Page 1

Installation Instructions

Compact I/O Modules

AC Digital Modules 1769-IA8I, 1769-IA16, 1769-IM12, 1769-OA8, 1769-OA16

DC Digital Modules 1769-IG16, 1769-IQ16, 1769-IQ16F, 1769-IQ32, 1769-IQ32T, 1769-IQ6XOW4,

1769-OB8, 1769-OB16, 1769-OB16P, 1769-OB32, 1769-OB32T, 1769-OG16, 1769-OV16, 1769-OV32T

Contact Modules 1769-OW8, 1769-OW8I, 1769-OW16

Analog Modules 1769-IF4, 1769-IF4I, 1769-IF4XOF2, 1769-IF4FXOF2F, 1769-IF8, 1769-IF16C,

1769-IF16V, 1769-IR6, 1769-IT6, 1769-OF2, 1769-OF4, 1769-OF4CI, 1769-OF4VI, 1769-OF8C, 1769-OF8V

Speciality Modules 1769-ARM, 1769-ASCII, 1769-BOOLEAN, 1769-HSC

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Compact I/O, Rockwell Automation, Rockwell Software, RS Logix 500, RSLogix 5000, R SNetWorx for DeviceNet, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

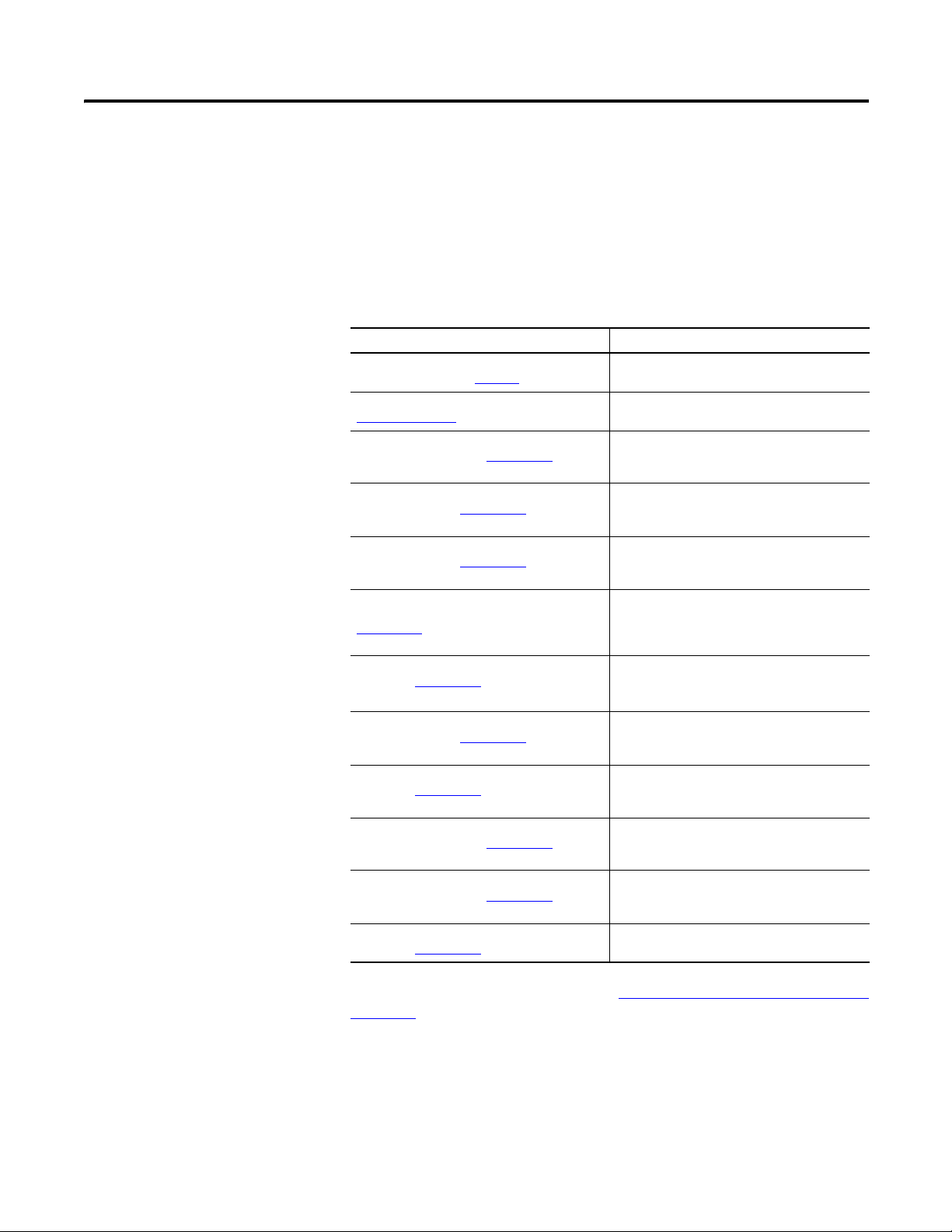

Table of Contents

Preface

Install a 1769 Module

Module Wiring

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environnements Dangereux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

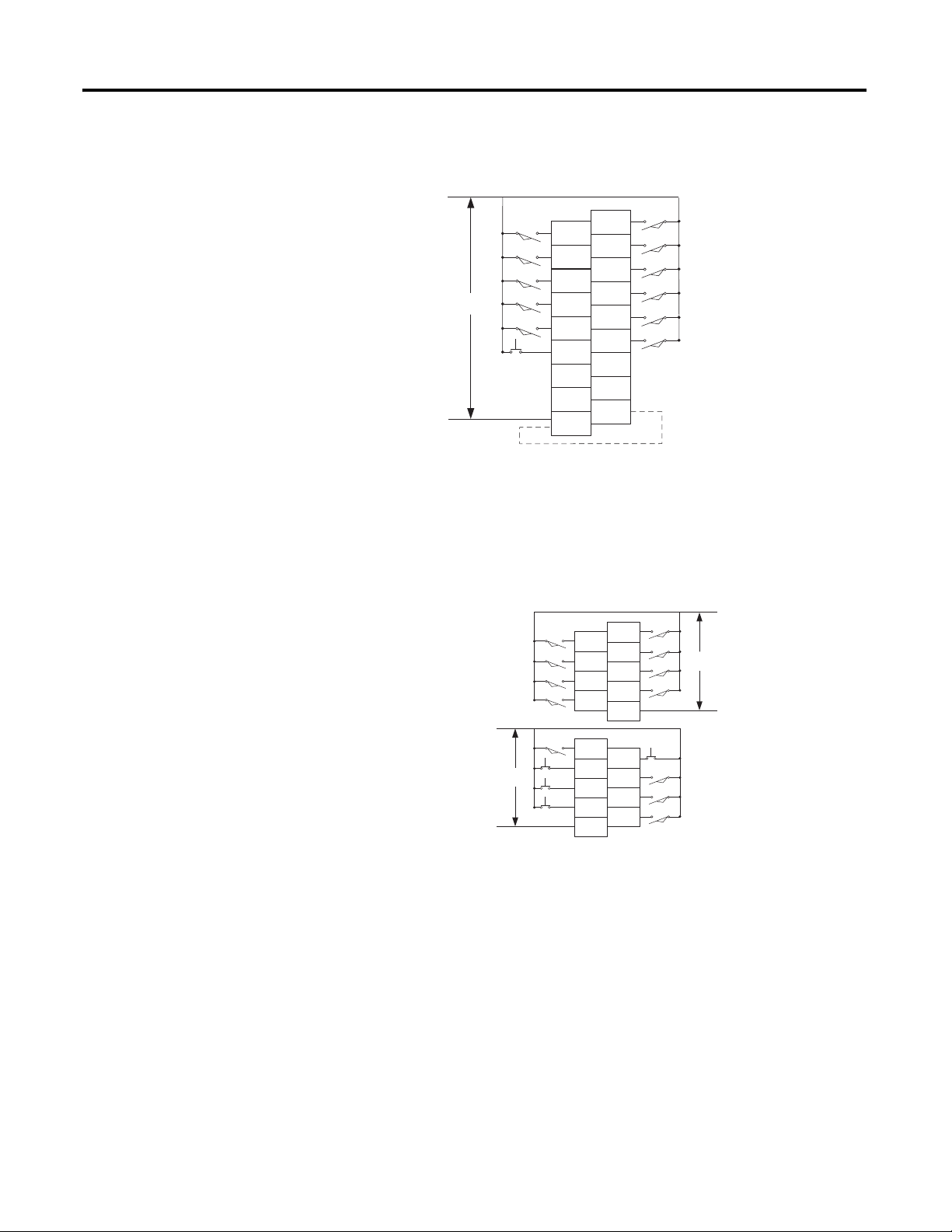

Minimum Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replace a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ground the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wire the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Label Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remove the Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wire the Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wire Size and Terminal Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2

1769-IA8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1769-IA16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

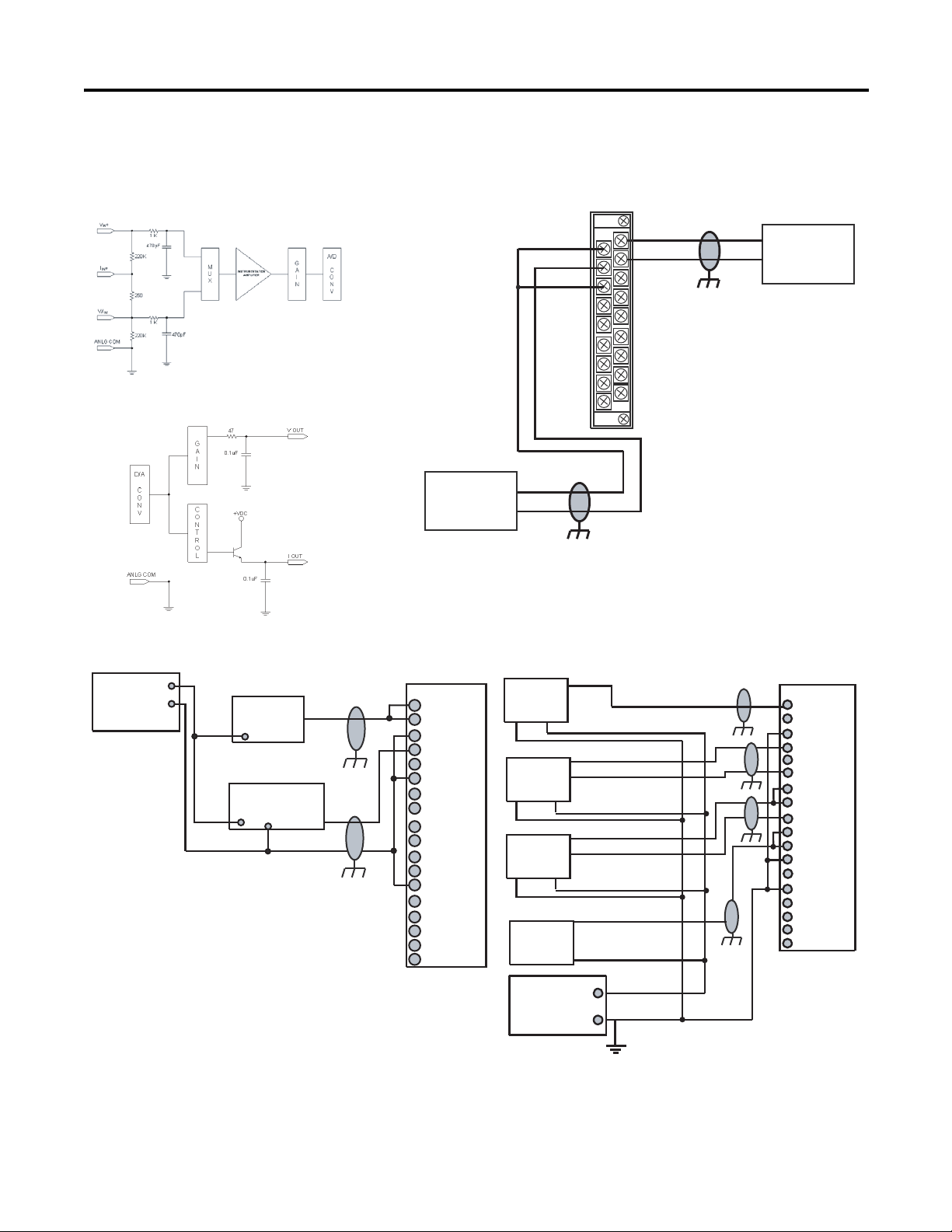

1769-IF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1769-IF4I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1769-IF4XOF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1769-IF4FXOF2F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1769-IF8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1769-IF16C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1769-IF16V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

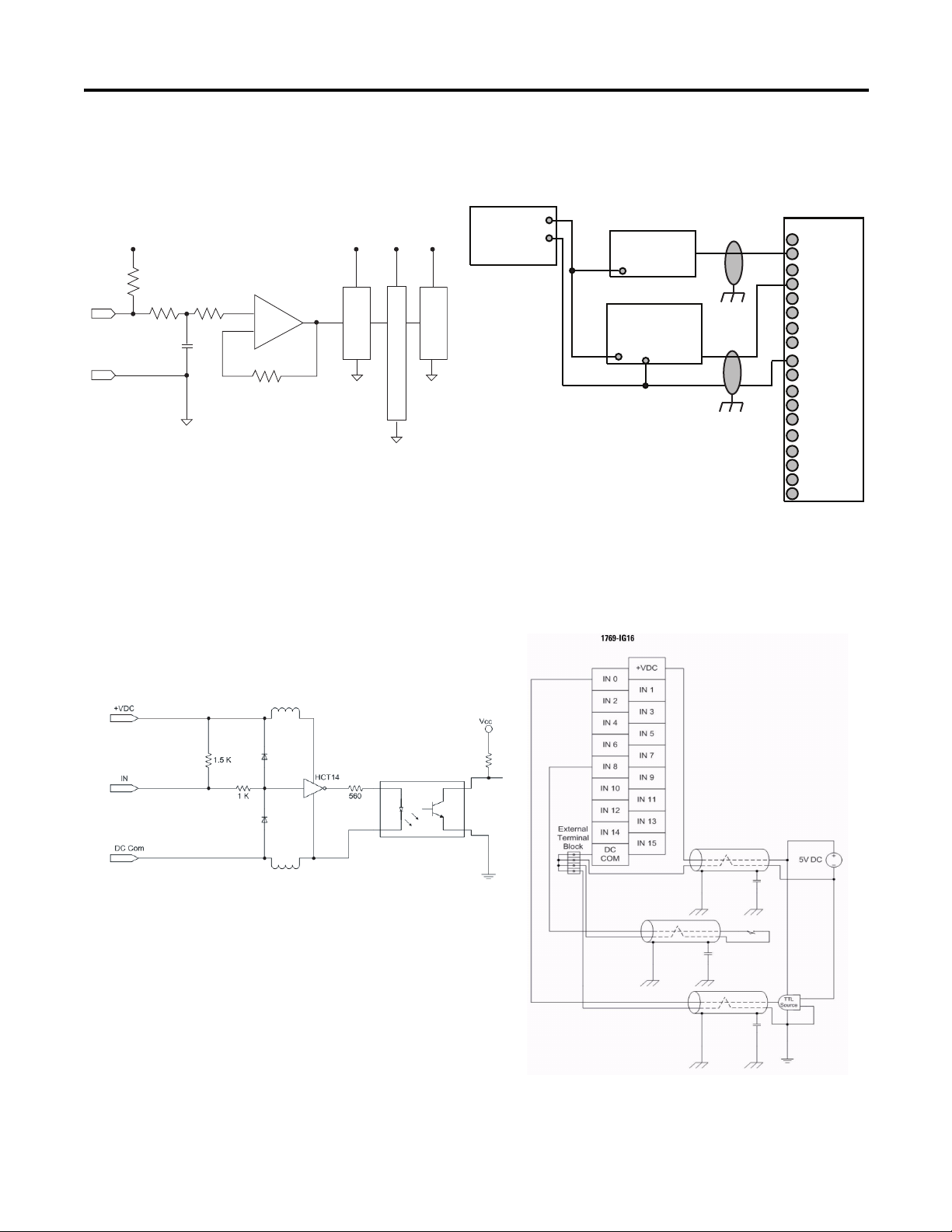

1769-IG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1769-IM12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1769-IQ16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1769-IQ16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1769-IQ32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1769-IQ32T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1769-IQ6XOW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1769-IR6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1769-IT6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1769-OA8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1769-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1769-OB8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1769-OB16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1769-OB16P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1769-OB32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1769-OB32T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 3

Page 4

Table of Contents

1769-OF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1769-OF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1769-OF4CI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1769-OF4VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1769-OF8C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1769-OF8V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1769-OG16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1769-OV16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1769-OV32T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1769-OW8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1769-OW8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1769-OW16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1769-ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1769-ASCII. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1769-BOOLEAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1769-HSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 3

I/O Memory Mapping

1769-IA8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1769-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

1769-IF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1769-IF4I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1769-IF4XOF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1769-IF4FXOF2F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1769-IF8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Controller Tags for RSLogix 5000, Version 15 or Later . . . . . . . . . . 75

1769-IF16C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 5

Table of Contents

Configuration Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1769-IF16V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configuration Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1769-IG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

1769-IM12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

1769-IQ16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

1769-IQ16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

1769-IQ32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

1769-IQ32T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1769-IQ6XOW4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

1769-IR6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configuration Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Module Configuration Word. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

1769-IT6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Configuration Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1769-OA8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

1769-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1769-OB8, Series A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

1769-OB16, Series B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 5

Page 6

Table of Contents

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

1769-OB16P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

1769-OB32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

1769-OB32T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

1769-OF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

1769-OF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

1769-OF4CI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

1769-OF4VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

1769-OF8C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Controller Tags for RSLogix 5000, Version 15 or Later

. . . . . . . . . 146

1769-OF8V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Controller Tags for RSLogix 5000, Version 15 or Later . . . . . . . . . 157

Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1769-OG16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

1769-OV16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 7

Table of Contents

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1769-OV32T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1769-OW8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1769-OW8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

1769-OW16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Output Module’s Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

1769-ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

1769-ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Alternate Mode (One Channel at a Time) Input File . . . . . . . . . . . 180

Alternate Mode (One Channel at a Time) Output File . . . . . . . . . 181

Simultaneous Mode (Two Channels) Input File . . . . . . . . . . . . . . . 182

Simultaneous Mode (Two Channels) Output File. . . . . . . . . . . . . . 184

Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

1769-BOOLEAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Configuration Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

1769-HSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Module Replacement Parts

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 7

Appendix A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 9

Preface

This manual describes how to install any 1769 Compact I/O module. Use this

manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use Compact I/O modules.

Additional Resources

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

http://www.ab.com

Compact I/O Thermocouple/mV Input Module

User Manual, publication 1769-UM004

Compact I/O RTD/Resistance Input Module User

Manual, publication 1769-UM005

Compact High-speed Counter Module User

Manual, publication 1769-UM006

Compact 8-Bit Low Resolution Analog I/O

Combination Module User Manual, publication

1769-UM008

Compact I/O ASCII Module User Manual,

publication 1769-UM012

Compact I/O Isolated Analog Modules User

Manual, publication 1769-UM014

Compact I/O BOOLEAN Module User Manual,

publication 1769-UM016

Compact High Density Analog Input Modules

User Manual, publication 1769-UM018

Compact Combination Fast Analog I/O Module

User Manual, publication 1769-UM019

Compact Analog Output Module User Manual,

publication 1769-UM020

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity, certificates,

and other certification details.

Provides a quick start and describes how to

install, configure, and troubleshoot the

CompactI/O Thermocouple/mV Input module.

Describes how to install, configure, program,

operate, and troubleshoot a control system using

the 1769-IR6 module.

Describes how to operate, install, wire,

configure, and troubleshoot the 1769-HSC

module.

Provides a quick start and describes how to

install, configure, program, operate, and

troubleshoot a control system using the 1769

combination analog I/O module.

Provides a quick start and describes how to

install, configure, and troubleshoot the

Compact I/O 1769-ASCII module.

Describes how to install, configure, program,

operate, and troubleshoot a control system using

1769 isolated analog I/O modules.

Describes how to install, configure, program,

operate, and troubleshoot a control system using

the 1769 BOOLEAN module.

Describes how to install, configure, and

troubleshoot 1769 compact high density analog

input modules.

Describes how to install, configure, and

troubleshoot the 1769 combination analog I/O

module.

Describes how to install, configure, and

troubleshoot the 1769 analog I/O module.

You can view or download publications at http://www.rockwellautomation.com/

literature/. To order paper copies of technical documentation, contact your local

Rockwell Automation distributor or sales representative.

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 11

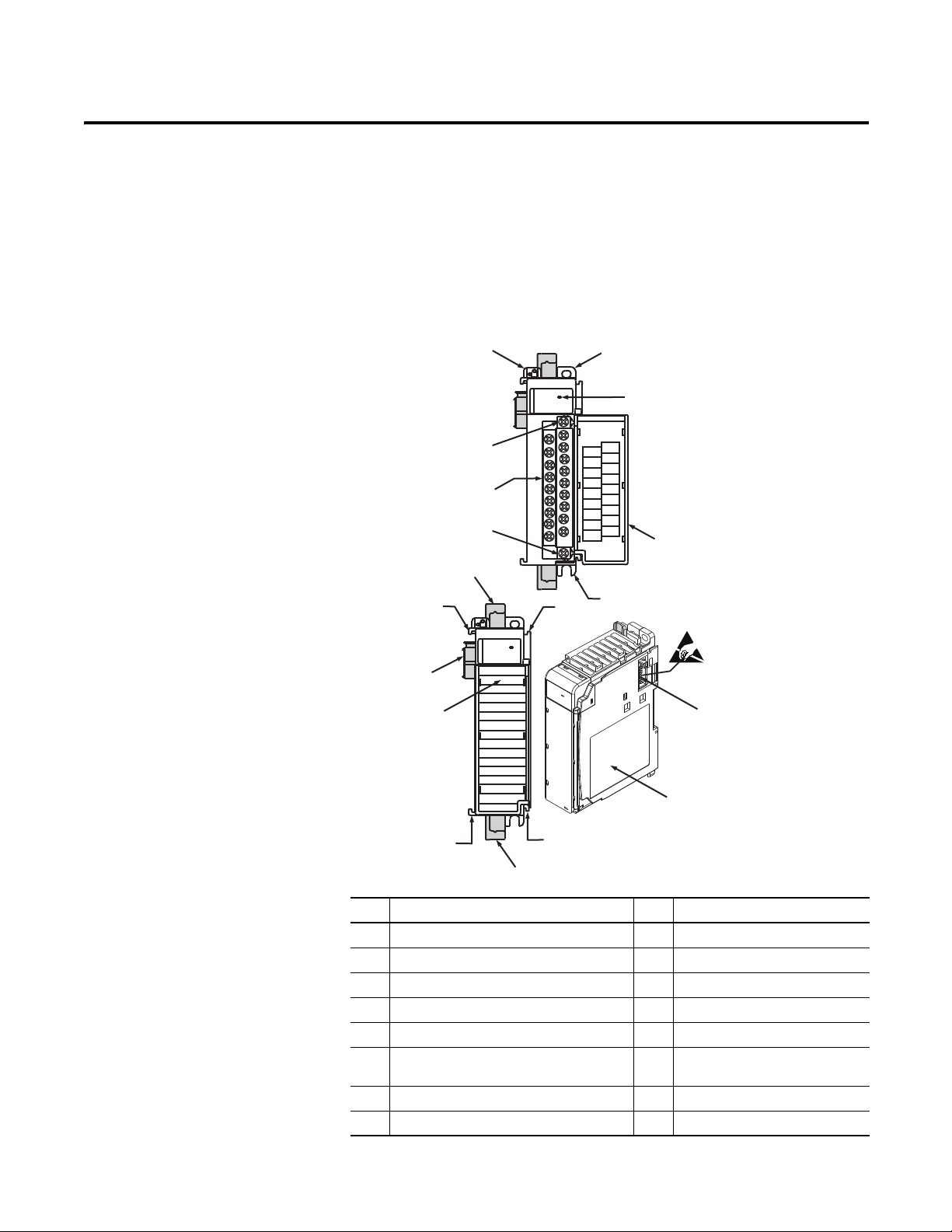

Install a 1769 Module

10a

10b

4

10

2b

3

2a

1

5a

9

5b

6

7a

7b

8b

7b

8a

7a

1769-OF4VI

DANGER

Do Not Remove RTB Under Power

Unless Area is Non-Hazardous

Ensure Adjacent

Bus Lever is Unlatched/Latched

Before/After

Removing/Inserting Module

N/C

V out 1 +

N/C

V out 2 +

N/C

V out 3 +

N/C

V out 0 +

N/C

N/C

V out 1 -

N/C

V out 2 -

N/C

V out 3 -

N/C

V out 0 -

N/C

OK

Analog

OK

Analog

Chapter

1

Before You Begin

Compact I/O is suitable for use in an industrial environment when installed in

accordance with these instructions.

Item Description Item Description

1 Bus lever (with locking function) 7a Upper tongue-and-groove slots

2a Upper panel mounting tab 7b Lower tongue-and-groove slots

2b Lower panel mounting tab 8a Upper DIN rail latch

3 Module status LED 8b Lower DIN rail latch

4 Module door with terminal identification label 9 Write-on label (user ID tag)

5a Movable bus connector with female pins 10 Removable terminal block (RTB)

with finger-safe cover

5b Stationary bus connector with male pins 10a RTB upper retaining screw

6 Nameplate label 10b RTB lower retaining screw

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 11

Page 12

Chapter 1 Install a 1769 Module

North American Hazardous Location Approval

The following information applies when operating this equipment

in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code. When

combining products within a system, the most adverse temperature code

(lowest "T" number) may be used to help determine the overall temperature

code of the system. Combinations of equipment in your system are subject

to investigation by the local Authority Having Jurisdiction at the time of

installation.

WARNING:

Explosion Hazard

• Do not disconnect equipment unless

power has been removed or the area is

known to be nonhazardous.

• Do not disconnect connections to this

equipment unless power has been

removed or the area is known to be

nonhazardous. Secure any external

connections that mate to this

equipment by using screws, sliding

latches, threaded connectors, or other

means provided with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they

must only be changed in an area known

to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des marquages sur

sa plaque d'identification qui indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code de température le

plus faible) peut être utilisé pour déterminer le code de température global du

système. Les combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l'installation.

AVERTISSEMENT:

Risque d’Explosion

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer

tous les connecteurs externes reliés à cet

équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de composants peut rendre

cet équipement inadapté à une utilisation

en environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé

non dangereux avant de changer les piles.

ATTENTION: Prevent Electrostatic Discharge

Electrostatic discharge can damage integrated circuits or semiconductors if you touch bus connector pins or the

terminal block. Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the bus connector or connector pins.

• Do not touch circuit components inside the module.

• Use a static-safe work station, if available.

• When not in use, keep the module in its static-shield box.

ATTENTION: Remove power before removing or inserting this module. When you remove or insert a module with

power applied, an electrical arc may occur. An electrical arc can cause personal injury or property damage in these

ways:

• Sending an erroneous signal to your system’s field devices causing unintended machine motion

• Causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and its mating connector. Worn contacts may

create electrical resistance.

12 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 13

Install a 1769 Module Chapter 1

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to

use in hazardous locations.

WARNING: EXPLOSION HAZARD

• Substitution of components may impair suitability for Class I, Division 2.

• When in hazardous locations, turn off power before wiring or replacing

modules.

• Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements Dangereux

Install Summary

Cet équipement est conçu pour être utilisé dans des environnements de Classe 1,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

WARNING: DANGER D’EXPLOSION

La substitution de composants peut rendre cet équipement impropre à une

utilisation en environnement de Classe 1, Division 2.

Ne pas remplacer de composants ou déconnecter l'équipement sans s'être

assuré que l'alimentation est coupée et que l'environnement est classé non

dangereux.

Ne pas connecter ou déconnecter des composants sans s'être assuré que

l'alimentation est coupée ou que l'environnement est classé non dangereux.

Ce produit doit être installé dans une armoire.

Follow these steps to install the module.

1. System Assembly

2. Ground the Module

3. Wire the Module

.

.

.

This publication describes these steps in detail.

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 13

Page 14

Chapter 1 Install a 1769 Module

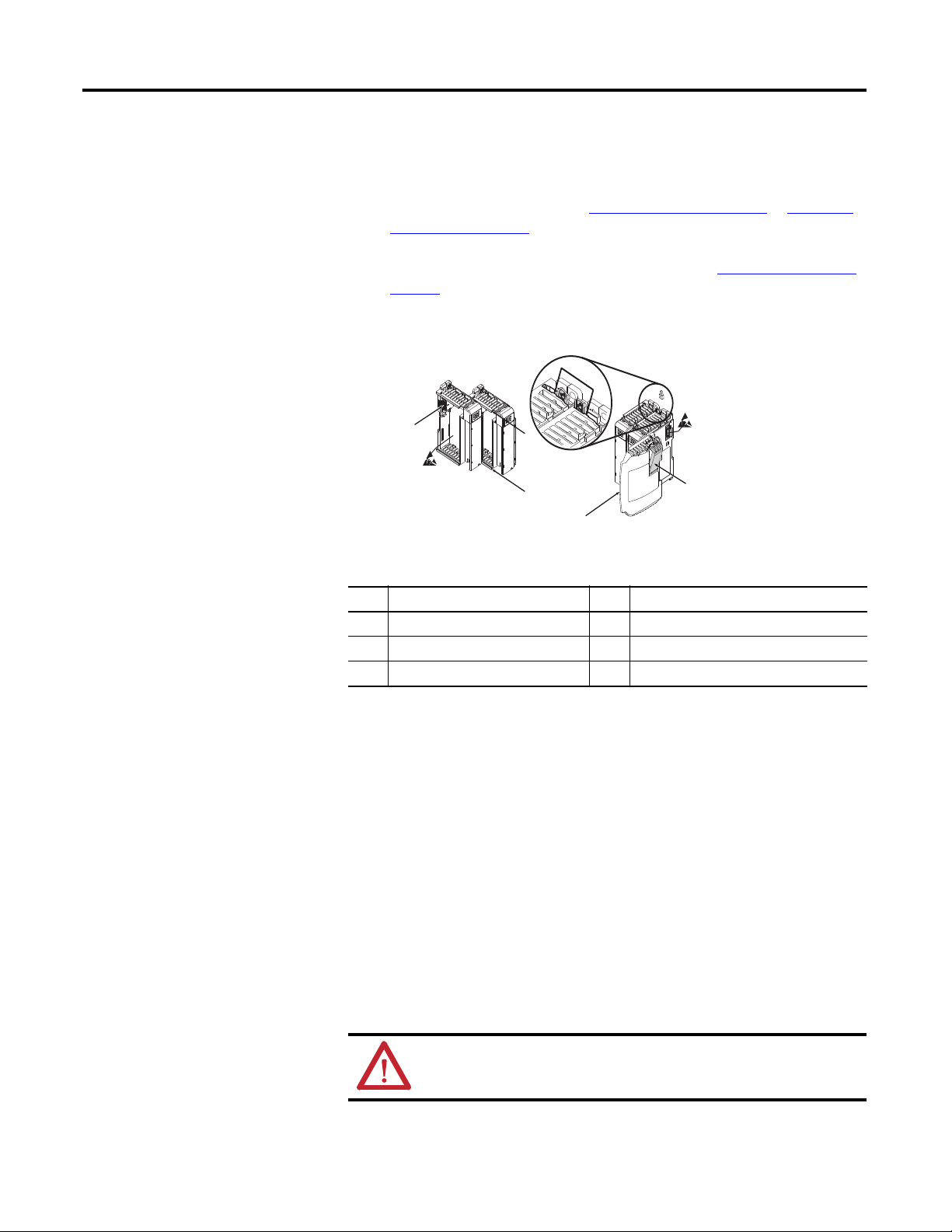

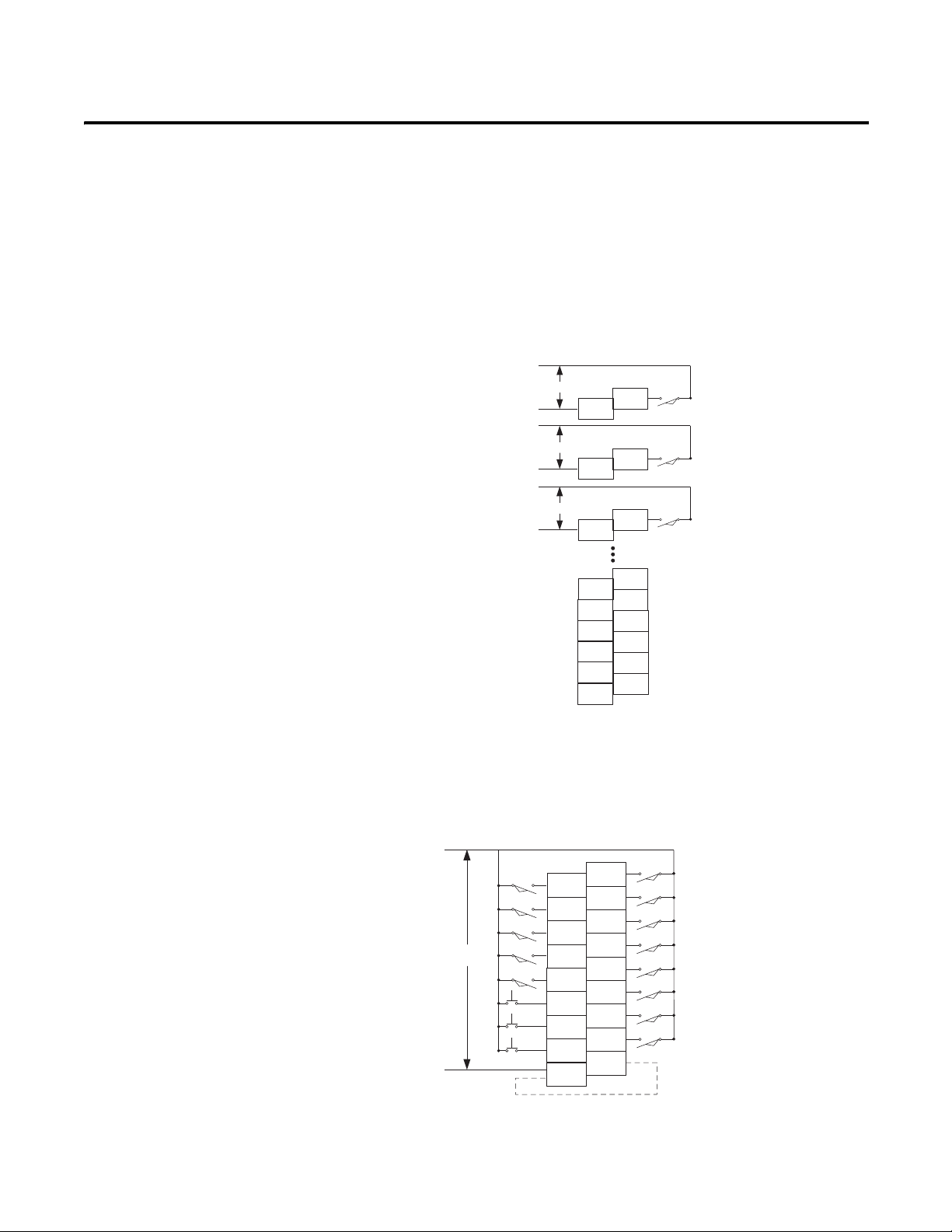

System Assembly

The module can be attached to the controller or an adjacent I/O module before

or after mounting.

• For mounting instructions, see Panel Mounting

on page 15 or DIN Rail

Mounting on page 16.

• To work with a system that is already mounted, see Replace a Module

on

page 17.

The following procedure shows you how to assemble the Compact I/O system.

3

4

2

Item Description Item Description

1 Tongue-and-groove slots 4 Bus lever

2 Bus connectors 5 End-cap terminator

3 Positioning tab 6 End-cap bus terminator

1

1

5

6

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the unlocked

(fully right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure the modules

together (or to a controller).

4. Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

5. Push the bus lever back slightly to clear the positioning tab (3).

Use your fingers or a small screwdriver.

6. To allow communication between the controller and module, move the

bus lever fully to the left (4) until it clicks.

7. Make sure the lever is locked firmly in place.

ATTENTION: When attaching I/O modules, it is very important that the

bus connectors are securely locked together to make a proper electrical

connection.

14 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 15

Install a 1769 Module Chapter 1

IMPORTANT

1

5

4

4

6

2

2

2

2

2

3

8. Attach an end-cap terminator (5) to the last module in the system by using

the tongue-and-groove slots as before.

9. Lock the end-cap bus terminator (6).

A 1769-ECR or 1769-ECL right or left end cap must be used to terminate

the end of the serial communication bus.

ATTENTION: During panel or DIN rail mounting of all devices, be sure

that all debris, such as metal chips and wire strands, is kept from falling

into the module. Debris that falls into the module could cause damage on

powerup.

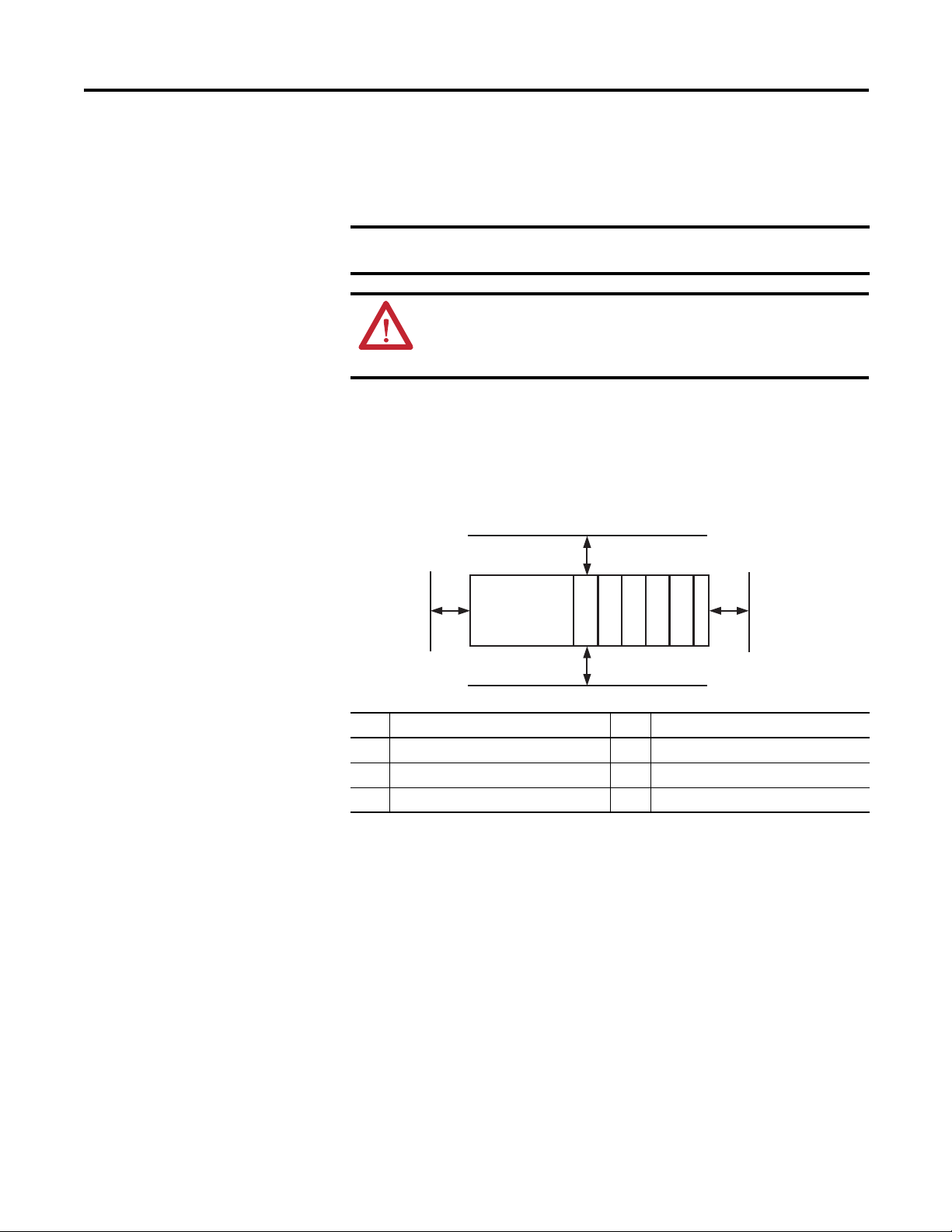

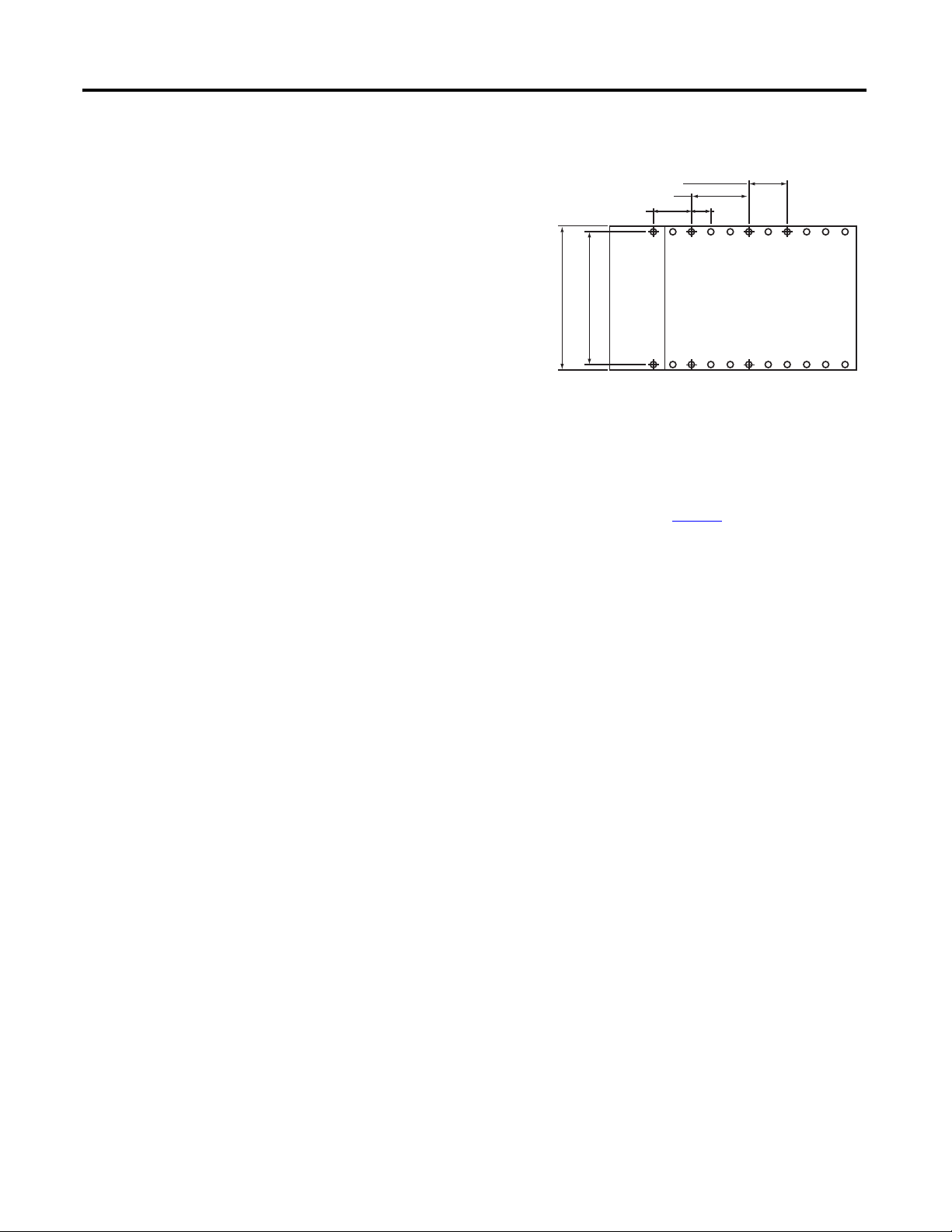

Minimum Spacing

Maintain spacing from enclosure walls, wireways, and adjacent equipment. Allow

50 mm (2 in.) of space on all sides for adequate ventilation.

Item Description Item Description

1Top 4Side

2 Compact I/O modules 5 Bottom

3 End cap 6 Host controller

Panel Mounting

Mount the module to a panel by using two screws per module. Use M4 or #8

panhead screws. Mounting screws are required on every module.

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 15

Page 16

Chapter 1 Install a 1769 Module

Spacing for single-wide modules 35mm (1.378 in.)

Spacing for one-and-a half-wide modules 52.5mm (2.067 in.)

Refer to host controller documentation for this dimension.

Host Controller

Note: Overall hole spacing

tolerance: ±0.4mm (0.016 in.).

30535-M

Host Controller

Note: Overall hole spacing

tolerance: +/- 0.4mm (0.016 in.).

Spacing for one-and-a half-wide modules 52.5mm (2.067 in.)

Refer to host controller documentation for this dimension.

Spacing for single-wide modules 35mm (1.378 in.)

TIP

Panel Mounting Using the Dimensional Template

Panel Mounting Procedure Using Modules as a Template

The following procedure lets you use the assembled modules as a template for

drilling holes in the panel. If you have sophisticated panel mounting equipment,

you can use the dimensional template provided on page 16

mounting hole tolerance, it is important to follow these procedures.

. Due to module

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel, and check for proper hole alignment.

6. Attach the modules to the panel using the mounting screws.

If you are mounting more modules, mount only the last one of this group

and put the others aside. This reduces remounting time during drilling

and tapping of the next group.

7. Repeat steps 1…6 for any remaining modules.

DIN Rail Mounting

The module can be mounted using the following DIN rails:

• 35 x 7.5 mm (1.38 x 0.30 in.; EN 50 022 - 35 x 7.5)

• 35 x 15 mm (1.38 x 0.59 in.; EN 50 022 - 35 x 15)

16 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Before mounting the module on a DIN rail, close the DIN rail latches. Press the

DIN rail mounting area of the module against the DIN rail. The latches will

momentarily open and lock into place.

Page 17

Install a 1769 Module Chapter 1

TIP

Replace a Module

To replace the module while the system is mounted to a panel or DIN rail, follow

these steps.

1. Remove power.

2. On the module to be removed, use a screwdriver to remove the upper and

lower mounting screws from the module or open the DIN latches.

3. Move the bus lever to the right to disconnect or unlock the bus.

4. On the right-side adjacent module, move its bus lever to the right to

disconnect it from the module to be removed.

5. Gently slide the disconnected module forward.

If you feel excessive resistance, check that the module has been

disconnected from the bus, and that both mounting screws have been

removed or DIN latches have been opened.

It may be necessary to rock the module slightly from front to back to

remove it, or, in a panel-mounted system, to loosen the screws of

adjacent modules.

Ground the Module

6. Before installing the replacement module, be sure that the bus lever on the

module to be installed and the bus lever on the right-side adjacent module

are in the unlocked (fully right) position.

7. Slide the replacement module into the open slot.

8. Connect the modules together by locking (fully left) the bus levers on the

replacement module and the right-side adjacent module.

9. Replace the mounting screws or snap the module onto the DIN rail.

This product is intended to be mounted to a well-grounded mounting surface,

such as a metal panel. Additional grounding connections from the module’s

mounting tabs or DIN rail are not required unless the mounting surface cannot

be grounded. Refer to the Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

, for additional information.

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 17

Page 18

Chapter 1 Install a 1769 Module

TIP

Wire the Module

Consider the following when wiring your system:

• Channels are isolated from each other.

• Use Belden 8761, or equivalent, shielded wire.

• Under normal conditions, the drain wire and shield junction must be

connected to earth ground with a panel or DIN rail mounting screw at the

analog I/O module end. Keep the shield connection to ground as short as

possible.

In environments where high frequency noise may be present, it may be

necessary to ground the shield via a 0.1 µF capacitor at the load end and

also ground the module end without a capacitor.

• For optimum accuracy, limit overall cable impedance by keeping your cable

as short as possible. Locate the I/O system as close to your sensors or

actuators as your application will permit.

• Load resistance for each voltage output channel must be equal to or greater

than 2K

Ω..

ATTENTION: Miswiring of the module to an AC/DC source will damage

the module.

Be careful when stripping wires. Wire fragments that fall into a module

could cause damage at powerup. Once wiring is complete, make sure the

module is free of all metal fragments.

Refer to Appendix 2

for wiring diagrams of each module.

Label Terminals

A removable, write-on label is provided with the module. Remove the label from

the door, mark the identification of each terminal with permanent ink, and slide

the label back into the door. Your markings (ID tag) will be visible when the

module door is closed.

18 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 19

Install a 1769 Module Chapter 1

TIP

TIP

1

3

2

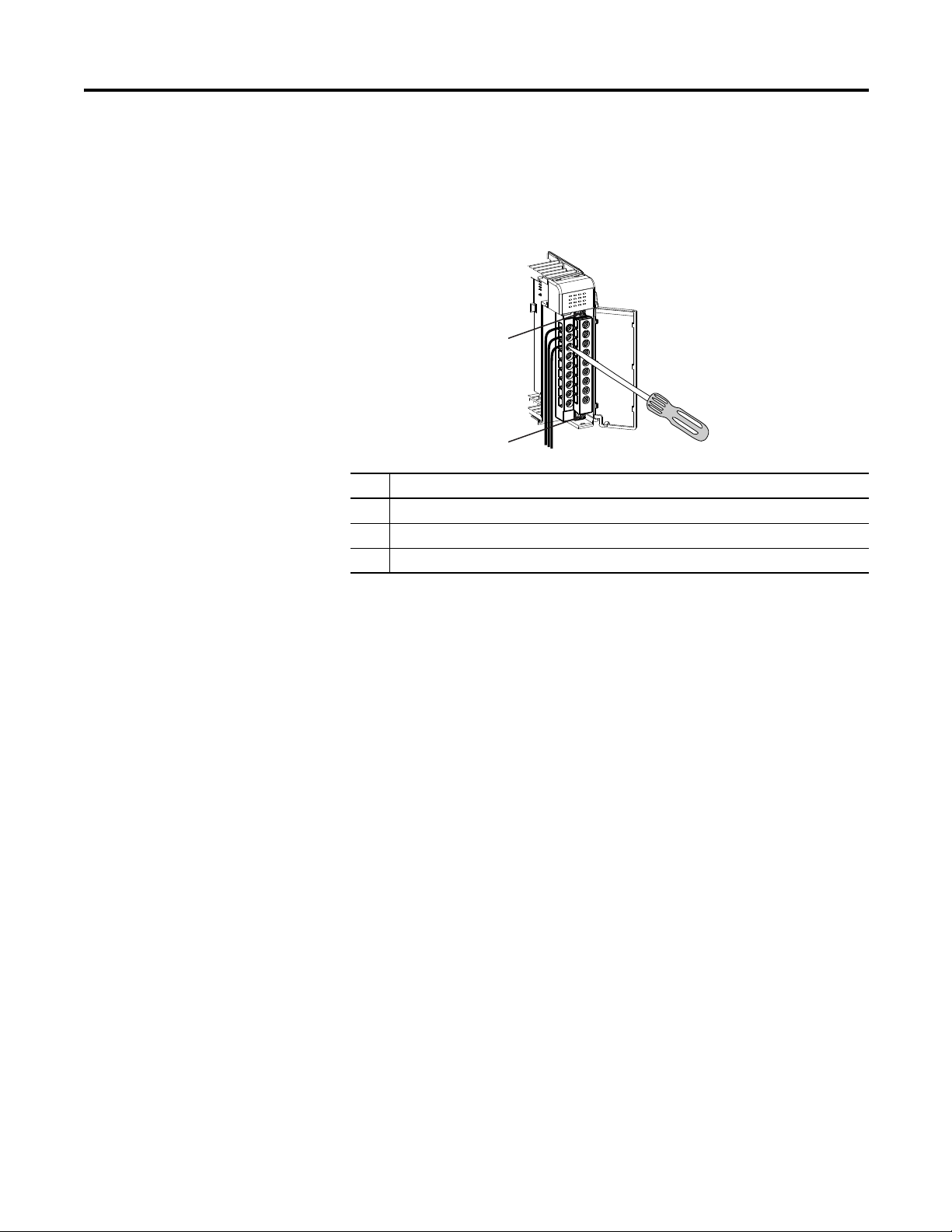

Remove the Terminal Block

To remove the terminal block, loosen the upper and lower retaining screws. The

terminal block will back away from the module as you remove the screws. When

replacing the terminal block, torque the retaining screws to 0.46 N

Item Description

1 Wiring the finger-safe terminal block

2 Lower retaining screws

3 Upper retaining screws

•m (4.1 lb•in).

Wire the Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the terminal screws to be wired.

2. Route the wire under the terminal pressure plate.

You can use the bare wire or a spade lug. The terminals will accept a 6.35

mm (0.25 in.) spade lug.

The terminal screws are non-captive. You can use a ring lug [maximum

6.35 mm (0.25 in.) o.d. with a 3.53 mm (0.139 in.) minimum i.d. (M3.5)]

with the module.

3. Tighten the terminal screw making sure the pressure plate secures the wire.

Recommended torque when tightening terminal screws is 0.68 N•m

(6 lb•in).

If you need to remove the finger-safe cover, insert a screwdriver into one

of the square wiring holes and gently pry the cover off. If you wire the

terminal block with the finger-safe cover removed, you will not be able to

put it back on the terminal block because the wires will be in the way.

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 19

Page 20

Chapter 1 Install a 1769 Module

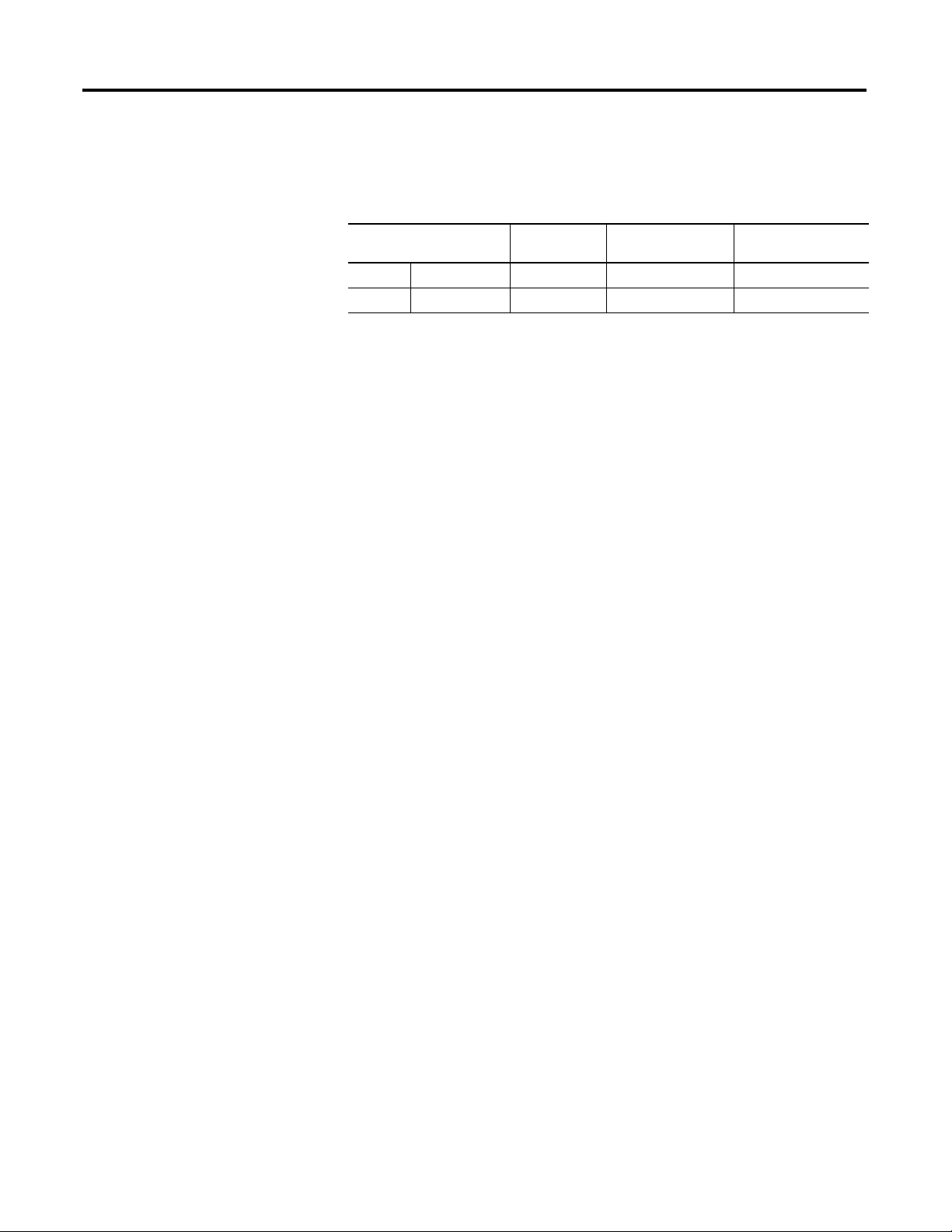

Wire Size and Terminal Screw Torque

Each terminal accepts one or two wires with the following restrictions.

Wire Type Wire Size Terminal Screw

Torque

Solid Cu-90 °C (194 °F) #14…#22 AWG 0.68 N•m (6 lb•in) 0.46 N•m (4.1 lb•in)

Stranded Cu-90 °C (194 °F) #16…#22 AWG 0.68 N•m (6 lb•in) 0.46 N•m (4.1 lb•in)

Retaining Screw

Torque

20 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 21

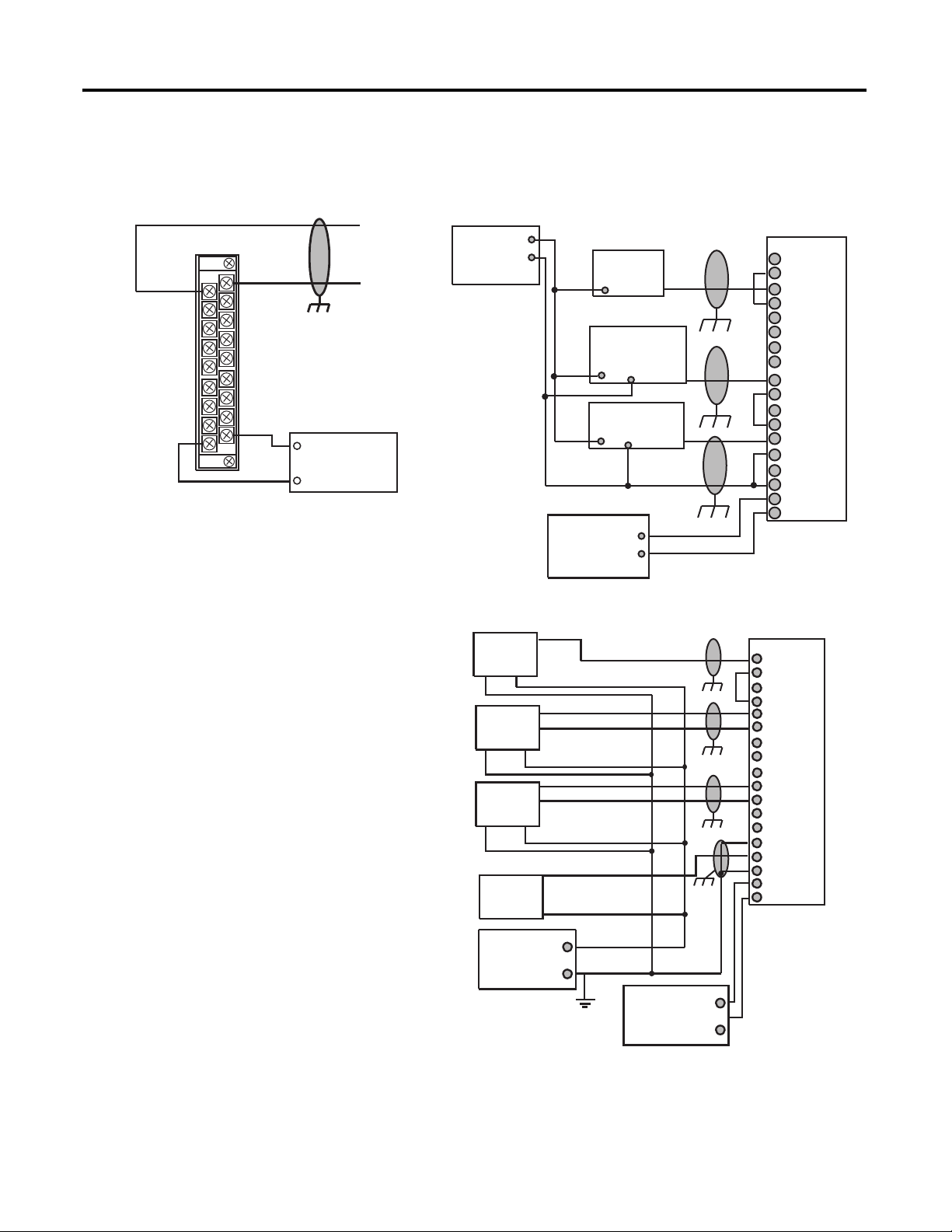

Module Wiring

AC

COM3

NC

IN 3

IN 7

IN 6

IN 5

IN 4

NC

AC

COM7

AC

COM6

AC

COM5

AC

COM4

AC

COM 0

IN 0

L1a

L2a

100/120V AC

AC

COM 1

IN 1

L1b

L2b

100/120V AC

AC

COM 2

IN 2

L1c

L2c

100/120V AC

1769-IA8I

Chapter

2

1769-IA8I

Compact individually-isolated 120V AC input module

1769-IA16

Compact 120V AC input module

1769-IA16

L1

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

100/120V AC

L2

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 21

IN 7

IN 9

IN 11

IN 13

IN 15

AC

COM

IN 6

IN 8

IN 10

IN 12

IN 14

AC

COM

Commons are

connected internally.

Page 22

Chapter 2 Module Wiring

+

–

V in 0 +

V/I in 0 -

I in 0+

ANLG Com

V in 1 +

V/I in 1 -

I in 1+

ANLG Com

V in 2 +

V/I in 2 -

I in 2+

ANLG Com

V in 3 +

V/I in 3 -

I in 3+

ANLG Com

DC NEUT

+24V DC

+

-

1769-IF4 Differential Inputs

The external power supply must be rated Class 2, with a 24V DC

range of 20.4…26.4V DC and 60 mA minimum. Series B and

later modules support this option.

External 24V

DC Power

Supply

External 24V

DC Power

Supply

External 24V

DC Power

Supply

Analog Source

Belden 8761 Cable (or equivalent)

Earth ground the shield

locally at the module.

Sensor/

Transmitter

Supply

Current

Voltage

Voltage

Sensor/

Transmitter

Supply

Single-ended

Volt age

Differential

Voltage

Differential

Current

Tw o- wi re

Current

Signal

Signal

Ground

Signal

Ground

Signal

Signal

Signal

Signal

1769-IF4

22 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Compact voltage/current analog input module

1769-IF4 Single-ended Sensor/Transmitter Inputs

+

-

+

+

–

–

–

+

1769-IF4 Mixed Transmitter Inputs

+

+

–

+

–

+

+

+

+

–

+

-

V in 0 +

V/I in 0 -

I in 0 +

ANLG Com

V in 1 +

V/I in 1 -

I in 1 +

ANLG Com

V in 2 +

V/I in 2 -

I in 2 +

ANLG Com

V in 3 +

V/I in 3 -

I in 3 +

ANLG Com

+24V DC

DC NEUT

V in 0 +

V/I in 0 -

I in 0 +

ANLG Com

V in 1 +

V/I in 1 -

I in 1 +

ANLG Com

V in 2 +

V/I in 2 -

I in 2 +

ANLG Com

V in 3 +

V/I in 3 -

I in 3 +

ANLG Com

+24V DC

DC NEUT

+

–

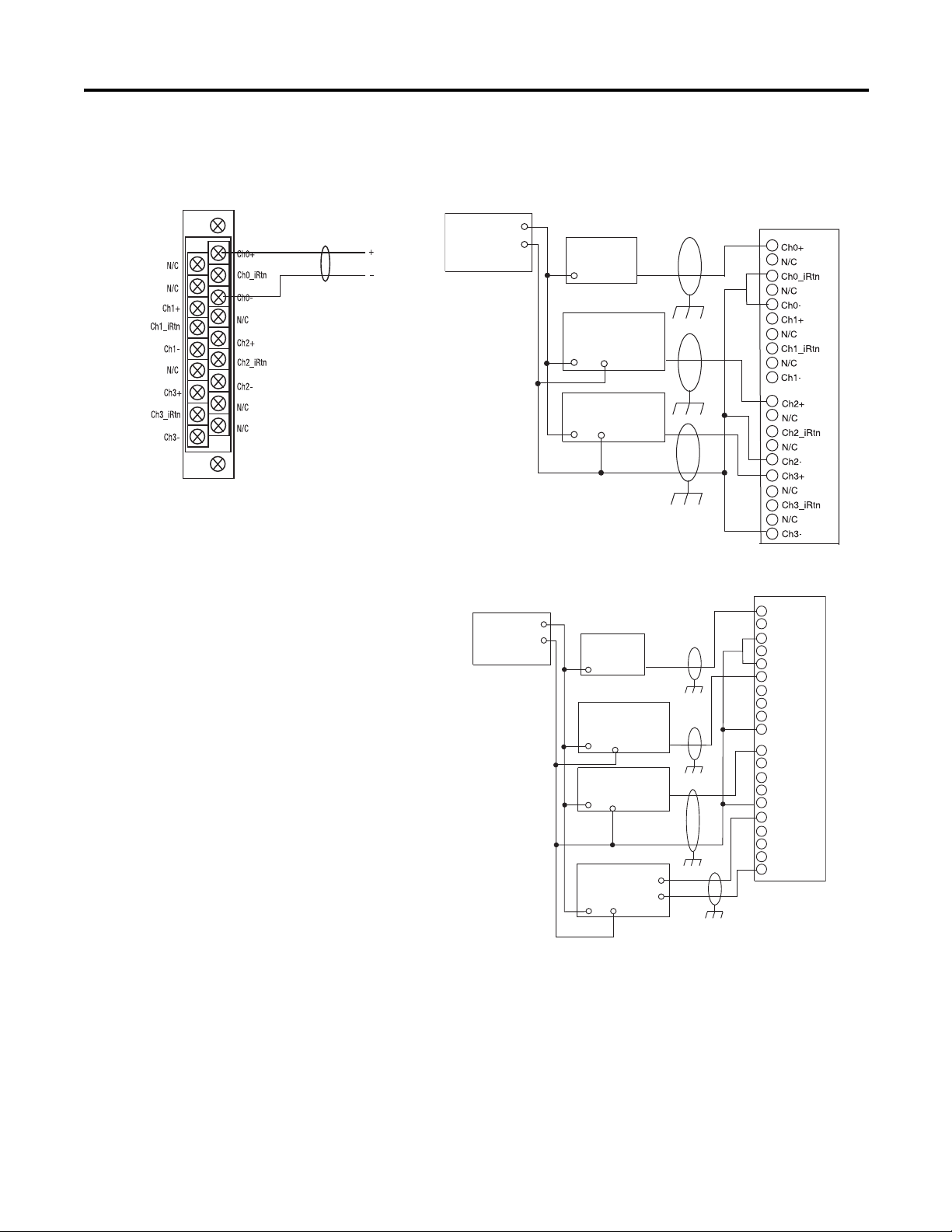

Page 23

Module Wiring Chapter 2

1769-IF4I Single-ended Sensor/Transmitter Inputs

+

+

+

+

-

Analog Source

Belden 8761 Cable (or equivalent)

Sensor/

Tr an sm it te r

Supply

Current

Voltage

Voltage

Sensor/

Transmitter

Supply

Differential

Voltage

Signal

Signal

Ground

Signal

Ground

Signal

Signal

Signal

Signal

Ground

Ground

Current

Voltage

Voltage

1769-IF4I

1769-IF4I Differential Inputs

Compact voltage/current analog, individually-isolated input module

1769-IF4I Mixed Transmitter Inputs

+

-

+

+

+

+

Ch0+

N/C

Ch0_iRtn

N/C

Ch0Ch1+

N/C

Ch1_iRtn

N/C

Ch1-

Ch2+

N/C

Ch2_iRtn

N/C

Ch2Ch3+

N/C

Ch3_iRtn

N/C

+

_

Ch3-

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 23

Page 24

Chapter 2 Module Wiring

1769-IF4XOF2 Differential Inputs

+

–

V in 1+

V in 3+

V in 0+

V/I in 0-

I in 1+

I in 3+

V/I in 1 -

I in 0+

I in 2+

V in 2 +

V/I in 3 -

V/I in 2-

ANLG Com

ANLG Com

V out 1+

I out 1+

V out 0+

I out 0+

1769-IF4XOF2 Outputs

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

Earth ground the shield

locally at the module.

Belden 8761 Cable (or equivalent)

Differential

Voltage

Tra ns mi tt er

Current

Voltage

Earth Ground

Earth Ground

1769-IF4XOF2 Single-ended Sensor/Tran smitter Inputs

+

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

+

+

-

1769-IF4XOF2 Mixed Transmitter Inputs

+

+

+

+

+

–

–

–

+

+–

–

–

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

Sensor/

Tra ns mi tt er

Supply

Sensor/

Transmitter

Supply

Current

Voltage

Signal

Signal

The sensor power supply must be rated Class 2.

Single-ended

Voltage

Differential

Voltage

Differential

Current

Tw o- wi re

Current

Signal

Signal

Signal

Signal

1769-IF4XOF2

Compact combination input/output analog module

24 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 25

Module Wiring Chapter 2

Earth ground the shield

locally at the module.

Belden 8761 Cable (or equivalent)

Differential

Voltage

Transmitter

Differential

Current

Transmitter

Earth ground the shield

locally at the module.

The sensor power supply must be rated Class 2.

Simplified Input Circuit Diagram

Simplified Output Circuit Diagram

1769-IF4FXOF2F Single-ended Sensor/Tran smitter Inputs

+

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

+

+

-

Sensor/

Tra ns mi tt er

Supply

Sensor/

Transmitter

Supply

Current

Voltage

Signal

Signal

The sensor power supply must be rated Class 2.

Single-ended

Voltage

Differential

Voltage

Differential

Current

Tw o- wi re

Current

Signal

Signal

Signal

Signal

1769-IF4FXOF2F

Compact combination fast input/output analog module

1769-IF4FXOF2F Differential Inputs

V in 1+

V/I in 1 -

I in 1+

V in 3+

V/I in 3 -

I in 3+

ANLG Com

V out 1+

I out 1+

V in 0+

V/I in 0-

I in 0+

V in 2 +

V/I in 2-

I in 2+

ANLG Com

V out 0+

I out 0+

+

–

+

–

1769-IF4FXOF2F Mixed Transmitter Inputs

V in 0+

+

–

+

–

+–

+

–

–

+

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 25

+

+

–

I in 0+

V/I in 0 V in 1+

I in 1+

V/I in 1-

V in 2+

I in 2+

V/I in 2-

V in 3+

I in 3+

V/I in 3-

ANLG Com

ANLG Com

V out 0+

I out 0+

V out 1+

I out 1 +

Page 26

Chapter 2 Module Wiring

1769-IF4FXOF2F Outputs

V in 0+

V/I in 0 -

I in 0+

V in 1+

V/I in 1-

I in 1+

V in 2+

V/I in 2-

I in 2+

ANLG Com

ANLG Com

V in 3+

I out 0+

V out 0+

I out 1 +

V out 1+

V/I in 3-

I in 3+

Current

Voltage

Earth Ground

Earth Ground

26 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 27

Module Wiring Chapter 2

+

–

–

The sensor power supply must be rated Class 2.

Analog SourceBelden 8761 Cable (or equivalent)

Earth ground the shield

locally at the module.

Sensor/

Transmitter

Supply

Current

Voltage

Voltage

Signal

Signal

Ground

Signal

Ground

Wiring for channels 4…7 are identical.

1769-IF8

V/I in 0-

ANLG Com

V/I in 1-

ANLG Com

V/I in 2-

ANLG Com

V/I in 3-

ANLG Com

1769-IF8 Differential Inputs

V in 0+

I in 0+

V in 1+

I in 1+

V in 2+

I in 2+

V in 3+

I in 3+

NC

NC

1769-IF8 Single-ended Sensor/Transmitter Inputs

+

-

+

+

+

Compact voltage/current analog input module

+

V/I in 4-

ANLG Com

V/I in 5-

ANLG Com

V/I in 6-

ANLG Com

V/I in 7-

ANLG Com

NC

V

V/I

I

ANLGC

V

V/I

I

ANLGC

V

V/I

I

ANLGC

V

V/I

I

ANLGC

NC

NC

V in 4+

I in 4+

V in 5+

I in 5+

V in 6+

I in 6+

V in 7+

I in 7+

NC

in

0

+

in

0

-

in

0

+

o

m

in

1

+

in

1

-

in

1

+

o

m

in

2

+

in

2

-

in

2

+

o

m

in

3

+

in

3

-

in

3

+

o

m

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 27

Page 28

Chapter 2 Module Wiring

1769-IF8 Mixed Transmitter Inputs

+

V in 0 +

V/I in 0 -

I in 0 +

ANLG Com

V in 1 +

V/I in 1 -

I in 1 +

ANLG Com

V in 2 +

V/I in 2 -

I in 2 +

ANLG Com

V in 3 +

V/I in 3 -

I in 3 +

ANLG Com

NC

NC

+

+

+

+

+

+

–

–

–

–

–

–

Sensor/

Transmitter

Supply

Single-ended

Voltag e

Differential

Voltage

Differential

Current

2-wire

Current

Signal

Signal

Signal

Signal

The sensor power supply must be rated Class 2.

Wiring for channels 4…7 are identical.

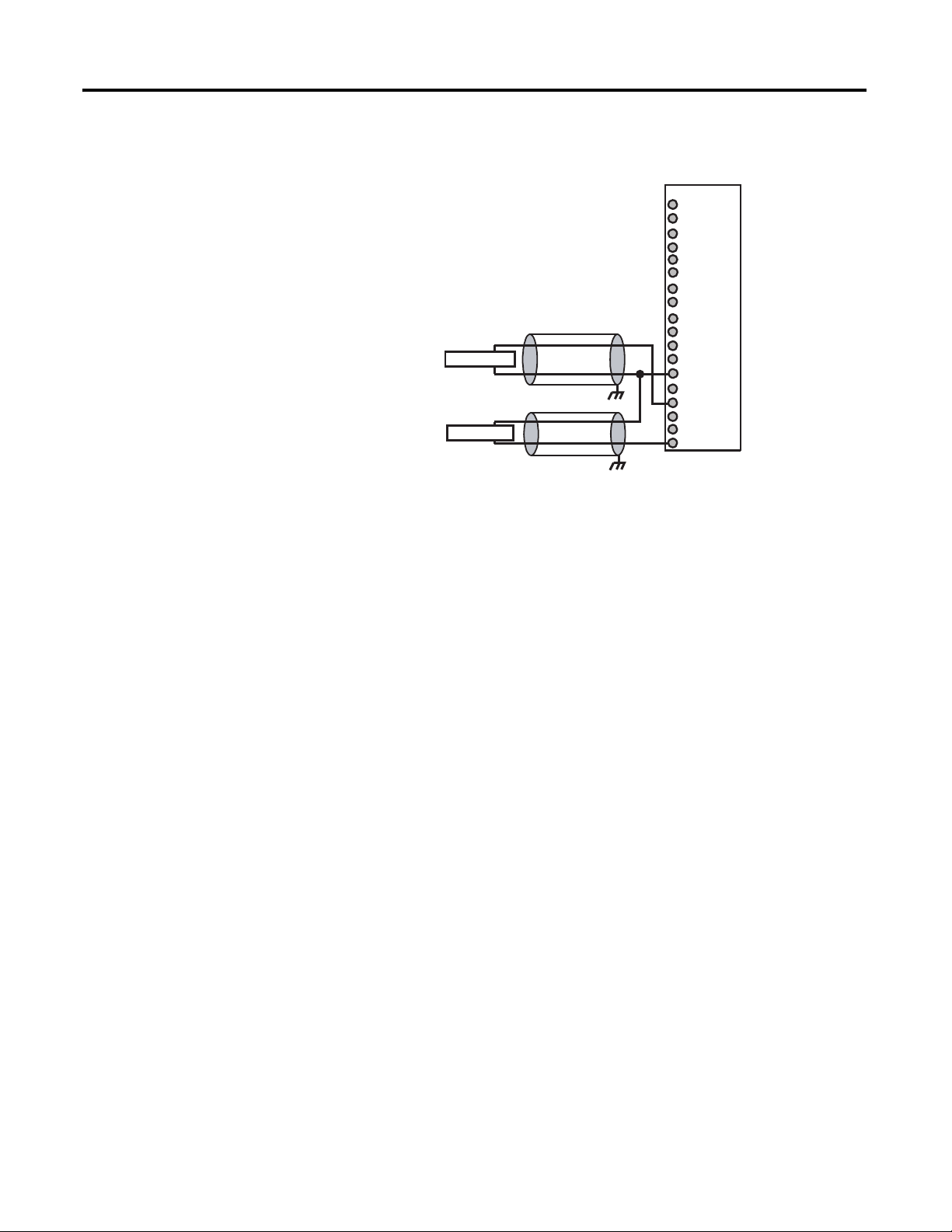

1769-IF16C Sensor/Transmittor Inputs

+

IN1+

IN0+

IN3+

IN2+

IN5+

IN4+

IN7+

IN8+

IN6+

IN9+

IN11+

IN10+

IN12+

IN13+

IN15+

IN14+

Com

Com

+

+

-

10 M

IN+

COM

0.1 μF

200

249

20 K

+

-

20 K

V

LOCALVLOCALVLOCAL

V

LOCAL

Gain A/D

M

u

l

t

i

p

l

e

x

e

r

The sensor power supply must be rated Class 2.

Sensor/

Transmitter

Supply

Current

Current

Signal

Signal

Ground

Simplified Input Circuit Diagram

1769-IF16C

28 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Compact current analog input module

Page 29

Module Wiring Chapter 2

1769-IF16V Sensor/Transmittor Inputs

+

IN1+

IN0+

IN3+

IN2+

IN5+

IN4+

IN7+

IN8+

IN6+

IN9+

IN11+

IN10+

IN12+

IN13+

IN15+

IN14+

Com

Com

+

+

-

The sensor power supply must be rated Class 2.

Sensor/

Transmitter

Supply

Voltage

Voltage

Signal

Signal

Ground

Simplified Input Circuit Diagram

Simplified Input Circuit Diagram

· Use Belden 8761, or equivalent, shielded wire.

· Do not connect more than 2 wires to any single terminal.

· DC power cable and I/O cables should not exceed 10 m (30 ft).

· The capacitors shown above must be 0.01 µF and rated for 2000V min.

· User power supply must be rated Class 2 with a 5V DC range of

4.5…5.5V DC.

1769-IF16V

V

LOCAL

10 M

IN+

COM

200

20 K

0.1 μF

+

-

20 K

Compact voltage analog input module

V

LOCALVLOCALVLOCAL

M

u

Gain A/D

l

t

i

p

l

e

x

e

r

1769-IG16

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 29

Compact TTL input module

Page 30

Chapter 2 Module Wiring

IN 7

IN 5

IN 3

IN 1

AC

COM

IN 6

IN 4

IN 2

IN 0

L1

L2

200/240V AC

NC

NC

IN 10

IN 8

AC

COM

NC

NC

IN 11

IN 9

Commons are

connected internally.

1769-IM12

Do not use the NC terminals as a connection.

IN 7

IN 5

IN 3

DC

COM 1

IN 6

IN 4

+DC (sinking)

-DC (sourcing)

-DC (sinki ng)

+DC (sourcing)

+DC (si nki ng)

-DC (sourcing)

-DC (si nking)

+DC (so urci ng)

24V DC

IN 12

IN 14

IN 10

IN 8

IN 15

DC

COM 2

IN 13

IN 11

IN 9

24V DC

IN 1

IN 2

IN 0

1769-IQ16

1769-IM12

1769-IQ16

Compact 240V AC input module

Compact 24V DC sink/source input module

30 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 31

Module Wiring Chapter 2

IN 7

IN 5

IN 3

DC

COM 1

IN 6

IN 4

+

DC (si nkin g)

-

DC (sourcing)

-

DC (si nkin g)

+

DC (sourcing)

+DC (sinking

)

-DC (sourcin

g)

-DC (si nking

)

+DC (sourcin

g)

24V DC

IN 12

IN 14

IN 10

IN 8

IN 15

DC

COM 2

IN 13

IN 11

IN 9

24V DC

IN 1

IN 2

IN 0

1769-IQ16F

1769-IQ16F

1769-IQ32

Compact 24V DC sink/source, high-speed input module

Compact 24V DC sink/source input module

1769-IQ32

+DC (Sinking)

– DC (Sourcing)

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

DC

COM 1

+ DC (Sinking)

– DC (Sourcing)

IN 9

24VDC

IN 11

IN 13

IN 15

DC

– DC (Sinking)

+ DC (Sourcing)

COM 2

– DC (Sinking)

+ DC (Sourcing)

IN 8

IN 10

IN 12

IN 14

24VDC

+ DC (Sinking)

– DC (Sourcing)

24VDC

– DC (Sinking)

+ DC (Sourcing)

IN 17

IN 19

IN 21

IN 23

IN 16

IN 18

IN 20

IN 22

DC

COM 3

IN 25

IN 27

IN 29

IN 31

DC

COM 4

+DC (Sinking)

– DC (Sourcing)

– DC (Sinking)

+ DC (Sourcing)

IN 24

IN 26

IN 28

IN 30

24VDC

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 31

Page 32

Chapter 2 Module Wiring

1769-IQ32T

1769-IQ32T

Compact 24V DC sink/source, terminated input module

32 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 33

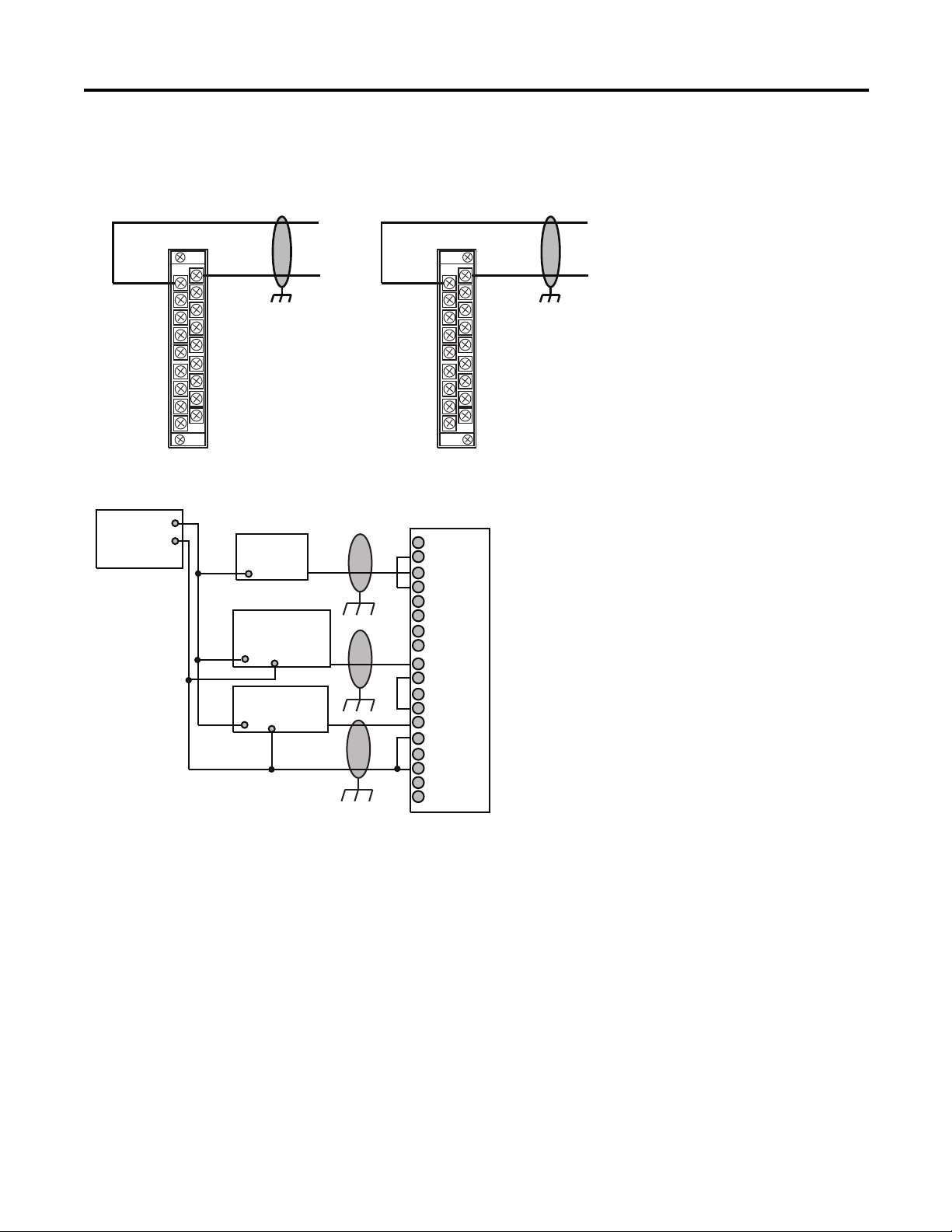

Module Wiring Chapter 2

3K

Vcc

IN

DC COM

536

0.1

μF

+24V

VAC-VDC

OUT

Simplified Input Circuit Diagram

Simplified Output Circuit Diagram

1769-IQ6XOW4

Compact combination 24V DC sink/source input and AC/DC relay output

module

1769-IQ6XOW4

+DC (sinking)

-DC (sourcing)

-DC (sinking)

+DC (sourcing)

24V DC

VAC

OUT 0

OUT 2

NC

NC

NC

IN 0

IN 2

IN 4

DC

COM

VDC

OUT 1

OUT 3

NC

NC

NC

IN 1

IN 3

IN 5

CR

CR

CR

CR

L1 or +DC

L2 or -DC

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 33

Page 34

Chapter 2 Module Wiring

EXC 3

SENSE 3

RTN 3

EXC 4

EXC 3

SENSE 3

RTN 3

EXC 4

EXC 3

SENSE 3

RTN 3

EXC 4

Two-wire RTD Configuration

Three-wire RTD Configuration

Add Jumper

Cable Shield (to Ground)

Return

RTD EXC

Return

RTD EXC

Belden 9501 Shielded Cable

Cable Shield (to Ground)

Sense

RTD EXC

Sense

RTD EXC

Belden 83503 or 9533 Shielded Cable

Return Return

Four-wire RTD Configuration

Cable Shield (to Ground)

Sense

RTD EXC

Sense

RTD EXC

Belden 83503 or 9533 Shielded Cable

Leave one sensor wire open.

Return Return

1769-IR6

Compact RTD/resistance input module

34 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 35

EXC 3

EXC 3

SENSE 3

RTN 3

EXC 3

SENSE 3

RTN 3

Two-wire Potentiometer Configuration

Three-wire Potentiometer Configuration

Add Jumper

Cable Shield (to Ground)

Return

RTD EXC

Belden 9501 Shielded Cable

Run RTD EXC and sense wires from the module to

potentiometer terminal and tie terminal to one point.

Sense

RTD EXC

Belden 83503 or 9533 Shielded Cable

Return

Potentiometer

Potentiometer

Return

RTD EXC

Belden 9501 Shielded Cable

Cable Shield (to Ground)

Add Jumper

Potentiometer

Potentiometer

Belden 83503 or 9533 Shielded Cable

Sense

RTD EXC

Return

Cable Shield (to Ground)

Cable Shield (to Ground)

Run RTD EXC and sense wires from the module to

potentiometer terminal and tie terminal to one point.

SENSE 3

Module Wiring Chapter 2

RTN 3

EXC 3

SENSE 3

RTN 3

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 35

Page 36

Chapter 2 Module Wiring

NC

IN 0+

IN 0-

IN 3+

IN 1 +

IN 3-

IN 1-

IN 4+

IN 2+

IN 4-

IN 2-

IN 5+

IN 5-

NC

+

-

+

-

+

-

CJC 0+

CJC 0-

CJC 1-

CJC 1+

CJC Sensor

Ungrounded

Thermocouple

CJC Sensor

Grounded Thermocouple

Grounded Thermocouple

Within 10V DC

Z

OUT

VAC

470V

27

0.015μF

51

Vcc

150

Simplified Output Circuit Diagram

1769-IT6

1769-OA8

Compact Thermocouple/mV input module

Compact 100/240V AC solid state output module

1769-OA8

L1

100 to 240V AC

L2

36 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

CR

CR

CR

CR

OUT0

OUT2

VAC 2

OUT4

OUT6

VAC1

OUT1

OUT3

OUT5

OUT7

CR

CR

CR

CR

L1

100 to 240V AC

L2

Page 37

Module Wiring Chapter 2

100 to 240V AC

L2

L1

L2

L1

OUT10

OUT 8

VAC 2

OUT6

OUT4

OUT11

OUT 9

OUT 7

OUT 5

OUT 3

CR

CR

CR

CR

CR

CR

CRCRCR

CR

CR

CR

CR

CR

100 to 240V

AC

VAC 1

OUT 1

OUT 0

OUT 2

CR

CR

CRCRCR

CRCRCR

OUT 12

OUT 14

OUT 13

OUT 15

1769-OA16

Simplified Output Circuit Diagram

DC+

DC-

OUT 6

OUT 4

NC

NC

NC

OUT 2

OUT 0

OUT 7

OUT 5

+VDC 2

NC

NC

NC

OUT 3

OUT 1

+VDC 1

CR

CR

CR

CR

DC COM

2

DC COM

1

CR

CR

DC -

DC+

1769-OB8

VCC

ASIC

VDC

OUT

COM

Simplified Output Circuit Diagram

Logic Side User Side

1769-OA16

1769-OB8

Vcc

Compact 120/240V AC solid state output module

51

VAC

Z

150

27

0.015 μF

470V

OUT

Compact solid state 24V DC source, high-current output module

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 37

Page 38

Chapter 2 Module Wiring

+DC

24V D C(source)

-DC

DC COM

OUT 14

OUT 12

OUT 10

OUT 8

OUT 6

OUT 4

OUT 2

OUT 0

OUT 15

OUT 13

OUT 11

OUT 9

OUT 7

OUT 5

OUT 3

OUT 1

+VDC

CR

CR

CR

CR

CR

CR

CR

CR

CR

CR

1769-OB16

Vcc

+VDC

OUT

DC COM

0.1μF

100pF

20K

15K

10K

G

S

D

Simplified Output Circuit Diagram

+VDC

OUT

DC COM

39V

39V

Vcc

47K

100pF

6V

Voltage

Regulator

Simplified Output Circuit Diagram

Protection circuit is not shown.

1769-OB16

1769-OB16P

Compact solid state 24V DC source output module

Compact solid state 24V DC source, protected output module

1769-OB16P

38 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

CR

CR

CR

CR

OUT 2

OUT 4

OUT 6

OUT 8

OUT 10

OUT 12

OUT 14

DC COM

OUT 1

OUT 3

OUT 5

OUT 7

OUT 9

OUT 11

OUT 13

OUT 15

CR

CR

CR

CR

CR

CR

+VDC

OUT 0

+DC

24V DC

-DC

Page 39

Module Wiring Chapter 2

VCC

ASIC

VDC

OUT

COM

TR1

G

S

D

Simplified Output Circuit Diagram

Logic Side User Side

Simplified Output Circuit Diagram

Logic Side User Side

1769-OB32

Compact solid state 24V DC source output module

1769-OB32

24V DC

+DC

-DC

CR

CR

CR

CR

OUT 18

OUT 20

OUT 22

OUT 24

OUT 26

OUT 28

OUT 30

DC

COM 2

OUT 17

OUT 19

OUT 21

OUT 23

OUT 25

OUT 27

OUT 29

OUT 31

+VDC 2

OUT 16

CR

CR

CR

CR

OUT 2

OUT 4

OUT 6

OUT 8

OUT 10

OUT 12

OUT 14

DC

COM 1

OUT 1

OUT 3

OUT 5

OUT 7

OUT 9

OUT 11

OUT 13

OUT 15

CR

CR

CR

CR

CR

CR

+VDC 1

OUT 0

+DC

CR

CR

CR

24V DC

CR

CR

CR

-DC

1769-OB32T

VCC

ASIC

Compact solid state 24V DC source, terminated output module

S

G

D

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 39

TR1

VDC

OUT

COM

+VDC 1

+VDC 1

1769-OB32T

+VDC 2

+VDC 2

V DC42 V DC42

Page 40

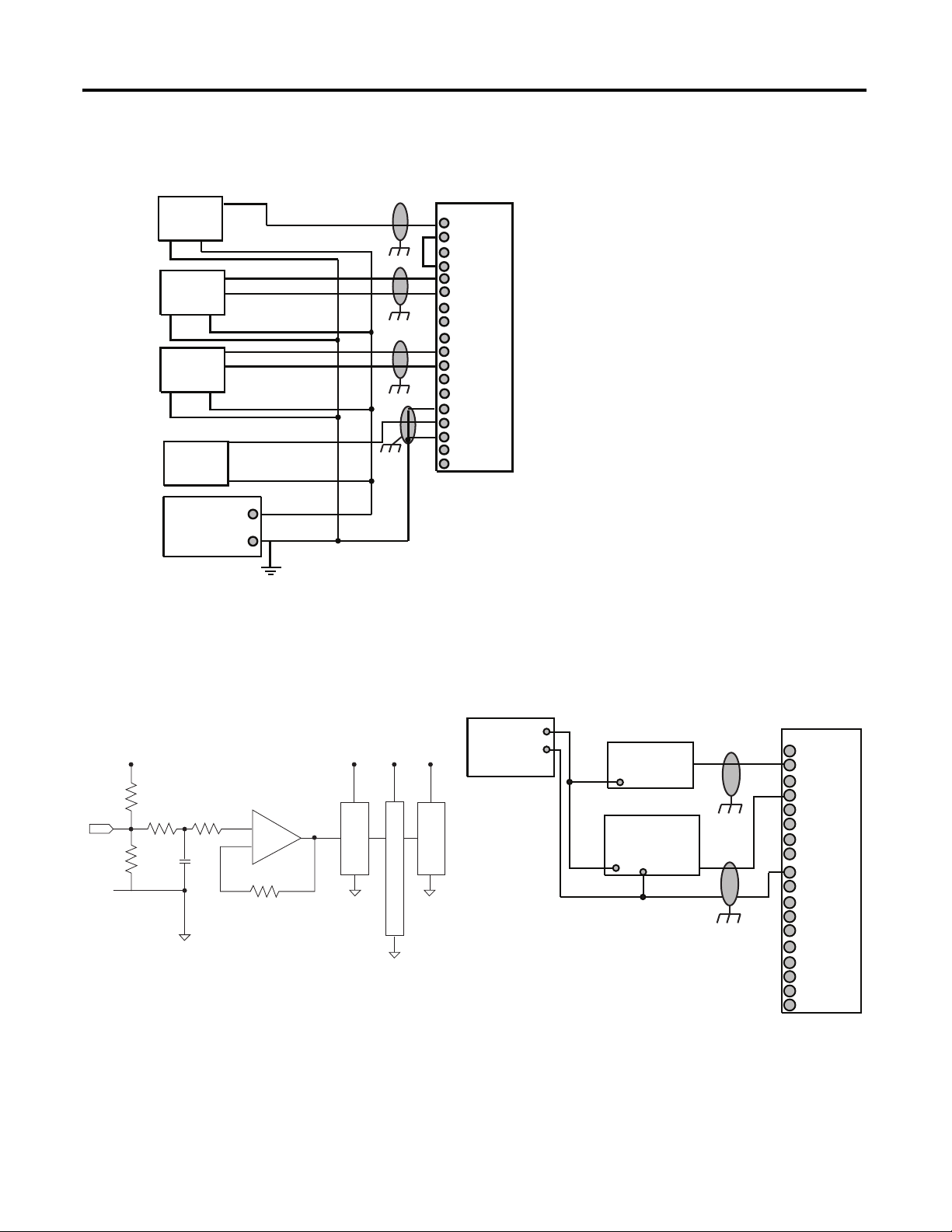

Chapter 2 Module Wiring

The external power supply must be rated Class 2, with a 24V DC

range of 20.4…26.4V DC and 60 mA minimum. Series B and

later modules support this option.

Earth Ground

External 24V DC

Power Supply

Current

Earth Ground

Voltage

V out 3+

ANLG Com

ANLG Com

I out 3+

I out 0+

V out 0+

I out 1 +

V out 1+

I out 2+

V out 2+

16-pin Backplane Connector

ASIC

Indicator

Isolated

DC to DC

Converter

Optocouplers

CPU

D to A

Converter

Voltage

Output

Current

Output

18-pin Terminal Block

+15V

+5V

-15V

GND

Isolation

Voltage Load

Current Load

Earth Ground

Earth Ground

Simplified Schematic

1769-OF2

1769-OF4

Compact voltage/current output analog module

1769-OF2

V out 0 +

I out 0 +

ANLG Com

NC

V out 1 +

I out 1 +

ANLG Com

NC

+

-

+24V DC

DC NEUT

Compact voltage/current output analog module

40 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 41

Module Wiring Chapter 2

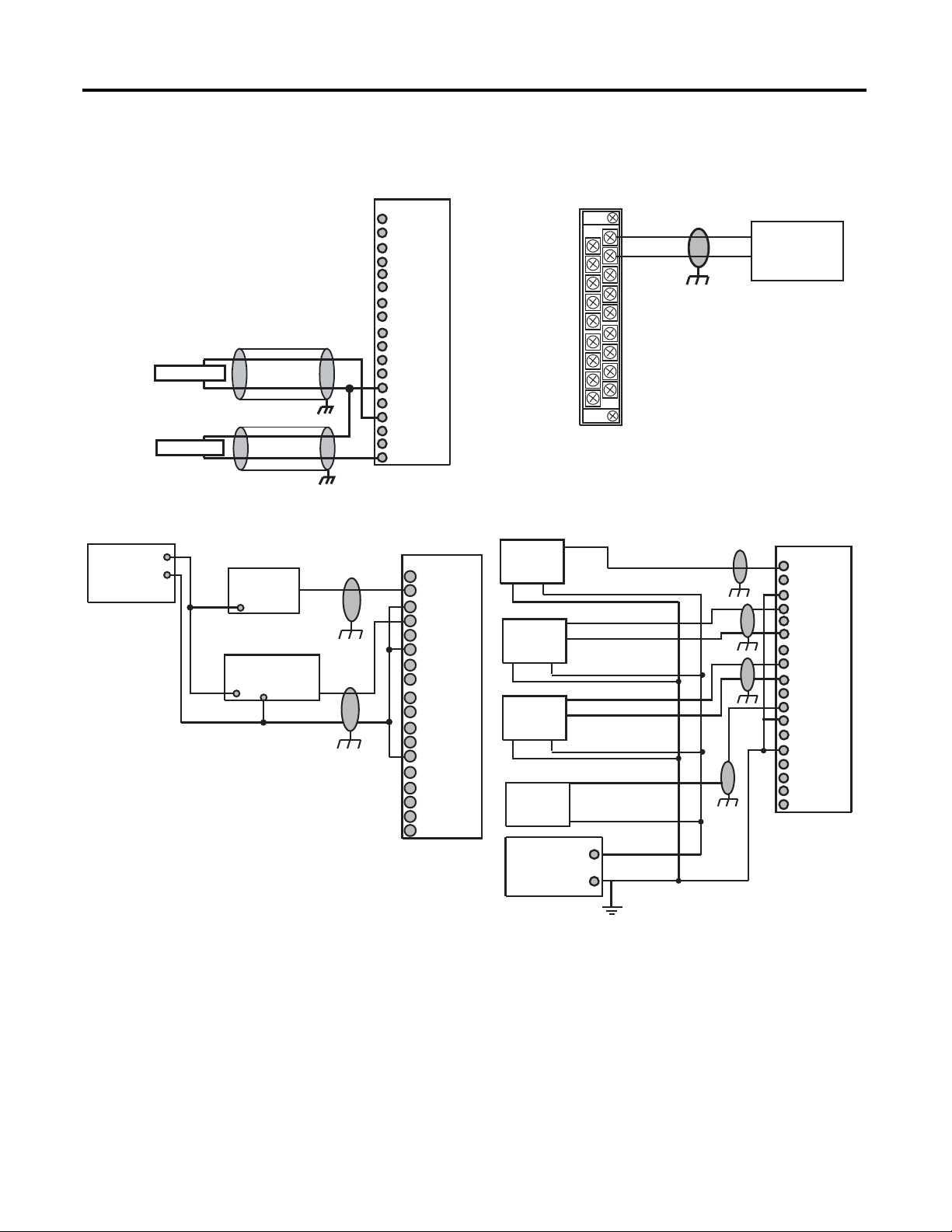

1769-OF4CI

Current

Earth Ground

1769-OF4VI

Earth Ground

Voltage

1769-OF4CI

Compact current output, individually isolated analog module

1769-OF4VI

Compact voltage output, individually isolated analog module

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 41

Page 42

Chapter 2 Module Wiring

Current

Earth Ground

The external power supply must be rated Class 2, with a 24V DC range of 20.4…6.4V DC

and 60 mA minimum. Series B and later modules support this option.

External 24V DC Power

Supply (optional)

1769-OF8C

Compact current output analog module

I out 0+

I out 1+

I out 2+

I out 3+

I out 4+

+

-

I out 5+

I out 6+

I out 7+

+24V DC

1769-OF8C

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

DC NEUT

42 Rockwell Automation Publication 1769-IN088A-EN-P - February 2011

Page 43

Module Wiring Chapter 2

Voltage

Earth Ground

The external power supply must be rated Class 2, with a 24V DC range of 20.4…6.4V DC

and 60 mA minimum. Series B and later modules support this option.

External 24V DC Power

Supply (optional)

1769-OF8V

Compact voltage output analog module

V out 0+

V out 1+

V out 2+

V out 3+

V out 4+

+

-

V out 5+

V out 6+

V out 7+

+24V DC

1769-OF8V

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

ANLG Com

DC NEUT

Rockwell Automation Publication 1769-IN088A-EN-P - February 2011 43

Page 44

Chapter 2 Module Wiring

Simplified Output Circuit Diagram

· Use Belden 8761, or equivalent, shielded wire.