Page 1

ControlLogix Drive

Module

1756-DMD30, 1756-DMF30

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “ Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls ” (Publication SGI-1.1

available from your local Rockwell Automation Sales Office or online at

http://www.ab.com/manuals/gi ) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

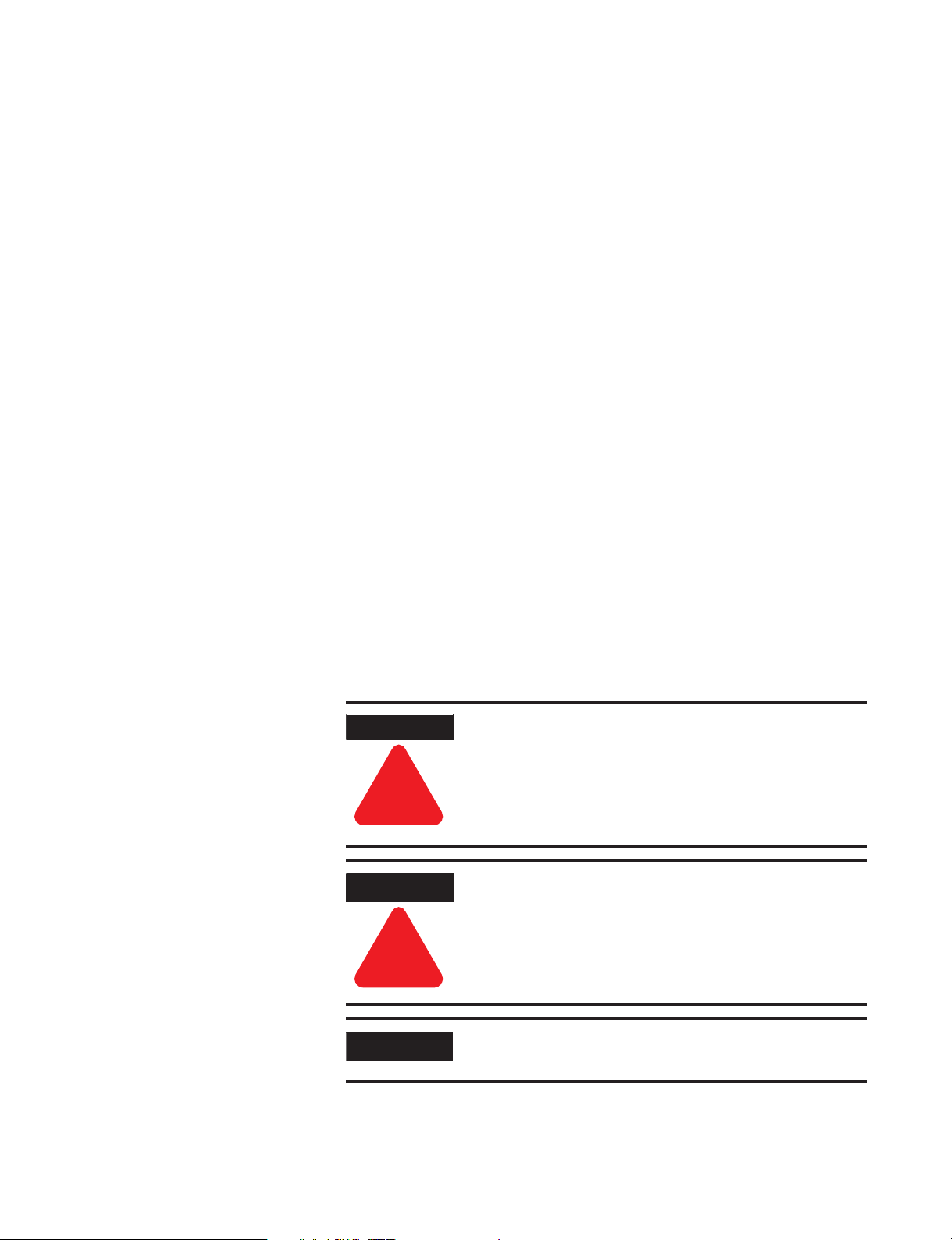

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

Page 3

Rockwell Automation Support

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained

in this publication first.

If the problem persists, call your local Rockwell Automation

representative or contact Rockwell Automation in one of the

following ways:

Phone

Internet

United

States/Canada

Outside United

States/Canada

⇒

1.262.512.8176

You can access the phone number for your

country via the Internet:

1. Go to http://www.ab.com

2. Click on Product Support

(http://support.automation.rockwell.com)

3. Under Support Centers , click on Contact

Information

1. Go to http://www.ab.com

2. Click on Product Support

(http://support.automation.rockwell.com)

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us by using one

of these two methods:

•

Filling out the enclosed "How Are We Doing" form

•

Filling out the "Tell Us How We Can Make Our Manuals Better"

form online at

http://www.ab.com/manuals/dr/manuals_feedback.html

Page 4

Page 5

1

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . 1-3

Your Questions or Comments on this Manual . . . . . . . . 1-3

Summary of Changes

Preface

What is the ControlLogix Drive

Module?

Drive Comm (Drive

Communication)

Drive Module Features

Installing the Drive Module

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

What This Manual Contains . . . . . . . . . . . . . . . . . . . . . . . . P-2

Related Products and Documentation. . . . . . . . . . . . . . . . . P-2

What is the ControlLogix

Drive Module?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What Are Some of the Features Available On the ControlLogix

Drive Module? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connecting the Drive Module to SynchLink and Drive Comm . .

1-3

SynchLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Drive Comm (Drive Communication) . . . . . . . . . . . . . . 1-3

Physical Features of the ControlLogix Drive Module . . . 1-4

Using Module Identification and Status Information . . . . . . 1-5

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . 1-7

Removal and Insertion Under Power . . . . . . . . . . . . . . . . . 1-7

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 1-8

Interface to DPS Drive Equipment . . . . . . . . . . . . . . . . . . . 2-1

Drive Communication Protocol . . . . . . . . . . . . . . . . . . . . . 2-1

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Synchronized Communication . . . . . . . . . . . . . . . . . . . . . . 2-2

Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Synchronization with CST. . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 2-3

General Module Features. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Removal and Insertion Under Power (RIUP) . . . . . . . . . 3-2

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Fully Software Configurable . . . . . . . . . . . . . . . . . . . . . 3-3

LED Status Information . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Class I Division 2 Certification . . . . . . . . . . . . . . . . . . . 3-4

Agency Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Configurable Module Features . . . . . . . . . . . . . . . . . . . . . . 3-4

Controller Communication Format . . . . . . . . . . . . . . . . 3-5

SynchLink Communications Format . . . . . . . . . . . . . . . 3-5

Module-Defined Data Tags. . . . . . . . . . . . . . . . . . . . . . 3-7

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . 3-10

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 3-10

Noting the Power Requirements . . . . . . . . . . . . . . . . . . . . 4-1

Installing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Connecting SynchLink Cables . . . . . . . . . . . . . . . . . . . . . . 4-3

Connecting (Drive Comm Drive Communication) Cables . . 4-5

Publication 1756-UM522B-EN-P - February 2003

Page 6

2

Configuring the Drive Module

Troubleshooting the Drive Module

Specifications

1756-DMD30 Specific Information

Removing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 4-7

Overview of the Configuration Process . . . . . . . . . . . . . . . 5-1

Planning the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Understanding the Controller - Drive Module Interface . 5-2

Choosing the SynchLink Communication Formats . . . . . 5-2

Choosing the SynchLink Network Topology . . . . . . . . . 5-4

Checking and Updating the DriveExecutive Database. . . . . 5-6

Checking the DriveExecutive Database . . . . . . . . . . . . . 5-6

Checking the DriveExecutive Database (continued). . . . 5-7

Updating the DriveExecutive Database . . . . . . . . . . . . . 5-8

Using RSLogix 5000 to Configure the Drive Module . . . . . . 5-9

Using DriveExecutive to Configure Drive Module. . . . . . . . 5-16

Return to RSLogix 5000 to Finish Configuring the Drive Module

5-23

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 5-24

Using the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using DriveExecutive to Troubleshoot the Module . . . . . . . 6-3

Warning Signal on Main Screen . . . . . . . . . . . . . . . . . . 6-3

Fault and Alarm Window . . . . . . . . . . . . . . . . . . . . . . . 6-4

Fault and Alarm Window (continued). . . . . . . . . . . . . . 6-5

Fault and Alarm Window (continued). . . . . . . . . . . . . . 6-6

Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Diagnostic Parameters (continued) . . . . . . . . . . . . . . . . 6-7

Using RSLogix 5000 to Troubleshoot the Module . . . . . . . . 6-8

Warning Signal on Main Screen . . . . . . . . . . . . . . . . . . 6-8

Module Properties Window . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 6-10

Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communication Specifications . . . . . . . . . . . . . . . . . . . . . . A-1

Control Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Speed Control - Reference . . . . . . . . . . . . . . . . . . . . . . B-3

Speed Control - Regulator . . . . . . . . . . . . . . . . . . . . . . B-4

Process Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Position Control - Interpolated/Direct . . . . . . . . . . . . . . B-6

Position Control - Point to Point . . . . . . . . . . . . . . . . . B-7

Position Control - Auxiliary . . . . . . . . . . . . . . . . . . . . . B-8

Torque Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Speed / Position Feedback. . . . . . . . . . . . . . . . . . . . . B-10

Peak Detector / Control Logix . . . . . . . . . . . . . . . . . . B-11

Field Economy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

How Parameters are Organized . . . . . . . . . . . . . . . . . B-15

Parameter Data In Linear List Format . . . . . . . . . . . . . B-24

Parameter Cross Reference By Name . . . . . . . . . . . . B-153

Publication 1756-UM522B-EN-P - February 2003

Page 7

1756-DMF30 Specific Information

Index

3

Interpretting Drive Module Faults in DriveExecutive . . . . B-159

Parameter 169 [Drive I/O Status]. . . . . . . . . . . . . . . . B-159

Parameter 323 [Fault Status 1] . . . . . . . . . . . . . . . . . . B-160

Parameter 324 [Fault Status 2] . . . . . . . . . . . . . . . . . . B-161

Parameter 326 [Alarm Status 1] . . . . . . . . . . . . . . . . . B-162

Parameter 327 [Alarm Status 2] . . . . . . . . . . . . . . . . . B-162

Parameter 1229 [SL Error Status] . . . . . . . . . . . . . . . . B-163

Parameter 2044 [Rail Port 0 Faults] . . . . . . . . . . . . . . B-164

Parameter 2050 [Rail Port 1 Faults] . . . . . . . . . . . . . . B-165

Parameter 2122 [MC Faults]. . . . . . . . . . . . . . . . . . . . B-166

Parameter 2123 [MC Warnings] . . . . . . . . . . . . . . . . . B-167

Parameter 2124 [Pwr Device Status] . . . . . . . . . . . . . B-169

Parameter 2125 [Interlock Code] . . . . . . . . . . . . . . . . B-170

Control Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Current Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Speed Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Peak Detector/Control Logic. . . . . . . . . . . . . . . . . . . . . C-4

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

How Parameters Are Organized . . . . . . . . . . . . . . . . . . C-7

Parameter Data In Linear List Format . . . . . . . . . . . . . C-14

Interpretting Drive Module Faults in DriveExecutive . . . . C-100

Parameter 323 [Fault Status 1] . . . . . . . . . . . . . . . . . . C-100

Parameter 324 [Fault Status 2] . . . . . . . . . . . . . . . . . . C-101

Parameter 326 [Alarm Status 1] . . . . . . . . . . . . . . . . . C-102

Parameter 327 [Alarm Status 2] . . . . . . . . . . . . . . . . . C-102

Parameter 1229 [SL Error Status] . . . . . . . . . . . . . . . . C-103

Parameter 2044 [Rail Port 0 Faults] . . . . . . . . . . . . . . C-104

Parameter 2050 [Rail Port 1 Faults] . . . . . . . . . . . . . . C-105

Parameter 2122 [MC Faults]. . . . . . . . . . . . . . . . . . . . C-106

Parameter 2123 [MC Warnings] . . . . . . . . . . . . . . . . . C-107

Parameter 2124 [Pwr Device Status] . . . . . . . . . . . . . C-108

Parameter 2125 [Interlock Code] . . . . . . . . . . . . . . . . C-109

Publication 1756-UM522B-EN-P - February 2003

Page 8

4

Publication 1756-UM522B-EN-P - February 2003

Page 9

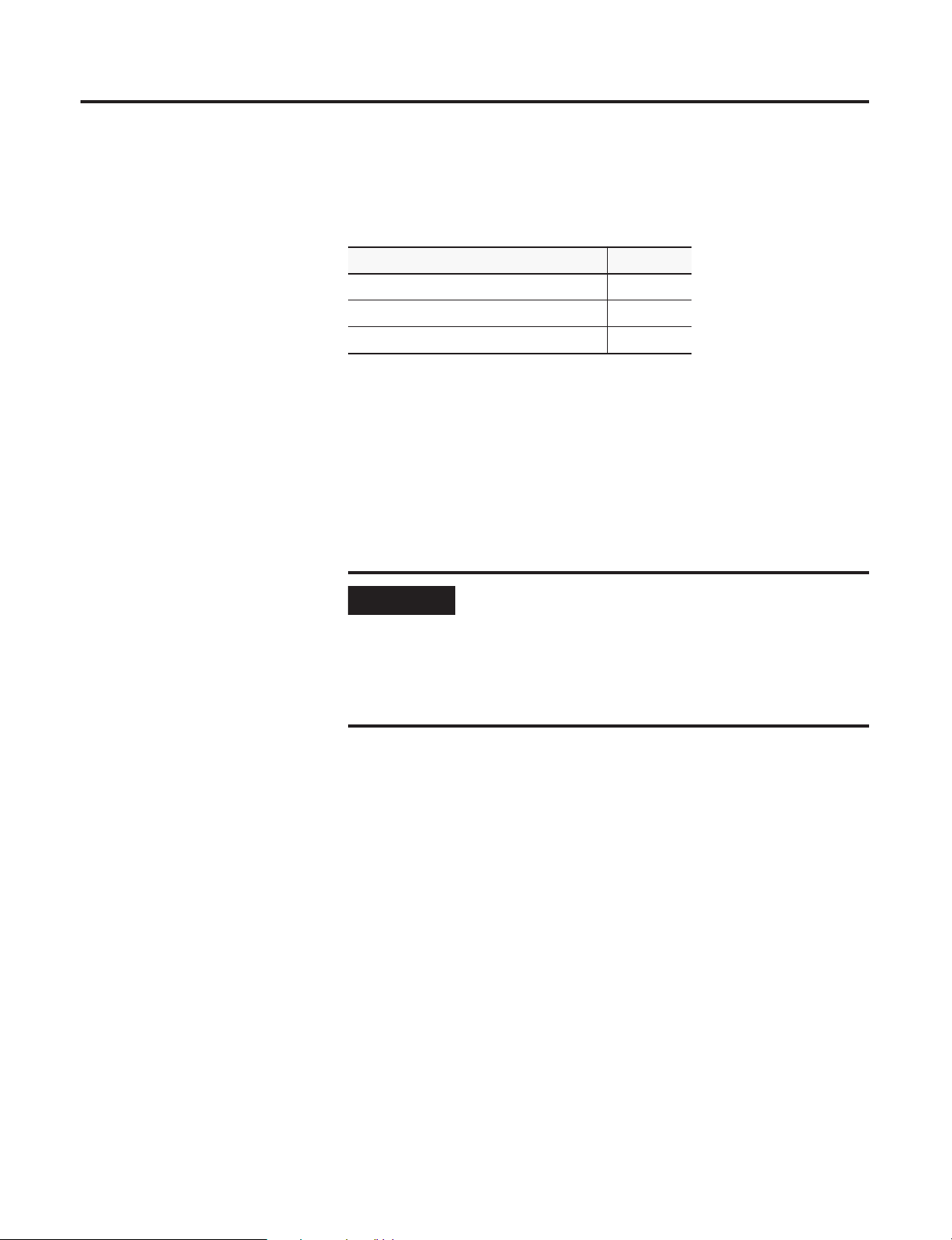

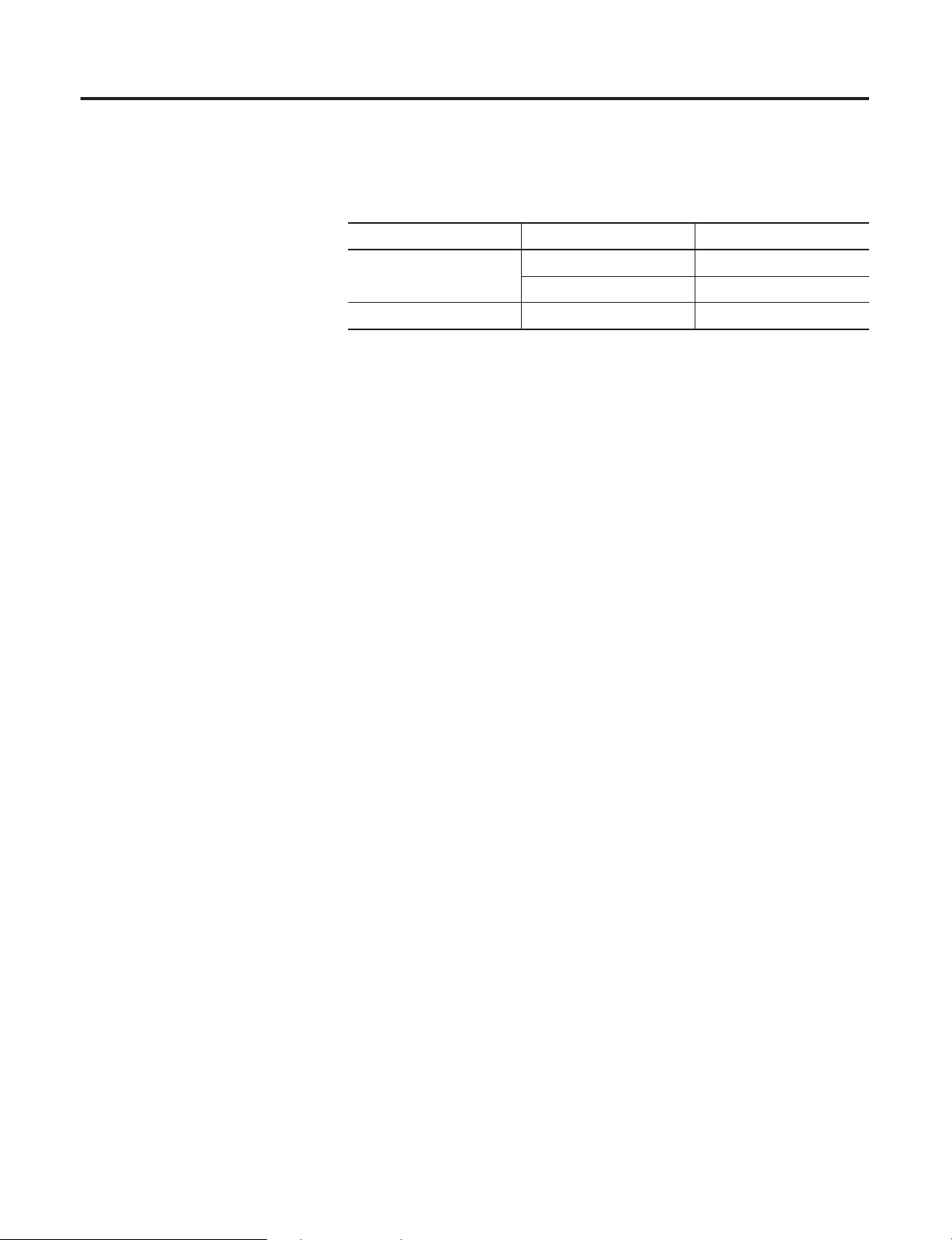

Summary of Changes

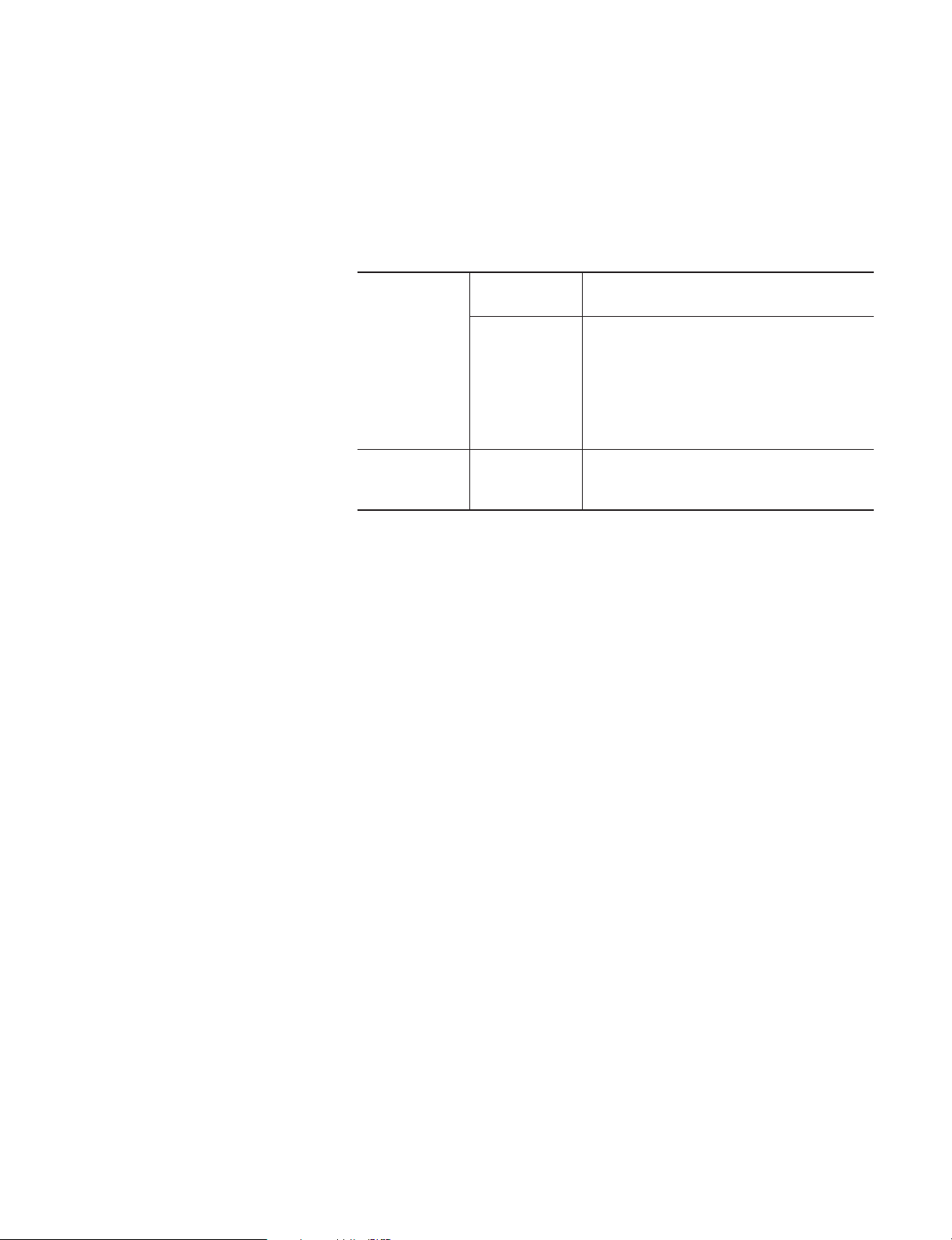

The table below summarizes the changes to this publication since the

last update:

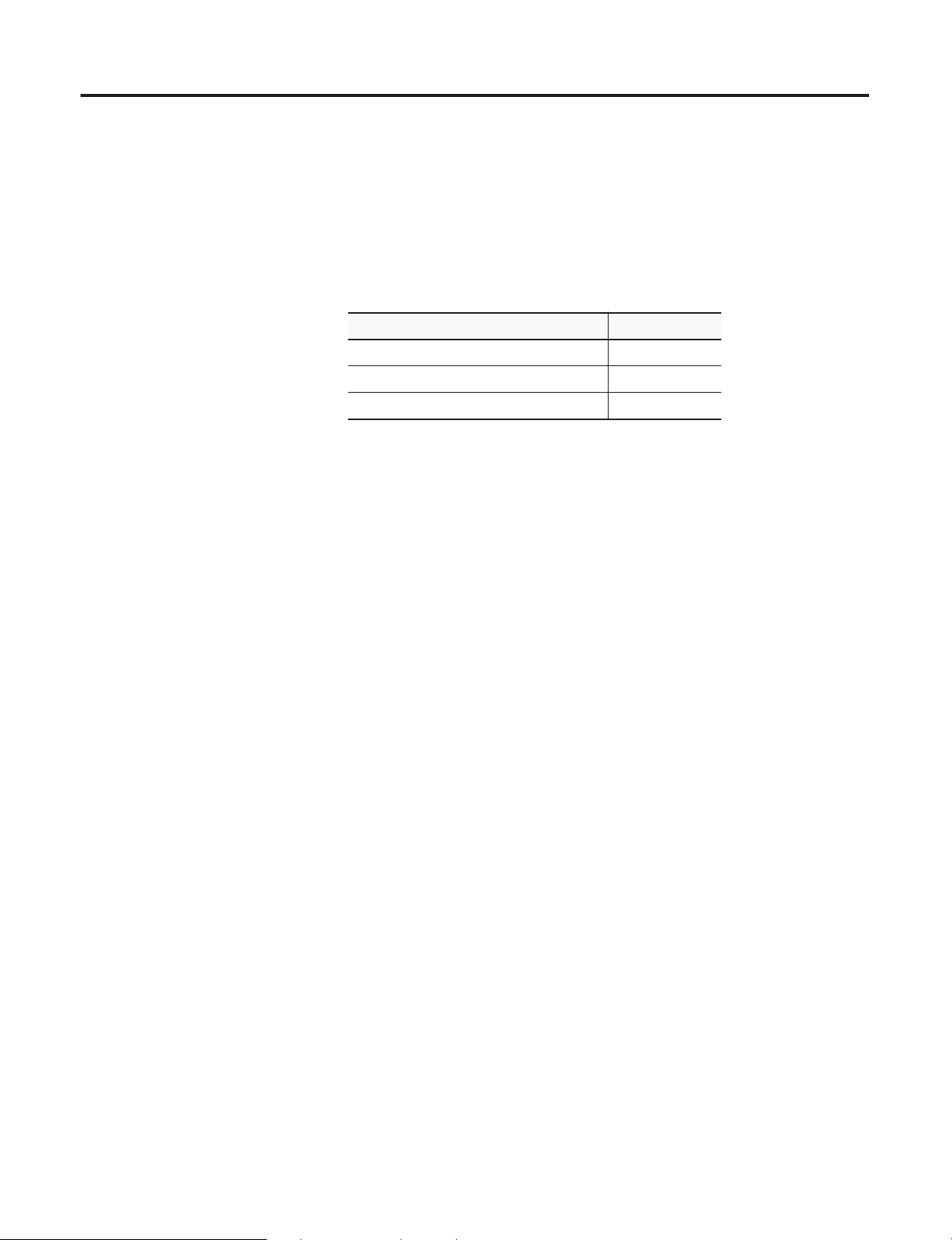

For this updated information: See:

Reliability specification A-1

Documentation of 1756-DMD30 (Firmware Revision 2.01) Algorithms,

Parameters and Faults

Documentation of 1756-DMF30 (Firmware Revision 1.09) Algorithms,

Parameters and Faults

B-1

C-1

1 Publication 1756-UM522B-EN-P - February 2003

Page 10

Summary of Changes 2

Notes:

Publication 1756-UM522B-EN-P - February 2003

Page 11

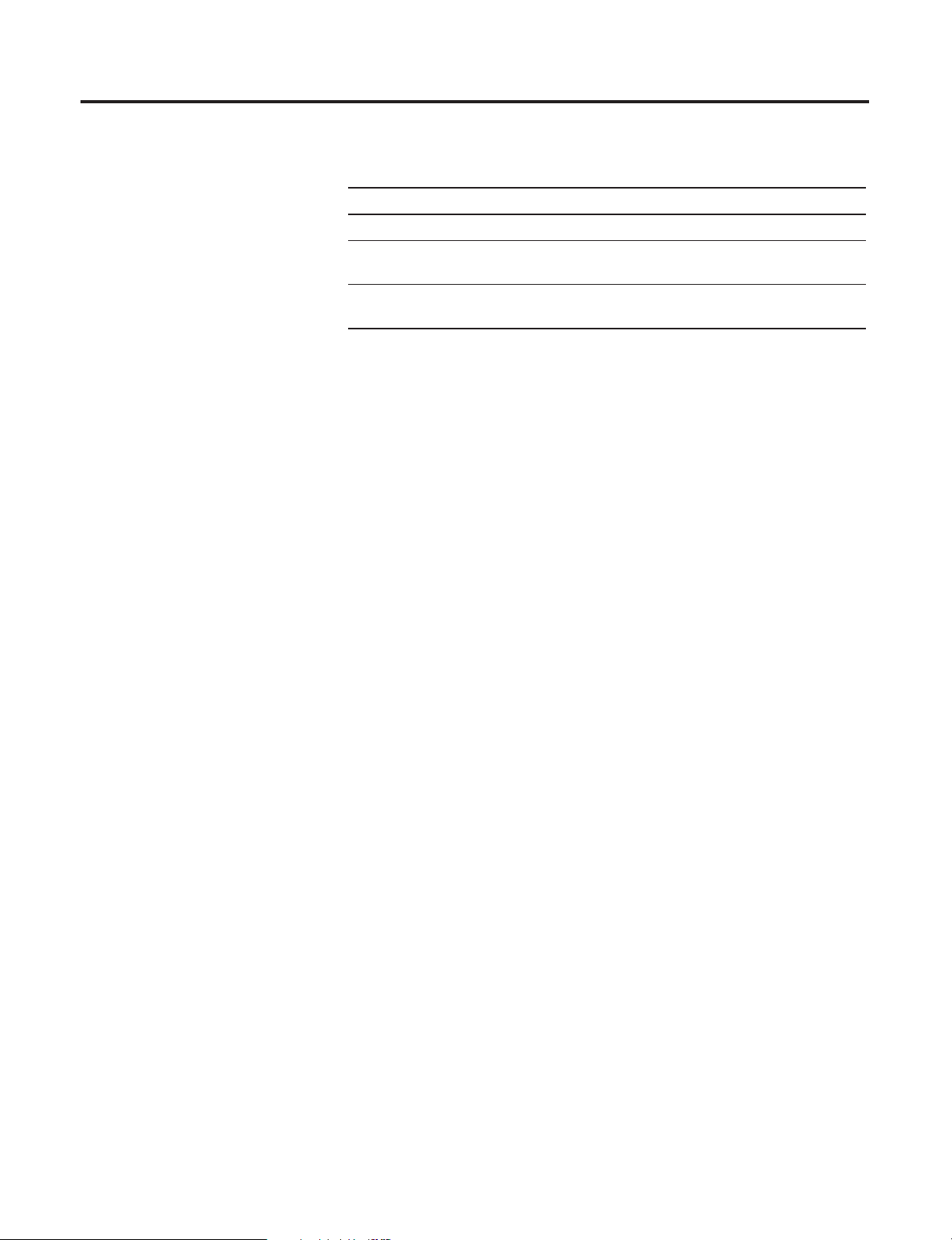

Preface

About This Preface

This preface describes how to use this manual. The following table

describes what this preface contains and its location.

For information about: See page:

Who Should Use This Manual Preface-1

Purpose of This Manual Preface-1

Related Products and Documentation Preface-2

Who Should Use This Manual

Purpose of This Manual

You must be able to program and operate an Allen-Bradley

Control

efficiently use your Drive module.

We assume that you know how to do this in this manual. If you do

not, refer to Related Documentation, before you attempt to use this

module.

IMPORTANT

This manual describes how to install, configure, and troubleshoot

your ControlLogix Drive module.

Logix

™ Logix controller and ControlLogix I/O modules to

SynchLink must be used in conjunction with a standard

control network, such as ControlNet or Ethernet. A

standard network is used for general control interlocking

and transfer of diagnostic data across the system.

SynchLink does not function as a standard control network

(e.g. it broadcasts data in a unidirectional manner).

1 Publication 1756-UM522B-EN-P - February 2003

Page 12

•

•

•

Preface 2

•

•

•

•

•

What This Manual Contains

Related Products and

This user manual contains the following sections:

The following table lists related Allen-Bradley products and

documentation:

Documentation

Table Preface.A

Related Documentation

Catalog

number:

1756-DM ControlLogix Drive Module Installation Instructions 1756-IN577

1756-A4, -A7,

-A10, -A13

1756-PA72,

-PB72

1756-PA75,

-PB75

1756-Series ControlLogix Module Installation Instructions

1756-Series ControlLogix System User Manual 1756-UM001

Multiple

numbers

1751-SLBA SynchLink Base Block Installation Instructions 1751-IN001

1751-SL4SP SynchLink 4-port Splitter Block Installation

1751-SLBP SynchLink Bypass Switch Block Installation

PowerFlex

700S

Description of the Drive module

Description of Drive Communication

Description of Drive module certifications and features

Description of how to install the Drive module and connect the

fiber optic cables

Description of how to configure the Drive module with RSLogix

5000 and DriveExecutive programming software

Description of how to troubleshoot the Drive module

Listing of Drive module specifications

Information specific to the SD3000 Interface (1756-DMD30)

Document title: Pub. number:

ControlLogix Chassis Installation Instructions 1756-IN080B

ControlLogix Power Supply Installation Instructions 1756-5.67

ControlLogix Power Supply Installation Instructions 1756-5.78

Multiple 1756-IN

(Each module has separate installation document.)

SynchLink Design Guide 1756-TD008

Instructions

Instructions

PowerFlex 700S User Manual 20D-UM001

numbers

1751-IN002

1751-IN003

Publication 1756-UM522B-EN-P - February 2003

Page 13

Preface 3

The following table lists related Reliance Electric products and

documentation:

Table Preface.B

Related Documentation

Catalog

Document title: Pub. number:

number:

Multiple

Distributed Power System Overview S-3005

numbers

SD3000,

SF3000

SD3000

SD3000,

SF3000

SD3000 Distributed Power System

SF3000 Distributed Power System

SD3000,

SF3000

Distributed Power System

SD3000/SF3000

Power Module Interface Rack and Modules

Distributed Power System

SD3000 Drive

Diagnostics, Troubleshooting, and Start-Up Guidelines

Distributed Power System

SD3000/SF3000

3-Phase DC Power Models

High Horsepower D-C Power Bridge

1000 HP Power Modules

SF3000 Panel-Mounted

Single-Phase Field Power Modules

Distributed Power System

SD3000/SF3000

Parallel Gate Amplifier System

S-3008

S-3011

S-3037

S-3039

S-3060

S-3045

If you need more information on these products, contact your local

Allen-Bradley integrator or sales office for assistance. Information and

manuals are also available online at http://www.ab.com/manuals/ and

http://www.theautomationbookstore.com/ .

Publication 1756-UM522B-EN-P - February 2003

Page 14

Preface 4

Notes:

Publication 1756-UM522B-EN-P - February 2003

Page 15

Chapter

1

What is the ControlLogix Drive Module?

This chapter describes the ControlLogix Drive module. It also

describes what you must know and do before using the Drive

module.

For information about: See page:

What is the ControlLogix Drive Module? 1-1

Connecting the Drive Module to SynchLink

and Drive Comm

Using Module Identification and Status

Information

Preventing Electrostatic Discharge 1-7

Removal and Insertion Under Power 1-7

Chapter Summary and What’s Next 1-8

1-3

1-5

What is the ControlLogix

Drive Module?

The 1756-DM Drive Module is a single slot ControlLogix based

module for interface to Reliance Electric Distributed Power System

(DPS) drive equipment. Each drive module interfaces with an

individual Power Module Interface (PMI) chassis, performing velocity

and position and outer torque control.

Figure 1.1 SD3000 System Example

ControlLogix Chassis

with Drive Module

Drive Communication

Motor with

resolver

DPS with PMI

Chassis

1 Publication 1756-UM522B-EN-P - February 2003

Page 16

•

•

•

•

1-2 What is the ControlLogix Drive Module?

There are two types of Drive module, each works with a different

type of DPS drive equipment.

Table 1.A

Drive Module DPS Equipment Description

1756-DMD30 SD3000 6 Pulse DC Drive S6 and S6R

SD3000 12 Pulse DC Drive S12 and S12R

1756-DMF30 SF3000 Three Phase Field Supply

What Are Some of the Features Available On the ControlLogix Drive Module?

The following are some of the features available on the ControlLogix

Drive module:

The 1756-DMD30 utilizes velocity and position and outer torque

control similar to the PowerFlex 700S

•

Motor Control capability mimics the respective Reliance Electric

Distributed Power drive

•

PC Tools, such as RSLogix 5000

DriveTools 2000

TM

program suite, used for programming,

TM

and DriveExecutive

TM

in the

configuring, monitoring and troubleshooting

Fiber optic connection to the Power Module Interface

SynchLink

TM

for advanced high performance synchronization

and data transfer.

Removal and insertion under power (RIUP) - This system feature

allows you to remove and insert the module while power is

applied. For more information on RIUP, see page 1-7.

•

Class I Division 2, UL, CSA, and CE Agency Certification

Publication 1756-UM522B-EN-P - February 2003

Page 17

What is the ControlLogix Drive Module? 1-3

Connecting the Drive Module to SynchLink and Drive Comm

SynchLink

The ControlLogix Drive module mounts in a ControlLogix chassis and

connects to other SynchLink nodes through a fiber optic cable system.

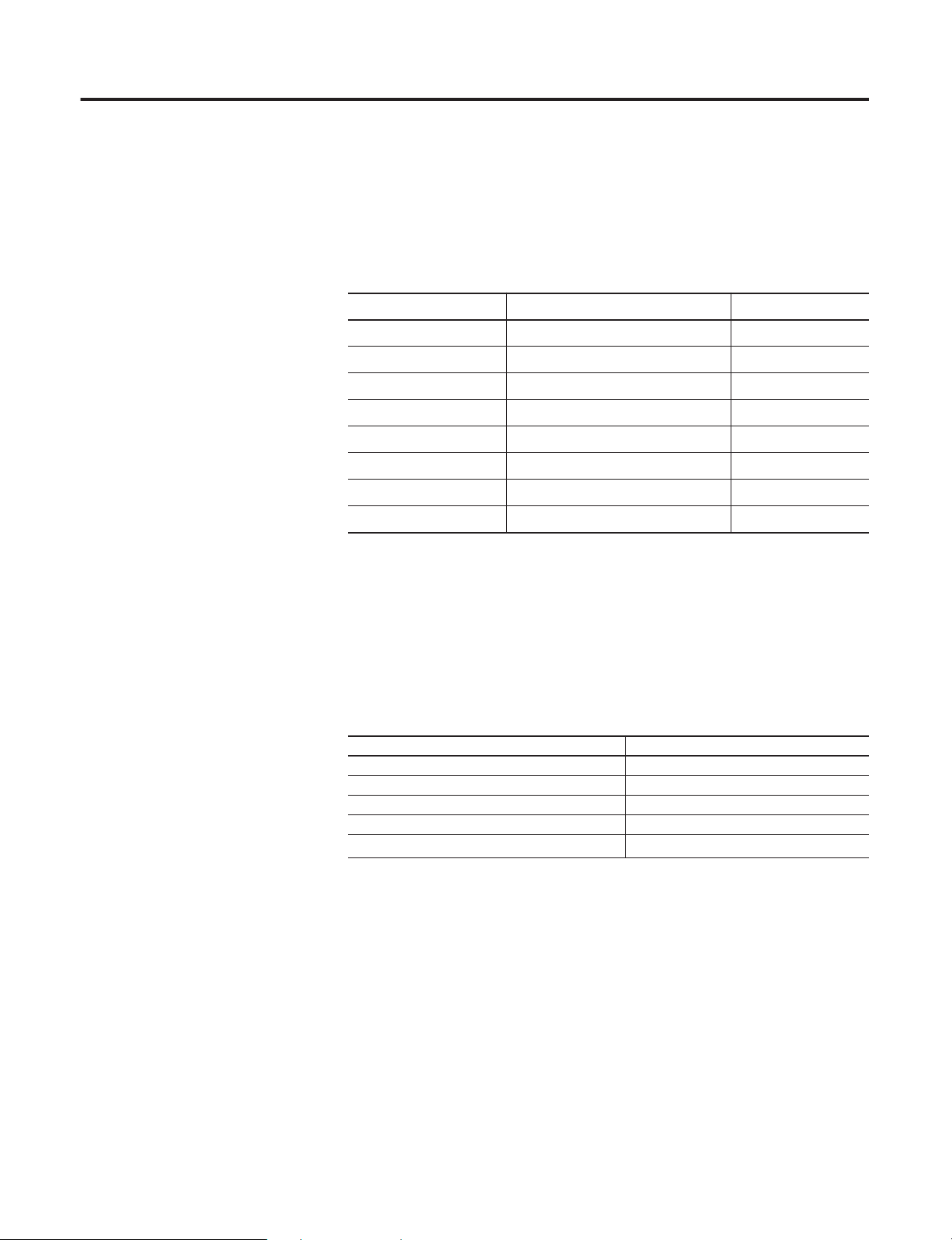

Table 1.B

Fiber Optic Cables for SynchLink

Catalog Number: Cable Length Cables per box:

1403-CF001 1 meter 2

1403-CF003 3 meters 2

1403-CF005 5 meters 2

1403-CF010 10 meters 1

1403-CF020 20 meters 1

1403-CF050 50 meters 1

1403-CF100 100 meters 1

1403-CF250 250 meters 1

Drive Comm (Drive Communication)

The ControlLogix Drive module connects to a PMI chassis through

special Drive Communication fiber optic cables.

Table 1.C

Fiber Optic Cables for Drive Communication

Catalog Number Length

1756-DMCF001 1 meter

1756-DMCF003 3 meters

1756-DMCF010 10 meters

1756-DMCF030 30 meters

1756-DMAF

(1)

Use the 1756-DMAF to connect existing UDC/PMI fiber optic cables to the Drive Module

(1)

N/A

Publication 1756-UM522B-EN-P - February 2003

Page 18

•

1-4 What is the ControlLogix Drive Module?

Before you install and use your module you should have already:

installed and grounded a 1756 chassis and power supply. For

more information, refer to the publications listed in Table 1.D.

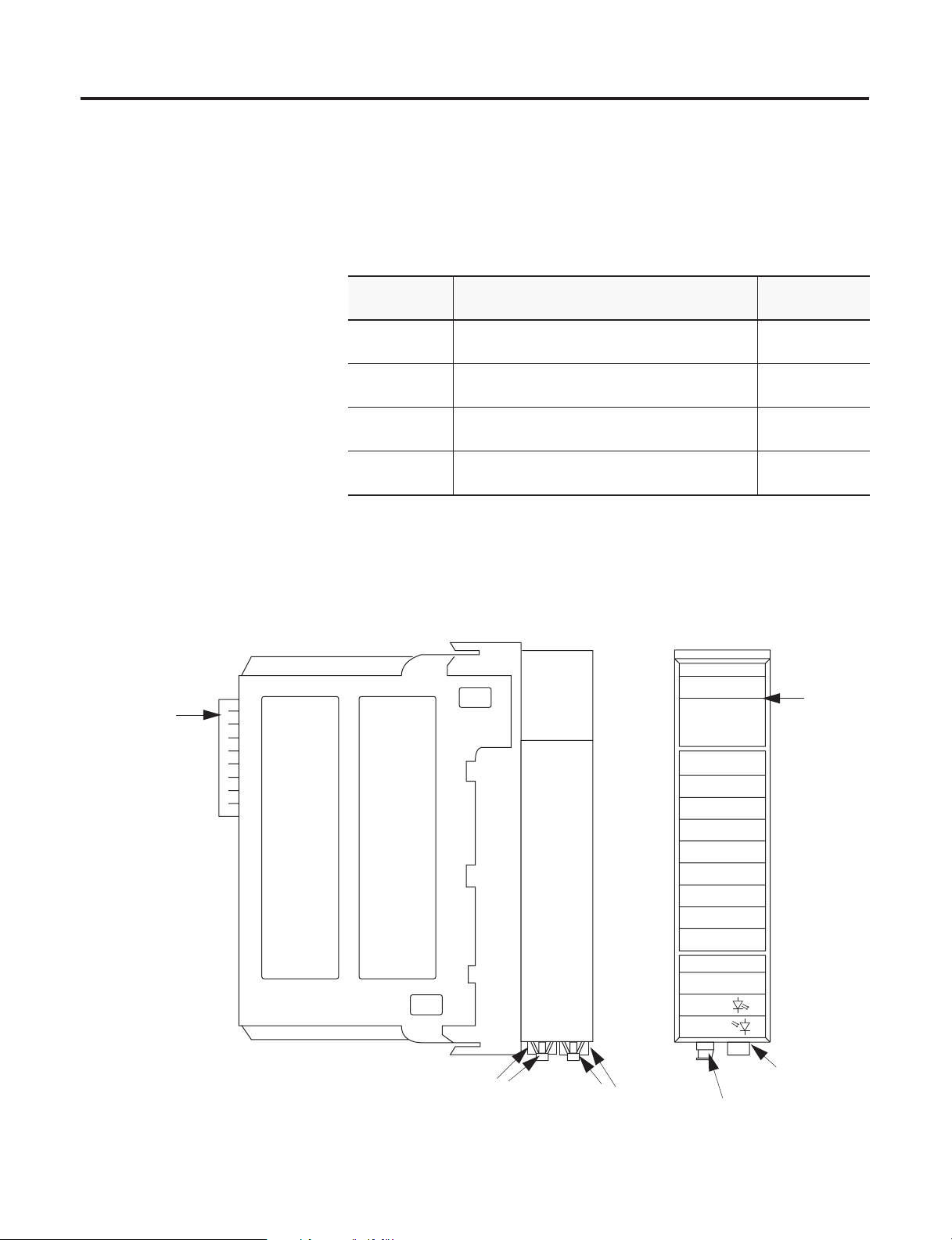

Table 1.D

Chassis and Power Supply Documentation

ControlBus

Connector-

Interface to the

ControlLogix

system

backplane

Catalog

Document title: Pub. number:

number:

1756-A4, -A7,

ControlLogix Chassis Installation Instructions 1756-IN080

-A10, -A13

1756-PA72,

ControlLogix Power Supply Installation Instructions 1756-5.67

-PB72

1756-PA75,

ControlLogix Power Supply Installation Instructions 1756-5.78

-PB75

1756-PA75R/A,

-PB75R/A

ControlLogix Redundant Power Supply Installation

Instructions

1756-IN573

Physical Features of the ControlLogix Drive Module

Module side view Module front view

SD3000 INTERFACE

LINK

LINK

COMM

SYNC

DRIVE

OS OK OK

DRIVE

FAULT

COMM OK

Status

Indicators

The 1756-DMD30, SD3000 Interface, is shown. Physical

features are common to all ControlLogix Drive Modules.

Publication 1756-UM522B-EN-P - February 2003

Transmit Ports

(in back)

Receive Ports

(in front)

Tx (rear)

Rx (front)

SynchLink

Ports

Drive

Communication

Ports

Page 19

What is the ControlLogix Drive Module? 1-5

Backplane Connector - The backplane connector connects the

module to the ControlLogix chassis backplane.

Status Indicators - The status indicators display the module’s

communications, Drive Communication and SynchLink system status.

SynchLink Transmit Fiber Port - The transmit fiber port allows

connection (via fiber optic cables) to other SynchLink modules so the

module can send data.

SynchLink Receive Fiber Port - The receive fiber port allows

connection (via fiber optic cables) to other SynchLink modules so the

module can receive data.

Drive Communication Transmit Fiber Port - The transmit fiber

port allows connection (via fiber optic cables) to the PMI processor of

the drive.

Using Module Identification

and Status Information

Drive Communication Receive Fiber Port - The receive fiber port

allows connection (via fiber optic cables) to the PMI processor of the

drive.

Each ControlLogix Drive module maintains specific identification

information that separates it from all other modules. This information

assists you in tracking all the components of your system.

For example, you can track module identification information to be

aware of exactly what modules are located in any ControlLogix rack

at any time. While retrieving module identity, you can also retrieve

the module’s status.

Each module maintains the following information:

Table 1.E

Module Identification and Status Information

Module Identification: Description:

Product Type Module’s product type, such as Digital I/O or

Analog I/O module

Catalog Code Module’s catalog number

Major Revision Module’s major firmware revision number

Minor Revision Module’s minor firmware revision number

Publication 1756-UM522B-EN-P - February 2003

Page 20

1-6 What is the ControlLogix Drive Module?

•

•

•

–

–

–

–

–

–

•

•

•

•

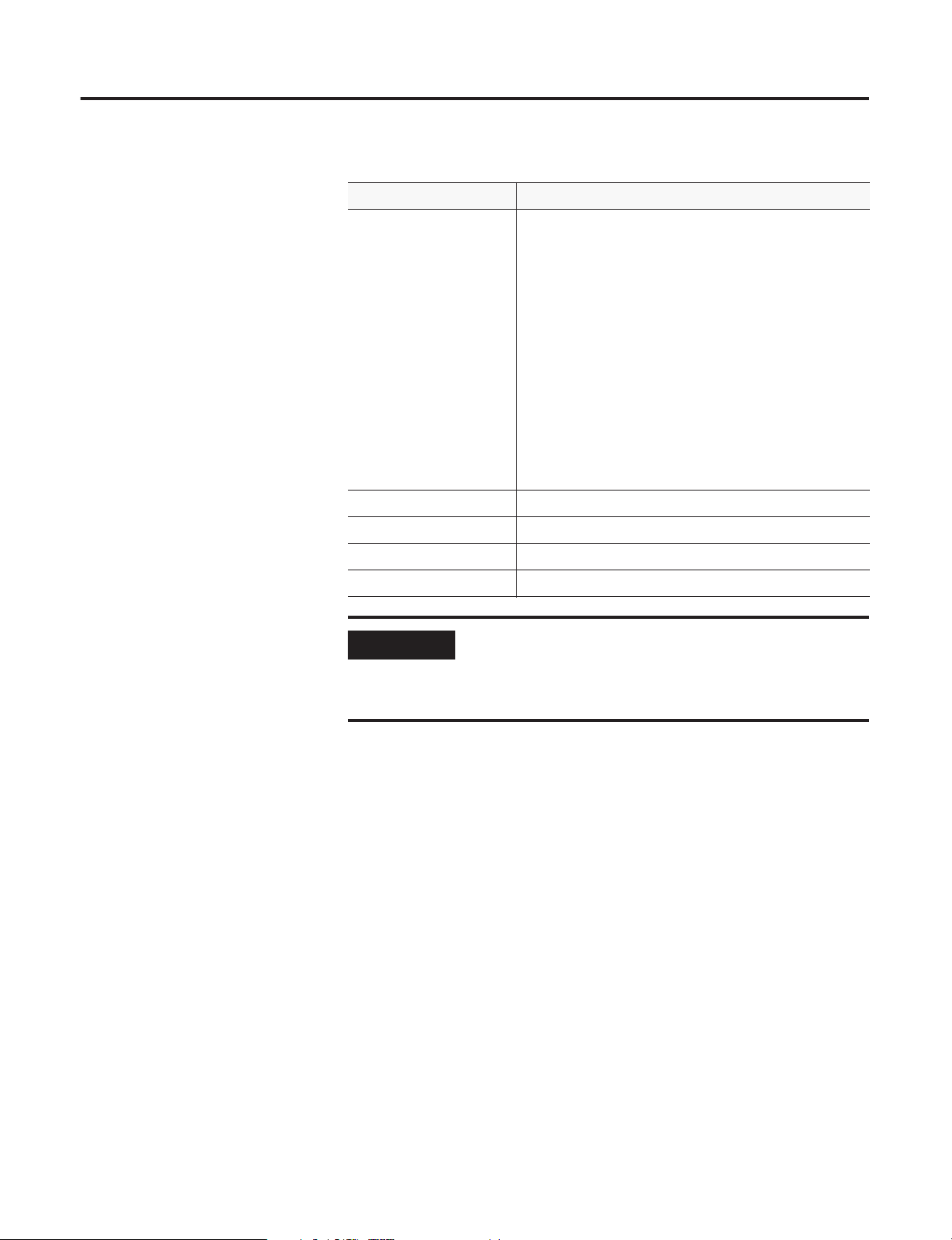

Table 1.E

Module Identification and Status Information

Module Identification: Description:

Status Module’s status. Returns the following information:

Controller ownership (if any)

Whether module has been configured

Device Specific Status, such as:

Self-Test

Flash update in progress

Communications fault

Not owned (outputs in program mode)

Internal fault (need flash update)

Run mode

Minor recoverable fault

Minor unrecoverable fault

Major recoverable fault

Major unrecoverable fault

Vendor ID Module manufacturer vendor, for example Allen-Bradley

Serial Number Module serial number

Length of ASCII Text String Number of characters in module’s text string

ASCII Text String Module name

IMPORTANT

To retrieve this information, you can use the WHO

service in the RSLinx software. For more information

on how to retrieve module identification information,

see the RSLinx online help.

Publication 1756-UM522B-EN-P - February 2003

Page 21

What is the ControlLogix Drive Module? 1-7

Preventing Electrostatic Discharge

This module is sensitive to electrostatic discharge.

ATTENTION

!

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment:

•

Touch a grounded object to discharge potential

static.

•

Wear an approved grounding wrist strap.

•

Do not touch connectors or pins on component

boards.

•

Do not touch circuit components inside the

equipment.

•

If available, use a static-safe workstation.

•

When not in use, store the equipment in

appropriate static-safe packaging.

Removal and Insertion Under Power

These modules are designed to be installed or removed while chassis

power is applied, while in non-hazardous locations only.

WARNING

!

ATTENTION

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

The removal of a Drive Module while under power

may cause personal injury or property damage. Make

sure that removal of the module does not adversely

impact other parts of the system.

!

IMPORTANT

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating

connector. Worn contacts may create electrical

resistance that can affect module operation.

Publication 1756-UM522B-EN-P - February 2003

Page 22

1-8 What is the ControlLogix Drive Module?

Chapter Summary and What’s Next

In this chapter, you learned about the ControlLogix Drive module.

Move to Chapter 2, Drive Comm (Drive Communication) for details

on the communications interface to DPS equipment.

Publication 1756-UM522B-EN-P - February 2003

Page 23

Chapter

2

Drive Comm (Drive Communication)

This chapter describes Drive Comm (Drive Communication), the

interface between the ControlLogix Drive module communicates and

Distributed Power System (DPS).

For information about: See page:

Interface to DPS Drive Equipment 2-1

Drive Communication Protocol 2-1

Initialization 2-2

Synchronized Communication 2-2

Chapter Summary and What’s Next 2-3

Interface to DPS Drive Equipment

Drive Communication Protocol

The main function of the Drive module is to interface to Distributed

Power System (DPS) drive equipment, enabling a ControlLogix

processor to control the drive equipment. A ControlLogix processor

performs high level control algorithms and drive coordination. The

Drive module performs outer control loop processing

Power Module Interface (PMI) performs real-time control of the

Power Module.

Each drive module interfaces with an individual Power Module

Interface (PMI) processor. It resides in a ControlLogix chassis and

connects to a PMI processor via fiber-optic and Drive Communication

protocol.

Drive Communication is a point to point serial link between the Drive

module and the Power Module Interface (PMI), on fiber-optic cable. It

is similar to the protocol used between the Universal Drive Controller

(UDC) and the PMI processor in an AutoMax DPS environment. The

data is Manchester-encoded and transmitted over the fiber-optic links

at a rate of 10M bits per second. Transfers on fiber-optic cables are

immune to electromagnetic interference (EMI).

(1)

, and the

During initialization, the Drive Module and PMI processor use an

asynchronous master-slave protocol to transfer the PMI operating

system to the PMI processor and to establish synchronized

communication. After initialization, they use synchronized “Set

(1)

The 1756-DMF30 does not perform outer control loop processing - it only functions as a bridge between the

ControlLogix controller and the PMI processor.

1 Publication 1756-UM522B-EN-P - February 2003

Page 24

2-2 Drive Comm (Drive Communication)

Point/Feedback Data Exchange” to transfer data. The Drive Module

sends set point data to the PMI processor, which returns feedback

data to the Drive Module.

Initialization

Synchronized Communication

At boot time, the Drive Module and PMI processor use an

asynchronous master-slave protocol to transfer the PMI operating

system and establish synchronized communication. The PMI

processor is the master, and commences by requesting its operating

system. The Drive Module responds by downloading the operating

system in a special message, containing up to 256 byte packets.

When the operating system transfer is complete, the Drive Module

sends a configuration message and a gain message. The configuration

message contains information that fixes the communication frequency

at 4 mS. Once the Drive Module and PMI processor have

synchronized communications, normal Set Point/Feedback data

transfer can begin.

The synchronized protocol is called “Set Point/Feedback Data

Exchange”. The drive module sends set point data to the PMI

processor. The set point data contains reference data, for drive

control, and a time stamp. This time stamp enables the PMI processor

to calculate what the proper time is for the next feedback message.

The PMI processor sends feedback messages to the Drive Module.

The feedback messages contains data about drive operation.

Publication 1756-UM522B-EN-P - February 2003

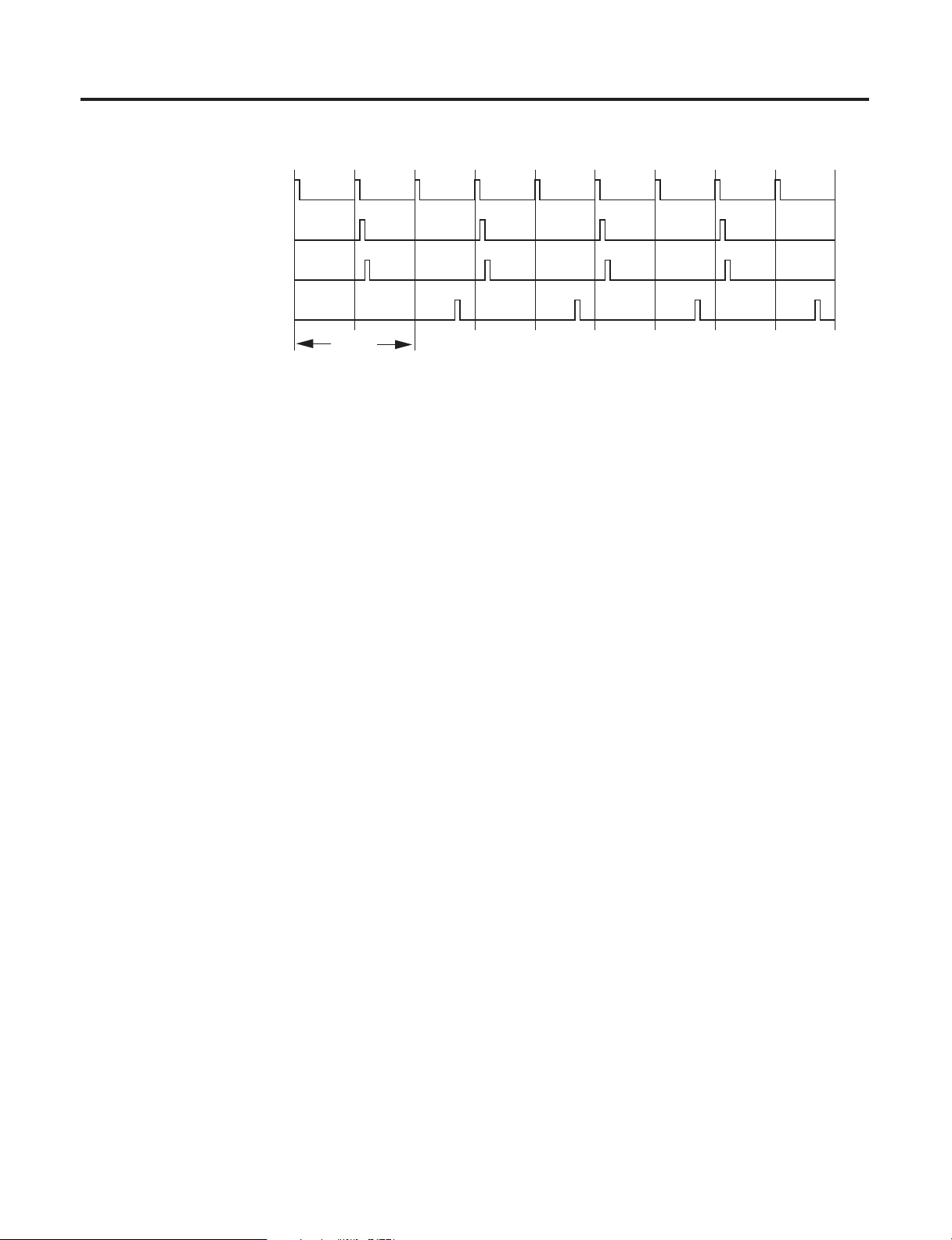

Timing

The velocity loop updates (reads from, and writes to Drive

Communication) every 2 mS. After every other velocity loop update

(at a 4 mS interval), the position loop performs its update. After every

position update, the Drive Module sends set point data to the PMI

processor. After the next velocity update (but before the following

one), the PMI processor sends feedback data to the Drive Module.

Refer to the following timing chart.

Page 25

Velocity Loop Update

Position Loop Update

Set Point Data to PMI

Feedback Data

to Drive Module

Drive Comm (Drive Communication) 2-3

Figure 2.1 Drive Communication Timing

4 mS

Synchronization with CST

Chapter Summary and What’s Next

Synchronization to Coordinated System Time (CST) is not necessary to

synchronize Drive Communication between the Drive Module and the

PMI processor. However, if the Drive Module is synchronized to the

CST, Drive Communication will also synchronize to the CST.

In this chapter, you learned about Drive Communication. For more

information on Drive Module features see Chapter 3, Drive Module

Features.

Publication 1756-UM522B-EN-P - February 2003

Page 26

2-4 Drive Comm (Drive Communication)

Notes:

Publication 1756-UM522B-EN-P - February 2003

Page 27

•

•

•

•

•

•

Chapter

Drive Module Features

This chapter describes the ControlLogix Drive module features.

For information about: See page:

General Module Features 3-1

Configurable Module Features 3-4

Chapter Summary and What’s Next 3-10

General

Under Power) that are supported on the module regardless of

configuration and application.

module features are features (e.g. Removal and Insertion

3

General Module Features

Configurable module features are features (e.g. Communications

Format) that can be configured to work differently in various

applications.

The following general module features are available with the

ControlLogix Drive module:

Removal and Insertion Under Power (RIUP)

Module Fault Reporting

Fully Software Configurable

LED Status Information

Class I Division 2 Certification

Agency Certification

1 Publication 1756-UM522B-EN-P - February 2003

Page 28

3-2 Drive Module Features

Removal and Insertion Under Power (RIUP)

All ControlLogix Drive modules may be removed and inserted from

the chassis while power is applied. This feature allows greater

availability of the overall control system because, while the module is

being removed or inserted, there is no additional disruption to the rest

of the controlled process.

WARNING

!

ATTENTION

!

IMPORTANT

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

The removal of a Drive Module while under power

may cause personal injury or property damage. Make

sure that removal of the module does not adversely

impact other parts of the system.

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating

connector. Worn contacts may create electrical

resistance that can affect module operation.

Publication 1756-UM522B-EN-P - February 2003

Module Fault Reporting

ControlLogix Drive modules provide both hardware and software

indication when a module fault has occurred. Each module’s LED fault

indicator as well as DriveExecutive and RSLogix 5000 will graphically

display this fault and include a fault message describing the nature of

the fault.

This feature allows you to determine how your module has been

affected and what action should be taken to resume normal

operation.

Page 29

Drive Module Features 3-3

Fully Software Configurable

RSLogix 5000 and DriveExecutive software packages use custom,

easily understood interfaces to determine the module configuration.

All module features are enabled or disabled through the configuration

portions of the software.

You can also use the software to interrogate any module in the system

to retrieve

•

serial number

•

revision information

•

catalog number

•

vendor identification

•

error/fault information

By eliminating such tasks as setting hardware switches and jumpers,

the software makes module configuration easier.

LED Status Information

The ControlLogix Drive module has LED indicators on the front of the

module that allow you to check the module health and operational

status.

The following status can be checked with the LED indicators:

•

SynchLink and ControlLogix backplane status

•

Drive Comm status

•

Drive status

•

Module health status

For examples of LED indicators, see page 6-1.

Publication 1756-UM522B-EN-P - February 2003

Page 30

3-4 Drive Module Features

•

•

•

•

•

•

Class I Division 2 Certification

The ControlLogix Drive module is certified for use in nonhazardous

locations as well as Class I, Division 2 hazardous Locations containing

gas groups A, B, C, and D. This equipment may be used as a

component of a control system which is certified to operate in

hazardous locations.

WARNING

!

ATTENTION

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

The removal of a Drive Module while under power

may cause personal injury or property damage. Make

sure that removal of the module does not adversely

impact other parts of the system.

!

Agency Certification

When the Drive module is marked appropriately, the following

agency certifications apply:

Configurable Module

Features

Publication 1756-UM522B-EN-P - February 2003

•

UL Listed Industrial Control Equipment

•

CSA Certified Process Control Equipment

•

CSA Certified for Class I, Division 2 Hazardous Locations

The following Drive module features are configurable via RSLogix

5000 and DriveExecutive:

Controller Communication Format

SynchLink Controller Communication Format

Electronic Keying

Requested Packet Interval

Transmitted Direct Words

SynchLink Mastership

Page 31

Drive Module Features 3-5

Each of these features is described in this section, including

information on which RSLogix 5000 and DriveExecutive configuration

screens should be used to configure the feature. For an overview of

the entire configuration process, see Chapter 5, Configuring the Drive

Module.

Controller Communication Format

The controller communications format defines the connection

between the owner-controller and the module (i.e. determines what

type of data is transferred between them). The 1756-DMD30 module

supports Velocity Control, Position Control, User-Defined and Custom

User-Defined communication formats. The 1756-DMF30 supports the

User-Defined communication format.

SynchLink Communications Format

The SynchLink communications format defines the connection at the

SynchLink Receive Port and the SynchLink Transmit Port. It

determines the type and number of data type in each connection.

SynchLink messages are structured as six 32-bit words; the words are

divided into three types:

•

Direct - Data delivered in a single message. A SynchLink

message can contain a maximum of four direct data words; each

word is 32 bits in length. Direct data can be automatically

forwarded to the next node in the daisy chain and ring

configurations.

•

Buffered - Data that exceeds the four word limit of a direct data

transfer. A maximum of 18 buffered are transfered every 500µS.

Buffered data is appropriately segmented at the transmitting

module and reassembled at the receiving module. Buffered data

cannot be automatically forwarded to the next node in the daisy

chain and ring configurations.

•

Axis - the Drive module does not support this data type.

Multiple Port Communications Formats in Single Module

You must set a communications format for receiving data (Receive

Port Communications Format) and transmitting data (Transmit Port

Communications Format) in each SynchLink node.

Publication 1756-UM522B-EN-P - February 2003

Page 32

3-6 Drive Module Features

•

The following requirements apply to communication format choices:

If a Drive module does not receive data (e.g. the first node in a

daisy chain topology), you must choose the

No Receive Data

Receive Port communication format.

•

If a Drive module does not transmit data (e.g. an end node), you

must choose the

No Transmit Data

Transmit Port

communications format.

•

The receive communication format for any Drive module that

receives data must match the transmit communications format of

the upstream node in the system.

IMPORTANT

The receive and transmit on the same module do not have

to match.

Also, once the module is created, the communications

format cannot be changed. The module must be deleted

and recreated.

Internal Scan on Drive Module

Every 500 µ S, the Drive module scans its internal hardware and

captures a “snapshot” of the data there. This data is then sent to the

local owner-controller at the Change of State (COS) instance,

independent of the requested packet interval (RPI) rate. But,

depending on the communications formats chosen during module

configuration, data types are transmitted between SynchLink nodes

(via the fiber optic cable) at various rates and may be transmitted

multiple times between the 500µS snapshots.

IMPORTANT

The transfer rate times listed in Table 3.A and

Table 3.B only represent the rate at which data is

passed between SynchLink modules over the fiber

optic cable.

Publication 1756-UM522B-EN-P - February 2003

Although the data is passed over the fiber optic cable

at various rates, depending on the communications

format choices, the

chassis only

receive the data

SynchLink module’s internal scan

owner-controllers

after the local

every 500µS

in each local

.

The Drive module updates its receive and transmit buffers once every

500µS. Because direct data can be passed through from node to node

once every 50µS, up to 10 nodes can be updated with direct data in a

single 500µS SynchLink scan. Pass-through functionality only applies

Page 33

Drive Module Features 3-7

to direct data in a daisy chain configuration, In order to pass-through

buffered data, the local controller must intervene to move data along.

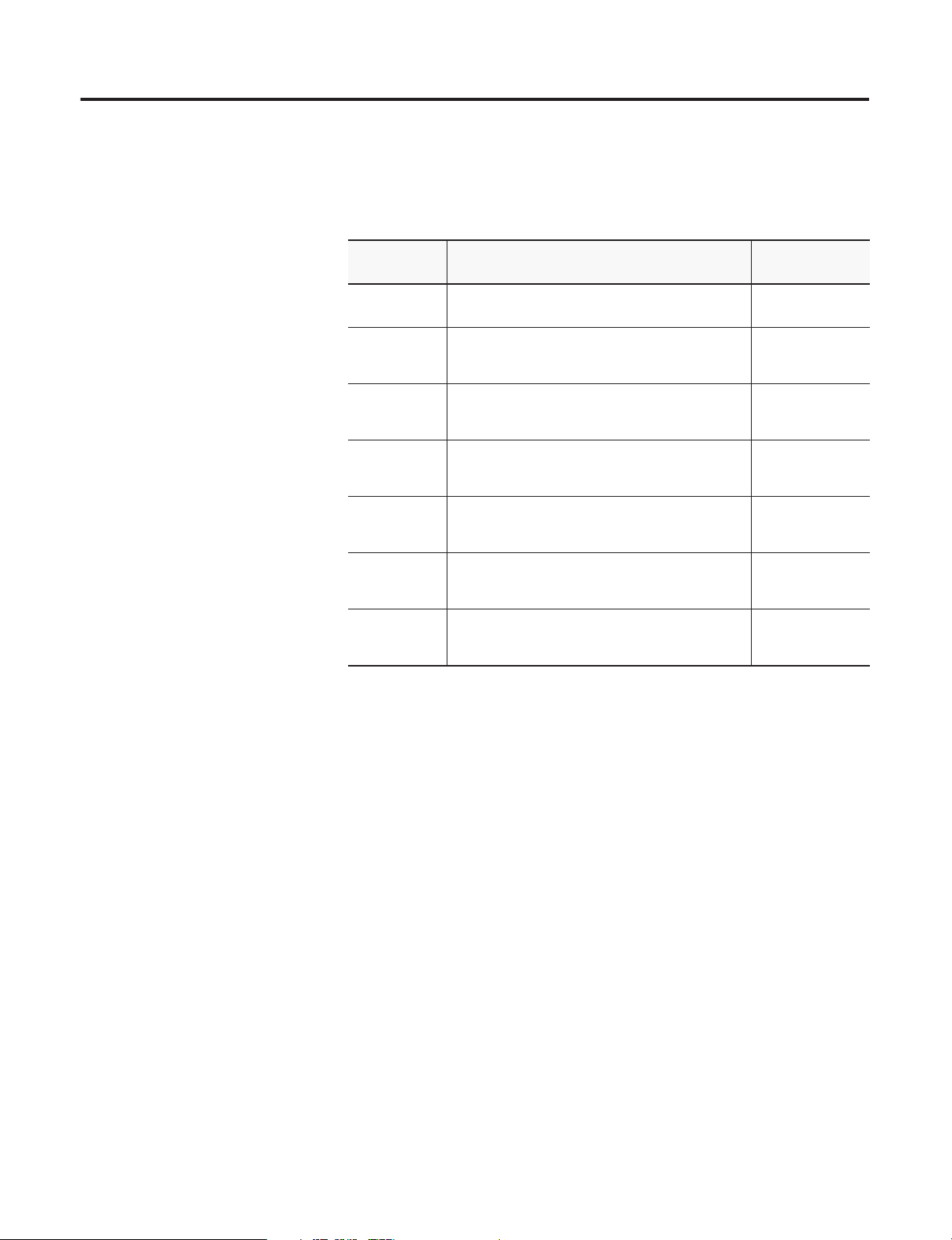

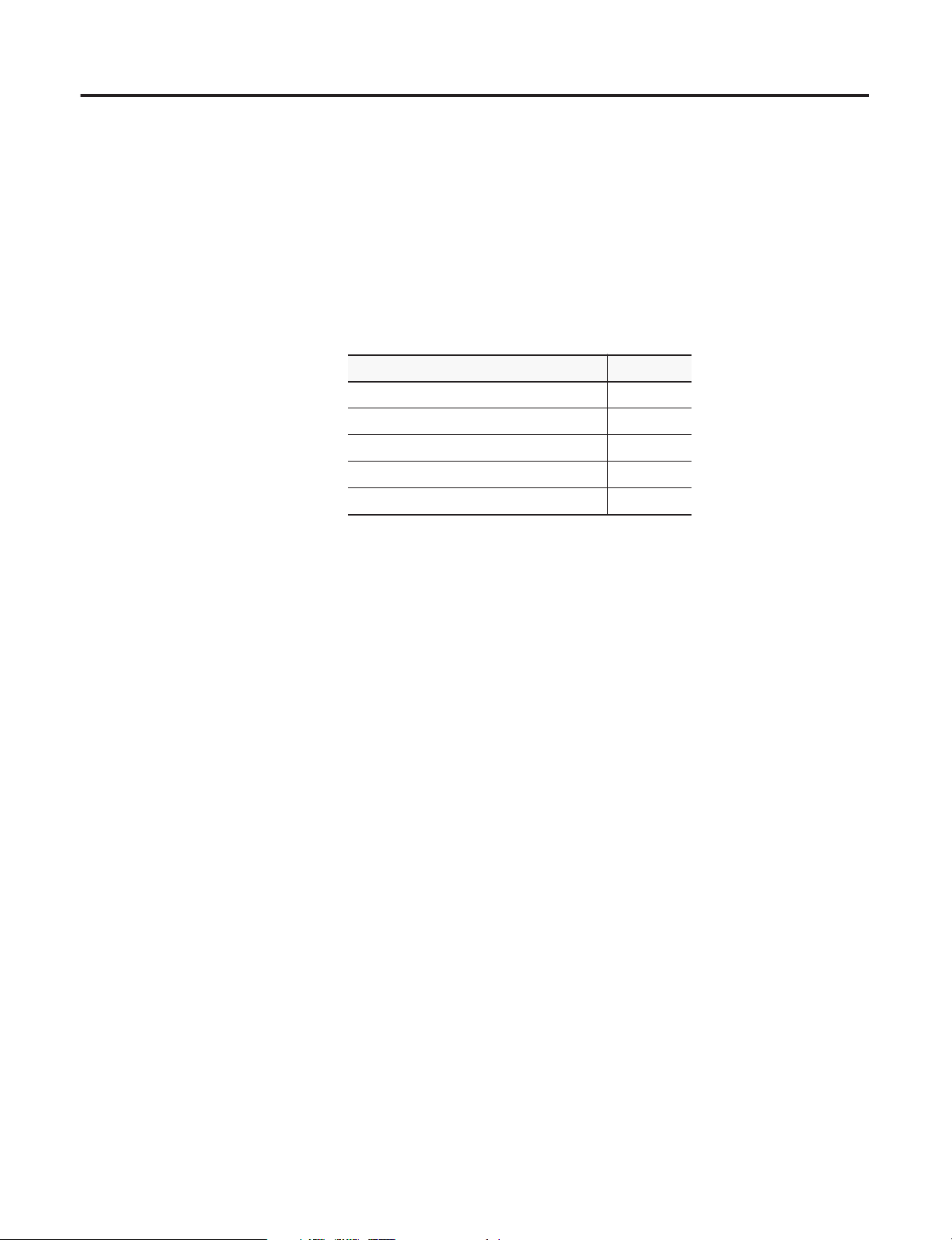

Table 3.A

Drive Module Receive Communications Formats

Receive Port Communications Format Transfer Rate (across the fiber optic

cable) for Each Data Type:

2 Direct Words, 18 Buffered Direct Data - Updated every 50 µ S

Buffered Data - Updated every 250 µ S

4 Direct Words, 18 Buffered Direct Data - Updated every 50 µ S

Buffered Data - Updated every 500 µ S

4 Direct Words, 8 Buffered Direct Data - Updated every 50 µ S

Buffered Data - Updated every 250 µ S

No Receive Data No data updated in this format

Table 3.B

Drive Module Transmit Communications Formats

Transmit Port Communications Format

2 Direct Words, 18 Buffered Direct Data - Updated every 50 µ S

4 Direct Words, 18 Buffered Direct Data - Updated every 50 µ S

4 Direct Words, 8 Buffered Direct Data - Updated every 50 µ S

Listen Only, No Transmit Data No data updated in this format

No Transmit Data No data updated in this format

Transfer Rate (across the fiber optic

cable) for Each Data Type:

Buffered Data - Updated every 250 µ S

Buffered Data - Updated every 500 µ S

Buffered Data - Updated every 250 µ S

Module-Defined Data Tags

When you create a module, module-defined data types and tags are

created in the RSLogix 5000 programming software. These tags allow

you to access the Input and Output Data of the module via the

controller’s ladder logic, if necessary

The types of tags created vary, depending on which communications

format you choose when creating a module. There are two types of

tags:

•

Input Data Tags

•

Output Data Tags

Publication 1756-UM522B-EN-P - February 2003

Page 34

3-8 Drive Module Features

Electronic Keying

Instead of plastic mechanical backplane keys, electronic keying

allows the ControlLogix system to control what modules belong in the

various slots of a configured system.

During module configuration, you must choose one of the following

keying options for your SynchLink module:

• Exact Match

• Compatible Match

• Disable Keying

When the controller attempts to connect to and configure a Drive

module (e.g. after program download), the module compares the

following parameters before allowing the connection and

configuration to be accepted:

• Vendor

• Product Type

• Catalog Number

• Major Revision

• Minor Revision

The comparison is made between the keying information present in

the Drive module and the keying information in the controller’s

program. This feature can guard against the inadvertent operation of a

control system with the wrong module in the wrong slot.

Exact Match

All of the parameters listed above must match or the inserted module

will reject a connection to the controller.

Compatible Match

The Compatible Match mode allows a Drive module to determine

whether it can emulate the module defined in the configuration sent

from the controller.

Publication 1756-UM522B-EN-P - February 2003

With ControlLogix Drive modules, the module can emulate older

revisions. The module will accept the configuration if the controller’s

major.minor revision is less than or equal to the physical

module’s revision.

Page 35

Drive Module Features 3-9

For example, if the configuration contains a major.minor revision of

2.7, the module inserted into the slot must have minor revision of 2.7

or higher for a connection to be made.

TIP

We recommend using Compatible Match whenever

possible. Remember, though, the module will only

work to the level of the configuration.

For example, if a slot is configured for a module

with major.minor revision of 2.7 and you insert a

module with a major.minor revision of 3.1, the

module works at the 2.7 level despite having been

previously upgraded.

If possible, we suggest you make sure configuration

is updated to match the revision levels of all Drive

modules. Failure to do so may not prevent the

application from working but may defeat the

purpose of upgrading your modules’ revision levels.

Disable Keying

The inserted module attempts to accept a connection to the controller

regardless of its type.

ATTENTION

Be extremely cautious when using the disable

keying option; if used incorrectly, this option can

lead to personal injury or death, property damage

or economic loss.

!

If keying is disabled, a controller makes a connection with most

modules of the same type as that used in the slot configuration.

A controller will not establish a connection if any of the following

conditions exist, even if keying is disabled:

• The slot is configured for one module type (e.g. digital input

module) and a module of another type (e.g. Drive module) is

inserted in the slot.

• The module inserted into the slot cannot accept some portion of

the configuration. This case should not arise if the slot is

configured for a Drive module and one is inserted.

Publication 1756-UM522B-EN-P - February 2003

Page 36

3-10 Drive Module Features

Requested Packet Interval

The Requested Packet Interval (RPI) is a configurable parameter that

defines when the module multicasts its data onto the local chassis

backplane.

In addition to the RPI, Change of State (COS) functionality also causes

the module to produce its data to the consuming controller whenever

the values of the data changes. The RPI timer is asynchronous to the

COS functionality. Both cause the module to produce data when

triggered.

Buffered, Direct and Diagnostic Data - RPI Effect on Output Data (from the

controller)

As a producing controller writes data to the Drive module, the output

data is placed in a local buffer until the next RPI reset occurs. When

the RPI timer expires, the output data is moved from the controller’s

local buffer to the Drive module.

Chapter Summary and What’s Next

The RPI timer is asynchronous to the program execution. Therefore, a

worst case update to the Drive module can be calculated by adding

the program execution time to the RPI timer setting, as configured by

the user.

In this chapter, you learned about the ControlLogix Drive module

features. Move to Chapter 4, Installing the Drive Module, to learn how

to install the module.

Publication 1756-UM522B-EN-P - February 2003

Page 37

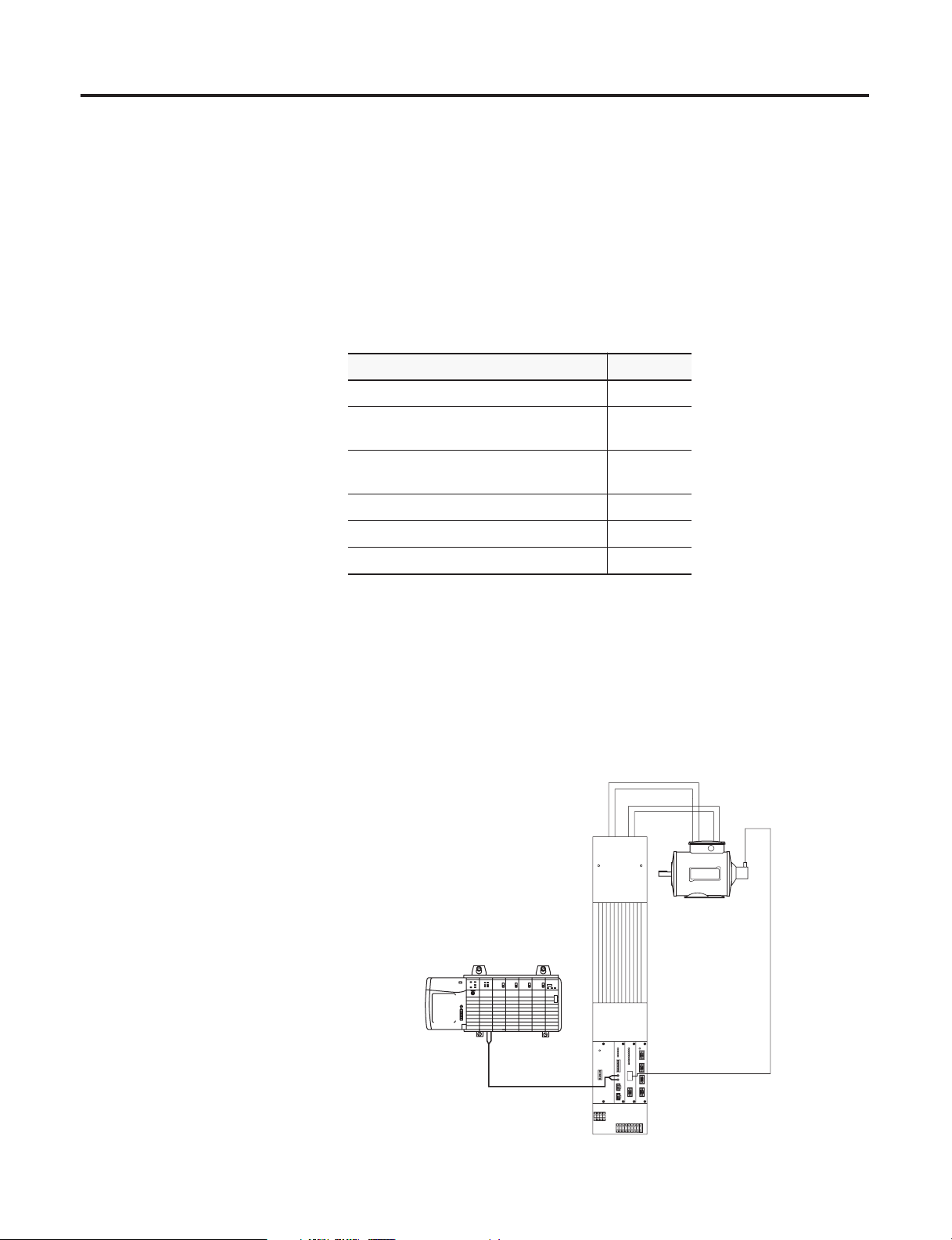

Installing the Drive Module

This chapter describes how to install the ControlLogix

Drive module.

For information about: See page:

Noting the Power Requirements 4-1

Installing the Module 4-2

Connecting SynchLink Cables 4-3

Connecting (Drive Comm Drive

Communication) Cables

Removing the Module 4-6

Chapter Summary and What’s Next 4-7

4-5

Chapter

4

Noting the Power Requirements

This module receives power from the 1756 chassis power supply and

requires 2 sources of power from the backplane:

•

1.35A at 5.1V dc

•

3.0mA at 24V dc

Account for this power consumption (6.96W) in addition to the

requirements of all other modules in the chassis to prevent

overloading the power supply.

1 Publication 1756-UM522B-EN-P - February 2003

Page 38

1.

4-2 Installing the Drive Module

Installing the Module

You can install or remove the module while chassis power is applied.

WARNING

!

ATTENTION

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

The removal of a Drive Module while under power

may cause personal injury or property damage. Make

sure that removal of the module does not adversely

impact other parts of the system.

!

IMPORTANT

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating

connector. Worn contacts may create electrical

resistance that can affect module operation.

Align the circuit board with the top and bottom chassis guides.

Printed

Circuit

Board

Publication 1756-UM522B-EN-P - February 2003

Page 39

2.

Installing the Drive Module 4-3

Slide the module into the chassis until the module locking

tabs ‘click’.

Locking tab

Connecting SynchLink Cables

The two fiber optic ports on the bottom-left of the module are for

SynchLink. The front-left port is receives SynchLink data, and the

rear-left port is transmits SynchLink data.

ATTENTION

The Drive module is a Class I LED product. Light

levels may cause damage to eyesight. Do not look

directly into the fiber ports or fiber cables.

!

TIP

Keep the plugs that were removed to connect the

fiber optic cables. When the cables are disconnected,

you can reinsert the plugs into the ports to protect

them.

Publication 1756-UM522B-EN-P - February 2003

Page 40

4-4 Installing the Drive Module

Figure 4.1 SynchLink Connections

Tx (rear)

Rx (front)

Tx Rx

Refer to See Table 1.B on page 1-3 for information on available

pre-configured fiber optic SynchLink cables.

Table 4.A lists the possible connections that might be made to your

1756-DM module and where to connect the fiber optic cable.

Table 4.A

Making Fiber Optic Cable Connections to the 1756-DM Module

If your 1756-DM module

is configured to:

transmit data only Connect the fiber optic cable to the rear port. The other end

receive data only Connect the fiber optic cable to the front port. The other end

transmit and receive data 1. Connect the fiber optic cable going to (i.e. transmitting

Make this fiber optic cable connection:

of the cable should be connected to a device receiving data

over the SynchLink from your 1756-DM module.

of the cable should be connected to a device transmitting

data to your 1756-DM module over the SynchLink.

the data to) a module receiving the data to the front port.

2. Connect the fiber optic cable coming from (i.e. receiving

the data from) a module transmitting data to the rear port.

Publication 1756-UM522B-EN-P - February 2003

Page 41

Installing the Drive Module 4-5

Connecting (Drive Comm Drive Communication) Cables

The two fiber optic ports on the bottom-right of the module are for

Drive Comm. The front-right port receives data from the PMI

processor on the drive. The rear-right port transmits data to the PMI

processor.

•

Connect the 1756-DM transmit port (Tx) to the PMI receive port

(RCV).

•

Connect the 1756-DM receive port (Rx) to the PMI transmit port

(XMT). .

ATTENTION

The Drive module is a Class I LED product. Light

levels may cause damage to eyesight. Do not look

directly into the fiber ports or fiber cables.

!

TIP

Keep the plugs that were removed to connect the

fiber optic cables. When the cables are disconnected,

you can reinsert the plugs into the ports to protect

them.

Figure 4.2 Drive Comm - Drive Module End Connections

Tx (rear)

Rx (front)

Tx Rx

Publication 1756-UM522B-EN-P - February 2003

Page 42

4-6 Installing the Drive Module

1.

2.

Figure 4.3 Drive Comm - PMI Processor Connections

XMT

C

O

RCV

M

M

Removing the Module

Refer to See Table 1.C on page 1-3 for information on available

pre-configured fiber optic Drive Comm cables.

ATTENTION

Before you remove the module, you must disconnect

the fiber optic cables.

!

Push in the top and bottom locking tabs.

TIP

If you kept the plugs that were removed to

connect the fiber optic cables, reinsert them to

protect the ports.

Publication 1756-UM522B-EN-P - February 2003

Pull the module out of the chassis as shown.

Page 43

Figure 4.4

Installing the Drive Module 4-7

Locking tabs

Chapter Summary and What’s Next

In this chapter, you learned how to install the ControlLogix Drive

module. Move to Chapter 5, Configuring the Drive Module, to learn

how to configure the module.

Publication 1756-UM522B-EN-P - February 2003

Page 44

4-8 Installing the Drive Module

Notes:

Publication 1756-UM522B-EN-P - February 2003

Page 45

1.

•

•

•

2.

3.

4.

Chapter

Configuring the Drive Module

This chapter describes how to configure the ControlLogix Drive

Module using RSLogix 5000 and DriveExecutive in the DriveTools

2000 programming suite.

For information about: See page:

Overview of the Configuration Process 5-1

Planning the System 5-2

Checking and Updating the DriveExecutive

Database

Using RSLogix 5000 to Configure the Drive

Module

Using DriveExecutive to Configure Drive

Module

Return to RSLogix 5000 to Finish

Configuring the Drive Module

Chapter Summary and What’s Next 5-24

5-6

5-9

5-16

5-23

5

Overview of the

Configuration Process

To configure your ControlLogix Drive Module, you must perform the

following steps:

Plan the system.

Choose Controller Communication format

Choose SynchLink communications format (if you are using

SynchLink)

Choose SynchLink topology (if you are using SynchLink)

Make sure DriveExecutive has database for the firmware

revision and configuration of the module.

Configure each Drive Module with RSLogix 5000.

Configure each Drive Module with DriveExecutive, and

download parameters and links to Drive module.

5.

Return to RSLogix 5000, and download program to ControlLogix

processor.

1 Publication 1756-UM522B-EN-P - February 2003

Page 46

5-2 Configuring the Drive Module

Planning the System

Before programming, you must choose a Controller - Drive Module

interface (Controller Communication Format) for each Drive Module

in the system.

If you are going to use SynchLink, you must choose the SynchLink

data format, and a SynchLink network topology. This chapter covers

these topics.

Understanding the Controller - Drive Module Interface

You must configure communications between the ControlLogix

controller and the Drive Module by selecting a “Controller

Communication Format”. A controller communication format is a set

of links that connects controller output tags to Drive Module sinking

parameters, and connects controller input tags to Drive Module

sourcing parameters. There are four controller communication formats

to choose from, depending on which module you are configuring:

•

Velocity Control

•

Position Control

•

User-Defined Control

•

Custom User-Defined Control

Each controller communication format contains both required

connections and user definable connections. You must use both

RSLogix 5000 and DriveExecutive to configure these connections. The

programming software will not allow you to choose Velocity Control

or Position control for the 1756-DMF30.

IMPORTANT

Once the module is created, the communications

format cannot be changed. The module must be

deleted and recreated.

Choosing the SynchLink Communication Formats

You must set a communications format for receiving data (Receive

Port Communications Formats) and transmitting data (Transmit Port

Communications Formats) in each module.

The following requirements apply to communication format choices:

Publication 1756-UM522B-EN-P - February 2003

Page 47

•

•

•

•

•

•

•

•

•

•

•

Configuring the Drive Module 5-3

If a Drive module does not receive data (e.g. the first module in

a non-loop topology), you must choose the No Receive Data

Receive Port communication format.

If a Drive module does not transmit data (e.g. an end node in

the daisy chain configuration or star), you must choose the No

Transmit Data Transmit Port communications format.

The receive communication format for any SynchLink node that

receives data must match the transmit communications format of

the previous node in the system.

Receive Port Communications Formats

The following communications formats are available for the receive

port of your Drive module:

2 Direct Words, 18 Buffered - Data updated every 500 µ S

4 Direct Words, 18 Buffered - Data updated every 500 µ S

4 Direct Words, 8 Buffered - Data updated every 500 µ S

No Receive Data - Data updated every 500 µ S

Transmit Port Communications Formats

The following communications formats are available for the transmit

port of your Drive module:

2 Direct Words, 18 Buffered - Data updated every 500 µ S

4 Direct Words, 18 Buffered - Data updated every 500 µ S

4 Direct Words, 8 Buffered - Data updated every 500 µ S

No Transmit Data - Data updated every 500 µ S

IMPORTANT

The update times referenced above are for data

updates across the SynchLink fiber optic cable only

and do not represent full processing time. Refer to

3-5 for more information regarding data updates and

processing times.

Publication 1756-UM522B-EN-P - February 2003

Page 48

5-4 Configuring the Drive Module

First Drive Module

(Master Node)

SynchLink Module

(Center Node)

•

•

Choosing the SynchLink Network Topology

You can use one of the following SynchLink topologies:

Daisy Chain

Drive Module

(Center Node)

SynchLink Module

(Center Node)

-DMD30

-SYNCH

-DMD30

-SYNCH

Drive Module

(Center Node)

Drive Module

(Center Node)

SynchLink Module

(Center Node)

-DMD30 -DMD30

-SYNCH -SYNCH

SynchLink Module

(End Node)

SynchLink

Drive Module

(End Node)

Note: the order of the modules is not important.

Star (asynchronous)

First Drive Module

(Master Node)

SynchLink

-DMD30

Hub

-DMD30

-DMD30 -DMD30

Hub

-DMD30 -DMD30

ControlNet)

Hub

-DMD30

Drive Module

(End Node)

Drive Module

(End Node)

Publication 1756-UM522B-EN-P - February 2003

Drive Module

(End Node)

Drive Module

(End Node)

Drive Module

(End Node)

Page 49

•

Hybrid (synchronous)

Configuring the Drive Module 5-5

Note: the first module must

be the SynchLink Master

Daisy Chain Connection

between first SynchLink

Module and first Drive

Module

SynchLink Module

(End Node)

Drive Module

(End Node)

-DMD30 -SYNCH

SynchLink Module

(End Node)

First SynchLink Module

(CST Time Master and

SynchLink Master)

-DMD30 -SYNCH -DMD30 -SYNCH

Drive Module

(End Node)

First Drive Module

-DMD30 -SYNCH

Hub

SynchLink Module

(End Node)

Drive Module

(End Node)

ControlNet)

-DMD30 -SYNCH

SynchLink Module

(End Node)

Star Connections for

all other modules

Drive Module

(End Node)

Publication 1756-UM522B-EN-P - February 2003

Page 50

5-6 Configuring the Drive Module

Checking and Updating the DriveExecutive Database

Select New from File

Menu

Checking the DriveExecutive Database

DriveExecutive must have a database for the Drive module firmware

revision and power module configuration, in order to configure the

module’s parameters and links. In addition, the database is required

for RSLogix and DriveExecutive to synchronize. Check the availability

of the database by attempting to create a new module with the

desired firmware revision level and power module configuration.

Select desired

Device Type

Publication 1756-UM522B-EN-P - February 2003

Click Next to move to

next page.

Page 51

Configuring the Drive Module 5-7

Checking the DriveExecutive Database (continued)

Check to see if desired

Firmware Revision is

available

Check to see if desired power module

configuration is available

(The configuration number is the same as

the power module’s part number)

Click Cancel to end

test

Publication 1756-UM522B-EN-P - February 2003

Page 52

5-8 Configuring the Drive Module

•

•

Updating the DriveExecutive Database

There are two ways to obtain the desired database if your computer

does not contain it.

Connecting to the module and creating the database in

DriveExecutive

Downloading the database from the DriveTools 2000 software

website ( http://www.ab.com/drives/drivetools_2000 )

If you have access to a Drive module with the desired firmware

revision, DriveExecutive can read the database from the module.

Select Create Database

from Drive Menu

From here, DriveExecutive and RSLinx will guide you to connect the

Drive module and create the database.

Publication 1756-UM522B-EN-P - February 2003

Page 53

Configuring the Drive Module 5-9

Using RSLogix 5000 to

Create a new RSLogix 5000 Project

Configure the Drive Module

Select New from File

Menu

Select the controller type

Enter the project name

Enter the project

description if desired

Select the chassis type

Click OK when all the

information is correct

Enter project location

Publication 1756-UM522B-EN-P - February 2003

Page 54

5-10 Configuring the Drive Module

Add a Drive Module to the Project

Select the correct catalog

number for the Drive Module

Place the cursor over the I/O

Configuration folder

Click the right

mouse button

and select New

Module

Select the correct major

revision level.

Publication 1756-UM522B-EN-P - February 2003

Click OK to open

Module Properties

window

Page 55

Add a Drive Module to the Project (continued)

Configuring the Drive Module 5-11

Enter the module name

Enter a description

Enter the correct minor

revision level

ATTENTION

!

Verify Slot Number

Select the Comm

Format

Be extremely cautious when using the disable

keying option; if used incorrectly, this option can

lead to personal injury or death, property damage or

economic loss.

Click Next to

advance the wizard

Select Electronic

Keying mode

Enter the desired RPI

Click Next to

advance the wizard

Publication 1756-UM522B-EN-P - February 2003

Page 56

5-12 Configuring the Drive Module

Add a Drive Module to the Project (continued)

Click Next to

advance the wizard

Click Next to

advance the wizard

Select the Power Unit Type

Select the Voltage

Select the Power

Structure Rating

(configuration)

Publication 1756-UM522B-EN-P - February 2003

Page 57

Add a Drive Module to the Project (continued)

Configuring the Drive Module 5-13

Enter a filename or click

browse to search for an

existing DriveExecutive

file

Click Finish

Monitor and Configure the Module

Place the cursor over

the Drive Module

Click the right

mouse button and

select Properties

Publication 1756-UM522B-EN-P - February 2003

Page 58

5-14 Configuring the Drive Module

Monitor and Configure the Module (continued)

Use the General tab to view

or modify the module name,

slot number, controller

communication format,

revision or keying

configurations

Use the Connection tab to

view or modify the

configuration of the

connection to the controller

and to view module faults.

Use the Module Info tab to

view module identification

information, module status

and CST status.

Publication 1756-UM522B-EN-P - February 2003

Page 59

Monitor and Configure the Module (contintued)

Use the Power tab to view or

modify configuration for the

power unit connected to the

Drive Module

Configuring the Drive Module 5-15

Click this button to

launch DriveExecutive

Publication 1756-UM522B-EN-P - February 2003

Page 60

5-16 Configuring the Drive Module

Using DriveExecutive to

Configure Drive Module

On the SynchLink Setup Tab

The settings you make on this tab determine what the

module does during every SynchLink Update cycle

Configure the Drive Module’s Peer Communication

Select Peer

Communication from

Drive Menu

Select sources

for Direct Data

transmissions

Select the Receive

and Transmit Formats

Configure the

Multiplier Block

Select source

parameters for

Buffered Data

transmissions

Select source

parameters for

Direct Data, if

the sources are

drive

parameters

Publication 1756-UM522B-EN-P - February 2003

Click SynchLink Node Configuration to open

SynchLink Node Configuration Window

Page 61

Check this box if the

module is to be the

Time Keeper

Configure the Drive Module’s Peer Communication (continued)

The value tab is useful for configuring the module as a Time Keeper

Configuring the Drive Module 5-17

Click OK when the

configuration is as

desired

Publication 1756-UM522B-EN-P - February 2003

Page 62

5-18 Configuring the Drive Module

Configure the Drive Module’s Peer Communication (continued)

Click the From

Controller tab

These links are part of the selected

Controller Communication Format.

They are not changeable.

Select parameters in the Drive

Module that will consume data

produced by tags in the controller.

This displays the Controller

Communication Format, chosen in

RSLogix 5000.

If you need to change the Controller

Communication Format, choose another

from the pull-down menu.

Publication 1756-UM522B-EN-P - February 2003

IMPORTANT

Conflicts between the DriveExecutive and RSLogix

5000 configurations cause communication faults.

Make sure the Controller Communication Format is

the same in DriveExecutive and RSLogix 5000 before

downloading.

Page 63

Configuring the Drive Module 5-19

Configure the Drive Module’s Peer Communication (continued)

Click the To Controller

tab

Select parameters

in the Drive

Module that will

produce data

consumed by tags

in the controller.

Click OK when all the data on these tabs is correct

Publication 1756-UM522B-EN-P - February 2003

Page 64

5-20 Configuring the Drive Module

Double - click on the parameter you

want to consume SynchLink data

Configure the Drive Module’s Links to SynchLink Data

On the Link List

Click on the Link Data tab

Publication 1756-UM522B-EN-P - February 2003

Page 65

Select Parameter

Enter parameter

number or

select

parameter from

list

Configuring the Drive Module 5-21

Configure the Drive Module’s Links to SynchLink Data (continued)

On the Link Data Tab

IMPORTANT

Click OK

The data format (e.g. Real or Integer) of the sink

parameter must match the data format of the source

parameter.

Publication 1756-UM522B-EN-P - February 2003

Page 66

5-22 Configuring the Drive Module

Select Save from the File menu

Save the Project

Download the Project

Select Download from the Drive menu

Publication 1756-UM522B-EN-P - February 2003

Page 67

Configuring the Drive Module 5-23

Return to RSLogix 5000 to

Finish Configuring the Drive

Module

Click on this button to cause additional user

defined links (links created in DriveExecutive

in addition to the default links associated

with the Controller Communication Format) to

be transferred from the Drive File into

RSLogix 5000.

Complete Setup Properties

Click Apply to make

the changes to the

configuration

IMPORTANT

Click OK when

satisfied with

configuration

Refreshed links will not take affect unless both the

RSLogix and Drive Executive projects have been

downloaded.

Publication 1756-UM522B-EN-P - February 2003

Page 68

5-24 Configuring the Drive Module

Select Save from the File menu

Save and Download

Chapter Summary and What’s Next

Select Download from the

Communications menu

In this chapter, you learned how to configure the ControlLogix Drive

Module. Move to Chapter 6, Troubleshooting the Drive Module, to

learn how to troubleshoot the module.

Publication 1756-UM522B-EN-P - February 2003

Page 69

Chapter

6

Troubleshooting the Drive Module

This chapter describes how to troubleshoot the ControlLogix Drive

module.

For information about: See page:

Using the Status Indicators 6-1

Using DriveExecutive to Troubleshoot the

Module

Using RSLogix 5000 to Troubleshoot the

Module

Chapter Summary and What’s Next 6-10

6-3

6-8

Using the Status Indicators

Bi-colored (red/green) LEDs indicate the status of several module

functions.

SD3000 INTERFACE

LINK

LINK

COMM

SYNC

DRIVE

DRIVE

COMM OK

FAULT

OS OK OK

SD3000 INTERFACE

Tx (rear)

Rx (front)

LINK

COMM

DRIVE

COMM OK

OS OK OK

Indicators shown are typical for all Drive Modules.

LINK

SYNC

DRIVE

FAULT

During power up, the OK indicator turns red for 5 seconds and then turns

to flashing green if it has passed the self-test.

1 Publication 1756-UM522B-EN-P - February 2003

Page 70

6-2 Troubleshooting the Drive Module

Use the table on the next page to troubleshoot your module.

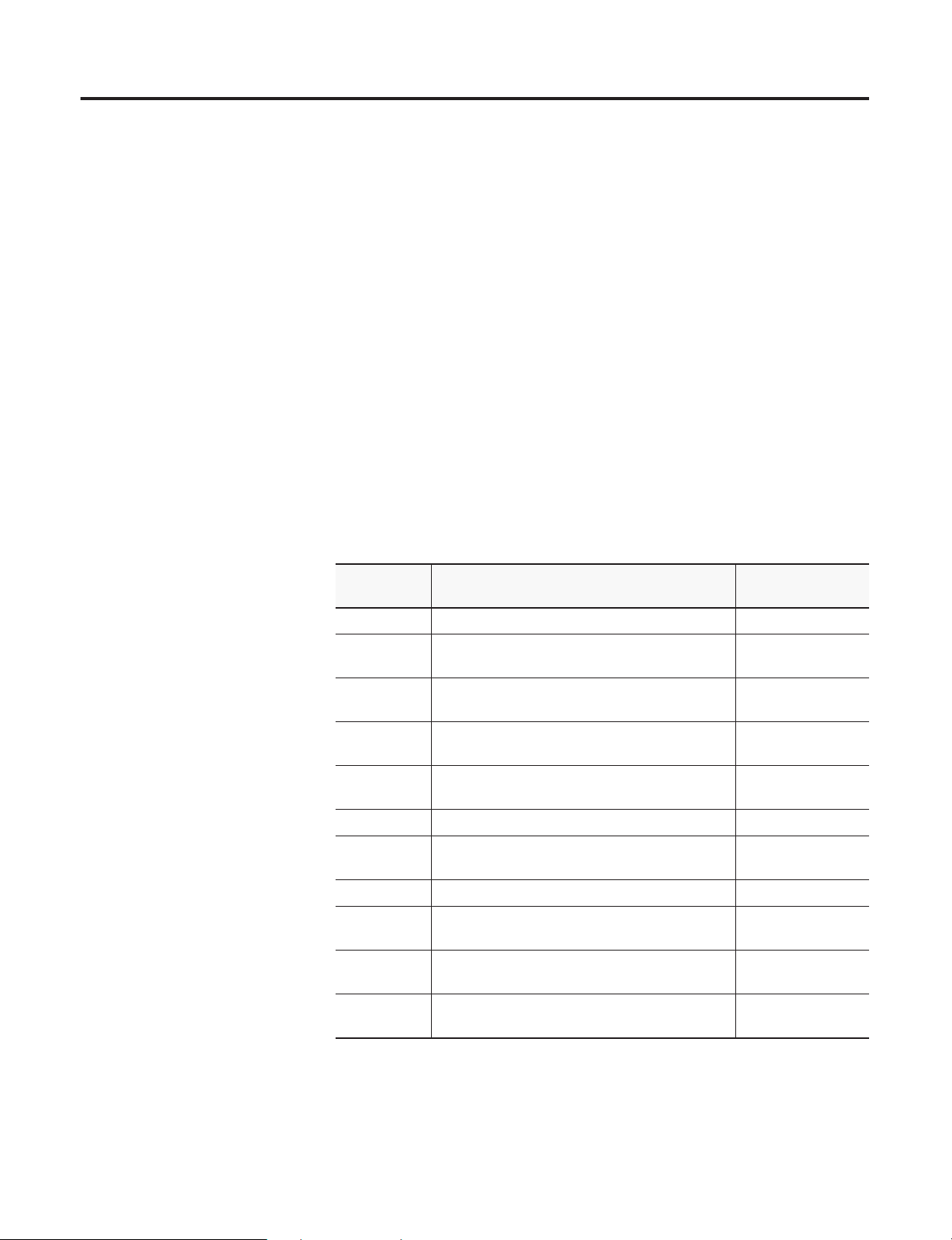

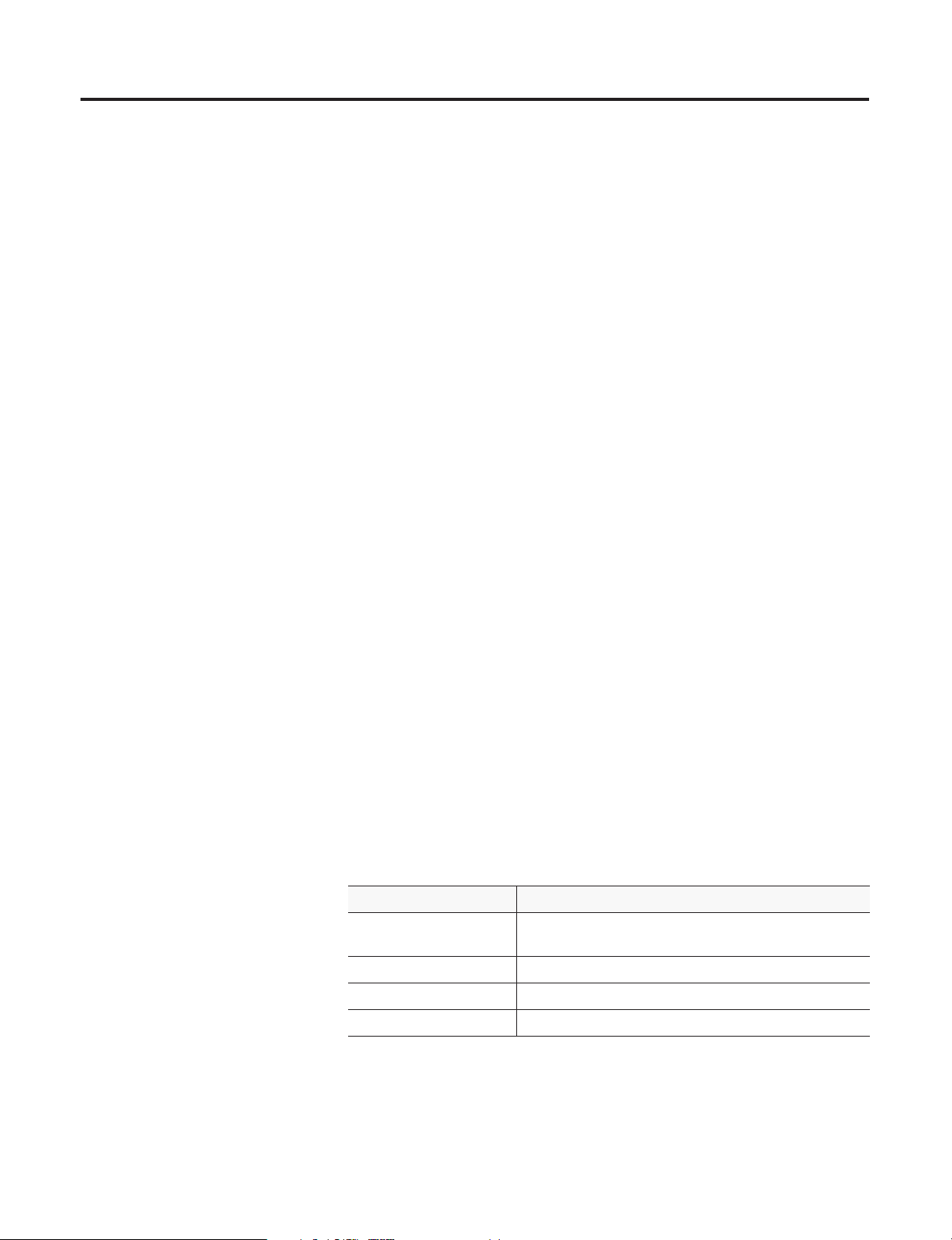

LED Indicator Display Means Take this Action

OK Green Connection is running. None

Flashing

Green

Red Non-Recoverable Fault Remove module from

Flashing Red Flash download in progress. None

Off Module is powered down. None

DRIVE

FAU LT

LINK

SYNC

OS OK Green System and parameter constants

DRIVE

COMM

OK

LINK

COMM

Red Module is faulted. See Fault Status

Off No fault is present or module is

Green The module is the time master or a

Flashing

Green

Flashing Red The module is configured as a CST

Off The module is not configured as a

Off Checksum failure. Reflash the module.

Green DPS communication is active and

Off DPS communication is not active, is

Green The module is configured and

Off The module is configured but not

Inhibited I/O connection. None

service

parameters.

powered down.

time relay and synchronization is

complete.

The module is configured as a time

relay from CST to SynchLink but is not

synchronized with a CST master on

the backplane.

The module is configured as a time

relay from SynchLink to CST but has

not synchronized with the upstream

device.

master and has detected another CST

master.

The module is configured as a time

master on SynchLink and has

received time information from another

time master on SynchLink.

time master or time relay or module is

powered down.

loaded.

synchronized.