Page 1

Serial

Converter

Module

22-SCM-232

FRN 2.xxx

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls” (Publication SGI-1.1 available from

your local Rockwell Automation Sales Office or online at http://www.ab.com/

manuals/gi) describes some important differences between solid state equipment

and hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each intended

application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

ATTENTION: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or economic

!

loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Allen-Bradley, ControlFLASH, DPI, DSI, DriveExplorer, DriveExecutive, MicroLogix, SLC, PLC-5, ControlLogix, and

CompactLogix are trademarks of Rockwell Automation, Inc.

PowerFlex® is a registered trademark of Rockwell Automation, Inc.

RSLogix is a trademark of Rockwell Software.

Windows, Windows CE, Windows NT, Windows ME, Windows 2000, Windows XP, and Microsoft are either registered

trademarks or trademarks of Microsoft Corporation.

Page 3

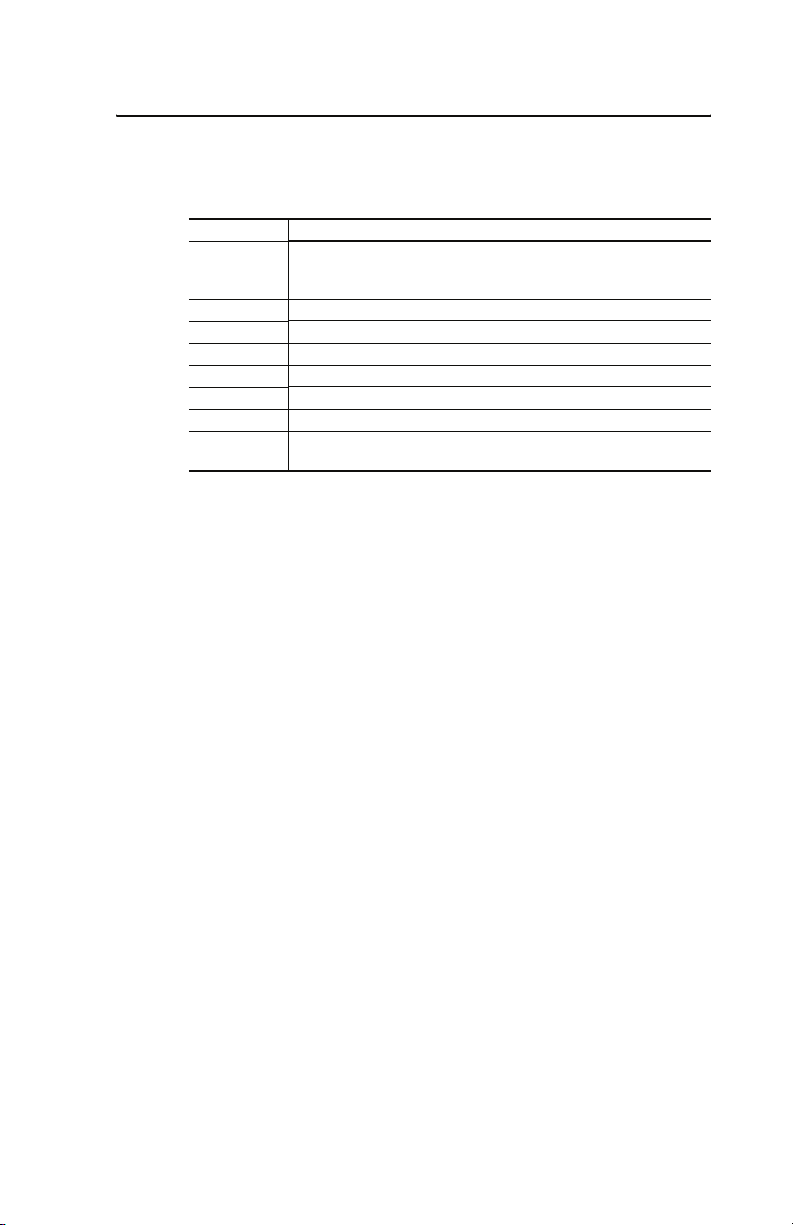

Summary of Changes

This is the second release of the 22-SCM-232 serial converter module

(FRN 2.xxx).

Location Description of Changes

Chapter 4 Added (before old Chapter 4 - Troubleshooting) to describe how to use

Chapter 5 Was Chapter 4 - renumbered to 5.

Appendix D Added to describe MicroLogix 1000 example ladder program.

Appendix E Added to describe MicroLogix 1200/1500 example ladder program.

Appendix F Added to describe SLC example ladder program.

Appendix G Added to describe PLC example ladder program.

Appendix H Added to describe ControlLogix example ladder program.

Appendix I Added to describe the Logic Command/Logic Status words that are

22-SCM-232 module with Allen-Bradley controllers to control and read/

write data to PowerFlex

used for PowerFlex 4 and 40 drives.

®

4 and 40 drives.

Page 4

soc-2

Notes:

Page 5

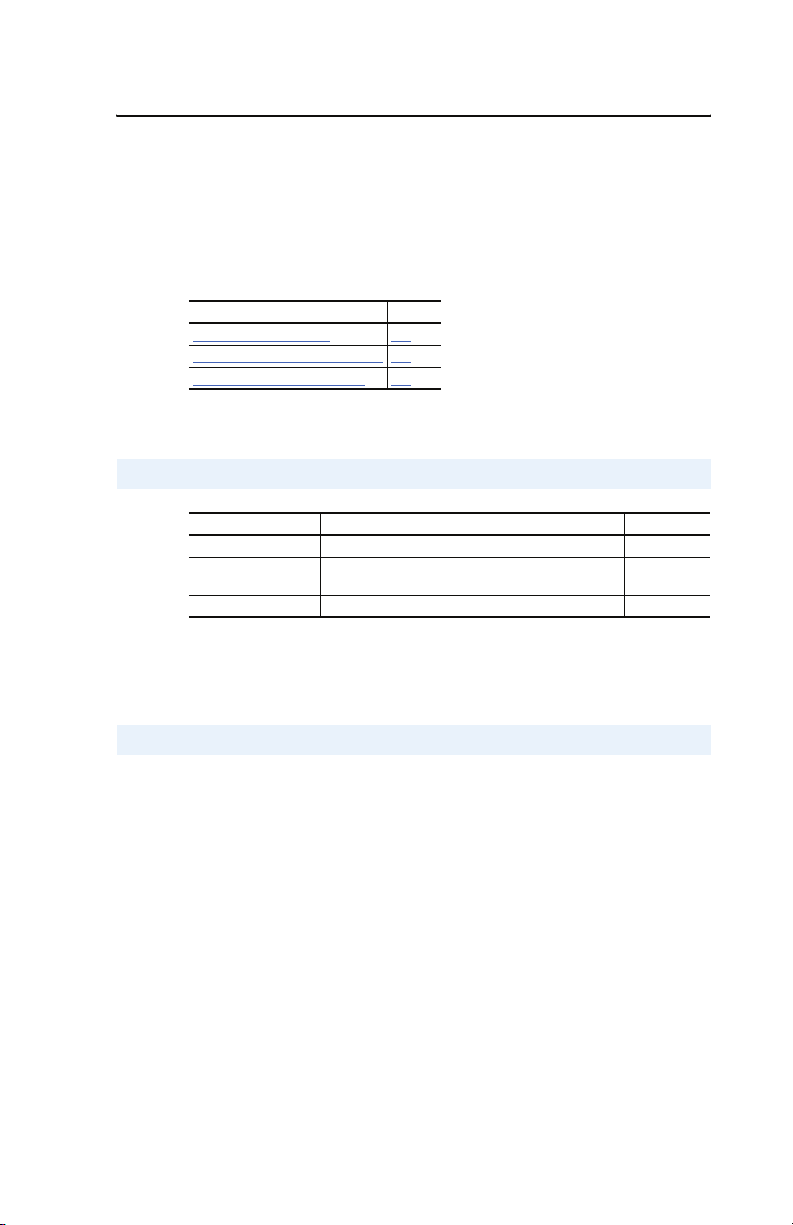

Table of Contents

Preface About This Manual

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Support. . . . . . . . . . . . . . . . . . . . . . . . P-2

Chapter 1 Getting Started

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2 Installing the Serial Converter Module

Selecting Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing the Serial Converter Module . . . . . . . . . . . . . . . . . 2-2

Removing the Serial Converter Module. . . . . . . . . . . . . . . . . 2-3

Chapter 3 Configuring the Serial Converter Module

Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using DriveExplorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using Terminal Emulation Software . . . . . . . . . . . . . . . . . . . 3-3

Setting the RS-232 Serial Port Rate. . . . . . . . . . . . . . . . . . . . 3-7

Setting the Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Resetting the Serial Converter Module . . . . . . . . . . . . . . . . . 3-9

Chapter 4 Controlling PowerFlex 4 and 40 Drives with

Allen-Bradley Controllers

Controller Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cabling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Messaging (MSG Instruction) . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PowerFlex 4 and 40 Memory Addressing . . . . . . . . . . . . . . . 4-4

Example Controller Programs . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chapter 5 Troubleshooting

Understanding the Status Indicators . . . . . . . . . . . . . . . . . . . 5-1

Module Diagnostic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Viewing and Clearing the Event Queue . . . . . . . . . . . . . . . . . 5-3

Viewing and Clearing DF1 Communication Statistics . . . . . 5-5

Troubleshooting Potential Problems . . . . . . . . . . . . . . . . . . . 5-6

Page 6

ii Table of Contents

Appendix A Specifications

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Agency Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B Serial Converter Module Parameters

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C Flash Updates

Preparing for a Flash Update . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Performing a Flash Update with HyperTerminal. . . . . . . . . . C-2

Troubleshooting Potential HyperTerminal Flash Problems. . C-3

Performing a Flash Update with DriveExplorer . . . . . . . . . . C-4

Appendix D MicroLogix 1000 Example Ladder Program

Appendix E MicroLogix 1200/1500 Example Ladder Program

Appendix F SLC Example Ladder Program

Appendix G PLC-5 Example Ladder Program

Appendix H ControlLogix/CompactLogix Example Ladder Program

Appendix I Logic Command/Status Words

PowerFlex 4 and PowerFlex 40 Drives . . . . . . . . . . . . . . . . . I-1

Glossary

Index

Page 7

Preface

About This Manual

Read this preface to become familiar with the rest of the manual.

Topic Page

Related Documentation

Conventions Used in this Manual P-1

Rockwell Automation Support P-2

Related Documentation

For Information On: Refer to: Publication

DF1 Protocol DF1 Protocol and Command Set Reference manual 1770-6.5.16

DriveExplorer™ 'ULYH([SORUHU*HWWLQJ5HVXOWV0DQXDO

DriveTools 2000™ KWWSZZZDEFRPGULYHVGULYHWRROVB

Documentation can be obtained online at http://www.ab.com/manuals

2QOLQHKHOSLQVWDOOHGZLWKWKHVRIWZDUH

P-1

9306-GR001…

Conventions Used in this Manual

The following conventions are used throughout this manual:

• Parameter names follow the format Parameter xx - [*]. The xx

represents the parameter number. The * represents the parameter

name. For example, Parameter 01 - [Adapter Cfg].

• Menu commands are shown in bold type face and follow the format

Menu > Command. For example, if you read “Select File > Open,”

you should click the File menu and then click the Open command.

• The firmware release is displayed as FRN X.xxx. The “FRN”

signifies Firmware Release Number. The “X” is the major release

number. The “xxx” is the minor update number.

Page 8

P-2 About This Manual

Rockwell Automation Support

Rockwell Automation, Inc. offers support services worldwide, with over

75 sales/support offices, over 500 authorized distributors, and over 250

authorized systems integrators located through the United States alone.

In addition, Rockwell Automation, Inc. representatives are in every

major country in the world.

Local Support

Contact your local Rockwell Automation, Inc. representative for:

• Sales and order support.

• Technical training.

• Warranty support.

• Support service agreements.

Technical Assistance

If you need to contact Rockwell Automation, Inc. for technical

assistance, please review the information in Chapter 5

first. If you still have questions, then contact your local Rockwell

Automation, Inc. representative.

, Troubleshooting

86$OOHQ%UDGOH\'ULYHV7HFKQLFDO6XSSRUW

(PDLO VXSSRUW#GULYHVUDURFNZHOOFRP

7HO

)D[

2QOLQH ZZZDEFRPVXSSRUWDEGULYHV

8.&XVWRPHU6XSSRUW&HQWHU

(PDLO HVXSSRUW#UDURFNZHOOFRP

7HO

)D[

*HUPDQ&XVWRPHU6HUYLFH&HQWHU

(PDLO UDJHUPDQ\FVF#UDURFNZHOOFRP

7HO

)D[

Page 9

Getting Started

The 22-SCM-232 serial converter provides a communications interface

between a computer or controller and any Allen-Bradley product

implementing DSI, such as PowerFlex 4 and 40 drives. It uses the

full-duplex, RS-232 DF1 protocol

Topic Page Topic Page

Components

Features 1-2 Quick Start 1-5

Compatible Products 1-2 Modes of Operation 1-6

Required Equipment 1-3

1-1 Safety Precautions 1-4

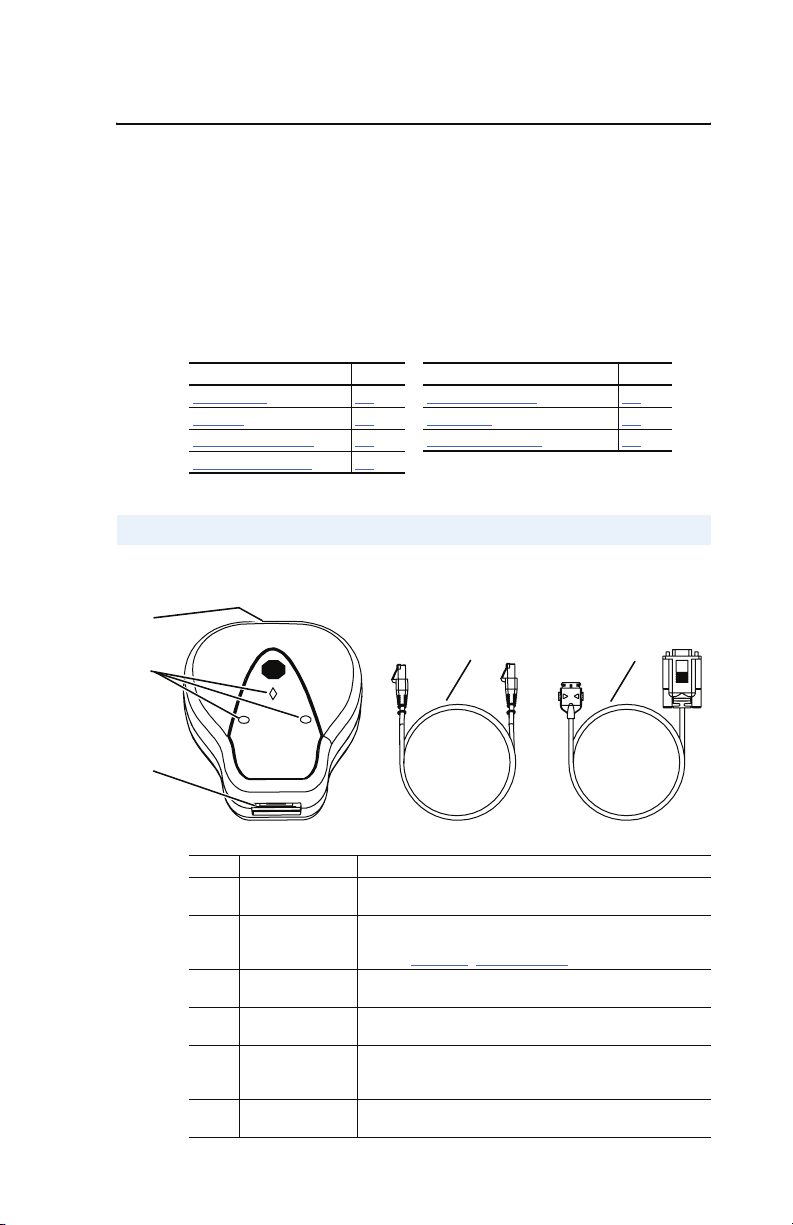

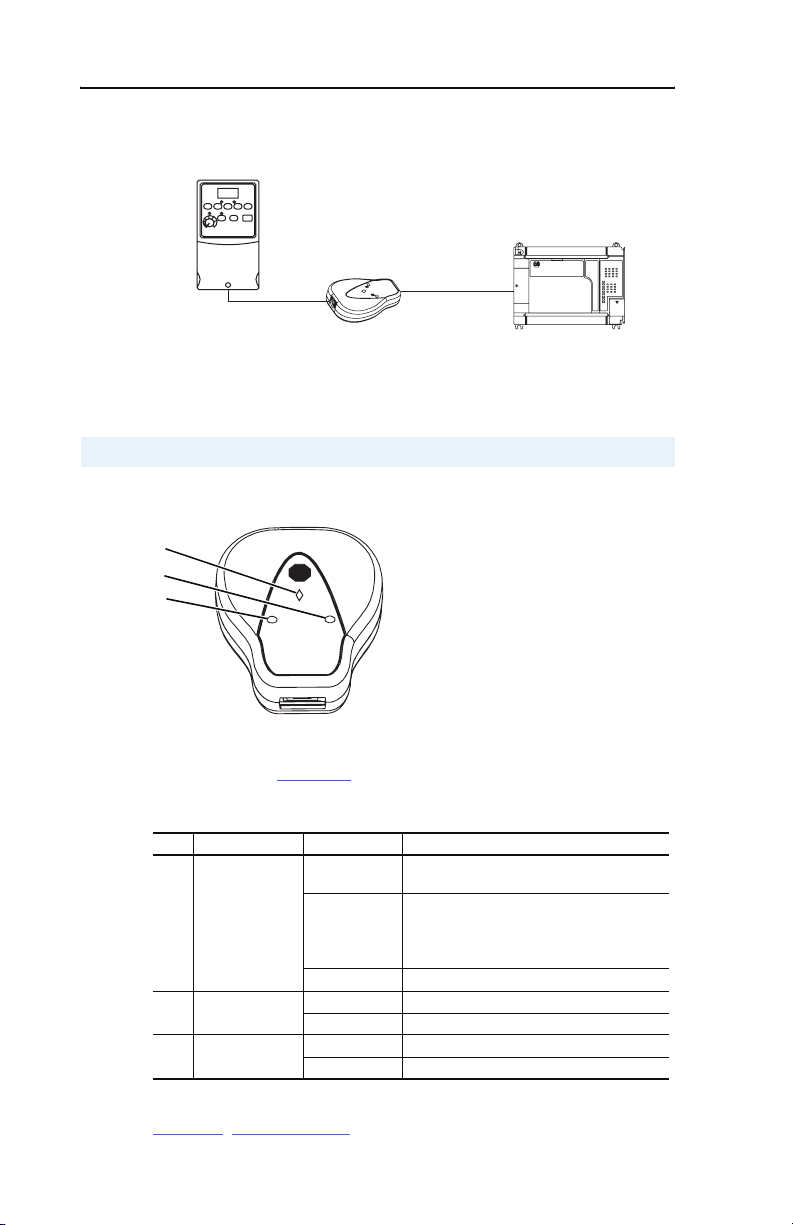

Components

Figure 1.1 Components of the Serial Converter

➊

.

Chapter 1

➋

AB

➌

# Part Description

DSI Connection Standard RJ45 connector. The 22-RJ45CBL-C20 cable is

➊

Status Indicators LEDs that indicate module operation, data is being received

➋

RS-232 Serial Port Locking low profile connector. The 1203-SFC serial cable is

➌

22-RJ45CBL-C20

➍

Cable

1203-SFC Serial

➎

Cable

Not

DriveExplorer Lite

Shown

CD-ROM

➍

plugged into this connector.

from and sent to the computer.

Refer to Chapter 5

plugged into this connector.

DSI cable (2 m) with male-to-male RJ45 connectors.

Serial cable (2 m) with a locking low profile connector to

connect to the serial converter and a 9-pin sub-miniature D

female connector to connect to a computer.

CD including DriveExplorer Lite software and

documentation.

, Troubleshooting, for more information.

➎

Page 10

1-2 Getting Started

Features

The 22-SCM-232 serial converter module features the following:

• The serial converter module can connect to products implementing

DSI such as PowerFlex 4 and 40 drives.

• Provides a means for DriveExplorer (version 3.01 or higher) and

DriveExecutive (version 1.01 or higher) software tools to access

PowerFlex 4 and 40 drives.

• Allows various Allen-Bradley controllers, from MicroLogix to

ControlLogix, to control and read/write data to PowerFlex 4 and 40

drives.

• Three status indicators (LEDs) report the operating status of the

module.

• DF1 serial baud rates of 9600 bps, 19.2 kbps, and 38.4 kbps are

supported. The factory default baud rate is 9600 bps.

• The serial converter module receives power from the DSI host

product. An outside power source is not needed.

• DriveExplorer (version 3.01 or higher), DriveExecutive (version 1.01

or higher), or terminal emulation software can be used to configure

the serial converter.

• The serial converter module is flash upgradeable to take advantage of

feature enhancements. For example, version 1.xxx SCM’s can be

flashed to version 2.xxx (or higher).

Compatible Products

The 22-SMC-232 serial converter module is compatible with

Allen-Bradley products that support DSI. At the time of publication,

compatible products include:

• PowerFlex 4 drives

• PowerFlex 40 drives

Page 11

Getting Started 1-3

Required Equipment

Equipment Shipped with the Serial Converter Module

When you unpack the serial converter module, verify that the package

includes:

❑ One 22-SCM-232 Serial Converter Module

❑ One 1203-SFC serial cable

❑ One 22-RJ45CBL-C20 cable

❑ One DriveExplorer Lite CD

❑ This manual

User-Supplied Equipment

To configure the serial converter, you must use one of the following:

❑ DriveExplorer software (version 3.01 or higher).

❑ DriveExecutive software (version 1.01 or higher).

❑ Terminal emulation software such as HyperTerminal.

❑ VT-100 compatible terminal.

Page 12

1-4 Getting Started

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Risk of injury or equipment damage exists. Only

personnel familiar with drive and power products and the associated

!

machinery should plan or implement the installation, start-up,

configuration, and subsequent maintenance of the product using the

serial converter module. Failure to comply may result in injury and/or

equipment damage.

ATTENTION: Risk of injury or equipment damage exists. If the serial

converter module is transmitting control I/O to the drive (indicated by a

!

solid green diamond LED), the drive may fault when you remove or

reset the serial converter module. Determine how your drive will

respond before removing or resetting a connected serial converter

module.

ATTENTION: Risk of injury or equipment damage exists.

Parameter 04 - [Comm Flt Action] lets you determine the action of

!

the serial converter module and connected drive if DF1 serial

communications are disrupted. By default, this parameter faults the

drive. You can set this parameter so that the drive continues to run.

Precautions should be taken to ensure that the setting of this parameter

does not create a hazard of injury or equipment damage.

Page 13

Getting Started 1-5

Quick Start

This section is designed to help experienced users quickly start using the

serial converter module. If you are unsure how to complete a step, refer

to the referenced chapter.

Step Action Refer to

1 Review the safety precautions for the serial converter

module.

2 Install the serial converter module.

Connect a 22-RJ45CBL-C20 cable to the serial converter

module and the DSI drive. Then, connect a 1203-SFC serial

cable to the serial conver ter module and a computer. Make

sure that power has been applied to the DSI drive.

3 Configure the serial converter module for your

application.

Use one of the following to configure parameters in the serial

converter module:

• DriveExplorer (v3.01 or higher)

• DriveTools 2000 (v1.01 or higher)

• Terminal emulation software

• VT-100 compatible terminal

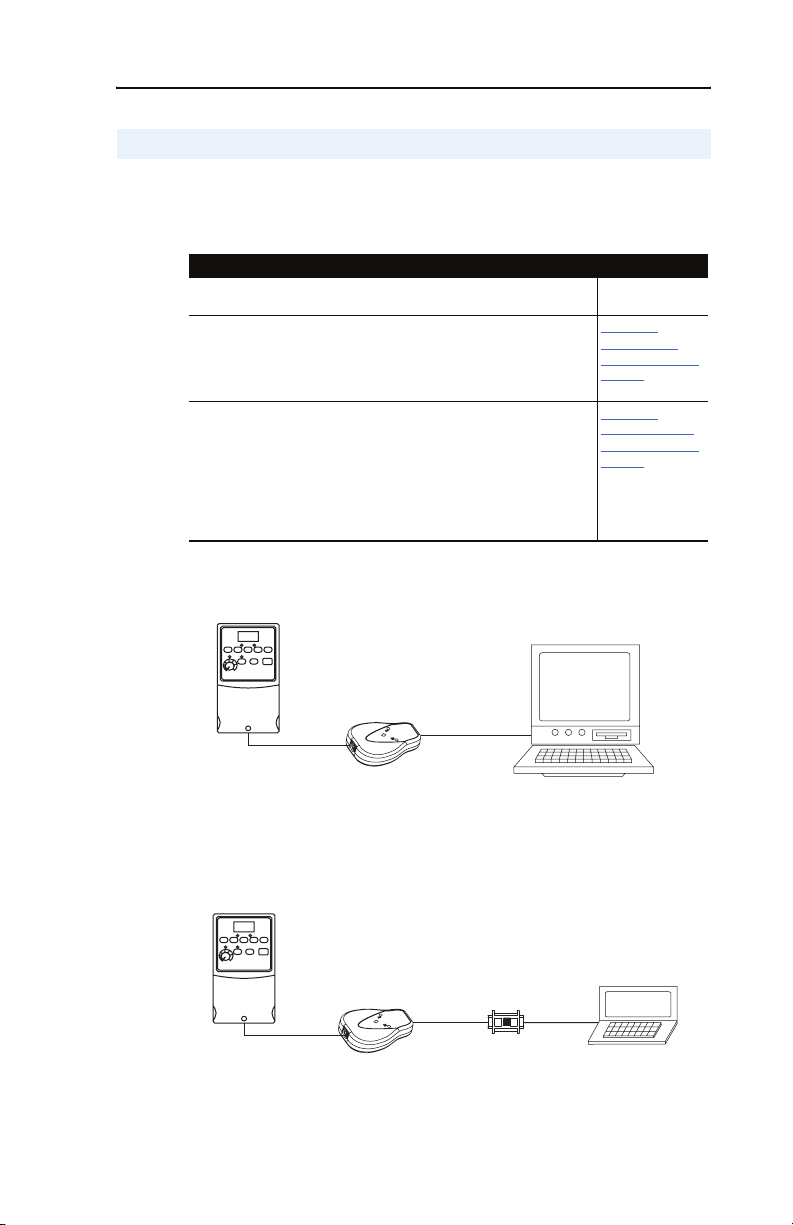

Figure 1.2 Example Serial Connection to a Personal Computer

Throughout This

Manual

,

Chapter 2

Installing the

Serial Converter

Module

Chapter

3,

Configuring the

Serial Converter

Module

22-RJ45CBL-C20

Cable

DSI Host

Serial

Converter

Figure 1.3 Example Serial Connection to a Hand-Held Computer

22-RJ45CBL-C20

Cable

DSI Host

Serial

Converter

1203-SFC

Cable

1203-SFC

Cable

(sold separately)

Computer

Serial

Cable

1203-SNM

Null Cable

Converter

Hand-Held

Computer

Page 14

1-6 Getting Started

Figure 1.4 Example Serial Connection to a Controller

22-RJ45CBL-C20

Cable

DSI Host

Serial

Converter

1203-SFC

Cable

MicroLogix

Modes of Operation

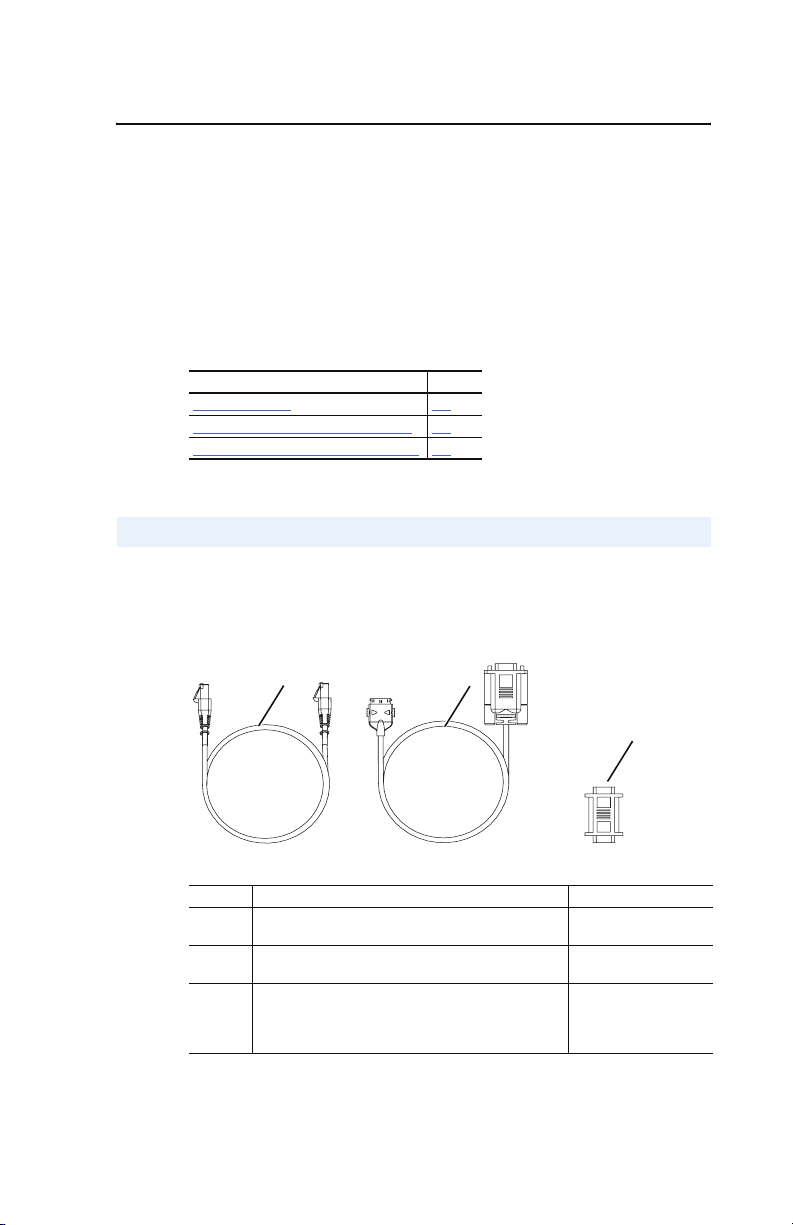

Figure 1.5 Status Indicators on the Serial Converter Module

➊

➋

AB

➌

The serial converter module uses three status indicators to report its

operating status (Figure 1.5). The following table describes the state of

the status indicators under normal operation:

# Status Indicator State Description

Diamond Flashing Green Serial converter is connected to a product

➊

Solid Green Serial converter is or was receiving control

Off No power or Flash operation in progress.

TX Off Not transmitting data.

➋

RX Off Not receiving data.

➌

Flashing Green Transmitting data.

Flashing Green Receiving data.

implementing DSI.

I/O. Removing or resetting the serial

converter may cause a serial fault in the

product.

If the diamond status indicator is red, there is a problem. Refer to

Chapter 5

, Troubleshooting.

Page 15

Chapter 2

Installing the Serial Converter

Module

Chapter 2 provides instructions for installing and removing the serial

converter module.

Topic Page

Selecting Cables

Installing the Serial Converter Module 2-2

Removing the Serial Converter Module 2-3

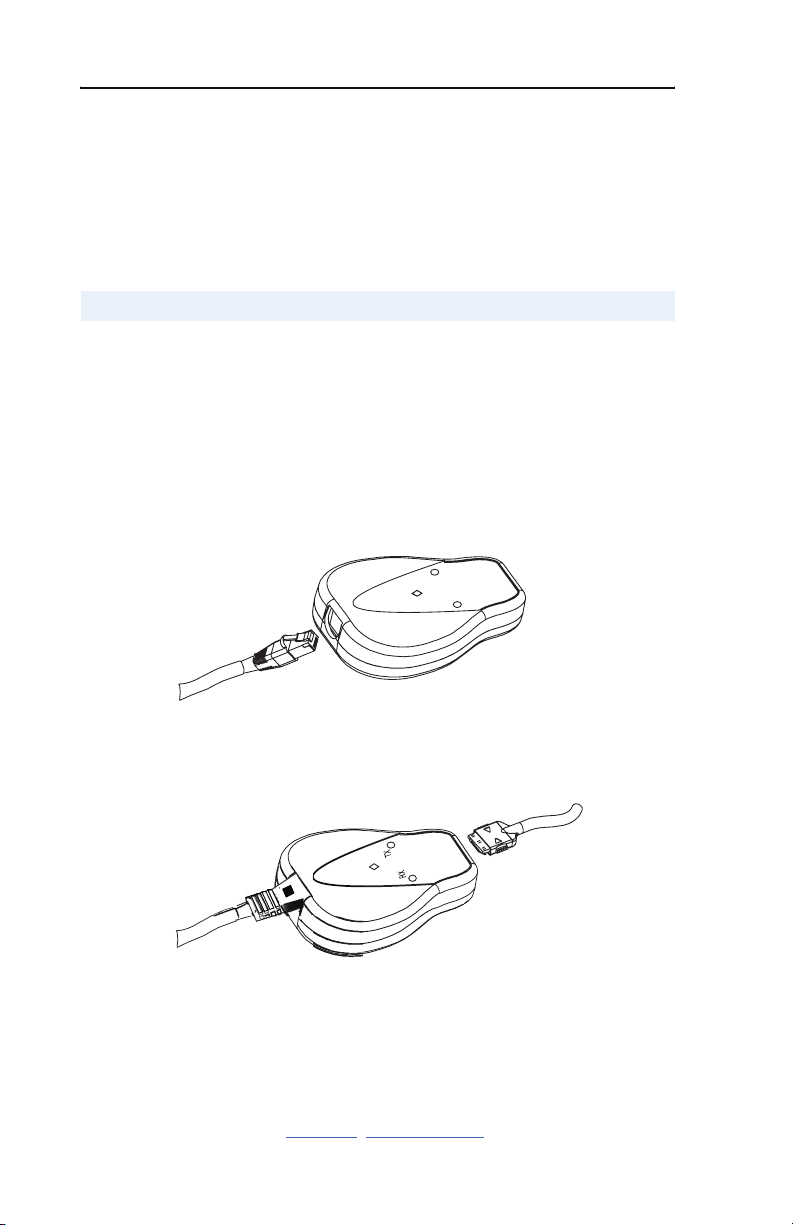

Selecting Cables

The following cables are all you should need to connect the serial

converter module to a drive and a computer.

Figure 2.1 Cables

2-1

➊

➋

➌

Number Description Catalog Number

➊

➋

➌

Important: To provide proper termination of the serial cable shield, the

DSI cable to connect the serial conver ter module to

the drive.

Serial cable to connect the serial converter module to

the computer.

When connecting the serial converter module to an

H/PC (Hand-Held PC), you must use a null modem

cable with two male 9-pin sub-miniature D

connectors. These must be purchased separately.

chassis of the computer should be properly grounded. If it is

not possible or practical to ground this, then a ground wire

22-RJ45CBL-C20

1203-SFC

1203-SNM

(sold separately)

Page 16

2-2 Installing the Serial Converter Module

should be connected to the serial cable shield at the shell of

the 9-pin sub-miniature D connector.

Important: The DSI cable shield must be properly grounded in order to

provide EMC protection. On the PowerFlex 4 and 40 drive

that means that Pin 16 of the drive control terminal block

must be connected to the drive earth ground terminal.

Installing the Serial Converter Module

Important: The module must not be installed in an area where the

ambient atmosphere contains volatile or corrosive gas,

vapors or dust. If the module is not going to be installed for

a period of time, it must be stored in an area where it will

not be exposed to a corrosive atmosphere.

1. Connect the module to the drive using the

Figure 2.2 Connecting a 22-RJ45CBL-C20 Cable to the Serial Converter

22-RJ45CBL-C20 cable.

TX

RX

2. Connect the module to the computer using the 1203-SFC cable.

Figure 2.3 Connecting a 1203-SFC Cable to the Serial Converter

3. Verify that power is applied to the DSI-enabled drive. The serial

converter module receives power from the drive, so it must be

powered before the serial converter module will operate.

The diamond light on the serial converter module flashes green to

indicate that the module is properly installed and receiving power. If it is

not green, refer to Chapter 5

, Troubleshooting.

Page 17

Installing the Serial Converter Module 2-3

Removing the Serial Converter Module

ATTENTION: Risk of injury or equipment damage exists. If the serial

converter module is transmitting control I/O to the drive (indicated by a

!

solid green diamond LED), the drive may fault when you remove or

reset the serial converter. Determine how your drive will respond before

removing or resetting a connected serial converter module.

1. Disconnect the 22-RJ45CBL-C20 cable from the DSI-enabled drive

and then from the converter module. To disconnect the cable, press

on the cable latch and then pull it out.

2. Disconnect the 1203-SFC serial cable from the serial converter

module and then the computer.

Page 18

2-4 Installing the Serial Converter Module

Notes:

Page 19

Chapter 3

Configuring the Serial Converter

Module

Chapter 3 provides instructions and information for configuring the

serial converter module.

Topic Page

Configuration Tools

Using DriveExplorer 3-2

Using Terminal Emulation Software 3-3

Setting the RS-232 Serial Port Rate 3-7

Setting the Fault Action 3-8

Resetting the Serial Converter Module 3-9

For a list of parameters, refer to Appendix B, Serial Converter Module

Parameters. For definitions of terms in this chapter, refer to the Glossary.

Configuration Tools

3-1

The serial converter module stores parameters and other information in

its own non-volatile memory. You must, therefore, access the module to

view and edit its parameters. The following tools can be used to access

the module parameters.

Tool Refer To

DriveExplorer software (version 3.01 or higher) page 3-2

DriveExecutive software (version 1.01 or higher) KWWSZZZDEFRPGULYHV

Terminal emulation software page 3-3

VT100-compatible terminal Documentation for the terminal

Important: The RS-485 serial port on DSI products, such as PowerFlex

4 and 40 drives, does not need to be configured before using

the serial converter module. DSI communications are

configured automatically (19.2K baud and 8-N-1).

in this manual

GULYHWRROVB

in this manual

Page 20

3-2 Configuring the Serial Converter Module

Using DriveExplorer

With DriveExplorer software, you can edit parameters in both the serial

converter module and the connected DSI-enabled drive. On PowerFlex

4/40 drives (or other DSI products), you can also edit parameters in any

of the attached peripherals. DriveExplorer Lite is shipped with the serial

converter module and is a free, limited-feature version of DriveExplorer.

Important: Parameter 1 - [Adapter Cfg] must be set to “Auto”

(default) for DriveExplorer to operate. HyperTerminal can

be used if Parameter 1 - [Adapter Cfg] needs to be

changed (see Using Terminal Emulation Software

DriveExplorer Lite Quick Start

This section is designed to help you quickly start using DriveExplorer

Lite. If you are unsure how to complete a step, refer to the online help

(select Help > Help Topics) or the DriveExplorer Getting Results

Manual, Publication 9306-5.2, which is included on the CD.

1. Select Explore > Configure Communication. Select the

communications port and baud rate that you are using. Select either

checksum, and accept the default time for the time-out.

section).

2. Select Explore > Connect > Local. A node will appear under Devices.

3. In the left pane, click the + signs to expand the tree. Click the product

or serial converter module to display parameters in the right pane.

Double-click a parameter to edit it.

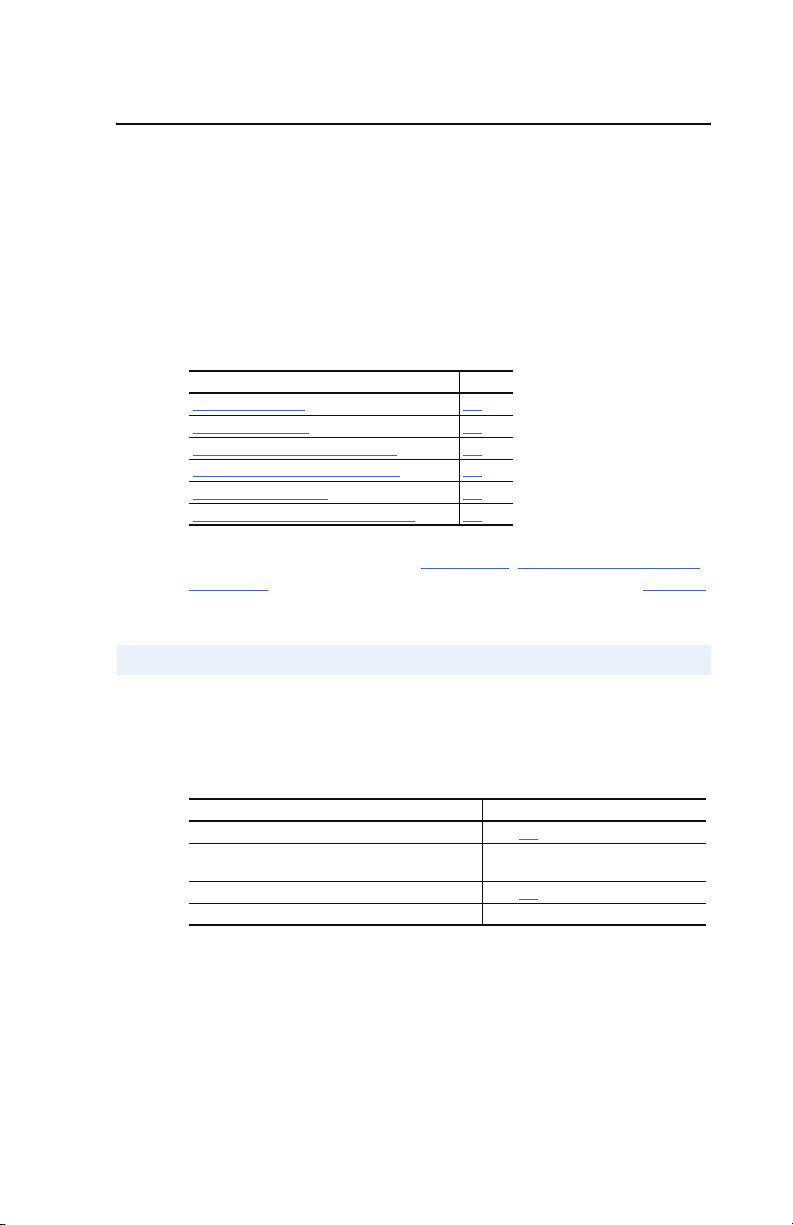

Figure 3.1 DriveExplorer

Page 21

Configuring the Serial Converter Module 3-3

Using Terminal Emulation Software

This section provides detailed instructions on how to use terminal

emulation software to access the serial converter module so that you can

view and edit its parameters or view its event queue.

A variety of terminal emulation programs can be used to establish a

serial connection between a computer and the serial converter module.

The following instructions describe how to establish the initial serial

connection to the serial converter module using a computer running

HyperTerminal – terminal emulation software provided with most

Windows 95/98/NT 4.0/2000/XP operating systems.

Important: The following instructions use screen captures from

Windows 95 HyperTerminal. If you are using a different

operating system the screens may differ.

To use HyperTerminal to access the serial converter module

1. Verify that the serial converter module is installed correctly. Refer to

Chapter 2, Installing the Serial Converter Module.

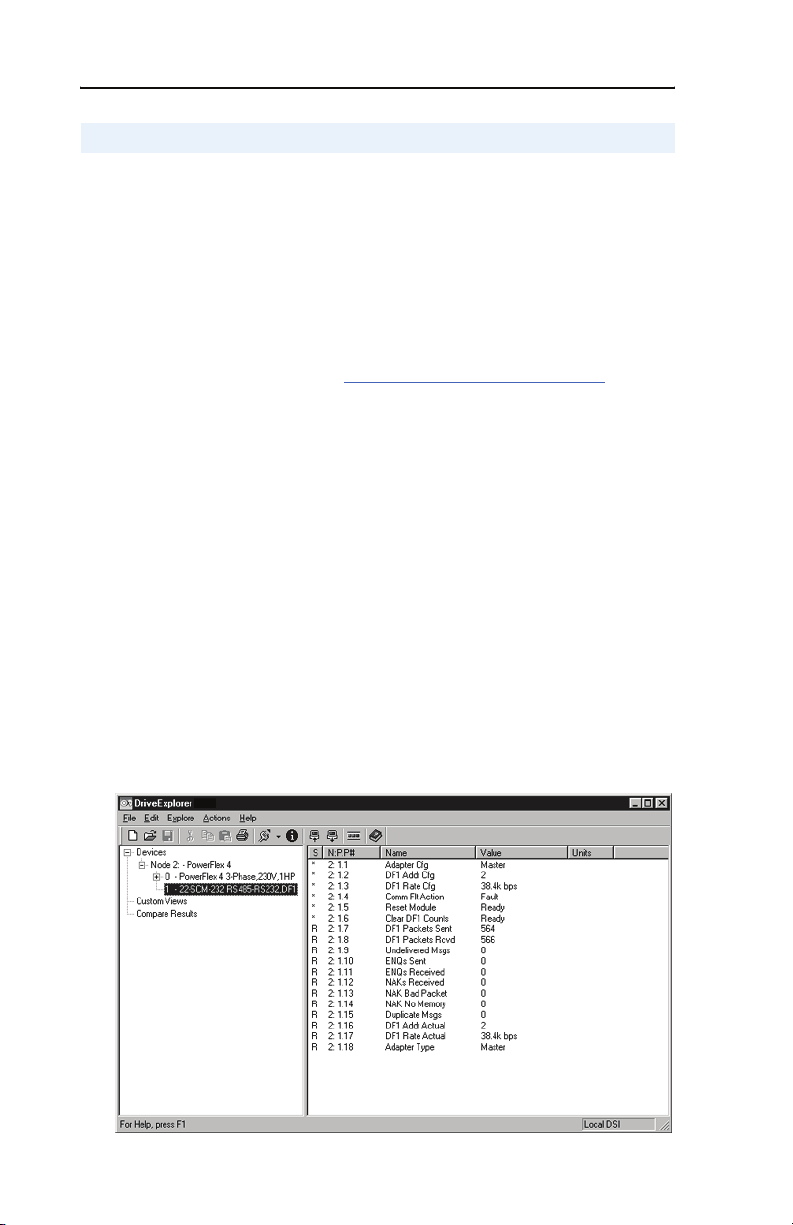

2. On the Windows 95 desktop, click the Start button, and then select

Programs > Accessories > HyperTerminal to display the

HyperTerminal dialog box (see Figure 3.2

look slightly different.

). Your dialog box may

Figure 3.2 HyperTerminal Dialog Box in List View

On the Windows NT desktop, click the Start button, and then select

Programs > Accessories > HyperTerminal to display the

Connection dialog box (see Figure 3.3

3. Double-click Hypertrm.exe.

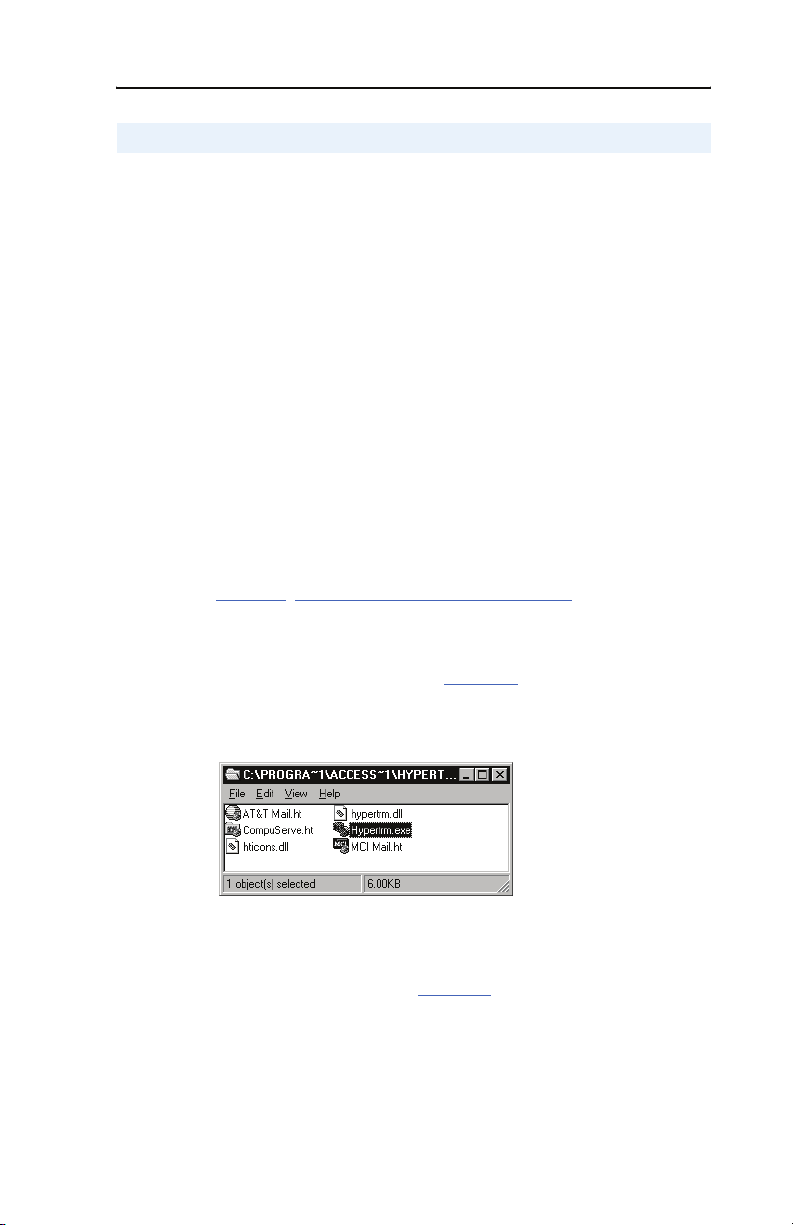

The Connection Description dialog box appears in the

HyperTerminal workspace.

). Then, go to step 4.

Page 22

3-4 Configuring the Serial Converter Module

Figure 3.3 Connection Dialog Box

4. In the Name window, type any name (for example, converter), and

then select any icon in the Icon box.

5. Click OK to display the Phone Number dialog box (see Figure 3.4

Figure 3.4 Phone Number Dialog Box

6. In the Connect Using window, select the communications port that

you intend to use (usually Com1 or Com2).

7. Click OK to display the Properties dialog box.

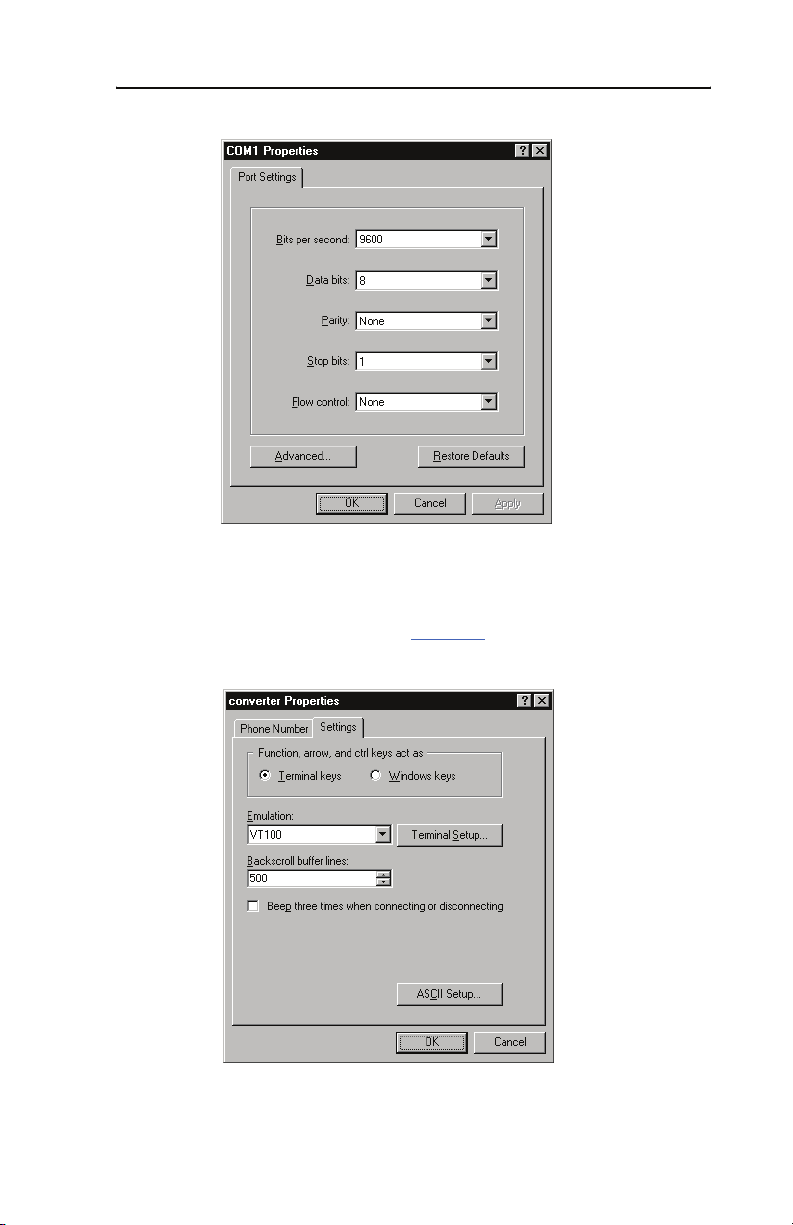

8. Select the settings shown in Figure 3.5

.

Important: If Parameter 03 - [DF1 Rate Cfg] was previously set

to 19.2K or 38.4K, select that value in the Bits per

second window.

).

Page 23

Configuring the Serial Converter Module 3-5

Figure 3.5 Properties Dialog Box

9. Click OK. A blank HyperTerminal workspace appears.

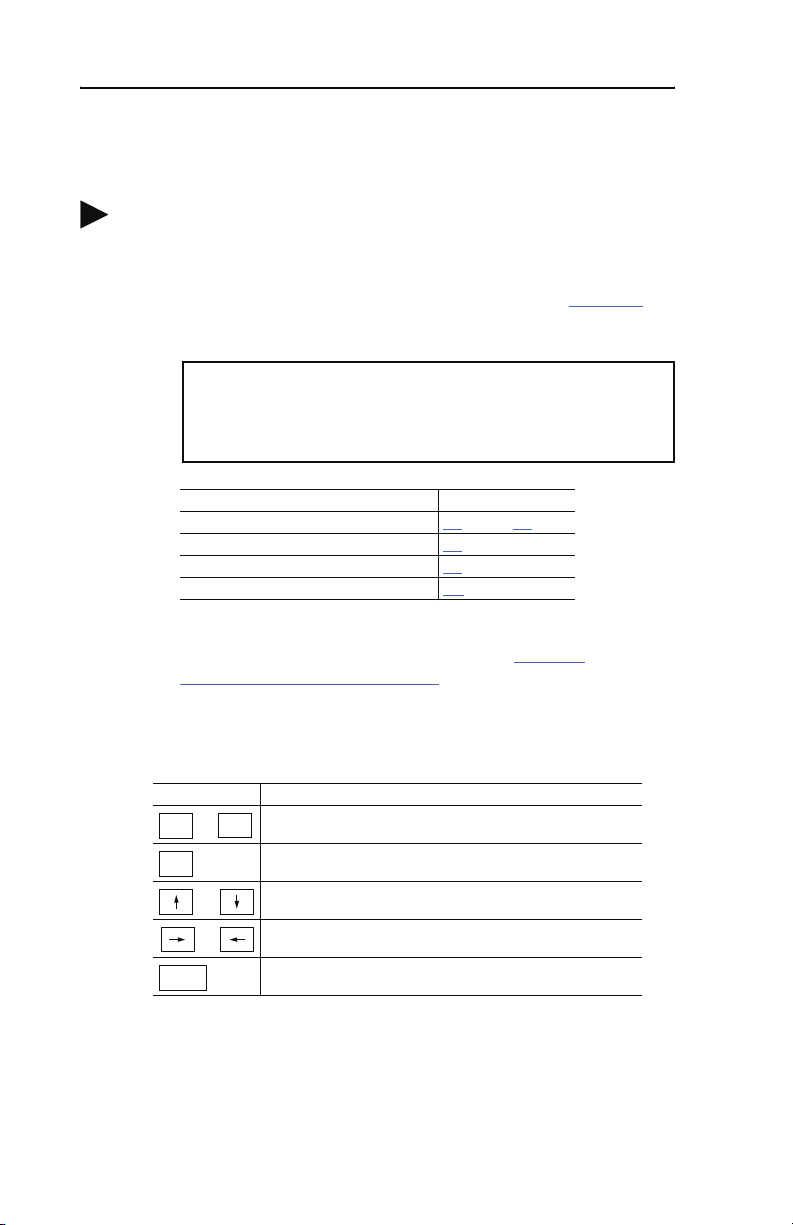

10. Select File > Properties to display the Properties dialog box.

11. Click the Settings tab (see Figure 3.6

Figure 3.6 Properties Dialog Box

).

12. Under Function, arrow, and ctrl keys act as, select Termi n a l keys .

Page 24

3-6 Configuring the Serial Converter Module

13. In the Emulation window, select VT100.

14. Click OK to display the HyperTerminal workspace.

TIP: Select File > Save to save the HyperTerminal configuration that

you just created. In future connections, you can select the saved

configuration and quickly connect to the serial converter module.

15. Press the Enter key until the main menu appears (see Figure 3.7).

Figure 3.7 Main Menu

Main Menu - Enter Number for Selection

1> Display Setup Parameters

2> Display Event Queue

3> Flash Upgrade

What do you want to do? Page

Edit the serial port rate, or fault action 3-7

View the event queue 5-3

View DF1 data 5-5

Update the firmware C-1

If no text or meaningless text appears instead of the Main Menu,

adjust the baud rate in your software. Refer to Chapter

Troubleshooting Potential Problems section for detailed instructions.

through 3-9

5 in the

To navigate in the terminal emulation software

Key Description

0

Esc

Enter

.. .

OR

OR

In the main menu, keys 1 – 3 select a menu option.

9

In the parameter screen, keys 0 – 9 enter a value.

Display the main menu or abort changes to a parameter.

Scroll through parameters or events.

Scroll through the values for a parameter.

Save a value for a parameter.

Page 25

Configuring the Serial Converter Module 3-7

Setting the RS-232 Serial Port Rate

The serial port rate, sometimes called baud rate or DF1 rate, is the speed

at which the computer and serial converter module communicate over

RS-232. You can select a serial port rate of 9600, 19.2K, or 38.4K. The

factory-default serial port rate is 9600.

Important: If you change the serial port rate in the serial converter

module, you must set your software to use the same serial

port rate. The serial converter module must be reset or

power cycled before baud rate changes take affect.

To set the serial port rate

1. Set Parameter 03 - [DF1 Rate Cfg] to the desired rate.

Figure 3.8 DF1 Rate Cfg Parameter in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW

or RIGHT ARROW key to modify parameter values.

Press the ENTER key to save a new value.

3> DF1 Rate Cfg = 9600

2. Reset the serial converter module. Refer to Resetting the Serial

Converter Module section in this chapter.

3. Set the serial port rate in your software to match the new serial port

rate in the serial converter module.

Page 26

3-8 Configuring the Serial Converter Module

Setting the Fault Action

By default, when DF1 serial communications are disrupted (for example,

a serial cable is disconnected) and control I/O is being transmitted, the

serial converter module and connected drive respond by faulting. You

can set a different response to communication disruptions using

Parameter 04 - [Comm Flt Action].

ATTENTION: Risk of injury or equipment damage exists.

Parameter 04 - [Comm Flt Action] lets you determine the action of

!

the serial converter module and connected drive if communications are

disrupted. By default, this parameter faults the drive. You can set this

parameter so that the drive continues to run. Precautions should be

taken to ensure that the setting of this parameter does not create a

hazard of injury or equipment damage.

To change the fault action

• Set the value of Parameter 04 - [Comm Flt Action] to the desired

response:

Action Description

Fault The drive is faulted and stopped. (Default)

Stop The drive is stopped, but not faulted (DSI host products only).

Zero data The drive is sent 0 for output data after a communications disruption.

Hold last The drive continues in its present state after a communications

This does not command a stop.

disruption.

Figure 3.9 Comm Flt Action Parameter in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW or

RIGHT ARROW key to modify parameter values. Press

the ENTER key to save a new value.

4> Comm Flt Action = Fault

Changes to this parameter take effect immediately. A reset is not

required.

Page 27

Configuring the Serial Converter Module 3-9

Resetting the Serial Converter Module

Change to settings on some module parameters require that you reset the

serial converter module before the new settings take effect. You can reset

the module by cycling power to the module or by using Parameter 05 -

[Reset Module].

ATTENTION: Risk of injury or equipment damage exists. If the serial

converter module is transmitting control I/O to the drive (indicated by a

!

solid green diamond LED), the drive may fault when you remove or

reset the module. Determine how your drive will respond before

removing or resetting a connected serial converter module.

To reset the serial converter

• Set Parameter 05 - [Reset Module] to either Reset Module or Set

Defaults. “Reset Module” will reset the serial converter. “Set

Defaults” will set all parameters in the serial converter to their

factory-default values.

Figure 3.10 Reset Module Parameter in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW

or RIGHT ARROW key to modify parameter values.

Press the ENTER key to save a new value.

5> Reset Module = Reset Module

After you enter the “Reset Module” value, the serial converter will be

reset. This parameter will then be reset to “Ready.”

Page 28

3-10 Configuring the Serial Converter Module

Notes:

Page 29

Chapter 4

Controlling PowerFlex 4 and 40

Drives with Allen-Bradley Controllers

Chapter 4 illustrates how to use the 22-SCM-232 serial converter with

Allen-Bradley controllers to control and read/write data to PowerFlex 4

and 40 drives.

Topic Page

Controller Compatibility

Cabling Requirements 4-2

Messaging (MSG Instruction) 4-3

PowerFlex 4 and 40 Memory Addressing 4-4

Example Controller Programs 4-4

Controller Compatibility

Any Allen-Bradley controller capable of initiating and receiving DF1

messages can be used with the 22-SCM-232 serial converter:

4-1

• MicroLogix 1000 (Series C or later discrete controllers, and all

analog controllers)

• MicroLogix 1200/1500

• SLC 5/03, 5/04, 5/05

• PLC5

• ControlLogix/CompactLogix

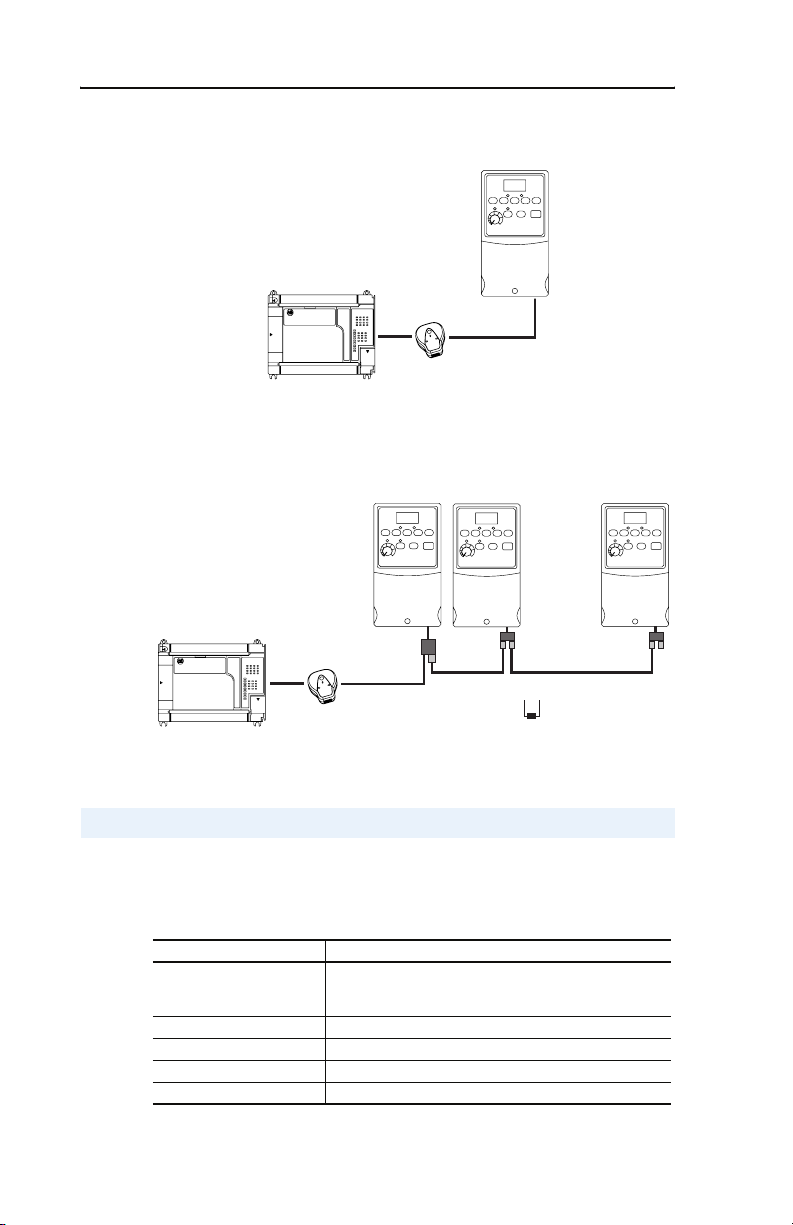

The 22-SCM-232 converts the protocol from DF1 to Modbus RTU, and

the media from RS232 to RS485. It can be used for point-to-point and

multiple drive applications (see Figure 4.1

Important: DSI HIMs (22-HIM-*) and/or DSI communication adapters

(22-COMM-*) cannot be used in an Allen-Bradley

controller/22-SCM-232 system.

and Figure 4.2 respectively).

Page 30

4-2 Controlling PowerFlex 4 and 40 Drives with Allen-Bradley Controllers

A

B

A

B

Figure 4.1 Point-to-Point Example

Drive

Controller

RS232

DF1

RS485

Modbus RTU

22-SCM-232

Serial Converter

Figure 4.2 Multiple Drive Example

Drive # 1

Drive # 2

Drive # 31

Controller

RS232

DF1

22-SCM-232

Serial Converter

RS485

Modbus RTU

AK-U0-RJ45-SC1

Splitter Cable

AK-U0-RJ45-TB2P

Ter minal Blocks

1/4W, 120 Ω

Ter minating Resistors

(on first and last drives)

Cabling Requirements

In addition to using the 22-SCM-232 serial converter module, the

required cabling depends on the type of Allen-Bradley controller being

used:

Controller Type Requires 22-SCM-232 plus …

MicroLogix 1000/1200/1500

LSP

1761-CBL-PM02 or 1761-CBL-AP00 (8-pin DIN to 9-pin

Female) and 1203-SNM Serial Null Modem adapter (9-pin

Male to 9-pin Male)

MicroLogix 1500 LRP —

SLC 5/03, 5/04 or 5/05 —

PLC5 9-pin Male to 25-pin Male adapter (3rd party)

ControlLogix/CompactLogix —

Page 31

Controlling PowerFlex 4 and 40 Drives with Allen-Bradley Controllers 4-3

Messaging (MSG Instruction)

Communications are handled via Message (MSG) instructions, which

vary between the different controllers.

Figure 4.3 MicroLogix 1200/1500 MSG Setup Screen Example

The following descriptions are for the user configurable items of the

MSG instruction.

MSG User Configurable Item Description

Channel Channel # to which the 22-SCM-232 is connected

Communication Command Message type used

Data Table Address Source of write data/destination of read data

Size in Elements Number of words to read/write (32 max.)

Message Timeout Number of seconds before the message times out

Data Table Address Memory address in PowerFlex 4/40 to be accessed

Local Node Addr (dec) PowerFlex 4/40 node address (decimal)

Local Node Addr (octal) PowerFlex 4/40 node address (octal)

Local/Remote Type of communication used

For additional information on MSG instruction setups, refer to the

respective controller instruction set reference manuals:

Publication Name Publication Number

MicroLogix 1000 1761-6.3

MicroLogix 1200/1500 Instruction Set Reference Manual 1762-RM001…

SLC 1747-RM001…

PLC5 1785-6.1

ControlLogix Manual 1756-RM003…

CompactLogix Manual 1769-UM007…

Page 32

4-4 Controlling PowerFlex 4 and 40 Drives with Allen-Bradley Controllers

PowerFlex 4 and 40 Memory Addressing

PowerFlex 4 and 40 control and status information, and parameters are

addressed using N: file addressing.

Logic Command/Reference

Control Data Address

Logic Command N182:192

Reference N182:193

Logic Status/Feedback/Additional Monitor Data

Monitor Data Address

Logic Status N183:198

Drive Error Code N183:199

Frequency Command N183:200

Output Frequency (Feedback) N183:201

Output Current N183:202

DC Bus Voltage N183:203

Output Voltage N183:204

Step # of Multi-Step Speed Operation N183:205

Step # of PLC Operation N183:206

Time of PLC Operation N183:207

Counter Value N183:208

The Logic Command and Logic Status bit definitions are described in

Appendix I.

Parameters

PowerFlex 4 and 40 parameters are addressed using Integer File N150:x,

where “x” equals the actual parameter number in the drive. For example:

N150:39 = Parameter 39 - [Accel Time 1]

Example Controller Programs

Example ladder logic programs are provided for each type of controller

platform. Refer to the appropriate appendix:

Controller Type Example Ladder Logic Program

• MicroLogix 1000 See Appendix D

• MicroLogix 1200/1500 See Appendix E

• SLC See Appendix F

• PLC See Appendix G

• ControlLogix/CompactLogix See Appendix H

Page 33

Chapter 5

Troubleshooting

Chapter 5 provides information for troubleshooting potential problems

with the serial converter module.

Topic Page

Understanding the Status Indicators

Module Diagnostic Items 5-3

Viewing and Clearing the Event Queue 5-3

Viewing and Clearing DF1 Communication Statistics 5-5

Troubleshooting Potential Problems 5-6

Understanding the Status Indicators

The serial converter module has three status indicators to reports its

operating status. See Figure 5.1

Figure 5.1 Status Indicators on the Serial Converter

.

5-1

➊

➋

AB

➌

# Status Indicator Description Refer To

Diamond Serial converter status Diamond Status Indicator

➊

TX Serial converter is transmitting

➋

RX Serial converter is receiving

➌

data

data

on page 5-2

TX Status Indicator on

page 5-2

RX Status Indicator on

page 5-2

Page 34

5-2 Troubleshooting

Diamond Status Indicator

ATTENTION: Risk of injury or equipment damage exists. If the serial

converter module is transmitting control I/O to the drive (indicated by a

!

solid green diamond LED), the drive may fault when you remove or

reset the module. Determine how your drive will respond before

removing or resetting a serial converter module.

Status Cause Corrective Action

Off Serial converter module

is not powered or in Flash

programming mode.

Flashing

Serial converter module

Green

is operating and not

transmitting control I/O.

Solid

Serial converter module

Green

is operating and is or was

transmitting control I/O.

Flashing

The drive has not

Red

acknowledged the serial

converter module.

Solid

Link failure. • Securely connect cables.

Red

Orange Contact Rockwell Automation Technical Support.

• Securely connect cables.

• Apply power to the drive.

• Wait while Flash is in progress.

No action. Removing or resetting the serial

converter module will not cause a serial fault in the

drive.

No action. Removing or resetting the serial

converter will cause a serial fault in the drive.

• Securely connect cables.

• Verify Parameter 1 - [Adapter Cfg] is set to

“Auto.”

• Replace the cable.

• Cycle power to the drive.

RX Status Indicator

Status Cause Corrective Action

Off Serial converter module

is not receiving data.

Flashing

Serial converter module

Green

is receiving data from the

computer.

• Verify that data is being transmitted by the PC.

• Securely connect cables.

• Apply power to the drive.

• Configure the computer software to use the

same serial port rate as the converter module.

No action.

TX Status Indicator

Status Cause Corrective Action

Off Serial converter module

is not transmitting data.

Flashing

Serial converter module

Green

is transmitting data to the

computer.

• Verify that data is being transmitted.

• Securely connect cables.

• Apply power to the drive.

No action.

Page 35

Troubleshooting 5-3

Module Diagnostic Items

The following diagnostic items can be accessed using DriveExplorer

(version 3.01 or higher).

No. Name Description

1 Field Flash Cnt Number of times the module has been Field Flashed.

2 Adapter Events The number of events in the event queue.

3 Reference Current value of the Reference being transmitted to the

4 Logic Command Current value of the Logic Command being transmitted to

5 Logic Status Current value of the Logic Status being received from the

6 Feedback Current value of the Feedback being received from the

drive by this module.

the drive by this module.

drive by this module.

drive by this module.

Viewing and Clearing the Event Queue

The serial converter module has an event queue that reports the history

of its actions.

To view the event queue

1. Access the event queue using a configuration tool. Refer to the

Configuration Tools section in Chapter 3.

2. Scroll through events in the event queue. The most recent event can

be found at 2R > Event Queue 1. The “R” stands for Read Only.

Figure 5.2 Example Event Queue in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW or

RIGHT ARROW key to modify parameter values. Press

the ENTER key to save a new value.

2R> Event Queue 1 = Normal Startup

Page 36

5-4 Troubleshooting

Events

Many events in the Event queue occur under normal operation. If you

encounter unexpected communications problems, the events may help

you or Allen-Bradley personnel troubleshoot the problem. The following

events may appear in the event queue:

Code Event Description

F0 No Event No event present in the module event queue.

F1 Adapter Reset The module was reset by the user.

F2 Slave Detected Slave was detected to be present by master.

F3 Slave Removed Slave was detected to be removed by master.

F4 Host Timeout Timeout condition on Msg to Host.

F5 Slave Timeout Timeout condition on Msg to Slave.

F6 Master Timeout Timeout condition on Msg to Master.

F7 Serial Timeout Timeout on Serial 232 side (w/control enabled).

F8 Control Enabled The module has sent a “Soft Control Enable” command

F9 Control Disabled The module has sent a “Soft Control Disable”

F10 EEPROM Sum Flt Startup sequence detected corrupt EEPROM storage

To clear the event queue

to the drive.

command to the drive.

in the module.

1. Access the event queue using a configuration tool. Refer to the

Configuration Tools section in Chapter 3.

2. Set the value of 1 > Clr Event Queue to Enable, and then press

Enter to clear the event queue.

Figure 5.3 Reset Event Queue in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW or

RIGHT ARROW key to modify parameter values. Press

the ENTER key to save a new value.

1> Clr Event Queue = Enable

Page 37

Troubleshooting 5-5

Viewing and Clearing DF1 Communication Statistics

If you encounter unexpected communications problems or are creating

an application that uses DF1 data, you can view the communications

statistics in the serial converter module. Parameters 06 through 17 store

this data.

To view and clear DF1 data, you must access the main menu in the serial

converter module firmware. Refer to the Configuration Tools section in

Chapter 3

To view DF1 data

1. Access the parameters in the serial converter using a configuration

2. Scroll through the DF1 parameters. Parameters 06 through 17

Figure 5.4 Example Parameter Display in HyperTermina

l

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW or

RIGHT ARROW key to modify parameter values. Press

the ENTER key to save a new value.

.

tool. Refer to the Configuration Tools section in Chapter 3.

contain DF1 data. For a description of each parameter, refer to

Appendix B

, Serial Converter Module Parameters.

7R> DF1 Packets Sent = 0

To clear DF1 counters

1. Access the parameters in the serial converter using a configuration

tool. Refer to the Configuration Tools section in Chapter 3.

2. Set the value of Parameter 06 - [Clear DF1 Counts] to Clear

Counts, and then press Enter to clear the DF1 data.

Figure 5.5 Example Parameter Display in HyperTerminal

Press the UP ARROW or DOWN ARROW key to scroll

through the parameter list. Press the LEFT ARROW or

RIGHT ARROW key to modify parameter values. Press

the ENTER key to save a new value.

6> Clear DF1 Counts = Clear Counts

Page 38

5-6 Troubleshooting

Troubleshooting Potential Problems

Description Action

You are unable to establish a

connection between your computer

and the serial converter module.

After changing the serial port rate,

you are no longer able to

communicate with the serial

converter module and connected

drive.

For example, in HyperTerminal,

meaningless text appears on the

screen when you press Enter. In

DriveExplorer, parameter values are

not updated.

You set a new serial port rate, but the

serial converter module is still using

the old serial port rate.

No communications to the drive. • Verify cable connections.

• If the status indicators are off, connect the

cables and apply power to the drive.

• Configure your software and serial converter

module to use the same COMM port and serial

port rate (baud rate).

Reset the serial por t rate in the software.

Instructions are included here to reset the serial

port rate in HyperTerminal and DriveExplorer. If

you are using a different configuration tool, refer

to its user manual.

HyperTerminal

1. Select File > Properties, and then click

Configure.

2. Select the new baud rate, and then click OK.

3. Save and close HyperTerminal.

4. Double-click on your HyperTerminal file (*.ht)

to restart HyperTerminal.

5. Press Enter until the main menu appears.

DriveExplorer

1. Select Explore > Configure Communication.

2. Select the new baud rate. DriveExplorer

should start updating values again. If it does

not, restart DriveExplorer.

Reset the serial conveter module. Refer to

Chapter 3

, Configuring the Serial Converter

Module.

• Make sure Parameter 1 - [Adapter Cfg] is set

to “Auto.”

Page 39

Appendix A

Specifications

Appendix A presents the specifications for the serial converter module.

Topic Page Topic Page

Communications

Electrical A-1 Agency Certification A-2

Mechanical A-1

Communications

RS-232 side

Protocol

Port Rate

Data Bits

Parity

Stop Bits

Flow Control

Error

DSI Host side

Protocol

Data Rates

A-1 Environmental A-2

RS-232 Serial DF1, Full Duplex

9600, 19.2K, or 38.4K

8

None

1

None

CRC or BCC (Auto-Detected)

Drive Serial Interface (DSI)

19.2K

Electrical

Consumption 170mA at + 5V DC

The serial converter draws the required power

from the connected product. An external power

source is not required.

Mechanical

Dimensions

Height

Width

Depth

Weight 70.88 g (2.5 oz.)

103.5 mm (4.08 inches)

73.4 mm (2.89 inches)

23.6 mm (0.93 inches)

Page 40

A-2 Specifications

Environmental

Temperature

Operating

Storage

Relative Humidity 5 to 95% non-condensing

Atmosphere Important: Serial converter module must not be

Vibration

Operating

Non-Operating

Shock

Operating

Non-Operating

Agency Certification

0 to +50° C (32 to 122° F)

-40 to +85° C (-40 to 185° F)

installed in an area where the ambient

atmosphere contains volatile or corrosive gas,

vapors or dust. If the module is not going to be

installed for a period of time, it must be stored in

an area where it will not be exposed to a corrosive

atmosphere.

2.5G @5Hz-2KHz

5G @5Hz-2KHz

30 G peak acceleration, 11 (±1) ms pulse width

50 G peak acceleration, 11 (±1) ms pulse width

UL

cUL

CE

CTick AS/NZS 2064, Group 1, Class A

UL508C

CAN/CSA C22.2 No. 14-M91

EN50178 and EN61800-3

Important: For this product to be CE and CTick compliant, the shield

of the serial cable and DSI cable must be terminated as

described on Page 2-2

.

Page 41

Serial Converter Module Parameters

Appendix B provides information about the serial converter module

parameters.

Parameter List

No. Name and Description Details

01 [Adapter Cfg]

Sets the operation of the serial converter module on

DSI. Leave at “Auto” (setting) when used with software

tools.

Important: Parameter 1 - [Adapter Cfg] must be set to

“Auto” (default) for DriveExplorer to operate.

HyperTerminal can be used if Parameter 1 - [Adapter

Cfg] needs to be changed (See Using Terminal

Emulation Software).

02 [DF1 Addr Cfg]

Sets the DF1 node address for the serial converter

module. This is a decimal value.

03 [DF1 Rate Cfg]

Sets the serial port rate for the RS-232 DF1 serial port

on the serial converter module.

Important: If you change the serial port rate in the

serial converter module, you must set your software to

use the same serial port rate. The serial converter

module must be reset or power cycled before baud

rate changes take affect.

04 [Comm Flt Action]

Sets the action that the serial convertermodule and

drive take if the module detects that DF1 serial

communications are disrupted. This setting is effective

only if I/O that controls the drive is transmitted through

the serial converter module.

Default: 0 = Auto

Values: 0 = Auto

Type: Read/Write

Reset Required:

Default: 1

Minimum: 0

Maximum: 254

Type: Read/Write

Reset Required: Yes

Default: 0 = 9600

Values: 0 = 9600

Type: Read/Write

Reset Required: Yes

Default: 0 = Fault

Values: 0 = Fault

Type: Read/Write

Reset Required: No

Appendix B

1 = Master

2 = Slave

3 = RTU Master

4 = RTU Passthru

1 = 19.2K

2 = 38.4K

1 = Stop

2 = Zero Data

3 = Hold Last

ATTENTION: Risk of injury or equipment damage exists. Parameter 04 -

[Comm Flt Action] lets you determine the action of the serial converter

module and connected drive if communications are disrupted. By default,

!

this parameter faults the drive. You can set this parameter so that the drive

continues to run. Precautions should be taken to ensure that the setting of

this parameter does not create a hazard of injury or equipment damage.

Page 42

B-2 Serial Converter Module Parameters

No. Name and Description Details

05 [Reset Module]

No action if set to “Ready.” Resets the serial converter

module if set to “Reset Module.” Restores the module

to its factory-default settings if set to “Set Defaults.”

This parameter is a command. It will be reset to “0 =

Ready” after the command has been performed.

ATTENTION: Risk of injury or equipment damage exists. If the serial

converter module is transmitting I/O that controls the drive (indicated by a

solid green diamond LED), the drive may fault when you remove or reset the

!

module. Determine how your drive will respond before removing or resetting

a connected serial converter module.

06 [Clear DF1 Counts]

No action if set to “Ready.” Resets the DF1 statistical

parameters (numbers 07 – 15) to 0 if set to “Clear

Counts.” This parameter is a command. It will be reset

to “0 = Ready” after the command has been

performed.

07 [DF1 Packets Sent]

Displays the number of DF1 packets sent by the serial

converter module. The value of this parameter is

normally approximately equal to the value of

Parameter 08 - [DF1 Packets Rcvd].

08 [DF1 Packets Rcvd]

Displays the number of DF1 packets received by the

serial converter module. The value of this parameter is

normally approximately equal to the value of

Parameter 07 - [DF1 Packets Sent].

09 [Undelivered Msgs]

Displays the number of DF1 messages that were sent

but not acknowledged.

10 [ENQs Sent]

Displays the number of ENQ characters sent by the

serial converter module.

11 [ENQs Received]

Displays the number of ENQ characters received by

the serial converter module.

12 [NAKs Received]

Displays the number of NAK characters received by

the serial converter module.

13 [NAK Bad Packet]

Displays the number of NAKs sent by the serial

converter module because of corrupt packets

(improper protocol messages) as determined by the

module.

(1)

This value is normally a low value. If it is continually incrementing and you are having

communications problems, use a lower baud rate or replace the 1203-SFC serial cable.

(1)

(1)

(1)

(1)

(1)

Default: 0 = Ready

Values: 0 = Ready

Type: Read/Write

Default: 0 = Ready

Values: 0 = Ready

Type: Read/Write

Reset Required: No

Default: 0

Minimum: 0

Maximum: 4294967295

Type: Read Only

Default: 0

Minimum: 0

Maximum: 4294967295

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

1 = Reset Module

2 = Set Defaults

1 = Clear Counts

Page 43

Serial Converter Module Parameters B-3

No. Name and Description Details

14 [NAK No Memory]

Displays the number of NAKs sent by the serial

converter module because it did not have sufficient

memory to buffer the incoming messages. The module

runs out of memory if a command has not completed

and there is no place to save the new commands.

15 [Duplicate Msgs]

Displays the number of duplicate messages sent to the

serial converter module. This value contains the total

number of consecutive messages received by the

module with the same TNS (Transaction Sequence)

number.

16 [DF1 Addr Actual]

Displays the DF1 address actually used by the serial

converter module.

17 [DF1 Rate Actual]

Displays the serial port rate actually used for the DF1

serial port on the serial converter module.

(1)

(1)

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 0

Minimum: 0

Maximum: 65535

Type: Read Only

Default: 1

Minimum: 0

Maximum: 254

Type: Read Only

Default: 0 = 9600

Values: 0 = 9600

Type: Read Only

18 [Adapter Type]

Displays the present operating mode for the serial

converter module.

Default: 0 = Master

Values: 0 = Master

Type: Read Only

(1)

This value is normally a low value. If it is continually incrementing and you are having

communications problems, use a lower baud rate or replace the 1203-SFC serial cable.

1 = 19.2K

2 = 38.4K

1 = Slave

2 = RTU Master

3 = RTU Passthru

Page 44

B-4 Serial Converter Module Parameters

Notes:

Page 45

Appendix C

Flash Updates

Appendix C provides information on updating peripheral product

firmware.

Topic Page

Preparing for a Flash Update

Performing a Flash Update with

HyperTerminal

Troubleshooting Potential HyperTerminal

Flash Problems

Preparing for a Flash Update

Please take the following precautions to ensure a successful Flash:

• Obtain the new firmware version from Rockwell Automation, Inc.

Save it to the hard drive of the computer. Do not attempt to perform a

Flash from a floppy disk or a network.

C-1

C-2

C-3

• Read all instructions supplied with the new firmware file.

• Use a computer running terminal emulation software that supports

Xmodem transfers (e.g. HyperTerminal). In this manual, we show

how to use HyperTerminal.

• Record parameter values in the device that will be flashed. Updates

may reset parameters to their default settings.

• Ensure that the DSI-enabled drive (e.g. PowerFlex 4) is stopped.

• Close all programs except the terminal emulation program that you

are using to Flash the serial converter module.

• If you are using a laptop computer, turn off the FIFO buffers in

HyperTerminal. In HyperTerminal, select File > Properties to

display the Properties dialog box. Click Configure, and then click

Advanced. Ensure that a check mark does not appear next to Use

FIFO buffers.

Page 46

C-2 Flash Updates

Performing a Flash Update with HyperTerminal

1. In the main menu (Figure 3.7

The screen in Figure C.1 will immediately appear.

Figure C.1 Flash Menu

To update the Flash memory, you need a terminal

program capable of downloading a binary file using

the XMODEM protocol and a Flash update file from

Rockwell Automation. When you press 'Y' to signal

that you are ready to proceed, the terminal

program will start displaying the letter 'C'. This

signals the XMODEM protocol that the download may

proceed. You then have one minute to start the

transfer. Press CTRL-X to cancel an update started

by mistake. Are you ready to proceed? (Y/N)

ATTENTION: Risk of injury or equipment damage

exists. When you perform a Flash update, the drive will

!

fault if it is receiving control I/O from the serial converter

module. Verify that the drive has stopped safely or is

receiving control I/O from an alternate source before

beginning a Flash update.

ATTENTION: Risk of equipment damage exists. If you

interrupt a flash procedure that is updating boot code, the

!

device may become inoperable. To prevent this damage,

follow the instructions provided with the new firmware

file and do not interrupt a flash procedure while boot

code is being flashed.

), press 3 to Update Flash program.

2. If the Flash can be completed safely, type Y. The letter “C”

repeatedly appears. It is the Xmodem prompt and continues to

appear until you send a binary file.

Important: Press Ctrl + X to cancel a Flash update procedure.

3. Select Transfer > Send File to display the send file dialog box.

4. Click Browse and navigate to the Flash file.

5. Double-click the file. Its name appears in the Filename box (see

Figure C.2

).

Page 47

Flash Updates C-3

6. In the Protocol box, select Xmodem.

Figure C.2 Example Send File Dialog Box

7. Click Send. A dialog box appears and reports the progress of the

download. When it is complete, the message “Operation Complete”

appears.

Important: Keep the device powered for 15 seconds after the

operation has completed.

8. Press the Enter key to return to the main menu.

Troubleshooting Potential HyperTerminal Flash

Problems

Description Corrective Action

“Transfer Cancelled by Remote

System” message appears and the

Flash is not completed.

The “Xmodem File Send” for dialog

box appears, but the Flash file is not

transferred.

After completing a Flash, you are

unable to communicate with the serial

converter module. For example,

meaningless text appears on the

HyperTerminal screen.

• Restart HyperTerminal and repeat the Flash

procedure.

• If you are using Windows NT 4.0, install SP3

or later. Windows NT service packs are

available from the Microsoft web site:

http://www.microsoft.com.

• Download a HyperTerminal Private Edition

update from the Hilgraeve web site:

http://www.hilgraeve.com.

(Please note that there is a license

requirement with this software.) Then, perform

the Flash procedure again.

• Verify that you have selected the Xmodem

protocol in the Send file dialog box.

• Verify that the new file is on your hard disk. Do

not attempt to Flash from a floppy disk or a

network.

• Verify that you are sending the file within 60

seconds of pressing “Y” to confirm that you

want to perform the Flash.

Set the serial port rate to 9600. If parameters are

changed during a Flash update, all parameters

are set to their default settings.

Page 48

C-4 Flash Updates

Performing a Flash Update with DriveExplorer

DriveExplorer version 4.xx and higher can perform flash updates on DSI

products that use flash memory, such as the 22-SCM-232 Serial

Converter Module and 22-COMM-D DeviceNet adapter. A 22-SCM-232

(version 2.01 or higher) is required to perform the update.

DriveExplorer utilizes the same files used by ControlFlash, which can be

downloaded from www.ab.com/drives.

The following steps illustrate how to flash update a 22-SCM-232, and

can be applied to flashing other DSI products.

1. Connect the 22-SCM-232 using DriveExplorer, and select “Explore |

Device Properties …” Click on the Details tab to display the

information about the 22-SCM-232. Click on the F

button.

lash Update

2. Select the revision of firmware that you wish to update to, and click

on the Next> button.

Page 49

Flash Updates C-5

3. Confirm that this is what you want to do by clicking the FLASH button.

4. The following dialog boxes will display information about the

progress of the flash.

Page 50

C-6 Flash Updates

5. When the flash is completed, the “FLASH” button changes to

“Close” and the “Cancel” button is grayed out.

6. DriveExplorer will prompt you to reconnect since the device may

have changed its database because of the flash. Click “Yes” to

reconnect.

Page 51

Appendix D

MicroLogix 1000 Example Ladder

Program

Appendix D provides information on a MicroLogix 1000 example ladder

program. The following ladder example demonstrates:

• Writing Logic Command and Reference

• Reading Logic Status, Feedback, and additional monitor data

• Writing/reading Parameter 39 - [Accel Time 1]

Page 52

D-2 MicroLogix 1000 Example Ladder Program

Figure D.1 Example MicroLogix 1000 Ladder Logic Program

Connection:

The 22-SCM-232 connects to the front port on the MicroLogix 1000 by using a 1203-SNM Null Modem

adapter and a 1761-CBL-AP00 programming cable. The RJ45 cable on the 22-SCM-232 conencts to the

RJ45 port on the PowerFlex 4/40. The SCM provides both media (RS232 to RS485) and protocol (DF1 to

Modbus RTU) conversions.

Additional PF4/40 drives can be added. Use one AK-U0-RJ45-SC1 Splitter Cable for connecting to the

first drive, and one AK-U0-RJ45-TB2P for every drive. The "Local Node Address" in the MSG instruction

indentifies the drive node to communicate with.

PF4 Parameters: 22-SCM-232 parameters:

36 [Start Source] = 5 (Comm Port) 1[Adapter Cfg] = RTU Master

38 [Speed Reference] = 5 (Comm Port) 2[DF1 Addr Cfg] = 1 (this MUST equal Parameter 104 of the PF

4/40 it is connected to)

103 [Comm Data Rate] = 4 (19.2K) 3 [DF1 Rate Cfg] = 19.2k bps

104 [Comm Node Addr] = 1

107 [Comm Format] = 0 (RTU 8-N-1)

For the PowerFlex 4/40 drives, 19.2K and 8-N-1 are a requirement and can not be changed. The data rate

of the controller and SCM MUST be equal to each other, but can be set faster or slower than the drives

baud rate if desired. It is recommended that 19.2K be used for ALL serial connections (controller, SCM,

and drives) to be consistent and to avoid any errors.

This rung clears the read data area (N7:10-19) on the first program scan (N7:0 = a constant 0) and starts the

messaging process by clearing the EN bit of the first MSG instruction.

0000

This rung sets the timeout value for the first MSG instruction.

0001

MicroLogix 1000 communications to a PowerFlex 4/40 using a 22-SCM-232

First Pass

S:1

15

Logic Status

Enable

(EN)

N7:50

15

Error

(ER)

N7:50

12

Done

(DN)

N7:50

13

MSG #1

Time Out

Timer

TON

TON

Timer On Delay

Timer T4:0

Time Base 0.01

Preset 200<

Accum 0<

COP

COP

Copy File

Source #N7:0

Dest #N7:10

Length 10

Enable

(EN)

N7:50

U

15

EN

DN

MSG #1

Time Out

Timer

T4:0

DN

Time Out

(TO)

N7:50

L

8

Page 53

MicroLogix 1000 Example Ladder Program D-3

Figure D.1 Example MicroLogix 1000 Ladder Logic Program (Continued)

This rung sets the timeout value for the second MSG instruction.

Enable

(EN)

0002

0003

0004

N7:60

This rung sets the timeout value for the third MSG instruction.

Enable

(EN)

N7:70

This rung sets the timeout value for the fourth MSG instruction.

Enable

(EN)

N7:80

Error

(ER)

N7:60

15

Error

(ER)

N7:70

15

Error

(ER)

N7:80

15

Done

(DN)

N7:60

12

12

12

13

Done

(DN)

N7:70

13

Done

(DN)

N7:80

13

MSG #2

Time Out

Timer

TON

TON

Timer On Delay

Timer T4:1

Time Base 0.01

Preset 200<

Accum 0<

MSG #2

Time Out

Timer

T4:1

DN

MSG #3

Time Out

Timer

TON

TON

Timer On Delay

Timer T4:2

Time Base 0.01

Preset 200<

Accum 0<

MSG #3

Time Out

Timer

T4:2

DN

MSG #4

Time Out

Timer

TON

TON

Timer On Delay

Timer T4:3

Time Base 0.01

Preset 200<

Accum 0<

EN

DN

Time Out

(TO)

N7:60

L

8

EN

DN

Time Out

(TO)

N7:70

L

8

EN

DN

MSG #4

Time Out

Timer

T4:3

DN

Time Out

(TO)

N7:80

L

8

Page 54

D-4 MicroLogix 1000 Example Ladder Program

Figure D.1 Example MicroLogix 1000 Ladder Logic Program (Continued)

Messages must be interlocked and queued to run one at a time. In this example, (4) MSG's are used:

MSG #1 Writes Logic Command and Reference continuously

MSG #2 Reads a block of data, including Logic Status and Feedback, continuously

MSG #3 Writes Parameter 39 [Accel Time 1] on demand (one time per request)

MSG #4 Reads Parameter 39 [Accel Time 1] on demand (one time per request)

Write the Logic Command (N182:192) and Reference (N192:193) to the drive.

First Pass

0005

0006

0007

S:1

15

After the previous MSG is complete, this MSG reads a block of data (starting at N183:198) containing:

N7:10 Logic Status (N183:198)

N7:11 Drive Error Code (N183:199)

N7:12 Frequency Command (= Reference) (N183:200)

N7:13 Output Frequency (Feedback) (N183:201)

N7:14 Output Current (N183:202)

N7:15 DC Bus Voltage (N183:203)

N7:16 Output Voltage (N183:204)

Done

(DN)

N7:50

13

Error

(ER)

N7:50

12

If a write is requested elsewhere in the user program (B3:0/0) and the previous MSG is complete, this MSG

will write a value to Parameter 39 - [Accel Time 1]. Uses N150:x addressing, where 'x' equals the

parameter number.

Note: A parameter write causes an EEPROM write cycle on the drive. Do not develop a ladder program

that will perform frequent writes.

Pr. 39

Write

Request

B3:0

0

Done

(DN)

N7:60

13

Error

(ER)

N7:60

12

MSG

MSG

Read/Write Message

Read/Write Write

Target Device 500CPU

Control Block N7:50

Control Block Length 7

Setup Screen

MSG

MSG

Read/Write Message

Read/Write Read

Target Device 500CPU

Control Block N7:60

Control Block Length 7

Setup Screen

MSG

MSG

Read/Write Message

Read/Write Write

Target Device 500CPU

Control Block N7:70

Control Block Length 7

Setup Screen

EN

DN

ER

EN

DN

ER

EN

DN

ER

Page 55

MicroLogix 1000 Example Ladder Program D-5

Figure D.1 Example MicroLogix 1000 Ladder Logic Program (Continued)

If a read is requested elsewhere in the user program (B3:0/1) and the previous MSG is complete, this MSG

will read Parameter 39 - [Accel Time 1]. Uses N150:x addressing, where 'x' equals the parameter number.

0008

Pr. 39

Read

Request

B3:0

1

Pr. 39

Write

Request

B3:0

0

Pr. 39

Write

Request

B3:0

0

Done

(DN)

N7:70

13

Error

(ER)

N7:70

12

Done

(DN)

N7:60

13

Error

(ER)

N7:60

12

MSG

MSG

Read/Write Message

Read/Write Read

Target Device 500CPU

Control Block N7:80

Control Block Length 7

Setup Screen

EN

DN

ER

Page 56

D-6 MicroLogix 1000 Example Ladder Program

Figure D.1 Example MicroLogix 1000 Ladder Logic Program (Continued)

This rung resets all MSG instructions when the last MSG instruction has completed. Since the Parameter

39 Write and Read MSG's are on demand and not continuous, the "last" MSG in the sequence can vary.

The Write (B3:0/0) and Read (B3:0/1) requests are also reset. This prevents these MSG's from operating

continuously while providing feedback to the user program that they have completed.

0009

Pr. 39

Write

Request

B3:0

Pr. 39

Read

Request

B3:0

0

1

Done

(DN)

N7:60

13

Error

(ER)

N7:60

12

Pr. 39

Write

Request

B3:0

0

Done

(DN)

N7:80

13

Error

(ER)

N7:80

12

Pr. 39

Read

Request

B3:0

1

Done

(DN)

N7:70

13

Error

(ER)

N7:70

12

Enable

(EN)

N7:50

U

15

Page 57

MicroLogix 1000 Example Ladder Program D-7

Figure D.1 Example MicroLogix 1000 Ladder Logic Program (Continued)

Enable

(EN)

N7:60

U

15

Enable

(EN)

N7:70

U

15

Enable

(EN)

N7:80

U

15

Pr. 39

Write

Request

B3:0

U

0

Pr. 39

Read

Request

B3:0

U

1

0010

END

Page 58

D-8 MicroLogix 1000 Example Ladder Program

The data table used by the example ladder program is explained below:

Figure D.2 MicroLogix 1000 Ladder Example Data Table Values

N7:

Address

0 Constant “0” 0 Fixed to “0” and used to clear

10 Logic Status 1567 See Logic Status bit

11 Drive Error Code 0 No errors

12 Commanded Frequency 222 22.2 Hz

13 Output Frequency (feedback) 1 0.1 Hz

14 Output Current 1 0.01 A

15 DC Bus Voltage 3235 323.5 V

16 Output Voltage 118 11.8 V

20 Logic Command 18 See Logic Command bit

21 Reference 222 22.2 Hz

30 Pr. 39 - [Accel Time 1] Write Value 100 10.0 Seconds

31 Pr. 39 - [Accel Time 1] Read Value 100 10.0 Seconds

Name Example

Val ue

(decimal)

Example Value Description

read data on the first scan of

the ladder program

descriptions (Appendix I)

descriptions (Appendix I)

The following screens (Figure D.3 to Figure D.6) provide details of the

MSG instructions used in the ladder example:

Page 59

MicroLogix 1000 Example Ladder Program D-9

Figure D.3 Rung 5 Logic Command/Reference Write Message

Figure D.4 Rung 6 Logic Status/Feedback/Other Monitor Data Read Message

Page 60

D-10 MicroLogix 1000 Example Ladder Program

Figure D.5 Rung 7 Parameter 39 - [Accel Time 1] Write Message

Figure D.6 Rung 8 Parameter 39 - [Accel Time 1] Read Message

Page 61

Appendix E

MicroLogix 1200/1500 Example

Ladder Program

Appendix E provides information on a MicroLogix 1200/1500 example

ladder program. The following ladder example demonstrates:

• Writing Logic Command and Reference

• Reading Logic Status, Feedback, and additional monitor data

• Writing/reading Parameter 39 - [Accel Time 1]

The example ladder program is for a MicroLogix 1500, but can also be

applied to the MicroLogix 1200.

Page 62

E-2 MicroLogix 1200/1500 Example Ladder Program

Figure E.1 Example MicroLogix 1200/1500 Ladder Logic Program

MicroLogix 1500 (LRP) communications to a PowerFlex 4/40 using a 22-SCM-232

Connection:

The 22-SCM-232 connects directly to Channel 1 on the LRP (DB9 connector) and the RJ45 port on the

PowerFlex 4/40. It provides both media (RS232 to RS485) and protocol (DF1 to Modbus RTU)

conversions.

Additional PF4/40 drives can be added. Use one AK-U0-RJ45-SC1 Splitter Cable for connecting to the

first drive, and one AK-U0-RJ45-TB2P for every drive. The "Local Node Address" in the MSG instruction

indicates the drive node to communicate with.

PF4 Parameters: 22-SCM-232 Parameters:

36 [Start Source] = 5 (Comm Port) 1 [Adapter Cfg] = RTU Master

38 [Speed Reference] = 5 (Comm Port) 2 [DF1 Addr Cfg] = 1 (this MUST equal Parameter 104 of the

PF4/40 it is connected to)

103 [Comm Data Rate] = 4 (19.2K) 3 [DF1 Rate Cfg] = 19.2k bps