Page 1

Adjustable

Frequency AC

Drive

FRN 1.xx - 2.xx

User Manual

www.abpowerflex.com

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation

and Maintenance of Solid State Controls (Publication SGI-1.1 available from your

local Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature)

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be respo

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

pur

poses. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circu

its, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes

considerations.

WARNING: Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

describes some important

nsible or liable for indirect or

or in part, without written

to make you aware of safety

Important: Ide

ntifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or economic

loss. Attentions help you:

• i

dentify a hazard

void the hazard

• a

• recognize the consequences

Shock Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may be present.

Burn Hazard labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be at dangerous

temperatures.

Allen-Bradley, Rockwell Automation, and PowerFlex are registered trademarks of Rockwell Automation, Inc.

DriveExplorer, DriveExecutive, and SCANport are trademarks of Rockwell Automation, Inc.

PLC is a registered trademark of Rockwell Automation, Inc.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Page 3

Summary of Changes

The information below summarizes the changes to the PowerFlex 4M

User Manual since the July 2008 release.

Manual Updates

Description of New or Updated Information Page(s)

Minimum Enclosure Volume column and new footnotes added. 1-8

Drive, Fuse & Circuit Breaker Ratings topic updated. A-1

Electronic Motor Overload Protection description updated. A-4

The information below summarizes the changes to the PowerFlex 4M

User Manual since the August 2007 release.

Manual Updates

Description of New or Updated Information Page(s)

Footnote (2) deleted from “EN61800-3 Second Environment” in Table 1.I

Note to stop drive before changing parameter t211 [Anlg In 0-10V Lo]

removed.

New option 13, I/O Control, for parameter t221 [Relay Out Sel] added. 3-15

Fault description for F3 corrected. 4-3

Corrected Ta bl e B .F by adding the 0.75 kW (1.0 HP) and 1.5 kW (2.0 HP)

ratings for the 22F-RF025-BL EMC line filter.

Description for bits 14, 13, and 12 of register address 8192 corrected. C-4

Information on reading register address 8192 clarified. C-4

Description for bits 6, 7, and 15 of register address 8192 updated. C-4

Information on reading register address 8193 clarified. C-5

Figure C.1, Network Wiring Diagram, updated. C-1

Guidelines on standard RS485 wiring practices added. C-1

, A-2

. 1-22

3-14

B-4

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 4

soc-2

The information below summarizes the changes to the PowerFlex 4M

User Manual since the February 2007 release.

Manual Updates

Description of New or Updated Information Page(s)

Input description and attention text for Multiple Digital Input Connection

example corrected.

Description for option 21 of parameter t221 [Relay Out Sel] corrected. 3-15

Invalid catalog number for L Type Filter deleted. B-4, B-10

Graphic for the “Connecting an RS-485 Network” section corrected D-3

1-18

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 5

Preface Overview

Who Should Use this Manual? . . . . . . . . . P-1

Reference Materials . . . . . . . . . . . . . . . . . P-1

Manual Conventions . . . . . . . . . . . . . . . . . P-2

Drive Frame Sizes . . . . . . . . . . . . . . . . . . . P-2

General Precautions . . . . . . . . . . . . . . . . . P-3

Catalog Number Explanation . . . . . . . . . . P-4

Chapter 1 Installation/Wiring

Opening the Cover . . . . . . . . . . . . . . . . . . 1-1

Mounting Considerations . . . . . . . . . . . . . 1-2

AC Supply Source Considerations . . . . . . 1-3

General Grounding Requirements . . . . . . 1-5

Fuses and Circuit Breakers . . . . . . . . . . . . 1-7

Power Wiring . . . . . . . . . . . . . . . . . . . . . . 1-9

I/O Wiring Recommendations . . . . . . . . 1-13

Start and Speed Reference Control . . . . . 1-19

EMC Instructions . . . . . . . . . . . . . . . . . . 1-21

Chapter 2 Start Up

Prepare For Drive Start-Up . . . . . . . . . . . . 2-1

Integral Keypad. . . . . . . . . . . . . . . . . . . . . 2-3

Viewing and Editing Parameters. . . . . . . . 2-4

Chapter 3 Programming and Parameters

About Parameters . . . . . . . . . . . . . . . . . . . 3-1

Parameter Organization. . . . . . . . . . . . . . . 3-2

Display Group . . . . . . . . . . . . . . . . . . . . . . 3-3

Basic Program Group . . . . . . . . . . . . . . . . 3-8

Terminal Block Group. . . . . . . . . . . . . . . 3-13

Communications Group . . . . . . . . . . . . . 3-17

Advanced Program Group. . . . . . . . . . . . 3-19

Parameter Cross Reference – by Name. . 3-31

Chapter 4 Troubleshooting

Drive Status. . . . . . . . . . . . . . . . . . . . . . . . 4-1

Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Fault Descriptions . . . . . . . . . . . . . . . . . . . 4-3

Common Symptoms and Corrective Actions . .

4-5

Appendix A Supplemental Drive Information

Drive, Fuse & Circuit Breaker Ratings. . . A-1

Specifications . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B Accessories and Dimensions

Product Selection . . . . . . . . . . . . . . . . . . . B-1

Product Dimensions . . . . . . . . . . . . . . . . . B-6

Table of Contents

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 6

ii Table of Contents

Appendix C RS485 (DSI) Protocol

Network Wiring. . . . . . . . . . . . . . . . . . . . . C-1

Parameter Configuration . . . . . . . . . . . . . . C-3

Supported Modbus Function Codes . . . . . C-3

Writing (06) Logic Comman

Writing (06) Reference . . . . . . . . . . . . . . . C-5

Reading (03) Logic Status Data. . . . . . . . . C-5

Reading (03) Feedback . . . . . . . . . . . . . . . C-6

Reading (03) Drive Error Codes . . . . . . . . C-6

Reading (03) and Writing (06) Dri

Additional Information . . . . . . . . . . . . . . . C-7

Appendix D RJ45 DSI Splitter Cable

Connectivity Guidelines . . . . . . . . . . . . . . D-1

DSI Cable Accessories . . . . . . . . . . . . . . . D-2

Connecting an RS-485 Network . . . . . . . . D-3

Index

d Data. . . . . . C-4

ve

Parameters . . . . . . . . . . . . . . . . . . . . . . C-7

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 7

Preface

Overview

The purpose of this manual is to provide you with the basic information

needed to install, start-up and troubleshoot the PowerFlex 4M

Adjustable Frequency AC Drive.

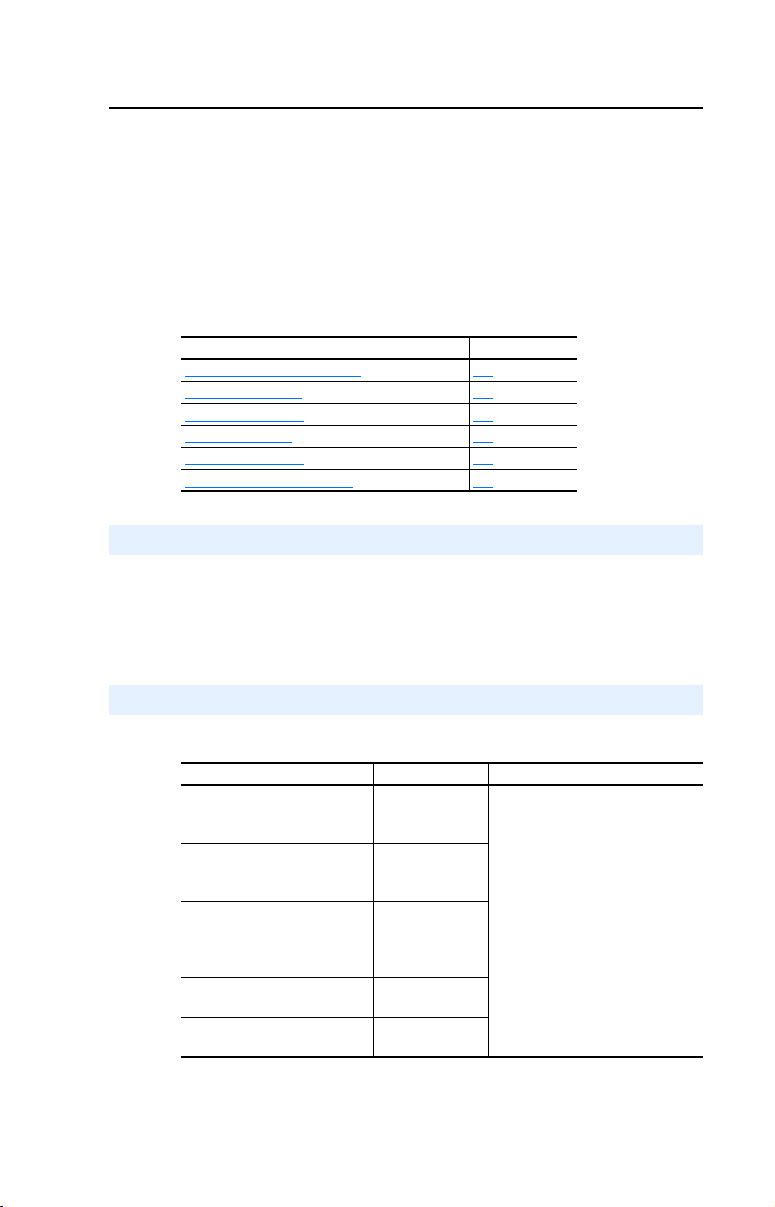

For information on… See page…

Who Should Use this Manual?

Reference Materials P-1

Manual Conventions P-2

Drive Frame Sizes P-2

General Precautions P-3

Catalog Number Explanation P-4

Who Should Use this Manual?

This manual is intended for qualified personnel.

program and operate Adjustable Frequency AC Drive devices. In

addition, you must have an understanding of the parameter settings and

functions.

P-1

You must be able to

Reference Materials

The following manuals are recommended f

Title Publication Available Online at …

Wiring and Grounding

Guidelines

Modulated (PWM) AC Drives

Preventive Maintenance of

In

System Equipment

Safety Guidelines for the

Applica

Maintenance of Solid State

Control

A Global Reference Guide for

Read

Guarding Against Electrostatic

Damag

for Pulse Width

dustrial Control and Drive

tion, Installation and

ing Schematic Diagrams

e

DRIVES-IN001…

DRIVES-SB001…

SGI-1.1

0100-2.10

8000-4.5.2

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

or general drive information:

www.rockwellautomation.com/

terature

li

Publication 22F-UM001D-EN-E

Page 8

P-2 Overview

Manual Conventions

• In this manual we refer to the PowerFlex 4M Adjustable Frequency

AC Drive as: drive, PowerFlex 4M or PowerFlex 4M Drive.

arameter numbers and names are shown in this format:

• P

P101 [Motor NP Volts]

• The following words are used throughout the manual to describe an

action:

Wor d Meaning

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not Recommended

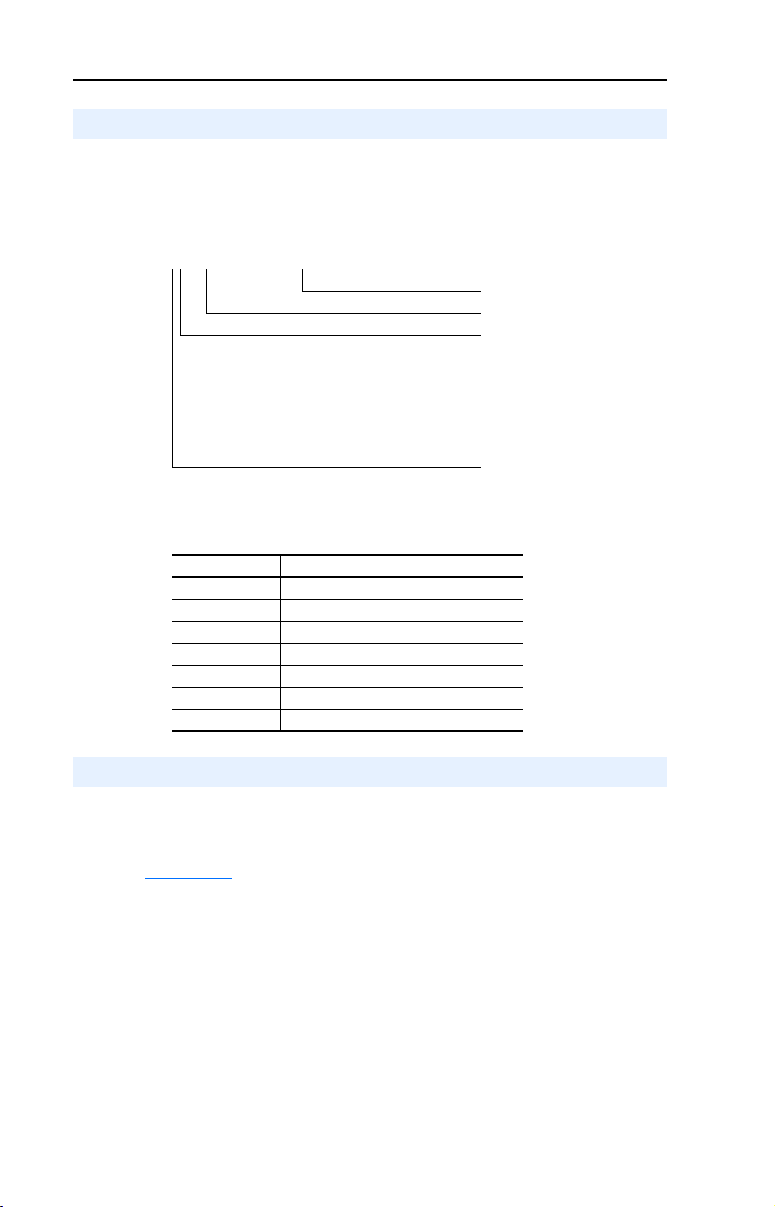

Name

Number

Group

d = Display Group

P = Basic Program Group

t = Terminal Block Group

C = Communications Group

A = Advanced Program Group

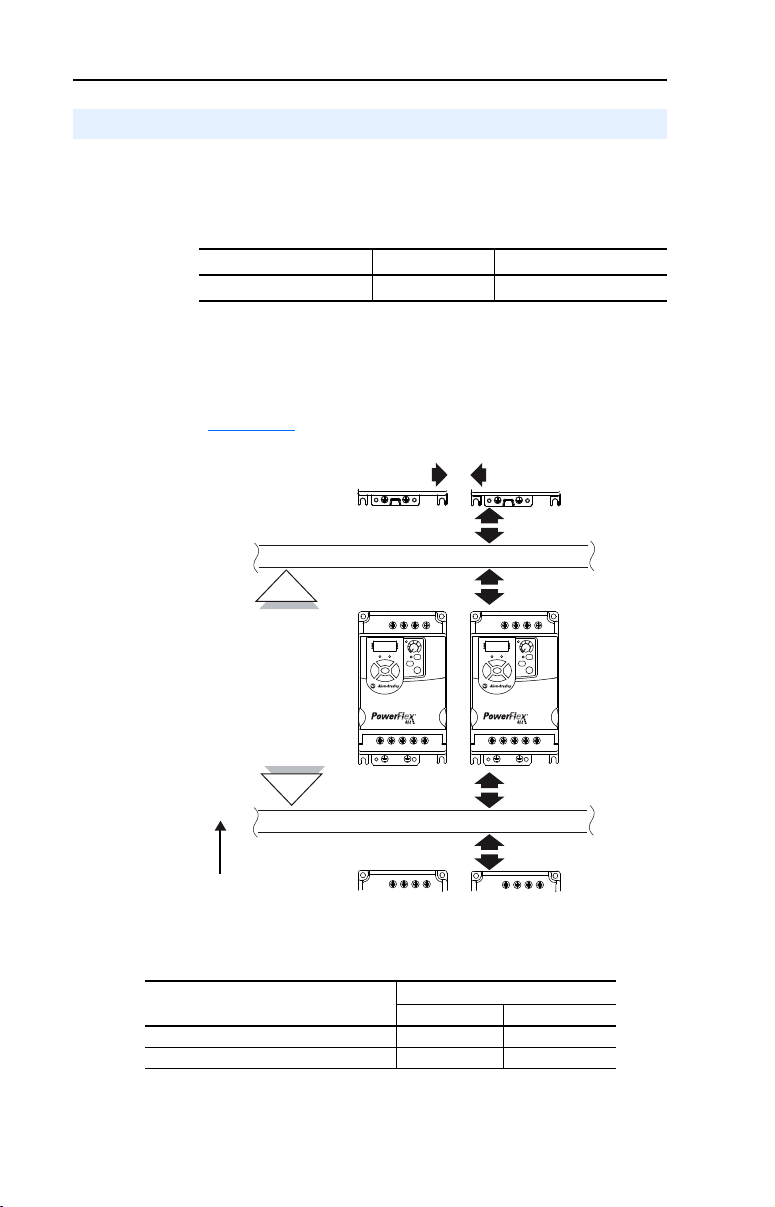

Drive Frame Sizes

Similar PowerFlex 4M drive sizes are

simplify spare parts ordering, dimensioning, etc. A cross-reference of

drive catalog numbers and their respective frame sizes is provided in

Appendix B.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

grouped into frame sizes to

Page 9

Overview P-3

!

!

!

!

!

General Precautions

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing any

work on the drive. Measure the DC bus voltage at the –DC and +DC

terminals on the Power Terminal Block (refer to

Terminal descriptions). The

Darkened LEDs or a darkened LCD display is not an indication that

capacitors have discharged to safe voltage levels.

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of the

system. Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

errors, such as, undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

voltage must be zero.

Chapter 1 Power

ATTENTION: The bus regulator function is extremely useful for

preventing nuisance overvoltage faults resulting from aggressive

decelerations, overhauling loads, and eccentric loads. However, it can

also cause either of the following two conditions to occur.

1. Fast positive changes in input voltage o

can cause uncommanded positive speed changes;

2. Actual deceleration times can

deceleration times.

However, a “Stall Fault” is generated if the drive remains in this state

for 1 minute. If this condition is unacceptable, the bus regulator must be

disabled (see parameter

dynamic brake resistor will provide equal or better performance in most

cases.

A441). In addition, installing a properly sized

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

be longer than commanded

r imbalanced input voltages

Publication 22F-UM001D-EN-E

Page 10

P-4 Overview

Code Vol ta ge Ph.

V 120V AC 1

A 240V AC 1

B 240V AC 3

D 480V AC 3

Code Version

3 No Brake IGBT

4 Standard

Code Interface Module

1 Fixed Keypad

Code Enclosure

N Panel Mount - IP 20 (NEMA Type Open)

1-3 4 5 6-8 9 10 11 12 13-14

22F - D 8P7 N 1 1 3 AA

Drive Dash Voltage Rating Rating Enclosure HIM Emission Class Type Optional

Code

22F PowerFlex 4M

Code Purpose

AA Reserved for

thru custom firmware

ZZ

Output Current @ 380-480V Input

Code Amps kW (HP)

1P5 1.5 0.4 (0.5)

2P5 2.5 0.75 (1.0)

4P2 4.2 1.5 (2.0)

6P0 6.0 2.2 (3.0)

8P7 8.7 3.7 (5.0)

013 13.0 5.5 (7.5)

018 18.0 7.5 (10.0)

024 24.0 10.0 (15.0)

Output Current @ 100-120V Input

Code Amps kW (HP)

1P6 1.6 0.2 (0.25)

2P5 2.5 0.4 (0.5)

4P5 4.5 0.75 (1.0)

6P0 6.0 1.1 (1.5)

Output Current @ 200-240V Input

Code Amps kW (HP)

1P6 1.6 0.2 (0.25)

2P5 2.5 0.4 (0.5)

4P2 4.2 0.75 (1.0)

8P0 8.0 1.5 (2.0)

011 11.0 2.2 (3.0)

012 12.0 2.2 (3.0)

017 17.5 3.7 (5.0)

025 25.0 5.5 (7.5)

033 33.0 7.5 (10.0)

Code Rating

0 Not Filtered

1Filtered

Additional accessories, options and adapters are available. See Appendix B

for details.

Catalog Number Explanation

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 11

Chapter 1

!

Installation/Wiring

This chapter provides information on mounting and wiring the

PowerFlex 4M Drive.

For information on… See page For information on… See page

Opening the Cover

Mounting Considerations 1-2 Power Wiring 1-9

AC Supply Source Considerations 1-3 I/O Wiring

General Grounding Requirements 1-5 EMC Instructions 1-21

Most start-up difficulties are the result of incorrect wiring. Every

precaution must be taken to assure that the wiring is done as instructed.

All items must be read and understood before the actual installation

begins.

ATTENTION: The following information is merely a guide for proper

installation. Rockwell Automation, Inc. cannot assume responsibility

for the compliance or the noncompliance to any code, national, local or

otherwise for the proper installation of this drive or associated

equipment. A hazard of personal injury and/or equipment damage

exists if codes are ignored during installation.

1-1 Fuses and Circuit Breakers 1-7

1-13

Recommendations

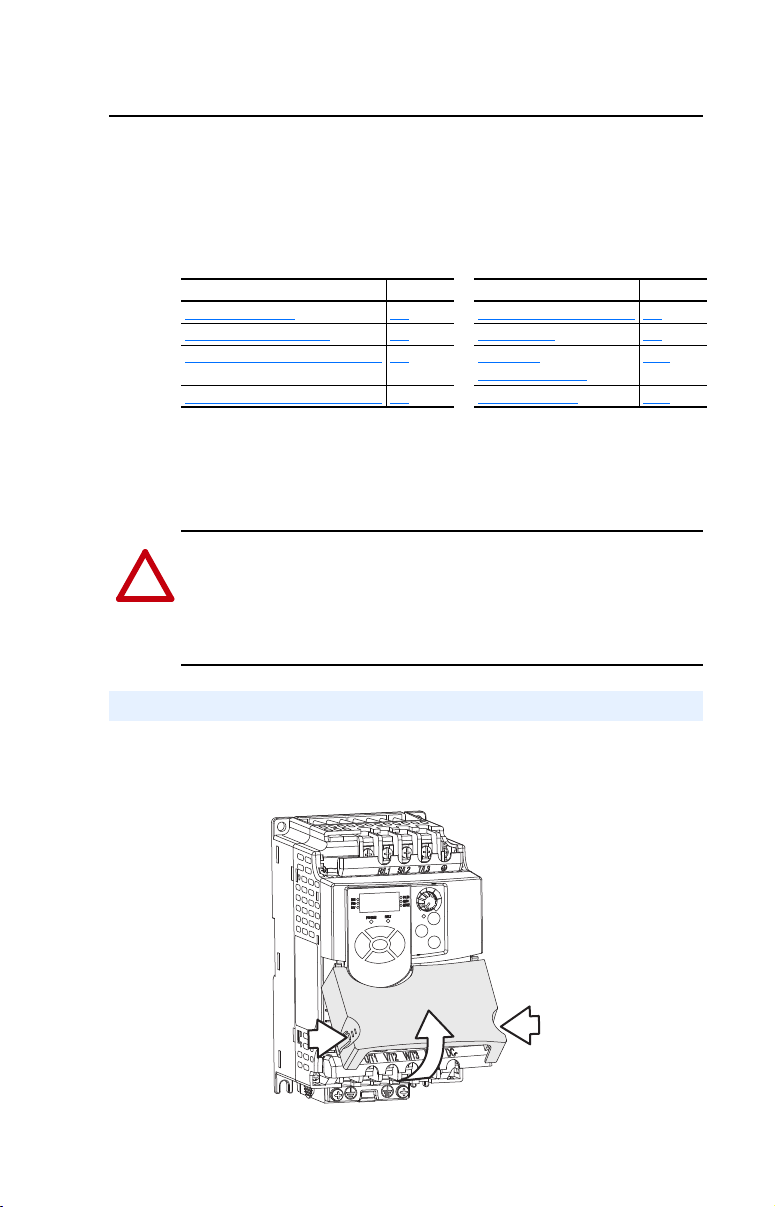

Opening the Cover

1. Press and hold in the tabs on each side of the cover.

2. Pull the cover out and up to release.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 12

1-2 Installation/Wiring

76.2 mm (3.0 in.)

76.2 mm (3.0 in.)

Closest object that

may obstruct air flow

through the drive

heat sink and chassis

76.2 mm (3.0 in.)

76.2 mm (3.0 in.)

Airflow

See Table 1.B

Mounting Considerations

• Mount the drive upright on a flat, vertical and level surface.

– Install on 35 mm DIN Rail (for frames A and B).

or

– Install with screws.

Table 1.A Screw Mounting Recommendations

Minimum Panel Thickness Screw Size Mounting Torque

1.9 mm (0.0747 in.) M4 (#8-32) 1.56-1.96 N-m (14-17 lb.-in.)

• Protect the cooling fan by avoiding dust or metallic particles.

• Do not expose to a corrosive atmosphere.

• Protect from moisture and direct sunlight.

Minimum Mounting Clearances

Refer to Appendix B for mounting dimensions.

Ambient Operating Temperatures

Table 1.B Enclosure and Clearance Requirements

Horizontal Clearance between drives

0 mm and greater -10°C (14°F) 40°C (104°F)

25 mm and greater -10°C (14°F) 50°C (122°F)

Drive enclosure is rated IP20, NEMA/UL Type Open.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Minimum Maximum

Ambient Temperature

Page 13

Installation/Wiring 1-3

!

Important:

Tighten screw after

jumper removal.

Storage

• Store within an ambient temperature range of -40° to +85°C.

• Store within a relative humidity range of 0% to 95%,

non-condensing.

• Do not expose to a corrosive atmosphere.

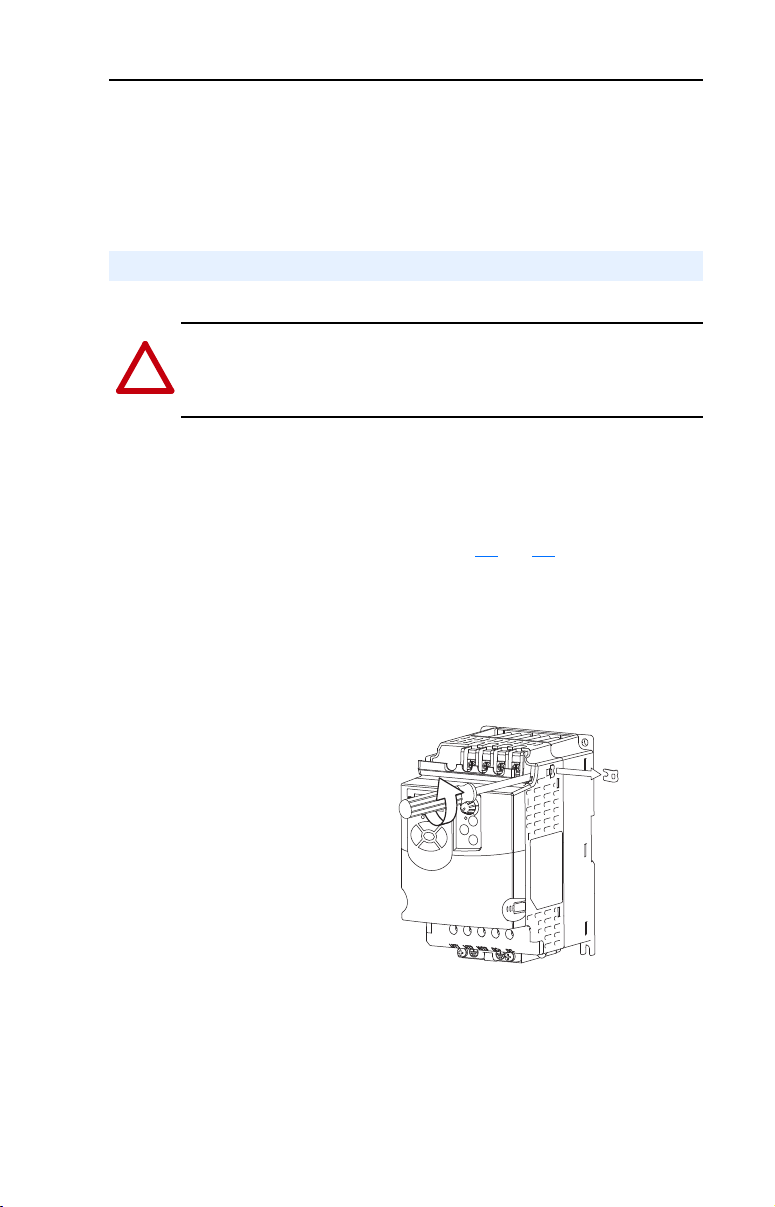

AC Supply Source Considerations

Ungrounded Distribution Systems

ATTENTION: PowerFlex 4M drives contain protective MOVs that

are referenced to ground. These devices must be disconnected if the

drive is installed on an ungrounded or resistive grounded distribution

system.

Disconnecting MOVs

To prevent drive damage, the MOVs connected to ground shall be

disconnected if the drive is installed on an ungrounded distribution

system where the line-to-ground voltages on any phase could exceed

125% of the nominal line-to-line voltage. To disconnect these devices,

remove the jumper shown in the Figures 1.1

1. Turn the screw counterclockwise to loosen.

2. Pull the jumper completely out of the drive chassis.

3. Tighten the screw to keep it in place.

and 1.2.

Figure 1.1 Jumper Location (Frame A shown)

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 14

1-4 Installation/Wiring

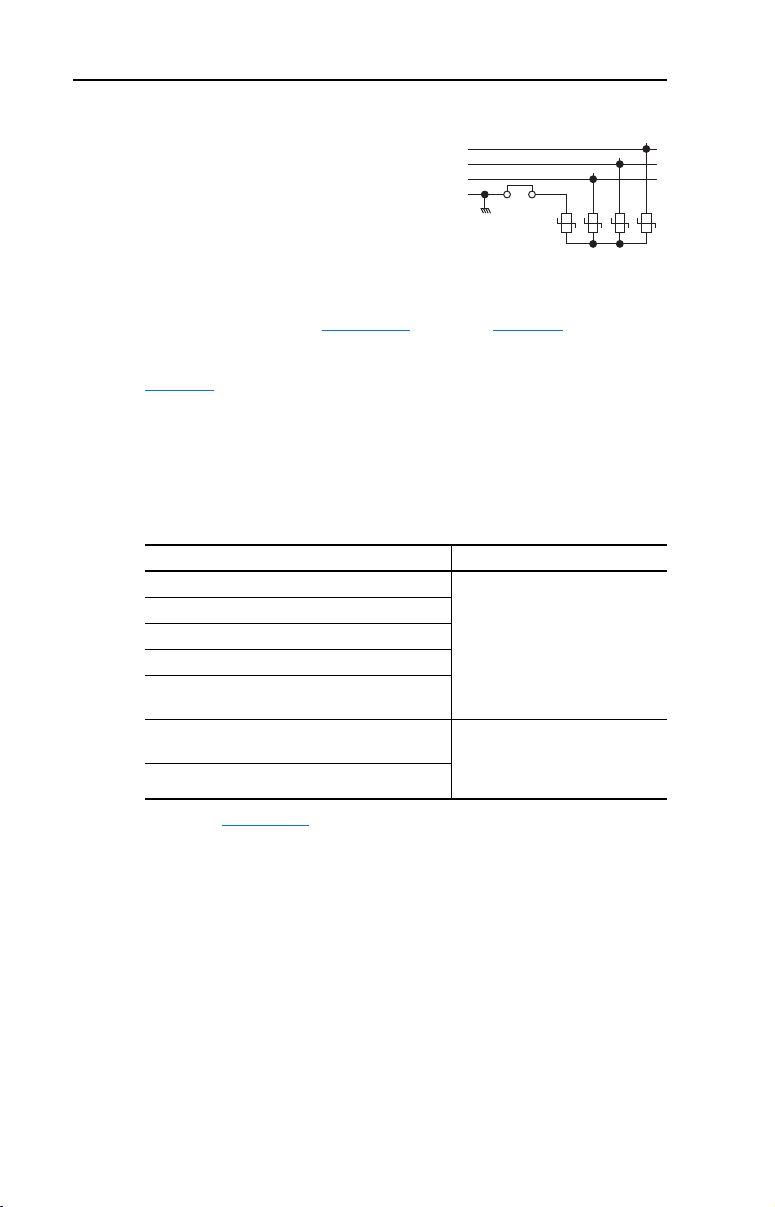

Figure 1.2 Phase to Ground MOV Removal

Input Power Conditioning

The drive is suitable for direct connection to input power within the rated

voltage of the drive (see Appendix

input power conditions which may cause component damage or

reduction in product life. If any of the conditions exist, as described in

Table 1.C

Action on the line side of the drive.

Important: Only one device per branch circuit is required. It should be

Table 1.C Input Power Conditions

, install one of the devices listed under the heading Corrective

mounted closest to the branch and sized to handle the total

current of the branch circuit.

AC Input

R/L1

S/L2

T/L3

Jumper

123

Three-Phase

A). Listed in Table 1.C are certain

4

Input Power Condition Corrective Action

Low Line Impedance (less than 1% line reactance) • Install Line Reactor

Greater than 120 kVA supply transformer

• or Isolation Transformer

Line has power factor correction capacitors

Line has frequent power interruptions

Line has intermittent noise spikes in excess of

6000V (lightning)

Phase to ground voltage exceeds 125% of normal

line to line voltage

Ungrounded distribution system

(1)

Refer to Appendix B for accessory ordering information.

• Remove MOV jumper to ground.

• or Install Isolation Transformer

with grounded secondary if

necessary.

(1)

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 15

Installation/Wiring 1-5

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

SHLD

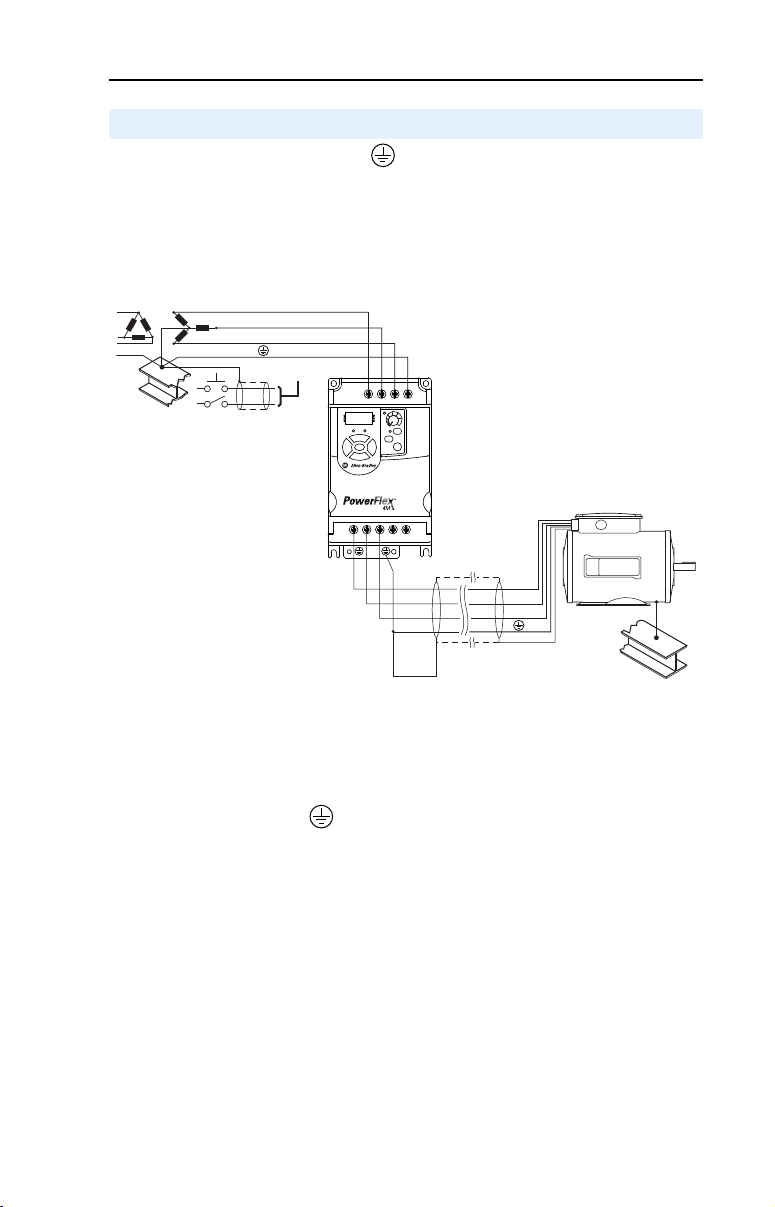

General Grounding Requirements

The drive Safety Ground - (PE) must be connected to system ground.

Ground impedance must conform to the requirements of national and

local industrial safety regulations and/or electrical codes. The integrity

of all ground connections should be periodically checked.

Figure 1.3 Typical Grounding

Ground Fault Monitoring

If a system ground fault monitor (RCD) is to be used, only Type B

(adjustable) devices should be used to avoid nuisance tripping.

Safety Ground - (PE)

This is the safety ground for the drive that is required by code. One of

these points must be connected to adjacent building steel (girder, joist), a

floor ground rod or bus bar. Grounding points must comply with national

and local industrial safety regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the ground terminals on

the drive.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 16

1-6 Installation/Wiring

Shield Termination - SHLD

Either of the safety ground terminals located on the power terminal

block provides a grounding point for the motor cable shield. The motor

cable shield connected to one of these terminals (drive end) should also

be connected to the motor frame (motor end). Use a shield terminating or

EMI clamp to connect the shield to the safety ground terminal. The

conduit box option may be used with a cable clamp for a grounding point

for the cable shield.

When shielded cable is used for control and signal wiring, the shield

should be grounded at the source end only, not at the drive end.

RFI Filter Grounding

Using single phase drives with integral filter, or an external filter with

any drive rating, may result in relatively high ground leakage currents.

Therefore, the filter must only be used in installations with grounded

AC supply systems and be permanently installed and solidly

grounded (bonded) to the building power distribution ground. Ensure

that the incoming supply neutral is solidly connected (bonded) to the

same building power distribution ground. Grounding must not rely on

flexible cables and should not include any form of plug or socket that

would permit inadvertent disconnection. Some local codes may require

redundant ground connections. The integrity of all connections should be

periodically checked.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 17

Installation/Wiring 1-7

!

Fuses and Circuit Breakers

The PowerFlex 4M does not provide branch short circuit protection. This

product should be installed with either input fuses or an input circuit

breaker. National and local industrial safety regulations and/or electrical

codes may determine additional requirements for these installations.

ATTENTION: To guard against personal injury and/or equipment

damage caused by improper fusing or circuit breaker selection, use only

the recommended line fuses/circuit breakers specified in this section.

Fusing

The PowerFlex 4M has been UL tested and approved for use with input

fuses. The ratings in the table that follows are the maximum

recommended values for use with each drive rating. The devices listed in

this table are provided to serve as a guide.

Bulletin 140M (Self-Protected Combination Controller)/UL489

Circuit Breakers

When using Bulletin 140M or UL489 rated circuit breakers, the

guidelines listed below must be followed in order to meet the NEC

requirements for branch circuit protection.

• Bulletin 140M can be used in single and group motor applications.

• Bulletin 140M can be used up stream from the drive without the

need for fuses.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 18

1-8 Installation/Wiring

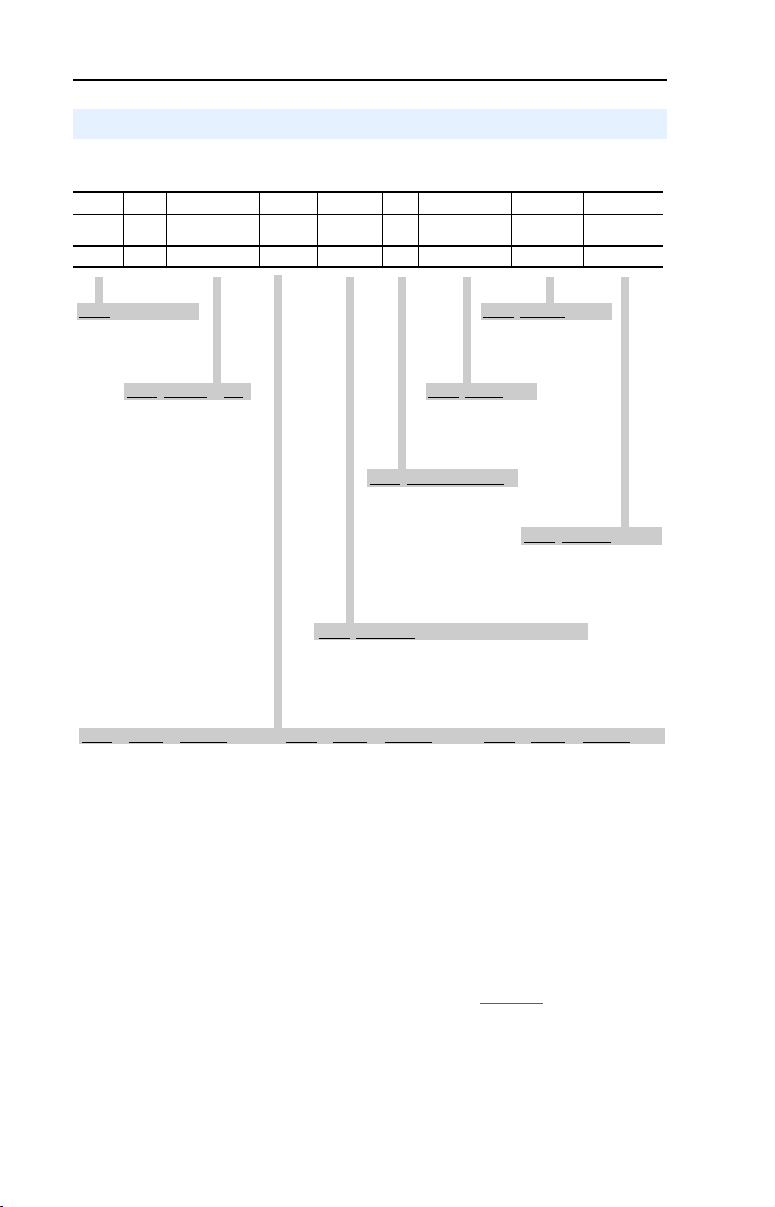

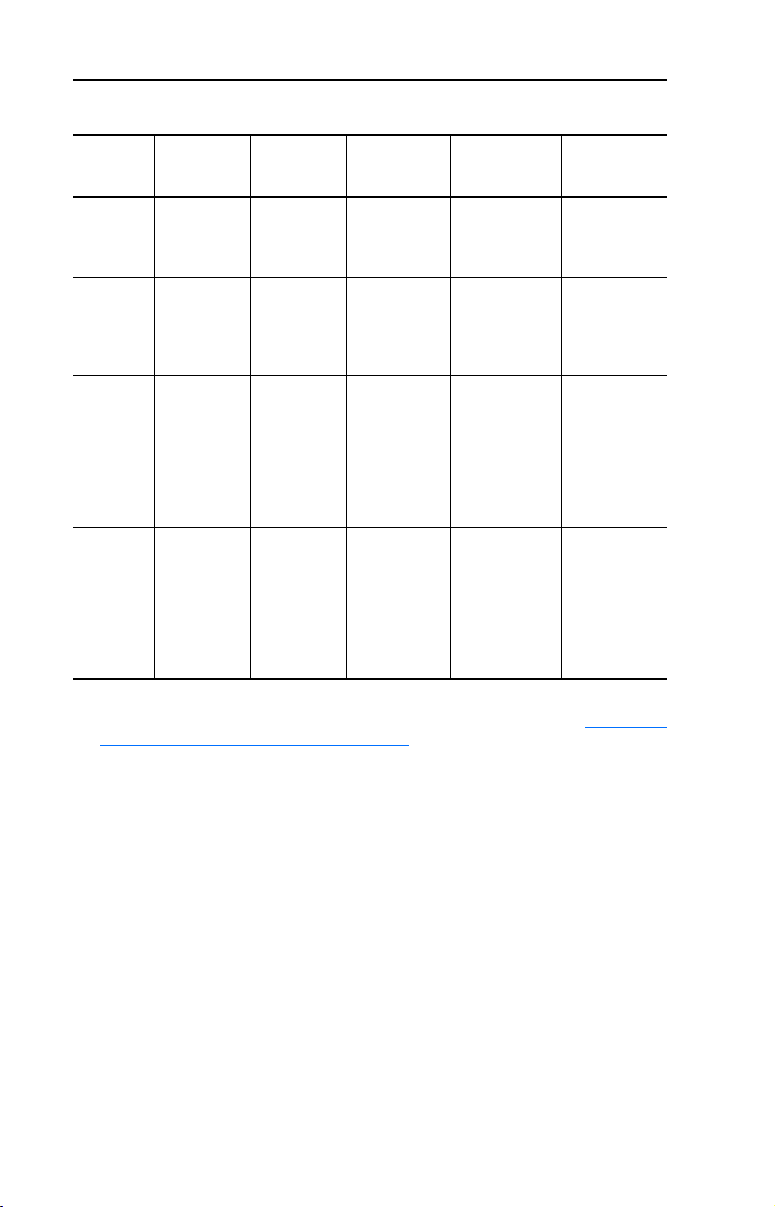

Table 1.D Minimum Recommended Branch Circuit Protective Devices

(1)

(2) (3)

Voltage

Rating

120V AC –

1-Phase

240V AC –

1-Phase

240V AC –

3-Phase

480V AC –

3-Phase

(1)

(2)

(3)

Drive Rating

kW (HP)

0.2 (0.25)

0.4 (0.5)

0.75 (1.0)

1.1 (1.5)

0.2 (0.25)

0.4 (0.5)

0.75 (1.0)

1.5 (2.0)

2.2 (3.0)

0.2 (0.25)

0.4 (0.5)

0.75 (1.0)

1.5 (2.0)

2.2 (3.0)

3.7 (5.0)

5.5 (7.5)

7.5 (10.0)

0.4 (0.5)

0.75 (1.0)

1.5 (2.0)

2.2 (3.0)

3.7 (5.0)

5.5 (7.5)

7.5 (10.0)

11.0 (15.0)

Fuse Rating

Amps

10

15

30

40

10

10

15

35

40

3

6

10

15

25

35

45

60

3

6

10

10

15

25

30

50

Recommended Fuse Type: UL Class J, RK1, T or Type BS88; 600V (550V) or equivalent.

The AIC ratings of the Bulletin 140M Motor Protector Circuit Breakers may vary. See Bulletin 140M

Motor Protection Circuit Breakers Application Ratings.

Manual Self-Protected (Type E) Combination Motor Controller, UL listed for 208 Wye or Delta, 240

140M

Catalog No.

140M-C2E-C10

140M-C2E-C16

140M-D8E-C20

140M-F8E-C32

140M-C2E-B63

140M-C2E-C10

140M-C2E-C16

140M-D8E-C25

140M-F8E-C32

140M-C2E-B25

140M-C2E-B40

140M-C2E-B63

140M-C2E-C16

140M-D8E-C20

140M-F8E-C25

140M-F8E-C32

140M-F8E-C45

140M-C2E-B25

140M-C2E-B40

140M-C2E-C10

140M-C2E-C10

140M-C2E-C16

140M-D8E-C20

140M-F8E-C25

140M-F8E-C32

Wye or Delta, 480Y/277 or 600Y/347. Not UL listed for use on 480V or 600V Delta/Delta, corner

ground, or high-resistance ground systems.

(4)

When using a Manual Self-Protected (Type E) Combination Motor Controller, the drive must be

installed in a ventilated or non-ventilated enclosure with the minimum volume specified in this

column. Application specific thermal considerations may require a larger enclosure.

Recommended

MCS Contactors

Catalog No.

100-C09

100-C12

100-C23

100-C30

100-C09

100-C09

100-C12

100-C23

100-C30

100-C09

100-C09

100-C09

100-C12

100-C23

100-C23

100-C37

100-C60

100-C09

100-C09

100-C09

100-C09

100-C12

100-C23

100-C23

100-C30

Min. Enclosure

Vol um e

Inches

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

1655

3441

3441

1655

1655

1655

1655

1655

3441

3441

3441

(4)

3

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 19

Installation/Wiring 1-9

!

!

Power Wiring

ATTENTION: National Codes and standards (NEC, VDE, BSI, etc.)

and local codes outline provisions for safely installing electrical

equipment. Installation must comply with specifications regarding wire

types, conductor sizes, branch circuit protection and disconnect

devices. Failure to do so may result in personal injury and/or equipment

damage.

ATTENTION: To avoid a possible shock hazard caused by induced

voltages, unused wires in the conduit must be grounded at both ends.

For the same reason, if a drive sharing a conduit is being serviced or

installed, all drives using this conduit should be disabled. This will help

minimize the possible shock hazard from “cross coupled” power leads.

Motor Cable Types Acceptable for 200-600 Volt Installations

General

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3

meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases,

long parallel runs must be avoided. Do not use cable with an insulation

thickness less than 15 mils (0.4 mm/0.015 in.). Do not route more than

three sets of motor leads in a single conduit to minimize “cross talk”. If

more than three drive/motor connections per conduit are required,

shielded cable must be used.

UL installations in 50°C ambient must use 600V, 75°C or 90°C wire.

UL installations in 40°C ambient should use 600V, 75°C or 90°C wire.

Use copper wire only. Wire gauge requirements and recommendations

are based on 75 degree C. Do not reduce wire gauge when using higher

temperature wire.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry

environments provided adequate free air space and/or conduit fill rates

limits are provided. Do not use THHN or similarly coated wire in wet

areas. Any wire chosen must have a minimum insulation thickness of

15 mils and should not have large variations in insulation concentricity.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 20

1-10 Installation/Wiring

Shielded

Location Rating/Type Description

Standard

(Option 1)

Standard

(Option 2)

Class I & II;

Division I & II

600V, 75°C or 90°C (167°F

or 194°F) RHH/RHW-2

Belden 29501-29507 or

equivalent

Tray rated 600V, 75°C or

90°C (167°F or 194°F)

RHH/RHW-2

Shawflex 2ACD/3ACD or

equivalent

Tray rated 600V, 75°C or

90°C (167°F or 194°F)

RHH/RHW-2

• Four tinned copper conductors with XLPE insulation

• Foil shield and tinned copper drain wire with 85% braid

coverage

• PVC jacket

• Three tinned copper conductors with XLPE insulation

• 5 mil single helical copper tape (25% overlap min.)

with three bare copper grounds in contact with shield

• PVC jacket

• Three tinned copper conductors with XLPE insulation

• 5 mil single helical copper tape (25% overlap min.)

with three bare copper grounds in contact with shield

• PVC copper grounds on #10 AWG and smaller

Reflected Wave Protection

The drive should be installed as close to the motor as possible.

Installations with long motor cables may require the addition of external

devices to limit voltage reflections at the motor (reflected wave

phenomena). See Table 1.E

The reflected wave data applies to all frequencies 2 to 10 kHz.

For 240V ratings, reflected wave effects do not need to be considered.

Table 1.E Maximum Cable Length Recommendations

Reflected Wave

380-480V Ratings Motor Insulation Rating Motor Cable Only

(1)

Longer cable lengths can be achieved by installing devices on the output of the drive.

Consult factory for recommendations.

for recommendations.

1000 Vp-p 15 meters (49 feet)

1200 Vp-p 40 meters (131 feet)

1600 Vp-p 170 meters (558 feet)

(1)

Output Disconnect

The drive is intended to be commanded by control input signals that will

start and stop the motor. A device that routinely disconnects then

reapplies output power to the motor for the purpose of starting and

stopping the motor should not be used. If it is necessary to disconnect

power to the motor with the drive outputting power, an auxiliary contact

should be used to simultaneously disable drive control run commands.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 21

Installation/Wiring 1-11

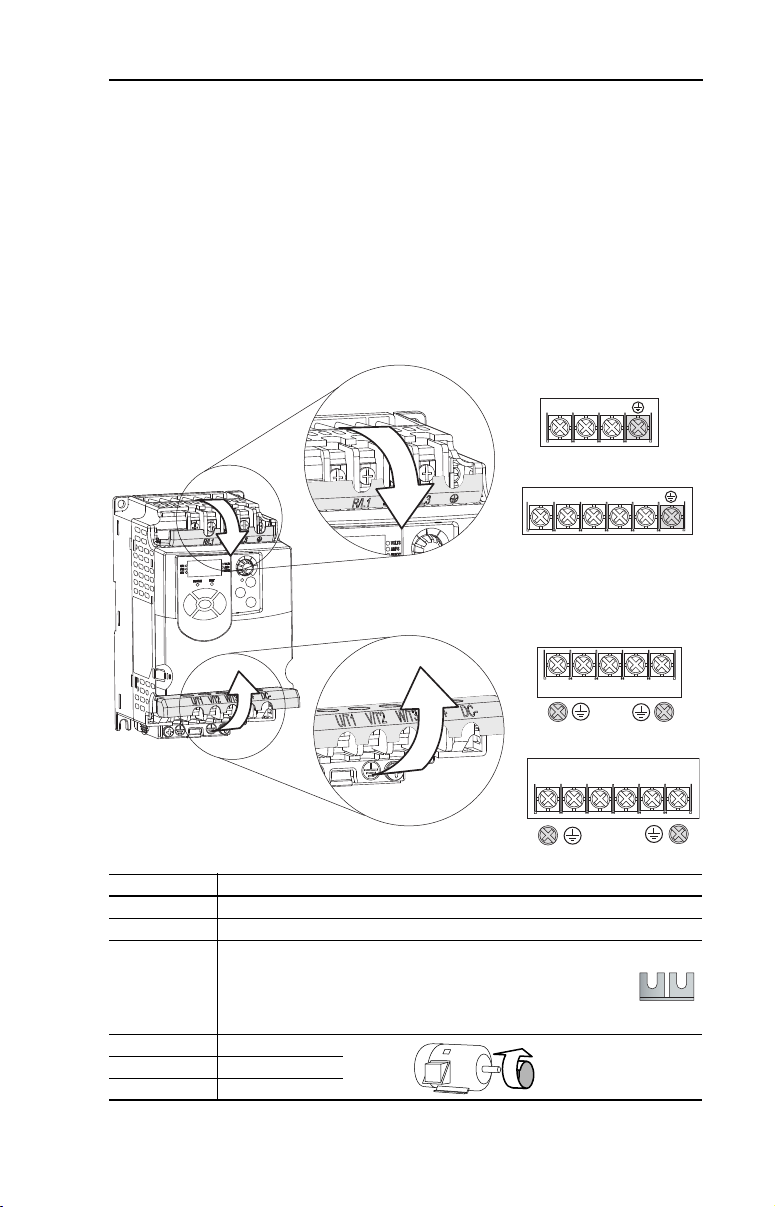

Power Terminal Block

The drive utilizes a finger guard over the power wiring terminals.

To remov e:

1. Press in and hold the locking tab.

2. For the finger guard on the top of the drive, slide it down and out.

For the finger guard at the bottom of the drive, slide it up and out.

Replace the finger guard when wiring is complete.

Figure 1.4 Power Terminal Block

Frame A and B

T/L3S/L2R/L1

Frame C

P1

T/L3S/L2R/L1

P2

Frame A and B

Terminal Description

R/L1, S/L2 1-Phase Input

R/L1, S/L2, T/L3 3-Phase Input

DC Bus Inductor Connection (Frame C drives only.)

P1

(1)

, P2

The Frame C drive is shipped with a jumper between Terminals P1

(1)

and P2. Remove this jumper only when a DC Bus Inductor will be

connected. Drive will not power up without a jumper or inductor

connected.

U/T1 To Motor U/T1

V/T2 To Motor V/T2

W/T3 To Motor W/T3

DC+

W/T3V/T2U/T1

DC-

Frame C

BR+

DC+

W/T3V/T2U/T1

DC-BR-

Switch any two motor

=

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

leads to change forward

direction.

Publication 22F-UM001D-EN-E

Page 22

1-12 Installation/Wiring

!

!

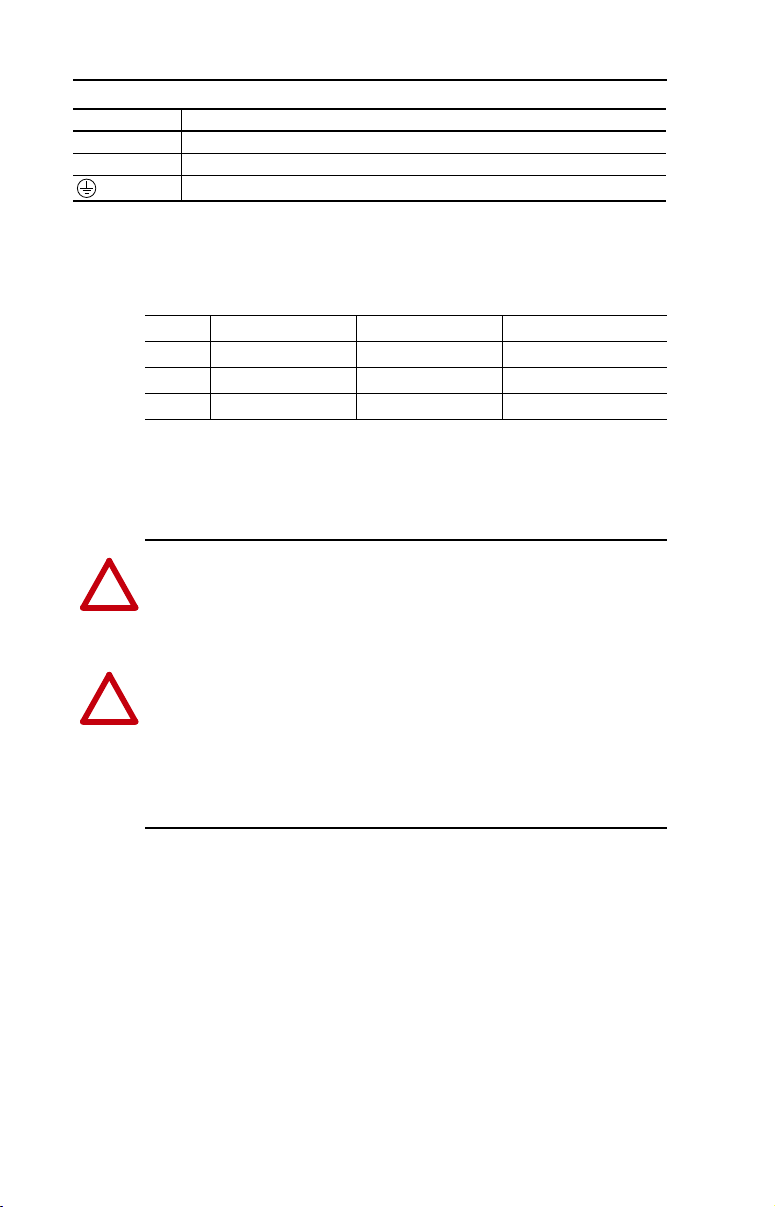

Terminal Description

(2)

DC+

BR+

(1)

(2)

(2)

, DC-

(1)

, BR-

For Frame C only [5.5 kW (7.5 HP) ratings and higher].

Not applicable to 120 V, 1-Phase drives.

DC Bus Connection

(1)

Dynamic Brake Resistor Connection

Safety Ground - PE

Table 1.F Power Terminal Block Specifications

Frame Maximum Wire Size

A 3.3 mm

B 8.4 mm

C 13.3 mm

(1)

Maximum/minimum sizes that the terminal block will accept - these are not

recommendations.

2

(12 AWG) 0.8 mm2 (18 AWG) 1.4-1.6 N-m (12-14 lb.-in.)

2

(8 AWG) 0.8 mm2 (18 AWG) 1.6-1.9 N-m (14-17 lb.-in.)

2

(6 AWG) 3.3 mm2 (12 AWG) 2.7-3.2 N-m (24-28 lb.-in.)

(1)

Motor Start/Stop Precautions

ATTENTION: A contactor or other device that routinely disconnects

and reapplies the AC line to the drive to start and stop the motor can

cause drive hardware damage. The drive is designed to use control input

signals that will start and stop the motor. If used, the input device must

not exceed one operation per minute or drive damage can occur.

ATTENTION: The drive start/stop control circuitry includes

solid-state components. If hazards due to accidental contact with

moving machinery or unintentional flow of liquid, gas or solids exist,

an additional hardwired stop circuit may be required to remove the AC

line to the drive. When the AC line is removed, there will be a loss of

any inherent regenerative braking effect that might be present - the

motor will coast to a stop. An auxiliary braking method may be

required.

Minimum Wire Size

(1)

Tor qu e

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 23

Installation/Wiring 1-13

!

I/O Wiring Recommendations

Important points to remember about I/O wiring:

• Always use copper wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

Important: I/O terminals labeled “Common” are

not referenced to the

safety ground (PE) terminal and are designed to greatly

reduce common mode interference.

ATTENTION: Driving the 4-20mA analog input from a voltage

source could cause component damage. Verify proper configuration

prior to applying input signals.

Control Wire Types

Table 1.G Recommended Control and Signal Wire

Wire Type(s) Description Minimum

2

Belden 8760/9460

(or equiv.)

Belden 8770

(or equiv.)

(1)

If the wires are short and contained within a cabinet which has no sensitive circuits,

the use of shielded wire may not be necessary, but is always recommended.

(18AWG), twisted pair, 100%

0.8 mm

shield with drain.

0.8 mm

remote pot only.

(1)

2

(18AWG), 3 conductor, shielded for

(1)

Insulation Rating

300V

60 degrees C

(140 degrees F)

I/O Terminal Block

Table 1.H I/O Terminal Block Specifications

Maximum Wire Size

2

(16 AWG) 0.2 mm2 (24 AWG) 0.5-0.8 N-m (4.4-7 lb.-in.)

1.3 mm

(1)

Maximum/minimum sizes that the terminal block will accept - these are not

recommendations.

(1)

Minimum Wire Size

(1)

Torque

Maximum Control Wire Recommendations

Do not exceed control wiring length of 30 meters (100 feet). Control

signal cable length is highly dependent on electrical environment and

installation practices. To improve noise immunity, the I/O terminal block

Common must be connected to ground terminal/protective earth. If using

the RS485 (DSI) port, I/O Terminal 16 should also be connected to

ground terminal/protective earth.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 24

1-14 Installation/Wiring

Potentiometer

must be

1-10k ohm

2 Watt Min.

30V DC 125V AC 240V AC

Resistive 3.0A 3.0A 3.0A

Inductive 0.5A 0.5A 0.5A

(1)

Important: I/O Terminal 01 is always a coast to stop input except

when P106 [Start Source] is set to “3-Wire” control. In three wire

control, I/O Terminal 01 is controlled by P107 [Stop Mode]. All other

stop sources are controlled by P107 [Stop Mode].

Important: The drive is shipped with a ju mper installed between I/O

Terminals 01 and 11. Remove this jumper when using I/O Terminal

01 as a stop or enable input.

(2)

Two wire control shown. For three wire control use a momentary

input on I/O Terminal 02 to command a start. Use a

maintained input for I/O Terminal 03 to change direction.

P106

[Start Source]

Stop

I/O Terminal 01

Stop

Keypad Per P107 Coast

3-Wir e Per P 107 Per P107

2-Wire Per P107 Coast

RS485 Port Per P107 Coast

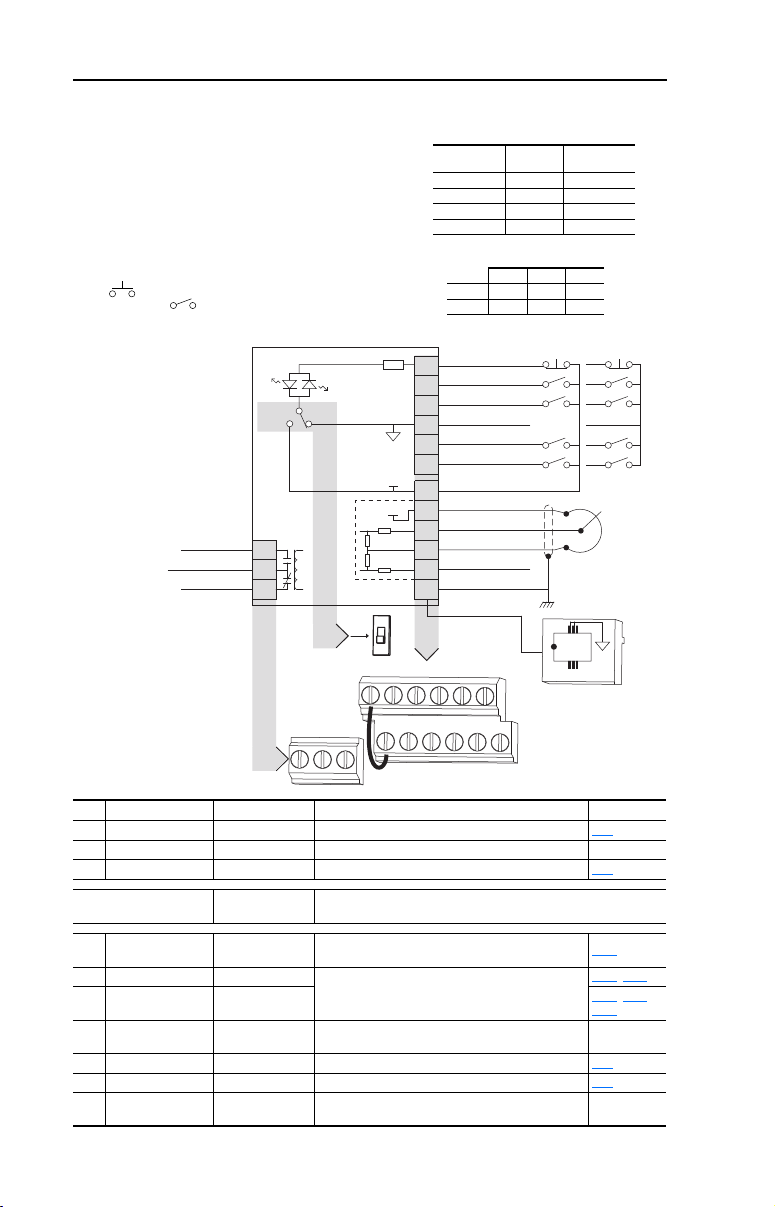

Figure 1.5 Control Wiring Block Diagram

SRCSNK

Relay N.O.

Relay Common

Relay N.C.

R1

R2

R3

R1 R2 R3

No. Signal Default Description Param.

R1 Relay N.O. Fault Normally open contact for output relay. t221

R2 Relay Common – Common for output relay.

R3 Relay N.C. Fault Normally closed contact for output relay. t221

Sink/Source DIP Switch Source (SRC)

01 Stop

(1)

Coast

02 Start/Run FWD Not Active

03 Direction/Run REV Not Active

04 Digital Common –

Inputs can be wired as Sink (SNK) or Source (SRC) via DIP Switch

setting.

The factory installed jumper or a normally closed input

must be present for the drive to start.

Command comes from the integral keypad by default. To

disable reverse operation, see A095 [Reverse Disable].

For digital inputs. Electronically isol ated with digital inputs

from analog I/O.

05 Digital Input 1 Preset Freq Program with t201 [Digital In1 Sel]. t201

06 Digital Input 2 Preset Freq Program with t202 [Digital In2 Sel]. t202

11 +24V DC –

Drive supplied power for digital inputs.

Maximum output current is 100mA.

Stop

01

Start/Run FWD

02

Direction/Run REV

03

Digital Common

04

Digital Input 1

05

Digital Input 2

06

+24V

+10V

SNK

SRC

01 02 03 04 05 06

11 12 13 14 15 16

+24V DC

11

+10V DC

12

0-10V In

13

Analog Common

14

4-20mA In

15

RS485 Shield

16

(1)

(1)

SRC Wiring

(2)

Typical

RS485

(DSI)

Typical

SNK Wiring

18

P106

P106, P107

P106

A434

(1)

, P107,

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 25

Installation/Wiring 1-15

13

14

+

Common

No. Signal Default Description Param.

12 +10V DC –

13 0-10V In

14 Analog Common –

15 4-20mA In

16 RS485 (DSI) Shield –

(3)

(3)

Only one analog frequency source may be connected at a time. If more than one reference is connected at the same

time, an undetermined frequency reference will result.

Not Active

(3)

Not Active

Drive supplied power for 0-10V external potentiometer.

Maximum output current is 15mA.

For external 0-10V input supply

(input impedance = 100k ohm) or potentiometer wiper.

For 0-10V In or 4-20mA In. Electronically isolated with

analog inputs from digital I/O.

For external 4-20mA input supply

(input impedance = 250 ohm).

Terminal should be connected to safety ground - PE

when using the RS485 (DSI) communications port.

P108

P108

P108

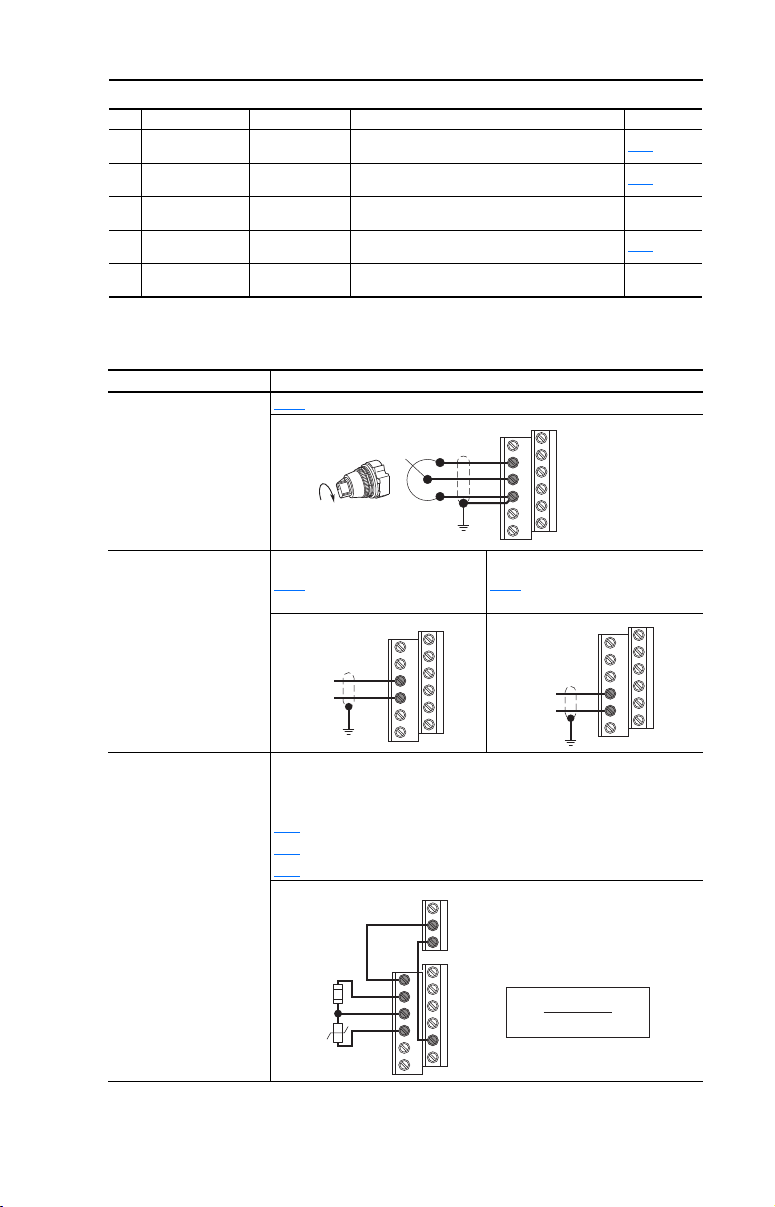

I/O Wiring Examples

Input Connection Example

Potentiometer

1-10k Ohm Pot.

Recommended

(2 Watt minimum)

Analog Input

0 to +10V, 100k ohm

impedance

4-20 mA, 100 ohm

impedance

[Speed Reference] = 2 “0-10V Input”

P108

Voltage

P108

[Speed Reference] = 2 “0-10V

Input”

12

13

14

Current

P108 [Speed Reference] = 3

“4-20mA Input”

Common

14

15

+

Analog Input, PTC

For Drive Fault

Wire the PTC and External Resistor (typically matched to the PTC Hot

Resistance) to I/O Terminals 12, 13, 14.

Wire R2/R3 Relay Output (SRC) to I/O Terminals 5 & 11.

[Digital In1 Sel] = 3 “Aux Fault”

t201

[Relay Out Sel] = 10 “Above Anlg V”

t221

t222

[Relay Out Level] = % Voltage Trip

R2

R3

11

R

e

R

PTC

12

13

14

05

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

R

PTC (hot)

V

=

Tri p

R

PTC (hot)

+ R

×

100

e

Publication 22F-UM001D-EN-E

Page 26

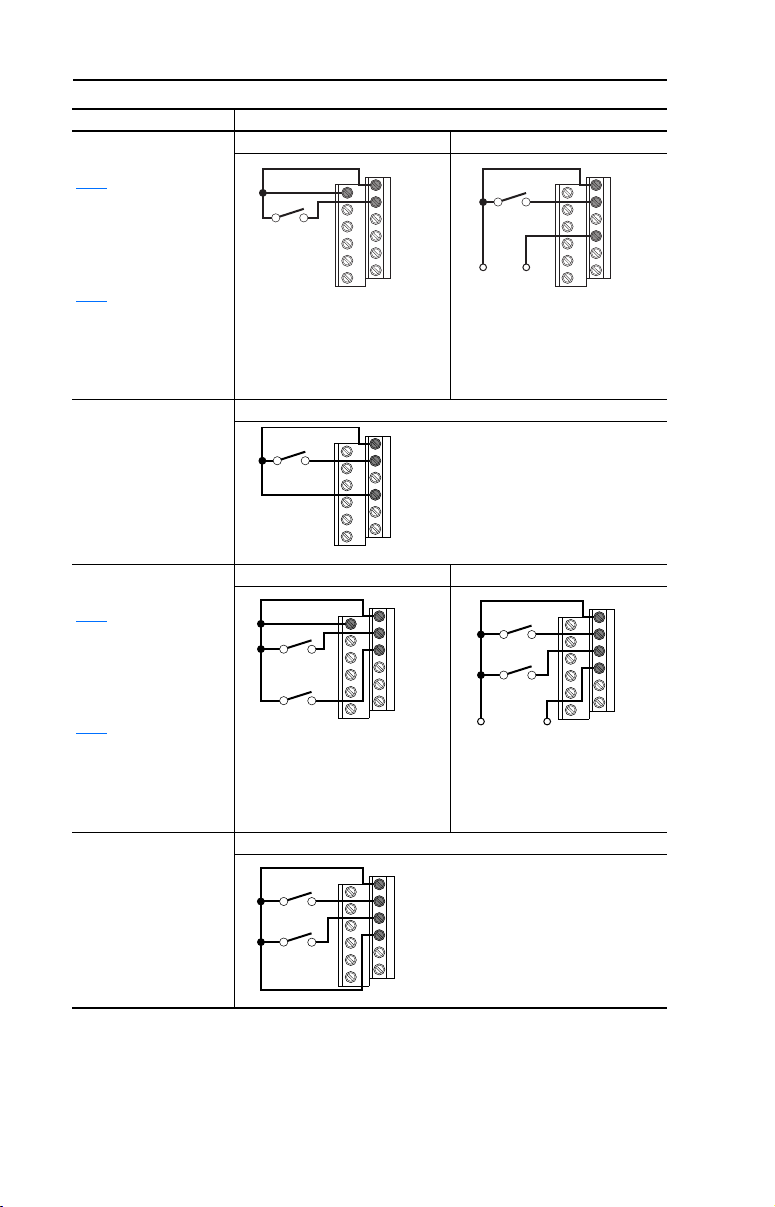

1-16 Installation/Wiring

11

01

02

Stop-Run

01

02

04

Stop-Run

11

01

02

03

Stop-Run

Forward

Stop-Run

Reverse

Common

01

02

03

04

Stop-Run

Forward

Stop-Run

Reverse

+24V

Each digital input draws 6 mA.

Stop-Run

Forward

Stop-Run

Reverse

01

02

03

04

Input Connection Example

2 Wire SRC Control -

Non-Reversing

[Start Source] = 2, 3

P106

or 4

Input must be active for

the drive to run. When

input is opened, the drive

will stop as specified by

[Stop Mode].

P107

If desired, a User Supplied

24V DC power source can

be used. Refer to the

“External Supply (SRC)”

example.

2 Wire SNK Control Non-Reversing

Internal Supply (SRC) External Supply (SRC)

Internal Supply (SNK)

01

Stop-Run

+24V Common

02

04

Each digital input draws 6 mA.

2 Wire SRC Control Run FWD/Run REV

[Start Source] = 2, 3

P106

or 4

Input must be active for

the drive to run. When

input is opened, the drive

will stop as specified by

[Stop Mode].

P107

If both Run Forward and

Run Reverse inputs are

closed at the same time,

an undetermined state

could occur.

2 Wire SNK Control Run FWD/Run REV

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Internal Supply (SRC) External Supply (SRC)

Internal Supply (SNK)

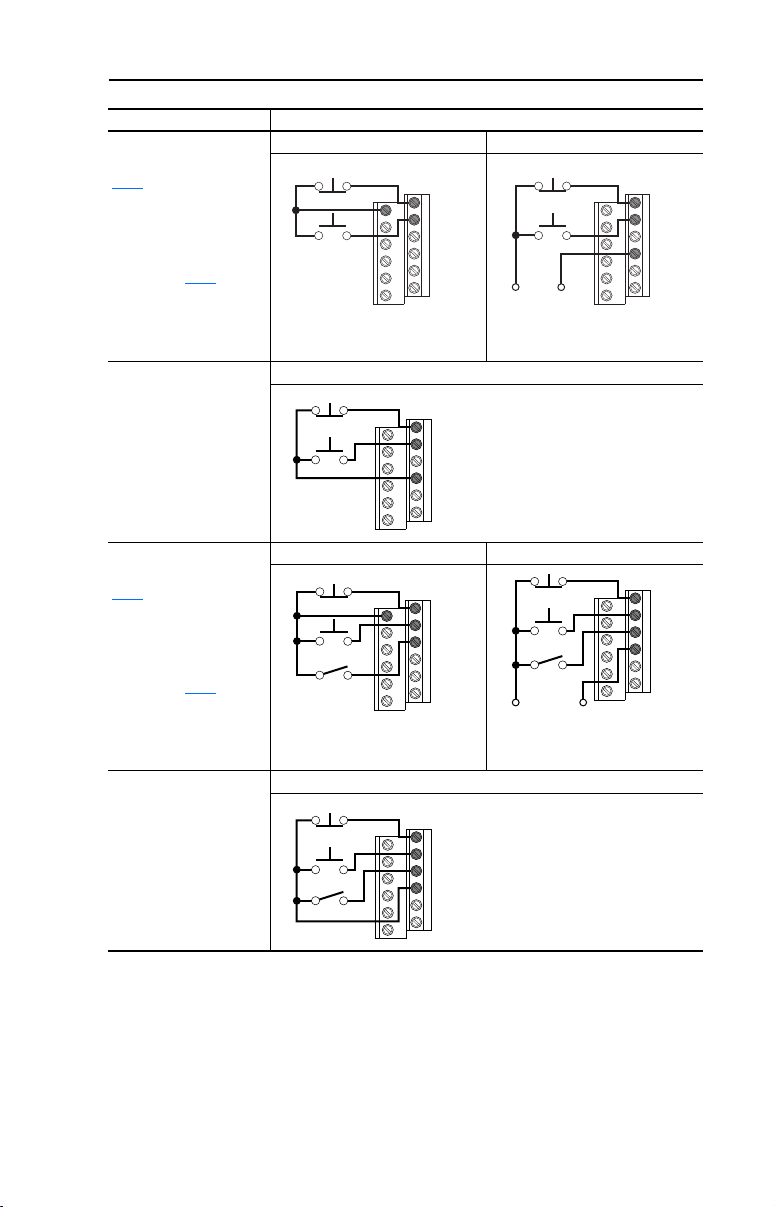

Page 27

Input Connection Example

Each digital input draws 6 mA.

Stop

Start

01

02

03

04

11

01

02

03

Stop

Start

Direction

+24V Common

Stop

Start

Direction

01

02

03

04

Each digital input draws 6 mA.

Stop

Start

Direction

01

02

03

04

3 Wire SRC Control -

Internal Supply (SRC) External Supply (SRC)

Non-Reversing

[Start Source] = 1

P106

A momentary input will

Stop

11

start the drive. A stop

input to I/O Terminal 01

will stop the drive as

specified by P107

[Stop

Start

Mode].

Installation/Wiring 1-17

+24V

Stop

Start

Common

01

02

04

01

02

3 Wire SNK Control Non-Reversing

3 Wire SRC Control Reversing

[Start Source] = 1

P106

A momentary input will

start the drive. A stop

input to I/O Terminal 01

will stop the drive as

specified by P107

[Stop

Mode]. I/O Terminal 03

determines direction.

3 Wire SNK Control Reversing

Internal Supply (SNK)

Internal Supply (SRC) External Supply (SRC)

Internal Supply (SNK)

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 28

1-18 Installation/Wiring

04

Customer Inputs

Optional Ground Connection

02 0402 0402 0402

!

ATTENTION: Digital inputs on multiple drives should not be

tied together when using SNK (Internal Supply) mode. In SNK

mode, if power is removed from one drive, inadvertent operation

of other drives that share the same I/O Common connection

may occur.

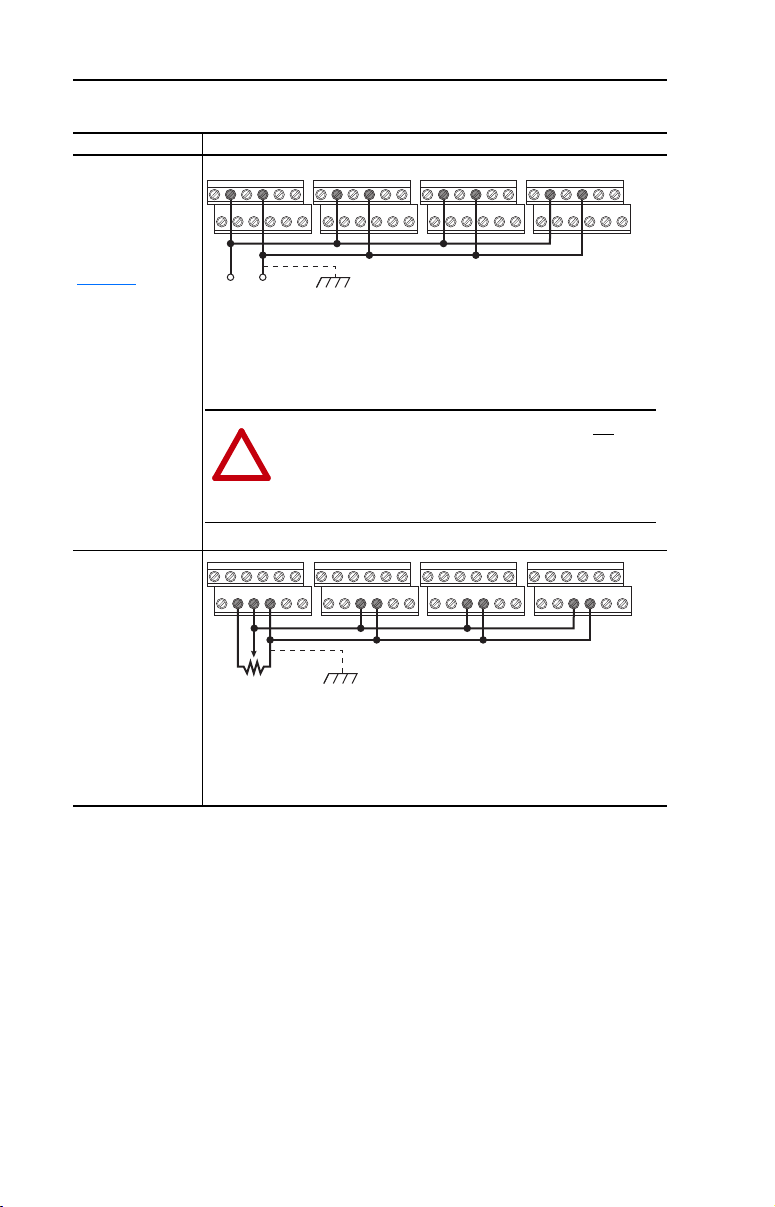

Typical Multiple Drive Connection Examples

Input Connection Example

Multiple Digital

Input Connections

Customer Inputs can

be wired per

External Supply

(SRC) examples on

.

page 1-16

When connecting a single input such as Run, Stop, Reverse or Preset Speeds

to multiple drives, it is important to connect I/O Terminal 04 common together

for all drives. If they are to be tied into another common (such as earth ground

or separate apparatus ground) only one point of the daisy chain of I/O Terminal

04 should be connected.

Multiple Analog

Connections

12 13 14 13 14 13 14 13 14

Remote Potentiometer Optional Ground Connection

When connecting a single potentiometer to multiple drives it is important to

connect I/O Terminal 14 common together for all drives. I/O Terminal 14

common and I/O Terminal 13 (potentiometer wiper) should be daisy-chained to

each drive. All drives must be powered up for the analog signal to be read

correctly.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 29

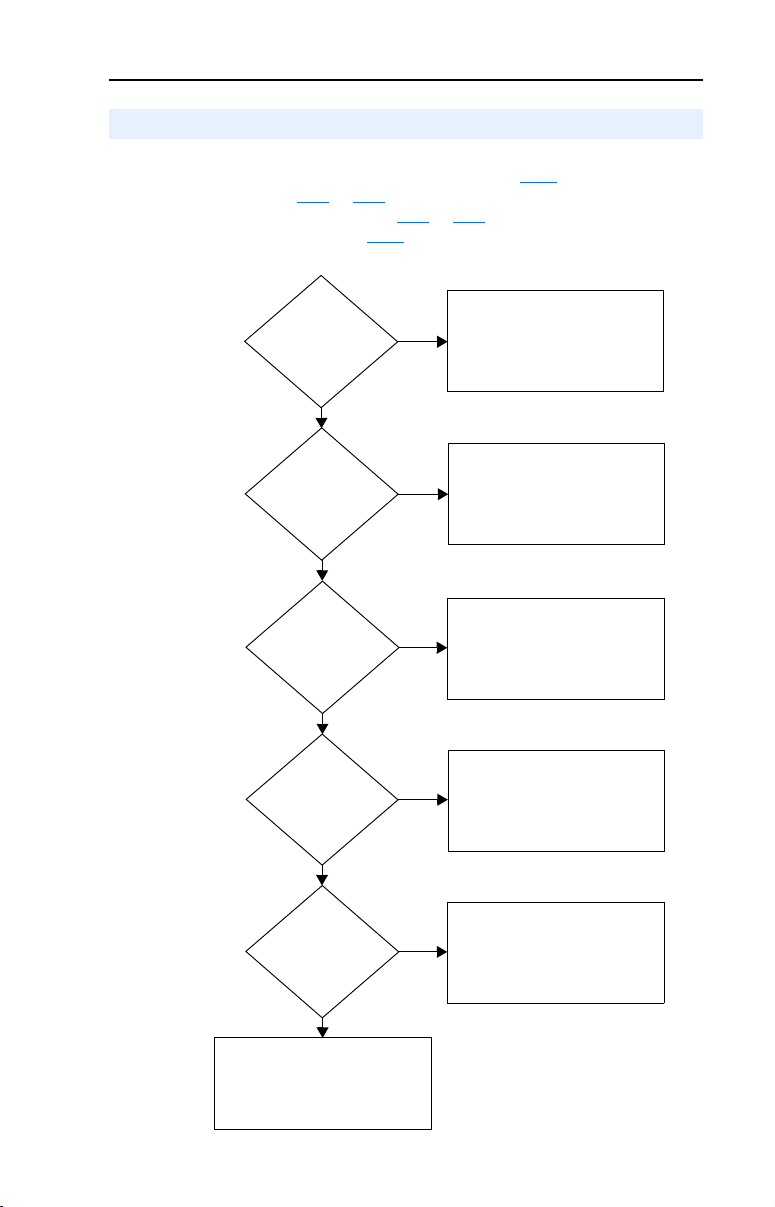

Installation/Wiring 1-19

Jog Input

Enabled and Active:

t201 or t202 = 2

Ye s

Drive will Start and Run at Jog Speed.

Direction comes from

Terminal 03 Dir/Run REV

Local/Remote Input

Enabled and Active:

t201 or t202 = 5

Ye s

Start, Speed and Direction commands

come from Integral Keypad.

Comm Select Input

Enabled and Active:

t201 or t202 = 6

Ye s

Start, Speed and Direction commands

come from RS485 (DSI) port.

P108 [Speed Reference]

= 4 or 5

Ye s

Run as specified by

P108 [Speed Reference].

Start and Direction commands come

from P106 [Start Source].

t201 / t202

Preset Inputs Active

Ye s

Run as specified by

A411-A413 [Preset Freq 1-3].

Start and Direction commands come

from P106 [Start Source].

Run as specified by

P108 [Speed Reference].

Start and Direction commands

come from P106 [Start Source].

No

No

No

No

No

Start and Speed Reference Control

The drive speed command can be obtained from a number of different

sources. The source is normally determined by P108

However, when t201

and the digital input is active, t201

reference commanded by P108

or t202 Digital Inx Sel is set to option 2, 4, 5 or 6,

or t202 will override the speed

[Speed Reference]. See the chart below

for the override priority.

[Speed Reference].

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 30

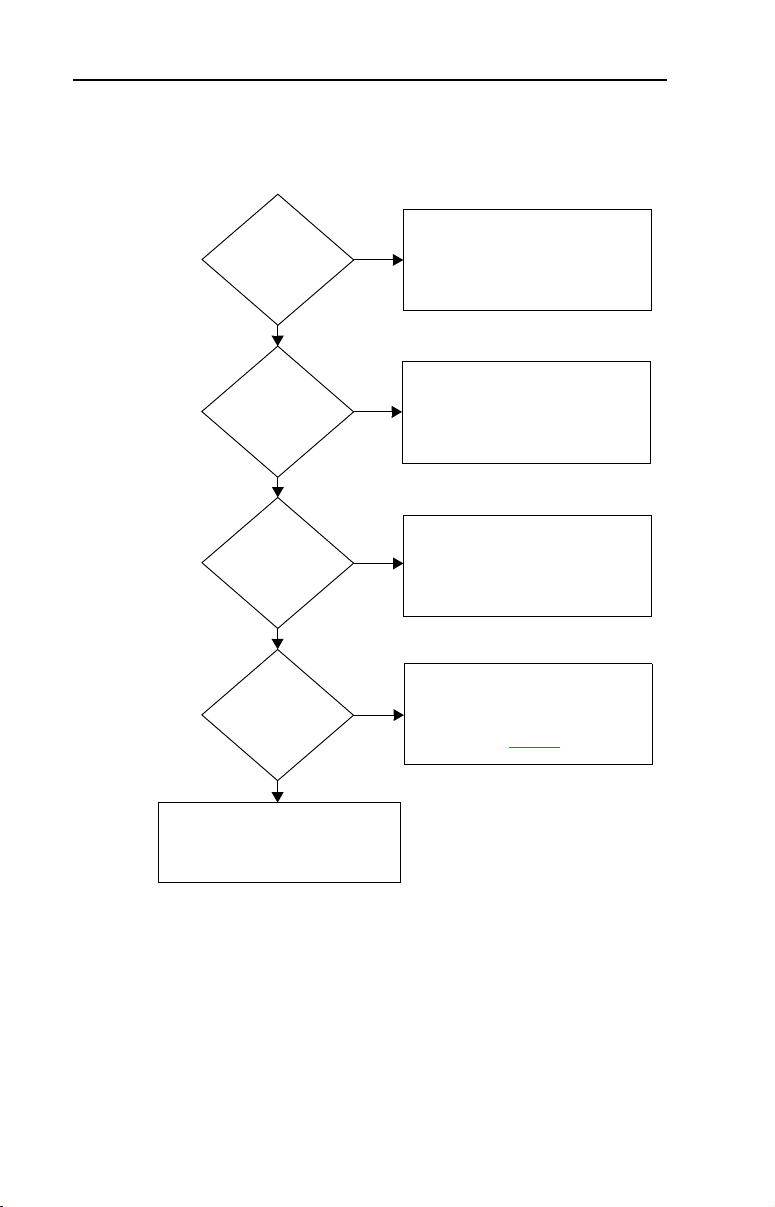

1-20 Installation/Wiring

Jog Input

Enabled and Active:

t201 or t202 = 2

Ye s

A405 [Jog Accel/Decel] used.

P109 [Accel Time 1]/P110 [Decel Time 1]

are used.

RS485 (DSI) Port

Controls Speed

Active when

A401 [Accel Time 2]/A402 [Decel Time 2]

is selected by RS485 (DSI) port.

Input is programmed

as “Accel 2 & Decel 2”

t201 or t202 = 1

A401 [Accel Time 2]/A402 [Decel Time 2]

is active when input is active.

Speed is controlled

by [Preset Freq x]

t201 or t202 = 4

P109 [Accel Time 1]/P110 [Decel Time 1];

A401 [Accel Time 2]/A402 [Decel Time 2]

determined by the active Preset Frequency.

See A410-A413 [Preset Freq 0-3]

on page 3-21

.

No

No

Ye s

Ye s

Ye s

No

No

Accel/Decel Selection

The selection of Accel/Decel rates can be made through digital inputs,

RS485 (DSI) communications and/or parameters.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 31

Installation/Wiring 1-21

EMC Instructions

CE Conformity

Conformity with the Low Voltage (LV) Directive and Electromagnetic

Compatibility (EMC) Directive has been demonstrated using

harmonized European Norm (EN) standards published in the Official

Journal of the European Communities. PowerFlex Drives comply with

the EN standards listed below when installed according to the User

Manual.

CE Declarations of Conformity are available online at:

http://www.ab.com/certification/ce/docs.

Low Voltage Directive (73/23/EEC)

• EN50178 Electronic equipment for use in power installations

EMC Directive (89/336/EEC)

• EN61800-3 Adjustable speed electrical power drive systems Part 3:

EMC product standard including specific test methods.

General Notes

• The motor cable should be kept as short as possible in order to avoid

electromagnetic emission as well as capacitive currents.

• Use of line filters in ungrounded systems is not recommended.

• Conformity of the drive with CE EMC requirements does not

guarantee an entire machine installation complies with CE EMC

requirements. Many factors can influence total machine/installation

compliance.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 32

1-22 Installation/Wiring

U/T1

V/T2

W/T3

EMI Fittings and Metal Conduit

Shielded Enclosure

(1)

Building Structure Steel

Enclosure Ground Connection

R/L1

S/L2

T/L3

(2)

EMI Filter

L1'

L2'

L3'

L1

L2

L3

Shielded Motor Cable

Esc

Sel

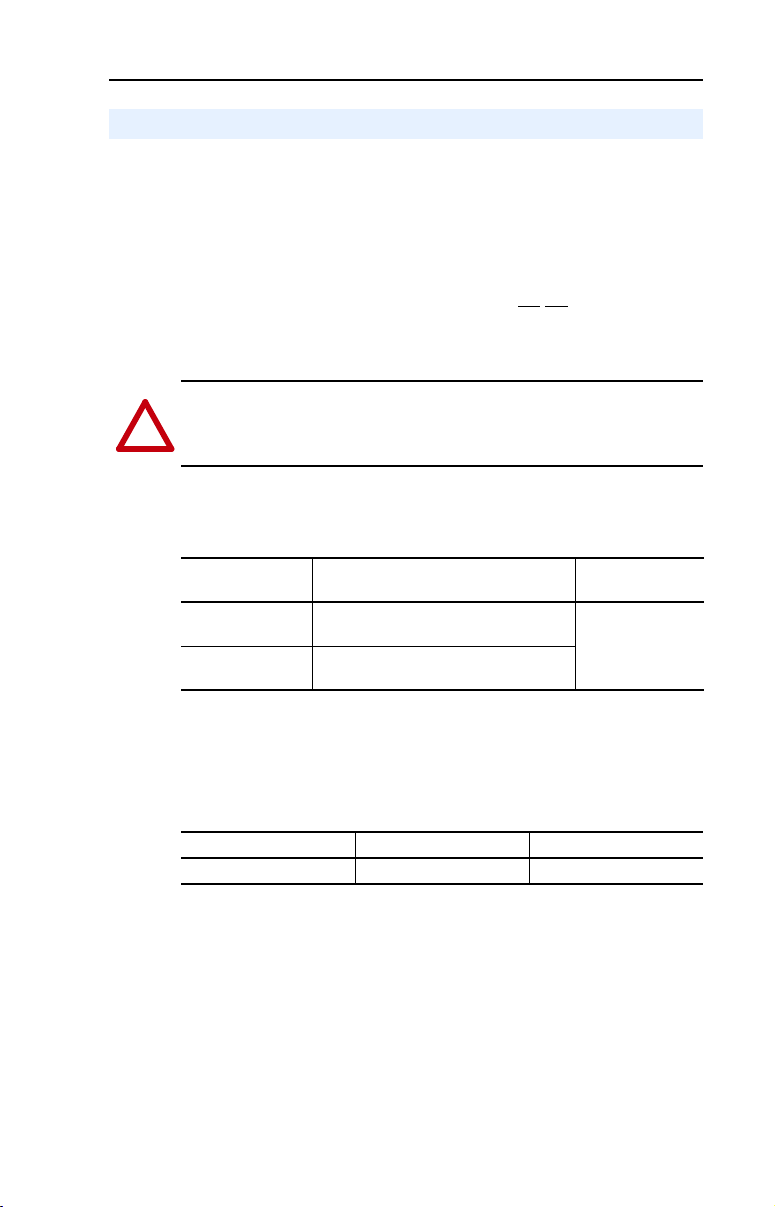

Essential Requirements for CE Compliance

Conditions 1-3 listed below must be satisfied for PowerFlex drives to

meet the requirements of EN61800-3.

1. Grounding as described in Figure 1.6

. Refer to page 1-6 for

additional grounding recommendations.

2. Output power, control (I/O) and signal wiring must be braided,

shielded cable with a coverage of 75% or better, metal conduit or

equivalent attenuation.

3. Allowable cable length in Table 1.I

Table 1.I Allowable Cable Length

Filter Type EN61800-3

Integral, 240V 5 meters (16 feet) 5 meters (16 feet) 1 meter (3 feet)

Integral, 480V 10 meters (33 feet)

External - S Type

External - L Type

(1)

Refer to Appendix B for details on optional external filters.

(2)

Equivalent to EN55011 Class A.

(3)

Equivalent to EN55011 Class B.

Figure 1.6 Connections and Grounding

Second

Environment

(1)

5 meters (16 feet) 5 meters (16 feet) 1 meter (3 feet)

(1)

100 meters (328 feet) 100 meters (328 feet) 25 meters (82 feet)

is not exceeded.

EN61800-3 First

Environment

Restricted

Distribution

––

(2)

EN61800-3 First

Environment

Unrestricted

Distribution

(3)

(1)

First Environment Unrestricted Distribution installations require a shielded enclosure.

Keep wire length as short as possible between the enclosure entry point and the EMI

filter.

(2)

Integral EMI filters are available on 240V, 1-Phase drives and 380V, 3-Phase drives.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 33

Installation/Wiring 1-23

EN61000-3-2

• 0.75 kW (1 HP) 240V 1-Phase and 3-Phase drives and

0.4 kW (0.5 HP) 240V 1-Phase drives are suitable for installation on

a private low voltage power network. Installations on a public low

voltage power network may require additional external harmonic

mitigation.

• Other drive ratings meet the current harmonic requirements of

EN61000-3-2 without additional external mitigation.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 34

1-24 Installation/Wiring

Notes:

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 35

Chapter 2

!

Start Up

This chapter describes how to start up the PowerFlex 4M Drive. To

simplify drive setup, the most commonly programmed parameters are

organized in a single Basic Program Group.

Important: Read the Gener

ATTENTION: Power must be applied to the drive to perform the

following start-up procedures. Some of the voltages present are at

incoming line potential. To avoid electric shock hazard or damage to

equipment, only qualified service personnel should perform the

following procedure. Thoroughly read and understand the procedure

before beginning. If an event does not occur while performing this

procedure, Do Not Proceed. Remove All Power including user

supplied control voltages. User supplied voltages may exist even when

main AC power is not applied to the drive. Correct the malfunction

before continuing.

al Precautions section before proceeding.

Prepare For Drive Start-Up

Before Applying Power to the Drive

❏ 1. Confirm that all inputs are connected to the correct terminals and are

secure.

❏ 2. Verify that AC line power at the disconnect device is within the rated

value of the drive.

❏ 3. Verify that any digital control power is 24 volts.

❏ 4. Verify that the Sink (SNK)/Source (SRC) Setup DIP Switch is set to

match your control wiring scheme. See Figure 1.5 on page 1-14 for

location.

Important: The def

ault control scheme is Source (SRC). The Stop

terminal is jumpered (I/O Terminals 01 and 11) to allow

starting from the keypad. If the control scheme is changed

to Sink (SNK), the jumper must be removed from I/O

Terminals 01 and 11 and installed between I/O Terminals

01 and 04.

❏ 5. Verify that the Stop input is present or the drive will not start.

Important: If I/O T

erminal 01 is used as a stop input, the jumper

between I/O Terminals 01 and 11 must be removed.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 36

2-2 Start Up

Applying Power to the Drive

❏ 6. Apply AC power and control voltages to the drive.

❏ 7. Familiarize yourself with the integral keypad features (see page 2-3)

before setting any Program Grou

Start, Stop, Direction and Speed Control

Factory default parameter values allow the drive to be controlled from

the integral keypad. No programming is required to start, stop, change

direction and control speed directly from the integral keypad.

p parameters.

Important: T

If a fault appears on power up, refer to Fault Descriptions on page 4-3

for an explanation of the fault code.

o disable reverse operation, see A434 [Reverse Disable].

Variable Torque Fan/Pump Applications

For improved motor tuning performance when using a premium efficient

motor on a variable torque load, set

“35.0, VT”.

A453 [Boost Select] to option 2

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 37

Integral Keypad

➊

➋

➍

➏

➒

➎

Menu Description

Display Group (View Only)

Consists of commonly viewed drive operating

conditions.

Basic Program Group

Consists of most commonly used programmable

functions.

Terminal Block Group

Consists of programmable functions for control

terminals.

Communications Group

Consists of programmable functions for

communications.

Advanced Program Group

Consists of remaining programmable functions.

Fault Designator

Consists of list of codes for specific fault

conditions. Displayed only when fault is present.

➌

➑

➐

No. LED LED State Description

Run/Direction

➊

Status

Alphanumeric

➋

Display

Displayed Units Steady Red Indicates the units of the parameter value being displayed.

➌

Program Status Steady Red Indicates parameter value can be changed.

➍

Fault Status Flashing Red Indicates drive is faulted.

➎

Pot Status Steady Green Indicates potentiometer on Integral Keypad is active.

➏

Start Key Status Steady Green Indicates Start key on Integral Keypad is active.

➐

No. Key Name Description

➑

Start Up 2-3

Steady Red Indicates drive is running and commanded motor direction.

Flashing Red Drive has been commanded to change direction. Indicates

Steady Red Indicates parameter number, parameter value, or fault code.

Flashing Red Single digit flashing indicate

Escape

tual motor direction while decelerating to zero.

ac

All digits flashing indicates a fault condition.

The Reverse key is also active unless disabled by

[Reverse Disable].

Back one step in programming menu.

Cancel a change to a parameter value and exit Program Mode.

s that digit can be edited.

A434

Select Advance one step in programming menu.

Up Arrow

Down Arrow

Enter Advance one step in programming menu.

Select a digit when viewing parameter value.

Scroll through groups and parameters.

Increase/decrease the value of a flashing digit.

Save a change to a parameter value.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 38

2-4 Start Up

or

or

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

No. LED LED State Description

➒

Speed

Potentiometer

Used to control speed of drive. Default is active.

Controlled by parameter P108 [Speed Reference].

Start Used to start the drive. Default is active.

Reverse Used to reverse direction of the drive. Default is active.

Controlled by parameter

Controlled by parameters

[Reverse Disable].

P106 [Start Source].

P106 [Start Source] and A434

Stop Used to stop the drive or clear a fault. This key is always

tive. Controlled by parameter

ac

P107 [Stop Mode].

Viewing and Editing Parameters

The last user-selected Display Group parameter is saved when power is removed and is displayed by

default when power is reapplied.

The following is an example of basic integral keypad and display functions. This example provides basic

vigation instructions and illustrates how to program the first Program Group parameter.

na

Step Key(s) Example Displays

1. When power is applied, the last user-selected

y Group parameter number is briefly

Displa

displayed with flashing characters. The display

then defaults to that parameter’s current value.

(Example shows the value of d001 [Output

Freq] with the drive stopped.)

2. Press Esc once to display the Display Group

ameter number shown on power-up. The

par

parameter number will flash.

3. Press Esc again to enter the group menu. The

roup menu letter will flash.

g

4. Press the Up Arrow or Do

wn Arrow to scroll

through the group menu (d, P, t, C and A).

Press Enter or Sel to enter a group. The

ightmost digit of the last viewed parameter in

r

that group will flash.

5. Press the Up Arrow or Do

wn Arrow to scroll

through the parameters in the group.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

Page 39

Start Up 2-5

or

or

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

Step Key(s) Example Displays

6. Press Enter or Sel to view the value of a

ameter. If you do not want to edit the value,

par

press Esc to return to the parameter number.

7. Press Enter or Sel to enter program mode to

edit the paramet

er value. The rightmost digit will

flash and the Program LED will illuminate if the

parameter can be edited.

8. Press the Up Arrow or Down Arrow to change

e parameter value.

th

If desired, press Sel to move from digit to digit

bit to bit. The digit or bit that you can change

or

will flash.

9. Press Esc to cancel a change. The digit will

op flashing, the previous value is restored and

st

the Program LED will turn off.

Or

Press Enter to save a change. The digit will stop

hing and the Program LED will turn off.

flas

10.Press Esc to return to the parameter list.

VOLTS

AMPS

HERTZ

FAULTPROGRAM

Continue to press Esc to back out of the

ogramming menu.

pr

If pressing Esc does not change the display,

en d001 [Output Frequency] is displayed.

th

Press Enter or Sel to enter the group menu

again.

The Basic Program Group (page 3-8) contains the most commonly changed parameters.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 40

2-6 Start Up

Notes:

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 41

Chapter 3

32

Programming and Parameters

Chapter 3 provides a complete listing and description of the PowerFlex

4M parameters. Parameters are programmed (viewed/edited) using the

integral keypad. As an alternative, programming can also be performed

using DriveExplorer™ or DriveExecutive™ software, a personal

computer and a serial converter module. Refer to

numbers.

For information on… See page…

About Parameters 3-1

Parameter Organization 3-2

Display Group 3-3

Basic Program Group 3-8

Terminal Block Group 3-13

Communications Group 3-17

Advanced Program Group 3-19

Parameter Cross Reference – by Name 3-31

About Parameters

To configure a drive to operate in a specific way, drive parameters may

have to be set. Three types of parameters exist:

Appendix B for catalog

UM

• EN

ENUM parameters allow a selection from 2 or more items. Each item

is represented by a number.

umeric Parameters

• N

These parameters have a single numerical value (i.e. 0.1 Volts).

• B

it Parameters

Bit parameters have four individual bi

conditions. If the bit is 0, the feature is off or the condition is false. If

the bit is 1, the feature is on or the condition is true.

Some parameters are marked as follows.

= Stop drive before changing this parameter.

= 32 bit parameter. Parameters marked 32 bit will have two

parameter numbers when using RS485 communications and

programming software.

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

ts associated with features or

Publication 22F-UM001D-EN-E

Page 42

3-2 Programming and Parameters

Display Group

Advanced

Program Group

Advanced

Program Group

Advanced

Program Group

Parameter Organization

Group Parame ters

Basic Display Output Freq d001

Basic Program Motor NP Volts P101

Basic

Program Group

Commanded Freq d002

Output Current d003

Output Voltage d004

DC Bus Voltage d005

Drive Status d006

Fault 1 Code d007

Fault 2 Code d008

Fault 3 Code d009

Process Display d010

Motor NP Hertz P102

Motor OL Current P103

Minimum Freq P104

Maximum Freq P105

Start Source P106

Control Source d012

Contrl In Status d013

Dig In Status d014

Comm Status d015

Control SW Ver d016

Drive Type d017

Elapsed Run Time d018

Testpoint Data d019

Analog In 0-10V d020

Analog In 4-20mA d021

Drive Temp d022

Stop Mode P107

Speed Reference P108

Accel Time 1 P109

Decel Time 1 P110

Motor OL Ret P111

Reset To Defalts P112

Term inal B lock Digital In1 Sel t201

Communications Language C301

Advanced Program Accel Time 2 A401

Digital In2 Sel t202

Analog In 0-10V Lo t211

Analog In 0-10V Hi t212

Comm Data Rate C302

Comm Node Addr C303

Comm Loss Action C304

Comm Loss Time C305

Comm Format C306

Comm Write Mode C307

Decel Time 2 A402

S Curve % A403

Jog Frequency A404

Jog Accel/Decel A405

Internal Freq A409

Preset Freq 0 A410

Preset Freq 1 A411

Preset Freq 2 A412

Preset Freq 3 A413

Skip Frequency A418

Skip Freq Band A419

DC Brake Time A424

DC Brake Level A425

DB Resistor Sel A427

DB Duty Cycle A428

Start At PowerUp A433

Reverse Disable A434

Flying Start En A435

Analog In 4-20mA Lo d213

Analog In 4-20mA Hi d214

Relay Out Sel t221

Relay Out Level t222

Compensation A436

Slip Hertz @ FLA A437

Process Time Lo A438

Process Time Hi A439

Process Factor A440

Bus Reg Mode A441

Current Limit A442

Motor OL Select A444

PWM Frequency A446

SW Current Trip A448

Fault Clear A450

Auto Rstrt Tries A451

Auto Rstrt Delay A452

Boost Select A453

Maximum Voltage A457

Program Lock A458

Testpoint Sel A459

Motor NP FLA A461

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 43

Programming and Parameters 3-3

Display Group

d001 [Output Freq] Related Parameter(s): d002, d010, P104, P105, P108

Output frequency present at T1, T2 & T3 (U, V & W).

Values Default Read Only

Min/Max: 0.0/

Display: 0.1 Hz

d002 [Commanded Freq] Related Parameter(s): d001, d013, P104, P105, P108

Value of the active frequency command. Displays the commanded frequency even if the drive is not

running.

Important: Th

Reference Control on page 1-19 for details.

Values Default Read Only

e frequency command can come from a number of sources. Refer to Start and Speed

Min/Max: 0.0/

Display: 0.1 Hz

d003 [Output Current]

The output current present at T1, T2 & T3 (U, V & W).

Values Default Read Only

Min/Max: 0.00/(Drive Rated Amps × 2)

Display: 0.01 Amps

P105 [Maximum Freq]

P105 [Maximum Freq]

d004 [Output Voltage] Related Parameter(s): P101, A453, A457

Output voltage present at terminals T1, T2 & T3 (U, V & W).

Values Default Read Only

Min/Max: 0/Drive Rated Volts

Display: 0.1 VAC

d005 [DC Bus Voltage]

Present DC bus voltage level.

Values Default Read Only

Min/Max: Based on Drive Rating

Display: 1 VDC

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 44

3-4 Programming and Parameters

1 = Condition True, 0 = Condition False

Running Bit 0

Forward Bit 1

Accelerating Bit 2

Decelerating Bit 3

32

Output

Freq

Process

Fact or

Process

Display

=

x

Display Group (continued)

d006 [Drive Status] Related Parameter(s): A434

Present operating condition of the drive.

Values Default Read Only

Min/Max: 0/1

Display: 1

d007 [Fault 1 Code]

d008 [Fault 2 Code]

d009 [Fault 3 Code]

A code that represents a drive fault. The codes will appear in these parameters in the order they occur

d007 [Fault 1 Code] = the most recent fault). Repetitive faults will only be recorded once.

(

Refer to

Chapter 4 for fault code descriptions.

Values Default Read Only

Min/Max: F2/F122

Display: F1

d010 [Process Display] Related Parameter(s): d001, A440, A438, A439

32 bit parameter.

The output frequency scaled by

[Process Time Hi].

Values Default Read Only

Min/Max: 0.00/9999

Display: 0.01 – 1

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

A440 [Process Factor] or by A438 [Process Time Lo] and A439

Page 45

Programming and Parameters 3-5

Start Command Digit 0

0 = Keypad

1 = 3-Wire

2 = 2-Wire

3 = 2-Wire Level Sensitive

4 = 2-Wire High Speed

5 = RS485 (DSI) Port

9 = Jog

Speed Command Digit 1

0 = Drive Potentiometer

1 =

A409 [Internal Freq]

2 = 0-10V Input/Remote Potentiometer

3 = 4-20mA Input

4 =

A410 - A413 [Preset Freq x]

(

t201 - t202 [Digital Inx Sel] must be set to 4)

5 = RS485 (DSI) Port

9 = Jog Freq

Reserved Digit 2

Reserved Digit 3

1 = Input Present, 0 = Input Not Present

Start / Run FWD Input (I/O Terminal 02) Bit 0

Direction / Run REV Input (I/O Terminal 03) Bit 1

Stop Input

(1)

(I/O Terminal 01) Bit 2

(1)

The stop input must be present in order to start the drive.

When this bit is a 1 the drive can be started.

When this bit is a 0 the drive will stop.

Dynamic Brake Transistor ON (Frame C only) / Reserved (Other Frames) Bit 3

Display Group (continued)

d012 [Control Source] Related Parameter(s): P106, P108, t201, t202

Displays the active source of the Start Command and Speed Command which are normally defined

by the settings of

inputs. Refer to the flowcharts on pages

Values Default Read Only

P106 [Start Source] and P108 [Speed Reference] but may be overridden by digital

1-19 and 1-20 for details.

Min/Max: 0/9

Display: 1

d013 [Contrl In Status] Related Parameter(s): d002, P104, P105

Status of the control terminal block control inputs.

Important: Ac

Values Default Read Only

tual control commands may come from a source other than the control terminal block.

Min/Max: 0/1

Display: 1

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 46

3-6 Programming and Parameters

1 = Input Present, 0 = Input Not Present

Digital In1 Sel (I/O Terminal 05) Bit 0

Digital In2 Sel (I/O Terminal 06) Bit 1

Reserved Bit 2

Reserved Bit 3

1 = Condition True, 0 = Condition False

Receiving Data Bit 0

Transmitting Data Bit 1

RS485 (DSI) Based Option Connected Bit 2

(Allen-Bradley devices only.)

Communication Error Occurred Bit 3

Display Group (continued)

d014 [Dig In Status] Related Parameter(s): t201, t202

Status of the control terminal block digital inputs.

Values Default Read Only

Min/Max: 0/1

Display: 1

d015 [Comm Status] Related Parameter(s): C302 - C306

Status of the communications ports.

Values Default Read Only

Min/Max: 0/1

Display: 1

d016 [Control SW Ver]

Main Control Board software version.

Values Default Read Only

Min/Max: 1.00/99.99

Display: 0.01

d017 [Drive Type]

Used by Rockwell Automation field service personnel.

Values Default Read Only

Min/Max: 1001/9999

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Display: 1

Page 47

Programming and Parameters 3-7

Display Group (continued)

d018 [Elapsed Run Time]

Accumulated time drive is outputting power. Time is displayed in 10-hour increments.

Values Default Read Only

Min/Max: 0/9999 Hrs

Display: 1 (= 10 Hrs)

d019 [Testpoint Data] Related Parameter(s): A459

The present value of the function selected in A459 [Testpoint Sel].

Values Default Read Only

Min/Max: 0/FFFF

Display: 1 Hex

d020 [Analog In 0-10V] Related Parameter(s): t211, t212

The present value of the voltage at I/O Terminal 13 (100.0% = 10 volts).

Values Default Read Only

Min/Max: 0.0/100.0%

Display: 0.1%

d021 [Analog In 4-20mA] Related Parameter(s): t213, t214

The present value of the current at I/O Terminal 15 (0.0% = 4mA, 100.0% = 20mA).

Values Default Read Only

Min/Max: 0.0/100.0%

Display: 0.1%

d022 [Drive Temp]

Present operating temperature of the drive power section.

Values Default Read Only

Min/Max: 0/120 degC

Display: 1 degC

PowerFlex 4M Adjustable Frequency Drive FRN 1.xx - 2.xx User Manual

Publication 22F-UM001D-EN-E

Page 48

3-8 Programming and Parameters

Basic Program Group

P101 [Motor NP Volts] Related Parameter(s): d004, A453

Stop drive before changing this parameter.

Set to the motor nameplate rated voltage.

Values Default Based on Drive Rating

Min/Max: 20/Drive Rated Voltage

Display: 1 VAC