Page 1

Adjustable Frequency AC Drive

Drehzahlveränderbarer Frequenzumrichter

Variateur de vitesse c.a.

Inverter CA a frequenza variabile

Variador de Frecuencia Ajustable de CA

AC Drive

Inversor CA de Freqüência Ajustável

FRN 5.xx - 6.xx

Quick Start

Kurzanleitung

Guide de mise en route

Avviamento rapido

Inicio rápido

Snel aan de slag

Início rápido

www.abpowerflex.com

Page 2

Page 3

Quick Start

PowerFlex 40 Adjustable

Frequency AC Drive

FRN 5.xx - 6.xx

This Quick Start guide summarizes the basic steps needed to install,

start-up and program the PowerFlex 40 Adjustable Frequency AC Drive.

The information provided Does Not

intended for qualified drive service personnel only.

For detailed PowerFlex 40 information including EMC instructions,

application considerations and related precautions, refer to the

PowerFlex 40 User Manual, Publication 22B-UM001… at

www.rockwellautomation.com/literature.

General Precautions

ATTENTION: The drive contains high voltage capacitors which take

time to discharge after removal of mains supply. Before working on

!

drive, ensure isolation of mains supply from line inputs [R, S, T (L1,

L2, L3)]. Wait three minutes for capacitors to discharge to safe voltage

levels. Failure to do so may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.

ATTENTION: Equipment damage and/or personal injury may result

if parameter A092 [Auto Rstrt Tries] or A094 [Start At PowerUp] is

!

used in an inappropriate application. Do not use this function without

considering applicable local, national and international codes,

standards, regulations or industry guidelines.

replace the User Manual and is

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up and subsequent maintenance of the

system. Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

!

errors, such as, undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

Page 4

English-2

Mounting Considerations

• Mount the drive upright on a flat, vertical and level surface.

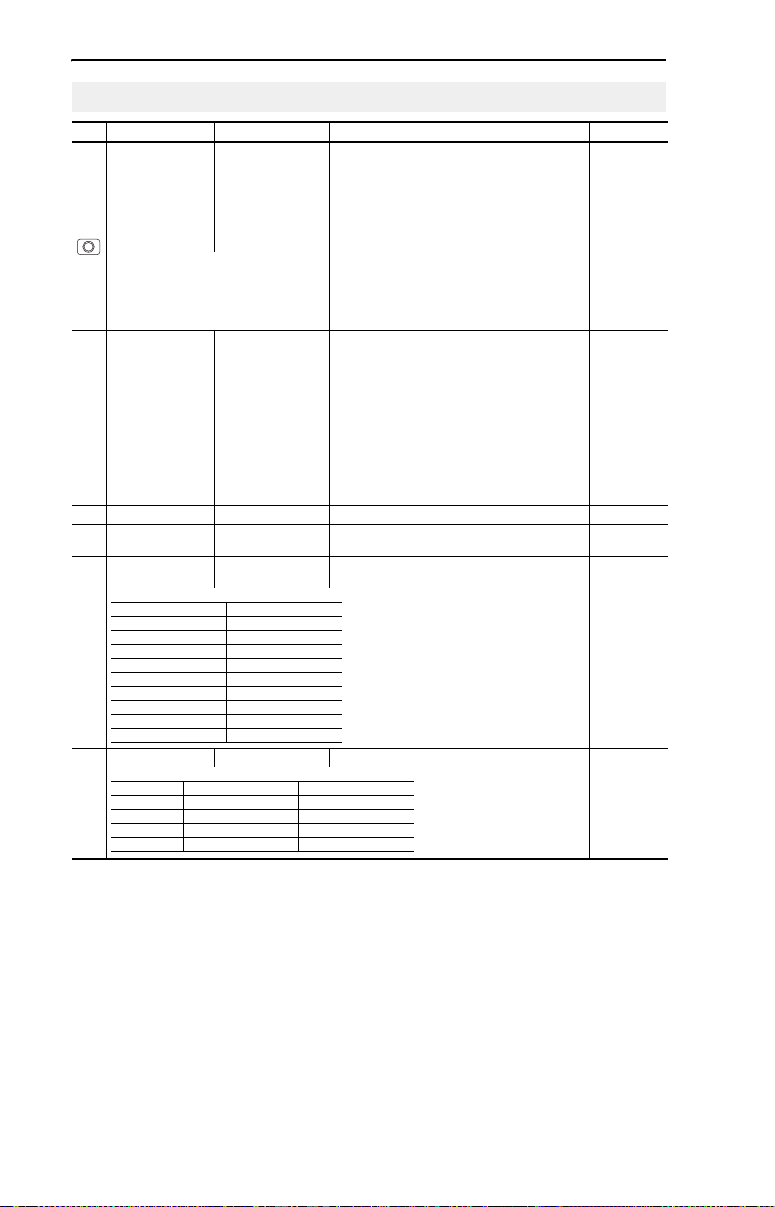

Frame Screw Size Screw Torque DIN Rail

B M4 (#8-32) 1.56-1.96 N-m (14-17 lb.-in.) 35 mm

C M5 (#10-24) 2.45-2.94 N-m (22-26 lb.-in.) –

B (IP66,

Type 4X)

• Protect the cooling fan by avoiding dust or metallic particles.

• Do not expose to a corrosive atmosphere.

• Protect from moisture and direct sunlight.

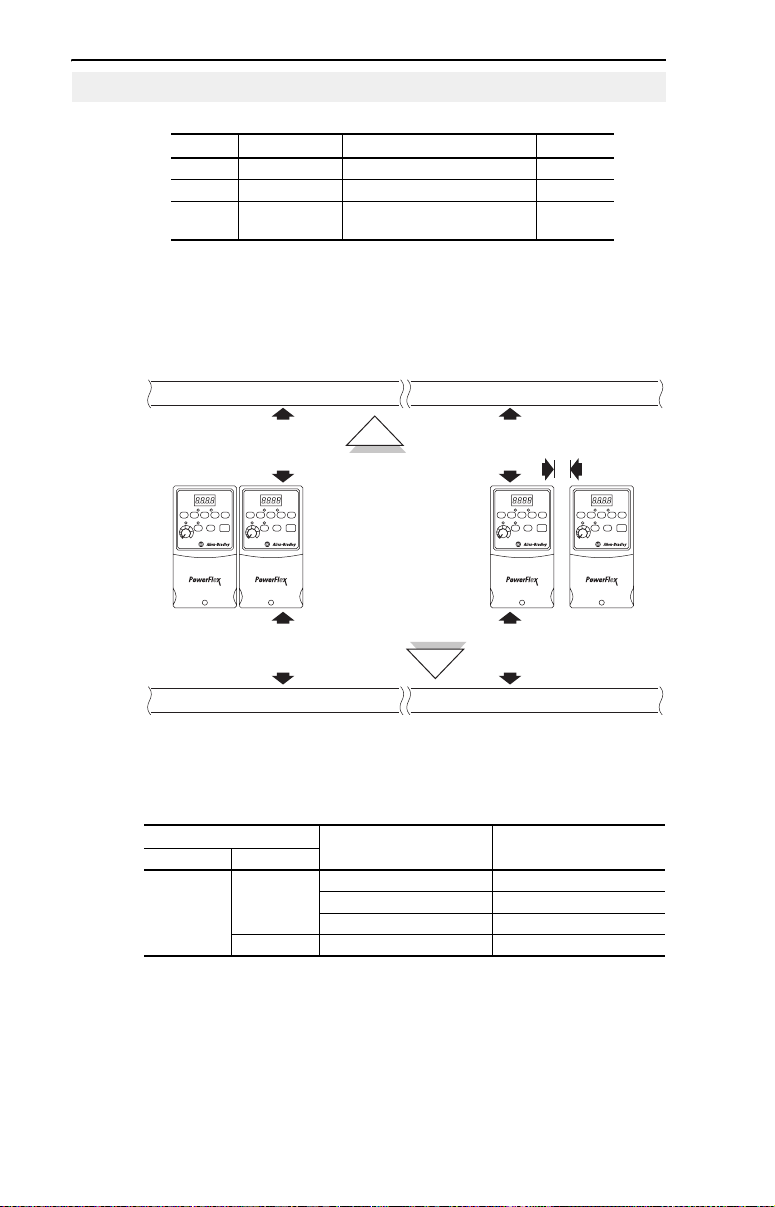

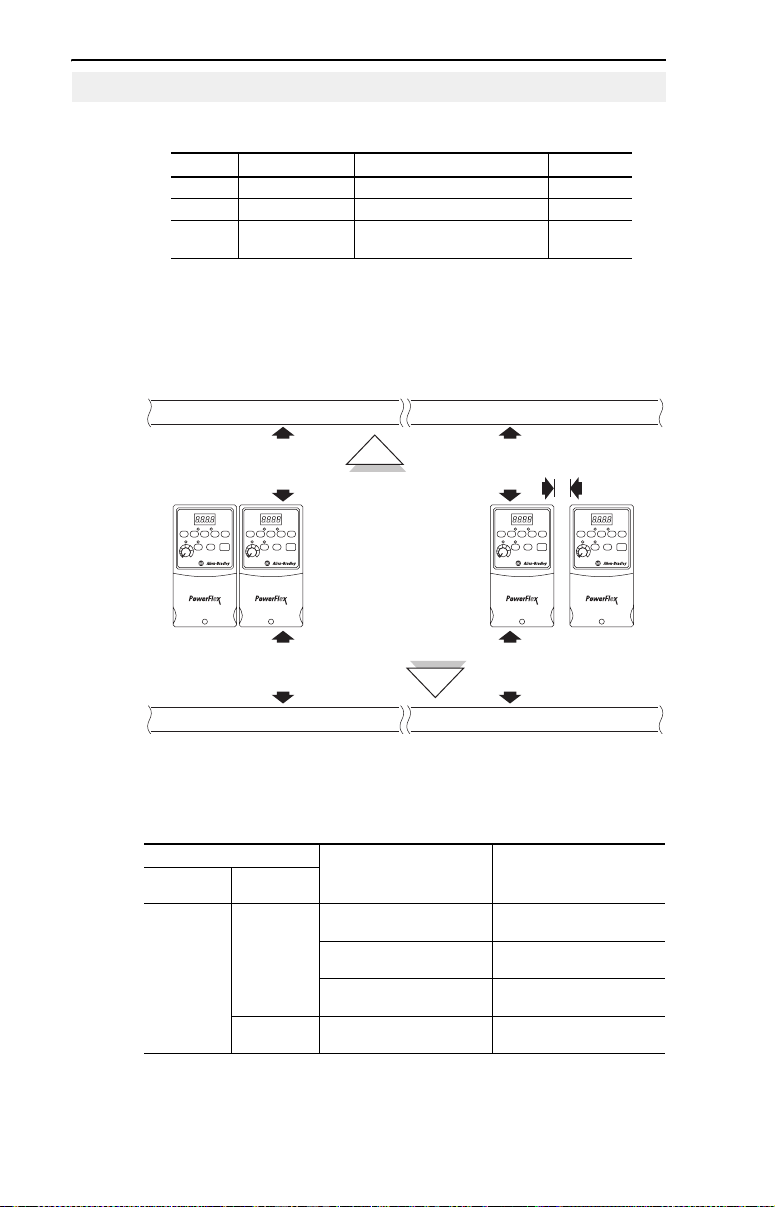

Minimum Mounting Clearances

See Page 21 for mounting dimensions.

M6 (#12-24) 3.95-4.75 N-m (35-42 lb.-in.) –

120 mm

(4.7 in.)

120 mm

(4.7 in.)

25 mm

(1.0 in.)

Closest object that

may restrict air flow

through the drive heat

sink and chassis

120 mm

(4.7 in.)

Mounting Option A

No clearance required

between drives.

120 mm

(4.7 in.)

Mounting Option B

Ambient Operating Temperatures

Ambient Temperature Enclosure Rating Minimum Mounting

Minimum Maximum

IP20, NEMA/UL Type Open Use Mounting Option A

-10°C (14°F)

40°C (104°F)

IP66, NEMA/UL Type 4X Use Mounting Option A

IP30, NEMA/UL Type 1

50°C (122°F) IP20, NEMA/UL Type Open Use Mounting Option B

(1)

Rating requires installation of the PowerFlex 40 IP 30, NEMA/UL Type 1 option kit.

Clearances

(1)

Use Mounting Option B

Page 5

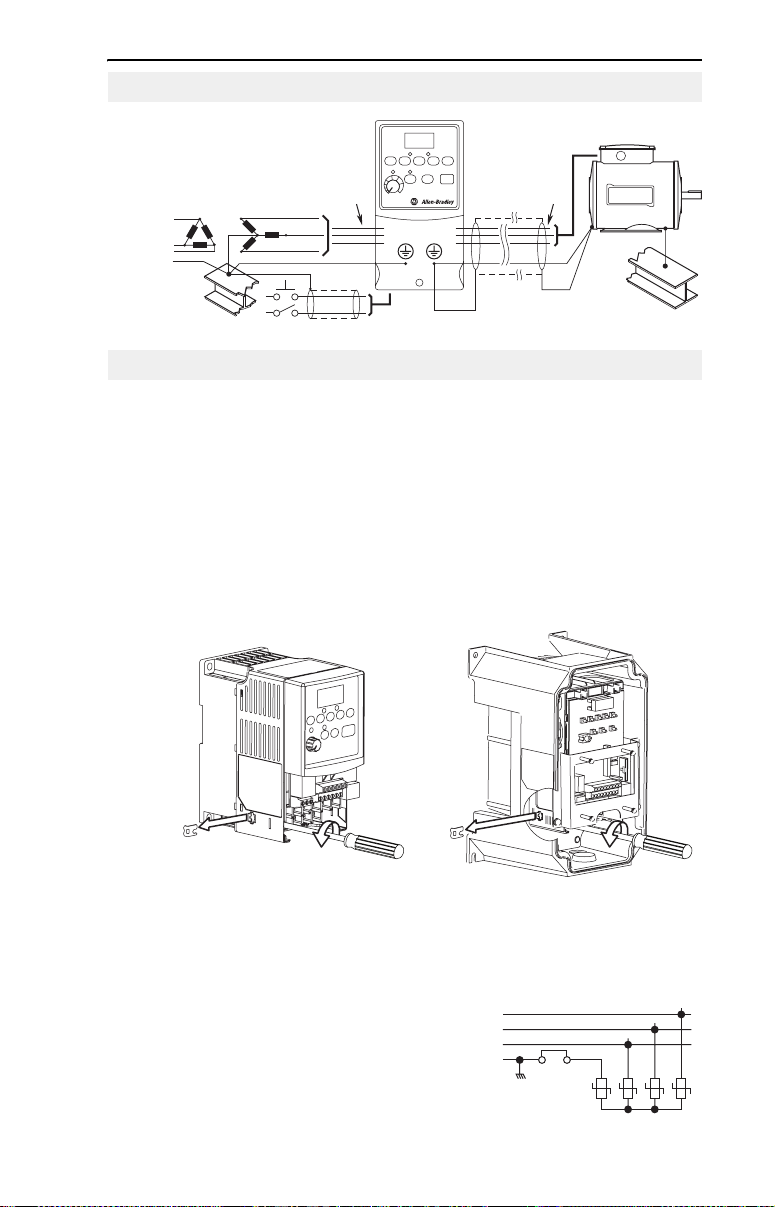

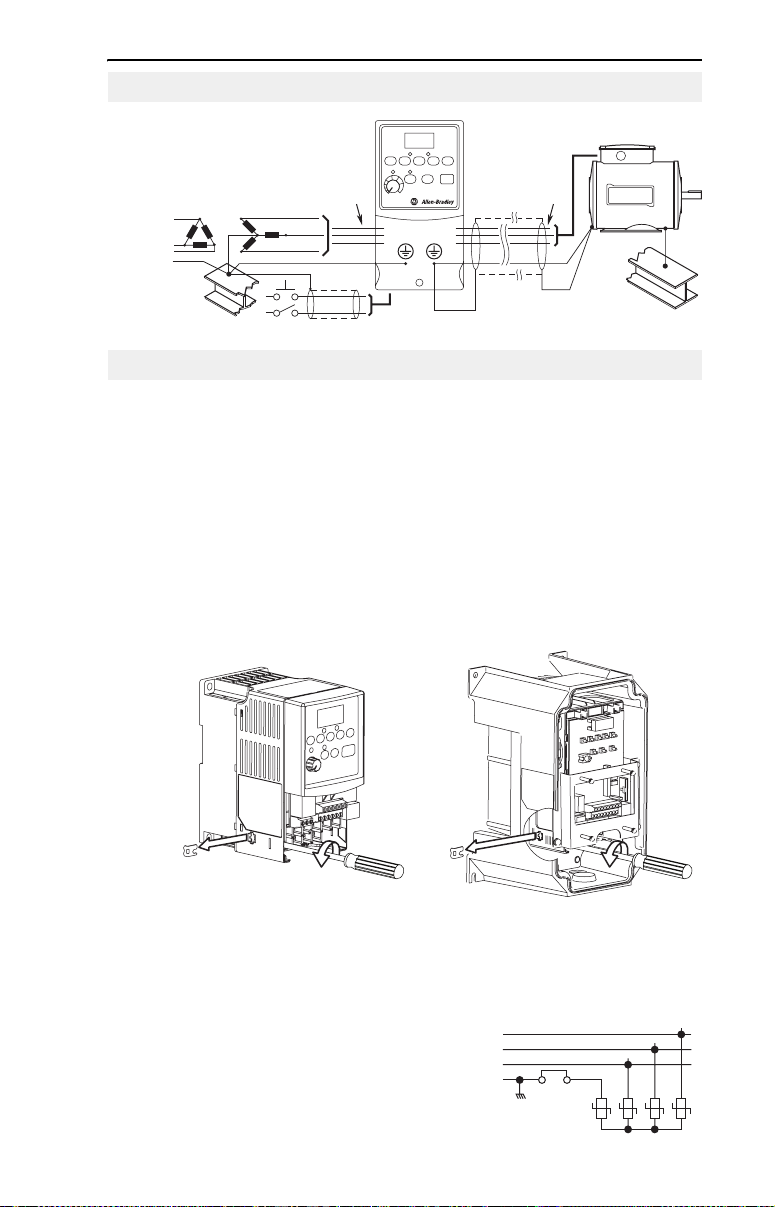

Typical Grounding

English-3

R/L1

S/L2

T/L3

SHLD

U/T1

V/T2

W/T3

Disconnecting MOVs

To prevent drive damage, the MOVs connected to ground shall be

disconnected if the drive is installed on an ungrounded distribution

system where the line-to-ground voltages on any phase could exceed

125% of the nominal line-to-line voltage. To disconnect these devices,

remove the jumper shown in the figures below.

1. Turn the screw counterclockwise to loosen.

2. Pull the jumper completely out of the drive chassis.

3. Tighten the screw to keep it in place.

Jumper Location

IP66, NEMA/UL Type 4XIP20, NEMA/UL Type Open

Important: Tighten screw after jumper removal.

Phase to Ground MOV Removal

AC Input

R/L1

S/L2

T/L3

Three-Phase

Jumper

123

4

Page 6

English-4

CE Conformity

Refer to the PowerFlex 40 User Manual for details on how to comply

with the Low Voltage (LV) and Electromagnetic Compatibility (EMC)

Directives.

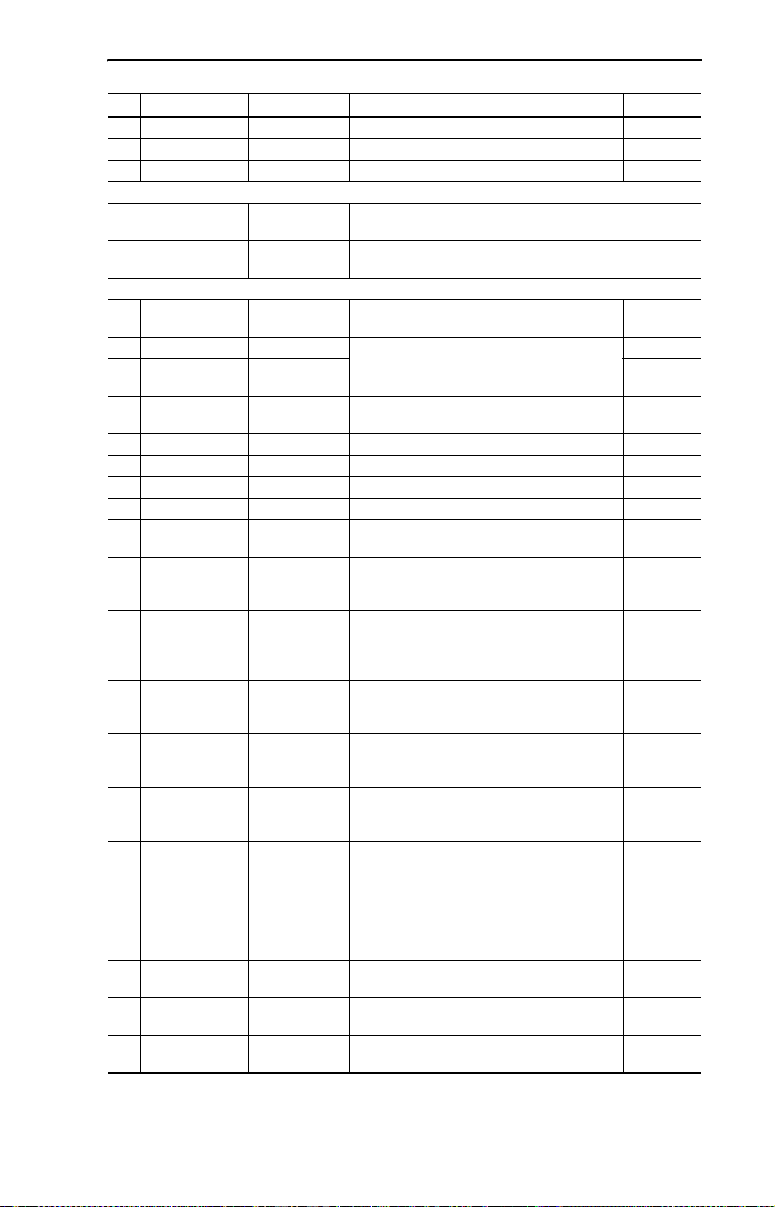

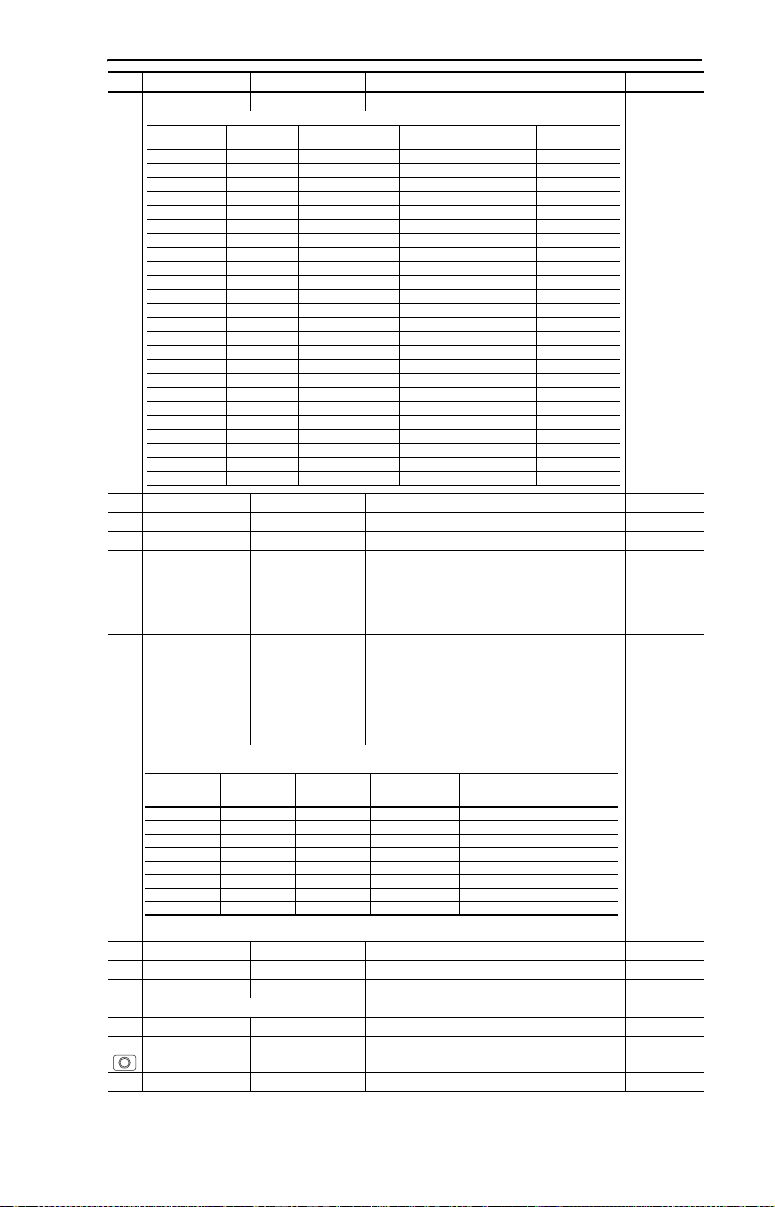

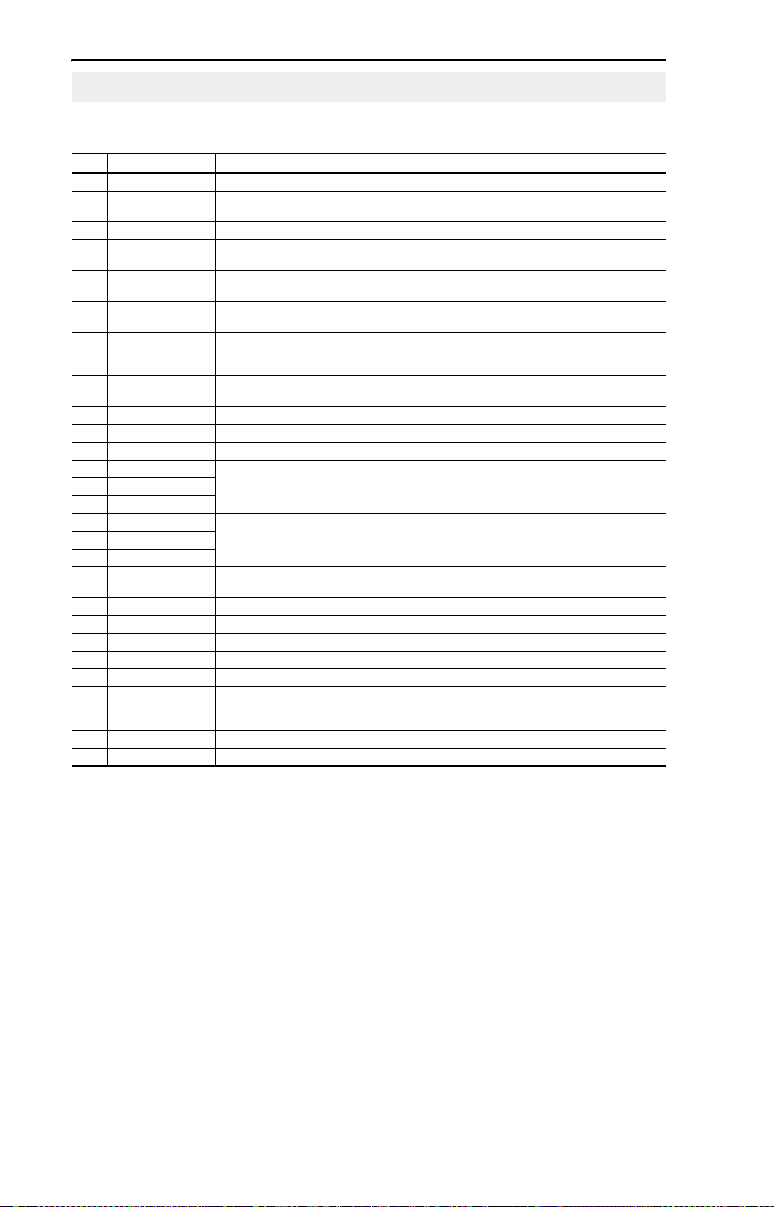

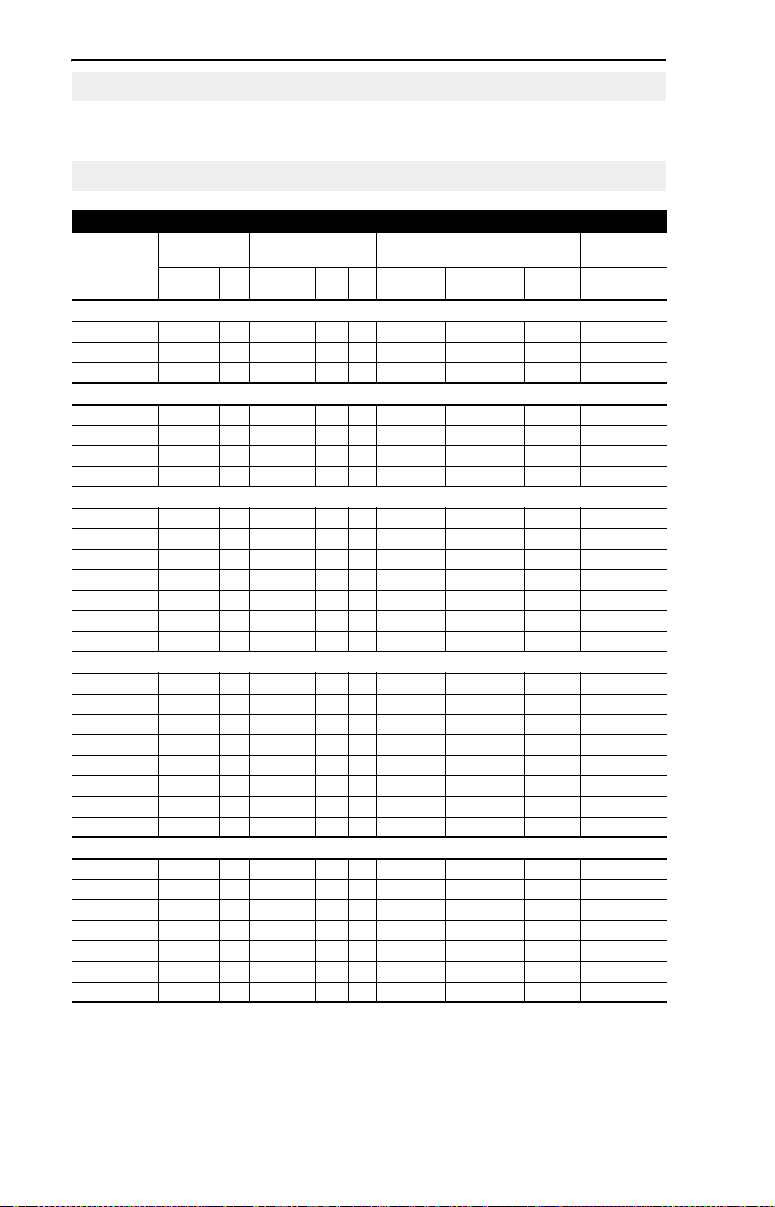

Specifications, Fuses and Circuit Breakers

Drive Ratings

Catalog

Number

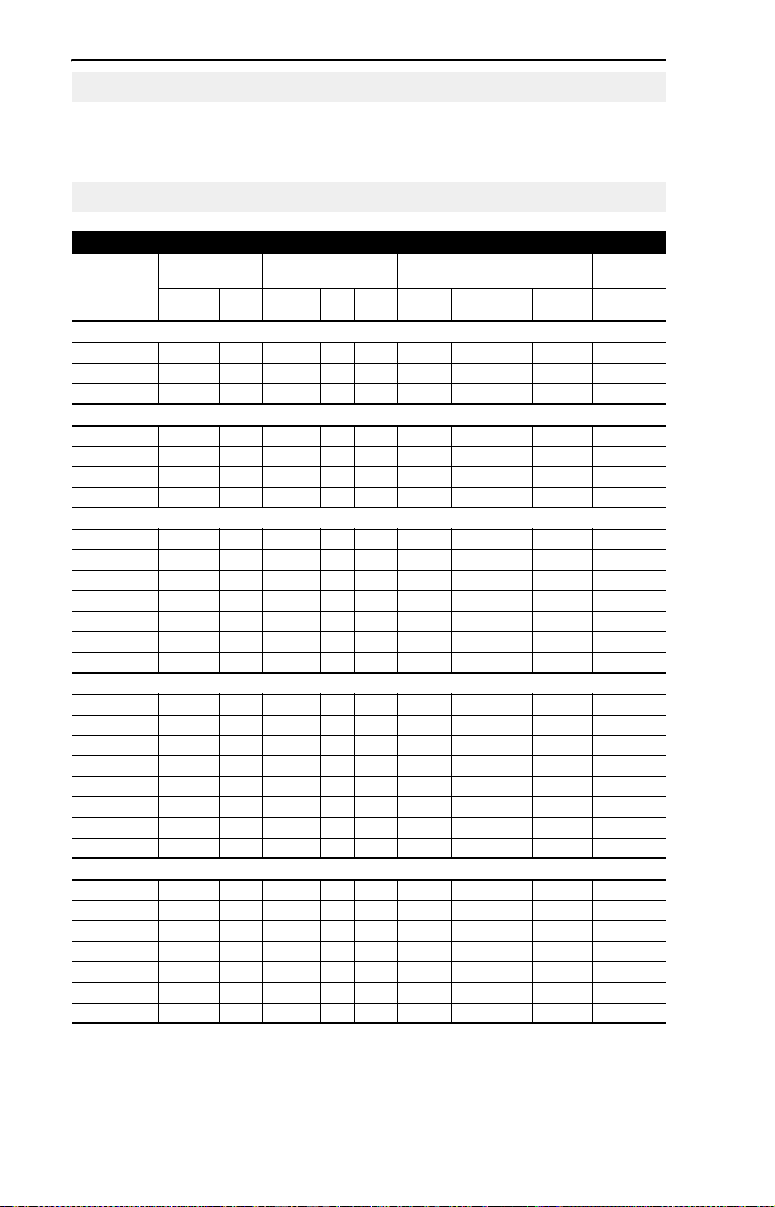

100 - 120V AC (±10%) – 1-Phase Input, 0 - 230V 3-Phase Output

22B-V2P3x104 0.4 (0.5) 2.3 90-132 1.15 9.0 15 140M-C2E-C16 100-C12 40

22B-V5P0x104 0.75 (1.0) 5.0 90-132 2.45 20.3 35 140M-D8E-C20 100-C23 60

22B-V6P0x104 1.1 (1.5) 6.0 90-132 3.0 24.0 40 140M-F8E-C32 100-C37 80

200 - 240V AC (±10%) – 1-Phase

22B-A2P3x104 0.4 (0.5) 2.3 180-264 1.15 6.0 10 140M-C2E-B63 100-C09 40

22B-A5P0x104 0.75 (1.0) 5.0 180-264 2.45 12.0 20 140M-C2E-C16 100-C12 60

22B-A8P0x104 1.5 (2.0) 8.0 180-264 4.0 18.0 30 140M-D8E-C20 100-C23 85

22B-A012x104 2.2 (3.0) 12.0 180-264 5.5 25.0 40 140M-F8E-C32 100-C37 125

200 - 240V AC (±10%) – 3-Phase Input, 0 - 230V 3-Phase Output

22B-B2P3x104 0.4 (0.5) 2.3 180-264 1.15 2.5 6 140M-C2E-B40 100-C07 40

22B-B5P0x104 0.75 (1.0) 5.0 180-264 2.45 5.7 10 140M-C2E-C10 100-C09 60

22B-B8P0x104 1.5 (2.0) 8.0 180-264 4.0 9.5 15 140M-C2E-C16 100-C12 85

22B-B012x104 2.2 (3.0) 12.0 180-264 5.5 15.5 25 140M-C2E-C16 100-C23 125

22B-B017x104 3.7 (5.0) 17.5 180-264 8.6 21.0 30 140M-F8E-C25 100-C23 180

22B-B024x104 5.5 (7.5) 24.0 180-264 11.8 26.1 40 140M-F8E-C32 100-C37 235

22B-B033x104 7.5 (10.0) 33.0 180-264 16.3 34.6 60 140M-G8E-C45 100-C60 305

380 - 480V AC (±10%) – 3-Phase Input, 0 - 460V 3-Phase Output

22B-D1P4x104 0.4 (0.5) 1.4 342-528 1.4 1.8 3 140M-C2E-B25 100-C07 35

22B-D2P3x104 0.75 (1.0) 2.3 342-528 2.3 3.2 6 140M-C2E-B40 100-C07 50

22B-D4P0x104 1.5 (2.0) 4.0 342-528 4.0 5.7 10 140M-C2E-B63 100-C09 70

22B-D6P0x104 2.2 (3.0) 6.0 342-528 5.9 7.5 15 140M-C2E-C10 100-C09 100

22B-D010x104 4.0 (5.0) 10.5 342-528 10.3 13.0 20 140M-C2E-C16 100-C23 160

22B-D012x104 5.5 (7.5) 12.0 342-528 11.8 14.2 25 140M-D8E-C20 100-C23 175

22B-D017x104 7.5 (10.0) 17.0 342-528 16.8 18.4 30 140M-D8E-C20 100-C23 210

22B-D024x104 11.0 (15.0) 24.0 342-528 23.4 26.0 50 140M-F8E-C32 100-C43 300

460 - 600V AC (±10%) – 3-Phase Input, 0 - 575V 3-Phase Output

22B-E1P7x104 0.75 (1.0) 1.7 414-660 2.1 2.3 6 140M-C2E-B25 100-C09 50

22B-E3P0x104 1.5 (2.0) 3.0 414-660 3.65 3.8 6 140M-C2E-B40 100-C09 70

22B-E4P2x104 2.2 (3.0) 4.2 414-660 5.2 5.3 10 140M-C2E-B63 100-C09 100

22B-E6P6x104 4.0 (5.0) 6.6 414-660 8.1 8.3 15 140M-C2E-C10 100-C09 160

22B-E9P9x104 5.5 (7.5) 9.9 414-660 12.1 11.2 20 140M-C2E-C16 100-C16 175

22B-E012x104 7.5 (10.0) 12.2 414-660 14.9 13.7 25 140M-C2E-C16 100-C23 210

22B-E019x104 11.0 (15.0) 19.0 414-660 23.1 24.1 40 140M-D8E-C25 100-C30 300

(1)

In the Catalog Numbers listed “x” represents enclosure type. Specifications are valid for all

enclosure types. IP66, NEMA/UL Type 4X drive ratings are only available as Frame B drives.

(2)

200-240V AC - 1-Phase drives are also available with an integral EMC filter. Catalog suffix

changes from N104 to N114. Filter option is not available for IP66, NEMA/UL Type 4X rated drives.

Output Ratings Input Ratings Branch Circuit Protection

(1)

kW (HP) Amps

Voltage

Range kVA Amps Fuses

(2)

Input, 0 - 230V 3-Phase Output

140M Motor

Protectors Contactors

Power

Dissipation

IP20 Open

Watt s

Page 7

English-5

Input/Output Ratings

Output Frequency: 0-400 Hz (Programmable)

Efficiency: 97.5% (Typical)

Approvals

D

9

E

6

T

6

S

X

I

L

U

UL508C

L

®

I

N

Q

D

E

C

T

O

N

D

9

E

6

T

6

S

X

I

L

U

CSA 22.2

L

C

®

I

N

Q

D

E

C

T

O

N

EMC Directive 89/336

LV: EN 50178, EN 60204

EMC: EN 61800-3, EN 50081-1, EN 50082-2

Digital Control Inputs (Input Current = 6mA) Analog Control Inputs

SRC (Source) Mode:

18-24V = ON

0-6V = OFF

SNK (Sink) Mode:

0-6V = ON

18-24V = OFF

4-20mA Analog: 250 ohm input impedance

0-10V DC Analog: 100k ohm input impedance

External Pot: 1-10k ohms, 2 Watt minimum

Control Output

Programmable Output (form C relay)

Resistive Rating: 3.0A at 30V DC, 3.0A at 125V AC, 3.0A at 240V AC

Inductive Rating: 0.5A at 30V DC, 0.5A at 125V AC, 0.5A at 240V AC

Opto Outputs

30V DC, 50mA

Non-inductive

Analog Outputs (10 bit)

0-10V, 1k ohm Min.

4-20mA, 525 ohm Max.

Fuses and Circuit Breakers

Recommended Fuse Type: UL Class J, CC, T or Type BS88; 600V (550V) or equivalent.

Recommended Circuit Breakers: HMCP circuit breakers or equivalent.

Protective Features

Motor Protection: I2t overload protection - 150% for 60 Secs, 200% for 3 Secs (Provides Class 10 protection)

Overcurrent: 200% hardware limit, 300% instantaneous fault

Over Voltage: 100-120V AC Input – Trip occurs at 405V DC bus voltage (equivalent to 150V AC incoming line)

Under Voltage: 100-120V AC Input – Trip occurs at 210V DC bus voltage (equivalent to 75V AC incoming line)

200-240V AC Input – Trip occurs at 405V DC bus voltage (equivalent to 290V AC incoming line)

380-460V AC Input – Trip occurs at 810V DC bus voltage (equivalent to 575V AC incoming line)

460-600V AC Input – Trip occurs at 1005V DC bus voltage (equivalent to 711V AC incoming line)

200-240V AC Input – Trip occurs at 210V DC bus voltage (equivalent to 150V AC incoming line)

380-480V AC Input – Trip occurs at 390V DC bus voltage (equivalent to 275V AC incoming line)

460-600V AC Input – If P042 = 3 “High Voltage” trip occurs at 487V DC bus voltage (344V AC incoming line);

If P042 = 2 “Low Voltage” trip occurs at 390V DC bus voltage (275V AC incoming line)

Control Ride Through: Minimum ride through is 0.5 Secs - typical value 2 Secs

Faultless Power Ride Through: 100 milliseconds

Dynamic Braking

Internal brake IGBT included with all ratings except No Brake versions. Refer to Appendix B of the PowerFlex 40 User Manual

for DB resistor ordering information.

Page 8

English-6

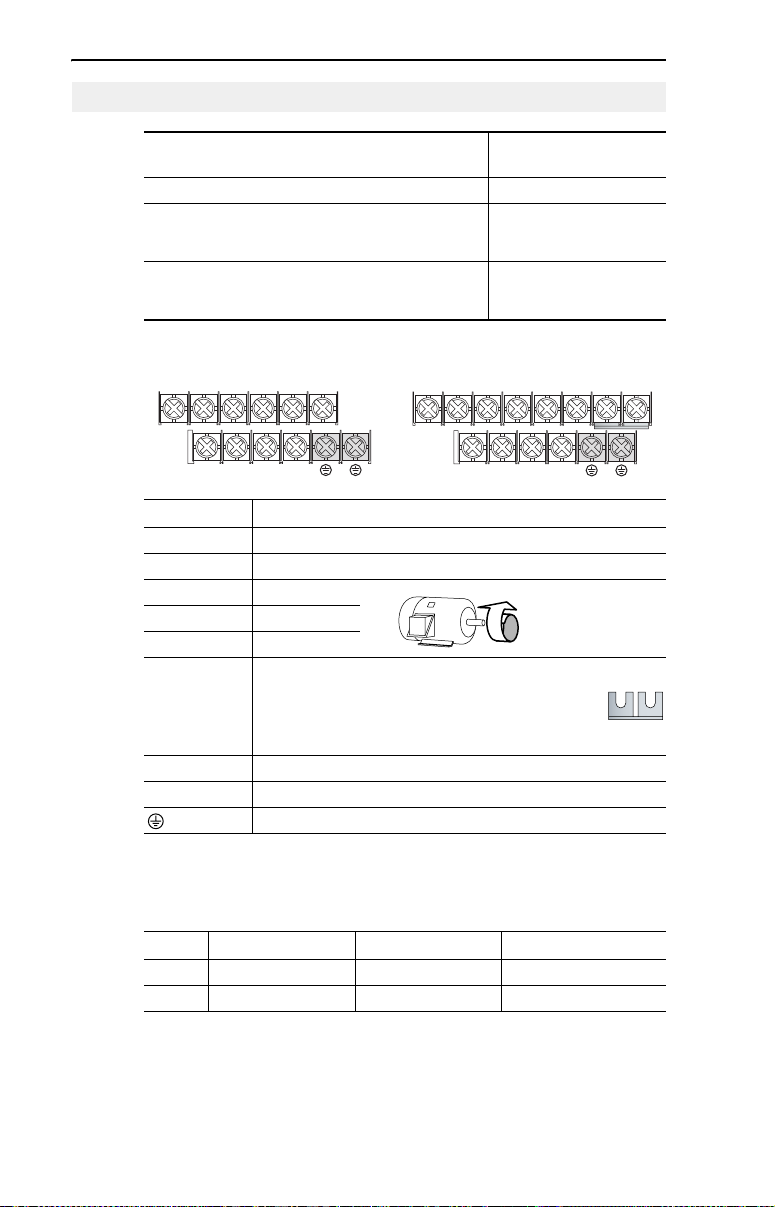

Power Wiring

Power Wire Rating Recommended Copper

Wire

Unshielded 600V, 75°C (167°F) THHN/THWN 15 Mils insulated, dry location

Shielded 600V, 75°C or 90°C (167°F or 194°F) RHH/

RHW-2

Shielded Tray rated 600V, 75°C or 90°C (167°F or 194°F)

RHH/RHW-2

Anixter OLF-7xxxxx,

Belden 29501-29507 or

equivalent

Anixter 7V-7xxxx-3G

Shawflex 2ACD/3ACD or

equivalent

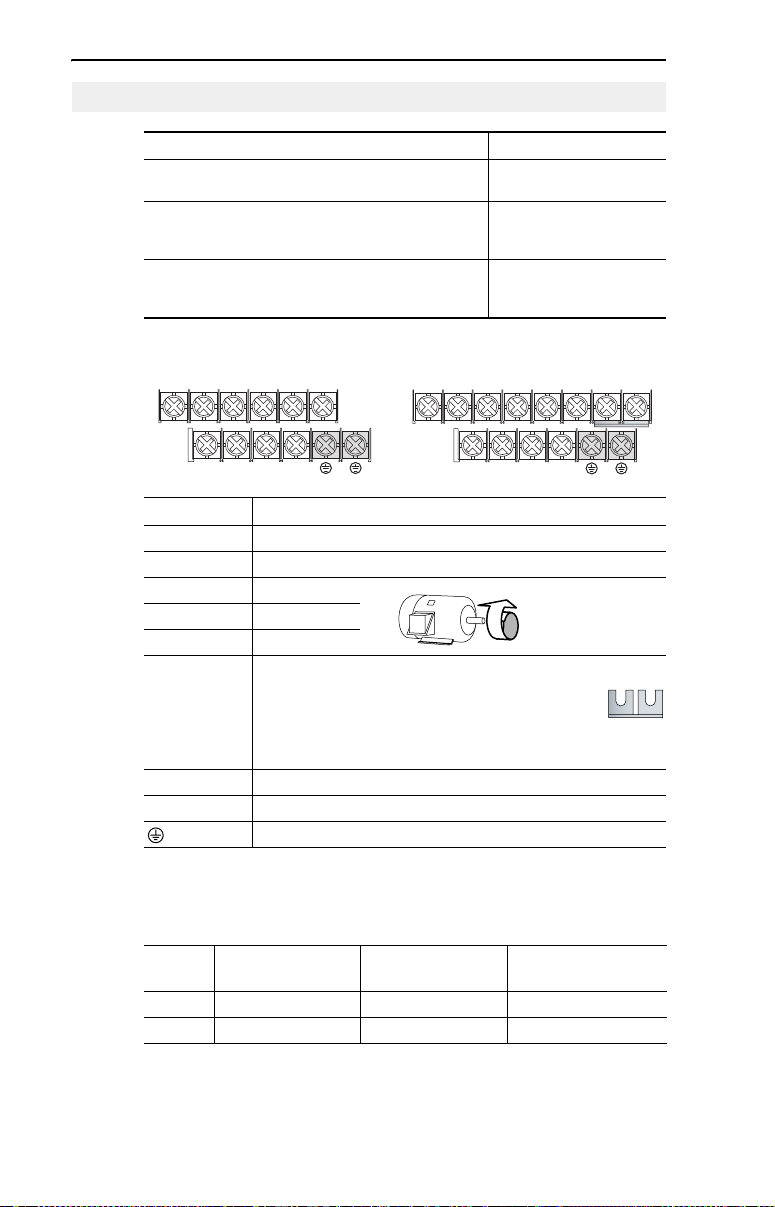

Power Terminal Block

B Frame C Frame

Terminal

(1)

DC+

V/T2T/L3S/L2R/L1 U/T1 W/T3

BR+ BR-DC-

Description

DC+

BR+ BR-DC-

V/T2T/L3S/L2R/L1 U/T1 W/T3 P2 P1

R/L1, S/L2 1-Phase Input

R/L1, S/L2, T/L3 3-Phase Input

U/T1 To Motor U/T1

V/T2 To Motor V/T2

W/T3 To Motor W/T3

=

Switch any two motor

leads to change

forward direction.

DC Bus Inductor Connection (C Frame drives only.)

P2, P1

The C Frame drive is shipped with a jumper between

Terminals P2 and P1. Remove this jumper only when a DC

Bus Inductor will be connected. Drive will not power up

without a jumper or inductor connected.

DC+, DC- DC Bus Connection

BR+, BR- Dynamic Brake Resistor Connection

Safety Ground - PE

(1)

Important: Terminal screws may become loose during shipment. Ensure that all

terminal screws are tightened to the recommended torque before applying power to

the drive.

Power Terminal Block Specifications

Frame Maximum Wire Size

2

B 5.3 mm

C 8.4 mm

(2)

Maximum/minimum sizes that the terminal block will accept - these are not

(10 AWG) 1.3 mm2 (16 AWG) 1.7-2.2 N-m (16-19 lb.-in.)

2

(8 AWG) 1.3 mm2 (16 AWG) 2.9-3.7 N-m (26-33 lb.-in.)

(2)

Minimum Wire Size

(2)

Torque

recommendations.

Page 9

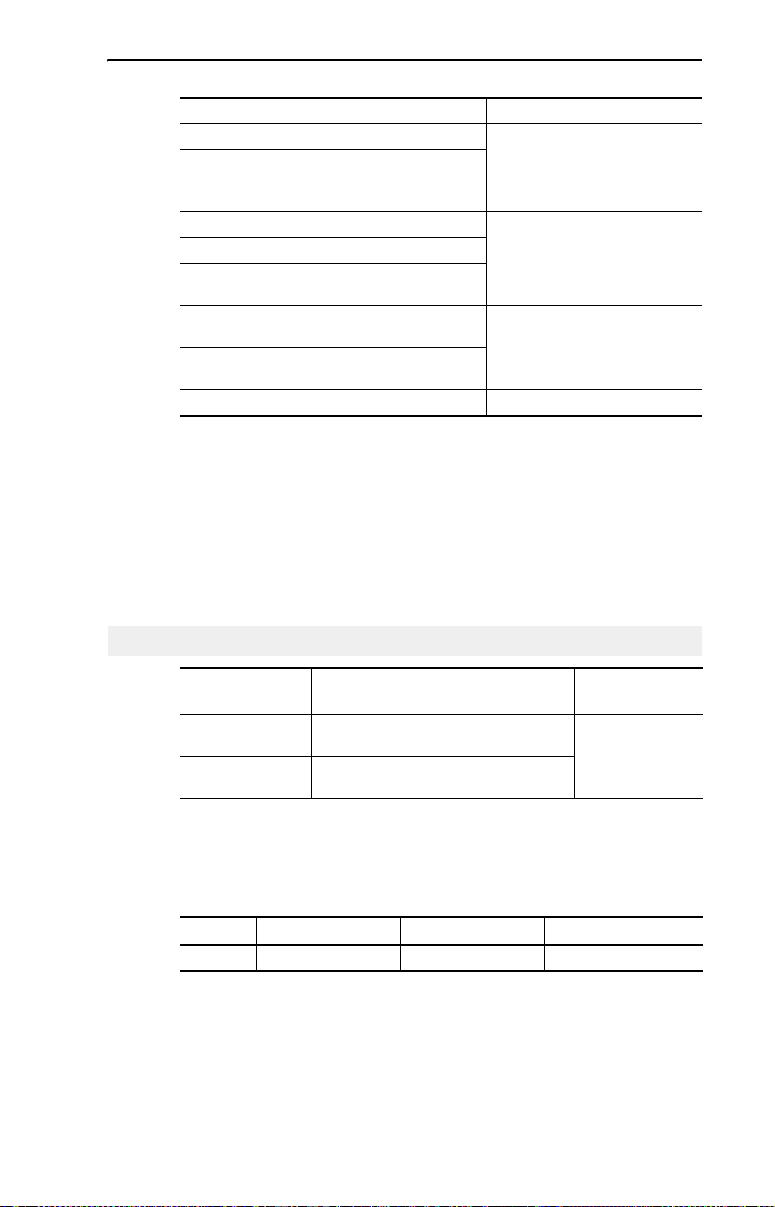

Input Power Conditions

Input Power Condition Corrective Action

Low Line Impedance (less than 1% line reactance) • Install Line Reactor

Greater than 120 kVA supply transformer

• or Isolation Transformer

(2)

• or Bus Inductor – 5.5-11 kW

(7.5-15 HP) drives only

Line has power factor correction capacitors • Install Line Reactor

Line has frequent power interruptions

Line has intermittent noise spikes in excess of

6000V (lightning)

Phase to ground voltage exceeds 125% of normal

line to line voltage

Ungrounded distribution system

240V open delta configuration (stinger leg)

(1)

For drives applied on an open delta with a middle phase grounded neutral system, the

• or Isolation Transformer

• Remove MOV jumper to ground.

• or Install Isolation Transformer

with grounded secondary if

necessary.

(1)

• Install Line Reactor

phase opposite the phase that is tapped in the middle to the neutral or earth is

referred to as the “stinger leg,” “high leg,” “red leg,” etc. This leg should be identified

throughout the system with red or orange tape on the wire at each connection point.

The stinger leg should be connected to the center Phase B on the reactor. Refer to the

PowerFlex 40 User Manual for specific line reactor part numbers.

(2)

Refer to Appendix B of the PowerFlex 40 User Manual for accessory ordering

information.

English-7

I/O Wiring Recommendations

Wire Type(s)

(4)

Description Minimum Insulation

(3)

Rating

2

Belden 8760/9460

(or equiv.)

Belden 8770

(or equiv.)

(3)

If the wires are short and contained within a cabinet which has no sensitive circuits,

the use of shielded wire may not be necessary, but is always recommended.

(4)

Stranded or solid wire.

(18AWG), twisted pair, 100% shield

0.8 mm

with drain.

2

(18AWG), 3 conductor, shielded for

0.8 mm

remote pot only.

300V

60 degrees C

(140 degrees F)

I/O Terminal Block Specifications

(5)

Frame Maximum Wire Size

B & C 1.3 mm

(5)

Maximum / minimum that the terminal block will accept - these are not

2

(16 AWG) 0.2 mm2 (24 AWG) 0.5-0.8 N-m (4.4-7 lb.-in.)

Minimum Wire Size

recommendations.

Refer to the PowerFlex 40 User Manual for recommendations on

maximum power and control cable length.

(5)

Torque

Page 10

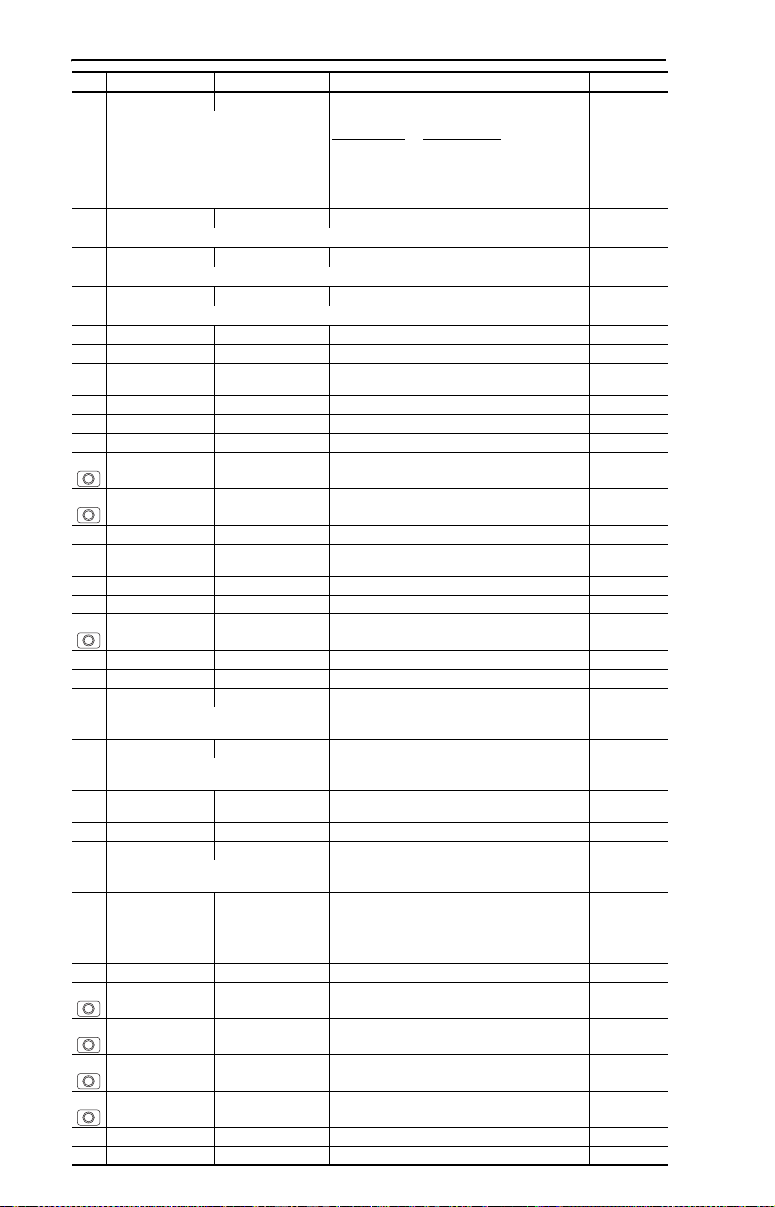

English-8

Control Terminal Block

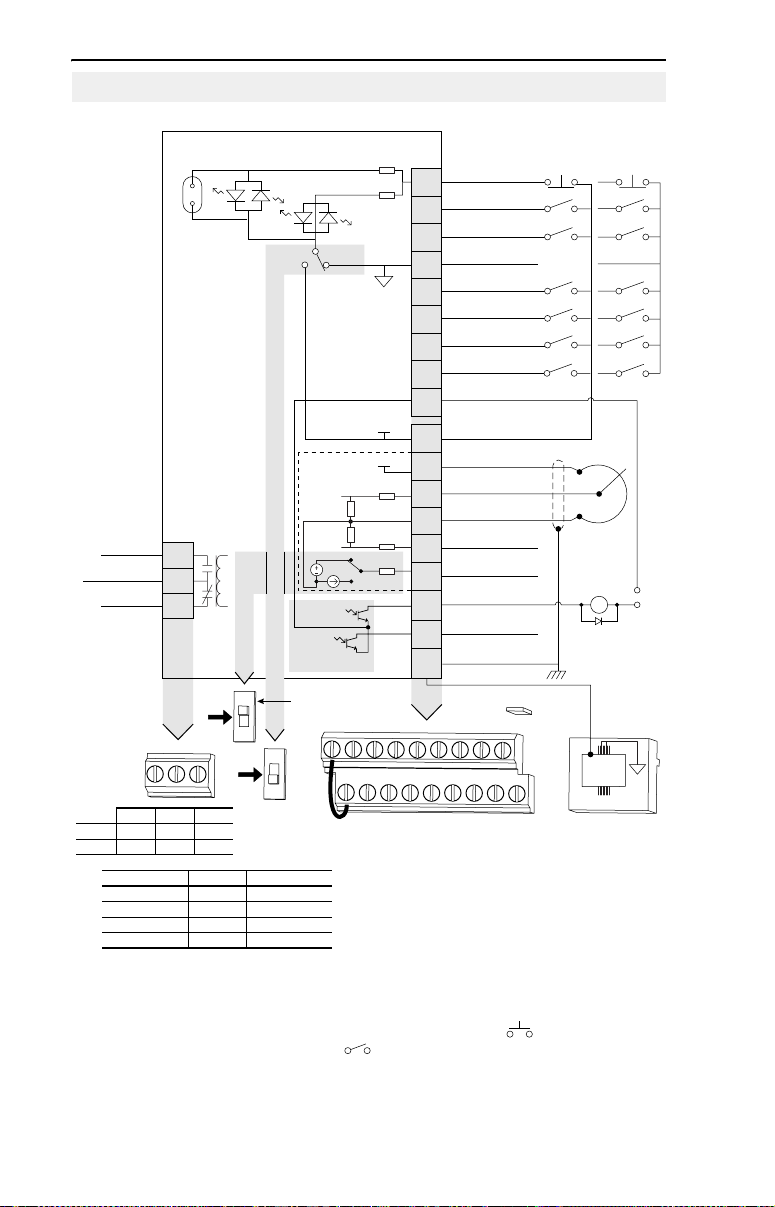

Control Wiring Block Diagram

(4)

Enable

Jumper

Relay N.O.

Relay Common

Relay N.C.

Resistive 3.0A 3.0A 3.0A

Inductive 0.5A 0.5A 0.5A

P036 [Start Source] Stop I/O Terminal 01 Stop

R1

R2

R3

0-10V

0-20mA

R1 R2 R3

30V DC 125V AC 240V AC

Keypad Per P037 Coast

3-Wire Per P037 Per P037

2-Wire Per P037 Coast

RS485 Port Per P037 Coast

SNK

SRC

SRCSNK

+24V

+10V

0-10V

0/4-20mA

30V DC

50mA

Non-inductive

Analog Output Select

01 02 03 04 05

11 12 13 14 15

(1)

(1)

Important: I/O Terminal 01 is always a coast to

stop input except when P036 [Start Source] is set to

“3-Wire” or “Momt FWD/REV” control. In three wire

control, I/O Terminal 01 is controlled by P037 [Stop

Mode]. All other stop sources are controlled by P037

(1)(4)

Stop

01

Start/Run FWD

02

Direction/Run REV

03

Digital Common

04

Digital Input 1

05

Digital Input 2

06

Digital Input 3

07

Digital Input 4

08

Opto Common

09

+24V DC

11

+10V DC

12

0-10V (or ±10V) Input

13

Analog Common

14

4-20mA Input

15

Analog Output

16

Opto Output 1

17

Opto Output 2

18

RS485 Shield

19

ENBL

06 07 08 09

16 17 18 19

[Stop Mode].

Important: The drive is shipped with a jumper installed between I/O Terminals 01 and 11. Remove

this jumper when using I/O Terminal 01 as a stop or enable input.

(2)

Two wire control shown. For three wire control use a momentary input on I/O Terminal 02 to

command a start. Use a maintained input for I/O Terminal 03 to change direction.

(3)

When using an opto output with an inductive load such as a relay, install a recovery diode parallel

to the relay as shown, to prevent damage to the output.

(4)

When the ENBL jumper is removed, I/O Terminal 01 will always act as a hardware enable, causing

a coast to stop without software interpretation. Refer to the PowerFlex 40 User Manual for more

information.

Typical

SRC Wiring

(2)

Enable

Jumper

Pot must be

1-10k ohm

2 Watt Min.

Common

(4)

RS485

(DSI)

Typical

SNK Wiring

(3)

24V

1

Page 11

English-9

Control I/O Terminal Designations

No. Signal Default Description Param.

R1 Relay N.O. Fault Normally open contact for output relay. A055

R2 Relay Common – Common for output relay.

R3 Relay N.C. Fault Normally closed contact for output relay. A055

Analog Output Select

DIP Switch

Sink/Source

DIP Switch

(1)

01 Stop

02 Star t/Run FWD Not Active Command comes from the integral keypad by default.

03 Direction/Run REV Not Active P036, P037,

04 Digital Common – For digital inputs. Electronically isolated with digital

05 Digital Input 1 Preset Freq Program with A051 [Digital In1 Sel]. A051

06 Digital Input 2 Preset Freq Program with A052 [Digital In2 Sel]. A052

07 Digital Input 3 Local Program with A053 [Digital In3 Sel]. A053

08 Digital Input 4 Jog Forward Program with A054 [Digital In4 Sel]. A054

09 Opto Common – For opto-coupled outputs. Electronically isolated with

11 +24V DC – Referenced to Digital Common.

12 +10V DC – Referenced to Analog Common.

13 ±10V In

14 Analog Common – For 0-10V In or 4-20mA In. Electronically isolated

15 4-20mA In

16 Analog Output OutFreq 0-10 The default analog output is 0-10V. To covert to a

17 Opto Output 1 MotorRunning Program with A058 [Opto Out1 Sel] A058, A059,

18 Opto Output 2 At Frequency Program with A061 [Opto Out2 Sel] A061, A062,

19 RS485 (DSI) Shield – Terminal should be connected to safety ground - PE

(1)

(2)

(2)

See Footnotes (1) and (4) on page 8.

0-10V In and 4-20mA In are distinct input channels and may be connected simultaneously.

0-10V Sets analog output to either voltage or current. Setting must match

Source (SRC) Inputs can be wired as Sink (SNK) or Source (SRC) via DIP Switch

Coast The factory installed jumper or a normally closed

Not Active For external 0-10V (unipolar) or ±10V (bipolar) input

(2)

Not Active For external 4-20mA input supply

A065 [Analog Out Sel].

setting.

input must be present for the drive to start.

To disable reverse operation, see A095 [Reverse

Disable].

inputs from analog I/O and opto outputs.

opto outputs from analog I/O and digital inputs.

Drive supplied power for digital inputs.

Maximum output current is 100mA.

Drive supplied power for 0-10V external

potentiometer.

Maximum output current is 15mA.

supply (input impedance = 100k ohm) or

potentiometer wiper.

with analog inputs and outputs from digital I/O and

opto outputs.

(input impedance = 250 ohm).

current value, change the Analog Output Select DIP

Switch to 0-20mA. Program with A065 [Analog Out

Sel]. Max analog value can be scaled with A066

[Analog Out High].

Maximum Load: 4-20mA = 525 ohm (10.5V)

when using the RS485 (DSI) communications port.

0-10V = 1k ohm (10mA)

(1)

P036

P036, P037

A095

P038

P038,

A051-A054,

A123, A132

P038,

A051-A054,

A132

A065, A066

A064

A064

Inputs may be used independently for speed control or jointly when operating in PID mode.

Page 12

English-10

Prepare For Drive Start-Up

ATTENTION: Power must be applied to the drive to perform the

following start-up procedures. Some of the voltages present are at

!

incoming line potential. To avoid electric shock hazard or damage to

equipment, only qualified service personnel should perform the

following procedure. Thoroughly read and understand the procedure

before beginning. If an event does not occur while performing this

procedure, Do Not Proceed. Remove All Power including user

supplied control voltages. User supplied voltages may exist even when

main AC power is not applied to the drive. Correct the malfunction

before continuing.

Before Applying Power to the Drive

❏ 1. Confirm that all inputs are connected to the correct terminals and are

secure.

❏ 2. Verify that AC line power at the disconnect device is within the rated

value of the drive.

❏ 3. Verify that any digital control power is 24 volts.

❏ 4. Verify that the Sink (SNK)/Source (SRC) Setup DIP Switch is set to

match your control wiring scheme. See page 8 for location.

Important: The default control scheme is Source (SRC). The Stop

terminal is jumpered (I/O Terminals 01 and 11) to allow

starting from the keypad. If the control scheme is changed

to Sink (SNK), the jumper must be removed from I/O

Terminals 01 and 11 and installed between I/O Terminals

01 and 04.

❏ 5. Verify that the Stop input is present or the drive will not start.

Important: If I/O Terminal 01 is used as a stop input, the jumper

between I/O Terminals 01 and 11 must be removed.

Applying Power to the Drive

❏ 6. Apply AC power and control voltages to the drive.

❏ 7. Familiarize yourself with the integral keypad features (see next page)

before setting any Program Group parameters.

If a fault appears on power up, refer to page 20 for an explanation of the

fault code. For complete troubleshooting information, refer to the

PowerFlex 40 User Manual.

Page 13

English-11

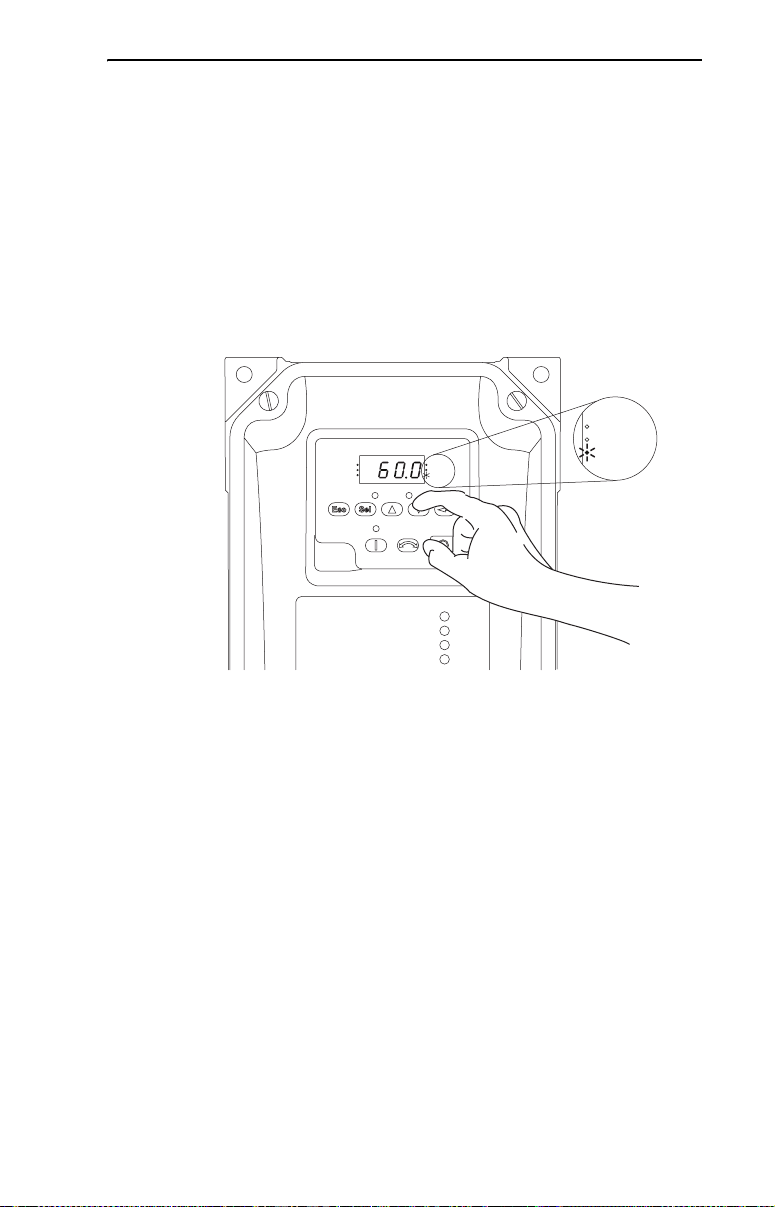

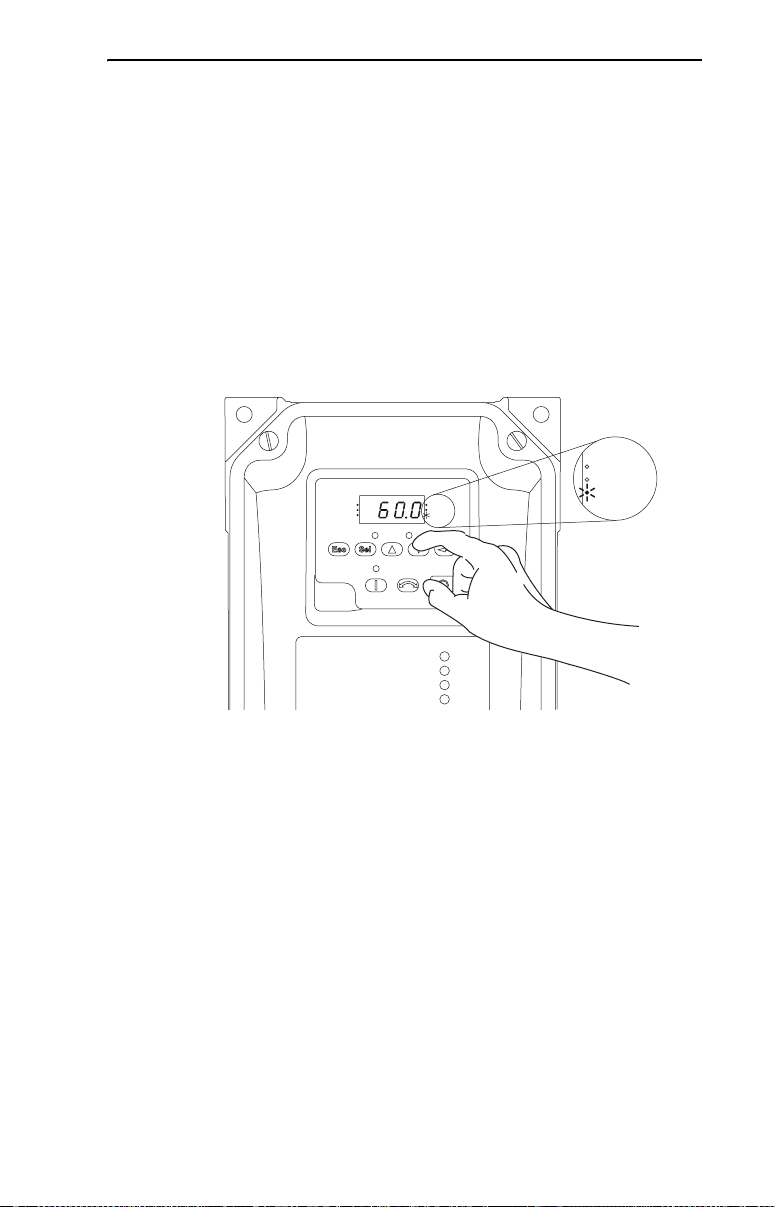

Start, Stop, Direction and Speed Control

Factory default parameter values allow the drive to be controlled from

the integral keypad. No programming is required to start, stop, change

direction and control speed directly from the integral keypad.

Important: To disable reverse operation, see A095 [Reverse Disable].

Changing the Speed Reference of an IP66, NEMA/UL Type 4X rated

drive

When a Display Group parameter, for example, d001 [Output Freq] is

displayed, and P038 [Speed Ref] is set to A069 [Internal Freq], you can

change the internal frequency using the Up Arrow and Down Arrow

keys.

VOLTS

AMPS

RUN

FWD

REV

PROGRAM

VOLTS

AMPS

HERTZ

FAULT

HERTZ

When the internal frequency is being adjusted, its value is displayed and

the Hertz LED flashes. Any changes are saved immediately. The display

then returns to the Display Group parameter previously shown.

TIP: By default, the speed reference of an IP66, NEMA/UL Type 4X

rated drive is set to the internal frequency, A069 [Internal Freq].

TIP: You can also change the speed reference by editing the parameter

A069 [Internal Freq] in program mode. For details on how to enter the

program mode, see the section, “Viewing and Editing Parameters.”

The default value of A069 [Internal Freq] is 0 Hz. For IP20 rated

PowerFlex 40 drives, the default value of this parameter is 60 Hz.

Page 14

English-12

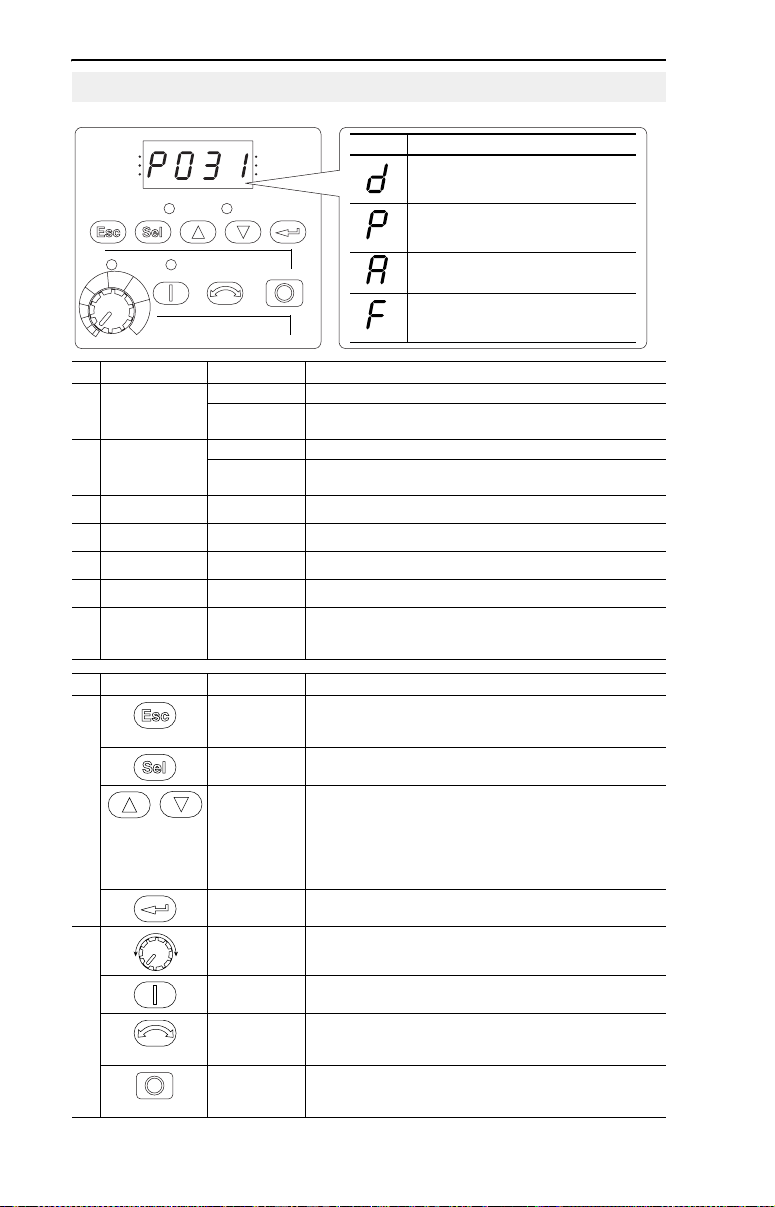

Integral Keypad

➏

➍

➋

PROGRAM

➎

➊

RUN

FWD

REV

FAULT

➌

VOLTS

AMPS

HERTZ

➐

➑

➒

Menu Description

Display Group (View Only)

Consists of commonly viewed drive operating

conditions.

Basic Program Group

Consists of most commonly used

programmable functions.

Advanced Program Group

Consists of remaining programmable functions.

Fault Designator

Consists of list of codes for specific fault

conditions. Displayed only when fault is present.

No. LED LED State Description

Run/Direction

➊

Status

Steady Red Indicates drive is running and commanded motor direction.

Flashing Red Drive has been commanded to change direction. Indicates

actual motor direction while decelerating to zero.

Alphanumeric

➋

Display

Displayed Units Steady Red Indicates the units of the parameter value being displayed.

➌

Program Status Steady Red Indicates parameter value can be changed.

➍

Fault Status Flashing Red Indicates drive is faulted.

➎

Pot Status Steady Green Indicates potentiometer on Integral Keypad is active.

➏

Start Key Status Steady Green Indicates Start key on Integral Keypad is active.

➐

Steady Red Indicates parameter number, parameter value, or fault code.

Flashing Red Single digit flashing indicates that digit can be edited.

All digits flashing indicates a fault condition.

The Reverse key is also active unless disabled by A095

[Reverse Disable].

No. Key Name Description

➑

Escape Back one step in programming menu.

Select Advance one step in programming menu.

Up Arrow

Down Arrow

Cancel a change to a parameter value and exit Program

Mode.

Select a digit when viewing parameter value.

Scroll through groups and parameters.

Increase/decrease the value of a flashing digit.

Used to adjust internal frequency of IP66, NEMA/UL Type 4X

rated drives only when a Display Group parameter is shown

and P038 [Speed Reference] is set to internal frequency,

A069 [Internal Freq].

➒

Enter Advance one step in programming menu.

Potentiometer

Save a change to a parameter value.

(1)

Used to control speed of drive. Default is active.

Controlled by parameter P038 [Speed Reference].

Start Used to start the drive. Default is active.

Controlled by parameter P036 [Start Source].

Reverse Used to reverse direction of the drive. Default is active.

Stop Used to stop the drive or clear a fault.

Controlled by parameters P036 [Start Source] and A095

[Reverse Disable].

This key is always active.

Controlled by parameter P037 [Stop Mode].

(1)

IP66, NEMA/UL Type 4X rated drives are not equipped with a potentiometer.

(1)

Page 15

See the PowerFlex 40 User Manual for more information on parameters.

English-13

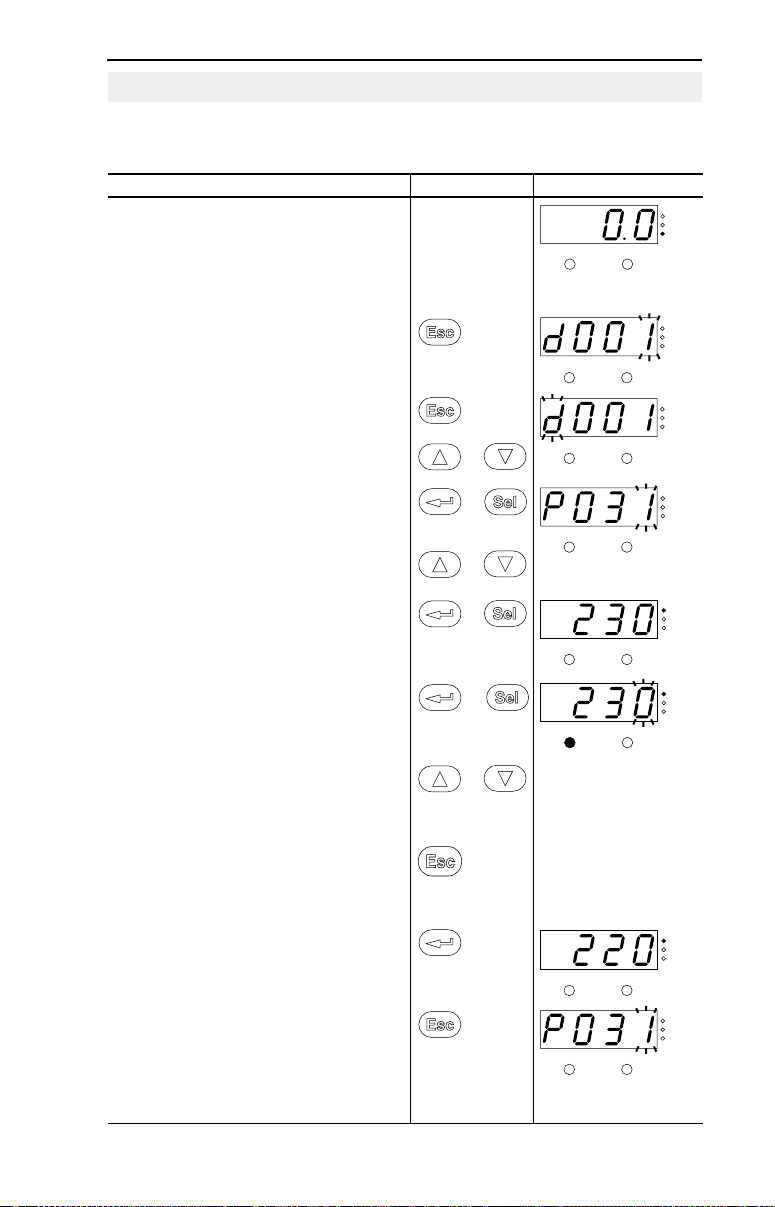

Viewing and Editing Parameters

The last user-selected Display Group parameter is saved when power is removed and is displayed by

default when power is reapplied.

The following is an example of basic integral keypad and display functions. This example provides basic

navigation instructions and illustrates how to program the first Program Group parameter.

Step Key(s) Example Displays

1. When power is applied, the last user-selected

Display Group parameter number is briefly

displayed with flashing characters. The display

then defaults to that parameter’s current value.

(Example shows the value of d001 [Output

Freq] with the drive stopped.)

2. Press Esc once to display the Display Group

parameter number shown on power-up. The

parameter number will flash.

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

3. Press Esc again to enter the group menu. The

group menu letter will flash.

4. Press the Up Arrow or Down Arrow to scroll

through the group menu (d, P and A).

5. Press Enter or Sel to enter a group. The right

digit of the last viewed parameter in that group

will flash.

6. Press the Up Arrow or Down Arrow to scroll

through the parameters that are in the group.

7. Press Enter or Sel to view the value of a

parameter. If you do not want to edit the value,

press Esc to return to the parameter number.

8. Press Enter or Sel to enter program mode to

edit the parameter value. The right digit will

flash and the Program LED will illuminate if the

parameter can be edited.

9. Press the Up Arrow or Down Arrow to change

the parameter value. If desired, press Sel to

move from digit to digit or bit to bit. The digit or

bit that you can change will flash.

10.Press Esc to cancel a change. The digit will

stop flashing, the previous value is restored and

the Program LED will turn off.

Or

Press Enter to save a change. The digit will stop

flashing and the Program LED will turn off.

VOLTS

AMPS

HERTZ

or

or

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

or

or

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

11.Press Esc to return to the parameter list.

Continue to press Esc to back out of the

programming menu.

If pressing Esc does not change the display,

then d001 [Output Frequency] is displayed.

Press Enter or Sel to enter the group menu.

The Basic Program Group contains the most commonly changed parameters.

VOLTS

AMPS

HERTZ

FAULTPROGRAM

Page 16

English-14

See the PowerFlex 40 User Manual for more information on parameters.

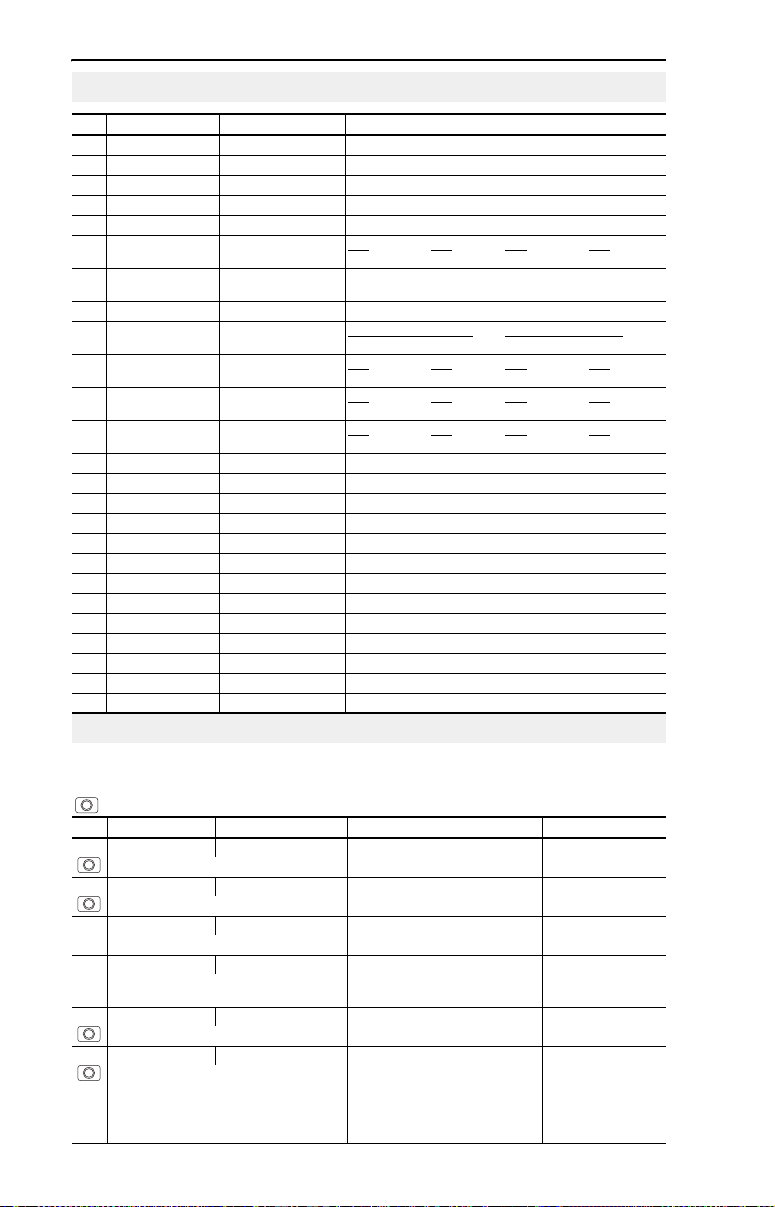

Display Group Parameters

No. Parameter Min/Max Display/Options

d001 [Output Freq] 0.0/ [Maximum Freq] 0.1 Hz

d002 [Commanded Freq] 0.0/ [Maximum Freq] 0.1 Hz

d003 [Output Current] 0.00/(Drive Amps × 2) 0.01 Amps

d004 [Output Voltage] 0/Drive Rated Volts 1 VAC

d005 [DC Bus Voltage] Based on Drive Rating 1 VDC

d006 [Drive Status] 0/1 (1 = Condition True) Bit 3

d007-

[Fault x Code] F2/F122 F1

d009

d010 [Process Display] 0.00/9999 0.01 – 1

d012 [Control Source] 0/9 Digit 1 = Speed Command

d013 [Contrl In Status] 0/1 (1 = Input Present) Bit 3

d014 [Dig In Status] 0/1 (1 = Input Present) Bit 3

d015 [Comm Status] 0/1 (1 = Condition True) Bit 3

d016 [Control SW Ver] 1.00/99.99 0.01

d017 [Drive Type] 1001/9999 1

d018 [Elapsed Run Time] 0/9999 Hrs 1 = 10 Hrs

d019 [Testpoint Data] 0/FFFF 1 Hex

d020 [Analog In 0-10V] 0.0/100.0% 0.1%

d021 [Analog In 4-20mA] 0.0/100.0% 0.1%

d022 [Output Power] 0.00/(Drive Power × 2) 0.01 kW

d023 [Output Powr Fctr] 0.0/180.0 deg 0.1 deg

d024 [Drive Temp] 0/120 degC 1 degC

d025 [Counter Status] 0/9999 1

d026 [Timer Status] 0.0/9999 Secs 0.1 Secs

d028 [Stp Logic Status] 0/7 1

d029 [Torque Current] 0.00/(Drive Amps × 2) 0.01 Amps

Decelerating Accelerating Forward Running

(See P038; 9 = “Jog Freq”) (See P036; 9 = “Jog”)

DB Trans On Stop Input Dir/REV In Start/FWD In

Digital In 4 Digital In 3 Digital In 2 Digital In 1

Comm Error DSI Option Transmitting Receiving

Bit 2 Bit 1 Bit 0

Digit 0 = Start Command

Bit 2 Bit 1 Bit 0

Bit 2 Bit 1 Bit 0

Bit 2 Bit 1 Bit 0

Smart Start-Up with Basic Program Group Parameters

The PowerFlex 40 is designed so that start up is simple and efficient. The Program Group

contains the most commonly used parameters.

= Stop drive before changing this parameter.

No. Parameter Min/Max Display/Options Default

P031 [Motor NP Volts] 20/Drive Rated Volts 1 VAC Based on Drive Rating

Set to the motor nameplate rated volts.

P032 [Motor NP Hertz] 15/400 Hz 1 Hz 60 Hz

Set to the motor nameplate rated frequency.

P033 [Motor OL Current] 0.0/(Drive Rated Amps× 2) 0.1 Amps Based on Drive Rating

Set to the maximum allowable motor current.

P034 [Minimum Freq] 0.0/400.0 Hz 0.1 Hz 0.0 Hz

Sets the lowest frequency the drive will output

continuously.

P035 [Maximum Freq] 0/400 Hz 1 Hz 60 Hz

Sets the highest frequency the drive will output.

P036 [Start Source] 0/6 0 = “Keypad”

Sets the control scheme used to star t the drive.

(1)

When active, the Reverse key is also active

unless disabled by A095 [Reverse Disable].

1 = “3-Wire”

2 = “2-Wire”

3 = “2-W Lvl Sens”

4 = “2-W Hi Speed”

5 = “Comm Port”

6 = “Momt FWD/REV”

(1)

0

Page 17

See the PowerFlex 40 User Manual for more information on parameters.

= Stop drive before changing this parameter.

No. Parameter Min/Max Display/Options Default

P037 [Stop Mode] 0/9 0 = “Ramp, CF”

Active stop mode for all stop sources [e.g. keypad,

run forward (I/O Terminal 02), run reverse (I/O

Terminal 03), RS485 port] except as noted below.

Important: I/O Terminal 01 is always a coast to

stop input except when P036 [Start Source] is set

for “3-Wire” control. When i n three wire control, I/O

Terminal 01 is controlled by P037 [Stop Mode].

P038 [Speed Reference] 0/7 0 = “Drive Pot”

Sets the source of the speed reference to the

drive.

Important: When A051 or A052 [Digital Inx Sel] is

set to option 2, 4, 5, 6, 13 or 14 and the digital

input is active, A051, A052, A053 or A054 will

override the speed reference commanded by this

parameter. Refer to Chapter 1 of the PowerFlex 40

User Manual for details.

1 = “Coast, CF”

2 = “DC Brake, CF”

3 = “DCBrkAuto,CF”

4 = “Ramp”

5 = “Coast”

6 = “DC Brake”

7 = “DC BrakeAuto”

8 = “Ramp+EM B,CF”

9 = “Ramp+EM Brk”

(1)

1 = “InternalFreq”

2 = “0-10V Input”

3 = “4-20mA Input”

4 = “Preset Freq”

5 = “Comm Port”

6 = “Stp Logic”

7 = “Anlg In Mult”

(1)

(1)

(1)

(1)

Stop input also clears active fault.

0

0

1 (IP66, Type 4X)

P039 [Accel Time 1] 0.0/600.0 Secs 0.1 Secs 10.0 Secs

Sets the rate of accel for all speed increases.

P040 [Decel Time 1] 0.1/600.0 Secs 0.1 Secs 10.0 Secs

Sets the rate of decel for all speed decreases.

P041 [Reset To Defalts] 0/1 0 = “Ready/Idle”

Resets all parameter values to factory defaults.

P042 [Voltage Class] 2/3

Sets the voltage class of 600V drives.

P043 [Motor OL Ret] 0/1 0 = “Disabled”

1 = “Factory Rset”

2 = “Low Voltage” (480V)

3 = “High Voltage” (600V)

1 = “Enabled”

0

3

0

Enables/disables the Motor Overload Retention function.

English-15

Page 18

English-16

See the PowerFlex 40 User Manual for more information on parameters.

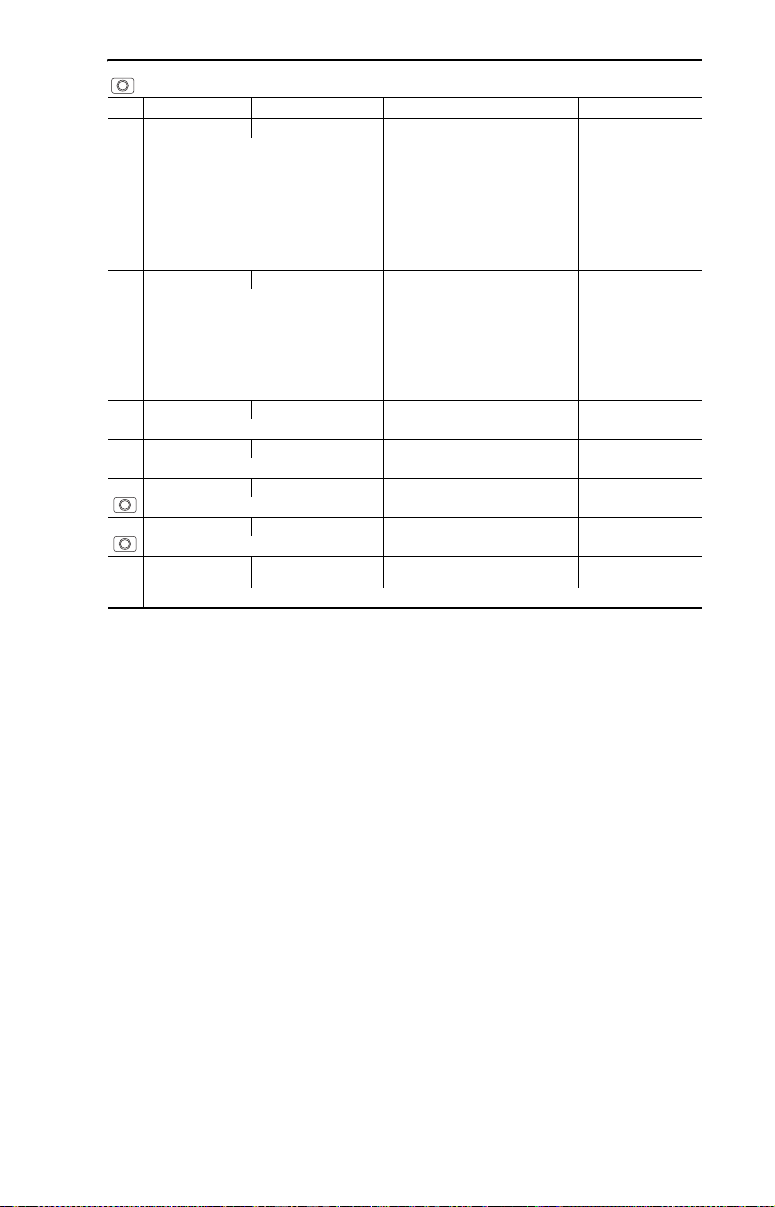

Advanced Group Parameters

No. Parameter Min/Max Display/Options Default

[Digital In1 Sel]

A051

I/O Terminal 05

[Digital In2 Sel]

A052

I/O Terminal 06

[Digital In3 Sel]

A053

I/O Terminal 07

[Digital In4 Sel]

A054

I/O Terminal 08

(1)

Important: Speed source for IP66, NEMA/

UL Type 4X rated drives comes from A069

[Internal Freq].

A055 [Relay Out Sel] 0/24 0 = “Ready/Fault”

A056 [Relay Out Level] 0.0/9999 0.1 0.0

A058

[Opto Out1 Sel]

A061

[Opto Out2 Sel]

A059

[Opto Out1 Level]

A062

[Opto Out2 Level]

A055, A058 & A061 Setting A056, A059 & A062 Min/Max

6 0/400 Hz

7 0/180%

8 0/815 Volts

10 0/100%

16 0.1/9999 Secs

17 1/9999 Counts

18 1/180 degs

20 0/1

23 0/400 Hz

A064 [Opto Out Logic] 0/3 1 0

A064 Option Opto Out1 Logic Opto Out2 Logic

0 NO (Normally Open) NO (Normally Open)

1 NC (Normally Closed) NO (Normally Open)

2 NO (Normally Open) NC (Normally Closed)

3 NC (Normally Closed) NC (Normally Closed)

0/27 0 = “Not Used”

1 = “Acc & Dec 2”

2 = “Jog”

3 = “Aux Fault”

4 = “Preset Freq”

(1)

5 = “Local”

6 = “Comm Port”

7 = “Clear Fault”

8 = “RampStop,CF”

9 = “CoastStop,CF”

10 = “DCInjStop,CF”

11 = “Jog Forward”

12 = “Jog Reverse”

13 = “10V In Ctrl”

1 = “At Frequency”

2 = “MotorRunning”

3 = “Reverse”

4 = “Motor Overld”

5 = “Ramp Reg”

6 = “Above Freq”

7 = “Above Cur”

8 = “Above DCVolt”

9 = “Retries Exst”

10 = “Above Anlg V”

11 = “Logic In 1”

12 = “Logic In 2”

14 = “20mA In Ctrl”

15 = “PID Disable”

16 = “MOP Up”

17 = “MOP Down”

18 = “Timer Start”

19 = “Counter In”

20 = “Reset Timer”

21 = “Reset Countr”

22 = “Rset Tim&Cnt”

23 = “Logic In1”

24 = “Logic In2”

25 = “Current Lmt2”

26 = “Anlg Invert”

27 = “EM Brk Rlse”

13 = “Logic 1 & 2”

14 = “Logic 1 or 2”

15 = “StpLogic Out”

16 = “Timer Out”

17 = “Counter Out”

18 = “Above PF Ang”

19 = “Anlg In Loss”

20 = “ParamControl”

21 = “NonRec Fault”

22 = “EM Brk Cntrl”

23 = “Above Fcmd”

24 = “MsgControl” (for

FRN 6.01 and later)

0/24 See A055 for Options. 2

4

4

5

11

0

1

0.0/9999 0.1 0.0

Page 19

See the PowerFlex 40 User Manual for more information on parameters.

English-17

No. Parameter Min/Max Display/Options Default

A065 [Analog Out Sel] 0/23 1 0

Option Output Range Minimum Output Value

0 “OutFreq 0-10” 0-10V 0V = 0 Hz P035 [Maximum Freq] 0-10V

1 “OutCurr 0-10” 0-10V 0V = 0 Amps 200% Drive Rated FLA 0-10V

2 “OutVolt 0-10” 0-10V 0V = 0 Volts 120% Drive Rated Output Volts 0-10V

3 “OutPowr 0-10” 0-10V 0V = 0 kW 200% Drive Rated Power 0-10V

4 “TstData 0-10” 0-10V 0V = 0000 65535 (Hex FFFF) 0-10V

5 “OutFreq 0-20” 0-20 mA 0 mA = 0 Hz P035 [Maximum Freq] 0-20 mA

6 “OutCurr 0-20” 0-20 mA 0 mA = 0 Amps 200% Drive Rated FLA 0-20 mA

7 “OutVolt 0-20” 0-20 mA 0 mA = 0 Volts 120% Drive Rated Output Volts 0-20 mA

8 “OutPowr 0-20” 0-20 mA 0 mA = 0 kW 200% Drive Rated Power 0-20 mA

9 “TstData 0-20” 0-20 mA 0 mA = 0000 65535 (Hex FFFF) 0-20 mA

10 “OutFreq 4-20” 4-20 mA 4 mA = 0 Hz P035 [Maximum Freq] 0-20 mA

11 “OutCurr 4-20” 4-20 mA 4 mA = 0 Amps 200% Drive Rated FLA 0-20 mA

12 “OutVolt 4-20” 4-20 mA 4 mA = 0 Volts 120% Drive Rated Output Volts 0-20 mA

13 “OutPowr 4-20” 4-20 mA 4 mA = 0 kW 200% Drive Rated Power 0-20 mA

14 “TstData 4-20” 4-20 mA 4 mA = 0000 65535 (Hex FFFF) 0-20 mA

15 “OutTorq 0-10” 0-10V 0V = 0 Amps 200% Drive Rated FLA 0-10V

16 “OutTorq 0-20” 0-20 mA 0 mA = 0 Amps 200% Drive Rated FLA 0-20 mA

17 “OutTorq 4-20” 4-20 mA 4 mA = 0 Amps 200% Drive Rated FLA 0-20 mA

18 “Setpnt 0-10” 0-10V 0V = 0% 100.0% Setpoint Setting 0-10V

19 “Setpnt 0-20” 0-20 mA 0 mA = 0% 100.0% Setpoint Setting 0-20 mA

20 “Setpnt 4-20” 4-20 mA 4 mA = 0% 100.0% Setpoint Setting 0-20 mA

21 “MinFreq 0-10” 0-10V 0V = Min. Freq P035 [Maximum Freq] 0-10V

22 “MinFreq 0-20” 0-20 mA 0 mA = Min. Freq P035 [Maximum Freq] 0-20 mA

23 “MinFreq 4-20” 4-20 mA 4 mA = Min. Freq P035 [Maximum Freq] 0-20 mA

Maximum Output Value

[Analog Out High] DIP Switch Position

A066 [Analog Out High] 0/800% 1% 100%

A067 [Accel Time 2] 0.0/600.0 Secs 0.1 Secs 20.0 Secs

A068 [Decel Time 2] 0.1/600.0 Secs 0.1 Secs 20.0 Secs

A069 [Internal Freq] 0.0/400.0 Hz 0.1 Hz 0.0 Hz (for IP66,

A070

A071

A072

A073

A074

A075

A076

A077

[Preset Freq 0]

[Preset Freq 1]

[Preset Freq 2]

[Preset Freq 3]

[Preset Freq 4]

[Preset Freq 5]

[Preset Freq 6]

[Preset Freq 7]

(1)

(I/O Terminal 05)

(2)

(1)

0.0/400.0 Hz 0.1 Hz 0.0 Hz

To activate [Preset Freq 0] set P038 [Speed Reference] to option 4.

Input State

of Digital In 1

When a Digital Input is set to “Accel 2 & Decel 2”, and the input is active, that input overrides the settings in this table.

Input State

of Digital In 2

(I/O Terminal 06)

0 0 0 [Preset Freq 0] [Accel Time 1] / [Decel Time 1]

1 0 0 [Preset Freq 1] [Accel Time 1] / [Decel Time 1]

0 1 0 [Preset Freq 2] [Accel Time 2] / [Decel Time 2]

1 1 0 [Preset Freq 3] [Accel Time 2] / [Decel Time 2]

0 0 1 [Preset Freq 4] [Accel Time 1] / [Decel Time 1]

1 0 1 [Preset Freq 5] [Accel Time 1] / [Decel Time 1]

0 1 1 [Preset Freq 6] [Accel Time 2] / [Decel Time 2]

1 1 1 [Preset Freq 7] [Accel Time 2] / [Decel Time 2]

Input State

of Digital In 3

(I/O Terminal 07)

Frequency Source Accel / Decel Parameter Used

(2)

NEMA/UL Type

4X drives)

60.0 Hz (for

IP20 drives)

5.0 Hz

10.0 Hz

20.0 Hz

30.0 Hz

40.0 Hz

50.0 Hz

60.0 Hz

A078 [Jog Frequency] 0.0/[Maximum Freq] 0.1 Hz 10.0 Hz

A079 [Jog Accel/Decel] 0.1/600.0 Secs 0.1 Secs 10.0 Secs

A080 [DC Brake Time] 0.0/99.9 Secs 0.1 Secs 0.0 Secs

A setting of 99.9 Secs = Continuous

A081 [DC Brake Level] 0.0/(Drive Amps × 1.8) 0.1 Amps Amps × 0.05

A082 [DB Resistor Sel] 0/99 0 = “Disabled”

1 = “Normal RA Res”

2 = “NoProtection”

3-99 = % of Duty Cycle

0

A083 [S Curve %] 0/100% 1% 0% (Disabled)

Page 20

English-18

See the PowerFlex 40 User Manual for more information on parameters.

No. Parameter Min/Max Display/Options Default

A084 [Boost Select] 0/14 Settings in % of base voltage. 8

Only active when A125 [Torque Perf Mode] is

set to 0 “V/Hz”.

A085

[Start Boost] 0.0/25.0%

Only active when A084 [Boost Select] and A125 [Torque Perf Mode] are set to “0”.

A086

[Break Voltage] 0.0/100.0%

Only active when A084 [Boost Select] and A125 [Torque Perf Mode] are set to “0”.

A087

[Break Frequency] 0.0/400.0 Hz

Only active when A084 [Boost Select] and A125 [Torque Perf Mode] are set to “0”.

A088 [Maximum Voltage] 20/Rated Volts 1 VAC Rated Volts

A089 [Current Limit 1] 0.1/(Drive Amps × 1.8) 0.1 Amps Amps × 1.5

A090 [Motor OL Select] 0/2 0 = “No Derate” 1 = “Min Derate”

A091 [PWM Frequency] 2.0/16.0 kHz 0.1 kHz 4.0 kHz

A092 [Auto Rstrt Tries] 0/9 1 0

A093 [Auto Rstrt Delay] 0.0/300.0 Secs 0.1 Secs 1.0 Secs

A094 [Start At PowerUp] 0/1 0 = “Disabled” 1 = “Enabled” 0

A095 [Reverse Disable] 0/1 0 = “Rev Enabled” 1 = “Rev Disabled” 0

A096 [Flying Start En] 0/1 0 = “Disabled” 1 = “Enabled” 0

A097 [Compensation] 0/3 0 = “Disabled”

A098 [SW Current Trip] 0.0/(Drive Amps × 2) 0.1 Amps 0.0 (Disabled)

A099 [Process Factor] 0.1/999.9 0.1 30.0

A100 [Fault Clear] 0/2 0 = “Ready/Idle” 1 = “Reset Fault”

A101 [Program Lock] 0/9999 0 = “Unlocked” 1 = “Locked” 0

A102 [Testpoint Sel] 400/FFFF 1 Hex 400

A103 [Comm Data Rate] 0/5 0 = “1200”

Power to drive must be cycled before any

changes will affect drive operation.

A104 [Comm Node Addr] 1/247 1 100

Power to drive must be cycled before any

changes will affect drive operation.

A105 [Comm Loss Action] 0/3 0 = “Fault”

A106 [Comm Loss Time] 0.1/60.0 Secs 0.1 Secs 5.0 Secs

A107 [Comm Format] 0/5 0 = “RTU 8-N-1”

Power to drive must be cycled before any

changes will affect drive operation.

A108 [Language] 1/10 1 = “English”

A109 [Anlg Out Setpt] 0.0/100.0% 0.1% 0.0%

A110 [Anlg In 0-10V Lo] 0.0/100.0% 0.1% 0.0%

0 = “Custom V/Hz”

Var iab le Tor que

1 = “30.0, VT” 5 = “0.0, no IR” 10 = “10.0, CT”

2 = “35.0, VT” 6 = “0.0” 11 = “12.5, CT”

3 = “40.0, VT” 7 = “2.5, CT” 12 = “15.0, CT”

4 = “45.0, VT” 8 = “5.0, CT” 13 = “17.5, CT”

0.1% 2.5%

0.1% 25.0%

0.1 Hz 15.0 Hz

1 = “Electrical”

1 = “2400”

2 = “4800”

1 = “Coast Stop”

1 = “RTU 8-E-1”

2 = “RTU 8-O-1”

2 = “Français”

3 = “Español”

4 = “Italiano”

5 = “Deutsch”

Constant Torque

9 = “7.5, CT” 14 = “20.0, CT”

2 = “Max Derate”

2 = “Mechanical”

3 = “Both”

2 = “Clear Buffer”

3 = “9600”

4 = “19.2K”

5 = “38.4K”

2 = “Stop”

3 = “Continu Last”

3 = “RTU 8-N-2”

4 = “RTU 8-E-2”

5 = “RTU 8-O-2”

6 = “Reserved”

7 = “Português”

8 = “Reserved”

9 = “Reserved”

10 = “Nederlands”

7 4-11 kW

(5-15 HP)

0

1

0

3

0

0

1

A111 [Anlg In 0-10V Hi] 0.0/100.0% 0.1% 100.0%

A112 [Anlg In4-20mA Lo] 0.0/100.0% 0.1% 0.0%

A113 [Anlg In4-20mA Hi] 0.0/100.0% 0.1% 100.0%

A114 [Slip Hertz @ FLA] 0.0/10.0 Hz 0.1 Hz 2.0 Hz

A115 [Process Time Lo] 0.00/99.99 0.01 0.00

Page 21

See the PowerFlex 40 User Manual for more information on parameters.

English-19

No. Parameter Min/Max Display/Options Default

A116 [Process Time Hi] 0.00/99.99 0.01 0.00

A117 [Bus Reg Mode] 0/1 0 = “Disabled” 1 = “Enabled” 1

A118 [Current Limit 2] 0.1/(Drive Amps × 1.8) 0.1 Amps Amps × 1.5

A119 [Skip Frequency] 0/400 Hz 1 Hz 0 Hz

A120 [Skip Freq Band] 0.0/30.0 Hz 0.1 Hz 0.0 Hz

A121 [Stall Fault Time] 0/5 0 = “60 Seconds”

A122 [Analog In Loss] 0/6 0 = “Disabled”

A123 [10V Bipolar Enbl] 0/1 0 = “Uni-Polar In” 1 = “Bi-Polar In” 0

A124 [Var PWM Disable] 0/1 0 = “Enabled” 1 = “Disabled” 0

A125 [Torque Perf Mode] 0/1 0 = “V/Hz” 1 = “Sensrls Vect” 1

A126 [Motor NP FLA] 0.1/(Drive Amps × 2) 0.1 Amps Rated Amps

A127 [Autotune] 0/2 0 = “Ready/Idle”

A128 [IR Voltage Drop] 0.0/230.0 VAC 0.1 VAC Rated Volts

A129 [Flux Current Ref] 0.00/[Motor NP FLA] 0.01 Amps Rated Amps

A130 [PID Trim Hi] 0.0/400.0 0.1 60.0

A131 [PID Trim Lo] 0.0/400.0 0.1 0.0

A132 [PID Ref Sel] 0/8 0 = “PID Disabled”

A133 [PID Feedback Sel] 0/2 0 = “0-10V Input”

A134 [PID Prop Gain] 0.00/99.99 0.01 0.01

A135 [PID Integ Time] 0.0/999.9 Secs 0.1 Secs 0.1 Secs

A136 [PID Diff Rate] 0.00/99.99 (1/Secs) 0.01 (1/Secs) 0.01 (1/Secs)

A137 [PID Setpoint] 0.0/100.0% 0.1% 0.0%

A138 [PID Deadband] 0.0/10.0% 0.1% 0.0%

A139 [PID Preload] 0.0/400.0 Hz 0.1 Hz 0.0 Hz

A140-

[Stp Logic 0-7] 0001/bAFF 4 Digits

A147

A150-

[Stp Logic Time 0-7] 0.0/999.9 Secs 0.1 Secs 30.0 Secs

A157

A160 [EM Brk Off Delay] 0.01/10.00 Secs 0.01 Secs 2.00 Secs

A161 [EM Brk On Delay] 0.01/10.00 Secs 0.01 Secs 2.00 Secs

A162 [MOP Reset Sel] 0/1 0 = “Zero MOP Ref” 1 = “Save MOP Ref” 1

A163 [DB Threshold] 0.0/110.0% 0.0% 100.0%

A164 [Comm Write Mode] 0/1 0 = “Save” 1 = “RAM Only” 0

A165 [Anlg Loss Delay] 0.0/20.0 Secs 0.1 Secs 0.0 Secs

A166 [Analog In Filter] 0/14 1 0

A167 [PID Invert Error] 0/1 0 = “Not Inverted” 1 = “Inverted” 0

1 = “120 Seconds”

2 = “240 Seconds”

1 = “Fault (F29)”

2 = “Stop”

3 = “Zero Ref”

1 = “Static Tune”

1 = “PID Setpoint”

2 = “0-10V Input”

3 = “4-20mA Input”

4 = “Comm Port”

1 = “4-20mA Input”

For a list of digit options, refer to the PowerFlex 40

User Manual.

3 = “360 Seconds”

4 = “480 Seconds”

5 = “Flt Disabled”

4 = “Min Freq Ref”

5 = “Max Freq Ref”

6 = “Int Freq Ref”

2 = “Rotate Tune” 0

5 = “Setpnt, Trim”

6 = “0-10V, Trim”

7 = “4-20mA, Trim”

8 = “Comm, Trim”

2 = “Comm Port” 0

0

0

0

00F1

Page 22

English-20

Fault Codes

To clear a fault, press the Stop key, cycle power or set A100 [Fault Clear] to 1 or

2.

No. Fault Description

F2 Auxiliary Input

F3 Excessive DC Bus

voltage ripple

F4 UnderVoltage

F5 OverVoltage

F6 Motor Stalled

F7 Motor Overload

F8 Heatsink OvrTmp

F12 HW OverCurrent Check programming. Check for excess load, improper DC boost setting, DC brake volts set too

F13 Ground Fault Check the motor and external wiring to the drive output terminals for a grounded condition.

F29 Analog Input Loss

F33 Auto Rstrt Tries Correct the cause of the fault and manually clear.

F38 Phase U to Gnd Check the wiring between the drive and motor. Check motor for grounded phase.

F39 Phase V to Gnd

F40 Phase W to Gnd

F41 Phase UV Short Check the motor and drive output terminal wiring for a shorted condition.

F42 Phase UW Short

F43 Phase VW Short

F48 Params Defaulted The drive was commanded to write default values to EEPROM. Clear the fault or cycle power to

F63 SW OverCurrent

F64 Drive Overload Reduce load or extend Accel Time.

F70 Power Unit Cycle power. Replace drive if fault cannot be cleared.

F71 Net Loss The communication network has faulted.

F80 SVC Autotune The autotune function was either cancelled by the user of failed.

F81 Comm Loss If adapter was not intentionally disconnected, check wiring to the port. Replace wiring, port

F100 Parameter Checksum Restore factory defaults.

F122 I/O Board Fail Cycle power. Replace drive if fault cannot be cleared.

(1)

Auto-Reset/Run type fault. Configure with parameters A092 and A093.

(1)

Check remote wiring.

Monitor the incoming line for phase loss or line imbalance. Then, check input line fuse.

(1)

Monitor the incoming AC line for low voltage or line power interruption.

(1)

Monitor the AC line for high line voltage or transient conditions. Bus overvoltage can also be

caused by motor regeneration. Extend the decel time or install dynamic brake option.

(1)

Increase [Accel Time x] or reduce load so drive output current does not exceed the current set

by parameter A089 [Current Limit].

(1)

An excessive motor load exists. Reduce load so drive output current does not exceed the

current set by parameter P033 [Motor OL Current].

(1)

Check for blocked or dirty heat sink fins. Verify that ambient temperature has not exceeded

40°C (104 °F) for IP 30/NEMA 1/UL Type 1 installations or 50°C (122°F) for Open type installations.

Check fan.

high or other causes of excess current.

(1)

An analog input is configured to fault on signal loss. A signal loss has occurred.

Replace drive if fault cannot be cleared.

Replace drive if fault cannot be cleared.

the drive. Program the drive parameters as needed.

(1)

Check load requirements and A098 [SW Current Trip] setting.

expander, adapters or complete drive as required. Check connection. An adapter was

intentionally disconnected. Turn off using A105 [Comm Loss Action].

Page 23

English-21

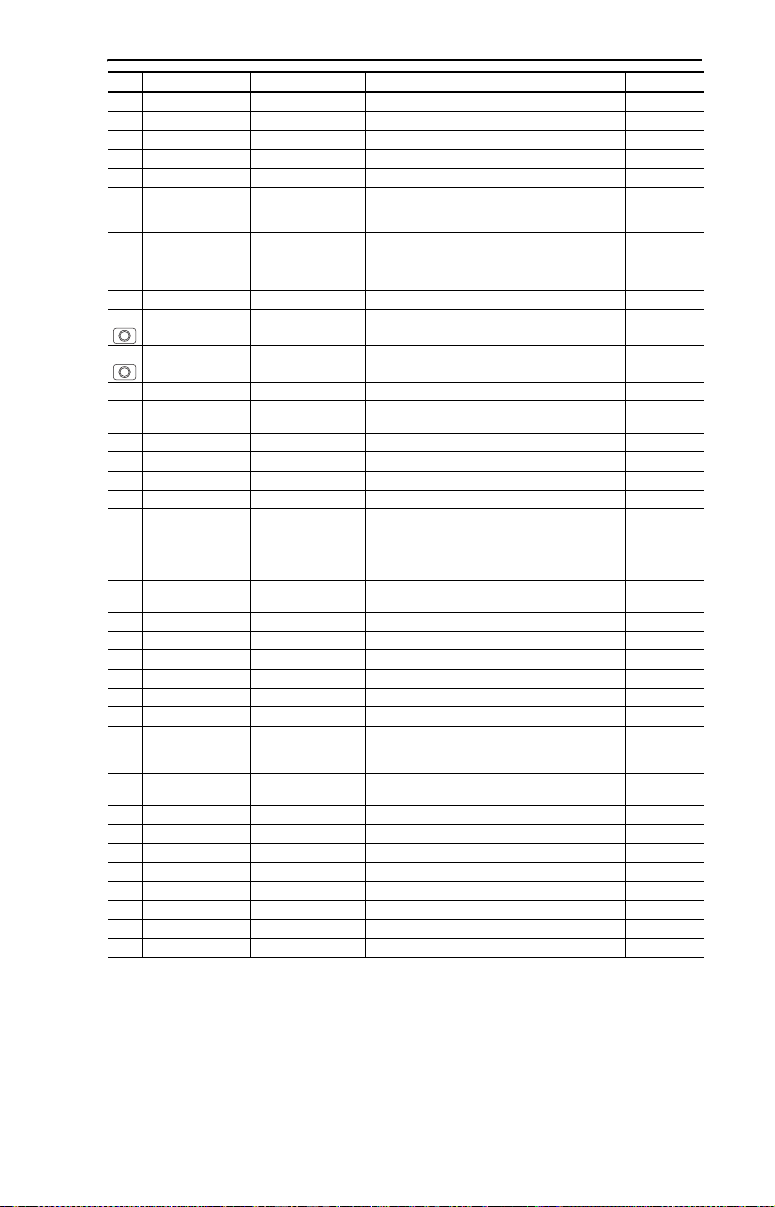

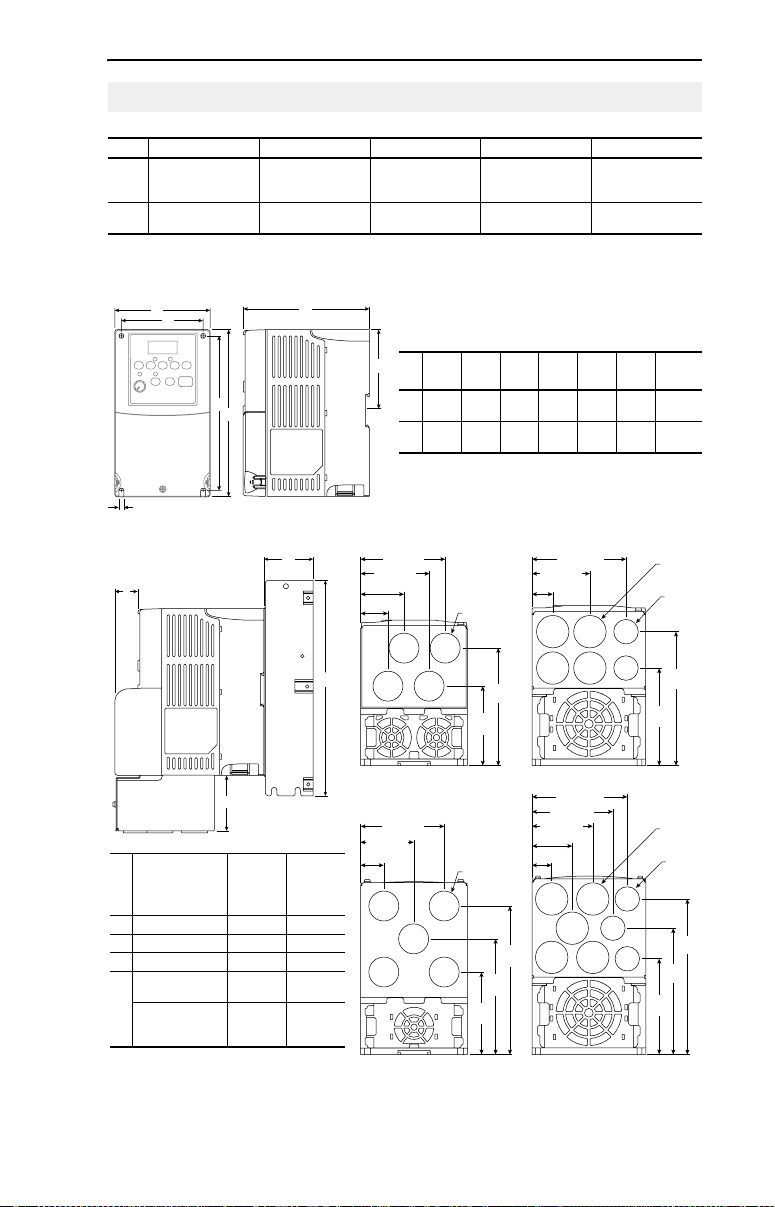

Drive Dimensions

PowerFlex 40 Frames – Ratings are in kW and (HP)

Frame 120V AC – 1-Phase 240V AC – 1-Phase 240V AC – 3-Phase 480V AC – 3-Phase 600V AC – 3-Phase

B 0.4 (0.5)

0.75 (1.0)

1.1 (1.5)

(1)

C

(1)

IP66, NEMA/UL Type 4X rated drives are not availble in Frame C drive ratings.

IP20, NEMA/UL Type Open

A

D

0.4 (0.5)

0.75 (1.0)

1.5 (2.0)

2.2 (3.0) 5.5 (7.5)

0.4 (0.5)

0.75 (1.0)

1.5 (2.0)

7.5 (10.0)

C

2.2 (3.0)

0.4 (0.5)

2.2 (3.0)

3.7 (5.0)

0.75 (1.0)

1.5 (2.0)

5.5 (7.5)

7.5 (10.0)

0.75 (1.0)

4.0 (5.0)

1.5 (2.0)

2.2 (3.0)

11.0 (15.0) 5.5 (7.5)

7.5 (10.0)

Dimensions are in millimeters and (inches).

Weights are in kilograms and (pounds).

4.0 (5.0)

11.0 (15.0)

E

B

5.5 (0.22)

Communication, RFI Filter, IP 30/NEMA 1/UL Type 1 Option Kits

B

A

C

D

B Frame

Option

Dimension

A Comm Cover 25 (0.98) 25 (0.98)

B EMC Line Filter 50 (1.97) 60 (2.36)

C EMC Line Filter 229 (9.02) 309 (12.17)

D IP30/NEMA 1/UL

Typ e 1

IP30/NEMA 1/UL

Type 1 for Comm

Cover

C Frame

Drive

Drive

33 (1.30) 60 (2.36)

64 (2.52) 60 (2.36)

F

ABCDEF

Frame

B100

(3.94)

C130

(5.1)

79.1 (3.11)

64.1 (2.52)

40.6 (1.60)

25.6 (1.01)

B Frame - 22-JBAB

77.5 (3.05)

50.0 (1.97)

22.5 (0.89)

B Frame - 22-JBCB

(used with Comm Cover)

180

(7.09)

260

(10.2)

∅

(0.87)

74.3

(2.93)

∅

(0.87)

76.3

(3.00)

136

(5.35)87(3.43)

180

(7.1)

22.2

109.9

(4.33)

22.2

134.3

(5.29)

105.3

(4.15)

(used with Comm Cover)

168

87.4

(6.61)

246

(9.7)

(3.44)

–4.3

116

(4.57)

107.0 (4.21)

66.0 (2.60)

24.0 (0.94)

C Frame - 22-JBAC

108.7 (4.28)

92.2 (3.63)

69.2 (2.72)

45.7 (1.80)

22.2 (0.87)

C Frame - 22-JBCC

Ship

Weigh t

2.2

(4.9)

(9.5)

∅

111.2

(4.38)

∅

(5.70)

109.8

(4.32)

(1.12)

∅

152.2

(5.99)

(1.12)

∅

144.8

28.5

22.2

(0.87)

28.5

22.2

(0.87)

179.8

(7.08)

Page 24

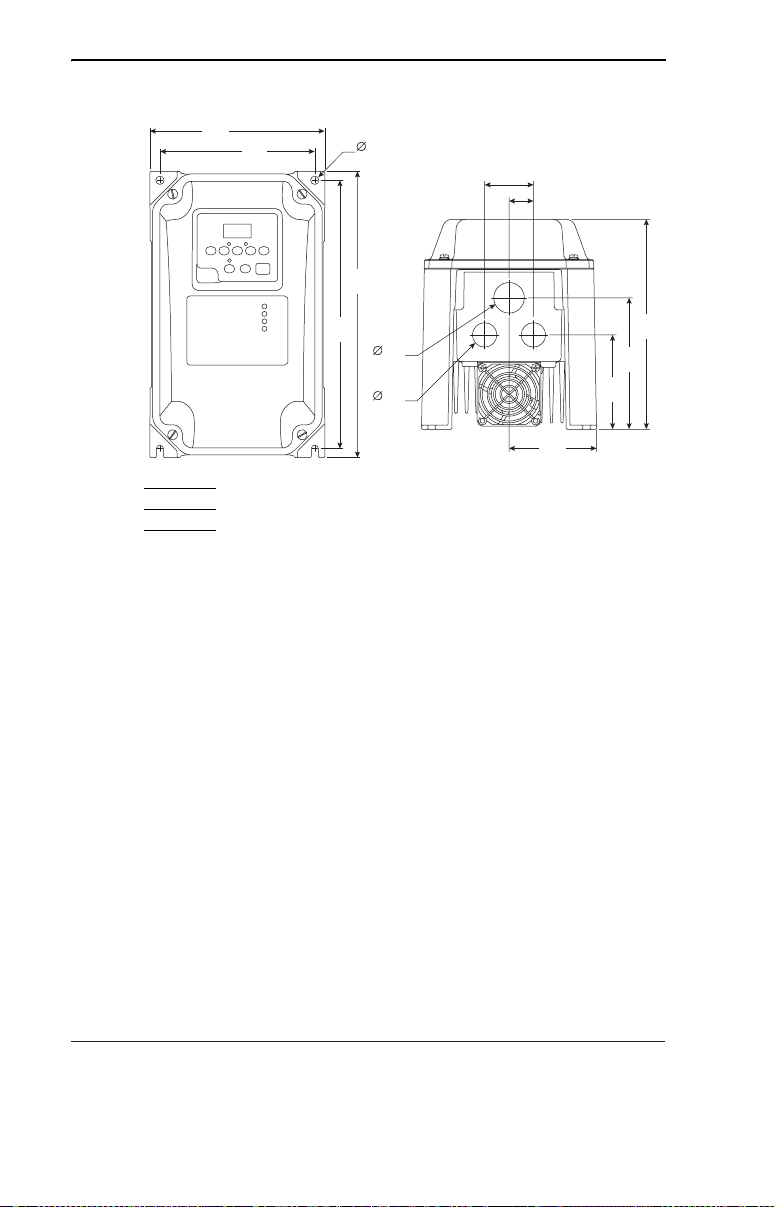

English-22

A

A

IP66, NEMA Type/UL Type 4X – Dimensions are in millimeters and (inches) Weights are

in kilograms and (pounds).

165

(6.50)

Weight

5.2 (11.5)

146

(5.75)

253

(9.96)

270

(10.63)

6.5

(0.26)

28

(1.10)

22

(0.87)

46

(1.81)

23

(0.91)

82.5

(3.25)

89

(3.50)

124

(4.88)

198

(7.80)

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberpor t 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 22B-QS001F-EN-P – December 2008

Supersedes May 2008 Copyright © 2008 Rockwell Automation, Inc. All rights reserved.

Page 25

Kurzanleitung

Frequenzumrichter

PowerFlex 40

FRN 5.xx - 6.xx

In dieser Kurzanleitung wird beschrieben, wie Sie den Frequenzumrichter

PowerFlex 40 installieren, in Betrieb nehmen und programmieren. Die hierin

enthaltenen Informationen sind jedoch kein

Benutzerhandbuch und sind nur für qualifiziertes FU-Wartungspersonal

vorgesehen.

Genauere Informationen über den PowerFlex 40, einschließlich EMV-Hinweise,

Anwendungsaspekte und die entsprechenden sicherheitstechnischen Hinweise,

finden Sie im PowerFlex 40-Benutzerhandbuch, Publikation 22B-UM001…,

www.rockwellautomation.com/literature.

unter

Allgemeine Vorsichtshinweise

ACHTUNG: Der FU enthält Hochspannungskondensatoren, die sich erst nach

gewisser Zeit nach der Trennung vom Netz entladen. Vor Arbeiten am

Frequenzumrichter muss sichergestellt werden, dass die Netzspannung von den

!

Netzanschlüssen [R, S, T (L1, L2, L3)] getrennt ist. Warten Sie drei Minuten, bis

die Kondensatoren sich auf eine ungefährliche Spannung entladen haben.

Nichtbeachtung kann schwere oder tödliche Verletzungen zur Folge haben.

Eine dunkle LED-Anzeige bedeutet nicht, dass sich die Kondensatoren auf eine

ungefährliche Spannung entladen haben.

ACHTUNG: Die sachwidrige Verwendung des Parameters A092 [Fhl

Neustartvers] oder A094 [Autostart] kann zu Schäden am Gerät und/oder

Verletzungen führen. Diese Funktionen sind nur unter Beachtung der lokal,

!

national und international geltenden Gesetze, Standards, Vorschriften und der in

der Industrie geltenden Bestimmungen anzuwenden.

ACHTUNG: Die Planung und Ausführung der Installation sowie die

Inbetriebnahme und spätere Wartung des Systems sollten nur von qualifiziertem

Fachpersonal ausgeführt werden, das mit Frequenzumrichtern und den daran

!

angeschlossenen Maschinen vertraut ist. Zuwiderhandlungen können zu

Personen- und/oder Sachschäden führen.

ACHTUNG: Dieser FU enthält Teile und Baugruppen, die empfindlich auf

elektrostatische Entladung reagieren. Bei der Installation, Prüfung, Wartung

oder Reparatur des Geräts müssen daher Vorsichtsmaßnahmen getroffen werden,

!

die solch eine elektrostatische Entladung verhindern, da Komponenten

andernfalls beschädigt werden können. Sollten Sie mit dem Verfahren zur

Verhinderung statischer Entladung nicht vertraut sein, ziehen Sie die

A-B-Publikation 8000-4.5.2, „Guarding Against Electrostatic Damage“ oder ein

entsprechendes Handbuch heran.

ACHTUNG: Wird ein FU nicht ordnungsgemäß eingesetzt bzw. installiert,

können Komponenten beschädigt und die Lebensdauer des Produkts dadurch

verkürzt werden. Verdrahtungs- bzw. Anwendungsfehler wie unzureichende

!

Motorgröße, falsche oder unzureichende Netzversorgung und zu hohe

Umgebungstemperaturen können zu Fehlfunktionen im System führen.

Ersatz für das

Page 26

Deutsch-2

Erläuterungen zum Aufstellen des FU

• Befestigen Sie den FU aufrecht an einer flachen, senkrechten und

ebenen Fläche.

Baugröße Schraubengröße Anzugsmoment DIN-Schiene

B M4 (#8-32) 1,56–1,96 Nm 35 mm

C M5 (#10-24) 2,45–2,94 Nm –

B (IP66,

Typ 4X)

• Kühlgebläse vor Staub und Metallpartikeln schützen.

• Keiner korrosiven Umgebung aussetzen.

• Vor Feuchtigkeit und direktem Sonnenlicht schützen.

Beim Aufstellen zu beachtende Mindestabstände

Einbauabmessungen finden Sie auf Seite 23.

M6 (#12-24) 3,95–4,75 Nm –

120 mm

(4.7 in.)

120 mm

(4.7 in.)

25 mm

(1.0 in.)

Nächstes Objekt, das

den Luftstrom durch

den Kühlkörper und

das Gehäuse des FU

blockieren könnte

120 mm

(4.7 in.)

Befestigungsoption A

Kein Abstand zwischen

den FUs erforderlich.

120 mm

(4.7 in.)

Befestigungsoption B

Umgebungs-/Betriebstemperatur

Umgebungstemperatur Schutzart Beim Aufstellen zu

Minimum Maximum

IP20, NEMA/UL-Typ „offen“

40 °C

IP66, NEMA/UL-Typ 4X

–10 °C

IP30, NEMA/UL-Typ 1

50 °C IP20, NEMA/UL-Typ „offen“

(1)

Nennwert erfordert die Installation des PowerFlex 40-Optionskits IP 30,

NEMA/UL-Typ 1.

beachtende

Mindestabstände

Befestigungsoption A

verwenden

Befestigungsoption A

verwenden

Befestigungsoption B

(1)

verwenden

Befestigungsoption B

verwenden

Page 27

Allgemeine Voraussetzungen für die Erdung

Deutsch-3

R/L1

S/L2

T/L3

SHLD

U/T1

V/T2

W/T3

Entfernen von MOVs

Um Schäden am FU zu vermeiden, sollte die MOV-Verbindung zur

Erde bei Installation des FU in einem nicht geerdeten

Verteilungssystem, in dem die Nennspannung zwischen einer der

Phasen 125 % des Phase-Phase-Potenzials übersteigen könnten,

unterbrochen werden. Dazu sind die in den nachstehenden Abbildungen

aufgeführten Brücken zu entfernen.

1. Zum Lösen der Schraube, diese gegen den Uhrzeigersinn drehen.

2. Brücke abziehen und aus dem FU-Gehäuse enfernen.

3. Schraube fest ziehen.

Brückenposition

IP66, NEMA/UL-Typ 4XIP20, NEMA/UL-Typ „offen“

Wichtig: Schraube nach dem Entfernen der Brücke fest ziehen.

Phase-Erde-MOV – Entfernung

AC Input

R/L1

S/L2

T/L3

Jumper

123

Three-Phase

4

Page 28

Deutsch-4

Einhaltung der EU-Richtlinien

Einzelheiten zur Einhaltung der Niederspannungs- und der EMV-Richtlinie

finden Sie im PowerFlex 40-Benutzerhandbuch

.

Sicherungen und Leistungsschalter – Technische Daten

FU-Nennwerte

Ausgangs-

(1)

nennwerte

kW (HP) A

Bestellnummer

100–120 V AC (±10 %) – Einphaseneingang, 0–230-V-Dreiphasenausgang

22B-V2P3x104 0,4 (0,5) 2,3 90–132 1,15 9,0 15 140M-C2E-C16 100-C12 40

22B-V5P0x104 0,75 (1,0) 5,0 90–132 2,45 20,3 35 140M-D8E-C20 100-C23 60

22B-V6P0x104 1,1 (1,5) 6,0 90–132 3,0 24,0 40 140M-F8E-C32 100-C37 80

200–240 V AC (±10 %) – Einphaseneingang

22B-A2P3x104 0,4 (0,5) 2,3 180–264 1,15 6,0 10 140M-C2E-B63 100-C09 40

22B-A5P0x104 0,75 (1,0) 5,0 180–264 2,45 12,0 20 140M-C2E-C16 100-C12 60

22B-A8P0x104 1,5 (2,0) 8,0 180–264 4,0 18,0 30 140M-D8E-C20 100-C23 85

22B-A012x104 2,2 (3,0) 12,0 180–264 5,5 25,0 40 140M-F8E-C32 100-C37 125

200–240 V AC (±10 %) – Dreiphaseneingang, 0–230-V-Dreiphasenausgang

22B-B2P3x104 0,4 (0,5) 2,3 180–264 1,15 2,5 6 140M-C2E-B40 100-C07 40

22B-B5P0x104 0,75 (1,0) 5,0 180–264 2,45 5,7 10 140M-C2E-C10 100-C09 60

22B-B8P0x104 1,5 (2,0) 8,0 180–264 4,0 9,5 15 140M-C2E-C16 100-C12 85

22B-B012x104 2,2 (3,0) 12,0 180–264 5,5 15,5 25 140M-C2E-C16 100-C23 125

22B-B017x104 3,7 (5,0) 17,5 180–264 8,6 21,0 30 140M-F8E-C25 100-C23 180

22B-B024x104 5,5 (7,5) 24,0 180–264 11,8 26,1 40 140M-F8E-C32 100-C37 235

22B-B033x104 7,5 (10,0) 33,0 180–264 16,3 34,6 60 140M-G8E-C45 100-C60 305

380–480 V AC (±10 %) – Dreiphaseneingang, 0–460-V-Dreiphasenausgang

22B-D1P4x104 0,4 (0,5) 1,4 342–528 1,4 1,8 3 140M-C2E-B25 100-C07 35

22B-D2P3x104 0,75 (1,0) 2,3 342–528 2,3 3,2 6 140M-C2E-B40 100-C07 50

22B-D4P0x104 1,5 (2,0) 4,0 342–528 4,0 5,7 10 140M-C2E-B63 100-C09 70

22B-D6P0x104 2,2 (3,0) 6,0 342–528 5,9 7,5 15 140M-C2E-C10 100-C09 100

22B-D010x104 4,0 (5,0) 10,5 342–528 10,3 13,0 20 140M-C2E-C16 100-C23 160

22B-D012x104 5,5 (7,5) 12,0 342–528 11,8 14,2 25 140M-D8E-C20 100-C23 175

22B-D017x104 7,5 (10,0) 17,0 342–528 16,8 18,4 30 140M-D8E-C20 100-C23 210

22B-D024x104 11,0 (15,0) 24,0 342–528 23,4 26,0 50 140M-F8E-C32 100-C43 300

460–600 V AC (±10 %) – Dreiphaseneingang, 0–575-V-Dreiphasenausgang

22B-E1P7x104 0,75 (1,0) 1,7 414–660 2,1 2,3 6 140M-C2E-B25 100-C09 50

22B-E3P0x104 1,5 (2,0) 3,0 414–660 3,65 3,8 6 140M-C2E-B40 100-C09 70

22B-E4P2x104 2,2 (3,0) 4,2 414–660 5,2 5,3 10 140M-C2E-B63 100-C09 100

22B-E6P6x104 4,0 (5,0) 6,6 414–660 8,1 8,3 15 140M-C2E-C10 100-C09 160

22B-E9P9x104 5,5 (7,5) 9,9 414–660 12,1 11,2 20 140M-C2E-C16 100-C16 175

22B-E012x104 7,5 (10,0) 12,2 414–660 14,9 13,7 25 140M-C2E-C16 100-C23 210

22B-E019x104 11,0 (15,0) 19,0 414–660 23,1 24,1 40 140M-D8E-C25 100-C30 300

(1)

In den aufgeführten Bestellnummern steht „x“ für den Gehäusetyp. Für alle Gehäusetypen sind

technische Daten verfügbar. FUs mit Nennwerten gemäß IP66, NEMA/UL-Typ 4X, sind nur in Baugröße

B erhältlich.

(2)

200–240 V AC – Einphasen-FUs sind auch mit integriertem EMV-Filter erhältlich. Das

Bestellnummern-Suffix ändert sich von N104 zu N114. Die Filteroption ist für FUs der Schutzart IP66,

NEMA/UL-Typ 4X, nicht erhältlich.

Eingangsnennwerte Netzstromleitungsschutz Verlustleistung

Spannungsbereich kVA A Sicherungen

(2)

, 0–230-V-Dreiphasenausgang

Motorschutzschalter 140M Schütze IP20 offen (W)

Page 29

Deutsch-5

Eingangs-/Ausgangsnennwerte

Ausgangsfrequenz: 0–400 Hz (programmierbar)

Wirkungsgrad: 97,5 % (typisch)

Zulassungen

D

9

E

6

T

6

S

X

I

L

U

UL508C

L

®

I

N

Q

D

E

C

T

O

N

D

9

E

6

T

6

S

X

I

L

U

CSA 22.2

L

C

®

I

N

Q

D

E

C

T

O

N

EMC Directive 89/336

LV: EN 50178, EN 60204

EMC: EN 61800-3, EN 50081-1

Digitalsteuereingänge (Eingangsstrom = 6 mA) Analogsteuereingänge

SRC-Modus (stromliefernd):

18–24 V = EIN

0–6 V = AUS

SNK-Modus (stromziehend):

0–6 V = EIN

18–24 V = AUS

Analogeingang (4–20 mA): 250 Ohm Eingangsimpedanz

Analogeingang (0–10 V DC): 100 kOhm Eingangsimpedanz

Externer Poti: 1–10 kOhm, 2 W Min.

Steuerausgang

Programmierbarer Ausgang (Relaiskontakt, Form C)

Ohmsche Last: 3,0 A bei 30 V DC, 3,0 A bei 125 V AC, 3,0 A bei 240 V AC

Induktivlast: 0,5 A bei 30 V DC, 0,5 A bei 125 V AC, 0,5 A bei 240 V AC

Optische Ausgänge

30 V DC, 50 mA

Induktionsfrei

Analogausgänge (10 Bit)

0–10 V, 1 kOhm min.

4–20 mA, 525 Ohm max.

Sicherungen und Leistungsschalter

Empfohlener Sicherungstyp: UL-Klasse J, CC, T oder Typ BS88; 600 V (550 V) oder gleichwertig.

Empfohlene Leistungsschalter: HMCP-Leistungsschalter oder gleichwertig.

Schutzvorrichtungen

Motorschutz: I2t-Überlastschutz – 150 % für 60 s, 200 % für 3 s (bietet Schutz der Klasse 10)

Überstrom: 200 % Hardwaregrenze, 300 % Impulsgrenze

Überspannung: 100–120 V AC Eingang – Auslösung bei 405 V DC Busspannung

Unterspannung:100–120 V AC-Eingang – Auslösung bei 210 V DC Busspannung

(entspricht einer Netzeingangsspannung von 150 V AC)

200–240 V AC Eingang – Auslösung bei 405 V DC Busspannung

(entspricht einer Netzeingangsspannung von 290 V AC)

380–460 V AC Eingang – Auslösung bei 810 V DC Busspannung

(entspricht einer Netzeingangsspannung von 575 V AC)

460–600 V AC Eingang – Auslösung bei 1005 V DC Busspannung

(entspricht einer Netzeingangsspannung von 711 V AC)

(entspricht einer Netzeingangsspannung von 75 V AC)

200–240 V AC Eingang – Auslösung bei 210 V DC Busspannung

(entspricht einer Netzeingangsspannung von 150 V AC)

380–480 V AC Eingang – Auslösung bei 390 V DC Busspannung

(entspricht einer Netzeingangsspannung von 275 V AC)

460–600 V AC Eingang –Wenn P042 = 3 erfolgt die Hochspannungsauslösung bei 487 V DC Busspannung

(344 V AC Netzeingangsspannung);

Wenn P042 = 2 erfolgt die Niederspannungsauslösung bei 390 V DC Busspannung

(275 V AC Netzeingangsspannung)

Steuervermögen bei Netzausfall: Minimale Toleranz beträgt 0,5 s – typischer Wert beträgt 2 s

Fehlerfreie Netzausfall-Überbrückung: 100 ms

Dynamischer Brems-Chopper

Alle FUs mit allen Nennwerten sind mit internem Brems-IGBT ausgestattet (ausgenommen Versionen ohne Brems-Chopper).

Bestellinformationen für DB-Widerstände sind Anhang B des PowerFlex 40-Benutzerhandbuchs zu entnehmen.

Page 30

Deutsch-6

Netzanschluss

Verdrahtungsnennwerte Empfohlener Kupferdraht

Nicht abgeschirmt, 600 V, 75 °C THHN/THWN

Abgeschirmt, 600 V, 75 °C oder 90 °C RHH/RHW-2

Abgeschirmter Kabelkanal, 600 V, 75 °C oder 90 °C

RHH/RHW-2

Klemmenblock für den Netzanschluss

B Frame C Frame

V/T2T/L3S/L2R/L1 U/T1 W/T3

DC+

BR+ BR-DC-

(1)

Anschluss

Beschreibung

R/L1, S/L2 1-Phasen-Eingang

R/L1, S/L2, T/L3 3-Phasen-Eingang

U/T1 Zu Motor U/T1

V/T2 Zu Motor V/T2

=

W/T3 Zu Motor W/T3

DC-Bus-Induktoranschluss (nur bei FUs der Baugröße C)

Beim FU der Baugröße C ist bei Anlieferung zwischen den

P2, P1

Klemmen P2 und P1 eine Brücke installiert. Entfernen Sie

diese Brücke nur, wenn ein DC-Bus-Induktor angeschlossen

werden soll. Der FU kann nicht ohne eine angeschlossene

Brücke oder einen angeschlossenen Induktor gestartet werden.

DC+, DC– DC-Busverbindung

BR+, BR– Anschluss des Widerstands für den Brems-Chopper

Schutzerde – PE

(1)

Wichtig: Die Klemmenschrauben können sich während des Transports lösen. Stellen

Sie vor dem Einschalten des FU sicher, dass alle Klemmenschrauben mit dem

empfohlenen Drehmoment angezogen sind.

Klemmenblock für den Netzanschluss – Technische Daten

Baugröße Maximaler

Leiterquerschnitt

2

B 5,3 mm

C 8,4 mm

(2)

Der angegebene Leiterquerschnitt bezeichnet Maximal- bzw. Minimalgrößen, die in

(10 AWG) 1,3 mm2 (16 AWG) 1,7–2,2 Nm

2

(8 AWG) 1,3 mm2 (16 AWG) 2,9–3,7 Nm

Minimaler

(2)

Leiterquerschnitt

den Klemmenblock passen – es handelt sich nicht um Empfehlungen.

0,4 mm, isoliert, für trockene

Standorte

Anixter OLF-7xxxxx,

Belden 29501-29507 oder

gleichwertig

Anixter 7V-7xxxx-3G

Shawflex 2ACD/3ACD oder

gleichwertig

V/T2T/L3S/L2R/L1 U/T1 W/T3 P2 P1

DC+

BR+ BR-DC-

Zwei Motorkabel

vertauschen, um

Drehrichtung zu

ändern.

Drehmoment

(2)

Page 31

Deutsch-7

Netzeigenschaften

Netzeigenschaft Abhilfemaßnahme

Niedrige Leitungsimpedanz

(weniger als 1 % Reaktanz)

Größer als 120-kVA-Netztransformator

Leitung verfügt über

Blindleistungskompensationskondensatoren

Häufige Netzunterbrechungen

Kurzfristige Spannungsspitzen von mehr als

6000 V (Blitzschlag)

Phase-Erde-Spannung überschreitet 125 % der

normalen Phase-Phase-Spannung.

Ungeerdetes Verteilungssystem

Offene Delta-Konfiguration (240 V)

(1)

Für FUs, die in offenen Delta-Konfigurationen mit einem neutralen System eingesetzt

werden, bei dem die mittlere Phase geerdet ist, wird die Phase gegenüber der in der Mitte

der Masse oder Erdung abgenommen Phase als „Hauptzweig“, „Spannungszweig“, „roter

Zweig“ o. Ä. bezeichnet. Dieser Zweig sollte im gesamten System jeweils am

Anschlusspunkt mit rotem oder orangefarbenem Klebeband gekennzeichnet werden. Der

Hauptzweig sollte an der mittlere Phase B der Drossel angeschlossen werden. Die genauen

Artikelnummern der Netzdrosseln sind dem PowerFlex 40-Benutzerhandbuch zu

entnehmen.

(2)

Bestellinformationen für Zubehörteile sind Anhang B des PowerFlex 40-Benutzerhandbuchs

zu entnehmen.

(1)

• Netzdrossel

• oder Trenntransformator

installieren

• oder Businduktor installieren – nur

bei FUs zwischen 5,5 und 11 kW

• Netzdrossel

• oder Trenntransformator

installieren

• MOV-Brücke zu Erde entfernen

• oder Trenntransformator mit

geerdeter Sekundärwicklung

installieren.

• Netzdrossel installieren

(2)

Empfohlene E/A-Verdrahtung

Leiterarten

Belden 8760/9460

(oder gleichw.)

Belden 8770

(oder gleichw.)

(3)

(4)

(4)

Wenn die Kabel kurz sind und sich in einem Schaltschrank befinden, der keine

empfindlichen Schaltungen enthält, ist zwar keine Abschirmung für diese Kabel

erforderlich, jedoch wird diese empfohlen.

Beschreibung Minimale

0,8 mm2(18AWG), verdrillt, 100 %

abgeschirmtes Kabel mit Ableiter

0,8 mm2(18AWG), 3-adrig, abgeschirmt nur für

Fernpoti

Litze oder Volldraht.

(3)

Isolationsspannung

300 V

60 °C

E/A-Klemmenblock – Technische Daten

Baugröße Maximale Leitergröße

(5)

Minimale Leitergröße

B und C 1,3 mm2 (16 AWG) 0,2 mm2 (24 AWG) 0,5–0,8 Nm

(5)

Der angegebene Leiterquerschnitt bezeichnet Maximal- bzw. Minimalgrößen, die in den

Klemmenblock passen – es handelt sich nicht um Empfehlungen.

Empfehlungen zu den maximalen Längen für Netz- und Steuerkabel sind

dem PowerFlex 40-Benutzerhandbuch zu entnehmen.

(5)

Drehmoment

Page 32

Deutsch-8

Steuerein- und Steuerausgänge

Steuerleitungsblockdiagramm

(4)

Enable

Jumper

Relay N.O.

Relay Common

Relay N.C.

Ohmscher

Widerstand

Induktiv 0,5 A 0,5 A 0,5 A

P036 [Startquelle] Stopp E/A-Klemme 01 Stopp

RS485-Anschluss Über P037 Auslauf

R1

R2

R3

0-10V

0-20mA

R1 R2 R3

30 V DC 125 V AC 240 V AC

3,0 A 3,0 A 3,0 A

Tastatur Über P037 Auslauf

3-Draht Über P037 Über P037

2-Draht Über P037 Auslauf

SNK

SRC

SRCSNK

+24V

+10V

0-10V

0/4-20mA

30V DC

50mA

Non-inductive

Analog Output Select

01 02 03 04 05

11 12 13 14 15

(1)

(1)

Wichtig: An E/A-Klemme 01 erfolgt nur dann kein Auslauf,

wenn P036 [Startquelle] auf „3-Draht“-Steuerung oder

„MomVW/RWStrg“ eingestellt ist. Bei der 3-Draht-Steuerung

wird E/A-Klemme 01 über P037 [Stoppmodus] gesteuert. Alle

weiteren Stoppquellen werden über P037 [Stoppmodus]

gesteuert.

(1)(4)

Stop

01

Start/Run FWD

02

Direction/Run REV

03

Digital Common

04

Digital Input 1

05

Digital Input 2

06

Digital Input 3

07

Digital Input 4

08

Opto Common

09

+24V DC

11

+10V DC

12

0-10V (or ±10V) Input

13

Analog Common

14

4-20mA Input

15

Analog Output

16

Opto Output 1

17

Opto Output 2

18

RS485 Shield

19

ENBL

06 07 08 09

16 17 18 19

Typical

SRC Wiring

(2)

Enable

Jumper

Pot must be

1-10k ohm

2 Watt Min.

Common

(4)

RS485

(DSI)

Typical

SNK Wiring

(3)

24V

1

Wichtig: Bei Anlieferung des FU ist zwischen E/A-Klemme 01 und 11 eine Brücke installiert. Wenn E/A-Klemme

01 als Stopp- oder Aktivierungseingang verwendet wird, muss diese Brücke entfernt werden.

(2)

Hier 2-Draht-Steuerung. Bei der 3-Draht-Steuerung ist an E/A-Klemme 02 ein einmaliger Befehl für einen

Start erforderlich. Zur Richtungsänderung an E/A-Klemme 03 ist ein Dauerbefehl erforderlich.

(3)

Bei Verwendung eines Optoausgangs mit einer induktiven Last (z. B. ein Relais) installieren Sie eine

Seriendiode parallel zum Relais (siehe Abbildung), um Schäden am Ausgang zu vermeiden.

(4)

Wenn die ENBL-Brücke entfernt ist, fungiert die E/A-Klemme 01 immer als Hardwareaktivierung und bewirkt

einen Auslauf. Weitere Informationen dazu finden Sie im PowerFlex 40-Benutzerhandbuch.

Page 33

Deutsch-9

Steuerungs-E/A-Klemmenbezeichnungen

Nr. Signal Werkseinstellung Beschreibung Param.

R1 Schließerrelais Fehler Schließerkontakt für Ausgangsrelais A055

R2 Relais-

Bezugspotenzial

R3 Öffnerrelais Fehler Öffnerkontakt für Ausgangsrelais A055

– Ausgangsrelais-Bezugspotenzial

Anwahl-DIP-Schalter

für Analogausgang

DIP-Schalter für

stromziehend/stromliefernd

01 Stopp