Page 1

Installation Instructions

InView Communication Modules

Catalog Numbers 2706-PxM, 2706-PxK, 2706-PxP

Topic Page

About This Publication 1

Important User Information 2

Power Supply Requirements 3

Mount the Communication Module to the 2706-P42 and 2706-P44 Displays 3

Wire the Communication Module to the 2706-P42 and 2706-P44 Displays 3

Mount the Communication Module to the 2706-P72 and 2706-P74 Displays 5

Wire the Communication Module to the 2706-P72 and 2706-P74 Displays 6

Mount the Communication Module to the 2706-P92 and 2706-P94 Displays 7

Wire the Communication Module to the 2706-P92 and 2706-P94 Displays 8

Using the Communication Module with a 2706-P22R Display 10

Specifications 11

Additional Resources 11

Configuration Utilities 11

About This Publication

This publication shows how to connect the InView communication module to the

InView display.

Publication 2706-IN015E-EN-P - May 2007

Page 2

2 InView Communication Modules

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you to identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Publication 2706-IN015E-EN-P - May 2007

Page 3

InView Communication Modules 3

Power Supply Requirements

• The 2706-PxM and 2706-PxK modules are powered by the InView 2706-P4x,

2706-P7x, and 2706-P9x displays.

• The 2706-PxP module requires an external 24V ±25%, 1 A dc power supply

for use with the InView 2706-P22R panel mount display.

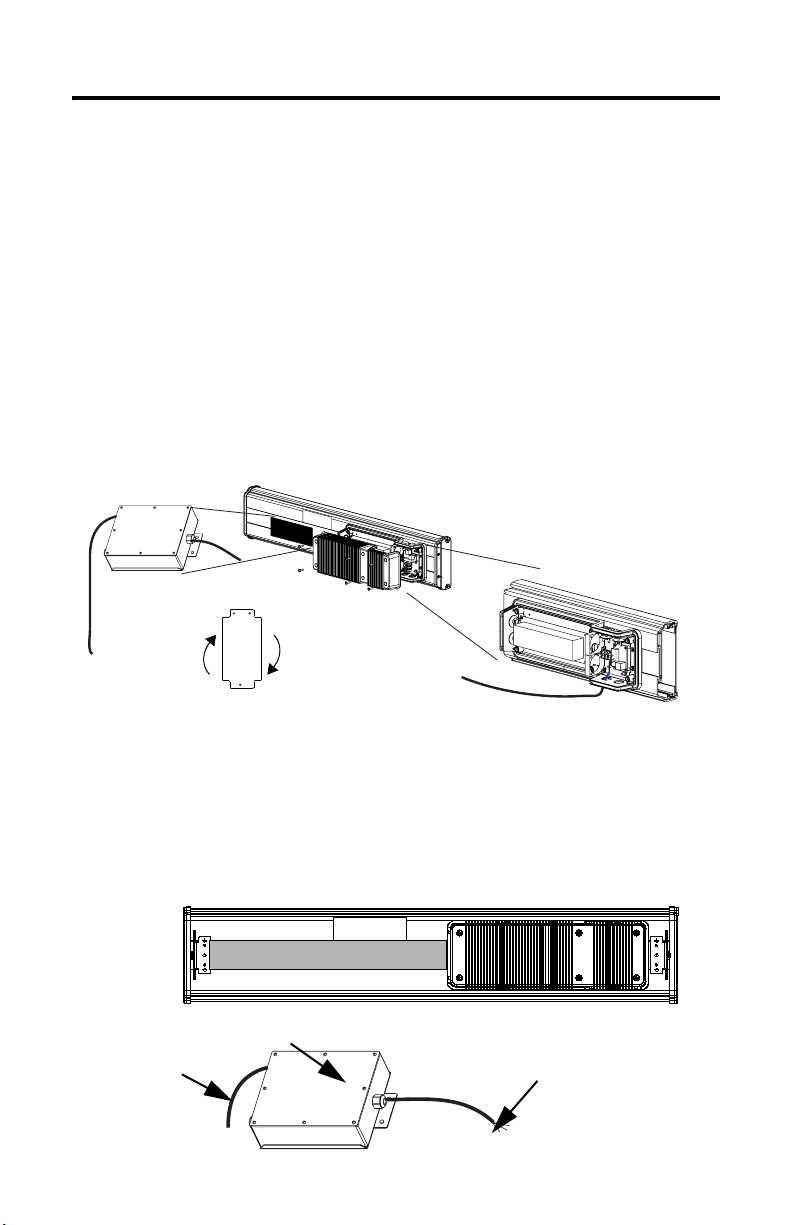

Mount the Communication Module to the 2706-P42 and 2706-P44 Displays

The InView communication module, catalog number 2706-PxM, is designed to

mount to the track of the InView 2706-P42 and 2706-P44 displays. The back plate of

the module has tabs for attaching to the track. Tighten mounting screws until they

bottom out against the back plate.

To T B1

For ease in mounting, rotate

To Controller

(user-supplied

cable)

module 90° so that the

mounting holes are on top and

bottom. Rotate the module

clockwise over track until the

alignment is horizontal.

TB1

Wire the Communication Module to the 2706-P42 and 2706-P44 Displays

Below is an illustration and description of the InView communication module and

its connectors with relation to an InView 2706-P4x display.

Back of InView Display (2706-P42 and 2706-P44)

User-supplied cable

routed through

NEMA-rated cable

grip (supplied).

NEMA Type 12 enclosure with removable cover.

Torque enclosure cover screws to 0.68 Nm (6 lb-in).

2706-PxM

Publication 2706-IN015E-EN-P - May 2007

Serial cable to be connected

to terminal block inside

power supply cover on back

of InView display. Cable to

be routed through cable grip

(supplied).

Page 4

4 InView Communication Modules

1. Disconnect power to the InView display.

ATTENTION

Hazardous voltage. Contact with high voltage may cause death or serious

injury. Always disconnect power to the InView display prior to servicing.

2. Remove the six screws from the power supply cover and remove cover.

Set the screws and cover aside for a later step.

2706-P42 and 2706-P44

Cover Screws

3. Feed the serial cable through the cable grip (shipped with module).

Cover Screws

4. Insert the serial wires through the conduit opening on either the top or the

bottom of the InView display.

TB1 Terminal Block for Serial Connection

Insert the serial wires with

the cable grip into one of

these conduit openings.

Power Line

5. Mount the cable grip to the InView display housing, tighten the locknut

finger-tight, and rotate an additional 1/2 turn.

Publication 2706-IN015E-EN-P - May 2007

Page 5

InView Communication Modules 5

6. Connect the incoming serial wires to the TB1 terminal block.

TIP

TIP

Be sure to place the wires so they are not caught by screws when replacing the

power supply cover and so they do not interfere with fan operation.

TB1

Red (PWR, +5V)2

Incoming

Serial Wires

TB1

Black (GND)1

Orange (TX)3

Brown (RX)4

5

6

7

8

Incoming

Serial Wires

The 2706-PxM communication modules are powered through the serial cable

by the display (series C).

7. Torque the cable grip cap until the cable is securely fastened.

8. Replace the power supply back-cover with the six screws, torquing the

screws to 2.7 Nm (24 lb-in).

9. Connect the power supply to a power source.

Mount the Communication Module to the 2706-P72 and 2706-P74 Displays

The 2706-P72 and 2706-P74 displays are equipped with a mounting plate inside the

case for mounting the 2706-P_K communication kit.

Follow these steps for mounting the communication kit.

ATTENTION

Hazardous voltage. Contact with high voltage may cause death or serious

injury. Always disconnect power to the InView display prior to servicing.

1. Disconnect power to the InView display.

Publication 2706-IN015E-EN-P - May 2007

Page 6

6 InView Communication Modules

2. Open the front of the InView display case by turning the latches counter

clockwise and carefully lowering (opening) the front of the case.

3. Install the communication module to the mounting plate located near the

TB1 terminal block by using the supplied standoffs and screws.

4. Torque the screws to 0.68 Nm (6 lb-in).

TB1

To Controller

(user-supplied

To T B1

cable)

ATTENTION

A label is included in the hardware kit that indicates the default IP address for

the 2706-PENETK EtherNet/IP communication module. The module is shipped

with a default IP address of 192. 168. 1.1. Please consult with personnel who

will be configuring communication for the most appropriate placement of the

label.

Wire the Communication Module to the 2706-P72 and 2706-P74 Displays

The power to the communication module is provided by the InView display

(series C).

Follow these steps for wiring the communcation module.

1. Connect the serial wires to the TB1 terminal block in the InView display.

TB1

Black (GND)1

TIP

Red (PWR, +5V)2

Orange (TX)3

Brown (RX)4

5

6

7

8

The 2706-PxK communication modules are powered through the serial cable by

the display (series C).

Serial Wires

Publication 2706-IN015E-EN-P - May 2007

Page 7

InView Communication Modules 7

2. Route the user-supplied network cable through the cable grip and locknut

that is provided.

3. Connect the user-supplied network cable to the communication module.

4. Verify that there is adequate slack in the cable by making a loop of cable

inside the InView case.

5. Mount the cable grip to the InView display housing, tighten the locknut

finger-tight, and rotate an additional 1/2 turn.

6. Torque the cable grip cap until the cable is securely fastened.

7. Carefully close the InView case and tighten the latches by turning them

clockwise.

8. Connect the InView display to a power source.

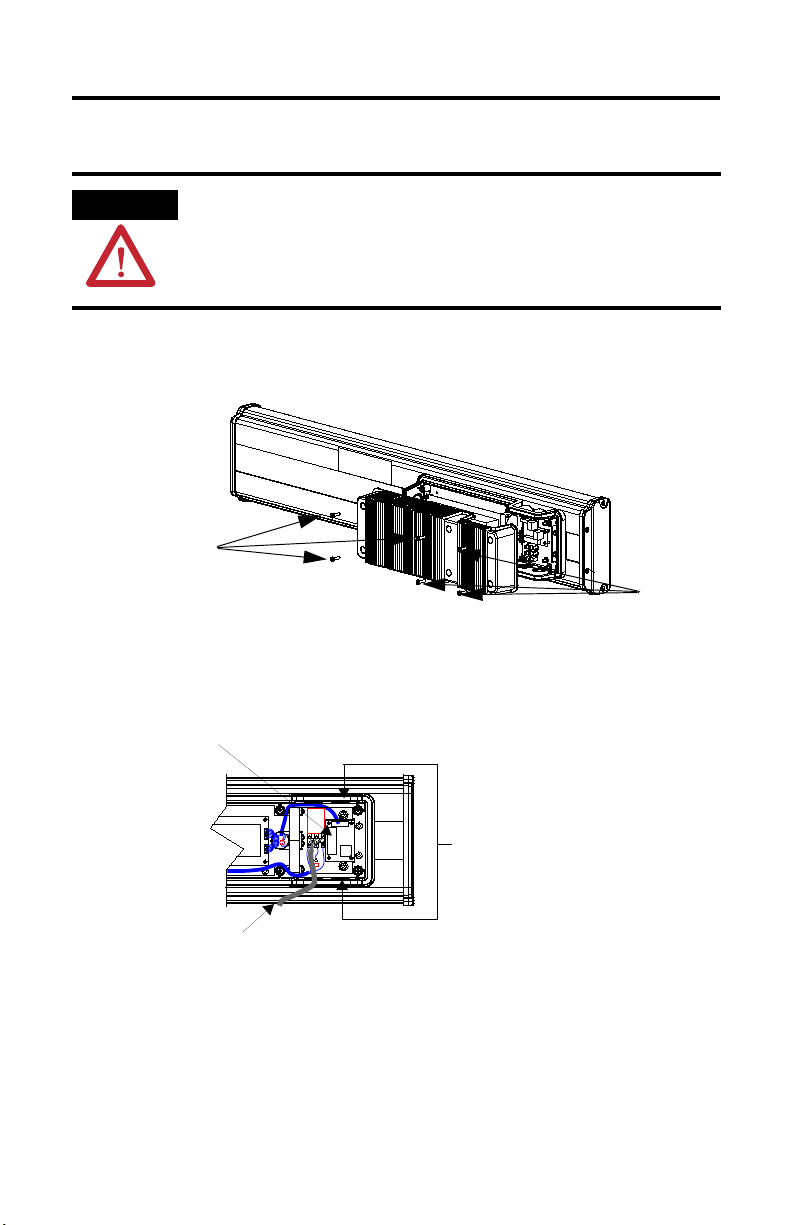

Mount the Communication Module to the 2706-P92 and 2706-P94 Displays

The 2706-P92 and 2706-P94 displays are equipped with a mounting plate inside the

case for mounting the 2706-P_K communication module.

Follow these steps for mounting the communication kit.

ATTENTION

Hazardous voltage. Contact with high voltage may cause death or serious

injury. Always disconnect power to the InView display prior to servicing.

1. Disconnect power to the InView display.

2. Open the front of the InView display case by turning the latches

counterclockwise and carefully lowering (opening) the front of the case.

Publication 2706-IN015E-EN-P - May 2007

Page 8

8 InView Communication Modules

3. Install the communication module to the mounting plate located near the

TB1 terminal block by using the supplied standoffs and screws.

4. Torque the screws to 0.68 Nm (6 lb-in).

Communication Module

Front Cover

ATTENTION

A label is included in the hardware kit that indicates the default IP address for

the 2706-PENETK EtherNet/IP communication module. The module is shipped

with a default IP address of 192. 168. 1.1. Please consult with personnel who

will be configuring communication for the most appropriate placement of the

label.

Wire the Communication Module to the 2706-P92 and 2706-P94 Displays

The power to the communication module is provided by the InView display.

Follow these steps for wiring the communcation module.

Publication 2706-IN015E-EN-P - May 2007

Page 9

InView Communication Modules 9

1. Connect the serial wires to the TB2, TB3 terminal block in the InView

display.

Communication Module

TB2 - Aux +5V

+5V (Red) GND (Black)

TB3 - RS-232

TXD (Orange) CTS

RXD (Brown) GND

RTS EGND

TIP

The 2706-PxK communication modules are powered through the serial cable by

the display (series A).

TB2

To TB2 and TB3

TB3

2. Route the user-supplied network cable through the cable grip and locknut

that is provided.

3. Connect the user-supplied network cable to the communication module.

4. Verify that there is adequate slack in the cable by making a loop of cable

inside the InView case.

5. Mount the cable grip to the InView display housing, tighten the locknut

finger-tight, and rotate an additional 1/2 turn.

6. Torque the cable grip cap until the cable is securely fastened.

7. Carefully close the InView case and tighten the latches by turning them

clockwise.

8. Connect the InView display to a power source.

Publication 2706-IN015E-EN-P - May 2007

Page 10

10 InView Communication Modules

1 2 3 4 5

6 7 8 9

RS-232

1 2 3 4 5

6 7 8 9

RS-232

Using the Communication Module with a 2706-P22R Display

The 2706-P22R InView panel-mount display can be used with a 2706-PxP

communication module. The module is mounted on a DIN rail inside the enclosure

in which the 2706-P22R display is mounted. This maintains the NEMA 4x, 12, or 13

rating. The 2706-PxP communication module also requires a separate 24V dc power

supply. This module does not receive power from the InView display.

Follow these steps to mount and connect the communication module.

ATTENTION

Hazardous voltage. Contact with high voltage may cause death or serious

injury. Always disconnect power to the InView display prior to servicing.

1. Disconnect power to the enclosure.

2. Mount the DIN rail somewhere in the enclosure, near the 2706-P22R display.

3. Snap the communication module to the DIN rail and lock the latches.

4. Connect the user-supplied network cable to the communication module.

24V dc

(user-supplied)

DIN Rail

2706-NC13 Serial Cable (supplied)

Publication 2706-IN015E-EN-P - May 2007

Network Port

To Controller

(user-supplied cable)

24V dc

Class 2

24V dc

Page 11

InView Communication Modules 11

5. Connect the communication module to the 2706-P22R display by using the

supplied serial cable.

6. Provide 24V ±25%, 1 A dc to the communication module.

Specifications

InView Communication Module - 2706-PxM, 2706-PxK, 2706-PxP

Attribute Value

Temperature, operating (inside panel) 0…55 °C (32…131 °F)

Temperature, storage -25…70 °C (-13…158 °F)

Humidity (operating and noncondensing) 5…95%

Shock 15 g max pulse operating

Vibration - channel mount 10 Hz < f < 57 Hz 0.012 in. p-p displacement 57 Hz < f 500 Hz 1.0 g

Vibration - DIN rail mount 10 Hz < f < 57 Hz 0.012 in. p-p displacement 57 Hz < f 500 Hz 2.0 g

30 g max pulse nonoperating

Additional Resources

For more information regarding the InView communication module, see these

publications.

Resource Description

InView Communication Module User Manual,

publication 2706-UM017

2706-PSW1 Online Help Details configuration set-up software.

You can view or download publications at

http://literature.rockwellautomation.com

documentation, contact your local Rockwell Automation distributor or sales

representative.

Configuration Utilities

A copy of the utilities to configure the InView communication modules is included

on the InView Messaging Software CD, version 1.3 or later (catalog number

2706-PSW1).

Provides information about the InView

communication module.

. To order paper copies of technical

Publication 2706-IN015E-EN-P - May 2007

Page 12

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact

your local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwellautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

you can find technical and application notes, sample code, and links to software

for software updates, support chats

at

, or contact your

.

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley, InView, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 2706-IN015E-EN-P - May 2007 PN-19616

Supersedes Publication 2706-IN015D-MU-P - April 2004 Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

.

Loading...

Loading...