Page 1

InView Marquee

Message Display

2706-P22R, 2706-P42, 2706-P43,

2706-P44, 2706-P72, 2706-P74,

2706-P92, 2706-P94

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

) describes some important

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that dangerous voltage may be present.

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that surfaces may be dangerous

temperatures.

Page 3

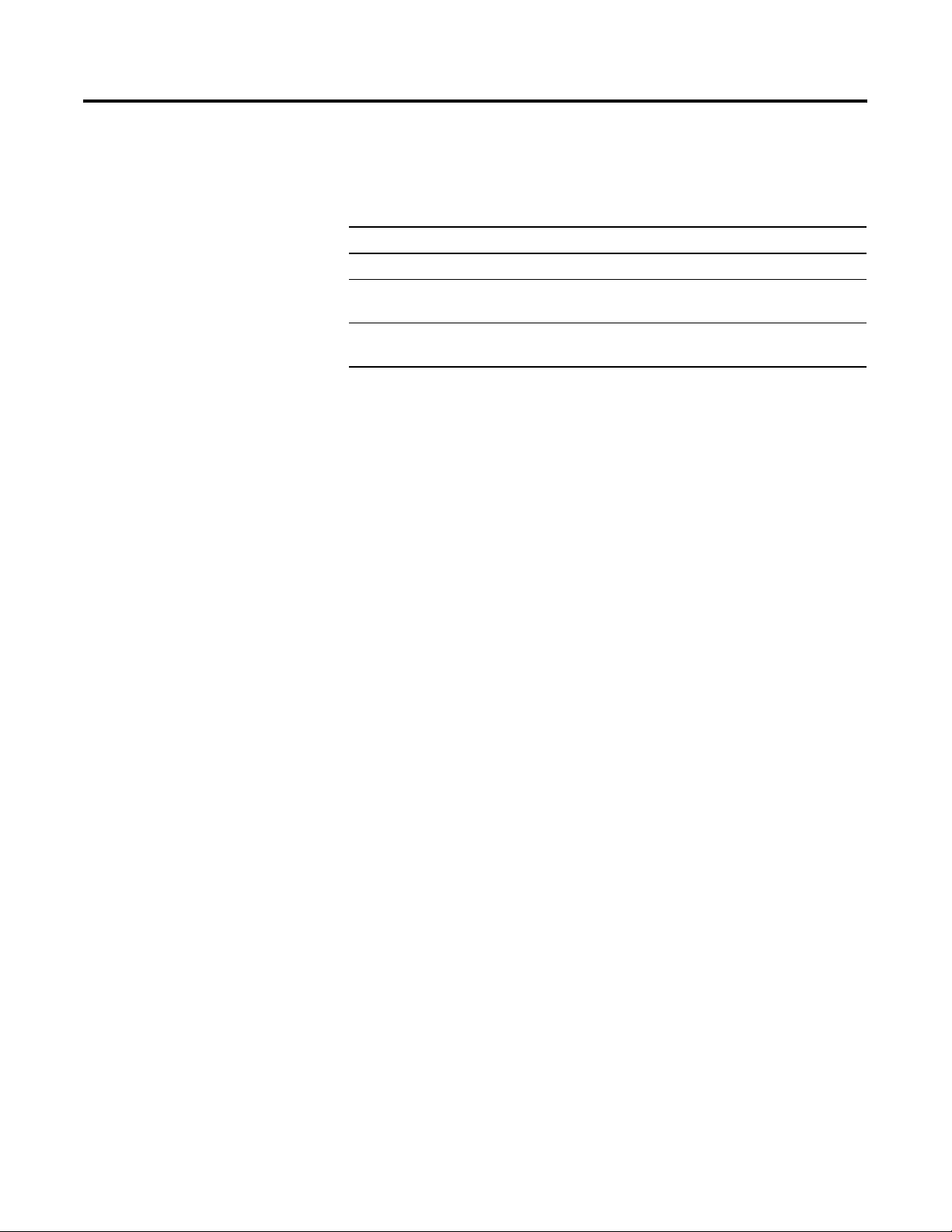

Summary of Changes

This document describes the InView Marquee Message Display.

Revision bars in the margin identify updated information. Changes for

this version of the document include:

Change Page

Updated information on how to change the serial address 1-2

Added information about how to use the 2706-PCABLE1 to

download a message application

Added information about the communication module when

you set the IP address.

1-27

2-11

1 Publication 2706-UM016D-EN-P - March 2006

Page 4

2 Summary of Changes

Publication 2706-UM016D-EN-P - March 2006

Page 5

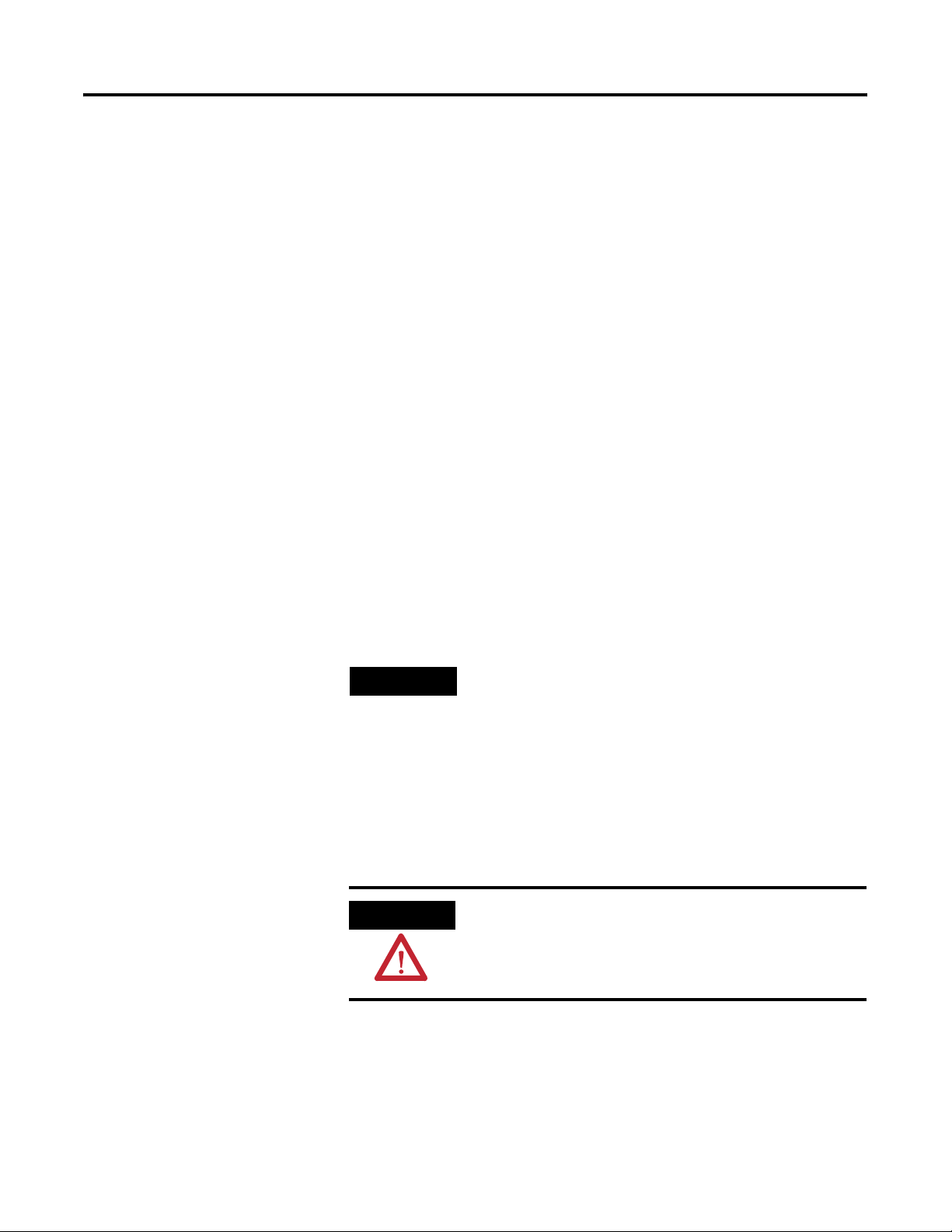

Install InView Marquee Message

Display

Table of Contents

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Wire and Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Change the Serial Address . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Electrical Connections for 2706-P42, 2706-P43 and

2706-P44 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Mount the 2706-P42, 2706-P43 and 2706-P44 Displays . . . . 1-6

Wall Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Ceiling Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Stack Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Back-to-back Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Mount the 2706-P72 and 2706-P74 series NEMA 4

and 4x models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Electrical Connections for 2706-P72 and 2706-P74 Signs . . . 1-14

Mount the 2706-P92C and 2706-P94C Sign . . . . . . . . . . . . . 1-17

Back-to-back Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Electrical Connections for 2706-P92C and 2706-P94C Signs . 1-19

Mount the 2706-P22R Display . . . . . . . . . . . . . . . . . . . . . . 1-23

Panel Cutout Dimensions for 2706-P22R Display . . . . . . 1-23

Dimensions for 2706-P22R Display . . . . . . . . . . . . . . . . 1-24

Electrical Connections for 2706-P22R Display . . . . . . . . . . . 1-24

Communication Connections for 2706-P22R Display . . . . . . 1-25

DIP Switch Settings for 2706-P22R Display . . . . . . . . . . . . . 1-26

Download a Message Application . . . . . . . . . . . . . . . . . . . 1-27

RS-232 to RS-485 Networking. . . . . . . . . . . . . . . . . . . . . . . 1-27

RS-485 Echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Global Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Ground and Terminate the RS-485 Network . . . . . . . . . . . . 1-29

Chapter 2

InView System Connectivity

i Publication 2706-UM016D-EN-P - March 2006

Serial ASCII Communications. . . . . . . . . . . . . . . . . . . . . . . 2-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2706-P42, 2706-P43, 2706-P44, 2706-P72, and 2706-P74

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2706-P22 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Dip Switch Information for the 2706-P9x . . . . . . . . . . . . . . 2-4

Switch 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Switch 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Additional Information for 2706-P9x Displays . . . . . . . . 2-6

Power-up Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2706-P42, 2706-P43, 2706-P44, 2706-P72, 2706-P74,

2706-P92, and 2706-P94 Displays . . . . . . . . . . . . . . . . . 2-10

2706-P22: Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Set the IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Page 6

ii Table of Contents

Serial ASCII Communications

Gateway Address and Subnet Mask Setup . . . . . . . . . . . 2-15

Create the Message File. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Attach a Note to a Message . . . . . . . . . . . . . . . . . . . . . 2-17

Text Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Date, Time and Variables . . . . . . . . . . . . . . . . . . . . . . . 2-17

Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Message Priorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Pause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Message Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Preview Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Set the Display Address . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Download Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Clear Memory/Message Queue . . . . . . . . . . . . . . . . . . 2-22

Chapter 3

Use a PLC5 out Channel Zero . . . . . . . . . . . . . . . . . . . . . . 3-1

Use an SLC 5/03, 5/04, or 5/05 out Channel Zero . . . . . . . . 3-2

Use a MicroLogix out Channel Zero or One . . . . . . . . . . . . 3-3

Use ControlLogix Processor out Channel Zero . . . . . . . . . . 3-4

Use the CompactLogix Processor out Channel Zero or One 3-5

Use FlexLogix Processor out Channel Zero. . . . . . . . . . . . . 3-6

InView Protocol

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Trigger Messages and Update Variables . . . . . . . . . . . . . . . 4-1

The CTRL-T Function Frame. . . . . . . . . . . . . . . . . . . . . 4-1

The CTRL-V Function Frame - Numeric Variables . . . . . 4-3

The CTRL-V Function Frame - Alphanumeric Variables . 4-4

Examples of the Control-T Function. . . . . . . . . . . . . . . . . . 4-5

Trigger a Message on all Displays using

Priority Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Trigger a Message on a Specific Display using Priority

Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Add a Message on all Displays . . . . . . . . . . . . . . . . . . . 4-7

Adding a Message on a Specific Display . . . . . . . . . . . . 4-7

Remove all Messages on all Displays . . . . . . . . . . . . . . 4-7

Remove all Messages on a Specific Display . . . . . . . . . . 4-8

Remove a Message on a Specific Display . . . . . . . . . . . 4-9

Examples of the Control-V Function. . . . . . . . . . . . . . . . . . 4-9

Update a Variable on all Displays . . . . . . . . . . . . . . . . . 4-9

Update Variable on a Specific Display . . . . . . . . . . . . . 4-10

Modbus ASCII Protocol to Download and

Preview Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

How InView Sign Communication Protocol is used

with Modbus ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . 4-11

Publication 2706-UM016D-EN-P - March 2006

Page 7

Table of Contents iii

Mode of Transmission . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

InView Display Memory Map . . . . . . . . . . . . . . . . . . . . 4-12

Methods of Transmission . . . . . . . . . . . . . . . . . . . . . . . 4-13

Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Longitudinal Redundancy Check (LRC) Error

Detection and Calculation . . . . . . . . . . . . . . . . . . . . . . 4-16

Examples of Modbus ASCII Functions . . . . . . . . . . . . . . . . 4-17

Heartbeat Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Clear the Display Memory . . . . . . . . . . . . . . . . . . . . . . 4-20

Clear the Message Queue using Modbus ASCII

in Broadcast Mode (Recommended) . . . . . . . . . . . . . . . 4-20

Clear the Message Queue using Modbus ASCII in

Guaranteed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Set Time in Broadcast Mode with AM/PM Format . . . . . 4-21

Set Time in Broadcast Mode with 24 Hour Format. . . . . 4-22

Set Day and Date in Broadcast Mode . . . . . . . . . . . . . . 4-23

Preview a Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Download Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Add/Remove a Message using a Modbus ASCII 10

Frame Query (Recommended) . . . . . . . . . . . . . . . . . . . 4-33

Add/Remove a Message using Modbus ASCII 10

Frame Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Priority Messaging using a Modbus ASCII Query

(Recommended) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Priority Messaging using a Modbus ASCII Transmission . 4-35

Update a Variable using a Modbus ASCII 06 Frame in

Broadcast Mode (Recommended) . . . . . . . . . . . . . . . . . 4-35

Update a Variable using a Modbus ASCII 06 Frame in

Guaranteed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Update Variables using a Modbus ASCII 10 frame

in Broadcast mode (Recommended) . . . . . . . . . . . . . . . 4-36

Update Variables using a Modbus ASCII 10 frame in

Guaranteed mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Read the Message Queue using a Modbus ASCII 03

frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Read Variables in a Display using a Modbus ASCII 03

frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Change the InView Display Address . . . . . . . . . . . . . . . 4-40

InView Display Communication Protocol Functions and

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

InView Message Format used within Modbus ASCII

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Special Function Command . . . . . . . . . . . . . . . . . . . . . 4-45

Text Position Placement . . . . . . . . . . . . . . . . . . . . . . . . 4-51

ASCII Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Reference Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Publication 2706-UM016D-EN-P - March 2006

Page 8

iv Table of Contents

InView Control and

InView Control API

Specifications

Catalog Number Explanation

Temperature Protection in

NEMA-Rated Enclosures

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Quick Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Appendix A

2706-P43, 2706-P42, 2706-P44, 2706-P72 Specifications . . . . A-1

2706-P92, 2706-P94 Specifications . . . . . . . . . . . . . . . . . . . A-2

2706-P22R Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B

Appendix C

Index

Publication 2706-UM016D-EN-P - March 2006

Page 9

Chapter

Install InView Marquee Message Display

1

Introduction

Wire and Safety Guidelines

These instructions show how to change the serial address and how to

mount InView series signs with NEMA Types 4, 4X, and 12 enclosures.

These signs are intended for indoor use only. Type 4 enclosures are

intended to provide a degree of protection against windblown dust

and rain, splashing water, and hose-directed water. Type 4X

enclosures are intended to provide a degree of protection against

corrosion, windblown dust and rain, splashing water, and

hose-directed water. Type 12 enclosures are in a sealed case that is,

dust free, gasketing, and spray down resistant.

Install the InView display conforming to NFPA 70E, Electrical Safety

Requirements for Employee Workplaces. In addition to the NFPA

general guidelines, refer to the following.

• Careful cable routing helps minimize electrical noise. Route

incoming power to the module by a separate path from the

communication cables.

TIP

Do not run communications wiring and power

wiring in the same conduit!

• Where communication and wire paths must cross, make their

intersection perpendicular.

• Grounding helps limit the effects of noise due to

electromagnetic interference (EMI). To avoid problems caused

by EMI, properly ground all equipment and use shielded cables.

WARNING

1 Publication 2706-UM016D-EN-P - March 2006

EXPLOSION HAZARD

Do not connect or disconnect equipment unless

power has been switched off and area is known to

be non-hazardous.

Page 10

1-2 Install InView Marquee Message Display

Change the Serial Address

Checkout Procedure

IMPORTANT

A serial address for an InView sign is a number from 1 to 254 in

hexadecimal (01 to FE). All signs leave the factory with a default

address of 1 or 01.

This serial address is resident in the InView display and is used for

RS485 networking. If one of the factory network communications

modules are used (2706-Pxxxx), this serial address is typically left at

its factory default and the network node or IP address is set in the

factory network communication module.

After you install a sign according to the Electrical and Mounting

Instructions, make sure the sign is installed properly by applying

power to it. The following information should be displayed on the

sign.

Power wiring must be in accordance with Class I,

Class II and Class III Division 2 wiring methods

(Articles 501-4(b), 502-4(b) and 503-3(b) of the

National Electrical Code, NFPA70) and in

accordance with the local authority having

jurisdiction.

Electrical Connections for 2706-P42, 2706-P43 and 2706-P44 Displays

• Firmware part number and version letter (xxxx).

• Amount of RAM in the sign, (256K).

• Serial address of the sign (a number from 01 to FE or from 1 to

254).

WARNING

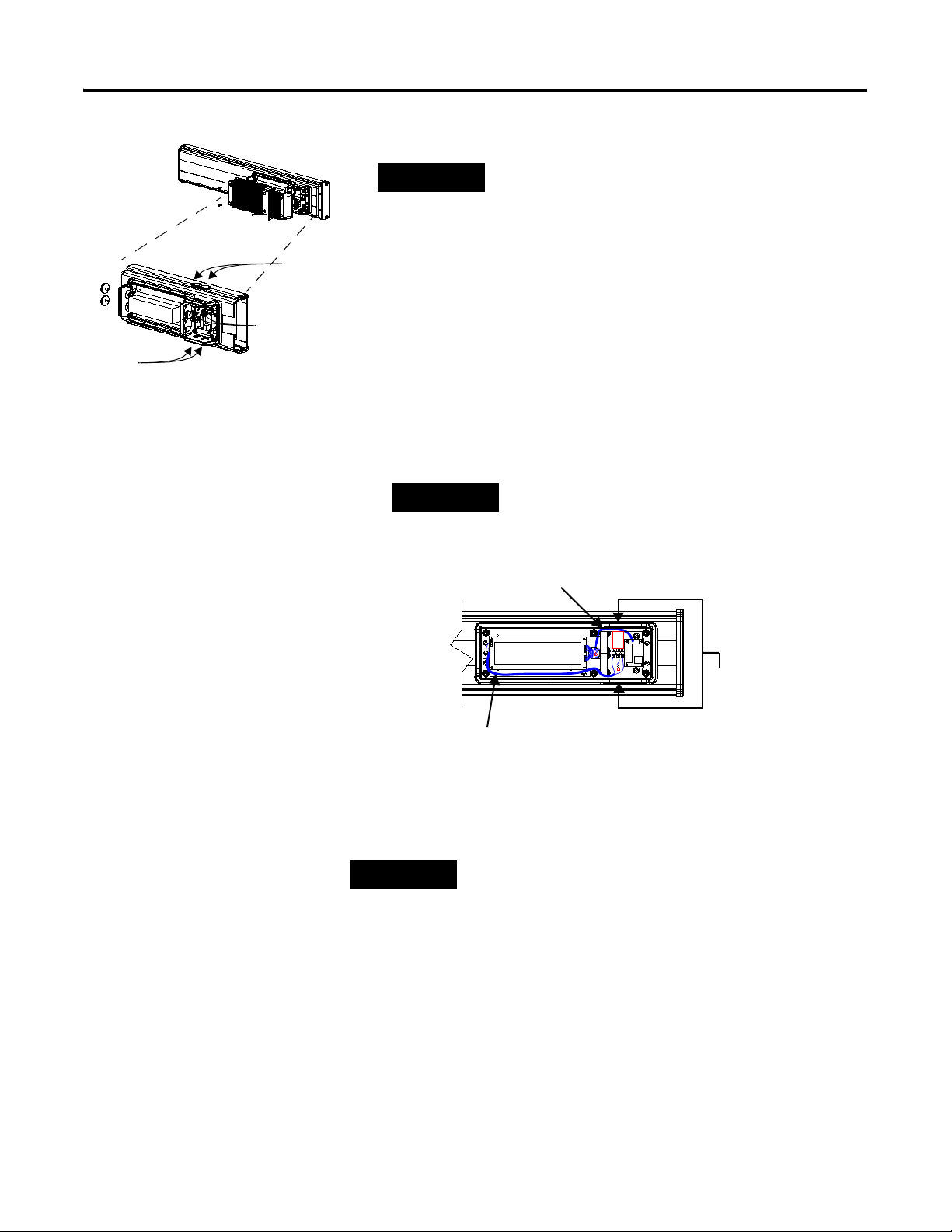

To connect the 2706-P42, 2706-P43, and 2706-P44 displays:

1. Remove the power supply cover by unscrewing its 6 screws.

Save the screws for a later step.

Hazardous voltage. Contact with high voltage may

cause death or serious injury. Always disconnect

power to sign prior to servicing.

Publication 2706-UM016D-EN-P - March 2006

Page 11

Install InView Marquee Message Display 1-3

Hole plugs,

bottom, removed

Hole plugs,

top, removed

Wing nuts for

hole plugs

TIP

It is recommended that you install power and

serial wires at the bottom of the power supply

enclosure to reduce noise from power wires

crossing serial wires.

You can install the power or serial wires at the

top of the enclosure if necessary.

2. Remove the left or right conduit hole plug from the top of the

enclosure by removing its wing nut inside the enclosure.

Save the hole plug for a later step.

3. Insert the power wires through the left conduit hole on either

the top or the bottom of the sign.

TIP

Use watertight conduit connectors only.

Flexible conduit should be used.

Internal

serial wires

Insert the

power wires

into one of

Internal wiring for

power supply

these

conduits.

4. Strip the wires back 6.35 mm (1/4 in.). Connect the incoming

electrical wires.

TIP

Be sure to place the wires so they are not caught by

screws when replacing the power supply cover, and

also so they do not interfere with fan operation.

Publication 2706-UM016D-EN-P - March 2006

Page 12

1-4 Install InView Marquee Message Display

Line

(Hot)

BLACK

Hot (Line 1)

H

N

Ground

Neutral

(Line 2)

Ground

GREEN

w/

Yel low

Neutral

(Line 2):

WHITE

100 to 240V ac

@ 50/60 Hz

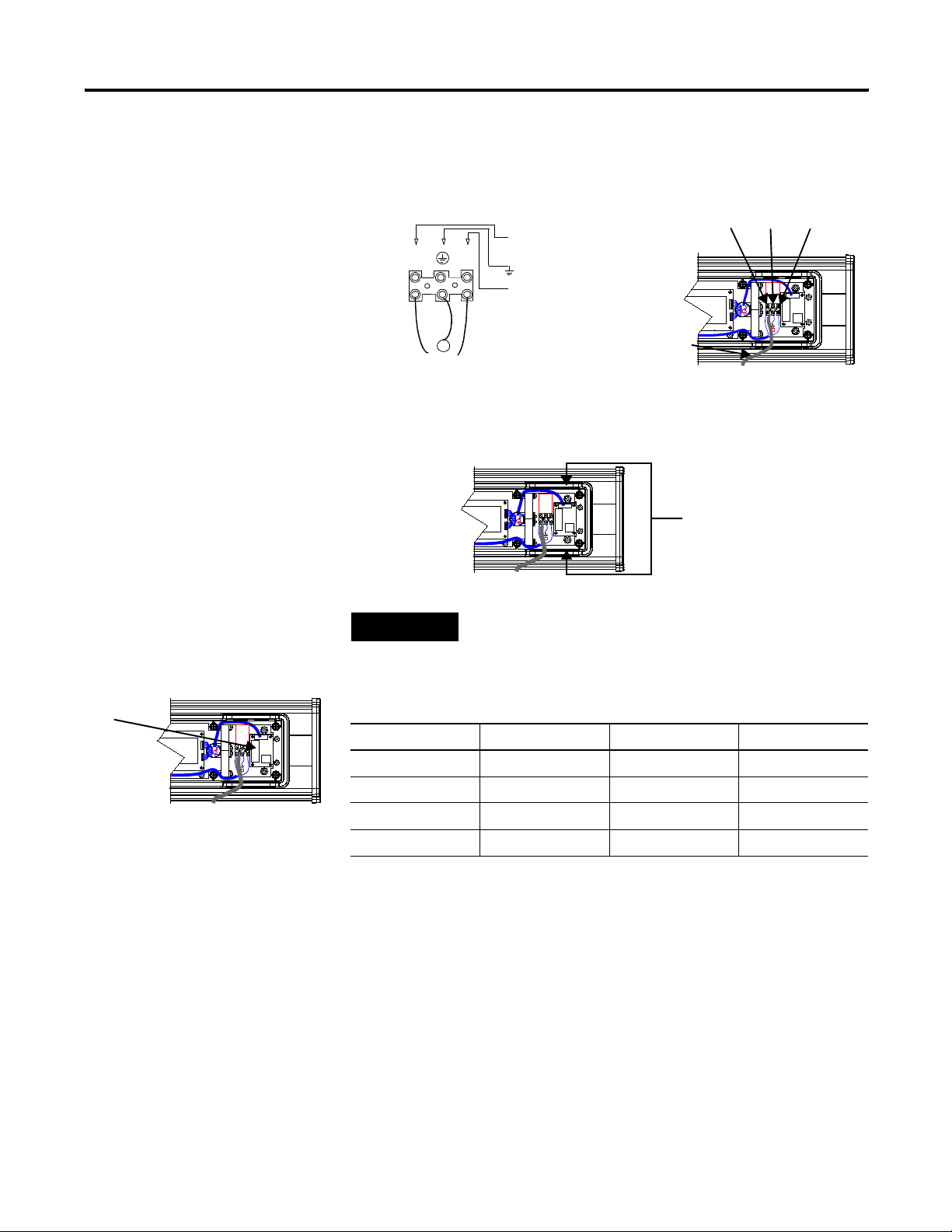

5. Insert the serial wires through the right conduit hole on either

the top or the bottom of the sign.

Insert the

serial wires

into one of these

conduit holes.

TB1

TIP

TB1 can be used for incoming serial connection for

RS-232 or RS-485.

TB1 - Full

Pin Pin Name Pin Pin Name

1. GND 5. RS-485(+)

2. +5V 6. RS-485(-)

3. RS-232 TX 7. NC

4. RS-232 RX 8. SHIELD

6. Connect the incoming serial wires.

Publication 2706-UM016D-EN-P - March 2006

Page 13

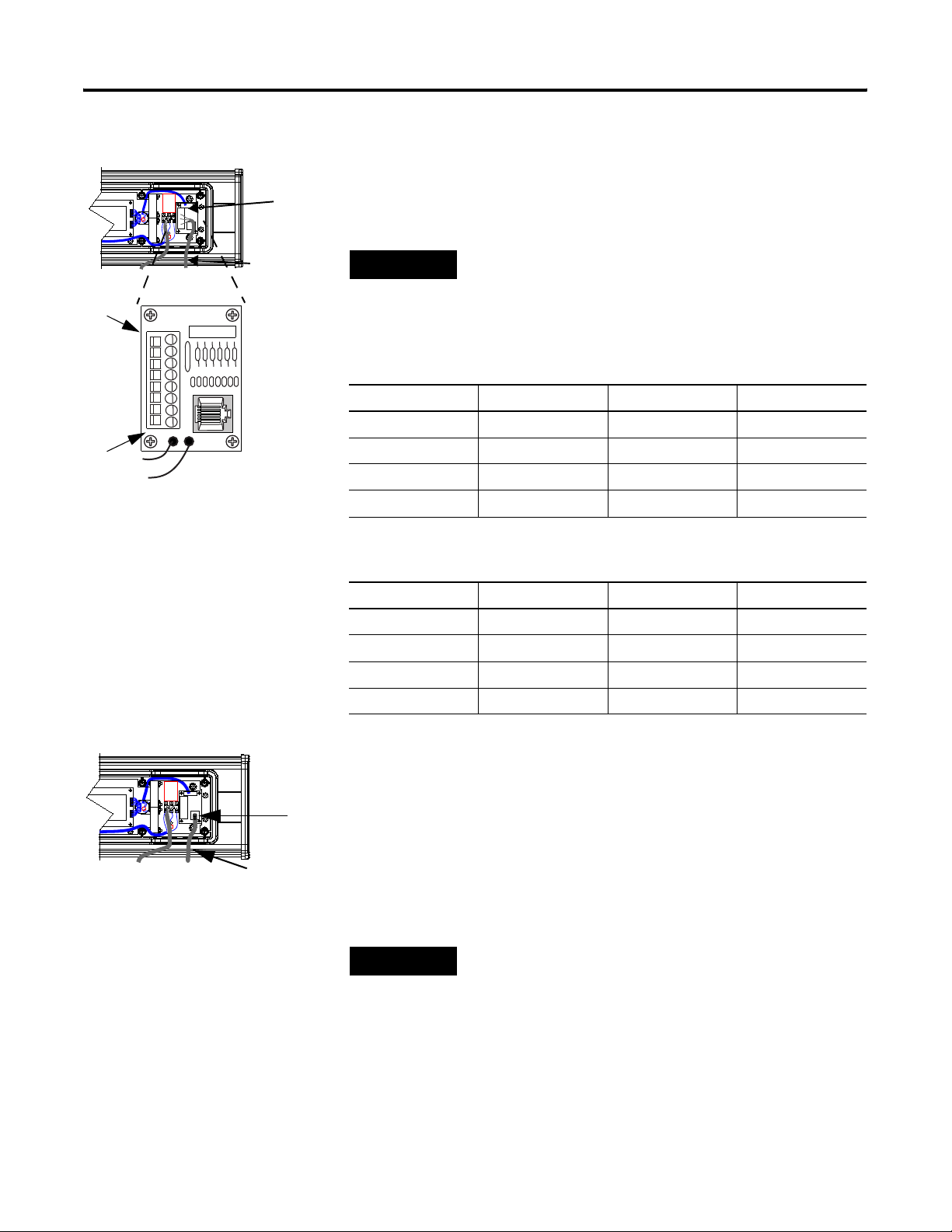

TB1

Install InView Marquee Message Display 1-5

TB1 can be used for incoming RS-232 or RS-485 serial

connection. They cannot be connected at the same time. RS-485

is recommended to reduce undesirable electrical interference.

Incoming serial

wires

TIP

Be sure to place the wires so they are not caught by

screws when replacing the power supply cover, and

also so they do not interfere with fan operation.

8

7

6

5

4

3

2

1

TB1 - RS-232

Pin Pin Name Pin Pin Name

1. GND 5. NC

2. NC 6. NC

3. RS-232 TX 7. NC

4. RS-232 RX 8. NC

TB1 - RS-485

Pin Pin Name Pin Pin Name

1. NC 5. RS-485(+)

2. NC 6. RS-485(-)

3. NC 7. NC

4. NC 8. SHIELD

P1

Incoming

serial wires

7. P1 can be used for incoming RS-232 only, although it is optional

and not recommended.

P1 is intended for RS-232 application downloads and RS-485

terminating resistor connection.

See publication 2706-IN007 for more information on RS-485

termination.

TIP

Be sure to place the wires so they are not caught by

screws when replacing the power supply cover, and

also so they do not interfere with fan operation.

8. To maintain NEMA compliance and to prevent EMI emissions,

install hole plugs in any open conduit holes in the power supply

enclosure.

Publication 2706-UM016D-EN-P - March 2006

Page 14

1-6 Install InView Marquee Message Display

Mount the 2706-P42, 2706-P43 and 2706-P44 Displays

If needed, there is an extra hole plug supplied in addition to any

hole plugs removed in Step 2 on page 3.

9. Replace the power supply cover using the 6 screws from when

the cover was removed.

10. Torque the screws to 2.7 Nm (24 lb-in).

11. Connect the power cable to a power source.

TIP

Only qualified personnel should install the InView

signs.

InView signs are for indoor use only and should not

be continuously exposed to direct sunlight.

Mounting hardware that is used to hang or suspend

signs must be capable of supporting at least 4 times

the total weight of any/all signs mounted together.

For integrity of the case, do not drill holes in or

modify the case.

Disconnect power before you mount a sign.

WARNING

Hazardous voltage. Contact with high voltage may

cause death or serious injury. Always disconnect

power to sign prior to servicing.

Publication 2706-UM016D-EN-P - March 2006

Page 15

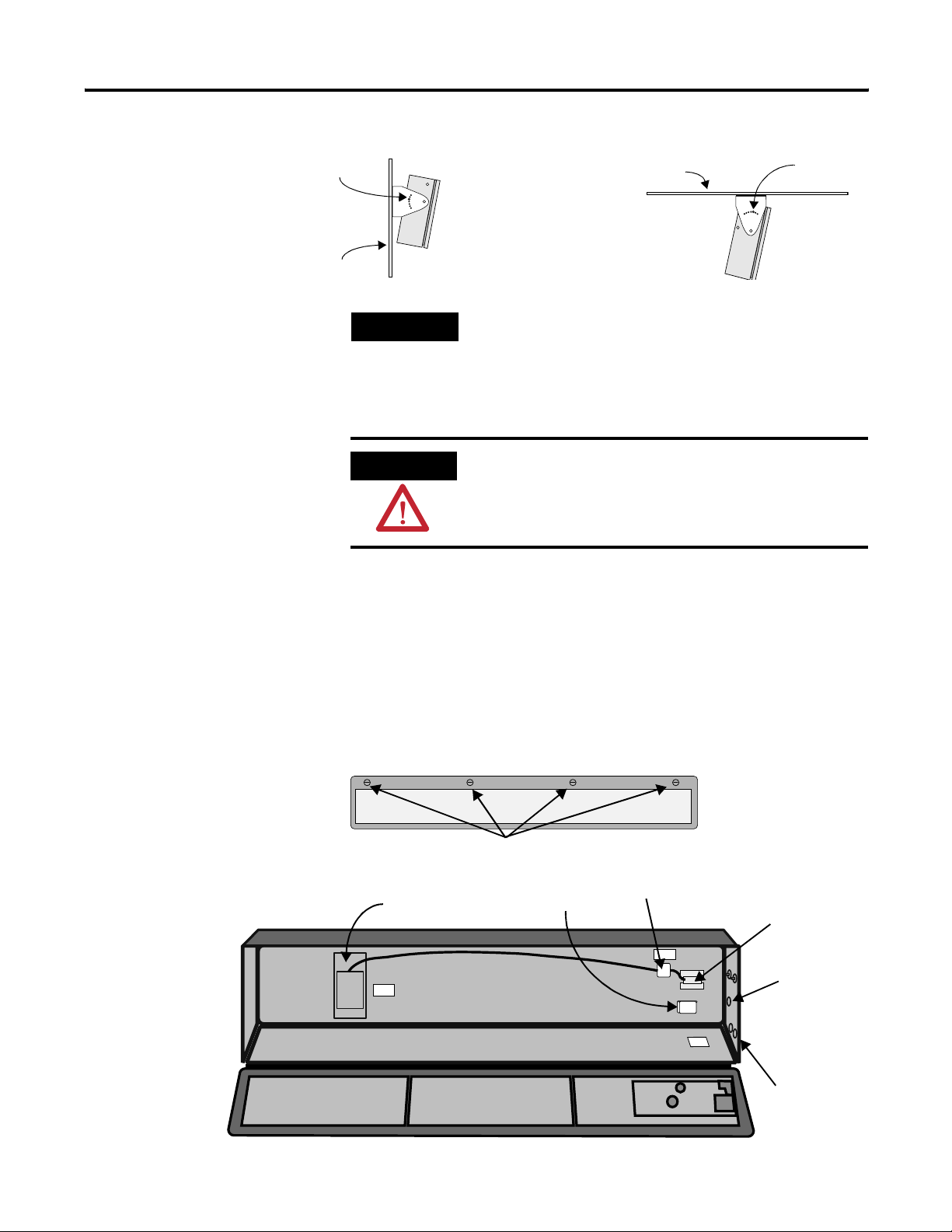

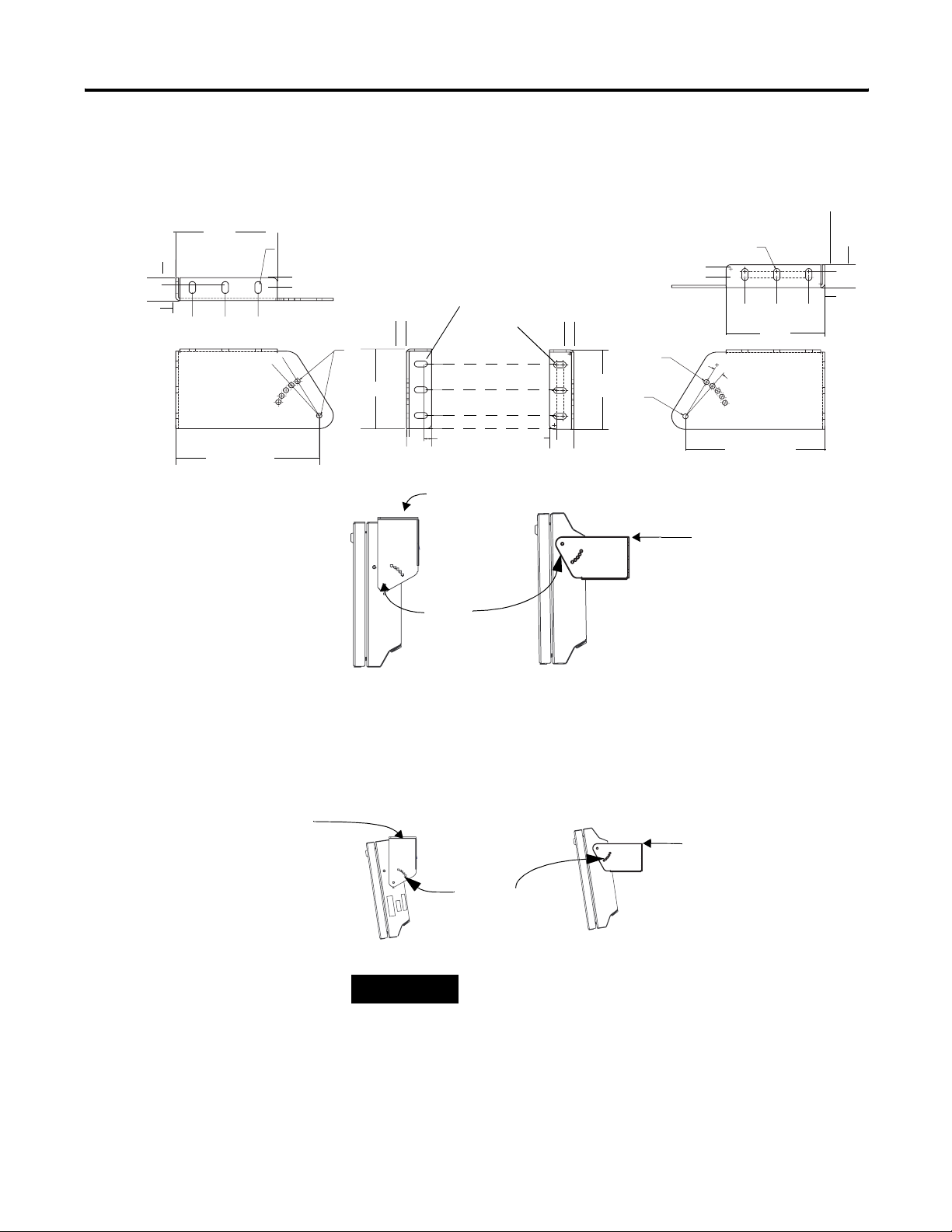

Wall Mount

Install InView Marquee Message Display 1-7

Remove

these

screws.

TIP

Remove only one end cap at a time.

To mount the display to a wall:

1. Remove the 4 screws and the end cap from one end of the sign.

2. Slide one of the wall mounting brackets onto the back of the

sign until it is approximately 13 mm (0.5 in.) away from the end

of the sign.

0.5”

Wall mounting

bracket

127 (5.00)

33.13 (1.30)

25.40 (1.00)

12.70 (0.50)

7.62 (0.30)

17.65 (0.70)

Wall

mounting

bracket

Phillips

screws go

here.

Fasten

these

screws.

33.13 (1.305)

Dimensions are in mm (inches).

2.65 (0.105)

30.35 (1.195)

30.35 (1.195)

75.95 (2.99)

40.64 (1.60)

4.04 (0.159) 10- 32 UNC-2B 2 Holes

7.11 (0.280) Thru 3 Holes

3. Use two 10-32 x 1/4 Phillips screws (supplied) to secure the wall

mounting bracket to the back of the sign.

4. Torque the screws to 2.7 Nm (24 lb-in).

5. Replace the end cap using the 4 screws removed in Step 1

above.

6. Torque the screws to 2.7 Nm (24 lb-in).

7. Repeat Steps 1 to 6 for the other end of the sign.

Approximate distances between the bracket holes,

center-to-center, are shown below.

Publication 2706-UM016D-EN-P - March 2006

Page 16

1-8 Install InView Marquee Message Display

94 cm (37 in.) for 2706-P42

183 cm (72.2 in.) for 2706-P43

185.4 cm (73 in.) for 2706-P44

8. Attach the two remaining wall mounting brackets to a wall so

that they align with the brackets on the sign.

Mounting bracket

on the sign

TIP

Do not install the sign directly to drywall or

plaster-board. The sign must be fastened to a wall

capable of supporting at least four times the weight

of the sign.

9. Connect the mounting brackets on each end of the sign together

using a 5/16 Phillips screw and a 5/16 washer through the

mounting holes, as shown below, securing with a 5/16 nut.

Do not tighten the nut at this time.

Screw and

washer through

mounting holes

Mounting

holes

Nut

Brackets

Top viewSide view

Washer Screw

10. Match the alignment holes of the brackets on the sign with the

alignment holes of the brackets on the wall so that the sign is at

the desired viewing angle.

Mounting

bracket on the

wall

Publication 2706-UM016D-EN-P - March 2006

Alignment holes

TIP

The second mounting bracket is shown here for

illustration only. It is actually mounted to the wall.

11. Fasten the mounting brackets together using two 10-32 x 3/4

Phillips screws, two 10-32 washers, and two 10-32 lock nuts

through selected alignment holes on each end of the sign.

12. Torque to 2.7 Nm (24 lb-in).

Page 17

Lock

nuts

Install InView Marquee Message Display 1-9

13. Torque the 5/16 nuts in the mounting holes (See Step 9) to

2.7 Nm (24 lb-in).

Washers

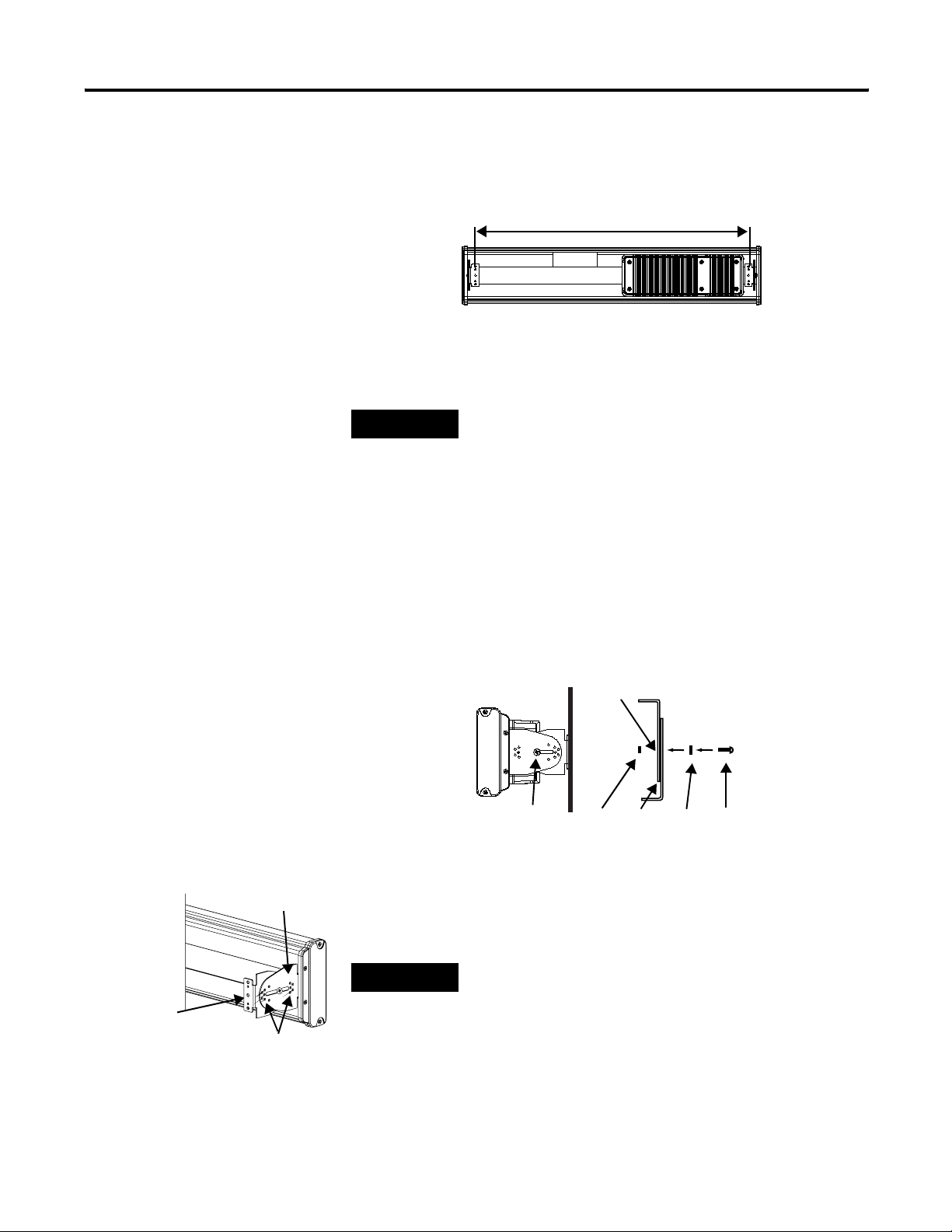

Ceiling Mount

Phillips

screws

To mount the display to the ceiling:

1. Remove one screw from the top of the end cap.

Remove

this screw.

2. Line up a ceiling bracket with the top hole on the sign’s end cap

so the bracket fits in the indentation.

There are left and right ceiling brackets. Use the one that fits

with the screw hole’s countersunk side facing out.

3. Secure the ceiling bracket with the screw removed in Step 1 and

torque the screw to 2.7 Nm (24 in-lb).

Screw hole

Screw

Ceiling

bracket

Ceiling

bracket

mounted to

end cap.

4. Repeat steps 1 through 3 for the other end of the sign.

5. Use chains (not supplied) to hang the sign from a ceiling.

TIP

TIP

Use chains capable of supporting 4 times the total

weight of the sign(s).

The hole you select in the ceiling bracket for the

chain determines the angle at which the sign hangs.

Publication 2706-UM016D-EN-P - March 2006

Page 18

1-10 Install InView Marquee Message Display

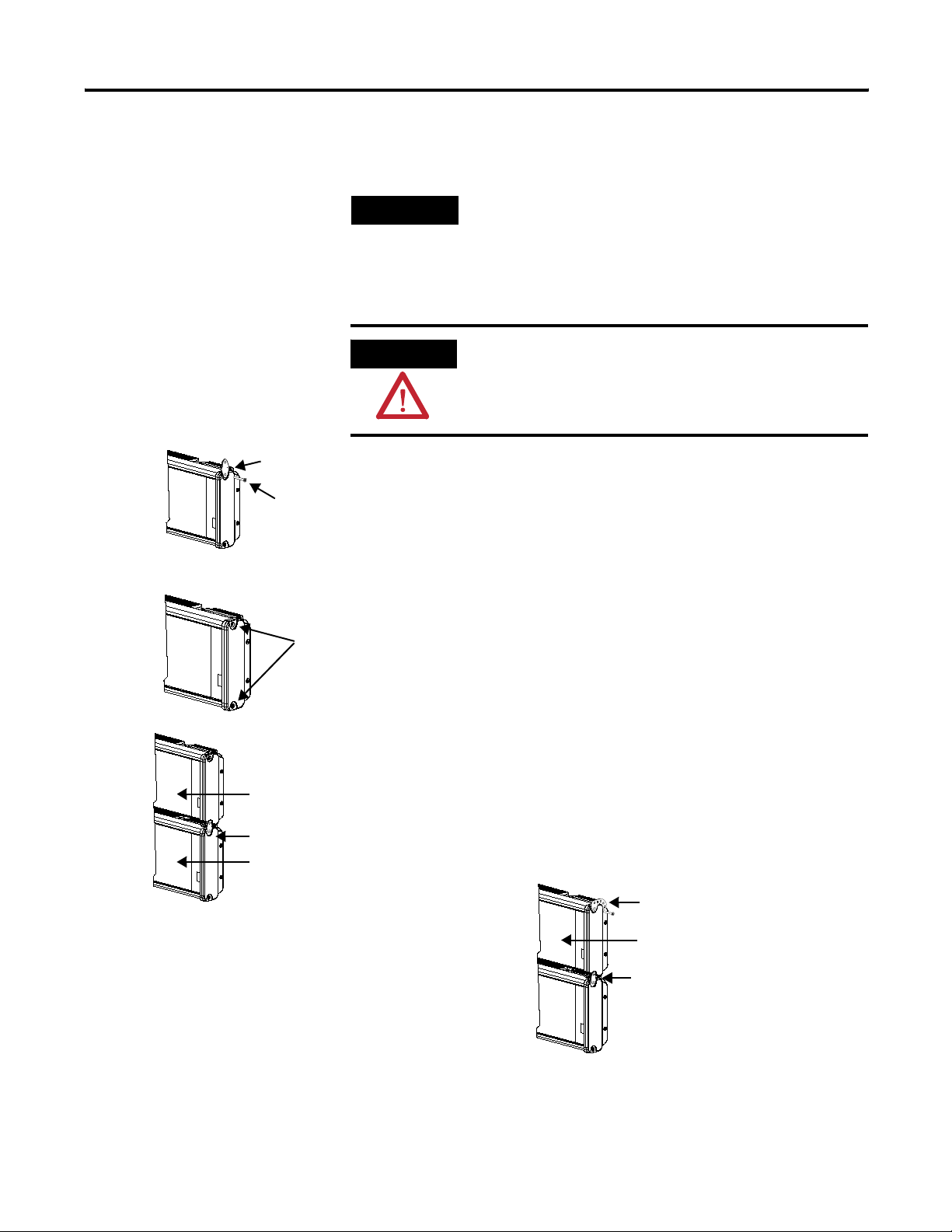

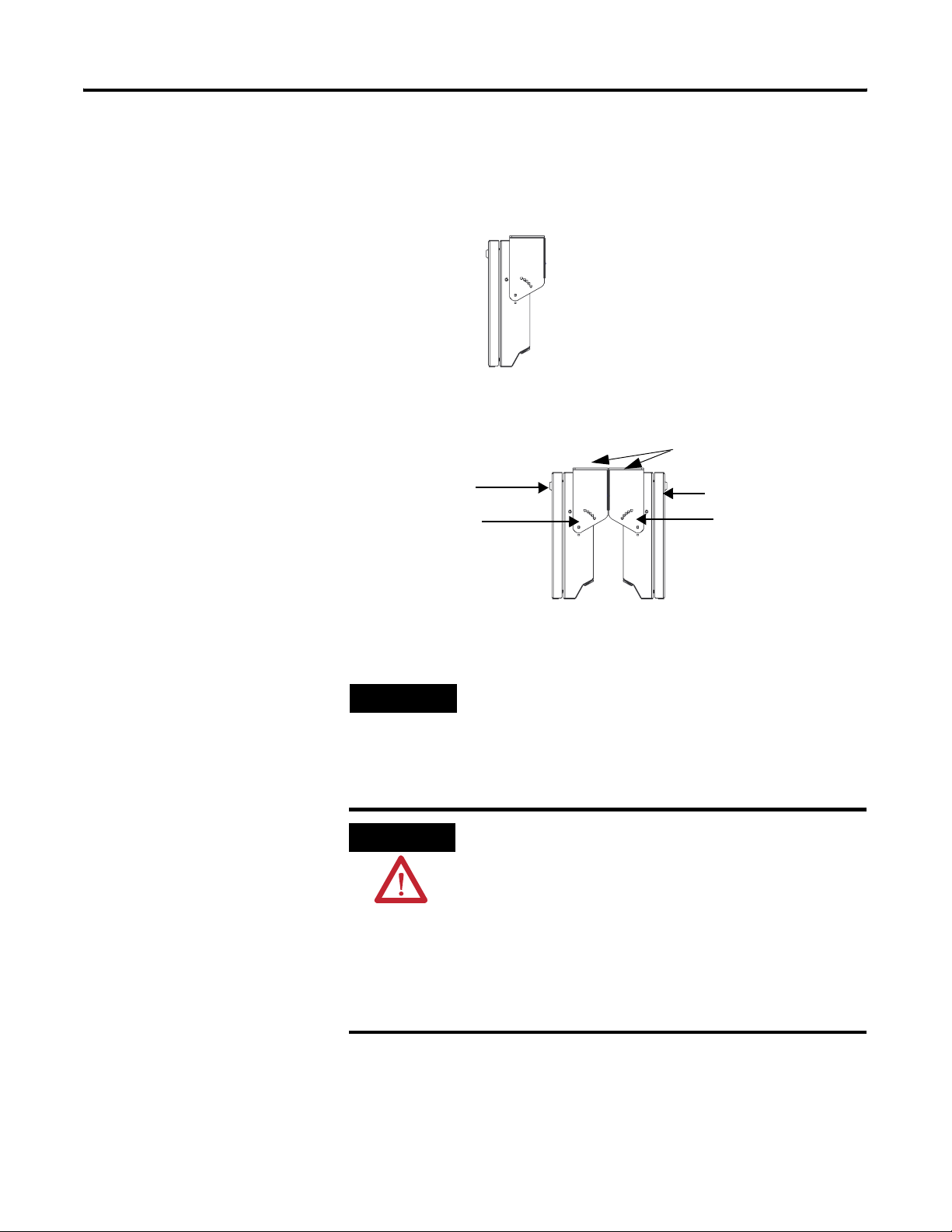

Stack Mount

Stacking

bracket

Screw

Remove

these

screws.

TIP

Up to 4 signs can be hung together vertically

(‘stacked’). Mounting system for stack mounting must

support a minimum of four times the total weight of

all signs being stacked.

WARNING

Possible crush hazard. Do not stack more than 4

signs. Otherwise signs may fall causing serious injury

or death.

To stack the signs:

1. Remove the top screw from each end cap of the bottom sign

2. Use the screw removed in Step 1 to fasten a stacking bracket to

each end cap, countersunk side out, and torque to 2.7 Nm

(24 lb-in).

3. Remove the top and bottom screws from each end of the

remaining signs.

Next sign

Stacking bracket

Bottom sign

4. For each end of the signs, secure the stacking bracket from the

bottom sign to the next sign using one of the screws removed in

Step 3 and torque to 2.7 Nm (24 lb-in).

5. Secure a ceiling bracket to the top of each end cap on the top

sign.

See Step 2 of the Ceiling Mount instructions on page 1-9.

Ceiling

bracket

Top sign

Stacking

bracket

6. Use a chain (not supplied) to hang the signs from the ceiling.

Publication 2706-UM016D-EN-P - March 2006

Page 19

Install InView Marquee Message Display 1-11

Follow the notes in Step 4 of the Ceiling Mount instructions on

page 1-9.

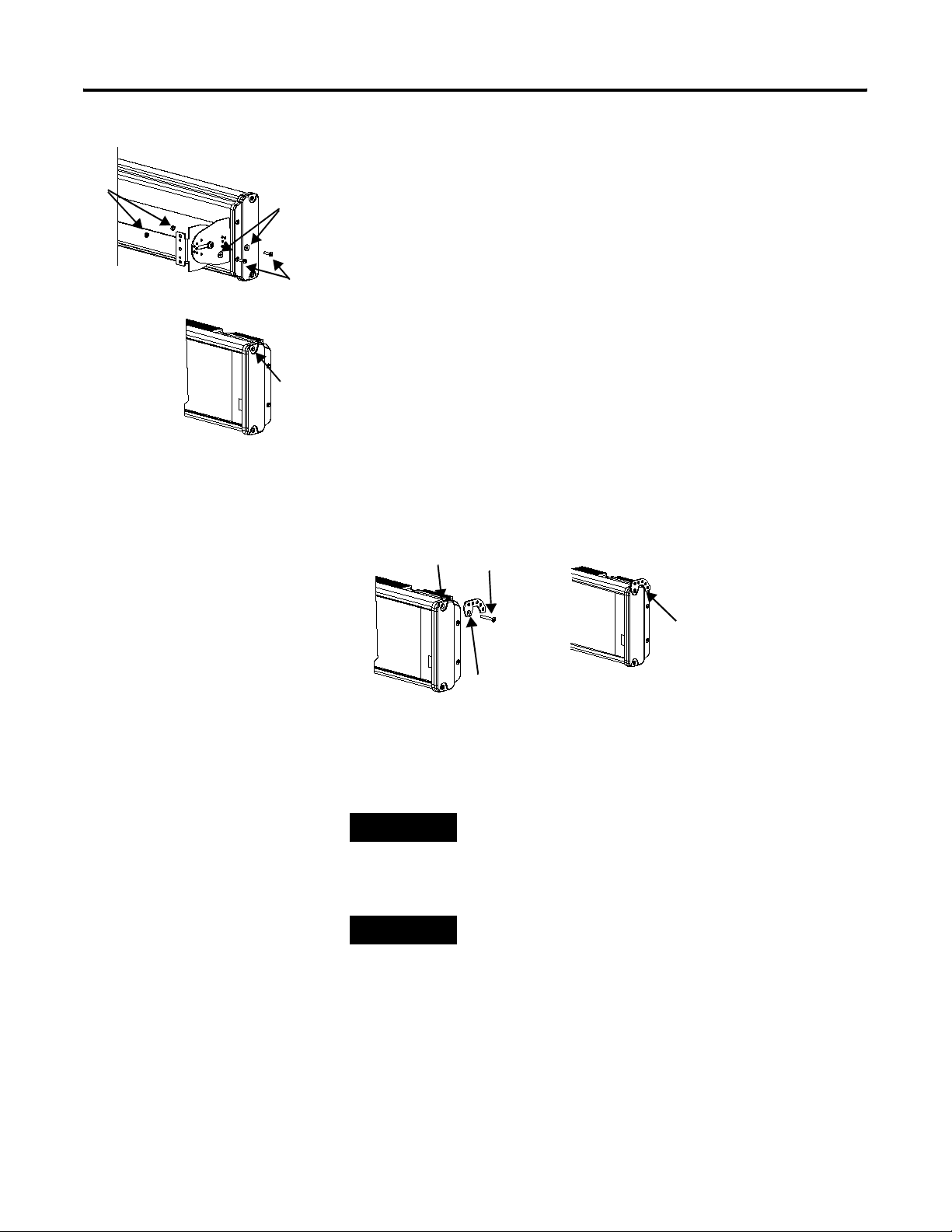

Back-to-back Mount

TIP

Remove only one end cap at a time for each sign.

To mount the signs back-to-back:

1. Attach a mounting bracket on each end of the signs and replace

the end caps.

Follow Steps 1 to 5 of the Wall Mount instructions.

2. However, replace only the bottom three screws for each end cap

and torque the screws to 2.7 Nm (24 lb-in).

Do this for each end of both signs.

TIP

Do NOT fasten the top screws to the end caps. The

top screws are used to fasten the ceiling mounting

brackets to the end caps in the next step.

Do NOT fasten this screw to the end cap.

Fasten these three screws to each end cap.

3. Attach ceiling mounting brackets to all the end caps and torque

the screws to 2.7 Nm (24 lb-in).

See Step 2 of the Ceiling Mount instructions.

Publication 2706-UM016D-EN-P - March 2006

Page 20

1-12 Install InView Marquee Message Display

Ceiling

mounting

bracket

4. Match the signs together back-to-back and connect them

together.

Follow Steps 7 through 10 of the Wall Mount instructions on

page 1-8.

First

sign

Second

sign

Mounting

brackets

First

sign

First

mounting

bracket

Second

sign

Second

mounting

bracket

5. Use chains (not supplied) to hang the signs from the ceiling.

TIP

Use chains capable of supporting 4 times the total

weight of the signs.

Publication 2706-UM016D-EN-P - March 2006

Page 21

Install InView Marquee Message Display 1-13

n

3

Mount the 2706-P72 and 2706-P74 series NEMA 4 and 4x models

Mounted so flanges are hidden behind the sign

2706-P72CNx: 104.8 cm (41.25 in.)

2706-P74CNx: 165.8 cm (65.25 in.)

To mount the sign:

1. Attach the two sign brackets to a wall, ceiling, or other surface.

Be sure to place the brackets so the bracket flanges face

appropriately as shown below. Mount the brackets the following

distance apart (measured from the center of the mounting holes

in each bracket):

Mounted so flanges show on the sides of the sig

2706-P72CNx: 110.5 cm (43.5 in.)

2706-P74CNx: 171.4 cm (67.5 in.)

Wall

or

ceiling

Sign brackets, facing

in behind the sign

IMPORTANT

Do not install the sign directly to drywall or

Sign brackets, facing

out from the sign

plasterboard. The sign must be fastened to a surface

capable of supporting at least four times the weight

of the sign.

0.48 (1.20)

184.15

(7.25 REF)

2. Mount the sign on the sign brackets using the two large hex

bolts supplied.

(0.50 REF)

(0.36 TYP)

End view,

wall-mounted

End view,

ceiling-mounted

Hex bolt

139.70 (5.50)

69.85

(2.75)

19.05

(0.75)

8.74 x 12.70 (0.344 x 0.50)

OBRound Slot (3 Places)

Wall

3. Tilt the sign to select a viewing angle.

4. To hold the sign in place, insert a Phillips screw (supplied)

through one of the small holes on each bracket into the screw

hole in the sign case.

Ceiling

Hex bolt

Publication 2706-UM016D-EN-P - March 2006

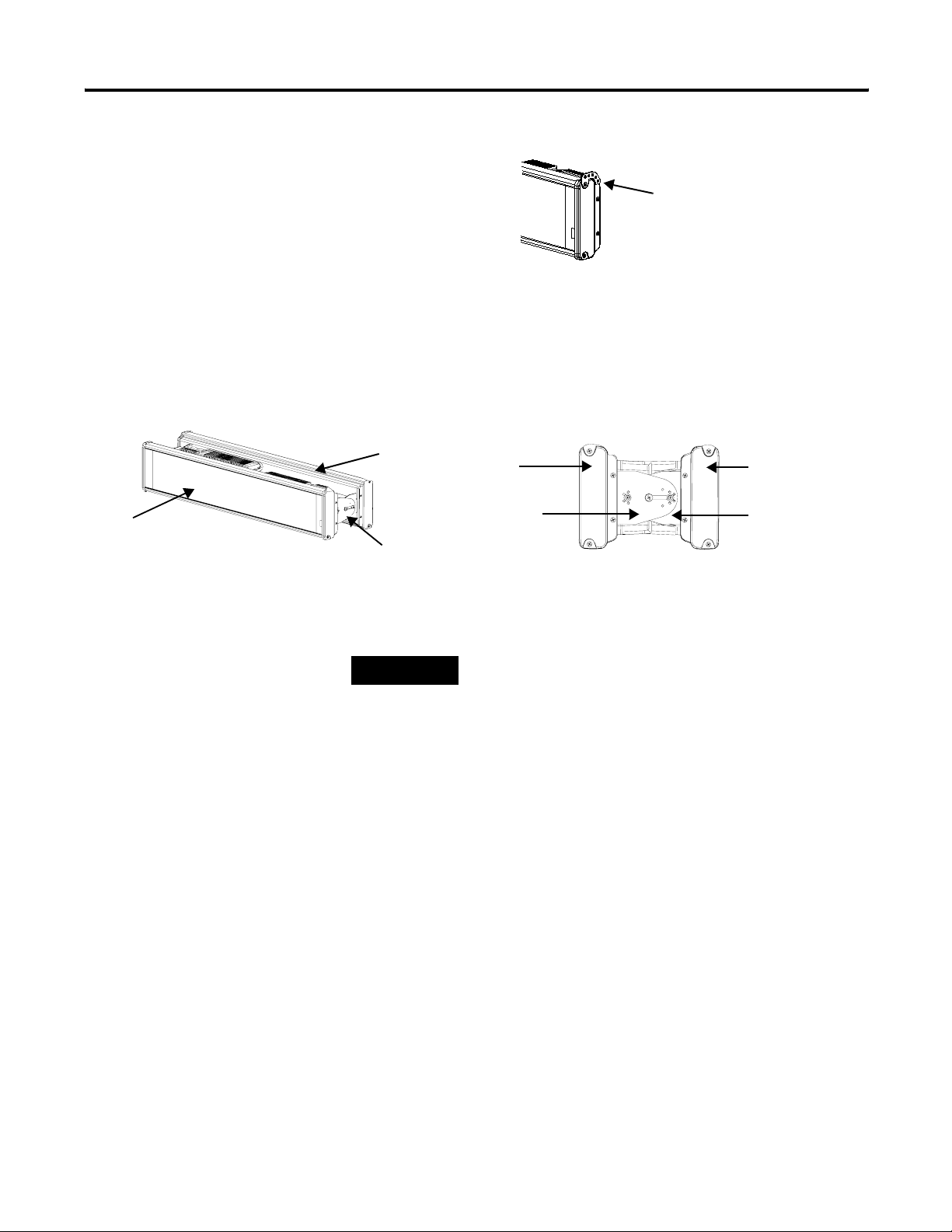

Page 22

1-14 Install InView Marquee Message Display

Phillips screw

End view,

wall-mounted

Electrical Connections for 2706-P72 and 2706-P74 Signs

Ceiling

End view,

ceiling-mounted

Wall

TIP

WARNING

Keep a minimum 2.54 cm (1.0 in.) clearance on all

sides of the sign for adequate ventilation.

Hazardous voltage. Contact with high voltage may

cause death or serious injury. Always disconnect

power to sign prior to servicing.

To connect the sign:

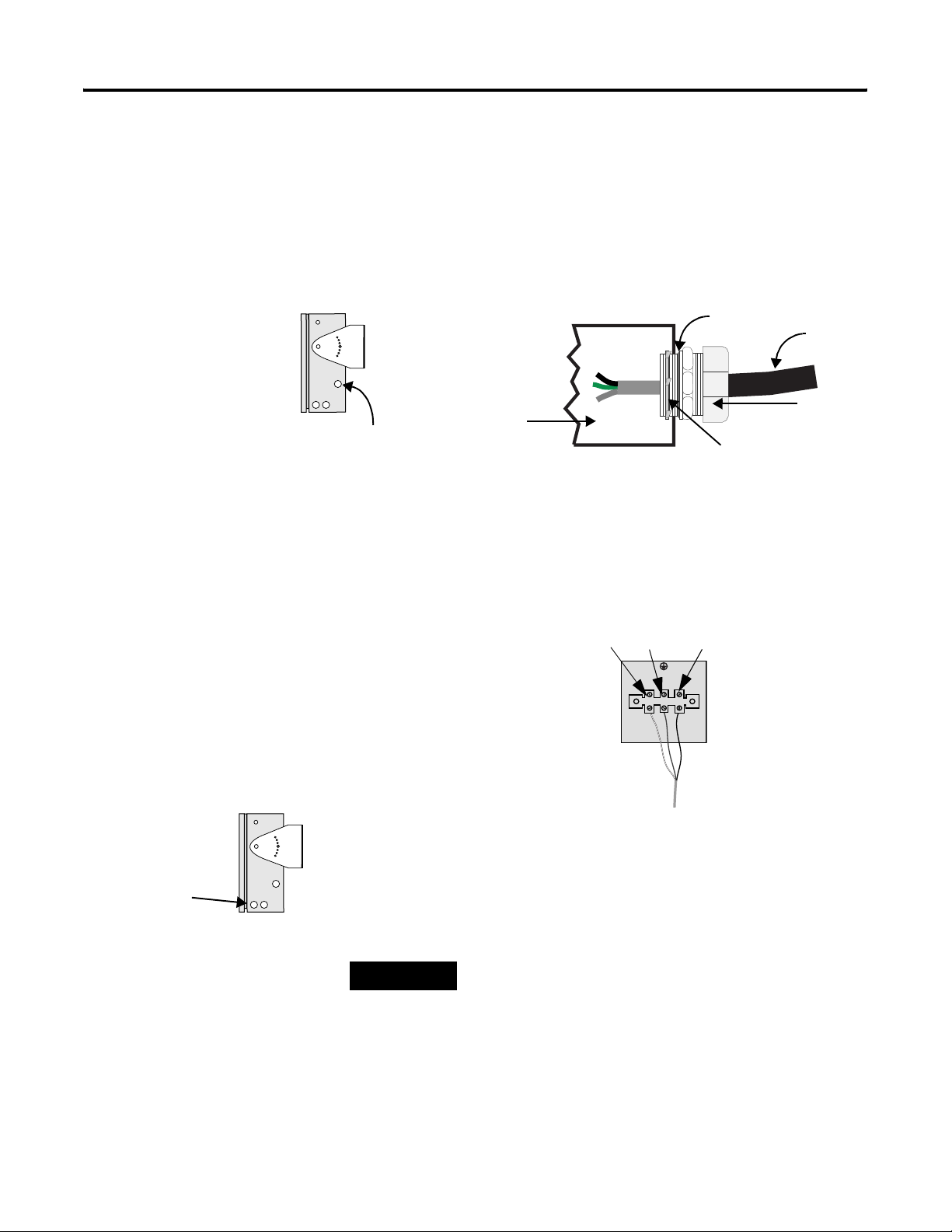

1. Open the front of the sign case by turning the quarter-turn

latches to the left with a large screwdriver.

Phillips screw

Front view,

closed

Front view, open

(On the 2706-P72CNx, there are 3 quarter-turn latches; on the

2706-P74CNx there are 4.) Carefully let the front of the case drop

forward.

Quarter-turn latches

Power supply

on an 2706-P74 sign

Serial

connection

Power line

filter

Power

connection

terminal block

Electrical

opening

Serial

device

opening

Publication 2706-UM016D-EN-P - March 2006

Page 23

Right-end

view

Install InView Marquee Message Display 1-15

2. Feed electrical cable through 2.54 cm (1 in.) water-tight conduit,

the outside end of the connector (supplied), the electrical

opening in the sign case, and then through the inside end of the

connector.

3. Screw the inside and outside ends of the connector together

until water-tight.

Rubber gasket

Front view

Conduit

Right-end view

Serial device hole

plug/opening

Sign case,

Electrical opening

inside

Connector nut, with teeth

facing the sign case

4. Strip the electrical wires back 6.35 cm (0.25 in.).

5. Connect the wires by screwing the end of each wire into the

power connection.

Line

(Hot)

BLACK

Power connection

Ground

GREEN

w/

Yel low

GROUND

LINE 1

GROUND

LINE 1

208 - 240 VAC INPUT

LINE 2 OR

NEUTRAL

LINE 2 OR

NEUTRAL

Neutral

(Line 2):

WHITE

6. If the sign is to be used with serial communications, remove one

or both of the hole plugs from the lowest holes on the right end

of the sign case.

Otherwise, proceed to Step 7.

Connector,

outside end

TIP

TB1 can be used for incoming serial connection for

RS-232 or RS-485. The full pinout diagram is shown

below.

Publication 2706-UM016D-EN-P - March 2006

Page 24

1-16 Install InView Marquee Message Display

TB1 Full

Pin Pin Name Pin Pin Name

1. GND 5. RS-485(+)

2. +5V 6. RS-485(-)

3. RS-232 TX 7. NC

4. RS-232 RX 8. SHIELD

7. Connect the incoming serial wires per pinout.

TB1 can be used for incoming RS-485 or RS-232 serial

connection. They cannot be connected at the same time.

RS-485 is recommended to reduce undesirable electrical

interference.

TB1 RS-485

Pin Pin Name Pin Pin Name

1. NC 5. RS-485(+)

2. NC 6. RS-485(-)

3. NC 7. NC

4. NC 8. SHIELD

TB1 RS-232

Pin Pin Name Pin Pin Name

1. GND 5. NC

2. NC 6. NC

3. RS-232 TX 7. NC

4. RS-232 RX 8. NC

TB1

Controller Board

1

2

3

4

5

6

7

8

Publication 2706-UM016D-EN-P - March 2006

Page 25

Install InView Marquee Message Display 1-17

n

P1 can be used for incoming RS-232 only, although it is optional

and not recommended.P1 is intended for RS-232 application

downloads and RS-485 terminating resistor connection.

See publication 2706-IN007 for more information on RS-485

termination.

8. Carefully close the front of the sign case and turn the

quarter-turn latches to the right with a large screwdriver.

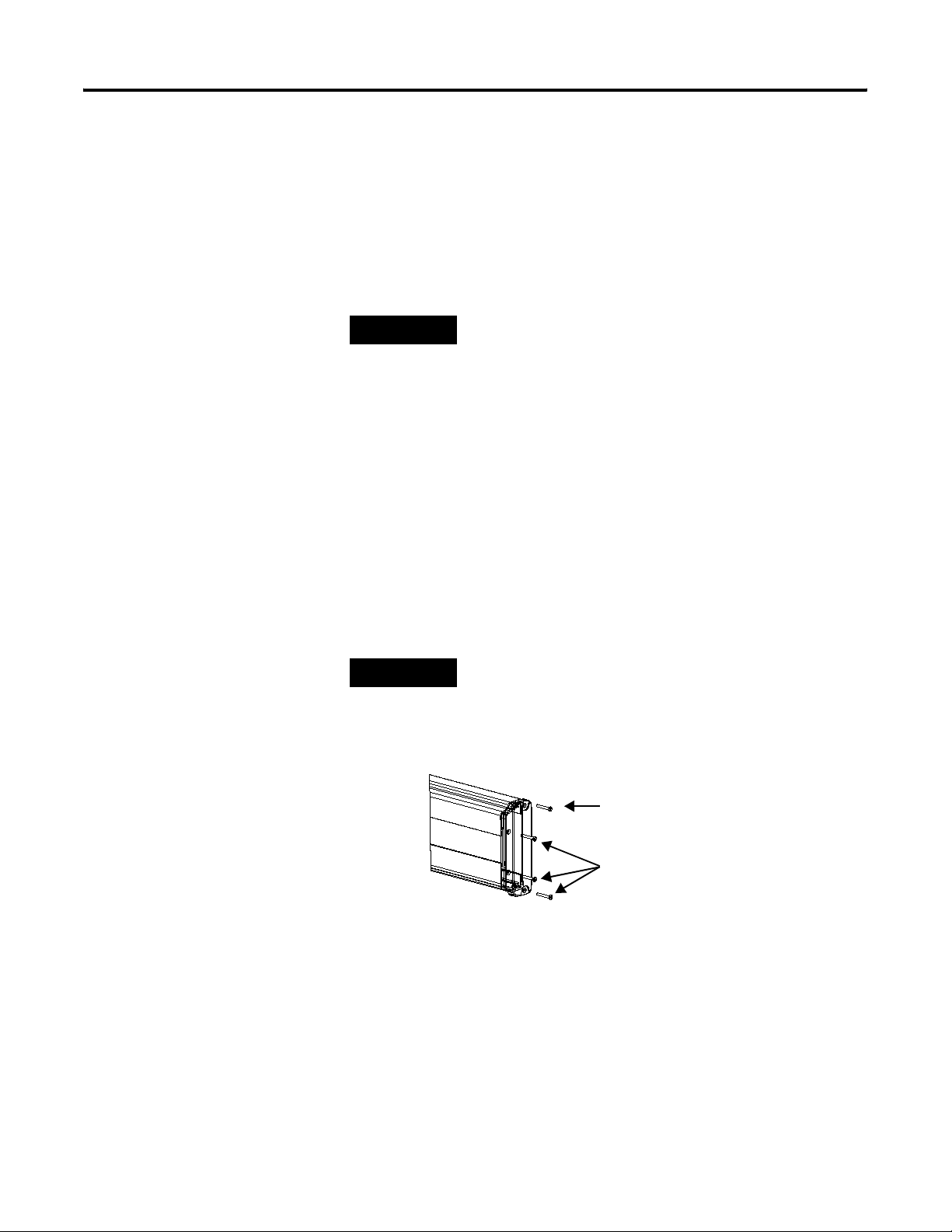

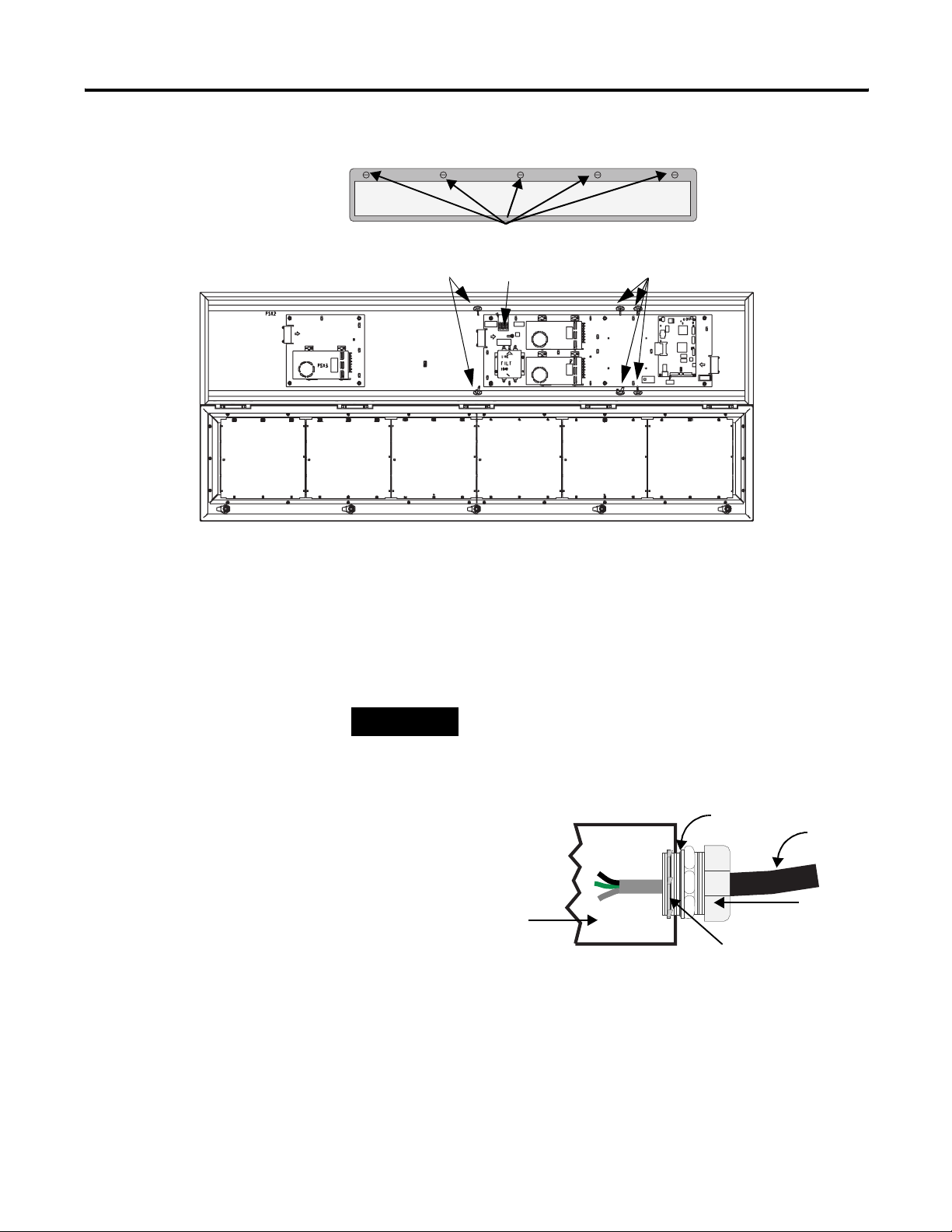

Mount the 2706-P92C and 2706-P94C Sign

Mounted so flanges are hidden behind the sign

2706-P92C 103.0 cm (40.55 in.)

2706-P94C: 194.4 cm (76.55 in.)

To mount the sign:

1. Attach the two sign brackets to a wall, ceiling, or other surface.

Be sure to place the brackets so the bracket flanges face

appropriately as shown below. Mount the brackets the following

distance apart (measured from the center of the mounting holes

in each bracket).

Mounted so flanges show on the sides of the sig

2706-P92C: 107.8 cm (43.22 in.)

Sign brackets, facing

in behind the sign

IMPORTANT

Wall

or

ceiling

Do not install the sign directly to drywall or

2706-P94C: 201.2 cm (79.22 in.)

Sign brackets, facing

out from the sign

plasterboard. The sign must be fastened to a surface

capable of supporting at least four times the weight

of the sign.

2. Mount the sign on the sign brackets using the hex bolts

supplied.

3. Insert the bolts into the far single holes first, until the desired

viewing angle is determined.

Publication 2706-UM016D-EN-P - March 2006

Page 26

1-18 Install InView Marquee Message Display

10.16 (.40)

33.78 (1.33)

22.35

(.88)

139.16

(5.40)

44.45

(1.75)

44.45

(1.75)

193.93

(7.635)

8.74 x 17.48

(.344 x .688)

OBROUND

10°

Left Bracket

14.53 (0.572)

Ø 7.14

(.281)

117.60 (4.63)

14.53

(0.572)

3.43 (.135)

33.78

(1.33)

Dimensions are shown in mm (in.) approx.

8.74 x 17.48

(.344 x .688)

OBROUND

10.16(.40)

Ceiling

Hex bolt

for single

hole

38.10 (1.50)

38.10 (1.50)

19.30(.76)

10.16(.40)

14.53

(0.572)

117.60 (4.63)

33.78

(1.33)

0.572 (14.53)

Ø 7.14

(.281)

Ø 7.14

(.281)

8.74 x 17.48

(.344 x .688)

OBROUND

10°

Right Bracket

Wall

44.45

(1.75)

139.16

(5.40)

193.93

(7.635)

44.45

(1.75)

10.16

(.40)

33.78

(1.33)

22.35

(.88)

Ceiling

End view,

wall/ceiling

mounted

4. Tilt the sign to select a viewing angle.

5. To hold the sign in place, insert the remaining bolts into the

desired viewing angle hole on each bracket.

Wall

Desired viewing

angle hole

TIP

Keep a minimum 2.54 cm (1.0 in.) clearance on all

sides of the sign for adequate ventilation.

Publication 2706-UM016D-EN-P - March 2006

Page 27

Install InView Marquee Message Display 1-19

Back-to-back Mount

1. Attach the brackets to the sign in the ceiling mount position with

the hex bolts supplied.

2. Match the signs together back-to-back and connect them

together using a total of six 5/16” bolts and nuts (not supplied).

Attach chains here

First

sign

First

mounting

bracket

Second

sign

Second

mounting

bracket

Electrical Connections for 2706-P92C and 2706-P94C Signs

3. Attach chains (not supplied) to the top mounting holes of the

bracket to hang the signs from the ceiling.

TIP

WARNING

Use chains capable of supporting 4 times the total

weight of the signs.

HAZARDOUS VOLTAGE

• Contact with high voltage may cause death or

serious injury. Always disconnect power to sign

prior to servicing.

• Maintain Separation of circuits. Route the

incoming power directly to the power connection

terminal block.

• Do not run the power wiring over the logic board

or optional Communication board.

Open the front of the sign case by turning the half-turn latches

to the left with a large screwdriver. On the 2706-P92C, there are

3 half-turn latches; on the 2706-P94C there are 5. Carefully let

the front of the case drop forward.

Publication 2706-UM016D-EN-P - March 2006

Page 28

1-20 Install InView Marquee Message Display

Front view,

closed

Front view, open

Half-turn latches on an 2706-P94C sign

Electrical

opening

Power connection

terminal block

Communication

opening

4. Feed electrical cable through 12.7 mm (0.5 in.) water-tight

conduit, the outside end of the connector (supplied), the

electrical opening in the sign case, and then through the inside

end of the connector.

5. Screw the inside and outside ends of the connector together

until water-tight.

TIP

Use either of the two holes nearest the power

connection terminal block.

Rubber gasket

Front view

Sign case,

inside

Connector nut, with teeth

facing the sign case

6. Strip the electrical wires back 6.35 mm (0.25 in.).

Conduit

Connector,

outside end

Publication 2706-UM016D-EN-P - March 2006

Page 29

Install InView Marquee Message Display 1-21

7. Insert the wires into the appropriate terminal connection and

tighten the screw to 0.79 Nm (7 lb-in).

The terminal block is UL rated for wire ranges of 14 to 8 AWG.

Ground

Line

(Hot) BLACK

GREEN w/ Yellow

LINE 2 OR

NEUTRAL

GROUND

LINE 1

Neutral

(Line 2): WHITE

Power connection

GROUND

LINE 1

208 - 240 VAC INPUT

LINE 2 OR

NEUTRAL

8. Remove the necessary hole plugs before connecting the

communications cables.

9. Connect the incoming communication wires per the tables

below.

ATTENTION

Use shielded Ethernet cable. Shielded Ethernet

cable is required to maintain noise immunity.

The 2706-PCable1 is used for downloading

messages only and must be removed after

downloading is complete.

TB1 is used for P9x pass-through. TB2 is used for supplying

power to the optional InView Legacy Communication board kit.

Communication

Openings

Ethernet

TB1

TB2

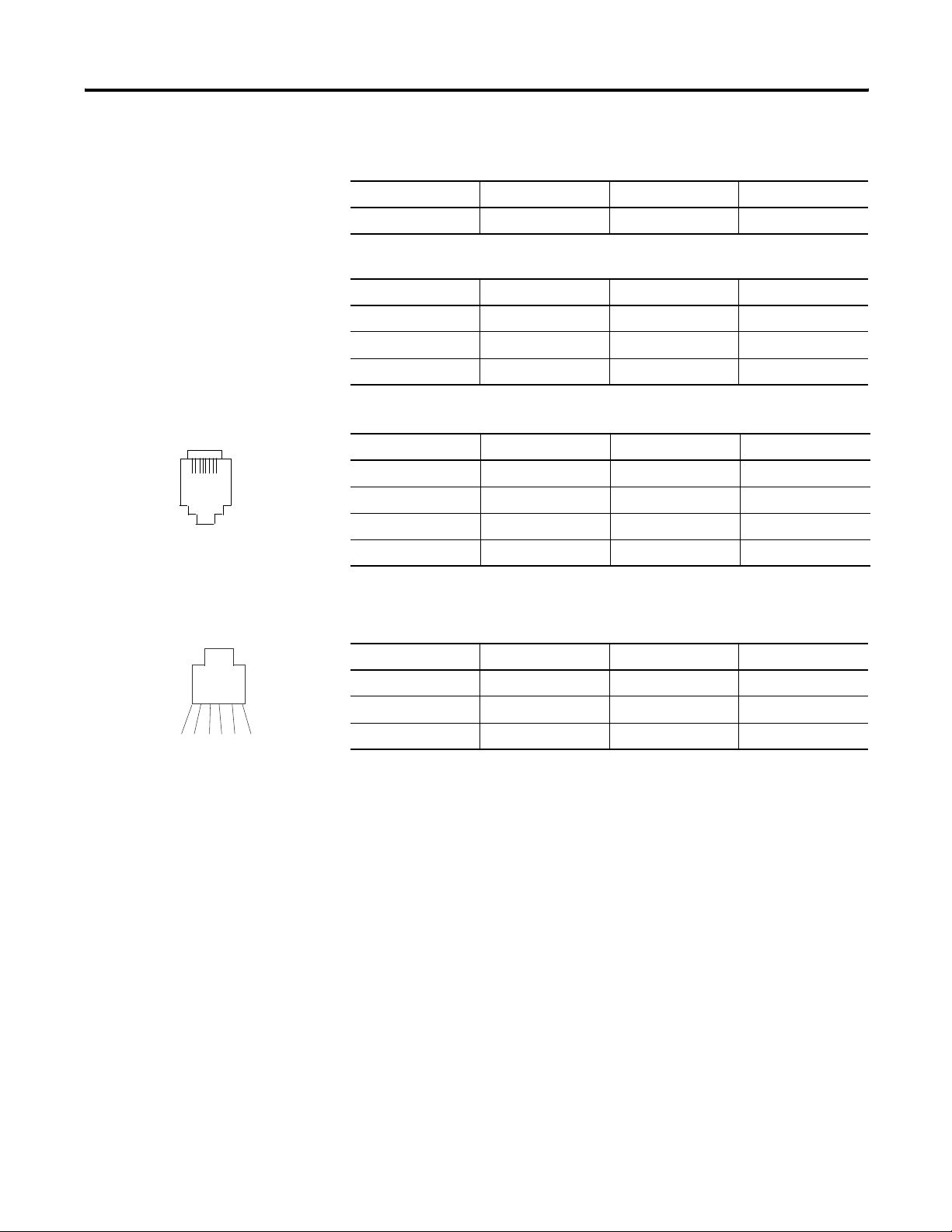

TB1 RS-485

Pin Pin Name Pin Pin Name

1. GND 4. CH A

2. SHLD 5. CH B

3. COMM 6. TERM

Publication 2706-UM016D-EN-P - March 2006

RJ-12

TB3

Page 30

1-22 Install InView Marquee Message Display

TB2 - Aux +5V

Pin Pin Name Pin Pin Name

1. +5V 2. GND

TB3 - RS-232

Pin Pin Name Pin Pin Name

1. TXD 4. CTS

2. RXD 5. GND

3. RTS 6. EGND

8

1

RJ12

12 345 6

+5V NC TX RX NC GND

Ethernet (RJ-45)

(1)

Pin Pin Name Pin Pin Name

1. TD+ 5. NC

2. TD- 6. RD-

3. RD+ 7. NC

4. NC 8. NC

(1)

Use shielded Ethernet cable to maintain noise immunity.

Download Port (RJ-12)

(1)

Pin Pin Name Pin Pin Name

1. Aux +5V 4. RX

2. NC 5. NC

3. TX 6. GND

(1)

The 2706-PCable1 is used for downloading messages only and must be removed after downloading is

complete.

10. Carefully close the front of the sign case and turn the half-turn

latches to the right with a large screwdriver.

Publication 2706-UM016D-EN-P - March 2006

Page 31

Install InView Marquee Message Display 1-23

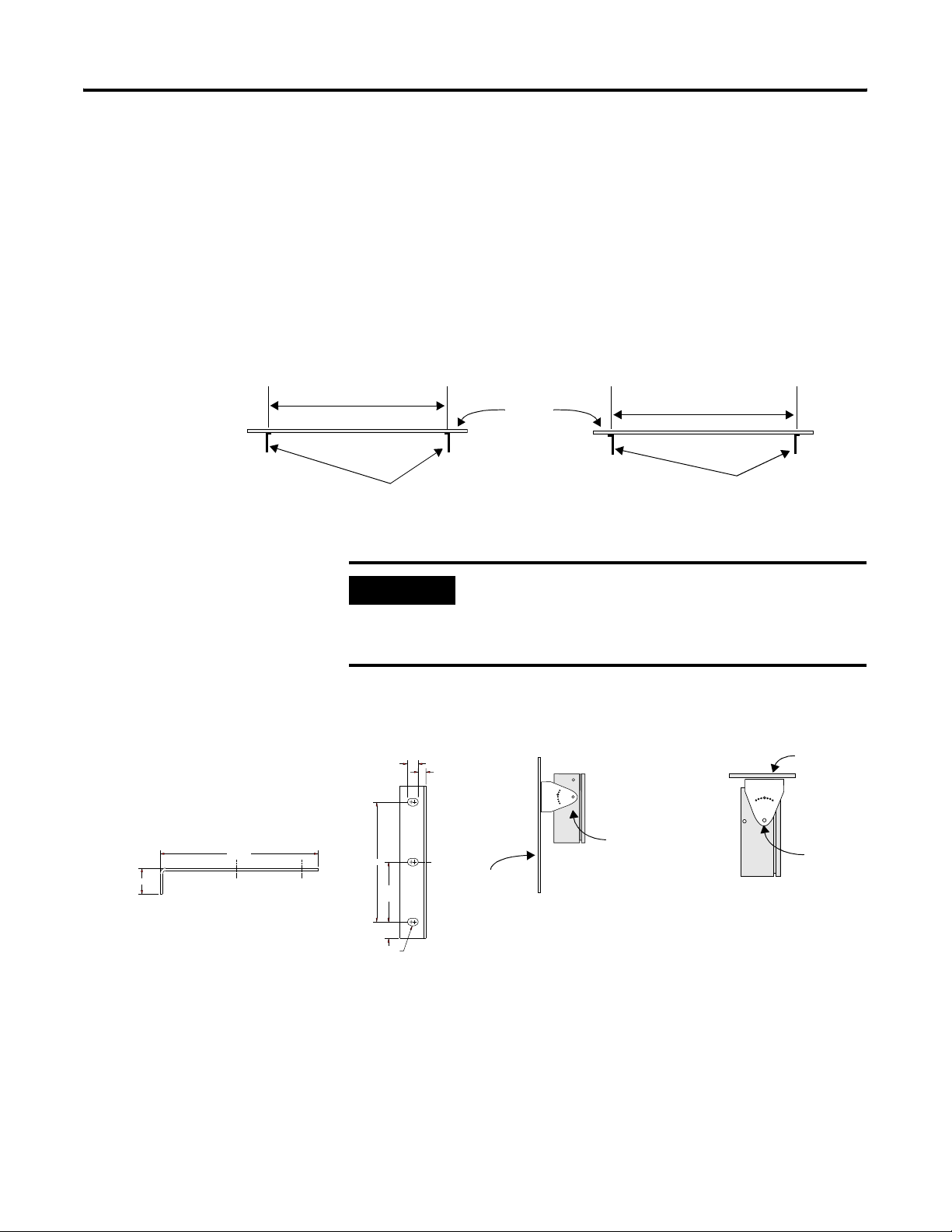

Mount the 2706-P22R Display

The following provides panel cutout dimensions and overall

dimensions for the InView P22R panel mount display.

The InView P22R mounts in a custom panel or enclosure. When it is

properly installed, the faceplate provides a NEMA Type 12, 13, and

4X(indoor) rating.

To mount the display:

1. Cut and drill the appropriate mounting holes in the enclosure or

panel.

Refer to Panel Cutout Dimensions for 2706-P22R Display on

page 1-23

2. Remove the six mounting nuts and washers from the hardware

bag provided with the display.

3. Position the InView Display in the panel or enclosure mounting

hole.

4. Install washers and nuts and alternately tighten the nuts to a

torque of 0.904 Nm (8 lb-in).

TIP

InView P22R mounting and panel cutout are

identical to DL40 Plus, DL40, DL20 and DL10 two

line displays.

Panel Cutout Dimensions for 2706-P22R Display

All dimensions are in millimeters (inches)

4.8 (0.19)

Cutout

173.0 (6.81)

Cutout

88.9

(3.50)

4.8 (0.19)

176.1 (6.94)

Cutout 345.9 (13.62)

2706-P22R Display

352.3 (13.87)

98.4

(3.88)

6.4 (0.25)

Diameter

Hole

6 places

Publication 2706-UM016D-EN-P - March 2006

Page 32

1-24 Install InView Marquee Message Display

Dimensions for 2706-P22R Display

111.3

(4.38)

337.3

(13.29)

365.0 (14.357)

All dimensions are in millimeters (inches)

Electrical Connections for 2706-P22R Display

83.8

(3.30)

61.7

(2.43)

The InView display requires 18 to 30V dc, 0.5 A at 18V dc.

ATTENTION

Before making power connections, make sure that

the power is turned off. Improper wiring of the

power connections may result in personal injury or

damage to the InView display. Make sure the area

around the panel cutout is clear. Make sure metal

cuttings or debris did not enter any components

that may have been installed in the panel.

InView P22R Power Connection

68.8

(2.71) with fuse

Publication 2706-UM016D-EN-P - March 2006

IMPORTANT

TIP

To satisfy all agency requirements and ensure

proper operation, power this product using a

24V dc, class 2 SELV power supply.

Use a small screwdriver to remove the terminal

block’s header to ease product wiring.

Page 33

Communication Connections for 2706-P22R Display

Install InView Marquee Message Display 1-25

RJ12

RS-485

1 - E-GND

2 - SHLD

3 - COMM

4 - CH A

5 - CH B

6 - TERM

12345 6

+5V NC TX RX NC GND

RS-232

12345

67 8 9

RJ11 Connections

Pin Pin Name Pin Pin Name

1. +5 V 4. RX

2. NC 5. NC

3. TX 6. GND

RS-485 Connections

Pin Pin Name Pin Pin Name

1. E-GND 4. CH A

2. SHLD 5. CH B

3. COMM 6. TERM

RS-232 Connection

Pin Pin Name Pin Pin Name

1. NC 6. NC

2. RX 7. RTS

3. TX 8. CTS

4. NC 9. NC

5. GND

Publication 2706-UM016D-EN-P - March 2006

Page 34

1-26 Install InView Marquee Message Display

DIP Switch Settings for 2706-P22R Display

ATTENTION

Switch Settings

11

22

34

48

516

632

764

8 128

Dip Switches

Dip Switch Label

LSB

Serial

Address

MSB

Diagnostics

Not Used

Disconnect power from the InView display before

setting any switch. Switch settings are scanned only

on power-up.

Dip Switch Settings

Switch Switch Setting Switch Switch Setting

1. 1 (LSB) 6. 32

2. 2 7. 64

3. 4 8. 128 (MSB)

4. 8 9. Diagnostics

5. 16 10. Not Used

Publication 2706-UM016D-EN-P - March 2006

Page 35

Install InView Marquee Message Display 1-27

Download a Message Application

InView message applications are created using the InView messaging

software (2706-PSW1). After creating the Message Application, you

need to download it into your InView display memory.

InView applications can be downloaded using:

• Point-to-point serial communications (RS-232) from the

communication port on a personal computer.

• Multi-drop RS-485 serial communications. Utilizing a

1761-NET-AIC to convert RS-232 to RS-485 from a personal

computer allows you to download to multiple displays over

RS-485.

• 2706-PCABLE1 which connects from your PC, running InView

messaging software, to the phone jack type connector on your

InView display. In larger InView models, this phone jack may be

behind the power supply cover.

• EtherNet TCP/IP networking. With the InView 2706-PENET1

EtherNet TCP/IP communication module you can download

message applications from a personal computer over Ethernet.

For more information on this communications option, see

publication 2706-IN008.

RS-232 to RS-485 Networking

• InView communication modules. The communication modules

allow the displays to communicate on the core Allen-Bradley

networks.

With the use of an Allen-Bradley 1761-NET-AIC, you can convert

RS-232 to RS-485 and daisy chain InView Displays up to 1219 m

(4000 ft).

1761-NET-AIC (AIC+)

Publication 2706-UM016D-EN-P - March 2006

Page 36

1-28 Install InView Marquee Message Display

RS-485 Echo

The RS-485 echo feature addresses the issue of increased network

traffic often caused by multiple node addresses and high consumption

of communication bandwidth. The display’s design enables users to

daisy-chain numerous InView displays off an InView P9x via the

RS-485 communication network.

2706-P9x - Master InView

RS-485 Network

In order to set the 2706-P92C display or the 2706-P94C display as a

Master, the echo dip switch must be enabled.

See Dip Switch Information for the 2706-P9x in Chapter 2.

TIP

Only one 2706-P9x InView display can be set as the

master per RS-485 network.

When the echo feature is enabled, all incoming packets, whether it is

over the RS-232 port, RJ12 download port, or the RJ45 10/100 base-T

Ethernet port, are echoed out the RS-485 port.

An InView master display inspects the incoming packets and

determine if the packet is addressed to itself and take the appropriate

action. The master shall ignore all packets that are not addressed to

itself. The only exception is for a packet with an address of 255. This

is the broadcast address and must be accepted by all displays on the

network.

TIP

When the 2706-P9x display, echo feature is enabled,

the RS-485 port of the 2706-P9x display, does not

accept incoming packets. The port is exclusively

used to echo out data.

Publication 2706-UM016D-EN-P - March 2006

Page 37

Install InView Marquee Message Display 1-29

Global Addressing

The 2706-P92C and 2706-P94C displays can both set their serial

address to 255, which is the global (broadcast) address. A display with

the serial address of 255, accepts all message packets regardless of the

address actually given in the packet. This allows the user to route all

messages to the 2706-P9x InView display.

See Dip Switch Information for the 2706-P9x in Chapter 2, for serial

address configuration.

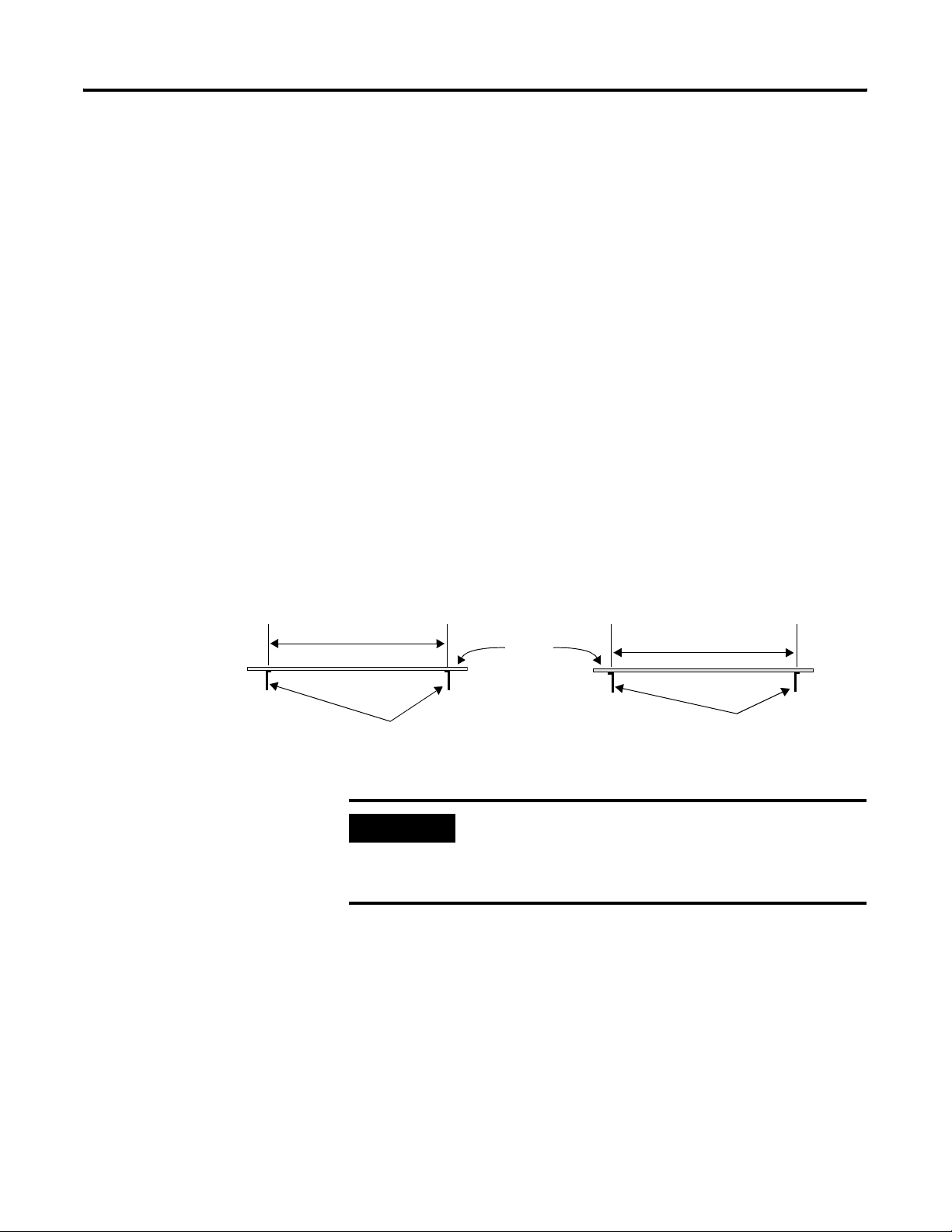

Ground and Terminate the RS-485 Network

TIP

Only one device at either end of the link must have earth ground and

shield jumpered together. This provides an earth ground connection

for the shield of this communication cable. If the connection is made

at an AIC or AIC+, jumper terminals 1 and 2. If the connection is made

at a 2706-P4x or 2706-P7x display, jumper terminals 1 and 8. If the

connection is made at a 2706-P22 display, jumper terminals 1 and 2.

Both ends of the network must be terminated. There is an impedance

of 120 ohms built into each AIC and AIC+ as required by the RS-485

specification. Jumper terminals 5 and 6 of the AIC or AIC+ for

end-of-line termination.

End-of-Line Termination for AIC and AIC+

A global address of 255 can only be set by hardware

and cannot be set using software.

Jumper

Belden #3106A or #9842 Cable

1219 m (4000 ft) Maximum

Jumper

Publication 2706-UM016D-EN-P - March 2006

Page 38

1-30 Install InView Marquee Message Display

RJ11 RJ11

Network Wiring

6

Term

A

B

COM

SHLD

GND

1

1761-NET-AIC

8

1

8

SHLD

AUX

RS485(-)

RS485(+)

RxD

TxD

+5V

GND

1

2706-P44C2706-P74C

6

Term

B(-)

A(+)

COM

SHLD

E-GND

1

2706-P9x

6

Term

B(-)

A(+)

COM

SHLD

E-GND

1

2706-P22R

End-Of-Line Display

TIP

End-of-line InView display should have terminating

resistor in RJ11 (P1). If a 2706-P22R display is the

end-of-line display, jumper terminals 5 and 6. There

is a built in impedance of 120 ohms similar to that of

the AIC and AIC+.

Publication 2706-UM016D-EN-P - March 2006

Page 39

Chapter

2

InView System Connectivity

This chapter demonstrates how the InView display connects to control

networks. In the following chapters we show controller configuration

and sample ladder for serial ASCII networks. This chapter also

discusses how to set-up the display attributes, communications and

create messages.

Serial ASCII Communications

Features

Refer to Chapter 3 for more information on Serial ASCII

communications from Channel Zero of an Allen-Bradley controller.

Serial Connections

Point-to-Point

CH 0

Multi-Drop

CH 0

The features are separated into sections for the 2706-P4x and

2706-P7x displays and the 2706-P22R displays.

RS-232

RS-232

AIC+ Converter

RS-485

InView Display

InView Display

InView Display

2706-P42, 2706-P43, 2706-P44, 2706-P72, and 2706-P74 Displays

These displays operate at 100 to 240V ac. They have an eight position

terminal block that contains an auxiliary +5V dc, RS-232 signals, and

RS-485 signals. There is also an RJ-12 port that is in parallel with the

RS-232 signals from the terminal block. The RJ-12 port is used

primarily for downloading messages to the display via the

2706-PCABLE1 download cable.

1 Publication 2706-UM016D-EN-P - March 2006

Page 40

2-2 InView System Connectivity

TB1 Connections

8

7

6

5

4

3

2

1

TB1

Incoming serial

wires

These displays have a single channel UART and therefore can only

have one of the three communication options connected at a time.

• RJ-12

• RS-232 terminal block connections

• RS-485 terminal block connections

TB1 - Full

Pin Pin Name Pin Pin Name

1. GND 5. GND RS-485(+)

2. +5V 5. +5V RS-485(-)

3. RS-232 TX 6. RS-232 TX NC

4. RS-232 RX 7. RS-232 RX SHIELD

2706-P22 Display

This display operates at 18 to 30V dc. It has three communication

ports. These are the RJ-12, DB-9, and a six position terminal block

ports. The RJ-12 port is used primarily for downloading messages to

the display via the 2706-PCABLE1 download cable. The DB-9 port is

used for RS-232 communications and the signals are in parallel with

the RJ-12 port. Therefore, only one of the ports may be connected at a

time. The six position terminal block is used for RS-485

communications. The 2706-P22R display has a two-channel UART.

This means that one of the RS-232 ports and the RS-485 port can be

connected at the same time.

Publication 2706-UM016D-EN-P - March 2006

2706-P22R Display Communication Connections

RJ11 Pin-out

1 - +5V

2 - NC

3 - TX

4 - RX

5 - NC

6 - GND

RJ12

12 345 6

+5V NC TX RX NC GND

RS-232

12345

67 8 9

RS-485

1 - E-GND

2 - SHLD

3 - COMM

RS-232 Pin-out

1 - NC

2 - RX

3 - TX

4 - NC

5 - GND

6 - NC

7 - RTS

8 - CTS

9 - NC

4 - CH A

5 - CH B

6 - TERM

RS-485 Pin-out

1 - E-GND

2 - SHLD

3 - COMM

4 - CH A

5 - CH B

6 - TERM

Page 41

InView System Connectivity 2-3

RJ11 Connections

Pin Pin Name Pin Pin Name

1. +5 V 4. RX

2. NC 5. NC

3. TX 6. GND

RS-485 Connections

Pin Pin Name Pin Pin Name

1. E-GND 4. CH A

2. SHLD 5. CH B

3. COMM 6. TERM

RS-232 Connection

Pin Pin Name Pin Pin Name

1. NC 6. NC

2. RX 7. RTS

3. TX 8. CTS

4. NC 9. NC

5. GND

The 2706-P22R display has a ten-position dip switch. The first eight

positions are used to set the address of the display. Position nine is

used to put the display in diagnostic mode. Position ten is a spare.

The dip switch is read only on power-up.

The diagnostic mode causes the display of LED patterns to visually

indicate if any pixels are not turning on. It also performs a memory

check.

IMPORTANT

After one complete LED scan is done, a RAM check

is performed and the display’s memory is cleared. To

ensure that the display’s memory is not cleared, turn

off power to the display after the LED block test is

performed. Make sure that the download or message

file has been saved before diagnostic test is allowed

to run completely through.

Publication 2706-UM016D-EN-P - March 2006

Page 42

2-4 InView System Connectivity

2706-P22R Display Dip Switch Settings

Switch Settings

11

22

34

48

516

632

764

8 128

Dip Switches

Dip Switch Label

LSB

Serial

Address

MSB

Diagnostics

Not Used

Dip Switch Settings

Switch Switch Setting Switch Switch Setting

1. 1 (LSB) 6. 32

2. 2 7. 64

3. 4 8. 128 (MSB)

4. 8 9. Diagnostics

5. 16 10. Not Used

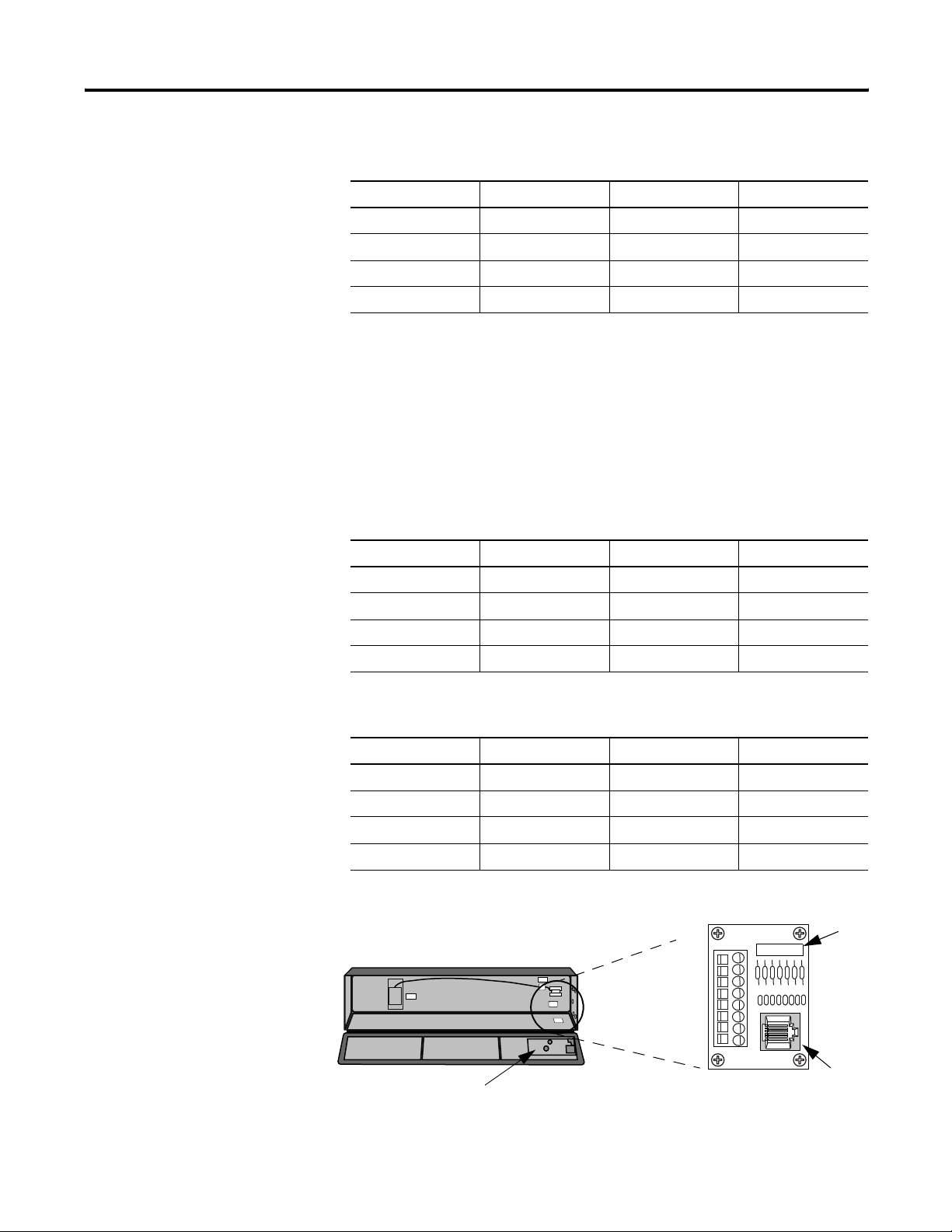

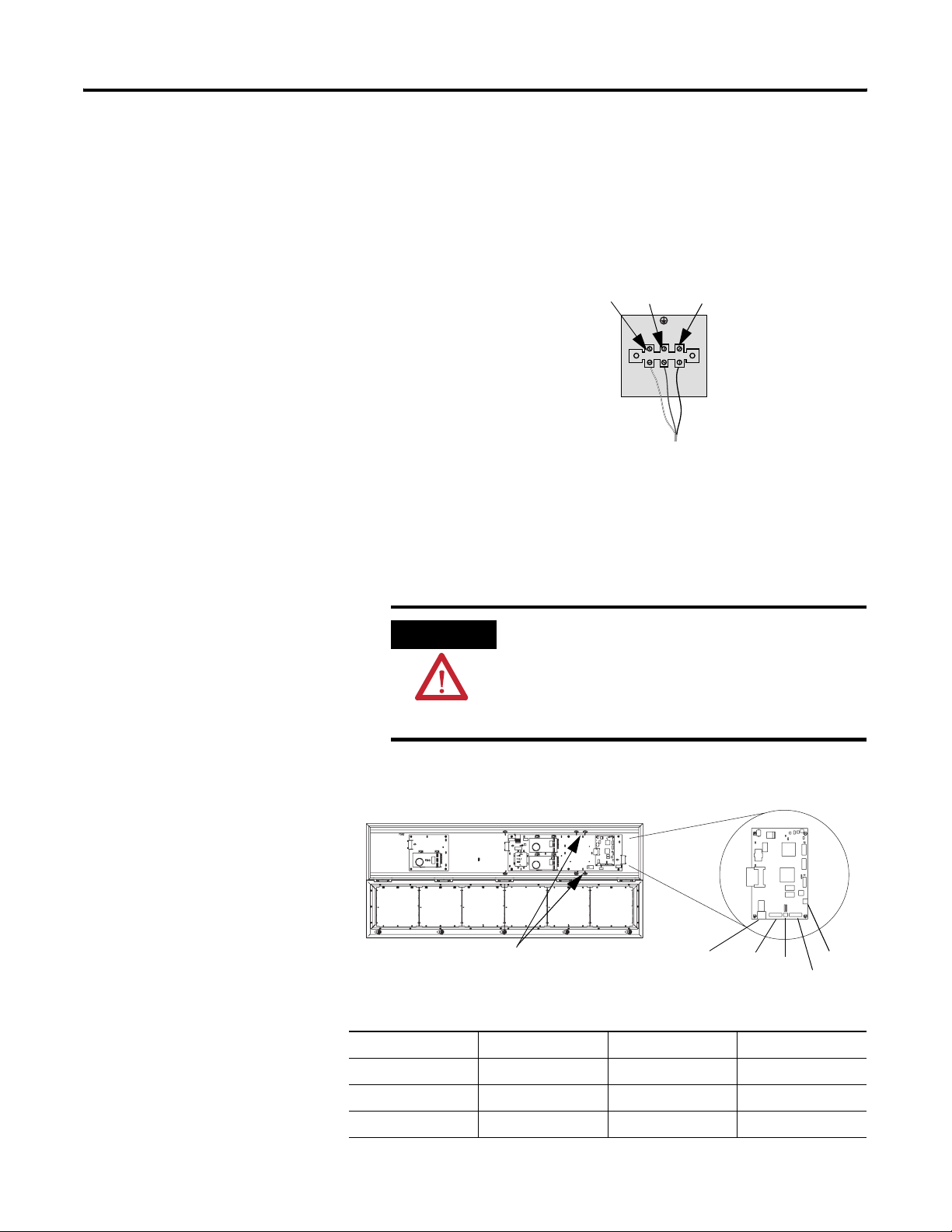

Dip Switch Information for the 2706-P9x

There are two dip switches located on the controller board, Switch 1

and Switch 2.

2706-P9x Dip Switch

Switch 1

Switch 2

Switch 1

Switch 1 is used to configure the display’s RS485 echo enable,

communication rate settings, and display size.

Publication 2706-UM016D-EN-P - March 2006

Page 43

InView System Connectivity 2-5

Position 1 enables or disables the echo function.

When you enable the RS485 echo function, this allows any packets

that come in on COM 0 (download, RJ-12 port), COM 1 (RS-232, TB3

port), and the Ethernet TCP/IP port to be sent out the RS485 port. This

allows Ethernet TCP/IP and other communication protocols to be

converted to RS485 by a single 2706-P92 or 2706-P94 and then sent

out to multiple RS485 networked displays.

TIP

Only enable the echo function on one

2706-P9x display.

Positions 3 and 4 set the communication rate.

Refer to page 2-6 for default positions.

If both switches are off, the communication rate can be set via the

InView messaging software. The dip switches take priority over the

software setting. If the communication rate is set to 19200 using the

software (positions 3 and 4 set to off) and then set to 9600 using

Switch 1 (position 3 on and 4 off), the communication rate is 9600.

Also, once positions 3 and 4 are used to set the communication rate

and then they are switched off, the communication rate setting

remains until it is changed by software or a different dip switch

setting.

Position 5 is used to set the display size. This is set by the factory.

Position 6 is used to turn on diagnostics.

Position 7 disables download message.

Switch 2

Switch 2 is used to set the serial address of the display. Position 1 is

the LSB of the address and position 8 is the MSB of the address.

If position 1 is on and all other positions are off, the display address is

1.

If position 8 is on and all other positions are off, the display address is

128.

If all positions are set to off, the serial address is set using the InView

messaging software.

Publication 2706-UM016D-EN-P - March 2006

Page 44

2-6 InView System Connectivity

The dip switch setting takes priority over the software setting. If the

serial address is set to 2 using the software (all the dip switches set to

off) and then Switch 2 is used to set the serial address to 3 (position 1

and 2 set to on and the remaining positions set to off), the serial

address is 3. Also, once Switch 2 is used to set the serial address and

then all switch positions are set to off, the serial address setting

remains until it is changed by software or the dip switch is set.

.2706-P9x Dip Switch Settings

Baud Rate

3 4

OFF OFF = Software

Default

ON OFF = 9600

OFF ON = 19200

ON ON = 38400

RS485

Echo

Not

Used

Size

ON = P92C

OFF = P94C

Not

Used

ON =

Disable

Download

Message

ON =

Diagnostics

LSB

Display Address

Switch12345678

Value1248163264128

MSB

Additional Information for 2706-P9x Displays

For additional information on communication port wiring and display

configuration, refer to the InView Marquee Message Display User

Manual, publication 2706-UM016.

This product contains a Lithium battery. See publication 2711P-IN009

for information regarding battery replacement and disposal.

Communications Board Kits

Publication 2706-UM016D-EN-P - March 2006

There are optional Communications Board Kits available for the

2706-P9 series displays. There are a total of six board kits:

• Remote I/O (2706-PRIOK)

• DH+ (2706-PDHPK)

• DH-485 (2706-PDH485K)

• ControlNet (2706-PCNETK)

• DeviceNet (2706-PDNETK)

• EtherNet/IP (2706-PENETK).

Page 45

InView System Connectivity 2-7

The Communications Board Kits convert the six protocols to RS-232.

The board kit mounts on the four PEM spacers that are attached to the

internal mounting plate.

See publication 2706-IN015 for more information on how to install the

board kits.

Spacer Location

PEM Spacers

Compact Flash Card

This product uses a Type I Compact Flash Card for message file

storage.

Refer to publication 2706-IN017 for information on replacement and

installation of the Compact Flash Card.

Multiple Communication Rate Support

The 2706-P92C and 2706-P94C displays allow the user to select serial

communication rates of 9600, 19200,or 38400 bps. The communication

rates are both hardware (dip switches) and software selectable.

TIP

The communication rate of the display is set using the InView

messaging software, provided the communication rate dip switches

are all off.

For selecting the communication rate using the dip

switches, see the section entitled Dip Switch Settings

Publication 2706-UM016D-EN-P - March 2006

Page 46

2-8 InView System Connectivity

To set the communication rate using the messaging software:

1. Highlight the 2706-P9x display you wish to set the

communication rate.

2. Select Set Display Baud Rate under the Tools menu.

Publication 2706-UM016D-EN-P - March 2006

3. Choose the communication rate you wish to set the display at

and click on the Set button.

TIP

There is no confirmation that the command was sent.

The display must be power cycled to view the new

communication rate settings.

Page 47

InView System Connectivity 2-9

Isolated Communication Ports

The isolated communication ports consist of RS-232, RS485, 10/100

Ethernet port and a RS-232 download port. This allows the 2706-P92C

and 2706-P94C displays to support multiple networks simultaneously.

This allows programmers to change the messages or tie into an

information database, while control operators can continue delivering

alarms and messages to the plant floor.

Isolated Communication Ports

Flash Programmable Firmware

The programmable Compact Flash card is located inside the 2706-P9x

display on the controller board as shown below.

TIP

Compact Flash Card

The Compact Flash card must be at least 32 MB,

anything less is not supported.

Publication 2706-UM016D-EN-P - March 2006

Page 48

2-10 InView System Connectivity

Power-up Messages

After the power cable and the download cable (attaches to the RJ-12

port) have been attached per the installation document, apply power

to the display.

TIP

If a display is connected to Ethernet via TCP/IP by

using a 2706-PENET1 module or a 2706-P9x display

is connected to Ethernet via TCP/IP, the display

configuration and message download can be done

over Ethernet. For more information on this

communication option, see publication 2706-IN008.

2706-P42, 2706-P43, 2706-P44, 2706-P72, 2706-P74, 2706-P92, and

2706-P94 Displays

After power is applied to the display the following messages are

displayed.

• firmware number and revision

• memory size and partition

• memory checksum message

• date and time

• address of the display; and background message, if one was

created

2706-P22: Display

After power is applied to the display the catalog number, firmware

revision, and address is displayed on one screen. Then the

background message is displayed.

See the help file for more details on the following topics.

Publication 2706-UM016D-EN-P - March 2006

Page 49

InView System Connectivity 2-11

Display Setup

To set up your display:

1. Start the InView messaging software.

2. Create a project.

The software prompts for a project file name, a project name,

and description. Once this is done, the project name and

description appears in the Displays box.

3. The software then prompts for a display name, display

description, display type, and the number of that particular

display that is used in the system (1 to 100 of the same display

type).

4. Select one for the number of displays (once displays have been

assigned a unique address, more than one can be added at

once).

5. Select Next.

6. The software then prompts for the address of the display,

heartbeat, TCP/IP settings (if applicable), and the serial com port

settings.

Set the IP Address

Use the default settings of 9600, None, 8, and 1.

7. Select Next.

8. When the software prompts for a message file association, check

Create a New Message File.

9. Enter the message file name and select Finish.

The message editor window is displayed.

For the 2706-P22, 2706-P4x, and 2706-P7x terminals, separate

communication modules are needed to place the display on the

network. The 2706-P9x displays have Ethernet TCP/IP built in. To add

any other network protocol to the 2706-P9x, a separate

communication module is needed.

The Ethernet TCP/IP configuration utility is installed as part of the

Inview messaging software package. When first opening the InView

messaging software, you are asked to create a display and a message

file. After the display is created you can configure the IP address of

the 2706-PENET1 module.

Publication 2706-UM016D-EN-P - March 2006

Page 50

2-12 InView System Connectivity

The 2706-PENET1 module is the communication interface for Ethernet

TCP/IP. This module is used with the 2706-P22, 2706-P4x, and

2706-P7x displays. The 2706-P9x displays have this protocol built in.

Note that the 2706-PENET1 is Ethernet TCP/IP or Office type Ethernet

and is not Ethernet I/P, which is Ethernet Industrial Protocol available

on Rockwell Automation logic controllers.

To set the IP address:

1. Select the display you created, which use a the Ethernet module.

2. Right click on the display and select Edit Display.

TIP

Double-clicking on the display takes you to the

same window.

3. When the Edit Display window appears, go to the

Communications tab.

This is where the configuration utility is located.

Publication 2706-UM016D-EN-P - March 2006

Page 51

InView System Connectivity 2-13

Under the section with the heading TCP/IP settings is the

Configure Communications button.

4. By clicking this button you are taken to the Ethernet TCP/IP

Communications window.

This is where the IP address will be set.

5. At the top of the window labeled IP Address, enter the desired

IP address.

Publication 2706-UM016D-EN-P - March 2006

Page 52

2-14 InView System Connectivity

6. Enter 3001 for the Port if using a 2706-PENET1 module.

7. Enter the MAC Address of the module under the heading Assign

IP Address.

The MAC Address is found on the module itself.

TIP

The 2706-P9x display does not use MAC Address. IP

Address changes must be done serially.

8. Click the Setup button located in the section titled Assign IP

Address once the desired IP Address, Port, and MAC Address

have been entered.

If the IP Address is already in use, an error message window

appears.

TIP

If the Invalid IP Address window appears, click

OK, choose a different desired IP Address, and

click the Setup button again. Once a valid IP

Address is entered, the following window should

appear saying it is ready to assign an IP address.

Publication 2706-UM016D-EN-P - March 2006

As the message instructs, you need to either turn the display on

or power cycle the display if it is already turned on. Upon

successfully assigning an IP Address the following window

appears.

Page 53

InView System Connectivity 2-15

Gateway Address and Subnet Mask Setup

Set up the Gateway address and Subnet Mask if needed based on your

Ethernet Network configuration. Default values typically are for

Subnet Mask, 255.255.255.0 and as a default the Gateway address is

left blank.

Subnet Mask is a parameter that interprets IP addresses when the

network is divided into multiple networks. The IP address is formatted

as four sets of decimal numbers with periods between them

(255.255.255.1). The range of values for the first set of decimal

numbers is 1 to 255. The range of values for the last three sets of

decimal numbers is 0 to 255. The value 0.0.0.0 is not a valid subnet

mask.

Gateway Address is a unique address of the Gateway connecting two

individual IP networks into a system of networks. When a node needs

to communicate with a node on another network, the Gateway

transfers the data between the two networks. The IP address is

formatted as four sets of decimal numbers (from 1 to 255) with

periods between them (130.0.0.1). The first field cannot be 0 if any

other fields contain a 0.

Once the desired Gateway Address and Subnet Mask have been

entered, click on the Setup button located just below where the

Subnet Mask was entered. If for some reason, the settings are not

received by the 2706-PENET1 module, the following error message

will appear.

However, upon successfully setting up the Gateway Address and

Subnet Mask, the following message appears telling you to cycle

power to the module.

Publication 2706-UM016D-EN-P - March 2006

Page 54

2-16 InView System Connectivity

After the IP Address, Gateway Address and Subnet Mask have all been

established, click the OK button on the bottom of the Ethernet TCP/IP

Communications window. This allows the settings to be saved and

configuration is now complete.

Once the settings have been saved, they can now be viewed by

clicking on the Advanced button located in the section titled TCP/IP

settings on the Edit Display window.

Create the Message File

A background message of Rockwell Automation is automatically

created. This is also indicated by the letter B in the message list below

the message creation box. Message number 1 is highlighted and ready

for creation. Create a message by typing in the message box.

Attributes for the messages can be changed or added using the pull

down menus located above the message creation box or from the

toolbar. Once message number 1 has been created, select the down

arrow or type 2 in the box and select the Goto button. This allows

message number 2 to be created.

There is a size displayed in the lower right of the window. This is the

size of the message that is being created. This number starts from 11

and increases to a maximum number that is determined by setting the

partition size in software. This is based on a total of 200,000 bytes.

The smaller the partition size the more messages are available. The

limits are 450 bytes per message, 444 messages minimum to 50 bytes

per message, 4000 messages maximum. To change the partition size,

select File then Partition.

See the following sections for more information regarding the

message attributes.

Publication 2706-UM016D-EN-P - March 2006

Message File Additional Information

Task Page

Attach a Note to a Message 2-17

Text Color 2-17

Date, Time and Variables 2-17

Category 2-18

Message Priorities 2-18

Page 55

InView System Connectivity 2-17

Message File Additional Information

Ta sk P ag e

Pause 2-19

Message Header 2-19

Preview Messages 2-19

Set the Display Address 2-19

Download Messages 2-20

Clear Memory/Message Queue 2-22

Attach a Note to a Message

Select a message from the message list. Select Tools and Edit Note.

Then a Message X Note window appears. The X is the message

number for the message that a note is being created for. These

message notes can only be viewed with the InView messaging

software and are not downloaded to the display.

Text Color

There are three color options if a display is classified as color. They

are red, green, or yellow. The color of the message is the color that is

selected. The color of individual text within the message is changed

by inserting a color before the text. The text after the color insert stays

that color until a new color insert is performed.

Date, Time and Variables

The date, time and variables are also inserted into a message. These

are found under the Edit menu then Insert or via the toolbar buttons.

If inserting the date, a pop-up window appears and shows various

formats and a pre-viewer that displays the data for the selected format.

If inserting a variable, a pop-up window appears that allows the

selection of the variable number and whether the variable is numeric

or alpha numeric. The maximum number of variables per message file

is 100 (00 to 99). The numeric variable ranges from 32,767 to -32,768

decimal. It also allows the selection of the type of padding and a

check box for a sign (+/-). An alpha numeric variable is ASCII text

except for the “. It also varies in length from 1 to 128 characters. There

is a pre-viewer that displays the options selected. The format for the

time is either standard or military. The selection for this is found in the

Publication 2706-UM016D-EN-P - March 2006

Page 56

2-18 InView System Connectivity

InView configuration window (the project window) under Tools and

Set Display Date and Time. Note that the time format is set for each

display individually by address. The default format is standard. The

data and time is also set here.

Category

The Category option is used to assign categories to messages. This

helps in organizing messages for certain operations and when

performing a find.

Message Priorities

The Priority option is used to give messages a priority of low,

medium, and high. As an example, a normal operating water

temperature reading of a generator is a low priority message. A

pre-alarm message of high water temperature is a medium priority

message. An alarm message of high water temperature shutdown is a

high priority message.

In our example, the water temperature is part of the generator signals

that are constantly being monitored and displayed as low priority

signals in the message queue (the message queue can hold up to 64

messages). When the water temperature rises above a pre-alarm

threshold, the medium priority high water temperature message is

added to the message queue. When this happens, only medium

priority messages are displayed. If other medium priority messages

were added to the queue, they are also displayed until a high priority

message is added to the queue. When the water temperature rises

above an alarm threshold, the high priority high water temperature

shutdown messages are displayed.