Page 1

DTAM Plus Operator Interface

(Catalog Nos. 2707-L8PxX, -L40PxX, -V40PxX)

Installation Instructions

This document describes how to install a DTAM Plus terminal and

connect power.

• Wiring and Safety Guidelines

• Enclosures

• Equipment Required

• Clearances

• Mounting Dimensions

• Installation

• Wire and Cable Length Restrictions

• Connecting Power

• Powerup Sequence

• Upload/Download DIP Switch Settings

• Upload/Download Connections

• Connecting to Devices

• Specifications

• Agency Ratings

• European Union Directive Compliance

For more information on the DTAM Plus terminal, refer to the

following publications.

• DTAM Plus User Manual 2707-UM001B–EN–P

• Intrinsically Safe DTAM Plus (2707-L40P4) 2707-800.6

• DTAM Plus DeviceNet Operator Interface 2707-800.7

These publications are available for viewing and download from the

Rockwell Automation/Allen-Bradley Website at www.ab.com.

Page 2

2

Wiring Guidelines

Safety Guidelines

Here are some recommendations on how to reduce electromagnetic

noise on the communications connections:

• Careful wire routing helps reduce or minimize electrical noise.

Route incoming power to the terminal by a separate path from the

communications cables.

• Do not run communications wiring and power wiring in the same

conduit.

• Where communications and power wiring must cross, make their

intersection perpendicular.

• Proper grounding helps to reduce the effects of noise due to

Electromagnetic Interference (EMI). To avoid problems caused

by EMI, all cables must be shielded and grounded at one end.

Grounding is also an important safety measure in electrical

installations. A source for grounding recommendations is the

National Electrical Code published by the National Fire

protection Association of Boston Massachusetts.

Install the DTAM Plus using publication NFPA 70E, Electrical

Safety Requirements for Employee Workplaces as a guide.

Be certain to follow all directions for installing and connecting

power to the DTAM Plus.

When used in a hazardous environment, the ultimate enclosure must

be in accordance with Class 1, Division 2 wiring methods as

described in the National Electrical Code (ANSI/NFPA 70) and the

Canadian Electrical Code.

All peripheral equipment must be suitable for the location in which it

is used.

For P1 powered units, use only a Class 2 power source as described

in the National Electrical Code (ANSI/NFPA 70) and the Canadian

Electrical Code.

Page 3

3

ATTENTION:

EXPLOSION HAZARD: SUBSTITUTION OF

!

!

!

COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS 1, DIVISION 2.

RISQUE D’EXPLOSION: LA SUBSTITUTION DE

COMPOSANTS PEUT RENDRE CE MATÉRIEL

INACCEPTABLE POUR LES EMPLACEMENTS DE

CLASSE 1, DIVISION 2.

ATTENTION: USE P1 POWERED UNITS ONLY

WITH CLASS 2 POWER SOURCE LIMITED TO 30

VDC OPEN CIRCUIT AND 8A SHORT CIRCUIT.

ATTENTION: UTILISER AVEC UNE TENSION

D’ALIMENTATION CLASSE 2 DE 30 VCC MAXI

EN CIRCUIT OUVERT AVEC UN COURANT DE

COURT-CIRCUIT DE 8A MAXI.

ATTENTION:

EXPLOSION HAZARD: DO NOT CONNECT OR

DISCONNECT EQUIPMENT WHILE CIRCUIT IS

LIVE UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

Enclosures

RISQUE D’EXPLOSION: NE PAS BRANCHER

OU DEBRANCHER TANT QUE LE CIRCUIT EST

SOUS TENSION, A MOINS QU’IL NE S’AGISSE

D’UN EMPLACEMENT NON DANGEREUX.

The terminal must be mounted in a panel or enclosure to protect the

internal circuitry. The terminal meets NEMA Type 4, 12, 13 (indoor

use only) or 4X (indoor 2707-V40P2N, -V40P2NR) ratings only

when mounted in a panel or enclosure with the equivalent rating.

Allow enough spacing within an enclosure for adequate ventilation.

For some applications, you may have to consider heat produced by

other devices within a panel. The ambient temperature around the

terminal must be maintained as specified. See Specifications Section

for ratings.

Make sure that provisions are made for accessing the back panel of

the terminal for wiring, routine maintenance, and troubleshooting.

Page 4

4

Equipment Required

Clearances

Other than the tools required to make the panel cutout, the tools

required for installation are:

• 7mm (M4) deep well socket wrench or nut driver

• small slotted screwdriver

• torque wrench (in. / lbs).

The terminal is tightened against the panel with six self-locking nuts.

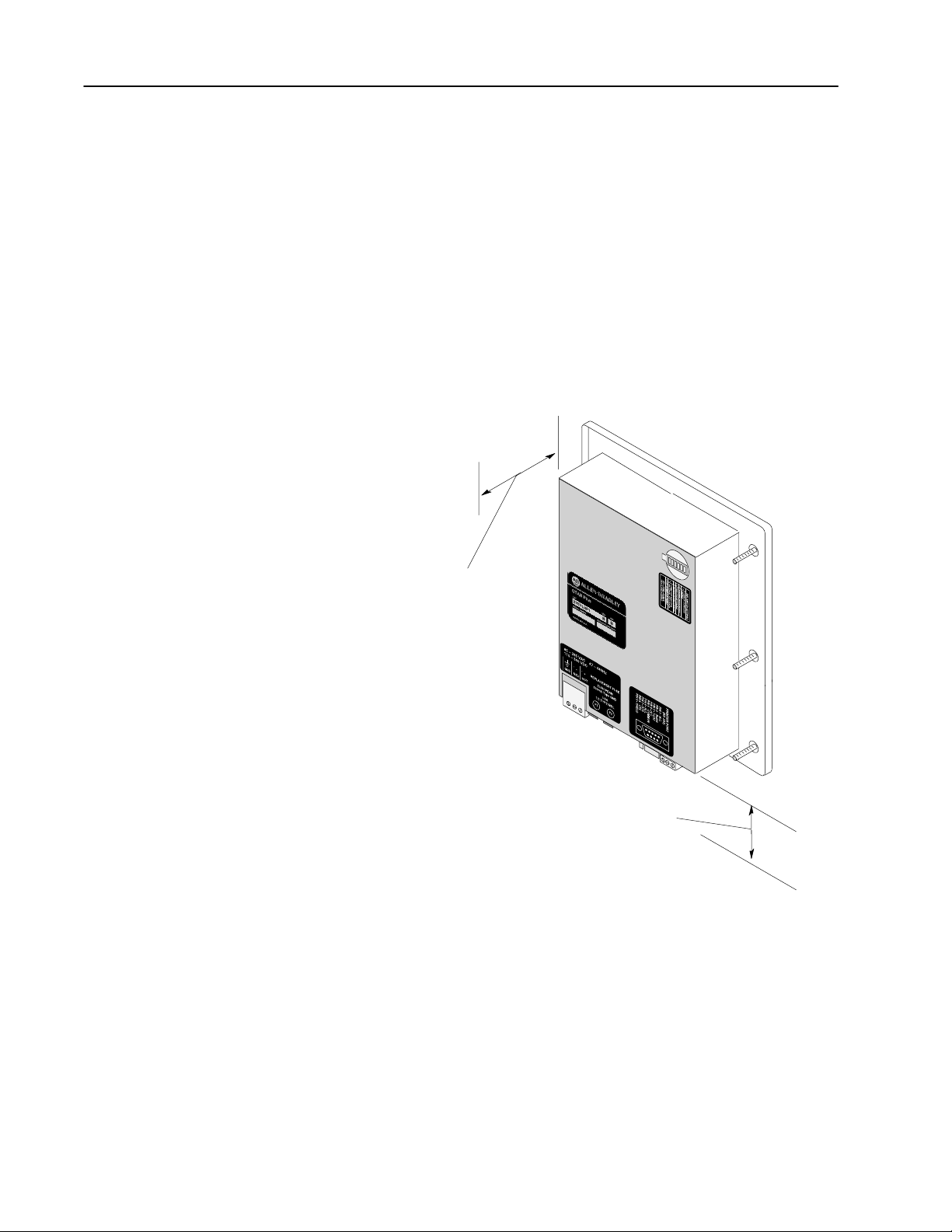

Make sure that you leave adequate room, as shown in Figure 1, for

mounting, air flow, cabling and access to DIP switches.

Figure 1

Recommended Clearances

Leave 3 inches (76.2 mm)

for Mounting, Air Flow, and

access to DIP Switches.

Leave 3 inches (76.2 mm) for

communications port connectors.

Page 5

5

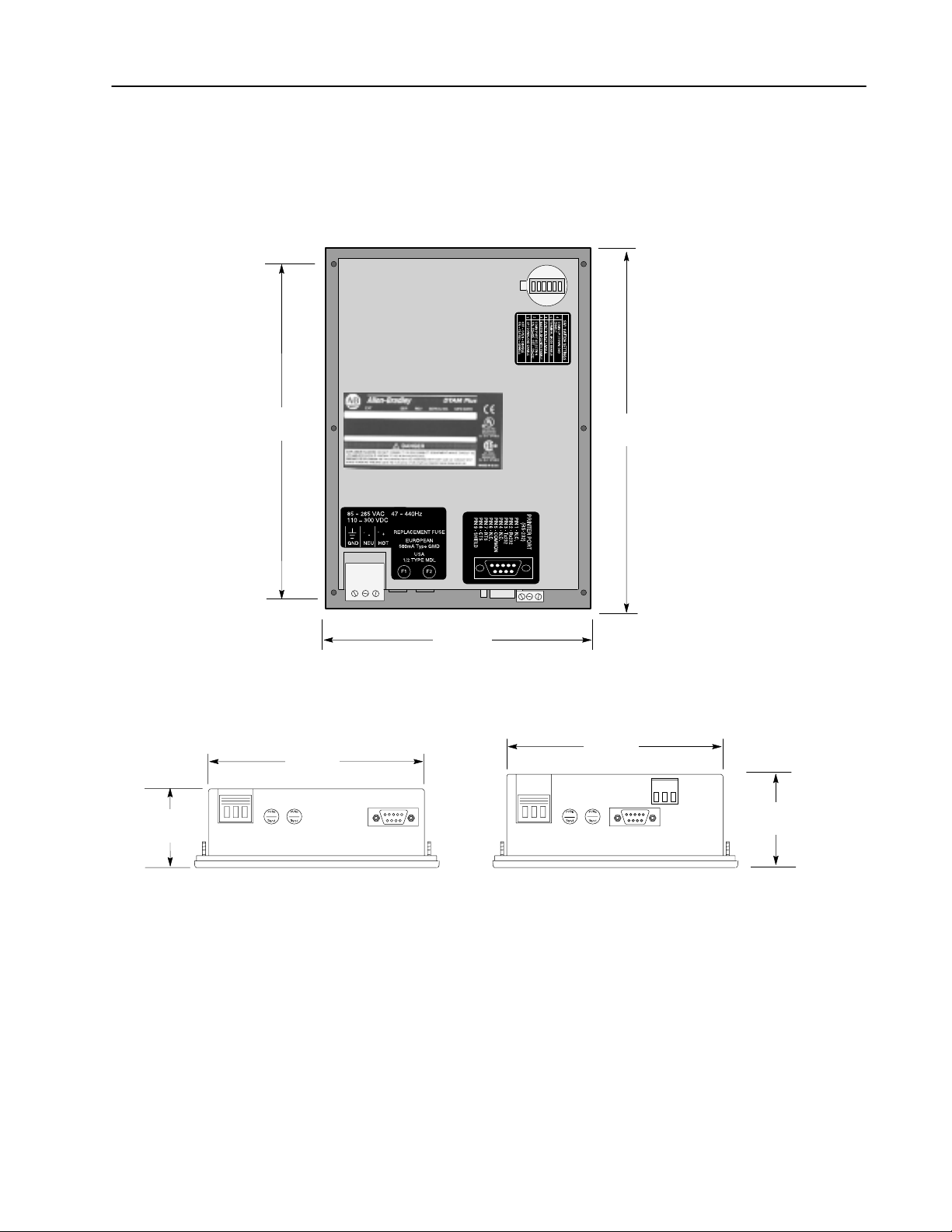

Mounting Dimensions

7.876

(200.1)

Figure 2 shows the mounting dimensions of the terminal.

Figure 2

Mounting Dimensions in Inches (Millimeters)

Back View

8.50

(215.9)

2.0

(50.8)

5.5

(139.7)

6.9

(175.3)

Bottom View

5.5

(139.7)

2.35

(59.7)

Remote I/O and DN VersionsRS-232 / RS-485 Versions

Page 6

6

Installation

To install the DTAM Plus Operator Module:

ATTENTION:

!

1. Using the cutout template shown in Figure 3, cut an opening in

the panel. Remove any sharp edges or burrs.

2. Make sure the sealing gasket is properly positioned on the DTAM

Plus. This gasket forms a compression type seal. Do not use

sealing compounds.

Disconnect all electrical power from the panel before

making cutout.

Make sure that area around panel cutout is clear.

Take precautions so that metal filings or other debris do not

fall into the DTAM Plus ventilation slots or enter any

components that may already be installed in panel.

Make sure that no objects are inserted or fall into the terminal

through the ventilation slots or DIP switch access hole.

Failure to follow these warnings may result in personal injury

or damage to the panel components.

3. Place the DTAM Plus in the panel cutout.

ATTENTION:

!

4. Install the six self locking mounting nuts hand tight.

5. Alternately tighten the mounting nuts until the DTAM Plus is

held firmly against the panel. Tighten mounting nuts to a torque

of 8 to 10 inch-pounds. Do not over-tighten nuts.

Mounting nuts must be tightened to a torque of 8 to 10 inch

pounds to provide a proper seal and to prevent potential

damage to the terminal. Allen-Bradley assumes no

responsibility for water or chemical damage to the terminal or

other equipment within the panel enclosure because of

improper installation.

Page 7

Figure 3

Panel Cutout Dimensions in Inches (Millimeters)

7

Page 8

8

Wire and Cable Length Restrictions

Connecting Power

The following wire and cable length restrictions apply to DTAM

products that are CE marked when used in installations that require

compliance to European EMC Directive 89/336:

DC Power Wiring 10 meters

Ground Terminal Wire 3 meters

Communication Cables 30 meters

These restrictions apply to catalog numbers 2707–L8P1 Series D,

2707–L40P1 Series D and 2707–V40P1 Series D.

The DTAM Plus accepts supply voltages in the following ranges

depending upon the power supply designation.

• Versions with P1 power supply, accept 15-23V AC (47 to 440 Hz)

or 20-30V DC

• Series D versions with P1 Power supply only, accepts 20–30 V

DC

• Versions with P2 power supply, accept 85-265V AC (47 to 440

Hz) or 110-300V DC

• Versions with P4 power supply, accept 11-13V DC

To connect the DTAM Plus to a power source:

ATTENTION: Verify that the power is disconnected from the

power source before wiring. Failure to disconnect power may

!

result in electrical shock.

Make sure that the supply voltage to the DTAM Plus is correct,

refer to the voltage label on back of unit. The incorrect voltage

may damage the DTAM Plus.

Do not overtighten the power connector screw terminals.

Overtightening the terminals may damage the DTAM Plus.

1. Make sure that the voltage source is not turned on.

2. Use AWG#16 or #14 stranded wire to connect the DTAM Plus

screw terminals to the power source (see below).

Note: The power supply terminal block on the DTAM Plus is not

removeable.

Page 9

Figure 4

Power Connections

9

(40K Remote I/O Version Shown, Others Are Similar)

DTAM Plus

For DC connections, connect the Positive Lead

to Hot and the Negative lead to NEU.

3. Connect communications cabling as described in Connecting to

Devices section on page 15.

4. Apply voltage and verify the DTAM Plus powerup sequence as

described in the next section.

Page 10

10

ÎÎÎ

ÎÎÎ

Powerup Sequence

The powerup sequence is automatic. The sequence depends upon the

setting of DIP switch position SW-1 (upload / download enable).

The DTAM Plus is shipped with SW-1 On.

Powerup Sequence (DIP Switch SW-1 ON)

The following steps show the powerup sequence if DIP switch SW-1

is ON.

1. The DTAM Plus verifies the system memory checksum, program

checksum, and system RAM. When done, the result is displayed

with the current DIP switch settings.

Memory Check: pass

DIP Switch: 101000

40K User Memory

2. The display is tested, every pixel of the display is turned on.

Use this display to verify that all pixels are operational.

3. The firmware version number and type of communication port(s)

is displayed (PPort, RS-232, RS-485 or Remote I/O).

Operator Interface

Core: X.XX RS-485

PPORT

4. The DTAM Plus waits for an application download.

Programming Mode

Waiting Up/Download

You cannot operate the DTAM Plus keypad while in the

upload/download mode. The DTAM Plus is waiting for

upload/download operations with a personal computer running

the DTAM Programming Software (DPS).

Page 11

11

Powerup Sequence (DIP Switch SW-1 OFF)

The following steps show the powerup sequence if DIP switch SW-1

is OFF.

1. The DTAM Plus verifies the system memory checksum, program

checksum, and system RAM. After the test is completed, the

result is displayed with the current DIP switch settings.

Checksum: passed

DIP Switch: 001000

RAM: pass

40K User Memory

2. The display is tested, every pixel of the display is turned on.

Use this display to verify that all pixels are operational.

3. The operating system firmware release number and protocol is

displayed (PLC5-DF1 or AB DH-485 or Remote I/O).

Allen-Bradley

Operator Interface

DTAM Plus (c) 1996

FRN: 01.20 AB-RIO

4. On 40K versions with a clock, the current time setting is

displayed.

DATE: W ed Aug 12 98

TIME: 01:12:47

Diagnostics Complete

5. The first application screen displays. When the DTAM Plus is

powered up for the first time you see:

Bul. 2707 DTAM Plus

No Program Loaded

Page 12

12

Upload / Download DIP Switch Settings

Before you can upload or download an application, you must verify

that DIP switch SW-1 is ON. (DTAM Plus is shipped in this

position).

To access the DIP switch, remove the cover from the access hole on

the back of the DTAM Plus (align cover tabs with notches in hole to

remove). The DTAM Plus is shipped without the cover installed,

you can find it in the hardware bag.

On versions with both a Comm and a Printer port, you can transfer

applications using the communication port or the printer port:

• Set DIP switch position SW-6 ON to select the Comm port

• Set DIP switch position SW-6 OFF to select the Printer port

Note: Turn DIP switch SW-6 ON after downloading through the

printer port. This allows communications to occur with the

controller.

All other versions of the DTAM Plus use a single port to transfer

applications; either the Comm port or the Printer port.

If using the Comm port, make sure DIP switch SW-2 is in the correct

position (OFF = RS-232 download, ON = RS-485 download).

Side View

ON =

DIP Switch SW-1

must be ON.

When using the RS-485 / RS-232

Comm Port for file download, set

SW-2 to the correct port selection.

ON = RS-485

OFF = RS-232

123456

OPEN

On Versions with a Printer Port

DIP Switch SW-6 must be:

ON to download using the

Comm port.

OFF to download using the

Printer port (only if the

Comm port is connected to

a host).

Page 13

13

Upload / Download RS-232 Connections

Remote I/O Version With

Printer Port RS-232 Connector

(9 Pin Male)

Gender

Adapter

Cable

(2707-NC2)

T o Computer

RS-232 Port

Comm 1 or 2

Printer Port

Power Connector

Remote I/O Connector

To connect a DTAM Plus RS-232 port to a computer, use the RS-232

Upload/Download cable (Catalog No. 2707-NC2). Use the

communications or printer port (see below). You may need a 9-to-25

pin adapter to connect the cable to your computer. A male to female

gender adapter is required to connect the cable to the printer port or

you can create your own cable. Appendix B of the DTAM Plus User

Manual (2707-UM001B–EN–P).

(T erminal Block)

Remote I/O Version With

Comm Port

Remote I/O Connector

(T erminal Block)

Cable

(2707-NC2)

Power Connector

Comm Port Connector

(9 Pin Female)

To Computer

RS-232 Port

Comm 1 or 2

Versions with a Comm Port Only Versions with a Comm Port

and Printer Port

Cable

(2707-NC2)

Power Connector

Comm Port Connector

(9 Pin Female)

T o Computer

RS-232 Port

Printer Port RS-232 Connector

(9 Pin Male)

Gender

Adapter

Cable

(2707-NC2)

Power Connector

Cable

(2707-NC2)

Comm 1 or 2

T o Computer

RS-232 Port

Comm 1 or 2

Comm Port Connector

(9 Pin Female)

Use Either Port

(Set DIP Switch #6 to

correspond)

Page 14

14

Upload / Download RS-485 Connections

Versions with a Comm Port

Power Connector

RS-485 / RS-232 Connector

(9 Pin Female)

It’s recommended that you use the RS-232 port for transferring

applications. On DTAM Plus versions with a Comm (RS-485 /

RS-232) port, you can also download applications using an RS-485

connection.

Versions with a Comm Port

and Printer Port

Power Connector

Printer Port RS-485 / RS-232 Connector

(9 Pin Female)

Create your own cable

To Computer

RS-485 Port or

Converter

Remote I/O Version With

Comm Port

Remote I/O Connector

(T erminal Block)

Power Connector

RS-485 / RS-232 Connector

(9 Pin Female)

To download through the RS-485 port, you must:

• set DIP switch position SW-2 ON

• create a communication cable. The RS-485 port connections are:

DTAM Plus Comm Port

RS-485/RS-232 Connector

Pin 1 = Tx485 Pin 2 = Tx485 +

Pin 3 = Rx485 Pin 4 = Rx485 +

Page 15

15

Connecting to Devices

To connect the DTAM Plus to an RS-232 device:

1. Make sure that the DTAM Plus is not connected to a voltage source.

2. Use the proper cabling to connect the DTAM Plus Comm port to the

port of the controller (PLC-5 channel 0 or SLC 5/03, 5/04 or 5/05

RS-232 port).

• Use cable, Catalog No. 2707-NC3 for PLC-5 channel 0

connection.

• Use cable, Catalog No. 1747-CP3 for SLC 5/03, 5/04 or 5/05

port connection. This cable requires a 9-pin female to male

gender adapter.

If you need to make your own cable, refer to the cable diagrams in

Appendix B of the DTAM Plus User Manual

(2707–UM001B–EN–P). The maximum recommended cable length

is 50 feet (15.2 meters).

3. Make sure that the communication parameters of the DTAM Plus

match the host device.

4. Apply power and verify that communications are established.

To connect the DTAM Plus terminal to an RS-485 device:

1. Make sure that the power to the DTAM Plus is off.

2. Use the proper cabling to connect the DTAM Plus communications

port to the port of the controller (PLC-5 channel 0 or SLC 5/03, 5/04

or 5/05 RS-232 port).

• Use cable, Catalog No. 2707-NC4 for PLC-5 channel 0

RS-422 connection

• Use cable, Catalog No. 2707-NC5 for PLC-5 channel 0

RS-232 connection. The 2707-NC5 cable converts the signals

from the RS-485 port to RS-232 levels.

• Use cable, Catalog No. 1747-CP3 for SLC 5/03, 5/04 or 5/05

port connection

If you need to make your own cable, refer to the connection

diagrams in Appendix B of the DTAM Plus User Manual

(2707–UM001B–EN–P). The maximum cable length is 200 feet

(60.8 meters).

Important: The DH-485 network cable requires proper shielding,

grounding, and termination. Refer to Data Highway / Data Highway

Plus / Data Highway-485 Cable Installation Manual (1770-6.2.2).

3. The DH-485 connectors are not electrically isolated. If electrical

isolation is required, use Link Couplers (Catalog No. 1747-AIC).

ATTENTION: Electrical isolation using Link Couplers (Catalog

No. 1747-AIC) is required in applications where the distance

!

between the DTAM Plus terminal and the SLC is greater than 6.5

feet (2 meters).

Page 16

16

4. Make sure that the communication parameters of the DTAM Plus

terminal match the host device.

5. Apply power and verify that communications are established.

To connect the DTAM Plus terminal to Remote I/O:

1. Make sure that the power to the DTAM Plus is off.

2. The Remote I/O port of the DTAM Plus provides access via a

Remote I/O link directly to a controller or subscanner. Use cable

(Catalog No. 1770–CD) Belden 9463 for all Remote I/O

connections. Refer to Publication 1770–4.1 for detailed grounding

and wiring guidelines. The User Manual for your controller or

subscanner will also provide cabling instructions.

3. Make sure that the communication parameters of the DTAM Plus

terminal match the host device.

4. Apply power and verify that communications are established.

Page 17

17

DTAM Plus Specifications

Display

Column and Character 4 lines x 20 characters

Display Technology

LCD (2707-L versions) Twisted-nematic type with adjustable

LED (yellow) backlighting

VFD (2707-V versions) Vacuum Fluorescent Display with viewing

distance that exceeds 25 feet (7.6 meters)

Backlight Settings for LCD Version

(via Keypad) Four (0,33,66 and 100%)

Contrast Ratio 10:1

Contrast/Brightness Settings (Keypad)

LCD (2707-L versions) 4 settings

VFD (2707-V versions) 2 settings

Display Size (H x W)

LCD (2707-L versions) 1.0 x 3.0 in (25.2 x 76.0 mm)

VFD (2707-V versions) 1.3 x 3.9 in (33.0 x 99.0 mm)

Character Size (H x W) 0.19 x 0.12 in (4.75 x 2.95 mm)

Keypad

Keypad Type Embossed, sealed membrane

Tactile Feedback Stainless steel dome

Operation Force 12 oz. ± 3 oz. (340 grams ± 85 grams)

Operational Life 1 million cycles

Electrical

Comm Port RS-485 or RS-232C (configurable)

Printer Port (40K memory units) RS-232C

Serial Communication Distances

RS-485 4,000 ft (1219 meters) maximum with the

Link Coupler (Catalog No. 1747-AIC)

RS-232C 50 ft (15 meters) maximum

RS-422 200 ft (61 meters) maximum to a PLC-5

Remote I/O Communication Distances

57.6K 10,000 ft (2800 meters) maximum

115.2K 5,000 ft (1400 meters) maximum

230.4K 2,500 ft (700 meters) maximum

Voltage, Current, Fusing Requirements

Power

Supply

P1 15 - 23V AC, 47 - 440 Hz or 20 - 30V DC 800 mA max. 1 amp

P2 85 - 265V AC, 47 - 440 Hz or 110 - 300V DC 300 mA max. 1/2 amp

P4 11 - 13V DC 250 mA max. 1/2 amp

Port Isolation

Communication Port 500V isolation

Printer Port 500V isolation

Voltage Current Fuse

Page 18

18

Environmental

Ambient Temperature Rating

Operating

LCD Display 0 to

VFD Display 0 to

+45° C (32 to 113° F)

+60° C (32to 140° F)

Storage -20 to +85° C (-4 to 185° F)

Relative Humidity 5 to 95%, noncondensing

Mechanical

Dimensions (Approximate)

Height: 7.6 inch (193.0 mm)

Width: 5.5 inch (139.7 mm)

Depth:

RS-232 / RS 485 Versions 1.8 inch (45.7 mm)

Remote I/O Versions 2.35 inch (59.7 mm)

Front Panel Size:

Height: 8.5 inch (215.9 mm)

Width: 6.5 inch (165.1 mm)

Weight

All except 2707-V40P2N,

-V40P2NR 2.1 lbs (0.95 kg)

2707-V40P2N, -V40P2NR 4.6 lbs (2.09 kg)

Agency Ratings

LED Indicators

RUN LED Green

Alarm LED Red

Function LED Yellow

NEMA Type 4, 12, 13 (indoor use only)

NEMA Type 4X (2707-V40P2N, 2707-V40P2NR only)

Class 1 Division 2 Groups A, B, C, D, hazardous locations

Class 1 Division 2 Groups A, B, C, D, hazardous locations

Class 1 Division 2 Groups C & D, hazardous locations

Temperature Code T3C (2707–L40P4 only)

①

①

Series B or higher – Cat. Nos. 2707–L8P1R, –L8P2R, –L40P1R, –L40P2R,

–V40P1R, –V40P2R, –V40P2NR, –L40P4, –L8P1D, –L8P2D, –L40P1D, –L40P2D,

–V40P1D, –V40P2D, –V40P2ND

Series C or higher – Cat. Nos. 2707–L8P1, –L8P2, –L40P1, –L40P2, –V40P2,

–VP40P1, –VP40P2, –V40P2N

Series D Only – Cat. Nos. 2707–L8P1, –L40P1, –V40P1

①

①

①

Page 19

19

European Union Directive

Compliance

If this product is installed within the European Union or EFTA

regions, the following regulations apply:

This apparatus is tested to meet Council Directive 89/336

Electromagnetic Compatibility (EMC) standards:

• EN50081–2 Class A (Industrial) Emissions

• EN50082–2 Class A (Industrial) Immunity

• EN61000–6–2 Class A (Industrial) Immunity (Series D Only;

2707–L8P1, –L40P1, –V40P1: Series C Only; 2707–L8P2,

–L40P2, –V40P2, V40P2N)

According to these Standards, the factor which determines, for EMC

pruposes, whether an apparatus is deemed to be “Industrial” or

“Residential, commercial and light industrial”, is given in Clause 1

of EN50081–2 as follows:

Apparatus covered by this standard is not intended for

connection to a public mains network, but is intended to be

connected to a power network supplied from a high– or

medium–voltage transformer dedicated for the supply of an

installation feeding a manufacturing or similar plant.

The product described in this document is intended solely for use in

an industrial environment as defined above. When installed in

Europe, any other application is in contravention of the European

Union Directives, and a breach of those laws.

Page 20

Publication 2707-IN005C-EN-P - July 2002 PN 41061-113-01(3)

Supersedes Publication 41061-11 3-01(1) Copyright © 2002 Rockwell Automation. A ll rights reserved. Printed in the U.S.A.

Loading...

Loading...