Page 1

Smart Transmitter Interface Products

(HARTr Protocol)

Cat. Nos. 1770-HT1, 1770-HT8, 1770-HT16

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation, the

Allen-Bradley Company, Inc. does not assume responsibility or liability (to

include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley Publication SGI-1.1, “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Control” (available from your local

Allen-Bradley office) describes some important differences between solid-state

equipment and electromechanical devices which should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted manual, in whole or in part,

without written permission of the Allen-Bradley Company Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

Interchange, ControlView, Data Highway Plus and DH+ are trademarks and PLC is a registered

trademark of Allen-Bradley Company, Inc.

HART is a registered trademark of Rosemount Inc.

IBM is a registered trademark of International Business Machines Corporation.

Page 3

Table of Contents

Preface P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose

Organization

How to Use This Manual P1

Related

Related Products P3

Glossary

of the Manual

of the Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience P2

AllenBradley

HART

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

Publications

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of T

erms and Abbreviations P3. . . . . . . . . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P2. . . . . . . . . . . . . . . . . . . . . . . . . . .

P2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introducing the Smart Transmitter Interface 11. . . . . . . . . . . .

Product Overview 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1770HT1 Communications Controller 11

1770HT8/16 Terminal Block 13

The

Remote I/O Port of the Communications Controller

The RS232C Port of the Communications Controller 15

The

HAR

T Protocol 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HAR

The

Poll/Response Mode 110

Burst Mode 110

Features

Benefits of Using the Smart Transmitter Interface 111

Compatibility 112

PLC5

HART Field Devices 112

Analog

Hand Held Terminal 113

T Protocol and the Smart Transmitter Interface 19. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Smart T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Family

I/O Devices

ransmitter Interface 110. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

14. . . . . . .

. . . . . . . .

. . . . . . . . . . . . .

112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Smart Transmitter Interface Products 21. . . . . .

Before You Begin 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Damage 22

Overview of the Installation Procedure 22

Mounting Smart Transmitter Interface Products in a Cabinet 23

Connecting the Communications Controller to the Terminal Blocks 24

Digital Communications Cables 24

Linear Connection 25

Star Connection 26

Star/Linear Connection 27

Connector and Pinout 28

Setting the Board Address Jumpers 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Marking the Terminal Block Labels 211. . . . . . . . . . . . . . . . . . . . . .

Connecting the T

Connecting to 1771 I/O Devices 212

Connecting

Connecting a Hand Held Terminal 216

Grounding 218

Grounding

Grounding

erminal Blocks to I/O and HAR

T Field Devices 211. . .

. . . . . . . . . . . . . . . . . . . . . . .

to HAR

T Field Devices 213. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the HAR

T Field Device Cable Shield 218. . . . . . . . . . . .

the Analog I/O Cable Shield

218. . . . . . . . . . . . . . . . . .

Supplying Power to the Communications Controller and

Terminal Blocks 219

Fuses for the Communications Controller 219

Connecting Power to the Communications Controller 220

Supplying Loop Power for HART Field Devices 220

Power Supply Requirements 221

Connecting the Power Supply for Loop Power 221

Connecting

the Communications Controller to the RIO Host

Termination 223

Activity Indicator 224

Connecting the Communications Controller to the RS232C Host 224

RS232C Baud Rates 224

Cables 224

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activity Indicator 224

Connector and Pinout 224

Modem Connections 229

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

222. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Communications Controller 31. . . . . . . . . . .

Overview of Configuration Procedures 31. . . . . . . . . . . . . . . . . . . . .

Displays 31

Push

Configuration Step by Step 33

Enter Configuration Mode 33

Configure Basic Parameters 34

Configure Advanced RS232C Parameters 34

Save and Exit 34

Exit Without Saving 35

Setting Factory Defaults 36

Communication Parameters 36

Basic Parameters 36

Basic Parameters 36

Advanced RS232C Communication Parameters 38

Verifying the Communication Parameters 310

Marking the Communications Controller Label 310

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buttons

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

Communicating with the Smart Transmitter Interface 41. . . .

Data Routing and Protocol Conversion 41. . . . . . . . . . . . . . . . . . . . .

Data Routing In Poll and Response Mode 42

Data Routing in Burst Monitor Mode 42

Protocol Conversion 43

of T

Definition

erms 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HART Poll Packets 45

Preamble 45

HART

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delimiter

HART Address 45

HART Command 48

Byte Count 48

Data 49

Check Byte 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HART Response and Burst Data Packets 49

Preamble 49

HART

HART Address 410

HART Command 411

Byte Count 411

Response Code 412

Data 413

Check Byte 413

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delimiter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smart Transmitter Interface Packets Received by the

Smart Transmitter Interface 414

. . . . . . . . . . . . . . . . . . . . . . . . . .

Smart Transmitter Interface Command 414

Smart Transmitter Interface Channel 414

Smart Transmitter Interface Control 415

Smart Transmitter Interface Parameter 416

Smart Transmitter Interface Data 416

. . . . . . . . . . . . . . . . . . . . . . .

Smart Transmitter Interface Packets Sent by the Smart

Transmitter Interface 416

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smart Transmitter Interface Command 416

Smart Transmitter Interface Channel 417

Smart Transmitter Interface Error Code 417

Smart Transmitter Interface Status 417

Smart Transmitter Interface Data 419

. . . . . . . . . . . . . . . . . . . . . . .

Valid Smart Transmitter Interface Commands and Responses 419

No Operation (hexadecimal command 00) 420

Enable Poll and Response Mode (hexadecimal command 01) 420

Enable Burst Monitor Mode (hexadecimal command 02) 420

Send Message to Device (hexadecimal command 10) 420

Read Burst Data (hexadecimal command 11) 421

Set Number of Preambles (hexadecimal command 20) 421

Set Number of Retries (hexadecimal command 21) 422

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . .

. .

. . . . . .

. . . . . . . .

. . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . .

Page 6

Table of Contentsiv

Read Status and Statistics (hexadecimal command 30) 422. . . . . . .

Reset Statistics Counters (hexadecimal command 31) 422

Read ID (hexadecimal command 32) 422

Programmable

Short Frame Word Contents Programmable Controller to Smart

Transmitter Interface (Of

Short Frame Word Contents Smart Transmitter Interface to

Programmable Controller (Of

Long Frame Word Contents Programmable Controller to Smart

Transmitter Interface (Of

Long Frame Word Contents Smart Transmitter Interface to

Programmable Controller (Of

Serial

Communication with the Smart T

Full Duplex 435

Half Duplex 435

DF1 Packet Formation 437

Data Highway Plus and the Smart Transmitter Interface 440

Controller Communication with HAR

fset at D9:00)

fset at D9:10)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

fset at D9:40)

fset at D9:40)

ransmitter Interface 434. . . . . .

. . . . . . . .

T Field Devices 425

428. . . . . . . . . . . . . . . .

430. . . . . . . . . . . . .

431. . . . . . . . . . . . . . . .

433. . . . . . . . . . . . .

. . . . . . . . .

Troubleshooting 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interpreting the Terminal Block LEDs 51. . . . . . . . . . . . . . . . . . . . . .

Interpreting the Communications Controller Status LEDs 52

Interpreting the Communications Controller Status LEDs 52

Interpreting the Communications Controller Numeric Displays 53

. . . . . . . .

. . . . . .

. . . .

Product Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Controller (1770HT1) A1. . . . . . . . . . . . . . . . . . . .

RS232 Interface A1

RIO Interface A1

Terminal Block (1770HT8/16) Interface A1

Electrical A2

Physical A2

Environmental A2

8 Channel Terminal Block (1770HT8) A2

1770HT1 Interface A2

420 mA Current Loop Interfaces (see Figure A.1) A2

Electrical A3

Physical A3

Environmental A3

16 Channel Terminal Block (1770HT16) A3

1770HT1 Interface A3

420 mA Current Loop Interfaces (see Figure A.1) A4

Electrical A4

Physical A4

Environmental A4

HART

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A5. . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents v

DF1 Diagnostic Command Support B1. . . . . . . . . . . . . . . . . .

Diagnostic Command Support B1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Loop B1

Diagnostic Read B2

Diagnostic

Diagnostic Counter Reset B3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

B2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Length and Power Supply Requirements C1. . . . . . . . .

Cabling Requirements Between the Communications Controller

and the Terminal Blocks C1

Maximum Power Cable Lengths C2

Using a Separate Power Supply for a Terminal Block C4

Connecting Power to the Terminal Blocks C4

Cabling and Power Supply Requirements for Loop Power C5

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . .

Page 8

Preface

Preface

Purpose of the Manual

Organization of the Manual

This manual shows you how to use the Smart Transmitter Interface

products with Allen-Bradley programmable controllers and other

intelligent host computers. It describes how to install and configure the

Smart Transmitter Interface products, as well as how to perform

trouble-shooting procedures.

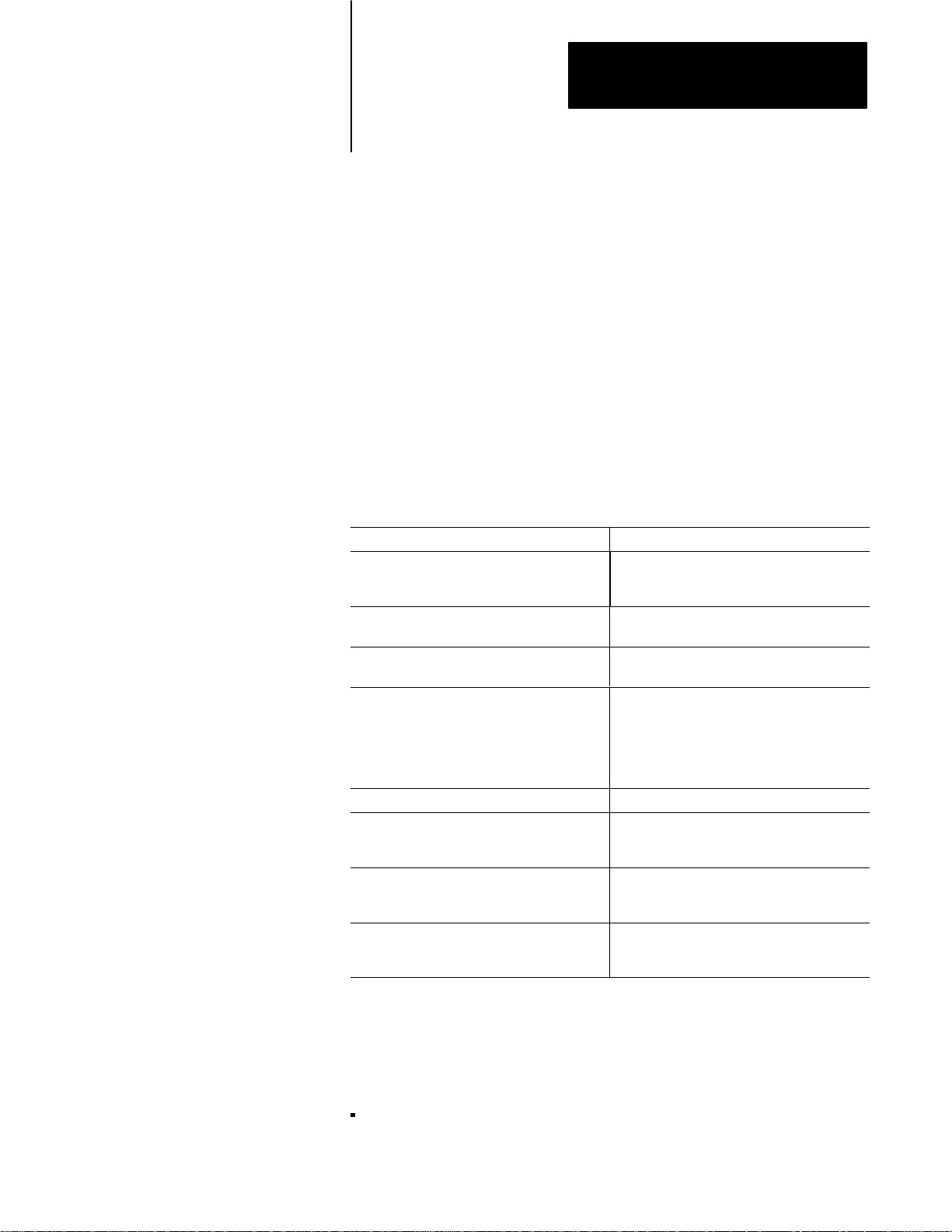

This manual contains five chapters and three appendices. They address the

following topics:

Chapter Topics Covered

Chapter 1: Introducing the Smart Transmitter

Interface

Chapter 2: Installing the Smart Transmitter

Interface

Chapter 3: Configuring the Communications

Controller

Chapter 4: Communicating with the Smart

Transmitter Interface

Chapter 5: Troubleshooting diagnosing communications problems

Appendix A: Product Specifications technical specifications for 1770HT1, HT8 and

Appendix B: DF1 Diagnostic Command Support diagnostic commands for use on the RS232C

Appendix C: Cable Length and Power Supply

Requirements

overview of the Smart Transmitter Interface;

introduction to the HART protocol, and features

and benefits of using them

installation procedure, power supply

requirements and connection instructions

the communication parameters and how to set

them on the Communications Controller

Smart Transmitter Interface data routing and

protocol conversion, communication terms,

HART and Smart Transmitter Interface data

packets, PLC5 programming example, and

serial host communication with the Smart

Transmitter Interface

HT16, and HART communications

specifications

link between a host processor and the

Communications Controller

cable length requirements between the

Communications Controller and the Terminal

Blocks, and power supply requirements

How to Use This Manual

This manual explains the features, functions and specifications of three

products designed to provide communication between Allen-Bradley

products and HARTr field devices. These products are:

Communications Controller Cat. No. 1770-HT1

P-1

Page 9

Preface

8 Channel Terminal Block Cat. No. 1770-HT8

16 Channel Terminal Block Cat. No. 1770-HT16

Audience

This manual is intended for use by:

persons installing Smart Transmitter Interface products, in connection

with Allen-Bradley PLC controllers or other intelligent controllers

system integrators who are designing and establishing network systems

involving plant floor machinery, programmable controllers, HART field

devices, Smart Transmitter Interface products and host computers

maintenance personnel who maintain such systems and who must

locate, define and correct problems arising during their day-to-day

operation

Related Publications

AllenBradley Publications

Publication Reference Number and Date

AllenBradley Data Highway/Data Highway Plust/DH485

Communication Protocol and Command Set Reference

Manual

Analog Input Module User Manual cat. no. 1771IFE 17716.5.90, September 1991

ControlView Core User Manual 61906.5.1, November 1992

PLC5 Family Programmable Controllers Hardware

Installation Manual

PLC5 Programming Software 62006.4.7

6008SI IBM PC Scanner User's Manual

17706.5.16, November 1991

17856.6.1

60086.5.3

A complete list of publications relating to ControlView and its options is

available in the ControlView Core User Manual. For a list of publications

on Allen-Bradley programmable controller products refer to the

Allen-Bradley publication index (SD499).

HART Publications

Publication Reference Number and Date

HART - Smart Communications Protocol

Specification

Revision 5.1, January 4, 1991

Rosemount, Inc. Document No. D9000047,

Revision A

P-2

Page 10

Preface

Related Products

Glossary of Terms and

Abbreviations

The Smart Transmitter Interface Products create a communication interface

between programmable controllers and HART field devices. They are

compatible with HART field devices and with hand-held terminals capable

of supporting the physical and data link layers of the HART protocol.

This manual uses the following terms as defined below.

Actuator: any one of several field devices that provide control functions

using a 4-20mA input control signal. Actuators that support the HART

protocol are designated as being “smart”.

BTR: Block Transfer Read

BTW: Block Transfer Write

Clear: (a bit) equal to 0

Hand-held terminal: a smart terminal product capable of functioning as

either a primary or secondary master to one single HART device, using the

HART protocol; this terminal allows the operator to monitor and configure

the HART field device (e.g. Rosemount 268)

HART: Highway Addressable Remote Transducer

HART field device: a transducer or actuator that supports the HART

protocol

- 4-wire: refers to a HART field device drawing power from an

external power source

- 2-wire: refers to a HART field device drawing power from the 4-20

mA loop

HART protocol: a protocol that provides digital communication over an

industry-standard 4-20 mA process control loop at the same time as the

value of a process control variable is being transmitted as a 4-20 mA signal

Host Processor: the programmable controller or host computer (generally

a PC) connected to the Communications Controller over the RIO, or the

host computer connected to the Communications Controller’s RS-232 port

mA: milliamp; one-thousandth of an Ampere

Multidrop: multiple HART field devices (to a maximum of 15), connected

in parallel, per channel on a terminal block

PLC: Programmable Logic Controller; an Allen-Bradley programmable

controller

P-3

Page 11

Preface

Point-to-point: one HART field device per channel on a terminal block

RIO: Remote Input Output link that supports remote, time-critical, I/O

and control communications between a master PLC controller and its

remote I/O and adapter mode slave processors

Transducer/Transmitter: any one of several field devices that can

measure pressure, temperature, level, flow, density or other process control

variables, and then transmit the value of that variable as a 4-20 mA signal.

Transducers that support the HART protocol are designated as being

“smart”.

P-4

Page 12

Chapter

1

Introducing the Smart Transmitter Interface

This chapter provides an overview of the Smart Transmitter Interface

products, a brief introduction to the HART protocol and a description of

the different system architectures which can be implemented. It also

describes the features and benefits of using the Smart Transmitter Interface

and lists some of the products that are compatible with the 1770-HT1,

1770-HT8 and 1770-HT16.

Product Overview

The Smart Transmitter Interface products provide a communication

interface between Allen-Bradley PLC controllers or host computers and

HART field devices (transmitters, transducers and actuators). These

products give host processors access to the digital information encoded

with the 4-20 mA analog process control signal. The digital information

can be passed to and from the host processor using either a remote I/O

(RIO) or an RS-232C port.

A Smart Transmitter Interface consists of one Communications Controller

(1770-HT1), and one or more Terminal Blocks (1770-HT8 or 1770-HT16).

These products can be mounted on a DIN rail in a control cabinet and the

field wiring brought directly to the Terminal Blocks.

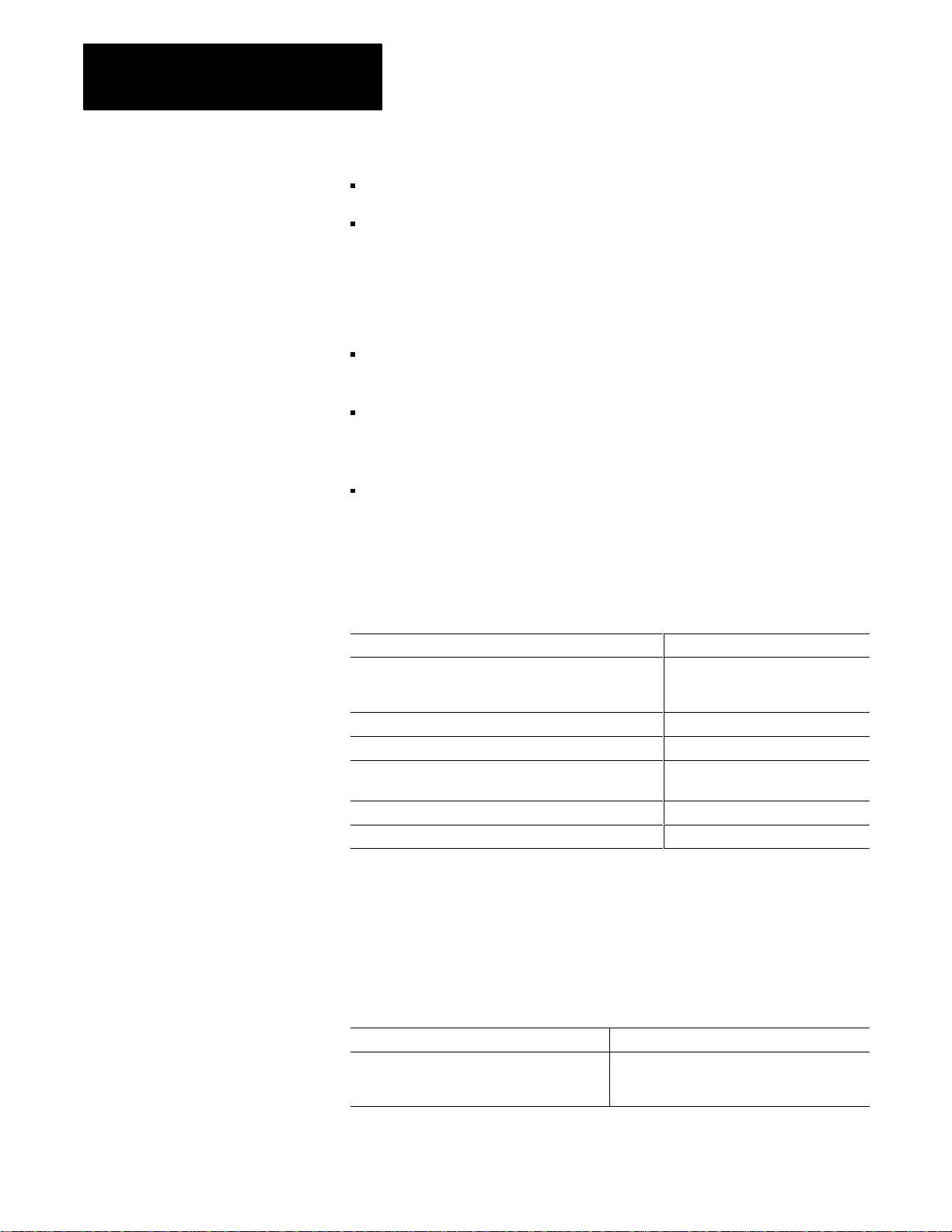

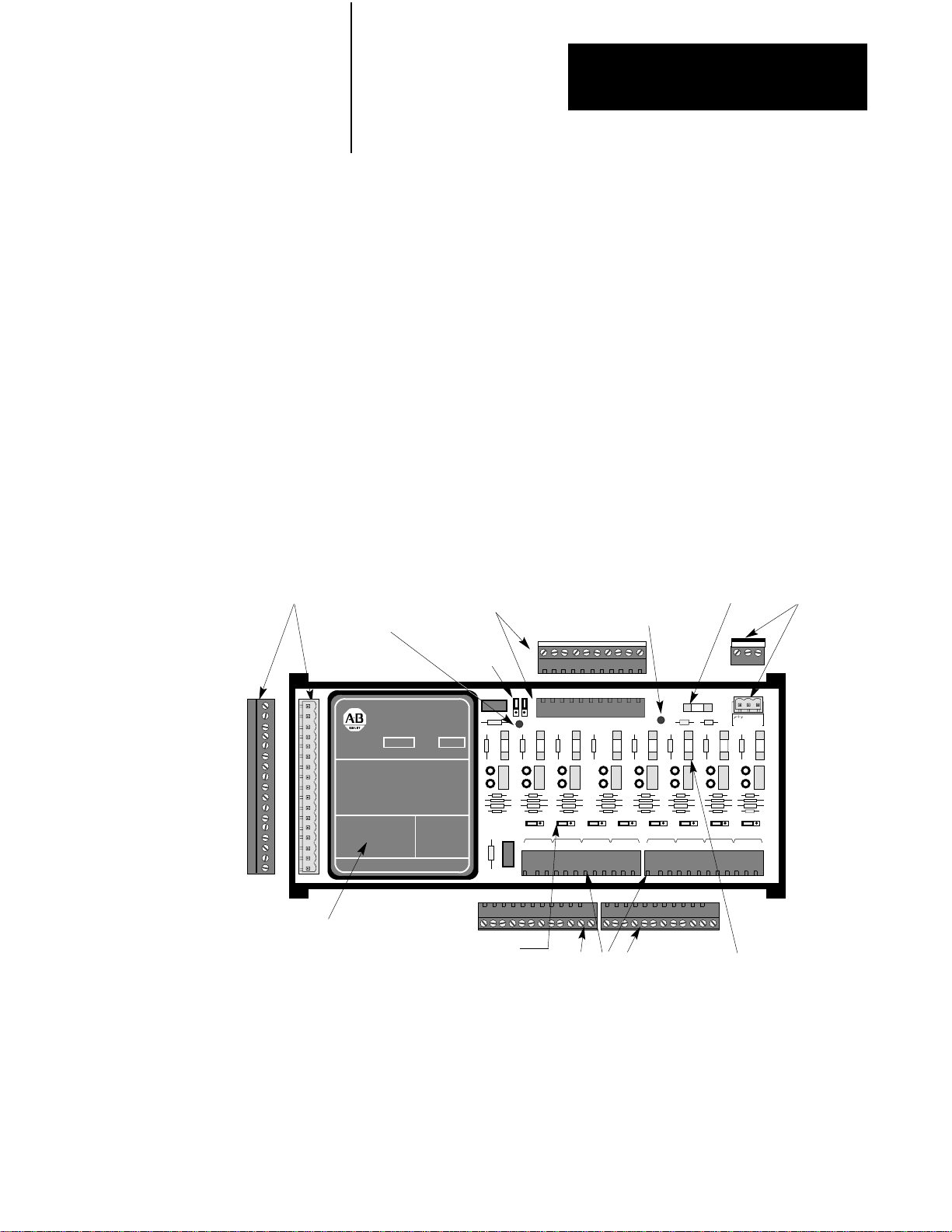

1770HT1 Communications Controller

The 1770-HT1 Communications Controller receives commands from a

host processor and passes them on, via the 1770-HT8/16 Terminal Blocks,

to HART field devices. Responses from the HART field devices go

through the Terminal Blocks to the Communications Controller and then

on to the host processor.

The Communications Controller communicates through its Remote I/O or

RS-232C port to the host processor. The combination of hardware and

software used by the host determines which port is used.

Use the Remote I/O port (labelled RIO in Figure 1.1) with the following:

a programmable controller as host processor using ladder logic to

perform block transfer reads and writes. On the DH+ network the

programmable controller can connect to a computer running software

applications, such as ControlView, to monitor and supervise the ongoing

processes.

1-1

Page 13

Chapter 1

Introducing the Smart Transmitter

Interface

a programmable controller with Allen-Bradley’s pass-through

functionality connected to a host computer on the DH+ network running

application software to initiate communications

Use the RS-232C port (labelled RS-232 in Figure 1.1) with the following:

a host computer using Allen-Bradley DF1 protocol, connected to the

Communications Controller by an RS-232 cable (if the distance is less

than 50 feet)

a host computer using Allen-Bradley DF1 protocol, connected to the

Communications Controller by telephone lines and modems

The Communications Controller requires an external 24 VDC power

supply. It provides a multiplexed, 32 channel interface to the Terminal

Blocks. All of the Remote I/O and RS-232C communications parameters

are set on the Communications Controller using push buttons and a seven

segment LED display.

RS-232C

Connector

1 SH 2

RIO

POWER

RIO

RS-232

RS-232

HART

FAULT

VIEW DATA EXIT

SAVE

Push Button Switches

RIO - Connector

Status LEDs

OPTN

1

2

3

4

5

6

7

8

7-Segment LED

Display

Figure 1.1

1770HT1

Parameter # Parameter

OPTION

NOTES

OPTNDATA DATA

0.

1.

2.

3.

4.

5.

6.

7.

A.

User writeable

areas

Communications Controller

DATA

Setting

Power Connector

Power Fuse

SMART TRANSMITTER

COMMUNICATIONS

CONTROLLER

Connector to Terminal Block(s)

1

+ -

24 VDC

HT8/HT16 INTERCONNECT

17

90002

1-2

Page 14

Chapter 1

Introducing the Smart Transmitter

Interface

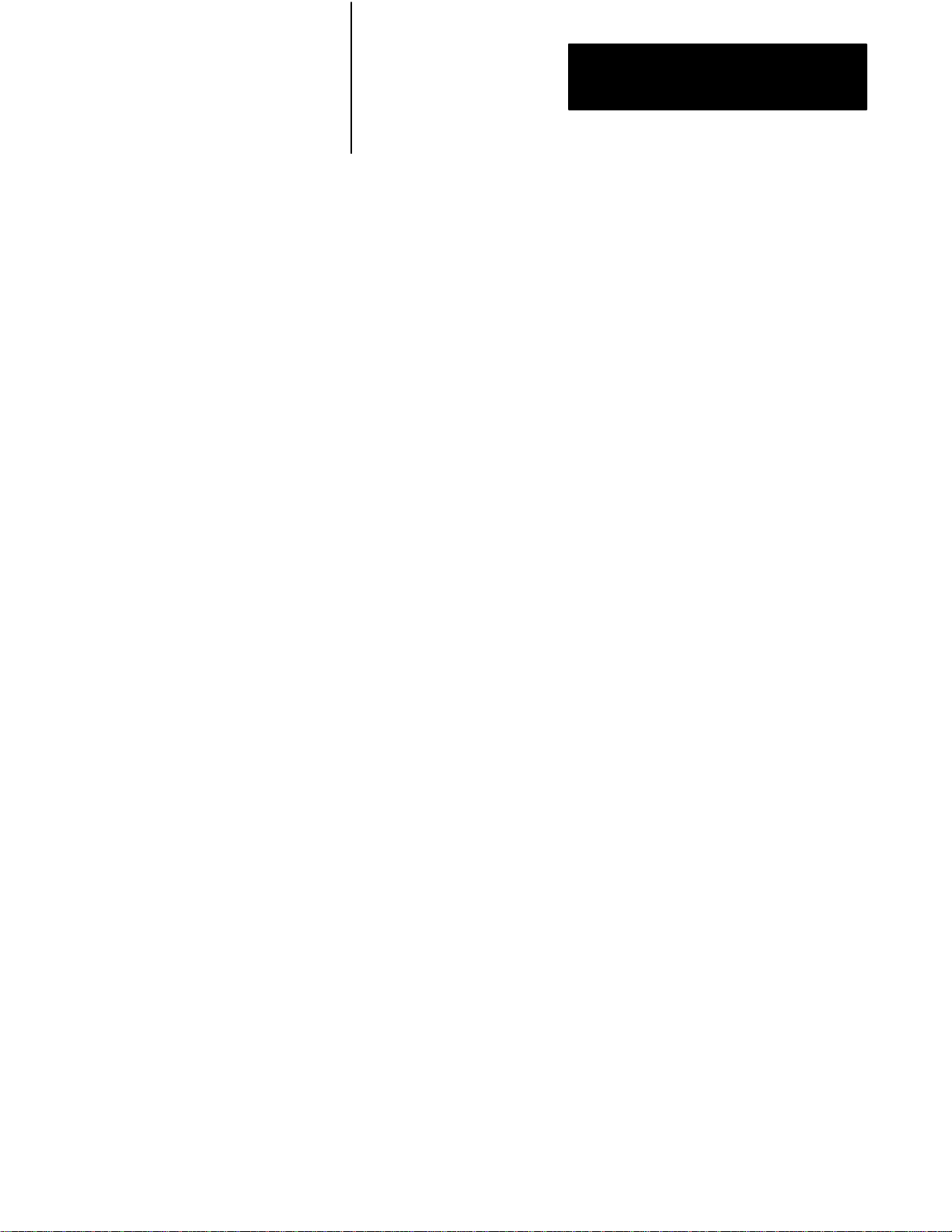

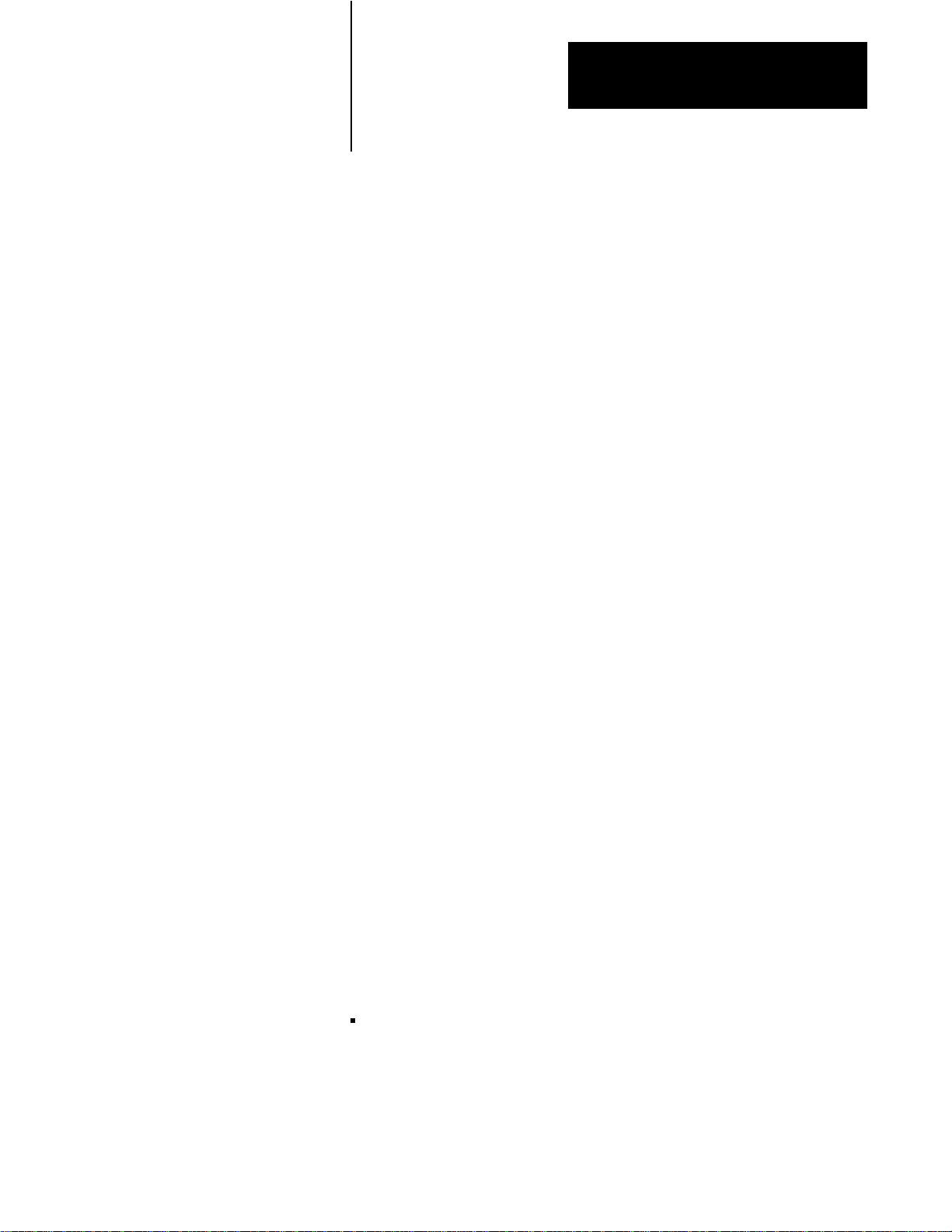

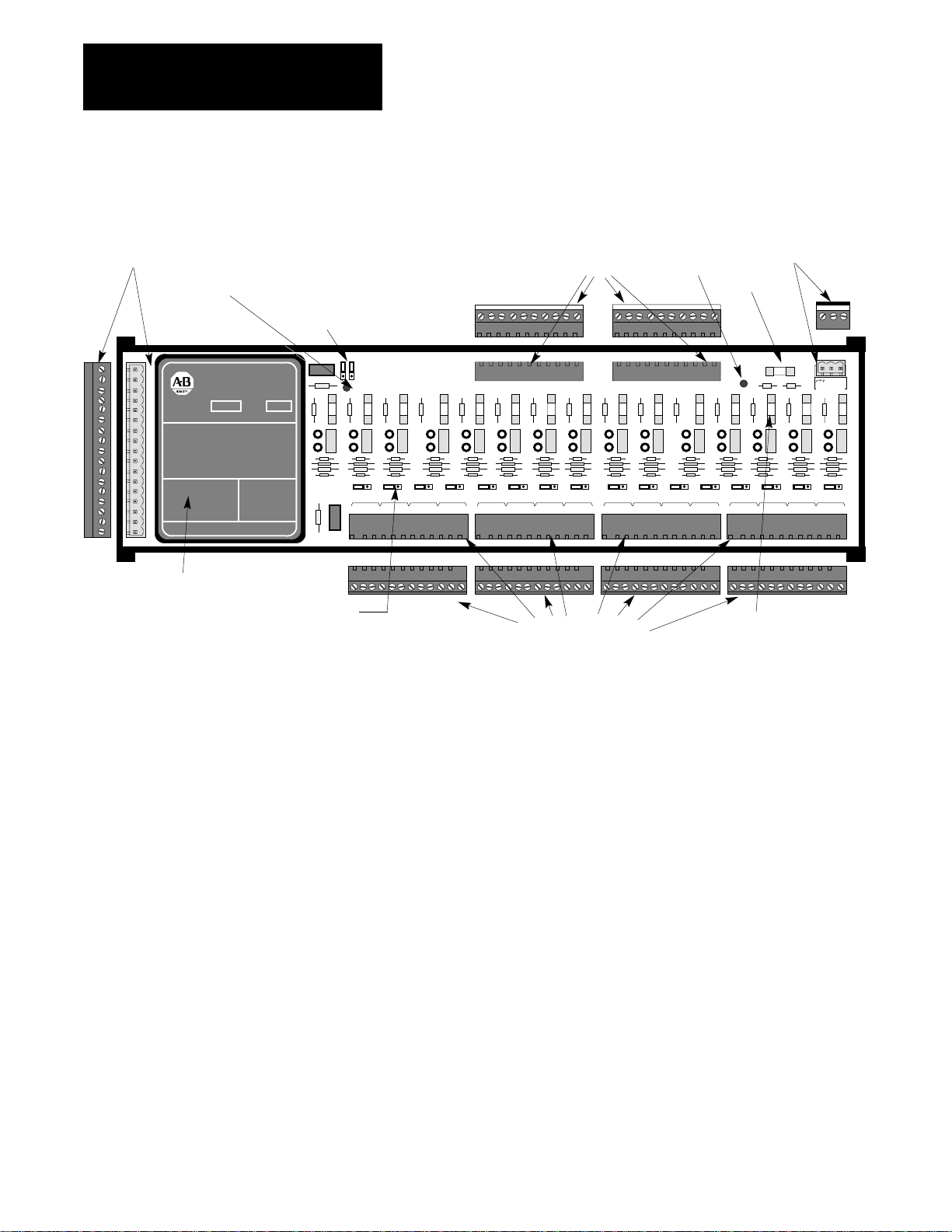

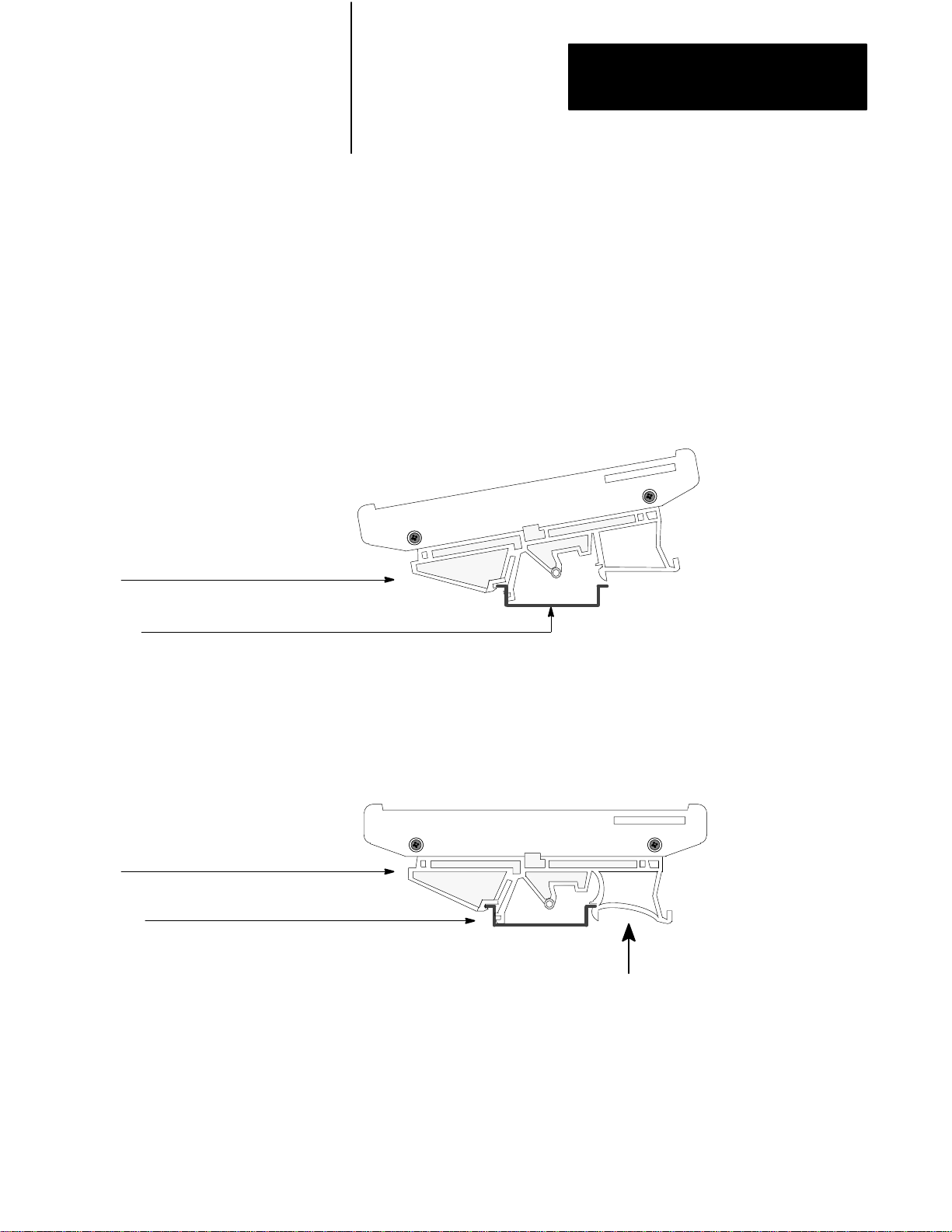

1770HT8/16 Terminal Block

The Terminal Blocks pass both analog and digital signals to and from the

HART field devices. The analog signal is passed on to devices such as the

Allen-Bradley 1771-IFE Analog I/O module. The digital signal is routed to

the Communications Controller.

Each Terminal Block provides either 8 (1770-HT8) or 16 (1770-HT16)

channels. Each channel has connection points for HART field devices and

Analog I/O modules, loop fuses and loop power selection jumpers. Any

combination of 8 and 16 channel Terminal Blocks can be used to make up

the 32 channel maximum. The board address jumpers (see Figure 1.2 and

Figure 1.3) indicate to the Communications Controller which set of

channels a particular Terminal Block will use. These are set when the

Terminal Block is installed (see Chapter 2).

Figure 1.2

1770HT8

Connection to Communications

Controller or other Terminal Blocks

Board Selected LED

1

CATALOG NO. 1770-HT8 VOLTS 24 VDC

HT1/HT8/HT16 INTERCONNECT

17

User writeable area

Jumpers to select Loop Power

8 Channel T

8

CHANNEL

TERMINAL BLOCK

erminal Block

Analog I/O Module

Connector

Board Address

Jumpers

1 2 3 4 5 6 7 8 RTN SH

JP1 JP1

JP1

E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

E D

E D E D

HART Transmitters -

Connectors

Loop

Power

LED

JP1

JP1 JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

Power Fuse

JP1

E D

E D

Loop Fuses

Power Connector

+ Loop Power

JP1

E D

90018

1-3

Page 15

Chapter 1

Introducing the Smart Transmitter

Interface

Connection to Communications

Controller or other Terminal Blocks

Board Selected LED

1

8

CHANNEL

TERMINAL BLOCK

CATALOG NO. 1770-HT8 VOLTS 24 VDC

HT1/HT8/HT16 INTERCONNECT

17

User writeable area

Jumpers to select Loop Power

Board Address

Jumpers

Figure 1.3

1770HT16

JP1 JP1

E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

16 Channel Terminal Block

JP1

E D

E D E D

1 2 3 4 5 6 7 8 RTN SH

JP1

JP1 JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

Analog I/O Module

JP1

E D

E D

E D

HART Transmitters -

Connectors

Connector

1 2 3 4 5 6 7 8 RTN SH

JP1

JP1 JP1

E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

Loop

Power

LED

Power Fuse

E D

JP1

JP1 JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

JP1

E D E D

Loop Fuses

Power Connector

+ -

Loop Power

JP1

E D

E D

E D

JP1

90017

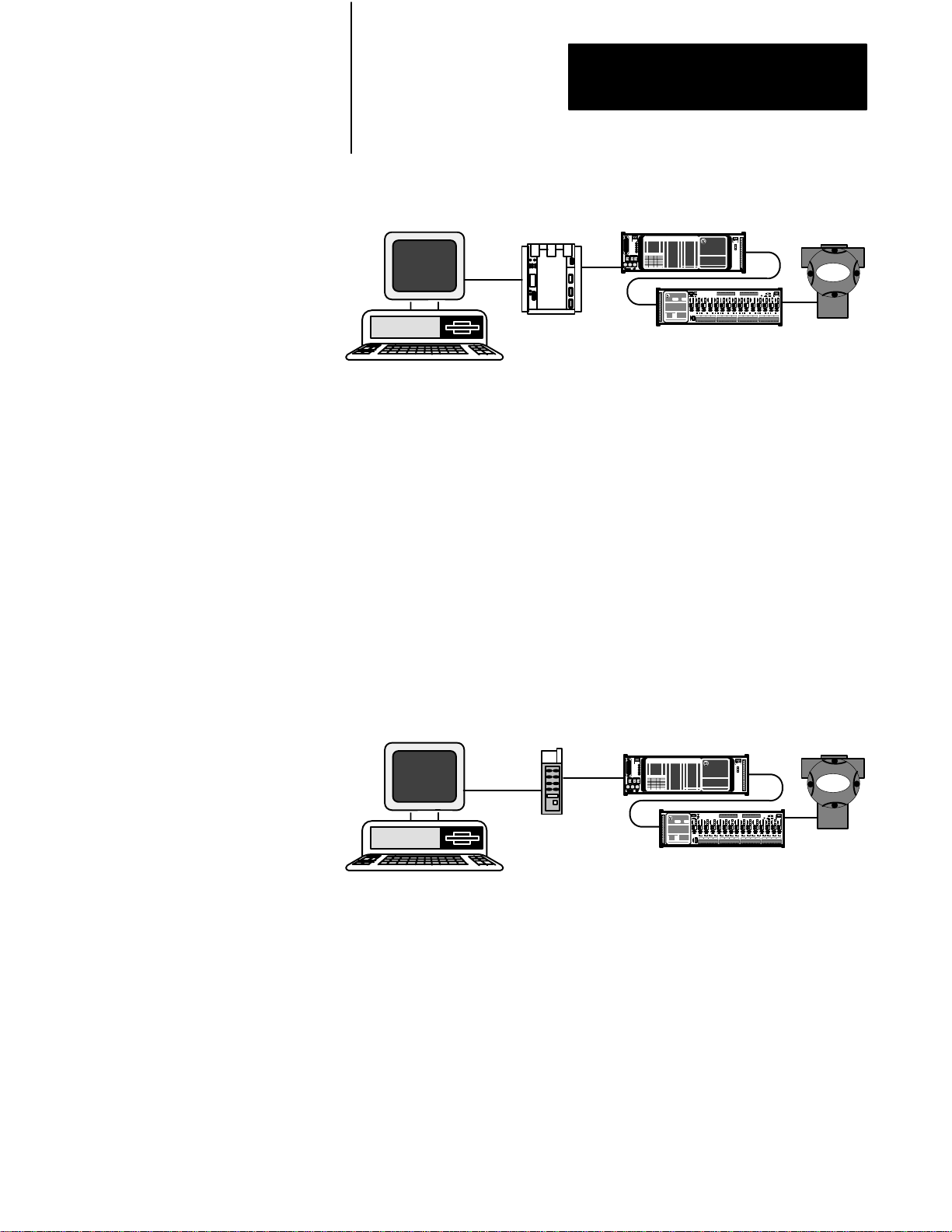

The Remote I/O Port of the Communications Controller

Programmable Controller Host Communications

Using programmable controller ladder logic to initiate Block Transfer

Writes and Reads (BTW and BTR), data can be sent to and received from

the HART field devices. A host computer on the DH+ network running

application programs (such as ControlView) can read and display the data

which the programmable controller has obtained from the HART field

devices. (See Figure 1.4)

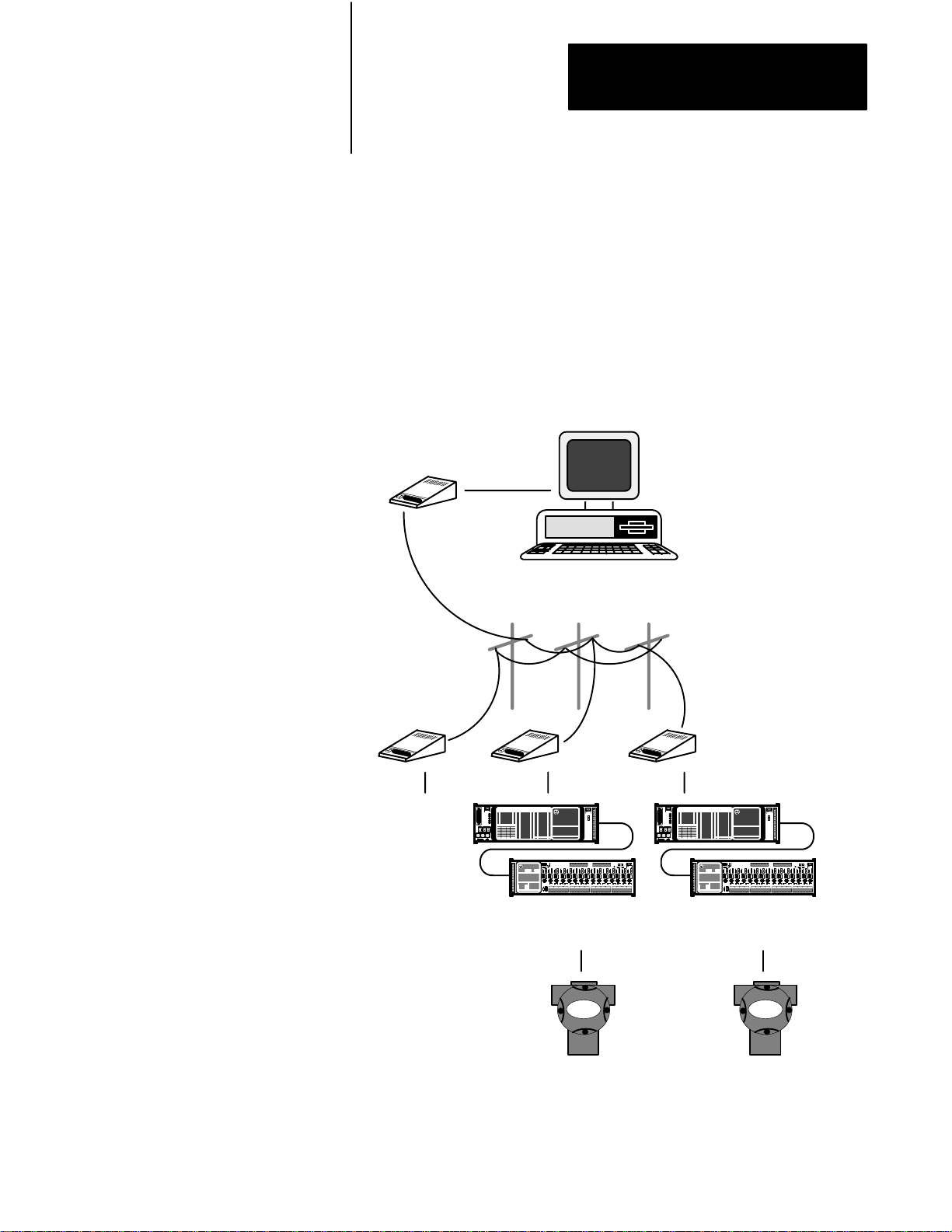

1-4

Page 16

Figure 1.4

T

Smart

ransmitter Interface with Programmable Controller Host

Chapter 1

Introducing the Smart Transmitter

Interface

CONTROLVIEW

DH+

Programmable

Controller with

Ladder Logic

RIO

Smart

Transmitter

Interface

HART

Field

Devices

90032

DH+ Host Communications (Using Programmable Controller

Pass-through)

Data can also be sent to and received from HART field devices using the

pass-through feature of the programmable controller to initiate Block

Transfer Reads and Writes (BTR and BTW). No dedicated programmable

controller ladder logic programs are required when the pass-through

feature is used. A host computer on the DH+ network, running programs

with pass-through support, can be used to communicate with the HART

field devices.

Figure 1.5

T

Smart

(Using Passthrough)

ransmitter Interface with DH+ Host

THIRD

PARTY

SOFTWARE

DH+

Programmable

Controller with

Passthrough

Feature

RIO

Smart

Transmitter

Interface

HART

Field

Devices

The RS232C Port of the Communications Controller

The RS-232C port on the Communications Controller allows the HART

field devices to communicate with either a local host or, via modem, a

remote host.

90033

1-5

Page 17

Chapter 1

Introducing the Smart Transmitter

Interface

Full Duplex Communications

With DF1 full duplex systems, you can communicate directly to a single

Smart Transmitter Interface. No programmable controllers are

necessary—just a computer running the appropriate software, the HART

field devices, and the Smart Transmitter Interface between them. The host

computer and the Smart Transmitter Interface should be connected with

either an RS-232 cable for distances equal to or less than 50 feet, or two

modems for distances greater than 50 feet. (See Figure 1.6 and Figure 1.7.)

This gives end users with less complex applications, inexpensive access to

HART field devices and to the advantages of the HART protocol.

Figure 1.6

Duplex Communication with no Modem

Full

HOST COMPUTER

RS-232 CABLE

HOST COMPUTER

Figure 1.7

Duplex with Modems

Full

RS-232 CABLE

Smart

Transmitter

Interface

Smart

Transmitter

Interface

HART

Field

Devices

90050

HART

Field

Devices

90049

1-6

Page 18

Chapter 1

Introducing the Smart Transmitter

Interface

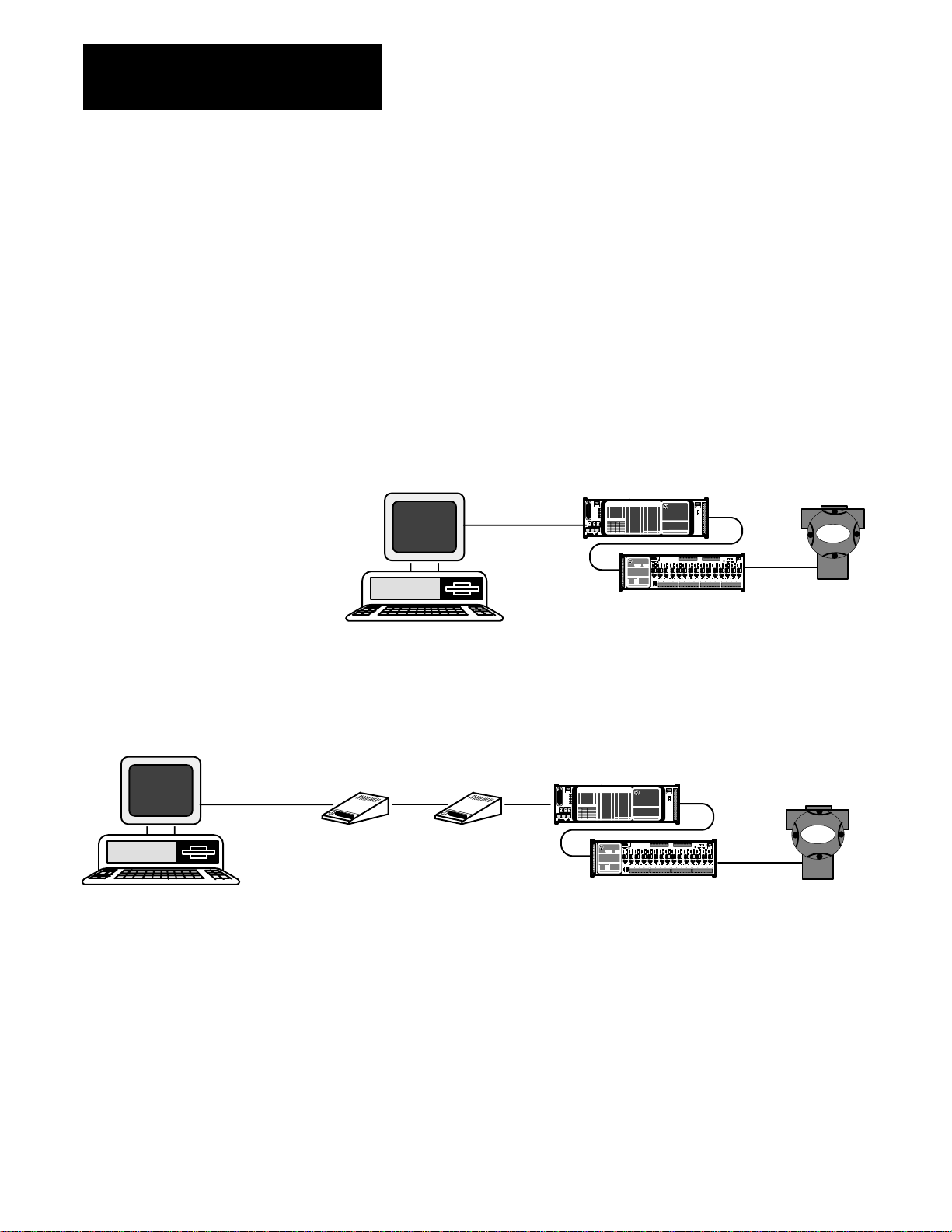

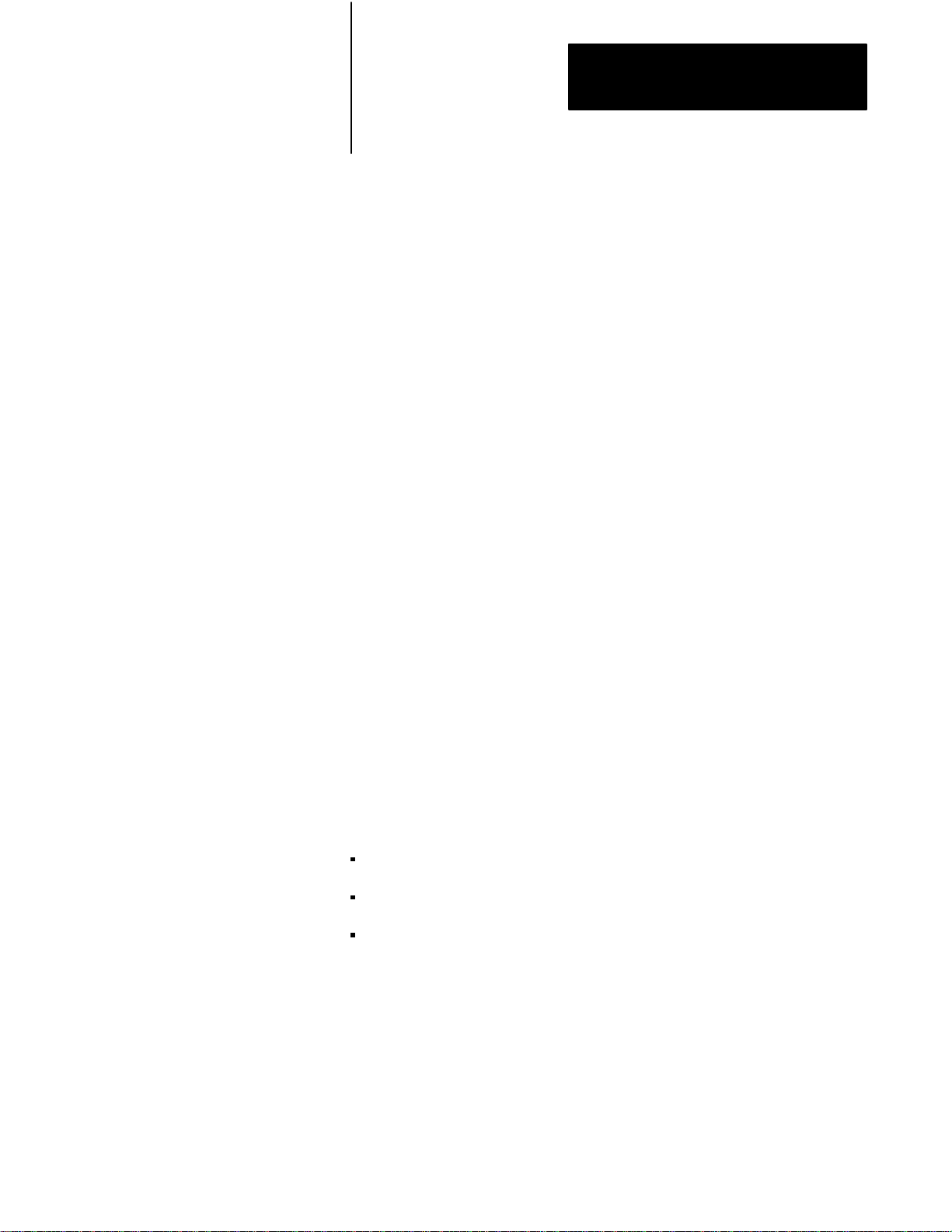

Half Duplex Communications

DF1 half duplex systems can be considerably more extensive. The host

computer can communicate via modems to a number of Smart Transmitter

Interfaces spread out over great distances. Once again, though

programmable controllers can certainly be a part of such a network, they

are not required, and any host with third party software can be used with

the Smart Transmitter Interface.

Figure 1.8

Duplex Communications with Modems

Half

Half Duplex

ETC.

MODEM

HOST COMPUTER

Smart

Transmitter

Interface

Smart

Transmitter

Interface

HART

Field

Devices

HART

Field

Devices

90048

1-7

Page 19

Chapter 1

Introducing the Smart Transmitter

Interface

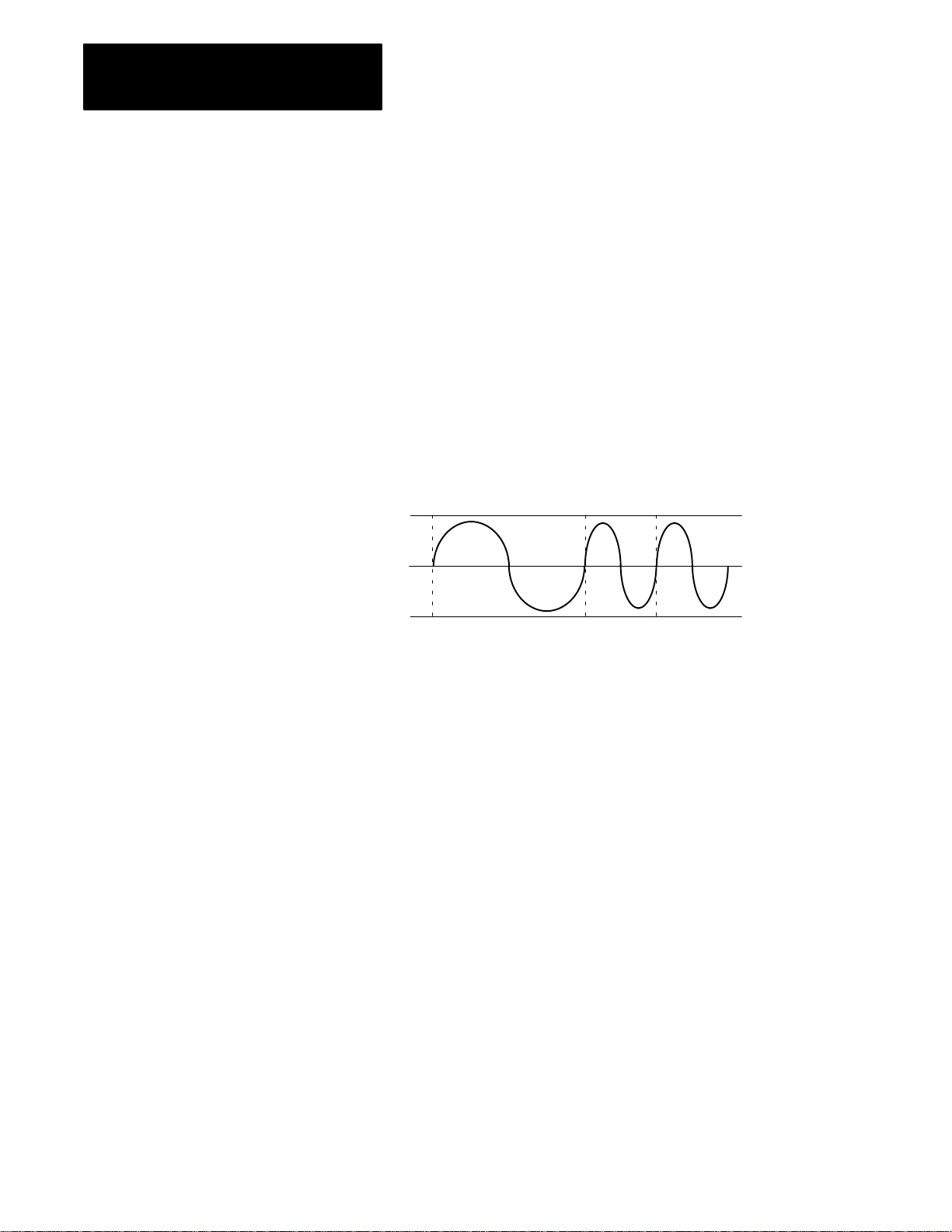

The HART Protocol

The HART field communications protocol carries digital information with

the analog signal over industry-standard 4-20 mA process control loops.

Both the digital and analog signals occur simultaneously on the same loop

wiring without disrupting the process signal.

The HART protocol uses the Frequency Shift Keying technique, based on

the Bell 202 communication standard. Digital communication is

accomplished by superimposing a frequency signal over the 4-20 mA

current, as shown in Figure 1.9. Two individual frequencies, 1200 and 2200

Hz, represent the digits 1 and 0. The sine wave formed by the two frequency

levels has an average value of zero, so digital communication takes place

without disruption to the analog signal.

Figure 1.9

Analog

and Digital Signals on 420 mA Current

+0.5 mA

Analog

Signal

90047

-0.5 mA

0

1200 Hz

1"

Average Current Change During Communication = 0

2200 Hz

0"

Field devices (transducers, actuators) can use the HART protocol to

transmit or receive a process variable as a 4-20 mA analog signal at the

same time as they are transmitting or receiving device or process data (e.g.

smart pressure, temperature, density, etc.) as a modulated digital signal.

The analog signal, with its faster update rate, can be used for control, while

the digital signal can be used for diagnostic, maintenance and additional

process data. Communication can be in either poll/response or burst

transmission mode.

The HART protocol supports digital communication from both a control

system and a hand-held communications device. It also allows multidrop

networking by which several smart HART field devices can be connected

to a single twisted-pair wire, and can operate over leased telephone lines.

1-8

Page 20

Chapter 1

Introducing the Smart Transmitter

Interface

The HART Protocol and the Smart Transmitter Interface

Each Communications Controller can communicate with a maximum of 32

channels via the 1770-HT8 and 1770-HT16 Terminal Blocks. As all

channels are multiplexed, communications can only occur over one

channel at a time. Each channel can have one HART field device

connected to it in point-to-point mode, or up to 15 devices in a multidrop

network. The host addresses these channels using channel numbers 0–31

(decimal).

The Communications Controller in the Smart Transmitter Interface

receives HART protocol commands from the host processor (via Remote

I/O or RS-232C connection) and routes these commands (via the Terminal

Blocks) to the HART field devices. The Smart Transmitter Interface

receives responses from the HART field devices and transmits the

responses to the host when it polls for them.

In both multidrop and point-to-point networks each device has a unique

address that is included in every HART message. A device picks up

messages destined to it via this unique address.

When the Terminal Block receives the composite digital/analog signal

from the HART field devices, it filters out the digital portion of the signal

(see Appendix A for more information on the filtering circuitry), and

passes the analog portion on to an Allen-Bradley Analog I/O module, such

as the 1771-IFE. The Analog I/O module decodes the analog data and

passes it along to the programmable controller.

At the same time, the Terminal Block reads the digital portion of the signal

and multiplexes it to the Communications Controller. The Communications

Controller embeds the digital data into messages conforming to the RIO or

DF1 protocol format, and passes it to the appropriate host processor and its

application program in one of three ways:

to a programmable controller via the remote I/O link

to a computer via the RS-232C port

to a host on the Data Highway Plus network via the pass-through feature

of an Allen-Bradley PLC-5 family programmable controller

Important: You cannot have more than one DH+ host computer using the

pass-through feature or more than one RS-232C host.

1-9

Page 21

Chapter 1

Introducing the Smart Transmitter

Interface

Poll/Response Mode

The HART protocol supports two modes of digital communications,

poll/response and burst. In poll/response mode the host processor requests

information from (polls) the smart device. Both point-to-point and

multidrop networks can employ this mode.

When the host processor sends a request or control information to the

HART field devices, the Smart Transmitter Interface reads the routing

information in the header portion of the data. It then strips the header off

the message and sends the data down the appropriate channel to the HART

device. Responses from the HART devices are returned to the host

processor when the host polls for them.

If there are no more messages to be forwarded, the Smart Transmitter

Interface stays on the last used channel and watches the traffic. This allows

higher throughput if consecutive messages are sent to the same channel.

Features of the Smart

Transmitter Interface

Burst Mode

In burst mode the HART field device continuously transmits digital data to

the Communications Controller in burst monitor mode without the need for

request messages from the host. This mode cannot be used with multidrop

networks.

In burst monitor mode, the host processor sends the Smart Transmitter

Interface a list of all the channels whose devices are preset to burst mode.

If the list changes, the host must provide a new list. The Smart Transmitter

Interface continuously monitors the channels on the list in order, returning

to the first as soon as the last has been checked. The data collected from

the burst channels is stored in a Burst Data table. The latest information on

any channel is sent to the host processor upon request.

While in burst monitor mode, the Smart Transmitter Interface still

responds to requests from the host to poll any channel. When the polling is

complete, it resumes monitoring the burst channels.

The Smart Transmitter Interface (1770-HT1 and 1770-HT8/16) features

include:

1-10

remote I/O port for interface to programmable controllers (RIO

scanners) and DH+ hosts

RS-232C port for interface to serial hosts

7-segment display and push buttons for communications configuration

Page 22

Chapter 1

Introducing the Smart Transmitter

Interface

clips for DIN rail mounting

connections to 32 HART field devices in point-to-point configuration

point to point and multidrop wiring support

poll and response or burst digital transmission mode support

connector for providing loop power

interface to Analog I/O modules with 4-20 mA loop support

2 wire and 4 wire transmitters supported

Benefits of Using the Smart

Transmitter Interface

The benefits of using the Smart Transmitter Interface to take advantage of

the HART protocol include the following:

extend programmable controller use in the process area by enabling

Allen-Bradley PLCs to communicate with HART field devices, thus

allowing process monitoring with ControlView or similar applications

software

Because of the added intelligence supplied by the HART field devices,

and the wide range of accurate data available from such devices,

(pressure, temperature, level, flow and density, among others),

automated processes can be monitored accurately over considerable

distances.

reduce downtime and installation time through remote wiring

verification, remote transmitter programming and simple retrofitting

capabilities of HART field devices

Many HART devices are “smart” enough to tell you what is wrong with

them, and how they can be readjusted by remote programming. They

can be, in effect, remote diagnostic tools, as well as remote repair units.

Maintenance becomes simpler and less costly since you no longer need

to send technicians out to the field to perform these tasks manually.

add Smart device capabilities to existing analog systems while

maintaining existing devices

You can add the Smart Transmitter Interface to an existing 4-20 mA

system without having to change the wiring, thus reducing installation

time and expense. Digital capabilities can be gradually implemented,

including digital process variables monitoring, without modifying field

devices.

1-11

Page 23

Chapter 1

Introducing the Smart Transmitter

Interface

perform configuration and diagnostics of HART field devices using

third party software and the pass-through feature

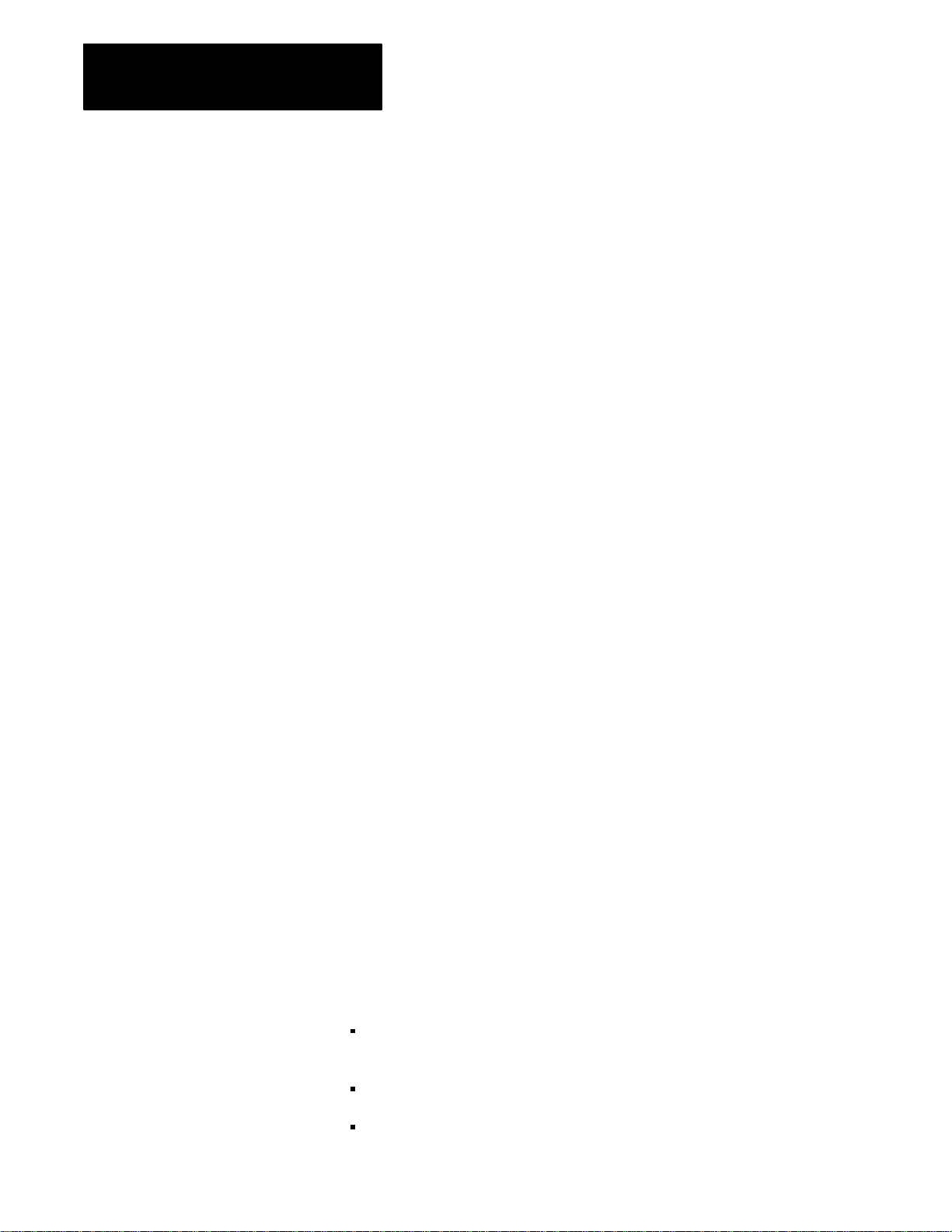

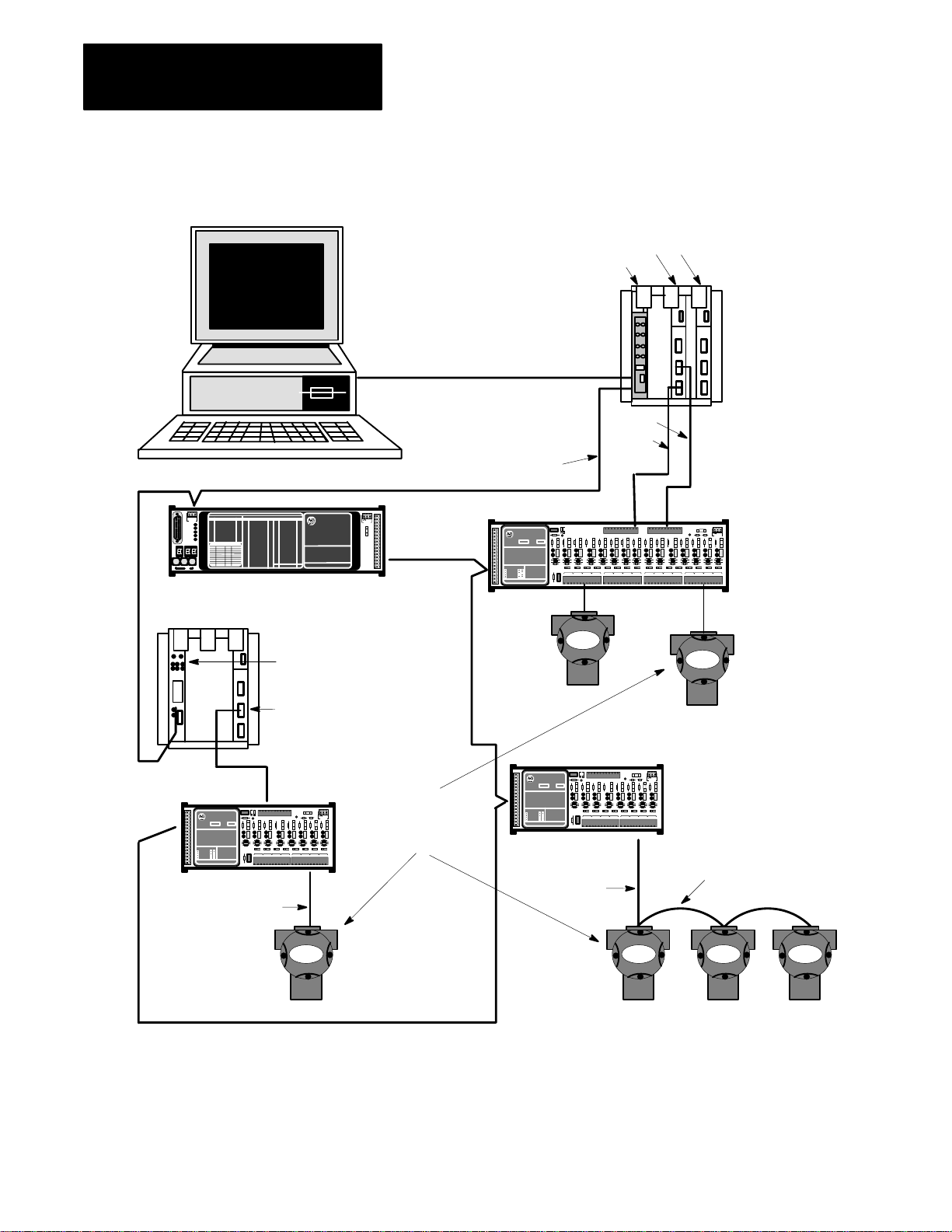

Compatibility

The Smart Transmitter Interface Products create a communication interface

between programmable controllers and HART field devices. (See

Figure 1.10.)

The Smart Transmitter Interface is compatible with HART field devices

and with hand-held terminals capable of supporting the physical and data

link layers of the HART protocol.

Host computers can be any 100% PC compatible computers.

The following products have been tested in connection with the Smart

Transmitter Interface:

PLC5 Family

PLC-5/11

PLC-5/15

PLC-5/20

PLC-5/25

1-12

PLC-5/30

PLC-5/40

PLC-5/60

PLC-5/250

You can connect one or more Smart Transmitter Interfaces directly to a

PLC-5 Remote I/O Port (in scanner mode) along with other I/O racks. In

addition, the Smart Transmitter Interface can also be connected to other

remote I/O scanner modules such as the 1771-SN I/O Subscanner module.

For details about which programmable controllers support the pass-through

feature, contact your A-B representative.

HART Field Devices

ABB Kent Taylor K-SC

ABB Kent Taylor K-ST

Page 24

Chapter 1

Introducing the Smart Transmitter

Interface

Fischer & Porter 50XM1000B

Micro Motion RFT9739

Moore Products 340B

Princo 50PL4610

Rochester Instrument System SC-6500

Rosemount 1151S

Rosemount 3001C

Rosemount 3001S

Rosemount 3044C

Rosemount 3051C

Rosemount 8712C

Rosemount 8800

Rosemount 9712

Rosemount Analytical 2054pH

Smar LD301

Analog I/O Devices

1771-IE05

1771-IF

1771-IFE

Hand Held Terminal

Rosemount Model 268 Smart Family Interface

1-13

Page 25

Chapter 1

Introducing the Smart Transmitter

Interface

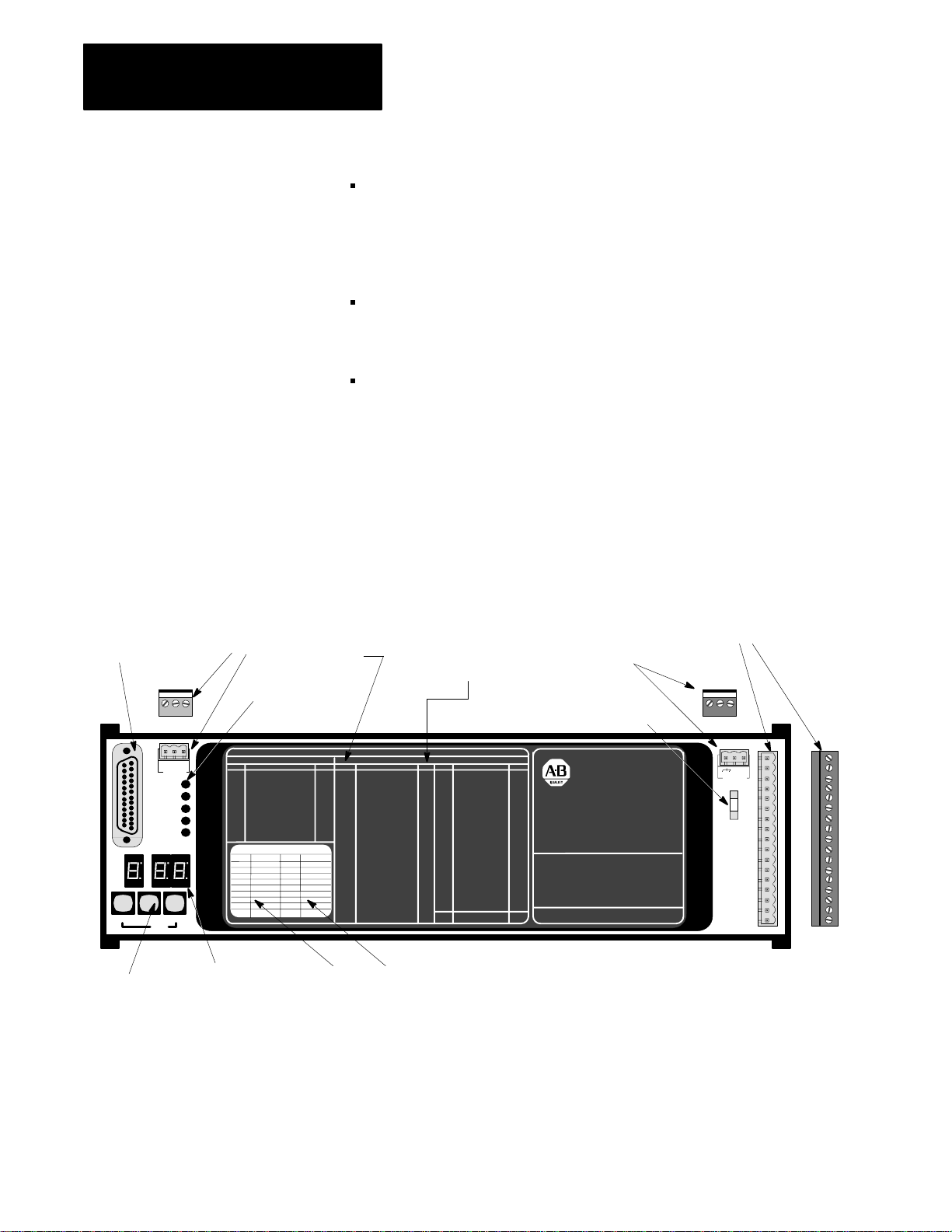

Figure 1.10

T

ypical Network

A

Host Computer

1770

1771ASB

RIO Adapter

HT1

DH+

RIO

PLC5

1771IFE Modules

Shielded

Cables

- max.

30 ft.

1770HT16

1770HT8

Point-to-point

1771IFE

HART

Field

Devices

1770HT8

Cable

- max.

10000 ft.

Multidrop

90027

1-14

Page 26

Chapter

2

Installing the Smart Transmitter

Interface Products

This chapter explains how to install the Smart Transmitter Interface

products. It includes the following information:

an overview of the general installation procedure

how to connect the Communications Controller and Terminal Blocks to

each other so they can communicate

how to connect Terminal Blocks to Analog I/O and HART field devices

Before You Begin

system grounding requirements

power supply requirements and connections for the Communications

Controller and Terminal Blocks

how to provide power for HART field devices through the Terminal

Blocks

how to connect the Communications Controller to the host processor

Before installing the Smart Transmitter Interface you should:

determine where the Communications Controller and Terminal Blocks

are to be placed

The Terminal Blocks should be mounted in the same equipment cabinet

as the Analog I/O modules to which they are to be connected. The

distance between a given Terminal block and its HART field devices

must conform to the HART Protocol specifications and meet the

requirements in Appendix C.

review your setup to ensure that the maximum cable length between the

Communications Controller and the Terminal Blocks is not exceeded.

See the section Connecting the Communications Controller to the

Terminal Blocks for details.

calculate the power requirements of the Communications Controller

(1770-HT1), the Terminal Blocks (1770-HT8/16) and the HART field

devices

2-1

Page 27

Chapter 2

Installing the Smart Transmitter Interface

Products

Electrostatic Damage

Overview of the Installation

Procedure

Electrostatic discharge can damage semiconductor devices inside the Smart

Transmitter Interface products. To guard against electrostatic damage,

observe the following precautions:

wear an approved wrist strap grounding device, or touch a grounded

object to rid yourself of electrostatic charge before handling the

products

keep the products in their static-shield bags when not in use

The general procedure for installing the Smart Transmitter Interface

products is as follows:

1. Mount the Communications Controller and the Terminal Blocks in

their appropriate equipment cabinet (or cabinets).

2. Connect the Communications Controller to the Terminal Blocks and

set the board address jumpers on the Terminal Blocks.

3. Connect the Terminal Blocks to I/O modules (1771 I/O devices) and

HART field devices.

4. Establish the necessary ground connections.

5. Connect the Communications Controller and Terminal Blocks to a

power supply.

6. Configure the communications parameters on the Communications

Controller as detailed in Chapter 3.

7. Connect the Communications Controller to the host through the RIO

or RS-232C port.

2-2

Page 28

Chapter 2

Installing the Smart Transmitter Interface

Products

Mounting Smart Transmitter

Interface Products in a Cabinet

Foot

DIN Rail

Mount the Terminal Blocks in the same equipment cabinet as the Analog

I/O modules to which they will be connected. This ensures the integrity of

the 4-20 mA analog signal being received by the Analog I/O module.

Each unit of the Smart Transmitter Interface is equipped with two plastic

feet designed to attach to an EN 50 022 or EN 50 035 DIN rail. Using

these feet, clip the unit(s) to the DIN rail in the desired position

(Figure 2.1). The units can be mounted in any orientation—horizontally,

vertically, diagonally, etc.

Figure 2.1

Mounting

on a DIN Rail

90037

Foot

DIN Rail

To release the feet from the rail, press on the plastic as shown in Figure 2.2

so that the clip is pulled back far enough to release the unit.

Figure 2.2

Releasing

From a DIN Rail

Press Here

90038

2-3

Page 29

Chapter 2

Installing the Smart Transmitter Interface

Products

Connecting the

Communications Controller to

the Terminal Blocks

The Communications Controller can support a maximum of 32 HART

channels via the Terminal Blocks. Use any of the following combinations:

one or two 16 Channel Terminal Blocks (1770-HT16)

one, two, three or four 8 Channel Terminal Blocks (1770-HT8)

one 16 Channel Terminal Block and one or two 8 Channel Terminal

Blocks

Digital Communications Cables

The connecting cables should be shielded multi-conductor cables with 8

twisted 20-24 AWG wire pairs. These are not supplied with the Smart

Transmitter Interface. Belden #9508 (24 gauge) or # 85168 cable (20

gauge) or equivalent is recommended. Line 1 is shield, line 2 power and

lines 3 to 17 are control.

The connections between the Communications Controller and the Terminal

Blocks can be either a linear or star topography. You can use any

combination of linear/star connections as long as you adhere to the cabling

length requirements.

If your particular setup requires cable lengths greater than the ones

indicated in Figure 2.3 to Figure 2.5 or is substantially different, refer to

Appendix C.

2-4

Page 30

Chapter 2

Installing the Smart Transmitter Interface

Products

Linear Connection

For linear connection the cables go from the 17 pin connector on the

Communications Controller to the connector on the first Terminal Block.

Another cable of the same kind leads from the connector on the first

Terminal Block to the connector on the second Terminal Block, from there

to the connector on the third Terminal Block, and so on.

1770

Figure 2.3

Example

1: Linear Connection

+ -

a

b

HT1

1770HT16

c

1770HT8

Example 1 assumes that the modules (HT1, HT16 and two HT8’s) are

installed in separate cabinets. The maximum cable lengths allowed for the

setup shown in this example are given in the table below.

+ -

+ -

1770HT8

+ -

90031

Cable Size Cable a Cable b Cable c

Belden # 85168 250 ft 250 ft 250 ft

If you are using a linear arrangement, the connector at the

Communications Controller will have one set of 17 wires leading out of it.

The connector at each Terminal Block (except the last one) will have two

sets of wires in the same holes: the one coming from the previous

connection, (either the Communications Controller or the previous

Terminal Block), and the one leading to the next Terminal Block.

2-5

Page 31

Chapter 2

Installing the Smart Transmitter Interface

Products

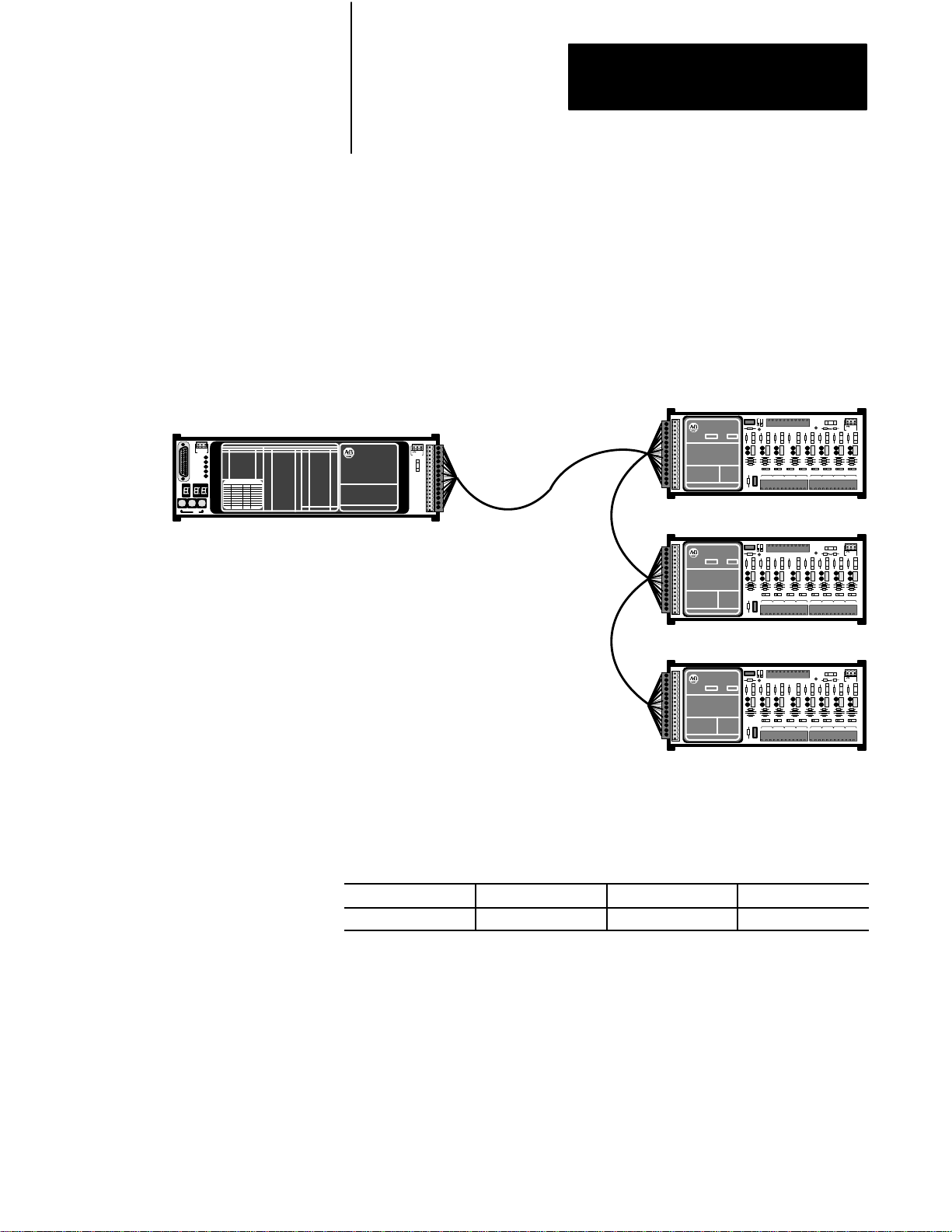

Star Connection

For star connection the cables to each Terminal Block lead to the connector

on the Communications Controller directly. If you are using a star

arrangement, the connector at the Communications Controller will have as

many sets of wires leading into it as there are Terminal Blocks. The

connector at each Terminal Block will have only one set of wires, leading

directly back to the Communications Controller.

Figure 2.4

Example

2: Star Connection

+ -

+ -

1770HT8

+ -

a

b

1770HT8

c

+ -

d

1770HT8

+ -

2-6

1770HT8

90030

Example 2 assumes that the modules (HT1, and four HT8’s) are installed

in separate cabinets. The table below gives one example of possible cable

lengths.

Cable Size Cable a Cable b Cable c Cable d

Belden #85168 250 ft 250 ft 250 ft 250 ft

Page 32

1770

Chapter 2

Installing the Smart Transmitter Interface

Products

Star/Linear Connection

Example 3 shows a setup where a combination of star and linear

connections are used. In this example, two HT8’s are joined in a linear

connection by cable a (a1 and a2) and the other two HT8’s are joined to the

HT1 in a star connection by cables b and c.

Figure 2.5

Example

3: Star/linear Connection

+ -

a1

a2

1770HT8

HT1

b

+ -

+ -

c

1770HT8

1770HT8

1770HT8

Cable Size Cable a1 Cable a2 Cable b Cable c

Belden #85168 250 ft 200 ft 200 ft 100 ft

+ -

+ -

90064

2-7

Page 33

Chapter 2

Installing the Smart Transmitter Interface

Products

Connector and Pinout

Attach the 17 position Phoenix COMBICON plugs (supplied) to each end

of the cable (see Figure 2.6) then plug them into the units. Use the bare

wire for chassis ground (to be connected at one end only, preferably to the

Communications Controller end). Use only one twisted pair for each "

pair of signals. The colors in the table below are intended as examples

only. You can use any pair you like for any pair of signals. The pinout for

the connector is in the table below.

Signal Pin Examples of Colors

Chassis Ground 1 (Shield) Bare Silver

+24 VDC 2 (Power) Red and White twisted pair;

RedisVDCWhiteisGround

Signal Ground 3 (Control)

+ Transmit Enable 4 (Control) Red and Black twisted pair;

- Transmit Enable 5 (Control)

+ Channel Select 1 6 (Control) Blue and Black twisted pair

- Channel Select 1 7 (Control)

+ Channel Select 2 8 (Control) White and Black twisted pair;

- Channel Select 2 9 (Control)

+ Channel Select 3 10 (Control) Orange and Black twisted pair;

- Channel Select 3 11 (Control)

+ Channel Select 4 12 (Control) Brown and Black twisted pair;

- Channel Select 4 13 (Control)

+ Channel Select 5 14 (Control) Green and Black twisted pair;

- Channel Select 5 15 (Control)

+ HART Tx/Rx 16 (Control) Yellow and Black twisted pair;

- HART Tx/Rx 17 (Control)

Red is VDC, White is Ground

(see Appendix C)

Red is +, Black is -

Redis+Blackis

Blueis+Blackis

Blue is +, Black is -

White is +, Black is -

Whiteis+Blackis

Orangeis+Blackis

Orange is +, Black is -

Brown is +, Black is -

Brownis+Blackis

Greenis+Blackis

Green is +, Black is -

Yellow is +, Black is -

Yellowis+Blackis

2-8

Page 34

Chapter 2

Installing the Smart Transmitter Interface

Products

Figure 2.6

Attaching

1

1770HT1

17

Setting the Board Address

Jumpers

shield

The Communications Controller can handle up to 32 HART channels via

the Terminal Blocks. However, since the 32 channels can be divided

Plugs to the Digital Communications Cable

*N/C = no connection

1

N/C*

17

among as many as four separate terminal blocks, the Communications

Controller needs to know where one Terminal Block ends and the next

begins. That is, it needs to know which of the 32 channels belong to which

individual Terminal Block, and whether it is an 8 or a 16 channel block.

1770HT8

90074

Each Terminal Block has a set of board address jumpers located just to the

right of the black cover near the top edge of the board (see Figure 1.2 and

Figure 1.3). To set a jumper block, lift the black jumper off the pins it is

currently on, re-position it, then push into place. (See Figure 2.7.) Set the

board address jumpers as shown in Figure 2.8.

Figure 2.7

Jumper

and Pins

90057

2-9

Page 35

Chapter 2

Installing the Smart Transmitter Interface

Products

Figure 2.8

Terminal

Block Board Address Jumpers

1770-HT8

Figure 2.9

Example T

Channels 1 - 8

Channels 9 - 16

Channels 17 - 24

Channels 25 - 32

erminal Block Channel Setup

1770-HT16

Channels 1 - 16

Channels 9 - 24

Channels 17 - 32

Invalid

90019

HT1

TERMINAL BLOCK

HT8

HT16

HT8

1st block

2nd

block

3rd block

CHANNELS

1 - 8

9 - 24

25 - 32

ADDRESS

JUMPERS

90051

2-10

Page 36

Chapter 2

Installing the Smart Transmitter Interface

Products

Marking the Terminal Block Labels

On the label on top of each Terminal Block is a place in the lower left hand

corner to record how you have configured the board address jumpers. The

jumper address configuration options for the unit are listed (3 options for

the 16 channel block and 4 for the eight channel block). Mark the box to

indicate which configuration you have used for this Terminal Block. (See

Figure 1.2 and 1.3.) Use a pencil so you can erase the marking if you

change the configuration.

Connecting the Terminal

Blocks to I/O and HART Field

Devices

As shown in Figure 1.10, a Terminal Block can be connected to Analog

I/O devices such as the 1771 IFE module, and to HART field devices. In

addition, a hand held terminal can be connected to the Terminal Block for

communication with HART field devices.

2-11

Page 37

Chapter 2

Installing the Smart Transmitter Interface

Products

Connecting to 1771 I/O Devices

Attach the wires from the 1771 Analog I/O devices to the 10 position

Phoenix COMBICON plugs supplied with the Terminal Block. Insert the

plug(s) into the 10 position Phoenix COMBICON connectors on the upper

edge of the Terminal Block (see Figure 2.10). The 1771-HT8 has one

connector; the 1771-HT16 has two. Figure 2.11 shows a 1771-IFE

connected to a Terminal Block. The cable between them must be no longer

than 30 feet. Single ended Analog I/O devices are recommended.

Figure 2.10

Connecting

the T

erminal Block to an Analog I/O Module

To Analog I/O

10 position COMBICON plug

10 position COMBICON connector on Terminal Block

1 2 3 4 5 6 7 8 RTN SH 1 2 3 4 5 6 7 8 RTN SH

90023

2-12

Page 38

Chapter 2

Installing the Smart Transmitter Interface

Products

Figure 2.11

1771IFE

HT8/16

Connection Example

1

2

3

4

5

6

7

8

RTN

SH

N/C

Shield

Ground Shield

at I/O chassis

mounting bolt

Channel 1

Channel 2

Channel 3

Channel 4

Module Common

Channel 5

Channel 6

Channel 7

Channel 8

Module Common

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1771-WG

Field Wiring Arm

90052

Connecting to HART Field Devices

To connect a HART field device to a Terminal Block attach the wires from

the HART field device to a 12 position Phoenix COMBICON plug

supplied with the Terminal Block. Insert the plug into the 12 position

Phoenix COMBICON connector on the lower edge of the Terminal Block

(see Figure 2.12). The 1770-HT8 has two of these connectors; the

1770-HT16 has four. HART field devices can be connected to the Terminal

Block in either a point-to-point or multidrop connection.

For 2-wire transmitters connect the positive (+) terminal of the transmitter

to position 2 on the Terminal Block, and the negative (–) terminal of the

transmitter to position 1 on the Terminal Block. For 4-wire transmitters

connect the positive terminal on the transmitter to position 1 on the

Terminal Block and the negative terminal on the transmitter to position 2

on the Terminal Block.

2-13

Page 39

Chapter 2

Installing the Smart Transmitter Interface

Products

12 position COMBICON connector

on Terminal Block

12 position COMBICON plug

From HART Field Devices

Figure 2.12

Connecting

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

HART Field Devices to the T

Point-to-point Connection

erminal Block

CH 5

+ -

C

90021

A point-to-point connection exists when only one HART field device is

connected to any particular Terminal Block channel. This arrangement

allows the transmission of both analog and digital data to and from the

HART field device.

Multidrop Connection

A maximum of 15 HART field devices can be connected to each channel

on the Terminal Block in a multidrop network. A multidrop connection

supplies only digital data through the Terminal Block. See Figure 1.10 and

Figure 2.13 for illustrations of both point-to-point and multidrop

connections.

Any channel on the Terminal Block can be used for either point-to-point or

multidrop networking, and the same Terminal Block can support both at

the same time without any special settings or configuration of the

hardware.

2-14

Page 40

Chapter 2

Installing the Smart Transmitter Interface

Products

Phoenix 12 position

COMBICON Header

Phoenix 12 position

COMBICON Plug

Shielded Twisted

Pair Cable

Figure 2.13

Pointtopoint

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

and Multidrop Connections

CH 5

1 2

Shield Connected

at one end only

Shield bridged

between cables

HART Field

Devices

Multidrop

Link

90056

2-15

Page 41

Chapter 2

Installing the Smart Transmitter Interface

Products

Connecting a Hand Held Terminal

Because the HART protocol supports up to two digital communication

masters at one time, you can use a hand-held terminal to communicate with

the HART field devices without disrupting their connection to the Terminal

Blocks.

To do this, attach the clips of your hand held terminal to either end of the

resistor on the Terminal Block that corresponds to the channel to which

you wish to connect. (See Figure 2.14.) Figure 2.15 and Figure 2.16 show

the channels and their corresponding resistors.

Figure 2.14

Connecting

the Hand Held T

JP1 JP1

E D

CH 1 CH 2

E D

erminal

Hand Held

Terminal

2-16

`

`

90063

Page 42

Figure 2.15

T

erminal Block Channels

HT8

and Corresponding Resistors

1

8 CHANNEL

TERMINAL BLOCK

CATALOG NO. 1770-HT8 VOLTS 24 VDC

HT1/HT8/HT16 INTERCONNECT

Chapter 2

Installing the Smart Transmitter Interface

Products

1 2 3 4 5 6 7 8 RTN SH

+ Loop Power

1

8 CHANNEL

TERMINAL BLOCK

CATALOG NO. 1770-HT8 VOLTS 24 VDC

HT1/HT8/HT16 INTERCONNECT

17

Channel 1 resistor

Figure 2.16

T

erminal Block Channels

HT16

and Corresponding Resistors

1 2 3 4 5 6 7 8 RTN SH

JP1 JP1

JP1

E D

E D E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

E D

JP1

JP1 JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

JP1

E D

E D

JP1 JP1

JP1

E D

E D E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

Channel 2 resistor Channel 8 resistor

1 2 3 4 5 6 7 8 RTN SH

JP1

JP1 JP1

E D

E D

E D E D

CH 1 CH 2 CH 3 CH 4

1 2 SH 1 2 SH 1 2 SH 1 2 SH

E D

JP1

E D

E D

JP1

JP1 JP1

JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

. . .

JP1

JP1 JP1

E D

CH 5 CH 6 CH 7 CH 8

1 2 SH 1 2 SH 1 2 SH 1 2 SH

E D

JP1

E D

E D

E D

JP1

+ -

Loop Power

E D

90068

JP1

17

Channel 1 resistor

Channel 2 resistor

. . .

Channel 16 resistor

90067

2-17

Page 43

Chapter 2

Installing the Smart Transmitter Interface

Products

Grounding

Grounding the Communications Controller and Terminal Block

Chassis

Because the Communications Controller and the Terminal Blocks can be as

far as 1000 feet apart it is best to ground each unit locally. To ground the

Communications Controller, connect a wire from the Earth Ground

terminal of its 3 position COMBICON power connector (see Figure 2.18)

to the local ground bus.

Ground each Terminal Block in the same way and insert the plug in the

power connection header for loop power (see Figure 2.19). Each Terminal

Block must be grounded in this way regardless of whether or not it is to

provide 4-20 mA loop power for HART field devices.

Grounding the HART Field Device Cable Shield

Connectors to the HART field devices on the Terminal Blocks are

internally grounded to the power connector. Once the power connector is

properly grounded, these connectors are also properly grounded.

Grounding the Analog I/O Cable Shield

Important: The shield connection in the cable between the Terminal

Blocks and the Analog I/O modules must be grounded at one end only. The

cable must not be more than 30 feet long.

If the Analog I/O module is a 1771-IFE module, ground the shield

connection to the chassis of the 1771-IFE as shown in the documentation

for that module. Do not ground the shield to the Terminal Block connector.

If the Analog I/O module is of another kind, and grounding at that end is

not feasible, you must first connect the cable’s shield wire to the position

on the Terminal Block plug marked SH for Shield (see Figure 2.17).

2-18

Page 44

Chapter 2

Installing the Smart Transmitter Interface

Products

To Analog I/O

10 position COMBICON plug

10 position COMBICON connector on Terminal Block

Supplying Power to the

Communications Controller

and Terminal Blocks

Figure 2.17

Grounding

Analog I/O

1 2 3 4 5 6 7 8 RTN SH

90045

The Communications Controller requires an external 24 VDC power

supply with " 1% voltage regulation. The power supply must provide the

Communications Controller with 200 mA of current. It must also provide

an additional 100 mA of current for each Terminal Block that is connected

to the Communications Controller. For example, the setup in Figure 2.3

requires a 24 VDC power supply that can provide at least 500 mA. Please

refer to Appendix C if your cable length requirement exceeds those shown

in Figure 2.3 to Figure 2.5. For recommended power supplies see

Appendix C, Table C.A.

Fuses for the Communications Controller

Overload protection for external power is provided by a 1 Amp

user-replaceable fuse located immediately below the power connector on

the Communications Controller. The fuse is UL 198G and CSA 22.2, No.

59 rated, 5mm x 20mm, 250V fast acting.

2-19

Page 45

Chapter 2

Installing the Smart Transmitter Interface

Products

Connecting Power to the Communications Controller

To connect the power supply to the Communications Controller:

1. Turn the power supply off.

2. Attach the 3 position Phoenix COMBICON plug (supplied) to the

3. Insert the plug into the power connection header on the upper right

4. Turn the power supply on.

Important: Be sure to turn the power off while connecting the cables.

output cable of the power supply.

corner of the Communications Controller (Figure 2.18).

Supplying Loop Power for

HART Field Devices

Figure 2.18

Connecting

+ 24 VDC

GROUND

the Power Supply to the Communications Controller

EARTH

+ 24V DC

Communications

COMMON

Controller

90020

HART field devices are of two types:

those that draw power from the 4–20 mA loop (2 wire transmitters)

2-20

those that require an external power supply (4 wire transmitters)

The HT8/16 Terminal Blocks support both types, and they can be mixed on

the same Terminal Block. Each channel on the Terminal Block has a

jumper block associated with it, JPn. The ‘n’ is the number of the channel

(1 to 8 or 1 to 16). This jumper block indicates the type of HART

transmitter connected to the channel in question.

Page 46

Chapter 2

Installing the Smart Transmitter Interface

Products

If a HART field device is a four wire transmitter it must be connected to its

own external power supply and the jumper on the Terminal Block for the

channel in question set to D (disable).

If a HART field device is a two wire transmitter it can be powered through

the Transmitter Block. This requires that the Terminal Block be connected

to an external power supply by the power connection header in the upper

right corner of the block. See Figure 2.19. The jumper on the Terminal

Block for the channel must be set to E (enable).

Set Jumper JP to this position For this type of HART transmitter

D (Disable loop supply) External power supply

E (Enable loop supply) Power drawn from the 420 mA loop

Power Supply Requirements

The external power supply required to power the HART field devices may

be from 24 to 32 VDC. The exact power supply needed depends on the

type of HART field device and the length and gauge of the cable

connecting it to the Terminal Block. For example, a 24 VDC " 0.1%

power supply with a 1 Ampere output would be adequate to supply loop

power to 32 Rosemount 3051C or 3044C field devices over a 20 gauge, or

larger, cable with a length of 1000 feet or less. See Appendix C for further

details.

Fuses for the Terminal Blocks

One fuse on the Terminal Block (either the 1770-HT8 or 1770-HT16) is

for the external power supply providing loop power to HART field devices

through the Terminal Block. It is located immediately to the left of the

power connector. The 1770-HT8 requires a 0.25 Amp fuse and the

1770-HT16 requires a 0.5 Amp fuse. Both fuses should be UL 198G and

CSA 22.2, No. 59 rated, 5mm x 20mm, 250V fast acting.

Connecting the Power Supply for Loop Power

To connect the power supply to the Terminal Block.

1. Turn the power supply off.

2. Attach the 3 position Phoenix COMBICON plug supplied with the

product to the output cable of the power supply.

3. Insert the plug into the power connection header on the upper right

corner of the Terminal Block (Figure 2.19).

2-21

Page 47

Chapter 2

Installing the Smart Transmitter Interface

Products

4. Turn the power supply on.

Important: The loop power and ground common wires are only needed if

the HART field devices connected to the Terminal Blocks draw power

from the 4-20 mA current loop instead of from their own individual power

supplies. The earth ground wire is needed, whether or not loop power is

being supplied.

Figure 2.19

Connecting

Field Devices

LOOP POWER

EARTH

GROUND

an External Power Supply to a T

COMMON

+ -

Loop Power

Terminal

Block

90028

erminal Block for Loop Power to HART

Connecting the

Communications Controller to

the RIO Host

2-22

The RIO connector is a 3 position Phoenix COMBICON connector located

at the left end of the unit, just to the right of the DB-25 connector, at the

top edge of the board (see Figure 2.20). Attach the matching plug (supplied

with the Communications Controller) to the RIO cable. Insert the plug into

the connector to make the RIO connection.

Page 48

Figure 2.20

Connector

RIO

Twinaxial Cable (1770-CD)

Blue

1 SH 2

RIO

POWER

RIO

Chapter 2

Installing the Smart Transmitter Interface

Products

Shield

Clear

90014

The pinout is:

Signal Label Cable

A1 1 Blue wire

A2 SH Shield

A3 2 Clear wire

Use Twinaxial Cable (1770-CD) for the RIO connections. Maximum

length for the cable depends on the baud rate:

For this baud rate: Maximum cable length is:

57600 10,000 feet (3,048 m)

115200 5,000 feet (1,524 m)

230400 2,500 feet (762 m)

Termination

Terminate the farthest physical nodes on the RIO link with a 150 or 82

Ohm termination resistor. If the Communications Controller is the last

device on the RIO link, connect a 1/2 watt resistor across pins 1 and 2 of

the plug. The value of the resistor depends on the Remote I/O baud rate: