Rockwell Automation 1756-EN2T, 1756-EN2TXT, 1756-ENBT, 1756-EN2F, 1756-EN2TP Installation Instructions Manual

...Page 1

Installation Instructions

EtherNet/IP Modules

Catalog Numbers 1756-ENBT, 1756-EN2F, 1756-EN2T, 1756-EN2TP, 1756-EN2TPXT, 1756-EN2TR, 1756-EN2TXT,

1756-EN2TRXT, 1756-EN2TSC, 1756-EN3TR, 1756-EWEB, 1768-ENBT, 1768-EWEB, 1769-AENTR

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Summary of Changes New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preface Download the Add-on Profiles and Firmware. . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Install a 1756 EtherNet/IP

Communication Module

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set the Network IP Address on a Module . . . . . . . . . . . . . . . . . . . . . . . 14

Determine Module Slot Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Use the following information to wire the module. . . . . . . . . . . . 17

Connect the Module to an EtherNet/IP Network Via an RJ45

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connect the Module to an EtherNet/IP Network Via a Fiber

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connect to the Module Via the USB Port . . . . . . . . . . . . . . . . . . . . . . . 19

Apply Chassis Power and Check Status Indicators . . . . . . . . . . . . . . . 19

Install or Remove the Module Under Power (RIUP) . . . . . . . . . . . . . 21

Install a 1768 EtherNet/IP

Communication Module

Install a 1769 EtherNet/IP

Adapter

Chapter 2

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set the Network IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mount the Module with Screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mount on a DIN Rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wire the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connect the Module to an EtherNet/IP Network via an RJ45

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Apply Chassis Power and Check Status Indicators . . . . . . . . . . . . . . . 30

Remove the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 3

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Example Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Grounding Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Set the Network IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Install the Adapter in a 1769 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Adapter Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

System Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Mount the Adapter and I/O Modules . . . . . . . . . . . . . . . . . . . . . . . 41

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 3

Page 4

Table of Contents

Wire the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Remove or Replace the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 4

Set the Network IP Address Set the Network IP Address with the Rotary Switches . . . . . . . . 46

Set the Network IP Address with the BOOTP/DHCP Server . . . . 47

Use DHCP Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Set the Network IP Address with RSLinx Software or the Studio 5000™

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Reset the Module IP Address to a Factory Default Value . . . . . . 54

Chapter 5

Configure a Workstation to

Operate on an EtherNet/IP

Select the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configure the Ethernet Communication Driver . . . . . . . . . . . . . . . . . 56

Network

Chapter 6

USB Communication Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configure a Module Via the USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Set Up a USB Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Load Firmware Through a USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix A

1756 EtherNet/IP Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Indicators

Appendix B

1768 EtherNet/IP Module Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Indicators

Appendix C

1769 EtherNet/IP Adapter Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Indicators

Appendix D

Fiber Cable and LC Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 5

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This table contains the changes made in this revision.

Top ic Pag e

Added graphic of the 1756-EN2TP Parallel Redundancy Protocol Ethernet Communication Module. 19

Added content about the 1756-EN2TP module status indicators. 63

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 5

Page 6

Summary of Changes

Notes:

6 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 7

Preface

This manual describes how to install and start up EtherNet/IP module systems

™

with Logix5000

Use this manual if you program applications that use an EtherNet/IP network

with one of these Logix5000 controllers:

• CompactLogix

• ControlLogix

Understand the following:

• Networking concepts

• How to the use Studio 5000

• How to use RSLinx

controllers.

™

®

®

™

environment

Classic programming software

Download the Add-on Profiles and Firmware

If a communication module has a later firmware revision than recognized in the

current version of the Logix Designer™ application, you must download the latest

firmware. When you download the Add-on Profile (AOP) for the module, it can

be recognized in the Controller Organizer.

Download the Add-on Profile and the latest module firmware from the Product

Compatibility and Download website at http://www.ab.com

.

If the procedure is performed while the web pages are already enabled, they

continue to be enabled and the password is reset to the serial number of the

adapter.

Additional Resources

For more information on the products that are described in this publication, use

these resources.

Resource Description

EtherNet/IP Modules Installation Instructions,

publication ENET-IN002

EtherNet/IP Secure Communication User Manual,

publication ENET-UM003

Ethernet Design Considerations Reference Manual, publication ENET-RM002

EtherNet/IP Socket Interface Application Technique, publication ENET-AT002 Describes the socket interface that you can use to program MSG instructions. These instructions

EtherNet/IP Embedded Switch Technology Application Guide, publication

ENET-AP005

Troubleshoot EtherNet/IP Networks Application Technique, publication

ENET-AT003

Provides information about how to complete these tasks with EtherNet/IP communication modules in

a Logix5000 control system:

• Install the module

• Configure initial application setup

• Troubleshoot application anomalies related to EtherNet/IP communication module use

Provides information on how to configure authentication, encryption, and firewalls, typical

architectures, and diagnostics for modules equipped with secure communication function.

Provides details about how to use EtherNet/IP communication modules with Logix5000 controllers

and communicate with other devices on the EtherNet/IP network.

communicate between a Logix5000 controller via an EtherNet/IP module and Ethernet devices that do

not support the EtherNet/IP application protocol. These include bar code scanners, RFID readers, or

other standard Ethernet devices.

Provides details about how to install, configure, and maintain linear and Device Level Ring (DLR)

networks by using Rockwell Automation EtherNet/IP devices equipped with embedded switch

technology.

Provides details about how to assign IP addresses to and how to troubleshoot EtherNet/IP networks

and devices.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 7

Page 8

Preface

Resource Description

EtherNet/IP Parallel Redundancy Protocol (PRP) Application Technique,

publication ENET-AT006

EtherNet/IP Network Configuration User Manual, publication ENET-UM001 Describes how you can use EtherNet/IP communication modules with

EtherNet/IP Media Planning and Installation Manual

This manual is available from the Open DeviceNet Vendor Association

(ODVA) at: http://www.odva.org.

Provides details about how to install, and configure a Parallel Redundancy Protocol (PRP) networks by

using Rockwell Automation EtherNet/IP devices equipped with embedded switch technology.

your Logix5000 controller and communicate with various devices on the Ethernet network.

Provides details about how to install, configure, and maintain linear and Device Level Ring (DLR)

networks by using Rockwell Automation® EtherNet/IP devices equipped with embedded switch

technology.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

8 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 9

Notes:

Preface

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 9

Page 10

Preface

10 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 11

Chapter 1

Install a 1756 EtherNet/IP Communication

Module

Top ic Pag e

Installation Summary 14

Install the Module 16

Determine Module Slot Location 15

Install the Module 16

Connect the Module 17

Connect to the Module Via the USB Port 19

Apply Chassis Power and Check Status Indicators 19

Install or Remove the Module Under Power (RIUP) 21

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication can contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 11

Page 12

Chapter 1 Install a 1756 EtherNet/IP Communication Module

North American Hazardous Location Approval

The following information applies when operating this

equipment in hazardous locations.

Produc ts marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class

I Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code.

When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help

determine the overall temperature code of the system. Combinations

of equipment in your system are subject to investigation by the local

Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à

une utilisation en environnements de Classe I Division 2 Groupes A, B,

C, D dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé

pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de

l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION –

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

12 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 13

Install a 1756 EtherNet/IP Communication Module Chapter 1

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the

Essential Health and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive

atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

WARNING: Special Conditions for Safe Use

• This equipment shall be mounted in an ATEX Zone 2 certified enclosure with a minimum ingress protection rating of at least

IP54 (as defined in EN 60529) and used in an environment of not more than Pollution Degree 2 (as defined in EN 60664-1)

when applied in Zone 2 environments. The enclosure must be accessible only by the use of a tool.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

• The USB port is intended for temporary local programming purposes only and not intended for permanent connection and do

not use the USB port in hazardous locations.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 140% of the

rated voltage when applied in Zone 2 environments.

• This equipment must be used only with ATEX-certified Rockwell Automation backplanes.

• The instructions in the user manual shall be observed.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 13

Page 14

Chapter 1 Install a 1756 EtherNet/IP Communication Module

Installation Summary

Follow these steps to install a communication module in a 1756 ControlLogix®

chassis.

1. Set the Network IP Address on a Module

2. Determine Module Slot Location

3. Install the Module

4. Connect the Module

5. Apply Chassis Power and Check Status Indicators

6. Install or Remove the Module Under Power (RIUP)

If needed, see Download the Add-on Profiles and Firmware on page 7

.

.

.

.

.

. - Optional

.

Grounding Considerations

The grounding and bonding must be of equal potential between all devices in the

communication coverage area.

ATT EN TI ON : If this equipment is used in a manner that is not specified by the

manufacturer, the protection that is provided by the equipment can be

impaired.

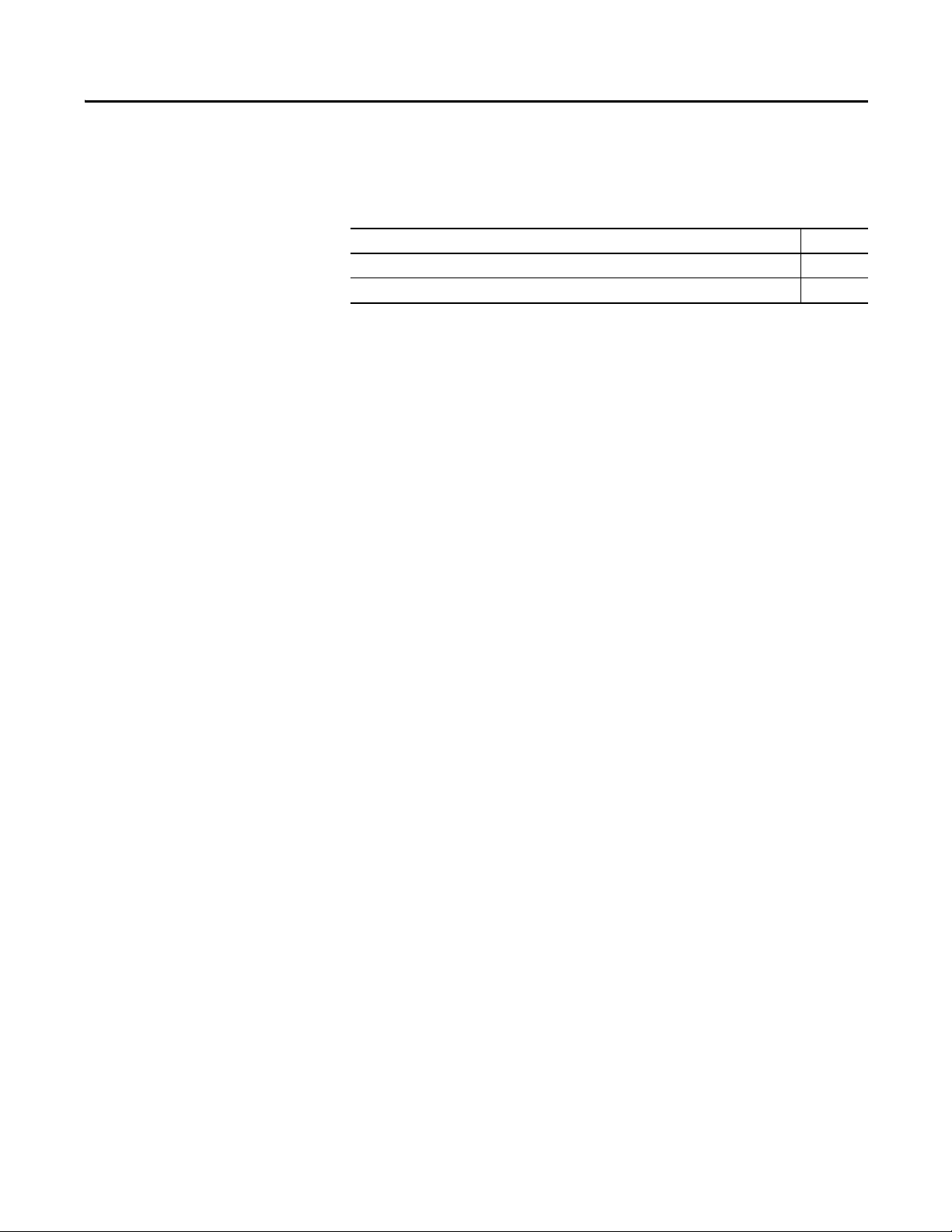

Set the Network IP Address on a Module

To operate an EtherNet/IP communication module on an EtherNet/IP network,

you must set a network IP address.

14 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 15

Install a 1756 EtherNet/IP Communication Module Chapter 1

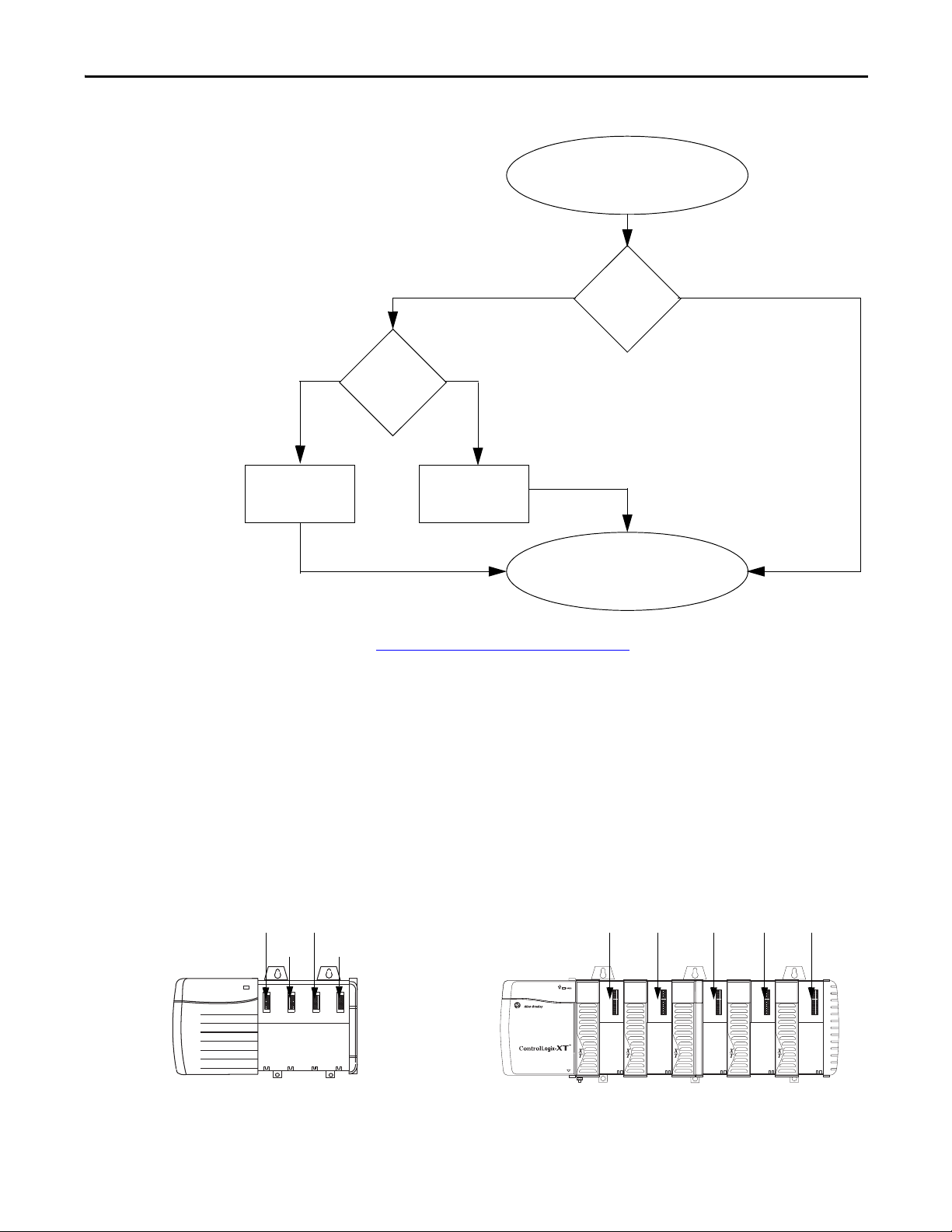

Module Powerup

Module has an IP

address.

Switches set

from

001…254?

YesNo

Is DHCP or

BOOTP

enabled?

YesNo

Module requests

address from DHCP/

BOOTP server.

Module uses IP address

stored in nonvolatile

memory.

20806

Slot 2Slot 0

Slot 1 Slot 3

ControlLogix Chassis ControlLogix-XT Chassis

31896

Slot 0 Slot 4Slot 1 Slot 2 Slot 3

Figure 1 - How the IP Address for the Module is Set

See Set the Network IP Address on page 45 to view all steps for setting the IP

address.

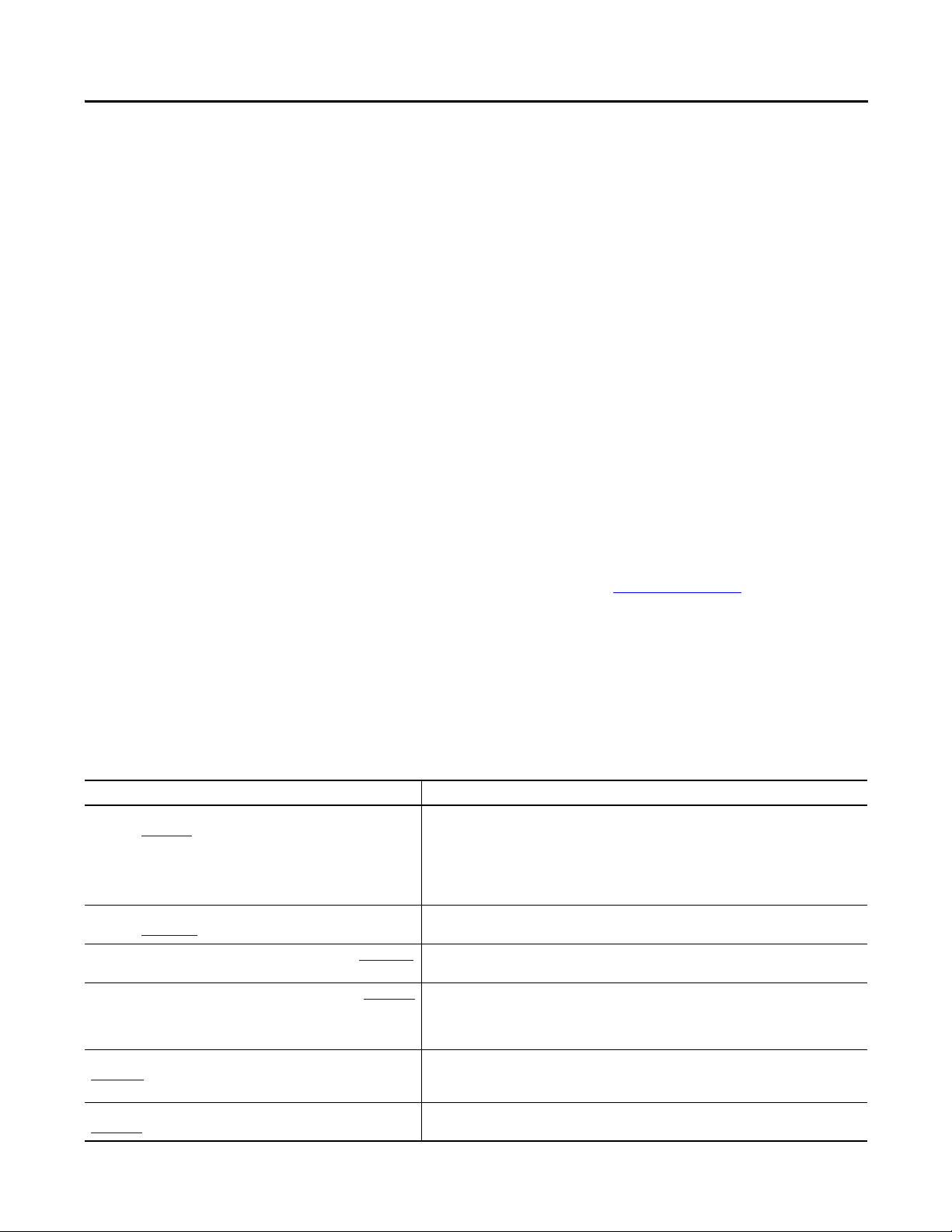

Determine Module Slot Location

Install the communication module in any slot in a ControlLogix® or

ControlLogix-XT™ chassis. You can install multiple communication modules in

the same chassis.

This example shows the chassis slot numbering in a 4-slot ControlLogix chassis

and a 5-slot ControlLogix-XT™ chassis. Slot 0 is the first slot and is always the

leftmost slot in the chassis.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 15

Page 16

Chapter 1 Install a 1756 EtherNet/IP Communication Module

IMPORTANT

32455

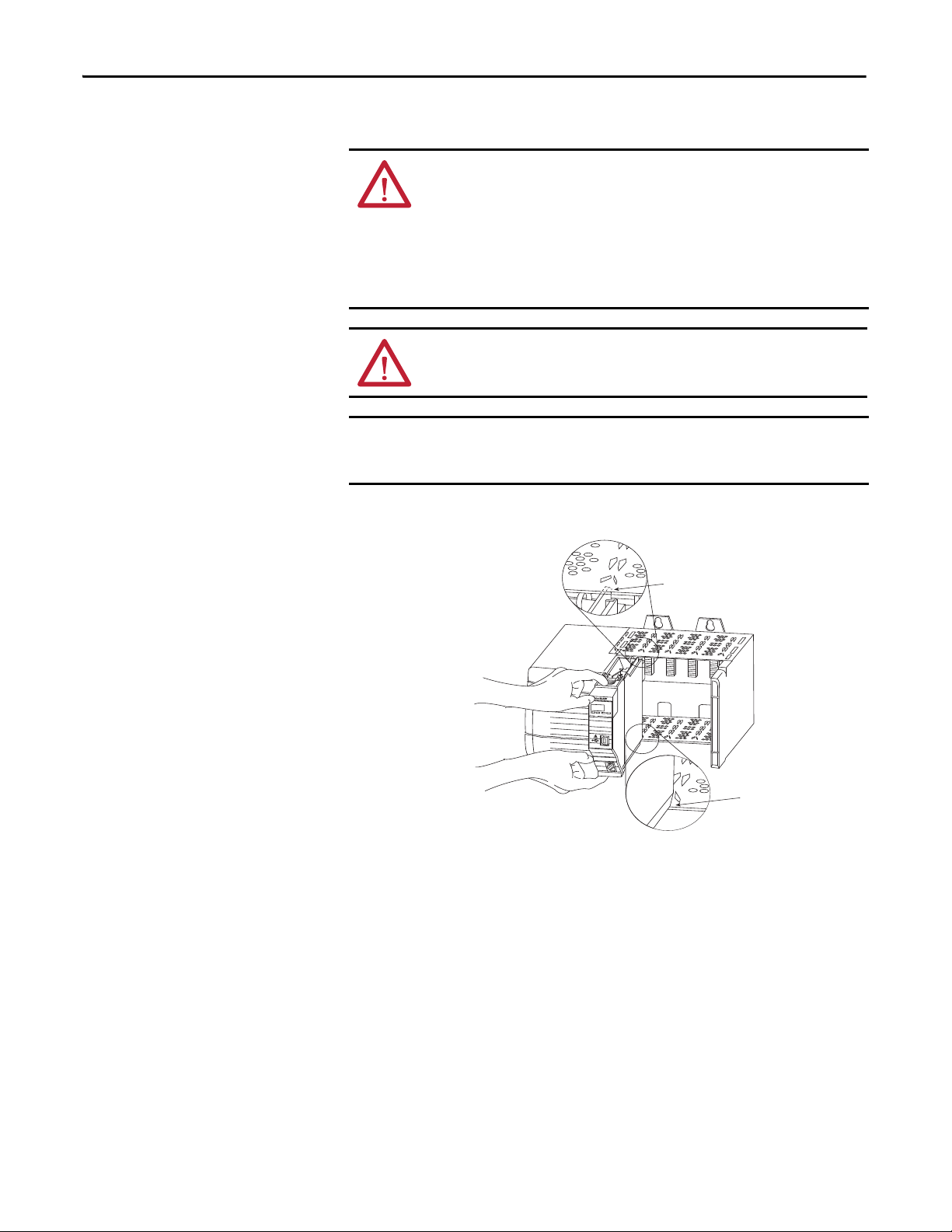

Install the Module

Follow these steps to install the module.

WARNING: When you insert or remove the module while backplane power is

on, an electric arc can occur. An electrical arc can cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Rep eated ele ctric al arc s caus es exce ssive wear to contacts on both t he mod ule an d

its mating connector. Worn contacts can create electrical resistance that can affect

module operation.

ATTENTION: Use caution when handling the module. One side of the module is

a heat sink and can be hot.

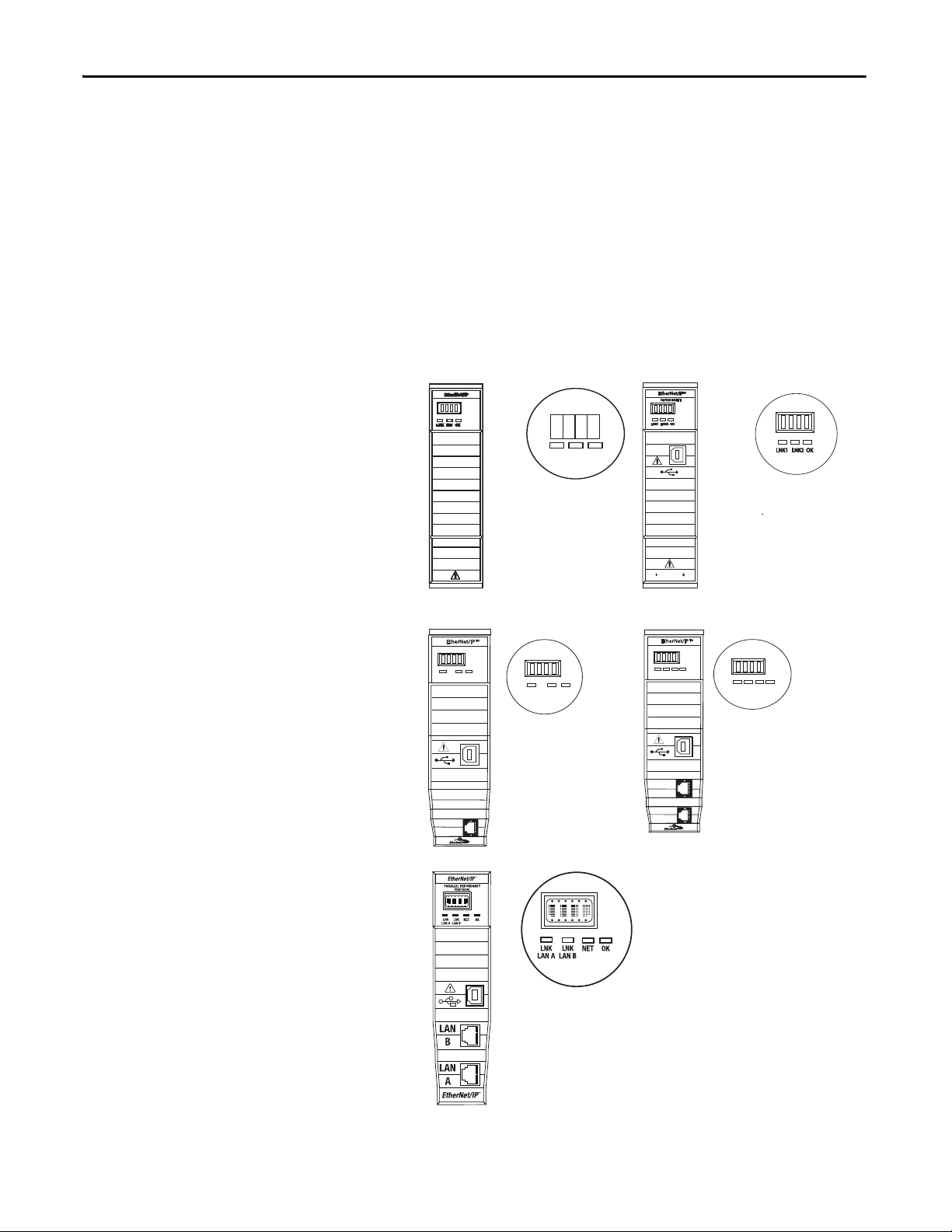

Your module resembles one of the modules that are shown in the illustrations. The

extreme temperature (XT) versions of the modules are not shown in the

illustrations.

1. Align the circuit board with top and bottom guides in the chassis.

2. Slide the module into the chassis.

16 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 17

Install a 1756 EtherNet/IP Communication Module Chapter 1

8 ------ NC

7 ------ NC

6 ------ RD5 ------ NC

4 ------ NC

3 ------ RD+

2 ------ TD1 ------ TD+

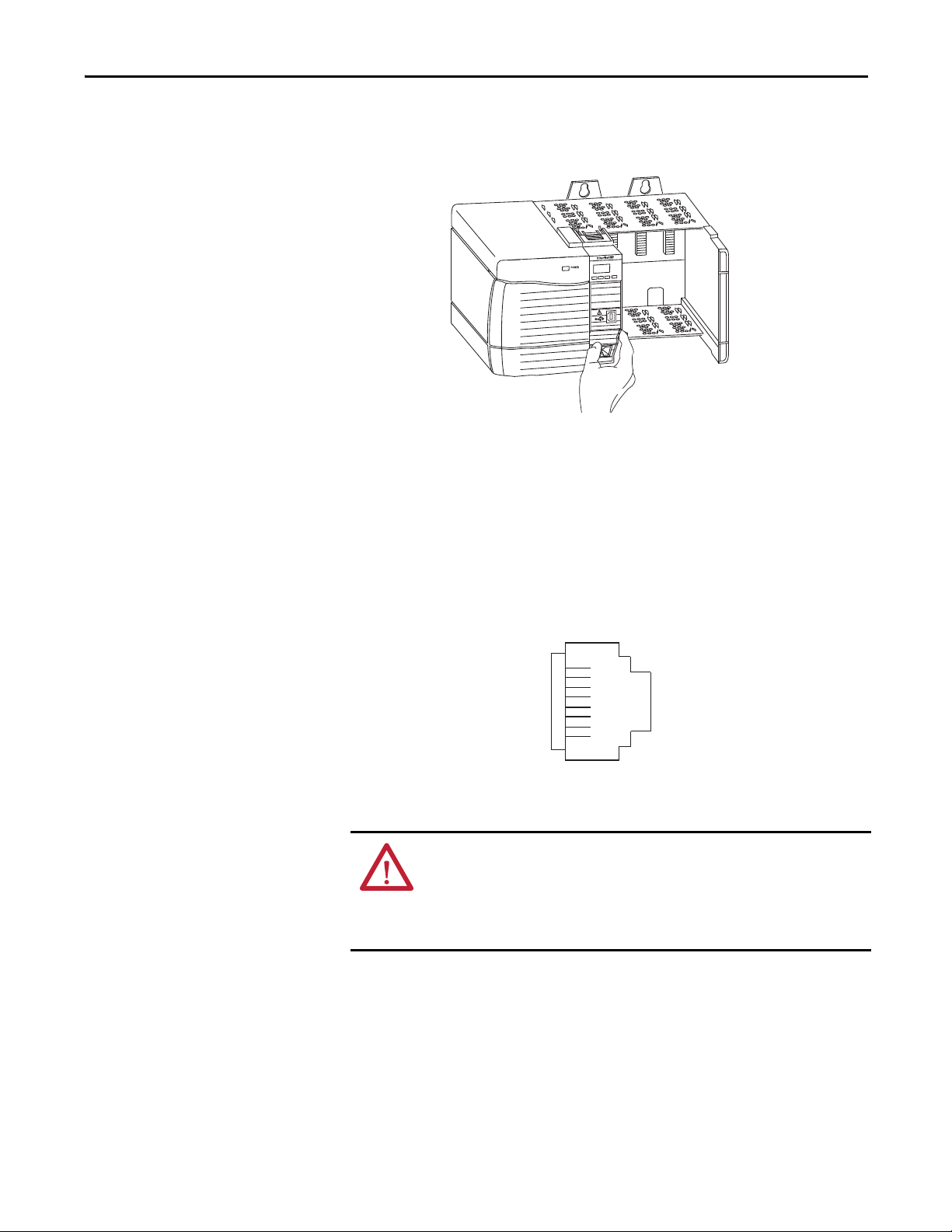

Make sure that the module backplane connector properly connects to the

chassis backplane. The module is properly installed when it is flush with

the power supply or other installed modules.

Connect the Module

Use the following information to wire the module.

Connect the Module to an EtherNet/IP Network Via an RJ45 Connection

Wire the RJ45 connector as shown.

Follow these steps to connect the module to the network.

WARNING: If you connect or disconnect the communication cable with power

that is applied to this module or any device on the network, an electric arc can

occur. An electric arc can cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 17

Page 18

Chapter 1 Install a 1756 EtherNet/IP Communication Module

Dual-port Module

(Single port not shown)

32457

Dual-port

Module

Single-port

Module

1. Attach the cable with the RJ45 connector to the Ethernet port on the

module as shown.

2. Attach the other end of the cable to the devices in your network.

Connect the Module to an EtherNet/IP Network Via a Fiber Connector

Attach the LC2 multimode fiber cable to the Ethernet port on the bottom of the

module as shown.

ATTENTION: Do not look directly into the optical port. When you view the

optical port under certain conditions, can expose the eye to hazard. When

viewed under some conditions, the optical port can expose the eye beyond the

maximum permissible exposure recommendations.

Class 1 laser product. Laser radiation is present when the system is open and

interlocks bypassed. Only trained and qualified personnel are allowed to install,

replace, or service this equipment.

18 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 19

Connect to the Module Via the USB Port

Install a 1756 EtherNet/IP Communication Module Chapter 1

WARNING: Do not use the USB port in hazardous locations.

ATTENTION: The USB port is intended for temporary local programming

purposes only and not intended for permanent connection. The USB cable is not

to exceed 3.0 m (9.84 ft) and must not contain hubs. The USB cable can be

ordered from Rockwell Automation, catalog number 9300-USBCBL-ABHR.

If the module has a USB port, is it a Type B receptacle. To use the USB port, you

must have RSLinx® Classic software, version 2.55 or later, installed on your

computer.

Use a USB cable to connect your computer to the USB port. You can download

programs to controllers and configure Ethernet modules directly from your

computer over a USB connection.

For more information about USB setup and configuration, see Chapter 6, USB

Communication on page 59.

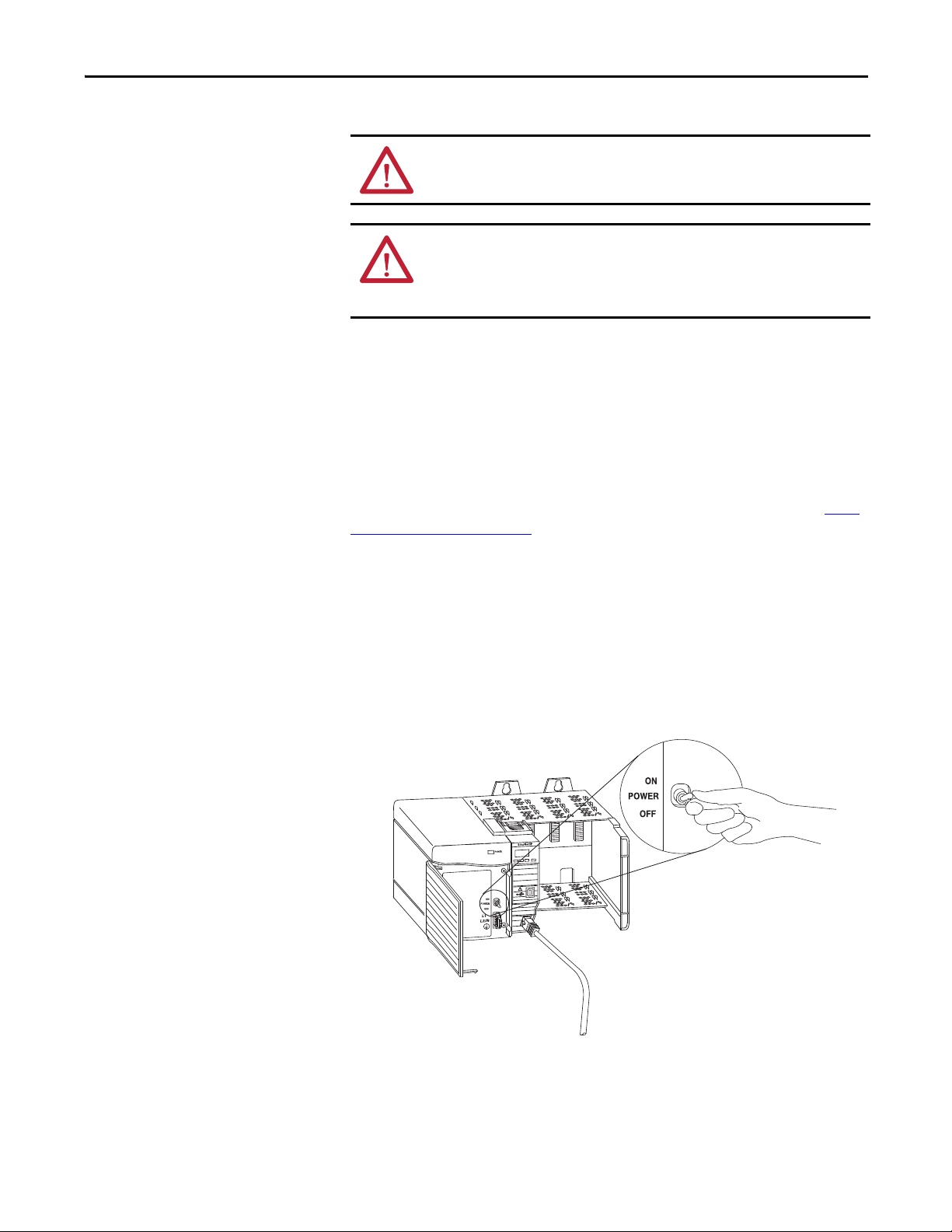

Apply Chassis Power and Check Status Indicators

Before you apply power, you must install and connect a ControlLogix chassis and

power supply.

Follow these steps to apply power.

1. Flip the switch to the ON position.

32458

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 19

Page 20

LINK

LINK

NET

OK

32452

NET

OK

1

LNK1LNK1LNK2LNK2 NETNET

OKOK

LNK1LNK1

1

2

LNK2

LNK2

NETNET OKOK

3245332453

Single-port

Module

Dual-port

Module

LINKLINK

NETNET

OKOK

Single-port

Module

Dual-port

Module

32730

1756-EN2TP

Chapter 1 Install a 1756 EtherNet/IP Communication Module

2. To determine that the power supply and module are operating properly,

check the power supply and Module Status indicators and alphanumeric

display.

The alphanumeric display cycles through the following states: TEST PASS - OK - REV x.x, where x.x is the firmware revision of the module.

The display then alternates between OK and port link status for both

ports.

This graphic shows the front of the module for these modules (extendedtemperature versions [catalog numbers 1756-EN2TXT and 1756EN2TRXT] not shown).

LINK

OK

NET

LINK

OK

NET

32452

20 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

32730

Page 21

Install a 1756 EtherNet/IP Communication Module Chapter 1

IMPORTANT

32460

32461

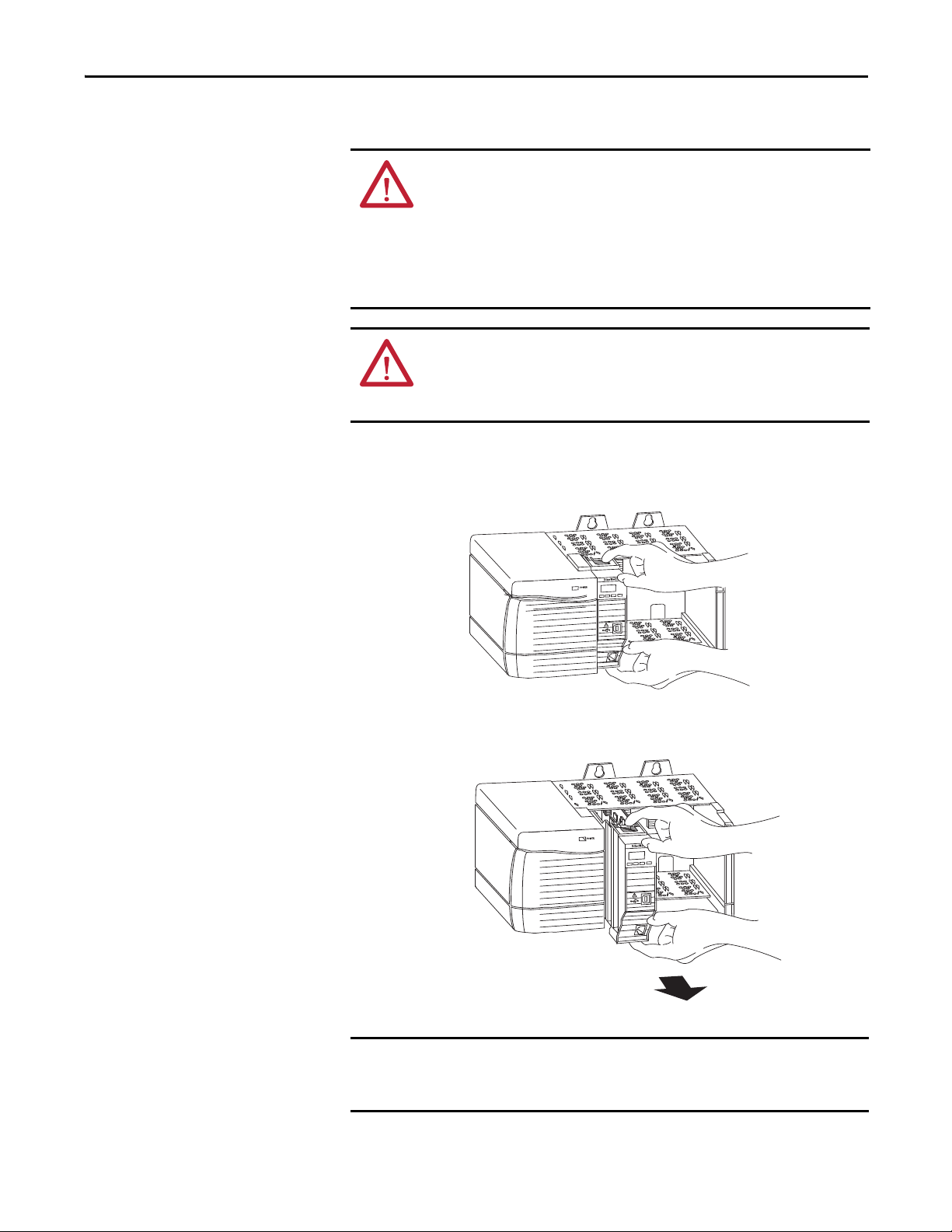

Install or Remove the Module Under Power (RIUP)

You can install or remove this module while chassis power is applied.

WARNING: When you insert or remove the module while backplane power is

on, an electric arc can occur. An electric arc can cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcs can cause excessive wear to contacts on both the module

and its mating connector. Worn contacts can create electrical resistance that can

affect module operation.

ATT EN TI ON : Although the module is designed to support RIUP, when you

remove or insert the module with field-side power applied, unintended

machine motion or loss of process control can occur. Exercise extreme caution

when using this feature.

Follow these steps to remove or replace the module.

1. Push the upper and lower module tabs to disengage them.

2. Slide the module out of the chassis.

If you want to replace an existing module with an identical one, and you want

to resume identical system operation, you must install the new module in the

same slot and assign the same network configuration.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 21

Page 22

Chapter 1 Install a 1756 EtherNet/IP Communication Module

Notes:

22 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 23

Chapter 2

Install a 1768 EtherNet/IP Communication

Module

Top ic Pag e

Installation Summary 25

Set the Network IP Address 26

Install the Module 27

Wire the Module 29

Apply Chassis Power and Check Status Indicators 30

Remove the Module 30

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if non-metallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 23

Page 24

Chapter 2 Install a 1768 EtherNet/IP Communication Module

North American Hazardous Location Approval

The following information applies when operating this

equipment in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code. When

combining products within a system, the most adverse temperature

code (lowest "T" number) may be used to help determine the overall

temperature code of the system. Combinations of equipment in your

system are subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is known

to be nonhazardous. Secure any external connections

that mate to this equipment by using screws, sliding

latches, threaded connectors, or other means

provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le plus

défavorable (code de température le plus faible) peut être utilisé pour

déterminer le code de température global du système. Les combinaisons

d'équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

24 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 25

Install a 1768 EtherNet/IP Communication Module Chapter 2

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the

Essential Health and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive

atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX certified enclosure with a minimum ingress protection rating of at least IP54 ( as

defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when

applied in Zone 2 environments. The enclosure must utilize a tool removable cover or door.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 140% of the

rated voltage when applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Installation Summary

Follow these steps to install a communication module in a 1768 CompactLogix™

system.

1. Set the Network IP Address

2. Install the Module

.

.

3. Connect the Module to an EtherNet/IP Network via an RJ45

Connection.

4. Apply Chassis Power and Check Status Indicators

.

5. Remove the Module

If needed, see Download the Add-on Profiles and Firmware on page 7

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 25

. - Optional

.

Page 26

Chapter 2 Install a 1768 EtherNet/IP Communication Module

Module Powerup

Module has an IP

address.

Is DHCP or

BOOTP

enabled?

YesNo

Module requests

address from DHCP/

BOOTP server.

Adapter uses IP address

stored in nonvolatile

memory.

Grounding Considerations

ATTENTION: This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (for example, aluminum or plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding. Secure DIN rail to mounting surface approximately every 200 mm

(7.87 in.) and use end-anchors appropriately.

Set the Network IP Address

To operate an EtherNet/IP communication module on an EtherNet/IP network,

you must set a network IP address. This graphic shows the process that is used to

set the IP address for the module.

Figure 2 - Set the IP Address for the Module

See Set the Network IP Address on page 45 to view all steps for setting the IP

address.

26 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 27

Install a 1768 EtherNet/IP Communication Module Chapter 2

IMPORTANT

Install the Module

Follow these steps to install the module.

Mount the Module with Screws

Do not use screws and DIN rail to mount the modules. It is possible to break

off the mounting tabs if you screw the modules to the panel while they are on

the DIN rail.

Complete these steps to install the module with screws.

1. Use the modules as a template and mark pilot holes on your panel.

2. Drill the pilot holes for M4 or #8 screws.

3. Use M4 or #8 screws to mount the modules to your panel, by using

1.16 N•m (10 lb•in) of torque.

4. Ground the module on a ground bus with a dedicated earth ground stake.

5. Connect the ground bus to a functional earth ground on the DIN rail

or panel.

See the Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

, for additional information.

Mount on a DIN Rail

Follow these steps to install the module on a DIN rail.

1. Mount the DIN rail in a suitable location.

ATTENTION: This product is grounded through the DIN rail to chassis

ground. Use zinc-plated yellow-chromate steel DIN rail to assure proper

grounding. The use of other DIN rail materials (for example, aluminum

or plastic) that can corrode, oxidize, or are poor conductors, can result in

improper or intermittent grounding. Secure DIN rail to mounting

surface approximately every 200 mm (7.87 in.) and use end-anchors

appropriately.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 27

Page 28

Chapter 2 Install a 1768 EtherNet/IP Communication Module

31597-M

2. Open the DIN rail latches on the module.

3. Align and press the module onto the DIN rail to the left of the controller.

4. Slide the module snugly against the controller.

5. Mount the 1768 power supply and additional 1768 modules to the left of

the controller.

6. Close the DIN rail latches.

31599-M

In this example, the 1768 EtherNet/IP communication module is installed in

slot 1 and the 1768 CompactLogix controller is installed in slot 0.

28 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 29

Install a 1768 EtherNet/IP Communication Module Chapter 2

8 ------ NC

7 ------ NC

6 ------ RD5 ------ NC

4 ------ NC

3 ------ RD+

2 ------ TD1 ------ TD+

Wire the Module

Use the following information to wire the module.

Connect the Module to an EtherNet/IP Network via an RJ45 Connection

Wire the RJ45 connector as shown.

Follow these steps to connect the module to the network.

WARNING: If you connect or disconnect the communication cable with power

that is applied to this module or any device on the network, an electric arc can

occur. An electric arc can cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Attach the cable with the RJ45 connector to the Ethernet port on the

bottom of the module as shown.

2. Attach the other end of the cable to the devices in your network.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 29

Page 30

Chapter 2 Install a 1768 EtherNet/IP Communication Module

1

2

IMPORTANT

Apply Chassis Power and Check Status Indicators

Before you apply power, you must install and mount a CompactLogix controller

and Compact I/O™ power supply on the DIN rail.

Follow these steps to apply power.

1. Flip the switch to the ON position.

2. Check the power supply (1) and module (2) status indicators.

3. Check the alphanumeric display to determine that the power supply and

module are operating properly.

Remove the Module

30 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Follow these steps to remove the communication module.

When you turn off the CompactLogix power supply, make sure that you wait for

all status indicators on the power supply and controller to turn off before

disconnecting any part from the system.

If you disconnect the CompactLogix system while the controller is still writing

its program to memory, the program write is not completed and your program

is lost.

Page 31

Install a 1768 EtherNet/IP Communication Module Chapter 2

1. Flip the switch to the OFF position.

2. Open the DIN rail latches of the communication module and the module

directly to the left of communication module.

3. Slide the communication module and other modules to the right.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 31

Page 32

Chapter 2 Install a 1768 EtherNet/IP Communication Module

4. Open the DIN rail latches of the controller.

5. Slide the controller and other modules away from the communication

module.

6. Pull the communication module off the DIN rail.

32 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 33

Install a 1769 EtherNet/IP Adapter

Top ic Pa ge

System Configuration 35

Installation Summary 37

Set the Network IP Address 37

Install the Adapter in a 1769 System 39

Wire the Adapter 43

Remove or Replace the Adapter 43

Chapter 3

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

, for additional installation requirements.

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 33

Page 34

Chapter 3 Install a 1769 EtherNet/IP Adapter

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code. When

combining products within a system, the most adverse temperature

code (lowest "T" number) may be used to help determine the overall

temperature code of the system. Combinations of equipment in your

system are subject to investigation by the local Authority Having

Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is known

to be nonhazardous. Secure any external connections

that mate to this equipment by using screws, sliding

latches, threaded connectors, or other means

provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le plus

défavorable (code de température le plus faible) peut être utilisé pour

déterminer le code de température global du système. Les combinaisons

d'équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l'installation.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l'environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

WARNING: When used in a Class I, Division 2, hazardous location, this equipment must be mounted in a suitable enclosure with

proper wiring method that complies with the governing electrical codes.

34 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 35

Install a 1769 EtherNet/IP Adapter Chapter 3

System Configuration

Follow these rules when planning your system configuration.

• The adapter must be the first and left-most module in the system (the first

module of Bank 1). See page 36

• The adapter can communicate with up to 30 modules in a system that is

distributed across three I/O banks.

• An end cap/terminator must be on the last I/O bank.

• Each bank of I/O must have its own power supply.

• A bank of I/O can have a maximum of 16 modules with a maximum of

eight on either side of the power supply, depending upon module loading

on the supply.

• A 1769 I/O power supply has limits in the amount of 5V DC and

24V DC current it can supply to the modules in its I/O bank. These limits

depend on the catalog number (for example, 1769-PA2) of the supply. A

bank of modules should not exceed the current limits of the I/O bank

power supply. See the Compact 1769 Expansion I/O Power Supplies

Installation Instructions, publication 1769-IN028

• The maximum amount of current the system supports in one direction

(either side of the power supply) is: 2 A @ 5V DC, 1 A @ 24V DC.

• If another bank of I/O is required due to module requirements or I/O

loading, you can use a cable to link them together. You can have a

maximum of three banks of I/O connected with up to two

communication cables.

• Each module type has its own distance rating (the number of modules

from the power supply). Each module must be within this rating for its

type.

• The adapter has a distance rating of five, therefore the adapter must be

within five modules of the power supply.

for an example configuration.

.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 35

Page 36

Chapter 3 Install a 1769 EtherNet/IP Adapter

TIP

Bank 1

Bank 2

Bank 3

Bank 3Bank 2Bank 1

Right-to-Right Cable

1769-AENTR

1769 I/O

1769 I/O

1769-CRRx

I/O Slot Number

12

I/O Slot Number

10 11 12

1769-CLLx

1769 I/O

1769 I/O

1769 I/O

1769-CRRx

1769 Power Supply

1769-CLLx

1769 I/O

1769 I/O

1769 I/O

1769 I/O

1769 Right End Cap

I/O Slot Number

20

1769 I/O

1769-CRLx

1769-CRLx

1769 I/O

1769 I/O

1769-CRLx

1769 Power Supply

1769-CRLx

1769 I/O

1769 Power Supply

1769 I/O

1769 Right End Cap

I/O Slot Number

12 3 4 5 6

Left-to -Left Cable

42131

1769 I/O

1769 I/O

1769 Power Supply

34 5

1769 I/O

1769 I/O

6

1769 I/O

1769 Power Supply

1769 I/O

1769 I/O

987

1769 I/O

1769 I/O

1769 I/O

1769 I/O

19181716151413

1769-AENTR

1769 I/O

1769 Power Supply

Right-to-Left Cable Right-to-Left Cable

Example Configurations

The following illustrations show examples of two valid system setups.

I/O modules are not required between either the adapter and an end cap

or between the power supply and an end cap.

36 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 37

Install a 1769 EtherNet/IP Adapter Chapter 3

Installation Summary

Complete these steps to install an adapter in a 1769 CompactLogix™ system.

1. Set the Network IP Address

2. Install the Adapter in a 1769 System

3. Wire the Adapter

4. Remove or Replace the Adapter

If needed, see Download the Add-on Profiles and Firmware on page 7

.

.

.

. - Optional

.

Grounding Considerations

ATTENTION: This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel. Additional grounding connections

from the mounting tabs on the adapter or DIN rail (if used) are not required

unless you cannot ground the mounting surface. See the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

additional information.

, for

Set the Network IP Address

To operate an EtherNet/IP adapter on an EtherNet/IP network, you must set a

network IP address. 'The 1769 EtherNet/IP adapters are shipped with BOOTP/

DHCP enabled.

The IP address uniquely identifies the module. The IP address is in the form

xxx.xxx.xxx.xxx where each xxx is a number from 000…254.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 37

Page 38

Chapter 3 Install a 1769 EtherNet/IP Adapter

Module Powerup

Module has an IP address.

Switches set

from

001…254?

YesNo

Is DHCP or

BOOTP

enabled?

YesNo

Module requests

address from DHCP/

BOOTP server.

Module uses IP address

stored in nonvolatile

memory.

Figure 3 - Set the IP Address for the Module

See Set the Network IP Address on page 45 to view all steps for setting the IP

address.

38 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 39

Install a 1769 EtherNet/IP Adapter Chapter 3

Comm Adapter

MOD

NET

LINK 1

LINK 2

X 100

X 10

X 1

LINK 1LINK 2

6a

1

2

3

4

6b

7a

5

7b

9

8

46269

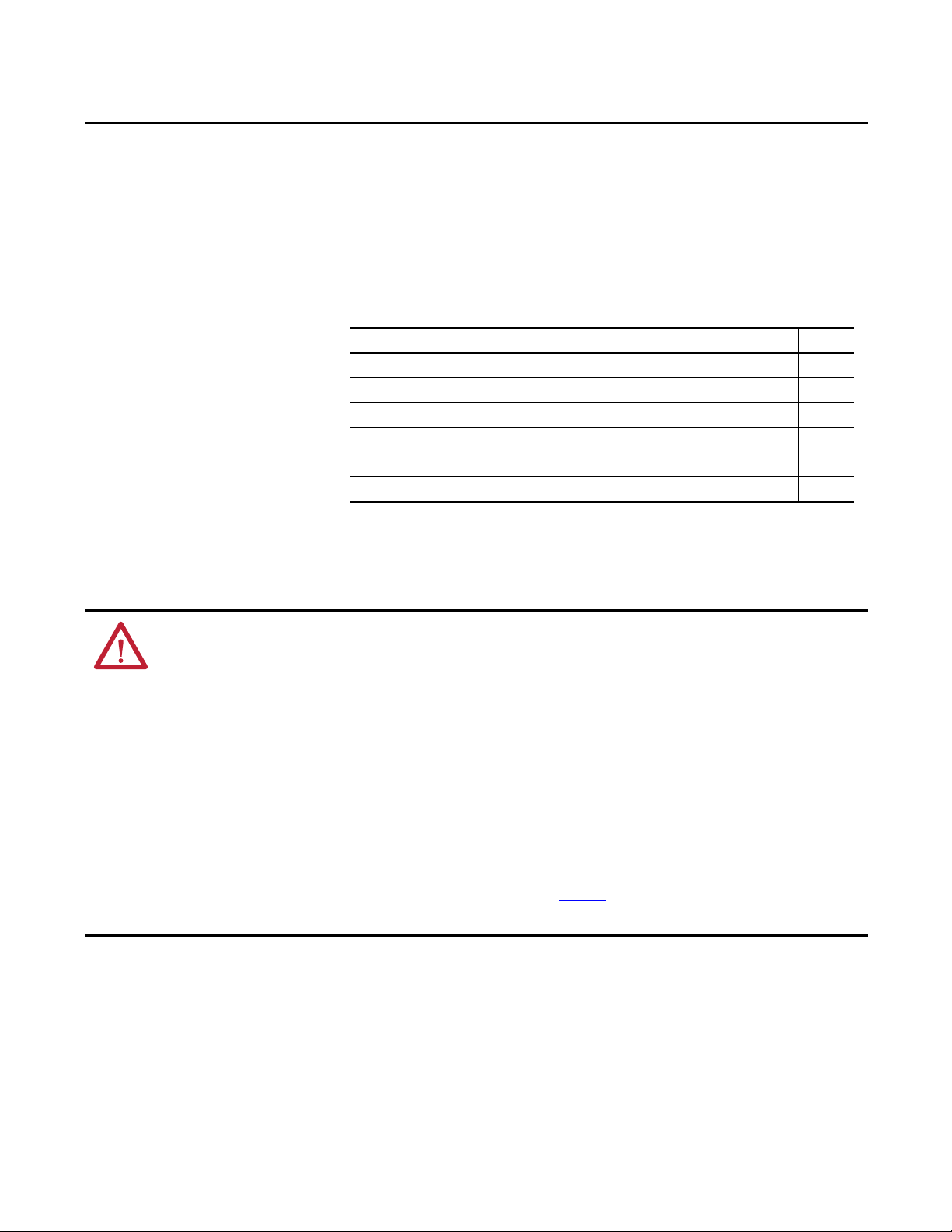

Install the Adapter in a 1769 System

Use the following information to install the adapter with the 1769 system.

Adapter Description

Item Description

1 Status indicators

2 IP address rotary switches

3 Ethernet port

4 Ethernet port for use in a Device Level Ring network

5 Nameplate label

6 Upper panel mounting tab

Lower panel mounting tab

7Upper DIN rail latch

8Bus lever

9 Stationary bus connector with male pins

Lower DIN rail latch

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 39

Page 40

Chapter 3 Install a 1769 EtherNet/IP Adapter

IMPORTANT

a

a

a

a

1769-

b

c

e

d

42126

System Assembly

The adapter can be attached to adjacent 1769 modules before or after mounting.

The 1769-AENTR adapter must be used with one of the following Rockwell

Automation® power supply models: 1769-PA2, 1769-PB2, 1769-PA4, or

1769-PB4.

For mounting instructions, see Mount the Adapter with Screws on page 41

Mount on a DIN Rail on page 42

.

Follow these steps to assemble the Compact I/O™ system.

1. Disconnect power.

WARNING: If you insert or remove the module while backplane power is on, an

electric arc can occur. An electric arc can cause an explosion in hazardous

location installations.

Be sure that power is removed before proceeding.

, or

2. Check that the bus lever of the module to the right of the adapter is in the

unlocked (fully right) position.

3. Use the upper and lower tongue-and-groove slots (a) to secure the modules

together.

4. Move the module back along the tongue-and-groove slots until the bus

connectors align with each other.

5. Use your fingers or a small screwdriver to push the bus lever of the module

to the right of the adapter back slightly to clear the positioning tab (b).

6. To allow communication between the adapter and I/O modules, move the

bus lever of the module to the right of the adapter fully to the left (c) until

it clicks. Make sure it is locked firmly into place.

ATT EN TI ON : When you attach the adapter, it is important that the bus

connectors are securely locked together to create a proper electrical connection.

40 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 41

Install a 1769 EtherNet/IP Adapter Chapter 3

IMPORTANT

1769 I/O

1769 I/O

1769 I/O

End Cap or Cable

42124

1769 I/O

1769 Power Supply

Side Side

Bottom

Top

1769 I/O

1769 I/O

1769-AENTR

For more than 1 module: Number of modules x 35 mm (1.38 in.)

28.5

(1.12)

35

(1.38)

132

(5.197)

(4.826+

0.008)

122.6+

0.2

1769-AENTR

1769 Power Supply

1769 I/O

Right End Cap

mm (in.)

Hole spacing tolerance:

±0.4 mm (0.016 in.)

42121

(1.38)

35

70

(2.76)

(1.58)

40

35

(1.38)

1769 I/O

7. Attach an end cap terminator (d) to the last I/O module in the system by

using the tongue-and-groove slots as before.

8. Lock the end-cap bus terminator (e).

A 1769-ECR or 1769-ECL right or left end cap must be used to terminate the

end of the serial communication bus.

Mount the Adapter and I/O Modules

ATT EN TI ON : During panel or DIN rail mounting of all devices, be sure that all

debris (metal chips, wire strands) is kept from falling into the adapter or

modules. Debris that falls into the adapter or modules can cause damage on

power-up.

Minimum Spacing

Maintain spacing from enclosure walls, wireways, and adjacent equipment.

Allow 50 mm (2 in.) of space on all sides for adequate ventilation, as shown.

Mount the Adapter with Screws

Mount the adapter or module to a panel by using two screws per adapter or

module. Use M4 or #8 panhead screws. Mounting screws are required on every

module. This figure illustrates panel mounting using the dimensional template.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 41

Page 42

Chapter 3 Install a 1769 EtherNet/IP Adapter

TIP

Mount to Module with Screws by Using the Modules as a Template

The following procedure lets you use the assembled adapter and modules as a

template for drilling holes in the panel. If you have sophisticated panel mounting

equipment, you can use the dimensional template that is provided on page 41

Due to the module-mounting hole tolerance, it is important to follow this

procedure.

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including all

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel and check for proper hole alignment.

6. Attach the modules to the panel with the mounting screws.

.

If mounting more modules, mount only the last one of this group

and put the others aside. This reduces remounting time during

drilling and tapping of the next group.

7. Repeat steps 1...6 for any remaining modules.

Mount on a DIN Rail

The adapter can be mounted using the following DIN rails:

• 35 x 7.5 mm (EN50022 - 35 x 7.5)

• 35 x 15 mm (EN 50022 - 35 x 15)

Follow these steps to mount the module.

1. Verify that the DIN rail latches are closed.

2. Press the DIN rail mounting area of the module against the DIN rail.

The latches momentarily open, then lock into place.

ATT EN TI ON : This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials, for example, aluminum and plastic, that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding.

42 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 43

Install a 1769 EtherNet/IP Adapter Chapter 3

8 ------ NC

7 ------ NC

6 ------ RD5 ------ NC

4 ------ NC

3 ------ RD+

2 ------ TD1 ------ TD+

8

1

TIP

Wire the Adapter

Use the following information to wire the adapter.

This product is intended to be mounted to a well-grounded mounting surface

such as a metal panel. Additional grounding connections from the mounting tabs

on the adapter or DIN rail (if used) are not required unless you cannot ground

the mounting surface. See the Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

, for additional information.

Connect the module to an EtherNet/IP network via an RJ45 cable.

WARNING: If you connect or disconnect the communication cable with power

that is applied to this module or any device on the network, an electric arc can

occur. An electric arc can cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Wire the RJ45 connector as shown.

Remove or Replace the Adapter

The adapter can be replaced while the system is mounted to a panel or DIN rail.

1. Remove power.

ATT EN TI ON : Do not remove or replace an adapter while power is applied.

Interruption of the backplane can result in unintentional operation or machine

motion.

2. Remove the EtherNet/IP cable from the module.

3. Remove the upper and lower mounting screws from the adapter or open

the DIN latches with a flat-blade or Phillips-style screwdriver.

4. On the right-side adjacent module, move its bus lever to the right (unlock)

to disconnect it from the adapter being removed.

5. Gently slide the disconnected adapter forward.

If you feel excessive resistance, make sure that you disconnected the

adapter from the bus and that you removed both mounting screws or

opened the DIN latches.

Rock the module slightly from front to back, if necessary, to remove it,

or, in a panel-mounted system, to loosen the screws of adjacent

modules.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 43

Page 44

Chapter 3 Install a 1769 EtherNet/IP Adapter

6. Before installing the replacement adapter, be sure that the bus lever on the

right-side adjacent module is in the unlocked (fully right) position.

7. Slide the replacement adapter into the open slot.

8. Connect the adapter and modules together by locking (fully left) the bus

levers on the right-side adjacent module.

9. Replace the mounting screws or snap the adapter onto the DIN rail.

10. Insert the Ethernet cable into the module.

11. Set the network address switches to the same value as the removed adapter.

44 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 45

Chapter 4

Set the Network IP Address

Top ic Pag e

Set the Network IP Address with the BOOTP/DHCP Server 47

Set the Network IP Address with RSLinx Software or the Studio 5000™ Environment 50

The IP address uniquely identifies the module. The IP address is in the form

xxx.xxx.xxx.xxx where each xxx is a number from 000…254.

There are some reserved values that you cannot use as the first octet in the

address. These numbers are examples of values you cannot use:

• 001.xxx.xxx.xxx

• 127.xxx.xxx.xxx

• 223 to 255.xxx.xxx.xxx

The specific reserved values that cannot be used vary by application.

For more information about how to configure an EtherNet/IP network, see

EtherNet/IP Network Configuration User Manual, publication ENET-UM001

Depending on the 1756 EtherNet/IP communication module, you can use some

or all of these tools to set the network Internet Protocol (IP) address:

• Rotary switches - The 1756-ENBT and 1756-EWEB modules do not offer

rotary switches. If you are using either of these modules, skip Set the

Network IP Address with the Rotary Switches on page 46

the Network IP Address with the BOOTP/DHCP Server on page 47

• Bootstrap Protocol (BOOTP)/Dynamic Host Configuration Protocol

(DHCP) server

• RSLinx® Classic software

• Studio 5000 environment

The module uses these tools sequentially to set the IP address.

and go to Set

.

.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 45

Page 46

Chapter 4 Set the Network IP Address

32454

Rotary Switches

Front of

Module

The 1756 EtherNet/IP communication modules are shipped with

this configuration:

• BOOTP/DHCP enabled

• Rotary switches set to 999 - when applicable

To reset the module factory default settings during normal module operation, see

Reset the Module IP Address to a Factory Default Value on page 54

.

These tools are used in this sequence to set the network IP address.

1. Set the Network IP Address with the Rotary Switches

2. Set the Network IP Address with the BOOTP/DHCP Server

3. Set the Network IP Address with RSLinx Software or the Studio 5000™

Environment

Set the Network IP Address with the Rotary Switches

This graphic shows the rotary switches on a 1756 EtherNet/IP communication

module. Depending on the module, the switches are on the top or the side of the

module.

At power-up, the module reads the rotary switches to determine if they are set to

a valid number for the last portion of the IP address. For example, if the numbers

are in the range from 001…254.

If the settings are a valid number, these conditions result:

• IP address = 192.168.1.xxx (where xxx represents the switch settings)

• Subnet mask = 255.255.255.0

• Gateway address

= 192.168.1.1 for firmware revision 5.008 or later

= 0.0.0.0 for firmware revision 5.007 or earlier

46 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 47

Set the Network IP Address Chapter 4

IMPORTANT

IMPORTANT

The gateway address of 192.168.1.1 applies only to the 1756-EN2T,

1756-EN2TR, 1756-EN2TRXT, 1756-EN2F, 1756-EN2TSC, and

1756-EN3TR modules with firmware revision 5.008 or later. Other

modules use the gateway address of 0.0.0.0 with firmware revision

5.007 or earlier.

For more information, see the Ethernet Design Considerations

Reference Manual, publication ENET-RM002

• The module does not have a host name that is assigned and does not use

any Domain Name System

We recommend that you set the rotary switches to a valid number before

installing the module.

If either of these conditions exist, the module attempts to use the BOOTP/

DHCP server to set the IP address:

• Rotary switches are not set to a valid number.

• Module does not have rotary switches.

.

Set the Network IP Address with the BOOTP/DHCP Server

The BOOTP/DHCP server is a standalone server that you can use to set an IP

address. When used, the BOOTP/DHCP server sets an IP address and other

Transport Control Protocol (TCP) parameters.

You can use the BOOTP/DHCP server to set the IP address of the module if one

of these conditions exists when you apply power:

• The rotary switches on the module are not set to a valid number and the

module is BOOTP/DHCP enabled.

• The module does not have rotary switches and the module is

BOOTP/DHCP enabled.

Access the BOOTP/DHCP server from one of these locations:

• Programs > Rockwell Software > BOOTP-DHCP Server

If you have not installed the server, you can download and install it from

http://www.ab.com/networks/ethernet/bootp.html

• Tools directory on the Studio 5000 environment installation CD

Before you start the BOOTP/DHCP server, make sure that you have the

hardware (MAC) address for the module. The hardware address is on a

sticker on the side of the communication module and uses an address

in a format similar to the following:

.

00-00-BC-14-55-35

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 47

Page 48

Chapter 4 Set the Network IP Address

Follow these steps to set the IP address of the module with a BOOTP/DHCP

server.

1. Start the BOOTP/DHCP software.

2. From the Tools menu, choose Network Settings.

3. Type the Subnet Mask of the network.

The Gateway address, Primary and/or Secondary DNS address, and

Domain Name fields are optional.

4. Click OK.

The Request History panel appears with the hardware addresses of all

modules that issue BOOTP requests.

5. Select the appropriate module.

6. Click Add to Relation List.

48 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 49

Set the Network IP Address Chapter 4

IMPORTANT

The New Entry dialog box appears.

7. Type an IP Address, Hostname, and Description for the module.

8. Click OK.

9. To assign this configuration permanently to the module, wait for the

module to appear in the Relation List panel and select it.

10. Click Disable BOOTP/DHCP.

When power is recycled, the module uses the assigned configuration and

does not issue a BOOTP request.

If you do not click Disable BOOTP/DHCP, on a power cycle, the host

controller clears the current IP configuration and begins sending

BOOTP requests again.

Use DHCP Software

Dynamic Host Configuration Protocol (DHCP) software automatically assigns

IP addresses to client stations logging on to a TCP/IP network. DHCP is based

on BOOTP and maintains some backward compatibility. The main difference is

that BOOTP allows for manual configuration (static), while DHCP allows for

both static and dynamic allocation of network addresses and configurations to

newly attached modules.

Be cautious when using DHCP software to configure a module. A BOOTP

client, such as the EtherNet/IP communication modules, can start from a DHCP

server only if the DHCP server is written to handle BOOTP queries. This is

specific to the DHCP software package used. Consult your system administrator

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 49

Page 50

Chapter 4 Set the Network IP Address

to see if a DHCP package supports BOOTP commands and manual IP

allocation.

AT TE NT IO N: The EtherNet/IP communication module must be assigned a

fixed network address. The IP address of this module must not be dynamically

provided.

Failure to observe this precaution can result in unintended machine motion or

loss of process control.

Set the Network IP Address with RSLinx Software or the Studio 5000™ Environment

This table describes when to set the network IP address with RSLinx software or

the Studio 5000 environment.

Conditions Software to Use Page

• A BOOTP server is not available.

• The EtherNet/IP communication module is connected to another

NetLinx network.

The Studio 5000® project is online with a controller that communicates to

or through the EtherNet/IP communication module.

RSLinx 51

Studio 5000 environment 53

Consider these factors when you determine how to set the network IP address:

• Network isolation from or integration into the plant/enterprise network

• Network size - For large networks, isolated networks, it can be more

convenient to use a BOOTP/DHCP server rather than the

Studio 5000 environment or RSLinx software. The BOOTP/DHCP

server also limits the possibility of assigning duplicate IP addresses.

• Company policies and procedures for plant-floor network installation and

maintenance

• Level of involvement by IT personnel in plant floor network installation

and maintenance

• Type of training that is offered to control engineers and maintenance

personnel

If you use the Rockwell Automation® BOOTP or DHCP server in an uplinked

subnet where an enterprise DHCP server exists, a module can get an address

from the enterprise server before the Rockwell Automation utility even sees the

module. You can disconnect from the uplink to set the address and configure the

module to retain its static address before reconnecting to the uplink. This is not a

problem if you have node names that are configured in the module and leave

DHCP enabled.

50 Rockwell Automation Publication ENET-IN002H-EN-P - August 2017

Page 51

Set the Network IP Address Chapter 4

IMPORTANT

Set the Network IP Address with RSLinx Software

Follow these steps to use RSLinx software to set the communication module’s

IP address.

1. From the Communications menu, choose RSWho.

The RSWho dialog box appears.

2. Navigate to the Ethernet network.

3. Right-click the EtherNet/IP module and choose Module Configuration.

The Module Configuration dialog box appears.

4. Click the Port Configuration tab.

5. For Network Configuration Type, click Static to assign this configuration

permanently to the port.

If you select Dynamic, on a power cycle, the controller clears the

current IP configuration and resumes sending BOOTP requests.

Rockwell Automation Publication ENET-IN002H-EN-P - August 2017 51

Page 52

Chapter 4 Set the Network IP Address

IMPORTANT