Page 1

Pico Controllers

Bulletin 1760

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

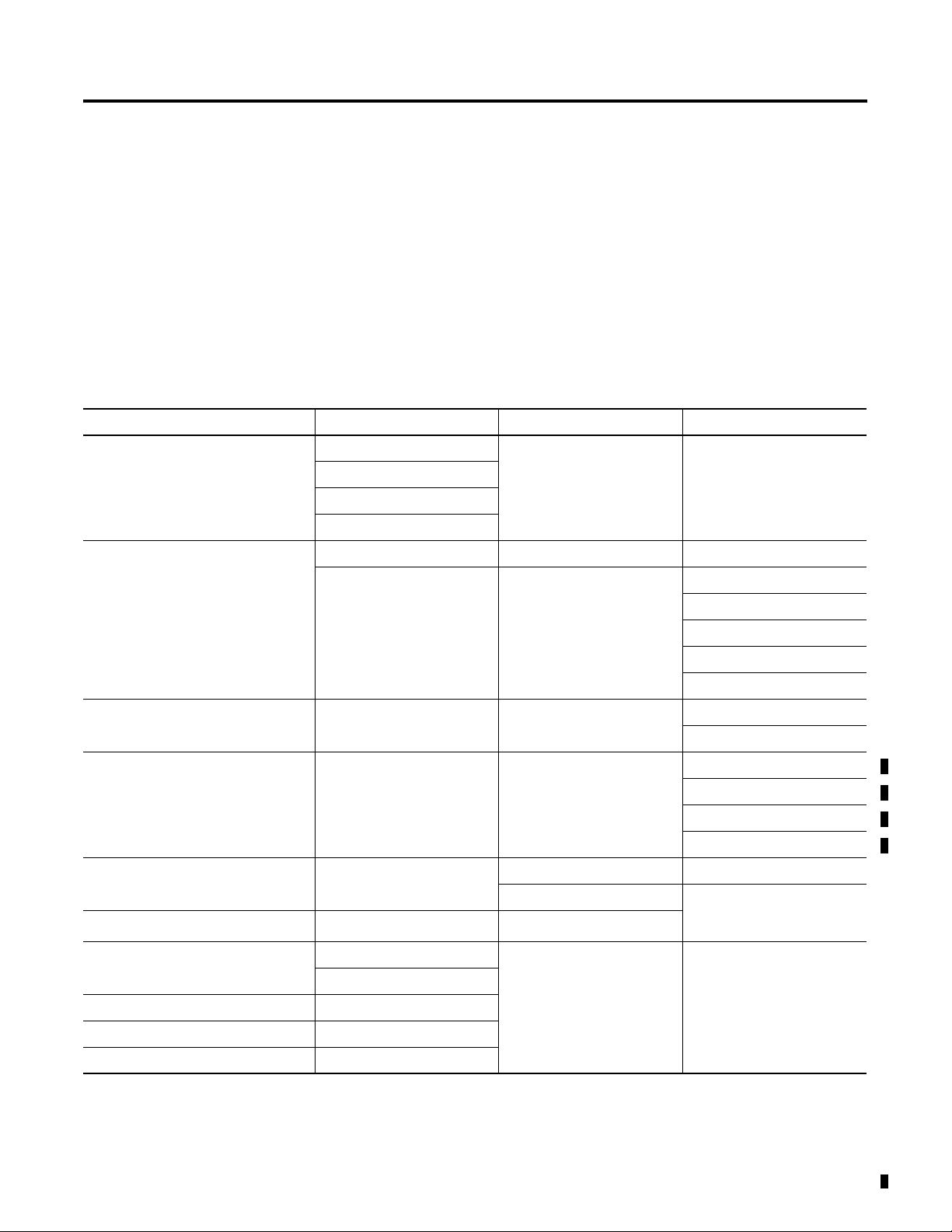

Summary of Changes

The information below summarizes the changes to this manual since

the last printing as publication 1760-UM001C-EN-P, April 2005.

To help you locate new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

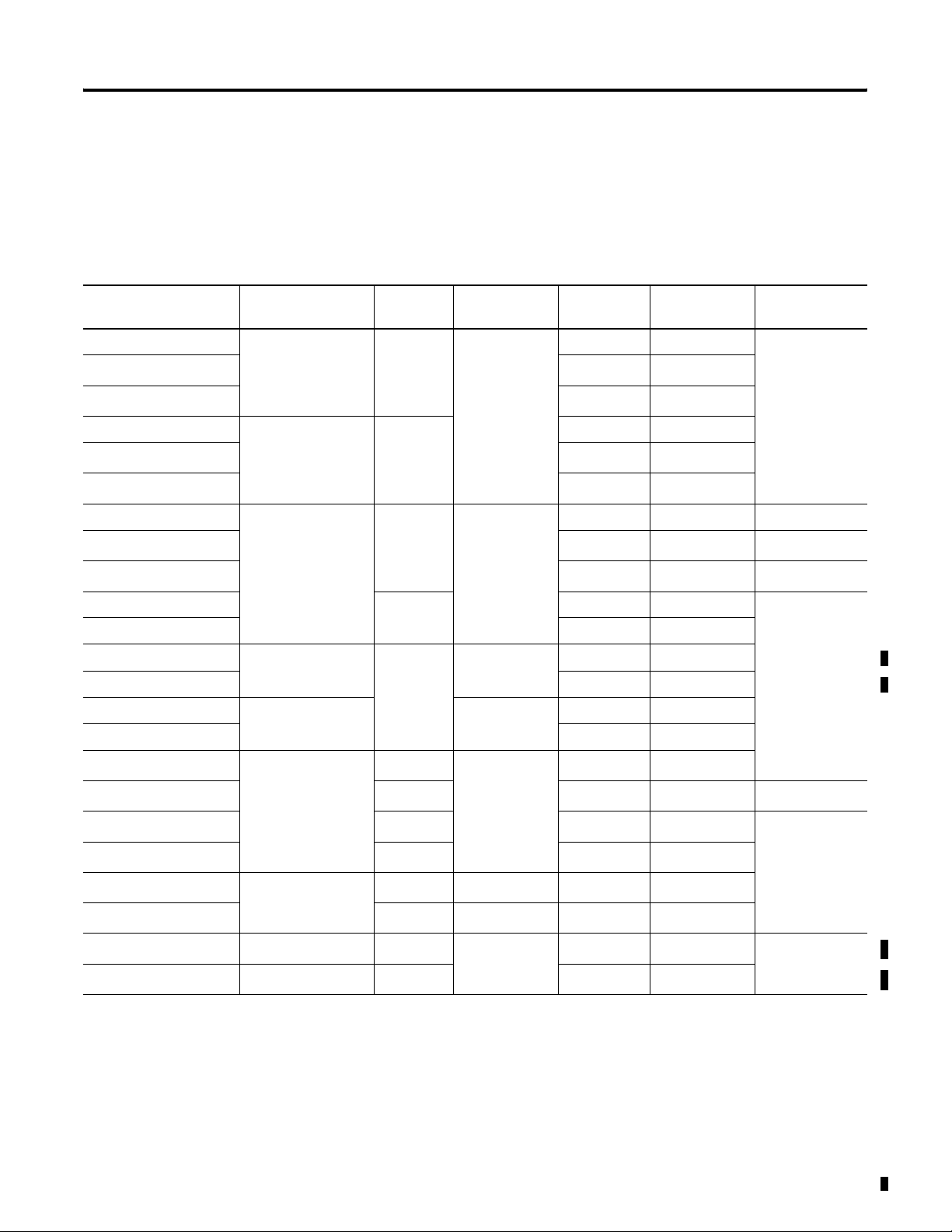

Catalog Number Release

The following table shows the history of Pico catalog numbers.

History

Description Released June 2000 Release August 2001 Release March 2005

120/240V ac Pico 1760-L12AWA 1760-L18AWA-EX 1760-L18AWA-EXND

1760-L12AWA-NC

1760-L12AWA-ND

1760-L18AWA

24V dc Pico 1760-L12BWB 1760-L12BWB-ND 1760-L12BBB

1760-L12BWB-NC 1760-L18BWB-EX 1760-L12BBB-ND

1760-L18BWB-EXND

1760-L18DWD-EX

1760-L20BBB-EX

1760-L20BBB-EXND

12V dc Pico 1760-L12DWD 1760-L18DWD-EXND

1760-L12DWD-ND

24V ac Pico 1760-L12NWN

1760-L12NWN-ND

1760-L18NWN-EX

1760-L18NWN-EXND

Expansion Modules 1760-IA12XOW6I 1760-IA12XOW4I

1760-IB12XOB8 1760-IB12XOW6I

Expansion Module Connector

Memory Modules 1760-MM1 1760-MM2B

Input/Output Simulator 1760-SIM

Programming Software 1760-PICOSOFT

Programming Cable 1760-CBL-PM02

(1) Included with expansion module. Catalog Number is listed as a replacement part.

1 Publication 1760-UM001D-EN-P - September 2005

(1)

1760-MM2

1760-RPLCONN

Page 4

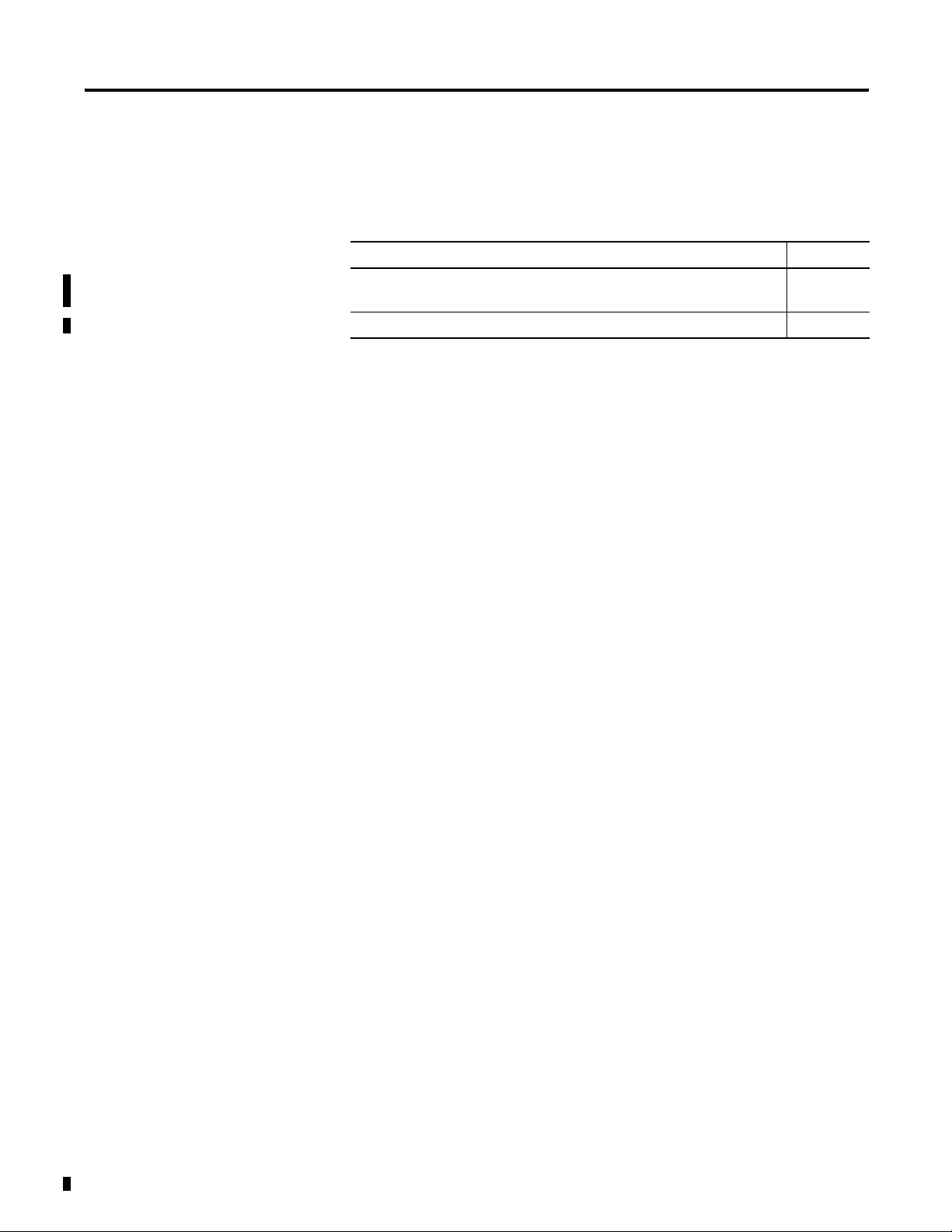

Summary of Changes 2

New Information

The table below lists sections where new information has been added.

For This New Information See

Changed Catalog Number 1760-L12NWA and 1760-L18NWA to

1760-L12NWN and 1760-L18NWN.

Changed inputs to 24V ac. page A-5

Throughout

manual

Publication 1760-UM001D-EN-P - September 2005

Page 5

Table of Contents

Preface

System Overview

Installation

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . Preface-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . Preface-1

Common Techniques Used in this Manual . . . . . . . . . Preface-2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . Preface-3

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

Prevent Electrical Shock . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

European Communities (EC) Directive Compliance . . . . . . 2-2

Connect the Expansion Module . . . . . . . . . . . . . . . . . . . . . 2-3

Mount the Pico Controller . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Install the Remote Processor . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wire Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Connect the Incoming Power . . . . . . . . . . . . . . . . . . . . . . 2-9

Use Surge Suppressors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Connect the Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Connect Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Connect Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Connect Transistor Outputs . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Commission the Pico

Draw a Circuit Diagram with Pico

Chapter 3

Power On Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Set the Menu Language . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Create a Circuit Diagram (Program) . . . . . . . . . . . . . . . . . . 3-4

Chapter 4

Pico Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Work with Contacts and Relays . . . . . . . . . . . . . . . . . . . . . 4-8

Function Relay Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Example with Timing and Counter Relays . . . . . . . . . . . . . 4-21

Timing Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Counter Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

High Speed Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Time Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Analog Comparators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Text Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Jumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Example Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

i Publication 1760-UM001D-EN-P - September 2005

Page 6

Table of Contents ii

Save and Load Circuit Diagrams

Pico System Settings

Chapter 5

Interface to Memory Module and Programming Cable . . . . 5-1

Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

PicoSoft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Chapter 6

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Change the Menu Language . . . . . . . . . . . . . . . . . . . . . . . 6-6

Change Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Set Date, Time, and Daylight Saving Time . . . . . . . . . . . . . 6-9

Change Between Winter/Summer Time

(Daylight Saving Time) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Activate Debounce (Input Delay). . . . . . . . . . . . . . . . . . . . 6-10

Activate and Deactivate P-Buttons . . . . . . . . . . . . . . . . . . . 6-11

Start-Up Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Set Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Display Device Information . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Retention

Inside Pico

Use of Expansion Modules

Troubleshoot Your Controller

Chapter 7

What is Retention?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Set Retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Delete Retentive Actual Values . . . . . . . . . . . . . . . . . . . . . 7-2

Transfer Retentive Behavior. . . . . . . . . . . . . . . . . . . . . . . . 7-3

Retentive Auxiliary Relays (Markers) . . . . . . . . . . . . . . . . . 7-4

Retentive Timing Relays . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Retentive Up/Down Counters C7 and C8 . . . . . . . . . . . . . . 7-14

Chapter 8

Circuit Diagram Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Determine Cycle Time of Circuit Diagrams. . . . . . . . . . . . . 8-3

Delay Times for Inputs and Outputs . . . . . . . . . . . . . . . . . 8-7

Chapter 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Module Status Example . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Chapter 10

Messages from the Pico System . . . . . . . . . . . . . . . . . . . . . 10-1

Possible Situations When Creating Circuit Diagrams . . . . . . 10-2

Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Publication 1760-UM001D-EN-P - September 2005

Page 7

DC Simulator

Specifications

Circuit Diagram Form

Table of Contents iii

Chapter 11

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Appendix A

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Appendix B

Glossary

Index

Publication 1760-UM001D-EN-P - September 2005

Page 8

Table of Contents iv

Publication 1760-UM001D-EN-P - September 2005

Page 9

Preface

Read this preface to familiarize yourself with the rest of the manual. It

provides information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

• Rockwell Automation support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use Pico

controllers.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

This manual is a reference guide for Pico controllers. It describes the

procedures you use to install, wire, and troubleshoot Pico.

Refer to publication 1760-GR001, Pico Controller Getting Results

Manual for a basic overview of Pico and an introduction to Pico

programming.

1 Publication 1760-UM001D-EN-P - September 2005

Page 10

Preface 2

Related Documentation

The following documents contain additional information concerning

Rockwell Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

For Read this Document Document Number

A basic overview of Pico and an introduction to Pico programming. Pico Controller Getting Results

Manual

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired electromechanical

devices

An article on wire sizes and types for grounding electrical equipment National Electrical Code - Published by the National Fire

A complete listing of current documentation, including ordering

instructions. Also indicates whether the documents are available on

CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

Allen-Bradley Programmable

Controller Grounding and Wiring

Guidelines

Application Considerations for

Solid-State Controls

Protection Association of Boston, MA.

Allen-Bradley Publication Index SD499

Glossary

1760-GR001

1770-4.1

SGI-1.1

AG-7.1

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

Publication 1760-UM001D-EN-P - September 2005

Page 11

Preface 3

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

please review the Troubleshooting section on page 10-1 in this

manual first. Then call your local Rockwell Automation representative.

You can also find a local Rockwell Automation Technical Support

contact at:

• http://support.automation.rockwell.com/contactinformation/

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions

for how this manual could be made more useful to you, please

contact us at the address below:

Rockwell Automation

Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

or visit our internet page at:

http://www.ab.com/pico or http://www.rockwellautomation.com

Publication 1760-UM001D-EN-P - September 2005

Page 12

Preface 4

Publication 1760-UM001D-EN-P - September 2005

Page 13

System Overview

Chapter

1

Overview

Pico is an electronic control relay with built-in logic, timer, counter,

and real-time clock functions. Pico is a control and input device that

can perform a variety of tasks in building and machine applications.

Pico is programmed using ladder diagrams. Each programming

element is entered directly via the Pico display. For example, you can:

• connect make and break contacts in series and in parallel,

• connect output relays and markers,

• define outputs as relays, flip-flop relays or latching relays,

• select timing relays with different functions,

• assign eight up and down counters,

• display text with variables,

• track the flow of current in the program, and

• load, save and password-protect programs.

Most controllers also offer a real-time clock, allowing up to 32

separate on and off times.

The dc versions can receive analog signals at two inputs and evaluate

the signals with eight analog comparators.

If you prefer to program Pico from a PC, use PicoSoft programming

software. PicoSoft allows you to create and test your programs on the

PC. It also enables you to print out your programs in DIN, ANSI or

Pico format.

1 Publication 1760-UM001D-EN-P - September 2005

Page 14

1-2 System Overview

Hardware Versions

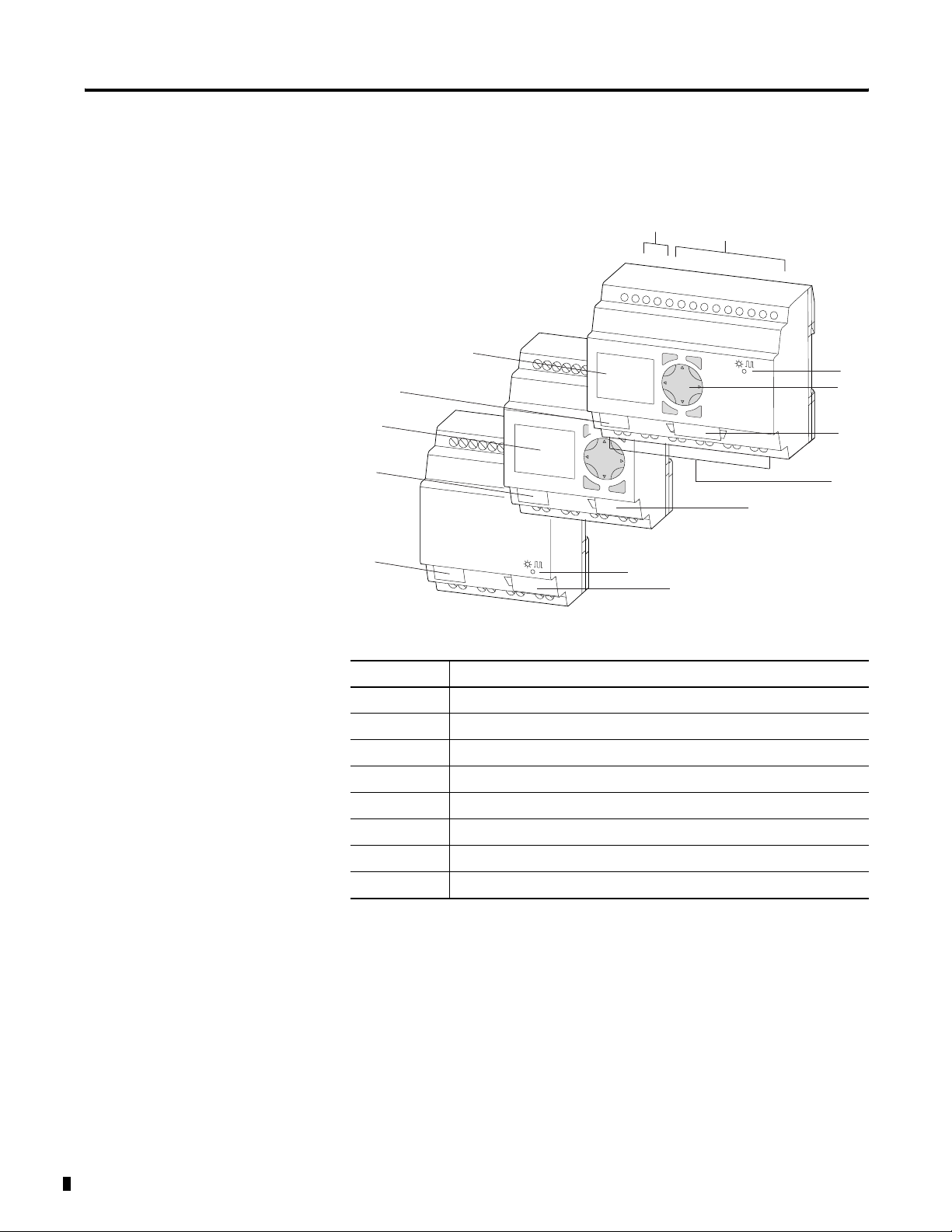

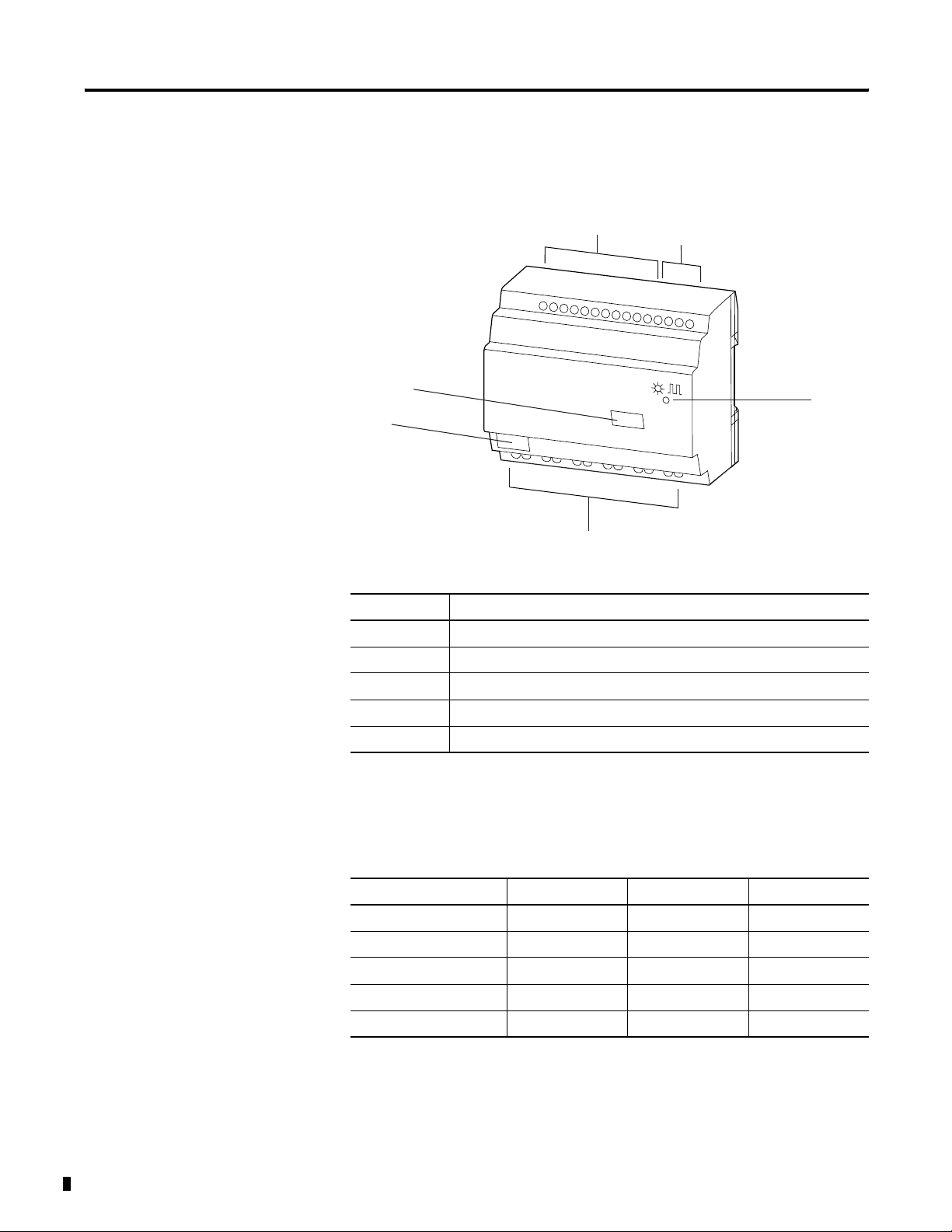

Pico Controllers

7

8

7

8

8

1

Del

2

Alt

3

4

Esc

Del

Alt

Esc

Ok

Ok

5

6

5

3

5

Item Description

1 Incoming Power

2 Inputs

3 Status LED

4 Buttons

5 Socket for memory module or PC interface cable

6 Outputs

7 LCD display

8 Write-On Surface

Publication 1760-UM001D-EN-P - September 2005

Page 15

System Overview 1-3

Pico controllers are available for 12V dc, 24V dc, 24V ac and 120/240V

ac operation and come in both 12-I/O and 18-I/O sizes. Pico is

available with and without a real-time clock, and with and without a

display and keypad. See the following table for details.

Catalog Number Inputs Outputs Line Power Real Time

Clock

Display and

Keypad

Analog

1760-L12AWA 8 (100 to 240V ac) 4 (relay) 100 to 240V ac Yes Yes No

1760-L12AWA-NC

1760-L12AWA-ND

(1)

(2)

No Yes

Yes No

1760-L18AWA 12 (100 to 240V ac) 6 (relay) Yes Yes

1760-L18AWA-EX

(3)

1760-L18AWA-EXND

(2)(3)

Yes Yes

Yes No

1760-L12BWB 8 (24V dc) 4 (relay) 24V dc Yes Yes 2 (0 to 10V dc)

1760-L12BWB-NC

1760-L12BWB-ND

(1)

(2)

No Yes

Yes No

1760-L12BBB 4 (MOSFET) Yes Yes 2 (0 to 10V dc)

1760-L12BBB-ND Yes No

1760-L12NWN 8 (24V ac) 4 (relay) 24V ac Yes Yes

1760-L12NWN-ND Yes No

1760-L12DWD 8 (12V dc) 12V dc Yes Yes

1760-L12DWD-ND Yes No

1760-L18BWB-EX

(3)

1760-L18BWB-EXND

1760-L20BBB-EX

(3)

1760-L20BBB-EXND

1760-L18DWD-EX

(3)

1760-L18DWD-EXND

1760-L18NWN-EX

(3)

1760-L18NWN-EXND

12 (24V dc) 6 (relay) 24V dc Yes Yes

(2)(3)

6 (relay) Yes No 2 (0 to 10V dc)

8 (MOSFET) Yes Yes 4 (0 to 10V dc)

(2)(3)

8 (MOSFET) Yes No

12 (12V dc) 6 (relay) 12V dc Yes Yes

(2)(3)

6 (relay) 12V dc Yes No

12 (24V ac) 6 (relay) 24V ac Yes Yes 4 (0 to 10V dc)

(2)(3)

12 (24V ac) 6 (relay) Yes No

(1) NC = no real time clock

(2) ND = no display

(3) EX = suitable for use with expansion modules

Publication 1760-UM001D-EN-P - September 2005

Page 16

1-4 System Overview

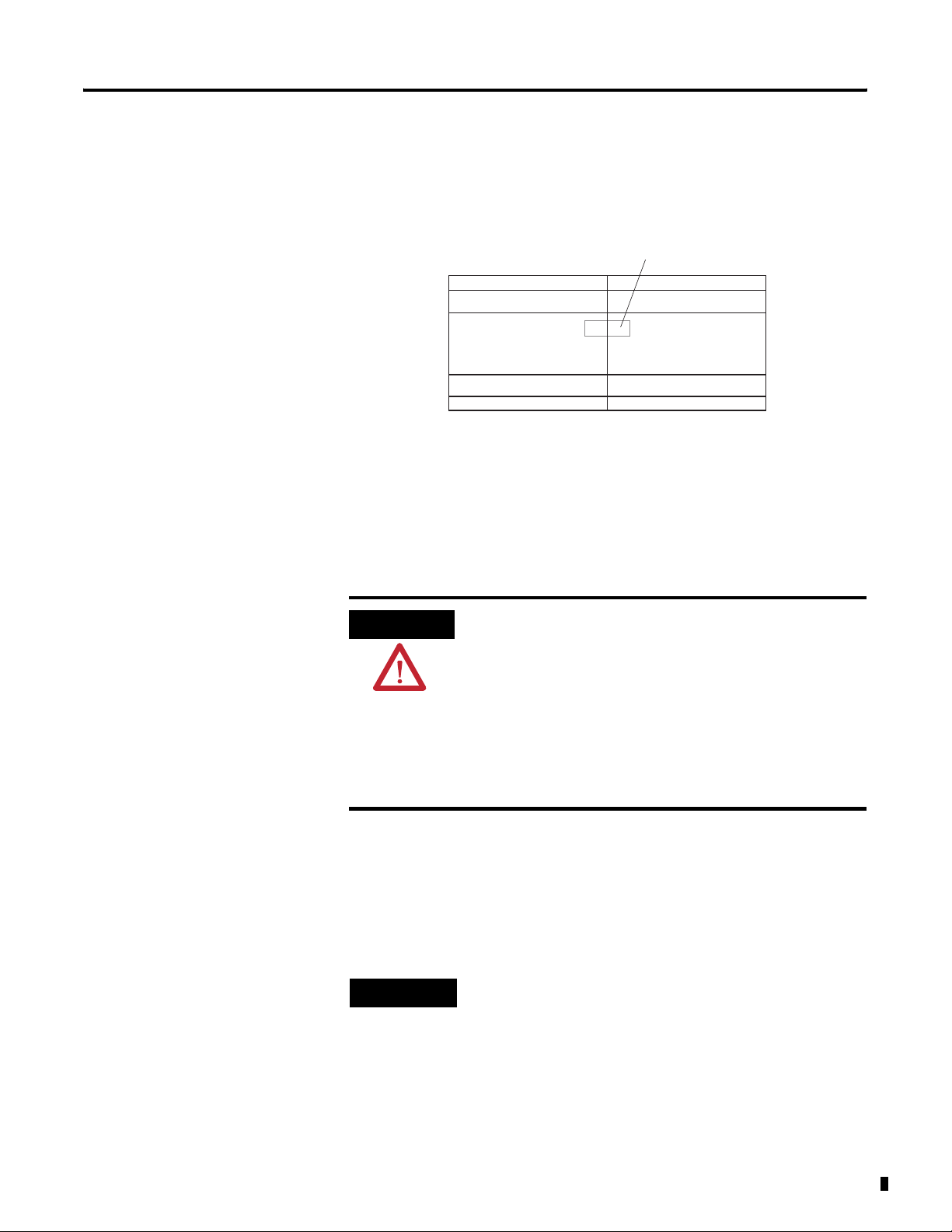

Expansion Modules

3

3

Item Description

1 Incoming Power

2 Inputs

3 Write-On Surface

2

4

1

5

4 Outputs

5 Status LED

Use Pico expansion modules with Pico ’-EX’ models to increase your

I/O capacity. The following modules are available.

Catalog Number Inputs Outputs Line Power

1760-IA12XOW6I 12 (100 to 240V ac) 6 (relay) 100 to 240V ac

1760-IA12XOW4I 12 (100 to 240V ac) 4 (relay) 100 to 240V ac

1760-IB12XOW6I 12 (24V dc) 6 (relay) 24V dc

1760-IB12XOB8 12 (24V dc) 8 (transistor) 24V dc

1760-OW2 - 2 (relay) 24V dc

Publication 1760-UM001D-EN-P - September 2005

Page 17

System Overview 1-5

Expansion modules connect directly to the Pico controller as shown

below.

ATTENTION

(1)

Pico Controller:

1760-L18AWA-EX

1760-L18BWB-EX

1760-L18AWA-EXND

1760-L18BWB-EXND

1760-L18DWD-EX

1760-L20BBB-EX

1760-L20BBB-EXND

Expansion Module Connector

(replacement part 1760-RPLCONN)

Expansion Module:

1760-IA12XOW6I

1760-IB12XOB8

1760-IA12XOW4IF

1760-IB12XOW6I

1760-OW2

(1) Included with expansion module. Catalog

Number is listed as a replacement part.

Electrical isolation is provided between the Pico

controller and the expansion module as follows:

• Basic Isolation: 400V ac (+10%)

• Reinforced Isolation 240V ac (+10%)

(1)

(2)

The controller and expansion units may be

destroyed if the potential between them exceeds the

Basic Isolation value provided. This may cause your

entire system or machine to malfunction.

(1) Basic Insulation - An insulation system which provides a minimal level of protection against electric shock up to

a stated voltage level. Refer to EN 61131-2 for additional information.

(2) Reinforced Insulation - An insulation system comprised of basic and supplemental insulation. This provides

protection against electric shock up to a stated voltage level and is tolerant of a single fault. Refer to EN

61131-2 for additional information.

TIP

The Pico controller and the expansion module can

be of different voltage types.

Publication 1760-UM001D-EN-P - September 2005

Page 18

1-6 System Overview

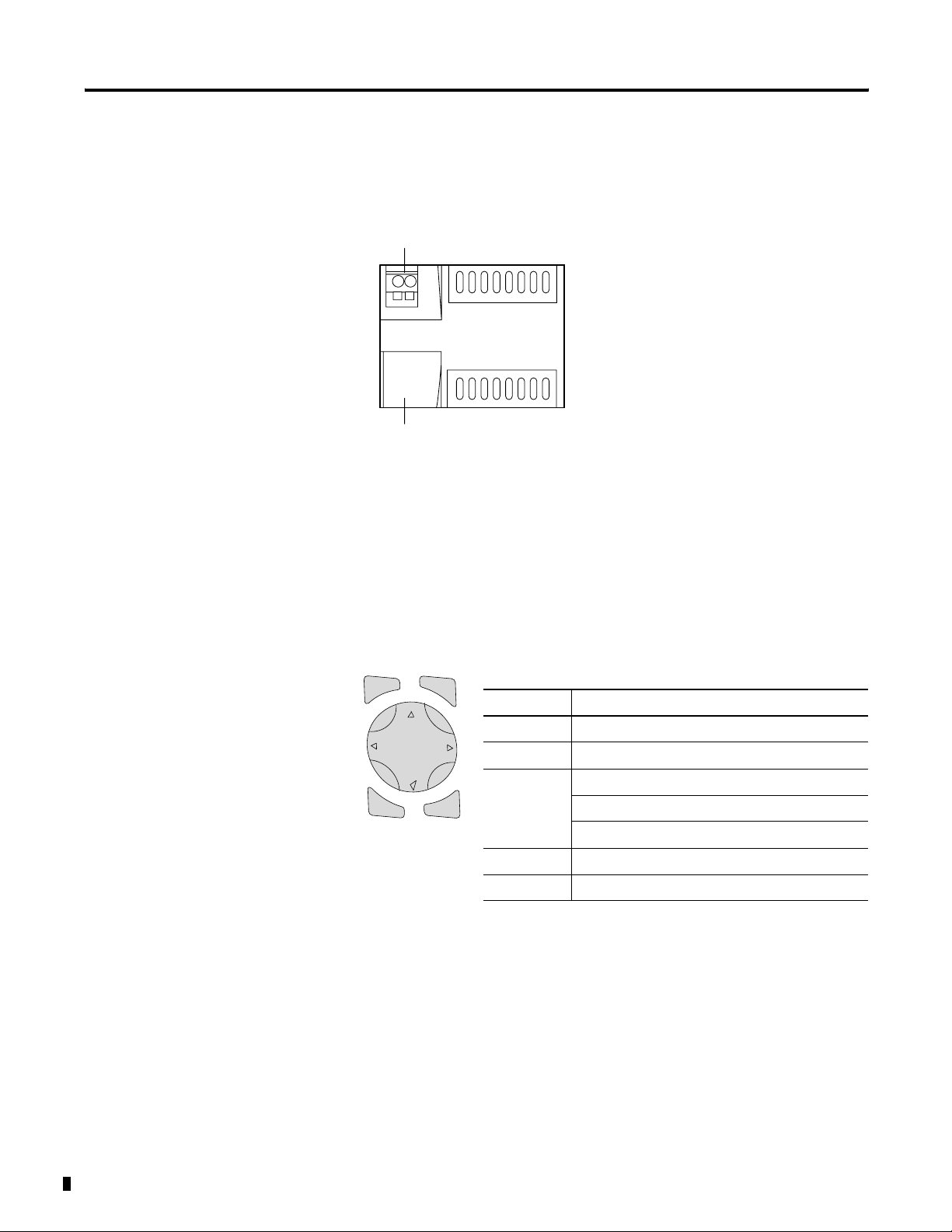

Remote Processor

Remote Processor Features

1

2

1. 24V dc Voltage supply

Operating Principles

2. Interface Terminal (with cover) for connecting cable

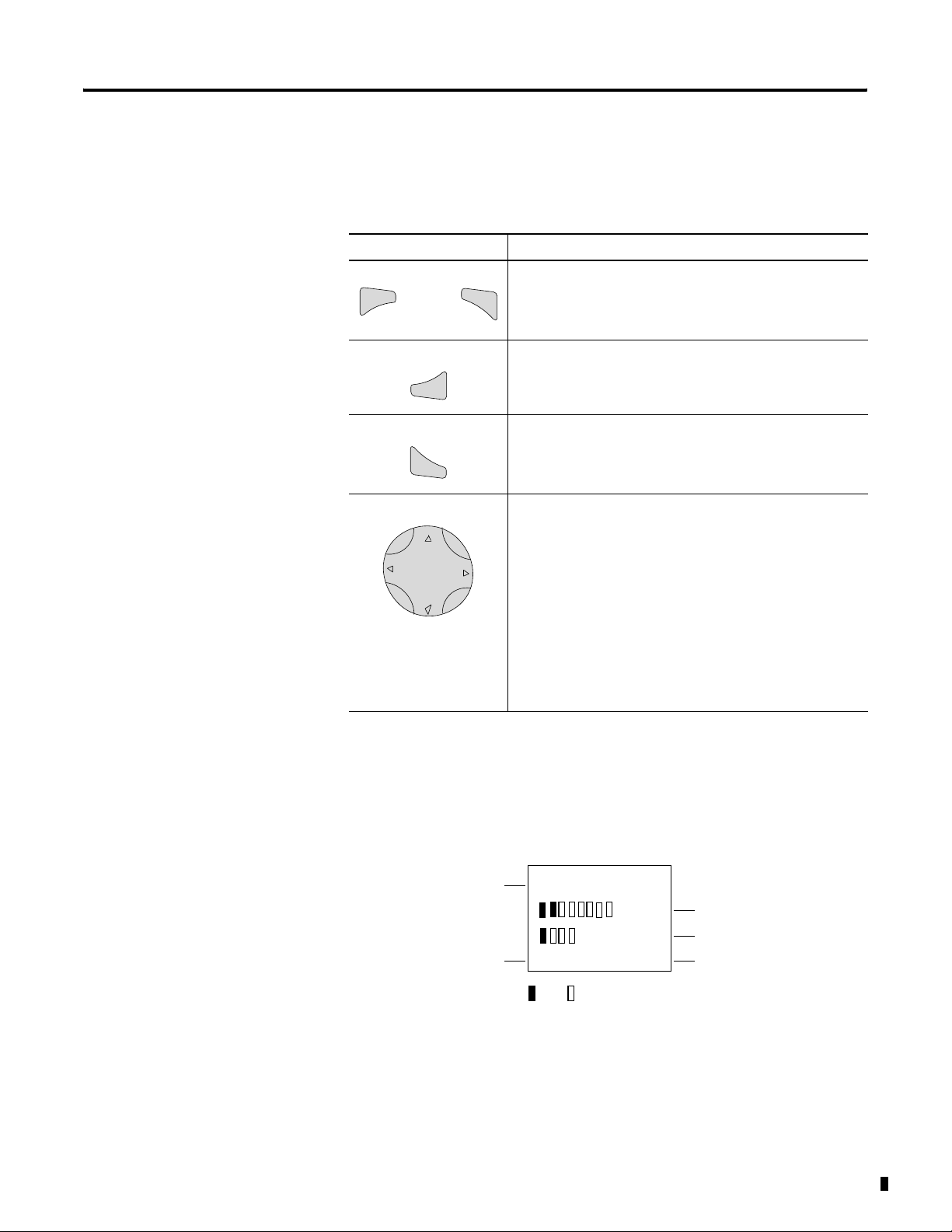

Operating Buttons

Del

Esc

Alt

Button Function

Del Delete object in the circuit diagram

Alt Special functions in the circuit diagram

Cursor

Buttons

Ok

Ok Next menu level, store your entry

Esc Previous menu level, cancel your entry

Move cursor

Select menu item

Choose contact numbers, values, times, etc.

Publication 1760-UM001D-EN-P - September 2005

Page 19

Using Menus to Choose Values

Press To

Show system menu

Del

and

together

Ok

Esc

Alt

• Go to next menu level.

• Select menu item.

• Store your entry.

• Return to last menu level.

• Cancel your entry since the last Ok.

• Change menu item.

• Change value.

• Change position.

System Overview 1-7

Cursor Button Set to P-Button Function (if enabled)

• Left Arrow = Input P1

• Right Arrow = Input P3

• Up Arrow = Input P2

• Down Arrow = Input P4

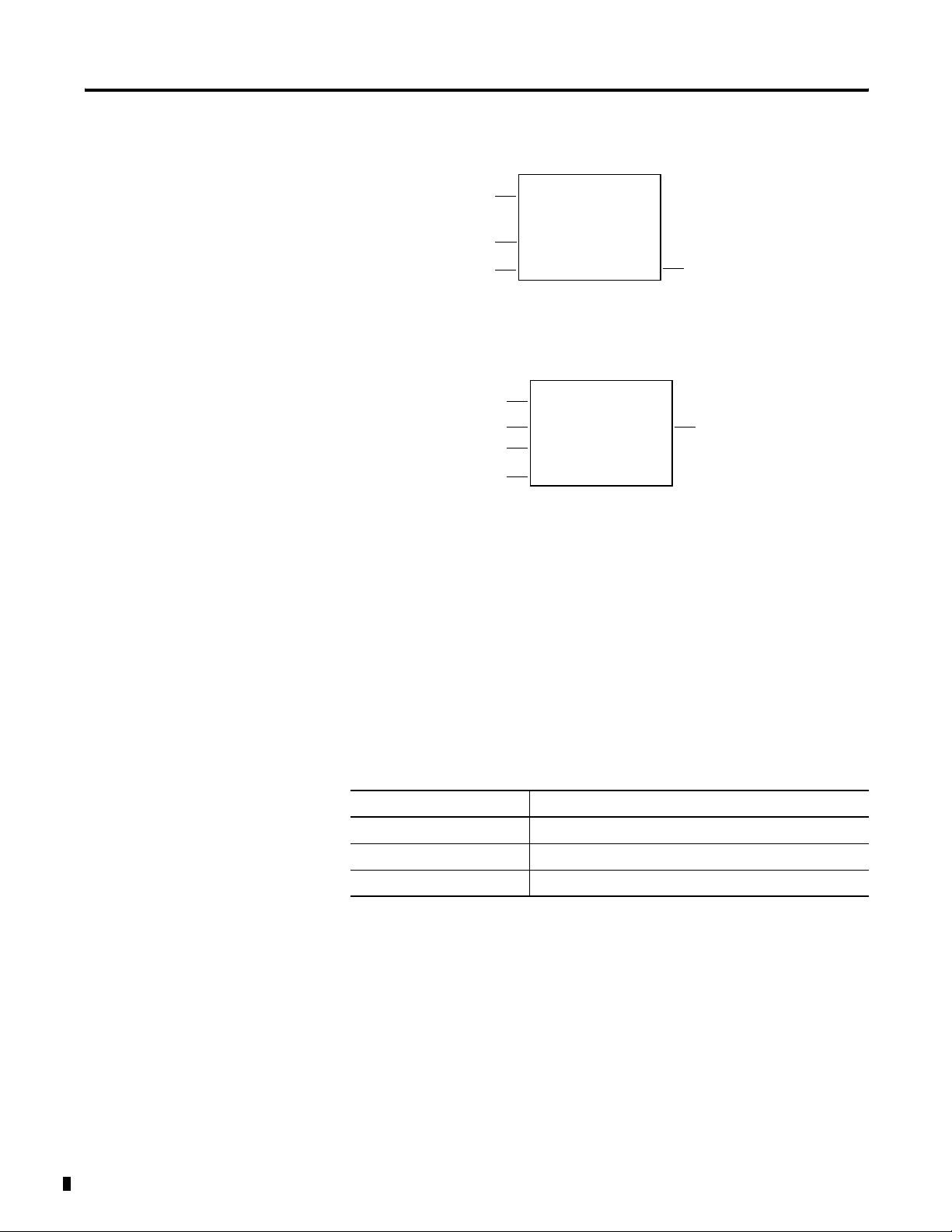

Selecting the Main and System Menus

1760-L12xxx Status Display

Inputs

Outputs

I12345678

12:50

Q1234 RUN

Off

On

MO

Weekday

Tim e

RUN/STOP Mode

Publication 1760-UM001D-EN-P - September 2005

Page 20

1-8 System Overview

1760-L18xxx Status Display

Inputs

Weekday/Time

Outputs

12...........

MO 02:00

..34.... RUN

Inputs 1 and 2 ON

Outputs 3 and 4 ON

RUN/STOP Mode

1760-L18xxx-EX and 1760-L20xxx Status Display for Expansion Module

Inputs

Expansion

Weekday/Time

Outputs

1..........12

RS

MO 10:42 ST

1.......8

RS = Expansion functioning correctly

AC = AC expansion functioning correctly

DC = DC expansion correctly

AC P-

AC Expansion OK/P Buttons

LED Indicators

Catalog numbers 1760-L12AWA-ND, 1760-L12BWB-ND, 1760-L18xxx,

1760-L20BBB-EXND, 1760-IA12XOW6I, 1760-IB12XOB8,

1760-IA12XOW4I and 1760-IB12XOW6I all feature an LED indicator

on the front that shows the status of the incoming power as well as

Run or Stop status.

Publication 1760-UM001D-EN-P - September 2005

LED Indicator Status Indicates

LED OFF No power

LED continuously lit Power present, Stop mode

LED flashing Power present, Run mode

Page 21

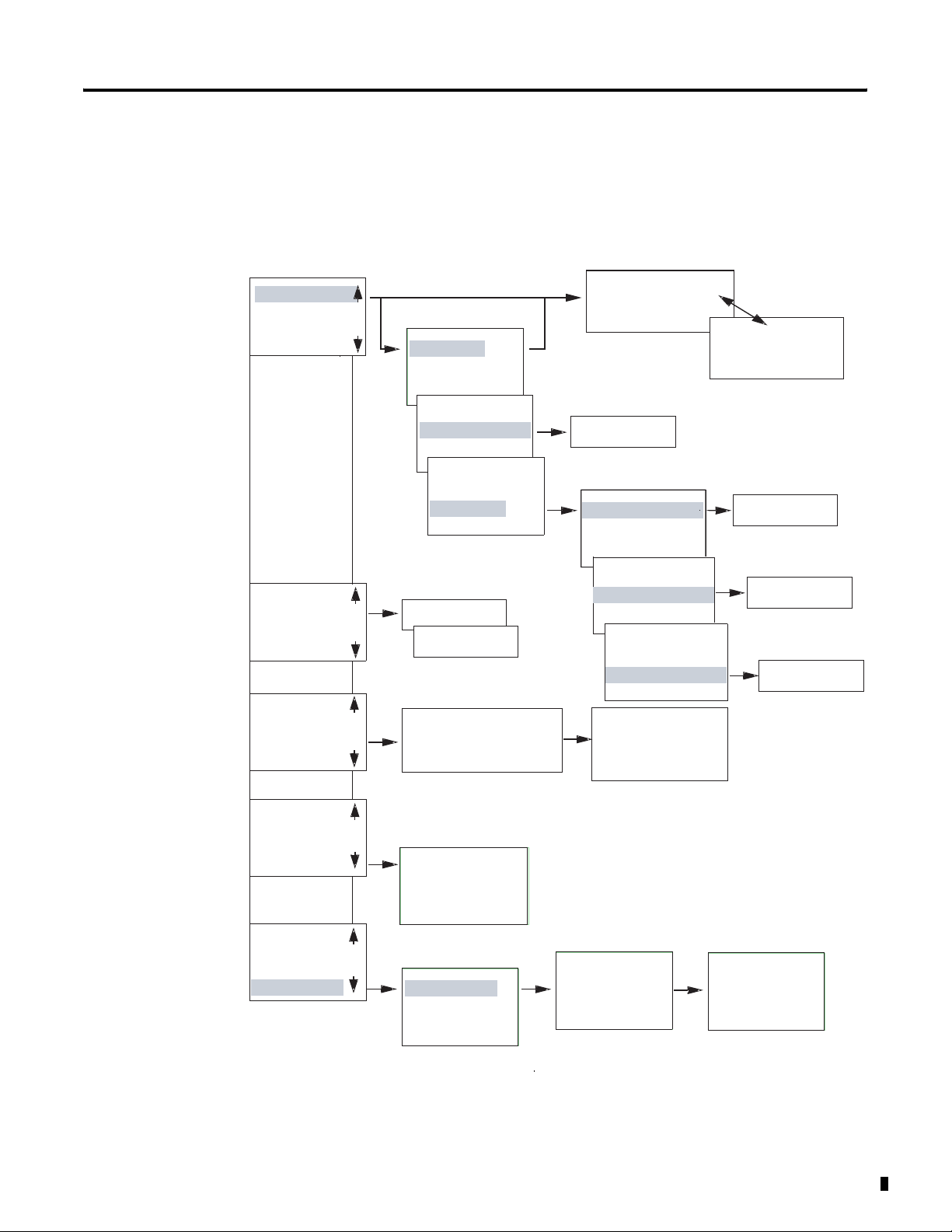

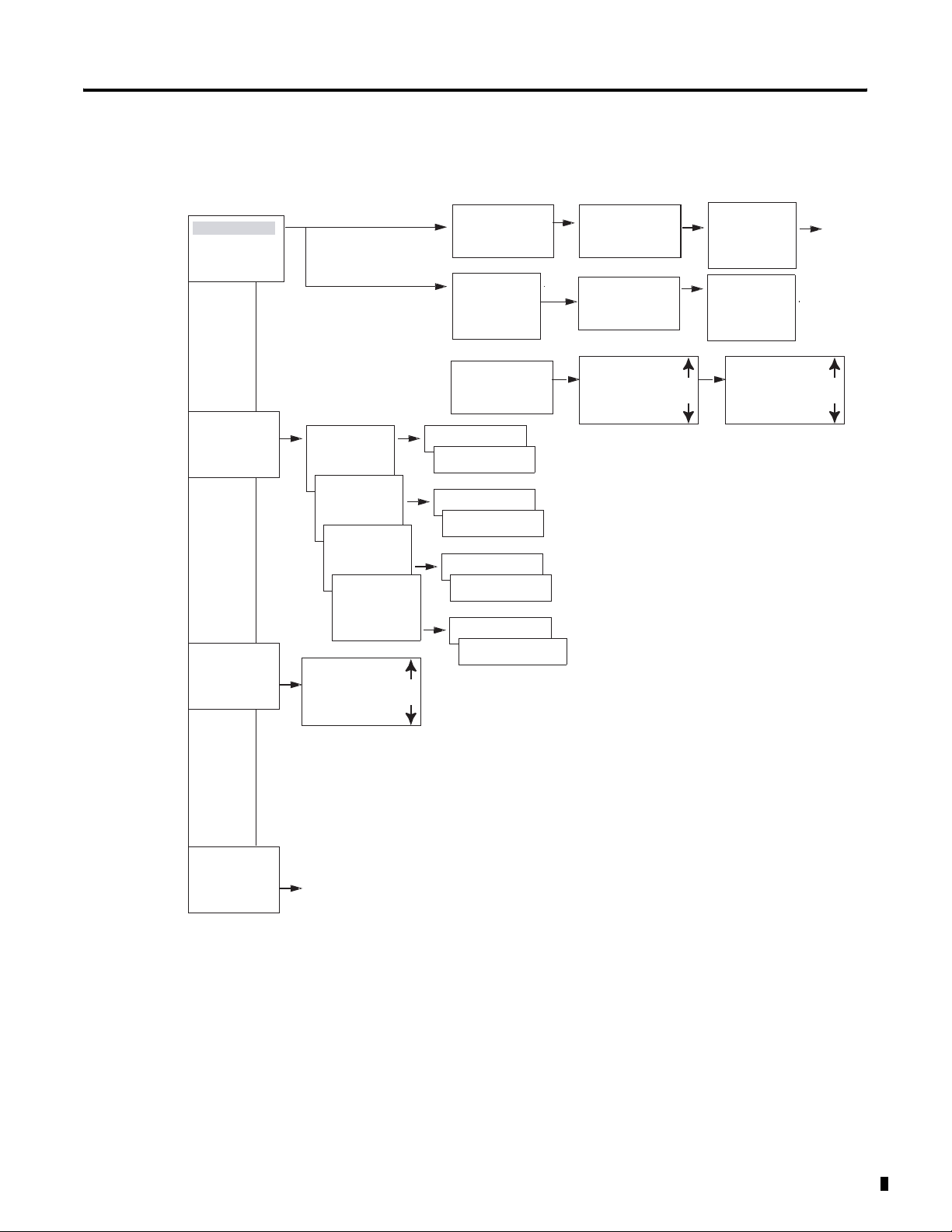

Menu Structure

Main Menu Without Optional Password Protection

STOP: Circuit diagram menu

RUN: Power flow display

System Overview 1-9

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

STOP RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

RUN

å

STOP

Circuit Diagram

PROGRAM

Parameter

Display

Parameters

DELETE PROG

CARD ...

PROGRAM

DELETE PROG

DELETE ?

CARD ...

PROGRAM

DELETE PROG

CARD ...

DEVICE->CARD

REPLACE ?

CARD->DEVICE

DELETE CARD

DEVICE->CARD

REPLACE ?

RUN

STOP

CARD->DEVICE

DELETE CARD

DEVICE->CARD

CARD->DEVICE

T1 X

T2

Ü

C1 N

O1

Parameter Display

S

M:S++

DELETE CARD

T1 X

+

+

S1 10.000

S2 +0

T:

Information Display of Device

+S

DELETE ?

DC TC LCD

OS: 1.00.027

CRC: 02752

SET CLOCK

SUMMER TIME

Display for

Setting Clock

HH:MM --:--

DD.MM

YEAR

--.--

----

HH:MM 14:23

DD.MM

YEAR

17.03

2004

Publication 1760-UM001D-EN-P - September 2005

Page 22

1-10 System Overview

Main Menu Setting Summer Time

PROGRAM...

RUN

PARAMETER

INFO...

SET CLOCK

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

SET CLOCK

SUMMER TIME

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

NONE

RULE...

EU

GB

US

å

SUMMER START

SUMMER END

AM -HH:MM --

--

DD.MM:00.00

HH.MM:00:00

DIFF: 0:00

SUMMER START

SUMMER END

SUMMER START

SUMMER END

AM -HH:MM --

--

DD.MM:00.00

HH.MM:00:00

DIFF: 0:00

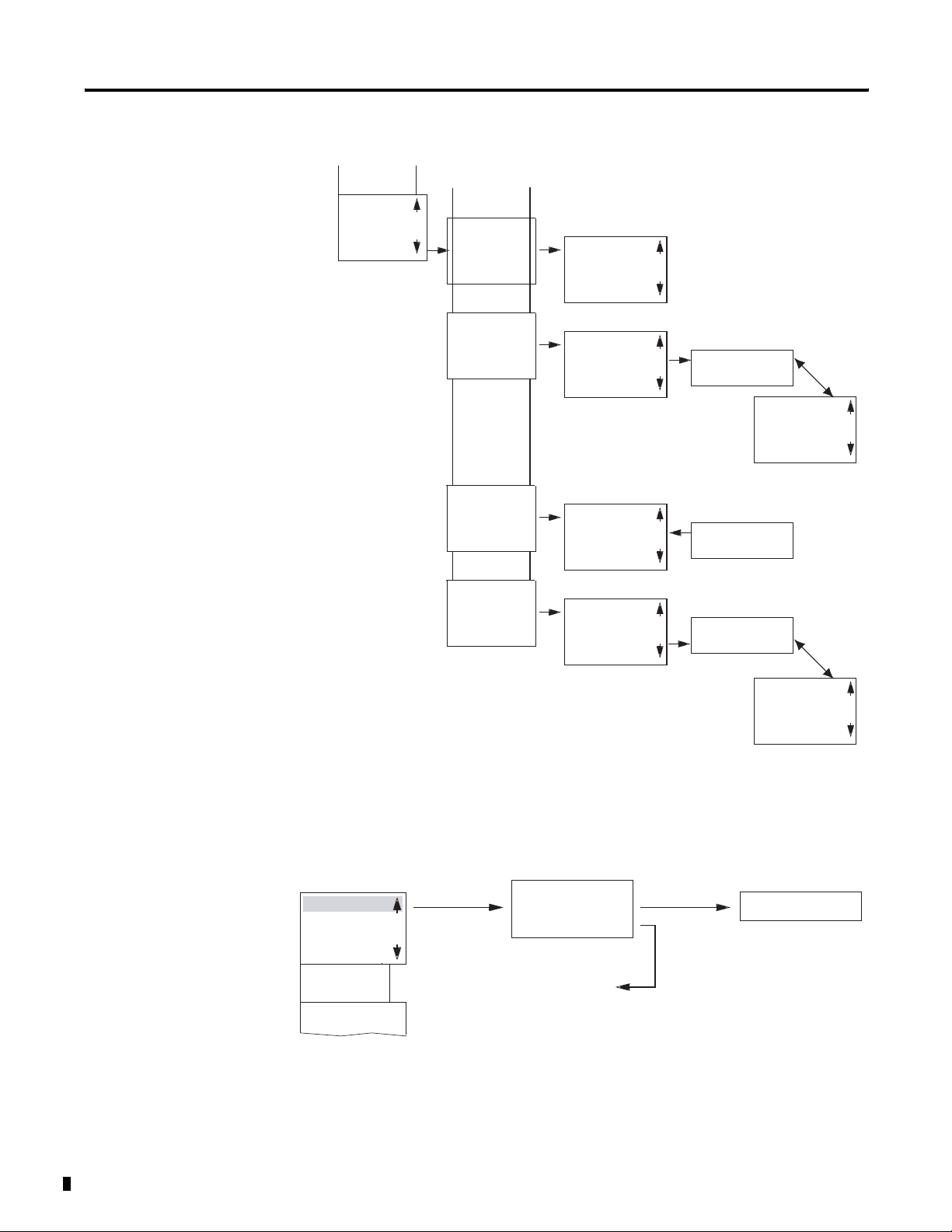

Main Menu

PASSWORD...

RUN

PARAMETER

INFO...

SET CLOCK

PASSWORD...

RUN

Publication 1760-UM001D-EN-P - September 2005

Main Menu with Password Protection

Password Entry

Unlock

Password

Status Display

Correct Entry

Four Wrong

Entries

DELETE ALL

Page 23

System Menu

System Overview 1-11

System

sECURITY...

SYSTEM...

LANGUAGE ...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

SECURITY...

SYSTEM...

LANGUAGE...

CONFIGURATOR

Set Password

Change Password

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

DEBOUNCE OFF

P ON

STOP MODE

RETENTION ON

ENGLISH

DEUTSCH

FRANCAIS

ESPANOL

ITALIANO

PORTUGUES

NEDERLANDS

SVENSKA

POLSKI

TURKCE

CESKY

MAGYAR

Password Entry

Password

RANGE...

ACTIVATE PW

CHANGE PW

Password

RANGE...

DEBOUNCE OFF

DEBOUNCE ON

P ON

P OFF

MODE: STOP

MODE: RUN

(2)

RETENTION ON

RETENTION OFF

ENTER PASSW:

XXXX

ENTER PASSW:

XXXX

PROGRAM å

PARAMETER

CLOCK

OPRTNG MODE

INTERFACE

DELETE FUNCT

(2)

(2)

(1) Only for Pico 1760-L18xxx

(2) Only for Pico 1760-L12BWB-xx,

-L12DWD and -L18xxx.

CHANGE PW

ACTIVATE PW

CHANGE PW

ACTIVATE PW

PROGRAM å

PARAMETER å

CLOCK å

OPRTNG MODE å

INTERFACE å

DELETE FUNCT å

Publication 1760-UM001D-EN-P - September 2005

Page 24

1-12 System Overview

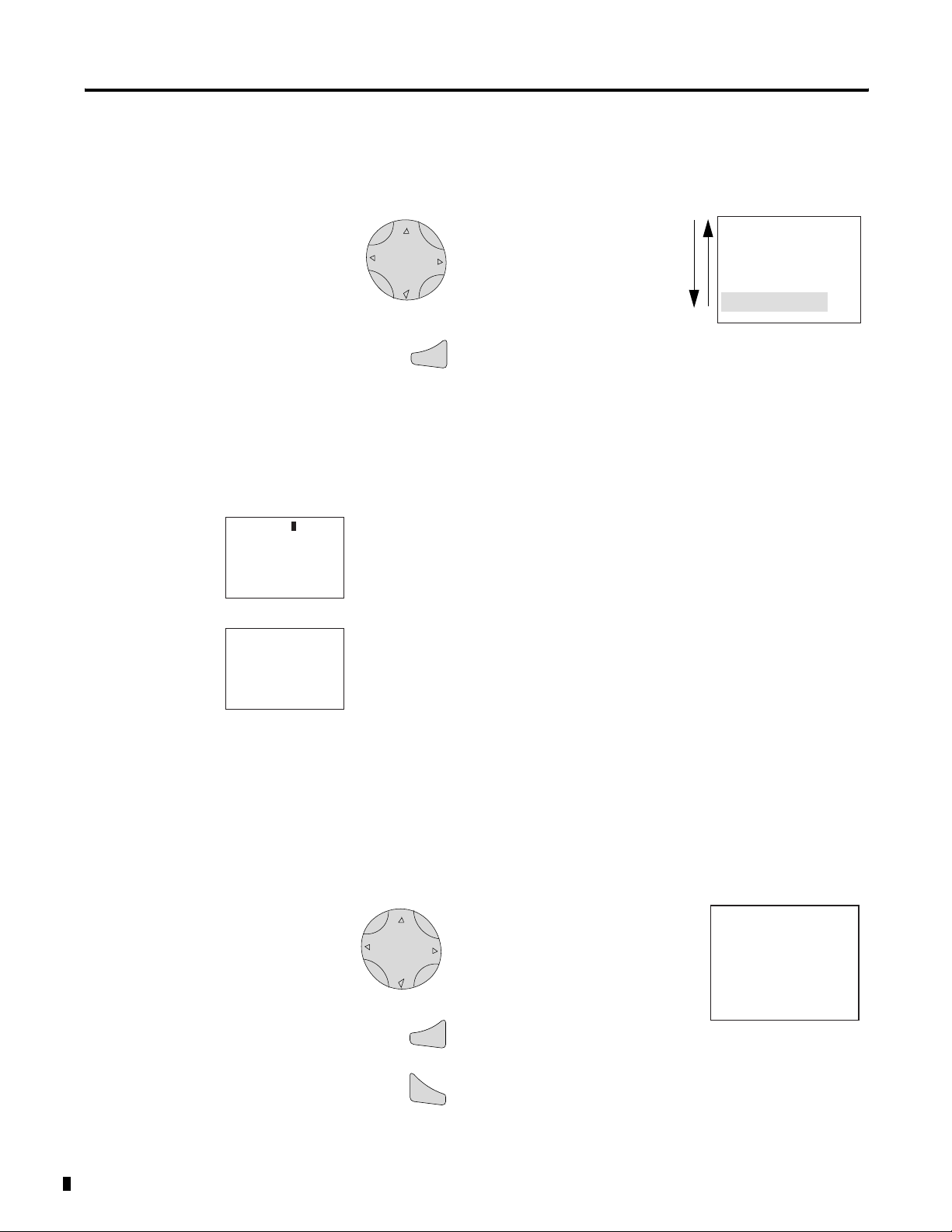

Selecting or Toggling Between Menu Items

HH:MM 14:23

DD.MM

YEAR

HH:MM 14:23

DD.MM

YEAR

17.03

2004

17.03

2004

Cursor up or down

Select or Toggle

Ok

PROGRAM ...

RUN

PARAMETER

INFO

Highlighted

choice flashes

Cursor Display

There are two different cursor types: flashing block and flashing

cursor.

Full block navigation is shown as a flashing block:

• Move cursor with the left/right arrows

• In circuit diagram also with up/down arrows

Parameter change cursor flashes the selected parameter:

• Change position with left/right arrows

• Change values with up/down arrows

Publication 1760-UM001D-EN-P - September 2005

Flashing values/menus are highlighted in grey in this manual.

Setting Values

Change value = up/down arrows

Move cursor between parameters = left/right

arrows

Stores Entries

Ok

Retain previous value

Esc

HH:MM 14:23

DD.MM

YEAR

Left/right arrow moves the

cursor between the day and

time digits.

Up/down arrow changes the

value of the parameter.

Up arrow = increment

Down arrow = decrement

17.03

2004

Page 25

Installation

Pico is installed in the following order:

• connect devices together, if necessary

• Mount

• Use surge suppressors

• Wire the inputs

• Wire the outputs

• Connect incoming power

Chapter

2

Prevent Electrical Shock

ATTENTION

Follow these guidelines when you handle the

controller:

• Remove power before working on any of the

wiring to Pico.

• Touch a grounded object to discharge static

potential.

• Wear an approved wrist-strap grounding device.

• If available, use a static-safe work station.

1 Publication 1760-UM001D-EN-P - September 2005

Page 26

2-2 Installation

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-1 EMC — Generic Emission Standard, Part 1 —

Residential, Commercial, and Light Industry

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 50178 Electric

Equipment for Power Installations Equipment Requirements and Tests.

For specific information required by EN 50178, see the appropriate

sections in this publication, as well as the Allen-Bradley publication

Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

Publication 1760-UM001D-EN-P - September 2005

Page 27

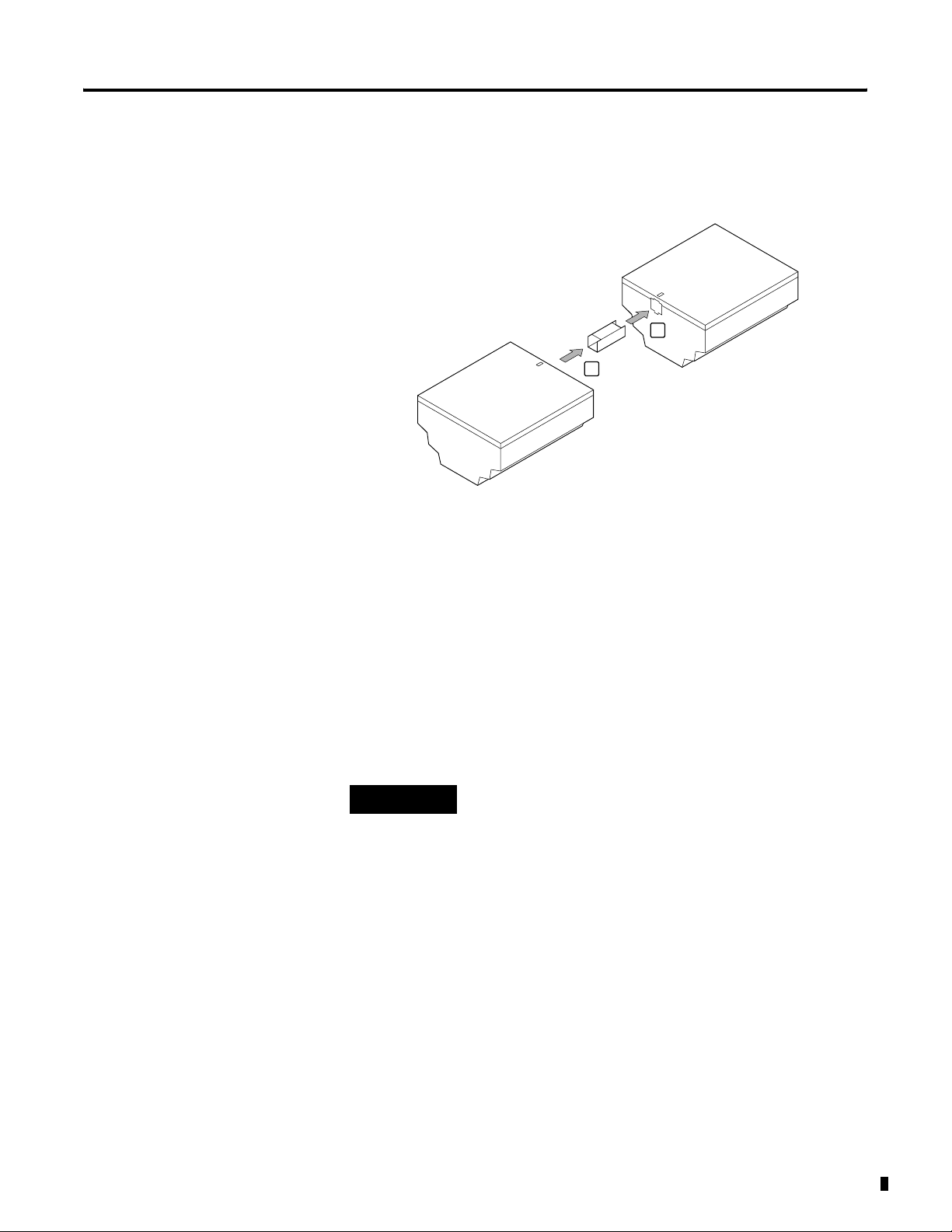

Installation 2-3

Connect the Expansion Module

Connect the expansion module to the controller using the connector

as shown below:

1

2

See Expansion Modules on page 1-4 for information on using the

modules with your Pico controller.

Mount the Pico Controller

Install Pico in an enclosure, switch cabinet, or distribution board so

that the power feed and terminal connections cannot be touched

accidentally during operation.

Clip Pico onto a DIN rail or install directly onto a panel using the

mounting feet. Pico can be mounted either vertically or horizontally.

TIP

When using a Pico expansion module, connect the

expansion module and Pico controller together

before mounting. See Connect the Expansion

Module.

Publication 1760-UM001D-EN-P - September 2005

Page 28

2-4 Installation

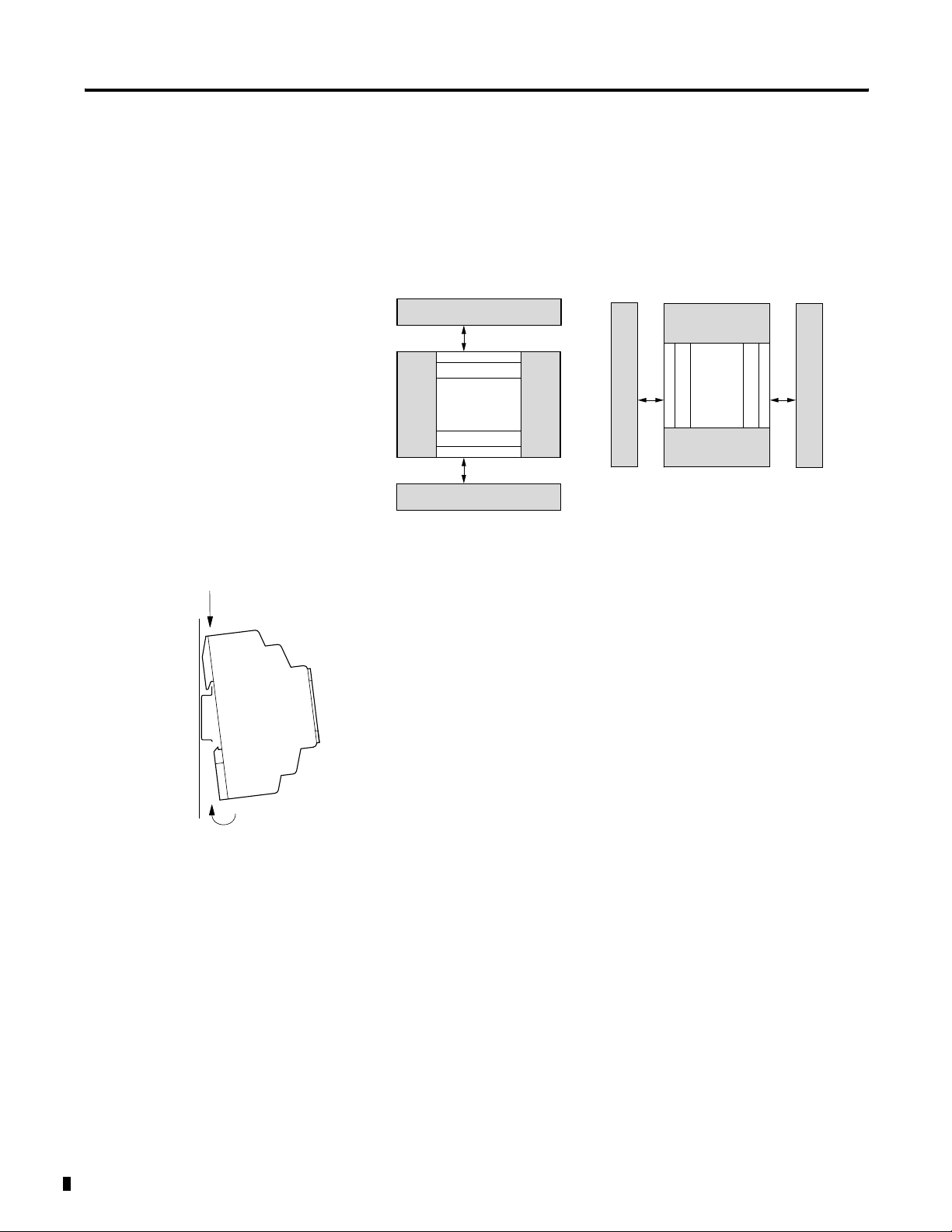

Minimum Spacing

Maintain spacing from enclosure walls, wireways, adjacent equipment,

etc. Allow 3 cm (1.18 in.) of space on all sides for adequate

ventilation, as shown:

3 cm (1.18 in.)

3 cm (1.18 in.)

3 cm (1.18 in.)

3 cm (1.18 in.)

DIN Rail Mount

1. Mount your DIN rail. Make sure that the placement of the Pico

unit on the DIN rail meets the recommended spacing

requirements.

2. Hook the top slot over the DIN rail.

3. While pressing the Pico unit down against the top of the rail,

snap the bottom of the unit into position. Ensure DIN latches are

in the up (secured) position.

Pico can be mounted vertically on a DIN rail in the same manner.

Publication 1760-UM001D-EN-P - September 2005

Page 29

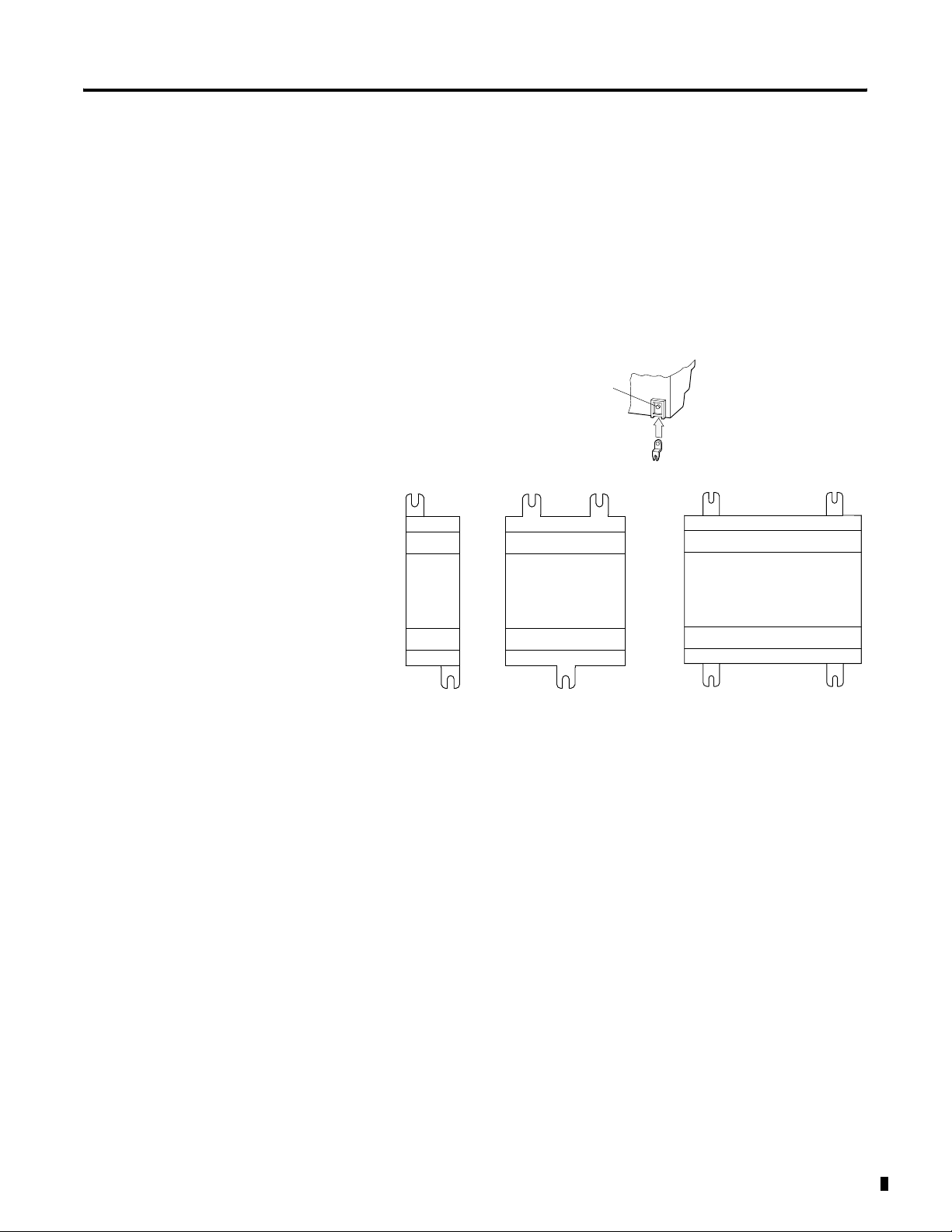

Install on a Mounting Plate

To install the unit using mounting screws:

1. Snap the mounting feet in place.

2. Drill holes at the mounting feet positions, shown below.

3. Mount the controller.

Click

Installation 2-5

1760-L18xxx, 1760-L20xxx and

Expansion Modules

1760-OW2

1760-L12xxx

For mounting dimensions, see Dimensions on page A-14.

Publication 1760-UM001D-EN-P - September 2005

Page 30

2-6 Installation

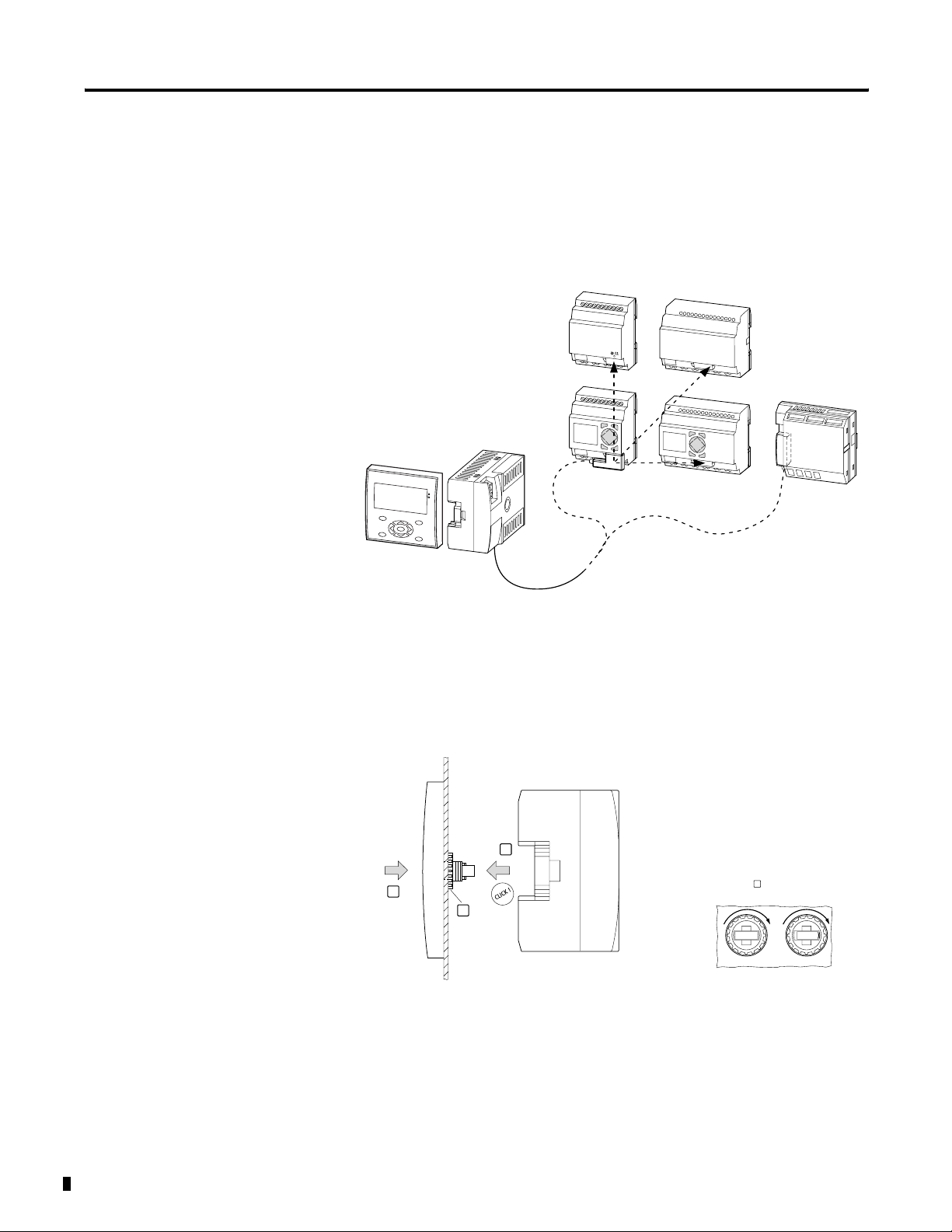

Install the Remote Processor

The remote processor is used for terminal mode operation of Pico

controllers and I/O modules. The remote processor is used with either

a Display or Display/Keypad Unit.

Remote Processor Terminal Operation

1760-L18...

1760-L20...

LED

LA

T

E

S

C

O

K

1760-RM-GFX

1760-LDF

...

1760-GFX

Display Unit

Front View

1760-RM

1760-L12...

D

E

L

LA

T

E

S

C

O

K

1760-RM-Pico

Flush Mount

Flush Mount the Display and Remote Processor

3

2

1

2

1. Insert the display unit through the mounting holes on the panel.

2. Attach the fixing rings.

3. Attach the processor unit.

M = 1.2 – 2 Nm

10.6 - 17.7 lb-in

Publication 1760-UM001D-EN-P - September 2005

Page 31

Removal Procedure

Remove the Remote Processor

3

2

1

1760 -RM

1. Insert the screwdriver into the mounting slide.

2. Push screwdriver to the right to open the slide.

Installation 2-7

3. Remove the processor unit from the display unit.

4. Loosen the fixing rings.

5. Remove the display unit from the panel.

Make Connections

Connect the Power Supply

Remote Processor Power Supply Connection

1760-RM…

L01+ L02+

L01–

> 1 A

Ue = 24 V dc

(20.4 – 28.8 V H dc)

Ie = 150 mA

0.6 x 3.5 x 100

0V24V

Publication 1760-UM001D-EN-P - September 2005

Page 32

2-8 Installation

Connect the Serial Cable

4

1

Wire Terminals

1760-RM cable

2

X5

X4

X3

X2

X1

3

Cable Wire Color Code

X5

green

X4 white

X3 yellow

X2 brown

X1 gray

1. Remove the interface cover.

2. Using a screwdriver, push on the terminal latch.

3. Insert each wire into its designated terminal on the interface

connector.

4. Replace the interface cover.

Plug the other end of the cable into the Pico controller or I/O module.

Required Tools

Publication 1760-UM001D-EN-P - September 2005

Slot-head screwdriver (width: 3.5 mm, torque: 0.57 to 0.79 Nm [5 to 7

in-lb])

Page 33

Wire Size

• Solid

AWG 22 to AWG 12

• Stranded

AWG 22 to AWG 12

Installation 2-9

Connect the Incoming Power

For incoming power technical specifications, refer to Appendix A.

ATTENTION

ELECTRICAL SHOCK HAZARD

The memory module and PC-cable socket are at the

potential of L2. There is a danger of electric shock if

L2 is not grounded. Do not make contact with

electrical components under the socket cover.

TIP

A brief current surge is produced when powering on

the unit for the first time. Do not switch the unit

using reed contacts, since these may burn or melt.

1760-L12AWA, -L12AWA-NC, -L12AWA-ND, -L18AWA,

L1

L2

F1

L1 L2 I2 I3 I4 I5 I6 I7 I8I1

100 - 240V ac

50/60Hz

Inputs x 100 - 240V ac

Publication 1760-UM001D-EN-P - September 2005

Page 34

2-10 Installation

1760-IA12XOW6I Expansion Module

L1

L2

F1

NCNC R2 R3 R4 R5 R6 R7 R8R1 R9 R10 R11 R12 L1

Inputs x 100 to 240V ac

1760-L12BWB, -L12BWB-NC, -L12BWB-ND, -L18BWB-EX

+24V

0V

F1

+24 V COM I2 I3 I4 I5 I6 I7 I8I1

24V dc

Inputs x 24V dc (I7,I8 0 to 10V)

L2

100 to 240V ac

50/60Hz

Publication 1760-UM001D-EN-P - September 2005

Page 35

1760-IB12XOB8 Expansion Module

+24V dc

0V dc

Installation 2-11

F1

NCNC R2 R3 R4 R5 R6 R7 R8R1 R9 R10 R11 R12 +24V

1760-L12DWD

+12V dc

0V

F1

+12 V COM I2 I3 I4 I5 I6 I7 I8I1

12V dc

Inputs x 24V dc

Inputs x 12V dc

COM

24V dc

The dc controllers are protected against polarity reversal. To ensure

that the unit works correctly, ensure that the polarity of each terminal

is correct.

Wiring Protection

Both AC and DC versions require wiring protection (F1) rated for at

least 1 A (slow).

When the unit is powered on for the first time, the power supply

circuit draws a larger surge current than usual. Use an appropriate

device for switching on the incoming power and do not use any reed

relay contacts or proximity switches.

Publication 1760-UM001D-EN-P - September 2005

Page 36

2-12 Installation

Use Surge Suppressors

Inductive load devices, such as motor starters and solenoids, require

the use of some type of surge suppression to protect and extend the

operating life of the controller’s output contacts. Switching inductive

loads without surge suppression can SIGNIFICANTLY reduce the life

expectancy of relay contacts. By adding a suppression device directly

across the coil of an inductive device, you prolong the life of the

output or relay contacts. You also reduce the effects of voltage

transients and electrical noise from radiating into adjacent systems.

The following diagram shows an output with a suppression device.

We recommend that you locate the suppression device as close as

possible to the load device.

ac or dc

Outputs

+dc or L1

VAC/DC

Out 0

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

COM

Suppression

Device

dc COM or L2

If the outputs are dc, we recommend that you use an 1N4004 diode

for surge suppression, as shown below.

+24V dc

VAC/D

Out 0

Out 1

Relay or Solid

State dc Outputs

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

COM

IN4004 Diode

24V dc common

Suitable surge suppression methods for inductive ac load devices

include a varistor, an RC network, or an Allen-Bradley surge

suppressor, all shown below. These components must be

appropriately rated to suppress the switching transient characteristic of

the particular inductive device. See the table on page 2-14 for

recommended suppressors.

Publication 1760-UM001D-EN-P - September 2005

Page 37

Surge Suppression for Inductive ac Load Devices

Installation 2-13

Output Device

Varistor RC Network Surge

Output Device

For inductive dc load devices, a diode is suitable. A 1N4004 diode is

acceptable for most applications. A surge suppressor can also be used.

See the table on page 2-14 for recommended suppressors.

As shown in the illustration below, these surge suppression circuits

connect directly across the load device.

Surge Suppression for Inductive dc Load Devices

_

Output Device

+

Output Device

Suppressor

Diode

(A surge suppressor can also be used.)

Publication 1760-UM001D-EN-P - September 2005

Page 38

2-14 Installation

Recommended Surge Suppressors

Use the Allen-Bradley surge suppressors shown in the following table

for use with relays, contactors, and starters.

Suppressor Device Coil Voltage Catalog Number

Bulletin 509 Motor Starter

Bulletin 509 Motor Starter

Bulletin 100 Contactor

Bulletin 100 Contactor

120V ac

240V ac

120V ac

240V ac

599-K04

599-KA04

199-FSMA1

199-FSMA2

Bulletin 709 Motor Starter 120V ac 1401-N10

Bulletin 700 Type R, RM Relays ac coil None Required

Bulletin 700 Type R Relay

Bulletin 700 Type RM Relay

Bulletin 700 Type R Relay

Bulletin 700 Type RM Relay

Bulletin 700 Type R Relay

Bulletin 700 Type RM Relay

Bulletin 700 Type R Relay

Bulletin 700 Type RM Relay

Bulletin 700 Type R Relay

Bulletin 700 Type RM Relay

12V dc

12V dc

24V dc

24V dc

48V dc

48V dc

115-125V dc

115-125V dc

230-250V dc

230-250V dc

700-N22

700-N28

700-N10

700-N13

700-N16

700-N17

700-N11

700-N14

700-N12

700-N15

Bulletin 700 Type N, P, or PK Relay 150V max, ac or DC 700-N24

Miscellaneous electromagnetic

150V max, ac or DC 700-N24

devices limited to 35 sealed VA

Connect the Inputs

Publication 1760-UM001D-EN-P - September 2005

Pico inputs switch electronically. Once you have connected a device

via an input terminal, you can reuse it as a relay contact in your

program as often as you like.

L1

+24 V

S1

L2

com

I1

I1

I1

Connect devices such as buttons or switches to Pico input terminals.

Page 39

Connecting AC Inputs

Installation 2-15

ATTENTION

For Pico controllers with ac inputs, connect the

inputs to the same phase as the power feed L1, in

accordance with VDE, IEC, UL and CSA safety

regulations. Otherwise, Pico may not detect the

switching level or, it may be damaged by excess

voltage.

Input Specification

Input Signal

Voltage Range

Input Current I1 to I6, I9 to I12, R1 to R12: 0.25 mA at 120V ac, 0.5 mA at 240V ac

Example Using 1760-L12AWA

L1

L2

OFF signal: 0 to 40V ac

ON signal: 79V to 264V ac

I7 and I8: 4 mA at 120V ac, 6 mA at 240V ac,

F1

L1 L2 I2 I3 I4 I5 I6 I7 I8I1

100 to 240V ac

50/60Hz

Example Using 1760-IA12XOW6I

F1

L1

L2

NCNC R2 R3 R4 R5 R6 R7 R8R1 R9 R10 R11 R12 L1

Inputs x 100 to 240V ac

Inputs x 120/240V ac

Publication 1760-UM001D-EN-P - September 2005

120/240V ac

L2

50/60Hz

Page 40

2-16 Installation

Wire Lengths

Severe electromagnetic interference to wires can cause inputs to signal

1 without the proper signal being applied. Observe the following

maximum cable lengths:

• I1 to I6, I9 to I12, R1 to R12: 40m (130 ft) without additional

circuits

• I7 and I8: 100m (330 ft) without additional circuits

ATTENTION

Do not use reed relay contacts on I7 or I8. These

may burn or melt due to the high current of I7 and

I8.

Two-wire proximity sensors have a residual off-state leakage current.

If this residual current is too high, the input may indicate the input is

ON when the device is actually off.

Use inputs I7 and I8 for these types of input devices. If more inputs

are required, use a bleeder resistor or bleeder capacitor for inputs I1

through I6, and I9 through I12.

Increase the Input Current

Use the following input circuit for electrical noise immunity and when

using two-wire proximity switches:

L1

L2

Publication 1760-UM001D-EN-P - September 2005

1A

30K Ω, 5W resistor; or

100 nF, 275V ac capacitor

L1 L2 I2 I3 I4 I5 I6 I7 I8I1

100 to 240V ac

50/60Hz

Inputs x 100 to 240V ac

When using a 100 nF capacitor, the drop-off time of the input

increases by 66.6 ms at 60 Hz (80 ms at 50 Hz). Also, a capacitor

increases the amount of current seen by the input device. Do not use

a bleeder capacitor in conjunction with reed switches.

Page 41

Installation 2-17

To limit the current to 400 mA, connect a 1K Ω resistor in series

upstream from the circuit as shown.

.

L1

L2

1A

1K Ω

0.25W

resistor

L1 L2 I2 I3 I4 I5 I6 I7 I8I1

100 to 240V ac

50/60Hz

100 nF, 275V ac capacitor

Inputs x 100 to 240V ac

Connect 24 V dc Inputs

Use input terminals I1 to I8 (or I12 for 18-point Pico) to connect

push-buttons, switches, or 3- or 4-wire proximity switches. Given the

high off-state leakage current, do not use 2-wire proximity switches.

Input Specification

Input Signal Voltage Range OFF signal: 0 to 5V dc

ON signal: 15V to 28.8V dc

Input Current I1 to I6, I9 to I12, R1 to R12: 3.3 mA at 24V dc

I7 and I8: 2.2 mA at 24V dc

Example Using 1760-L12BWB-xx

+24V

0V

1A

+24 V COM I2 I3 I4 I5 I6 I7 I8I1

24V dc

Inputs x 24V dc (I7,I8 0 to 10V)

Publication 1760-UM001D-EN-P - September 2005

Page 42

2-18 Installation

Example Using 1760-IB12XOB8

+24V dc

F1

0V

NCNC R2 R3 R4 R5 R6 R7 R8R1 R9 R10 R11 R12 +24V

Inputs x 24V dc

COM

24V dc

Connect 12 V dc Inputs

Use input terminals I1 to I8 to connect push-buttons, switches, or 3 or

4-wire proximity switches. Given the high off-state leakage current, do

not use 2-wire proximity switches.

Input Specification

Input Signal Voltage Range OFF signal: 0 to 4V dc

ON signal: 8V to 15.6V dc

Input Current I1 to I6, I9 and I10: 3.3 mA at 12V dc

I7 and I8, I11 and I12: 1.1 mA at 12V dc

Example Using 1760-L12DWD

+12V dc

0V

1A

+12 V COM I2 I3 I4 I5 I6 I7 I8I1

12V dc

Inputs x 12V dc

Publication 1760-UM001D-EN-P - September 2005

Page 43

Installation 2-19

Connect Analog Inputs (1760-LxxBWB-xx or 1760-LxxDWD only)

Inputs I7 and I8, and if present I11 and I12, can also be used to

connect analog devices ranging from 0 to 10V dc.

ATTENTION

Analog signals are more sensitive to interference than

digital signals. Consequently, more care must be

taken when routing and connecting the signal lines.

Route the analog wiring:

• away from power lines, load lines and other

sources of electrical noise such as hard-contact

switches, relays, and AC motor drives

• away from sources of radiated heat

Incorrect switching states may occur if the analog

wiring is not installed correctly.

Use shielded, twisted-pair cables to prevent interference with the

analog signals. For short cable lengths, ground the shield at both ends

with a large contact area. If the cable length exceeds 30m (98.4 ft),

grounding at both ends can result in ground loops between the two

grounding points and thus to the interference of analog signals. In this

case, only ground the cable at one end. Do not route signal lines

parallel to power cables.

Connect inductive loads to be switched via Pico outputs to a separate

power feed, or use a suppressor circuit for motors and valves. If loads

such as motors, solenoid valves or contactors are operated via the

same power feed, switching may result in interference on the analog

input signals.

Publication 1760-UM001D-EN-P - September 2005

Page 44

2-20 Installation

The following four circuits illustrate application examples for analog

value processing.

Ensure that the reference potential is connected. Connect the 0V of

the power supply unit for the different setpoint potentiometers and

sensors to the 0V of the power feed.

Setpoint Potentiometers

V dc

0V

F1

V dc COM I2 I3 I4 I5 I6 I7 I8I1

V dc

V dc = 12Vdc for 1760-L12DWD

V dc = 24V dc for 1760-LxxBWB-xx

Inputs x V dc (I7,I8 0 to 10V)

~

0V

+12V

Use a potentiometer with a resistance of less than or equal to 1K Ω,

e.g. 1K Ω, 0.25W.

Light Intensity Sensors

V dc

0V

12V

F1

0 to 10V

0V

~

0V

+12V

Publication 1760-UM001D-EN-P - September 2005

V dc COM I2 I3 I4 I5 I6 I7 I8I1

V dc

V dc = 12Vdc for 1760-L12DWD

V dc = 24V dc for 1760-LxxBWB-xx

Inputs x V dc (I7,I8 0 to 10V)

Page 45

Temperature Sensors

Installation 2-21

V dc

0V

V dc = 12Vdc for 1760-L12DWD

V dc = 24V dc for 1760-LxxBWB-xx

20 mA Sensors

V dc

0V

F1

V dc COM I2 I3 I4 I5 I6 I7 I8I1

V dc

1A

+V dc

-0V

Out

0 to 10V

Inputs x V dc (I7,I8 0 to 10V)

4 to 20 mA

(12V dc or 24V dc)

-35 to +55˚C

(-31 to +131˚F)

500Ω

V dc COM I2 I3 I4 I5 I6 I7 I8I1

V dc

V dc = 12Vdc for 1760-L12DWD

V dc = 24V dc for 1760-LxxBWB-xx

Inputs x V dc (I7,I8 0 to 10V)

Connect 4 to 20 mA (0 to 20 mA) sensors using an external 500Ω

resistor, as shown above. The resultant impedance to the sensor is

approximately 478Ω.

The following values result (Based on V = R x I = 478Ω x 10 mA =

4.8V dc):

• 4 mA = 1.9V dc

• 10 mA = 4.8V dc

• 20 mA = 9.5V dc

Publication 1760-UM001D-EN-P - September 2005

Page 46

2-22 Installation

Connect Outputs

The Q output terminals function as isolated contacts, as shown below.

Q1

Q1

12

Q1

Outputs are controlled via the corresponding output relays:

• Q1 to Q4

• Q1 to Q8

• S1 to S6

• S1 to S8

You can use the signal states of the output relays as make or break

contacts in the Pico program to provide additional logic conditions.

The relay or transistor outputs are used to switch loads such as

fluorescent tubes, filament bulbs, contactors, relays or motors. Check

the technical thresholds and output data before installing such devices

(see Relay Outputs on page A-10).

Connect Relay Outputs

1760-L12AWA-xx, 1760-L12BWB-xx and 1760-L12DWD

.

10 000 000

0 V , N

< 8 A / B 16

L1, L2, L3 (120/240V)

+ 24 V

1

2

Q1

1

2

2

1

Q3 Q4

Q2

2

1

R

24 V 8 A

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

L

2 A

2 A

2 A

25.000

Publication 1760-UM001D-EN-P - September 2005

Page 47

1760-L18AWA-xx and 1760-L18BWB-EX

Installation 2-23

10 000 000

0 V , N

< 8 A / B 16

L1, L2, L3 (120/240 V)

+ 24 V

1760-IA12XOW6I

10 000 000

0 V , N

< 8 A / B 16

L1, L2, L3 (120/240 V)

+ 24 V

12 2 2 2 2 2

S1

S2

12 2 2 2 2 2

S1

S2

1

1

1

1

1

1

S6S5S4S3

1

1

S6S5S4S3

1

1

R

24 V

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

R

24 V

120 V 8 A

240 V 8 A

1000 W

10 x 58 W

8A

8A

2A

2A

2A

2A

2A

2A

25.000

25.000

1760-OW2

Unlike inputs, you can connect different phases to the outputs.

.

ATTENTION

Do not exceed the maximum voltage of 250V ac on a

relay contact.

If the voltage exceeds this threshold, arcing may

occur at the contact, resulting in damage to the

device or to a connected load.

Publication 1760-UM001D-EN-P - September 2005

Page 48

2-24 Installation

Connect Transistor Outputs

1760-Ixxx

1760-Ixxx

0 V Q1 Q2 Q3 Q4

+24 V

Q

F 10 A

0 V H

f 2.5 A

+ 24 V H

20.4 – 28.8 V H

+24 V 0 V Q1 Q2 Q3Q4Q5Q6Q7

Q

24 V

Q

Q

5 W/24 V

0.5 A

R

L

0.5 A

Q8

1760-IB12XOB8

F 10 A

0 V H

f 2.5 A

0V

24V 0.5A 0.5A

+ 24 V H

(20.4 – 28.8 V H)

R

24 V H

S1 S2 S3 S4 S5 S6 S7 S8

5W/24V

0.5 A

R

2.5A

≤

0.5 A

5 W/24 V

+24V dc

+ 24V dc

(20.4-28.8V dc )

COM

10A

Publication 1760-UM001D-EN-P - September 2005

Page 49

Installation 2-25

Parallel Connection

Up to four outputs can be connected in parallel in order to increase

the load current. The output current will increase to a maximum of

2A.

ATTENTION

Outputs may only be connected in parallel within a

group (S1 to S4) or (S5 to S8) such as (S1 and S3) or

(S5, S7 and S8). Outputs connected in parallel must

be switched ON and OFF at the same time.

Switch Inductive Loads

ATTENTION

If inductive loads are not suppressed, only one inductive load should

be switched off at any one time to prevent the output transistors from

overheating. If, in the event of an emergency stop, the +24V dc power

supply is to be switched off by means of a contact, and this would

mean switching off more than one controlled output with an inductive

load, then you must provide suppressor circuits for these loads. See

the following diagrams.

Observe the following when switching off inductive

loads:

Suppressed inductive loads cause less interference in

the entire electrical system. For optimum

suppression, the suppressor circuits are best

connected directly to the inductive load. See Use

Surge Suppressors on page 2-12.

+24V

0V

S

Ue max. < Uz < 33V

S

0 V

Publication 1760-UM001D-EN-P - September 2005

Page 50

2-26 Installation

Short Circuit and Overload Behavior

If a short circuit or overload occurs on a transistor output, this output

will switch off. The output will switch on up to maximum temperature

after the cooling time has elapsed. This time depends on the ambient

temperature and the current involved. If the fault condition persists,

the output will continue to switch off and on until the fault is

corrected or until the power supply is switched off.

For information on using the 1760-IB12XOB8 expansion module to

monitor outputs for a fault, see Monitor for Short Circuit or Overload

on page 9-4.

Publication 1760-UM001D-EN-P - September 2005

Page 51

Commission the Pico

Chapter

3

Power On Unit

Before powering up Pico, check that you have connected the power

supply terminals and inputs correctly.

12V dc version:

• +12V terminal: +12V dc voltage

• COM terminal: 0V voltage

• terminals I1 to I8: actuation via +12V dc

24V dc version:

• +24V terminal: +24V dc voltage

• COM terminal: 0V voltage

• terminals I1 to I12, R1 to R12: actuation via +24V dc

100 to 240V ac version:

• terminal L1: phase conductor L1

• terminal L2: neutral conductor L2 (grounded)

• terminals I1 to I12, R1 to R12: actuation via phase conductor L1

ATTENTION

1 Publication 1760-UM001D-EN-P - September 2005

If you have already installed Pico into a system,

ensure that the working area of all connected

devices is secure. Advise all personnel of start-up to

avoid injury in the event of unexpected operation.

Page 52

3-2 Commission the Pico

Set the Menu Language

When you power-up Pico for the first time, you are asked to select the

menu language.

Use the up and down cursor buttons to select a language. Definitions

of the language abbreviations are shown below.

Language LCD display Abbreviaton

English ENGLISH GB

German DEUTSCH D

French FRANCAIS F

Spanish ESPANOL E

Italian ITALIANO I

Portuguese PORTUGUES –

Dutch NEDERLANDS –

Swedish SVENSKA –

Polish POLSKI –

Turkish T UR KCE –

Czech CESKY –

Hungarian MAGYAR –

Press Ok to confirm your choice or press Esc to exit the menu. The

unit then switches to the status display. You can also change the

language setting at a later date, see Chapter 6 for more information.

If you do not set the language, Pico displays this menu and waits for

you to select a language every time the unit is powered up.

ENGLISH

DEUTSCH

FRANCAIS

ESPANOL

ITALIANO

PORTUGUES

NEDERLANDS

SVENSKA

POLSKI

TURKCE

CESKY

MAGYAR

Publication 1760-UM001D-EN-P - September 2005

Page 53

Commission the Pico 3-3

Modes of Operation

Pico has two operating modes: Run and Stop.

In Run mode, the unit continuously processes a stored program or

circuit diagram until you select Stop or disconnect the power. The

circuit diagram, parameters, and settings are retained in the event of a

power failure. If the back-up time has elapsed after a power failure,

you will need to reset the real-time clock. Circuit diagram entry is only

possible in Stop mode.

ATTENTION

In Run mode, Pico immediately runs the circuit

diagram saved in the unit when the incoming power

is turned on. This happens unless Stop mode was set

as start-up mode. In Run mode, outputs are activated

according to the program.

In models with an LCD display, a circuit diagram inside an installed

memory module is not run automatically. The circuit diagram must

first be transferred from the memory module to the unit.

In Run mode, the 1760-L12xxx-ND and 1760-L18xxx-xxND load the

circuit diagram from the memory module automatically and run it

immediately.

Publication 1760-UM001D-EN-P - September 2005

Page 54

3-4 Commission the Pico

Create a Circuit Diagram (Program)

The following small circuit diagram example takes you step-by-step

through programming your first Pico circuit diagram. This example

demonstrates most of the basic programming rules.

As with conventional wiring, you use contacts and relays in the Pico

circuit diagram. With Pico, however, you no longer have to connect

components individually. With the push of a few buttons, the Pico

circuit diagram produces all the wiring. All you have to do is connect

any switches, sensors, lamps or contactors you wish to use.

+24V dc 0V dc

S1

S2

CR1

CR1

M1

In the following example, Pico carries out all the wiring and performs

the tasks of the circuit diagram shown above.

.

+24V

0V

F1

S1

S2

I1

com

+24V

Q1

2

1

H1

0V

I2

Publication 1760-UM001D-EN-P - September 2005

Page 55

..............

I

MO 02:00

......... STOP

Expansion Module

Status Screen

1..........12

RS

MO 10:42 ST

1.......8

AC P-

Commission the Pico 3-5

Start Point: Status Display

When you power up the unit, it opens the status display immediately

to show the state of the inputs and outputs. It also indicates whether

Pico is already running a program.

Press Ok to switch to the main menu. If there is an expansion module

installed, the expansion module status screen is displayed. Press Ok

again to switch to the main menu.

You can then press Ok to move forward to the next menu level or Esc

to go back one level. Ok has two other functions:

• Press Ok to save modified settings.

• Press Ok to insert and modify contacts and relay coils. In this

case, Pico must be in Stop mode.

Press Ok two times (3 times with an expansion module installed) to

enter the circuit diagram display from the status display(s). This is

where you create the circuit diagram.

I1-I2-----{Q1

Circuit Diagram Display

.The circuit diagram display is currently empty. The cursor is flashing

at the top left, which is where you start to create your program

Move the cursor, using the cursor buttons, across the hidden grid lines

The first three double columns are contact fields and the right-hand

triple column forms the coil field. Each line is a circuit connection.

Pico adds the first contact automatically.

Now try to program the following Pico circuit diagram.

Switches S1 and S2 are wired to inputs I1 and I2. Relay K1 is

represented by the relay coil {Q1. The symbol “{” identifies the coil's

function, in this case a relay coil acting as a contactor. Q1 is one of up

to six Pico output relays.

Publication 1760-UM001D-EN-P - September 2005

Page 56

3-6 Commission the Pico

From the First Contact to the Output Coil

With Pico, you work from the input to the output.

1

I

I1 I1

1. The first input contact is I1. Press Ok. Pico inserts the first

contact I1 at the cursor position.

The ’I’ flashes and can be changed, for example, to a ’P’ for a

button input using the up or down cursor buttons. However,

nothing needs to be changed at this point.

2. Press Ok twice to move the cursor across the 1 to the next

contact field.

You could also move the cursor to the next contact field using

the right cursor button.

3. Press Ok.

Again, Pico creates a contact I1 at the cursor. Change the contact

number to I2 since break contact (normally closed) S2 is

connected to input terminal I2.

4. Press Ok. Then, press the up or down cursor button to change

the number to 2. Press DEL to delete a contact at the cursor

position.

I1-I2

5. Press Ok to move the cursor to the third contact field. You do

not need a third relay contact, so you can now wire the contacts

directly to the coil field.

Publication 1760-UM001D-EN-P - September 2005

Page 57

Commission the Pico 3-7

Wire Inside of Your Program

Pico displays a small arrow when creating a circuit connection.

Pressing Alt activates the arrow and the cursor buttons to move it. Alt

also has two other functions:

• From the left contact field, press Alt to insert a new, empty

circuit connection (rung).

• Press Alt to set the contact currently under the cursor to either a

make or break contact.

The wiring arrow works between contacts and relays. When you

move the arrow onto a contact or relay coil, it changes back to the

cursor and can be reactivated with Alt if required. Pico automatically

wires adjacent contacts in a circuit connection up to the coil.

1. Press Alt to wire the cursor from I2 through to the coil field.

The cursor changes into a flashing wiring arrow and

automatically jumps to the next possible wiring position.

2. Press the right cursor button.

Contact I2 is connected up to the coil field. Use the Del button

to delete wiring at the cursor or arrow position. Where

connections intersect, the vertical connections are deleted first,

then, if you press Del again, the horizontal connections are

deleted.

3. Press the right cursor button again.

The cursor will move to the coil field.

4. Press Ok.

Pico inserts relay coil Q1. The specified coil

function ’

{’ and the output relay Q1 are

correct and do not have to be changed.

Your first working Pico circuit diagram now

I1-I2-----{ Q 1

looks like this:

5. Press Ok. Then press Esc to leave the circuit

diagram display. The diagram will be

automatically saved.

Once you have connected buttons S1 and

S2, you can test your circuit diagram.

Publication 1760-UM001D-EN-P - September 2005

I1-I2-------{Q1

Page 58

3-8 Commission the Pico

Test the Circuit Diagram

PROGRAM...

STOPå RUN

PARAMETER

INFO...

1. Switch to the main menu and select the RUN menu option

(press Esc to go back to the Main Menu and use the arrow keys

to highlight RUN).

2. Toggle between RUN and STOP to set the operating mode

required (use the Ok button to toggle between RUN and STOP).

Pico is in Run mode if the STOP menu option is displayed.

Menu options that toggle between two functions always show

the next possible setting.

The status display shows the current mode and the switching

states of the inputs and outputs.

3. Change to the Status display by pressing Esc and actuate

push-button S1.

Pico 1760-L12xxx Pico 1760-L18xxx

I12345678

MO

12:50

Q1234 RUN

12..........

MO 02:00

1..........RUN

I1-I2-------{Q1

I1-I2-------{Q1

The boxes for inputs I1 and I2 are activated and relay Q1 is energized.

Power Flow Display

Pico allows you to check programs in Run mode. This means that you

can check your circuit diagram via the built-in power flow display

while it is being processed by Pico.

1. Press Ok twice to change to the Circuit diagram display and

actuate push-button S1.

The relay energizes and Pico shows the flow of current.

2. Press push-button S2, that has been connected as a break

contact.

The circuit connection is interrupted and relay Q1 drops out.

Publication 1760-UM001D-EN-P - September 2005

Page 59

PROGRAM

DELETE PROG

Commission the Pico 3-9

3. Press Esc to return to the Main Menu. A circuit diagram does not

have to be completed before you can test parts of it with Pico.

Pico simply ignores any incomplete wiring that is not yet

working and only uses the finished wiring.

Delete a Circuit Diagram

1. Switch Pico to Stop mode.

The RUN option is displayed. Pico must be in Stop mode in

order to extend, delete or modify the program.

2. Select ’PROGRAM’. Press Ok to switch from the main menu to

the next menu level.

3. Select ’DELETE PROG’

Pico displays the prompt ’DELETE?’.

4. Press Ok to delete the program or Esc to cancel.

5. Press Esc to return to the Main Menu.

Fast Circuit Diagram Entry

You can create a circuit diagram in several ways. The first option is to

enter the elements in the circuit diagram and then wire all the

elements together. The other option is to use the enhanced operator

guidance and create the circuit diagram, from the first contact through

to the last coil.

If you use the first option, you have to select some of the elements in

order to create and connect your circuit diagram.

The second, faster option is what you learned in the example. In this

case you create the entire circuit connection from left to right.

Publication 1760-UM001D-EN-P - September 2005

Page 60

3-10 Commission the Pico

Publication 1760-UM001D-EN-P - September 2005

Page 61

Chapter

4

Draw a Circuit Diagram with Pico

By working through the example, Create a Circuit Diagram (Program)

on page 3-4, you should have gained an initial impression on how to

create a program in Pico. This chapter describes the full range of Pico

functions and provides further examples of how to use Pico.

Pico Operation

Buttons for Drawing Circuit Diagrams

Press To

Delete branch, contact, relay, or empty rung in the circuit

Alt

diagram.

• Toggle between break and make contact.

• Connect contacts and relays.

• Add circuit connections (rungs).

Del

1 Publication 1760-UM001D-EN-P - September 2005

Page 62

4-2 Draw a Circuit Diagram with Pico

Up/Down Arrows

• Change value.

• Move cursor up and down.

Left/Right Arrows

• Change between parameters.

• Move cursor left and right.

Cursor Button Set to P-Button Function (if enabled)

• Left Arrow = Input P1

• Right Arrow = Input P3

• Up Arrow = Input P2

• Down Arrow = Input P4

• Undo settings from previous Ok

• Exit current display

Esc

Ok

• Change or add a contact/relay.

• Save the setting.

Publication 1760-UM001D-EN-P - September 2005

Page 63

Draw a Circuit Diagram with Pico 4-3

Button Operation

The cursor buttons in the Pico circuit diagram perform three functions.

The current mode is indicated by the appearance of the flashing

cursor:

• Move

• Enter

• Connect

In Move mode, you can use the arrow keys to move the cursor

around the circuit diagram in order to select a branch, contact or relay

coil.

I 1

Use Ok to switch to Enter mode so that you can enter or change a

value at the current cursor position. If you press Esc in Enter mode,

Pico will undo the most recent changes.

Press Alt to switch to Connect mode for wiring contacts and relays.

Press Alt again to return to Move.

Press Esc to leave the circuit diagram and parameter display. Pico

performs many of these cursor movements automatically. For

example, Pico switches the cursor to Move mode if no further entries

or connections are possible at the selected cursor position.

Opening the Parameter Display

If you specify the contact of a relay type in Enter mode, Pico

automatically switches from the contact number to the parameter

display when you press Ok.

Press the right arrow

entering any parameters.

to switch to the next contact or coil field without

Publication 1760-UM001D-EN-P - September 2005

Page 64

4-4 Draw a Circuit Diagram with Pico

Contacts

Contacts are used to modify the flow of current in the circuit diagram.

Contacts in the circuit diagram are either make or break contacts.

Make contacts are open when off (de-energized) and closed when on.

Break contacts are closed when off and open when on.

Usable Contacts

Contact Pico Representation

Make contact; Open when off

Break contact; Closed when off

Pico works with different contacts, which can be used in any order in

the contact fields of the circuit diagram.

I, Q, M, N, A, Ö, Y, C, T, O, P, :, D, S, R, Z

I, Q, M, N, A, Ö,Y, C, T, O, P, D, S, R, Z

Contact Type Make

Contact

Controller Inputs I I

Break

Contact

1760-L12xxx 1760-L18xxx

1760-L20xxx

I1 to I8 I1 to I12

0 signal I13 I13

Expansion Status –

I14

(3)

Short-circuit/overload I16 I15 to I16

Soft Inputs - Keypad P P

Controller Outputs Q Q

Internal Marker Bits M M

Internal Marker Bits N N

Counters C C

Timers T T

Real Time Clock

Analog Setpoint

Compare

(1)

AAA1 to A16 A1 to A16

(2)

Text Display D D

Expansion Outputs or

SS

P1 to P4 P1 to P4

Q1 to Q4 Q1 to Q8

M1 to M16 M1 to M16

N1 to N16 N1 to N16

C1 to C16 C1 to C16

T1 to T16 T1 to T16

1 to 8 1 to 8

D1 to D16 D1 to D16

S1 to S8 S1 to S8

Internal Marker Bits

Publication 1760-UM001D-EN-P - September 2005

Jump to Label : – :1 to :8 :1 to :8

Expansion Inputs R R

Expansion Overload

RR

–R1 to R12

–

R15 and R16

Detection

(3)

Page 65

Draw a Circuit Diagram with Pico 4-5

Contact Type Make

Contact

Break

Contact

1760-L12xxx 1760-L18xxx

1760-L20xxx

Operating Hours Counter O O O1 to O4 O1 to O4

Year Time Switch Y Y

Master Reset Z Z

(1) Not available on “-NC” models.

(2) This applies only to the 1760-LxxBWB-xx and 1760-L12DWD.

(3) This applies only to 1760-L18xxx-EX models. R15 and R16 are used for expansion overload detection for the

transistor expansion module, 1760-IB12XOB8, as described on page 9-4.

Y1 to Y8 Y1 to Y8

Z1 to Z3 Z1 to Z3

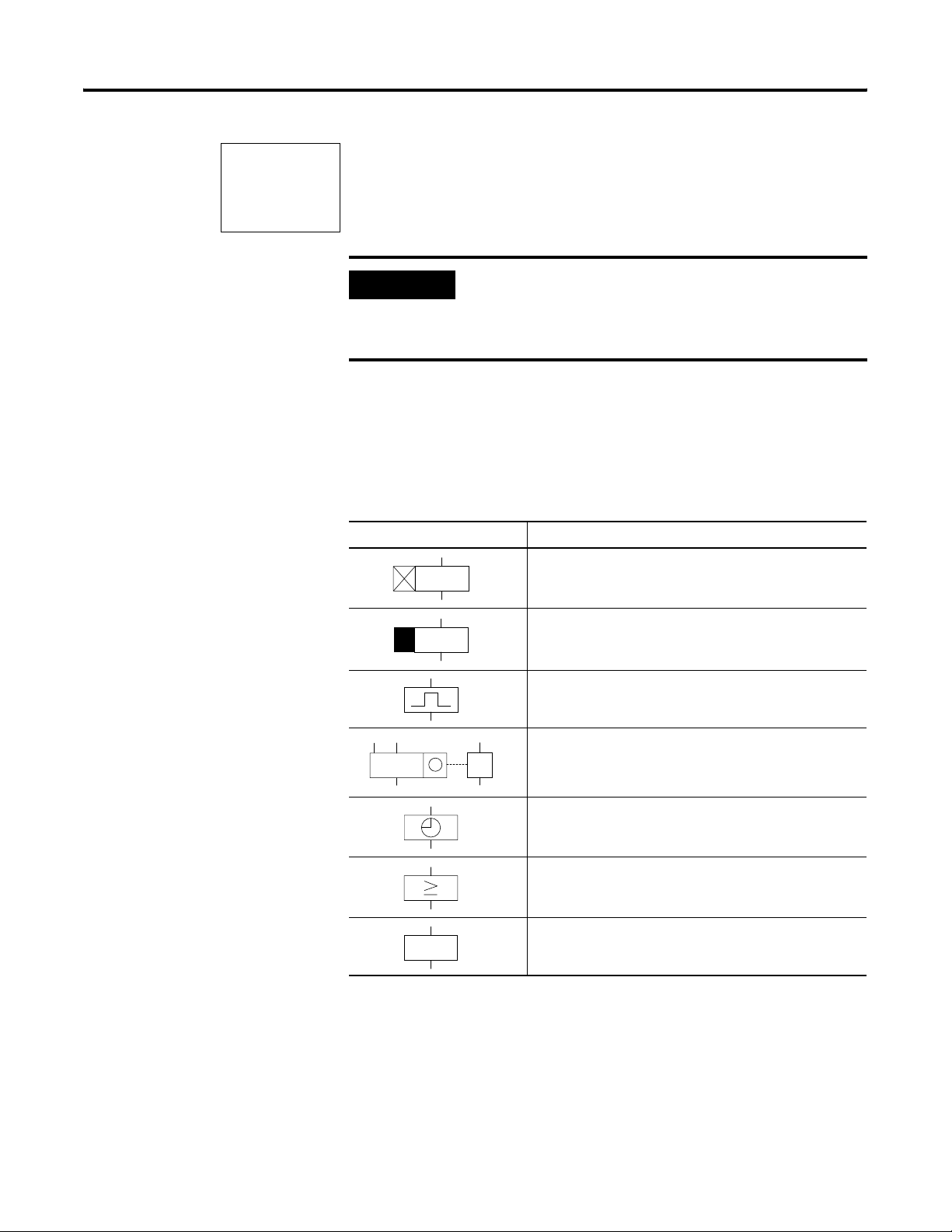

Relays

Pico has nine different types of relay for use in a circuit diagram.

Relay type Pico Symbol 1760-L12xxx 1760-L18xxx

1760-L20xxx

Controller Outputs Q Q1 to Q8 Q1 to Q8 X –

Internal Marker Bits M M1 to M16 M1 to M16 X –

Coil

Function

Parameter

Internal Marker Bits N N1 to N16 N1 to N16 X –

Counters C C1 to C16 C1 to C16 X X

Timers T T1 to T16 T1 to T16 X X

Real Time Clock

(1)

1 to 8 1 to 8

–X

Operating Hours Counters O O1 to O4 O1 to O4 X X

Analog Setpoint Compare

(2)

A A1 to A16 A1 to A16 – X

Text Display D D1 to D16 D1 to D16 X X

Jump to Label : :1 to :8 :1 to :8 X –

Expansion Outputs or Internal Marker

S S1 to S8 (as marker) S1 to S8 X –

Bits

Year Time Switch Y Y1 to Y8 Y1 to Y8 – X

Master Reset Z Z1 to Z3 Z1 to Z3 X –

(1) Not available on “-NC” models.

(2) This applies only to the 1760-LxxBWB-xx and 1760-L12DWD.

Publication 1760-UM001D-EN-P - September 2005

Page 66

4-6 Draw a Circuit Diagram with Pico

The switching behavior of these relays is set using coil functions and

parameters. The coil functions and parameters are listed with the

description of each function relay type.

The options for setting output and marker relays are listed with the

description of each coil function.

Circuit Diagram Display

In the circuit diagram, contacts and coils are connected from left to

right - from contact to coil. The circuit diagram is created on a hidden

grid containing contact fields, coil fields and circuit connections. It is

then wired with connections.

Insert relay contacts in the three contact fields. The first contact field is

automatically connected to the voltage.

Insert the relay coil to be controlled together with its function and

designation in the coil field.

Every line in the circuit diagram forms a circuit connection or ladder

logic rung. Pico enables 128 circuit connections/rungs.

Coil FieldContact Fields

I1 -I2 -T1 -{Q1

Circuit

Q1 -

connections/rungs

1

Connections

Connections are used to produce the electrical continuity between

relay contacts and the coil. Connections can be created across several

rungs. Each point of intersection is a connection. The circuit diagram

display performs two functions:

Publication 1760-UM001D-EN-P - September 2005

• In Stop mode, it is used to edit the circuit diagram.

• In Run mode, it is used to check the circuit diagram using the

Power flow display.

Page 67

Draw a Circuit Diagram with Pico 4-7

Save and Load Circuit Diagrams

There are two ways of saving circuit diagrams in Pico:

• Save to a memory module.

• Save to a PC running PicoSoft programming software.

Once they are saved, programs can be reloaded into Pico, edited, and