Page 1

Data Highway Plus/DH485 Communication Adapter Module

(Cat. No. 1785KA5/B, KA5P/B)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc. is

prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

- Identify a hazard

- Avoid the hazard

- recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

1995 AllenBradley Company, Inc.

IBM

is a registered trademark of International Business Machines Corporation

PLC, PLC2, PLC3 and PLC5 are registered trademarks of AllenBradley Co. Inc.

DH+,

DHII,

PLC5/10, PLC5/12, PLC5/15, PLC5/25, PLC5/30, PLC5/40, PLC5/60, PLC5/250, SLC, SLC 5/01, SLC 5/02, SLC 5/03

and

SLC 500 are trademarks of AllenBradley Co., Inc.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This publication contains new information not included in the last release.

New Information

European Union Directive Compliance

Information on the European Union Directive is located on pages 2-1

and A-1.

Auto Routing Feature

Detailed information on using the Auto Routing Feature is located on

pages 2-4 and 2-5.

Power Supply Requirements

Detailed information on power supply requirements for the European

Union Directive is located on page 2-13.

Change Bars

The areas in this manual which are different from the previous edition are

marked with change bars (as shown to the right of this paragraph) to

indicate the addition of new or revised information.

P-1

Page 4

Table of Contents

Using this Manual

Purpose

Who Should Read this Manual

Frequently Used Terms

Related

Updated

of this Manual

Publications

Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Changes P1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of the 1785KA5

Communication Adapter Module 11. . . . . . . . . . . . . . . .

What this Chapter Contains 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is the 1785KA5 Communication Adapter Module? 11

DH+ and DH485 Networks 12

The DH485 Network 14

Compatible Products 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

Installing the 1785KA5

Communication Adapter Module 21. . . . . . . . . . . . . . . .

What this Chapter Contains 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

European Union Directive Compliance 21

the Switches

Setting

Mounting the 1785KA5 Communication Adapter Module

in an I/O Rack

Panelmounting the 1785KA5 Communication Adapter Module 29

Connecting the 1785KA5 Module 210

Powering Up the 1785KA5 Module 216

. . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

ii

ii

i

i

i

i

Communicating through the 1785KA5

Communication Adapter Module 31. . . . . . . . . . . . . . . .

What this Chapter Contains 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internet Protocol Addressing 31

1785KA5 Router Communication 34

1785KA5

PLC5

Controlling

Gateway Communication

to SLC Communication

the Flow of Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

36. . . . . . . . . . . . . . . . . . . . . .

38. . . . . . . . . . . . . . . . . . . . . . . . . . .

317. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Using this Manual

Preface

Purpose

of this Manual

Who Should Read this

Manual

Frequently Used Terms

This manual describes the 1785-KA5 Data Highway Plus/DH485

communication adapter module. It contains information for:

installing and troubleshooting the module

using the module

We assume that you are already familiar with:

Allen-Bradley PLC and SLC processors

Allen-Bradley DH485 and Data Highway Plus

In this manual, we use the following terms:

This term Means

1785KA5 module,

or 1785KA5

DH+ Data Highway Plus

DH485 DH485 Data Highway

link a physical network

PLC programmable logic controller

SLC small logic controller

station (or node) the interface point at which devices, such as programmable

1785KA5 Data Highway Plus/DH485 communication adapter module

controllers, connect to the network. Usually the station is an interface

module, except for the PLC5

directly to the Data Highway Plus

and T50 terminal, which connect

i

Page 6

Preface

Using this Manual

Related

Publications

Updated Information

These Allen-Bradley publications contain related information:

Publicaton Publication Number

SLC 500 Overview brochure 17461.1

Bulletin 1746/47 SLC 500 Modular Hardware Style

Programmable Controllers I/O manual

Hand Held Terminal user's manual 1747809

Programming Terminals (Cat. Nos. 1784T45, T47, T50)

product data

DH+ LAN product data 17852.6

PLC5 Family Processor product data 17852.1

DH/DH+/DH485 Protocol and Command Set reference

manual

1747804

17842.1

17706.5.16

Also see the Advanced Programming Software (APS) user’s manual

(Cat. No. 1747-NM002 Series A.)

Since the last release of this manual, some information has changed. We

call your attention to the new information with a black revision bar in the

margin as shown here.

ii

Page 7

Chapter

1

Overview of the 1785KA5

Communication Adapter Module

What this Chapter Contains

What is the 1785KA5

Communication Adapter

Module?

Read this chapter for information on:

what the 1785-KA5 communication adapter module is

what DH+ and DH485 networks are

compatible products

The 1785-KA5 communication adapter module lets devices on the Data

Highway Plus (DH+) network communicate with devices on the RS-485

Data Highway (DH485) network for:

uploading/downloading of SLC 500 programs from a DH+ device

message communication between DH+ PLC processors and DH485

SLC 500 processors

The 1785-KA5 communication adapter module features:

concurrent operation as a gateway or router:

- in gateway mode, DH+ devices must initiate messages; DH485

devices cannot initiate messages

- in router mode, both DH+ and DH485 devices that implement

internet protocol (IP) can initiate messages (SLC 5/01, SLC 5/02,

and fixed controllers do not support IP)

support for existing IP

compatibility with other Allen-Bradley DH+ hardware and software

products

a baud rate of 57.6 Kbps on the DH+ network and 300bps-19.2 Kbps on

the DH485 network

1-1

Page 8

Chapter 1

Overview of the 1785KA5

Communication Adapter Module

DH+ and DH485 Networks

This section describes the DH+ and DH485 networks. For more

information on these networks, see the DH/DH+/DH485 Protocol and

Command Set reference manual (publication 1770-6.5.16).

DH+ Networks

DH+ is a baseband local area network (LAN) that allows peer-to-peer

communication among a maximum of 64 nodes. Each node has a unique

station address between 0–63 decimal and 0–77 octal. Use DH+ when you

want to connect a small number of nodes on a common link or with other

industrial networks as a part of a plant-wide CIM facility. DH+ features:

remote programming of PLC-2, PLC-3, and PLC-5 processors on your

network (using Allen-Bradley 6200 Series software)

direct connections to PLC-5 processors and industrial programming

terminals

easy reconfiguration and expansion if you want to add more nodes later

a communication rate of 57,600 bits per second

The DH+ implements peer-to-peer communication with a token-passing

scheme to rotate link mastership among its nodes. Since this method does

not require polling, it helps provide time-efficient reliable data transport.

The DH+ uses factory set timeouts to restart token-passing communication

if the token is lost because of a defective node.

1-2

Page 9

Chapter 1

Overview of the 1785KA5

Communication Adapter Module

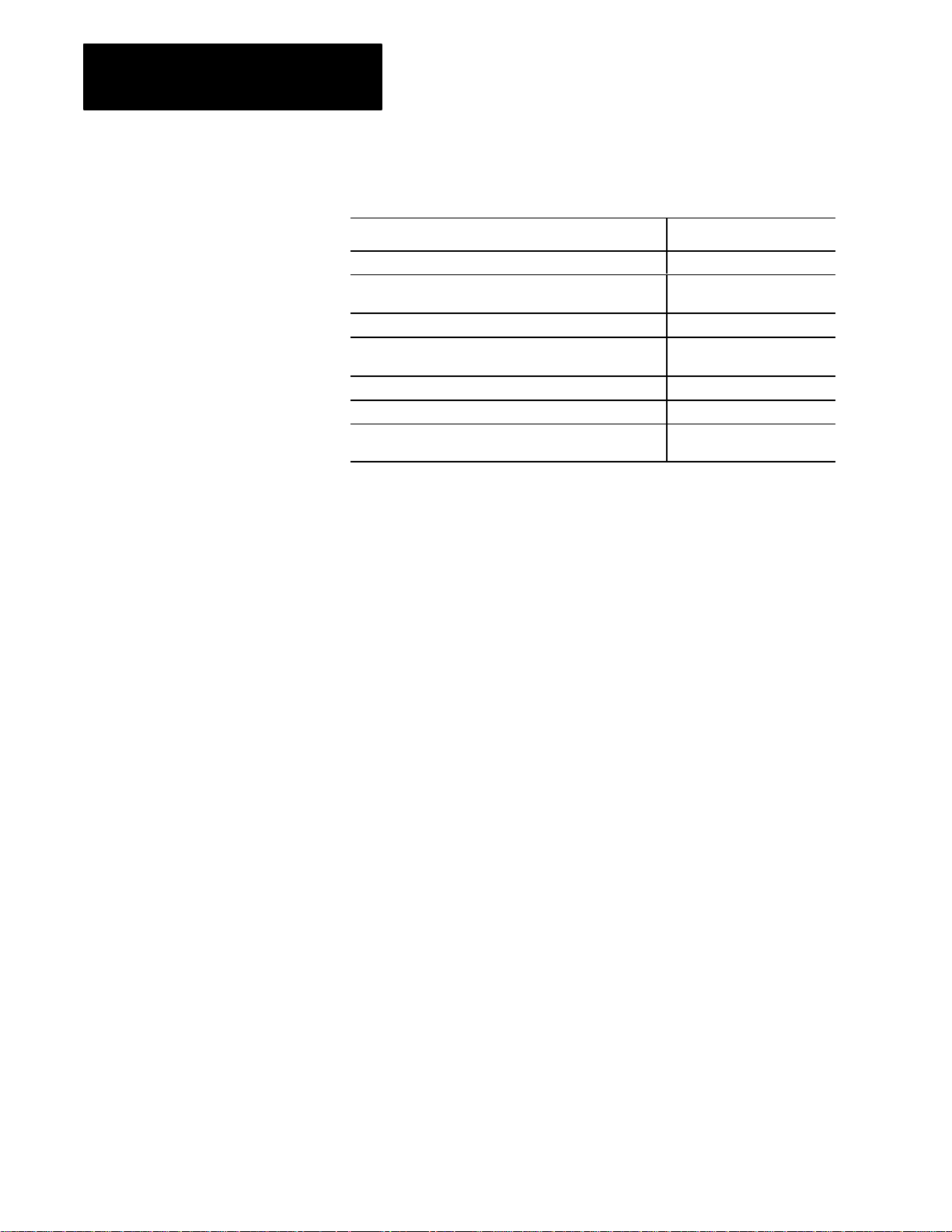

The 1785-KA5 communication adapter module is available in two

versions:

Use this version If your application is

1771 I/O rack mount

(Cat. No. 1785-KA5/B)

standalone panel mount

(Cat. No. 1785KA5P/A)

primarily DH+ with multiple 1771 I/O racks and SLC 500

subnetworks within close proximity

primarily a SLC (DH485) environment with no 1771 I/O racks in

close proximity

Figure 1.1 shows the module’s hardware features:

Figure 1.1

1785KA5

module

Status LEDs

DH+ connection

(3-pin Phoenix

connector)

DH+ remote

programming port

(9pin)

Dshell

programming

connection (8pin

modular connector)

DH485 connection

(6 - pin

Phoenix

connector)

1785-KA5/B I/O rack mount

External power (+ 5Vdc) connector

(4 -pin Phoenix connector)

1785-KA5P/B panel mount

19190

1-3

Page 10

Chapter 1

Overview of the 1785KA5

Communication Adapter Module

The DH485 Network

This section describes the DH485 network. For more information on this

network, see the DH/DH+/DH485 Protocol and Command Set reference

manual (publication 1770-6.5.16).

DH485 is a low cost, peer-to-peer programming and data acquisition link

for a variety of Allen-Bradley products, such as the SLC 500 family of

programmable controllers. A DH485 network provides a networking

solution for smaller applications (up to 32 nodes) within a small radius.

Each node has a unique station address between 0–31 decimal. The

maximum cable length is 4,000 feet. The DH485 link has a maximum

communication rate of 19,200 bits per second.

A DH485 network has a topology that is similar to that of a DH or DH+

network. DH485 is based on the EIA Standard RS-485 Electrical

Signalling Specification and implements token-passing protocol with

rotating mastership. The link protocol delimits messages, detects and

signals errors, retries after errors and controls message flow.

A variety of Allen-Bradley products, such as the SLC 500 family of

controllers, the SLC 500 APS programming software, the 1784-KTX,

-KTXD and -KR modules, and the 1770-KF3 module act as token-passing

masters on the DH485 network. The DH485 protocol also supports slave

(respond-only) mode for low-level devices on the network.

The 1784-KTX, -KTXD and -KR modules provide an IBM PC backplane

link to the DH485. It provides an asynchronous link to connect devices on

the network. An asynchronous device can interface with a DH485 module

directly or through a modem link.

1-4

Page 11

Chapter 1

Overview of the 1785KA5

Communication Adapter Module

Compatible Products

You can use the following Allen-Bradley products with the 1785-KA5

module:

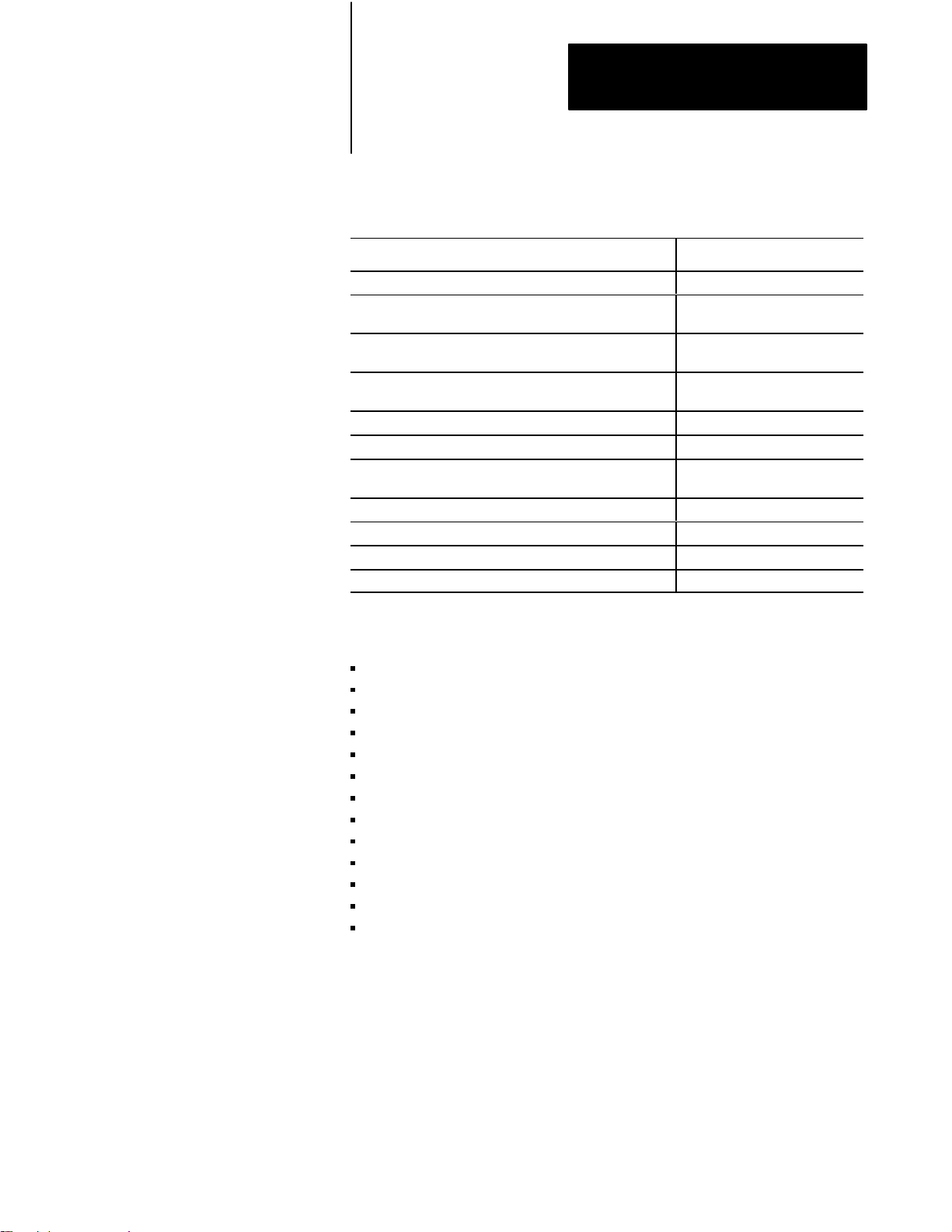

This product Has this Cat. No.

DH+ PLC2 Communication Module 1785KA3

Processor Communication Interface Module

(for IBM PC/XT/AT)

Processor Communication Interface Module

(for IBM PS/2)

Communication Interface Module for the 1784T47

Programming Terminal

I/O ScannerCommunication Adapter Module 1775S5

DH+ PLC3 Communication Module 1775S5, SR5

SLC 500 Hand Held terminal 1747PT1 (with 1747PTA1E

Portable Programming Terminal 1784T45, T47

Advanced Programming Software 1747PA2E (series x and up)

Standard Driver Software 6001F1E, F1E2

6001NET (for VAX) Network Communication Software 6001A1D, G1D, A1DB, G1DB

1784KT

1784KT2

1784KL

firmware)

The following Allen-Bradley PLC and SLC processors are compatible with

the 1785-KA5 module:

PLC-5/10

PLC-5/12

PLC-5/15

PLC-5/25

PLC-5/30

PLC-5/250

PLC-5/40

PLC-5/60

SLC 5/03

SLC 5/04

SLC 500 (can only reply to remote messages)

SLC 5/01 (can only reply to remote messages)

SLC 5/02 (can only reply to remote messages)

1-5

Page 12

Chapter

2

Installing the 1785KA5

Communication Adapter Module

What this Chapter Contains

European Union Directive Compliance

This chapter explains how to install the 1785-KA5 module in a 1771 I/O

rack or in a stand-alone panel mount setup. It contains the following

sections:

the European Union Directive Compliance

setting the switches

installing the 1785-KA5 module in an I/O rack

installing the 1785-KA5 panel-mount version

connecting the module

powering up

If this product is installed within the European Union or EEA regions and

has the CE mark, the following regulations apply.

EMC Directive

This apparatus is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) using a technical construction file

and the following standards, in whole or in part:

EN 50081-2 EMC – Generic Emission Standard, Part 2 – Industrial

Environment

EN 50082-2 EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

The product described in this manual is intended for use in an industrial

environment.

Low Voltage Directive

This apparatus is also designed to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and Tests.

For specific information that the above norm requires, see the appropriate

sections in this manual, as well as the following Allen-Bradley publications:

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

Guidelines for Handling Lithium Batteries, publication AG-5.4

Automation Systems Catalog, publication B111

2-1

Page 13

Chapter 2

Installing the 1785KA5

Communication Adapter Module

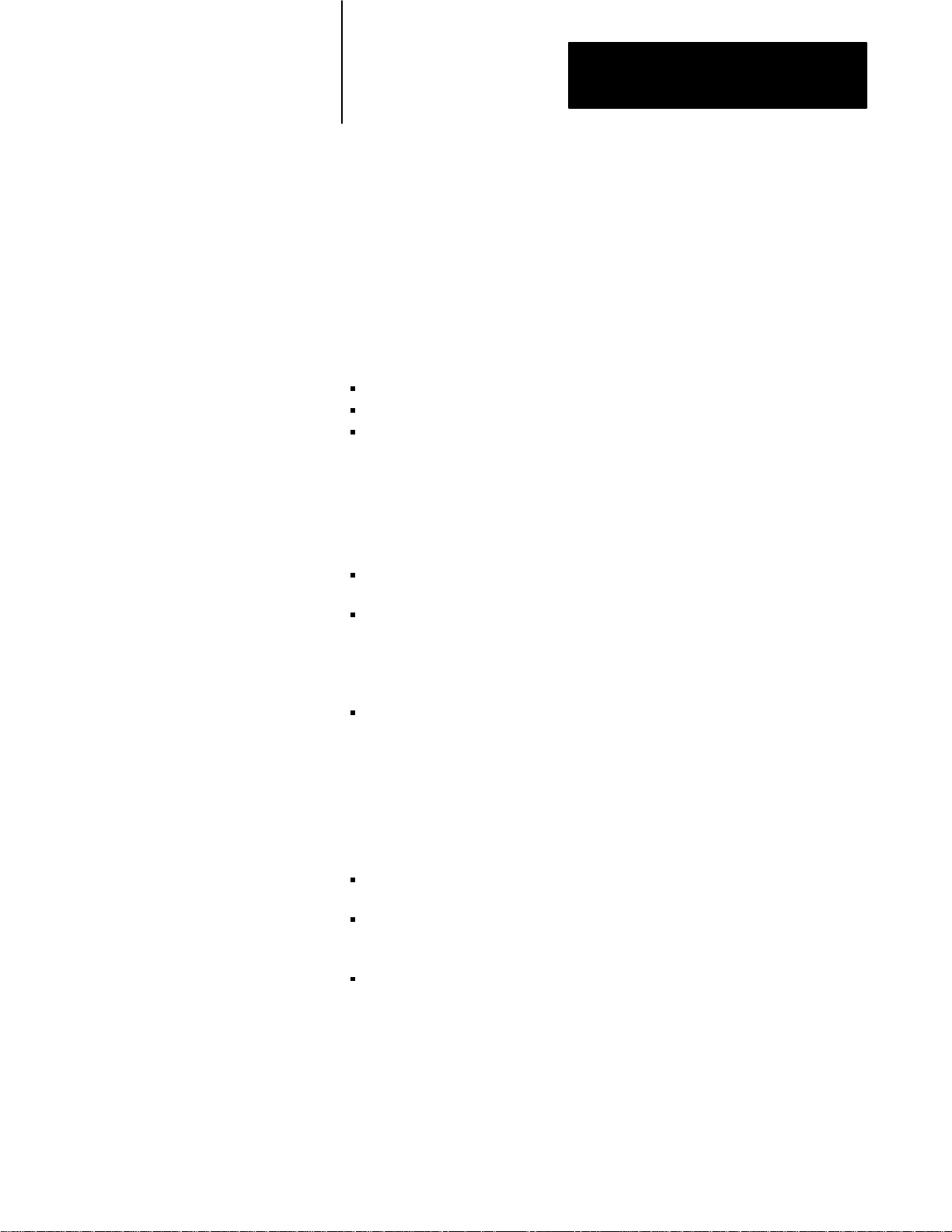

Setting the Switches

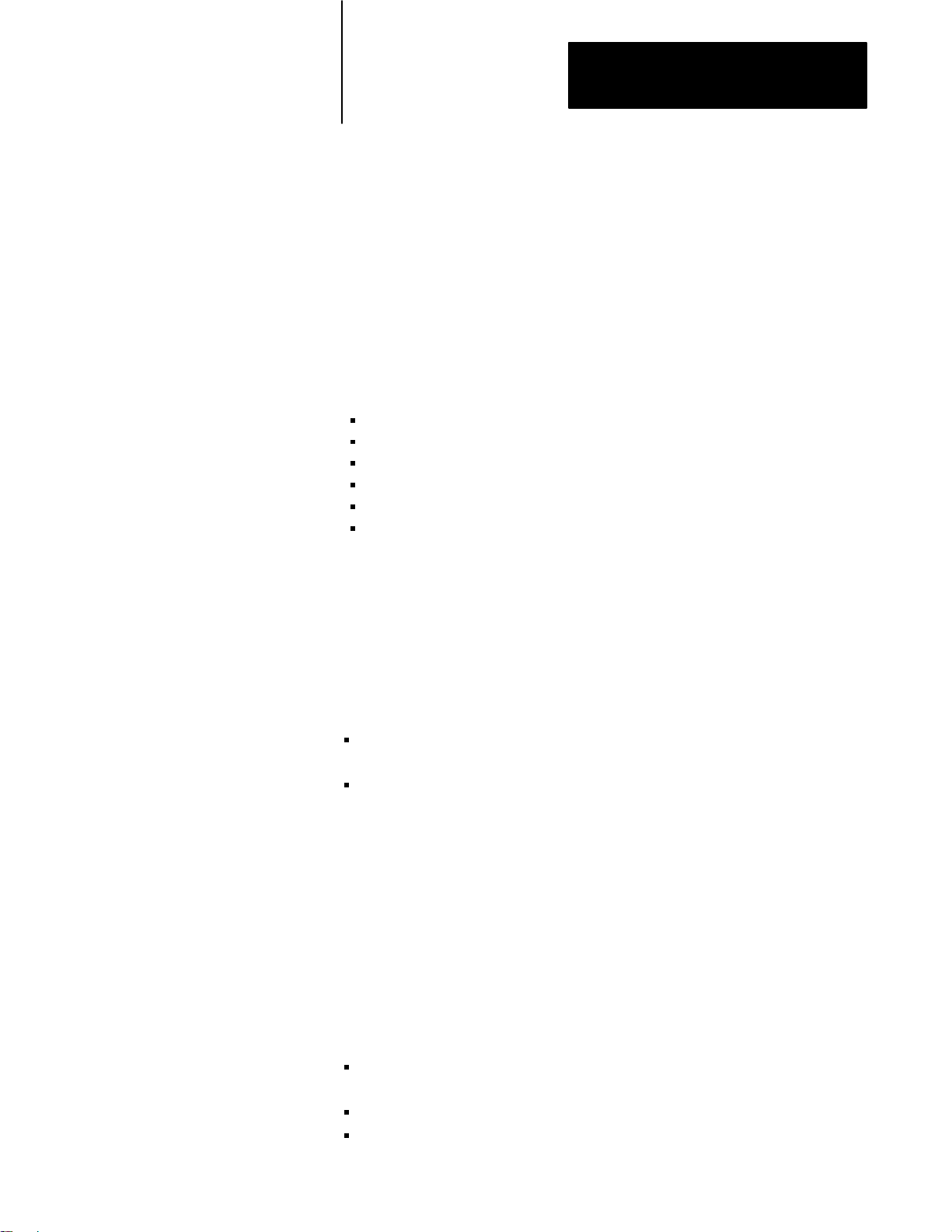

The 1785-KA5 module has three banks of DIP switches that let you select

various communication options. The switch assemblies and their

corresponding options are:

To set the Use switch assembly

DH485 station address and baud rate SW1

DH+ station address and the auto route enable option SW2

DH485 and DH+ channel LINK_IDs SW3

Figure 2.1 shows the location of the switches on the 1785-KA5 module.

Figure 2.1

1785KA5

1785KA5/B shown)

DH485 BAUD RA

communication adapter module switch assemblies (cat. no.

TE

LEGEND

DH485 STATION ADDRESS

B0

B1

B2

B3

B4

ON

OFF

SW - 1 SW - 2

switch assemblies

Important: The 1785-KA5 uses the following convention:

on = binary 1

off = binary 0

SW - 3

B7

RESERVED

B6

AUTO ROUTE ENABLE

B5

B4

B3

DH+ STA

B2

B1

B0

B3

B2

B1

B0

B3

B2

B1

B0

TION ADDRESS

DH485 CHANNEL DH+ IP LINK ID

DH+ CHANNEL LINK ID

19191

OFF

ON

(0)

(1)

2-2

Page 14

Chapter 2

Installing the 1785KA5

Communication Adapter Module

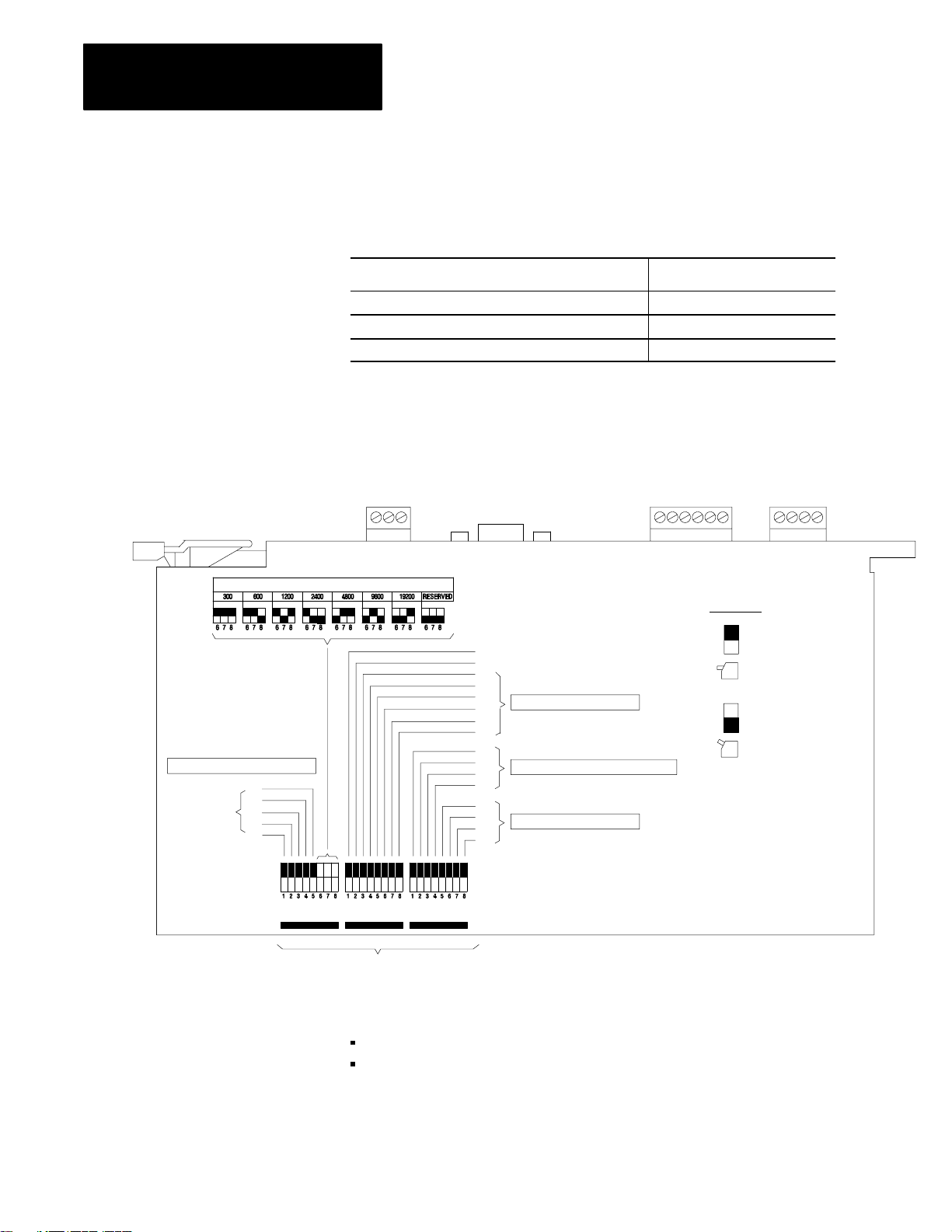

SW1: DH485 Station Address and DH485 Baud Rate

Use switch assembly SW-1 to select the DH485 station address and baud

rate for the 1785-KA5 module. The following sections show you how.

Setting the DH485 Station Address

Set switches 1-5 of SW-1 to the DH485 station address for the 1785-KA5.

Valid addresses are 0-31 decimal or 0-37 octal. Set the switches as

follows:

Most significant octal digit (switches 12)

To set to Set switch 1 to Set switch 2 to

0 0 0

1 0 1

2 1 0

3 1 1

Least significant octal digit (switches 35)

To set to Set switch 3 to Set switch 4 to Set switch 5 to

0 0 0 0

1 0 0 1

2 0 1 0

3 0 1 1

4 1 0 0

5 1 0 1

6 1 1 0

7 1 1 1

For example

To set the module’s DH485 station address to 15 decimal or 17 octal, set

the SW-1 switches as follows:

Set switch To

1 0

2 1

3 1

4 1

5 1

most significant octal digit = 1

least significant octal digit = 7

2-3

Page 15

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Setting the DH485 Baud Rate

Set switches 6-8 of SW-1 to the DH485 baud rate as follows:

To set this baud rate Set switch 6 to Set switch 7 to Set switch 8 to

300 0 0 0

600 0 0 1

1200 0 1 0

2400 0 1 1

4800 1 0 0

9600 1 0 1

19200 1 1 0

RESERVED 1 1 1

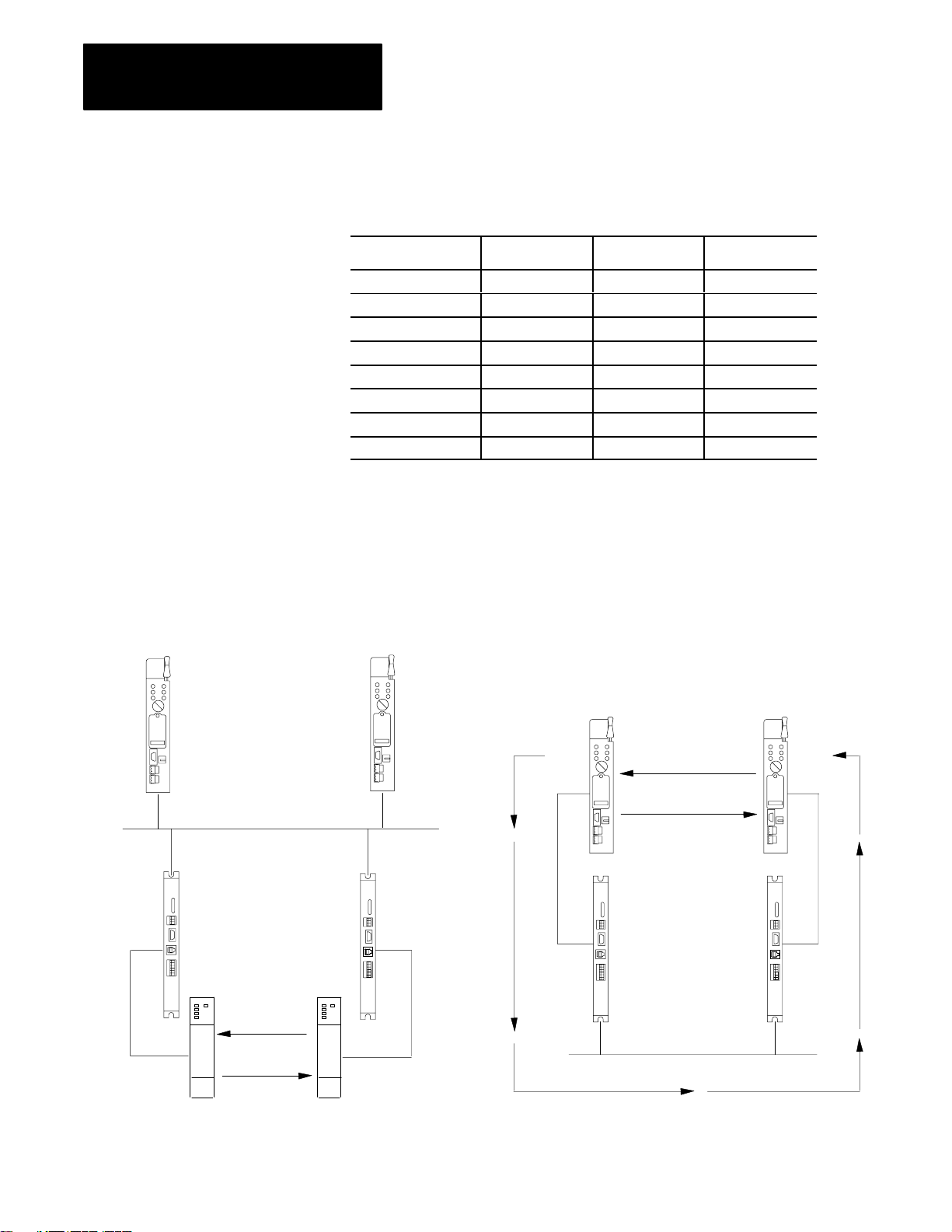

SW2: Auto Routing and DH+ Station Address

The module has an auto routing feature that broadcasts an information

packet over the Data Highway network every 30 seconds.

The following illustration shows the only two network configurations

that you must use auto routing with:

PLC5 PLC5

Data Highway Plus

1785KA51785KA5

DH+

PLC5

PLC5

Desired

Communication

DH+

DH485

2-4

SLC5/03

Desired

Communication

SLC5/03

DH485

1785KA5

1785KA5

DH485

Page 16

Chapter 2

Installing the 1785KA5

Communication Adapter Module

If you are not using one of these two network configurations, do not use

the auto routing feature.

If you: Then:

do not plan to use the auto routing feature skip to the next section, How to Enable or

Disable the Module for Auto Routing to

learn how to disable the auto routing

feature

plan to use the auto routing feature continue with this section to determine if

you can use the auto routing feature in

your network

ATTENTION: Do not use auto routing in a network that

includes any of the following components:

1785-KE module

6008-LTV module

1785-KA module

1785-KA3 module

1775-S5 module

1784-KT card

1784-KTX card

1784-KTXD card

Module and system faults occur when you use auto routing in a system that

includes any of these network components. Be sure to disable the auto

routing feature when using these components.

How to Enable or Disable the Module for Auto Routing

Use switch assembly SW-2 to enable or disable the module for auto

routing.

To: Set switch 2 to

enable auto routing 1

disable auto routing 0

Important: Switch 1 of SW-2 is reserved. Always set this switch to (0).

2-5

Page 17

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Setting the DH+ Station Address

Set switches 3-8 of SW-2 to the DH+ station address for the 1785-KA5.

Valid addresses are 0-77 octal Set the switches as follows:

Most significant octal digit (switches 35)

To set to Set switch 3 to Set switch 4 to Set switch 5 to

0 0 0 0

1 0 0 1

2 0 1 0

3 0 1 1

4 1 0 0

5 1 0 1

6 1 1 0

7 1 1 1

Least significant octal digit (switches 68)

To set to Set switch 6 to Set switch 7 to Set switch 8 to

0 0 0 0

1 0 0 1

2 0 1 0

3 0 1 1

4 1 0 0

5 1 0 1

6 1 1 0

7 1 1 1

For example

To set the module’s DH+ station address to 64 octal, set the switches as

shown below:

Set switch To

3 1

4 1

5 0

6 1

7 0

8 0

most significant octal digit = 6

least significant octal digit = 4

2-6

Page 18

Chapter 2

Installing the 1785KA5

Communication Adapter Module

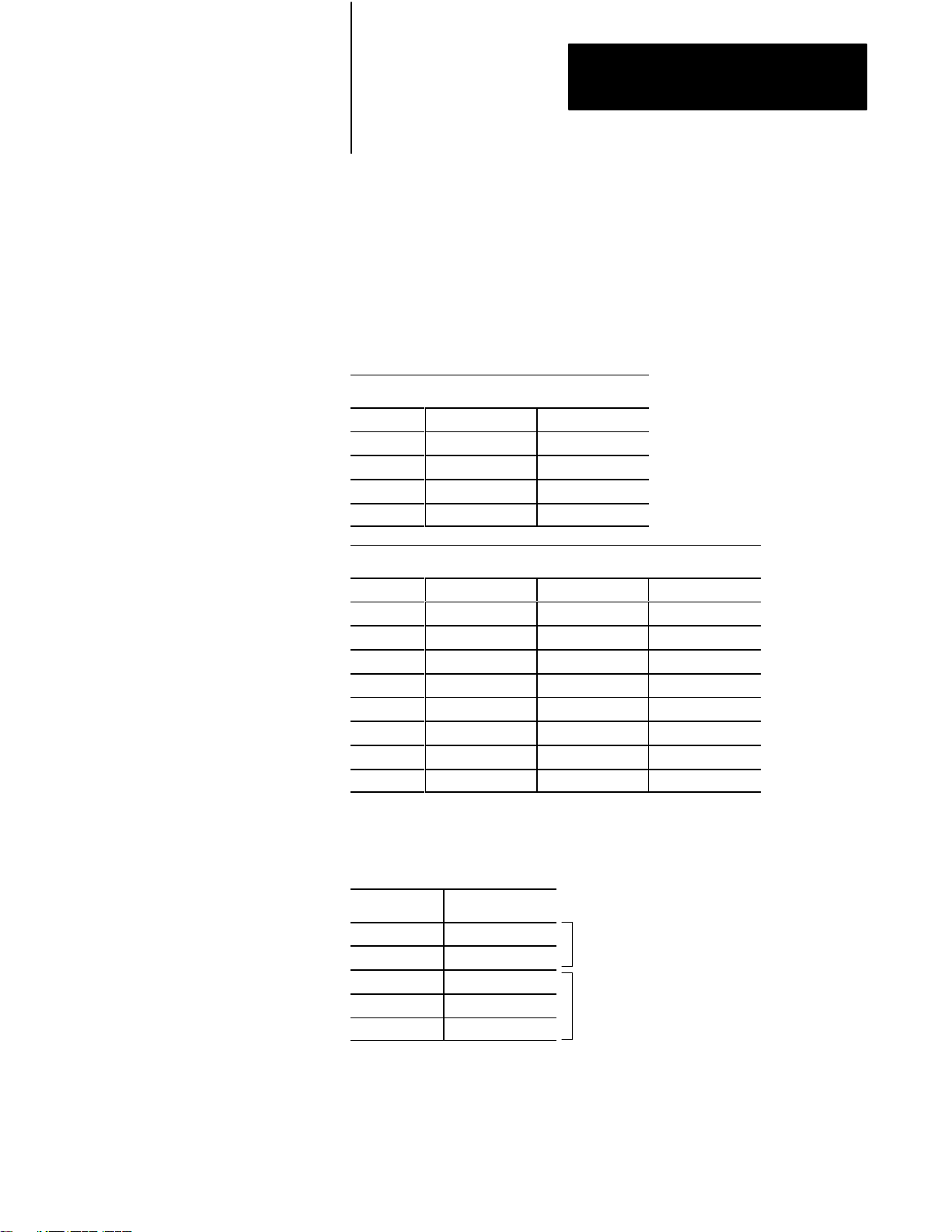

SW3: DH485 Channel LINK_ID and DH+ Channel LINK_ID

The 1785-KA5 module has two LINK_ID addresses: one for its DH485

side and one for its DH+ side. See the following table to set switches 1-8

of SW-3.

Important: Do not use a LINK_ID of 0 (zero). This address is reserved. If

you have more than one 1785-KA5 module on a single physical network,

the LINK_IDs for the two modules must be the same.

To set the DH485

LINK_ID to

To set the DH+

LINK_ID to

1 0 0 0 1

2 0 0 1 0

3 0 0 1 1

4 0 1 0 0

5 0 1 0 1

6 0 1 1 0

7 0 1 1 1

8 1 0 0 0

9 1 0 0 1

10 1 0 1 0

11 1 0 1 1

12 1 1 0 0

13 1 1 0 1

14 1 1 1 0

15 1 1 1 1

Set switch 1 to Set switch 2 to Set switch 3 to Set switch 4 to

Set switch 5 to Set switch 6 to Set switch 7 to Set switch 8 to

For example

To set the module’s DH485 LINK_ID to 4 and DH+ LINK_ID to 8, set the

switches as follows:

Set switch To

1 0

2 1

3 0

4 0

5 1

6 0

7 0

8 0

DH485 LINK_ID = 4

DH+ LINK_ID = 8

2-7

Page 19

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Important: Each physical network link must have a unique LINK_ID

address.

The next section shows you how to mount the module in a 1771 I/O rack.

See page 2-9 for instructions on mounting the stand-alone version.

Mounting the 1785KA5

Communication Adapter

Module in an I/O Rack

The 1785-KA5 mounts in any slot of an Allen-Bradley 1771 bulletin I/O

rack, except slot zero. If you are using a dropline/trunkline configuration,

mount the 1785-KA5 module within 10-100 feet of the DH+ trunkline. The

maximum cable length for DH485 trunk connections is 4,000 ft., with

individual stations “daisy-chained” together.

To install the 1785-KA5 module in a 1771 bulletin I/O rack:

1. Perform an orderly power down of the rack and its controlling PLC

processor.

ATTENTION: Remove system power before removing or

installing the module in the 1771 I/O chassis. Failure to observe

this warning could result in:

damage to the module’s circuitry

undesired operation and possible injury to personnel

2. Insert the optional keying bands provided with the 1771 I/O rack on

the backplane (The 1785-KA5 is keyed to protect against installing it

in the wrong I/O rack slot). Insert one band between keying positions

6 and 8. Insert the other between positions 12 and 14. The figure

below shows the keying positions:

2-8

Keying

Bands

19193

Page 20

Chapter 2

Installing the 1785KA5

Communication Adapter Module

3. Slide the 1785-KA5 module into one of the slots in the 1771 I/O rack.

Make sure the module is seated properly. Snap down the latch on the

top of the module to secure proper placement in the rack (You can

change the position of the keying bands if subsequent system design

requires the insertion of a different type of module in this slot).

Now you are ready to connect the module (see page 2-10.)

Panelmounting the

1785KA5 Communication

Adapter Module

The rear edge of the 1785-KA5 panel-mount version contains a mounting

bracket that lets you install the module. If you are using a

dropline/trunkline configuration, mount the 1785-KA5 panel-mount

module within 10-100 feet of the DH+ trunkline. Figure 2.2 shows the

mounting dimensions for the module.

Figure 2.2

1785KA5

288mm

(11.35")

panelmount module (Cat. No. 1785KA5P/B) dimensions

149mm

(5.87")

305mm

(12.0")

39mm

(1.53")

hole size

accommodates

up to 1/4 - 20

size screw

19194

To protect the module from harmful environmental conditions, enclose it in

a standard industrial enclosure (NEMA type 12 or equivalent.)

2-9

Page 21

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Important: Make sure the enclosure leaves a 6 inch (minimum) clearance

at the top and bottom of the module for air flow.

After you mount the module, you are ready to make connections.

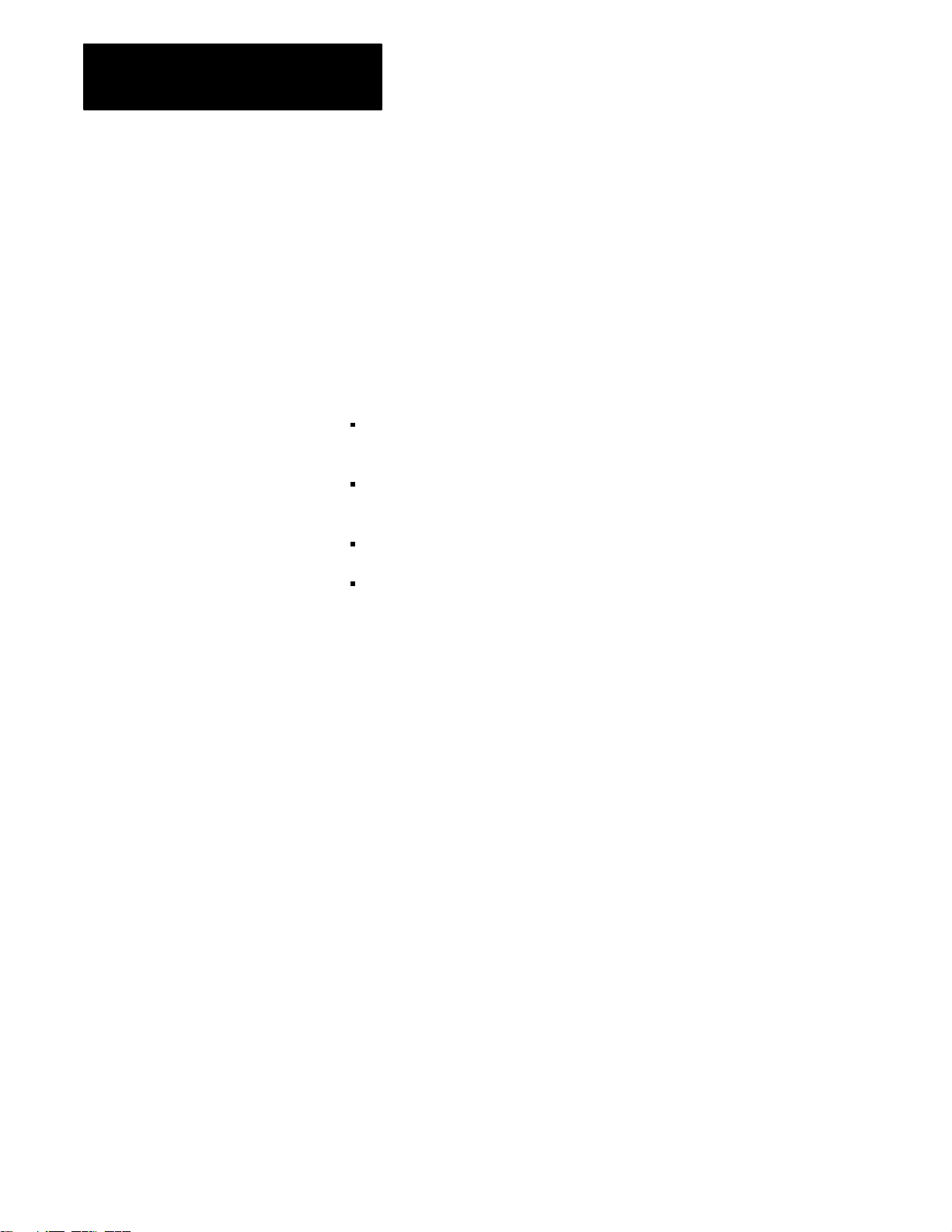

Connecting the 1785KA5

Module

Figure 2.3 shows the ports on the front panel of the 1785-KA5 module:

Figure 2.3

1785KA5

connectors

DH+

DH+

Programming

Terminal

AUX

(for

programmer)

DH485

2-10

Cat. No. 1785KA5/A

rackmount module

Power Supply

Cat. No. 1785KA5P/A

panelmount module

19195

Page 22

Chapter 2

Installing the 1785KA5

Communication Adapter Module

To connect the 1785-KA5 module:

1. Use the 3-pin port labeled Data Hwy Plus to connect the DH+

dropline (100 ft. max.) or the daisy-chained cable to the 1785-KA5

module. Connect the Allen-Bradley cable (cat. no. 1770-CD) to the

3-pin plug as shown:

1770CD

Cable

Blue (2)

Shield (SH)

Clear (1)

20224

2. Use the 9-pin D-shell port labeled Data Hwy Plus to connect your

programming terminal (such as the 1784-T50 programming terminal

used with a 1784-CP cable) to the DH+ network:

Pin Signal

1 (clear) signal wire

5 (blue) signal wire

7 (bare) cable shield wire

2-11

Page 23

Chapter 2

Installing the 1785KA5

Communication Adapter Module

3. Use the 8-pin modular port labeled AUX to connect the SLC 500

programmer. Use an Allen-Bradley cable (cat. no. 1747-C10

series A):

Pin Signal

1 data

2 -data (B)

3 (not used)

4 24v enable (internally connected to ground

5 TXEN (from HHT)

6 earth ground (chassis)

7 signal ground

8 +24V dc @ 105 ma

(A)

pin 7)

4. Use the 6-pin terminal block labeled DH485 to connect to the DH485

dropline. Use Belden #9842 cable:

Pin Signal

1 earth ground (chassis)

2 cable shield

3 signal ground/common

4 data (B)

5 -data (A)

6 termination

2-12

Colors for the Belden #9842 cable are shown below:

earth ground

drain cable shield

blue/whitestripe

white/orangestrip data(B)

orange/whitestripe -data(A)

termination

1

2

3

4

5

6

a. Cut the white wire with the blue stripes from the twisted

wire pair. Do not use this wire.

b. Connect only one end of the trunk cable to earth ground

(chassis) by jumpering pins 1 and 2 together on the connector.

Page 24

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Important: If the 1785-KA5 module is attached at either end of the

DH485 network trunk cable, install a wire jumper between pins 4 and 6 of

the 6-pin mating connector supplied with the module. This is the

termination resistor for the network.

5. If you are connecting a 1785-KA5P/B panel-mount module, you need

to connect the external power supply:

Important: To meet the Low Voltage Directive regulations within the

European Union or EEA Regions, you must use a Class 2 Safety Extra-low

Voltage power supply.

a. Wire a power supply cable as shown below:

5V dc

supply @

3 Amps

(CHASSIS GROUND) Green/Yellow

0V dc (dc GND) Black

+5V dc Red

14 AWG standard colorcoded wire

4pin Phoenixstyle connector

supplied with 1785KA5P/B module

4

3

2

1

(connect to power

connector on the

1785KA5P/B module)

(no connection)

The earth ground or chassis ground wire should be color-coded

green with a yellow stripe.

b. Wire the cable using the 4-pin connector you received with your

module and connect the cable to the EXT PWR connector on the

module.

Pin Signal

1 no connection

2 +5V dc @ 2.0 amps (red)

3 0Vdc (dc GND) black

4 (Chassis Ground) green/yellow

2-13

Page 25

Chapter 2

Installing the 1785KA5

Communication Adapter Module

The following figure shows how typical connections are made on the

DH485 link.

1785KA5

Gateway Module

Belden

#9842

DH485

Belden

#9842

DH485

Connector

Connector

1784KTX,

KTXD or

KR

Interface

Module

Connector

19196Link Coupler 1747AIC

2-14

Page 26

Chapter 2

Installing the 1785KA5

Communication Adapter Module

The figure below shows a typical system connection using the 1785-KA5

module:

PLC-5/15

1785-KA5 module

DH+

DH+ Remote

Terminal

AUX

DH485

SLC 500

controller

Connect DH485 stations at any point along the length of the cable using a

link coupler (cat. no. 1747-AIC) and daisy-chain connections.

Data Highway Plus

T70 Terminal

(with 1784KT,

KTX or KTXD)

DH485 daisy chain

1747-AIC

Link coupler

1747-C11 Cable

19197

2-15

Page 27

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Powering Up the 1785KA5

Module

After you have:

set the switch assemblies on the 1785-KA5 module

mounted your 1785-KA5 module

connected the 1785-KA5 module to the DH+ and DH485 (and,

optionally, the 1784-T50 programming terminal, the SLC 500

programmer and the external power supply)

you are ready to power up the 1785-KA5 module. To power up the

module:

1. Perform a power up of the I/O rack and PLC processor (refer to your

PLC user’s manual for more information.)

At power-up, the 1785-KA5 performs internal memory and device

diagnostic checks. Both the DH+ and DH485 have duplicate address

protection. During these tests, the red FAULT LED lights up and the

top three green LEDs (DH+TX, DH+RX, DH485TX) sequence

through test values.

2. Use the LEDs to verify that the module was installed properly. The

diagnostic check is complete when the red FAULT LED turns off

(tests normally complete within 10 seconds.) The figure below shows

the LEDs.

2-16

DH+ transmit (green)

DH+ receive (green)

DH485 transmit (green)

DH485 receive (green)

CPU Fault (red)

DH+TX

DH+RX

DH485TX

DH485RX

FAULT

19198

Page 28

Chapter 2

Installing the 1785KA5

Communication Adapter Module

Use the following table to determine if the installation was

successful:

If the installation was Then

successful -only the green LEDs flash on and of

-the DIP switches are read. All DIP switches are read at this

time only. Changes you make after this time are ignored.

Important: Always power down the module before you change

DIP switch settings.

unsuccessful -the red LED remains on and the green LEDs freeze at the

failed value

-the 1785KA5 is removed from both the DH+ and DH485

networks. Originating devices can not send packets through

the module and do not receive responses.

f.

Use the module’s LEDs and the following table to interpret an

installation failure:

DH+TX DH+RX DH485TX Problem

off off on bad ROM checksum

off on off RAM address test failed

off on on RAM pattern test failed

on off off CTC timer tests failed

Important: If only the red FAULT LED lights up, there are two possible

causes:

a duplicate station address was detected on the DH+ or DH485

the KA5P is indicating that there is a problem with the external

power supply or cable

2-17

Page 29

Chapter

3

Communicating through the 1785KA5

Communication Adapter Module

What this Chapter Contains

Internet Protocol Addressing

This chapter includes information on:

network addressing

how the 1785-KA5 module operates as a router

how the 1785-KA5 module operates as a gateway

PLC-5 to SLC communication

controlling the flow of data

Each station on the internet must have a unique Internet Protocol (IP)

address to help a packet reach its intended receiver. The IP address is the

high level address used to send message packets back and forth across the

internet. The IP address must be unique over all physical networks that are

connected, not just one local network channel. It is needed because a

device on the DH+ network may have the same address as a device on the

DH485 network. The IP address has two parts:

LINK_ID address

DH+/DH485 STATION address

LINK_ID Address

The LINK_ID is the address of the link (individual cable or channel). Each

network link in the internet should have a unique LINK_ID address. You

set the LINK_ID address using the switches on the interface module for

each station.

Important: If more than one 1785-KA5 module is attached on one

physical link, each must have the same LINK_ID address.

3-1

Page 30

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

For example:

In Figure 3.1, the DH+ LINK_IDs for all three 1785-KA5 modules must

be set to 1 (the DH+ LINK_ID.)

Figure 3.1

addressing

IP

DH+ (LINK_ID = 1)

1785 -KA5

5

DH+ LINK_ID 1,

station 2

DH485 LINK_ID 2,

station 10

DH485 (LINK_ID = 2)

1785 -KA5

DH+ LINK_ID 1,

station 3

DH485 LINK_ID 3,

station 11

DH485 (LINK_ID = 4)

DH485 (LINK_ID = 3)

5

1785 -KA5

DH+ LINK_ID 1,

station 4

DH485 LINK_ID 4,

station 12

19199

Important: The following LINK_ID addresses are reserved:

This LINK_ID address Is reserved for the

LINK_ID = 0 local network. When a station does not know its own LINK_ID, it can

specify 0 until it determines the value (from a router, for example)

LINK_ID = FFFFh internet broadcast address. When using this address, the STATION

fields must also be all ones. The broadcast address is only permitted

in the destination field. The broadcast packet is routed to all internet

addresses

3-2

Page 31

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

DH+/DH485 STATION Address

The DH+ and DH485 address is the low level physical address that

identifies a device on a single physical network. Each physical device must

have a unique STATION address on that link. You set the STATION

address using the switches on the interface module. Valid physical

addresses are 0-77 octal for the DH+ network and 0-31 decimal for the

DH485 network.

Important: Each physical device on a link must have a unique address on

that link. Two devices can not have the same address.

For example:

Figure 3.1 on page 3-2 shows a DH+ network with a LINK_ID of 1

connected to a DH485 network with a LINK_ID of 2 by a 1785-KA5

module. Both networks have stations with addresses of 5, yet each device

has a unique IP address.

This device Has this IP address

device 3 on the DH+ network LINK_ID = 1, station = 3

device 3 on the DH485 network LINK_ID = 2, station = 3

3-3

Page 32

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

1785KA5 Router

Communication

This section explains:

router mode addressing

how the 1785-KA5 operates as a router

Router Mode Addressing

A DH+ device wishing to send an internet packet to a DH485 device must

set the internet destination address (LINK_ID, STATION) to the:

LINK_ID of the DH485 network

STATION address to the DH485 device

How the 1785KA5 Module Operates as a Router

The 1785-KA5 module operates as a router when attached DH485 stations

fully implement IP protocol (if they do not, it acts as a gateway) DH485

stations that implement IP can initiate commands, as well as send reply

messages.

Important: SLC 5/01, SLC 5/02 and fixed controllers do not support IP.

To communicate with one of these processors, use the 1785-KA5 module

as a gateway.

When the 1785-KA5 module receives an internet packet, it acts as an

intermediate station and passes the packet along in the correct direction.

Unlike the gateway process, no packet conversion is necessary because

stations on both sides of the 1785-KA5 “speak the same language.”

3-4

Page 33

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

The figure below demonstrates internet router mode communication from a

PLC-5 processor (on DH+) to another PLC-5 (on a remote DH+ network)

across the DH485. The auto route enable switch, switch 2 of SW-2 (see

page 2-2) is set to on (1) for both 1785-KA5 modules.

PLC5 PLC5

DH+LINK_ID1,

station10

DH+LINK_ID3,

station15

DH+

LINK_ID=1

DH+LINK_ID1,

station11

DH485 LINK_ID 2,

station 12

DH485LINK_ID=2

1785-KA5 1785-KA5

DH+

LINK_ID=3

DH+LINK_ID3,

station14

DH485 LINK_ID 2,

station 13

19235

The message instruction below (as shown in Allen-Bradley 6200 Series

software) shows the PLC-5 on the left writing 64 words from its data file

N20:0 to data file N21:0 of the remote PLC-5 on the right. The 1785-KA5

modules (in router mode) determine which device in the internet to route

the message, so if the internet contains multiple 1785-KA5 modules, the

message still reaches its intended destination.

Figure 3.2

Message

instruction

In this message transfer process:

the message is first sent to the

local node, which is the 1785KA5

module (DH+ LINK_ID = 1, STATION 11)

the 1785KA5 determines the

location of the remote station in the

internet and reroutes it to the proper

destination, which is the PLC5

(DH+LINK_ID = 3, STATION 15)

MESSAGE INSTRUCTION DATA ENTRY FOR CONTROL BLOCK N10:0

Communication command: PLC-5 typed write

PLC-5 data table address: N20:0

size in elements: 64

Local/Remote: Remote

Remote station: 15

LINK_ID: 3

Remote link type: DATA HIGHWAY

Local node address: 11

Destination data table address: N21:0

Block size = 11 words

3-5

Page 34

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

1785KA5

Gateway

Communication

This section explains:

gateway mode addressing

how the 1785-KA5 operates as a gateway

“single-hop” mode packets

Gateway Mode Addressing

All DH+ and DH485 destination and source addresses are contained in the

lower address byte, leaving the upper byte free for “sub-addressing.” An

internet device sends a packet to a non-internet device on the DH485 link

by:

addressing the lower byte of the STATION address (D_STATION[0]) to

the 1785-KA5 adapter module for packet processing

addressing the upper byte of the STATION address (D_STATION[1]) to

the actual destination device. The upper byte of the STATION field is

defined as follows:

3-6

Page 35

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

How the 1785KA5 Module Operates as a Gateway

The 1785-KA5 module operates as a gateway when attached DH485

stations do not fully implement IP. It converts IP packets to DH485 local

packets and sends them to their DH485 destination stations.

Important: SLC 5/01, SLC 5/02 and fixed controllers do not support IP.

DH+ devices that wish to send packets to DH485 devices that do not

implement IP protocol must address the 1785-KA5 DH+ or DH485

gateway service internet address (You set these addresses before you

install the 1785-KA5 module. See page 2-7.)

The 1785-KA5 communicates with DH+ devices using IP and DH485

devices using DH485 packets only. The 1785-KA5 module automatically

converts between the DH+ and the DH485 as necessary. Neither side is

aware of the packet conversion process.

Only devices that fully implement IP protocol may initiate PCCC

command packets. DH485 devices that do not implement IP may only send

reply packets.

Internet Protocol Singlehop Packets

The IP “single-hop” packet is a special type of IP-to-DH485 remote packet

where the DH+ device sending the packet believes it is connected to a

gateway that only has two networks – the network it is connected to, and

its opposite network.

A single-hop packet is formatted like an IP remote data packet, except that

the destination (DST) and source link (S_LINK_ID) fields are zero, so the

packet is not routed using the normal IP routing algorithm. When the

1785-KA5 module receives the packet, it automatically retransmits the

packet on the network opposite the one on which the packet was received.

Important: The 1785-KA5 module will accept single-hop packets from its

DH+ side only (no DH485 software can generate these packets.) New

software running on DH485 devices wanting to send packets off of the

DH485 network should only implement full IP-formatted packets – not

single-hop packets.

3-7

Page 36

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

PLC5 to SLC

Communication

A PLC-5 can communicate with a SLC 500, SLC 5/01, SLC 5/02, or SLC

5/03 using a PLC-5 ladder rung message instruction. These SLC devices

do not provide a message instruction, but will respond to UNSOLICITED

READ and UNSOLICITED WRITE commands.

Read and write commands are addressed to the SLC’s data file 9 (also

referred to as its common interface file, or CIF.) Data file 9 must be

created before the read or write command can be executed. File 9 can be

created in the SLC 500 using Advanced Programming Software (APS),

which must be locally configured. Contact your sales office for third party

software support.

The following example demonstrates communication in an internet using

gateway mode. The message instruction shows that the PLC-5 sends 10

words from its data file N40:0 to file 9 (CIF) of the remote SLC 5/02. Note

the following:

DH+ LINK_ID = 1,

station = 20

PLC 5

DH +

LINK_ID = 1

SLC 5/02

DH485 LINK_ID = 2

DH+ station = 11

DH485 station = 12

1785KA5P/A

MESSAGE INSTRUCTION DATA ENTRY FOR CONTROL

BLOCK N20:0

Communication command: PLC-2 Unprotected Write

PLC-5 data table address: N40:0

size in elements: 10

local/remote: remote

remote station: 012

LINK_ID: 0

remote link type: Data Highway

local node address: 011

destination table address: 010

DH485 LINK_ID = 2

station = 10

19236

3-8

size in blocks = 10 words

Page 37

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

The following information applies to this transaction:

The command must be a PLC-2-type command.

The message is a remote message because the destination is not on the

local link.

The remote station is the octal equivalent of the decimal address of the

destination (for example, SLC 5/02 address = 10 decimal = 12 octal.)

In the message instruction, set the LINK_ID to zero (0) even though the

actual LINK_ID does not equal zero.

The local node is the DH+ station address of the 1785-KA5.

File 9 must exist in the SLC 5/02.

Important: File 9 must contain a minimum of 17 elements. The PLC-5

begins writing into element 16 because the destination table address

contains a minimum of 10 elements.

The destination data table address specifies the data word number to be

accessed within file 9. The PLC-5 automatically converts this address to

a byte address by doubling the decimal equivalent of the word address.

For example: 010

= 1610 and 1778 = 25410.

8

SLC 500 processors use two types of addressing:

word addressing

byte addressing

To Use this type

access only even

words

access both even and

odd words

word addressing. SLC 500, 5/01, and 5/02 processors use

word addressing. Therefore, you can address only even

addresses in file 9 between word 1610 and word 254

byte addressing. The SLC 5/02, series C, FRN 3 or later can

use byte addressing when bit S:2/8 is set. Therefore, you can

address both even and odd addresses between word 810 and

word 255

If the SLC 5/02 is in word addressing mode, the destination

data table address, when doubled and converted to decimal,

represents the word number to be accessed.

If the SLC 5/02 is in byte addressing mode, the destination

data table address, when converted to decimal, represents the

word number to be accessed (see Table 3.A.)

in file 9.

10

10.

3-9

Page 38

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

Table 3.A

5/02 byte addressing mode

SLC

PLC5 destination table

address

010 word N9:16

011 word N9:18

176 word N9:252

177 word N9:254

010 byte N9:8

011 byte N9:9

176 byte N9:254

177 byte N9:255

Type of addressing SLC address

3-10

Page 39

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

The next sections describe two types of remote messaging. Refer to

Figure 3.3 with the following examples:

remote read from a 500CPU

remote read from a 485CIF

Node 2

DH - 485

network

Node 9

(11 octal)

Figure 3.3

Connections

1747-AIC 1747-AIC

DH - 485 network

Node 6

DH - 485

network

SLC 5/02

Data Highway Plus network

LINK_ID = #

Node 8

for a remote message.

SLC 5/03

Node 3

DH - 485 network

Node 1

LINK_ID = 1

PLC-5 processor with

a 1785-KA5 module

Node 2

Node 4

LINK_ID = 3

Node 7

PLC-5 processor with

a 1785-KA5 module

LINK_ID = 2

DH - 485

network

Node 3

Node 5

DH - 485 network

1747-AIC 1747-AIC

SLC 5/02

PLC5/40 processor

DH - 485

network

Node 1

SLC 5/02

T60 Workstation

Node 6 is the orginating node of MSG

instruction. (You do not need to specify

its address.)

Node 4 is the Local Bridge

node address.

Node 7 is the remote node address of

the local bridge. (You do not need to

specify its address.)

STATION 8 is the Remote

Bridge Address.

Node 5 is the remote node address

of the remote bridge.

Node 3 is the Target station address.

Link ID = 2 is the Remote Link_ID

20096

3-11

Page 40

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

Remote Read from a 500CPU

DH485 supports remote messaging. Below is the data entry screen for a

remote read.

Display Area:

Message:

Prompt:

Data/Cmd Entry:

Status:

Main Functions:

Type:

Read/Write:

Target Device:

Local/Remote:

Control Block:

Channel:F10

Target Node:F1

Remote Bridge Link ID:F2

Remote Bridge Node Address:F3

Local Bridge Node Address:F4

Destination/Source File Address:F5

Target SRC/Dst File Address:F6

Message Length in Elements:F7

Message Timeout (seconds):F8

ERROR CODE:

0 control bit address: N10 : 0/8

Peer-to-Peer

READ

500CPU

Remote

N10 : 0

N7 : 0

N7 : 50

20

ignore if timed out:

to be retried:

awaiting execution:

1

3

2

0

4

continuous run:

error:

message done:

message transmitting

message enabled

waiting for queue space:

5

Error Code Desc:

Press a function key: <ENTER> to save and exit, or <ESC> to abort

offline no forces INSTR INSERT File 009

TARGET

NODE

REMOTE

LINK ID

REMOTE

ADDRESS

LOCAL

ADDRESS

FILE

ADDRESS

TARGET

ADDRESS

MESSAGE

LIMIT

MESSAGE

TIMEOUT

TOGGLE

BIT CHANNEL

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

0

TO

0

NR

0

EW

0

CO

0

ER

0

DN

0

ST

0

EN

0

WQ

3-12

Page 41

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

Function Key

Description

[F1] Target Node Specifies the node number of processor that is receiving the message.

[F2] Remote LINK_ID

[F3] Remote Bridge Node Address

1

2

Specifies the LINK_ID of the remote network where the remote target processor resides.

Use when the remote target device is a SLC fixed, 5/01, 5/02, or any other noninternet device. The value

must be 0 anytime your remote target device is a SLC 5/03, PLC5, or other internet device. Valid range is

0 - 15 decimal.

[F4] Local Address Specifies the node address of the bridge residing on the local network that provides the link to the remote

target processor. Specifies DH485 address.

[F5] File Address For a Read (Destination) this is the address in the initiating processor which is to receive data.

For a Write (Source) this is the address in the initiating processor that is to send data.

Valid file types are S, B, T, C, R, N, I, O, M0, M1.

[F6] Target Address For a Read (Destination) this is the address in the remote target processor that is to send data.

For a Write (Source) this is the address in the remote target processor that is to receive data.

Valid file types are S, B, T, C, R, N, I, O, M0, M1.

[F7] Message Length Defines the length of the message in elements. One word elements are limited to a maximum length of 1

-112. Three word elements are limited to a maximum length of 1 - 37.

[F8] Message Timeout Defines the length of the message timer in seconds. A timeout of 0 seconds means that there is no timer

and the message will wait forever for a reply. Valid range is 0 - 255 seconds.

[F10] Channel Identifies the physical channel used for the message communication. Available channels are (0, RS232) or

(1, DH485).

1

The Remote Bridge Node Address refers to the side of the remote bridge that is connected to the local bridge's remote side. This address must be

within the range of 1 15 decimal. When this value is between 1 and 15, the MSG instruction sends gateway" packets. Gateway packets need to

contain the Remote Bridge Node Address to function. The 1785KA5 module only accepts gateway packets between 1 - 15. The 5/03 MSG instruction

contains a gateway packet anytime the Remote Bridge Node Address field is nonzero.

2

In the cases of MSG instructions to noninternet devices and end devices residing directly on the DH+ link, the Remote LINK_ID is the DH+ LINK_ID.

In all other cases, the Remote LINK_ID is the DH485 LINK_ID.

3-13

Page 42

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

The monitor display screen allows you to monitor the status of the

message instruction while the processor is running.

Display Area:

In this screen, the 5/03 processor reads 5 elements (words)

from Target node 3 of Remote Bridge LINK_ID 2, starting at

word N7:50. If 20 seconds elapse without a reply,

error bit N10:012 will be set, indicating that the instruction

has timed out. The device at node 3 of Remote Bridge

LINK_ID 2 understands the SLC family protocol.

Message:

Prompt:

Data/Cmd Entry:

Status:

Main Functions:

Type:

Read/Write:

Target Device:

Local/Remote:

Control Block:

Channel:F10

Target Node:F1

Remote Bridge Link ID:

Remote Bridge Node Address:

Local Bridge Node Address:

Destination/Source File Address:

F6

Target SRC/Dst File Address:

Message Length in Elements:

Message Timeout (seconds):F8

ERROR CODE:

0 control bit address: N10 : 0/8

Peer-to-Peer

READ

500CPU

Remote

N10 : 0

N7 : 0

N7 : 50

20

ignore if timed out:

awaiting execution:

1

continuous run:

3

2

0

4

message transmitting

message enabled

waiting for queue space:

5

to be retried:

error:

message done:

Error Code Desc:

Press a function key or press <ESC> to exit monitor

offline no forces INSTR INSERT File 009

TARGET

NODE

TARGET

ADDRESS

MESSAGE

TIMEOUT

TOGGLE

BIT

F1 F6 F8 F9

0

TO

0

NR

0

EW

0

CO

0

ER

0

DN

0

ST

0

EN

0

WQ

3-14

Page 43

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

Remote Read from a 485CIF

If you select a remote read from a 485CIF, the following screen appears:

Display Area:

Message:

Prompt:

Data/Cmd Entry:

Status:

Main Functions:

Type:

Read/Write:

Target Device:

Local/Remote:

Control Block:

Channel:F10

Target Node:F1

Remote Bridge Link ID:F2

Remote Bridge Node Address:F3

Local Bridge Node Address:F4

Destination/Source File Address:F5

Target OffsetF6

Message Length in Elements:F7

Message Timeout (seconds):F8

ERROR CODE:

0 control bit address: N10 : 0/8

Peer-to-Peer

READ

485CIF

Remote

N10 : 0

N7 : 0

ignore if timed out:

to be retried:

awaiting execution:

0

3

3

0

4

continuous run:

error:

message done:

message transmitting

message enabled

waiting for queue space:

20

5

10

Error Code Desc:

Press a function key: <ENTER> to save and exit, or <ESC> to abort

offline no forces INSTR INSERT File 009

TARGET

NODE

REMOTE

LINK ID

REMOTE

ADDRESS

LOCAL

ADDRESS

FILE

ADDRESS

TARGET

OFFSET

MESSAGE

LIMIT

MESSAGE

TIMEOUT

TOGGLE

BIT CHANNEL

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

0

TO

0

NR

0

EW

0

CO

0

ER

0

DN

0

ST

0

EN

0

WQ

Function Key Description

[F1] Target Node Specifies the node number of processor that is receiving the message. Valid range is 0 - 254 decimal.

[F2] Remote LINK_ID Specifies the LINK_ID of the remote network where the remote target processor resides.

[F3] Remote Bridge Node Address Use when the remote target device is a SLC fixed, 5/01, 5/02, or any other noninternet device. Valid range

is 0 - 15 decimal.

[F4] Local Address Specifies the node address of the bridge residing on the local network that provides the link to the remote

target processor. Valid range is 0 - 254 decimal.

[F5] File Address For a Read (Destination) this is the address in the initiating processor that is to receive data.

For a Write (Source) this is the address in the initiating processor that is to send data.

Valid file types are S, B, T, C, R, N, I, O, M0, M1.

[F6] Target Offset For a Read or Write this is the word offset value in the common interface file (byte offset for nonSLC

device).

[F7] Message Length Defines the length of the message in elements. One word elements are limited to a maximum length of 1

-112. Three word elements are limited to a maximum length of 1 - 37.

[F8] Message Timeout Defines the length of the message timer in seconds. A timeout of 0 seconds means that there is no timer

and the message will wait forever for a reply. Valid range is 0 - 255 seconds.

[F10] Channel Identifies the physical channel used for the message communication. Available channels are (RS232, 0) or

(DH485, 1).

3-15

Page 44

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

The monitor display screen allows you to monitor the status of the

message instruction while the processor is running:

Display Area:

In this screen, the 5/03 processor reads 5 elements (words)

from Target node 3 or Remote Bridge LINK_ID 3, starting at

byte offset 20 of its PLC 3 compatibility file. This is a byte

offset because the device at node 3 is a PLC-5/40.

The 5 elements are placed in the integer file starting at

word N7:0. If 10 seconds elapse without a reply,

error bit N10:0/12 will be set, indicating that the

instruction timed out. The device at node 3 of the

Remote Bridge LINK_ID 2 understands the

485CIF (PLC 2 emulation) protocol.

Message:

Prompt:

Data/Cmd Entry:

Status:

Main Functions:

Type:

Read/Write:

Target Device:

Local/Remote:

Control Block:

Channel:F10

Target Node:F1

Remote Bridge Link ID:

Remote Bridge Node Address:

Local Bridge Node Address:

Destination/Source File Address:

Target OffsetF6

Message Length in Elements:

Message Timeout (seconds):F8

ERROR CODE:

0 control bit address: N10 : 0/8

Peer-to-Peer

READ

485CIF

Remote

N10 : 0

N7 : 0

ignore if timed out:

awaiting execution:

1

continuous run:

3

3

0

4

message done:

message transmitting

message enabled

waiting for queue space:

20

5

10

to be retried:

error:

0

TO

0

NR

0

EW

0

CO

0

ER

0

DN

0

ST

0

EN

0

WQ

Error Code Desc:

Press a function key: <ENTER> to save and exit, or <ESC> to abort

offline no forces INSTR INSERT File 009

TARGET

NODE

TARGET

OFFSET

MESSAGE

TIMEOUT

TOGGLE

BIT

F1 F6 F8 F9

3-16

Page 45

Chapter 3

Communicating through the 1785KA5

Communication Adapter Module

Controlling the Flow of Data

The data transfer rate is much higher for DH+ links (57.6 KB) than for

DH485 links (19.2 KB), so DH+ devices must control the flow of data to

DH485 devices. For example, a DH+ device can send packets to the

1785-KA5 adapter three times faster than the gateway can send the packets

out to their DH485 destinations.

The 1785-KA5 adapter module provides only a limited amount of buffer

space to account for short term bursts of data transfer. The DH+ device

must meter out or otherwise provide other means for flow control to

prevent buffer overflow in the gateway.

3-17

Page 46

$SSHQGL[

6SHFLILFDWLRQV

&RPPXQLFDWLRQ 5DWHV

'DWD +LJKZD\ 3OXV '+ ELWV SHU VHFRQG

56 'DWD +LJKZD\ '+ VZLWFKVHOHFWDEOH IURP WR

ELWV SHU VHFRQG

)XQFWLRQ

LQWHUIDFH D SURJUDPPDEOH 56 FRPSDWLEOH GHYLFH ZLWK DQ

$OOHQ%UDGOH\ '+ QHWZRUN

0RXQWLQJ /RFDWLRQ

.$% VLQJOH VORW LQ EXOOHWLQ ,2 UDFN

.$3% VWDQGDORQH SDQHOPRXQW

&RPPXQLFDWLRQ 3RUWV

'+

'+

&DEOLQJ

'+ '+'+ VWDWLRQ FRQQHFWRU FDW QR 6&

8VH ZLWK $OOHQ%UDGOH\ &' RU FDEOHV OLVWHG RQ WKH $OOHQ%UDGOH\

DSSURYHG YHQGRU OLVW

'+ FXVWRPHUVXSSOLHG %HOGHQ

3RZHU 5HTXLUHPHQWV

$ # 9 GF

3RZHU 6RXUFH

.$% EXOOHWLQ ,2 UDFN SRZHU VXSSO\

.$3% XVHUVXSSOLHG 9 GF # $

$PELHQW 7HPSHUDWXUH 5DWLQJ

R&WRR& R)WRR) RSHUDWLRQDO

R&WRR& R)WRR) VWRUDJH

$PELHQW +XPLGLW\ 5DWLQJ

WR ZLWKRXW FRQGHQVDWLRQ

$JHQF\ &HUWLILFDWLRQ ZKHQ SURGXFW RU SDFNDJLQJ LV PDUNHG

PDUNHG IRU DOO DSSOLFDEOH GLUHFWLYHV

$

Page 47

Index

Numbers

1785-KA5 Communication Adapter module,

using more than one, 27

1785-KA5 communication adapter module

defined, 11

illustrated, 13

1785-KA5 gateway module

specifications, A1

using more than one, 31

1785-KA5 panel mount module, when to

use, 13

1785-KA5 rack mount module, when to

use, 13

C

compatible products, 15

connecting the module, 210

D

data flow control, 317

DH+ network, 12

setting the channel LINK_ID, 27

setting the station address, 24

DH485 network

setting the baud rate, 24

setting the channel LINK_ID, 27

setting the station address, 23

G

IP layer, address, 31

L

LED indicators, troubleshooting, 216

LINK_ID address, 31

LINK_ID addresses, 27

M

MAC layer, address, 33

mounting in an I/O rack, 28

P

panel-mounting, 29

PLC 5 to SLC500 communication, 38

powering up the module, 216

R

router mode, addressing, 34

router operation, 34

S

setting the switches, 22

single-hop packets, 37

Specifications, A1

station address, DH+ and DH485, 33

gateway

addressing, 36

communication, 37

I

installation, successful and unsuccessful,

217

T

troubleshooting with the LEDs, 216

Page 48

AllenBradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

worlds leading technology companies.

Worldwide representation.

Argentina •

Denmark • Ecuador

Ireland

Philippines •

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication

Supersedes

Australia • Austria • Bahrain

• Egypt • El Salvador • Finland • France •

• Israel • Italy • Jamaica •

• Belgium • Brazil •

Bulgaria • Canada

Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary

Japan • Jordan • Korea • Kuwait • Lebanon

• Chile •

China, PRC • Colombia

• Malaysia • Mexico •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore

• Switzerland • T

17856.5.5 - November 1995

Publication 17856.5.5 - June 1994

aiwan

• Thailand • T

urkey • United Arab Emirates • United Kingdom • United States • Uruguay

• Costa Rica •

Netherlands

• New Zealand •

• Slovakia • Slovenia •

Croatia • Cyprus

Norway

South Africa, Republic

• V

enezuela

Copyright

• Iceland •

• Yugoslavia

1995 AllenBradley Company

• Czech Republic •

India • Indonesia

• Pakistan •

Peru

•

• Spain •

PN

95512231

, Inc. Printed in USA

•

Loading...

Loading...