transferred between the DTAM Micro and a personal computer.

The following accessories are available for the DTAM Micro.

Table 2.B

Accessories

Item Catalog No. Description

RS-485 communication cable connects DTAM Micro to an

DH-485 Network

Interface Cable

RS-232

Upload/Download

Cable

RS-232

Communications Cable

RS-232

Communications Cable

RS-422

Communications Cable

RS-485

Upload/Download

Cable

RS-232

Communications Cable

120V AC to DC Adapter 1747-NP1

240V AC to DC Adapter 1747-NP2

➀ A 9-pin male to female gender adapter is required.

2707-NC1

2707-NC2

2707-NC3

1747-CP3➀

2707-NC4

2707-NC5

2707-NC10 RS-232 cable connects DTAM Micro to a MicroLogix 1000

SLC network. Cable has 9-pin male connector for the

communication port on the DTAM Micro and an 8-pin RJ

connector for the communication port on the SLC or Link

Coupler (Catalog No. 1747-AIC).

RS-232 cable connects DTAM Micro (RS-232 version)

and a personal computer. Use to upload or download

applications with a personal computer running DPS

software (Catalog No. 2707-NP, Series H or later).

RS-232 cable connects DTAM Micro to Channel 0 Port of

a PLC-5.

RS-232 cable connects DTAM Micro to Channel 0 Port

(configured for RS-232) of an SLC 5/03, 5/04, 5/05.

RS-422 cable connects DTAM Micro to Channel 0 Port

(configured for RS-422) of a PLC-5.

For use with RS-485 version of the DTAM Micro.

Transfers files between RS-485 port of the DTAM Micro

and the personal computer’s RS-232 port. Cable

converts RS-232 signals to RS-422 signals for the DTAM

Micro. Cable has a 25-pin male connector for the

computer port and a 9 pin male connector for the port on

the DTAM Micro.

Provides 18 to 30 VDC output for the DTAM Micro.

Operates on 120 VAC input line voltage.

Provides 18 to 30 VDC output for the DTAM Micro.

Operates on 240 VAC input line voltage.

2–13

Page 24

Chapter 2

DTAM Micro Overview

2–14

Page 25

Chapter

Objectives

A–B

3

Initial Setup and Mode Menu

This chapter describes how to apply power to and then configure the DTAM

Micro using the menu keys. Instructions on how to use the Simulate mode to

run an application are provided. This chapter contains the following

sections:

Section Page

Apply Power 3–2

Powerup Sequence 3–3

Mode Menu 3–4

Resetting the DTAM Micro 3–5

Setting Communication Parameters Manually 3–6

Special Functions for Controller Operations 3–7

Entering a New Master Security Code 3–8

Enabling / Disabling Scaling 3–9

Using the Simulate Mode 3–10

Test Functions 3–11

3–1

Page 26

Chapter 3

Initial Setup and Mode Main

Apply Power

This section describes power connections for initial desktop setup and

programming. Refer to Chapter 6 for installation wiring instructions.

The DTAM Micro is intended for 24 VDC systems. If 24 VDC is not

directly available, you can use the AC to DC Adapters: Catalog No.

1747-NP1 for 120 VAC or Catalog No. 1747-NP2 for 240 VAC power.

ATTENTION: Verify that the power is disconnected from the

power source before wiring. Failure to disconnect power may

!

result in electrical shock.

Make sure that the supply voltage to the DTAM Micro is 18 to 30

volts DC. The incorrect voltage may damage the DTAM Micro.

Do not overtighten the power connector screw terminals.

Overtightening the terminals may damage the DTAM Micro.

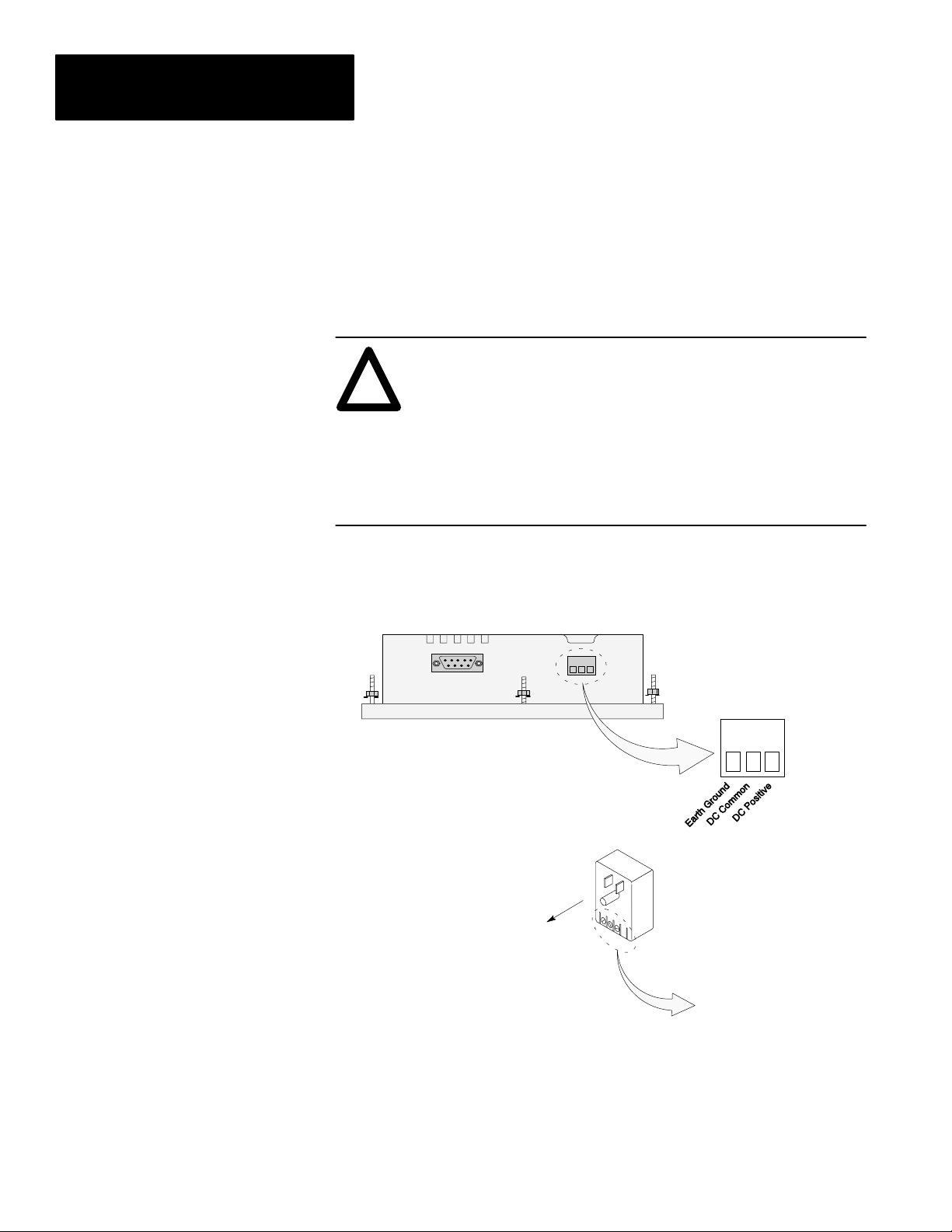

1. Connect the DC positive, DC common, and ground lines as shown below.

Verify the connections by checking the DC power supply labels on the

AC to DC Adapter (if used) and DTAM Micro.

DTAM Micro

Optional AC to DC Adapter

Catalog No. 1747-NP1, -NP2

To 120VAC (Catalog No. 1747-NP1)

To 240VAC (Catalog No. 1747-NP2)

To DTAM Micro. Check DC

power labels before making

connections.

2. Apply power to the DTAM Micro by plugging the AC to DC Adapter into

the proper power source (check Adapter label to verify voltage).

The DTAM Micro performs a powerup sequence.

3–2

Page 27

Chapter 3

ÎÎÎ

Initial Setup and Mode Menu

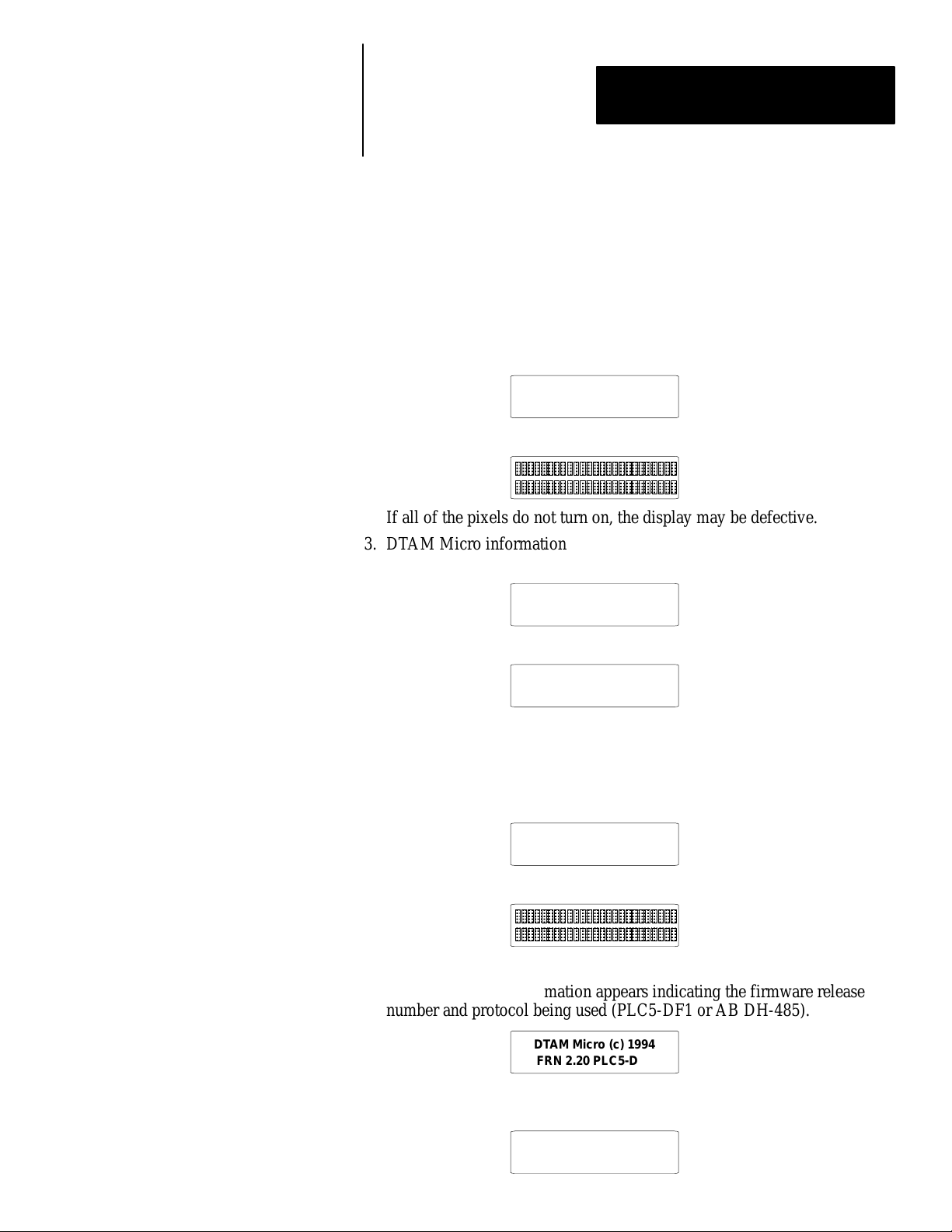

Powerup Sequence

The powerup sequence is automatic, you do not have to respond to

the screens. The sequence depends upon DIP switch position #1 (upload /

download enable). The DTAM Micro is shipped with this switch On.

Powerup Sequence (DIP Switch #1 On)

1. The DTAM Micro verifies the system memory checksum, program

checksum, and system RAM. After the test is completed, the result is

displayed with the current DIP switch settings.

Memory Check: pass

DIP Switch: 101000

2. The display is tested, every pixel of the display is turned on.

If all of the pixels do not turn on, the display may be defective.

3. DTAM Micro information appears indicating the microprocessor core

firmware version and communication port (RS-232 or RS-485).

Operator Interface

Core: 3.00 RS-232

4. The DTAM Micro waits for an application download.

Programming Mode

Waiting Up/Download

Powerup Sequence (DIP Switch #1 Off)

1. The DTAM Micro verifies the system memory checksum, program

checksum, and system RAM. After the test is completed, the result is

displayed with the current DIP switch settings.

Memory Check: pass

DIP Switch: 101000

2. The display is tested, every pixel of the display is turned on.

If all of the pixels do not turn on, the display may be defective.

3. Operating system information appears indicating the firmware release

number and protocol being used (PLC5-DF1 or AB DH-485).

DTAM Micro (c) 1994

FRN 2.20 PLC5-DF1

4. The first application screen displays. If the DTAM Micro is being

powered up the first time you will see:

Bul. 2707 DTAM Micro

No Program Loaded

3–3

Page 28

Chapter 3

Initial Setup and Mode Main

Mode Menu

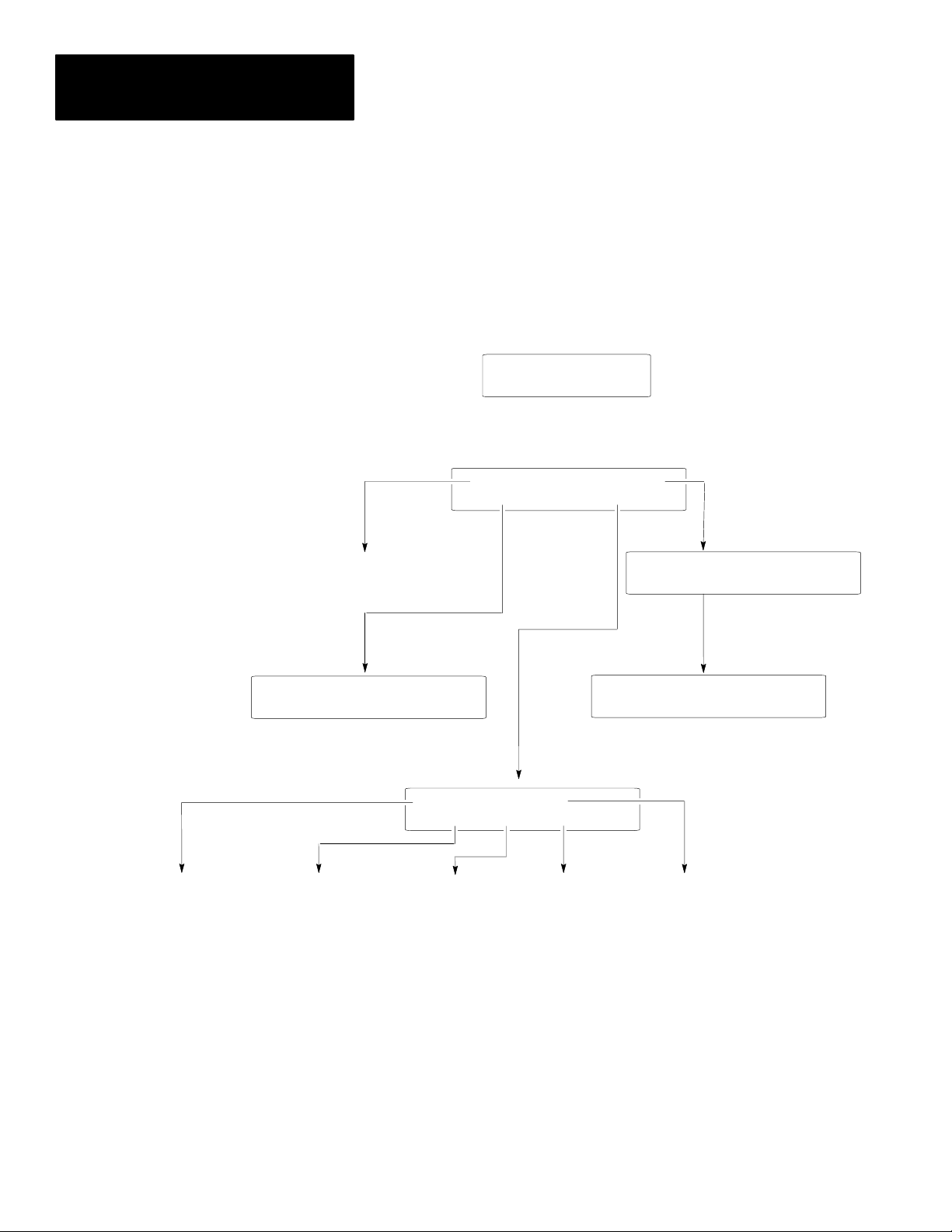

Access the Mode Menu by pressing the [MODE] key. All other functions are

halted when the menu is displayed.

Note: DIP switch SW-3 must be in the On position or the [MODE] key will

not function.

The Mode Menu provides access to four functions:

1 Reset 3 Special

2 Com-Port 4 Other

Select a menu item by pressing the corresponding numeric key [1] ! [4].

The menu structure is shown below:

1 Reset 3 Special

2 Com-Port 4 Other

Resets the DTAM Micro

SLC or 50X Address

1 = Edit Addr 0 = Bypass

(Only with DH485

Operating System)

1 Baud Rate 3 Parity

2 Data Bits 4 Exit

Configures DTAM Micro

Communications Port

Sets Master

Security Code ➀

➀ DIP switch position 2 must be On (master code enable).

Enables / Disables

Scaling

Functional Tests

1 Master 3 Simulate

2 Scale 4 Test 5 Ex

Performs

Exits to

Mode Menu

1 P-A/D 3 Mem Xfer

2 Mode 4 Clr Fault

Special

Controller Operations

Simulates Controller

Communications

3–4

Page 29

Chapter 3

Initial Setup and Mode Menu

Resetting the DTAM Micro

Use the reset function to reset the DTAM Micro after DIP switch changes or

a configuration change using the Mode Menu.

To reset the DTAM Micro:

1. From the Mode Menu select 1 Reset.

1 Reset 3 Special

2 Com-Port 4 Other

You are prompted:

1 = Reset DTAM Micro

0 = Abort

2. Press [1] on the keypad to initiate the reset.

The DTAM Micro resets. This has the same effect as turning the power

off and on. The DTAM Micro performs the self diagnostic tests and

powerup displays as described in the previous section.

3–5

Page 30

Chapter 3

Initial Setup and Mode Main

Setting Communication Parameters Manually

The Com-Port option on the Mode Menu lets you to manually adjust the

communication port parameters. Normally these parameters are set

automatically from the programming software when an application is

downloaded.

Select Com-Port from the Mode Menu.

1 Reset 3 Special

2 Com-Port 4 Other

This menu displays:

1 Baud Rate 3 Parity

2 Data Bits 4 Exit

Select an item by pressing the corresponding numeric key [1] ! [4].

Baud Rate

Selecting Baud Rate displays the current baud rate.

Baud Rate 19200

“Next” to change

Press [Next] to select a new rate: 300, 1200, 2400, 4800, 9600, 19200,

38400. DH-485 communications with an SLC or network cannot be set at

300 Baud.

Data Bits

Selecting Data Bits displays the current setting.

Data Bits 7

“Next” to change

Press [Next] to select either 7 or 8 bits.

Parity

Selecting Parity displays the current setting.

Parity Even

“Next” to change

Press [Next] to select Even, Odd, or No parity.

3–6

Page 31

Chapter 3

Initial Setup and Mode Menu

Special Functions for Controller Operations

The Special Menu item provides access to special features for the controller

operations. A security access code may be assigned in the application

restricting access to the Special Menu.

Select Special from the Mode Menu.

1 Reset 3 Special

2 Com-Port 4 Other

This menu displays:

1 P-A/D 3 Mem Xfr

2 Mode 4 Clr Fault

Note: Below are brief descriptions of each menu item.

Refer to Appendix C for instructions on using the Special Menu items.

P-A/D

Use the Point Access / Display function to display, and modify controller

data files. The P-A/D function does not allow you to write controller Input

and Output files. Appendix C provides a listing of the applicable file types

for SLC and PLC-5 controllers along with step-by-step instructions.

Mode

Select mode to place the controller in either the run or program modes. This

may be useful if you need to halt the controller for memory transfers.

Mem Xfer

Use the memory transfer function to initiate a transfer of data between a

memory module and an SLC or PLC controller. Memory transfers with a

PLC-5 are only to a memory module, you cannot transfer data from a

memory module to a PLC-5. Appendix C describes how to use the Mem

Xfer function.

Clr Fault

Use the Clear Fault function to clear all major and minor faults in the

controller.

3–7

Page 32

Chapter 3

Initial Setup and Mode Main

Entering a New Master Security Code

The master security code provides access to all security codes and allows

them to be modified. Two master security codes perform special functions:

00000000 allows the operator to modify the existing master code without

entering the current code.

99999999 does not allow operator to modify security codes. Changing of

the master security code is through DPS software.

To enter a new Master Security code:

1. From the Mode Menu, select item 4.

1 Reset 3 Special

2 Com-Port 4 Other

The Other Menu appears:

1 Master 3 Simulate

2 Scale 4 Test 5 Ex

2. Press [1] to select the Master security code function.

The master code entry screen displays:

Enter Current Master

Code:_

3. Enter the current code and press [ ].

You are prompted to enter the new code.

Enter New Master

Code:_

4. Enter a new code. The code must be 8 digits in length. If you enter less

than 8 digits the entry is padded with zeroes. For example, an entry of

1234 is entered as12340000.

Note: Security codes can contain the wildcard character ? Any entered

value will be seen as a match to the wildcard. You must make sure that the

master security code is different from security codes using wildcard entries.

Otherwise the master security code may be seen as a security code. For

example, if the:

Security Code =12??????

Master Code = 12368794

When the master security code above is entered, the DTAM Micro interprets

it as a security code.

3–8

Page 33

Chapter 3

Initial Setup and Mode Menu

Enabling / Disabling Scaling

Use scaling to convert data from a controller to engineering units such as

gallons or psi. When scaling is disabled, the values are not converted. Refer

to the DTAM Programming Software Manual for a description of how values

are scaled. The scaling factor is determined by the application designer, it

cannot be changed by the operator.

Flow = 16

Gallons Per Minute

Flow Rate

Transducer

Flow Rate

Transducer

Value = 510

PLC-5

Controller = 510

DTAM Micro displays

scaled value of

16 Gallons Per Minute

Value From

To enable or disable scaling:

1. From the Mode Menu, select item 4.

1 Reset 3 Special

2 Com-Port 4 Other

The Other Menu appears:

1 Master 3 Simulate

2 Scale 4 Test 5 Ex

2. Select item 2.

The scale enable screen displays:

Scale Enable OFF (0)

0=Off 1=On

Current Setting

3. Press [1] on the keypad to enable scaling and [0] to disable scaling.

You are returned to the Other Menu.

4. Select item 5 to exit to the Mode Menu.

3–9

Page 34

Chapter 3

Initial Setup and Mode Main

Using the Simulate Mode

The Simulate mode checks an application without having a controller

connected. All data that normally would be sent by the controller, such as

data for a display, is set to 0. Any ASCII data is set to ? (PLC5-DF1

operating system only). Selecting Simulate from the Mode Menu will:

• Halt communication between the DTAM Micro and the controller.

• Simulate communication with a controller.

Disabling the Simulate mode resumes normal operation.

To simulate an application:

1. Download the application from the DPS software.

2. Enable the Simulate mode.

3. From the Mode Menu, select item 4.

1 Reset 3 Special

2 Com-Port 4 Other

The Other Menu appears:

1 Master 3 Simulate

2 Scale 4 Test 5 Ex

4. Select item 3.

The simulate enable screen displays:

Simul Enable OFF (0)

0=Off 1=On

Current Setting

5. Press [1] to enable the Simulate mode.

6. Press [5] to exit the Other Menu and display the Mode Menu.

7. From the Mode Menu, reset the DTAM Micro. Refer to page 3–5.

The DTAM Micro displays a series of diagnostic tests, enters run mode,

loads the application and then displays the Mode Menu of the application.

8. Run the program as you normally would. Notice that all display registers

show data as a set of zeroes.

Pressure = 0000 PSI

Data Display

9. After verifying the operation of the program, press the [MODE] key.

All other functions are halted and the Mode Menu is displayed.

10. Disable the Simulate mode.

3–10

Page 35

Chapter 3

Initial Setup and Mode Menu

Test Functions

Selecting Test from the Other Menu displays the test screen:

DTAM Micro Diag Test

< Test Selection >

Current Test Selection

Use the Test menu to perform the following:

• Reset DUT (DTAM Under Test)

• DIP switch positions

• Display

• Keyboard

• Communications port

• Random Access Memory (RAM)

• System memory

• Program memory

• Transmit enable

Refer to Chapter 8 Troubleshooting and Maintenance for instructions on how

to perform these tests.

3–11

Page 36

Chapter 3

Initial Setup and Mode Main

3–12

Page 37

Chapter

Objectives

Upload / Download DIP Switch Settings

A–B

4

Transferring Applications

This chapter describes how to transfer applications between the offline

programing software (DPS) and the DTAM Micro. It contains the

following sections:

Section Page

Upload/Download DIP Switch Settings 4–1

Upload/Download Connections 4–2

Computer Setup 4–2

Downloading an Application 4–3

Uploading an Application 4–8

Before you can upload or download an application, you must verify that

DIP switch position #1 is On as shown. To access the DIP switch, remove

the cover from the access hole on the back of the DTAM Micro (align cover

tabs with notches in hole to remove). The DTAM Micro is shipped without

the cover installed, you can find it in the hardware bag.

Side View

ON =

DIP Switch Position #1

must be On as shown.

DIP Switch Positions #2

through #6 can be in any position.

123456

OPEN

Back of DTAM Micro

4–1

Page 38

Chapter 4

Transferring Applications

Upload / Download Connections

RS-485 Version (Catalog No. 2707-M485P3)

Use Upload/Download Cable (Catalog No. 2707-NC5)

RS-232 Version (Catalog No. 2707-M232P3)

Use Upload/Download Cable (Catalog No. 2707-NC2)

To download an application to the DTAM Plus, you must:

• connect a power supply (refer to Chapter 3)

• connect the (Catalog No. 2707-NC2) upload/download cable if you have

the RS-232 version

• connect the (Catalog No. 2707-NC5) upload/download cable if you have

the RS-485 version. This cable converts the computer’s RS-232 output to

RS-422 which is compatible with the DTAM Micro RS-485 port.

DTAM Micro

Refer to Chapter 3

for power connections.

To Computer

RS-232 Port

Computer Setup

4–2

Upload and download functions are initiated from a personal computer

running the programming software DPS (Catalog No. 2707-NP, series H or

later). Transfer functions automatically occur at 9600 Baud.

After the transfer is complete, the DTAM Micro Baud rate is set to the

parameters defined by the application program residing in the DTAM Micro.

Page 39

Chapter 4

Transferring Applications

Downloading an Application

. You will not see this prompt if

a monitor was specified during

installation.

This section shows how to download an application from a computer running

DPS software (Catalog No. 2707-NP, series H or later) to the DTAM Micro.

Refer to the DPS Programming Manual (Publication No. 2707-801) for

additional information.

1. Apply power to the DTAM Micro.

The following message appears in the window of the DTAM Micro.

Programming Mode

Waiting For Program

If you do not see this message, check the DIP switch settings.

DIP Switch position #1 must be in the Closed (ON) position.

2. On your computer, move to the /DPS subdirectory where the software

resides.

C:\DPS>

3. Type dps and press [Return] to start the program.

C:\DPS>dps [Return]

4. Specify whether you are using a color monitor. Enter Y or N.

5. The startup screen displays:

Technical Support

Voice: 440–646–6800

FAX: 440–646–6850 or 6890

E–mail: RACLEASKTHEEXPERT@RA.ROCKWELL.COM

4–3

Page 40

Chapter 4

Transferring Applications

. You will not see this prompt if

a product type was specified

during installation.

6. Press any key (other than [Esc]) to continue.

The Product Selection Menu appears.

7. Press [Return] to select the DTAM Micro product.

The Opening Menu appears.

4–4

Page 41

. You will not see this screen if a

communication port was

specified during installation.

Chapter 4

Transferring Applications

8. Highlight Download File to DTAM Micro and press [Return].

The Communication Port Selection screen appears.

☞If a communication link does not

occur in 10 seconds, you get an

error message. Check DIP switch

settings and cable connections.

9. Highlight the serial port on your computer that is connected to the

DTAM Micro (COMM 1 or COMM 2) and press [Return].

10. When communication is established, the following screen appears:

11. Enter or select the file name that you want to download. If the

application file type (DH-485 or PLC5 DF1) is different from the existing

operating system, you are prompted to download the new operating

system.

4–5

Page 42

Chapter 4

Transferring Applications

12. Press [Return] to load the application file.

The download begins and the following screen shows the progress of the

download operation.

13. During the download, the DTAM Micro alternately displays:

Programming Mode

Transfer in Progress

Programming Mode

Copying to Memory

4–6

Page 43

Chapter 4

Transferring Applications

14. When the download is complete, you are returned to the Opening Menu.

and the DTAM Micro displays:

Programming Mode

Waiting Up/Download

15. Press [Esc] to exit the software.

16. Press [Y] to return to DOS.

The application is now loaded into the DTAM Micro. You can test the

application using the simulate function described in Chapter 3 or you can

run the application as described in Chapter 5.

Important: If you are running the application, make sure that you set the

DIP switch position #1 to the OFF position.

4–7

Page 44

Chapter 4

Transferring Applications

Uploading an Application

. You will not see this prompt if

a monitor was specified during

installation.

This section shows how to upload an application from the DTAM Micro to a

computer running DPS software (Catalog No. 2707-NP, series C or later).

Refer to the DPS User manual (Publication No. 2707-801) for additional

instructions.

1. Apply power to the DTAM Micro.

The following message appears in the window of the DTAM Micro.

Programming Mode

Waiting For Program

If you do not see this message, check the DIP switch settings.

DIP Switch position #1 must be in the Closed (ON) position.

2. On your computer, move to the /DPS subdirectory.

C:\DPS>

3. Type dps and press [Return] to start the program.

C:\DPS>dps [Return]

4. Specify whether you are using a color monitor. Enter Y or N.

5. The startup screen displays.

4–8

Technical Support

Voice: 440–646–6800

FAX: 440–646–6850 or 6890

E–mail: RACLEASKTHEEXPERT@RA.ROCKWELL.COM

Page 45

. You will not see this prompt if

a product type was specified

during installation.

Chapter 4

Transferring Applications

6. Press any key (other than [Esc]) to continue.

The Product Selection Menu appears.

7. Press [Return] to select the DTAM Micro product.

The Opening Menu appears.

4–9

Page 46

Chapter 4

Transferring Applications

. You will not see this screen if a

communication port was

specified during installation.

8. Highlight Upload File from DTAM Micro and press [Return].

The Communication Port Selection screen appears.

9. Highlight the serial port on your computer that is connected to the

DTAM Micro (COMM 1 or COMM 2) and press [Return].

10. The upload begins and the following screen shows the progress of the

upload operation.

4–10

Page 47

Chapter 4

Transferring Applications

11. When the upload is complete, you are returned to the Opening Menu.

12. Press [Esc] to exit the software.

13. Press [Y] to return to DOS.

The application is now loaded into the DPS software. You can edit the

application as described in the DPS Programming Manual (Publication

No. 2707-801).

4–11

Page 48

Chapter 4

Transferring Applications

4–12

Page 49

Chapter

Chapter Objectives

A–B

5

Running Applications

This chapter describes screen types and operating procedures that are

common to most applications. It contains the following sections:

Section Page

DIP Switch Setting 5–1

Application Documentation 5–1

Bit Write Mode 5–1

Screen Types 5–2

Screen Navigation 5–2

Menu and Sub-Menu Screens 5–4

Security Screens 5–4

Data Display Screens 5–5

Data Entry Screens 5–5

Recipe Screens 5–6

Alarm Screens 5–6

DIP Switch Setting

Application Documentation

Bit Write Mode

Before running an application, verify that the DIP switch position #1 is in the

OFF position. This enables communication with the controller. Refer to DIP

switch description on page 2–7.

It is the responsibility of the application designer to document the operation

of an application program. This chapter only provides basic guidelines.

Before running an application, you should understand what processes are

being controlled and monitored.

ATTENTION: The function keys of the DTAM Micro can be

assigned different functions depending upon the application.

!

The application designer must document these functions. Make

sure you understand any function key operations prior to

operating the DTAM Micro. Failure to do so may result in

unintended operation.

The application designer can assign the function keys [F1] to [F8] to set or

clear a bit at a controller address. This bit may control a variety of processes.

It is the responsibility of the application designer to document the use of the

bit write mode function keys.

5–1

Page 50

Chapter 5

Running Applications

Screen Types

Screen Navigation

Application screens can have a variety of appearances. The DTAM Micro

can display six types of screens.

• Menu and Sub-Menu Screens

• Security Screens

• Data Display Screens

• Data Entry Screens

• Recipe Screens

• Alarm Screens

The DTAM Micro provides several options for changing the screen displays:

• Screen links

• Advisor option

• Function keys

Screen Links

Use the [NEXT] and [PREV] keys to step backward and forward through this

sequence.

Main Menu and Sub-Menu screens list screens that can be accessed by

pressing the assigned numeric key [0] through [9]. A typical Main Menu

screen provides links to individual screens or sub-menus:

1 Pump 2 Tank Status

3 Mixer Status 4 Recipe

In the example above, pressing [2] at the Main Menu displays the status of a

holding tank. Pressing [4] displays a Sub-Menu of the recipe screen options.

Advisor Option

Applications can allow screen changes that are controlled by an SLC or PLC

logic controller. When the logic controller writes a valid screen number to a

specified Advisor register, the corresponding screen is displayed. The

controller can initiate a screen change based upon a variety of inputs to the

controller. For example, a pressure limit switch can be used to initiate the

display of a pressure control screen. It is the responsibility of the application

designer to document when and what screen changes may occur.

5–2

Page 51

Chapter 5

Running Applications

Function Keys

An application designer can link function keys [F1] through [F8] to

individual screens (except alarm screens). Pressing an assigned function key

displays the function key number for approximately 0.5 seconds and then the

assigned screen. It is the responsibility of the application designer to

document the operations assigned to function keys. There are two function

key modes:

• Auto Return

• Continue

Auto Return

Auto return function keys return to the initial display after the linked screen

is executed. For example, assume that an application is displaying screen #6

and an auto return function key [F3] is linked to a recipe screen #10. When

[F3] is pressed, the recipe screen #10 is displayed. After the operator

downloads a new recipe on screen #10, the initial screen #6 is displayed.

The following table describes when the return to the initial screen occurs.

Function Key Linked To: Returns to Initial Screen After:

Data Display Screen [ ] , [PREV], or [NEXT] keys are pressed

Data Entry Screen A value is entered or

[PREV], or [NEXT] keys are pressed ➀

Recipe Screen Recipe data is downloaded or

[PREV], or [NEXT] keys are pressed ➀

➀ [NEXT] or [PREV] keys abort the operation.

Continue

Continue function keys do not return to the initial display but remain at the

linked screen. For example, assume that an application is displaying screen

#3 and a “continue” function key [F2] is linked to a data entry screen #5.

When [F2] is pressed, the data entry screen #5 is displayed. The application

continues from screen #5.

5–3

Page 52

Chapter 5

Running Applications

Menu and Sub-Menu Screens

Menus and Sub-Menus provide a convenient method of accessing a large

number of display screens.

Main Menu

Every application has a Main Menu screen. The Main Menu is the first

application screen displayed after an initial power-up or reset.

1 Pump 2 Tank Stat

3 Mixer Stat 4 Recipe

The Main Menu provides access to the next level of screens and Sub-Menus.

To access the Main Menu, press the [MENU] key. Pressing this key at any

time displays the Main Menu. The only time the Main Menu will not be

displayed is when an alarm screen has been triggered but not acknowledged.

You must acknowledge alarm screens, by pressing [

], before another

screen can be displayed.

Sub-Menus

Security Screens

Sub-Menu screens function like the Main Menu. The only difference is that

you must navigate through the other screens or use assigned function keys to

access the Sub-Menus. Refer to the previous section for more information.

Security screens limit access to parts of an application. Although the text on

a security screen may be changed by the application designer, many

applications will use the default text:

*RESTRICTED ACCESS*

ENTER CODE:

A security code is a series of 1 to 8 digits. Each security screen can have up

to 3 code entries. Entering any one of the codes provides access.

To enter a security code, use the numeric keypad. An asterisk (

displayed for each number entered. Press [

] after the entire code is

*

) is

entered.

If a valid security code has been entered, the next linked screen is displayed.

If an invalid security code is entered, an error message appears. Once the

error condition is acknowledged by pressing [

], you can re-enter the code

or return to the Main Menu.

5–4

Page 53

Chapter 5

Running Applications

Data Display Screens

Data Entry Screens

Data display screens show either the actual or scaled value of a logic

controller.

Data Display Field

Pump 1 Pressure = 150 PSI

Counter = 5

Data Display Field

Data displays are updated at different intervals depending upon the

application and the size of the network.

Data entry screens contain an entry field. The length and format of the data

entry field depends upon the application designer. In addition, the

application designer can place a data display field on the same screen:

Data Display Field

Temp = 120 Deg F

Enter New Temp:

Data Entry Field

The data entry field must always appear last on the screen. The application

designer cannot place text after a data entry field.

To enter data, use the numeric keypad. To modify an entry, press the clear

entry key [CE] and re-enter the value. Press the [

positive and negative values. Press [

] after the entire value is entered.

+

/–] key to toggle between

Data entry screens can have a default value appear in the data entry field.

A flashing cursor identifies the first digit of the default value. Pressing

[

] writes the default to the controller or you can enter a different value by

pressing the [CE] key.

If a data display is included on a data entry screen, the data display is only

updated when the screen is entered. Data does not update continuously.

5–5

Page 54

Chapter 5

Running Applications

Recipe Screens

Recipe screens allow the DTAM Micro to write multiple controller addresses

at the same time. Recipe screens can also be linked so that more than one

recipe is downloaded.

T4:14.2 (Timer Value)

Download Recipe 323?

Press ENTER to send

Operator Inititates

Recipe Download

N7:30 = 0 (Integer Value)

N7:31 = 100 (Integer Value)

T4:15.1 (Timer Value)

N7:200 = 500 (Integer Value)

B3:10 = 10 (Binary Value)

DTAM Micro Downloads

Data to Multiple Controller Addresses

Controller Modifies Process

Using New Recipe Data

Depending upon the application designer, recipe screens will either

automatically download data or display a prompt allowing the download to

be initiated when [

] is pressed.

Alarm Screens

Download Recipe 323?

Press ENTER to send

Once the download is initiated, the DTAM Micro writes the recipe data to the

various controller addresses. You cannot modify the recipe data that is sent,

recipe data is specified by the application designer.

Alarm screens indicate conditions that are not expected during normal

operation. Alarm screens are triggered when the controller writes the alarm

screen number to the Advisor register. Refer to page 5–2 for additional

information on the Advisor register.

You must respond to an alarm screen before any other screens can be

displayed. The [MENU] key will not function while an alarm screen is

displayed. Press [

] to acknowledge the alarm.

Conveyor Overload

PRESS ENTER TO CLEAR

5–6

Page 55

Chapter

Objectives

A–B

6

Installation

This chapter contains the following sections:

Section Page

Safety Guidelines 6–1

Operating Environment 6–1

Enclosures 6–2

Equipment Required 6–3

Clearances 6–3

Mounting Dimensions 6–4

Cutout Template 6–5

Installation 6–6

Connecting AC Power 6–7

Safety Guidelines

Install the DTAM Micro terminal using publication NFPA 70E, Electrical

Safety Requirements for Employee Workplaces as a guide.

In addition, grounding is an important safety measure in electrical

installations. A source for grounding recommendations is the National

Electrical Code published by the National Fire protection Association of

Boston Massachusetts.

Be certain to follow all directions for installing and connecting DC power to

the DTAM Micro.

When used in a hazardous environment, the ultimate enclosure must be in

accordance with Class 1, Division 2 wiring methods as described in the

National Electrical Code (ANSI/NFPA 70) and the Canadian Electrical Code.

All peripheral equipment must be suitable for the location in which it is used.

Use only a Class 2 power source as described in the National Electrical Code

(ANSI/NFPA 70) and Canadian Electrical Code. The recommended AC to

DC adapters (Catalog No. 1747-NP1 and Catalog No. 1747-NP2) meet this

requirement.

The DTAM Micro contains no user serviceable parts.

6–1

Page 56

Chapter 6

Installation

ATTENTION:

EXPLOSION HAZARD: SUBSTITUTION OF

!

!

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

1, DIVISION 2.

RISQUE D’EXPLOSION: LA SUBSTITUTION DE

COMPOSANTS PEUT RENDRE CE MATÉRIEL

INACCEPTABLE POUR LES EMPLACEMENTS DE

CLASSE 1, DIVISION 2.

ATTENTION

CAUTION: USE ONLY WITH CLASS 2 POWER SOURCE

LIMITED TO 30 VDC OPEN CIRCUIT AND 8A SHORT

CIRCUIT.

ATTENTION: UTILISER AVEC UNE TENSION

D’ALIMENTATION CLASSE 2 DE 30 VCC MAXI EN

CIRCUIT OUVERT AVEC UN COURANT DE

COURT-CIRCUIT DE 8A MAXI.

Operating Environment

Enclosures

DANGER

EXPLOSION HAZARD: DO NOT CONNECT OR

!

Refer to the inside front cover of this manual for additional guidelines.

The DTAM Micro is rated for an operating temperature range of 32 to 131°F

(0 to 55_C). The storage temperature range is -4 to 158°F (-20 to 70°C).

The humidity rating is 5 to 95% relative humidity (noncondensing).

If you are using a DC power supply, check the environmental ratings of the

supply. The AC to DC Adapters (Catalog No. 1747-NP1 and -NP2) are rated

at 32-104_F (0-40_C).

The terminal must be mounted in a panel or enclosure to protect the internal

circuitry. The terminal meets NEMA Type 4, 12, 13 (indoor use only)

ratings only when mounted in a panel or enclosure with the equivalent rating.

DISCONNECT EQUIPMENT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS

RISQUE D’EXPLOSION: NE PAS BRANCHER OU

DEBRANCHER TANT QUE LE CIRCUIT EST SOUS

TENSION, A MOINS QU’IL NE S’AGISSE D’UN

EMPLACEMENT NON DANGEREUX.

6–2

Allow enough spacing within an enclosure for adequate ventilation. For

some applications, you may have to consider heat produced by other devices

within a panel. The ambient temperature around the terminal must be

maintained between 32_ and 131_ F (0_ and 55_ C).

Make sure that provisions are made for accessing the back panel of the

terminal for wiring, routine maintenance, and troubleshooting.

Page 57

Chapter 6

Installation

Equipment Required

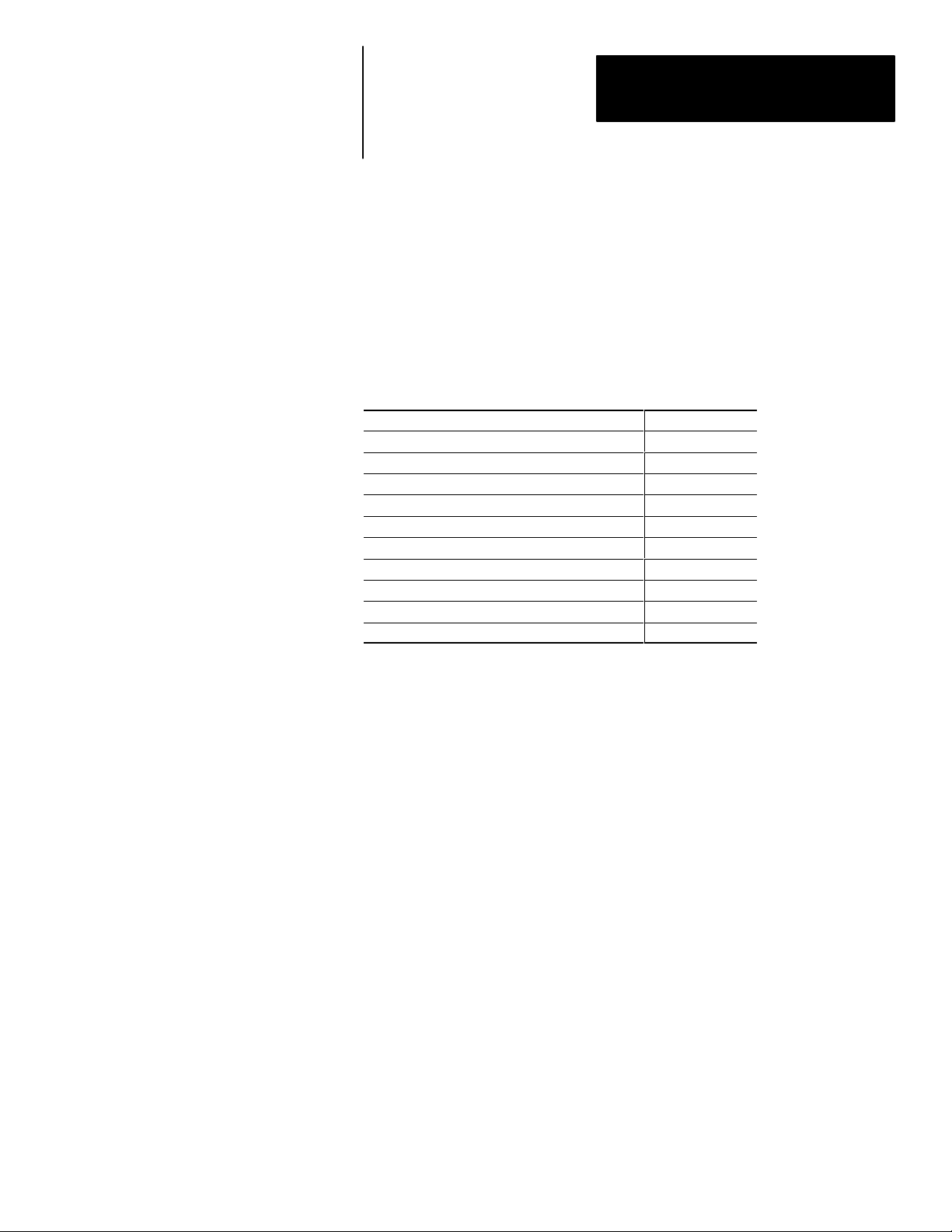

Clearances

Other than the tools required to make the panel cutout, the tools required for

installation are:

• 7mm (M4) deep well socket wrench or nut driver

• small slotted screwdriver

• torque wrench (in. / lbs).

The terminal is tightened against the panel with six self-locking nuts.

Make sure that you leave adequate room, as shown in Figure 6.1, for

mounting, air flow, cabling, and access to DIP switches.

Figure 6.1

Recommended Clearances

Leave 3 inches (76.2 mm)

for Mounting, Air Flow, and

access to DIP Switches.

Leave 3 inches (76.2 mm) for

communications port connector.

6–3

Page 58

Chapter 6

Installation

Mounting Dimensions

Figure 6.2 shows the mounting dimensions of the terminal.

Figure 6.2

Mounting Dimensions in Inches (Millimeters)

Back View

3.9

(99.1)

6.9

(175.3)

5.4

(137.2)

6–4

Bottom View

5.4

(137.2)

1.8

(45.7)

Page 59

Chapter 6

Installation

Cutout Template

3.04 inch = 77.22 mm

6.08 inch = 154.43 mm

3.97 inch = 100.84 mm

3.86 inch = 98.04 mm

4.55 inch = 115.57

5.50 inch = 139.70 mm

0.69 inch = 17.53 mm

0.29 inch = 7.37 mm

3.97 in

3.04 in

A cutout template is provided on the inside back cover of this manual to

mark the cutout dimensions. Figure 6.3 provides a reference copy, don’t

remove this page from the manual.

Figure 6.3

Panel Cutout Dimensions in Inches (Millimeters)

6.08 in

3.04 in

.187 in dia.

6 places

DTAM Micro

Panel Cutout

4.55 in

.29 in

3.86 in

.69 in

.29 in

5.50 in

6–5

Page 60

Chapter 6

Installation

Installation

To install the DTAM Micro Operator Module:

ATTENTION:

!

1. Cut an opening in the panel as shown in Figure 6.3. Use the cutout

template located inside the back cover of this manual. Remove any sharp

edges or burrs.

2. Make sure the sealing gasket is properly positioned on the DTAM Micro

This gasket forms a compression type seal. Do not use sealing

compounds.

Disconnect all electrical power from the panel before

making cutout.

Make sure that area around panel cutout is clear.

Take precautions so that metal filings or other debris does not

fall into the DTAM Micro ventilation slots or enter any

components that may already be installed in panel.

Make sure that no objects are inserted or fall into the terminal

through the ventilation slots or DIP switch access hole.

Failure to follow these warnings may result in personal injury

or damage to the panel components.

3. Place the DTAM Micro in the panel cutout.

ATTENTION:

!

4. Install the six self locking mounting nuts hand tight.

5. Alternately tighten the mounting nuts until the DTAM Micro is held

firmly against the panel. Tighten mounting nuts to a torque of 8 to 10

inch-pounds. Do not over-tighten nuts.

Mounting nuts must be tightened to a torque of 8 to 10 inch

pounds to provide a proper seal and to prevent potential

damage to the terminal. Allen-Bradley assumes no

responsibility for water or chemical damage to the terminal or