Page 1

User Manual

EtherNet/IP Secure Communication

Catalog Number 1756-EN2TSC

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation,, ControlFLASH, ControlLogix, FactoryTalk View, FLEX, Logix5000, POINT I/O, PowerFlex, RSLinx, RS View, and Studio 5000 are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

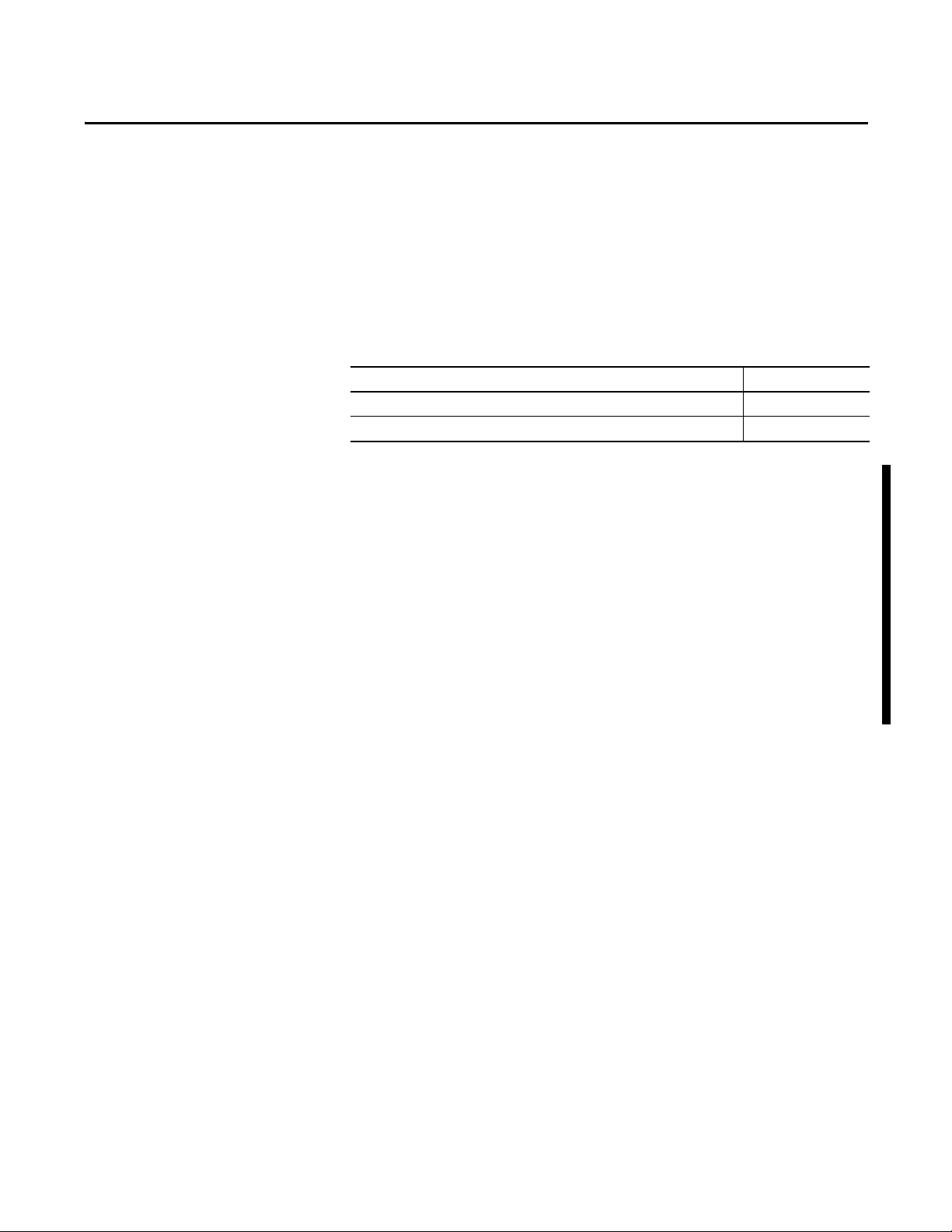

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Clearer information on configuring an L2TP connection for a secure tunnel

between the 1756-EN2TSC module and a Windows client

Chapter 3

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 5

Table of Contents

Preface

Secure Communication Architecture

Get Started

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Local Chassis Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Network Access Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IPsec Association . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Traffic Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Initial Powerup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Default Credentials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Assign Network Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Change Network Settings via the Module Web Page . . . . . . . . . . . . 19

Create User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Edit Access Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Generate HTTPS Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Backup / Restore. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configure a Secure Connection to a

Microsoft Windows Client

Configure Secure Communication

Between Two 1756-EN2TSC Modules

Configure a Secure Connection to a

VPN Appliance

Chapter 3

L2TP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configure a Mobile Client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configure a Connection to a Microsoft Windows Client . . . . . . . . . . . . 34

Interface Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Open the VPN Connection to the 1756-EN2TSC Module. . . . . . . . . . 42

Communicate to the Module via an RSLinx Driver . . . . . . . . . . . . . . . . . 43

Chapter 4

Configure the First (Local) Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configure the Second (Remote) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Test the Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Edit the Security Association. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5

Configure the Module to Connect to a VPN Appliance . . . . . . . . . . . . . 53

Edit the Security Association. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 6

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 5

Page 6

Table of Contents

Diagnostics

Index

Diagnostic Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Secure Tunnel Diagnostics Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Link (LINK) Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Network (NET) Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

OK Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 7

Preface

The 1756-EN2TSC is a security-enhanced version of the 1756-EN2T

EtherNet/IP communication module. This module is designed for applications

that need to limit network access to a control system from within the plant

network. This module is not intended to connect any devices in the local 1756

backplane to devices outside of the plant firewall.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

1756 ControlLogix Communication Modules Specifications Technical Data, publication

1756-TD003

EtherNet/IP Network Configuration User Manual, publication ENET-UM001

EtherNet/IP Modules Installation Instructions, publication ENET-IN002

Ethernet Design Considerations Reference Manual, publication ENET-RM002

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, http://www.ab.com Declarations of conformity, certificates, and other certification details

Specifications for ControlLogix communication modules

Guidelines for configuring EtherNet/IP network parameters

Guidelines for installing EtherNet/IP modules

Guidelines for Ethernet networks

Guidelines for installing a Rockwell Automation industrial system

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 7

Page 8

Preface

Notes:

8 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 9

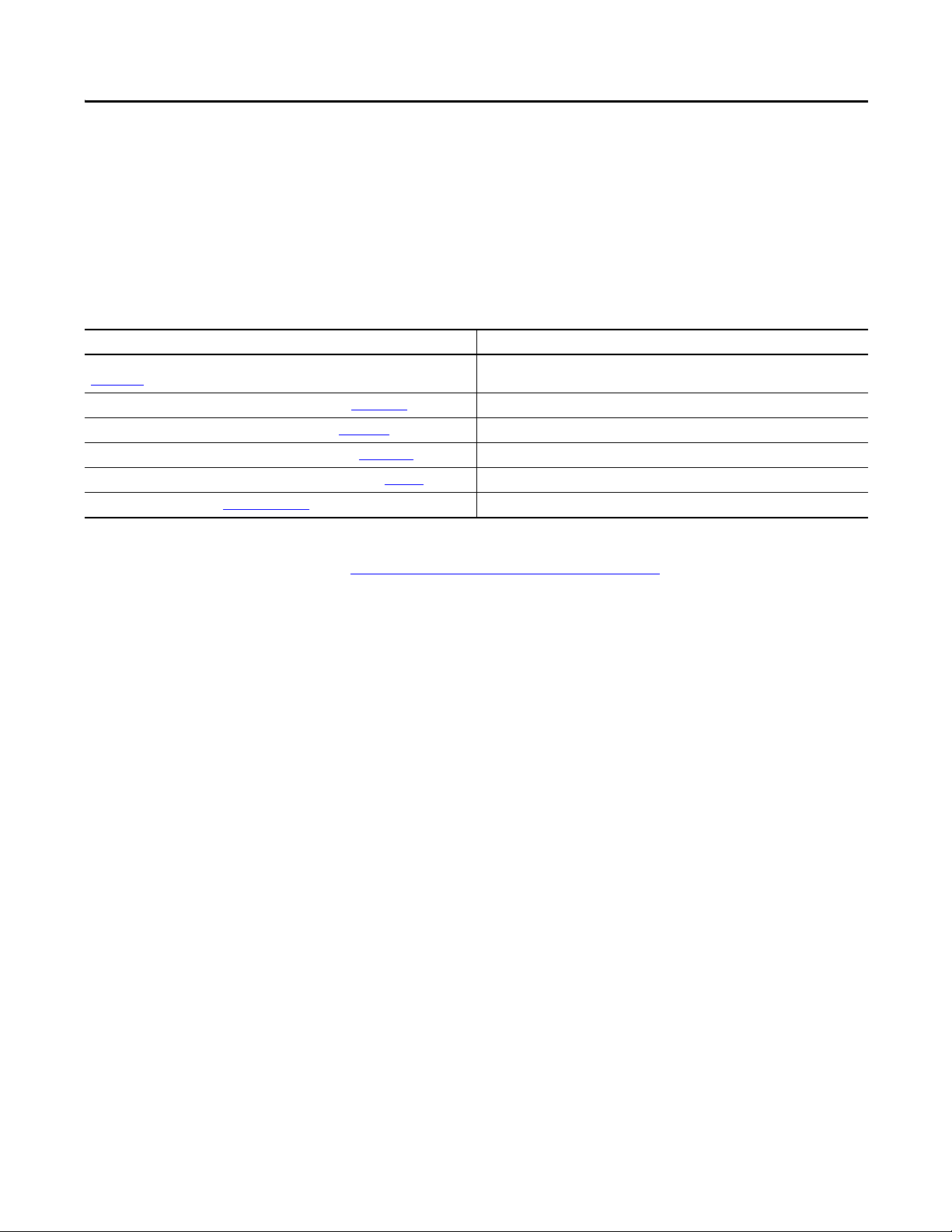

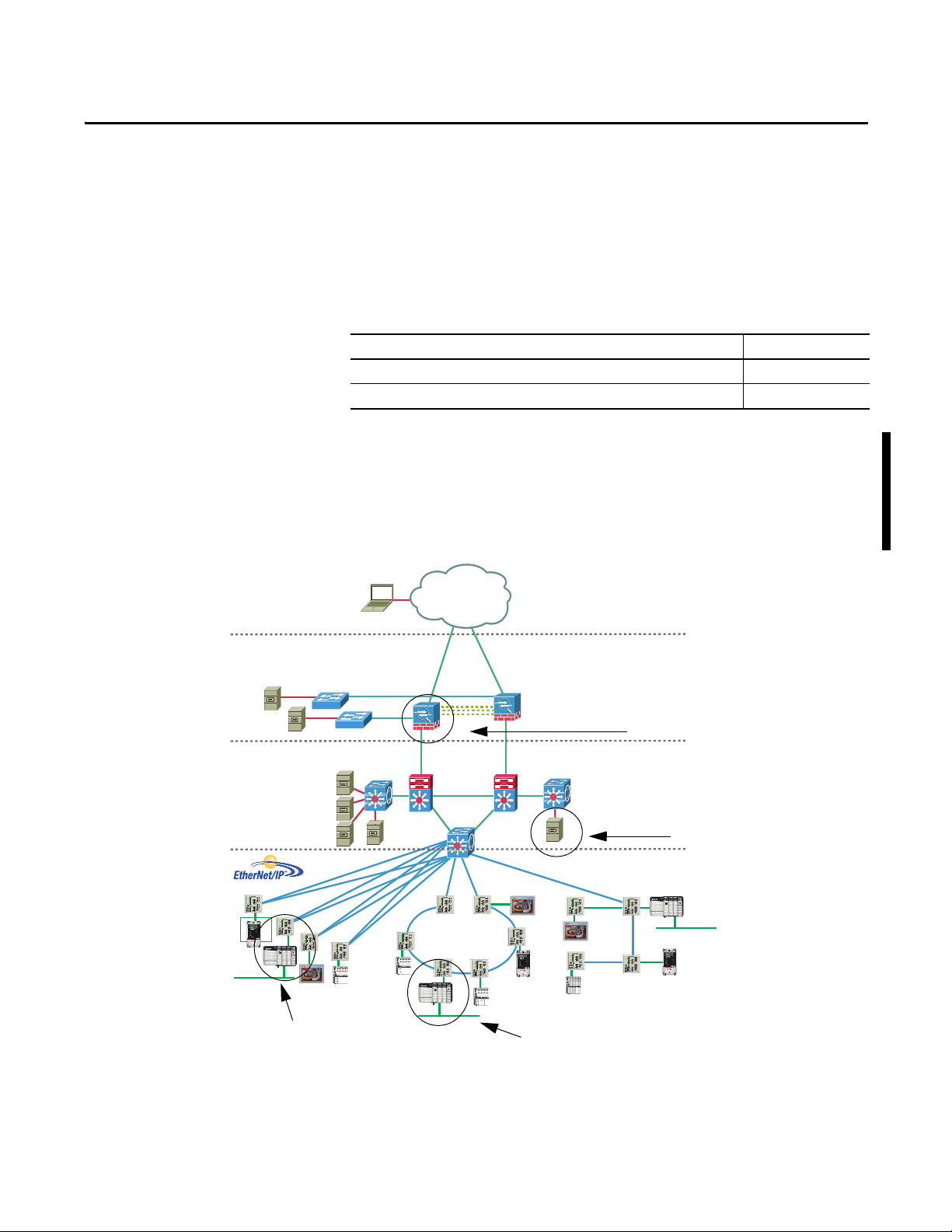

Chapter 1

Enterprise Zone

Levels 4 and 5

Demilitarized Zone (DMZ)

Demilitarized Zone (DMZ)

Manufacturing Zone

Site Manufacturing

Operations and Control

Level 3

Level 0…2

Secure Tunnel Between 1756-EN2TSC

Module and Windows 7 Client.

Peer-to-Peer Secure Tunnel

Between 1756-EN2TSC Modules

ControlLogix Chassis with

1756-EN2TSC Module

Secure Tunnel Between 1756-EN2TSC

Module and VPN Appliance

Secure Communication Architecture

Top ic Pag e

Network Access Security 12

Performance 14

Many control systems currently use 1756-EN2T and 1756-ENBT modules to

connect ControlLogix® systems to plant-level systems. A 1756-EN2TSC module

offers the same connectivity, as well as additional security options to protect

access to resources on the local backplane from the plant network Use the

1756-EN2TSC module to establish secure tunnels with peer modules,

Windows 7 clients, and VPN appliances.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 9

Page 10

Chapter 1 Secure Communication Architecture

The 1756-EN2TSC module provides a level of protection against unauthorized

network access, either malicious or accidental, to a ControlLogix controller via

an EtherNet/IP connection. The 1756-EN2TSC module uses the IPsec protocol

suite to provide a secure communication tunnel.

The 1756-EN2TSC module is intended for use behind an existing

firewall/DMZ that protects the plant network from outside access. This module

is not intended to be connected directly to the public Internet or to provide a

mechanism by which remote access is provided to a network. The module does

not provide the ability to expose a private network address range via IPsec; only

the module’s IP address is available.

Considerations

Out-of-the-box, the module functions just like a 1756-EN2T module, except

that the module does not support the following :

• Integrated motion on EtherNet/IP networks

• ControlLogix redundancy systems

• SIL 2 applications

• Email capabilities

• EtherNet/IP socket interface

Once security is enabled, modules like POINT I/O™ adapters, FLEX™ I/O

adapters, and PowerFlex® drives are not able to establish a secure connection

because they do not support secure tunnels.

When security is enabled, the module connects with:

• Upper level systems and user workstations with Windows 7 operating

systems

• Cisco ASA security appliances

• Other 1756-EN2TSC modules

The module supports the current versions of common web browsers, such as

Internet Explorer (8 and 9). For security reasons, Secure Sockets Layer (SSL) 2.0

is disabled in the module. Browsers must enable support for cryptographic

protocols SSL 3.0 or Transport Layer Security (TLS) 1.0.

The 1756-EN2TSC module lets only those devices with proper credentials

access the module. This module is intended for use behind an existing

firewall/DMZ that protects the plant network from outside access.

To minimize complexity, the module supports the following authentication and

encryption methods.

• IPsec technology with as many as 8 VPN tunnels (only one of which can

be a Cisco ASA connection)

• Pre-shared key authentication

• AES encryption (128, 192, and 256 bit)'

10 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 11

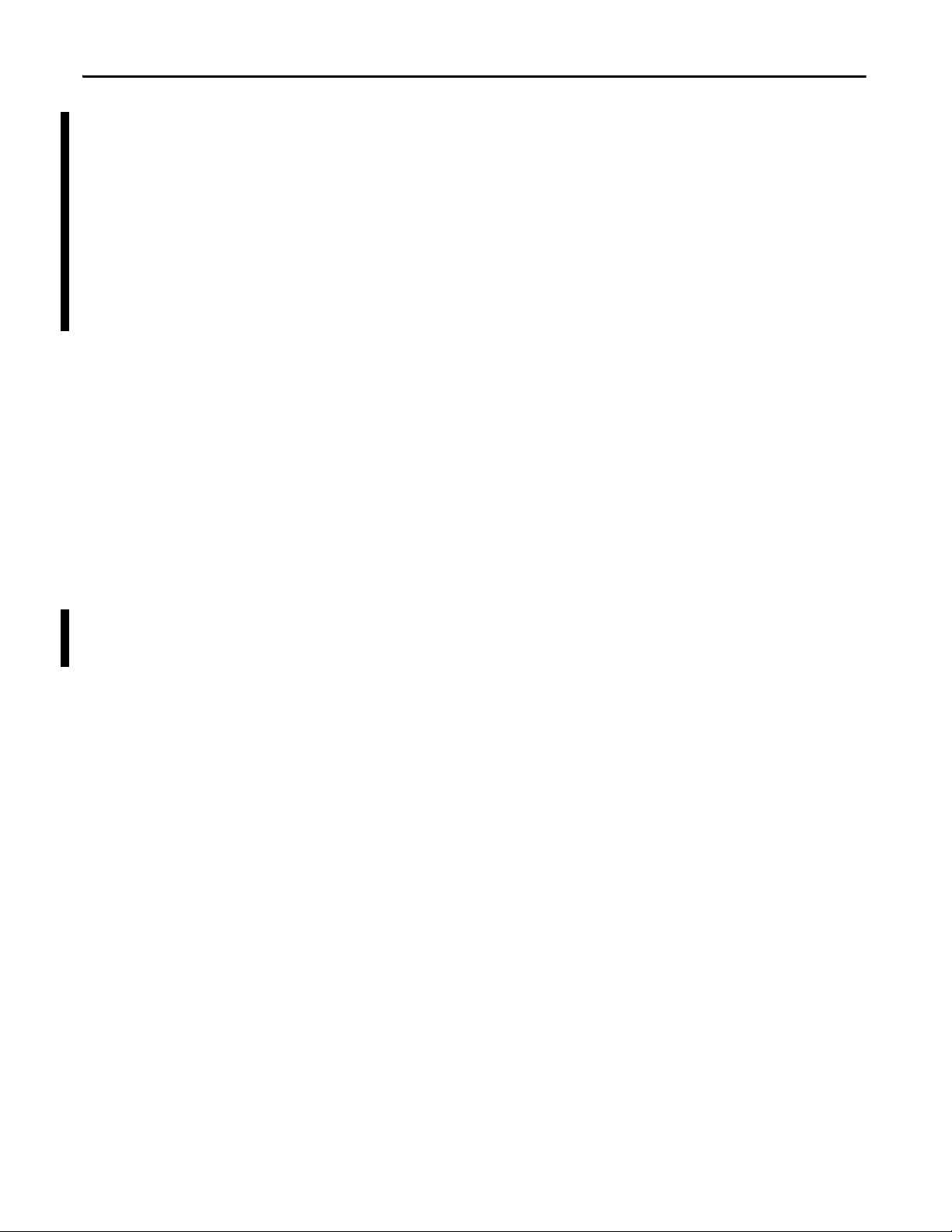

Secure Communication Architecture Chapter 1

Local Chassis Security

You can use the 1756-EN2TSC module with the following features to prevent

unauthorized access to a controller in the local chassis.

• The trusted slot feature (in the controller properties) designates slots in

the local chassis as trusted. When the trusted slot feature is enabled, the

controller denies communication through paths that are not trusted. This

requires authentication to the module for anyone to access the controller

with programming software.

• The serial number lock feature (in the 1756-EN2TSC module properties)

in conjunction with the trusted slot features restricts communication

through a module in the trusted slot with the specific serial number.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 11

Page 12

Chapter 1 Secure Communication Architecture

IMPORTANT

IMPORTANT

EtherNet/IP™

RUNSDOKFORCE

Logix5575

EtherNet/IP™

DeviceNet Access via 1756-DNB

EtherNet/IP Access via 1756-EN2T

Secure Plant Network Access via

1756-EN2TSC

ControlLog ix

Chassis

The trusted slot and serial number lock features are for applications that have

concern with physical access to and tampering with the controller.

Use caution with these features and make sure you have the controller project backed up in a

secure location. If the module becomes disabled for any reason, you have to download to the

controller to recover.

Network Access Security

The 1756-EN2TSC module uses the Internet Protocol Security (IPsec)

technology to provide secure communication over the Ethernet network. IPsec is

widely-deployed, and is often used to create Virtual Private Networks (VPN).

IPsec provides the following security features:

• Authentication of the communication end points (both client and server)

• Data authenticity and integrity (via message integrity checks)

• Data confidentiality (via encryption algorithms)

Use of the IPsec protocol suite lets you use the Microsoft Windows VPN client

to connect securely to the module. IPsec also lets the module create secure

tunnels with other 1756-EN2TSC modules and with off-the-shelf, VPN

appliances.

The module does not provide access to a private network.

While the module supports secure communication, the module is not intended

to be connected directly to the public Internet and provide a VPN function, or be

the mechanism by which remote access is provided to a network. The module

does not provide the ability to expose a private network address range via

IPsec—only the module’s IP address is available.

12 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

The module does the following:

• Secures access to the controller and I/O modules in the local chassis

• Secures bridge access to other networks accessible within the local chassis

Page 13

As part of establishing the secure tunnel, both endpoints must authenticate with

each other and exchange information to ensure secure data transfer. When

security is enabled, the module is able to connect only with the following:

• Upper level systems and user workstations with Windows 7 operating

systems

• Cisco ASA security appliances

• Other 1756-EN2TSC modules

IPsec Association

Once the IPsec association is established, data between the two endpoints is fully

encrypted (except for produced/consumed tags) or optionally sent unencrypted,

but with a cryptographic message integrity code.

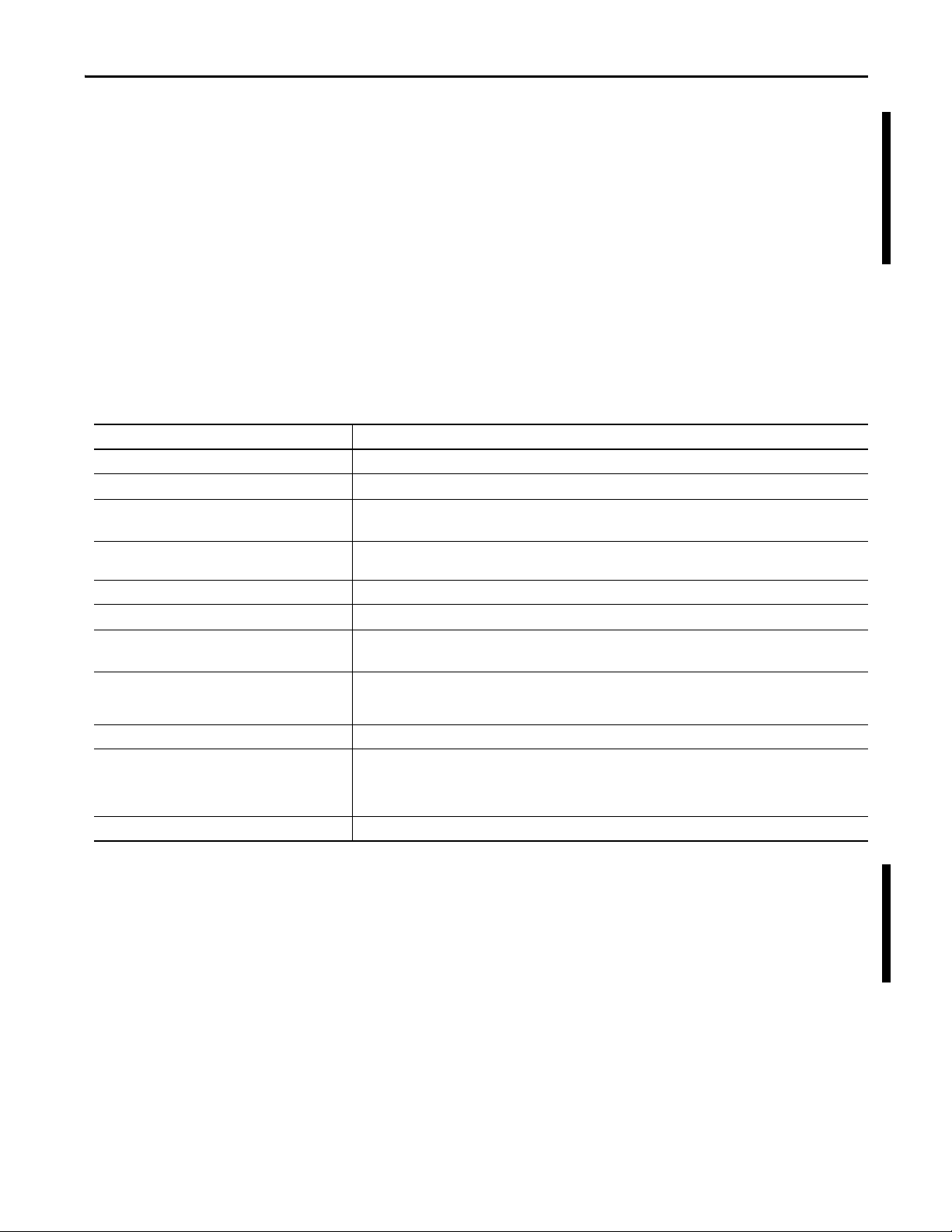

Capability Description

Authentication Method Pre-shared key (PSK). Configure a secret key on each of the endpoints.

Header Format Encapsulating Security Payload (ESP)

Mode Tunnel mode, default

Transport mode if the module cannot negotiate tunnel mode (such as a Microsoft Windows 7 client)

Internet Key Exchange • IKE version 1

• IKE version 2

Lifetime(s) IKE and IPsec lifetimes user-configurable

PFS Group None

DH Key Group Group 2 = modp1024, default

Groups 5,14,15,16,17, and 18 supported

IKE Encryption Algorithm • AES(128 bit)

• AES(192 bit)

• AES(256 bit)

IKE Authentication Algorithm SHA-1

IPsec Encryption Algorithm • AES(128 bit)

• AES(192 bit)

• AES(256 bit)

• None

IPsec Authentication Algorithm SHA-1

Secure Communication Architecture Chapter 1

As long as the IPsec traffic is received, the connection is considered alive. Your

VPN connection can recover without having to re-authenticate if you lose your

connection for a very short period of time (few seconds). However, if the time

since the last received packet is greater than the timeout interval, the connection

times out. This interval is common to all IPsec connections and is not

configurable. The default keepalive-timeout is 30 seconds.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 13

Page 14

Chapter 1 Secure Communication Architecture

Performance

The basic communication capability of the module is the same as the

1756-EN2T module.

• The module supports the same number of TCP and CIP connections as

the 1756-EN2T module (256 CIP connections and 128 TCP/IP

connections).

• The module supports configuration of IPsec associations with as many as

8 IP addresses (devices); only 1 of which can be a Cisco ASA connection.

• The module supports CIP Sync communication.

Traffic Filtering

When IPsec is enabled, the module blocks traffic that is not received via a VPN

client, another peer with an IPsec connection, or an appliance with an IPsec

connection, with these exceptions:

• BOOTP/DHCP traffic (to let the module obtain an IP address)

• HTTPS traffic (needed to configure the module)

• CIP Sync packets (you have the option to disable CIP Sync)

• Logix produced/consumed tags (the establishment of the

produced/consumed connection occurs over via IPsec)

• 1756 I/O connections in a remote chassis

If the 1756-EN2TSC module is the trusted slot for a ControlLogix chassis, the

following traffic to the controller must go through the 1756-EN2TSC module.

• RSLinx® Classic traffic (such as Studio 5000™ and ControlFLASH

communication)

• RSLinx Enterprise traffic (such as FactoryTalk View® SE and

FactoryTalk View ME communication)

14 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 15

Get Started

IMPORTANT

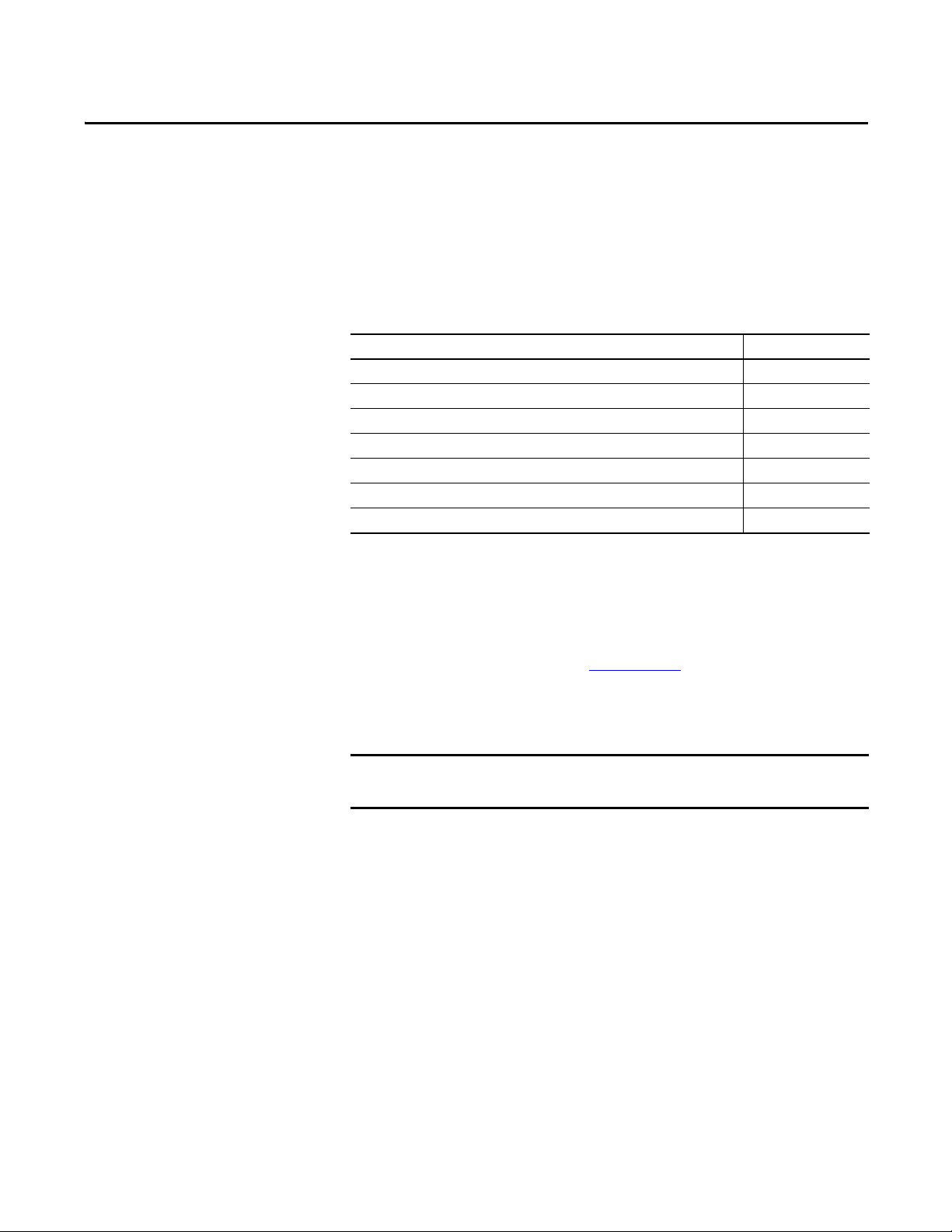

Top ic Pag e

Initial Powerup 16

Configuration Overview 18

Assign Network Settings 19

Configuration Overview 18

Create User Accounts 21

Generate HTTPS Certificate 23

Backup / Restore 25

Chapter 2

This chapter describes the initial configuration settings required for the module.

After setting up the module, see the next chapters for security configuration

examples.

For information on installing the module, see EtherNet/IP Network Modules

Installation Instructions, publication ENET-IN002

.

Add the module to a controller project the same as you add a 1756-EN2T

module. All security-related configuration is via the module web pages.

When you finish using the web pages, close the web browser. This prevents any

user on a shared computer from accessing the web pages.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 15

Page 16

Chapter 2 Get Started

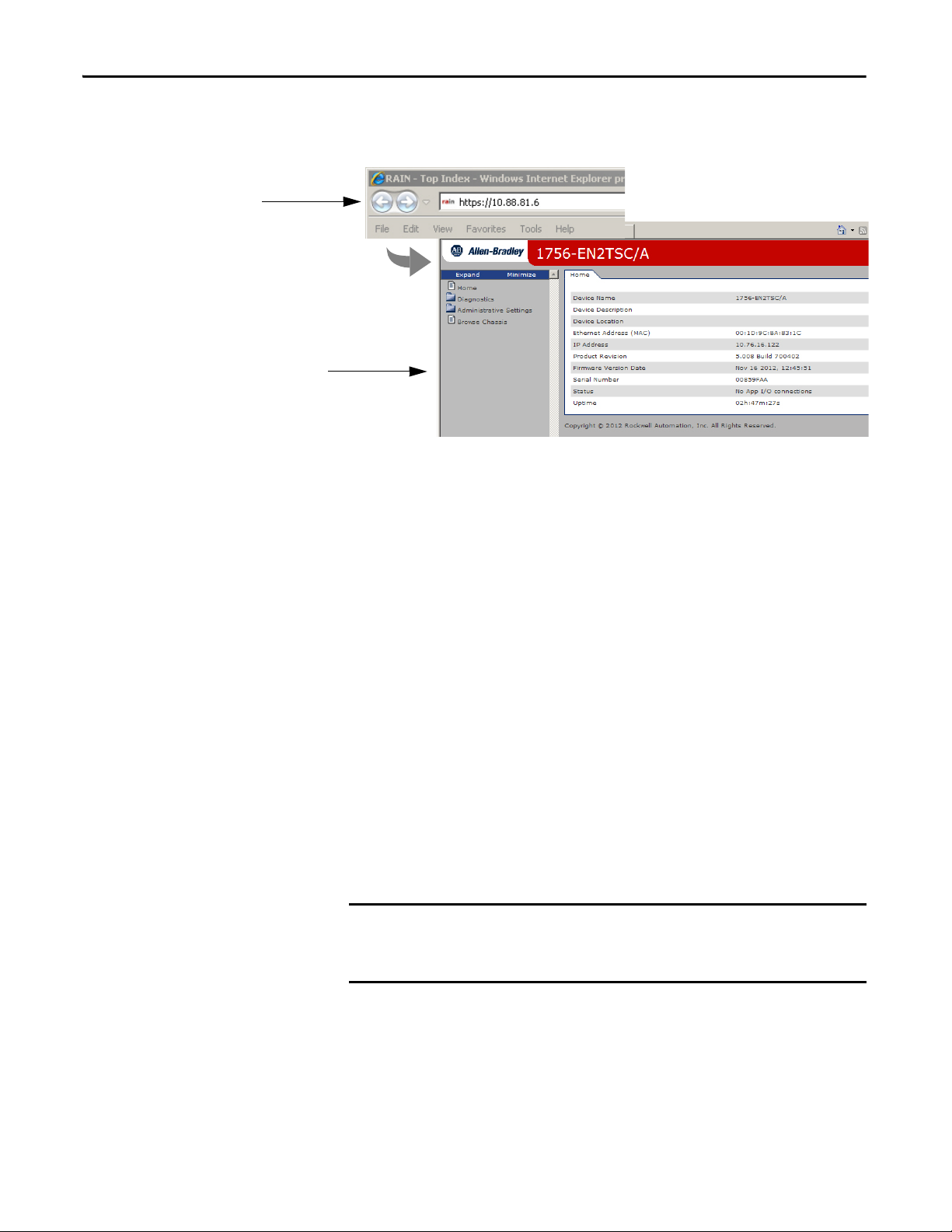

Specify the IP address of the web

server module in the Address

window of your web browser.

This is the module’s Home page.

IMPORTANT

Configure all security parameters via the web server. In the Address field of your

web browser, enter the IP address that displays on the front of the module.

'The 1756-EN2TSC module has an embedded HTTPS server that it uses to

provide secure web communication. An HTTPS server uses a certificate so that

the client can verify server authenticity. For web sites connected to the Internet,

certificates are normally signed by a trusted certificate authority. Web browsers

are then able to verify the authenticity of the web server by virtue of its certificate.

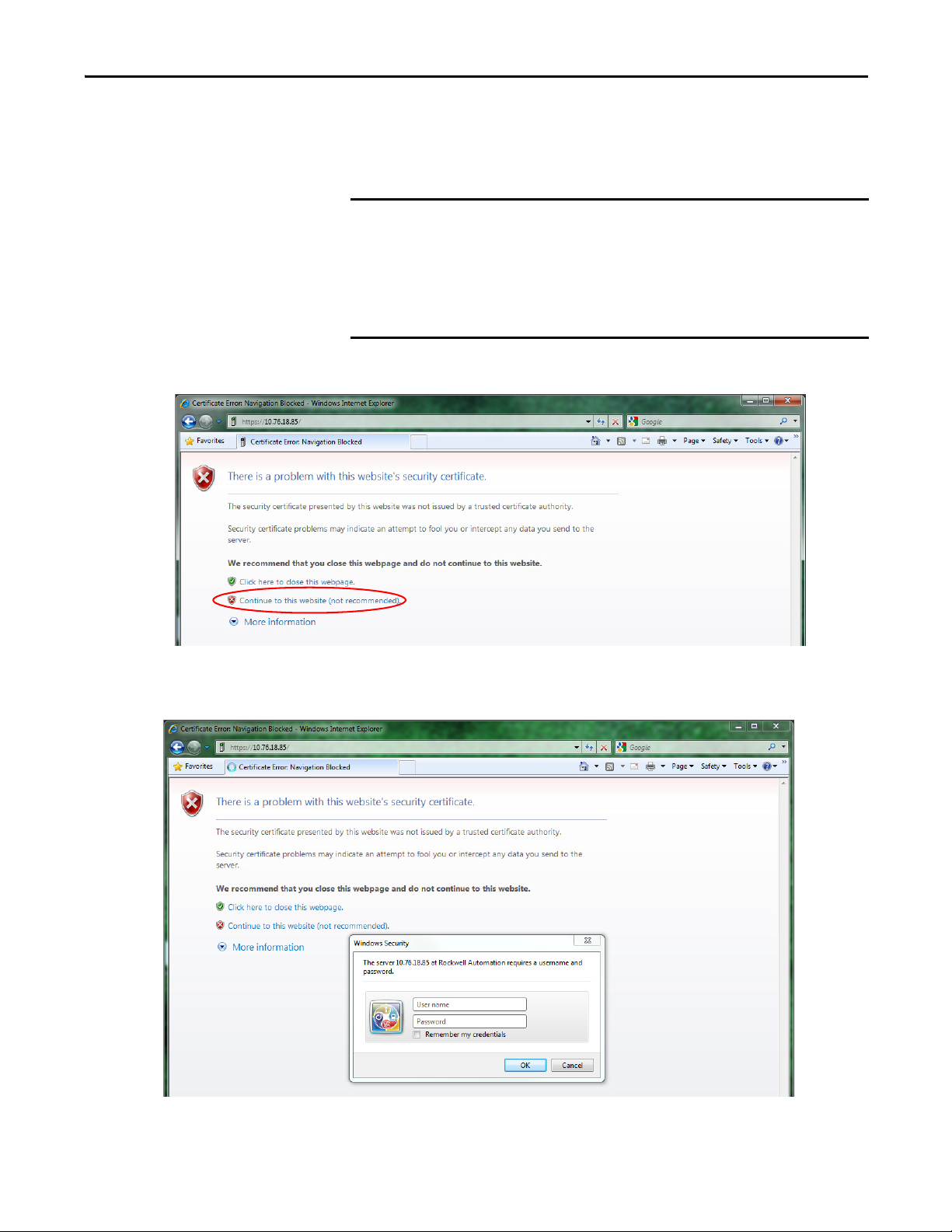

Initial Powerup

The module comes with a self-signed certificate because the module is not

directly connections to the Internet. Self-signed certificates are not signed by a

known, trusted authority, so they must explicitly be accepted by the user when

connecting via the web browser.

On initial powerup, the module generates a new certificate for the embedded

HTTPS server. This can take up to several minutes. During this process, the

message ‘SSL certificate generation in progress’ is shown on the module display.

Wait until the module is fully booted and ‘OK’ is shown on the display before

accessing the module by using a web browser.

1. In the Address field of your web browser, enter the IP address that displays

on the front of the module.

When you enter the IP address, you must enter the prefix https:// in the

address. If you enter an http:// prefix, the module redirects to the

https:// prefix.

16 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 17

Get Started Chapter 2

IMPORTANT

2. After the web browser connects to the server, a warning message is shown

about the certificate not being signed by a trusted authority.

Accept this message and continue to the web page.

In general, do not accept the certificate not being signed by a trusted authority.

But in the case of initial powerup, the module has a self-signed certificate, so

continue to the website even though the message says this option is not

recommended.

The self-signed certificate warning continues to display unless you add the

certificate to the list of exceptions for the web browser.

3. After accepting the self-signed certificate, enter the user name and

password.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 17

Page 18

Chapter 2 Get Started

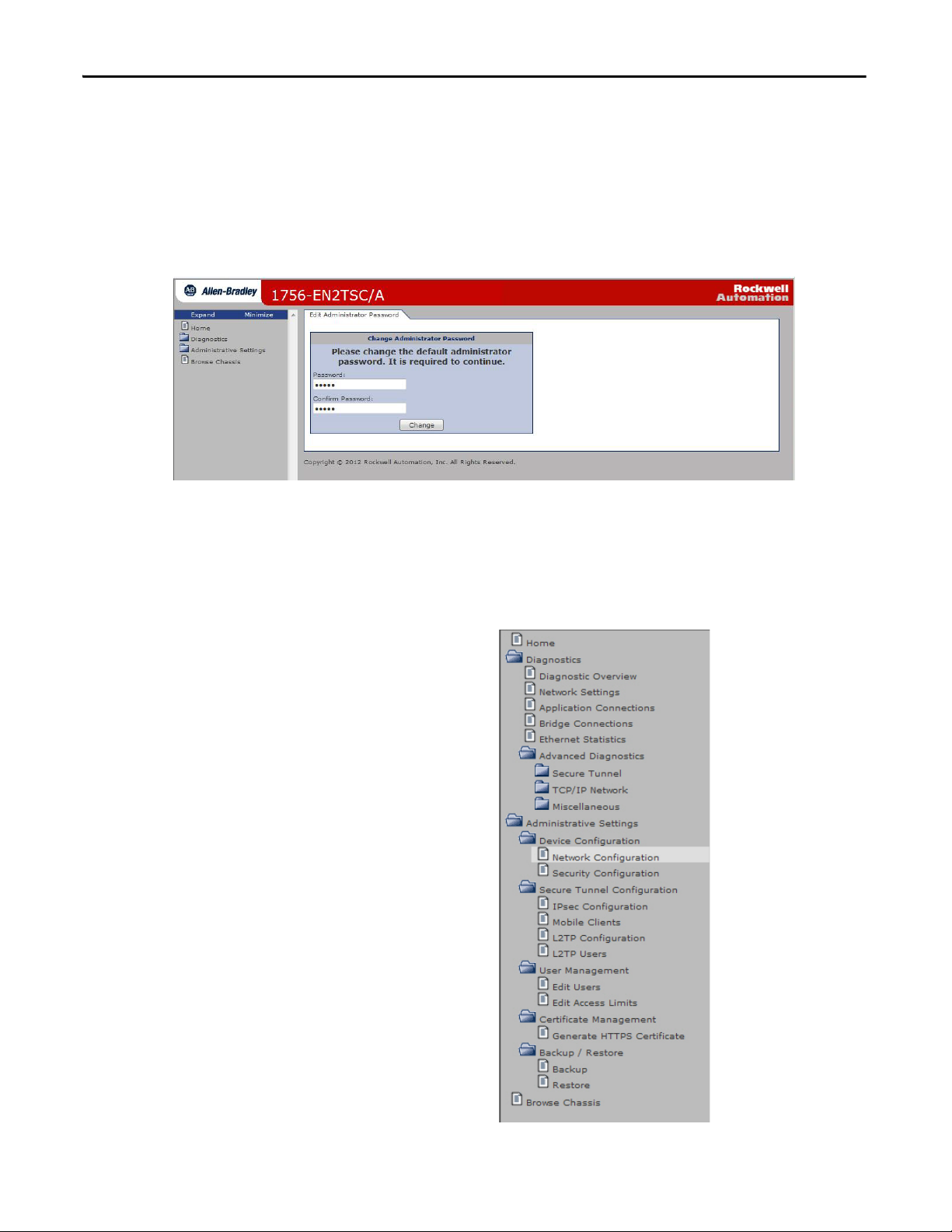

Default Credentials

Default credentials are case sensitive and are as follows:

• User name : Administrator

• Password: admin

You are prompted to change the password on the Administrator account. Enter

the new password and click Change.

The browser prompts you to authenticate again. Use the Administrator user

name and new password.

Configuration Overview

The left pane of the web browser is a navigation tree to configure and maintain

the module.

18 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 19

Get Started Chapter 2

IMPORTANT

See the next chapters in this manual for different security configurations.

Assign Network Settings

By default, the module is BOOTP enabled.

Do not simply configure the initial address assigned to the module as a

static IP address. Contact your network administrator for an appropriate

static IP address.

Choose one of the following methods to assign an IP address.

• Rotary switches on the module (before you install the module)

• Rockwell BOOTP/DHCP utility (available with RSLinx and

Studio 5000 software)

• RSLinx software

• Studio 5000 software

For information on assigning network parameters, see EtherNet/IP Network

Configuration User Manual, publication ENET-UM001

.

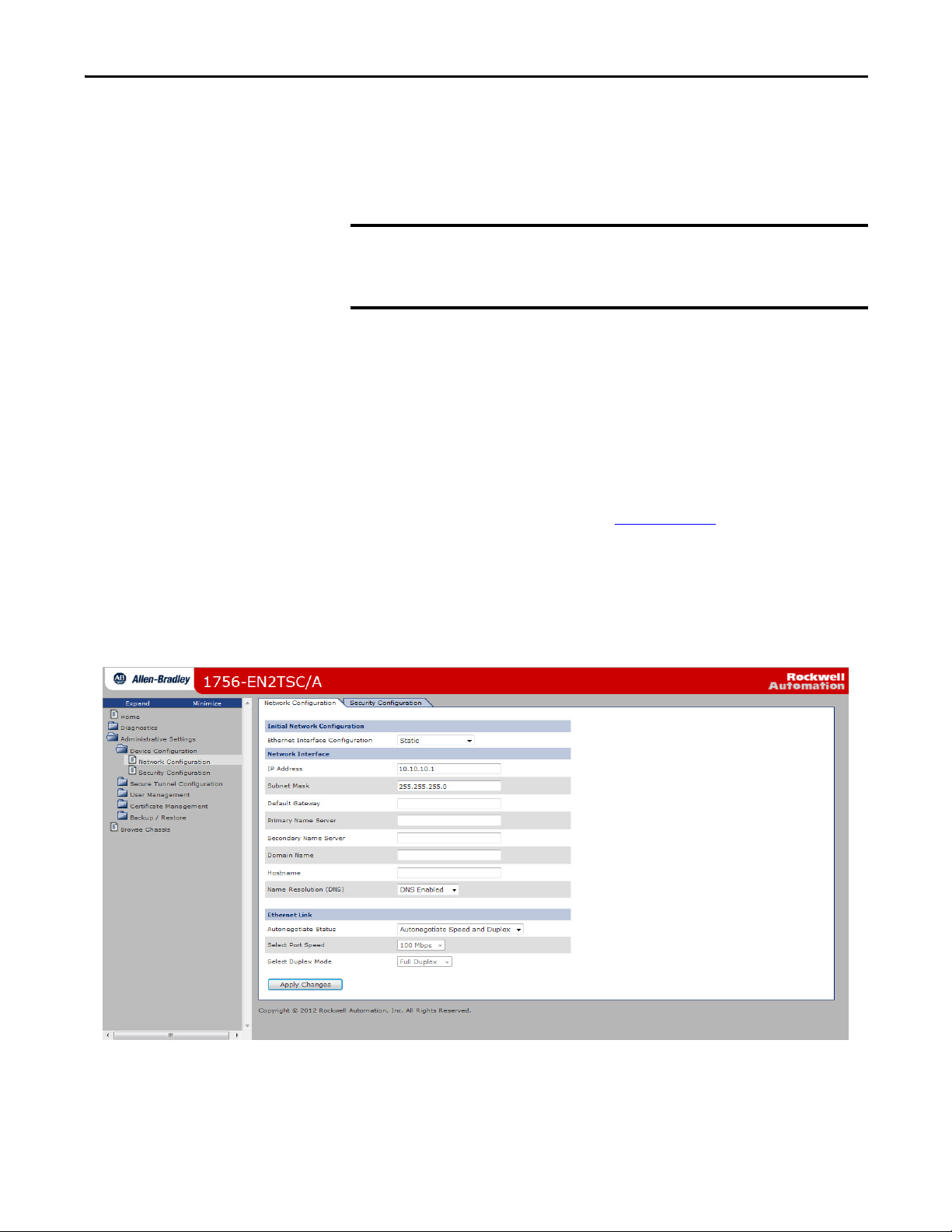

Change Network Settings via the Module Web Page

Choose Administrative Settings > Device Configuration > Network

Configuration. An authenticated user can modify network parameters.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 19

Page 20

Chapter 2 Get Started

In This Field Specify

Ethernet Interface Configuration The network configuration scheme:

IP Address IP address for the module:

Subnet Mask Subnet mask for the module.

Default Gateway Gateway address for the module.

Primary Ser ver Name

Secondary Server Name

Domain Name Domain name for the web server module, if you are using DNS addressing within your Logix program.

Host Name Host name for the module.

Name Resolution (DNS) Whether the module uses DNS addressing within your Logix program.

Autonegotiate Status How to determine port speed and duplex:

Select Port Speed Port speed (10 Mbps or 100 Mbps), if you chose to force speed and duplex.

Select Duplex Mode Duplex (full or half), if you chose to force speed and duplex.

• Dynamic BOOTP (default)

• Dynamic DHCP

• Static

If you want to specify a static IP address for the module, you must also choose Static for the Ethernet Interface

Configuration field.

DNS server addresses, if you are using DNS addressing within your Logix program.

• Autonegotiate speed and duplex (recommended)

• Force speed and duplex

20 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 21

Get Started Chapter 2

Create User Accounts

You can define user accounts for the web interface to the module. These accounts

are typically for administrators or others who need to access the module’s

diagnostic information.

Assign user accounts with access levels to manage who has access to change

configuration or to view module information. Define each user as a member of

the Users group or the Administrators group. Members of the Administrators

group have all access rights to the module. Administrators can limit access of

members in the Users group by editing their access limits.

Every user is authenticated by a user name and a password.

To add or remove a user, access Administrative Settings > User Management >

Edit Users.

To edit an existing user, click the Edit icon.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 21

Page 22

Chapter 2 Get Started

IMPORTANT

From this form, you can change the following :

• Password

• Group membership

• Status (enabled or disabled)

You cannot change the user name.

Edit Access Limits

To add or remove access rights for a user to web pages, access Administrative

Settings > User Management > Edit Access Limits.

Default access limits allow members of the Users group to access status and

diagnostic pages and diagnostics, but limit configuration pages to members of the

Administrators group.

Do not remove default access limits because that makes them available

without authentication.

22 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 23

Get Started Chapter 2

IMPORTANT

Some web pages use both .asp, form, and URL elements. In such cases, each

element is represented by a separate access limit. For example, the ‘Edit Access

Limits’ web page is composed of the following:

• editlimits.asp to generate a list of access limits

• /rokform/AddAccessLimits to add or update an existing limit

• /rokform/DeleteAccessLimit to delete an existing limit

Limiting access to the .asp file is not enough to limit its functionality. If

unsecured, a form handler could be used with externally prepared request.

Generate HTTPS Certificate

You can generate a new HTTPS certificate if needed. This is optional as the

module automatically generates a certificate when the module is turned on for

the first time after factory reset.

• The certificate generated at first powerup of the module is not bound to

any specific IP address. This can cause the browser to report a certificate

error and you can decide whether to generate a new certificate.

• If you generate a new certificate and then later change the IP address of the

module, the current certificate becomes invalid. Generate a new certificate

that uses the new IP address; otherwise the browser reports a certificate

error.

A newly-generated certificate has an advantage that the module uses the current

IP address. This can limit web browser certificate warnings, even though the

browser can still report an error due to a self-signed certificate.

You can specify the validity period of the certificate you generate. The period is

set from the current time on the module to a specified end time. Synchronize the

real-time clock on the Logix5000 controller with the current time. Generating a

short-validity period without the clock being synchronized can generate an

outdated certificate.

To generate a new certificate, choose Administrative Settings > Certificate

Management > Generate HTTPS Certificate.

Use the pull-down menu to choose a valid length of time for the certificate to be

enabled.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 23

Page 24

Chapter 2 Get Started

Certificates

On initial powerup, the subject common name (CN) of the self-generated

certificate is set to Rockwell Automation.

When you generate a new certificate, the CN is changed to the IP address of the

module and the new certificate is applied at the next restart of the module.

24 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 25

Get Started Chapter 2

IMPORTANT

Backup / Restore

To back up module configuration, choose Administrative Settings > Backup /

Restore > Backup.

Choose which items to include in the back-up configuration.

Configuration Item Description

Secure Tunnel Configuration Secure tunnel settings:

USB Configuration USB port enable/disable status

Security Configuration Security settings:

User Management Configuration User management settings

• IPsec Configuration

• Mobile Clients

• L2TP Configuration

• L2TP Users

• 888 Factory Reset

• Remote Factory Reset

• Remote Reset

• Control Flash Update

• Users, p asswords, group s

• Access limits

You can also enter a password if you need to protect the back-up file.

To restore module configuration, choose Administrative Settings > Backup /

Restore > Restore.

Restoring a configuration overwrites the current configuration settings in the module, including

user names and passwords. The restore operation can result in changes that do not allow further

web access to the device.

To reduce this risk, the 888 Factory Reset feature is enabled after every restore. If you want to

disable this feature, you must do so manually.

Rockwell Automation Publication ENET-UM003B-EN-P - August 2013 25

Page 26

Chapter 2 Get Started

1. Specify the back-up file to use.

2. If the back-up file is password protected, enter the password when

prompted.

3. When prompted that the restore overwrites the module, click OK.

When the restore is complete, the module displays a status message.

The module is now configured so that the 888 Factory Reset feature is enabled in

case you need to reset the module to factory settings.

26 Rockwell Automation Publication ENET-UM003B-EN-P - August 2013

Page 27

Chapter 3

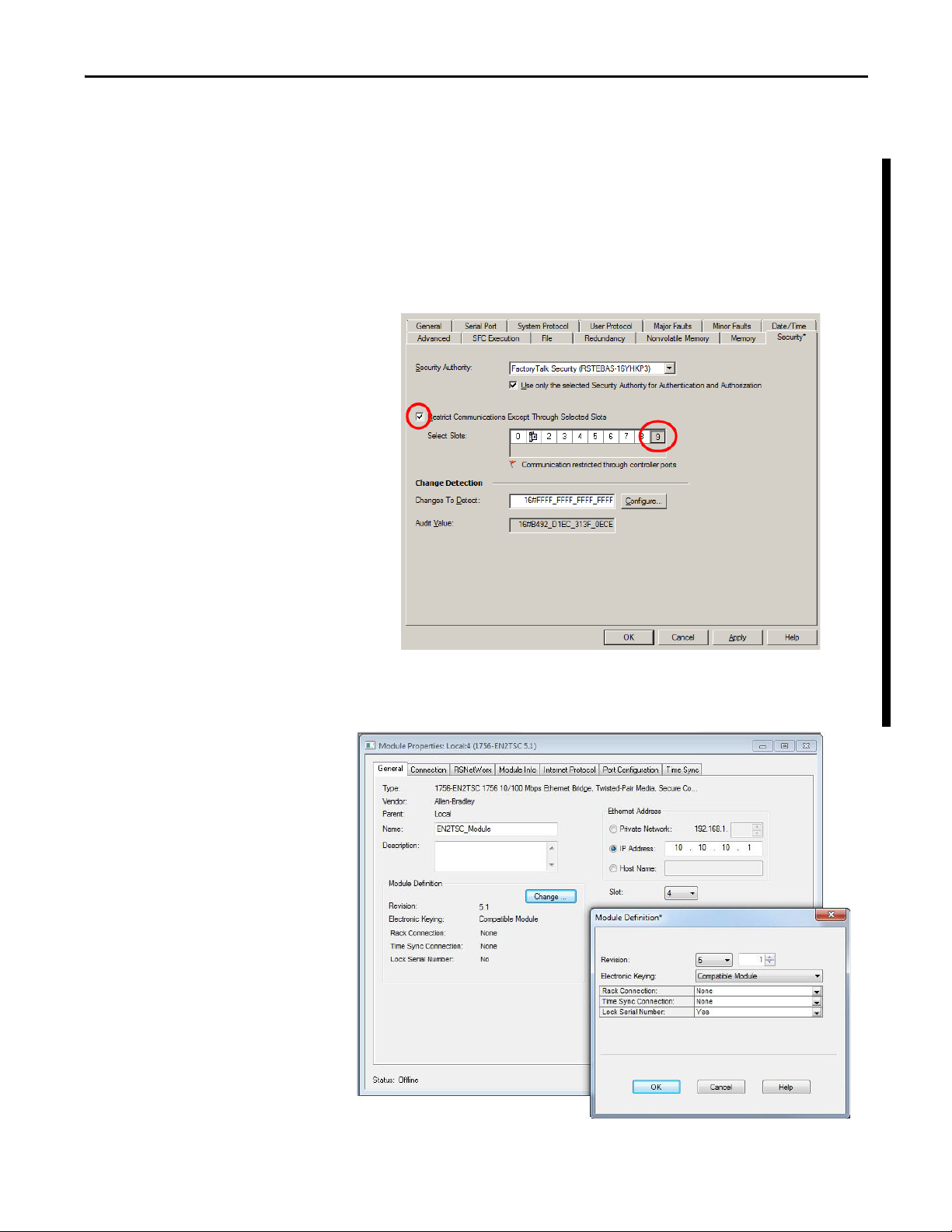

Enterprise Zone

Levels 4 and 5

Demilitarized Zone (DMZ)

Demilitarized Zone (DMZ)

Manufacturing Zone

Site Manufacturing

Operations and Control

Level 3

Level 0…2

ControlLogix Chassis with 1756-EN2TSC Module

Any servers or devices on this level need a

Windows 7 VPN client to connect to the

chassis with the 1756-EN2TSC module.

Configure a Secure Connection to a Microsoft Windows Client

Top ic Pag e

Configure a Mobile Client 29

Configure a Connection to a Microsoft Windows Client 34

Open the VPN Connection to the 1756-EN2TSC Module 42

Communicate to the Module via an RSLinx D river 43

In this scenario a Microsoft Windows 7 client establishes an IPsec association

with the 1756-EN2TSC module.

An example of a Windows 7 client is a personal computer running Studio 5000,

FactoryTalk View, or RSLinx software.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 27

Page 28

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

L2TP Server

(192.168.1.1)

1756-EN2TSC

10.10.10.1

L2TP Client

(192.168.1.2)

PC

10.10.10.2

1756-EN2TSC Module

Personal Computer (L2TP Client)

To configure this secure connection, do the following.

1. Configure the 1756-EN2TSC module to support a connection to a

mobile client.

2. Configure a connection to the Microsoft Windows client.

3. Open the connection.

L2TP Connections

The 1756-EN2TSC module uses Layer 2 Tunneling Protocol (L2TP)

connections for Windows clients. Communication occurs within an L2TP

tunnel (after VPN is already running). The server IP address is used to

communicate with the module. The client IP address is assigned from the client

address pool.

All communication generated by software products, such as RSLinx software, to

an L2TP server address of a 1756-EN2TSC module is sent via an IPsec

connection. This diagram shows how the physical and L2TP IP addresses differ.

• Client, physical IP address 10.10.10.2

• 1756-EN2TSC module, physical IP address 10.10.10.1

• L2TP server, virtual IP address 192.168.1.1

• L2TP client, pool of virtual IP addresses start 192.168.1.2 and end

192.168.1.100

The client uses IP address 10.10.10.2 to establish a connection with the

1756-EN2TSC module at IP address 10.10.10.1. The L2TP server on the

1756-EN2TSC module at IP address 192.168.1.1 establishes a secure connection

with the L2TP client on the client at an IP address from the pool 192.168.1.2

through 192.168.1.100.

Once the pool of addresses is configured, that pool is reserved for that specific

1756-EN2TSC module. If you have a second 1756-EN2TSC module in the

28 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

same controller chassis, you must use a separate subnet (such as 192.168.2.1),

even though the pool from the first address is not completely used.

Page 29

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

First L2T P Server

(192.168.1.1)

1756-EN2TSC

10.10.10.1

First L2T P Client

(192.168.1.2)

PC

10.10.10.2

First 1756-EN2TSC Module

Personal Computer (L2TP Client)

Second L2TP Server

(192.168.2.1)

1756-EN2TSC

10.10.10.6

Second 1756-EN2TSC Module

Second L2TP Client

(192.168.2.2)

The Microsoft IPSec client uses classful network-addressing architecture.

• The traffic from a Windows client is directed to a specific VPN based on

the class of the IP address set in the L2TP configuration.

• Class C addresses (192.168.0.0 through 192.168.255.255) provide the

fewest addresses and supports as many as 256 non-overlapping subnets.

Class C addresses also ensure that no IP address is masked by the active

VPN connection.

• Two 1756-EN2TSC modules connected to the same Windows client at

the same time must be assigned to non-overlapping subnets. Once the

secure tunnel exists, RSLinx software uses the L2TP server IP addresses to

communicate with the controllers through the 1756-EN2TSC modules.

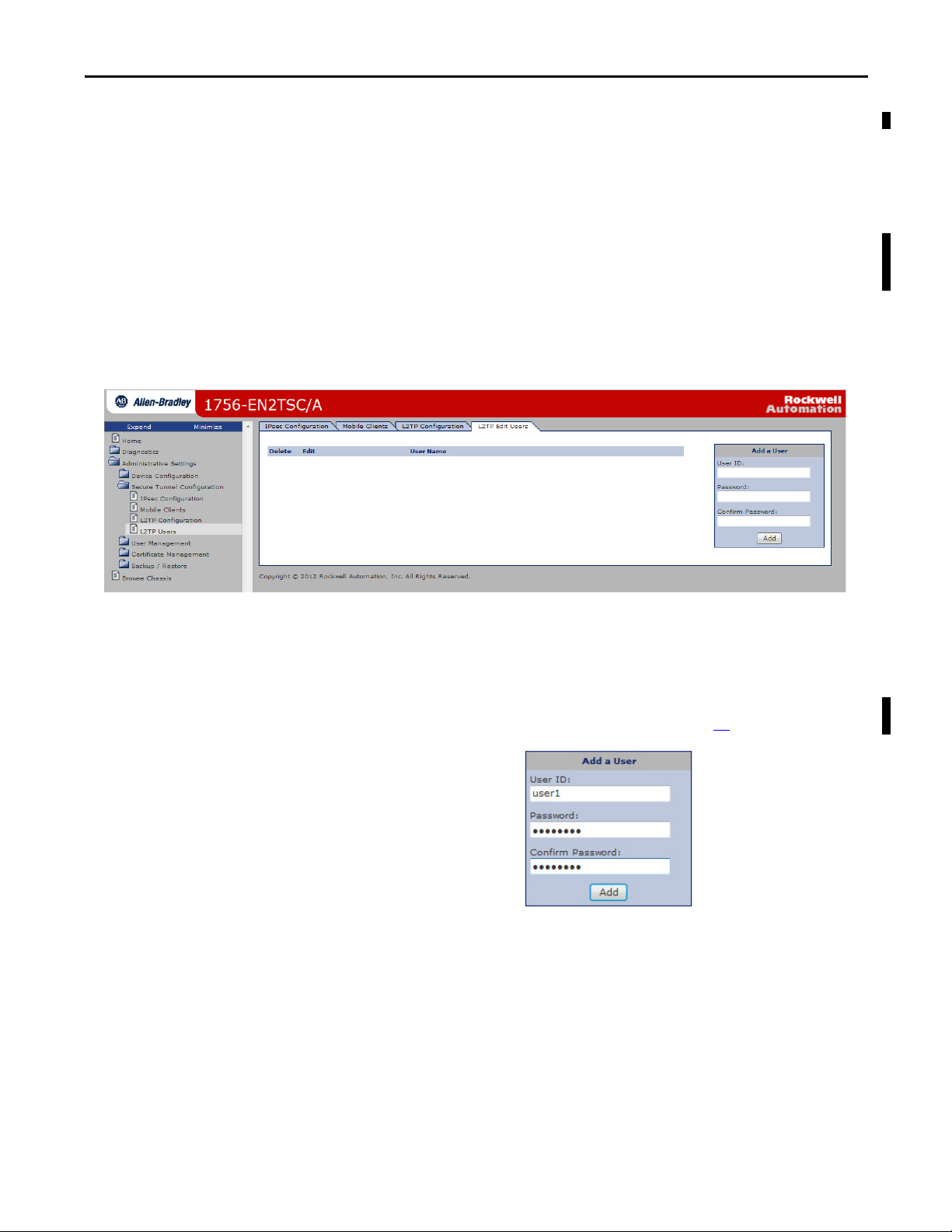

Configure a Mobile Client

A mobile client does not have a predetermined IP address explicitly configured in

the module. For example, a personal computer configured for DHCP connects

to the module. If the IP address of the personal computer changes, no

configuration changes are required on the module.

If the Windows client is a mobile client, make the following configurations on

the module.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 29

Page 30

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

1. Log in to the 1756-EN2TSC module and choose Administrative Settings

> Secure Tunnel Configuration> IPsec Configuration.

2. On the right side of the screen, check Enable to enable IPsec connections.

3. In the Add a Security Association (SA) area, do the following.

a. Enter the Identifier as a text description of the connection.

b. Choose the Windows Client profile.

c. Enter the Remote IP address.

The Windows client does not use this field but you must enter a value

to complete the configuration. Enter the physical IP address of the

client (10.10.10.2 in the above examples) to help identify the secure

tunnel and the client. This address is for display purposes only and does

not affect configuration.

d. Enter the pre-shared key and confirm the pre-shared key.

A pre-shared key is similar to a password. Enter a phrase or set of

characters. For example, you could enter ‘rockwell’ as a pre-shared key.

Remember the pre-shared key. You enter the same value when you

configure the Windows connection (see page 39

).

30 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 31

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

4. Click Add.

5. Click Apply Changes.

6. Verify IPsec connections are enabled.

7. Choose Administrative Settings > Secure Tunnel Configuration> Mobile

Clients.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 31

Page 32

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

8. Make the following configuration selections.

a. Check Enable Mobile Clients.

b. Enter the pre-shared key and confirm the pre-shared key.

c. Choose an encryption algorithm.

If there are already characters in the pre-shared key field, delete those

characters and re-enter the same pre-shared key you entered on the

IPsec Configuration tab.

9. Click Apply Changes.

10. Choose Administrative Settings > Secure Tunnel Configuration> L2TP

Configuration.

Make sure L2TP is enabled.

32 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 33

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

11. If needed, change the range of available client IP addresses

The IP addresses on this screen are the virtual IP addresses for the L2TP

server (in the 1756-EN2TSC module) and the pool of virtual IP addresses

(for Windows clients).

Once the secure tunnel is established, use the L2TP server IP address to

identify the 1756-EN2TSC module. The Windows client will use an IP

address from the L2TP pool.

12. Click Apply Changes.

13. Choose Administrative Settings > Secure Tunnel Configuration> L2TP

Use rs .

14. For each user, define a user ID and password.

Each L2TP user must authenticate when establishing a tunnel to the

module. Configure a user name and password for each LT2P user.

Remember the user names and passwords. You enter the same values when

you configure the Windows connection (see page 30

).

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 33

Page 34

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

15. Click Add.

Configure a Connection to a Microsoft Windows Client

An IPsec client is required to make a secure connection to the module. Without

an active IPsec association, the module drops packets, which appear as message

timeouts. The IPsec client comes pre-installed in the Windows 7 operating

system.

To configure a Microsoft Windows client, do the following.

1. From the Control Panel, open the Network and Sharing Center.

2. Click Setup a new connection or network.

3. Select Connect to a workplace and click Next.

34 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 35

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

4. Select No, create a new connection and click Next.

You do not see this screen if there are no connections set.

5. Choose Connect using a virtual private network (VPN) connection

through the internet.

6. If prompted, choose I’ll set up an Internet connection later.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 35

Page 36

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

7. Enter the physical IP address of the 1756-EN2TSC module and a name

for the connection.

8. Select Don’t connect now; just set it up so I can connect later and click

Next.

9. Enter the appropriate user name and password.

The user name and password must have already been configured as an

L2TP user on the 1756-EN2TSC module. See the L2TP Edit Users tab as

part of configuring the 1756-EN2TSC module (page 33

).

10. Check Remember this password.

11. Click Create.

36 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 37

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

12. Once the connection is created, click Close.

13. Click the network icon in the right, bottom corner of the Windows

taskbar.

14. Select the created connection, right-click, and choose Properties.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 37

Page 38

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

15. On the Options tab, do the following.

a. Check Display progress while connecting.

b. Check Prompt for name and password, certificate, etc.

c. Clear Include Windows logon domain.

d. Accept the defaults for PPP settings.

38 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 39

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

IMPORTANT

16. On the Security tab, do the following.

a. Choose Layer 2 Tunneling Protocol with IPsec (L2TP/IPsec) as the

type of VPN.

b. Choose Optional encryption (connect even if no encryption) as the

type of data encryption.

This setting means that the L2TP configuration does not enforce

encryption, but there still is IPsec encryption.

c. Click Allow these protocols.

d. Check Unencrypted password (PAP).

e. Check Challenge Handshake Authentication Protocol (CHAP).

f. Clear the Microsoft CHAP version 2 (MS-CHAP v2) checkbox.

17. On the Security tab, click Advanced Settings and enter the pre-shared key.

The pre-shared key must be same as defined for the mobile client as part of

configuring the 1756-EN2TSC module (page 29

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 39

).

Page 40

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

18. On the Networking tab, check Internet Protocol Version 4 (TCP/IPv4).

19. On the Networking tab, click Properties and then click Advanced.

By default all the traffic is forwarded through the established VPN tunnel.

To have both the VPN tunnel to the 1756-EN2TSC module and preserve

access to the local network (such as Internet or corporate mail server), do

the following.

a. Clear the Use default gateway on remote network checkbox.

b. Clear the Automatic metric checkbox.

c. In the Interface metric field, enter a value larger than the metric of the

default gateway route in the routing table.

20. Click OK until you exit the configuration tabs.

40 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 41

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

Interface Metric

The interface metric specifies an integer cost metric (1…9999) for the route. This

metric is used when choosing among multiple routes in the routing table that

most closely match the destination address of a packet being forwarded.

• Use the ipconfig command to identify the IP address of the default

gateway.

• Use the route print command to identify the metric of the default gateway.

If you do not want all network traffic to go through the VPN tunnel, set the

metric of the route though the VPN connection to be larger than the metric of

the route through the default gateway. In the example below, the metric is 10; the

interface field metric must be 11 or greater.

C:\>route print

===========================================================================

Interface List

34...........................1.EN2TSC VPN Connection

11...f0 4d a2 20 ee d7 ......Broadcom NetXtreme 57xx Gigabit Controller

18...00 50 56 c0 00 01 ......VMware Virtual Ethernet Adapter for VMnet1

20...00 50 56 c0 00 08 ......VMware Virtual Ethernet Adapter for VMnet8

1...........................Software Loopback Interface 1

12...00 00 00 00 00 00 00 e0 Microsoft ISATAP Adapter

13...00 00 00 00 00 00 00 e0 Teredo Tunneling Pseudo-Interface

19...00 00 00 00 00 00 00 e0 Microsoft ISATAP Adapter #2

21...00 00 00 00 00 00 00 e0 Microsoft ISATAP Adapter #3

22...00 00 00 00 00 00 00 e0 Microsoft ISATAP Adapter #4

===========================================================================

IPv4 Route Table

===========================================================================

Active Routes:

Network Destination Netmask Gateway Interface Metric

0.0.0.0 0.0.0.0 10.76.16.1 10.76.16.127 10 <- metric of default gateway

10.76.16.0 255.255.252.0 On-link 10.76.16.127 266

10.76.16.127 255.255.255.255 On-link 10.76.16.127 266

10.76.18.110 255.255.255.255 On-link 10.76.16.127 11

10.76.19.255 255.255.255.255 On-link 10.76.16.127 266

127.0.0.0 255.0.0.0 On-link 127.0.0.1 306

127.0.0.1 255.255.255.255 On-link 127.0.0.1 306

127.255.255.255 255.255.255.255 On-link 127.0.0.1 306

192.168.1.0 255.255.255.0 192.168.1.1 192.168.1.2 11 <- interface field metric for client

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 41

Page 42

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

TIP

Open the VPN Connection to the 1756-EN2TSC Module

Once the Windows client and 1756-EN2TSC module are configured, you must

establish the VPN connection.

1. From the Windows notification area, select the network icon.

2. Right-click the EN2TSC VPN Connection and click Connect.

3. Log on with your 1756-EN2TSC user name and password.

It can take 30 seconds or more to connect.

If you want to delete a VPN connection on the Windows client (for example, it

does not work and you want to create a new one).

1. Choose Control Panel > Network and Sharing Center > Change Adapter

Settings.

2. Right-click the connection and choose Delete.

42 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 43

Configure a Secure Connection to a Microsoft Windows Client Chapter 3

IMPORTANT

Communicate to the Module via an RSLinx Driver

If you communicate to the module through an RSLinx driver, you must use an

L2TP connection and the Ethernet devices (AB_ETH-1) driver.

Once the secure tunnel exists to the 1756-EN2TSC module, RSLinx software

uses the L2TP server IP addresses to communicate with the controller through

the 1756-EN2TSC module.

The Microsoft Windows client must use the module IP address specified (predetermined) on the

L2TP configuration tab for all communication to the module, including RSLinx and Studio 5000

connections. The original IP address for the module is not in the VPN tunnel and cannot be used.

In the AB_ETH driver configuration, enter the L2TP server IP address (virtual

IP address) of the 1756-EN2TSC module to the Station Mapping dialog box.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 43

Page 44

Chapter 3 Configure a Secure Connection to a Microsoft Windows Client

If you connect to the 1756-EN2TSC module without knowing the L2TP server

IP address, you can find that after the connection is established.

1. Click the network icon in the right, bottom of the Windows taskbar.

2. Choose Status.

3. Click the Details tab.

RSLinx software uses the L2TP server IP address to communicate with the

1756-EN2TSC module inside the secure tunnel.

44 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 45

Chapter 4

Configure Secure Communication Between Two 1756-EN2TSC Modules

Top ic Pag e

Configure the First (Local) Module 47

Configure the Second (Remote) Module 48

Test the Connection 49

Edit the Security Association 49

In this scenario an IPsec association is established between two 1756-EN2TSC

modules (peer-to-peer). In this case, there are remote and local IP networks

serviced by a VPN tunnel. There is one IP address at either end of the IPsec

association.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 45

Page 46

Chapter 4 Configure Secure Communication Between Two 1756-EN2TSC Modules

Enterprise Zone

Levels 4 and 5

Demilitarized Zone (DMZ)

Demilitarized Zone (DMZ)

Manufacturing Zone

Site Manufacturing

Operations and Control

Level 3

Level 0…2

Local ControlLogix Chassis with

1756-EN2TSC Module

Remote ControlLogix Chassis with

1756-EN2TSC Module

IMPORTANT

To create a security association with another module, each module must be

configured with the pre-shared key of the other module.

This peer-to-peer configuration does not maintain the security features of the module if you use

produced/consumed tags, CIP Sync packets, or multicast communication. Use MSG instructions

rather than produced/consumed tags to share data.

46 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 47

Configure Secure Communication Between Two 1756-EN2TSC Modules Chapter 4

Configure the First (Local) Module

1. Choose Administrative Settings > Secure Tunnel Configuration > IPsec

Configuration and make sure that Enable IPsec is enabled.

2. To create a new secure association, do the following.

a. Enter the Identifier as a text description of the connection.

b. Choose the Peer to Peer as the Profile.

c. Enter the IP address of the second (remote) module.

d. Enter the pre-shared key and confirm the pre-shared key.

3. Click Add.

4. Click Apply Changes after entering all configurations.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 47

Page 48

Chapter 4 Configure Secure Communication Between Two 1756-EN2TSC Modules

Configure the Second (Remote) Module

1. Choose Administrative Settings > Secure Tunnel Configuration > IPsec

Configuration and make sure that Enable IPsec is enabled.

2. To create a new secure association, do the following.

a. Enter the Identifier as a text description of the connection.

b. Choose the Peer to Peer as the Profile.

c. Enter the IP address of the first (local) module.

d. Enter the pre-shared key and confirm the pre-shared key.

3. Click Add.

4. Click Apply Changes after entering all configurations.

48 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 49

Configure Secure Communication Between Two 1756-EN2TSC Modules Chapter 4

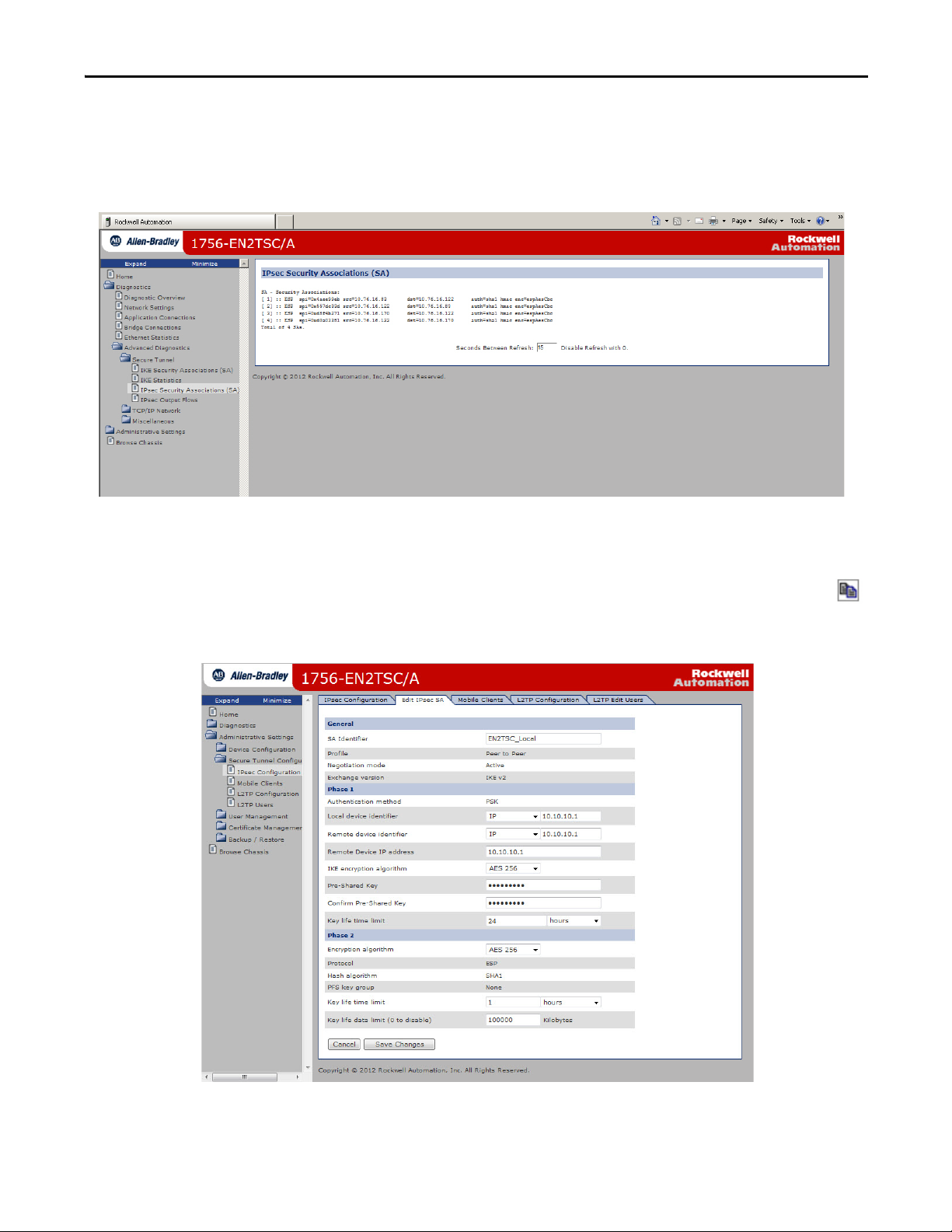

Test the Connection

When the security association is added on both sides of connection, the modules

take a few seconds to establish the IPsec tunnel between the modules. To verify

that the connection is established, access Diagnostics > Advanced Diagnostics >

Secure Tunnel > IPsec Security Associations.

Edit the Security Association

If you want to edit the settings for the association you just created, click

the Edit button next to the association in the list.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 49

Page 50

Chapter 4 Configure Secure Communication Between Two 1756-EN2TSC Modules

Notes:

50 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 51

Chapter 5

Configure a Secure Connection to a VPN Appliance

Top ic Pag e

Configure the Module to Connect to a VPN Appliance 53

Edit the Security Association 54

In this scenario, a VPN appliance (such as a firewall) establishes the IPsec

association with the 1756-EN2TSC module. Client workstations or other

modules then establish IPsec associations with the VPN appliance. The VPN

appliance then routes packets between the IPsec associations.

The IPsec association between the VPN appliance and module services multiple

remote (from the module’s point of view) devices and networks. You configure

the module to know which remote networks are routed via the VPN appliance.

This configuration lets you consolidate multiple VPN clients through a single

location (the VPN appliance). This limits the need for multiple secure tunnels to

each VPN client as you need only one secure tunnel between the 1756-EN2TSC

module and the VPN appliance.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 51

Page 52

Chapter 5 Configure a Secure Connection to a VPN Appliance

Enterprise Zone

Levels 4 and 5

Demilitarized Zone (DMZ)

Demilitarized Zone (DMZ)

Manufacturing Zone

Site Manufacturing

Operations and Control

Level 3

Level 0…2

ControlLogix Chassis with

1756-EN2TSC Module

Secure Tunnel to VPN Appliance

An appliance like the Cisco ASA supports multiple methods for authentication,

multiple encryption algorithms, and multiple types of VPN technology (such as

SSL VPN.

52 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 53

Configure a Secure Connection to a VPN Appliance Chapter 5

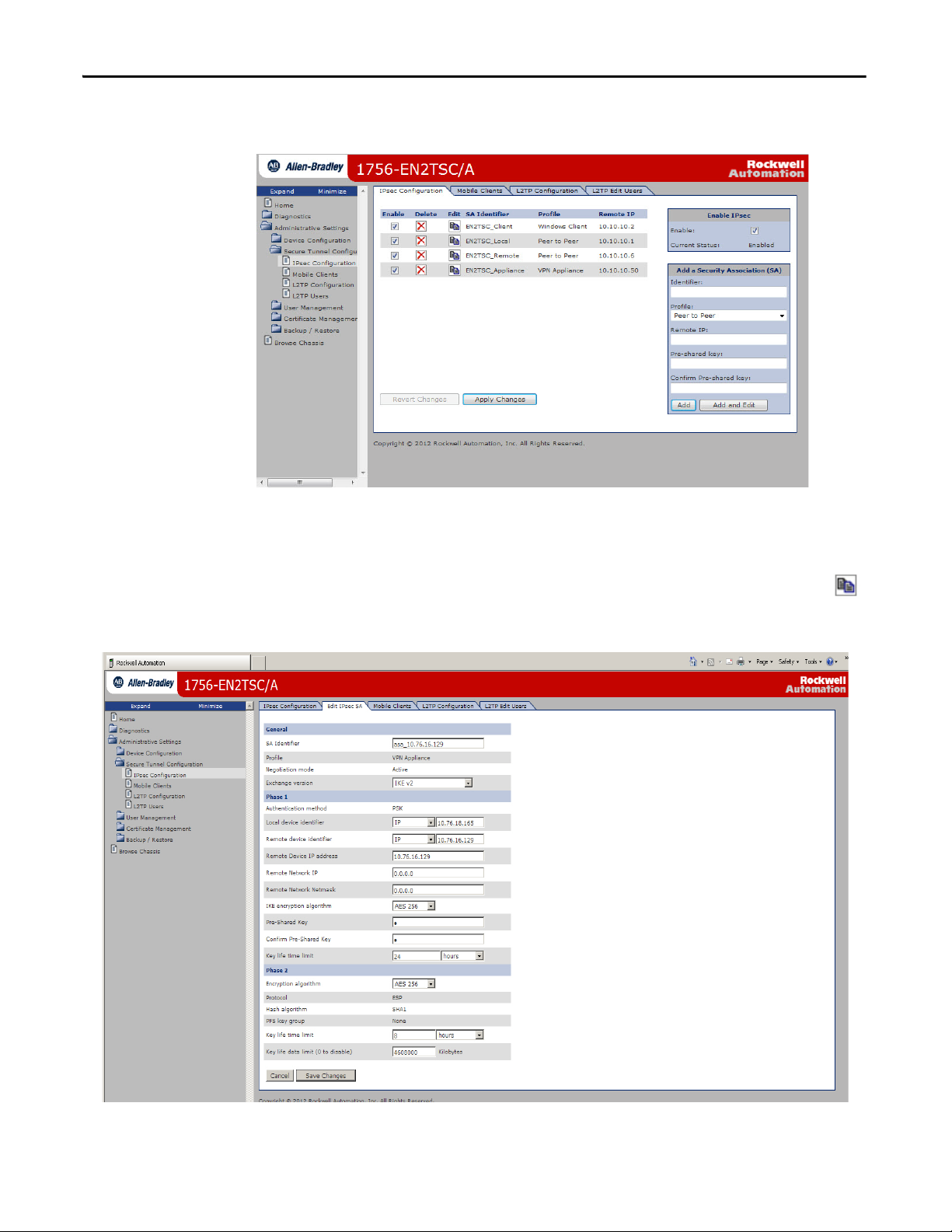

Configure the Module to Connect to a VPN Appliance

1. Choose Administrative Settings > Secure Tunnel Configuration > IPsec

Configuration and make sure that Enable IPsec is enabled.

2. To create a new secure association, do the following.

a. Enter the Identifier as a text description of the connection.

b. Choose the VPN Appliance as the Profile.

c. Enter the IP address of the VPN appliance.

d. Enter the pre-shared key and confirm the pre-shared key.

In This Field Specify

Identifier Name for the security association, such as VPN_connection

Profile VPN Appliance

Remote IP IP address of the VPN appliance

Pre-shared key Pre-shared key for the connection

Confirm Pre-shared key Same pre-shared key for the connection, as entered above

3. Click Add.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 53

Page 54

Chapter 5 Configure a Secure Connection to a VPN Appliance

4. Click Apply Changes.

Edit the Security Association

If you want to edit the settings for the association you just created, click

the Edit button next to the association in the list.

54 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 55

Configure a Secure Connection to a VPN Appliance Chapter 5

Set the key life time (10 min…8 hr) and key life data (1000…10000000 KB)

values to the same value as on the VPN appliance. If these values differ, there can

be issues with rekeying, even though the initial connection is successful.

You must specify a value for key life time. If key life data is not used, set the value

to 0.

You can specify a subnetwork accessible via the VPN appliance by specifying

addresses for Remote Network IP and Remote Network Netmask.

Default values of all zeroes direct all of the VPN network traffic to the VPN

appliance. However, other security associations, such as peer to peer connections,

still work as narrower address ranges take precedence over the wider range

specified for VPN appliance.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 55

Page 56

Chapter 5 Configure a Secure Connection to a VPN Appliance

Notes:

56 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 57

Diagnostics

Top ic Pag e

Diagnostic Web Pages 57

Secure Tunnel Diagnostics Web Page 58

Status Indicators 59

Chapter 6

Diagnostic Web Pages

The 1756-EN2TSC module supports the same diagnostic web pages as the

1756-EN2T modules, including these pages.

• Diagnostic Overview for a summary of the configuration and overall status

of the module

• Network Settings for the Ethernet configuration parameters of the module

• Ethernet Statistics for a summary of the status of communication activity

on the Ethernet network

For information on these standard diagnostic web pages, see EtherNet/IP

Network Configuration User Manual, publication ENET-UM001

.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 57

Page 58

Chapter 6 Diagnostics

Secure Tunnel Diagnostics Web Page

This Diagnostic Web Page Displays

IKE Security Associations (SA) Active IKE security associations

IKE Statistics Statistics of active exchanges and IKE security associations

For specific diagnostics regarding secure connections, choose Diagnostics >

Advanced Diagnostics > Secure Tunnel.

IPsec Security Associations (SA) Active IPsec security associations

IPsec Output Flows Defined IPsec output flow rules

58 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 59

Diagnostics Chapter 6

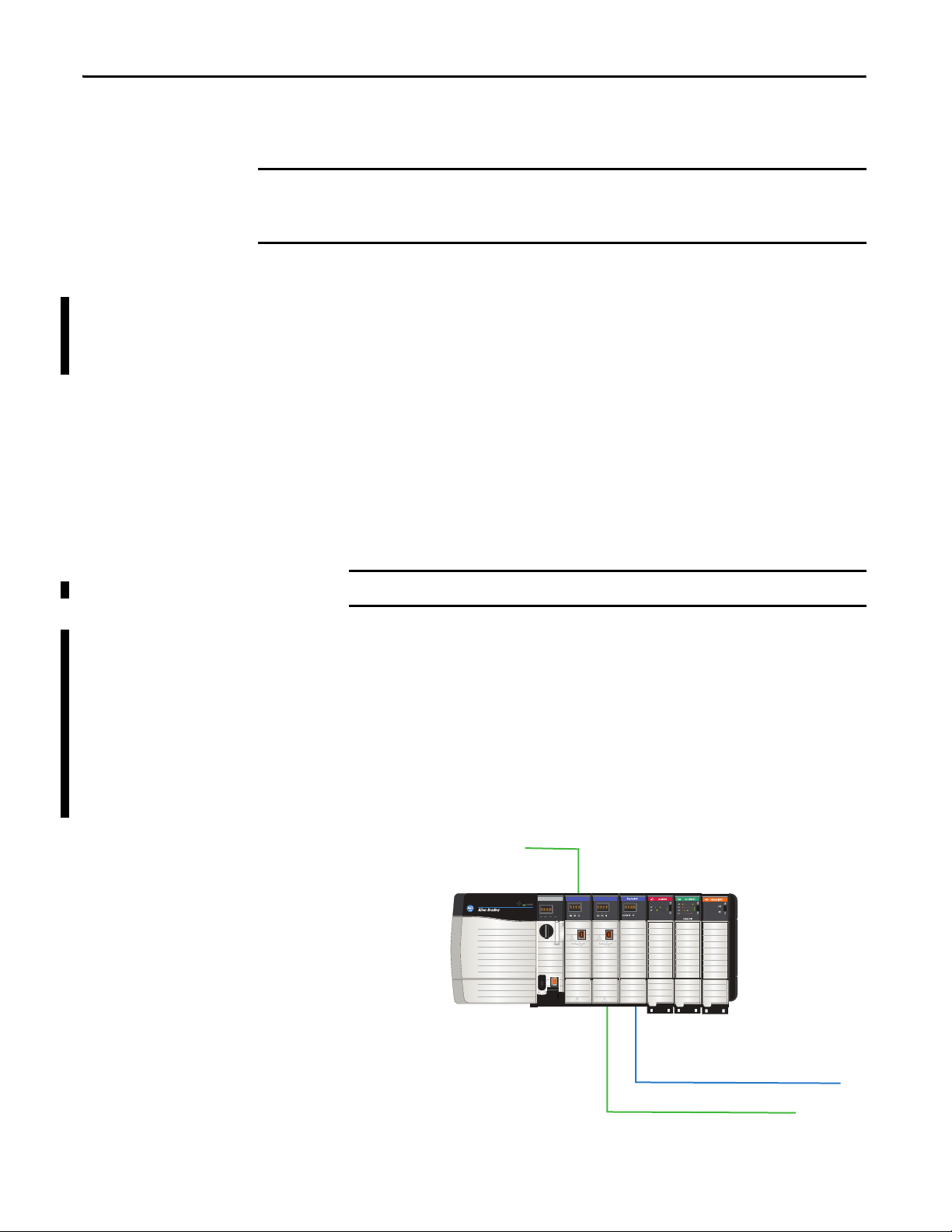

VPN

Module Status Display

OK Status Indicator

Network Status Indicator (NET)

Link Status

Indicator (LINK)

Status Indicators

The 1756-EN2TSC module uses the same status indicators as the 1756-EN2T

module:

• Module Status Display

• Link Status Indicator (LINK)

• Network Status Indicator (NET)

• OK Status Indicator (OK)

Link (LINK) Status Indicator

Status Description

Off One of these conditions exists:

• The module is not powered.

– Verify there is chassis power.

– Verify that the module is completely inserted into the chassis and backplane.

• No link exists on the port.

– Verify the RJ45 connector in the Ethernet port is completely inserted and the other end of the cable is connec ted

to a device in your network

Flashing green Activity exists on the port.

Green A link exists on the port.

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 59

Page 60

Chapter 6 Diagnostics

Network (NET) Status Indicator

Status Description

Off One of these conditions exists:

• The module is not powered.

– Verify there is chassis power.

– Verify that the module is completely inserted into the chassis and backplane.

– Make sure the module has been configured.

• The module is powered but does not have an IP address. Assign an IP address to the module.

Flashing green The controller has an IP address and one of these conditions exists:

• The module has not established any CIP connections.

If connections are configured for this module, check the connection originator for the connection error code.

• One or more connections have timed out. For example, an HMI or I/O connection has timed out.

Reestablish the connection.

Green The module has established at least 1 CIP connection and is operating properly. The module’s IP address scrolls across

Red The module is in conflict mode. The module shares an IP address with another device on the network. The module’s

Flashing

green/flashing red

the Module Status display.

current IP address scrolls across the Module Status display. The display scrolls: OK <IP_address_of_this_module>

Duplicate IP <Mac_address_of_duplicate_node_detected>

For example: OK 10.88.60.196 Duplicate IP - 00:00:BC:02:34:B4

Change the module’s IP address.

The module is performing its power-up testing.

OK Status Indicator

Status Description

Off The module is not powered.

• Verify there is chassis power.

• Verify that the module is completely inserted into the chassis and backplane.

• Make sure the module has been configured.

Flashing green The module is not configured. The Module Status display scrolls: BOOTP or DHCP<Mac_address_of_module>

Green The module is operating correctly. The module’s IP address scrolls across the Module Status display.

Flashing red The module detected a recoverable minor fault. Check the module configuration. If necessary, reconfigure the module.

Red The module detected an unrecoverable major fault. Cycle power to the module. If this does not clear the fault, replace

Flashing red/

flashing green

For example: BOOTP 00:0b:db:14:55:35

Configure the module.

the module.

The module is performing its power-up testing.

60 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 61

Index

A

access limits 22

additional resources

architecture

Microsoft Windows client to module

module to module

secure communication

VPN appliance to module 51

7, 15

45

B

backup 25

19

BOOTP

10

browers

C

certificate

23

generate

powerup

16

configure

access limits

client via RSLinx driver 43

interface metric

Microsoft Windows client

mobile client 29

module to module

network settings

overview 18

powerup

security association

user account

VPN appliance 53

web pages

credentials

22

41

47, 48

19

16

49, 54

21

16

18

D

default credentials 18

diagnostics

secure tunnel

status indicators

web pages

58

59

57

IPsec

12

capability

modes

13

27

9

L2TP

local chassis security

L

RSLinx driver

43

11

M

Microsoft Windows client to module scenario

27

mobile client

29

scenario

module

25

backup

browsers

10

certificate 23

34

default credentials

diagnostics

features 10

performance

restore

25

status indicators 59

traffic filtering

module to module scenario

18

57

14

14

45

N

network settings 19

P

performance 14

powerup

16

R

restore 25

RSLinx driver

43

F

features 10

G

generate certificate 23

scenario

secure communication

secure tunnel

I

interface metric 41

Internet Protocol Security

12

See IPsec

Rockwell Automation Publication ENET-UM003B-EN-P - September 2013 61

security association

serial number lock

status indicators

S

Microsoft Windows client to module

module to module

VPN appliance to module

architecture

scenarios

diagnostics

45

51

9

27, 45, 51

58

49, 54

11

59

27

Page 62

Index

T

test connection 49

traffic filtering

trusted slot

14

11

U

user account 21

V

VPM appliance to module scenario 51

W

web pages

diagnostics

network settings

57

19

62 Rockwell Automation Publication ENET-UM003B-EN-P - September 2013

Page 63

Page 64

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/literature/.

Publication ENET-UM003B-EN-P - September 2013

Supersedes ENET-UM003A-EN-P - February 2013 Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...